Klockner Moeller PS 416-TCS-200 Hardware And Engineering

Hardware and Engineering

PS 416-TCS-200

Telecontrol Card

08/97 AWB 27-1298 GB

1st published 1997, edition 08/97

© Klöckner-Moeller GmbH, Bonn

Author: Thomas Dahmen

Editors: Klaus Krüger, Thomas Kracht

Translators: Christopher Baker, Terence Osborn

Caution!

Dangerous electrical voltage!

Before commencing the installation

● Disconnect the power supply of the

device.

● Ensure that the device cannot be

accidentally restarted.

● Verify isolation from the supply.

● Earth and short circuit.

● Cover or enclose neighbouring units that

are live.

● Follow the engineering instructions

(AWA) of the device concerned.

● Only suitably qualified personnel may

work on this device/system.

● Before installation and before touching

the device ensure that you are free of

electrostatic charge.

● Connecting cables and signal lines

should be installed so that inductive or

capacitive interference do not impair the

automation functions.

● Install automation devices and related

operating elements in such a way that

they are well protected against

unintentional operation.

● Suitable safety hardware and software

measures should be implemented for

the I/O interface so that a line or wire

breakage on the signal side does not

result in undefined states in the

automation devices.

● Ensure a reliable electrical isolation of

the low voltage for the 24 volt supply.

Only use power supply units complying

with IEC 60 364-4-41 or HD 384.4.41 S2.

● Deviations of the mains voltage from the

rated value must not exceed the

tolerance limits given in the

specifications, otherwise this may cause

malfunction and dangerous operation.

● Emergency stop devices complying with

IEC/EN 60 204-1 must be effective in all

operating modes of the automation

devices. Unlatching the emergency-stop

devices must not cause uncontrolled

operation or restart.

● Devices that are designed for mounting

in housings or control cabinets must only

be operated and controlled after they

have been installed with the housing

closed. Desktop or portable units must

only be operated and controlled in

enclosed housings.

● Measures should be taken to ensure the

proper restart of programs interrupted

after a voltage dip or failure. This should

not cause dangerous operating states

even for a short time. If necessary,

emergency-stop devices should be

implemented.

IBM is a registered trademark of International

Business Machines Corporation.

All other brand and product names are

trademarks or registered trademarks of the

owner concerned.

All rights reserved, including those of the

translation.

No part of this manual may be reproduced in

any form (printed, photocopy, microfilm or

any otherprocess) or processed, duplicated

or distributed by means of electronic

systems without written permission of

Klöckner-Moeller GmbH, Bonn.

Subject to alterations without notice.

Contents

About This Manual 3

Other manuals (AWBs) 3

1 Setting Up A Telecontrol Station With

The PS 416 Controller 5

Procedure 8

2 About The Card 9

Task of the PS 416-TCS-200 9

Hardware and software requirements 9

Construction of the PS 416-TCS-200 10

Communication layers model 11

3 Engineering 13

Number of PS 416-TCS-200 cards in

the rack 13

Power supply 13

Terminal assignments 13

Selection of modem 15

Electromagnetic compatibility 15

4 Configuration 19

08/97 AWB 27-1298-GB

5 Installation 23

Installing the PS 416-TCS-200 in the rack 23

6 Operation 25

Function of the PS 416-TCS-200 card 25

Startup behaviour 26

Shutdown behaviour 27

7Diagnostics 29

Appendix 31

Technical data 31

Glossary 32

Index 35

1

2

08/97 AWB 27-1298-GB

About This Manual

This card has been developed for remote metering,

remote indication and remote control and supports

the data security protocols FT 1.2 and FT 3

(asynchronous) as per the IEC 870-5 standard for

telecontrol equipment and systems.

This manual describes the structure, planning,

configuration, installation, operation and also the

testing and diagnostics of the PS 416-TCS-200

communication processor. The PS 416-TCS-200 is a

communication processor for PS 416 programmable

logic controller. With the aid of the PS 416-TCS-200

communication processor the PS 416 can be

connected as telecontrol station to a telecontrol

network.

This documentation is intended for the project

planner, programmer and commissioning engineer.

This documentation will enable such users to

connect the PS 416 to a telecontrol system.

A general knowledge of control and communication

engineering is required for a good comprehension of

this technical documentation.

Other manuals (AWBs) The fundamentals of remote control using compact

PLCs are described in a separate manual. Each of

the individual components also has its own manual.

Guide to telecontrol, AWB 27-1299-GB

ZB 4-501-TC1:

Hardware and engineering, telecontrol card

ZB 4-501-TC1, AWB 27-1297-GB

08/97 AWB 27-1298-GB

3

About This Manual

PS 416-TCS-200:

Hardware and engineering, telecontrol card PS 416TCS-200, AWB 27-1298-GB

Leased line S 40-AM-TL:

Telecontrol via leased line, application module S 40AM-TL, AWB 27-1301-GB

Dial-up line S 40-AM-TD:

Telecontrol via dial-up line, application module

S 40-AM-TD, AWB 27-1300-GB

4

08/97 AWB 27-1298-GB

1 Setting Up A Telecontrol Station With

The PS 416 Controller

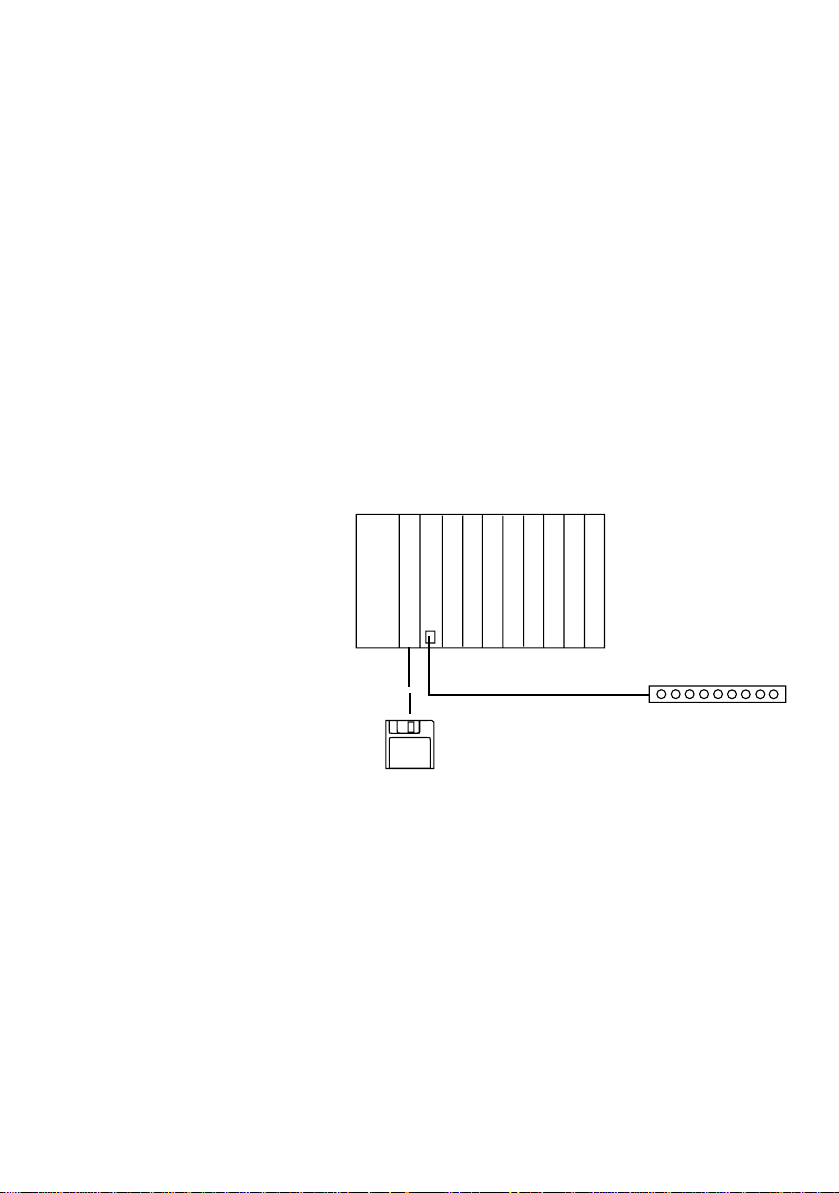

The PS 416-TCS-200 communication processor

forms part of the PS 416 modular control system.

With the PS 416-TCS-200 the individual controller

can be integrated into a telecontrol system. Here the

controller can be the central station or a substation.

Communication with the telecontrol network is

effected via modem and modem cable.

Communication is supported by task-specific

application modules (function blocks).

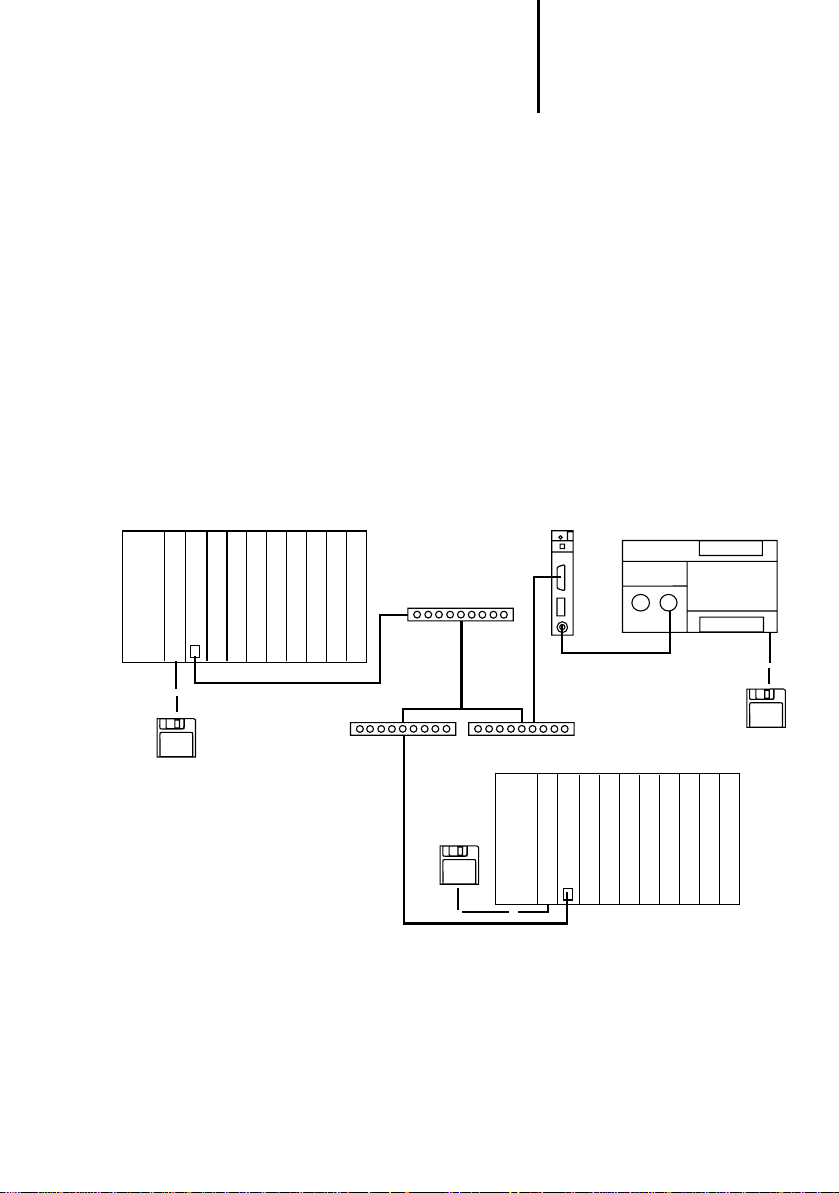

a

CPU PS 416

PS 416-TCS-200

08/97 AWB 27-1298-GB

ZB 4-254-KB1

S 40-AM-TD/TL

Figure 1: Layout of a telecontrol station with the PS 416

programmable controller

a Central station

b Modem

b

Either a dial-up line or a leased line can be used as the

transmission medium.

In the case of the dial-up line existing telephone

networks are used as transmission medium. All of the

modems in the central station and substations must

be modems with dialling capability. At the request of

5

Setting Up A Telecontrol

Station With The PS 416

Controller

the central station or the substation the modems set

up a connection with a specified telephone number.

In the case of the dial-up line both the central and also

the substation can take over the function of a primary

station or the function of a secondary station:

Primary station:

Station which initiates data transport

Secondary station:

Station which replies to a data request

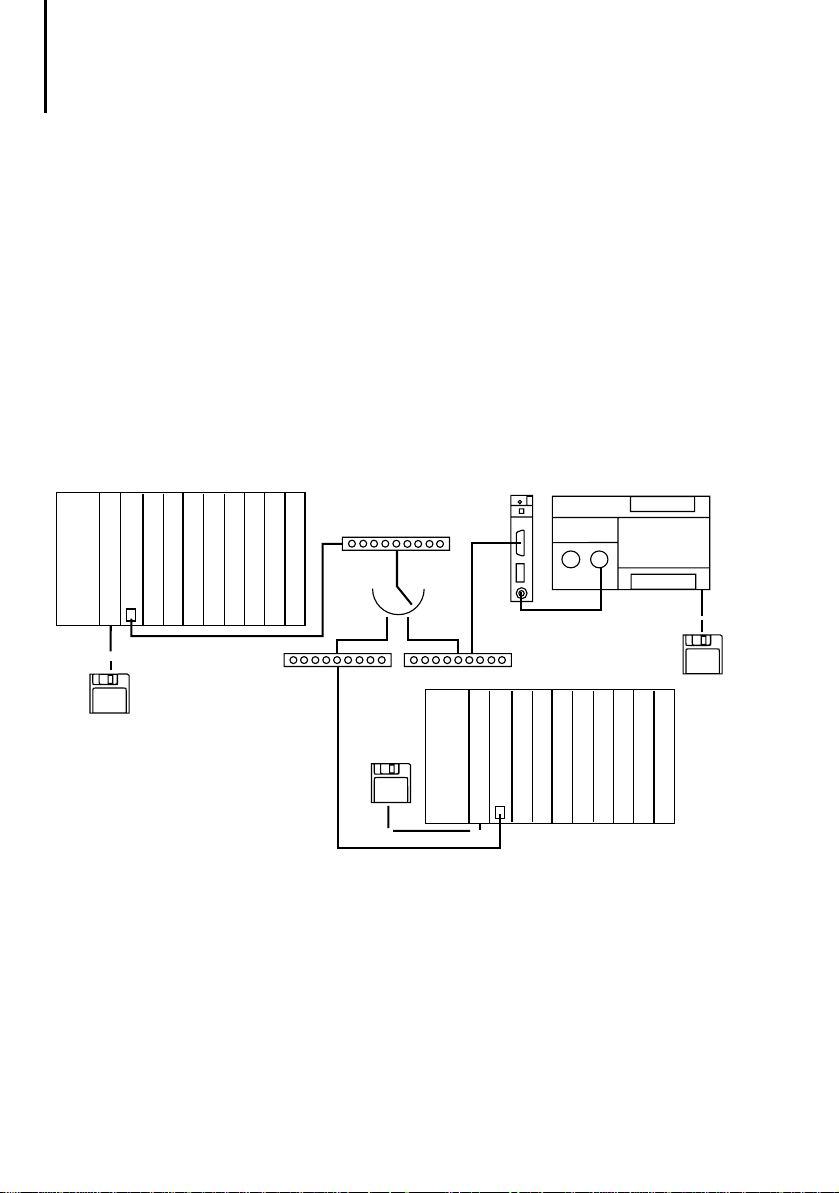

Communication of one station with several stations

simultaneously is not possible.

a

S 40-AM-TD

CPU PS 416

PS 416-TCS-200

ZB 4-254-KB1

ZB 4-501-TC1

b

c

b

S 40-AM-TD

b

S 40-AM-TD

PS 416-CPU-400

Figure 2: Telecontrol system with PS 416 components and

dial-up line configuration

a Central station – primary station / secondary station

b Dial-up modem

c Dial-up line

d Substation – primary station / secondary station

d

PS 416-TCS-200

d

PS 4-200

6

08/97 AWB 27-1298-GB

Other manuals (AWBs)

In the case of the leased line all substations are

permanently connected to the central station.

If more than one secondary station is addressed via

the leased line only point-to-point leased modems

(party line) may be used. The central station will in

this case always be a primary station and the

substations always secondary stations. This makes it

possible for the central station to send messages to

all substations simultaneously.

Only the central station can initiate communication.

A substation cannot autonomously initiate

communication with the central station or with

another substation.

a

CPU PS 416

S 40-AM-TL

PS 416-TCS-200

ZB 4-254-KB1

ZB 4-501-TC1

b

b

S 40-AM-TL

Figure 3: Telecontrol system with PS 416 components and

leased line configuration

a Central station – primary station

b Modem (party line)

c Substation – secondary station

b

c

CPU PS 416

c

PS 4-200

S 40-AM-TL

PS 416-TCS-200

08/97 AWB 27-1298-GB

7

Setting Up A Telecontrol

Station With The PS 416

Controller

Procedure The following procedure is recommended for

connecting the PS 416 to a telecontrol system.

E Define all requirements made on the telecontrol

system – for example, data security, number of

stations, and so on. A detailed description will be

found in the “Guide to telecontrol” manual.

E Select the application module which matches

your requirements. Relevant factors here include:

station type (modular – compact), station class

(primary – secondary), number of stations.

E Configure the interface parameters for the

PS 416-TCS-200 in the application module. See

Chapter 4, Configuration.

E Adjust the transmission parameters where

necessary to match the requirements of the data

integrity class. See the “Guide to telecontrol”

manual.

E Install the card in the rack. See Chapter 5,

Installation

E Connect the PS 416-TCS-200 to the modem via

the ZB 4-254-KB1 modem cable. See Chapter 5,

Installation

The card is now installed, programmed, configured

and is ready for operation.

8

08/97 AWB 27-1298-GB

2 About The Card

Task of the

PS 416-TCS-200

Hardware and software requirements

The PS 416-TCS-200 communication processor is

used for connecting the PS 416 programmable

controller via a modem to a telecontrol system. It

communicates with other telecontrol stations via a

point-to-point modem or dial-up modem.

The card has its own microcontroller. This means that

it handles the communication process autonomously

without taking up any of the capacity of the PS 416

central processing unit.

Table 1 provides an overview of the hardware and

software requirements for running the

PS 416-TCS-200 within the PS 416 PLC system.

Table 1: Hardware and software requirements

Software

Programming software

Operating system

Application modules

Hardware

Central processing unit

Power supply card:

Subrack

Modem cable

Sucosoft S 40 Manager, Version 2.0 and

higher for PS 416-CPU-400 Version 1.13 and

higher

S 40-AM-TD Version 1.0 (dial-up line)

S 40-AM-TL Version 1.0 (leased line)

PS 416-CPU-400

PS 416-POW-400

PS 416-POW-410

PS 416-POW-420

PS 416-BGT-400/410/420 or 421 with

PS 416-ZBX-401/402/403 potential

equalisation rail

ZB 4-254-KB1

08/97 AWB 27-1298-GB

9

About The Card

Construction of the

PS 416-TCS-200

e

d

r

x

d

c

/

tx

d

e

rro

r

b

f

a

T

CS

-

2

00

Figure 4: Elements of the PS 416-TCS-200

a Switches S1 / S2

b RS 232 – modem port

c LED (error)

d LED (RxD / TxD)

e Interface module

f System EPROM

10

08/97 AWB 27-1298-GB

Loading...

Loading...