Page 1

Self Powered LINE 212-6 - SP / LINE 212-9 - SP

Benutzer Handbuch

User's Manual

Important Information,

Wichtige Informationen,

Please Read Before Use!

vor Inbetriebnahme lesen!

KLING & FREITAG GmbH

KLING & FREITAG GmbH

Junkersstrasse 14

Junkersstrasse 14

D-30179 Hannover

D-30179 Hannover

PHONE 0 (049) 511- 969 97-0

TEL 0 (049) 511- 969 97-0

FAX 0 (049) 511- 67 37 94

FAX 0 (049) 511- 67 37 94

www.kling-freitag.de

www.kling-freitag.de

Released: 09.09.2014

Version 5.1

Page 2

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 2 of 44

Page 3

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

Thank you for your decision to buy a Kling & Freitag product. To guarantee a troublefree operating of the equipment and to allow the KLING & FREITAG --- ‘SP’ speaker

system to achieve its full potential please read the operating instructions carefully

before use.

With the purchase of a LINE 212 --- SP system with integrated power amplifier technology, you have acquired a speaker system with the highest possible quality and

performance capabilities.

As the owner of this system, you now have a versatile and highly professional tool

which, when operated properly, is a true pleasure to use.

Symbols in User's Manual

This symbol indicates the possibility of life-threatening danger and a

health risk for persons. Not following these instructions may result in

serious health problems including potentially fatal injuries.

Warning

This symbol indicates a possibly dangerous situation. Not following

these instructions may cause minor injuries or cause property damage.

Caution

This symbol gives instructions for the proper use of the described products. Not following these instructions may cause malfunctions or property damage.

Important

Information about this User's Manual

User's Manual K&F LINE 212-6 - SP / LINE 212-9 - SP, Version 5.0, 09.09.2014

© by André Figula, Kling & Freitag GmbH, 2003 - 2014; all rights reserved.

All specifications in this manual are based on information available at the time of pub-

lishing for the features and safety guidelines of the described products.

Technical specifications, measurements, weights and properties are not guaranteed.

The manufacturer reserves the right to make product alterations within legal provisions

as well as changes to improve product quality.

All persons who use the speaker system must have this guide and all further

information for safe operations available to them during assembly, disassembly, and use.

We appreciate any input with suggestions and improvements for this manual.

Please send this to us at the following address:

info@kling-freitag.de or to:

KLING & FREITAG GMBH, Junkersstr.14, D-30179 Hannover

Phone +49 (0) 511 - 96 99 70, Fax +49 (0) 511 - 67 37 94

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 3 of 44

Page 4

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

Contents

Chapter Page

1. General Safety Instructions 5

2. Introduction SP Loudspeakers 7

3. Connectors, Controls und Displays 9

4. Power Cord 13

5. Rigging Instructions for Line 212 Systems 14

5.1 Vertical Suspension 14

5.2 Horizontal Suspension 15

6. Using the ‘allsafe JUNGFALK’ Flying Points 16

7. Using the Rear Mounted ‘allsafe JUNGFALK’ Flying Track 17

7.1 Mounting the Single Stud Fittings 17

7.2 Mounting the Double Stud Fitting 18

8. Coverage Pattern of the Line 212 --- SP Systems 19

8.1 Changing the Coverage Pattern 19

9. Mounting Instructions for Speakers 20

9.1 Proper Arrangement of the Loudspeakers 20

9.2 Arrayed Speaker Systems (Cluster) 21

9.3 LINE 212 Systems on Top of SW 215E 22

10. Wiring 23

10.1 Avoiding Ground Loops 23

10.1.1 What is a Ground Loop? 23

10.1.2 Avoiding Ground Loops 23

10.2 Connecting the Power Connectors to the Connecting Terminal 24

11. Configurations and Connecting Diagrams 25

11.1 Operating the Systems without K&F System Controller 25

11.1.1 Full-Range Mode 25

11.1.2 Full Range Mode with Subwoofer 26

11.2 Operating the Systems with K&F System Controller 27

11.3 Maximum Configuration 27

12. Operating the Speakers 28

13. Touching Up Damage to Paint / Changing the Front Foam 28

14. Block Diagram LINE 212 - SP 29

15. Technical Specifications 30

15.1 LINE 212-6 - SP 30

15.2 LINE 212-9 - SP 32

16. Measuring Charts 33

16.1 LINE 212-6 - SP 33

16.2 LINE 212-9 - SP 35

17. Dimensions 37

18. Accessories for the LINE 212 System 38

19. Regulations for Disposal 39

19.1 Germany 39

19.2 EU, Norway, Iceland, and Liechtenstein 39

19.3 Other Countries 39

20. Declaration of Conformity and International Certificates 40

20.1 Declaration of Conformity 40

20.2 EMV Certificate Directive 89 / 336 / EWG 41

20.3 TÜV Certificatefor USA und Canada (UL 6500) 43

21. Included Instructions for Loudspeakers and Mounting Accessories

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 4 of 44

Page 5

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

CAUTION

1. General Safety Instructions

Risk of electric shock!

Do not open the units!

Warning: To avoid electric shock hazard, do not expose this

appliance to rain or moisture. The enclosures may only be

opened by qualified personnel!

Do not install devices in any of the following places:

− where the devices are permanently exposed to direct sunlight.

− near any heat sources and open fire. Do not put candles etc. on top of the speaker.

− where the airflow for cooling is blocked. A minimum distance of 10 cm to the heat

sink on the rear of the speaker must be kept.

− where the devices are exposed to high moisture. Objects filled with liquids, such as

a vase, must not be placed on the speaker.

− where the devices are exposed to strong vibrations and dust.

Power supply

Before connecting the AC power cable of the SP speaker, please check if the available

Warning

voltage is compatible with the operating voltage as indicated on the unit. If this is not

the case, then the unit needs to be adapted by the manufacturer or an authorized service centre. If the unit is not compatible with the available voltage, it should never be

connected! This could irreparably ruin the SP speaker.

Make sure that the power outlet supplies a ground connector, which must be connected to the unit via the PE conductor of the power cord!

All equipment, which is connected together using signal cables and has a connection to

protective earth, must be connected to a common PE conductor. If not, there is a risk of

an electric shock or the destruction of the connected equipment.

The power plug must always be used to disconnect from the power supply. Furthermore, the power plug must be easily accessible for use at all times.

Protection of electrical cables

Power cords should be laid in such a way that they are protected against footstep damages, tensile strain and against being trapped.

Transportation

When transporting the equipment, make sure that it is protected from vibrations.

Cleaning

The equipment should only be cleaned with a damp cloth when it is not plugged in.

Pauses in use

The power cord should be disconnected from the power source during longer pauses in

use.

Intrusion of objects or liquids

No objects or liquids should intrude or leak into the equipment.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 5 of 44

Page 6

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

Maintenance and technical service

The user should not perform any maintenance work on the equipment other than that

which is described in this manual. Repairs should be executed by a qualified service

technician only.

In the following cases, the unit should be serviced by an authorized technician only if:

− the power cord or the mains connectors have been damaged.

− objects or liquids have gotten into it.

− it was exposed to rain.

− it doesn't appear to be functioning properly.

− it has fallen down or the enclosure is damaged.

Warning

Mounting the speakers

If the weight of the speaker exceeds 25 kg then it is necessary for two people to carry it.

To prevent injury, this equipment must be securely placed on the floor or secured to the

wall according to the mounting instructions. Speakers, which are stacked, must be secured with securing straps. Please note that speakers can move as a result of vibrations.

To prevent them from falling from their mounted position, they must be secured

properly.

Speakers may only be suspended by qualified personnel.

Never use signal cables or power cords for suspending, aligning or securing the systems.

When laying the connecting cables, make sure that nobody can trip.

The speakers must be hung by using at least two of the designated flying points. The

same applies when lifting and aligning the speakers.

Never hang more than two speakers under one another without using the designated

Kling & Freitag rigging equipment.

Ensure that all installation connections comply with the applicable safety guidelines and

that the size and strength are sufficient. Further instructions are in our user's manual for

assembly equipment and in the general safety instructions for speakers and assembly

equipment.

For mobile and fixed installations, use only rigging equipment from KLING & FREITAG.

Make sure to observe the included safety and mounting instructions for loudspeakers

and accessories.

Unwanted interference

RF interference on the power cord or on the line signal cables may lead to unwanted

sound interference.

Damage caused by the speakers' magnetic fields

Speakers are permanently surrounded by a magnetic field, even when they are not operating. Therefore, during transport and placement of the speakers, it is important to

ensure that there is always approx. 1 m between the speakers and magnetic data media

and computer/video monitors.

The following signals may damage the speakers

− permanent high-pitched signals with high frequency and continuous noise from

feedback.

− permanently distorted signals with high power.

− noises, which occur when the SP speaker is connected while equipment is being

connected, disconnected or switched on.

Preventing hearing damage

To prevent the risk of hearing damage, avoid being too close to operating speakers,

even if the volume level seems to be low enough. In general, volume levels over 90 dB

can cause hearing damage.

Important

Caution

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 6 of 44

Page 7

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

2. Introduction SP Loudspeakers

‘SP’ denotes the ‘Self Powered’ product line in the K&F range of loudspeakers. Based

on selected K&F speaker systems, the ‘SP’ models are equipped with state-of-the-art

integrated driver circuits and Class D power amplifier technology. The extremely

lightweight system electronics replace ponderous racks, power amplifiers, controllers,

and speaker cables.

Aside from the integrated power amplifier and input modules with controller functions, the full-range systems possess a passive crossover so that the advantageous

features provided by the K&F passive technology (all-pass filter, protection circuits)

remain usable. The frequency separation for the subwoofers is controlled by an active

110 Hz low-pass filter.

Integrated phase optimisation allows for all systems in the ‘SP Series’ to be combinable with one another. With this, the ‘SP’ speakers, when the filter section is switched

off, have a completely comparable sound to the corresponding versions without integrated power amplifier technology. Operations using a K&F System Controller CD 44,

CD 24 (discontinued) and C2 (discontinued) are also possible, which is appropriate for

many applications.

Operating the ‘SP Series’ is incredibly easy: The full-range systems reproduce the complete frequency spectrum. If necessary, the ‘SP’ subwoofers in parallel operations can

provide an additional bass boost.

The Input Module

− Line signal input

− Limiter section (feed-forward RMS-limiter and peak limiter in feed-back design).

− High pass filter, 45 Hz tops, and 32 Hz subwoofers

− Low pass filter 110 Hz (only subwoofer systems)

− System specific, switchable frequency deemphasis (‘FILTERS ON/ OFF’) controllable

by a covered switch on the connecting terminal

− Phase correction

− Level adjustment (countersunk level control on the connecting terminal)

The Amplifier Module

− 1 x, or 2 x 1 kW Class D state-of-the-art power amplifier

− Minimal dimensions (speaker dimensions of the models without the ‘SP’ module are

retained)

− Low weight (weight increase of 2.5 / 4 kg as compared to systems without the ‘SP’

module; and with the Line 212 --- SP, the weight even stays identical)

− High efficiency enables convection cooling, because of which bothersome fans are

unnecessary

− High fidelity (even in high frequency range) and a large power bandwidth resulting

from impedance optimisation

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 7 of 44

Page 8

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

Modes of Operation

− Operations without external controller:

with activated filters (FILTERS ‘ON’), all K&F models in the ‘SP Series’ are combinable with one another by simply linking the signal from one speaker to the next.

− With optional K&F System Controller*:

via a K&F System Controller CD 44, CD 24 (discontinued) or C2 (discontinued,

with system plug-in card) or an Audio DSP*

− if used with BSS Soundweb, FDS 366, 336, 334, and XTA DP 226, 224, K&F sys-

tem parameters are available upon request

* The operation of the K&F ‘SP’ models with K&F System Controller or Audio DSP is

recommended for uses in which special filter presets are advisable, i.e. in combination

with passive systems of the ‘CA Series’, in cluster operations (top low cut), when bass

and high boost are necessary, adjustment to the room acoustics (EQ), etc.

The following K&F ‘SP’ speakers are available:

Full-range systems: CA 1001 - SP,

CA 1201 - SP,

CA1215-6 - SP, CA 1215-9 - SP

CA 1515-6 - SP, CA 1515-9 - SP

LINE 212-6 - SP, LINE 212-9 --- SP

Subwoofers: SW 112 - SP, SWi 112 - SP,

SW 115D - SP, SWi 115D - SP,

SW 118E - SP, SWi 118E - SP,

SW 215E - SP

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 8 of 44

Page 9

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

3. Connectors, Controls und Displays

1

2

3

4

Warning

5

6

7

8

1) LINE IN and LINE OUT (+6 dB)

Electronically balanced input and output connectors. Use the XLR female connector

(marked ‘IN’) as input. The parallel-wired XLR male connector (‘OUT’) is for connection to further ‘SP’ loudspeakers.

2) GROUND LIFT

When the ‘Ground Lift’ switch is set to LIFT, pin 1 of the LINE IN connector (ground)

is not connected to the chassis ground of the integrated amplifier module. The

ground connection between LINE IN (XLR male) and LINE OUT (XLR female) is maintained. The use of the ‘Ground Lift’ switch is sometimes necessary in dealing with

hum problems (see chapter 10.1 )

Never tape over the protective earth on the plug

Never tape over the protective earth on the plug ---

Never tape over the protective earth on the plug Never tape over the protective earth on the plug

3) PROTECTIVE COVER

--- danger to life!

danger to life!

------

danger to life!danger to life!

The protective cover prevents unwanted adjustment of the gain control and filter

ON / OFF switch. The cover has a snap-in lock. In order to reach the controls beneath, turn the cover sharply down in the direction of the arrow.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 9 of 44

Page 10

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

4) GAIN CONTROL (± 6 dB)

a) The gain control can be used to adjust the input level of the amplifier module

by ± 6dB. It serves to balance the volume levels of the various systems. In order to avoid overloading the input circuit or mixer’s output circuit, it should

normally be set in the case of K&F full-range systems at 0 dB (centre notch

setting).

b) When operating with K&F System Controller, set the input level of the ampli-

fier module on the controller (Input Gain). The gain control on the SP speaker

should be set at 0 dB (centre notch setting). One exception to this rule is a

cluster arrangement, in which the inner speakers should be set at a lower level than the outer ones. In this case, the level of the gain control on the inner

SP speakers can be adjusted downwards accordingly.

When operating with additional bass systems it is very important that the respective volume levels between the top speakers and the bass systems are correctly

balanced. To this end, the sound engineer should check the volume levels during

the set-up and adjust them accordingly. When setting up a system without a K&F

System Controller this adjustment should be carried out using the gain control of

the SP subwoofer; in the case of a system with K&F System Controller, set the

gain on the controller.

Normally we recommend the following settings*

Configuration:

Configuration: Gain control

Configuration:Configuration:

+

+

+

* These details may vary due to different room geometries. The position of a bass

speaker is also crucial for its actual sound level. A bass speaker, which is on the

floor, can be a few decibels louder than a flown bass system because of the floor

reflections. Because of this, a sound engineer must always fine-tune the system using the corresponding level controls.

or

or

Gain control

Gain controlGain control

Line 212:

---- 6 dB

6 dB

6 dB6 dB

Subwoofer:

+6 dB

+6 dB

+6 dB+6 dB

Line 212:

0 dB

0 dB

0 dB0 dB

Subwoofer:

+6 dB

+6 dB

+6 dB+6 dB

Line 212:

0 dB

0 dB

0 dB0 dB

Subwoofer:

0 dB

0 dB

0 dB0 dB

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 10 of 44

Page 11

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

5) FILTERS ON / OFF (High Pass / Low Pass / Equalizer)

This switch turns the filter in the SP module on (‘ON’), or off (‘OFF’).

a) The switch should always be in the ‘ON’ position when the speakers are being

driven without K&F System Controller.

b) The switch should always be in the ‘OFF’ position when the speakers are being

driven with K&F System Controller.

The filters consist of:

− high-pass: protects the speakers against mechanical stress due to frequen-

cies outside the speaker's frequency range (protection against subsonic

frequencies)

− EQ: filter for basic equalization, optimising the frequency response of the

speaker systems.

Furthermore, the SP filter module has a phase alignment, which prevents loss

of certain frequencies due to phase shift between mid-high and bass systems.

Thus the combination of all available K&F mid-high SP systems with all K&F

bass SP systems is possible, and 100% phase compatibility with all K&F speakers operating in conjunction with a K&F System Controller in the ‘2-way active’

mode is guaranteed.

6) LED POWER ON (GREEN) and LIMIT / PROTECT (RED)

The LED is dual-purpose:

a) When the LED is green, the speaker is connected to the supply voltage and

ready for operation

b) The LED will turn red if…

…the input signal is so high that the internal limiters reduce its level.

The limiters consist of a peak limiter, which limits the peaks of the signal,

and an RMS / thermal limiter, which continuously regulates excessive levels.

During normal operation, the red light may occasionally illuminate briefly

when the barely audible limiter cuts in to limit peak levels. It does indicate

that the level peaks are limited by the limiter circuit. The peak performance

of the speaker has then been reached.

Should the red light come on more frequently or remain illuminated, the

output level of the mixer should be reduced. When speakers with and

without SP module are in operation simultaneously, the gain control on the

SP speaker can be turned down, provided the level is sufficient for the other power amplifiers. The limiter protects the speaker from damage due to

excessive levels.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 11 of 44

Page 12

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

Fault

Measure

Function

LED remains red or flickers

Reduce output level on mixer until the

nal, LED shows red in spite

duced mixer output

Allow to cool. The amplifier module

switches itself on after a few minutes.

Temperature

ed after

Output signal is too low, no

bass frequencies or no high

c) The LED stays permanently red, if…

…the protection circuitry of the integrated power amplifier cuts in and as a

result, no further signal reaches the speaker (Protect Mode).

The protection circuitry switches off the integrated power amplifier,…

− …if the temperature of the amplifier module is too high. As soon as

the temperature falls below the critical value, the amplifier module is

switched on again automatically. Excessive temperatures can be

caused for example by inadequate ventilation of the heat sink. Make

sure that the heat sinks are not covered or positioned directly against a

wall.

− …if the output impedance is too low or in the case of a short circuit,

caused for example by a defective chassis or a faulty component on

the crossover.

− …if the amplifier has an internal fault. The SP amplifier module checks

that all is functioning correctly during operation. As soon as a fault becomes apparent, the module switches into protect mode. If only one

module has a fault, the input signal is attenuated by 70 dB, to prevent

damage to the other module.

Measures to be taken when LED is red:

Limiter

continually during operation.

LED goes out or flickers only occasionally

No or too low output sig-

protection

of re

Provide sufficient ventilation.

level.

No or too low output signal, LED stays r

Have loudspeaker checked by

authorized service technician.

Other

protection

cooling down.

Have loudspeaker checked by

authorized service technician.

Other

protection

frequencies.

7) AC MAINS ‘IN’

Connect this PowerCon socket using the mains cable supplied to a max. 16 A fused

mains socket, paying particular attention to the stated mains voltage! Connection

to an incorrect mains voltage can result in irreparable damage!

8) AC MAINS ‘OUT’

Socket for connection to further equipment such as further speakers with SP module. Use only connection cables, which conform to your national safety regul

Use only connection cables, which conform to your national safety regula-

Use only connection cables, which conform to your national safety regulUse only connection cables, which conform to your national safety regul

tions.

tions.

tions.tions.

Maximum power consumption: 230 V: 10 A / 2300 W

110 V: 10 A / 1150 W

a-

a-a-

Important

Warning

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 12 of 44

Page 13

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

4. Power Cord

In Germany, a pre-constructed ready for use power cord is included in the delivery.

For deliveries to foreign countries, a pre-constructed power cord incl. PowerCon plug is

included. Because of the different standards abroad, the power plug is not included.

This must be subsequently assembled only by qualified electrical specialists.

brown = BN = L

green / yellow = GNYE =

blue = BU = N

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 13 of 44

Page 14

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

5. Rigging Instructions for Line 212 Systems

The speakers may only be mounted by trained specialised pe

The speakers may only be mounted by trained specialised perrrrsonnel with proof

The speakers may only be mounted by trained specialised peThe speakers may only be mounted by trained specialised pe

of their qualifications as an e

of their qualifications as an experienced ‘rigger’.

of their qualifications as an eof their qualifications as an e

Please follow the accompanying instructions for speakers and assembly equipment.

Please follow the accompanying instructions for speakers and assembly equipment.

Please follow the accompanying instructions for speakers and assembly equipment.Please follow the accompanying instructions for speakers and assembly equipment.

xperienced ‘rigger’.

xperienced ‘rigger’.xperienced ‘rigger’.

sonnel with proof

sonnel with proof sonnel with proof

Ensure that all connections are secured to prevent their detaching on their own and that

only admissible statically tested and sufficiently sized connecting devices, ropes and

chains are used.

Warning

Pay attention to the required safety factors. Please follow the accompanying safety and

mounting instructions carefully.

A maximum load of 73 kg may be suspended from the two flying points of one Line

212 system. This

JUNGFALK’ flying point.

This means a maximum additional load of 36.5 kg on each

means a maximum additional load of 36.5 kg on each ‘allsafe

ThisThis

means a maximum additional load of 36.5 kg on each means a maximum additional load of 36.5 kg on each

flying point. This applies for both vertical (see details on this page) and

flying point.flying point.

horizontal suspension (see details on next page).

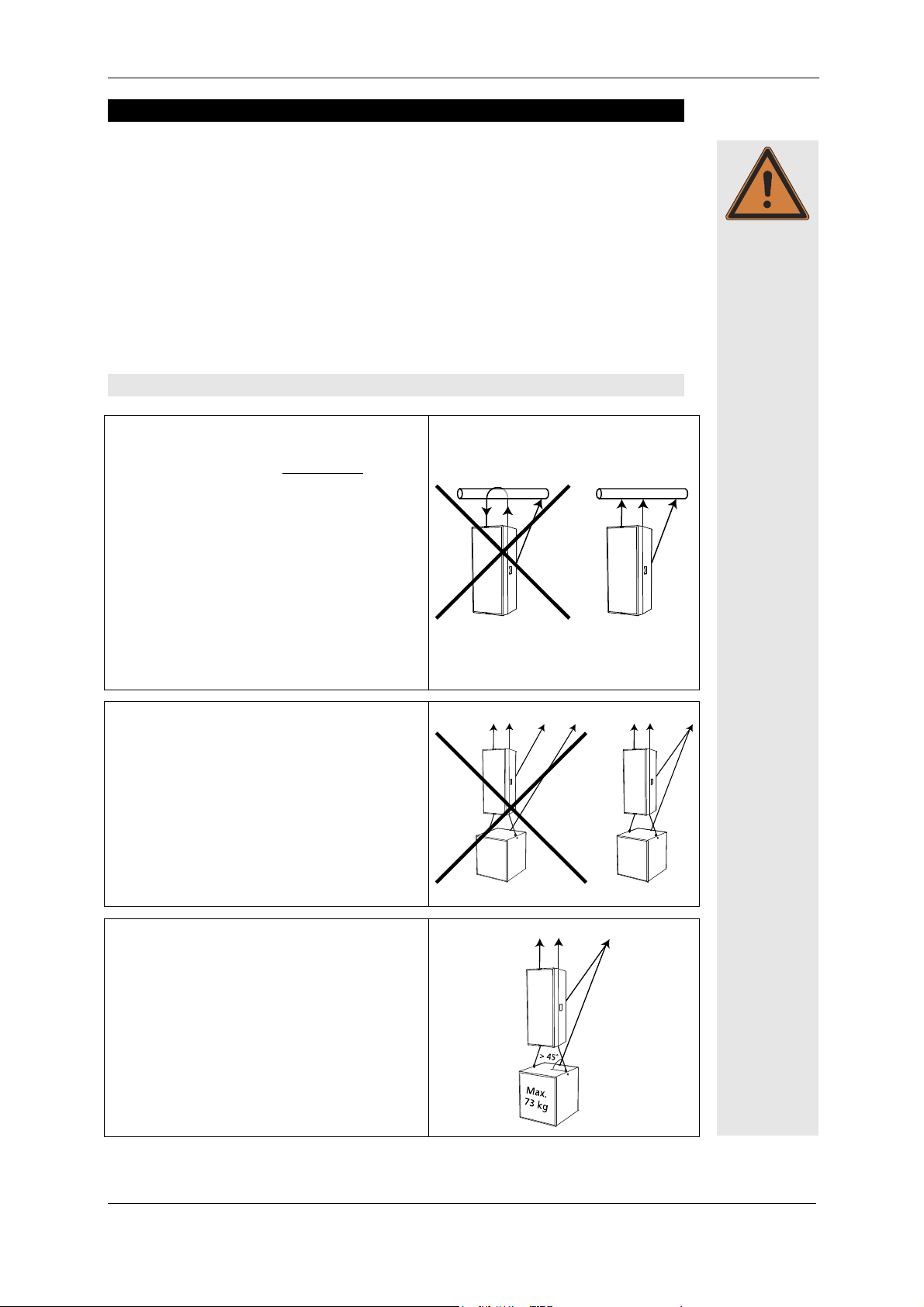

5.1 Vertical Suspension

The Line 212 System must always be mounted

with two wire ropes or chains, which are independent of one another! Furthermore, the systems, no matter if individual or connected to

one another, must be secured onto the ‘allsafe

JUNGFALK’ flying track on the rear. This safety

rope may be used for aligning the systems.

The safety rope must have a minimum length

The safety rope must have a minimum length

The safety rope must have a minimum length The safety rope must have a minimum length

of 100 cm and must be attached so that, in

of 100 cm and must be attached so that, in

of 100 cm and must be attached so that, in of 100 cm and must be attached so that, in

case it falls, the height of the fall is kept to a

case it falls, the height of the fall is kept to a

case it falls, the height of the fall is kept to a case it falls, the height of the fall is kept to a

minimum. A possible fall height of 20 cm may

minimum. A possible fall height of 20 cm may

minimum. A possible fall height of 20 cm may minimum. A possible fall height of 20 cm may

not be exceeded! With a higher fall height,

not be exceeded! With a higher fall height,

not be exceeded! With a higher fall height, not be exceeded! With a higher fall height,

the dyna

the dynamic load of a fall could be inadmiss

the dynathe dyna

bly high; potential risk of system crash.

bly high; potential risk of system crash.

bly high; potential risk of system crash.bly high; potential risk of system crash.

mic load of a fall could be inadmissi-

mic load of a fall could be inadmissmic load of a fall could be inadmiss

i-

i-i-

The safety ropes of different systems must always come together at one point.

Each of the utilised separate lifting accessories

(chains / wires / shackles) must be able to carry

the 12-fold load of the total weight.

While installing, be sure that the system can

swing in case a rigging point fails. With this in

mind, the speaker must be mounted so that no

people or objects are within the potential range

of the swinging speakers.

The weight of the speaker hung below may not

exceed 73 kg (this weight corresponds to the

approx. weight of a SW 215E-SP).

The angle of the rope / chain to the top of the

speaker mounted below may not exceed 45°.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 14 of 44

Page 15

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

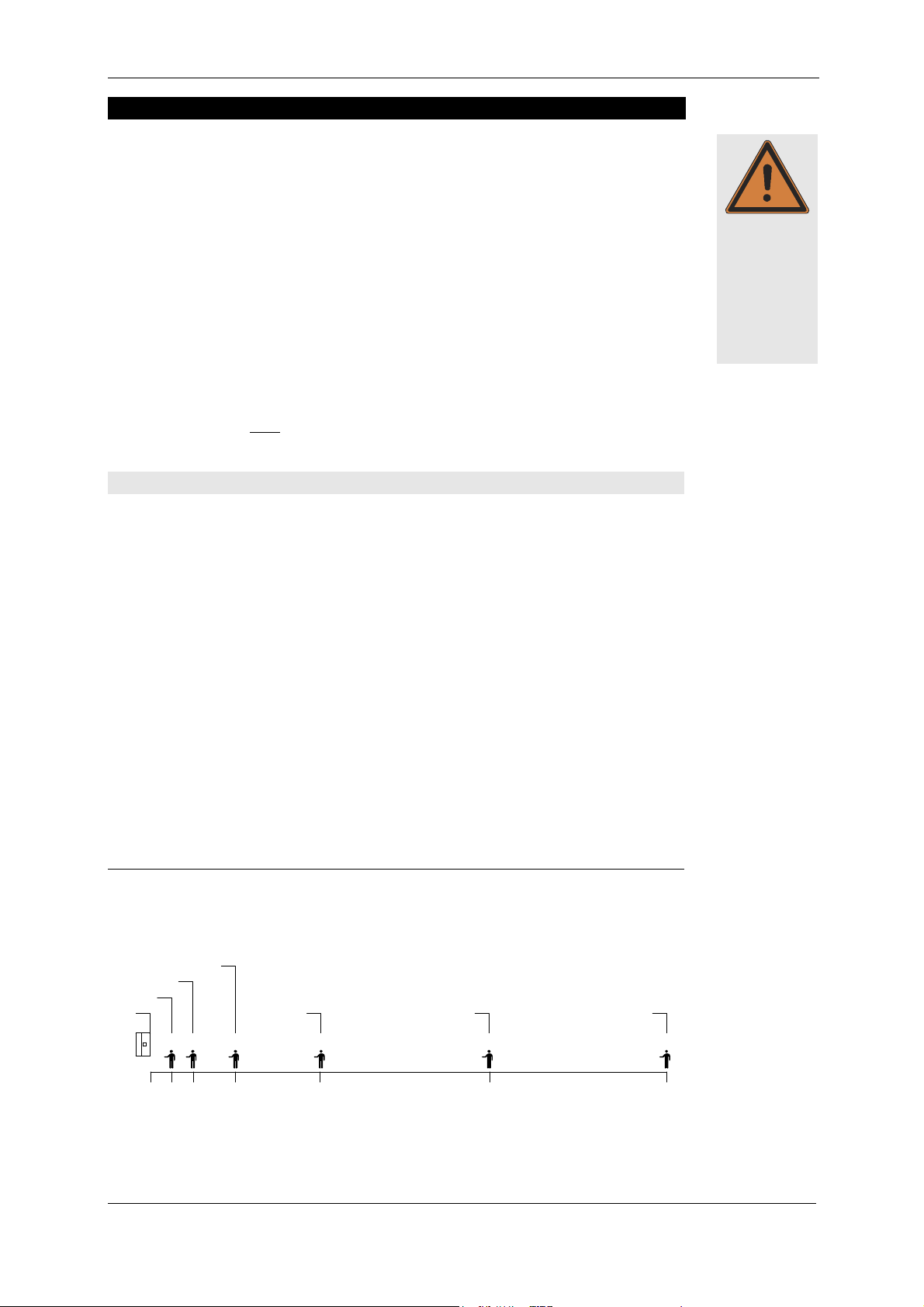

5.2 Horizontal Suspension

If a speaker unit consisting of several connected systems is to be

flown and aligned, then the individual speakers must be attached

to one another before connecting them to the ‘allsafe JUNGFALK’

Warning

Flying Track. Consult the provided illustration when doing so. For

the rear connection of the loudspeaker systems, use the double

stud fittings available from Kling & Freitag and a proven 1/2"

shackle (alternative single stud fittings and 3/8" shackle). Pull the

threaded bolt of the shackle with a torque of 10 Nm (hand

with 200 mm long lever, e.g. screwdriver).

with 200 mm long lever, e.g. screwdriver). Alternatively, you

with 200 mm long lever, e.g. screwdriver).with 200 mm long lever, e.g. screwdriver).

can use proven, high

can use proven, high----strength shackles with a cotter pin

can use proven, highcan use proven, high

in this way can you ensure that the bolt will not become loose.

The ‘allsafe JUNGFALK’ flying track can only support weights up

to 73 kg. Therefore, the load must be distributed on several flying tracks when suspending the systems.

For horizontal operations, the system is designed for a maximum array of three Line

212-6 systems. More of theses systems may not be flown below one another.

strength shackles with a cotter pin.... Only

strength shackles with a cotter pinstrength shackles with a cotter pin

(hand----tight

tight

(hand(hand

tight tight

Alternatively, you

Alternatively, you Alternatively, you

We recommend using the BGV C1 certified and type tested Click & Fly Rigging

System for mounting the Line 212 systems (see the ‘Click & Fly for Line 212 /

SW215E' user's manual).

Please follow the following instructions for flown operations without the Click

& Fly Rigging System:

Wrong:

− The upper rigging points of the top speaker

must carry the full load. Consequently, the

permissible max. load of the top points is exceeded.

− The speakers are not secured by the additional

safeties.

Right:

− The load of the individual speakers is threaded

through the bent continuous bracket. The load

is, therefore, held by the bracket and the

speakers’ flying points consequently only have

to carry the load of the corresponding speaker.

− The speakers are connected to one another on

the rear. The suspension point is located on the

connection of the two lower speakers. As a result, the load is distributed to both speakers.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 15 of 44

Page 16

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

6. Using the ‘allsafe JUNGFALK’ Flying Points

Single Stud Fitting

Used as fastener to the ‘allsafe

JUNGFALK’ Flying Point.

1.)

Take the single stud fitting in one

hand...

3.)

‘allsafe JUNGFALK’ Flying Point

Receptacle for special fasteners.

2.)

... and push the locking device up

against the spring tension.

4.)

Put the flat head of the holding

bolt into the guiding of the flying

point.

Release the locking device when

the single stud fitting is located in

the middle of the flying point.

Make sure that the locking device

clicks into place.

5.)

Warning

Check that the single stud fitting is

securely fastened and cannot be

pulled out.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 16 of 44

Page 17

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

7. Using the Rear Mounted ‘allsafe JUNGFALK’ Flying Track

The ‘allsafe JUNGFALK’ flying track can be used for fixing and adjusting the speaker systems.

The ‘allsafe JUNGFALK’ flying track can only support weights

up to 73 kg!

Please also consult the provided instructions for speakers and

assembly equipment.

Warning

7.1 Mounting the Single Stud Fittings

Single Stud Fitting

Used as fastener to the ‘allsafe

JUNGFALK’ Flying Point and the

‘allsafe JUNGFALK’ Flying Track.

1.)

Take the single stud fitting in one

hand...

3.)

2.)

4.)

‘allsafe JUNGFALK’ Flying Track

Receptacle for special fasteners such

as the single stud fitting.

... and push the locking device up

against the spring tension.

Warning

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 17 of 44

Slide the flat head of the holding

bolt into the guiding device of

the flying track and slide the single stud fitting sideways into the

flying track.

Release the locking device when the

single stud fitting is located over the

tabs of the track. Make sure that the

locking device clicks into place. Make

sure that it is secured tightly.

Page 18

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

7.2 Mounting the Double Stud Fitting

Double Stud Fitting

Used as fastener to the ‘allsafe

JUNGFALK’ Flying Point and the

‘allsafe JUNGFALK’ Flying Track.

‘allsafe JUNGFALK’ Flying Track

Receptacle for the double stud fitting.

1.)

Align the double stud fitting as

shown above and push it into the

track,…

2.)

... slide the pushed double stud fitting

to the middle of the speaker until it

clicks into place. Make sure that it is

secured tightly.

Warning

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 18 of 44

Page 19

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

8. Coverage Pattern of the Line 212 --- SP Systems

The Line 212 can be operated in a vertical or horizontal position. The coverage pattern

of the speaker can be adapted to special needs by a 90° rotatable horn.

The following graphics demonstrate how to recognize how the built-in horn emits in a

standing speaker: To determine the coverage pattern of the high frequency horn,

shine a flashlight through the front covering at the level of the horn. You will find a

silver stripe that determines the position and coverage angles of the horn.

DEFINITION:

DEFINITION:

DEFINITION:DEFINITION:

Warning

Warning

Horn not rotated

Horn not rotated

Standing speaker:

Model

Model

ModelModel

LINE 212-6 - SP 65° h x 50° v 50° h x 65° v

LINE 212-9 - SP 90° h x 50° v 50° h x 90° v

Horn not rotatedHorn not rotated

Horn rotated

Horn rotated

Horn rotatedHorn rotated

8.1 Changing the Coverage Pattern

The front grille of the Line 212 - SP is divided into two sections (except the version ‘Outdoor Installation’). Changing the coverage angle is possible by only removing the upper

section of the grille. To turn the horn, follow these steps:

1) Disconnect the power plug!

2) Make sure that no objects fall into the enclosure!

3) Remove the four grille mounting screws from the top on the sides of the speakers

with a 3 mm Allen key and remove the grille from the speaker enclosure. It may be

necessary to use a screwdriver in the middle of the top grille edge to pry up the

grille. There is a groove in the grille in this position (under the locking profile) just

for this purpose.

4) Remove the six screws from the high frequency horn (also using a 3 mm allen key).

Loosen the high frequency horn by using both hands, palms to the outside, to

grasp into the horn and lift the horn with even pressure from the palms of your

hands towards the outside. Never use a screwdriver or similar objects to reach behind the edge of the horn, as this could damage it.

5) Rotate the horn 90° and screw the horn on tightly again (do not force it!).

6) Screw the grille on tightly.

If the coverage angle needs to be changed often, make sure that the horn is not always

rotated in the same direction, as the connecting cable may cause the contacts of the

driver to become loose. Open wires may hit other live parts: Danger of electrical

shock.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 19 of 44

Page 20

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

-18 dB

9. Mounting Instructions for Speakers

Mount the speakers securely. To avoid injury or damage, always be sure to mount the

speakers securely so that they do not fall. Speakers, which are stacked, must be secured

with securing straps. When laying the connecting cables, make sure that nobody can

trip.

The stability of stacked systems (also valid for the use of stands and distance rods!) is

Warning

contingent upon the following stability requirement. These conditions must, therefore,

be guaranteed by the user:

Stacked systems may not fall over even if they are inclined by 10° in each direction. If this requirement is not fulfilled, then it is necessary to take steps to

achieve compliance. Possible measures include strapping it to an appropriate

base structure or fastening it using safety straps.

We recommend using the optionally available transport covers with castors when transporting and positioning the system. These covers have handles, which considerably

simplify the carrying and stacking of the Line 212 systems. We therefore recommend

removing the covers after the systems have been positioned. Always loosen the lower

catch first so that the cover does not fall over.

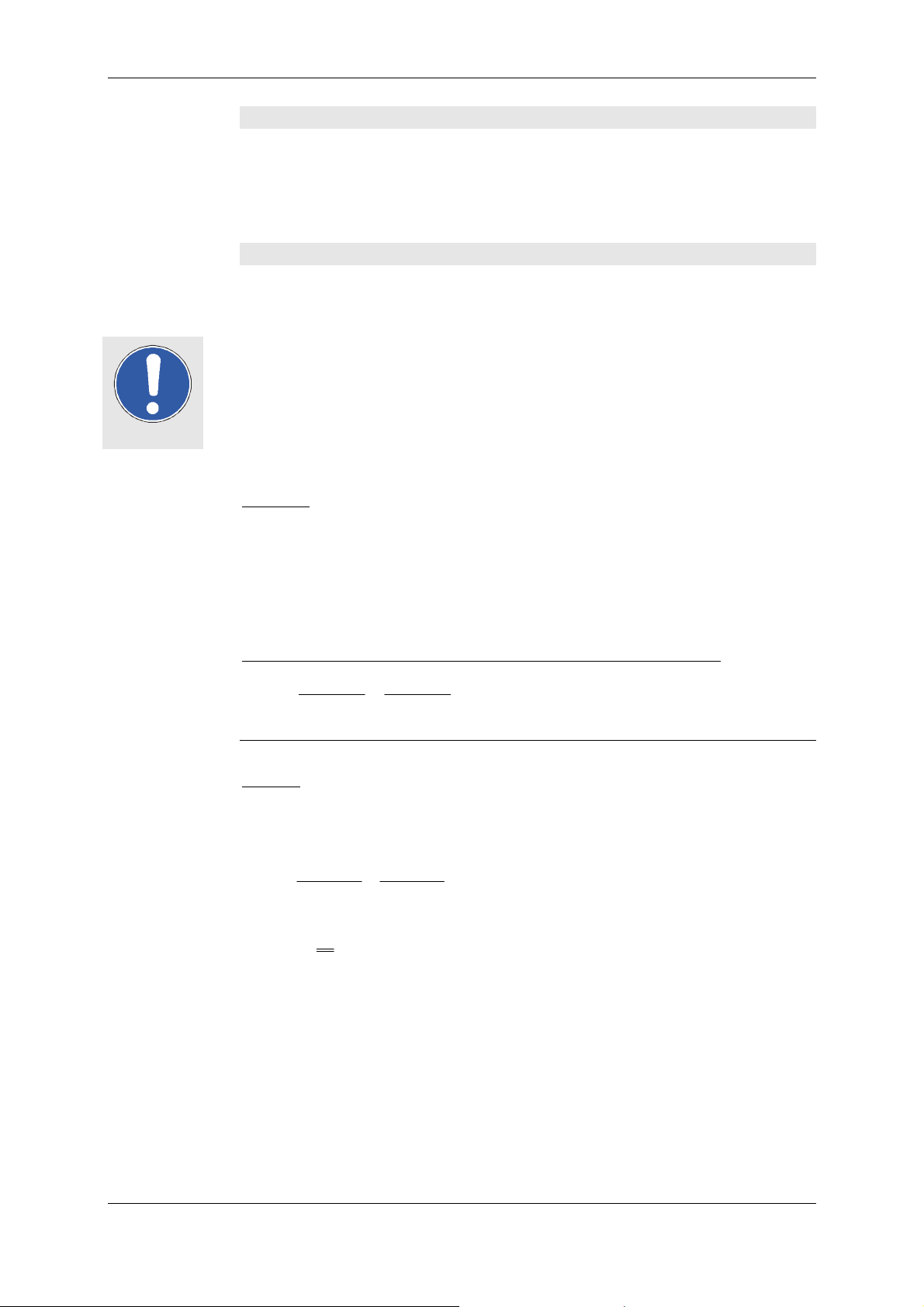

9.1 Proper Arrangement of the Loudspeakers

Be aware of the fact that the logical targeted alignment of this high quality speaker

system can lead to a significant qualitative increase in the acoustic result. It is not possible to make generalities about the alignment of specific systems because the room has

a substantial influence on the signal and the audible result.

As a rule, the mid- and high-transducers of loudspeakers should be mounted above the

audience's face value, so that the sound distribution cannot be shadowed.

In many cases, it is advisable to mount a loudspeaker higher, so that the sound will be

distributed throughout the room more evenly. Low standing systems result in a greater

difference in volume between front and back seats than higher standing systems.

Please note that this is only a general guideline and the best possible result may vary

from room to room.

To simulate the correct alignment of the speakers beforehand, there are various programs such as ‘Ease’ or ‘Ulysses’. ‘‘The Kling & Freitag speaker system data is available

for download on our website www.kling-freitag.de.

The following graphics will assist in making a rough estimate as to the distance range of

speaker systems. The graphics only take into consideration the sum of the direct sound

and not the influence of the room. Because of this there can, in some cases, be noticeable deviation.

Distance range of SPL (direct sound level):

-12 dB

0 dB

-6 dB

-24 dB -30 dB

2m 4m 8m 16m 32m 50m

-34 dB

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 20 of 44

Page 21

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

E

Q LOW CUT

Quality (Q)

Bandwidth (oct.)

Level

9.2 Arrayed Speaker Systems (Cluster)

If the loudspeakers are operated through an optional K&F System Controller, we recommend turning on the 'Top Low Cut' filter for clustered operation. Thus the frequency response for this application can be optimised (see user’s manual of the controller).

If the Line 212 Systems are operated in a cluster without a K&F System Controller

(speakers are set up directly next to one another), then lower the 'EQ LOW CUT' frequency as described below!

Frequency

120Hz

0.55

2.35

-2.95dB

1. If several Line 212-6 with a horn coverage pattern of 65°h x 50°v are arranged on

one side (cluster / array), it is recommended for the Line 212-6 to have a horizontal

array angle of 38.5° to one another (see fig. 2).

2. In a cluster comprised of a combination of the Line 212-6 with Line 212-9, we

recommend an array angle of 45° (see fig. 3).

3. With a rotated horn (Line 212-6 standing: 50°h x 65°v / Line 212-9 standing: 50°h

x 90°v), an array angle of 30° is recommended for both versions (see fig. 1).

Because increased interference effects occur when several 90° systems are arranged

next to one another, the clustering of several Line 212- 9 is only conditionally recommendable.

Fig.

Fig. 1111

Fig. Fig.

Fig.

Fig. 2222

Fig.Fig.

Fig.

Fig. 3333

Fig. Fig.

15,0°

8,5°

30,0°

Line 212

Line 212---- 6666

Line 212Line 212

(horn rotated)

horn 50° h x 65° v

Line 212

Line 212----9999

Line 212Line 212

(horn rotated)

horn 50° h x 65° v

Line 212

Line 212----6666

Line 212Line 212

(horn not rotated)

horn 65° h x 50° v

38,5°

Combination

(horns not rotated):

Line 212

Line 212----6666

Line 212Line 212

Horn 65°h x 50°v

with

Line 212

Line 212----9999

Line 212Line 212

45,0°

horn 90°h x 50°v

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 21 of 44

Page 22

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

9.3 LINE 212 Systems on Top of SW 215E

In addition to the stacking foot grooves for stacks of

idenctical enclosures, the subwoofer SW 215E also has

stacking foot grooves for the Line 212 System.

One Line 212 System can be quickly and safely positioned on top of a vertically placed SW 215E.

Two Line 212 Systems can be precisely arrayed on top of

a horizontally placed SW 215E.

Line 212

Line 212----6666

Line 212Line 212

with

with

withwith

Line 212

Line 212----6666

Line 212Line 212

Line 212

Line 212----6666

Line 212Line 212

with

with

withwith

Line 212

Line 212----9999

Line 212Line 212

Horn

Horn not

not rotated on

Horn Horn

notnot

standing Line 212 syste

standing Line 212 systemmmm

standing Line 212 systestanding Line 212 syste

8,5°

38,5°

15,0°

45°

rotated on

rotated onrotated on

Horn rotated

Horn rotated

Horn rotatedHorn rotated

standing Line 212 system

standing Line 212 system

standing Line 212 systemstanding Line 212 system

30°

Other combinations of Line 212 Systems are not recommended as they can cause unwanted interferences.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 22 of 44

Page 23

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

10. Wiring

Before connecting your SP system, be sure to switch off all connected appliances and

turn down all level controls.

− We recommend the use of high-quality cables provided by KLING & FREITAG.

− For connections to the line signal inputs, please use 2-pin shielded microphone cable

with high-quality connectors.

− Avoid ground loops (see chapter 10.1 )

− Make sure that the pin assignment of the line level connectors is correct. (2 +/ 3 - / 1 ┴).

10.1 Avoiding Ground Loops

10.1.1 What is a Ground Loop?

Every component of a P.A. or Hi-Fi System has its own internal 0V reference (ground). This

point is often connected to the protective earth connector (PE / Ground). If two or more

units are connected to one another with a line level audio cable, there may be a ground

connection through the ground of the power supply cable (yellow-green) as well as

through the shielding of the audio cable. The voltage difference between these two

ground points causes audible interference to come from the speaker.

Warning

10.1.2 Avoiding Ground Loops

If there is a loud humming or buzzing after the ‘SP’ System has been connected, then

set the ‘Ground Lift’ switches on the rear of the ‘SP’ speakers to the ‘Lift’ position (chapter: 3 / section 2)

If the noise is still audible, check if

1. the noise is caused by a ground loop before the speakers (e.g. mixing console,

effects or equalizers).

2. the system or parts of the system are connected to an ‘unclean’ power supply -

meaning one which is also running large motors or lighting systems. An ‘unclean’ supply voltage, electrostatic and electromagnetic fields can cause interference

Please observe the following basic rules:

− Never !!! try to avoid a ground loop by disconnecting or taping the ground

contact at the connector! Extremely dangerous!

− If possible, only use high-quality audio appliances with balanced signal outputs and

power cables with PE connectors.

− Use high-quality cables with good shielding.

− The point of ground for all connected components should merge at one central

point. The power connections should lead out in a radial manner from one point

and not be linked from one unit to the next.

− When installing appliances that create strong electrostatic or electromagnetic fields

(large transformers, switch-mode power supplies), maintain some distance from

other audio appliances. In extreme cases, the only solution is to create a completely

independent ‘audio ground’; in other cases, it is sufficient to connect a filter in front

of the audio equipment.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 23 of 44

Page 24

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

1.

10.2 Connecting the Power Connectors to the Connecting Terminal

2.

1.

2.

3.

Only use the supplied power cable and connect it to a mains outlet with a 16 A fuse.

See instructions in chapter 4‚ ‘Power Cord’ on page 13.

Warning

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 24 of 44

Page 25

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

EQ HIGH B

O

OST EQ LOW CUT

Bandw

idth (oct.)

Level

11. Configurations and Connecting Diagrams

11.1 Operating the Systems without K&F System Controller

The full-range system can be used alone or in conjunction with an SP subwoofer. The

subwoofer has an integrated filter for use in this mode, which limits the bandwidth.

The full-range system is protected against low frequency (subsonic) signals by a highpass filter and when used with bass speakers it is phase aligned with the subwoofers by

means of alignment filters.

11.1.1 Full-Range Mode

This mode of operation is ideal for speech and music applications without the need for

a high bass content. Should more bass be needed, the bass level can be increased between 50 and 80 Hz at the mixing console.

The switch ‘FILTERS’ on

The switch ‘FILTERS’ on

The switch ‘FILTERS’ on The switch ‘FILTERS’ on

the SP speaker must be

the SP speaker must be

the SP speaker must be the SP speaker must be

at ‘ON’ in this mode.

at ‘ON’ in this mode.

at ‘ON’ in this mode.at ‘ON’ in this mode.

If you need a high-boost for covering larger distances (compensation of high frequency

attenuation), then increase the ‘EQ HIGH BOOST’ frequency as described below!

If the mid-high systems are operated in a cluster (speakers are set up directly next to one

another), then lower the ‘EQ LOW CUT’ frequency as described below!

LINE

AC-MAINS

Frequency

Quality (Q)

INPUTChannel 2 Channel 1

14000Hz

2.6

0.55

+4.4dB

120Hz

0.55

2.35

-2.95dB

LINE

AC-MAINS

AC ~ 16 A max.AC ~ 16 A max.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 25 of 44

Page 26

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

EQ HIGH BOOST

EQ LOW CUT

Quality (Q)

Bandwidth (oct.)

Level

11.1.2 Full Range Mode with Subwoofer

You can link the input signal (for example from the mixer) from one loudspeaker to

another. It makes no difference whether the input signal reaches the bass speaker first

and is then transmitted to the mid-high speaker or the other way around.

The switch ‘FILTERS’ on

The switch ‘FILTERS’ on

The switch ‘FILTERS’ on The switch ‘FILTERS’ on

the SP speaker must be at

the SP speaker must be at

the SP speaker must be at the SP speaker must be at

‘ON’ in this mode.

‘ON’ in this mode.

‘ON’ in this mode.‘ON’ in this mode.

If you need a high-boost for covering larger distances (compensation of high frequency

attenuation), then increase the ‘EQ HIGH BOOST’ frequency as in the following table!

If the mid-high systems are operated in a cluster (speakers are set up directly next to one

another), then lower the ‘EQ LOW CUT’ frequency as described below!

LINE

AC-MAINS

Frequency

To next

'SP'-Top

or Sub

14000Hz

2.6

0.55

+4.4dB

120Hz

0.55

2.35

-2.95dB

To next

'SP'-Top

or Sub

LINE

AC-MAINS

LINE

AC-MAINS

AC ~ 16 A max.

Channel 1

INPUT

Channel 2

LINE

AC-MAINS

AC ~ 16 A max.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 26 of 44

Page 27

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

Ω

Ω

=

75

R

Ω

66

n

<

⇒

11.2 Operating the Systems with K&F System Controller

For optimal performance with an extended functional range we recommend using a

K&F system controller. Instructions for use, connecting diagrams and detailed descriptions of the latest controller models ‘CD 24’ and ‘CD 44’ you can find in the corresponding user’s manuals.

11.3 Maximum Configuration

It is possible to use a large number of SP speakers in parallel simultaneously, however,

this number is limited according to the permitted minimum load impedance of the signal source (e.g. mixer, equalizer, etc.).

The total input impedance of all SP speakers must be larger than the permitted minimum load impedance of the signal source. If no manufacturer’s recommendations can

be found, take the output impedance of the signal source. In this case, we recommend

a total input impedance at least 10 times higher than the stated output impedance of

Important

the signal source.

(The output impedance of your signal source can normally be found under ‘Technical

Specifications’ in the manufacturer’s instruction manual).

Definition:

OUT

IN

MAX

=

=

source signal of impedance output R

50.000Ω 50kΩ speaker - SP impedance input R

===

speakers SP of number drecommende maximum n

The maximum number of SP speakers can be calculated with this formula:

50

n

MAX.

R

IN

<

10

×

R

k

=

R

OUTOUT

10

×

Example:

OUT

n

MAX.

R

IN

<

OUT

10

×

000.50

Ω

1075

xR

=

MAX.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 27 of 44

Page 28

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

12. Operating the Speakers

− Switch off all equipment and make sure that the SP speakers are not connected to a

power source.

− Connect your SP systems in accordance with the preceding connection diagrams.

Use only mains cables, which comply with your national safety regulations.

− Upon completing the wiring, ensure that the connected speakers are working in phase. To

do so, use i.e. a phase checker. A phase error can also be recognized when the connected

channels are used simultaneously. During simultaneous use the bass frequencies become

notably quieter or the mid-frequencies such as voices cannot be located.

Warning

− Switch on first the peripheral units (mixer, effects, etc.), then, if used, the K&F System

Controller and connect lastly the SP loudspeakers. Always use the before mentioned

switching order. Otherwise switching noises may damage the system.

− If there is interference, turn off all appliances in the reverse order and check all cable

connections. Next, turn up all other peripheral units, and check these for interference.

− Your system should now be ready for operation.

− You can now turn up the level on the mixer.

− If you are using additional bass systems, you can now balance the respective volume

levels of the top speakers and bass systems. A fine adjustment of the system without

K&F System Controller can be obtained using the gain control on the SP loudspeakers

(not on the mixing console!).

− When switching off the system first disconnect the ‘SP’ loudspeakers. Then you can switch

off the remaining units.

13. Touching Up Damage to Paint / Changing the Front Foam

Although the PU structured paint used by KLING & FREITAG is extremely resistant, we

recommend using protective covers or cases to help avoid damaging the paint during

i.e. continuous mobile use. If paint damage occurs despite these precautions, it can be

touched up by using commercial acrylic paint in the appropriate RAL colour of the

speaker. To replace the filter foam, send the front grille incl. foam to KLING & FREITAG

GmbH. Upon payment for expenses, the grille with the new covering will be returned.

Important

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 28 of 44

Page 29

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

SCHEMATIC LINE 212 - 'SP'

14. Block Diagram LINE 212 - SP

12 V DC

±

LINE 212

CIRCUIT

POTECTION

POWER

SUPPLY

FILTER AMP

ERROR

SIGNAL

AMP

DIGITAL

THRESHOLD PEAKTHRESHOLD RMS

SIGNAL

RMS

+ PEAK

LIMITER

ERROR

POWER 'ON'

ERROR

CONTROLLER

FUSE

AMPLIFIER UNIT 2

HF-

CIRCUIT

POTECTION

CONTROL

AMP

DIGITAL

LED

BI-COLOUR

CORRECTION

FILTERBOARD 'LINE 212'

PHASE-CORRECTION

'

POWER SUPPLY

FUSE

F

F

O

'

/

'

N

O

'

S

R

E

T

L

I

F

HI-PASS

HI-PASS

AMPLIFIER UNIT 1

6 dB

±

GAIN

PASSIVE CROSSOVER

LINE 212 - SP

HF

LF 1

LF 2

T

F

I

L

L

L

N

N

D

N

G

2

3

2

3

1

INPUT UNIT

1

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 29 of 44

Page 30

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

15. Technical Specifications

15.1 LINE 212-6 - SP

Loudspeaker

Loudspeaker

LoudspeakerLoudspeaker

Design 2+1-way full-range system with integrated driver and

power amplifier technology,

completely horn loaded, bass reflex tuning

Frequency range -10 dB 51 Hz - 20 kHz ('FILTERS ON'), 65 Hz - 20 kHz ('FILTERS OFF')

49 Hz - 20 kHz ('FILTERS OFF' with K&F System Controller)

Frequency range ± 3 dB 66 Hz - 18 kHz ('FILTERS ON'), 130 Hz - 18 kHz ('FILTERS OFF')

60 Hz - 18 kHz ('FILTERS OFF' with K&F System Controller)

Nominal coverage angle 65° x 50° / rotatable horn

Directivity index (DI) 12 (+1.5/-3) 600 Hz - 16 kHz

Max. SPL 135 dB (SPL peak/1 m)

Components 1 x 12‘‘ woofer and 1 x 12‘‘ low-mid chassis with horns,

1.5‘‘ high freq. driver with 75 mm titanium dome on

rotatable CD horn

Crossover Active (1) and passive (2) in FLC technology, delay time

correction and phase optimisation, self-resetting

protection circuit for 1.5‘‘ driver

Supply voltage AC 195-250 V, 50 / 60 Hz (230 V version)

alternative AC 95-125 V, 50 / 60 Hz (115 V version)

Power consumption (nominal) @ 230 V: 1.25 A @ 115 V: 2.5 A

Max. Power consump. (Irms / <500 ms) @ 230 V: 8 A @ 115 V: 16 A

Idle current @ 230 V: 360mA @ 115 V: 720 mA

Power connectors Neutrik PowerCon, lockable, 1 input and 1 output

Input module

Input module

Input moduleInput module

Signal connectors Pin 1 = ground / pin 2 = + signal / pin 3 = - signal

LINE IN: XLR 3 pin female

LINE OUT: XLR 3 pin male, parallel with LINE IN

Input sensitivity +6 dB / 1.55 Vrms for rated output

Input impedance 50 kW (balanced / unbalanced)

Common mode rejection Min.: 74 dB, typical: 90 dB

Controls Level control ± 6 dB, bypass switch for the

active filters (for operations with K&F System Controller),

ground lift switch

Display Bi-coloured LED: green = Power On,

red = Limit / Protect

Driver circuit Peak limiter, RMS limiter

High-pass 45 Hz (-3 dB), 24 dB / octave (‘FILTERS ON’),

Phase correction, frequency equalisation (EQ)

Amplifier module (2 x)

Amplifier module (2 x)

Amplifier module (2 x)Amplifier module (2 x)

Type Class D

Power

Power bandwidth 10 Hz to 30 kHz

Damping factor > 500 (100 Hz), > 100 (10 kHz)

S / N ratio > 105 dB (A)

Cooling Air convection (without fan)

Protection circuits Short circuit, over-temperature, clipping, overload

Enclos

Enclosure

ure

EnclosEnclos

ureure

Trapezoidal, frame-reinforced 15 mm birch plywood with

with highly resistable grey or black structured paint,

2 butterfly handles, ball proof front grille with

exchangeable black acoustic foam

Rigging 4 flying points ‘allsafe JUNGFALK’

1 rear mounted flying track ‘allsafe JUNGFALK’

Dimensions 429 x 1025 x 510 mm (W x H x D)

Weight 57.5 kg

Options special finish in RAL colours

1000 W @ 8 Ω ( EIAJ / 1 kHz, 1% THD)

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 30 of 44

Page 31

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

Technical changes without prior notice reserved

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 31 of 44

Page 32

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

15.2 LINE 212-9 - SP

Loudspeaker

Loudspeaker

LoudspeakerLoudspeaker

Design 2+1-way full-range system with integrated driver and

power amplifier technology,

completely horn loaded, bass reflex tuning

Frequency range -10 dB 51 Hz - 20 kHz ('FILTERS ON'), 65 Hz - 20 kHz ('FILTERS OFF')

49 Hz - 20 kHz ('FILTERS OFF' with K&F System Controller)

Frequency range ± 3 dB 66 Hz - 18 kHz ('FILTERS ON'), 130 Hz - 18 kHz ('FILTERS OFF')

60 Hz - 18 kHz ('FILTERS OFF' with K&F System Controller)

Nominal coverage angle 90° x 50° / rotatable horn

Directivity index (DI) 10 (±1.5) 600 Hz - 12 kHz

Max. SPL 135 dB (SPL peak/1 m)

Components 1 x 12‘‘ woofer and 1 x 12‘‘ low-mid chassis with horns,

1.5‘‘ high freq. driver with 75 mm titanium dome on

rotatable CD horn

Crossover Active (1) and passive (2) in FLC technology, delay time

correction and phase optimisation, self-resetting

protection circuit for 1.5‘‘ driver

Supply voltage AC 195-250 V, 50 / 60 Hz (230 V version)

alternative AC 95-125 V, 50 / 60 Hz (115 V version)

Power consumption (nominal) @ 230 V: 1.25 A @ 115 V: 2.5 A

Max. Power consump. (Irms / <500 ms) @ 230 V: 8 A @ 115 V: 16 A

Idle current @ 230 V: 360mA @ 115 V: 720 mA

Power connectors Neutrik PowerCon, lockable, 1 input and 1 output

Input module

Input module

Input moduleInput module

Signal connectors Pin 1 = ground / pin 2 = + signal / pin 3 = - signal

LINE IN: XLR 3 pin female

LINE OUT: XLR 3 pin male, parallel with LINE IN

Input sensitivity +6 dB / 1.55 Vrms for rated output

Input impedance 50 kW (balanced / unbalanced)

Common mode rejection Min.: 74 dB, typical: 90 dB

Controls Level control ± 6 dB, bypass switch for the

active filters (for operations with K&F System Controller),

ground lift switch

Display Bi-coloured LED: green = Power On,

red = Limit / Protect

Driver circuit Peak limiter, RMS limiter

High-pass 45 Hz (-3 dB), 24 dB / octave (‘FILTERS ON’),

Phase correction, frequency equalisation (EQ)

Amplifier module (2 x)

Amplifier module (2 x)

Amplifier module (2 x)Amplifier module (2 x)

Type Class D

Power

Power bandwidth 10 Hz to 30 kHz

Damping factor > 500 (100 Hz), > 100 (10 kHz)

S / N ratio > 105 dB (A)

Cooling Air convection (without fan)

Protection circuits Short circuit, over-temperature, clipping, overload

Enclos

Enclosure

ure

EnclosEnclos

ureure

Trapezoidal, frame-reinforced 15 mm birch plywood with

with highly resistable grey or black structured paint,

2 butterfly handles, ball proof front grille with

exchangeable black acoustic foam

Rigging 4 flying points ‘allsafe JUNGFALK’

1 rear mounted flying track ‘allsafe JUNGFALK’

Dimensions 429 x 1025 x 510 mm (W x H x D)

Weight 57.5 kg

Options special finish in RAL colours

Technical changes without prior notice reserved

1000 W @ 8 Ω ( EIAJ / 1 kHz, 1% THD)

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 32 of 44

Page 33

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

-6dB Beamwidth (degr

ees)

20000

360

20

100

Dir

ectivityI ndex (DI), dB

SPL

(dB)

Filters 'OFF'

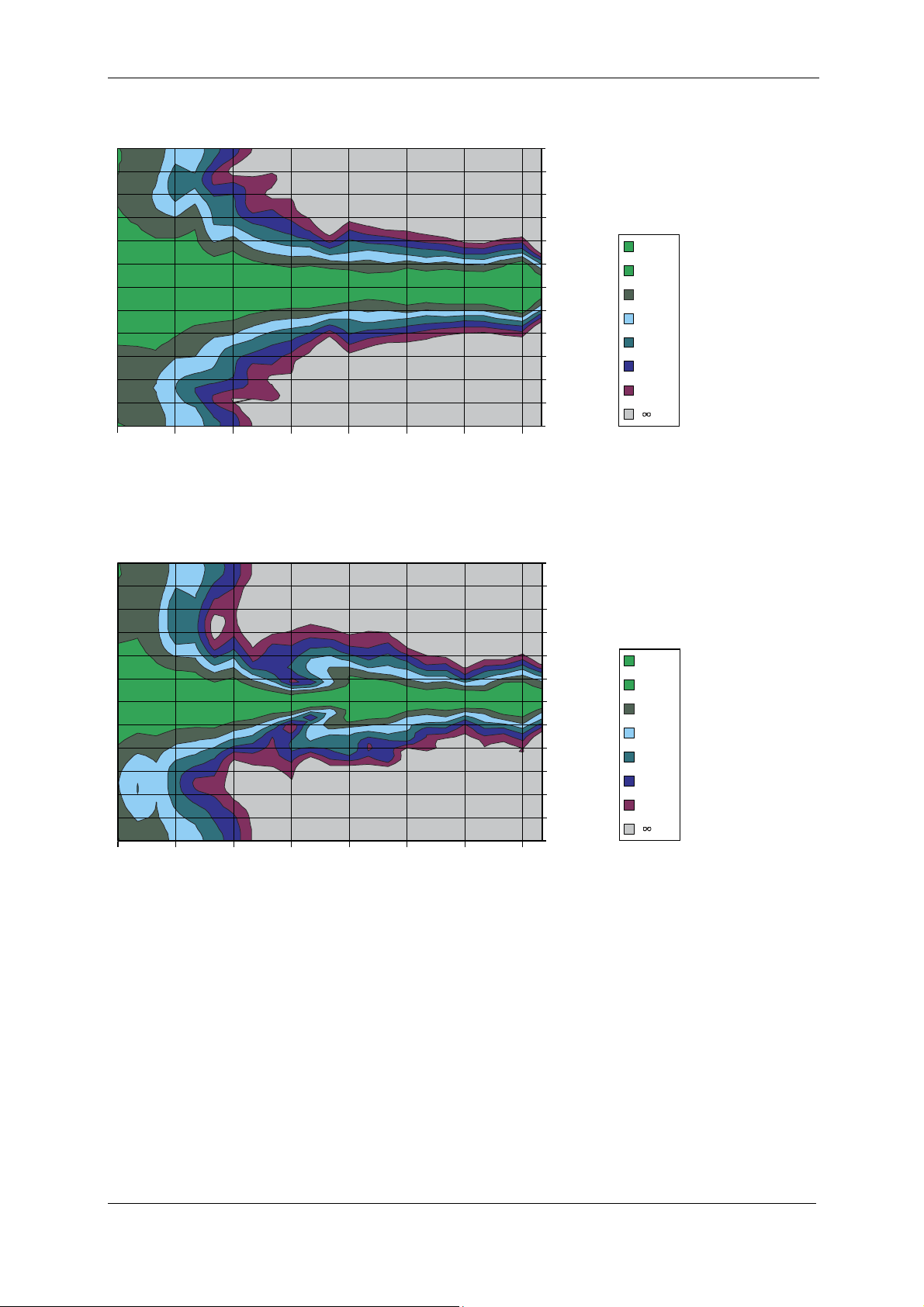

16. Measuring Charts

16.1 LINE 212-6 - SP

Frequency response ‘on axis’

115

105

95

85

75

20 100 1000 10000 20000

Frequency (Hz)

Beamwidth

Filters 'ON'

300

240

180

120

60

0

20

100 1000 10000

Frequency (Hz)

Horizontal

Vertical

Q-Index

10

0

20 100 1000 10000 20000

Frequency (Hz)

10

Directivity Factor (Q)

1

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 33 of 44

Page 34

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

1

180

°

180

°

Attenuation in dB

Horizontal coverage pattern

150°

120°

90°

60°

30°

0°

-30°

-60°

-90°

-120°

-150°

-180°

25 250 500 1k 2k 4k 8k 16K

f [Hz]

0-3

-3-0

-6--3

-9--6

-12--9

-15--12

-18--15

- --18

Vertical coverage pattern

125 250 500 1k 2k 4k 8k 16K

f [Hz]

150°

120°

90°

Attenuation in dB

60°

30°

0°

-30°

-60°

-90°

-120°

-150°

-180°

0-3

-3-0

-6--3

-9--6

-12--9

-15--12

-18--15

- --18

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 34 of 44

Page 35

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

-6dB Beamwidth (degr

ees)

20000

360

20

100

Dir

ectivityI ndex (DI), dB

PL

SPL

(dB)

Filters 'OFF'

16.2 LINE 212-9 - SP

Frequency response 'on axis'

115

105

95

(dB

S

85

75

20 100 1000 10000 20000

Frequency (Hz)

Beamwidth

Filters 'ON'

300

240

180

120

60

0

20

Q-Index

10

Horizontal

Vertical

100 1000 10000

Frequency (Hz)

10

Directivity Factor (Q)

0

20 100 1000 10000 20000

Frequency (Hz)

1

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 35 of 44

Page 36

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

1

180

°

1

180

°

Horizontal coverage pattern

150°

120°

90°

Attenuation in dB

60°

30°

0°

-30°

-60°

-90°

-120°

-150°

-180°

25 250 500 1k 2k 4k 8k 16K

f [Hz]

0-3

-3-0

-6--3

-9--6

-12--9

-15--12

-18--15

-21--18

Vertical coverage pattern

25 250 500 1k 2k 4k 8k 16K

f [Hz]

150°

120°

90°

60°

30°

0°

-30°

-60°

-90°

-120°

-150°

-180°

Attenuation in dB

0-3

-3-0

-6--3

-9--6

-12--9

-15--12

-18--15

-21--18

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 36 of 44

Page 37

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

ANCRA Jungfalk

[10.467"]

17. Dimensions

Flugpunkte

ANCRA Jungfalk

120030-31

Kunststofffüße

Flugschiene

71202

1015 mm

[39.961"]

10 mm

[0.033"]

429 mm

[16.890"]

Stapelmulden

222 mm

[8.740"]

15°

81.6 mm

[3.211"]

265.9 mm

510 mm

[20.079"]

507.5 mm

214.6 mm

[8.450"]

[19.980"]

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 37 of 44

Page 38

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

18. Accessories for the LINE 212 System

Click & Fly

Quick Release Pin

®

Connector 30° Connector 38.5° Connector 45°

Application examples Click & Fly® LINE 212

Single Stud Fitting Double Stud Fitting Rigging chain, adjustable (left / right)

Transport cover with castors

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 38 of 44

Page 39

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

19. Regulations for Disposal

19.1 Germany

It is not allowed to dispose of used electrical equipment as domestic waste.

But please do not dispose of them at official collecting points for recycling either!

All Kling & Freitag products are plain business-to-business (B2B) products.

Disposal of Kling & Freitag products labelled with a waste bin sign have thus to be disposed of by Kling & Freitag alone. Please call Kling & Freitag at the number stated below

if you have a Kling & Freitag product to be disposed. We will offer you a straightforward

and professional disposal not affecting costs.

If there is no dustbin sign on one of your Kling & Freitag products, because they have

been sold before March 2006 then by law the owner is in charge of the disposal. For

these we will be happy to assist and offer you proper ways of disposal.

Telephone number to call about the disposal of used Kling & Freitag products:

+49 (511)-96 99 7-0

Explanation: With the ElektroG (law relating to electrical and electronic equipment and appliances) we have complied with the EUdirective on waste electrical and electronic equipment (WEEE,

2002/96/EC)

The Kling & Freitag GmbH has thus labelled all products mentioned

in the WEEE from 03/24/2006 onwards with a sign with a crossed

out waste bin and a white bar below. This sign indicates that the

disposal into the domestic waste is prohibited and that the product

has been put into circulation at the 03/24/2006 earliest.

The Kling & Freitag GmbH has been legally registered as a manufacturer with the registration office EAR. Our WEEE Registration-Nr. is: DE64110372

For the German Registration office EAR we have accredited that our products are sole

B2B products.

19.2 EU, Norway, Iceland, and Liechtenstein

It is not allowed to dispose of used electrical equipment as

domestic waste.

The Kling & Freitag GmbH has thus labelled all products coming

from EU-Member countries as well as Norway, Island and Liechtenstein (except Germany) mentioned in the WEEE from 08/13/2005

onwards with a sign with a crossed out waste bin and a white bar

below. This sign indicates that the disposal into the domestic waste

is prohibited and that the product has been put into circulation at

the 08/13/2005 earliest.

Unfortunately the European directive WEEE has been complied with implementing different national provisions of law throughout all member countries, which makes it impossible for us to offer consistent solutions for the disposal throughout Europe.

Responsible for complying with these provisions of law is the local distributor (importer)

of each country.

For proper disposition of used products in accordance with these local provisions in

the mentioned countries of the European Union (except Germany) please ask your

local dealer or the local authorities.

19.3 Other Countries

For proper disposition of used products in accordance with local provisions in other

countries please ask your local dealer or the local authorities.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 39 of 44

Page 40

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

20. Declaration of Conformity and International Certificates

20.1 Declaration of Conformity

EG-Konformitätserklärung

EMV Richtlinie 89 / 336 / EWG

Niederspannungsrichtlinie: 73 / 23 / EWG

Wir: KLING & FREITAG GMBH

Junkersstraße 14

30179 Hannover

Deutschland

erklären eigenverantwortlich, dass folgende Produkte:

Art: Lautsprecher mit integrierten Endverstärkern

Modelle: CA 1001 - SP,

CA 1201 - SP,

CA 1215-6 - SP, CA 1215-9 - SP,

CA 1515-6 - SP, CA 1515-9 - SP,

LINE 212-6 - SP, LINE 212-9 - SP,

SW 112 - SP, SWi 112 - SP,

SW 115D - SP, SWi 115D - SP,

SW 115E - SP, SWi 115E - SP,

SW

118E - SP, SWi 118E - SP,

SW 215E - SP

den Anforderungen folgender Normen und Dokumente entsprechen:

EN 60065:1998;

E9 05 05 50454 004

Hannover, 23.03.2006

Ort, Datum Geschäftsführer

Akkreditiertes Prüflaboratorium: MIKES BABT PRODUCT SERVICE GmbH, Ohmstraße 2-4

D-94342 Strasskirchen

Jürgen Freitag

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 40 of 44

Page 41

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

20.2 EMV Certificate Directive 89 / 336 / EWG

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 41 of 44

Page 42

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

Das verknüpfte Bild kann nicht angezeigt werden. Mög licherweise wurde die Datei verschoben, umbenan nt oder gelöscht. Stellen Sie sicher, dass die Verknüpfu ng auf die korrek te Datei und den korrek ten Speicherort zeigt.

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 42 of 44

Page 43

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

20.3 TÜV Certificatefor USA und Canada (UL 6500)

KLING & FREITAG GMBH ©2003 - 2014 Version 5.0, 09.09.2014 Page 43 of 44

Page 44

User’s Manual LINE 212-6 - SP / LINE 212-9 - SP

KLING & FREITAG GMBH ©2003 - 2014 Version 5.1, 09.09.2014 Page 44 of 44

Loading...

Loading...