Page 1

K&F SEQUENZA 10 N/W/B & Flying Frame

User's Manual

Important Information,

Please Read Before Use!

KLING & FREITAG GmbH

Junkersstraße 14

D-30179 Hannover

TEL +49 (0) 511 96 99 70

FAX +49 (0) 511 67 37 94

www.kling-freitag.de

Version Version 6.1

Released: 18.06.2014

Page 2

Page 3

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

Table of contents

1

1.1 Symbols in User's Manual 6

1.2 Information about this User's Manual 6

2

2.1 Scope of Delivery SEQUENZA 10 N/W 7

2.2 Scope of Delivery SEQUENZA 10 B 7

2.3 Scope of Delivery SEQUENZA 10 Flying Frame 7

3

4

5

5.1 SEQUENZA 10 N/W 7

5.2 SEQUENZA 10 B 9

5.3 SEQUENZA 10 flying frame 10

Introduction 6

Scope of Delivery 7

Required Tools 7

System Requirements for Use 7

Product Description 7

5.1.1 Overview SEQUENZA 10 N/W Parts 7

5.2.1 Overview SEQUENZA 10 B Parts 9

5.3.1 Overview of flying frame Components 10

6

6.1 Safety Instructions for Flown Setup 11

6.2 Safety Instructions for Stacked Setups 12

6.3 Wind Loading 14

6.4 Preventing hearing damage 16

6.5 Protecting the Speakers / Operating Safety 16

7

8

9

10

10.1 Combining the Speaker Array 20

10.2 Lifting the Array 28

Safety Instructions 11

Using the Quick Release Pins 17

Removing the Transport Covers 17

Positioning of the Load Adapters 17

Flown Setup 20

10.1.1 Array with SEQUENZA 10 N/W 20

10.1.2 Array with SEQUENZA 10 B 24

10.1.3 Array with SEQUENZA 10 N/W and SEQUENZA 10 B 27

10.2.1 Arrays with SEQUENZA 10 B 28

10.2.2 Arrays with SEQUENZA 10 N/W and 5m maximal Length 28

10.2.3 Arrays with SEQUENZA 10 N/W exceeding a Length of 5m 30

11

11.1 Disassembly of arrays with SEQUENZA 10 N/W exceeding a Length of

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 3 of 70

Flown Disassembly 32

5m 33

Page 4

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

11.2 Disassembly of arrays with SEQUENZA 10 N/W and a maximum Length of

5m 33

12

12.1 SEQUENZA 10 N/W stacked 34

12.2 SEQUENZA 10 B stacked 38

12.3 SEQUENZA 10 N/W stacked on SEQUENZA 10 B 39

13

14

14.1 Setup instructions for a cardioid array 41

14.2 LSBlocks for cardioid use 43

15

16

16.1 Replacing the Fuses 44

17

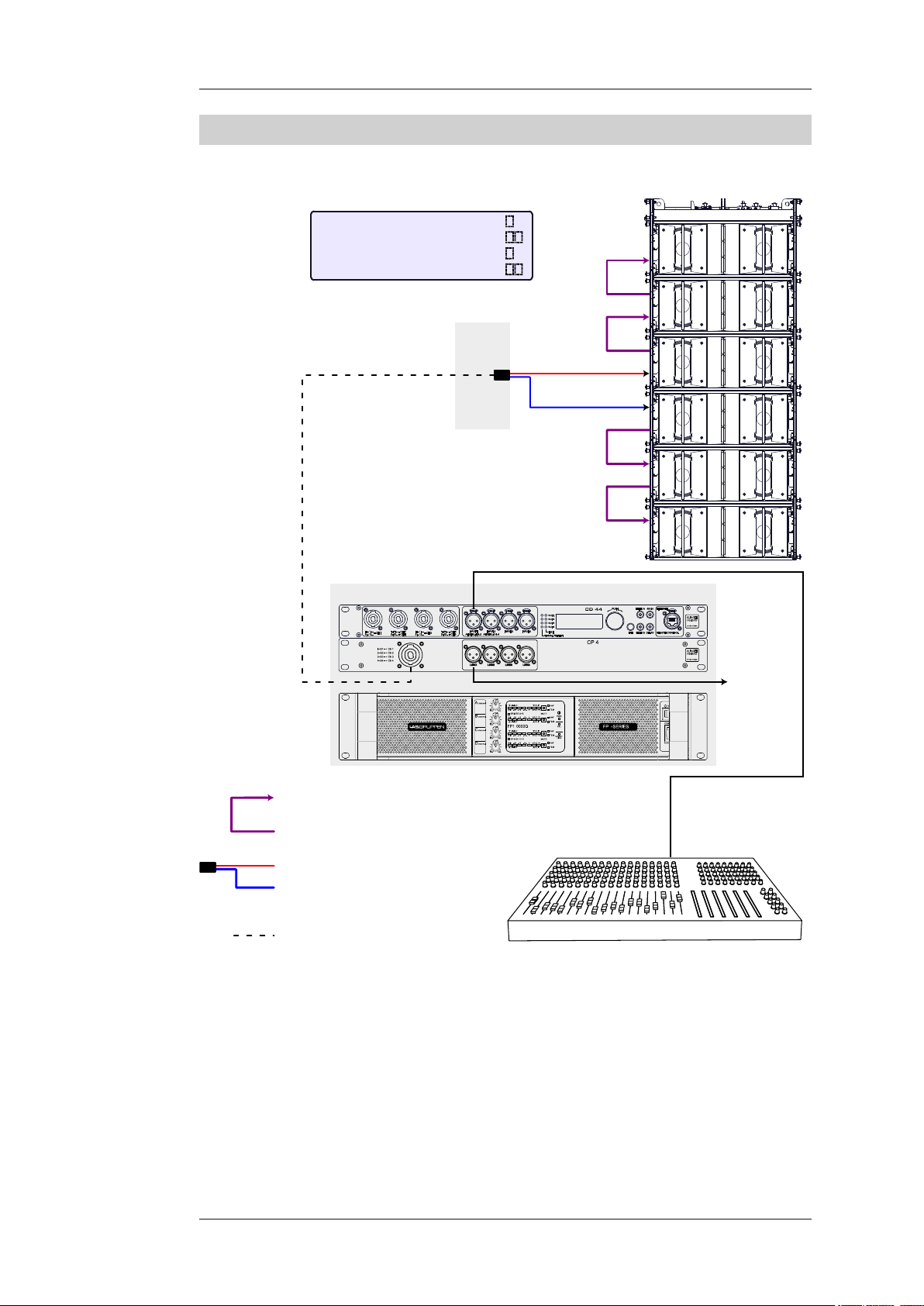

17.1 Cabling a K&F System Rack 44

17.2 Connecting the SEQUENZA 10 N/W 45

Stacked Setup 34

12.1.1 Preparing the Flying Frame 34

12.1.2 Mounting the Speakers 35

Disassambling the Stacked Array 40

Cardioid Arrays with SEQUENZA 10 B 40

SEQUENZA 10 B combined with other K&F tops. 43

Fuse in the SEQUENZA 10 B 44

Connection 44

17.3 Connecting the SEQUENZA 10 B 46

17.4 Fixating the Cables 47

18

19

19.1 Inspection Intervals and Items 48

20

21

21.1 Technical Specifications SEQUENZA 10 N 49

21.2 Technical Specifications SEQUENZA 10 W 51

21.3 Technical Specifications SEQUENZA 10 B 53

22

22.1 SEQUENZA 10 N diagrams 55

22.2 SEQUENZA 10 W diagrams 57

22.3 SEQUENZA 10 B diagrams 59

23

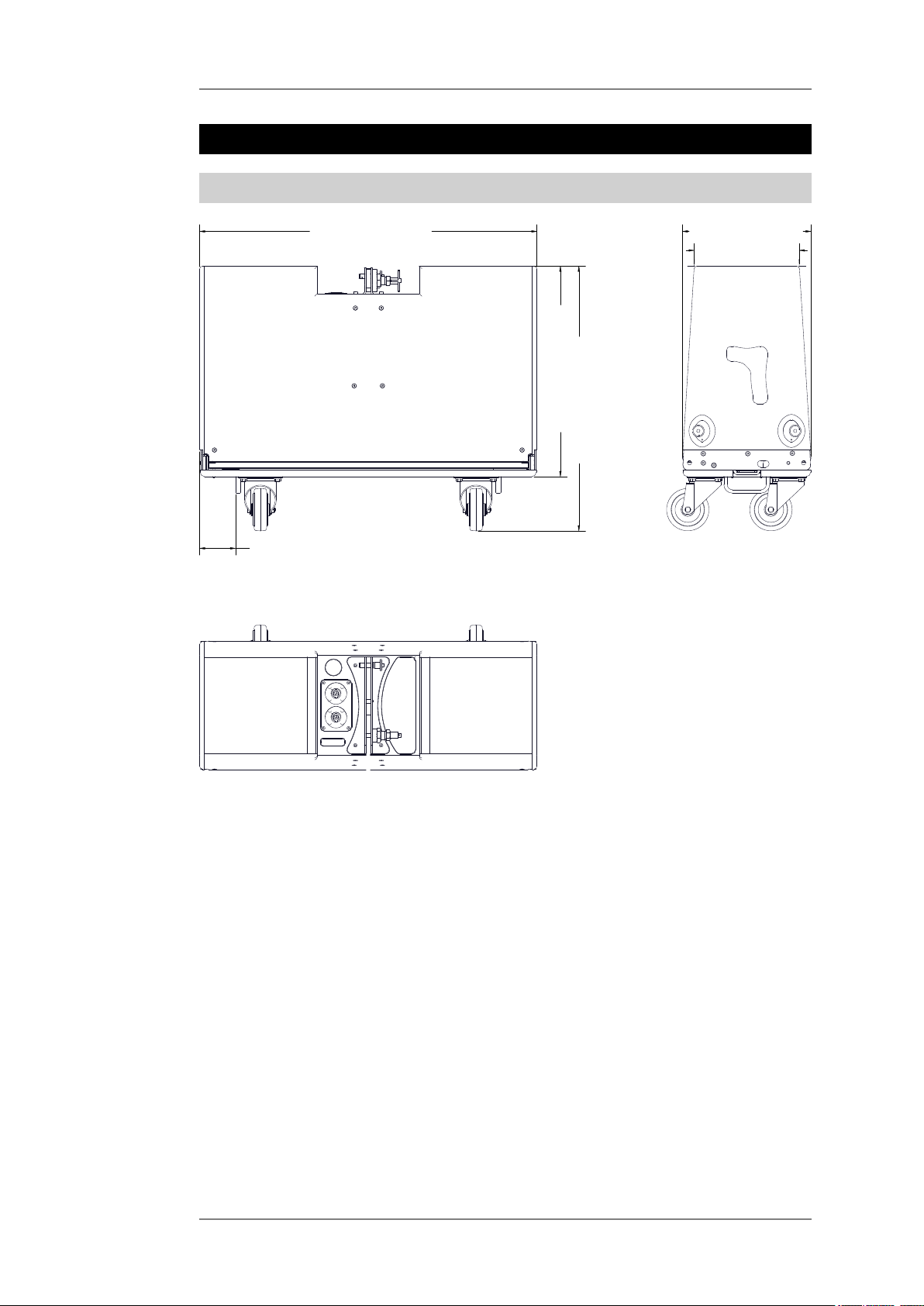

23.1 Dimensions SEQUENZA 10 N/W 61

Transport and Storage 47

Maintenance and Care 47

Optional BGV C1 Certification 48

Technical Specifications of Loudspeakers 49

Measuring Diagrams 55

Dimensions speaker 61

23.2 Dimensions SEQUENZA 10 B 62

24

25

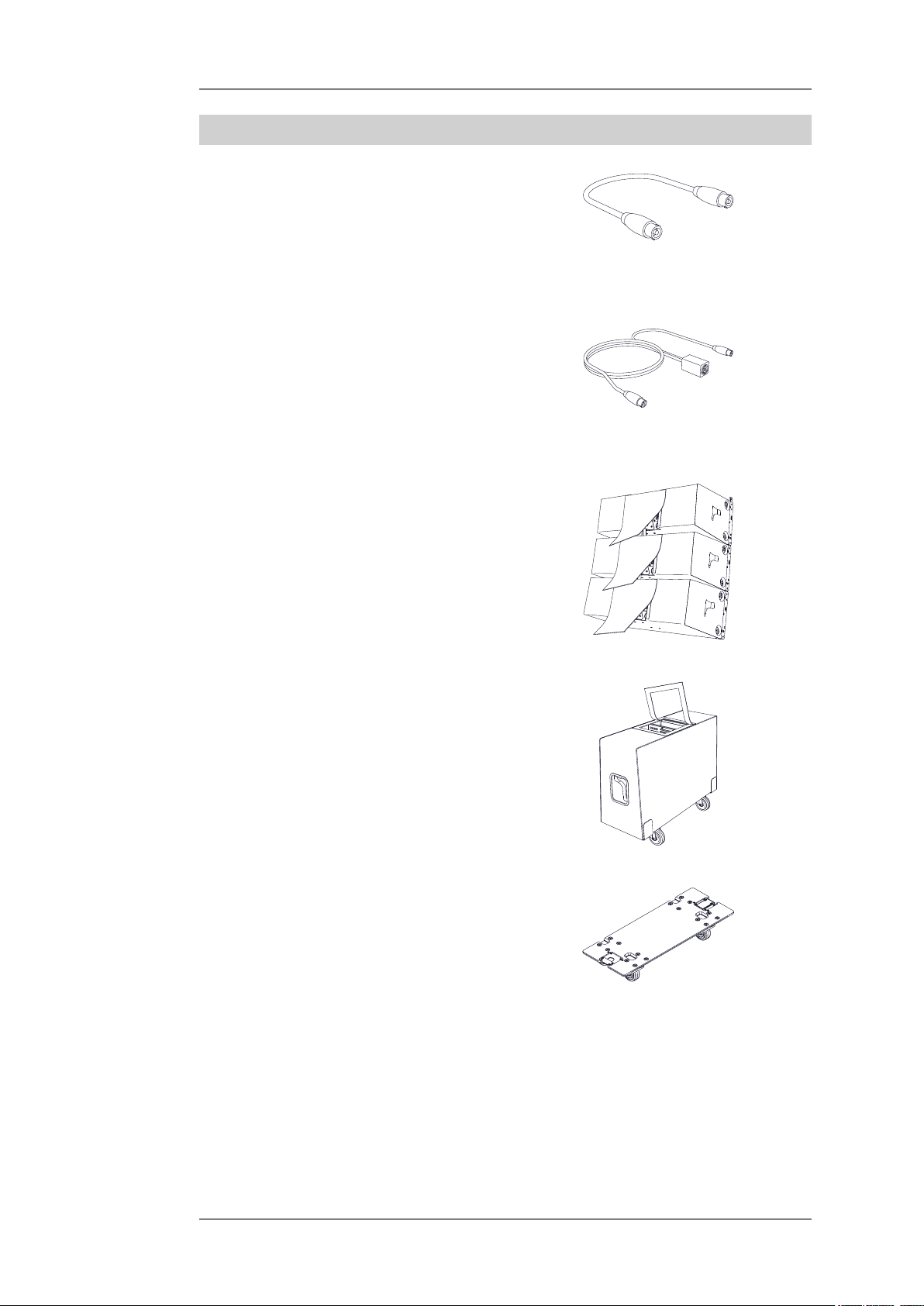

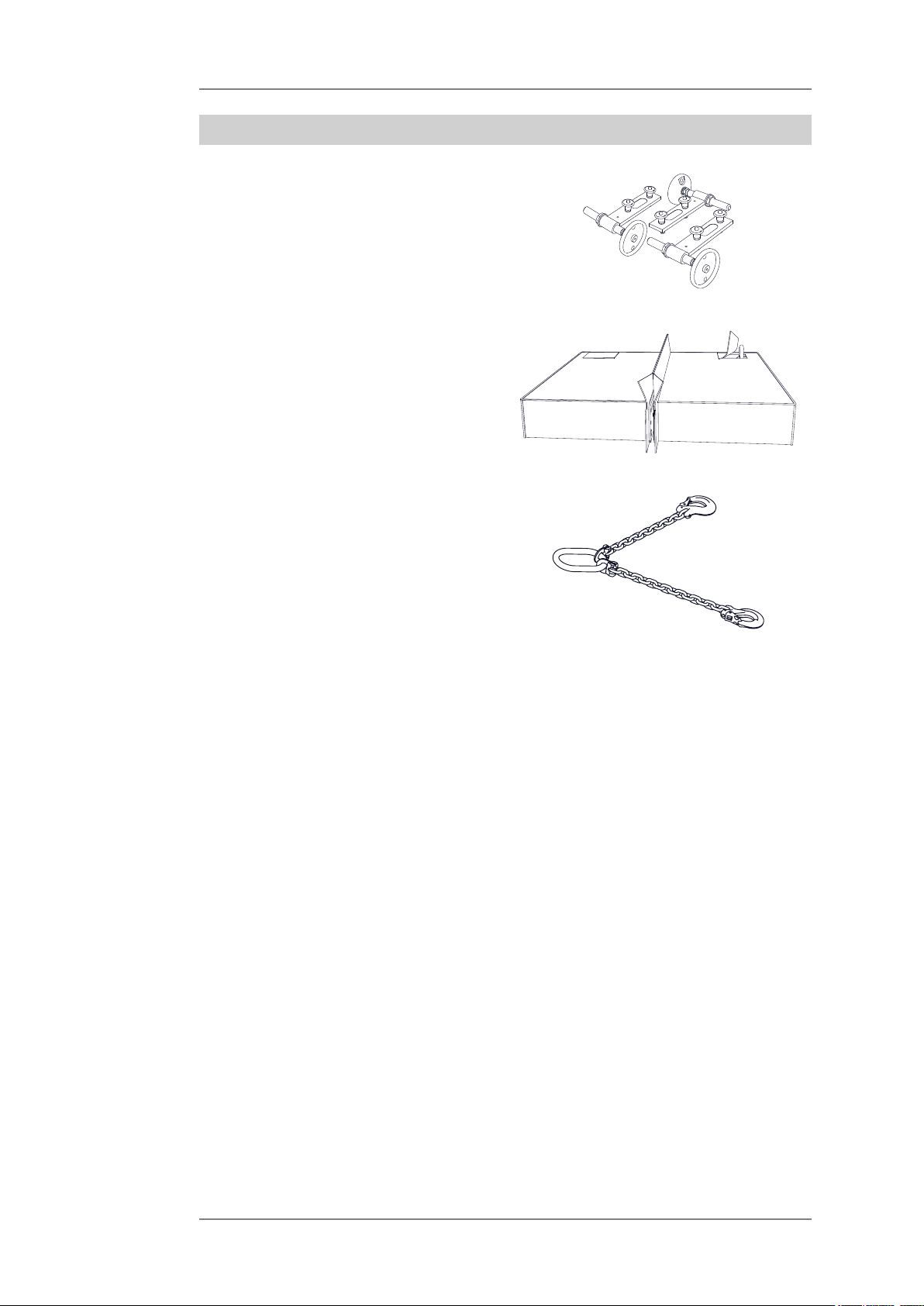

25.1 General Accessories for SEQUENZA 10 64

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 4 of 70

Dimensions and weight flying frame 63

Accessories 64

Page 5

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

25.2 Accessories for SEQUENZA 10 N/W 65

25.3 Accessories for SEQUENZA 10 B 66

25.4 Accessories for SEQUENZA 10 Flying Frame 67

26

26.1 Regulations for Disposal 68

27

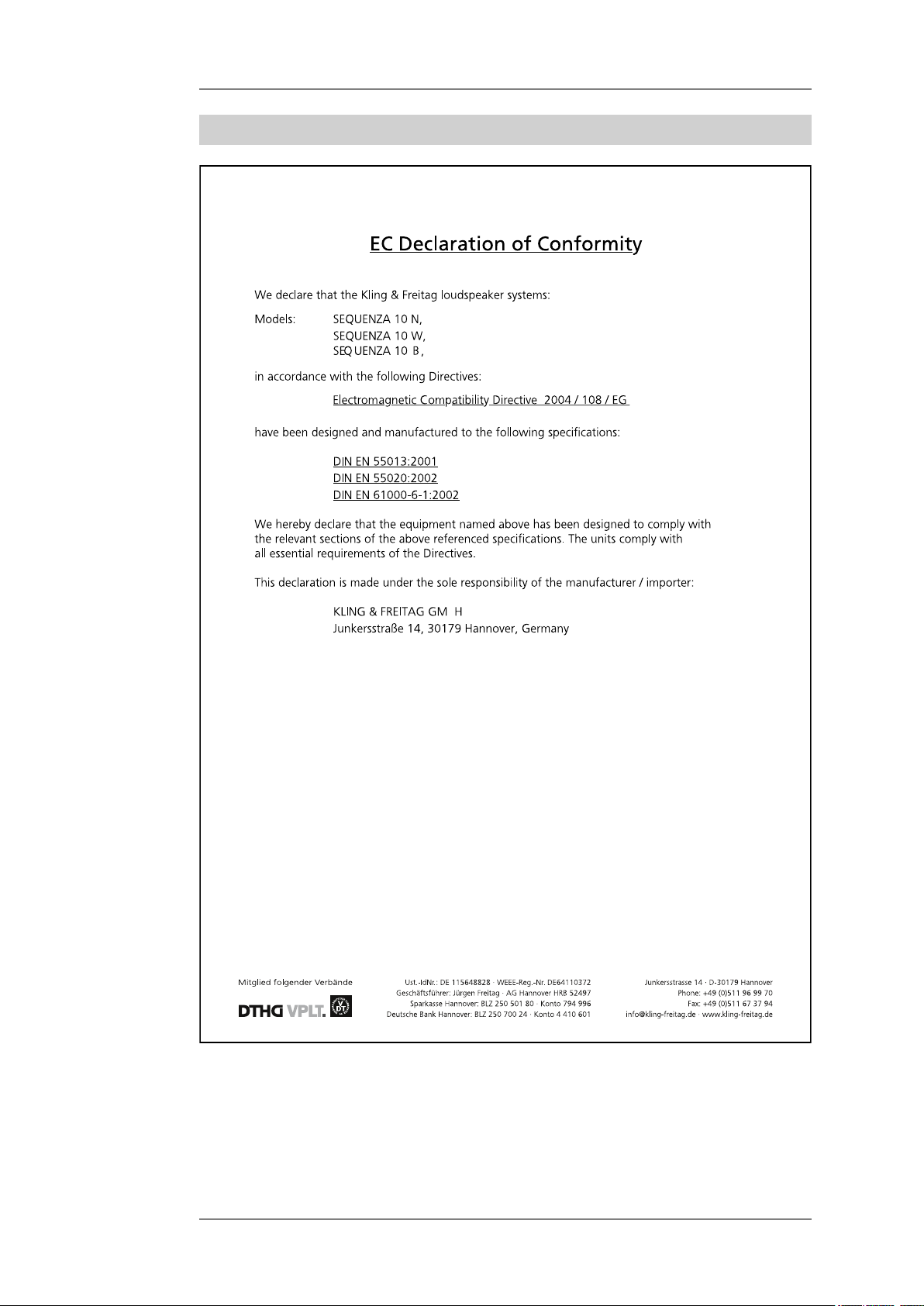

27.1 CE Rigging System 69

27.2 CE Loudspeaker 70

Disposal 68

26.1.1 Germany 68

26.1.2 EU, Norway, Iceland, and Liechtenstein 68

26.1.3 All other Countries 68

Declaration of Conformity (CE) 69

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 5 of 70

Page 6

Warning

Caution

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

1. Introduction

Thank you for your decision to buy a KLING & FREITAG product. To guarantee a trouble-free

operating of the equipment and to allow your KLING & FREITAG Sequenza 10 system to

achieve its full potential please read the operating instructions carefully before use. With

the purchase of a SEQUENZA 10, you have acquired a large sound system with the highest

possible quality and performance capabilities. As the owner of a SEQUENZA 10 loudspeaker,

you now have a versatile and highly professional tool which, when operated properly, is a

true pleasure to use.

1.1 Symbols in User's Manual

This symbol indicates the possibility of life-threatening danger and a health risk for persons.

Not following these instructions may result in serious health problems including potentially

fatal injuries.

This symbol indicates a possibly dangerous situation. Not following these instructions may

cause minor injuries or cause property damage.

Tip

This symbol gives instructions for the proper use of the described products. Not following

these instructions may cause malfunctions or property damage.

This symbol indicates notes that help you to handle the described products easier.

1.2 Information about this User's Manual

User's Manual SEQUENZA 10 N and SEQUENZA 10 W in Combination with the SEQUENZA 10

Flying Frame. SEQUENZA 10 N/WSEQUENZA 10 BSEQUENZA 10

© KLING & FREITAG GMBH, all rights reserved.

All specifications in this manual are based on information available at the time of publishing

for the features and safety guidelines of the described products.

Technical specifications, measurements, weights and properties are not guaranteed.

The manufacturer reserves the right to make product alterations within legal provisions as

well as changes to improve product quality.

All persons who use the speaker system must have this guide and all further information for

safe operations available to them during assembly, disassembly, and use. The speaker system

may neither be set up nor used until this manual has been read, understood and kept readily

available on site.

We appreciate any input with suggestions and improvements for this manual. Please send this

to us at the following address:

info@kling-freitag.de or to:

KLING & FREITAG GMBH Junkersstr.14 D-30179 Hannover.

Phone +49 (0) 511 - 96 99 70, Fax +49 (0) 511 - 67 37 94

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 6 of 70

Page 7

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

2. Scope of Delivery

2.1 Scope of Delivery SEQUENZA 10 N/W

• Full-range loudspeaker with integraten 'Snap&Fly' Rigging System incl. Quick Release

Pins (usable with SEQUENZA 10 Flying Frame only)

• User's Manual (1x)

2.2 Scope of Delivery SEQUENZA 10 B

• Subwoofer with integraten Rigging System incl. Quick Release Pins (usable with

SEQUENZA 10 Flying Frame only)

• User's Manual (1x)

2.3 Scope of Delivery SEQUENZA 10 Flying Frame

• Flying frame to hang and stack SEQUENZA 10 N/W speakers incl. Quick Release Pins

SEQUENZA 10

• 2 x 3.25t shackles (for optional safety chain)

• User's Manual (1x)

• Calculation software CON:SEQUENZA CON:SEQUENZA

The following material is optionally available for flying the flying frame:

• 3 level-adjustable hinged heavy-duty feet (mandatory for stacking speakers)

• 2 x 3.25t shackle for load adapter

• 2-strand safety chain: 2 x 8mm steel chain / Grade 8 / Length 380mm per strand

(Working load limit (WLL) BGV C1: 1250 kg) with 2 x hooks DIN 5691 WLL BGV C1: 1250

kg) / Rigging link shape A according to DIN 56882 (WLL BGV C1: 1750 kg)

3. Required Tools

For the optionally available hinged heavy-duty feet of the SEQUENZA 10 flying frame:

• 24 mm open-end wrench

• 17 mm open-end wrench

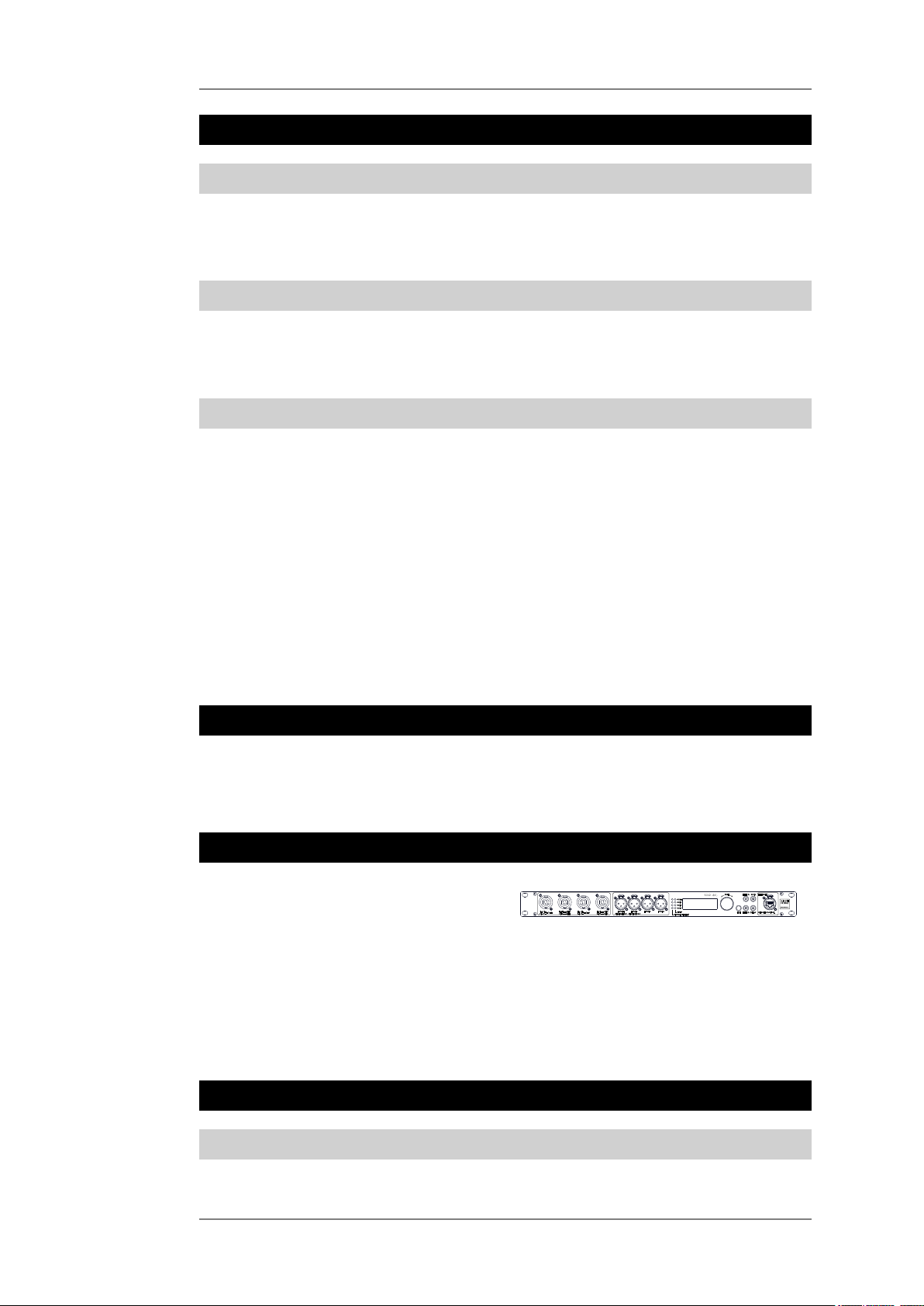

4. System Requirements for Use

K&F CD 44 Digital System Controller

LAB.GRUPPEN FP 10000Q:

Connector Panel CP 4:

These components will be referred to as 'K&F SystemRack' in this manual.

5. Product Description

5.1 SEQUENZA 10 N/W

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 7 of 70

Page 8

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

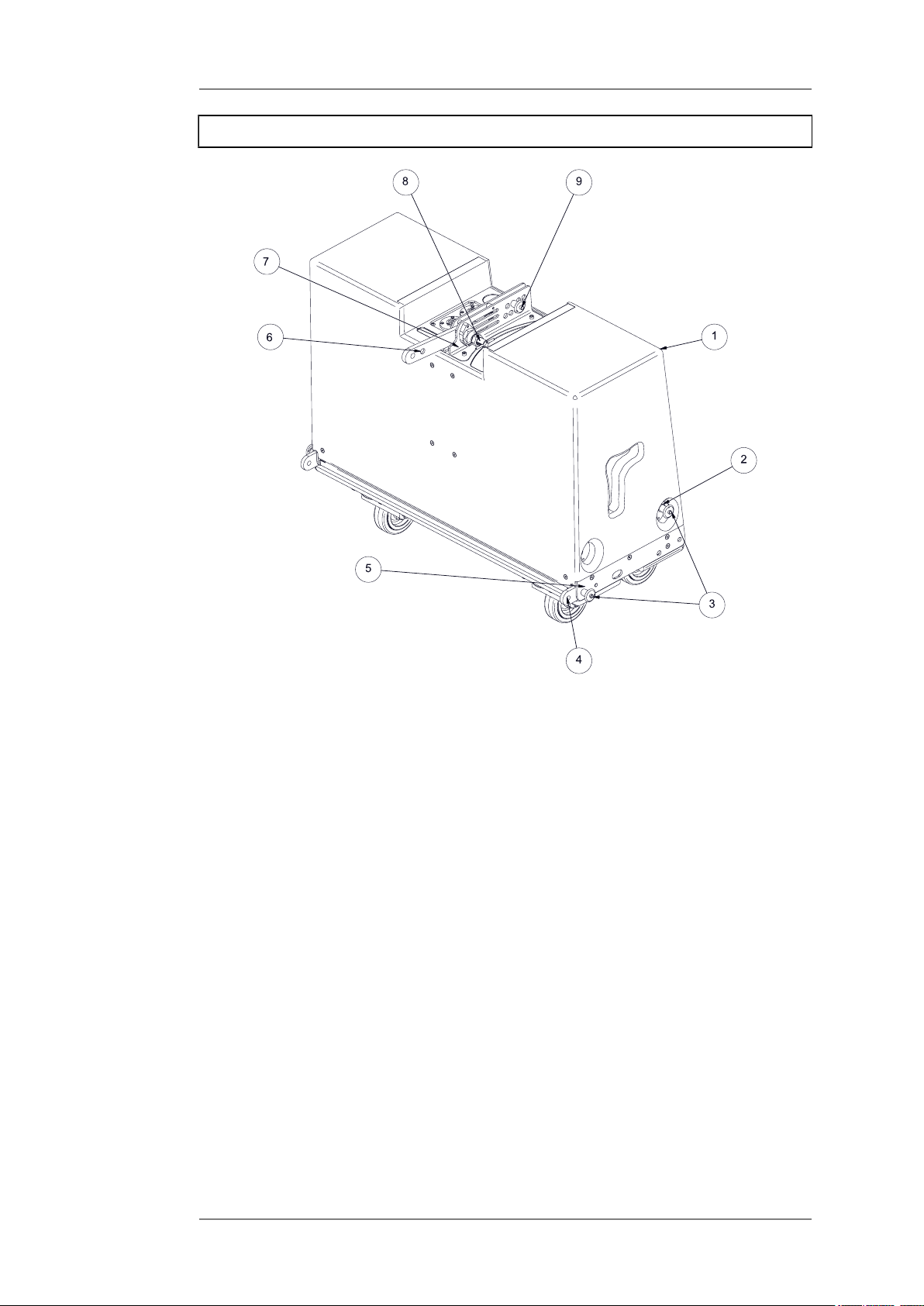

5.1.1 Overview SEQUENZA 10 N/W Parts

1. speaker enclosure

2. Park position Quick Release Pins

3. Quick Release Pins front

4. front joint plates

5. front connector bracket

6. rear joint plate

7. rear connector bracket

8. spring bolt

9. Quick Release Pin rear

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 8 of 70

Page 9

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

6

5

4

3

2

1

7

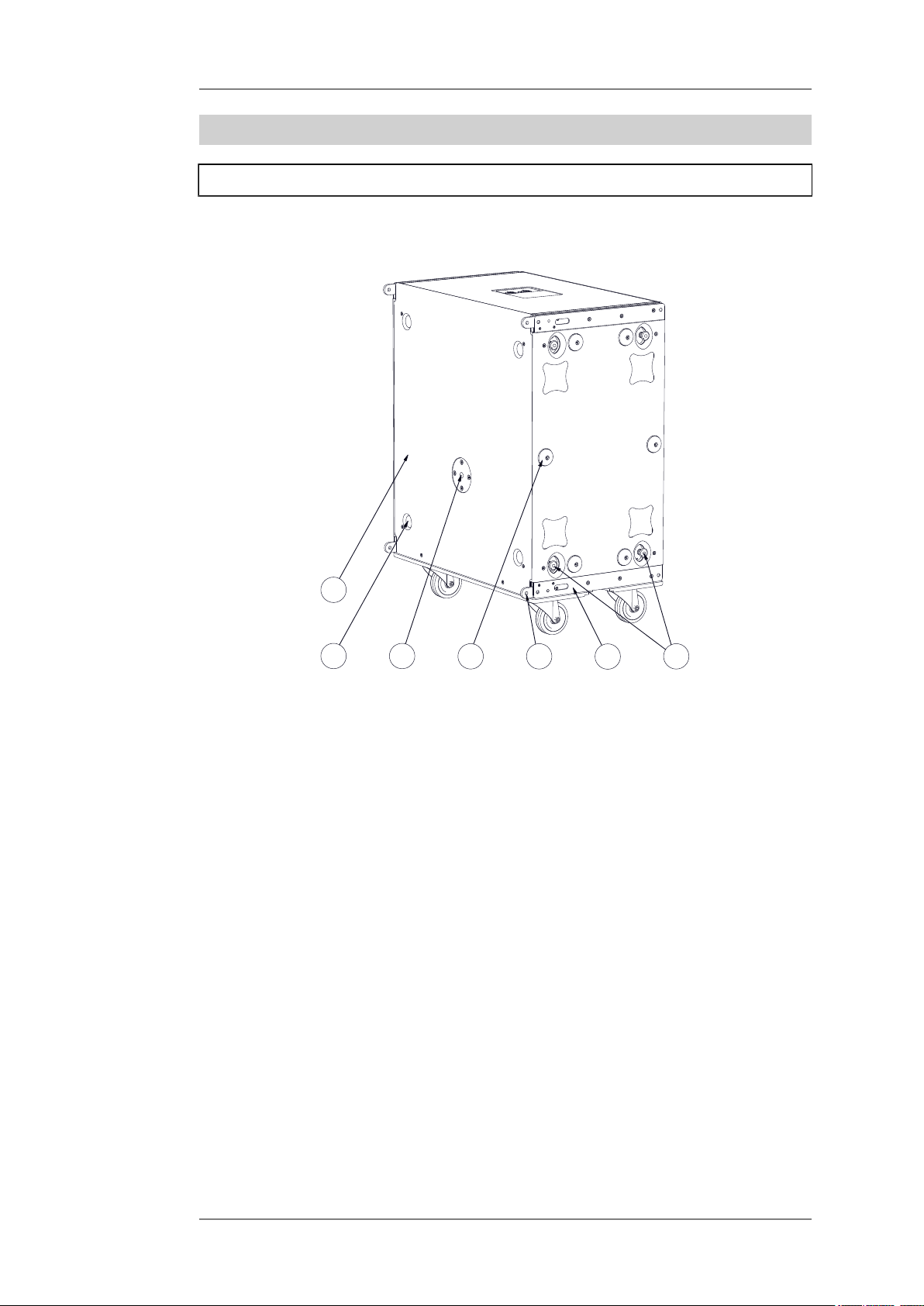

5.2 SEQUENZA 10 B

5.2.1 Overview SEQUENZA 10 B Parts

1. speaker enclosure

2. Stacking grooves / cover, adjacent: stacking feet / bottom

3. Threaded stand flange

4. Stacking feet / side, adjacent: stacking grooves / side

5. joint plates

6. connector brackets

7. Quick Release Pins in park position

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 9 of 70

Page 10

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

8

5

6

7

10

9

4

1

3

2

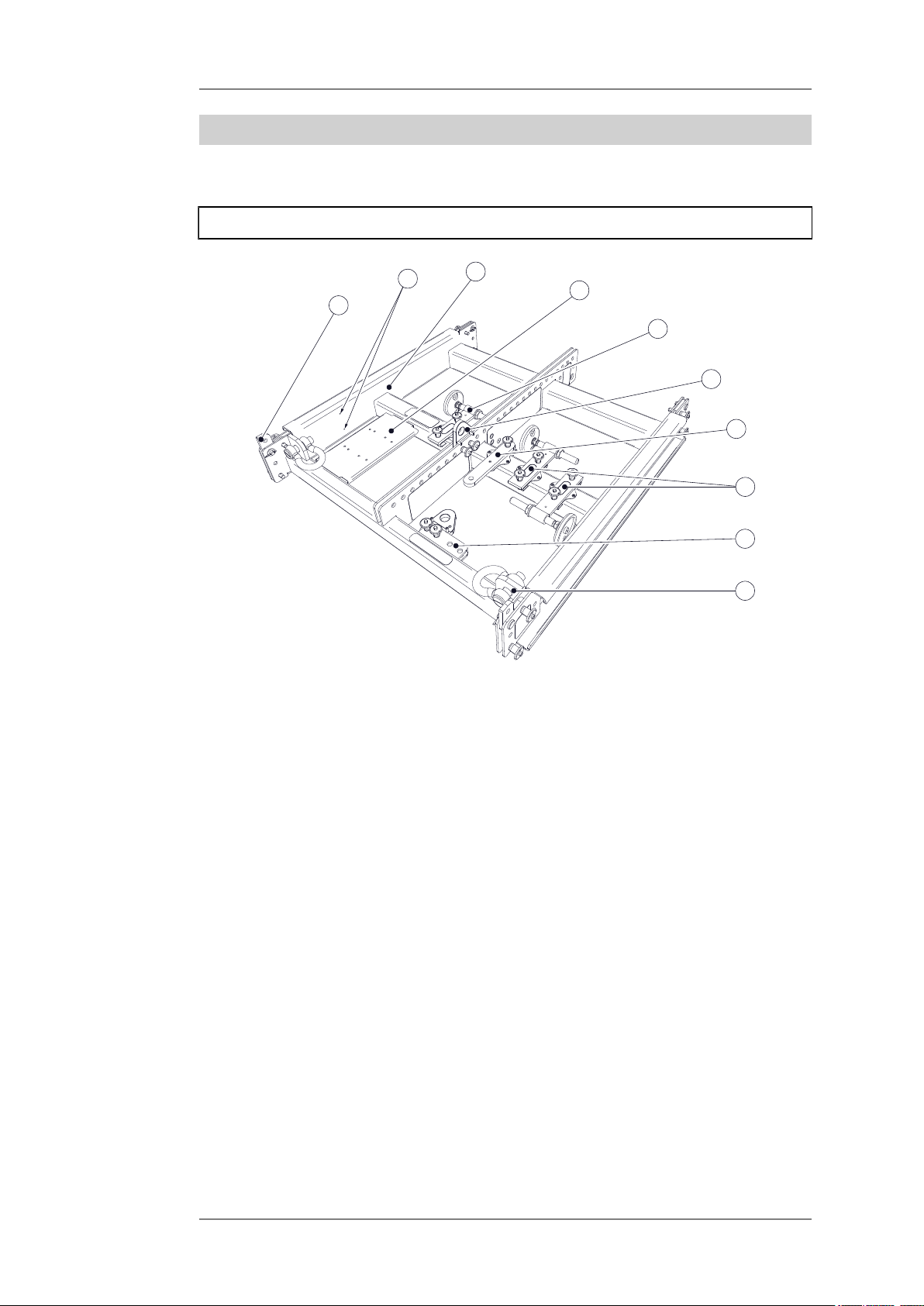

5.3 SEQUENZA 10 flying frame

This flying frame was designed to fly or stack the KLING & FREITAG speakers SEQUENZA 10 N/

W. SEQUENZA 10

5.3.1 Overview of flying frame Components

1. hinge fitting

2. fixing point for Rieker inclinometer

3. SEQUENZA 10 flying frame

4. fixing plate for SSE inclinometer

5. Hinged heavy-duty feet rear (optional)

6. Load adapter (in park position)

7. stacking link

8. Hinged heavy-duty feet front (optional)

9. park position for load adapter

10. fixing points for safety chain

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 10 of 70

Page 11

Warning

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

6. Safety Instructions

The information described here does not relieve the user of the duty to follow the given

safety requirements and legal regulations.

The technicians responsible for assembling the flying frame on site are responsible for the

safe setup and use of the flying frame and guarantee this.

To prevent damage to persons and property, you must set up or suspend the array in

compliance with the specifications of the German safety regulation BGV C1 or comparable

applicable national standards.

At least 2 people are necessary to set up the array.

The flying frame is solely for professional use and only for the suspension of the

KLING & FREITAG speaker models SEQUENZA 10 N, SEQUENZA 10 W, SEQUENZA 10 B in

the manner described here.

If the simulation software CON:SEQUENZA displays "Load-Failed", the array may not be set

up in the configuration simulated in the software. CON:SEQUENZA

When laying out the connecting cables, make sure that nobody can trip.

If not otherwise stated in this manual, only original KLING & FREITAG parts may be used for

mounting the speakers. The use of other parts - in particular parts by other manufacturers - is

not permitted.

For mobile and fixed installations, use only assembly equipment from KLING & FREITAG.

As a basic principle, you must visually inspect all components of the array before every use.

For fixed installations, you must inspect all components of the flying system for signs of

wear at regular intervals. The visual inspection includes checking the components of the

speakers, the flying frame, the load-bearing parts (cross beams, ceiling constructions, etc.)

and their bolted connections. When inspecting components of the flying frame, pay special

attention to any deformations, cracks, damage to threads, and corrosion as well as the

functional capability of the Quick Release Pins and the functional capability of the spring

bolts. Mounting devices such as shackles, chains and wire ropes also have to be checked for

signs of wear or deformation carefully. If there are signs of wear, cracks, or deformation,

etc. then you must replace the parts immediately. For further instructions, refer to chapter

'Maintenance and Care' on page 47.

Warning

6.1 Safety Instructions for Flown Setup

Falling speakers pose the threat of fatal injuries to people near them!

If you have even the slightest reason to doubt the safety of the flying system, then you may

not use it under any circumstance.

Only trained event technicians may suspend the flying frame.

Never suspend the speakers without the appropriate flying frame.

The maximum working load limit (WLL) of the flying frame is – depending on the selected

load bearing drillings and types of speakers – 625 kg - 1000 kg.

This specification includes cabling and additional fittings. The provided simulation software

'CON:SEQUENZA' must be used to determine if the frame is loaded permissibly. The

simulation software CON:SEQUENZA does not take the weight of cabling and additional

fittings into consideration! When following the specifications of the CON:SEQUENZA

calculation software, consider this additional weight and reduce the number of speakers

accordingly.

If the simulation software CON:SEQUENZA does not confirm the compliance with DIN 18 800,

the array may not be assembled in the simulated setup.

If the simulation software CON:SEQUENZA does not confirm the compliance with BGV C1,

no one may be situated in this area between the assembly and disassembly – not even those

involved in assembly and disassembly. You must effectively block off this area and secure it

from trespassing.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 11 of 70

Page 12

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

Warning The following arrays (maximum configurations) fulfil the stipulations of the BGV C1 with

their given design:

Maximum number of flown speakers:

• SEQUENZA 10 N and SEQUENZA 10 W:

Arrays of up to 13 speakers and a flying frame inclination less than +/- 4°.

• SEQUENZA 10 B:

Arrays of up to 12 speakers.

• SEQUENZA 10 N/W combined with SEQUENZA 10 B:

For combined arrays consisting of SEQUENZA 10 N/W and SEQUENZA 10 B, a special

verification with the CON:SEQUENZA simulation software is mandatory.

If these angles or the number of speakers is exceeded, it is mandatory that you separately

verify the array with the CON:SEQUENZA simulation software. CON:SEQUENZA

Ensure that all connections are secured against coming loose and that only authorized,

statically tested and correctly sized supports, mounting equipment, wire ropes and chains are

used.

Follow the relevant specified safety factors. The safety factors (SF) are stated on the back

of the speakers and they comply with the BGV C1. Be sure to follow the relevant national

specifications, norms, and safety regulations.

Note that every suspension point as well as the supporting structure of the building (i.e.

ceiling points, cross beams and stage or PA tower, etc.) must be capable of carrying the total

load of the system (including cabling and additional fittings).

Note that the suspension points on the hall ceiling (i.e. shackles, suspension points, or chain

points) must comply with the accident prevention regulation BGV C1 (Event and Production

Sites for Stage Presentations) or comparable applicable national standards, and the total load

must be approved by an authorised expert. If in doubt, have it checked by local authorities.

Also, follow the operating and safety instructions for the product from which you will

suspend the flying frame (i.e. truss). If there is no information regarding the safe use and the

working load limit, you may not fly the flying frame from it.

Every chain and every motor must be capable of carrying the total load of the array on its

own, even with two-strand rigging. Check to make sure that the chains of the hoist motors

are hanging straight down and are not twisted and that the hoist motors are in the intended

positions.

When operating with chain hoists that do not comply with the BGV C1 or the D8+, no one

may be present in the danger zone underneath or near the speaker array.

Secure the array from falling with a second independent safety fitting if no BGV C1 or D8+

motor is used.

Never use signal cables or power cords for suspending, aligning or securing the systems.

When laying out the connecting cables, make sure that nobody can trip.

Make sure you have enough free working space on site to assemble and suspend the array.

The array can swing out while being lifted!

Only personnel directly involved with assembly or disassembly may be in the working area.

Every time before the responsible technician raises or lowers the flying frame, he must

unmistakably signal this to all people. All persons must then move outside of the pivoting

and lifting range.

The flying frame may not be used to lift and secure people or objects other than the abovementioned speaker systems.

The array may not be used as a climbing aid.

The safe use of the flying frame and the speakers also depends on the various factors present

at the area of use. Weather conditions such as wind or rain, for example, can compromise

the safety of the flying frame and speakers. Always consider and evaluate these factors. (See

chapter 'Wind Loading' on page 14.)

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 12 of 70

Page 13

Warning

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

6.2 Safety Instructions for Stacked Setups

Falling speakers pose the threat of fatal injuries to people near them!

Be sure to follow the relevant national specifications, norms, and safety regulations.

Always make sure that a sufficient safety level is still given, even when outside forces have

an additional impact on the stacked speakers. Before setup, carefully ascertain if there are

any possible outside forces that could result in the array falling over. (Slant of the ground /

the bearing capacity of the ground / wind / person or vehicle impact, etc.). A technical expert

who is responsible for the setup must evaluate and determine necessary measures (including

calculating the statics). If necessary, obtain expert proof of stability.

For the standard safety inspection, you must always factor in an imperfection (tilt) of +/-5°

and destabilising loads. A planned tilt of the flying frame ist not permissible. In calculations,

the tilted setup serves the purpose of levelling out unevenness.

With the set-up systems for which you cannot verify the structural safety without safeguards,

you must secure them to prevent sliding or tipping in order to provide proof of this safety. To

secure the system from tipping over, use water tanks or floor bolts. Other possible measures

include strapping it to a suitable substructure or tying it using safety straps. The simulation in

the CON:SEQUENZA software is not valid as a verification of structural safety. This software

always states that you must secure stacked speakers to prevent their falling over.

For outdoor and trade fair venues in which wind loads must be considered, additional proof

of stability is necessary.

Only stack the SEQUENZA 10 N/W systems in conjunction with the SEQUENZA 10 flying

frame and the optionally available SEQUENZA 10 Ground Stack Kit (stacking feet), which

is intended to be used. Stacking of SEQUENZA 10 N/W without the optional feet is not

permissible!

Make sure that the stacking feet of subwoofers stacked on top of one another are securely

positioned in the grooves of the lower speaker.

Maximum number of stacked speakers (Valid for indoor operations without wind, with a

person impact of 10 kg at a height of 1.5 m and a flying frame tilt of 5°):

• SEQUENZA 10 N and SEQUENZA 10 W:

arrays with up to 7 x SEQUENZA 10 N/W. To fixate the system to the floor, you can use

the openings in the optional stacking feet (SEQUENZA 10 Ground Stack Kit).

• SEQUENZA 10 B flat:

Arrays with up to 6 x SEQUENZA 10 B

• SEQUENZA 10 B vertical:

Arrays with up to 2 x SEQUENZA 10 B You must additionally secure vertically

standing stacked SEQUENZA 10 B systems from falling since the structural safety is

not guaranteed, otherwise. Possible measures include strapping them to a suitable

substructure or tying them using safety straps.

• SEQUENZA 10 N/W combined with SEQUENZA 10 B

arrays with up to 7 x SEQUENZA 10 N/W on 6 x SEQUENZA 10 B.

SEQUENZA 10 B

If you are stacking a K&F top with feet (i.e. Line 212) on top of a SEQUENZA 10 B subwoofer

that is placed on its side, make sure that the Quick Release Pins have not been damaged in

their stand-by positions.

You must always strap such setups to one another and secure them from falling over.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 13 of 70

Page 14

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

6.3 Wind Loading

For open air events, obtain current local wind and weather data. The following chart

provides a preliminary indication

Bft m/s Windspeed Description

0 0-0.2 Calm Smoke rises

vertically

1 0.3-1.5 Light air Smoke drift

indicates wind

direction, vanes

do not move

2 1.6-3.3 Light Wind felt on face,

vanes begin to

move

3 3.4-5.4 Gentle Leaves, small

twigs in constant

motion, light flags

extended

Warning

4 5.5-7.9 Moderate Dust, leaves, and

loose paper raised

up, small branches

move

5 8.0-10.7 Fresh Small trees in leaf

begin to sway,

whitecaps on lakes

visible

6 10.8-13.8 Strong Larger branches

of trees in motion;

whistling heard in

wires

7 13.9-17.1 Near gale Whole trees in

motion; resistance

felt in walking

against wind

8 17.2-20.7 Gale Twigs and small

branches broken

off trees

For outdoor uses, we recommend using at least a BGV D8+ hoisting device to avoid wind

causing the release of the secondary safety device.

If wind speeds higher than Beaufort 5 are expected, you must constantly consider the wind

speed and its possible influence on the array as well as the fact that the wind speed increases

the higher the array is.

With expected wind speeds exceeding Beaufort 5, construct the rigging and safety points so

that they can carry at least twice the static load.

With wind speeds exceeding Beaufort 6 (14 m/sec.), arrays are not recommended.

As of a wind speed of Beaufort 6, you must clear the area under the speakers. Effectively

prevent the arrays from swaying in the wind by tying them off or using a lateral fixation.

If the suspended load sways, it can create significant inertial force that can result in the PA

tower structurally collapsing or tipping.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 14 of 70

Page 15

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

With wind speeds of Beaufort 8 or more, you must lower and disassemble the array.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 15 of 70

Page 16

Caution

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

6.4 Preventing hearing damage

Avoid beeing too close to operating speakers. This equipment is capable of delivering sound

pressure levels in excess of 90 dB SPL, which may cause permanent hearing damage.

6.5 Protecting the Speakers / Operating Safety

SEQUENZA 10 N/W/B speakers may only be used in combination with a K&F SystemRack.

In general, audio signals must not be overdriven. This may be caused by mixing consoles,

equalizers, effect equipment, etc. and should be indicated on this equipment. When a power

amplifier is overloaded at the output (clipping), then the amplifier activates a clipping

warning signal. In any case, the signal must be reduced as soon as it sounds unnaturally

distorted.

For damage caused by

• overloading the speakers

• using the speakers without K&F SystemRack

we do not assume warranty and excludes liability for possible consequential damage.

The following signals may damage the speakers:

• permanent high-level signals with high frequency and continuous noise from feedback.

• permanently distorted high-level signals.

• noises, which occur when the amplifier is on while equipment is being connected,

disconnected or switched on.

Do not install devices in any of the following places:

• where the devices are permanently exposed to direct sunlight.

• where the devices are exposed to high moisture or rain.

• where the devices are exposed to strong vibrations and dust.

Damage caused by the speakers' magnetic fields

Speakers are permanently surrounded by a magnetic field, even when they are not

connected. Therefore, during transport and placement of the speakers, it is important to

ensure that there is always approx. 1 m between the speakers and magnetic data media and

computer/video monitors.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 16 of 70

Page 17

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

1

2

3

7. Using the Quick Release Pins

The Quick Release Pins are equipped with retaining balls. By pushing the button in the

middle of the pin, you can release these balls and then insert or remove the pin. As long as

you do not push the button in the middle of the pin, you should not be able to pull out the

pin.

8. Removing the Transport Covers

In order to remove the transport cover,

push the latch in the round opening

towards the middle of the transport cover

(1), slightly pull the transport cover on

the side of the latch toward you (2), and

remove the cover to the side (3).

When doing this, do not pull the

transport cover towards you too much,

as this could cause the catch on the other

side of the cover to bend.

9. Positioning of the Load Adapters

You can calculate one- and two-strand riggings with the simulation software CON:SEQUENZA.

For one-strand rigging, use one load adapter; for two-strand rigging, use two load adapters.

The drill holes on the flying frame where the load adapters are to be attached are

determined by the simulation software CON:SEQUENZA. CON:SEQUENZAYou will find the

specifications on the relevant calculation printouts. The specification of the drill hole in the

simulation software refers to the drill hole in the load adapter that is facing the front side of

the frame. The front side of the frame is marked with a sticker (Front).

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 17 of 70

Page 18

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

26

REAR FOOT

PINS ONLY !

CABLE PICK

AND

ADJUSTMENT

POINT

5

9

FLYING +3°

FLYING 0°

STACKING

B

A

15

20

INCLINATION

STACKING TABLE

B

-2.4°

-3.2°

-4.4°

-5.2°

-6.4°

-7.3°

-8.5°

-9.2°

A

2.9

°

2.0

°

0.9

°

0.0

°

-1.1

°

-2.0

°

-3.1

°

-4.0

°

CABINET

7°

5°

6°

4°

3°

2°

1°

0°

MODEL:

SEQUENZA 10

FLYING FRAME 24

SECURE FRAME WITH A

SECONDARY 2 LEG SAFETY !

TO BE USED BY QUALIFIED

RIGGERS ONLY !

READ MANUAL AND SAFETY

INSTRUCTIONS BEFORE USE !

SUSPEND K&F SEQUENZA 10

Manufacturing Year:

41kg

Ser.-No.:

Weight:

SAVE WORKING LOAD:

(BGV C1 / SF 5 / SECONDARY SAFETY)

MINIMUM 625 kg

@ALL HOLE POSITIONS

MAXIMUM 1000 KG

FROM HOLE POSITION 1 TO 21

1, 2, 3, 4, 5, 6, 7, 8, 9,10...............15................20........................27

A

B

The drill holes in the flying frame are numbered consecutively from 1 to 27, beginning on the

front end of the frame (Front). For your orientation, the drill holes 5, 9, 15, 20, and 26 are

labelled.

You can set the position of the load adapters in 1/2-steps because they are usable on

both sides. This doubles the grid of the row of drill holes in the flying frame and thus the

adjustment possibilities. The load adapters are labelled with '1/1 Grid' on the one side and

'1/2 Grid' on the other. The simulation software CON:SEQUENZA gives you the information

whether a load adapter should be mounted in the 1/1 or the 1/2 position. In the 1/1 position

(A), the arrow on the 1/1 side of the load adapter must point toward the front side of the

flying frame (Front). In the 1/2 position (B), the arrow on the 1/2 side of the load adapter

must point toward the front side of the flying frame (Front).

Warning

A = Load adapter 1/1 grid position

B = Load adapter 1/2 grid position

Instructions for mounting the load adapter

Calculate the correct position of load adapters with the simulation software CON:SEQUENZA.

CON:SEQUENZAIn this calculated position, the array is guaranteed to fly at the desired angle

later, and the sound will be emitted correctly.

Always mount a load adapter with 2 Quick Release Pins!

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 18 of 70

Page 19

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

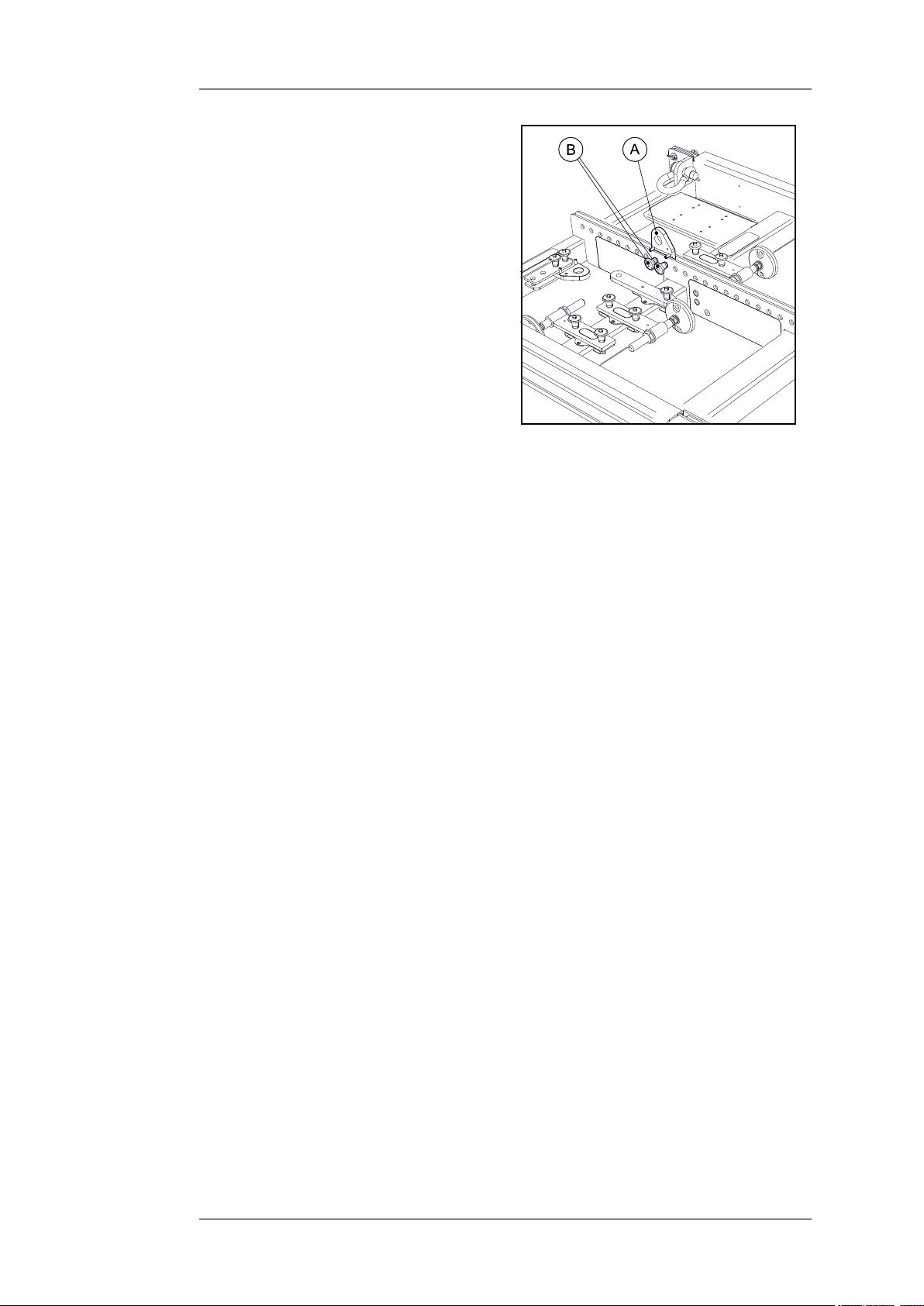

Take the load adapter (A) out of the

stand-by position and place it on the

hole position that was determined by the

simulation software CON:SEQUENZA.

Mount the load adapter with 2 Quick

Release Pins (A).

With a two-strand rigging, proceed with

the second load adapter accordingly.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 19 of 70

Page 20

Warning

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

10. Flown Setup

10.1 Combining the Speaker Array

10.1.1 Array with SEQUENZA 10 N/W

The splay angles of the individual speakers are determined by the simulation software

CON:SEQUENZA. CON:SEQUENZAYou will find the specifications on the relevant calculation

printouts. On the rear joint plate of the speakers, there are drill holes with the corresponding

angles marked.

Control the secure fit of every ball lock pin during setup.

1.

2.

Slide the front joint plates out of

the speaker by reaching into the

access opening (A) and pushing the

joint plate forwards.

Secure the joint plates(B) with the

Quick Release Pins(C).

Slide the speakers together so that

the joint plates protrude into the

front connecting bracket.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 20 of 70

Page 21

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

3.

4.

Secure the connection with the

Quick Release Pins.

Make sure all pins fit correctly and

are locked into place.

Proceed accordingly with all

speakers in the array.

5.

6.

Pull the rear Quick Release Pins of

all speakers out of the stand-by

position.

Pull out the spring bolts of all

speakers and turn them by 90° to a

vertical position (open).

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 21 of 70

Page 22

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

7.

8.

Align the drill hole in the joint plate

with the drill hole that is marked

with the desired angle.

Connect them using the Quick

Release Pin (A) and make sure the

pin fits correctly and is locked into

place.

Arrays with a maximal length of

5m (corresponding to an array with

max. 16 x SEQUENZA 10 N/W incl.

flying frame):

Turn all spring bolts (B) by 90° to a

horizontal position (closed), so that

they snap into the guide slot of the

spring bolt enclosure.

The spring bolts have not yet

snapped into the drill hole of the

rear joint plate. The spring bolts,

however, are all set so that they

automatically snap into place when

you fly the array, then creating

a positive connection with the

selected angle position.

Arrays with a length exceeding 5m

(corresponding to an array with

more than 16 x SEQUENZA 10 N/W

incl. flying frame):

Leave the spring bolts (B) in the

vertical position.

9.

Stand the flying frame up vertically

and remove the Quick Release Pins

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 22 of 70

Page 23

Caution

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

10.

Tipping of the flying frame with speakers can result in injuries. To prevent the frame

from tipping forward with the first speaker, always connect the speakers to one another

first before connecting the flying frame.

To prevent the frame from tipping forward with the first speaker, let the spring bolts of

the first two speakers snap into place before connecting the flying frame.

To do so, you must position the spring bolt of the second speaker horizontally and you

may need to tilt the speaker slightly until the spring bolt snaps into place.

11.

12.

Place the frame in front of the

top speaker so that all joint plates

(1) protrude into the frame, then

connect them using the Quick

Release Pins (2).

Insert the rear joint plate (1) of the

top speaker between the drill holes

for the desired angle, and secure it

with the Quick Release Pin (2).

The tilt angle of the speakers

relative to the flying frame is

determined by the simulation

software CON:SEQUENZA.

To fly the top speaker parallel (0°)

to the flying frame, use the drill

hole 'Flying 0°' (see illustration).

To tilt the top speaker upwards by

+3°, use the 'Flying +3°' hole (see

illustration).

13. Wire the speakers. Further information in chapter 'Connection' on page 44.

Detailed information for connecting the speakers and configuring the K&F system

amplifier TOPAS or the K&F SystemRack is in the hardware manuals.

14. Proceed as described in chapter Lifting the Array as of page 28.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 23 of 70

Page 24

Warning

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

10.1.2 Array with SEQUENZA 10 B

Control the secure fit of every ball lock pin during setup. As long as you do not push the

button in the middle of the pin, you should not be able to pull out the pin.

You may fly up to max. 12 SEQUENZA 10 B on the flying frame.

Connect the speakers as follows:

1.

Slide the 4 joint plates out of the

speaker by reaching into the access

opening (A) and pushing the plates

forwards.

Secure the joint plates(B) with the

Quick Release Pins(C).

2.

If you are planning a cardioid or

hypercardioid use, lay the middle

one of the 3 subwoofers with its

rear side onto the wheel board

before you connect the speakers

Further instructions for cardioide or

hypercardioide uses beginning on

page 40.

Push the speakers together so

that the 4 joint plates of the

one speaker protrude into the

corresponding connecting bracket

of the other speaker.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 24 of 70

Page 25

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

3.

4. Proceed accordingly with all speakers in the array.

5.

Connect the speakers, as illustrated,

on both sides with the Quick

Release Pins.

You create a speaker connection

by using a total of 8 Quick Release

Pins.

Make sure all pins fit correctly and

are locked into place.

Stand the flying frame up vertically

and remove the Quick Release Pins

Caution

6.

To prevent the frame from tipping forward with the first speaker, always connect the

speakers to one another first before connecting the flying frame. Tipping of the flying

frame with speakers can result in injuries.

7.

Place the frame in front of the top

speaker so that the joint plates

(1) protrude into the flying frame,

then connect them using the Quick

Release Pins (2).

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 25 of 70

Page 26

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

8. Wire the speakers. Further information in chapter 'Connection' on page 44.

Detailed information for connecting the speakers and configuring the K&F system

amplifier TOPAS or the K&F SystemRack is in the hardware manuals. SEQUENZA 10

9. Proceed as described in chapter Lifting the Array as of page 28.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 26 of 70

Page 27

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

10.1.3 Array with SEQUENZA 10 N/W and SEQUENZA 10 B

1. Create an array with SEQUENZA 10 N/W, see chapter Array with SEQUENZA 10 N/W as

of page 20.

2. Create an array with SEQUENZA 10 B, see chapter Array with SEQUENZA 10 B as of

page 24.

3.

Remove the 4 Quick Release Pins

(A) on the flying frame of the

SEQUENZA 10 N/W array and turn

out the 4 angled joint plates (B), as

illustrated.

Secure the angled joint plate (B)

with the Quick Release Pin (A) in

this position.

Proceed accordingly with the 3

remaining angled joint plates of the

flying frame.

4.

5.

Push the SEQUENZA 10 N/W array

and the SEQUENZA 10 B array

together so that all 4 angled joint

plates of the flying frame protrude

into the connecting brackets of the

lower SEQUENZA 10 B system.

Secure all 4 angled joint plates with

the remaining Quick Release Pins

on the bottom SEQUENZA 10 B

system.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 27 of 70

Page 28

Warning

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

6. Wire the speakers. Further information in chapter 'Connection' on page 44. Detailed

information for connecting the speakers and configuring the K&F system amplifier TOPAS

or the K&F SystemRack is in the hardware manuals. SEQUENZA 10

7. Proceed as described in chapter Lifting the Array as of page 28.

10.2 Lifting the Array

See the instructions in chapter 'Safety Instructions' from page 11 and in the corresponding

sub-section 'Safety Instructions for Flown Setup' from page 11.

10.2.1 Arrays with SEQUENZA 10 B

This description is valid for a maximum of 12 SEQUENZA 10 B systems connected to one

another. More than 12 SEQUENZA 10 B systems connected to one another may not be

flown.

1. Attach a certified 3.25 ton shackle for every speaker used.

Secure the shackles against self-loosening (i.e. split pin).

2. Hook the load hook of the hoist chain (i.e. of the hoist motor) into the load adapter's

shackle and begin to lift the array carefully.

3. When the first speakers are at working height, remove the front transport covers.

4. Lift the array evenly and slowly into its operating position so that it cannot swing out

during lifting, then secure it. In doing this, make sure that chain hoists and lifting

accessories do not get caught. Make sure that the speaker cables do not get crimped or

get caught.

10.2.2 Arrays with SEQUENZA 10 N/W and 5m maximal Length

This description is valid for arrays that only consist of SEQUENZA 10 N/W systems as well as

for mixed arrays of SEQUENZA 10 N/W and SEQUENZA 10 B whose total length does not

exceed 5m. (An array with 16 x SEQUENZA 10 N/W corresponds to a length of 5m).

1. Attach a certified 3.25 ton shackle for every speaker used.

Secure the shackles against self-loosening (i.e. split pin).

2.

3. Hook the load hook of the hoist chain (i.e. of the hoist motor) into the load adapter's

Verify that every spring bolt of

the SEQUENZA 10 N/W are in a

horizontal position (closed), so

that they can lock into place when

lifting the array.

shackle and begin to lift the array carefully.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 28 of 70

Page 29

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

4.

5. Check that the spring bolts protrude at least 0.5 mm out of the drill holes at the entire

Verify that every spring bolt locks

into place.

When the spring bolts snap into

place, they make a clearly audible

noise and protrude out of the drill

hole on the opposite side.

circumference (A).

During lifting, the spring bolts snap into place successively from the flying frame

downwards.

If the spring bolts do not properly snap into place, do not hoist the array any further

until you have corrected the error.

Warning

6. When the first speakers are at working height, remove the front transport covers.

7. When the first SEQUENZA 10 N/W speakers are at working height, you can attach the

protective weather covers for this speaker model, if necessary.

For outside uses, these optional protective weather covers with hook-and-loop fastener

serve as rain protection for the rear flying mechanics and the cable connections.

8. Lift the array evenly and slowly into its operating position so that it cannot swing out

during lifting, then secure it. In doing this, make sure that chain hoists and lifting

accessories do not get caught. Make sure that the speaker cables do not get crimped or

get caught.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 29 of 70

Page 30

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

10.2.3 Arrays with SEQUENZA 10 N/W exceeding a Length of 5m

This description is valid for arrays that only consist of SEQUENZA 10 N/W systems as well

as for mixed arrays of SEQUENZA 10 N/W and SEQUENZA 10 B whose total length exceeds

5m. (An array with 16 x SEQUENZA 10 N/W corresponds to a length of 5m).

1. Attach a certified 3.25 ton shackle for every speaker used.

Secure the shackles against self-loosening (i.e. split pin).

2.

When connecting the

SEQUENZA 10 N/W systems,

leave the spring bolts in a vertical

position so that they cannot snap

into place during lifting.

Risk of crushing hands!

The speakers move towards each

other during lifting.

3. Hook the load hook of the hoist chain (i.e. of the hoist motor) into the load adapter's

shackle and begin to lift the array carefully.

4.

Lift the array up far enough so that

the first speaker enclusures begin to

touch each other.SEQUENZA 10 N/

W

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 30 of 70

Page 31

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

Warning

5.

6.

Position each spring bolt

horizontally when the

corresponding speakers touch each

other during lifting.

The spring bolts do not snap into place until the speaker enclosures begin to move apart

again and the preselected angle position is reached. It is possible that this will happen

when the array is relatively high.

Check that the spring bolts

protrude at least 0.5 mm out

of the drill holes at the entire

circumference (A).

7. When the first speakers are at working height, remove the front transport covers.

8. When the first SEQUENZA 10 N/W speakers are at working height, you can attach the

protective weather covers for this speaker model, if necessary.

For outside uses, these optional protective weather covers with hook-and-loop fastener

serve as rain protection for the rear flying mechanics and the cable connections.

9. Lift the array evenly and slowly into its operating position so that it cannot swing out

during lifting, then secure it. In doing this, make sure that chain hoists and lifting

accessories do not get caught. Make sure that the speaker cables do not get crimped or

get caught.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 31 of 70

Page 32

Warning

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

11. Flown Disassembly

1. Basically, you disassemble the array in the reverse order of assembly.

2. Replace each transport cover when the speakers are hanging at working level.

3.

Just before the bottom speaker

touches the ground, pull the array

in the direction of the arrow.

This way, you make sure that the

array does not stand on the side of

the bottom speaker, but rather on

the castors.

Always make sure that the chain

hoist is hanging vertically during

lowering. If you do not do this,

the array could sway suddenly.

If the system is not standing on

the castors, this could lead to

diagonal pull during further

lowering.

4. Lower SEQUENZA 10 B arrays far enough that all systems are on the wheels, then

prepare the SEQUENZA 10 speakers for transport.

• Place the used Quick Release Pins back onto their intended stand-by positions on the

speaker and flying frame.

• Push all joint plates back into the speaker.

• Dismantle all other used components so that they are not exposed and get damaged

during transport.

For arrays with SEQUENZA 10 N/W and a length exceeding 5m, proceed as described in

sub-section Disassembly of arrays with SEQUENZA 10 N/W exceeding a Length of 5m.

For arrays with SEQUENZA 10 N/W and a maximum length of 5m, proceed as described

in sub-section Disassembly of arrays with SEQUENZA 10 N/W and a maximum Length of

5m.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 32 of 70

Page 33

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

1

2

2

11.1 Disassembly of arrays with SEQUENZA 10 N/W exceeding a Length of 5m

1. Replace each transport cover when the speakers are hanging at working level.

2.

3. Disassemble as many speakers in this manner until the array only has a remaining

Just before the bottom speaker

touches the ground, two people

must grab hold of the speaker at

the recessed handles.

Release the rear Quick Release Pins

(1) first and catch the speaker while

it is swinging down by holding it at

the recessed handles.

Then release the lower front Quick

Release Pins of the next highest

speaker (2) and remove the lowest

speaker.

length of max. 5m (For arrays only having SEQUENZA 10 N/W systems, this corresponds

to 16 speakers). Then proceed as described in sub-section Disassembly of arrays with

SEQUENZA 10 N/W and a maximum Length of 5m.

11.2 Disassembly of arrays with SEQUENZA 10 N/W and a maximum Length of 5m

1. When all four castors of the SEQUENZA 10 N/W speaker touch the ground, pull the

spring bolt until it comes free.

During lowering, starting with the lowest speaker, there is a point for each speaker at

which its rear connection is force-free. Pull the spring bolts out at this moment.

2. Prepare the SEQUENZA 10 system for transport:

• After you have completely lowered the array, release all Quick Release Pins and push

the speakers apart.

• With the SEQUENZA 10 N/W systems, set the Quick Release Pins of the rear

connecting brackets to the 0° position.

• Push all rear joint plates of the SEQUENZA 10 N/W systems into their park position

so that the spring bolts snap back into place. To put it into the park position, use the

drill hole that is not completely drilled through in the rear joint plate.

• Pull the front Quick Release Pins and put them into the park position of the speaker

enclosure. If the safety cords on the Quick Release Pins protrude out of the side of

the speaker, turn the Quick Release Pins so that the safety cords are in the grooves.

This way you can protect the safety cords from transport damage.

• Push the front joint plates into the speaker.

• Dismantle all other used components so that they are not exposed and get damaged

during transport.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 33 of 70

Page 34

Warning

A

B

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

12. Stacked Setup

12.1 SEQUENZA 10 N/W stacked

12.1.1 Preparing the Flying Frame

The feet are available as optional accessories and serve to guarantee the stability, balance out

unevenness, and align the frame. Keep in mind that under certain circumstances, the feet can

leave marks on the ground.

It is not permissible to stack the speakers on the flying frame without the optionally

available hinged heavy-duty feet!

Control the secure fit of every ball lock pin during setup. As long as you do not push the

button in the middle of the pin, you should not be able to pull out the pin.

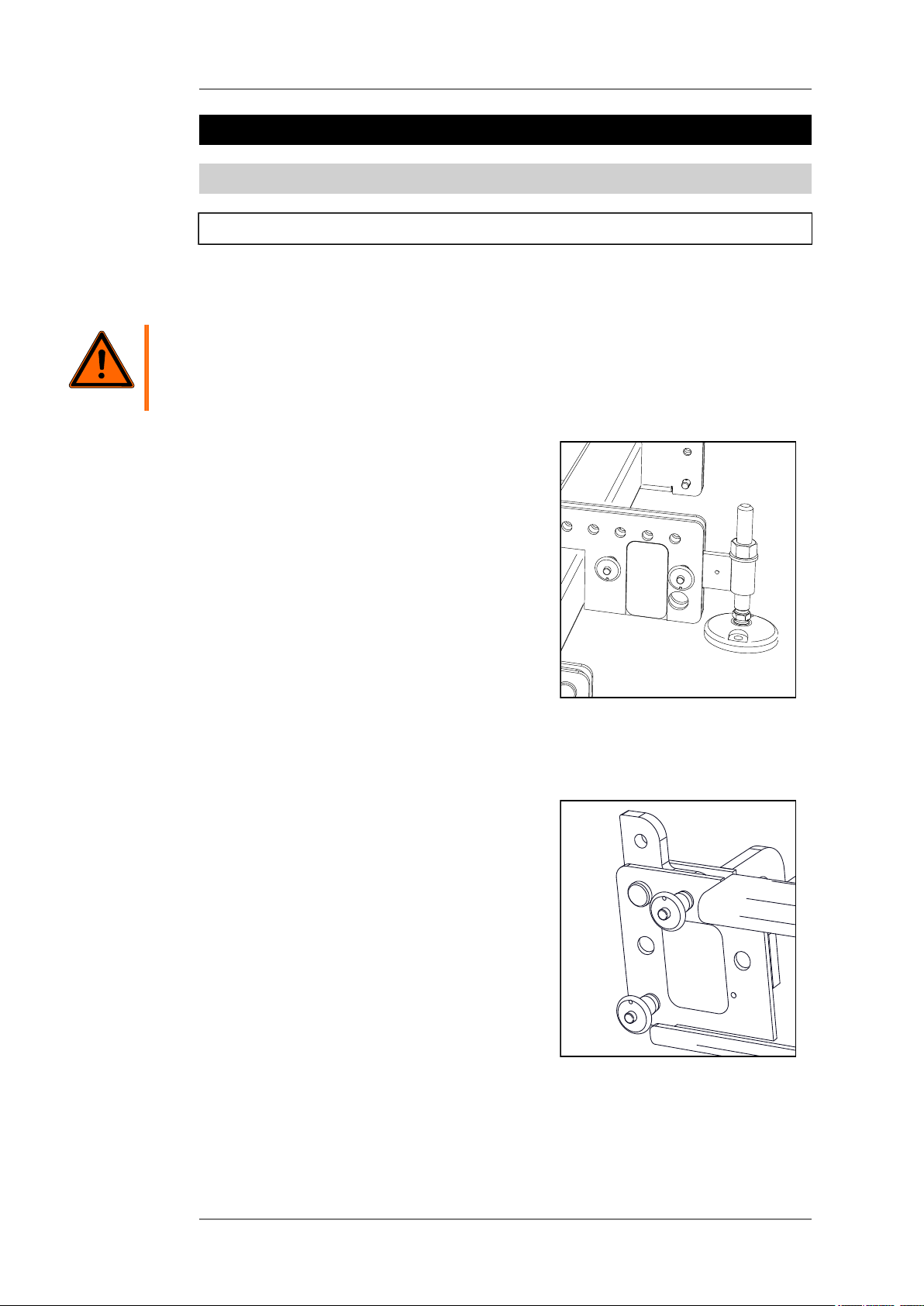

1.

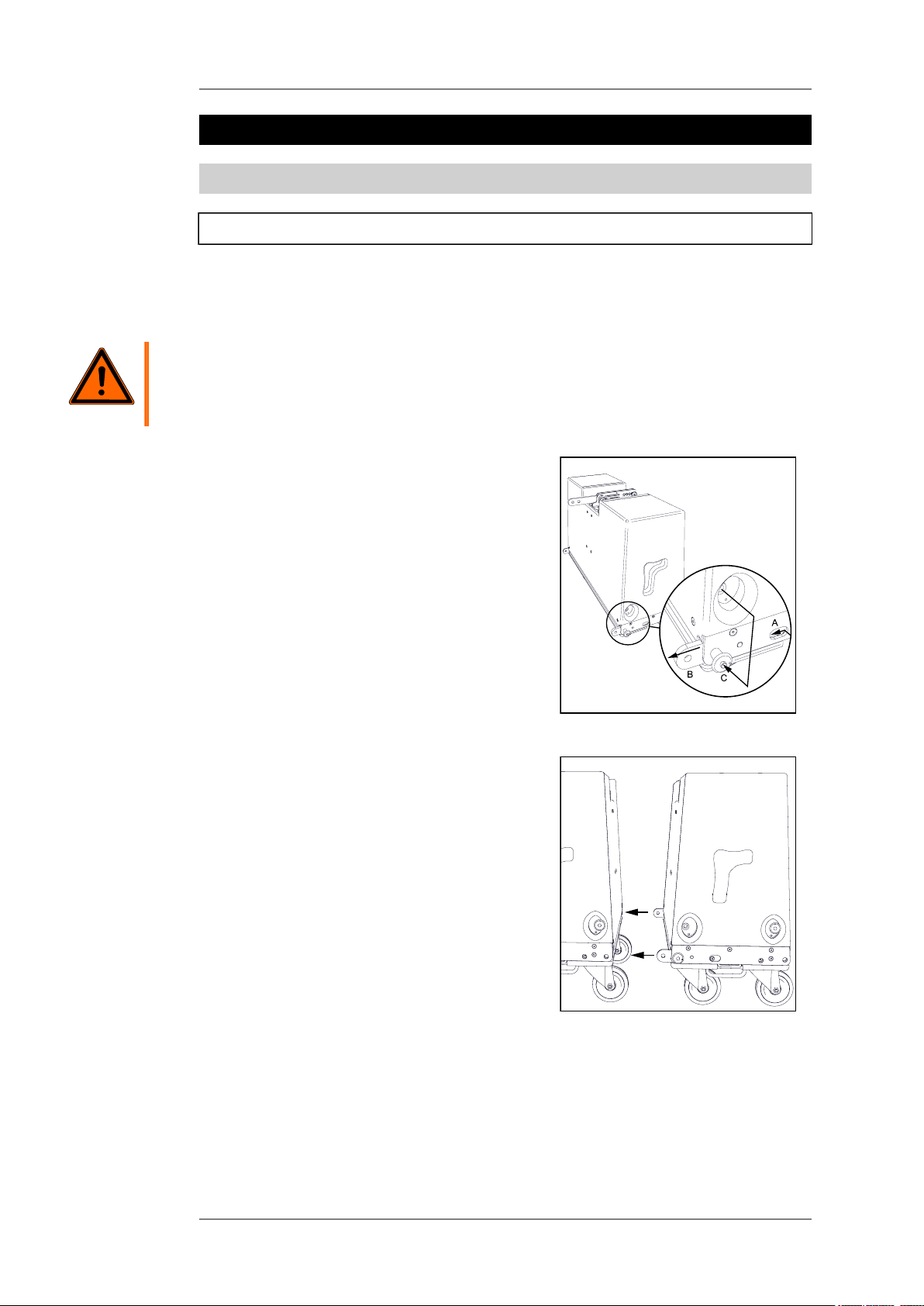

2. Remove the top Quick Release Pins on the front end of the flying frame and turn the

3.

Take the rear foot out of the park

position and insert it into the back

of the frame.

hinged fitting between the metal plates so that one leg of the hinged fitting is pointing

upwards.

Secure the hinged fitting (A) in this

position with the Quick Release Pin

(B).

4. Take one front foot out of the park position and insert it into the front of the frame.

5. Proceed accordingly with the other side.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 34 of 70

Page 35

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

A

B

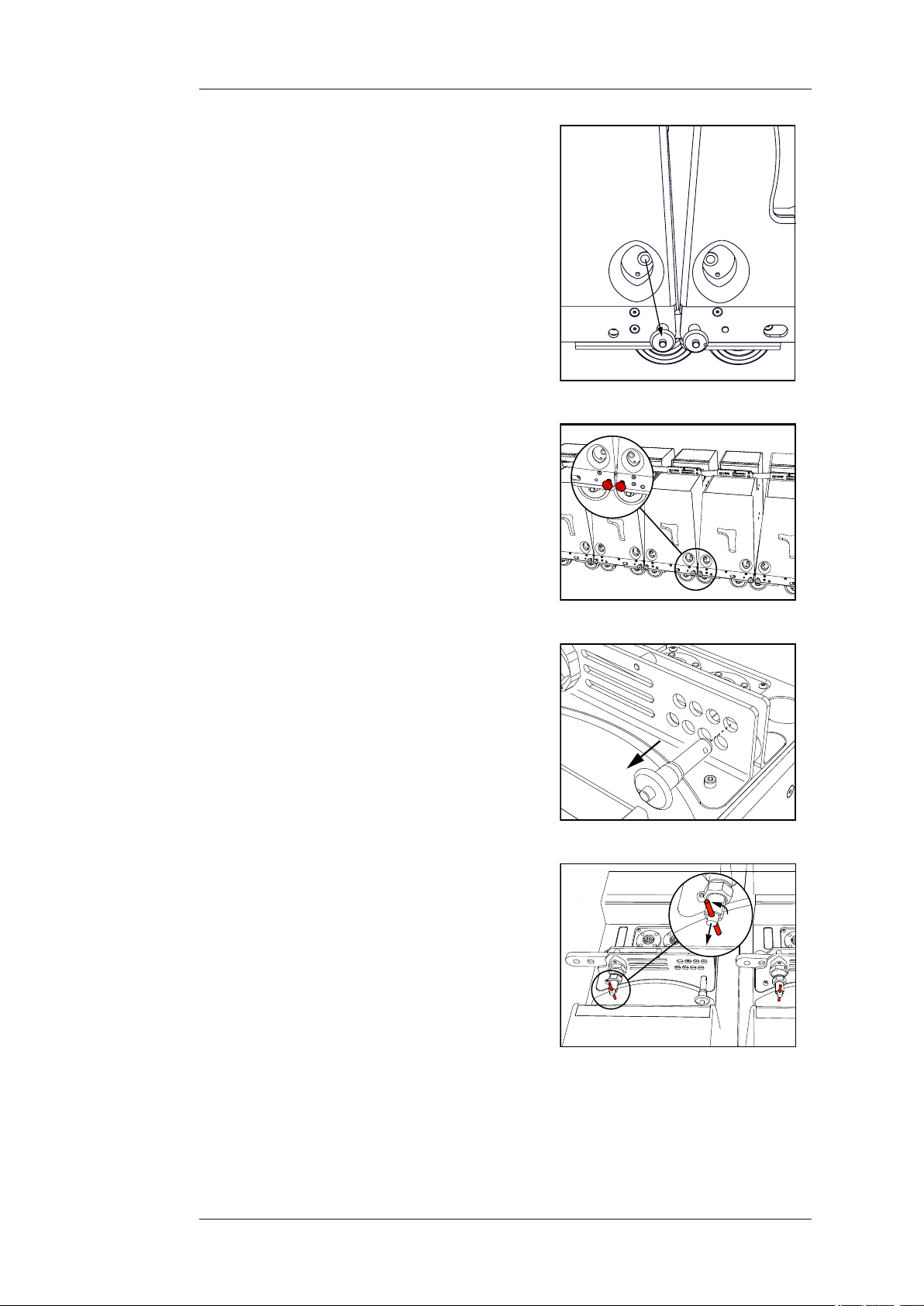

Warning

6.

Align the frame.

Loosen the lock nut (A) on top with

a 24 mm open-end wrench. Turn

the threaded rod (B) with a 17 mm

open-end wrench to adjust the

height. Re-tighten the lock nut. The

upper end of the thread is blank

so that the counternut cannot be

completely removed. Do not try to

clear the thread again.

12.1.2 Mounting the Speakers

See the instructions in chapter 'Safety Instructions' from page 11 and in the corresponding

sub-section 'Safety Instructions for Stacked Setups' from page 12.

It is not permissible to stack the speakers on the flying frame without the optionally available

hinged heavy-duty feet!

Control the secure fit of every ball lock pin during setup. As long as you do not push the

button in the middle of the pin, you should not be able to pull out the pin.

Caution

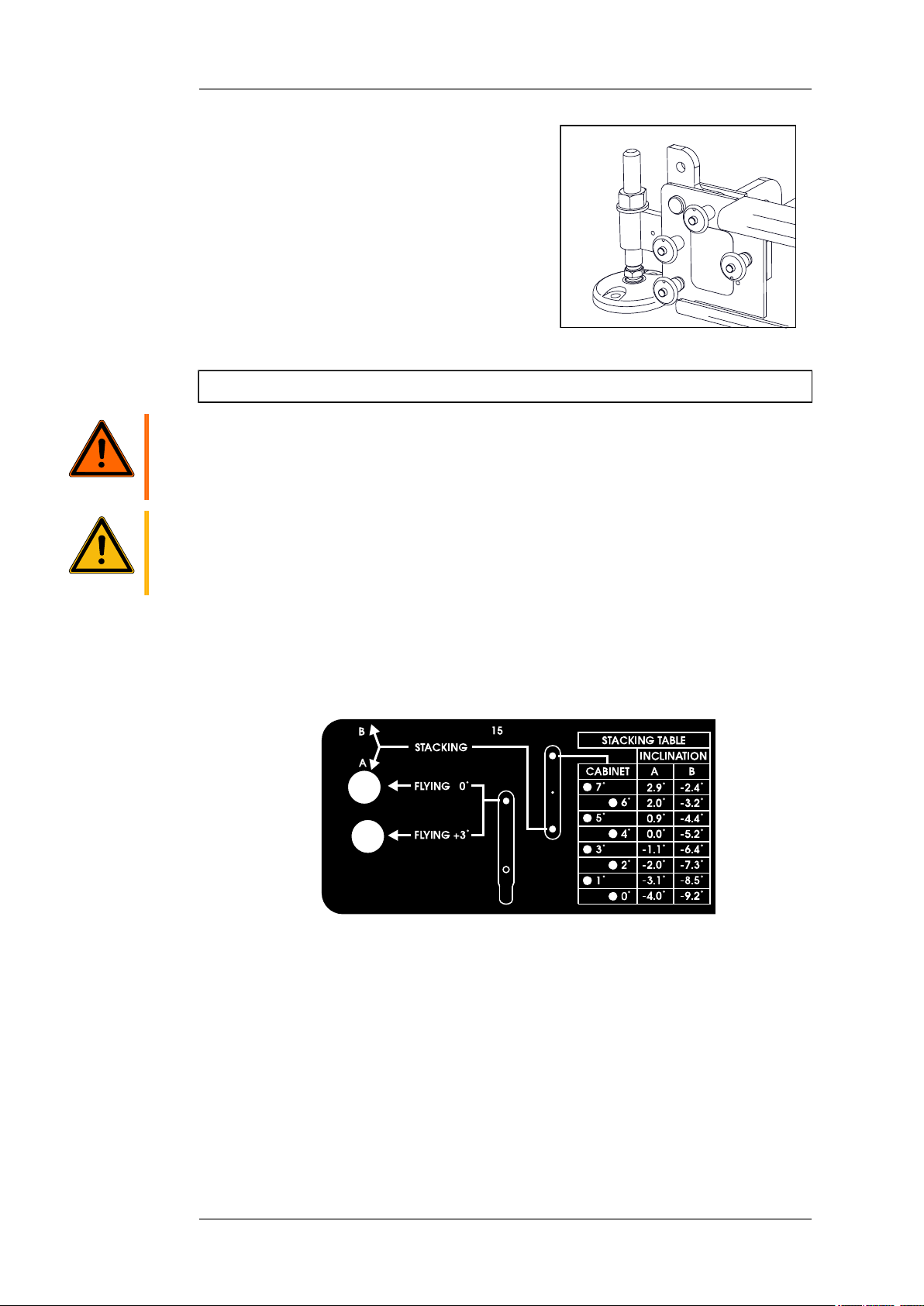

1. You will get the specifications for the setting angle of the bottom speaker on the frame

from the simulation software CON:SEQUENZA. CON:SEQUENZA(The angle specifications

refer to the centre axis of each speaker.)

To determine the correct drill holes on the speaker and frame for the desired angle, look

for the desired angle in one of the two right colums (see illustration below).

2. At the top of the appropriate column, the drill hole (A or B) in the flying frame is

indicated where you must insert the Stacking Link.

3. In the column "Cabinet", the drill hole in the rear joining plate of the speaker is

indicated where you must insert the Stacking Link on the speaker.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 35 of 70

Page 36

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

4.

5. Take the rear Quick Release Pins on the first speaker out of the park position.

6. Pull the spring bolt out and hold it. Pull out the joint plate approx. 10 cm towards the

7.

Take the stacking link out of the

park position and set it to the

desired position.

spring bolt and then let go of the spring bolt. By doing this, the rear joint plate is no

longer in the way when the speaker is stacked and then connected with the stacking link.

Place the speaker on the frame.

Make sure that the hinged fittings

protrude between the joining

plates on the speaker.

8. Secure the front connections with the Quick Release Pins from the speaker.

Risk of crushing hands! When

lowering the speakers, there is the

risk of crushing your hands while

the enclosure parts move towards

each other. Make sure that you do

not lower the speaker with jolting

movements.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 36 of 70

Page 37

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

A

B

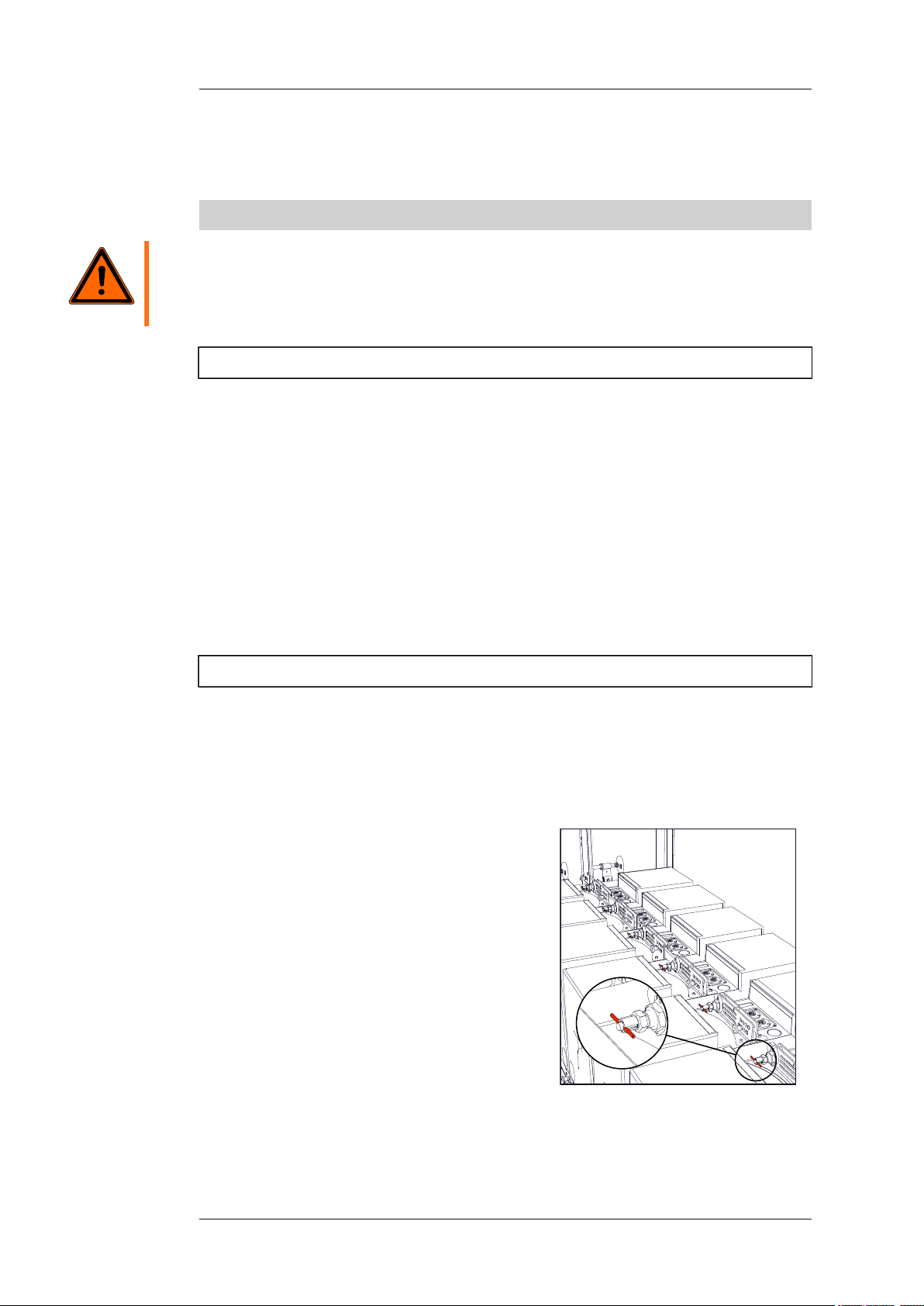

9.

10. Push the front joint plates out of the first speaker and secure them with the Quick

11. Prepare the next speaker as described in steps 2 - 3.

12. Place the next speaker on the stack and secure the front connections with two Quick

13. Place the joint plate between the drill holes for the desired angle and connect them with

14. Proceed accordingly with the remaining speakers.

15. Wire the array. Follow the instructions in chapter Connection beginning on page 44.

Lift up the back of the speaker,

align the Stacking Link (A) with

the drill hole for the desired angle

and secure the connection with the

Quick Release Pin (B).

Release Pins.

Release Pins.

the Quick Release Pin.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 37 of 70

Page 38

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

12.2 SEQUENZA 10 B stacked

1. Securely place the bottom subwoofer onto a level surface.

2.

Stack the subwoofers on top of one

another.

Make sure that the stacking feet of

subwoofers stacked on top of one

another are securely positioned in

the grooves of the lower speaker.

You can connect horizontally

stacked systems with the joint

plates.

You must additionally secure

vertically standing stacked

SEQUENZA 10 B systems from

falling since the structural safety is

not guaranteed, otherwise.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 38 of 70

Page 39

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

12.3 SEQUENZA 10 N/W stacked on SEQUENZA 10 B

1. Stack the subwoofers on top of one another.

2.

3. Proceed accordingly with the three remaining plates that connect the subwoofers.

4. As needed, repeat the process for the next subwoofers that are stacked on one another.

5.

Slide the joint plate out of the

speaker by reaching into the access

opening (A) and pushing the joint

plate up.

Secure the joint plates with the two

Quick Release Pins (B) and (C).

Lay the flying frame on top of

the uppermost subwoofer, as

illustrated.

Slide the joint plate out of the

speaker by reaching into the access

opening (A) and pushing the joint

plate up.

Secure the joint plates with the two

Quick Release Pins (B) and (C).

6. Proceed accordingly with the three remaining plates of the subwoofer.

7. The remainder of the setup is the same as the stacked SEQUENZA 10 N/W » Mounting

the Speakers, see page 35.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 39 of 70

Page 40

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

13. Disassambling the Stacked Array

1. Basically, you disassemble the array in the reverse order of assembly.

2. Replace the transport cover.

3. Prepare the SEQUENZA 10 N/W system for transport:

• Place the used Quick Release Pins back onto their intended stand-by positions on the

speaker and flying frame.

• Push all joint plates back into the speaker.

• Dismantle all other used components so that they are not exposed and get damaged

during transport.

• With the SEQUENZA 10 N/W systems, set the Quick Release Pins of the rear

connecting brackets to the 0° position.

• Push all rear joint plates of the SEQUENZA 10 N/W systems into their park position

so that the spring bolts snap back into place. To put it into the park position, use the

drill hole that is not completely drilled through in the rear joint plate.

14. Cardioid Arrays with SEQUENZA 10 B

The subwoofer SEQUENZA 10 B is designed so that it can be used as a cardioid and

hypercardioid system in an array of three subwoofers, or in multiples of three.

A cardioid array results in an increase of sound pressure towards the front because of the

rear-facing subwoofer. In the rear area (cardioid) or in the lateral side area (hypercardioid),

on the other hand, the sound pressure is clearly reduced.

With this, you achieve

• less unwanted sound on the stage

• low feedback

• simplified miking

• improved room acoustics with fewer reflections from the rear and side walls, or – when

flown – from the ceiling

• simplified adherence of sound emission limits and therefore less noise disturbance for

nearby residential areas during open air events.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 40 of 70

Page 41

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

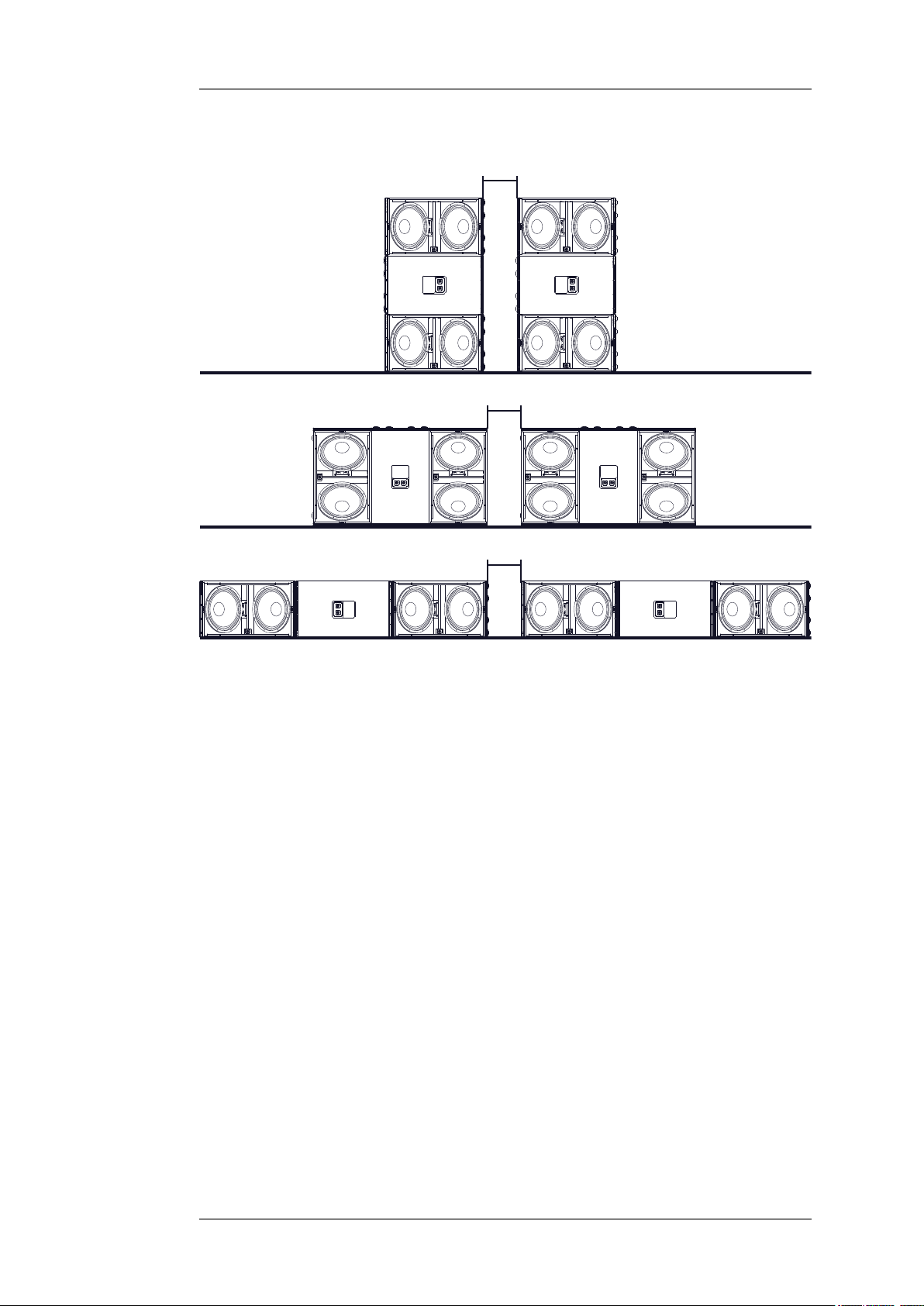

14.1 Setup instructions for a cardioid array

To achieve a cardioid or hypercardioid pattern, you must always have an array with 3

subwoofers - or a multiple of 3 subwoofers - setup next to one another (3, 6, 9, etc.). In

this set of three, the middle one must be stacked or flown rear-facing while both other

subwoofers are front-facing.

The subwoofer and the flying frame SEQUENZA 10 allow for these setup options with their

given design. You can stack the subwoofers even when they are facing opposite directions,

and you can connect them to front-facing systems.

There is an additional Speakon connector on the front grille so that you can connect the

cables to the rear-facing side of all subwoofers in a cardioid array.

You can choose from the following options for cardioid and hypercardioid setups:

3 x SEQUENZA 10 B horizontal

3 x SEQUENZA 10 B vertical

3 x SEQUENZA 10 B stacked

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 41 of 70

Page 42

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

40 cm [1,3 ft]

40 cm [1,3 ft]

40 cm [1,3 ft]

When cardioid arrays are stacked on the floor, ensure that there is always a distance of at least

40 cm between each unit of 3.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 42 of 70

Page 43

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

14.2 LSBlocks for cardioid use

The rear-facing subwoofer is controlled using the Controller CD 44 via LSBlock for cardioid /

hypercardioid arrays for rear-emitting subwoofers. The front-facing subwoofers are

controlled via LSBlock for cardioid / hypercardioid arrays for front-emitting subwoofers. The

following cardioid or hypercardioid setups are available in the CD 44:

Operation Mode of the SEQUENZA 10 B LSBlocks (SEQUENZA 10 N/W)

'Cardioid Front', front-facing Seq10B C-F

'Cardioid Rear', rear-facing Seq10B C-R

'Hypercardioid-Front', front-facing Seq10B HC-F

'Hypercardioid-Rear', rear-facing Seq10B HC-R

'Infrabass Cardioid Front', front-facing Seq10B C-F60Hz

'Infrabass Cardioid Rear', rear-facing Seq10B C-R60Hz

Warning

'Infrabass Hypercardioid Front', frontfacing

'Infrabass Hypercardioid Rear', rear-facing Seq10B HC-R60Hz

Seq10B HC-F60Hz

15. SEQUENZA 10 B combined with other K&F tops.

The SEQUENZA 10 B can also be combined with other K&F tops – in addition to the

SEQUENZA 10 N/W systems – using the Controller CD 44.

• To do so, select the desired LS blocks for the top in the Controller CD 44 or systemamp

TOPAS, and combine these with the desired LS block for the SEQUENZA 10 B.

In the respective Hardware Manuals, you will find detailed descriptions about connecting

the SEQUENZA 10 speakers and the settings necessary on the System Controller CD 44.

SEQUENZA 10 B

On the top side of the subwoofer, there is a threaded flange (M20) for screwing in an

optionally available distance rod.

All K&F tops with a flange connector or an assembled stand adapter can be placed onto this

distance rod.

When you assemble a top onto a subwoofer using a distance rod, the structural safety is

reduced. In this case, you must take suitable measures in order to guarantee the structural

safety.

For subsequent repositioning, always remove the top speaker that has been positioned using

a distance rod.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 43 of 70

Page 44

Caution

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

16. Fuse in the SEQUENZA 10 B

To increase the operating safety of the SEQUENZA 10 B, the subwoofers are equipped with

fuses at the signal input. These fuses reduce the risk of consequential damage resulting from

a short circuit (i.e. charred cables / connectors / fire damage).

16.1 Replacing the Fuses

To replace defective fuses, remove the front grille of the SEQUENZA 10 B.

The fuse holder is on the cable of the front connector (Speakon input).

When necessary, only replace the fuse with the following original fuse:

Bussmann S 506-8A, T 250V

17. Connection

The operating safety and the highest-possible performance is only guaranteed in conjunction

with the K&F Topas or K&F SystemRack.

17.1 Cabling a K&F System Rack

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 44 of 70

Page 45

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

MAIN OUT

6 x SEQUENZA 10 N/W

LF: CH 1: 1+ / 1-

LF / HF: CH 2: 2+ / 2-

1+

CH 1

Introduction

-

2+

CH 2

not_found

-

3+

CH 3

not_found

-

4+

CH 4

Symbols in User's Manual

-

LF: CH 3: 1+ / 1-

LF / HF: CH 4: 2+ / 2-

TO NEXT

SYSTEM RACK

Caption:

SEQUENZA 10 - Speaker - Patch - Cable

wi

th N

LT4FX cable connectors

SEQUENZA 10 - Speaker Cable Splice

1x NL8MPR Chassis connector to

2x

NLT4FX cable connector

SEQUENZA 10 - Prof. Speaker Cable

wi

th NLT8FX - BAG Cable Connectors

K&F SystemRack

K&F CD 44:

Loaded LS Blocks

InfoWindow 2

1:SEQ10LF FR

2:SEQ10LF/HF FR

3:SEQ10LF FR

4:SEQ10LF/HF FR

17.2 Connecting the SEQUENZA 10 N/W

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 45 of 70

Page 46

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

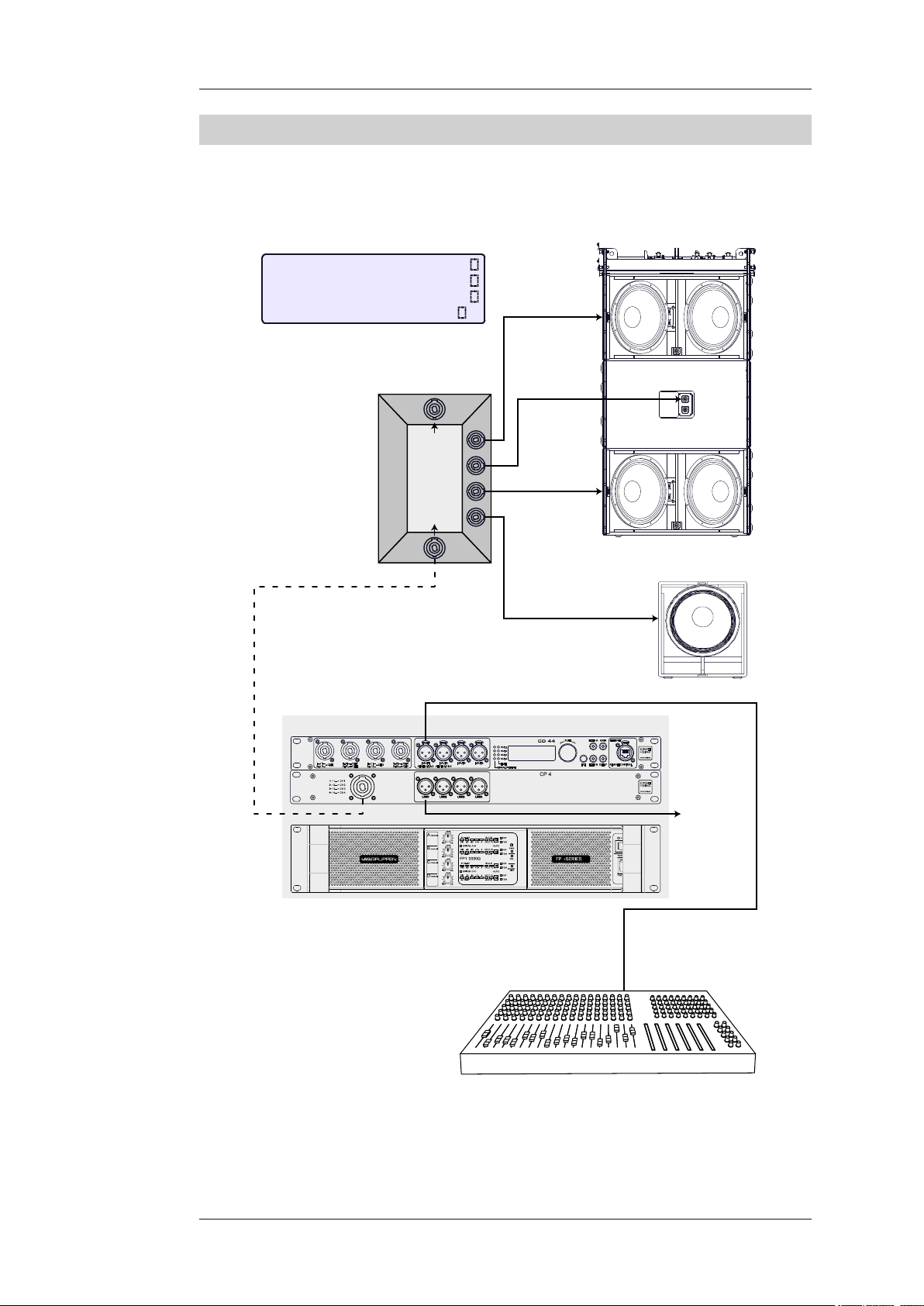

MAIN OUT

3 x SEQUENZA 10 B

Break Out Box

'K&F BOB'

TO NEXT

SYSTEM RACK

K&F SystemRack

K&F CD 44:

Example for Loaded LS Blocks

InfoWindow 2

1:SEQ10B C-F

2:SEQ10B C-R

3:SEQ10B C-F

4:SW115E

if required:

to extra Speaker

e.g.: SW 115E (Sidefill):

CH 4: 1+ / 1-

Sub3:

CH 3: 1+ / 1-

Sub2:

CH 2: 1+ / 1-

Sub1:

CH 1: 1+ / 1-

1+

CH 1

Introduction

-

2+

CH 2

not_found

-

3+

CH 3

not_found

-

4+

CH 4

Symbols in User's Manual

-

17.3 Connecting the SEQUENZA 10 B

The 3 subwoofers in a cardioid setup need to be controlled with an identical level and signal.

You can achieve this most easily by using the CD 44 routings '1in4out' or '1in3out+AUX'

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 46 of 70

Page 47

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

Cable Pick

17.4 Fixating the Cables

The array may not be used as a climbing

aid.

Fixate the cable to relieve the connectors.

In doing this, bear in mind that if you

fixate the cable on the cable pick in a

one-point rigging, the weight of the

cable can change the angle.

It is, therefore, only recommendable

to fixate the cable on the cable pick in

a two-point rigging. If necessary, use a

separate cable pick.

18. Transport and Storage

All metal components are protected against short-term moisture with a coating.

SEQUENZA 10The accessories has to be stored, transported and used in a dry enviroment.

The SEQUENZA 10 System is not designed for long-term use in a corrosive environment.

Make sure that the system is adequately ventilated during longer storage periods so that

possible residual moisture can escape from the equipment.

Furthermore, you should ensure that all components of the SEQUENZA 10 System are

protected from mechanical strain to prevent possible damage.

We recommend using suitable transport and storage cases and the optional soft cover that

protects from the above-mentioned influences.

19. Maintenance and Care

For the owner and user, it is mandatory to be aware of the fact that rigging systems are

highly safety critical.

Please note that the mains cables are delivered with varying connector options or with open

wires (mains side), depending on the country or order number.

The inspection requirements vary depending on application and country of use. Observe the

requirements that are relevant for you. If in doubt, contact local authorities.

In many countries, regular inspection of mounting components and accessories is required. It

is thus recommendable to carry through such an inspection for your own safety, too. In most

cases (e.g. german BGV C1), an additional annual inspection is required that must be done by

a technical expert. Additionally, a detailed inspection carried through by a legally certified or

official authority is required every four years.

In this context, it is very important to keep an inspection log book. In this inspection log

book, the data for every used accessory is entered at the periodic inspections, making the

data available at all times for possible inspections.

In addition an inspection book for the rigging components of the SEQUENZA 10 system

should be kept and maintained carefully. SEQUENZA 10This book should document

maintenance measures and inspection intervals and contain parts lists.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 47 of 70

Page 48

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

If as a result of these checks any uncertainty should arise with regard to safety or if specific

faults are found, the accessory may no longer be used and you must send in the product to

KLING & FREITAG GmbH for inspection and repairs, if necessary. If defects are ascertained,

then you must send in the product to KLING & FREITAG GmbH for inspection and repairs, if

necessary. SEQUENZA 10

If defects are ascertained, then you must send in the product to KLING & FREITAG GmbH for

inspection and repairs, if necessary.

You may not repair or straighten the components of the SEQUENZA 10 System (speakers and

flying frame) yourself! SEQUENZA 10If parts of the rigging system are damaged, send in the

speakers or the flying frame to KLING & FREITAG GmbH or recycle it at a professional scrap

processing plant. It must by all means be guaranteed that the parts can no longer be used in

any way after their disposal.

19.1 Inspection Intervals and Items

The SEQUENZA 10 system can exhibit signs of wear over the years, i.e. from mechanical

strain, transport damage, corrosion, or improper handling. In general, this always indicates an

increased accident risk.

As a basic principle, you must visually inspect the SEQUENZA 10 System every time you get

it out or box it up. SEQUENZA 10For fixed installations, you must inspect the SEQUENZA 10

System at regular intervals for signs of wear. SEQUENZA 10

During these inspections, you must especially look out for deformations, cracks, dents,

damage to threads, and corrosion. Mounting devices such as shackles, chains and wire ropes

also have to be checked for signs of wear or deformation carefully.

During the inspection, you must also carefully inspect the following items:

• Mobility of the spring bolts. The bolts must move easily and snap securely into place.

They must protrude at least 0.5 mm out of the joining plate on the opposite side.

• Impact and corrosion damage on the flying frame and on the speaker enclosure.

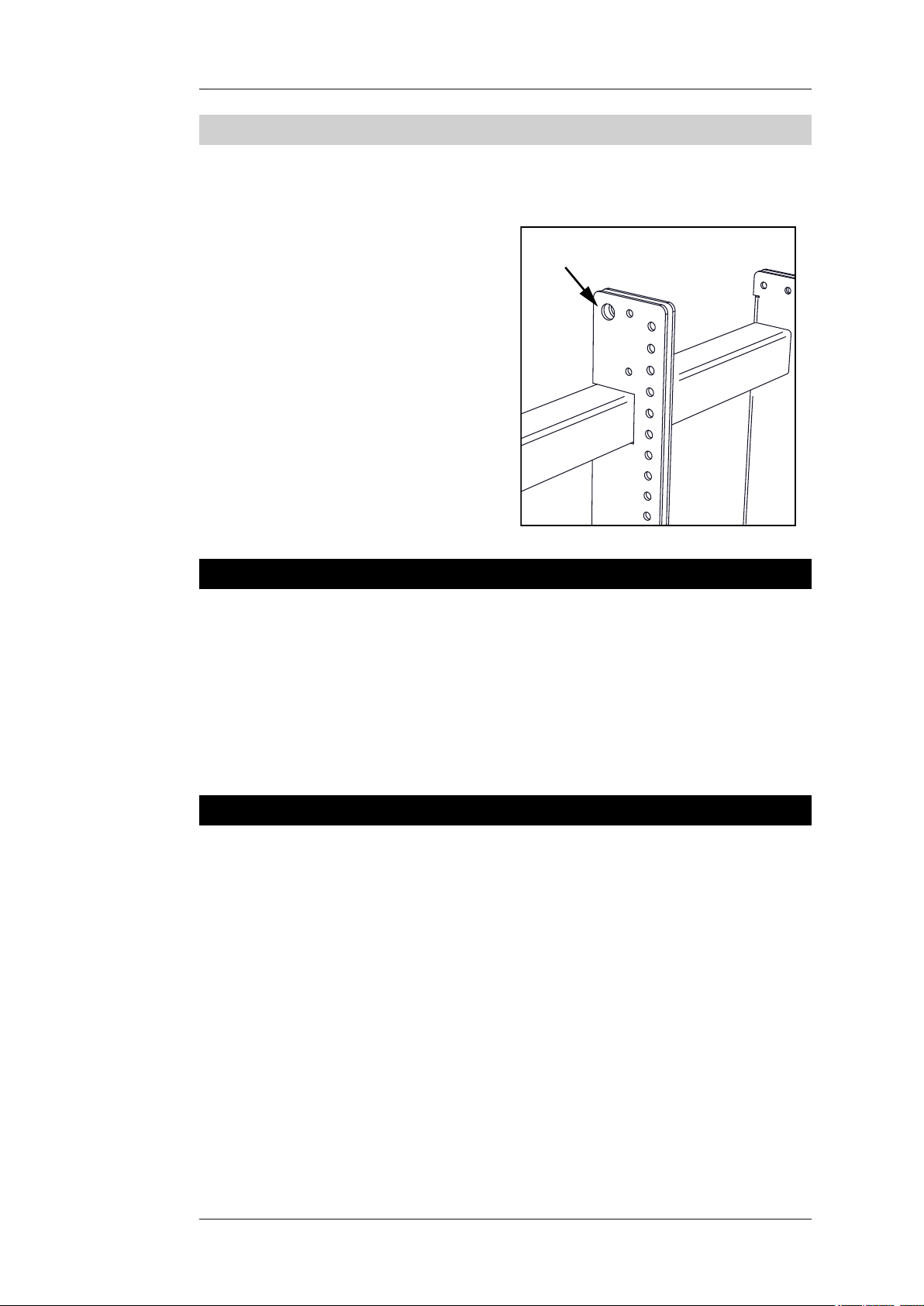

20. Optional BGV C1 Certification

In Germany, you have the possibility to have your system individually certified. If required,

you can request the necessary basis of calculation from KLING & FREITAG. On the speakers as

well as on the flying frame, there is a field where an inspection label can be affixed.

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 48 of 70

Page 49

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

21. Technical Specifications of Loudspeakers

21.1 Technical Specifications SEQUENZA 10 N

Design 2 + 1-way passive system with FLC®

technology,

completely horn loaded, bass reflex

tuning

Frequency range -10 dB 44 Hz - 22 kHz in 'FR mode'

58 Hz - 22 kHz in 'LCut mode'

Frequency range -5 dB 49 Hz - 18.5 kHz in 'FR mode'

87 Hz - 18.5 kHz in 'LCut mode'

Horizontal coverage angle 77°

Vertical coverage angle depending on configuration

Nominal power handling LF 1 300 W RMS, 600 W progam, 1200 W peak

Nominal power handling LF 2 + HF 300 W RMS, 600 W progam, 1200 W peak

Max. SPL (sinus burst 185 ms @ 10% THD) 134.5 dB RMS, 138 dB peak (1 x

SEQUENZA 10 N)

146.5 dB RMS, 150 dB peak (4 x

SEQUENZA 10 N)

Sinus burst 185 ms with Lab.Gruppen 134 dB RMS, 137.5dB peak (1 x

SEQUENZA 10 N)

FP 10000Q and CD 44* 146 dB RMS, 149.5 dB peak (4 x

SEQUENZA 10 N)

Components 1 x 10" woofer, 1 x 10" low-mid,

both with attached horn

3 x 1" high freqency driver with 44 mm

voice coil

Nominal impedance LF 1: 12Ohm, Zmin. 12.3Ohm @ 400 Hz

LF 2 + HF: 12 Ohm, Zmin. 10 Ohm @ 220

Hz

Connection 2 x Speakon 4 pin NLT-4FP

Enclosure Design Lightweight, water-resistant high-tech

multiplex

plywood with highly resilient Polyurea

synthetic

coating in black, integrated rigging

system,

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 49 of 70

Page 50

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

5 Quick Release Pins (undetachable), 2

angled handles,

2 locking profiles for optional transport

cover,

ball-proof grille with exchangeable

black acoustic foam

Rigging system 'Snap&Fly', integrated 3-point rigging

system

(patent pending)

Dimensions (W x H x D) 795 x 303 x 481 mm

Weight 34 kg

Accessories see catalogue or visit www.kling-

freitag.de

*Pink noise, depending on crest factor and amplifier output power

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 50 of 70

Page 51

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

21.2 Technical Specifications SEQUENZA 10 W

Design 2 + 1-way passive system with FLC®

technology,

completely horn loaded, bass reflex

tuning

Frequency range -10 dB 44 Hz - 23.5 kHz in 'FR mode'

58 Hz - 23.5 kHz in 'LCut mode'

Frequency range -5 dB 49 Hz - 23 kHz in 'FR mode'

87 Hz - 18.5 kHz in 'LCut mode'

Horizontal coverage angle 100°

Vertical coverage angle depending on configuration

Nominal power handling LF 1 300 W RMS, 600 W progam, 1200 W peak

Nominal power handling LF 2 + HF 300 W RMS, 600 W progam, 1200 W peak

Max. SPL (sinus burst 185 ms @ 10% THD) 134.5 dB RMS, 138 dB peak (1 x

SEQUENZA 10 W)

146.5 dB RMS, 150 dB peak (4 x

SEQUENZA 10 W)

Sinus burst 185 ms with Lab.Gruppen 134 dB RMS, 137.5dB peak (1 x

SEQUENZA 10 W)

FP 10000Q and CD 44* 146 dB RMS, 149.5 dB peak (4 x

SEQUENZA 10 W)

Components 1 x 10" woofer, 1 x 10" low-mid,

both with attached horn

3 x 1" high freqency driver with 44 mm

voice coil

Nominal impedance LF 1: 12Ohm, Zmin. 12.3Ohm @ 400 Hz

LF 2 + HF: 12 Ohm, Zmin. 10 Ohm @ 220

Hz

Connection 2 x Speakon 4 pin NLT-4FP

Enclosure Design Lightweight, water-resistant high-tech

multiplex

plywood with highly resilient Polyurea

synthetic

coating in black, integrated rigging

system,

5 Quick Release Pins (undetachable), 2

angled handles,

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 51 of 70

Page 52

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

2 locking profiles for optional transport

cover,

ball-proof grille with exchangeable

black acoustic foam

Rigging system 'Snap&Fly', integrated 3-point rigging

system

(patent pending)

Dimensions (W x H x D) 795 x 303 x 481 mm

Weight 34 kg

Accessories see catalogue or visit www.kling-

freitag.de

*Pink noise, depending on crest factor and amplifier output power

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 52 of 70

Page 53

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

21.3 Technical Specifications SEQUENZA 10 B

Design Bass reflex system

(via K&F SystemRack or K&F TOPAS)

Crossover frequencies (2-Way-Mode / 60

100Hz / 60 Hz

Hz)

Lower cut-off frequency (-3 dB / -10 dB) 39 Hz / 33 Hz

Coverage Omnidirectional (optional

in clusters of three via CD 44)

Power handling

1800 W nominal

3600 W program

1)

2)

Max. SPL 133 dB

Components 2 x 15“ long excursion chassis, 10mm

voice

coil with double centring, internal and

external ven-

tilation, double demodulation ring for

minimal

distortion

Impedance (nominal) 4 Ohm

Connection Rear: 2 x Speakon 4-pin NLT4MP (1+ / 1-)

2 IN parallel into 2 OUT

Front: 1 x Speakon 4-pin NLT4MP (1+ / 1-)

Enclosure Design 15 mm frame reinforced multiplex

plywood enclosure

with highly resilient Polyurea synthetic

black,

coating, K&M mounting plate with M20

thread for

distance rod, 'Snap&Fly' compatible

4-point rigging system, 8 butterfly

handles,

10 plastic sliding feet, 10 stacking grooves

for

save stackings of identical enclosures,

locking profiles for transport cover

Dimensions (W x H x D) 807 x 470 x 850 (without castors)

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 53 of 70

Page 54

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

807 x 470 x 990 (with castors)

Weight 62.0 kg

Accessories see catalogue or visit www.kling-

freitag.de

1) Pink noise 40 - 250 Hz, 2 h; 2) as 1) but with 50% duty cycle

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 54 of 70

Page 55

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

22. Measuring Diagrams

22.1 SEQUENZA 10 N diagrams

Horizontal coverage pattern

Vertical coverage pattern

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 55 of 70

Page 56

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

Frequency response 'on axis'

Impedance

Beamwidth

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 56 of 70

Page 57

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

22.2 SEQUENZA 10 W diagrams

Horizontal coverage pattern

Vertical coverage pattern

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 57 of 70

Page 58

User's manual K&F SEQUENZA 10 N/W/B & Flying Frame

Frequency response 'on axis'

Impedance

Beamwidth

KLING & FREITAG GMBH © 2014 Version Version 6.1 Page 58 of 70

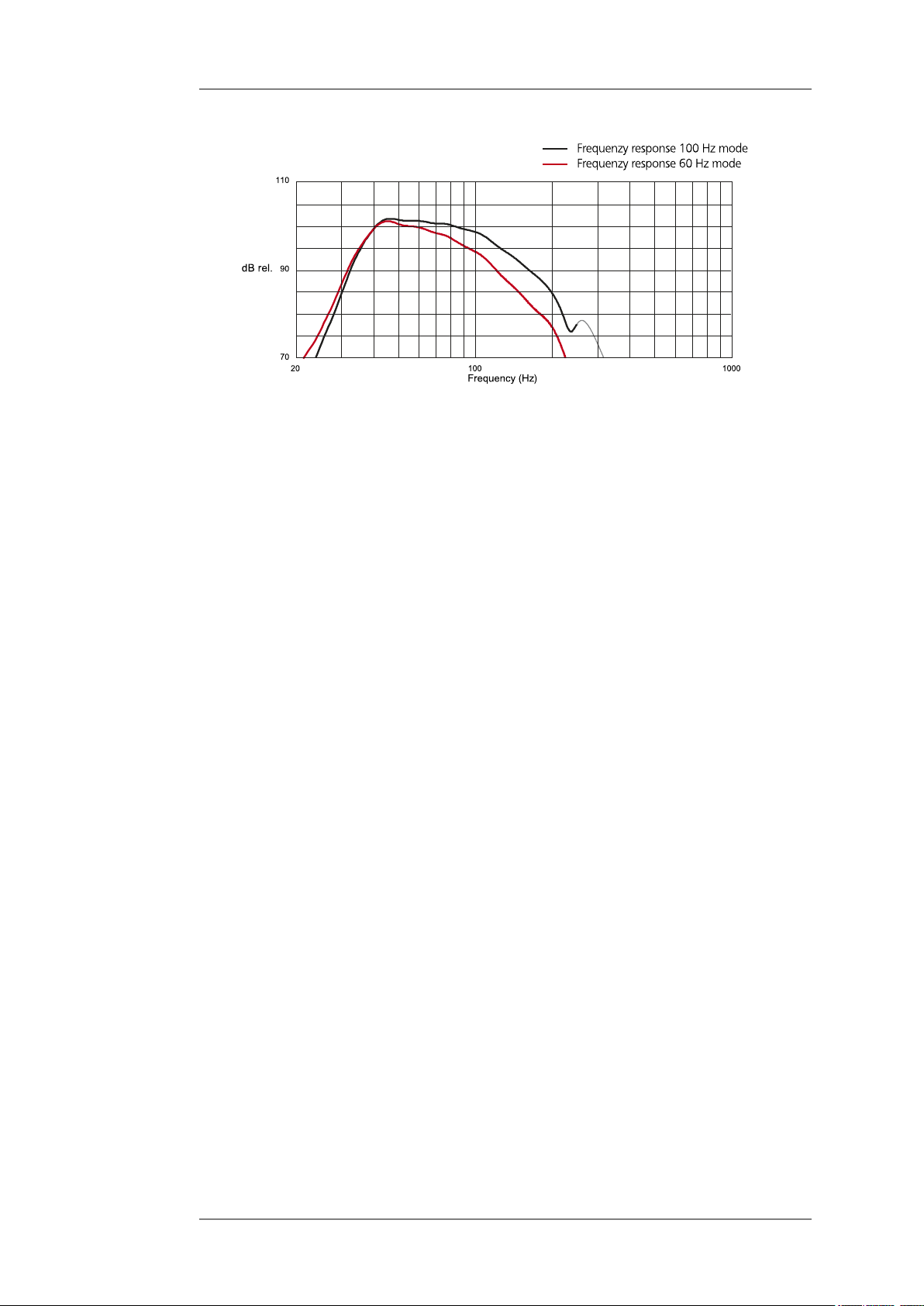

Page 59