Page 1

SOLAR HEATING SYSTEMS

FORCED

CIRCULATION

Vacuumm collectors

SKY 8 CPC 58

SKY 12 CPC 58

SKY 18 CPC 58

SKY 21 CPC 58

Reg. no. 011-7S124R

Page 2

Page 3

1

INDEX

• Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 2

• Solar collectors technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 5

• Dimensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 6

• Checks and parameters indispensable for dimensioning . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 7

• Connection example of collectors in series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 8

• Connection example of collectors in parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 9

• Preliminary warnings and checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 11

• Practical table for the choice of piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 13

• Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 15

• Flat roof kit assembly layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 16

• Sloped roof kit assembly layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 22

• Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 27

• Instructions for the assembly of the F1/PT 1000 probe . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 28

• Loading the system through the solar station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 29

• Inclinations of the solar collectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 30

• Orientation of the collectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 31

• Maintenance and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 32

• Safety systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 33

• Indications regarding transport and handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 34

• For the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 35

• Grand Soleil Medium Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 36

• Grand Soleil Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 37

• Grand Soleil Plus Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 38

• Totalenergy Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 39

• Totalenergy Plus Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 40

• Data detection card for solar heating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 41

• Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 42

Page 4

2

MAKING USE OF SOLAR ENERGY

Solar energy is among the most abundant and available free renewable energies on the earth’s surface. To have an idea of

the energy that the sun radiates onto the earth, according to the latitude, the average daily solar radiation in Italy varies

from 4 to 5.5 kWh on a surface of 1 square metre.

The use of a solar heat collector with vacuum technology is accredited, as shown by the experts in the solar sector and

by laboratory tests carried out according to EN European Standards, to be the most technically efficient system for capturing the energy released by the sun through the entire year.

Considering the daily heat energy request per person for domestic hot water use, the use of solar collectors with vacuum

technology with CPC reflector, combined with a standard state-of-the-art designed system, allows energy saving regarding

domestic hot water of up to 80%. While, considering the global load of heat energy requested for domestic hot water and

heating, the total saving can exceed 40%.

This considerable energy saving constitutes an important contribution to the reduction of the emissions of noxious

substances, deriving from combustion, into the atmosphere and particularly to the reduction of CO2, the main reason for

environmental heating due to the greenhouse effect.

The functioning principle of a solar heating system can be described simply.

The solar vacuum collector with CPC reflector captures solar radiation and heats up. The heat gathered is transferred by

heat exchage to a water tank, which acts as a storage tank. The amount of solar energy that the collector can transfer to

the tank depends on its capacity to absorb solar radiation and on the level of insulation, which reduces the loss of energy

captured by the collector.

The creation of the vacuum by removing the air from the gap in the glass tube achieves a layer of the best heat insulating

material existing in nature. The principle has been known about for a century and is appreciated in the form of the

thermos.

Using this arrangement, the collectors optimise the use of solar energy also during the change of seasons and during the

winter.

ADVANTAGES OF CPC DIFFUSION VACUUM TECHNOLOGY

- High temperatures and yields even in unfavourable atmospheric conditions, e.g. with low external temperatures.

- High absorption even with diagonal light thanks to the circular shape of the absorbing device.

- Top quality and high efficiency solar vacuum tube, of our own production and with high level of forced vacuum.

- Duration through time: no delicate glass-metal couplings that degenerate the level of vacuum in the glass pipe through

time.

- Duration through time: high resistance and duration of the selective capturing layer also thanks to the protection of the

vacuum.

- Loss of load contained thanks to the circulation of the flow in parallel in the circuit with "U"-shaped pipes.

- Maximum yield with less requirement for surfaces (half of the absorbant surfaces are normally necessary with respect

to a traditional absorbing panel).

- Treated spacial aluminium concentrator reflector, with double CPC paraboloidal section (Compound Parabolic

Concentrator) with optimised optics for the solar collector, to convey the sun’s non-incident rays onto the vacuum tube.

- High efficiency all year round.

- Low assembly costs: collector already assembled and easy to fix.

- Easy and immediate tube replacement with the EASY CHANGE system.

- Excellent heat insulation performance of the heat-carrying circuit also at low temperatures.

- Modern and elegant design.

Introduction

Page 5

3

Vacuum area

Multy-layer metal “CERMET” layer

Vacuum tube with double wall

Aluminium absorbing device

Copper pipe

THE VACUUM TUBE

AN OLD PRINCIPLE APPLIED TO AN INNOVATIVE TECHNOLOGY

The creation of the vacuum by removing the air from the gap in the glass tube achieves the best heat insulating material

possible. The principle has been known about for a century and is appreciated in the form of the thermos.

Using this arrangement, the collectors optimise the use of solar energy also during the change of seasons and during the

winter.

The internal surface of the vacuum gap is made selective to the absorption of the solar radiation by means of the laying,

by sputtering, of multiple metal layers with a micro-metric thickness, which is called CERMET and which cover the

absorption of the entire spectrum of electro-magnetic radiation of the sun.

The selective layer is designed especially to resist the high temperatures that are generated, through time. The presence

of the vacuum ensures the protection against infiltrations of humidity and atmospheric agents, thus guaranteeing unlimited duration and the maintenance of the capturing perfomance.

TRANSMISSION OF HEAT TO THE HEAT-CARRYING FLUID

The exchange of the heat collected takes place by a relevant absorbing device in aluminium, which on contact with a “U”

-shaped copper pipe transfers the heat to a heat-carrying fluid present in the solar collector circuit.

Page 6

4

WHY CHOOSE KLOBEN

The research carried out to increase the yield of the Kloben solar collectors have allowed to discover efficient and

innovative solutions to make the best of the sun and its diffused light. For this reason particular direct and diffused light

capturers, with CPC, Compound Parabolic Concentrator, geometry have been studied and realised using materials able to

supply optimal yields in total reflection (> 90%) and in reflection with diffused light.

The combination of vacuum tube technology and CPC reflectors applied to the solar collectors, guarantee the best yields,

most of all in situations of little radiation and low external temperatures. The advantage of the Kloben system therefore

has an immediate effect also at an economical level.

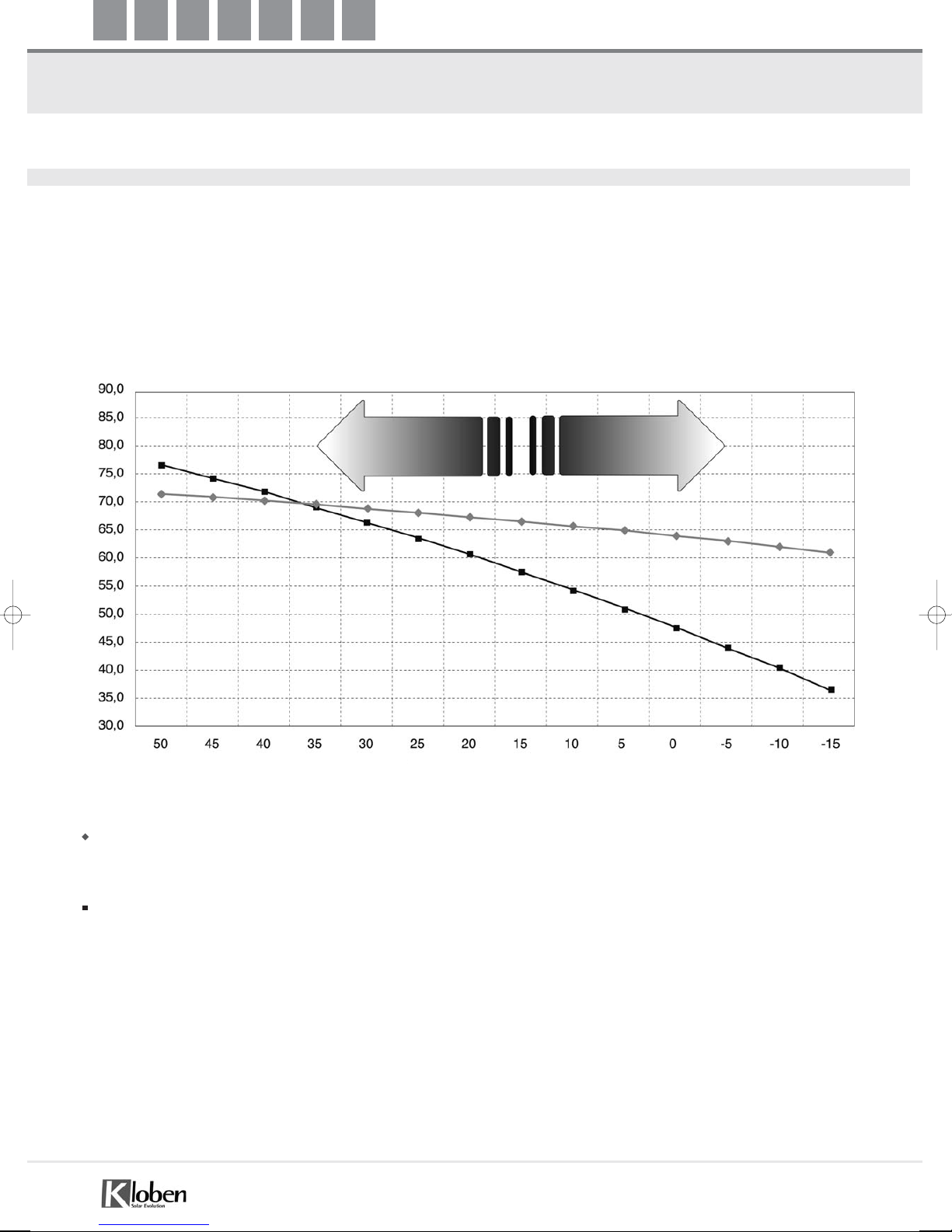

Efficiency curve with radiation at 800 W and average temperature inside heat-carrying fluid of 50°C of the Kloben SKY

CPC 58 DIFFISION model (Test Report no. 07COL623/1 (according to EN 12975-2:2006), ITW Institute, Stuttgart - Solar

Keymark certification).

Efficiency curve with radiation at 800 W and average temperature inside heat-carrying fluid of 50°C of a Solar Keymark

certified flat solar panel (data from Solar Keymark Database - Estif site, (European Solar Thermal Industry Federation))

From the comparison it was seen that for an average T of heat-carrying fluid of 50°C, the Kloben SKY CPC 58 Diffusion

vacuum collector has greater efficiency that the flat collector, up to 35°C of environment T. The difference in efficiency

increases even more on the decrease of the external temperature.

Yiled µ%

Environment temperature [°C]

Summer Winter

Page 7

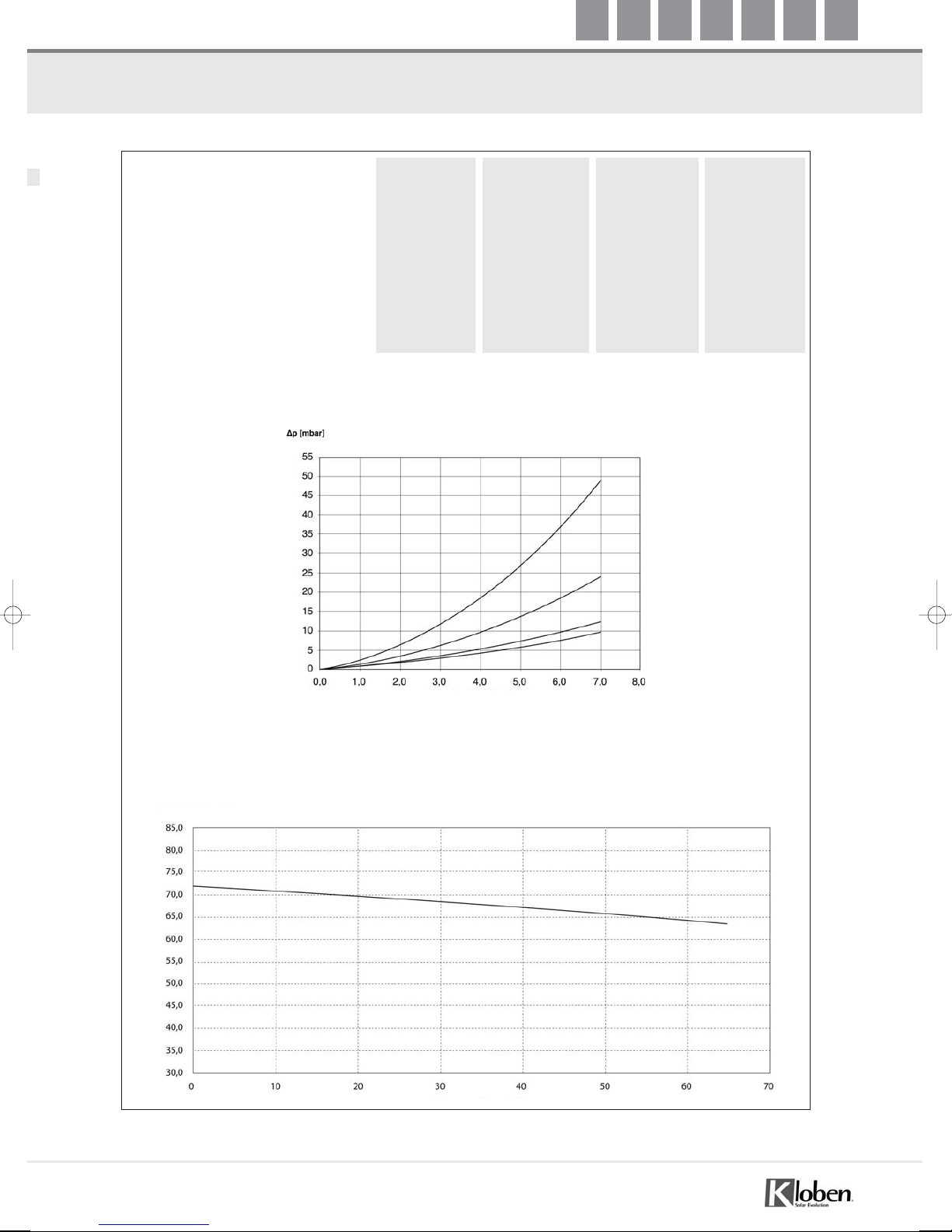

5

Solar collectors technical data

MODEL SKY 8 CPC 58 SKY 12 CPC 58 SKY 18 CPC 58 SKY 21 CPC 58

AMOUNT OF VACUUM TUBES (pc): 8 12 18 21

GROSS SURFACES (m

2

): 1.48 2.16 3.22 3.75

NET SURFACES (m

2

): 1.27 1.89 2.84 3.31

EMPTY WEIGHT (kg): 29 43 65 76

DIMENSIONS (mm)

Height: 1603 1603 1603 1603

Width: 920 1358 2018 2348

Thickness: 140 140 140 140

FEATURES

Circuit of the solar collector with “U”-shaped copper pipes with circulation in parallel

Maximum working pressure: 6.0 bar

Load loss:

Optimal flow rate: 1 l/min per m

2

Maximum working inclination: 90°

Minimum working inclination: 0°

Attachments: to tighten using soinner DN 18 mm

*Test Report no. 07COL623/1 (according to EN 12975-2:2006), ITW, Universität Stuttgart - SOLAR KEYMARK, Reg. no. 011-7S124R

SKY 8

SKY 12

SKY 18

SKY 21

Yield (square interpoling)*:

η0= 0.718%

a1= 0.974 [W·m-2·K-1]

a2= 0.005 [W·m-2·K-2]

(Taverage fluid - Tenvironmental) [K]

Volumetric flow rate [l/min]

Yiled µ%

Page 8

6

Dimensioning

Kloben makes use of a complex software that allows quick, precise and customised calculation of the enrgy requirements

requested, the number of panels necessary and the solar integration supplied, in relation to the destination of use of the

solar system, the details of the structure on which it is to be applied and the climatic data referring to the area of

installation.

For the dimensioning of all components, it is recommended to contact Kloben-authorised staff. However, it is possible to

perform approximate dimensioning of the components necessary for small solar systems (systems up to max 10 m

2

of solar

collector surface, optimal exposure of collectors max 20° from South and inclination at 45°, average daily consumption

per person of about 60 litres at 45°C), using the data shown below:

MAXIMUM DIMENSIONING OF SOLAR PANELS

MAXIMUM DIMENSIONING OF SYSTEM COMPONENTS

Expansion vessel: An approximate measurement consists in considering 6 l for every m2of solar surface installed.

For more accurate dimensioning refer to the solar calculation software of the vessel

available in the Kloben Intranet area.

Anti-freeze liquid: add the following parameters (A + B + C + D)

A. 1/2 of the capcity of the expansion vessel installed

B. 10 l for every 40 m of line (20 delivery + 20 return)

C. 1.17 l for every SKY 8 CPC 58

1.74 l for every SKY 12 CPC 58

2.60 l for every SKY 18 CPC 58

3.07 l for every SKY 21 CPC 58

D. about 15 l for storage from 300 to 500 l

about 20 l for storage from 500 to 750 l

about 30 l for storage from 750 to 1000 l

Solar Station: LOW FLOW for the management of systems with flow rate from 2 to 16 l/min

BIG FLOW for the management of systems with flow rate from 10 to 80 l/min

For more accurate dimensioning refer to the solar calculation software available in the Kloben

Intranet area.

Flow rate adjuster: 1 l/min for every m

2

of solar surface installed.

NORTH CENTRAL SOUTH

ITALY ITALY ITALY

Water at 45°C produced

per m

2

of solar surface (litres) 80 90 100

Heatable radiant surface

(laying distance 10 cm) from 10 to 15 m

2

from 12 to 16 m2from 14 to 18 m

2

for every m2of solar

Relation between solar and swimming pool sup.

(for summer use - ca. 35% ca. 30% ca. 25%

water 26°C - night cover use)

Page 9

7

Checks and parameters indispensable for dimensioning

In order to start with a correct design, aimed at the realisation of the solar system that is the most suitable for maximising

the benefits of the final customer, some important preliminary checks must be carried out and indispensable data must be

gathered for correct dimensioning:

PROJECT LOCALITY:

The locality where the system is to be installed supplies precious indications for dimensioning, such as: average monthly

radiation, average monthly external temperature, mains water average monthly temperature, average relative humidity

temperature, average monthly wind speed.

METHOD OF CONSUMPTION AND PERIOD OF USE OF THE SYSTEM:

Consider the daily requirement of the family; an approximate consumption of hot water at 45°C variable from 50 to 70

l/day per person. Identify any simultaneous requests for the use of domestic hot water. Check the period of use of the

system (seasonal or months of use).

TYPE OF SYSTEM USE:

heating domestic hot water: identify the consumption and temperature of the water requested and the capacity

of the existing storage tank. For maximum dimensionimg of the capacity of the storage tank to be envisioned, it

is possible to refer to about the double of the daily consumption envisioned for the family or inhabitants.

heating non-domestic hot water: hotel, gym etc.-indicating that stated previously regarding the methods of

consumption and periods of use. For this type of system, therefore, an ad hoc design by designers or Kloben tech

nical staff is always necessary.

room heating: only radiating - identify surfaces to be heated, space between tubes and type of insulation.

swimming pool: specifies if covered or outdoor, any night cover use, requested temperature, period of use.

FEATURES OF THE INSTALLATION STRUCTURE:

The surfaces that house the field of solar collectors are an important restriction of the design, which must be considered

as the positioning of the solar collector affects the capturing efficiency of the sun’s radiation. The checks to be carried out

are: possibility of assembly on flat or sloped roof, availability of roof pitch with orientation towards the south or

alternatively with orientation towards east or west, inclination of the pitch, presence of obstacles, etc.

From the existing Standard, UNI 9182, the data inherent to flow rates and requirement of domestic hot water according

to the activity in question and the single appliances, are gathered.

The dimensioning indications stated above refer to maximum dimensioning and are relative to homes with the standard

consumtion of an average family. However, for the correct dimensioning of all parts of the system, it is necessary to

consider the preliminary checks indicated along with all of the details of use of the final user to then proceed with the

definition of the energy requested, the modes of distribution (flow rates, temperatures, period of request) and

successively with the correct dimensioning of all system components on the basis of powers and exchange yields of the

various components: solar surface, solar heat exchanges, storage, etc.

For this reason and for accurate dimensioning refer to Kloben specialised technical staff.

N.B. IF THE SOLAR INSTALLATION IS INTRODUCED ONTO SYSTEMS THAT ALREADY

FUNCTION, IT IS INDISPENSABLE TO HAVE THE DETAILED LAYOUT OF THE EXISTING

HEATING STATION, WITHOUT WHICH IT WILL NOT BE POSSIBLE TO SUPPLY ANY

PERFORMANCE GUARANTEE.

Page 10

8

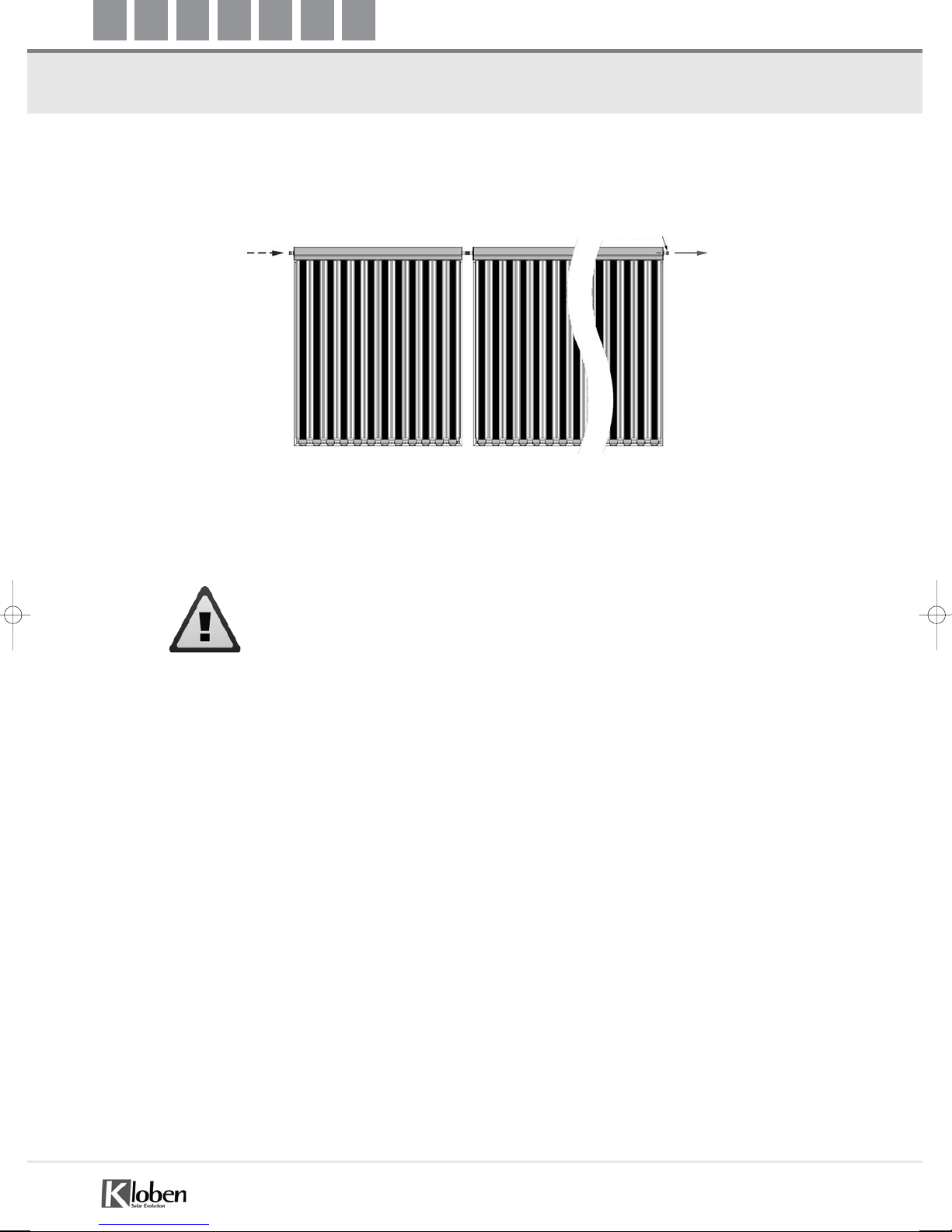

Example of connection of the collectors in series

ATTENTION: do not connect more than n° 4 collectors in series

Probe S1

Page 11

9

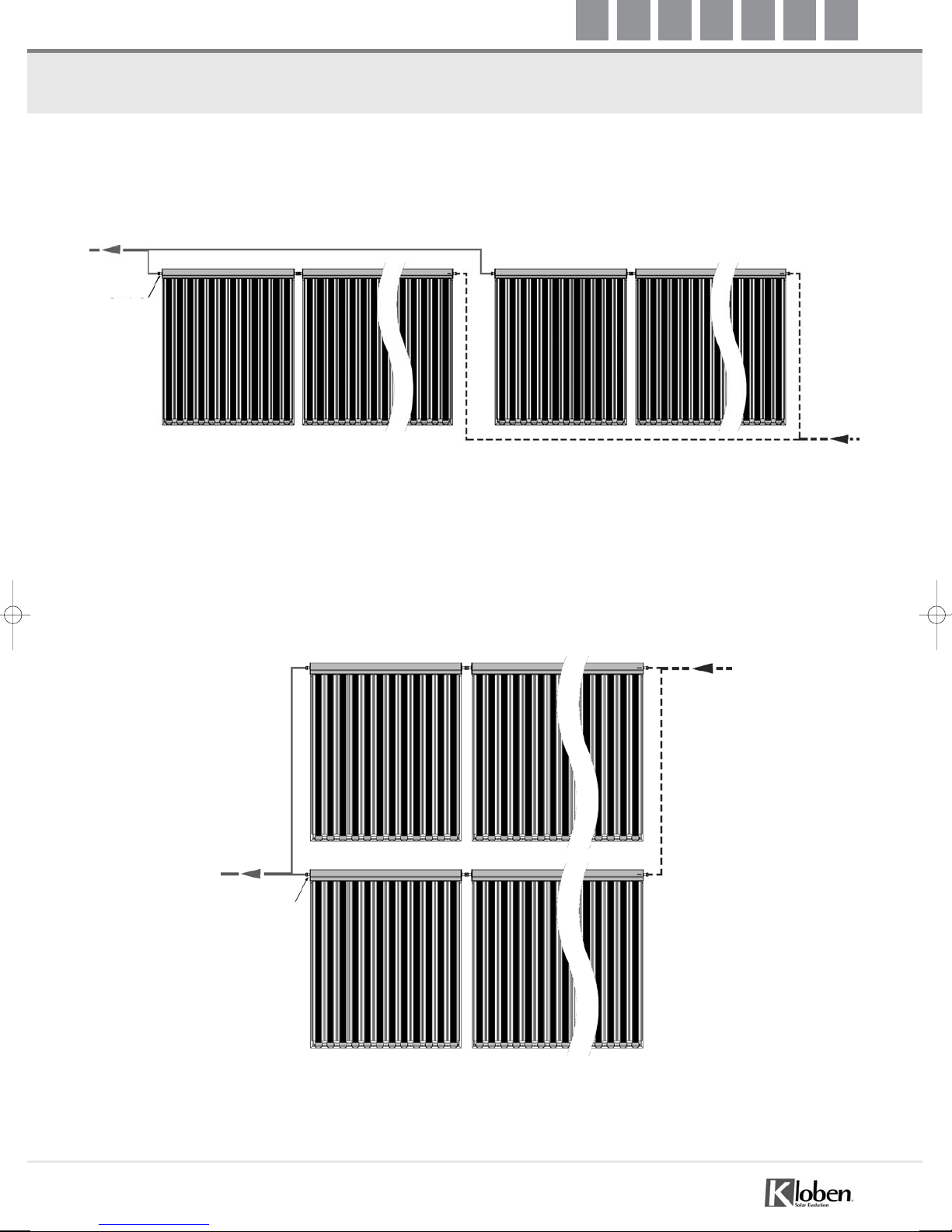

Example of connection of the collectors in parallel

TICHELMAN SYSTEM: consists in the hydraulic balancing of the collector coils.

EXAMPLE 1

EXAMPLE 2

Probe S1

Probe S1

Page 12

10

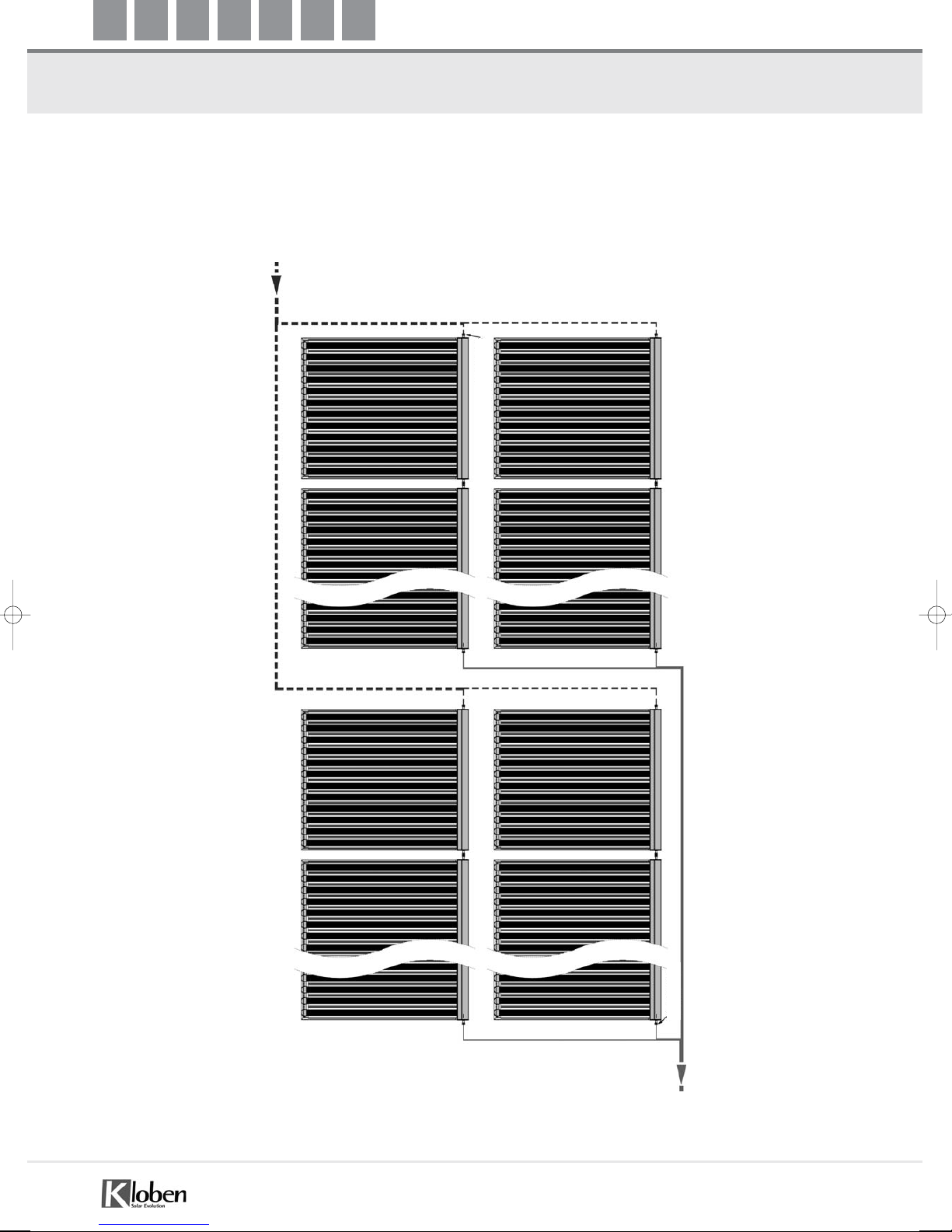

Example of connection of the collectors in parallel

TICHELMAN SYSTEM

EXAMPLE 3

Probe S1

Probe S1

Page 13

11

Warnings and preliminary checks

The installer is asked to carefully follow the recommendations and indications that are listed successively; as well as

performing all controls requested before system start-up.

ANTI-FREEZE HEAT-CARRYING FLUID:

The heat-carrying fluid used and supplied consists in a special liquid with anti-freeze properties, TYFOCOR LS. This fluid

is specially for use in solar plants with high heat yield like vacuum tube collectors. It is totally pre-mixed and ready for

use. It guarantees protection from freezing to -28°C.

It contains corrosion inhibitors that guarantee efficient protection and duration of the copper pipes, (and all other metals

and alloys used) in particular from corrosion and deposits.

Warnings: In order to maintain the protective features of TYFOCOR LS unaltered, it must not be mixed with other

heat-carrying fluids and anti-freeze or diluted with water. Any top-up owing to the loss of fluid must be compensated

exclusively with TYFOCOR LS. Before loading always check that there is no water in the circuit.

The use of deposited metals is advised for soldering. For welding points the use of deposited metals is recommended for

brazing in silver and copper.

TYFOCOR LS does not attack the sealing materials normally used in solar systems. However, attention must be paid that

all sealing materials are resistant to the maximum temperature of the heat-carrying fluid. Failure to comply with these

checks can lead to the warranty of the solar collector becoming void.

LOADING:

- Before starting the system loading operation, make sure that the solar collectors are at low temperature.

The panels must be covered at least 3 hours before loading.

- The system must be loaded by carefully following the instructions given on page 25 of this manual. The use of the

supplied system loading pump is also recommended (code 101010045).

Correct loading allows the complete elimination of air in the solar circuit and its correct functioning.

- The system’s optimal functioning pressure, to be calibrated in the loading phase is 3/3.5 bar in the heating station and

at least 2/2.5 bar at the panels, with the system at a standstill.

DIMENSIONING:

- Before starting the solar system it is good practice to check that dimensioning and the adjustment of the individual

components ( panels, expansion vessel, glycol, flow rate adjuster, solar station) are in compliance with that indicated on

page 5 of this manual.

- It is indispensable that the diameter of the copper pipes making up the solar circuit are in compliance with that

indicated on page 11 of the following manual. If in doubt, refer to Kloben authorised staff or our technical dept.

INSTALLATION AND RESISTANCE TO LOADING STRESS, WIND AND SNOW:

The installation of solar collectors on flat and sloped roofs envisions indispensable preliminary checks that clarify the

following critical aspects:

- Static stability of the roof for assembly of the collectors

- Accessibility of the roof housing the system and sufficient access and freedom of movement in safety

- Fixing quality of the structure connections and support devices of the solar collectors to the building support (loft

structure, flat roof structure, etc.).

On the basis of the place of installation selected, the locality, the height from the ground, exposure, topography of the

land, the climatic conditions of the areas, etc. preliminary checks must be made of the loading conditions owing to the

wind (average, peaks due to gusts and the presence of storms) and snow on the basis of that envisioned by the

"Departmental Circular dated 4 July 1996, n. 156" regarding implementation "technical standards relative to the general

criteria regarding the safety checks of the constructions and loads and overloads", Legislative Decree dated 16 January

1996.

In the calculations regarding the evaluation of stress of individual and combined loads owing to wind and snowfall, a

maximum sustainable load must be considered, normal to the surface of the collector of 0.90 kN/m2.

The solar collector has been designed to suitably resist combined conditions of wind and snow, the most serious

features of the Italian territory. However, if phenomena of an exceptional nature should occur or situations or loads

exceeding the maximum load of the panel it is good practice to prepare additional protections, such as tie-rods and

Page 14

12

reinforcements for stabilisation.

MATERIALS:

- All pipes making up the solar circuit must be in copper. The use of other materials such as zinc, stainless steel, plastic,

brass and similar is not recommended. If materials different from copper are used, it will be impossible to guarantee

correct functioning of the system.

- All joints must be welded or with tightening connections for copper pipes.

The use of any other materials can jeopardise the sealing of the joints through time.

- To prevent sealing problems of the hydraulic joints of the solar circuit owing to heat stress, always check the distance

at which the field of solar collectors is found with respect to the storage tanks. In all cases it is recommended always

to make the joints with high temperature Teflon.

- The copper pipes must be insulated using a sheath for high temperatures such as the Kloben Solare.

CHECKS:

- Check that, with the system unloaded, the expansion vessel is calibrated at 2 bar.

- Check the correct connection of the probes to the solar control unit.

- Check that the solar control unit is connected correctly to the mains.

- Check that the setting of the solar control unit parameters is in compliance with that prescribed in the design phase.

N.B.: The solar collectors cannot remain exposed to solar radiation for long periods of time without being

loaded (ten days).

Page 15

13

Practical table for the choice of piping

FLOW RATE AND PIPING SECTION

(WITH MAXIMUM LENGTH OF 20 METRES FOR DELIVERY AND 20 METRES FOR RETURN)*

* IF THE CIRCUITS HAVE A LONGER LENGTH OR A CONSIDERABLE NUMBER OF BENDS, PLEASE CONTACT

KLOBEN AUTHORISED STAFF.

For further indications regarding the choice of piping combinations refer tot he Kloben calculation software, present in

the intranet area at: http://solar.kloben.it/impianto

N.B.: As well as the choice of piping, for correct functioning of the solar system correct dimensioning of all components

is necessary (page 5 of this manual).

N.B.: Page 12 of this manual must be consulted for the choice of the solar station.

N.B.: If a greater solar surface is required, more parallel rows will be constituted, each with the same surface area,

connected to each other using the TICHELMAN method (page 8 and 9 of this manual).

N.B.: For systems with particular dimensions and non-standard features, specific calculations must be made to

determine loss of load, pipe diameter, etc.

Cylinder [litres] Type and number collector Flow rate [l/min] Ø Piping [mm]

150 1 x SKY 8 1.27 Copper 14

150 1 x SKY 12 1.89 Copper 16

200 1 x SKY 12 1.89 Copper 16

200 1 x SKY 18 2.84 Copper 16

300 1 x SKY 18 2.84 Copper 16

300 1 x SKY 21 3.31 Copper 16

300 2 x SKY 12 3.78 Copper 18

500 1 x SKY 12 + 1 x SKY 18 4.73 Copper 18

500 2 x SKY 18 5.68 Copper 18

600 2 x SKY 21 6.62 Copper 18

750 3 x SKY 18 8.52 Copper 22

800 3 x SKY 18 8.52 Copper 22

1000 4 x SKY 18 11.36 Copper 22

1500 6 x SKY 18 17.04 Copper 28

2000 8 x SKY 18 22.72 Copper 35

3000 12 x SKY 18 34.08 Copper 35

Page 16

14

LOW - FLOW STATION PUMP FEATURES Flow rate 2-16 l/min

BIG - FLOW STATION PUMP FEATURES Flow rate 10-80 l/min

For more accurate dimensioning, refer to the solar calculation software available in Intranet.

Current I: Onside thermal overload settings.

Measurements - Weight

Motor Data

Single-phase motor (EM) 2 poles - 1

˜

230 V, 50 Hz

Nom. Power

P. max

W

Speed/N. of revs.

n.

1/min.

Absorbed power

P.

W

Current

I

A

Condenser

µF/VDB

Motor

Protection

Measurements - Weight

Motor Data

Single-phase motor (EM) 2 poles - 1

˜

230 V, 50 Hz

Page 17

15

Clearance

Model A B

SKY 8 983 mm 910 mm

SKY 12 1424 mm 1350 mm

SKY 18 2084 mm 2010 mm

SKY 21 2414 mm 2340 mm

Page 18

Flat roof kit assembly layout

16

Position the fixing beams complete with base plate onto the ground,

taking care to respect the maximum distances indicated in the following figure.

Bolt the template support uprights to the fixing beams (see figure below)

ASSEMBLY LAYOUT FOR 1 SKY CPC 58 PANEL: 8 - 12 - 18 - 21

Model A max

SKY 8 300 mm

SKY 12 680 mm

SKY 18 1300 mm

SKY 21 1500 mm

Fixing beam with base plate

Small base plate

Template support uprights

Page 19

17

Flat roof kit assembly layout

Fix the frame to the loft suitably. The nuts and bolts to use must be made in relation to the sub-base material. Each base

plate has 4 holes measuring 12 mm.

Position and fix the support templates according to that indicated in the figure

Solar Panel

support template

Page 20

18

Flat roof kit assembly layout

ASSEMBLY LAYOUT FOR 2 SKY CPC 58 PANELS: 8 - 12 - 18

In the case of installation in series of 2 SKY CPC 58 8, 12, 18 panels, respect the distances indicated in the figure,

where P (support plate width) is a fixed measurement.

ASSEMBLY LAYOUT FOR 3 AND MORE SKY CPC 58 PANELS: 8 - 12 - 18

In the case of installation in series of 3 or more SKY CPC 58 8, 12, 18 panels, rrespect the distances indicated in the

figure where P (support plate width) and C are fixed measurements.

Model P B max

SKY 8 150 mm 535 mm

SKY 12 150 mm 970 mm

SKY 18 150 mm 1500 mm

Model P B max C

SKY 8 150 mm 535 mm 840 mm

SKY 12 150 mm 970 mm 1280 mm

SKY 18 150 mm 1500 mm 1940 mm

Page 21

19

Flat roof kit assembly layout

ASSEMBLY LAYOUT FOR 2 AND MORE SKY CPC 58 PANELS: 21

In the case of installation in series of 2 or more SKY CPC 58 21 panels, 2 support brackets for each collector are

necessary, as described in the figure. Respect the maximum distance A as indicated in the figure where P is the width of

the support plate.

Model P A

SKY 21 150 mm 1500 mm

Page 22

20

TITOLO

Flat roof kit assembly layout

CONNECTIONS AND VENT KIT

CONNECTION NUT DN 18

SPINNER DN 18

REINFORCEMENT INSERT DN 18

KLOBEN SOLAR VENT

CONNECTION DN 18

Page 23

21

Flat roof kit assembly layout

Position the collectors near to each other and bolt them (without tightening) to the support templates in the holes

already prepared (Figure 4), by means of the screws present on the panels (there are 4 screws for each collector).

Then join the panels using the tightening connections supplied and already positioned on the collector (Figure 6). After

this operation tighten the panels onto the templates.

Detail of collector joining by means of

tightening connection

Page 24

22

Sloped roof kit assembly layout

Position the fixing brackets, supplied in the kit, onto the sub-base as shown in the figure.

Each fixing bracket has 4 holes measuring 12 mm. the choice of nuts and bolts must be made keeping in mind the

structure and material of the sub-base.

Fixing bracket

ASSEMBLY LAYOUT FOR 1 SKY CPC 58 PANEL: 8 - 12 - 18 - 21

In the case of installation of 1 SKY CPC 58 8, 12, 18 or 21 panel, respect the distances indicated in the figure, where P

(support plate width) is a fixed measurement and A and Z are variable.

Model P A max Z max Z min

SKY 8 150 mm 280 mm 1500 mm 880 mm

SKY 12 150 mm 680 mm 1500 mm 880 mm

SKY 18 150 mm 1300 mm 1500 mm 880 mm

SKY 21 150 mm 1500 mm 1500 mm 880 mm

Page 25

23

Sloped roof kit assembly layout

ASSEMBLY LAYOUT FOR 2 SKY CPC 58 PANELS: 8 - 12 - 18 IN SERIES

In the case of installation in series of 2 SKY CPC 58 8, 12, 18 panels, respect the distances indicated in the figure,

where P (support plate width) is a fixed measurement and B is variable.

ASSEMBLY LAYOUT FOR 3 AND MORE SKY CPC 58 PANELS: 8 - 12 - 18 IN SERIES

In the case of installation in series of 3 or more SKY CPC 58 8, 12, 18 panels, respect the distances indicated in the

figure where P (support plate width) and C are fixed measurements, while B is variable

Model P B max C

SKY 8 150 mm 530 mm 840 mm

SKY 12 150 mm 970 mm 1280 mm

SKY 18 150 mm 1500 mm 1940 mm

Model P B max

SKY 8 150 mm 530 mm

SKY 12 150 mm 970 mm

SKY 18 150 mm 1500 mm

Page 26

24

ASSEMBLY LAYOUT FOR 2 AND MORE SKY CPC 58 PANELS: 21

In the case of installation in series of 2 or more SKY CPC 58 21 panels, 2 support brackets for each collector are

required as described in figure 2. Respect the maximum distance A as indicated in the figure, where P (support plate

width) is a fixed measurement, while A is variable.

Model P A max

SKY 21 150 mm 1500 mm

Page 27

25

Sloped roof kit assembly layout

Position the collectors near to each other and bolt them (without tightening) to the support templates in the

holes already prepared (Figure 4), by means of the screws present on the panels (there are 4 screws for each

collector).

Then join the panels using the tightening connections supplied and already positioned on the collector

(Figure 12). After this operation tighten the panels onto the templates.

Detail of collector joining by means of

tightening connection

Page 28

26

Sloped roof kit assembly layout

CONNECTION AND VENT KIT

CONNECTION NUT DN 18

SPINNER DN 18

REINFORCEMENT INSERT DN 18

KLOBEN SOLAR VENT

CONNECTION DN 18

Page 29

27

Hydraulic connections

ATTENTION

Once the hydraulic connections have been made, load the solar plant by means of the solar station, scrupulously

following the instructions given on page 25.

It is also fundamental to eliminate all air present in the circuit (to prevent system malfunctioning). Regarding this, the

use of the supplied loading pump is recommended (code art. 101010045).

When loading has been performed another check must be carried out that deaeration has been performed, using the

manual air vent valves mounted on the solar collector.

Position probe F1 ALWAYS ON THE DELIVERY.

For correct introduction of the probe follow the instructions given on page 24

DELIVERY

RETURN

Page 30

28

Instructions for assembly of the F1/PT 1000 probe

For correct introduction of the F1 probe (recognisable by the grey silicone cable) follow the indications given below:

1) Insert the sensitive element of the probe F1 into the relative probe-holder well mounted on the panel, in the direction

indicated in the figure above.

2) Leave the cable to run to the bottom of the well, making sure not to block it completely.

3) Successively, make the electric connections with the solar control unit, carefully following the instructions attached to

the same.

4) Connect the probe electrically to the control unit.

It is advised to wear work gloves and protective goggles in order to prevent injury if the

vacuum tube should accidentally break.

PT 1000/F1probe

(grey silicone cable)

Sensitive element

Probe-holder well

Direction of insertion of F1

Page 31

29

System loading using the solar station

SOLAR STATION: DISPLAY AND DESCRIPTION OF COMPONENTS

LOADING THE SYSTEM

1. Before starting loading, check that the panels have been covered for at least 5 hours.

2. Connect the loading pump delivery pipe to the ball valve (7).

3. Connect the loading pump return pipe to the ball valve (4).

4. Open the ball valves (7 and 4).

5. Close the non-return valve (10) (turning in a clockwise direction).

6. Switch the loading pump on in a way that the anti-freeze circulates in the opposite direction with respect to

normal functioning.

7. If there is a diverter valve on the solar line, check that it is open (manual)

to allow the circulation of anti-freeze in both circuits. At the end of this operation take the valve to its original

position (automatic).

8. Leave the pump to function for the time neecessary to allow the perfect deaeration of the system.

9. Quickly open and close the non-return valve for a few seconds (10). At the end of this operation leave the valve

in the “open” position.

10. Close the ball valve (4).

11. Take the system to a pressure of 3 bar (pressure displayed on the manometer (3)).

12. Close the ball valve (7).

13. Switch the loading pump off.

14. Switch the solar control unit on and check the correct settings and functioning.

15. Set the flow rate adjuster on the value suitable for dimensioning of the system (Page 14 of this manual).

16. Uncover the previously-covered panels.

Safety valve

Flexible pipe connction

for expansion vessel

Manometer

Ball valve

Pump

Flow adjuster

Ball valve

Flow gauge

Non-return valve

Non-return valve

Page 32

30

Inclinations of the solar collectors

On the basis of the way of fixing the rear template support upright of the bracket kit for flat roofs it is possible to obtain

3 different inclinations of the solar collector. The figure shows the 3 different configurations allowed by the brackets.

A larger inclination is used o favour the integration in the winter period. The choice of inclination is made in the design

phase on the basis of user requirements and by evaluating the surplus energy in the summer period.

Consult the Kloben technical dept. for inclinations different to those envisioned.

DISTANCE BETWEEN THE SETS OF COLLECTORS

The figure indicates, for every inclination configuration of the collectors, the minimum distances to be respected between one string of solar collectors in series and another to prevent shadows.

The calculation has been carried out for the inclination of solar rays at the latitude of Rome. For installations in areas

with considerably different latitudes, contact the Kloben technical dept.

INCLINATION 39° INCLINATION 45°INCLINATION 36°

Page 33

31

Orientation of the collectors

It is very important to check that there are no obstructions on the horizon that may jeopardise the radiation of the

collector during transit of the sun.

If obstacles are present they must be signalled as this information conditions the dimensioning of the necessary solar

collectors.

ANY ORIENTATION OF THE PANELS THAT IS DIFFERENT FROM THOSE STATED IN THIS

MANUAL DOES NOT GUARANTEE THE OPTIMAL PERFORMANCE OF THE SYSTEM

Azimuth

The distance of a celestial object from

the north of the horizon of th observer.

It is measured in degrees, starting from

north (that = 0°) in a clockwide

direction.

Zenith

The point of the celestial sphere

directly above the head of the observer.

In the altazimuth system it is the

meeting point of the straigth line,

perpendicular to the ground, passing

through the observer and the celestial

sphere. The opposite point is called

nadir.

Optimal orientation = 0° South

Maximum orientation recommended = 30° South/East -- 30° South/West

Page 34

32

Maintenance and repairs

A yearly inspection is recommended to check the general state of the collector and the solar system in order to

determine the necessity of any repair interventions.

In particular, the following periodic controls must be performed:

Yearly check of system pressure.

If pressure is lower than the optimal working pressure (cf.“WARNINGS AND PRELIMINARY CHECKS”) the causes that

determined the loss must be checked. Only a Kloben authorised after-sales centre can restore optimal working conditions.

Yearly check of anti-freeze protection efficiency.

The anti-freeze heat-carrying liquid must be checked yearly, before the winter. The Kloben authorised after-sales centres

can check and restore the optimal anti-freeze protection conditions of the solar system.

Yearly check of corrosion protection.

A periodical check of the anti-corrosive properties of the heat-carrying fluid must be implemented. TYFOCOR LS has a

pH that varies from 9.0 to 10.5. If, using litmus paper, sensitively lower pH values should be detected, generally < 7, it is

good practice to replace the TYFOCOR LS heat-carrying fluid.

Check regarding the operational efficiency of the vacuum tube collectors.

For efficient functioning of the vacuum glass tube it is necessary that the vacuum conditions in the gap remain unaltered

through time. An evident test that can be seen with the naked eye regarding the loss of vacuum conditions is the

presence of a white powder deposit on the reflecting area in the lower “pointed” part of the tube.

In the presence of damaged tubes the fragments of glass present in the housing of the vacuum tube in the solar collector

box and in the small cup that supports the tube, must be removed.

In order to replace a tube, first loosen the small cup following the OPEN arrow indicated on the back of the same. Slide

the vacuum tube delicately out of the housing in the solar collector box, keeping a more or less inclined position with

respect to the panel in order to prevent damage to the circuit U-shaped copper pipe. Recover the silicone gasket present

on the upper part of the extracted tube. Insert the gasket onto the upper part of the new vacuum tube, after having

lubricated the part with soapy water to ease insertion. Then house the tube in the collector, repeating the extraction

operation in reverse order and delicately inserting the U-shaped copper pipe with relative combined absorbing device.

Make sure, as previously, that the direction of insertion is not too inclined with respect to the solar collector panel. Push

the open head of the vacuum tube into the box housing of the solar collector until it is fully home. Position and fix the

tube-support cup into the lower part, screwing in a clockwise direction towards the CLOSE arrow. Accomodate the

vacuum tube and attach the gaskets well to the collector box.

Page 35

33

PASSIVE SAFETY

In a closed circuit with a pressure of 3-3.5 bar, the evaporation point of the heat-carrying fluid is about 130°C. During the

summer period and in particular in periods when hot water is not used, when the heat storage inertial unit, the cylinder,

reaches the maximum set temperature, the solar circuit pump is switched off by the control unit. In these conditions, the

temperature of the fluid in the solar collector circuit starts to rise until the collector is taken into the so-called stagnation

condition where evaporation of the fuid takes place at around 130°C. The expansion caused by the vapour formed forces

the content of heat-carrying fluid of the solar collectors into the prepared venting volume, contained in the expansion vessel that has been dimensioned especially to house this amount (cf.DIMENSIONING - Expansion vessel). At this point only

vapour will be present in the solar collectors. This stall situation guarantees that the temperature does not rise further.

When there is a withdrawal of heat from the boiler, this will determine the decrease of temperature in the collectors and

the condensation of the vapour will leave room for heat-carrying fluid, recalling it from the expansion vessel.

SAFETY VALVE

Each solar station with circulation pump has a safety valve with threshold pressure of 6 bar. This device is used to fix the

maximum theoretical pressure that can be reached inside the solar circuit.

SAFETY LOGIC

Every solar system functioning control and management control unit has safety logic control functions set itop revent any

damage to the system components and for the safety of the user:

- circulation block with T > 80-90°C to the solar collector (measured using PT 1000 probe);

- circulation block with T > 130°C to the storage tank (measured in the cylinder using NTC probe);

- start of the safety ANTI-FREEZE circulation with T < T minimum that can be set (measured in the piping using NTC probe);

- start of boiler integration for ANTI-LEGIONELLA safety with T < 65°C to the cylinder for more than a week

(measured in the cylinder using NTC probe or boiler probe).

PROTECTION AGAINST LIGHTENING

The solar collector must have a potential balancing device for protection against lightening, in compliance with the

Standard in force. An equipotential connection between the solar collector frame and the earth can be performed. An earth

conductor connection must be envisioned that is particularly efficient, with copper cable with minimum section of 10

mm2. If a lightening conductor is already available, connect the frame to the existing equipotential conductor. The

connection must intercept the delivery or return conductor as well as the frame.

For large solar systems consider a connection to the equipotential conductor every 200 m2.

PROTECTION AGAINST BURNS

The temperatures in the storage unit or cylinders can reach high levels. For this reason, the Kloben hydraulic layouts

always state the use of a mixer thermostatic valve to be inserted at the exit of the cylinder on the delivery for the DHW

utility. This valve guarantees a maximum T to the utility of 48°C + 5°C tolerance (cf. “FOR THE USER”).

Safety systems

Page 36

34

Indications regarding transport and handling

There are no specific warnings regarding the handling and transport of the solar collectors, if not the usual cautions to

consider when handling fragile objects.

The packaged panel must be loaded onto lorries or any other means of transport in a vertical position.

Wear rubber or PVC gloves during handling, installation and maintenance of the panels, so as to prevent injury due to the

accidental breakage of fragile material, such as glass.

The use of protective glasses is also recommended.

There are no particular measures for the use and handling of the heat-carrying liquid TYFOCOR LS. Just follow the

normal safety and hygiene measures relative to the use of chemical substances. Also refer to the information contained in

the TYFOCOR LS safety sheet.

Page 37

35

For the user

The management of the Kloben solar system does not require particular interventions by the user if not for the normal

periodic maintenance checks stated below. Once the plant is started by the installer it operates automatically and

completely autonomously, even when the user is not present.

The regulations contained in the Presidential Decree dated 26 August 1993, n. 412 (GU 14 October 1993, n. 96) lay

down the Standards for design, installation, working and maintenance of building heating systems in order to contain

energy consumption, in implementation of art.4, paragraphs 4, stated in Art.5 (sub 7):

In new heat plants and those undergoing restructuring, the heat generators destined for the centralised production of

domestic hot water for multiple utilities of the housing type must be dimensioned according to the UNI 9182 technical

standards, must have a hot water storage system with suitable capacity, be insulated depending on the diameter of the

tanks according to the indications valid for piping stated in the last column of attachment B and must be designed and

run in a way that the temperature of the water, measured at the emission point of the distribution network, does not

exceed 48°C, + 5°C tolerance.

Regarding this, we recommend the installation of a thermostatic mixer at the exit of the cylinder, as also indicated in

our layouts.

Kloben guarantees the products or materials for a period of five years, plus another five years after audit, with the

following exceptions regarding time:

- Electric motors, every electrical part and every part subject to wear (e.g.: diverter valves, circulation pumps, safety

thermostats, control unit) traded are covered by a warranty of two years, against construction or material defects.

- The cylinder test anode is subject to the warranty of two years, against construction or material defects.

The warranty terms come into force from the date of installation of the materials

Anti-freeze protection

It is indispensable that an efficient anti-freeze protection is guaranteed through time. In the basis of experience, the

TYFOCOR LS heat-carrying liquid keeps its anti-freeze and anti-corrosion properties unaltered for at least 5 years. It is

however indispensable that the user has Kloben authorised staff check the operational conditions of the heat-carrying fluid

every year in order to evaluate the status and integrate it or replace it if necessary.

Preventive measures in the case of non-use

In the case of long periods of inactivity of the solar system during the summer, it is good practice, where possible, to cover

the solar collectors with tarpaulin or similar material. If energy is not withdrawn from the storage unit the temperatures of

the solar collectors can reach high levels to about 300°C. In these situations the normal measures for facing these

conditions are more than sufficient to prevent damage to the solar collector. In fact the expansion vessel acts as a vent,

housing the collector’s liquid.

Failure to comply with this measure does not jeopardise normal functioning of the solar collector. On the other hand, this

however can contribute to lengthening the lifespan.

Anomalous functioning

If evident functioning anomalies are detected, such as falls in system pressure, lack of sealing, malfunctioning of the system

control and ajustment appliances, contact a Kloben authorised after-sales centre.

The executive design and consequent set-up, both electrical and hydraulic, must be realised with

respect to the laws in force.

Page 38

36

Grand Soleil Medium Kit

Kloben SKY CPC 58 Solar Connection

Kloben Low-Flow solar station

Power supply from mains water

Kloben cylinder with two coils

Kloben condensing boiler

Kloben open collector

System loading

Kloben EASY Heat adjustment

PROVISIONS

FOR THE REALISATION OF THE SOLAR SYSTEM

M

All of the piping making up the solar circuit must be in copper.

M All joints must be welded or with the tightening-type brass spinner

connections.

M The copper pipes must be insulated using high temperature sheaths

with minimum thickness of 19 mm (E.G. 100010305 Kloben list).

M For the boiler warranty, when filling the system use algicide consulting

the Kloben list.

DESCRITION

This layout is purely indicative and not binding

and does not constitute any liability for Kloben

or its collaborators. The executive design and

consequent set-up must be realised with

respect to the laws in force.

System loading (no automatic loading)

Probe S3

Probe S1

(PT1000)

Domestic hot water

thermostatic valve

30 + 65°C

Realise condensate

drain to sewer drain

Boiler with diverter

valve control

Traditional

Boiler

Direction of

insertion

Combustion gas evacuation

with pipe ø 80 mm

pressurised with respect to

standard UNI 10845

Air intake

DHW probe

supplied with

the boiler

Piping connection

with panel

Panel joints

with insulation

Manual air vent valve

Page 39

37

Grand Soleil Kit

Kloben SKY CPC 58 Solar Connection

Kloben Low-Flow solar station

Power supply from mains water

Kloben cylinder with two coils

Kloben condensing boiler

Kloben open collector

System loading

Kloben EASY Heat adjustment

PROVISIONS

FOR THE REALISATION OF THE SOLAR SYSTEM

M

All of the piping making up the solar circuit must be in copper.

M All joints must be welded or with the tightening-type brass spinner

connections.

M The copper pipes must be insulated using high temperature sheaths

with minimum thickness of 19 mm (E.G. 100010305 Kloben list).

M For the boiler warranty, when filling the system use algicide consul-

ting the Kloben list.

DESCRITION

This layout is purely indicative and not binding

and does not constitute any liability for Kloben

or its collaborators. The executive design and

consequent set-up must be realised with

respect to the laws in force.

System loading (no automatic loading)

Probe S3

Probe S1

(PT1000)

Domestic hot water

thermostatic valve

30 + 65°C

Realise condensate

drain to sewer drain

Traditional

Boiler

Direction of

insertion

Combustion gas evacuation

with pipe ø 80 mm

pressurised with respect to

standard UNI 10845

Air intake

Piping connection

with panel

Panel joints

with insulation

Manual air vent valve

Probe S6

Probe S4

Page 40

38

Grand Soleil Plus Kit

Kloben SKY CPC 58 Solar Connection

Kloben Low-Flow solar station

Power supply from mains water

Kloben cylinder with two coils

Kloben condensing boiler

Kloben open collector

System loading

Kloben EASY Heat adjustment

DESCRITION

PROVISIONS

FOR THE REALISATION OF THE SOLAR SYSTEM

M

All of the piping making up the solar circuit must be in copper.

M All joints must be welded or with the tightening-type brass spinner

connections.

M The copper pipes must be insulated using high temperature sheaths

with minimum thickness of 19 mm (E.G. 100010305 Kloben list).

M For the boiler warranty, when filling the system use algicide consul-

ting the Kloben list.

This layout is purely indicative and not binding

and does not constitute any liability for Kloben

or its collaborators. The executive design and

consequent set-up must be realised with

respect to the laws in force.

System loading (no automatic loading)

Probe S3

Probe S1

(PT1000)

Domestic hot water

thermostatic valve

30 + 65°C

KONDENS

27B 8-24

kW boiler

with diverter

valve kit

Direction of

insertion

Piping connection

with panel

Panel joints

with insulation

Manual air vent valve

DHW probe

supplied with

diverter valve kit

Page 41

39

TotalEnergy Kit

Kloben SKY CPC 58 Solar Connection

Kloben Low-Flow solar station

Power supply from mains water

Kloben boiler with SSP stroage tank

Kloben condensing boiler

System loading

Kloben Cosmet 4 Heat adjustment

DESCRITION

PROVISIONS

FOR THE REALISATION OF THE SOLAR SYSTEM

M

All of the piping making up the solar circuit must be in copper.

M All joints must be welded or with the tightening-type brass spinner

connections.

M The copper pipes must be insulated using high temperature sheaths

with minimum thickness of 19 mm (E.G. 100010305 Kloben list).

M For the boiler warranty, when filling the system use algicide consul-

ting the Kloben list.

This layout is purely indicative and not binding

and does not constitute any liability for Kloben

or its collaborators. The executive design and

consequent set-up must be realised with

respect to the laws in force.

System loading (no automatic loading)

Probe S4

Probe S1

(PT1000)

Domestic hot water

thermostatic valve

30 + 65°C

Realise condensate

drain to sewer drain

Traditional

Boiler

Direction of

insertion

Combustion gas evacuation

with pipe ø 80 mm

pressurised with respect to

standard UNI 10845

Air intake

Piping connection

with panel

Panel joints

with insulation

Manual air vent valve

Probe S6

Page 42

40

TotalEnergy Plus Kit

DESCRITION

PROVISIONS

FOR THE REALISATION OF THE SOLAR SYSTEM

M

All of the piping making up the solar circuit must be in copper.

M All joints must be welded or with the tightening-type brass spinner

connections.

M The copper pipes must be insulated using high temperature sheaths

with minimum thickness of 19 mm (E.G. 100010305 Kloben list).

M For the boiler warranty, when filling the system use algicide consul-

ting the Kloben list.

This layout is purely indicative and not binding

and does not constitute any liability for Kloben

or its collaborators. The executive design and

consequent set-up must be realised with

respect to the laws in force.

System loading (no automatic loading)

Probe S3

Probe S1

(PT1000)

Domestic hot water

thermostatic valve

30 + 65°C

KONDENS

27B 8-24

kW boiler

with diverter

valve kit

Direction of

insertion

Piping connection

with panel

Panel joints

with insulation

Manual air vent valve

DHW probe

supplied with

diverter

valve kit

Kloben SKY CPC 58 Solar Connection

Kloben Low-Flow solar station

Power supply from mains water

Kloben boiler with SSP stroage tank

Traditional condensing boiler

System loading

Kloben COSMET Heat adjustment

Page 43

41

Data detection card for solar heating systems

Agency:

Reference: Customer:

Project locality:

TYPE OF BUILDING:

single family multi family

existing under construction in design phase

SHAPE AND DIMENSIONING OF THE BUILDING:

ORIENTATION OF THE SLOPE

Sß = 0°

SSW/SSE ß = 22.5°

SW/SE ß = 45°

WSW/ESE ß = 67.5°

W/E ß = 90°

Lu (length of pitch usable):

h (height of the system):

α (inclination of the roof):

ß (orientation of the roof):

La (width of the pitch usable):

Shadowing (obstacles which, during sunlight

hours, pcast shadows on the panels)

OTHER IMPORTANT DATA:

Technical room:

Height available m:

Height and width of the access door m:

Total length of cylinder/panels connection piping m:

TYPE OF ROOF:

flat sloped

USES

DOMESTIC HOT WATER

low cons. (30l day per person) x n° persons =

average cons. (50l day per person) x n° persons =

high cons. (80l day per person) x n° persons =

washing machine connection

diswasher connection

average daily cons. of hot water: l/day

pump functioning hours: h/day

any other cons.:

SWIMMING POOL

indoor outdoor

suraces: m

2

depth: m

volume: m

3

use of the cover: h/day

(if not indicated, assume 8 h/day)

period of use

obstacles which, during sunlight hours, cast shadows on

the panels

Integration to radiant heating (fill in the relative form)

HEATING STATION

Boiler type: heating only diverter valve with integrated storage tank

with quick production water heater with external storage tank

Type of system offered: HeatPipe Grand Soleil Grand Soleil Plus Totalenergy Totalenergyplus

NOTE:

Page 44

42

Certifications

Page 45

43

Certifications

Page 46

44

Notes

Page 47

Page 48

Rev. 0 del 19-02-2008

Loading...

Loading...