klover DIVA SLIM Series, DIVA SLIM, DIVA SLIM WOOD Installation, Use And Maintenance, Useful Tips

ENGLISH

DIVA SLIM pellet

boiler stove

INSTALLATION, USE AND

MAINTENANCE, USEFUL TIPS

SERVICE DECLARATION

Ref. Annex III EU Regulation no. 305/2011

DoP/KLOVER-044

1. Identification number

:

DSL, DSLW

2. Model and/or lot no. and/or serial no. (Art. 11-4)

:

DIVA SLIM, DIVA SLIM WOOD

3. Intended use of the product according to the

relevant harmonised technical specification

:

Wood pellet-fired domestic heating appliance

4. Name or trademark of the manufacturer (Art11-5)

:

KLOVER s.r.l.

I - 37047 San Bonifacio (VR) – Via A. Volta, 8

5. Name and address of the representative (Art.12-2)

:

-

6. Assessment and verification system of the

performance constancy (Annex 5)

:

System 3

7. Notified laboratory

:

NB 0476

KIWA CERMET ITALIA S.p.A.

Number of test report (based on System 3)

:

2002365/C-371

8. Declared performances

HARMONISED TECHNICAL SPECIFICATION

EN 14785

PERFORMANCE FEATURES

PERFORMANCE

Fire resistance

A1

Distance from combustible material

200 mm

Fuel spillage risk

Compliant

Emission of combustion products

- Nominal power

- Reduced power

CO at 13% of O2 0.003 %

CO at 13% of O2 0.021 %

Effective temperature Compliant

Electrical safety

Compliant

Accessibility and cleaning Compliant

Maximum operating pressure -

Mechanical strength

NPD (performance not determined)

Thermal performance

- Nominal power (reduced)

- Nominal power (reduced) yielded to water

- Nominal power (reduced) yielded to the

environment

18.4 kW (4.3 kW)

13.8 kW (3.2 kW)

4.6 kW (1.1 kW)

Yield

- Nominal power

- Reduced power

ɳ 93.1 %

ɳ 92.9 %

Flue gas temperature

- Nominal power

- Reduced power

T 123.0 °C

T 82.3 °C

9. The performance of the product referred to in points 1 and 2 is compliant with the declared performance in

point 8.

This declaration is released on the sole responsibility of the manufacturer referred to in point 4.

Signed in the name and on behalf of the manufacturer by:

San Bonifacio (VR), 09/04/2018

Mario Muraro

Chairman of the Board

CONTENTS

CONTENTS ........................................................................................................................................................................ 1

INTRODUCTION ................................................................................................................................................................. 3

IMPORTANT SAFETY INSTRUCTIONS ................................................................................................................................... 3

THE MACHINE AND THE PELLETS ................................................................................................................................. 4

COMPONENTS OF THE APPLIANCE ..................................................................................................................................... 4

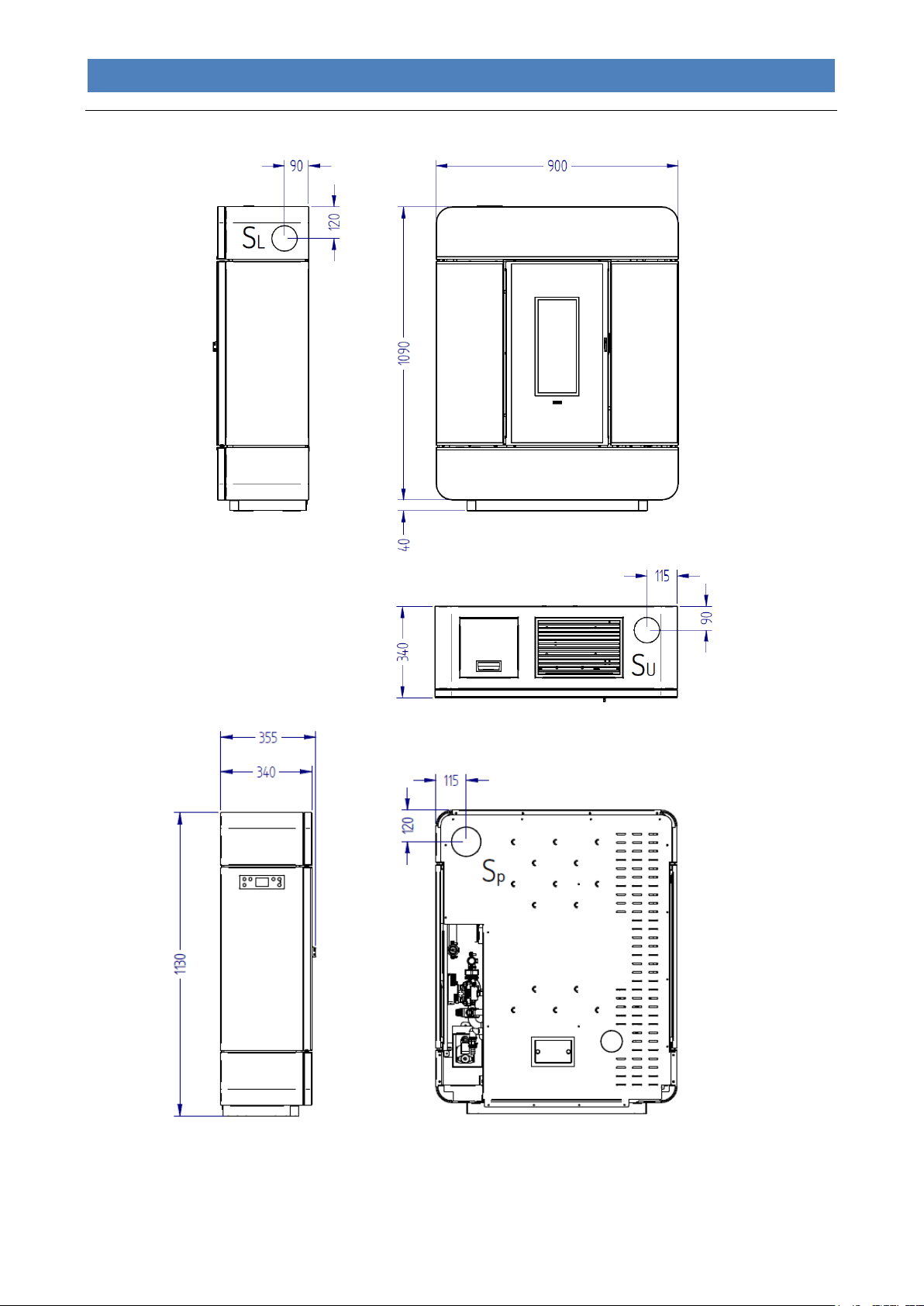

OVERALL DIMENSIONS ...................................................................................................................................................... 7

CONNECTIONS DATA SHEET .............................................................................................................................................. 8

TECHNICAL SPECIFICATIONS ............................................................................................................................................. 9

PELLET PROPERTIES ...................................................................................................................................................... 10

REQUIREMENTS OF THE PLACE OF INSTALLATION ................................................................................................. 10

POSITIONING .................................................................................................................................................................. 10

SPACES AROUND AND ABOVE THE APPLIANCE .................................................................................................................. 11

EXTERNAL AIR INTAKE .................................................................................................................................................... 11

THE FLUE AND CONNECTION TO THE SAME ....................................................................................................................... 12

CHIMNEY ....................................................................................................................................................................... 13

ELECTRICAL CONNECTION .......................................................................................................................................... 14

CONTROL OF ANY COUPLED BOILER ................................................................................................................................ 14

CONTROL OF A POSSIBLE THREE-WAY MOTORIZED VALVE FOR DHW SYSTEM MANAGEMENT ............................................. 15

CONNECTION TO THE ROOM THERMOSTAT ....................................................................................................................... 15

HYDRAULIC CONNECTION ............................................................................................................................................ 16

THE DISPLAY .................................................................................................................................................................. 17

THE MENU ....................................................................................................................................................................... 19

INITIAL START-UP .......................................................................................................................................................... 22

SYSTEM CONFIGURATION ............................................................................................................................................... 22

INITIAL FILLING OF THE SYSTEM ....................................................................................................................................... 24

PELLET LOADING AND CONNECTION TO THE MAINS POWER SUPPLY ................................................................................... 25

IGNITION CYCLE.............................................................................................................................................................. 25

SWITCH-OFF CYCLE ........................................................................................................................................................ 25

MODIFYING THE WORKING POWER .................................................................................................................................. 26

CHANGING THE WATER TEMPERATURE BOILER OR PUFFER ............................................................................................... 26

PROBLEMS, ALARMS, USEFUL TIPS ........................................................................................................................... 27

USEFUL INFO… .............................................................................................................................................................. 27

WHAT HAPPENS IF… ...................................................................................................................................................... 28

ALARM SIGNALS ............................................................................................................................................................. 29

CLEANING AND MAINTENANCE ................................................................................................................................... 29

PRECAUTIONS BEFORE CLEANING ................................................................................................................................... 29

ROUTINE CLEANING ........................................................................................................................................................ 29

NON-ROUTINE CLEANING ................................................................................................................................................ 30

ANNUAL CLEANING ......................................................................................................................................................... 32

CLEANING THE CERAMIC GLASS ...................................................................................................................................... 34

CLEANING THE FLUE ....................................................................................................................................................... 34

MAINTENANCE ............................................................................................................................................................... 34

PCB PARAMETERS ........................................................................................................................................................ 35

PARAMETERS TABLE ....................................................................................................................................................... 35

1

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

WIRING DIAGRAM ........................................................................................................................................................... 37

STANDARD WARRANTY CONDITIONS ......................................................................................................................... 38

Dear client,

First of all we would like to thank you for choosing a “KLOVER” product and we hope you will be satisfied with this

product.

Carefully read the manual and warranty certificate on the last page of this User guide.

In thanking you again for the trust accorded to us, we wish to inform you that these models are the result of forty years of

experience in the manufacture of solid fuel products using water as the heat transfer fluid.

Every single detail of the product is manufactured by qualified staff, using the most advanced equipment.

The manual contains a detailed description of the appliance and its operation, instructions for proper installation, basic

maintenance and control points, which must be periodically performed; furthermore it contains practical advice which

helps to obtain maximum performance from the appliance with minimum fuel consumption.

Stay warm with KLOVER!

Copyright

All rights reserved. The reproduction of any part of this manual, in any form, without the explicit written permission of

KLOVER Srl. is forbidden. The content of this manual may be modified without notice. Although the documentation

contained in this manual has been carefully compiled and checked, KLOVER srl cannot be held liable for any damages

arising from the use of the same.

Copyright © 2018 KLOVER srl

2

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

INTRODUCTION

Important safety instructions

Please read these instructions before installing and using the product.

- The installation and initial start-up of the appliance must be performed by skilled personnel trained in the relevant

safety standards. They will be responsible for the definitive installation of the appliance and its proper operation.

KLOVER srl shall not be held liable if these precautions are not observed.

- During the installation and use of the appliance, all local regulations - including those referring to national and

European Standards - must be observed.

- Connect the flue gas outlet to a flue with the specifications described in the “Flue and its connection” section of this

User guide.

- The appliance is not suitable for installation on a shared flue system.

- If the flue should catch fire, use appropriate fire extinguishing equipment or call the fire brigade.

- Connect the product to an earthed power socket. Avoid using sockets controlled by switches or automatic timers.

- Do not use the power supply cable if damaged or worn.

- If a multiple socket is used, make sure that the total voltage of the connected devices does not exceed the rated

voltage for the socket. Also make sure that the total voltage of all the devices connected to the socket does not

exceed the maximum permitted level.

- The plug on the appliance’s power cable should be connected only once the assembly and installation of the

appliance is complete. It should remain accessible after installation if the appliance is not fitted with a suitable and

accessible two-pole switch.

- Do not use flammable substances to clean the appliance or its parts.

- Do not leave flammable containers and substances in the place where the appliance is installed.

- The appliance works exclusively with wood pellets and only with the hearth door shut.

- NEVER open the appliance’s door during normal operation and avoid using it when the glass is broken or cracked.

- The use of poor-quality pellets or any other material can damage the appliance’s functions besides voiding the

warranty and exempting the manufacturer from all liability.

- Do not use the appliance as an incinerator or for any use other than that for which it was designed.

- Do not use fuels other than those recommended.

- Do not use liquid fuels.

- The appliance, and its outer surfaces in particular, become very hot to the touch during operation; handle with

caution in order to avoid burns.

- Keep fuel and flammable materials at a safe distance.

- Only use original spare parts recommended by the manufacturer.

- Do not make any unauthorised modifications to the appliance.

- Do not touch the hot components of the product (ceramic glass, flue pipe) during normal operation.

- Never touch the appliance if you are barefoot and/or if you have wet or damp parts of the body.

- Use the appropriate button to switch off the electrical panel. Do not disconnect the power supply cable while the

appliance is operating.

- Switch the appliance off in case of a fault or malfunctions.

- During the ignition phase and normal operation of the appliance, maintain the necessary safety distance and do not

remain standing in front of it.

- Keep children away from the appliance when it is running since they could get burned by touching its hot

components.

- Do not leave the packaging elements within reach of children or unassisted disabled persons.

- Children and inexperienced people must not be allowed to use the appliance.

- The appliance may be used by children no younger than 8 years of age and people with reduced physical, sensory or

mental capabilities, or those without experience of the appliance, as long as they are supervised or have received

instructions on how to use the appliance safely and understand the hazards inherent to the appliance.

- Children should not play with the appliance.

- User maintenance and cleaning operations should not be carried out by unsupervised children.

- Clean the appliance only when it is cold.

- Clean the brazier whenever the ignition fails and nonetheless at least once a week.

- Do not use the appliance in ways other than those indicated in this user guide.

- The appliance is designed for indoor use only.

3

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

Expansion tank

6 l

Safety valve

2.5 bar

Pressure gauge

0 – 4 bar

Automatic air vent valve

Yes

Heating system pump

Yes. Mod.25/70

Electrical setting for the connection of the domestic water flow switch

Yes

Electrical setting for boiler / puffer sensor

Yes

Remote control

Optional

Wi-Fi management module

Optional

- The appliance is designed for heating water and should therefore be connected to a plumbing system (radiators,

under-floor heaters, etc.). This system should be suitably designed and sized to distribute the power generated by

the appliance.

- This user guide constitutes an integral part of the appliance. If the product is sold to another user, this manual must

be passed on to the new owner.

KLOVER S.R.L. DECLINES ALL LIABILITY IN CASE OF ACCIDENTS DUE TO FAILURE TO COMPLY WITH THE

SPECIFICATIONS OF THIS MANUAL.

KLOVER S.R.L. DECLINES ALL LIABILITY DUE TO INCORRECT USE OF THE PRODUCT BY THE USER,

UNAUTHORISED MODIFICATION AND/OR REPAIRS, AND USE OF NON-ORIGINAL SPARE PARTS OR SPARE

PARTS NOT SPECIFICALLY DESIGNED FOR USE ON THIS PRODUCT MODEL.

KLOVER S.R.L. SHALL NOT BE HELD LIABLE FOR THE STOVE'S INSTALLATION. THE INSTALLER IS THE

SOLE PARTY RESPONSIBLE FOR THIS OPERATION AND IS ALSO ENTRUSTED WITH CHECKING THE FLUE,

EXTERNAL AIR VENT AND THE CORRECTNESS OF THE PROPOSED INSTALLATION SOLUTIONS. ALL THE

SAFETY REGULATIONS SET OUT IN THE SPECIFIC LAWS IN FORCE IN THE COUNTRY WHERE THE MACHINE

IS INSTALLED MUST BE OBSERVED.

NON-ROUTINE MAINTENANCE MUST ONLY BE PERFORMED BY AUTHORISED AND QUALIFIED STAFF.

To ensure the validity of the warranty, the user must comply with the instructions contained in this guide and, in

particular, must:

- Use the appliance within its operating limits;

- Regularly perform all maintenance activities;

- Authorise expert and competent people to use the appliance.

Failure to comply with the instructions contained in this guide shall automatically void the warranty.

THE MACHINE AND THE PELLETS

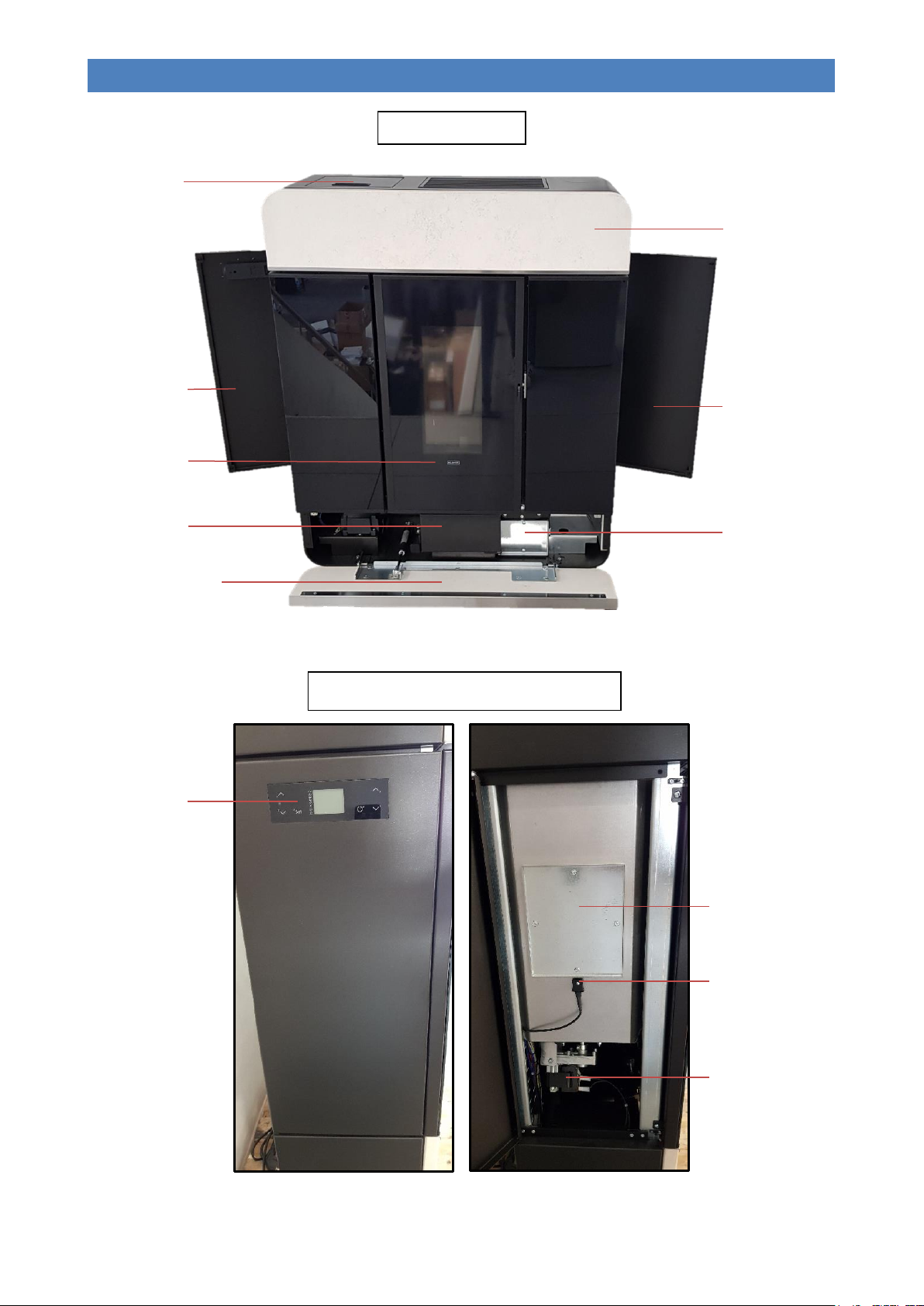

Components of the appliance

The table below shows the standard features of the appliance:

The appliance is delivered with the following equipment:

- 1 user, installation and maintenance guide;

- 1 power supply cable;

- 1 cool-touch handle;

- 1 conventional warranty certificate.

4

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

Pellet loading panel

Left-hand inspection

compartment

Combustion chamber

door

FRONT VIEW

LEFT-HAND INSPECTION COMPARTMENT

Right-hand inspection

compartment

(hydraulic circuit)

Ash tray door

Lower front inspection

compartment

(flue gas path and tray

cleaning)

TOUCH display

Tank inspection hatch

Pellet level

sensor

Gearmotor

Upper front

inspection

compartment

Flue gas path front

inspection plate

5

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

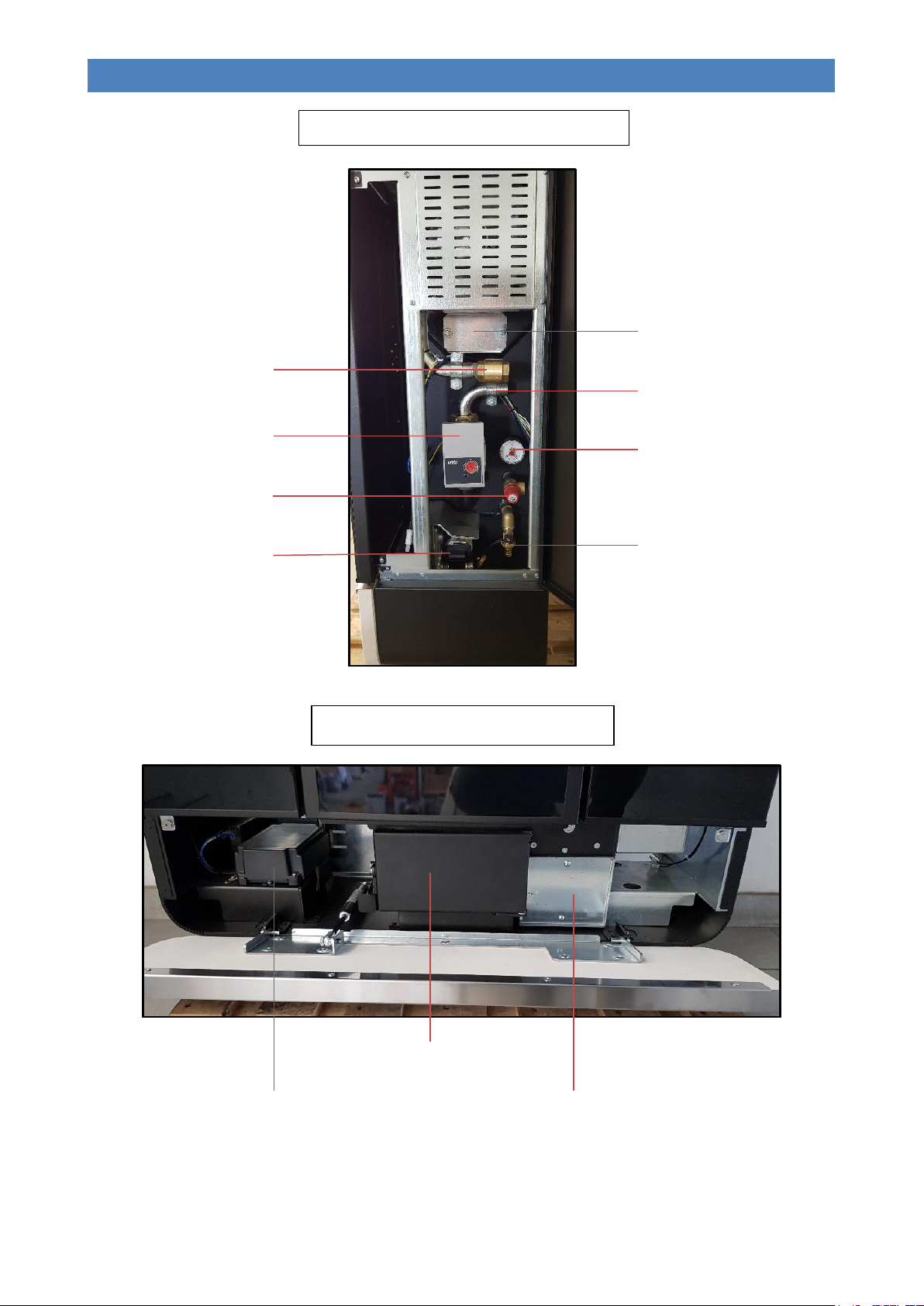

RIGHT-HAND INSPECTION COMPARTMENT

Flue gas path side

inspection plate

Delivery pipe

(YORK ¾" valve)

Return pipe

Pressure gauge

High-efficiency pump

Safety valve

(2.5 bar)

Boiler unit drain cock

Flue gas path

automatic cleaning

gearmotor

LOWER INSPECTION COMPARTMENT

Control unit

Ash tray inspection

panel

Flue gas path front

inspection plate

6

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

REAR VIEW

Overall dimensions

7

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

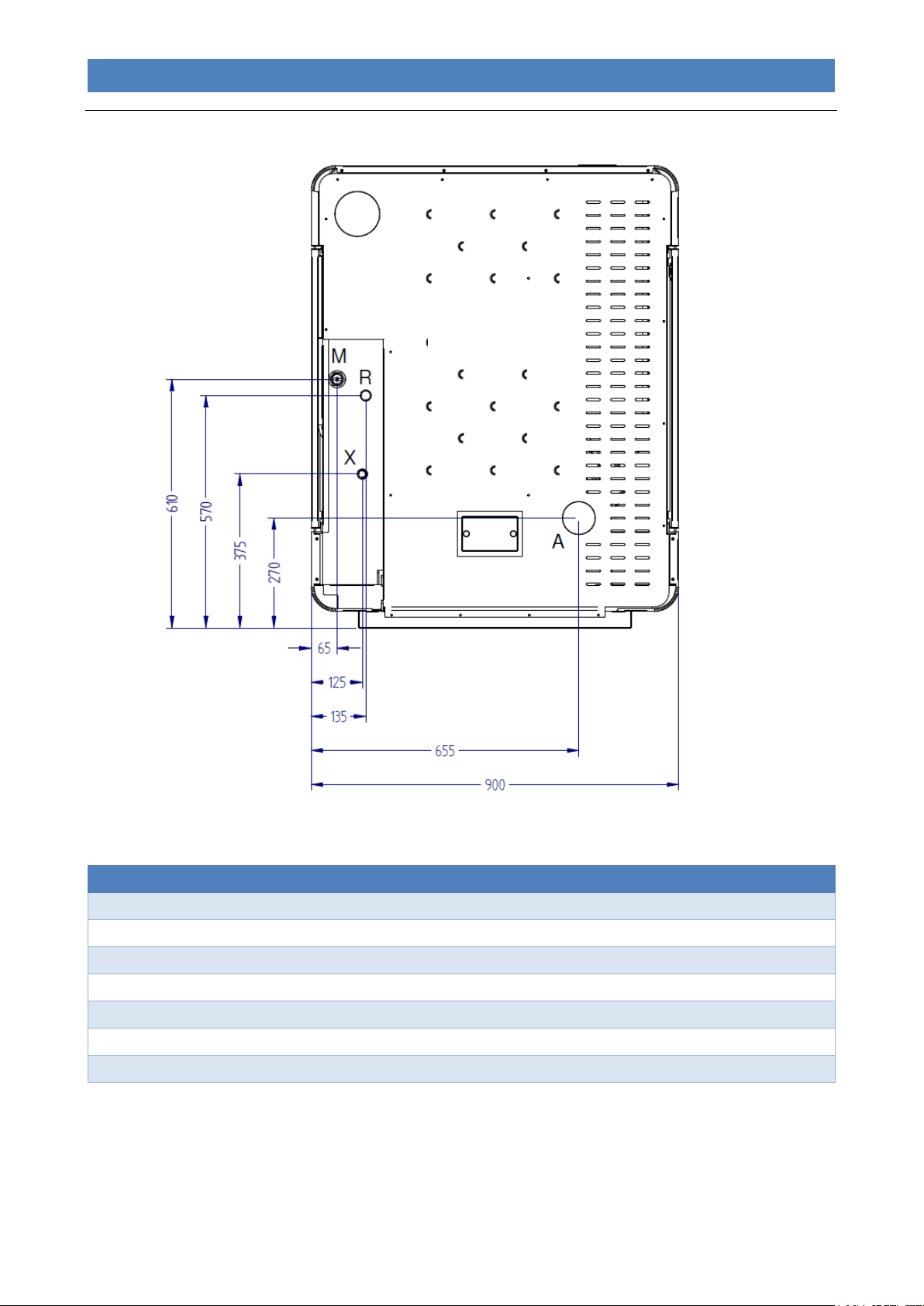

Description of connections

M = System Delivery

3/4" F

R = System Return

3/4" M

X = Safety valve drain

1/2" F

SL = Side flue gas outlet (refer to the “Overall dimensions” paragraph)

80 mm M

SU = Upper flue gas outlet (refer to the “Overall dimensions” paragraph)

80 mm M

SP = Rear flue gas outlet (refer to the “Overall dimensions” paragraph)

80 mm M

A = Rear fitting for connection of optional extraction pipe

40 mm

REAR VIEW

Connections data sheet

8

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

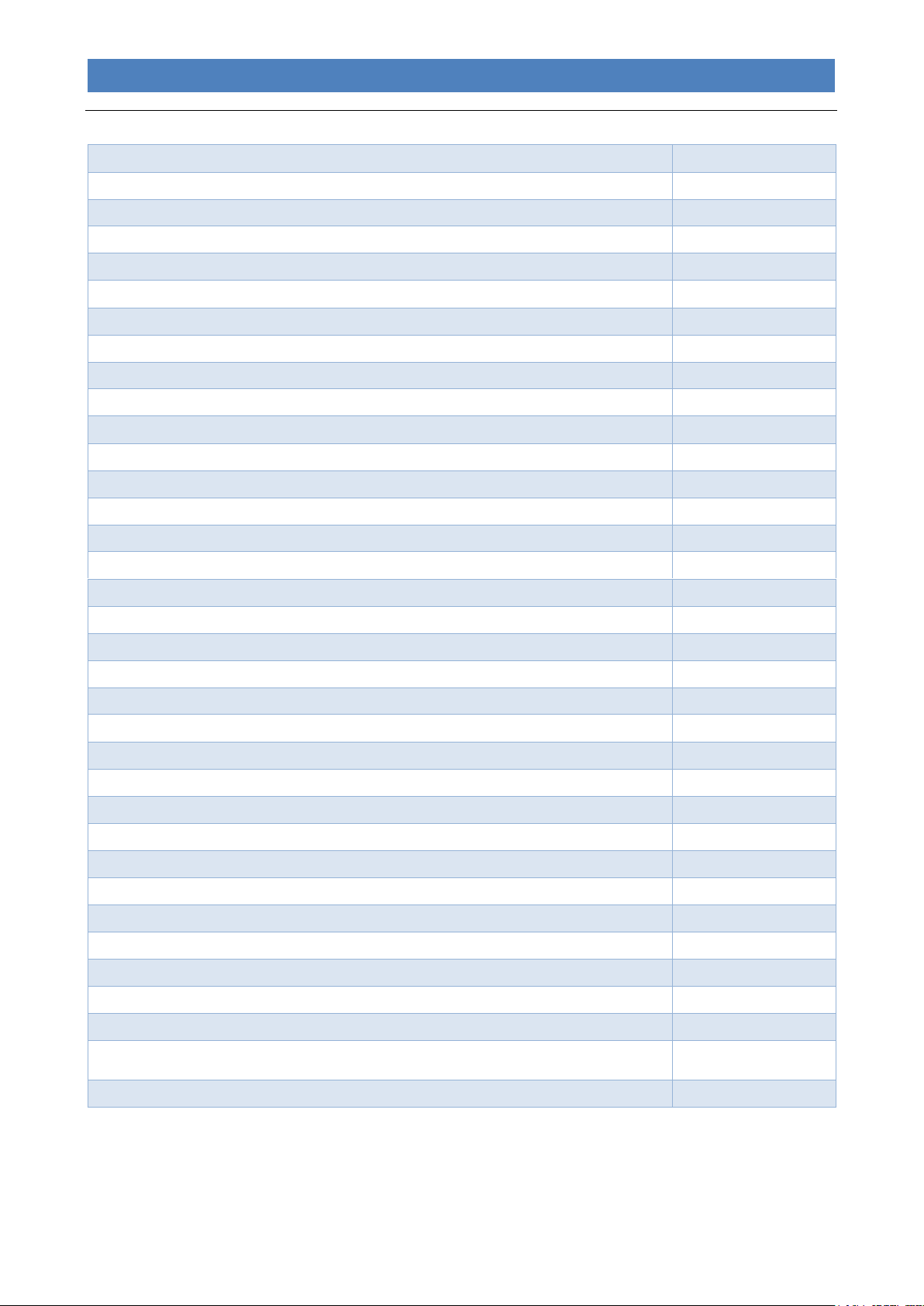

Heat input (nominal setting)

kW (Kcal/h)

19.8 (17,030)

Heat input (reduced setting)

kW (Kcal/h)

4.7 (4,050)

Nominal thermal output

kW (Kcal/h)

18.4 (15,830)

Reduced thermal power

kW (Kcal/h)

4.3 (3,700)

Nominal heat output ceded to water

kW (Kcal/h)

13.8 (11,900)

Nominal heat output ceded to the environment

kW (Kcal/h)

4.6 (3,950)

Reduced heat output ceded to water

kW (Kcal/h)

3.2 (2,750)

Reduced heat output ceded to the environment

kW (Kcal/h)

1.1 (950)

Combustion efficiency at nominal thermal power

%

93.1

Combustion efficiency at reduced thermal power

%

92.9

CO at 13% oxygen at nominal thermal power

%

0.003

CO at 13% oxygen at reduced thermal power

%

0.021

Maximum power uptake

Watt

400*

Power uptake during operation at nominal thermal power

Watt

40

Power uptake during operation at reduced thermal power

Watt

30

Power uptake in stand-by

Watt

2.0

Nominal voltage

V

230

Nominal frequency

Hz

50

Expansion vessel litres/preloading bar

6 / 1

Maximum operating/recommended pressure

bar

2.5 / 1.5

Flue outlet diameter

mm

80

Air intake pipe diameter

mm

40

Minimum chimney draught at nominal thermal power

Pa

10.5

Minimum chimney draught at reduced power

Pa

10.1

Combustion gas mass at nominal thermal power

g/s

11.0

Combustion gas mass at reduced power

g/s

4.8

Pellet tank capacity

Kg

25

Average exhaust flue gas temperature at nominal thermal power

°C

123.0

Average exhaust flue gas temperature at reduced power

°C

82.3

Boiler unit capacity

litres

20

Width

mm

900

Height

mm

1130

Depth

mm

340

Minimum safety distance from flammable materials

(side / rear / upper / front)

mm

200 / 200 / 750 / 800

Weight

Kg

225

Technical Specifications

* Power consumption only during the ignition cycle.

The appliance's heat output may vary depending on the type of pellets used.

9

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

Indication of the standard,

base reference for the quality

classes ENplus

Indication of the quality

class of the certified pellet

(preferable A1)

IT xxx

Code of the certified company

consisting of two elements:

- Symbol of the country of

production (example “IT”)

- Progressive number assigned at

the acquisition of the

certification (example "xxx")

Pellet properties

The appliance has been tested with all types of pellets available on the market. The pellets must have the following

properties:

- Diameter 6 mm.

- Maximum length 35 mm.

- Maximum humidity content 8 – 9 %.

- 100% wood. Totally additive-free.

- Maximum ash residue 1.1 %.

To obtain good performance from the appliance, we recommend using good quality pellets. Pellets should be poured

into the tank using a shovel, and not directly from the bag.

Good quality pellets should have the following properties:

- Constant diameter cylinders with a smooth, shiny surface;

- There should not be a lot of sawdust inside the packaging;

- After grabbing a bunch of pellets and placing them into a container filled with water, good-quality pellets will sink and

poor-quality ones will tend to float;

- The quality certification data, in particular conformity to international standards such as EN14961-2, DIN 51731 and

O-NORM M7135, should be indicated on the packaging;

- The packages should be intact since pellets tend to absorb humidity. Humidity not only reduces the calorific value

and increases the amount of flue gases expelled, but also causes swelling of the product which may create problems

with the appliance.

The production of pellets must be compliant with some international standards (such as EN14961-2, DIN 51731 and ONORM M7135) which establish minimum values for quality checks on pellets. To facilitate the right choice of the

combustible material you can find below one of the most common certification marks identifying the quality of the pellets:

The use of poor quality pellets or any other material can damage the appliance operation, voiding the warranty

and exempting the manufacturer from all liability.

In order to guarantee trouble-free combustion, the pellets must be stored in a dry place.

REQUIREMENTS OF THE PLACE OF INSTALLATION

Positioning

The initial phase for best installation of the appliance is to determine its optimum location; the following elements need to

be considered:

- The possibility of creating an external air vent;

- The possibility of creating a straight flue, preferably coaxial to the outlet of the appliance;

- Proximity to the main water drain and/or the boiler (if one already exists);

- Proximity or ease of connection to the water system;

- Ease of access for cleaning the appliance, the flue gas exhaust pipes and the flue.

10

DIVA SLIM PELLET BOILER STOVE

EN - Rev. 1.0

REAR VIEW

SIDE WALL

SIDE WALL

The unit must be installed on a floor with a suitable load capacity. If the existing building does not fulfil this requirement

appropriate measures (e.g. load distribution plate) must be taken.

The minimum safety distance from flammable materials must be at least 200 mm from the sides and back of the

appliance, 800 mm from the front and 750 mm from the upper part.

The installation must guarantee easy access for cleaning the appliance, the flue gas exhaust pipes and the flue, and any

subsequent maintenance operation by the Authorised technical assistance centre.

Once you have found the best location for the appliance, position it following the instructions given below.

The appliance must not be installed in small rooms, bedrooms, bathrooms or in areas with an explosive atmosphere

(e.g. garages).

Spaces around and above the appliance

The figure below shows the minimum distances from walls or other not-easily-removable furniture, that need to be taken

into consideration when positioning the appliance.

Any shelves or false ceilings mounted above the appliance must be at least 75 cm away from the top part of it.

Furniture and movable objects made from flammable materials must be positioned at least 20 cm from the side surfaces

of the appliance; these objects must be moved when performing maintenance on the appliance.

Protect all structures that can catch fire against the radiated heat of the fire.

Any extra intervention by the Authorised technical assistance centre, which requires the appliance to be

disconnected from the system, will not be covered under warranty as described in the chapter “Standard

Warranty Conditions”.

External air intake

During operation, the appliance takes in air from the environment in which it is installed; It is therefore essential that this

air is replaced through an external air vent. The absence of the air vent may affect the flue draught and therefore the

combustion and the safety of the appliance.

Therefore it is mandatory to install an external air vent with a minimum completely free passage of at least 80 cm2

(round hole with minimum diameter of 15 cm protected with a special fixed large mesh grille).

If it not possible to put the external air vent in the same room as where the appliance is installed, this hole can be made

in an adjoining room as long as this room communicates permanently, by means of a transit hole (15 cm minimum

diameter).

The hole must be protected externally with a fixed grille. The protective grille must be checked periodically to ensure that

it is not obstructed, thereby impeding the passage of air. Therefore keep the air vents clear of obstructions.

The UNI 10683 Standard FORBIDS the drawing of combustion air from garages, warehouses storing combustible

materials, or from business premises with a fire hazard.

11

Loading...

Loading...