Klingenburg AS2 User Manual

AS2 Cleaning Device for

Cleaning Rotary Heat Exchangers

ENERGY RECOVERY

Page 2

1. Cleaning Options

Page 3

2. Cleaning Device

Page 6

3. Cleaning Sensors

Page 10

4. AS2 Cleaning Control System

Page 16

5. Menu navigation

Page 23

6. Troubleshooting

Page 25

7. Technical Data

1. Cleaning options

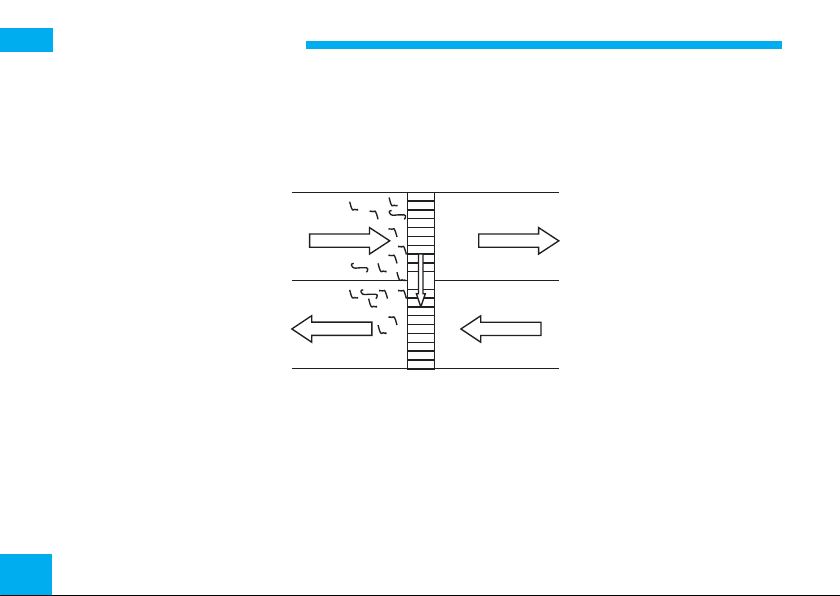

Self-cleaning effect

Under the usual conditions for the operation of ventilation systems and air conditioning systems, rotary heat

exchangers do not tend to become contaminated. This is due to the laminar airflow in the rotor mass and the

counter-current circuitry.

Counterflow Circuit:

Outside air

Supply air

Extract air

Air filtration before the rotor is only necessary for viscous, greasy and coarse contamination. As the self-cleaning effect occurs only when the rotor is rotating, idle rotors tend to become contaminated.

A cleaning cycle circuit offers a remedy here. The rotor mass is periodically rotated further in order to prevent

one-sided accumulation. This cleaning run cycle, also described as interval mode, is integrated in the rotor

control system (see control system description for the twist switch – latched controller).

2

Exhaust air

2. Cleaning device

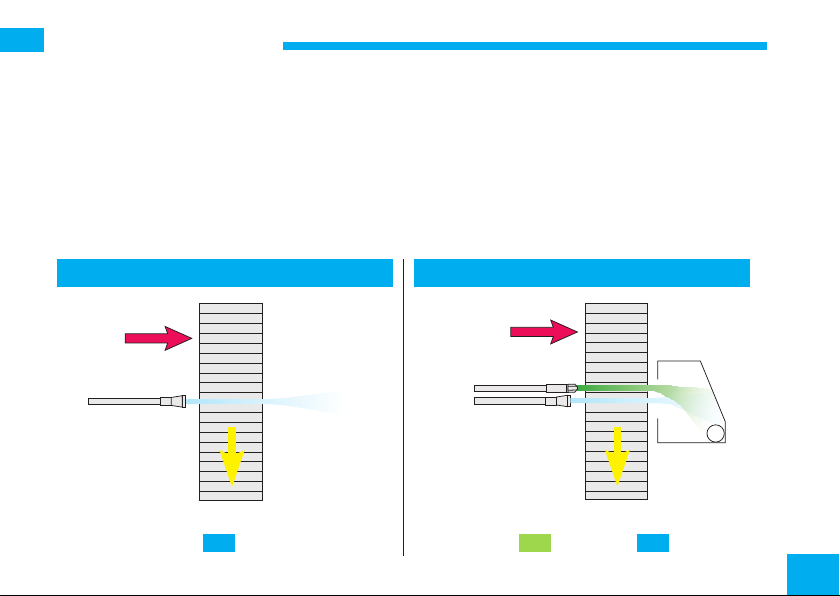

If strongly adhesive contamination is present in the air, the installation of an automatic cleaning apparatus may

be sensible. Usually, blowing out with compressed air is sufficient.

Cleaning with high-pressure warm water is necessary only with tenacious viscous and greasy contamination.

Please note that the residual water is to be blown out of the rotor following cleaning.

For water purification, a compressed air nozzle is therefore always required.

Compressed air cleaning High-pressure warm water cleaning

Exhaust air

Exhaust air

Air

Air Water Air

Water

Air

3

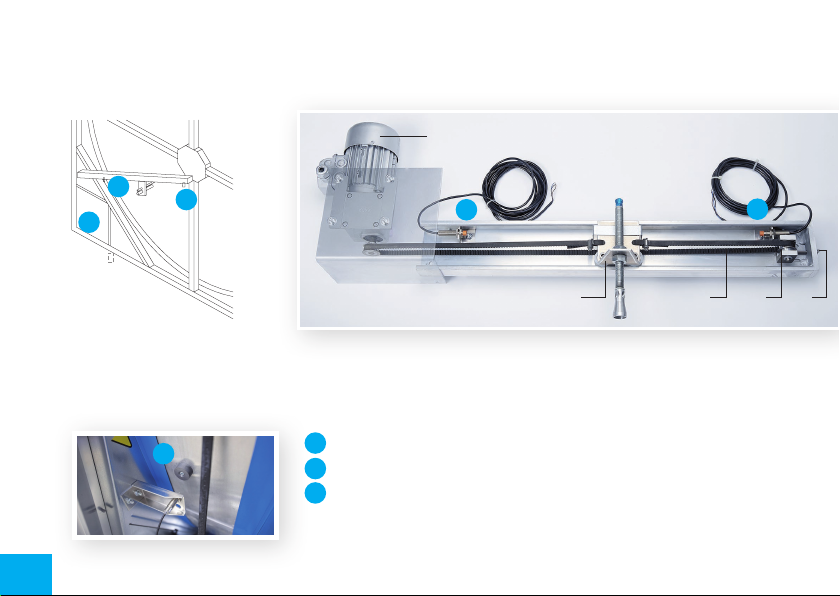

The slide is moved by an AC motor, and the power transmission is through a toothed belt.

Contactless proximity switches send an alert when the slide reaches either end position. Another proximity

switch is installed in the rotor casing and records the rotor speed.

1

B

C

A

* Sensors are installed on

the inside of the cleaning

track

A

A

4

B

C

2 543

A slide travels on a track over the radius of the rotor. The cleaning nozzles

for compressed air and possibly for water, depending on requirements, are

installed here.

A

Pulse sensor (for rotor speed) is located in the rotor casing

Rotor circumference sensor*

B

Rotor centre sensor*

C

(1) AS2 drive motor

(2) Nozzle slide

(3) Toothed belt

(4) Idler

(5) Clamping screw

Following each rotation of the rotor, the cleaning apparatus advances by the width of a nozzle stream. This

allows gap-free cleaning.

When the cleaning apparatus is switched off, the carriage is positioned on the periphery of the rotor. The

cleaning procedure can be started either by a built-in weekly time switch, by an external switch or by the Start

switch under the display.

Caution: Ensure that the heat exchanger wheel is released when starting cleaning and is turning for the whole

time the program is running. When the cleaning device is operating, the nozzle slide continuously travels to the

centre of the rotor. When the sensor reaches the centre, the air and possibly water cleaning begins.

A relay output for warm water and a compressed air valve are available. When the carriage reaches the

periphery of the rotor, the water valve relay falls and the rotor is dried with compressed air during the return

movement.

On reaching the centre sensor, the air relay switches off and the carriage travels to the starting position. During

the cleaning procedure, the rotor runs with variable speed under the control of the AS2 control system.

The external control signal (0 - 10 Volt) is not processed during the cleaning procedure, so this process should

be carried out during the idle times.

5

3. Cleaning Sensors

Manufacturer Klingenburg

Model

IP code IP67

Power supply 10-30 V=

Contact Magnet

Sensing distance <=30 mm

Connect. wire colours blue / brown / black

Usage Rotors Sorption wheel,

Connection to controller:

KR4/7

KR15 and Premium

KS 4/7/15

to cleaning device

AS2

6

MMG 120BDKX, PNP Switch

magnetic

Pulse sensor cleaning device

Clamp 4 = blue; Clamp 5 = brown; Clamp 6 = black

Clamp 6 = blue; Clamp 7 = brown; Clamp 8 = black

Clamp 4 = blue; Clamp 5 = brown; Clamp 6 = black

+Ub = brown

Sensor Pulse Tkt = black

GND = blue

Klingenburg Secatec

Steute

Connection to controller:

KR4/7

KR15, Premium

KS 4/7/15

to cleaning device

AS2

Manufacturer Steute

Model

IP code IP67 Atex

Power supply

Contact Magnet

Sensing distance <=7 mm

Connect. wire colours gr-yel / grey / brown / black

Usage Rotor, End position switch slide,

Clamp 5 = brown; Clamp 6 = black

Clamp 7 = brown; Clamp 8 = black

Clamp 5 = brown; Clamp 6 = black

+Ub = brown; Sensor centre Mit = black

Sensor circumference = black

Sensor pulse Tkt = black

EEX-RC-M 14W

Chanceover contact

Reed contact

changeover contact up to 250V

AC/DC

pulse sensor cleaning device

7

Manufacturer Schmersal

IFL-N4-12-10P

Model

PNP N/O

Inductively

IP code IP67

Power supply 10-30 Volt =

Contact Steel contact tabs

Sensing distance <=3 mm

Connect. wire colours blue / brown / black

Usage Cleaning device standard

Connection to controller

KR4/7

KR15 and Premium

KS 4/7/15

clamp 4 = blue; clamp 5 = brown; clamp 6 = black

clamp 6 = blue; clamp 7 = brown; clamp 8 = black

clamp 4 = blue; clamp 5 = brown; clamp 6 = black

Schmersal

to cleaning device

AS2

8

+Ub = brown

Sensor centre Mit = black

Sensor circumference Umf = black

GND = blue

Pepperl & Fuchs

Connection to controller

KR4/7

KR 15 and Premium

KS 4/7/15

to cleaning device

AS2

Manufacturer Pepperl & Fuchs

NBB 8-18GM50-E2-3G-3D

Model

PNP N/O

Inductively

IP code IP67Atex

Power supply 10-30 Volt=

Contact Steel contact tabs

Sensing distance <=7 mm

Connect. wire colours blue / brown / black

Usage ATEX cleaning decice, Rotors

clamp 4 = blue; clamp 5 = brown; clamp 6 = black

clamp 6 = blue clamp 7 = brown; clamp 8 = black

clamp 4 = blue; clamp 5 = brown; clamp 6 = black

+Ub = brown

sensor centre Mit = black; sensor circumference Umf = black

sensor pulse Tkt = black

GND = blue

9

4. AS2 Cleaning Control System

Functional characteristics

Processor-controlled monitoring of the cleaning sequence

Coloured display

Detailed error messages

Menu navigation

Cleaning takes place from the inside to the outside

(the contaminated water runs towards the outside)

10

Loading...

Loading...