Page 1

K&F ‘SW’ Series Subwoofer Systems

User's Manual

Benutzer Handbuch

Important Information,

Wichtige Informationen,

Please Read Before Use!

vor Inbetriebnahme lesen!

KLING & FREITAG GmbH

KLING & FREITAG GmbH

Junkersstrasse 14

Junkersstrasse 14

D-30179 Hannover

D-30179 Hannover

PHONE 0 (049) 511- 969 97-0

TEL 0 (049) 511- 969 97-0

FAX 0 (049) 511- 67 37 94

FAX 0 (049) 511- 67 37 94

www.kling-freitag.de

www.kling-freitag.de

Released: 29.05.2015

Version 5.1

Page 2

User's Manual K&F ‘SW’ Series Subwoofer Systems

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 2 of 2

Page 3

User’s Manual K&F ‘SW’ Series Subwoofer Systems

Thank you for your decision to buy a Kling & Freitag product. To guarantee a troublefree operating of the equipment and to allow the KLING & FREITAG - speaker system

to achieve its full potential please read the operating instructions carefully before use.

With the purchase of a K&F subwoofer system, you have acquired a speaker system

with the highest possible quality and performance capabilities.

As the owner of this system, you now have a versatile and highly professional tool

which, when operated properly, is a true pleasure to use.

Symbols in User's Manual

This symbol indicates the possibility of life-threatening danger and a

health risk for persons Not following these instructions may result in

serious health problems including potentially fatal injuries.

Warning

This symbol indicates a possibly dangerous situation. Not following

these instructions may cause minor injuries or cause property damage.

Caution

This symbol gives instructions for the proper use of the described products. Not following these instructions may cause malfunctions or property damage.

Important

Information about this User's Manual

User's Manual K&F 'SW' Series Subwoofer Systems, Version 5.1, 29.05.2015

© by Kling & Freitag GmbH, 1998 - 2015; all rights reserved.

All specifications in this manual are based on information available at the time of pub-

lishing for the features and safety guidelines of the described products.

Technical specifications, measurements, weights and properties are not guaranteed.

The manufacturer reserves the right to make product alterations within legal provisions

as well as changes to improve product quality.

All persons who use the speaker system must have this guide and all further information for safe operations available to them during assembly, disassembly,

and use.

We appreciate any input with suggestions and improvements for this manual. Please

send this to us at the following address:

info@kling-freitag.de or to:

KLING & FREITAG GMBH Junkersstr.14 D-30179 Hannover

Phone +49 (0) 511 - 96 99 70 Fax +49 (0) 511 - 67 37 94

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 3 of 3

Page 4

User's Manual K&F ‘SW’ Series Subwoofer Systems

Contents

Chapter Page

1. General Safety Instructions for Using Speakers 6

2. Product Descriptions and Versions 7

2.1 SW 112 7

2.2 SWi 112 8

2.3 SW 115E 8

2.4 SWi 115E 9

2.5 SW 118E 9

2.6 SWi 118E 10

2.7 SW 215E 10

3. Notes for the ‘Outdoor’ Option 11

3.1 ‘Outdoor Mobile’ 11

3.2 ‘Outdoor Installation’ 11

4. Notes for the SW112 / SWi 112 with Option ‘100V’ 12

4.1 Reasons for choosing Speakers with 100 V Technology 12

4.2 Connecting Diagram of the 100V Speaker Inputs 12

5. Instructions for Suspending the Speakers 13

5.1 SW 215E and Click & Fly Accessories 13

5.2 Subwoofers with ‘Flying Thread’ M12 (SWi Versions) 14

5.3 Subwoofers with ‘allsafe JUNGFALK’ Flying Points 15

5.4 SW 215E ‘Suspension’: Using the allsafe Flying Track 16

6. Mounting Instructions for Speakers 17

6.1 Using the Mounting Equipment ‘Distance Rod’ 17

6.2 LINE 212 Systems on Top of SW 115E 18

6.3 LINE 212 Systems on Top of SW 215E 18

7. Short Circuit Fuses in the K&F Subwoofer Systems 19

7.1 Risks of using High Performance Power Amplifiers 19

7.2 Identifying the Models with Short Circuit Fuses 19

7.3 Specification of the Fuses 19

7.4 Replacement and Positions of the Short Circuit Fuses 20

7.4.1 Subwoofers without Crossover (XO) 20

7.4.2 Subwoofers with Crossover (XO) 20

7.5 Add-On Kits for Subwoofers without Short Circuit Fuses 20

8. Wiring 21

8.1 Connecting the Speakon Connectors to the Connecting Terminal 21

8.2 Avoiding Ground Loops 22

8.2.1 What is a Ground Loop? 22

8.2.2 Avoiding Ground Loops 22

9. Configurations and Connecting Diagrams 23

9.1 Operating the Systems without K&F System Controller 23

9.1.1 ‘XO ON’ Subwoofer with optional Crossover (XO) 23

9.2 Operations with K&F System Controller 24

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 4 of 4

Page 5

User’s Manual K&F ‘SW’ Series Subwoofer Systems

10. Operating the Speakers 24

11. Internal Wiring of Subwoofers with Low-Pass Filter (XO) 25

11.1 SW 112 - XO / SW 118E - X0 25

11.2 SW 115E - XO 26

12. Touching Up Damage to Paint / Changing the Front Foam 26

13. Technical Specifications 27

13.1 SW 112 27

13.2 SWi 112 28

13.3 SW 115E 29

13.4 SWi 115E 30

13.5 SW 118E 31

13.6 SWi 118E 32

13.7 SW 215E 33

14. Frequency Diagrams 34

14.1 SW 112 / SWi 112 34

14.1.1 Without optional Low-Pass Filter or ‘XO OFF’ 34

14.1.2 With optional Low-Pass Filter ‘XO ON’ 34

14.2 SW 115E / SWi 115E 35

14.2.1 Without optional Low-Pass Filter or ‘XO OFF’ 35

14.2.2 With optional Low-Pass Filter ‘XO ON’ 35

14.3 SW 118E / SWi 118E 36

14.3.1 Without optional Low-Pass Filter or ‘XO OFF’ 36

14.3.2 With optional Low-Pass Filter ‘XO ON’ 36

14.4 SW 215E 37

15. Dimensions 38

15.1 SW 112 38

15.2 SWi 112 39

15.3 SW 115E 40

15.4 SWi 115E 41

15.5 SW 118E 42

15.6 SWi 118E 43

15.7 SW 215E 44

17. Beigefügte Sicherheits- und Montagehinweise für Lautsprecher und Zubehör

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 5 of 5

Page 6

User's Manual K&F ‘SW’ Series Subwoofer Systems

1. General Safety Instructions for Using Speakers

Mounting the speakers

To prevent injury, the speakers must be securely placed on the floor or secured to the

wall according to the instructions on page 17 (Mounting Instructions for Speakers).

Please note that speakers can move as a result of vibrations. To prevent them from falling from their mounted position, they must be secured properly. If the weight of the

speaker exceeds 20 kg then it is necessary for two people to carry it.

Speakers may only be suspended or mounted to walls or ceilings by qualified personnel.

The speakers must be hung by using at least two of the designated flying points. The

same applies when lifting and aligning the speakers.

Never use signal cables or power cords for suspending, aligning or securing the systems.

When laying the connecting cables, make sure that nobody can trip.

Never hang more than two speakers under one another without using the designated

Kling & Freitag rigging equipment.

Ensure that all installation connections comply with the applicable safety guidelines and

that the size and strength are sufficient. Further instructions are in our user's manual for

assembly equipment and in the general safety instructions for speakers and assembly

equipment.

For mobile and fixed installations, use only rigging equipment from KLING & FREITAG.

Make sure to observe the included safety and mounting instructions for loudspeakers

and accessories.

Speakers and rigging equipment must be visually examined at regular intervals. If there

are signs of wear, they must be replaced immediately. Furthermore, screwed connections of supporting parts must be checked routinely.

Warning

Protecting the Speakers

In general, audio signals should not be overdriven. This may be caused by mixing consoles,

equalizers, effect equipment, etc. and should be indicated on this equipment. When a power

amplifier is overloaded at the output (clipping), then the amplifier should activate a clipping

warning signal. Power amplifiers can also be overloaded at the input circuit without the

amplifier signalling the clipping, i.e. when there is not sufficient headroom in the input circuit. We, therefore, recommend turning up the power amplifiers all the way and adjusting

the level before the power amplifier in order to avoid overloading the input circuit. In any

case, the signal must be reduced as soon as it sounds unnaturally distorted.

To protect the speakers from being destroyed and to avoid fire hazard, they should

only be operated with professional power amplifiers with the following specifications:

− integrated clipping limiter

− without using a Kling & Freitag controller:

Integrated or preceding subsonic filter (approx. 20 Hz, min. 12 dB / octave)

For damage caused by overloading or use with power amplifiers other than those recommended above, Kling & Freitag GmbH does not assume warranty and excludes liability for possible consequential damage.

The following signals may damage the speakers

− permanent high-pitched signals with high frequency, and continuous noise from

feedback.

− permanently distorted signals with high power.

− noises, which occur when the amplifier is on while equipment is being connected,

disconnected or switched on.

Important

Do not install devices in any of the following places:

− where the devices are permanently exposed to direct sunlight.

− where the devices are exposed to high moisture.

− where the devices are exposed to strong vibrations and dust.

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 6 of 6

Page 7

User’s Manual K&F ‘SW’ Series Subwoofer Systems

Damage caused by the speakers' magnetic fields

Speakers are permanently surrounded by a magnetic field even when they are not operating. Therefore, during transport and placement of the speakers, it is important to

Important

ensure that there is always approx. 1 m between the speakers and magnetic data media

and computer/video monitors.

Preventing hearing damage

To prevent the risk of hearing damage, avoid being too close to operating speakers

even if the volume level seems to be low enough. In general, volume levels over 90 dB

Caution

can cause hearing damage.

2. Product Descriptions and Versions

2.1 SW 112

Short description:

Ultra compact high-performance subwoofer for mobile use with exponential tunnel

geometry, controllable with K&F System Controller, direct-emitting 12" long-excursion

chassis, bass reflex tuning.

Enclosure:

Frame-reinforced Finnish Multiplex enclosure with highly resistant black (RAL 9005)

structured paint, highly permeable, ball-proof steel grille with exchangeable black

acoustic foam. The subwoofer is equipped with a handle, K&M mounting plate with

M20 thread for a distance rod, non-abrasive plastic stacking feet and corresponding

stacking foot grooves for stacks of identical enclosures.

Optional versions:

− Option ‘XO’:

Version with integrated low-pass filter (110 Hz) for operations without system controller or signal processor, switchable (XO ‘On’/’Off’).

− Option ‘Suspension’:

Suspendable version with 6 flying points ‘allsafe Jungfalk’

− Option ‘100V’:

100 volts version with 300VA toroidal transformer

− Option ‘Outdoor Mobile’

Version for mobile outdoor applications under roofs.

− Option ‘Special Colour’:

Special finish in RAL colours

− SW 112 - SP:

Version with integrated power amplifier technology

’

SP’ speakers are shipped with a special user’s manual!

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 7 of 7

Page 8

User's Manual K&F ‘SW’ Series Subwoofer Systems

2.2 SWi 112

Short description:

Ultra compact high-performance subwoofer for fixed installations with exponential

tunnel geometry, controllable with system controller, direct-emitting 12" long-excursion

chassis, bass reflex tuning.

Enclosure:

Frame-reinforced Finnish Multiplex enclosure with highly resistant black (RAL 9005)

structured paint, highly permeable, ball-proof steel grille with exchangeable black

acoustic foam. The subwoofer is equipped with twelve M12 threads for ‘flown’ applications or mounting devices.

Optional versions:

− Option ‘XO’:

Version with integrated low pass filter (110 Hz) for operations without system controller or signal processor, switchable (XO ‘On’/’Off’).

− Option ‘100V’’:

100 volts version with 300VA toroidal transformer

− Option ‘Special Colour’:

Special finish in RAL colours

− SWi 112 - SP:

Version with integrated power amplifier technology

’SP’ speakers are shipped with a special user’s manual!

2.3 SW 115E

Short description:

High-performance subwoofer with exponential tunnel geometry, controllable with system controller. 1 15" long-excursion chassis with double centring, bass reflex tuning.

Enclosure:

Frame-reinforced Finnish Multiplex enclosure with highly resistant black (RAL 9005)

structured paint. Mounting plate with M20 thread for a distance rod mounted in the

top of the speaker, 2 butterfly handles, non-abrasive plastic stacking feet and corresponding stacking foot grooves for stacks of identical enclosures or SW215E and Line

212 enclosures. Locking profiles for optional transport cover, highly permeable, ballproof steel grille with exchangeable black acoustic foam.

Optional versions:

− Option ‘XO’:

Version with integrated low-pass filter (110 Hz) for applications with or without

system controller, switchable (XO ‘On’/’Off’).

− Option ‘Outdoor Mobile’

Version for mobile outdoor applications under roofs.

− Option ‘Special Colour’:

Special finish in RAL colours

− SW 115E - SP:

Version with integrated power amplifier technology

’SP’ speakers are shipped with a special user’s manual!

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 8 of 8

Page 9

User’s Manual K&F ‘SW’ Series Subwoofer Systems

2.4 SWi 115E

Short description:

High-performance subwoofer with exponential tunnel geometry, controllable with system controller. 1 15" long-excursion chassis with double centring, bass reflex tuning.

Enclosure:

Frame-reinforced Finnish Multiplex enclosure with highly resistant black (RAL 9005)

structured paint. Highly permeable, ball-proof steel grille with exchangeable black

acoustic foam. The subwoofer is equipped with 12 concealed M12 threads for ‘flown’

applications or for mounting devices.

Optional versions:

− Option ‚XO’:

Version with integrated low-pass filter (110 Hz) for applications with or without

system controller, switchable (XO ‘On’/’Off’).

− Option ‘Special Colour’:

Special finish in RAL colours.

− SWi 115E - SP:

Version with integrated power amplifier technology

’SP’ speakers are shipped with a special user’s manual!

2.5 SW 118E

Short description:

High-performance subwoofer for mobile use with exponential tunnel geometry, controllable with system controller. Direct-emitting 18" long excursion chassis, bass reflex

tuning.

Enclosure:

Frame-reinforced Finnish Multiplex enclosure with highly resistant black (RAL 9005)

structured paint. Highly permeable, ball-proof steel grille with exchangeable black

acoustic foam. The subwoofer is equipped with 2 butterfly handles, K&M mounting

plate with M20 thread for a distance rod, locking profiles for optional transport cover, 4

‘allsafe Jungfalk' flying points for suspension, 4 x 100 mm rear mounted transport castors, non-abrasive plastic stacking feet and corresponding stacking foot grooves for

stacks of identical enclosures.

Optional versions:

− Option ‘XO’:

Version with integrated low pass filter (110 Hz) for applications with or without

system controller or signal processor, switchable (XO ‘On’/’Off’).

− Option ‚Outdoor Mobile’

Version for mobile outdoor applications under roofs

− Option ‘Special Colour’:

Special finish in RAL colours

− SW 118E - SP:

Version with integrated power amplifier technology

’SP’ speakers are shipped with a special user’s manual!

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 9 of 9

Page 10

User's Manual K&F ‘SW’ Series Subwoofer Systems

2.6 SWi 118E

Short description:

High-performance subwoofer for fixed installations with exponential tunnel geometry,

controllable with system controller. Direct-radiating 18" long-excursion chassis, bass

reflex tuning.

Enclosure:

Frame-reinforced Finnish Multiplex enclosure with highly resistant black (RAL 9005)

structured paint. Highly permeable, ball-proof steel grille with exchangeable black

acoustic foam. The subwoofer is equipped with 12 concealed M12 threads for ‘flown’

application or mounting devices.

Optional versions:

− Option ‘XO’:

Version with integrated low pass filter (110 Hz) for applications with or without

system controller or signal processor, switchable (XO ‘On’/’Off’).

− Option ‘Outdoor Installation’

Version for fixed outdoor installations under roofs.

− Option ‘Special Colour’:

Special finish in RAL colours

− SWi 118E - SP:

Version with integrated power amplifier technology

’SP’ speakers are shipped with a special user’s manual!

2.7 SW 215E

Short description:

High-performance subwoofer with exponential tunnel geometry, controllable with system controller. 2 double-centred 15" long excursion chassis, bass reflex tuning.

Enclosure:

Frame-reinforced Finnish Multiplex enclosure with highly resistant black (RAL 9005)

structured paint. Highly permeable, ball-proof steel grille with exchangeable black

acoustic foam. The subwoofer is equipped with 4 butterfly handles, 4 integrated handles, K&M mounting plate with M20 thread for a distance rod, locking profiles for optional transport cover, 4 x 100 mm rear mounted transport castors, 8 non-abrasive plastic stacking feet and corresponding stacking foot grooves for stacks of identical enclosures as well as for stacks and clusters of Line 212 enclosures.

Optional versions:

− Option ‘Suspension’:

Suspendable version with 6 flying tracks ‘allsafe Jungfalk’

− Option ‚Outdoor Mobile’

Version for mobile outdoor applications under roofs

− Option ‘Special Colour’:

Special finish in RAL colours

− SW 215E - SP:

Version with integrated power amplifier technology

’SP’ speakers are shipped with a special user’s manual!

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 10 of 10

Page 11

User’s Manual K&F ‘SW’ Series Subwoofer Systems

bn

3. Notes for the ‘Outdoor’ Option

Speakers with the option ‘Outdoor Mobile’ and ‘Outdoor Installation’ have been optimised for outdoor use. They withstand temperature fluctuations in moderate climate

zones and do not accumulate condensation water.

In order to guarantee the longevity and safety of the speakers, the speakers with the

option ‘Outdoor’ must still be protected from direct effects of the weather.

Warning

They should be installed, for example, under a roof so that they also have sufficient

protection from driving rain from the side and direct sunlight.

3.1 ‘Outdoor Mobile’

Version for mobile outdoor use under roofs.

Features like standard version but with the following extras:

− multi-layered, temperature and UV-resistant high-tech PU marine primer,

− final coating with highly resistant structured 2K paint in RAL colours,

− waterproofed diaphragms and electronic components protected against cor-

rosion with protective coating.

3.2 ‘Outdoor Installation’

Version for fixed installations under roofs.

Features like standard SWi version combined with ‘Outdoor Mobile’ but with the

following extras:

− stainless steel grille

− acoustic foam behind grille

− visible screws made of stainless steel.

− stainless steel connecting terminal with single PG cable fitting, Ø 13

mm.

Wiring:

1

-

bl

2+

bl = blue

bn = brown

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 11 of 11

Page 12

User's Manual K&F ‘SW’ Series Subwoofer Systems

4. Notes for the SW112 / SWi 112 with Option ‘100V’

Kling & Freitag speakers with ‘100V’ option are fitted with high-quality toroidal transformers. This serves to minimize loss of sound. Highly professional sound reinforcement

results can be achieved by using 100 V Kling & Freitag speakers.

4.1 Reasons for choosing Speakers with 100 V Technology

− Reduction in conduction loss.

− Easy assembly of a loudspeaker network due to simple parallel wiring.

The sum of the output power of the individual speakers (stated as VA = W)

must not exceed the output power of the 100 V amplifier.

− Speakers are galvanically isolated.

Important

− Speakers can be integrated into existing 100 V systems.

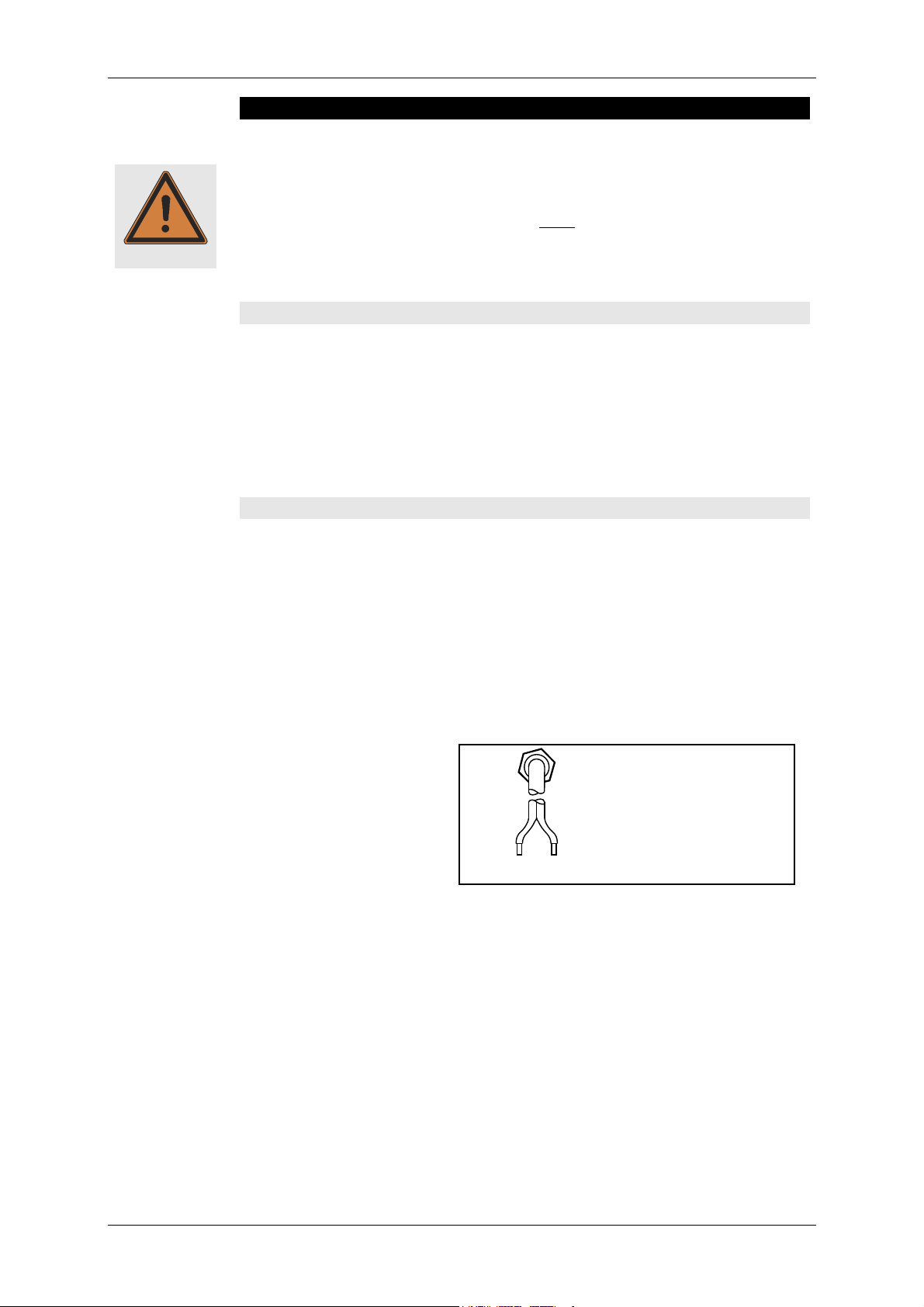

4.2 Connecting Diagram of the 100V Speaker Inputs

300VA transformer

300VA

0

all pins parallel to out

1+

1

IN

2+

-

2

-

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 12 of 12

Page 13

User’s Manual K&F ‘SW’ Series Subwoofer Systems

5. Instructions for Suspending the Speakers

The speakers may only be suspended by trained specialised personnel with

proof of their qualifications.

Observe the prescribed safety factors. Follow the safety instructions for

speakers and mounting equipment as well as the respective national rules,

Warning

norms and safety regulations.

Speaker systems, whether single or connected to one another, must always be secured

to a second separate point, even if two rigging points are used for suspending the

speaker system!

A maximum load of 73 kg may be hung below one SW 215E subwoofer. This means a

maximum additional load of 36.5 kg on each flying point.

A maximum load of 50 kg may be suspended from the two flying points of all other

subwoofers. This means a maximum additional load of 25 kg on each flying point.

Ensure that all connections are secured to prevent their detaching on their own and

that only admissible statically tested and sufficiently sized mounts, connecting devices,

ropes and chains are used.

5.1 SW 215E and Click & Fly Accessories

The Click & Fly rigging system is a certified and type tested rigging system for safe and

comfortable rigging of SW 215E or Line 212 systems.

Click & Fly Systems with the classification of ‘CLICK & FLY RIGGING SYSTEM’

may not be used with the SW 215E Systems without the supplementary

measures described below.

This is necessary due to safety measures for the subwoofer system, which have become

additionally necessary. Only when these new supplementary measures are observed can

it be guaranteed that you will have a safe and accordingly certified product for your

further use.

CLI CK & FLY LI NE 2 12 / S W 215E

Manufacturing Year:

SW-Load:

&

Weight:

Ser.-No.:

XXX XXX X XX XX

20 04

13 5, 0k g

3, 3k g

Made in

Germany

At this position, ‘LINE 212 / SW 215E’ must be

visible. If ‘RIGGING SYSTEM’ is present at this

position, then the Click & Fly rigging systems is

only approved for use with the Line 212 systems.

Supplementary measures which allow for an ‘old’ Click & Fly rigging system to be

used for mounting SW 215E Systems:

− Affix a new name plate, available from Kling & Freitag, recognisable by the classi-

fication 'CLICK & FLY LINE 212 / SW 215E'.

− Affix the following additional sticker, received from Kling &

Freitag, to the top side of the main bar:

DO NOT CONNECT

SPEAKERS WITH

CLICK & FLY

MAINBARS

− Receipt of a written version of this manual for each Click & Fly System.

− User's Manual made available for the user.

− Disposal of the old Users’ Manual.

Kling & Freitag GmbH has made all resources necessary for supplementation including a

detailed manual available free of charge to all buyers of the ‘old’ ‘CLICK & FLY RIGGING

SYSTEM’. If you did not receive these resources, please contact your retailer!

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 13 of 13

Page 14

User's Manual K&F ‘SW’ Series Subwoofer Systems

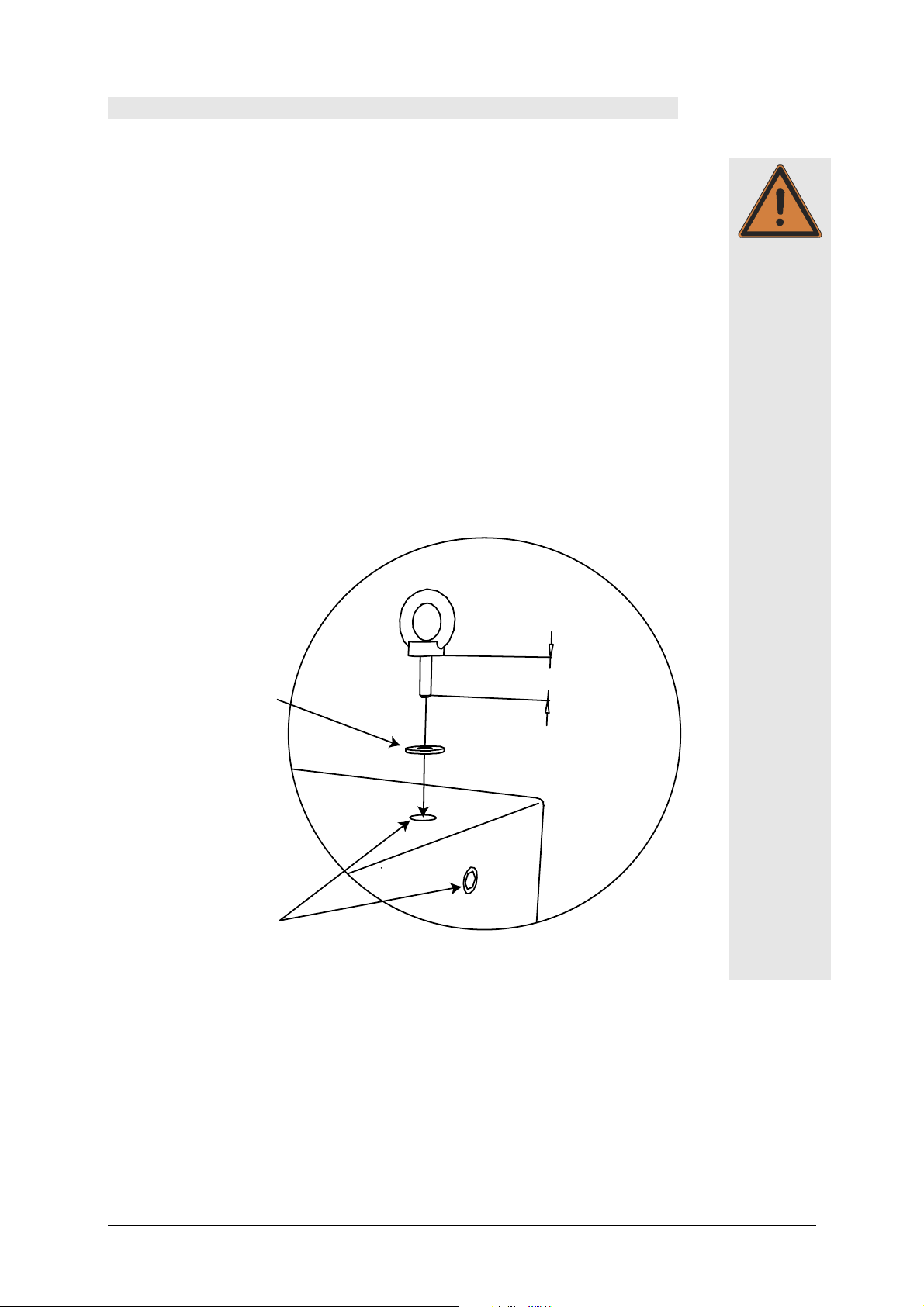

5.2 Subwoofers with ‘Flying Thread’ M12 (SWi Versions)

If you want to use the SP subwoofers equipped with ‘flying threads’ M12, please read

the following instructions.

Appropriate fastening mechanisms with an external screw thread of M12 and a minimum length of 35 mm! may be screwed on to the M 12 thread inserts. The internal

screw threads in the speaker enclosure are fastened during production with countersunk head screws M12.

The two internal screw threads of the inner enclosure edge are on an L-bracket. This Lbracket has the function of connecting the adjoining plates of the enclosure. It provides

sufficient tensile strength for flown operations. To guarantee that the enclosure plates

are correctly connected by the L-brackets, only one screw of the enclosure edge may be

loosened at a time. If both screws of an enclosure edge become loose, then, for safety

reasons, the L-bracket will collapse into the enclosure.

If the L-bracket has fallen into the enclosure the loudspeaker must on no account be used again until it has been repaired by an authorized repair service.

When mounting the speakers, use only fastening mechanisms with threads that extend

at least 35 mm into the speaker enclosure. Take into account the permissible load capacity of the fastening mechanisms while considering the safety factors. Mount the

speakers using at least two independently operating points. Secure all screws to prevent

loosening.

Warning

Always use flat

washers M12 with

the customary outer

diameter of 37 mm

Loosen only one of

these two screws at a

time!

35 mm minimum

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 14 of 14

Page 15

User’s Manual K&F ‘SW’ Series Subwoofer Systems

5.3 Subwoofers with ‘allsafe JUNGFALK’ Flying Points

Single Stud Fitting

Used as fastener to the ‘allsafe

JUNGFALK’ flying Point.

1.)

‘allsafe JUNGFALK’ Flying Point

Receptacle for special fasteners.

2.)

Warning

Take the single stud fitting in one

hand...

3.)

Put the flat head of the holding

bolt into the guiding of the flying

point.

... and push the locking device up

against the spring tension.

4.)

Release the locking device when

the single stud fitting is located in

the middle of the flying point.

Make sure that the locking device

clicks into place.

5.)

Check that the single stud fitting is

securely fastened and cannot be

pulled out.

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 15 of 15

Page 16

User's Manual K&F ‘SW’ Series Subwoofer Systems

5.4 SW 215E ‘Suspension’: Using the allsafe Flying Track

The subwoofer SW 215E with suspension option may only be suspended by using the

double stud fittings available from Kling & Freitag. The ‘allsafe JUNGFALK’ flying tracks

are used to suspend the SW 215E system.

We recommend using the certified Click & Fly Line 212 / SW 215E rigging system for

suspending the SW 212E.

The ‘allsafe JUNGFALK’ flying track can only support weights up to 73 kg on

one point!

Please follow the accompanying safety and assembly instructions carefully.

Double Stud Fitting

Used as fastener to the ‘allsafe

JUNGFALK’ Flying Point and the

‘allsafe JUNGFALK’ Flying Track.

1.)

Align the double stud fitting as

shown above and push it into the

track,…

‘allsafe JUNGFALK’ Flying Track

Receptacle for the double stud fitting.

2.)

... slide the pushed double stud fitting

to the middle of the speaker until it

clicks into place. Make sure that it is

secured tightly.

Warning

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 16 of 16

Page 17

User’s Manual K&F ‘SW’ Series Subwoofer Systems

Distance

rod 334

6. Mounting Instructions for Speakers

Mount the speakers securely. To avoid injury or damage, always be sure to mount the

speakers securely so that they do not fall. Speakers, which are stacked, must be secured

with securing straps. When laying the connecting cables, make sure that nobody can

Warning

trip.

The stability of stacked systems (also valid for the use of stands and distance rods!) is

contingent upon the following stability requirement. These conditions must, therefore,

be guaranteed by the user:

Stacked systems may not fall over even if they are inclined by 10° in each direction. If this requirement is not fulfilled, then it is necessary to take steps to

achieve compliance. Possible measures include strapping it to an appropriate

base structure or fastening it using safety straps.

6.1 Using the Mounting Equipment ‘Distance Rod’

The subwoofer is equipped with a threaded flange (M20) on the top of the enclosure

for mounting the optionally available distance rod (not on the SWi versions).

All K&F top speakers with a mounting flange or stand adapter may be mounted on the

distance rod. Only use authentic Kling & Freitag distance rods and stand adapters. We

can only guarantee safe operations when these parts are used.

Caution

When a top speaker is mounted on the subwoofer using a distance rod, the stability of

the speakers is reduced. Please follow the stability requirements in chapter 6!

When re-positioning after set-up, remove the upper speaker mounted on the distance

rod first.

Special note for the model SW 112

A top speaker with a maximum weight of 28 kg (i.e. CA 1201) may be mounted on this

speaker using a distance rod. Speakers, which are heavier than 28 kg, may not be

mounted on the distance rod flange and must be mounted on an additional speaker

stand.

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 17 of 17

Distance rod 337

(adjustable)

Distance rod 337

with stand adapter and

adjustable speaker mount

Page 18

User's Manual K&F ‘SW’ Series Subwoofer Systems

Stapelmulden

6.2 LINE 212 Systems on Top of SW 115E

für SW 115E

In addition to the stacking foot

grooves for stacking the same

Stapelmulden

für 'LINE 212'

enclosures, the subwoofer SW

115E also has stacking foot

grooves for the Line 212 system.

One Line 212 System can be

quickly and safely positioned on

top of the subwoofer.

Stapelmulden

für 'LINE 212' und SW 115E

6.3 LINE 212 Systems on Top of SW 215E

In addition to the stacking foot grooves for stacks of

identical enclosures, the subwoofer SW 115E also has

stacking foot grooves for the Line 212 system.

One Line 212 System can be quickly and safely positioned on top of a vertically placed SW 215E.

Two Line 212 systems can be precisely arrayed on top of

a horizontally placed SW 215E.

Horn not rotated on

standing Line 212 system

Line 212-6 --- SP

with

Line 212-6 - SP

8,5°

38,5°

Horn rotated on

standing Line 212 system

Line 212-6 --- SP

30°

with

Line 212-9 - SP

15,0°

45°

Other combinations of Line 212 Systems are not recommended as they can cause unwanted interferences. .

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 18 of 18

Page 19

User’s Manual K&F ‘SW’ Series Subwoofer Systems

7. Short Circuit Fuses in the K&F Subwoofer Systems

7.1 Risks of using High Performance Power Amplifiers

In recent years, power amplifiers have achieved increasingly higher levels of performance. Some of them can be operated with low-impedance loads. There are, therefore,

strong power amplifiers that can reliably work with impedances below 1 Ω. This development has led to an increased safety risk during defective operations.

When there is a defect, such as a short circuit in the speaker chassis or on the crossover,

it is possible that the power amplifier --- despite existing protective switches --- will not

shut off. Long cable lengths and contact resistance on the plug connections may already

have an electrical resistance of 1 Ω. As a result, the power amplifier cannot ‘‘recognise’’

the operations as being defective and, therefore, delivers unacceptable high currents. In

the worst-case scenario, this may lead to fire damage (hot and charred wiring / connectors as a result of overloaded conductors and connectors, etc.).

regulations are lagging behind this development and are thus not up-to-date with this

modern technology.

In order to give consideration to this development, Kling & Freitag now equips its subwoofer systems with short circuit fuses at the signal input. These fuses do not offer

protection for the speaker, but do reduce the risk of consequential damage in the case

of a short circuit.

The current safety

For systems, which are not serially equipped with a short circuit fuse, Kling & Freitag

offers simple add-on kits so that you can adapt your existing subwoofer systems to the

current power amplifier development.

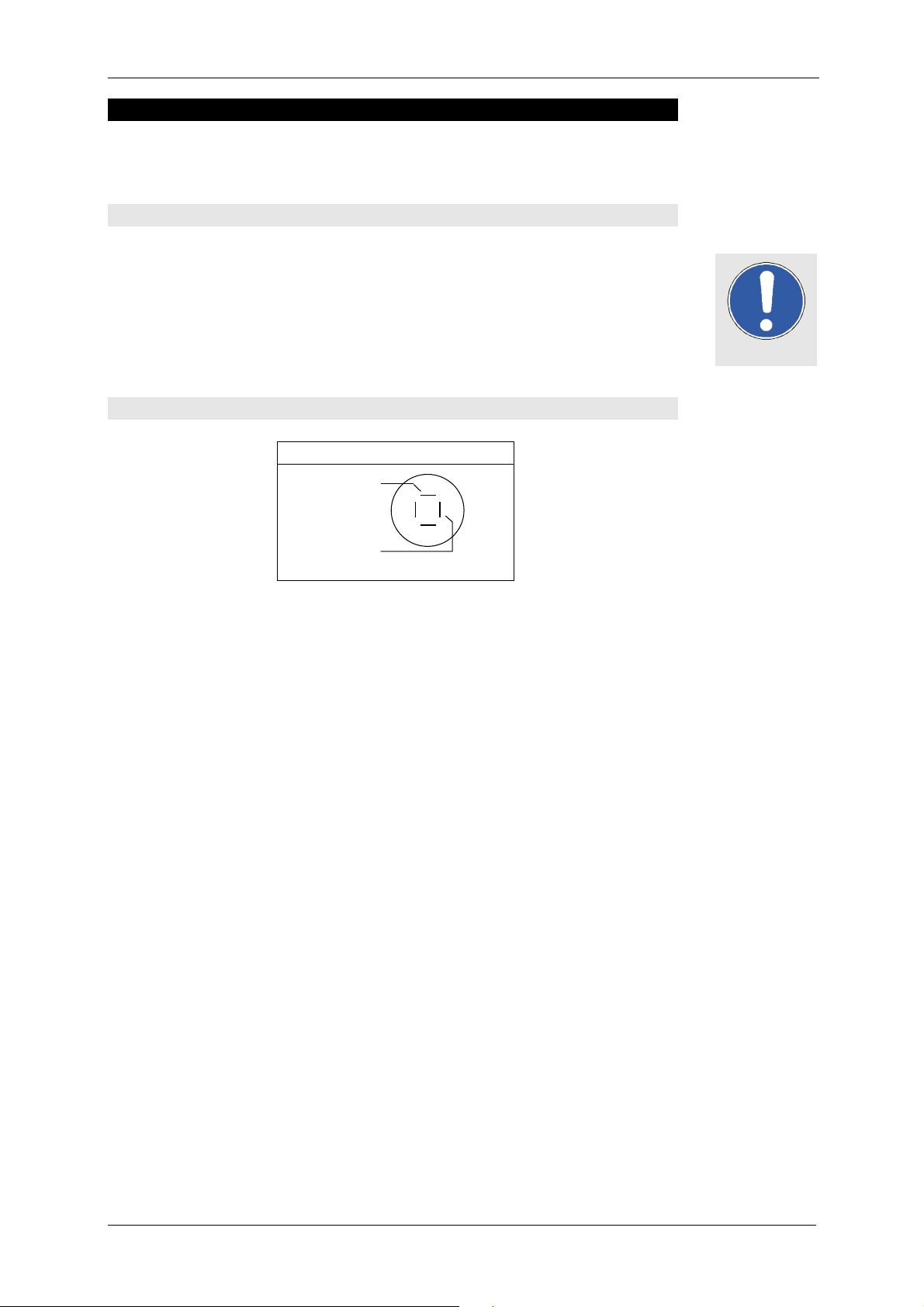

7.2 Identifying the Models with Short Circuit Fuses

The subwoofer systems, which are serially equipped with, fire safety fuses can be identified as follows; both mentioned stipulations must be fulfilled:

Adobe Systems

POWER: 700W

The first two

digits must be at

least 25.

XO-ON OFF

IMP: 6

SER.-NO.:

2 50 80 0 0 0 0 70

WT: 51,5kg

The next two

digits must be at

least 08.

All subwoofer systems, which are not serially equipped with short circuit fuses, can be, if

required, easily and inexpensively upgraded even by yourself.

An instruction manual for this upgrade is delivered with the add-on kit.

7.3 Specification of the Fuses

The fuses in all models have the following identical specifications:

Bussmann S 506

Bussmann S 506----8A slow

Bussmann S 506Bussmann S 506

8A slow

8A slow8A slow

When necessary, these fuses may only be replaced with the aforementioned original

fuse.

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 19 of 19

Page 20

User's Manual K&F ‘SW’ Series Subwoofer Systems

7.4 Replacement and Positions of the Short Circuit Fuses

When the fuse is burned out, then the chassis is most likely already ruined, as the fuse

just prevents consequential damage resulting from a short circuit of the chassis.

A disassembly of the chassis is, therefore, unavoidable.

7.4.1 Subwoofers without Crossover (XO)

The fuse holder of the subwoofers without a crossover (XO) is mounted on the signal

wiring behind the input connector. The subwoofers with two chassis have 2 fuses because the chassis are intended for parallel use.

When replacing the fuse, the chassis must be removed in order to reach the fuse holder.

Unscrewing the connecting terminal does not enable you to reach the fuse holder.

When the chassis is re-assembled, first loosely fasten the screws diagonal from one

another, then tighten them. By tightening the screws diagonally in two steps, a deformation of the chassis and thus a possible de-centring of the voice coil can be avoided.

7.4.2 Subwoofers with Crossover (XO)

The fuses of the subwoofers with a crossover are serially mounted on the crossover. The

exact position is described in the chapter ‘Internal Wiring of Subwoofers with Low-Pass

Filter (XO)’ beginning on page 25 for the particular models.

If it happens to be a model, which has already been upgraded, then the fuse holder is

mounted on the signal wiring behind the input connector.

When replacing the fuse in both cases, the chassis must be removed in order to reach

the fuse holder. Unscrewing the connecting terminal does not enable you to reach the

fuse holder.

When the chassis is re-assembled, first loosely fasten the screws diagonal from one

another, then tighten them. By tightening the screws diagonally in two steps, a deformation of the chassis and thus a possible de-centring of the voice coil can be avoided.

7.5 Add-On Kits for Subwoofers without Short Circuit Fuses

All subwoofer systems, which are not serially equipped with short circuit fuses, can be, if

required, easily and inexpensively upgraded even by yourself.

An instruction manual for this upgrade is delivered with the add-on kit.

Subwoofers with a crossover that are not serially equipped with short circuit fuses can

also be, if necessary, upgraded with fire safety fuses. The crossover does not need to be

replaced. For this, we offer an add-on kit that is mounted between the crossover input

and the input connector.

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 20 of 20

Page 21

User’s Manual K&F ‘SW’ Series Subwoofer Systems

1.

8. Wiring

The Speaker is equipped with two parallel-wired Speakon connectors.

Before connecting your speaker as shown in chapter 9 be sure to switch off all connected appliances and turn down all level controls.

− We recommend the use of high-quality speaker cables provided by KLING & FREITAG.

− For connections from the mixing console to the power amplifier inputs, please use 2-

pin shielded microphone cable with high-quality connectors.

− Avoid ground loops (see chapter 8.2 Avoiding Ground Loops)

− Please pay attention to the respective pin diagrams in this manual!

− Make sure that the +/- polarity between speaker and amplifier is correct. When simul-

taneously using power amplifiers from different manufacturers, be sure to use the

correct specific pin configuration. It may be necessary to modify the pin configuration

on the power amplifiers or on the connectors leading to them.

− To avoid loss of power, the cables should have a minimum wire gauge of 2.5 mm² -

more for longer cabled distances. A minimum wire gauge can be easily calculated

with the following formula:

Important

Minimum Wire Gauge (mm²) =

Required Cable Length (m)

2 x Speaker's Impedance (Ω)

If several loudspeakers are to be connected, the signal can be linked through from one

loudspeaker to the next. Please make sure that the total impedance of the loudspeakers

R(Ω) is not lower than the minimal impedance indicated on the power amplifier.

1/R1 + 1/R2 + 1/R3 + ... = 1/R

total

8.1 Connecting the Speakon Connectors to the Connecting Ter-

minal

2.

1.

2.

3.

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 21 of 21

Page 22

User's Manual K&F ‘SW’ Series Subwoofer Systems

8.2 Avoiding Ground Loops

8.2.1 What is a Ground Loop?

Every component of a P.A. or Hi-Fi System has its own internal 0V reference (ground). This

point is often connected to the protective earth connector (PE / Ground). If two or more

units are connected to one another with a line level audio cable, there may be a ground

connection through the ground of the power supply cable (yellow-green) as well as

through the shielding of the audio cable. The voltage difference between these two

ground points causes audible interference to come from the speaker.

8.2.2 Avoiding Ground Loops

If there is a loud humming or buzzing after the speaker has been connected, then check

that a ‘ground loop’ has not been built into the system. Some power amplifiers and

system controllers facilitate a ground lift switch. Set these ground lift switches to the

‘Lift’ position one after the other. If the noise is still audible, check if,

1. the noise is caused by a ground loop before the power amplifiers or controllers

(e.g. mixing console, effects or equalizers).

2. the system or parts of the system are connected to an ‘unclean’ power supply meaning one which is also running large motors or lighting systems. An ‘unclean’ supply voltage, electrostatic and electromagnetic fields can cause interference.

Please observe the following basic rules:

− Never!!! try to avoid a ground loop by disconnecting or taping the protec-

tive earth contact at the mains connector! Extremely dangerous! Extremely

dangerous!

− If possible, only use high-quality audio appliances with balanced signal outputs and

with power cables with PE connectors.

− Use high-quality cables with good shielding.

− The point of ground for all connected components should merge at one central

point. The power connections should lead out in a radial manner from one point

and not be linked from one unit to the next.

− When installing appliances that create strong electrostatic or electromagnetic fields

(large transformers, switch-mode power supplies), maintain some distance from

other audio appliances. In extreme cases, the only solution is to create a completely

independent ‘audio ground’; in other cases, it is sufficient to connect a filter in front

of the audio equipment.

Warning

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 22 of 22

Page 23

User’s Manual K&F ‘SW’ Series Subwoofer Systems

9. Configurations and Connecting Diagrams

9.1 Operating the Systems without K&F System Controller

The K&F subwoofers with integrated crossover (SW 112 - XO / SW 115D - XO or SW

118E - XO) can be combined with K&F top speakers by simply connecting them in parallel.

9.1.1 ‘XO ON’ Subwoofer with optional Crossover (XO)

In this mode of operation you can easily realise applications, where a higher bass level is

needed.

Important

Be sure to use only amplifiers, which can handle speaker impedances down to 3 Ω in

this mode.

When using the mid-high systems in a cluster (speakers in close proximity), reduce the

frequencies below 300 Hz by 3-4 dB!

Recommended combinations of CA systems, as described here, with K&F subwoofers:

2 CA systems + 2- 4 x SW 112-XO

or + 2 x SW 115E-XO

or + 1 - 2 x SW 118E-XO

Switch To 'XO ON' Switch To 'XO ON'

INPUT e.g. from

mixer, AUX or

Connector Panel

OUTPUTS

INPUT CH 2 INPUT CH 1

-

CH 2 CH 1

-

+

+

The switch XO on the connecting terminal of the subwoofer must be at ‘ON’ for this

mode of operation:

Switch on the subwoofers’ connecting terminal

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 23 of 23

Page 24

User's Manual K&F ‘SW’ Series Subwoofer Systems

9.2 Operations with K&F System Controller

For optimal performance and operating safety we recommend using a K&F System

Controller. Instructions for use, connecting diagrams and detailed descriptions of the

latest controller models ‘CD 24’ and ‘CD 44’ you can find in the corresponding user’s

manuals.

10. Operating the Speakers

− Switch off all equipment and turn down all level controls.

− Wire your subwoofer systems.

− Please pay attention to the user’s manual of your power amplifier!

− Upon completing the wiring, ensure that the connected speakers are working in

phase. To do so, use i.e. a phase checker. A phase error can also be recognized when

the connected channels are used simultaneously. During simultaneous use the bass

frequencies become notably quieter or the mid-frequencies such as voices cannot be

located.

− Now switch on the peripheral equipment first (mixing console, effects etc.), followed

by the K&F System Controller and lastly the power amplifiers. Always use the before

mentioned switching order. Otherwise switching noises may damage the system.

− If there is interference, turn off all appliances in the reverse order and check all cable

connections (see chapter 8.2 , Avoiding Ground Loops).

− Successively turn up the individual power amplifier channels and send a signal

with low volume to the system. Check to see if the desired signals are applied to

the intended speakers and make sure there is no interference. Make sure everything works properly, i.e. if the signals come from the correct speaker paths (high

signals from the tweeters, bass signals from the bass speaker). Your system should

now be ready for operation.

Important

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 24 of 24

Page 25

User’s Manual K&F ‘SW’ Series Subwoofer Systems

IN OUT

11. Internal Wiring of Subwoofers with Low-Pass Filter (XO)

11.1 SW 112 - XO / SW 118E - X0

Short circuit fuse:

Bussmann S 506

Bussmann S 506----8A slow

Bussmann S 506Bussmann S 506

8A slow

8A slow8A slow

(Only if serially equipped

with short circuit fuse)

LF

2-2+ 1-1+ 2-2+1-1+

Pin assignment Speakon NL4

‘IN’ 1+ 1- 2+ 2‘OUT’ parallel with ‘IN’

+ - / /

-

IN-+

LF

+

Switch

(Rear)

A1 B4

-

A2

+

B5

A3

B6

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 25 of 25

Page 26

User's Manual K&F ‘SW’ Series Subwoofer Systems

IN OUT

11.2 SW 115E - XO

Short circuit fuse:

Bussmann S 506

Bussmann S 506----8A slow

Bussmann S 506Bussmann S 506

8A slow

8A slow8A slow

-

+

IN IN

+

-

LFLF

Switch

(Rear)

A1 B4

-

LF

2-2+ 1-1+ 2-2+1-1+

Pin assignment Speakon NL4

‘IN’ 1+ 1- 2+ 2‘OUT’ parallel with ‘IN’

+ - / /

+

A2

B5

A3

B6

12. Touching Up Damage to Paint / Changing the Front Foam

Although the PU structured paint used by KLING & FREITAG is extremely resistant, we

recommend using protective covers or cases to help avoid damaging the paint during

i.e. continuous mobile use. If paint damage occurs despite these precautions, it can be

touched up by using commercial acrylic paint in the appropriate RAL colour of the

speaker. To replace the filter foam, send the front grille incl. foam to KLING & FREITAG

GmbH. Upon payment for expenses, the grille with the new covering will be returned.

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 26 of 26

Page 27

User’s Manual K&F ‘SW’ Series Subwoofer Systems

13. Technical Specifications

13.1 SW 112

Speaker

Design

Bass reflex system with exponential

tunnel geometry

Frequency range -10 dB 35 Hz --- 2.5 kHz

Frequency range ±3 dB 41 Hz - 350 Hz

Crossover frequencies max. 110 Hz with optional

low-pass filter (XO 'ON')

Power handling 500 W nominal

1000 W programme

Sensitivity 1 W / 1 m 92 dB (45 Hz - 350 Hz)

1)

2)

3)

93 dB (40 Hz - 110 Hz) with optional low-

pass filter (XO 'ON')

Max. SPL 124 dB (peak / 1 m / free field,

equivalent 130 dB half room)

Components 1 x 12‘‘ long excursion chassis, 100 mm

voice coil, internal and external ventilation

Impedance (nom.) XO 'ON'

Without crossover, XO 'OFF'

6 Ω, Zmin. 4 Ω

8 Ω, Zmin. 6 Ω

Connectors 2 x Speakon NL4MP (1+/1-)

Enclosure

15 mm frame reinforced Multiplex plywood

with highly resistant black structured paint (PU)

1 ergonomic handle

K&M mounting plate M20 for

distance rod, 4 non-abrasive

plastic feet,

stacking foot grooves

for stacks of identical

enclosures

ball-proof steel grille with exchangeable

black acoustic foam

Dimensions (W x H x T) 470 x 370 x 520 mm

Weight 27 kg / 28.7 kg with low-pass filter

Options 'XO' switchable low-pass filter,

'Barrier strip' instead of Speakon connector,

'100 Volt' with 300 VA toroidal transformer

(29.5 kg) --- not in combination with option 'XO'

‘Suspension‘ with 6 flying points ‘allsafe JUNGFALK'

'Outdoor Mobile'

Special finish in RAL colours

Accessories see catalogue or visit www.kling-freitag.de

1)

Pink noise 40 --- 400 Hz, 2 h; 2) as 1) but with 50% duty cycle; 3) 2.83 Vrms, free field

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 27 of 27

Page 28

User's Manual K&F ‘SW’ Series Subwoofer Systems

13.2 SWi 112

Speaker

Design Bass reflex system with exponential

tunnel geometry

Frequency range -10 dB 35 Hz --- 2.5 kHz

Frequency range ±3 dB 41 Hz - 350 Hz

Crossover frequencies 110 Hz with optional low-pass filter (XO 'ON')

Power handling 500 W nominal

1000 W programme

Sensitivity 1 W / 1 m 92 dB (45 Hz - 350 Hz)

Max. SPL 124 dB (SPL Peak / 1 m / free field,

equivalent 130 dB half room)

Components 12‘‘ long excursion chassis, 100 mm

voice coil, internal and external ventilation

Impedance (nominal)

6 Ω, Zmin. 4 Ω (XO 'ON')

8 Ω, Zmin. 6 Ω (XO 'OFF')

Connectors 2 x Speakon NL4MP (1+/1-)

Enclosure

15 mm frame reinforced Multiplex plywood

with highly resistant black structured paint (PU)

ball-proof steel grille with exchangeable

black acoustic foam

Rigging 12 x M 12 thread inserts

Dimensions (W x H x D) 470 x 370 x 520 mm (incl. castors)

Weight 27 kg

Options 'XO' switchable low-pass filter,

'Barrier strip' instead of Speakon connector,

'100 Volt' with 300 VA toroidal transformer

(29.5 kg) - not in combination with option 'XO'

'Special finish in RAL colours'

Accessories see catalogue or visit www.kling-freitag.de

1)

Pink noise 40 --- 400 Hz, 2 h; 2) as 1) but with 50% duty cycle; 3) 2.83 Vrms, free field

1)

2)

3)

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 28 of 28

Page 29

User’s Manual K&F ‘SW’ Series Subwoofer Systems

13.3 SW 115E

Speaker

Design Bass reflex system with exponential

tunnel geometry

Frequency range -10 dB 37 Hz - 320 Hz

Frequency range ±3 dB 43 Hz - 150 Hz

Power handling 750 W nominal

1500 W programme

Sensitivity 1 W / 1 m 95 dB (37 Hz - 320 Hz)

Max. SPL 127 dB (SPL Peak / 1 m free field,

equivalent 133 dB half room)

Components 15‘‘ long excursion chassis, double centred

100 mm voice coil,

internal and external ventilation,

Aluminium demodulation ring

Impedance (nominal)

8 Ω, Zmin. 6,2 Ω (XO 'OFF' or without filter)

6 Ω, Zmin. 4.5 Ω (XO 'ON')

Connectors 2 x Speakon NL4MP (1+/1-)

Enclosure

15 mm frame reinforced Multiplex plywood

with highly resistant black structured paint (PU)

2 ergonomic butterfly handles,

K&M mounting plate M 20 for distance rod,

4 non-abrasive plastic feet,

enclosures or SW 215E / Line 212,

2 locking profiles for optional transport cover,

ball-proof steel grille with exchangeable

black acoustic foam

Dimensions (W x H x D) 470 x 515 x 640 mm

stacking foot grooves for stacks of identical

Weight 35 kg / 37 kg with option 'XO'

Options 'XO' with switchable low-pass filter, crossover

frequency 110 Hz,

'Barrier strip' instead of Speakon connector,

'Outdoor Mobile',

'Special finish in RAL colours'

Accessories see catalogue or visit www.kling-freitag.de

1)

Pink noise 40 --- 400 Hz, 2 h;

2)

as 1) but with 50% duty cycle; 3) 2.83 Vrms, free field

1)

2)

3)

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 29 of 29

Page 30

User's Manual K&F ‘SW’ Series Subwoofer Systems

13.4 SWi 115E

Speaker

Design Bass reflex system with exponential

tunnel geometry

Frequency range -10 dB 37 Hz - 320 Hz

Frequency range ±3 dB 43 Hz - 150 Hz

Sensitivity 1 W / 1 m 110 Hz with optional low-pass filter (XO 'ON')

Power handling 750 W nominal

1500 W programme

Sensitivity 1 W / 1 m 95 dB 37 Hz - 320 Hz (43 Hz - 150 Hz)

Max. SPL 127 dB (SPL Peak / 1 m free field,

equivalent 133 dB half room)

Components 15‘‘ long excursion chassis, double

centred 100 mm voice coil,

internal and external ventilation,

Aluminium demodulation ring for minimal

distortions

Impedance (nominal)

6 Ω, Zmin. 4,5 Ω (XO 'ON')

8 Ω, Zmin. 6,2 Ω (XO 'OFF' or without filter)

Connectors 2 x Speakon NL4MP (1+/1-)

Enclosure

15 mm frame reinforced Multiplex plywood

with highly resistant black structured paint (PU)

ball-proof steel grille with exchangeable

black acoustic foam

Rigging 12 x M12 thread inserts

Dimensions (W x H x D) 470 x 504 x 640 mm

Weight 35.3 kg / 37,3 kg with option 'XO'

Options 'XO' switchable low-pass filter, crossover

frequency at 110 Hz,

‘Barrier strip’ instead of Speakon connectors,

'Special finish in RAL colours'

Accessories see catalogue or visit www.kling-freitag.de

1)

Pink noise 40 --- 400 Hz, 2 h; 2) as 1) but with 50% duty cycle; 3) 2.83 Vrms, free field

1)

2)

3)

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 30 of 30

Page 31

User’s Manual K&F ‘SW’ Series Subwoofer Systems

13.5 SW 118E

Speaker

Design Bass reflex system with exponential

tunnel geometry

Frequency range -10 dB 30 Hz --- 2.5 kHz

Frequency range ±3 dB 38 Hz - 300 Hz

Crossover frequencies 110 Hz with optional low-pass filter (XO 'ON')

Power handling 700 W nominal

1400 W programme

Sensitivity 1 W / 1 m 97 dB (40 Hz - 300 Hz)

Max. SPL 134 dB (SPL peak / 1 m / free field,

equivalent 140 dB half room)

Components 18‘‘ long excursion chassis, double

centred 100 mm voice coil,

internal and external ventilation,

demodulation ring (double DDR) for

minimised distortions

Impedance (nom.) XO 'ON'

without filter or XO 'OFF'

6 Ω, Zmin. 4 Ω

8 Ω, Zmin. 6 Ω

Connectors 2 x Speakon NL4MP (1+/1-)

Enclosure

15 mm frame reinforced Multiplex plywood

with highly resistant black structured paint (PU)

4 ergonomic butterfly handles,

K&M mounting plate M20 for

distance rod,

4 non-abrasive plastic feet,

4 stacking foot grooves for stacks of identical

enclosures,

2 locking profiles for optional transport cover

ball-proof steel grille with exchangeable

black acoustic foam

Rigging 4 flying points 'allsafe JUNGFALK'

Dimensions (W x H x D) 600 x 680 x 766 mm (incl. castors)

Weight 49.8 kg

Options 'XO' with switchable low-pass filter,

'Barrier strip' instead of Speakon connector,

'without 100 mm transport castors’,

'Outdoor Mobile',

'Special finish in RAL colours'

Accessories see catalogue or visit www.kling-freitag.de

1)

Pink noise 40 --- 400 Hz, 2 h;

2)

as 1) but with 50% duty cycle; 3) 2.83 Vrms, free field

1)

2)

3)

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 31 of 31

Page 32

User's Manual K&F ‘SW’ Series Subwoofer Systems

13.6 SWi 118E

Speaker

Design Bass reflex system with exponential

tunnel geometry

Frequency range -10 dB 30 Hz --- 2.5 kHz

Frequency range ±3 dB 38 Hz - 300 Hz

Crossover frequencies 110 Hz with optional low-pass filter (XO 'ON')

Power handling 700 W nominal

1400 W programme

Sensitivity 1 W / 1 m 97 dB (40 Hz - 300 Hz)

Max. SPL 134 dB (SPL peak / 1 m / free field,

equivalent 140 dB half room)

Components 18‘‘ long excursion chassis, double

centred 100 mm voice coil,

internal and external ventilation,

demodulation ring (double DDR) for minimised

distortions

Impedance (nom.) XO 'ON'

without filter or XO 'OFF'

6 Ω, Zmin. 4 Ω

8 Ω, Zmin. 6 Ω

Connectors 2 x Speakon NL4MP (1+/1-)

Enclosure

15 mm frame reinforced Multiplex plywood

with highly resistant black structured paint (PU)

ball-proof steel grille with exchangeable

black acoustic foam

Rigging 12 x M 12 thread inserts

Dimensions (W x H x D) 600 x 672 x 640 mm

Weight 46.2 kg

Options 'XO' switchable low-pass filter,

'Barrier strip' instead of Speakon connector,

'Outdoor Installation',

'Special finish in RAL colours'

Accessories see catalogue or visit www.kling-freitag.de

1)

Pink noise 40 --- 400 Hz, 2 h; 2) as 1) but with 50% duty cycle; 3) 2.83 Vrms, free field

1)

2)

3)

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 32 of 32

Page 33

User’s Manual K&F ‘SW’ Series Subwoofer Systems

13.7 SW 215E

Speaker

Design Bass reflex system with exponential

tunnel geometry

Frequency range -10 dB 36 Hz - 1 kHz

Frequency range ±3 dB 42 Hz - 250 Hz

Crossover frequencies max. 200 Hz

Power handling 1500 W nominal1)

3000 W programme2)

Sensitivity 1 W / 1 m 98 dB (42 Hz - 150 Hz)

Max. SPL 133 dB (peak / 1 m / free field,

equivalent 139 dB half room)

2 x 15‘‘ long excursion chassis, 100 mm

Components voice coil with double centring,

internal and external ventilation,

demodulation ring (double DDR) for minimal

distortion

Impedance (nominal)

4 Ω, Zmin. 3.1 Ω

Connectors 2 x Speakon NL4MP (1+/1-)

Enclosure

15 mm frame reinforced Multiplex plywood

with highly resistable black structured paint (PU)

4 ergonomic butterfly handles,

4 integrated handles,

K&M mounting plate M20 for distance rod,

8 non-abrasive plastic feet,

stacking foot grooves for stacks of identical

enclosures as well as for single or clustered

Line 212 enclosures

4 x 100 mm rear mounted castors,

2 locking profiles for optional transport cover,

ball-proof steel grille with exchangeable

black acoustic foam

Dimensions (W x H x D) 480 x 1015 x 765 mm (incl. castors)

Weight 68.5 kg

'Barrier strip' instead of Speakon connector,

‘without 100 mm transport castors’,

Options

‘Suspension’ with 6 flying tracks 'allsafe JUNGFALK',

'Outdoor Mobile',

'Special finish in RAL colours'

Accessories see catalogue or visit www.kling-freitag.de

1)

Pink noise 40 --- 400 Hz, 2 h; 2) as 1) but with 50% duty cycle; 3) 2.83 Vrms, free field

3)

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 33 of 33

Page 34

User's Manual K&F ‘SW’ Series Subwoofer Systems

SPL

(dB)

SPL (dB)

SPL

(dB)

SPL (dB)

14. Frequency Diagrams

14.1 SW 112 / SWi 112

14.1.1 Without optional Low-Pass Filter or ‘XO OFF’

Impedance (Ohm)

100

316

90

80

70

60

20 100 1000

Frequency (Hz)

14.1.2 With optional Low-Pass Filter ‘XO ON’

100

90

80

70

100

31,6

Impedance (Ohm)

10

3,16

Impedance (Ohm)

316

100

31,6

Impedance (Ohm)

10

60

20 100 1000

Frequency (Hz)

3,16

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 34 of 34

Page 35

User’s Manual K&F ‘SW’ Series Subwoofer Systems

Impedance (Ohm)

Impedance (Ohm)

14.2 SW 115E / SWi 115E

14.2.1 Without optional Low-Pass Filter or ‘XO OFF’

SPL (dB)

Impedance (Ohm)

105

316

95

85

SPL(dB)

75

65

20 100 1000

Frequency (Hz)

14.2.2 With optional Low-Pass Filter ‘XO ON’

105

95

85

SPL(dB)

100

31,6

10

3,16

SPL (dB)

Impedance (Ohm)

316

100

31,6

75

65

20 100 1000

Frequency (Hz)

10

3,16

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 35 of 35

Page 36

User's Manual K&F ‘SW’ Series Subwoofer Systems

SPL

(dB)

SPL (dB)

SPL

(dB)

SPL (dB)

14.3 SW 118E / SWi 118E

14.3.1 Without optional Low-Pass Filter or ‘XO OFF’

Impedance (Ohm)

110

316

100

90

80

70

20 100 1000

Frequency (Hz)

14.3.2 With optional Low-Pass Filter ‘XO ON’

110

100

90

80

100

31,6

Impedance (Ohm)

10

3,16

Impedance (Ohm)

316

100

31,6

Impedance (Ohm)

10

70

20 100 1000

Frequency (Hz)

3,16

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 36 of 36

Page 37

User’s Manual K&F ‘SW’ Series Subwoofer Systems

Impedance (Ohm)

14.4 SW 215E

SPL (dB)

Impedance (Ohm)

110

316

100

90

SPL(dB)

80

70

20 100 1000

Frequency (Hz)

100

31,6

10

3,16

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 37 of 37

Page 38

User's Manual K&F ‘SW’ Series Subwoofer Systems

DIMENSIONS

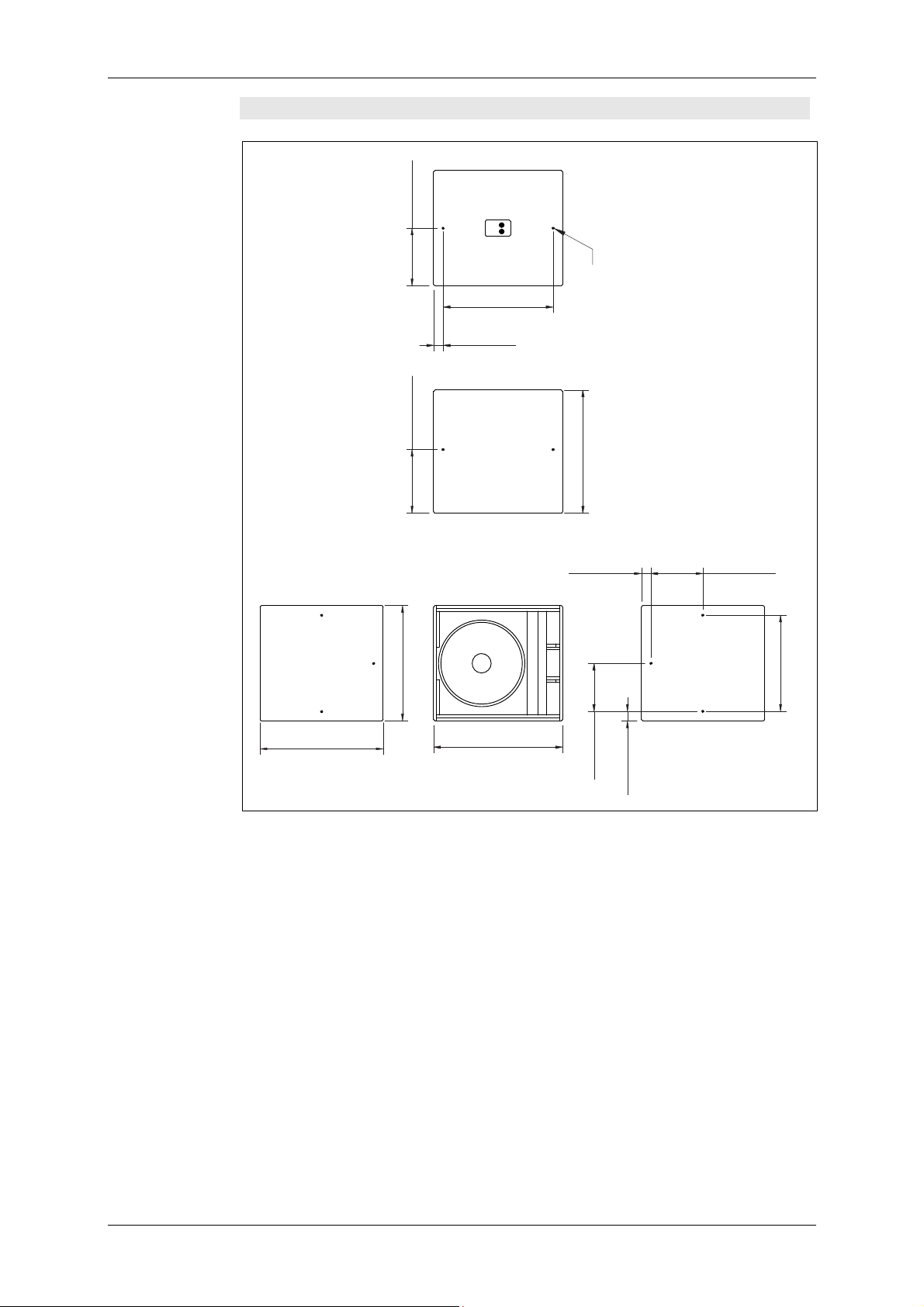

15. Dimensions

15.1 SW 112

235 mm

[9.252"]

[12.598"]

320 mm

[1.968"]

50 mm

Flugpunkte

520 mm

[20.472"]

ANCRA Jungfalk

120030-31

(nur mit Option 'Flug'!)

Befestigungsplatte für

Distanzrohre M20

470

[18.503"]

235 mm

[9.252"]

[7.874"]

200 mm

[20.472"]

520 mm

[14.566"]

370 mm

50 mm

[1.968"]

[10.236"]

260 mm

370 mm

[14.566"]

470 mm

[18.503"]

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 38 of 38

Page 39

User’s Manual K&F ‘SW’ Series Subwoofer Systems

DIMENSIONS

15.2 SWi 112

235 mm

[9.252"]

[12.598"]

320 mm

320 mm

[12.598"]

[1.968"]

50 mm

[1.968"]

50 mm

Flugpunkte, Innengewinde M12

520 mm

[20.472"]

[9.252"]

235 mm

470 mm

[18.503"]

[1.968"]

50 mm

[20.472"]

520 mm

[14.566"]

370 mm

[10.629"]

270 mm

370 mm

[14.566"]

50 mm

[1.968"]

470 mm

[18.503"]

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 39 of 39

Page 40

User's Manual K&F ‘SW’ Series Subwoofer Systems

DIMENSIONS

15.3 SW 115E

640 mm

[25.197 "]

Kunststoffgleitfüße

Stapelmulden

470 mm

[18.504 "]

Stapelmulden

für 'LINE 212'

Befestigungsplatte M 20 für

Distanzrohre (K&M 24115)

[19.843 "]

504 mm

[0.433 "]

11 mm

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 40 of 40

Page 41

User’s Manual K&F ‘SW’ Series Subwoofer Systems

DIMENSIONS

15.4 SWi 115E

235 mm

[9.252 "]

[1.969 "]

[17.874 "]

454 mm

50 mm

640 mm

[25.197 "]

340 mm

[13.386 "]

[1.969 "]

50 mm

10 x Flugpunkte,

[1.969 "]

50 mm

470 mm

[18.504 "]

[13.386 "]

340 mm

[19.843 "]

504 mm

[1.969 "]

50 mm

235 mm

[9.252 "]

Innengewinde M12

[13.386 "]

340 mm

50 mm

[1.969 "]

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 41 of 41

Page 42

User's Manual K&F ‘SW’ Series Subwoofer Systems

DIMENSIONS

15.5 SW 118E

gleitfüße

Kunststoff-

[22.535 "]

572.4 mm

ANCRA

Jungfalk

Flugpunkte

(120030-31)

310 mm

[12.205 "]

[1.961 "]

49.8 mm

640 mm

[25.197 "]

770 mm

[30.315 "]

[1.961 "]

49.8 mm

600 mm

[23.622 "]

[26.457 "]

672 mm

[0.394 "]

10 mm

Befestigungsplatte für

Distanzrohre M20

(K&M 24115)

[25.197 "]

640 mm

600 mm

[23.622 "]

300 mm

[11.811 "]

[12.205 "]

310 mm

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 42 of 42

Page 43

User’s Manual K&F ‘SW’ Series Subwoofer Systems

DIMENSIONS

15.6 SWi 118E

300 mm

[11.811"]

[22.534"]

572.4 mm

330 mm

[12.992"]

[1.961"]

49.8 mm

Flugpunkte,

Innengewinde M12

640 mm

[25.196"]

[1.961"]

49.8 mm

600 mm

[23.621"]

[25.196"]

640 mm

[26.456"]

672 mm

[9.851"]

250.2 mm

49.8 mm

[1.960"]

[10.637"]

270.2 mm

500.4 mm

[19.701"]

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 43 of 43

Page 44

User's Manual K&F ‘SW’ Series Subwoofer Systems

DIMENSIONS

15.7 SW 215E

470 mm

[18.504"

[5.054"]

128.37 mm

Clustermulden für

Lautsprecher 'LINE 212'

Stapelmulden

640 mm

[25.197"]

[39.961"]

1015 mm

Flugschiene

Ancra Jungfalk

(Nur mit Option 'Flug')

Kunststoff-

[12.008"]

305 mm

Befestigungsplatte für

gleitfüße

[19.980"][0.433"]

507.5 mm

Distanzrohre M20

11 mm

Stapelmulden

Stapelmulden für

Lautsprecher 'LINE

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 44 of 44

Page 45

User’s Manual K&F ‘SW’ Series Subwoofer Systems

Fehler! Kein gültiger Dateiname.

KLING & FREITAG GMBH ©1998 - 2015 Version 5.1, 29.05.2015 Page 45 of 45

Loading...

Loading...