K-Line SPEEDTILLER 2940U, SPEEDTILLER 2925U, SPEEDTILLER 2930U, SPEEDTILLER 2935U, SPEEDTILLER 2918U Operating Manual

OPERATING MANUAL

2918U- Shown

2918U

SPEEDTILLER®

2900 3 Point Linkage

Folding Wing, Non-Folding Wing

Universal Model

Serial No.

K-Line Ag ©

_______________________________________ ___________

K-Line Ag ©

Introduction

1

First Start-up

19

Identifying the machine

2

What do you need your Speedtiller® to do?

19

Tractor requirements

2

Problem Solving

20

Definitions used in this manual

2

Daily Maintenance

21

Safety Alert

3

To convert from Trailing mode to 3PL mode

22

Safety Alert Symbol

3

To convert from 3PL mode to Trailing mode

22

Signal words

3

Performing maintenance

23

Your Safety & the Safety of other Persons is

Important

4

Priming Hydraulic System

24

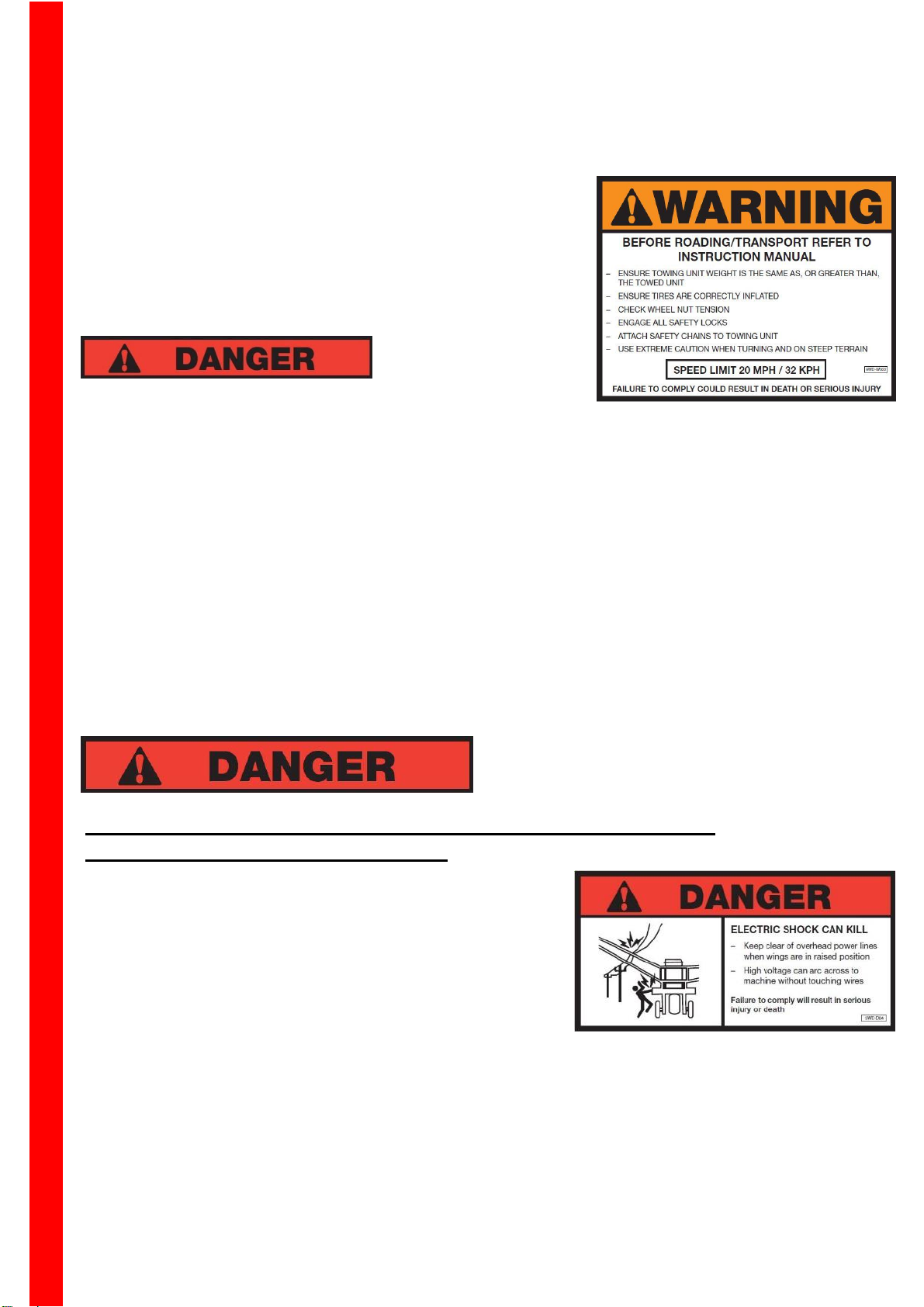

Safety sign locations

5

Lubrication of rear Roller bearings

24

Safety Decals

6

Tire Safety and Pressures

24

Safety sign care

8

Attaching jump arm to machine

25

To order Safety Decals

8

Standard Rear Roller bearing assembly

26

How to Install Safety Decals

8

Exploded view of disc arm bearing

27

Safe Operation

8

Exploded view of side coulter

28

Hitching and Un-hitching

9

Magna-Lite Wiring Harness Schematic

29

Hydraulic Hose hook-up

10

Bolt torque table Imperial

30

Electrical connection hook-up

10

Bolt torque table metric

31

Wheel transport safety locks

11

Speedtiller® Specifications

32

Transporting/Roading

11

Risk Management

34

Power lines can arc and electrocute

12

K-Line Agriculture risk assessment

36

Hydraulic System Failure

13

Warranty

37

Machine Operation

14

Warranty registration form

39

Setting & Adjustments

14

Warranty Request form

41

Speed Range

14

Depth control

15

Fore and Aft level (tilt) & correct tracking

15

Front disc gang lateral positioning sideways

adjustment

17

Side coulter adjustment

18

_______________________________________ ___________

Table of Contents

K-Line Ag has produced this manual as a guide for the operation of your machine.

While every care and precaution has been taken in compiling this booklet, K-Line Ag carries no responsibility for

errors and omissions.

This production is made available as is, without warranty of any kind expressed or implied.

K-Line Ag assumes no responsibility for damages resulting from the use of information contained herein.

This booklet is compiled to comply with the present state of the machine at the time of publication, and K-

Line Ag reserves the right to improve and revise their products at any time

K-Line Ag ©

_______________________________________ ___________

K-Line Ag ©

_______________________________________ ___________

Dear Customer

Thank you for purchasing a 2900 Three Point Linkage Universal Speedtiller®. We would

like to assure you that you have made a good choice, and will be able to rely on this

high quality piece of equipment. We ask you to follow the user’s instructions closely, as

this will ensure that you experience the benefits of using the machine without

experiencing the unnecessary down time caused by misuse.

When you receive the machine, make sure that it has not been damaged during

transportation and that no parts are missing. Contact your dealer immediately if any

parts are missing. Ensure that all components are correctly adjusted.

The return of the Warranty Registration Form (Page 41) will enable a prompt and

efficient identification of your 2900 Three Point Linkage Universal Speedtiller® and

attention to any concern you may have.

Before operating PLEASE TAKE THE TIME TO LEARN the process of operation. Do

not take the unit for granted; ease into becoming familiar with your new equipment. The

operator should be a responsible adult familiar with farm machinery and trained for this

purpose. Do NOT allow persons to operate or assemble the unit until they have read

this manual and understand how to use this machine, and observe the safety

precautions.

Never exceed the limits of this machine. If its ability to do a job, or to do so safely, is in

question - DO NOT TRY IT.

DO NOT attempt to operate this equipment under the influence of drugs or alcohol.

Remember - Your best assurance against accidents is a careful and responsible

operator.

If you have any questions not answered in this manual or require additional copies or

the manual is damaged, please contact your dealer or be free to Phone us on our Free

call Number: USA - 1800 445 6882 AUS - 1800 194 131

The team here at K-Line Agriculture trust you enjoy a good season and prove the

benefits of owning and operating a quality machine that is built to perform.

Signed:

James Larsen

General Manager

Page | 1

K-Line Ag ©

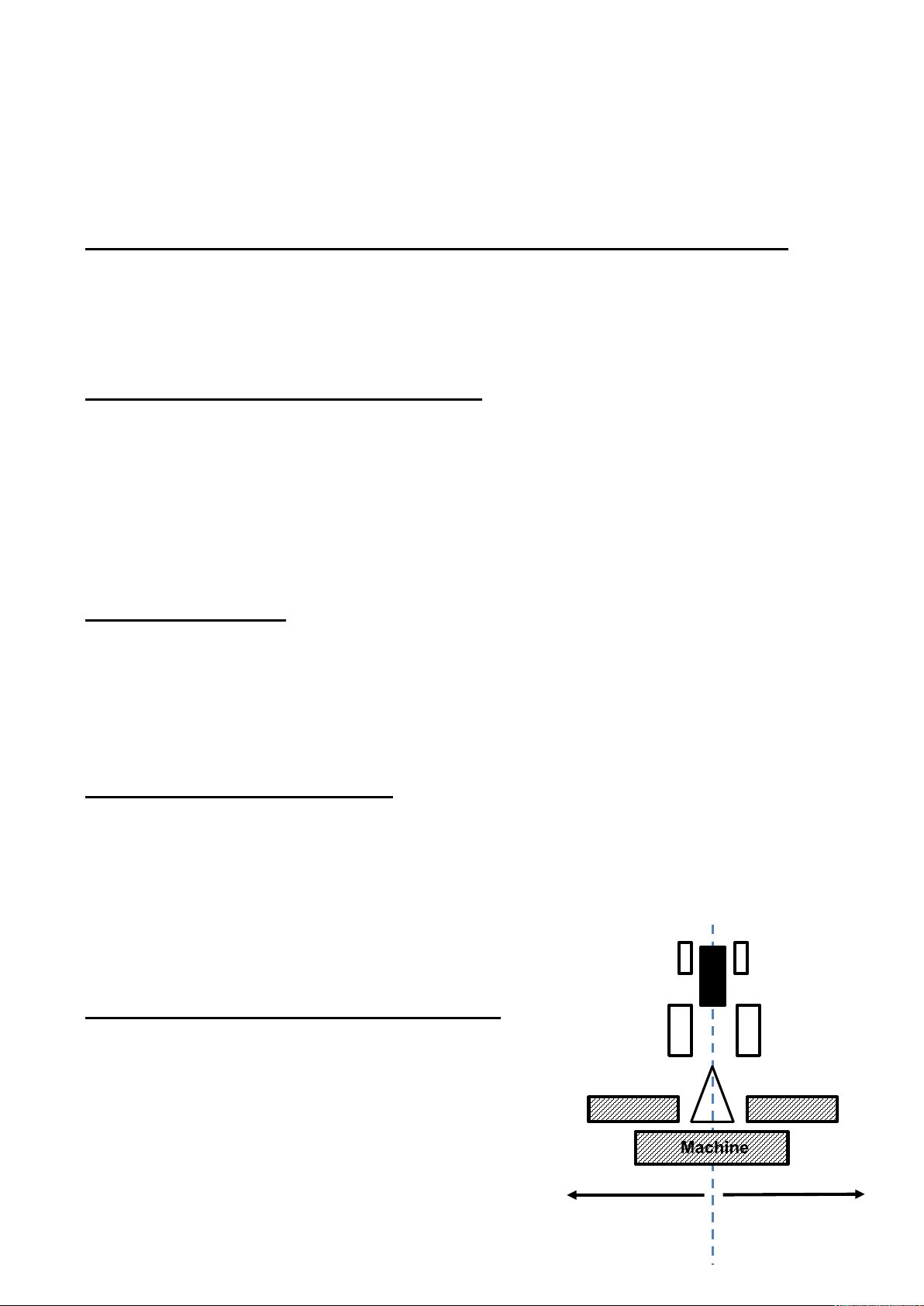

Left

Right

Hand

Hand

_______________________________________ ___________

IDENTIFYING THE MACHINE FOR REQUESTING SPARE PARTS

The machine is identified by the serial number on the metal plate on the machine. When

requesting spare parts or maintenance service, please indicate the model and number

of your equipment to ensure prompt and efficient attention.

AVAILABILITY OF GENUINE PARTS

K-Line spare parts and accessories have been specifically designed and developed for

the machines produced. We would call your attention to the fact that non-genuine parts

and accessories are not recommended by K-Line. The use of such replacement parts

frees K-Line from all liability and makes the warranty void. The installation and/or use of

non-genuine parts may, because of technical characteristics of construction, may modify

or influence the performance of the machine negatively.

AFTER DELIVERY

When you receive the machine, make sure that it has not been damaged during

transportation and that no parts are missing. Only by giving us immediate advice can the

necessary replacement parts be obtained. Ensure that all components are correctly

adjusted.

TRACTOR REQUIREMENTS

10-14 Horsepower x width of machine in feet

25-35 kilowatt x meter width of machine in meters

Check the tractor manufacturer specifications for weight and suitability of rear

mounted implements

1 x double spool

Hydraulic operating pressure 2800 PSI / 19000 KPA

DEFINITIONS USED IN THIS MANUAL

Page | 2

Side

Side

K-Line Ag ©

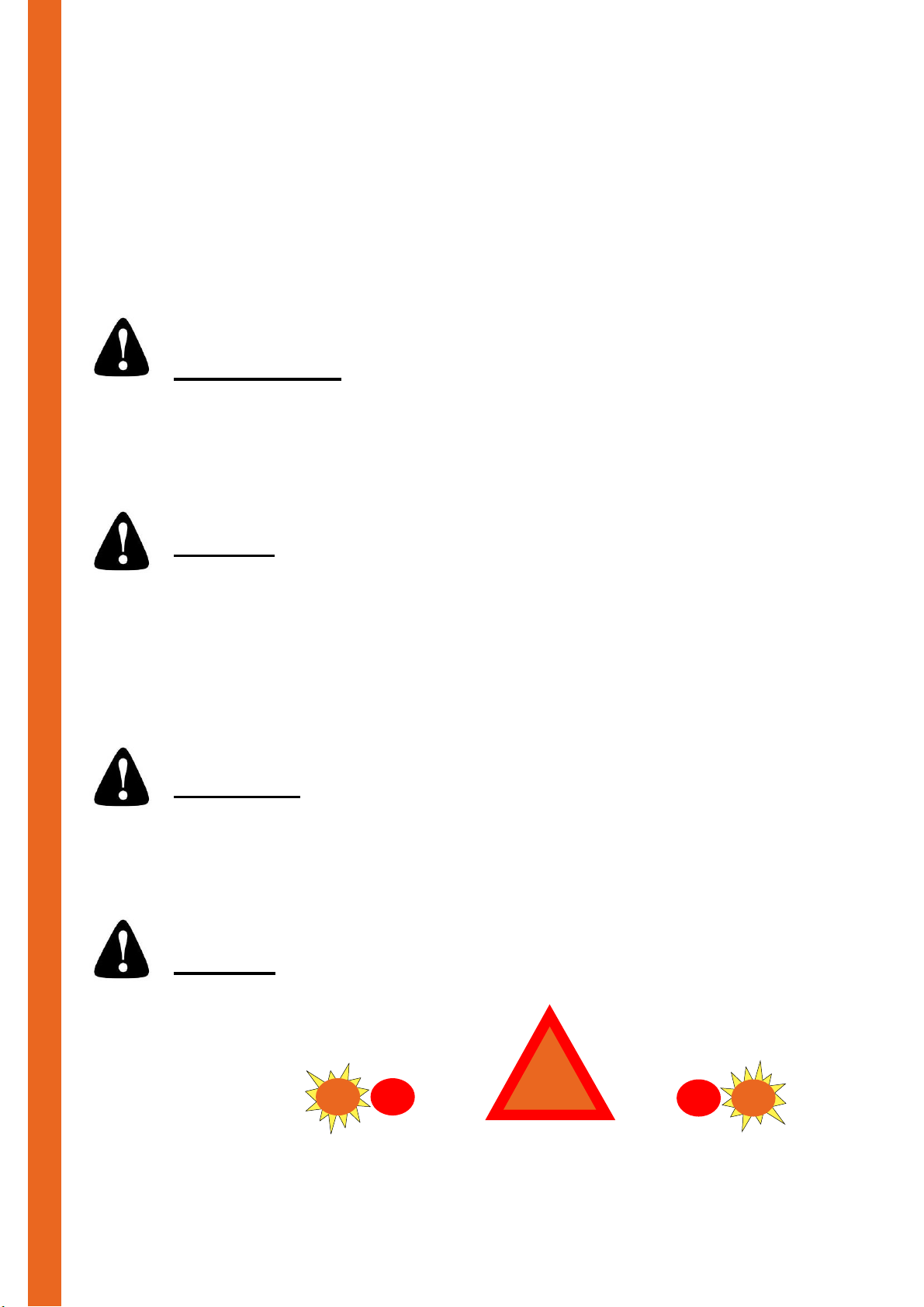

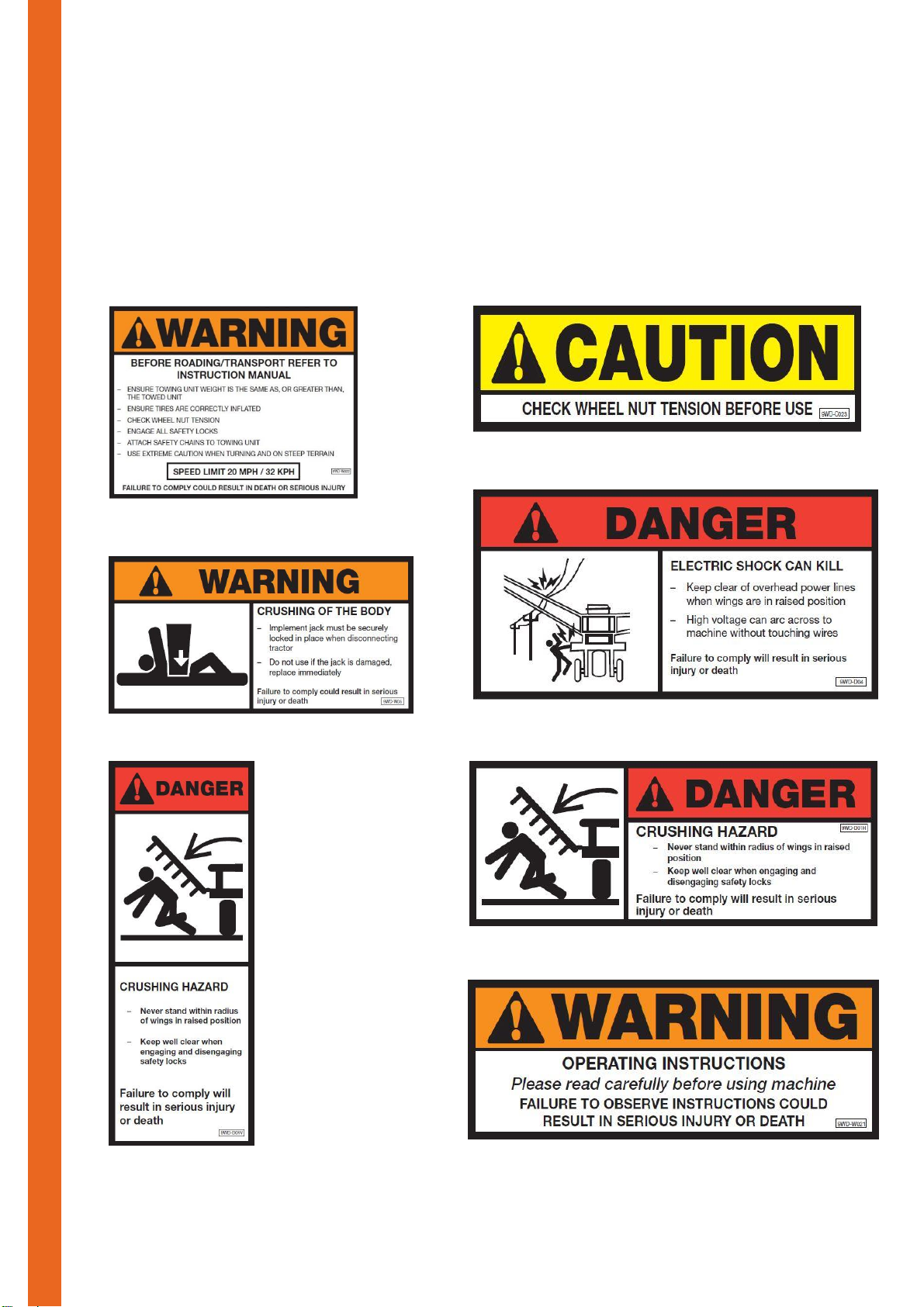

Be Familiar with Safety Decals

Read and thoroughly understand all

the ‘Safety Decals” on (Pages 8 &

9) and throughout this manual.

Safety Alert

___________________________________________________________________

Safety Alert!!

Safety…You Can Live With It

SAFETY ALERT SYMBOL

When you see this symbol, you must be

alert to the possibility of injury or death.

SIGNAL WORDS

The use of signal words DANGER, WARNING and CAUTION relating to the safety

messages. The appropriate Signal Word is selected using the following guidelines.

DANGER: indicates an imminently

hazardous situation that, if not avoided,

WILL result in serious injury or death if

proper safety measures are not taken.

WARNING: Indicates a potentially

hazardous situation that, if not avoided

COULD result in serious injury or death if

proper safety measures are not taken.

CAUTION: Indicates a potentially

hazardous situation that, if not avoided

MAY result in serious injury or death if

proper safety measures are not taken.

IT IS THE RESPONSIBILITY OF THE USER TO MAINTAIN IN AS NEW CONDITION

ALL SAFETY SIGNS AND DEVICES USED ON THIS MACHINE. FAILURE TO

OBSERVE THE INSTRUCTIONS OF THIS BOOKLET COULD RESULT IN SERIOUS

INJURY OR DEATH.

Page | 3

K-Line Ag ©

Safety Alert

___________________________________________________________________

Your safety and the safety of

other persons is important!

BE PREPARED

Wear suitable clothing – loose clothing is dangerous

Use hearing protection – loud noises can cause deafness

Use gloves and eye protection – high pressure fluids are dangerous. Release

pressure from hydraulic lines before disconnecting

BE SAFE

Attach safety chains to towing unit

Only operate machine from tractor seat

No riders on machine

Keep body well clear – machine components can suddenly move or fall

Shut down tractor while making adjustments

Do not exceed speed limit 20 mph (32 km/h) – UNBRAKED MACHINE

For road travel conform with All federal, state and local authority requirements

BE AWARE

Pay full attention to your task – distractions while operating machinery are

extremely dangerous

Check for overhead power lines

Keep clear of escaping high pressure fluid which can penetrate the eyes and skin

BE SEEN

Use approved safety signs and lighting

Page | 4

K-Line Ag ©

Figure 1

Safety Alert

H

A J K

C

G

___________________________________________________________________

Safety Sign Locations

Familiarise yourself with the safety sign location and type of warning for safety

awareness!

IMPORTANT

If safety signs have been damaged, removed, become illegible or parts replaced without

decals, new decals must be applied. New decals are available from your authorised

dealer or direct from factory.

Page | 5

K-Line Ag ©

A.

B.

C.

E.

G.

D.

F.

Safety Alert

___________________________________________________________________

SAFETY DECALS

TO REORDER FREE CALL AUS- 1800 194 131

USA- 1800 556 6882

(Re-order according to part numbers shown below)

*Affixed on every wheel

Page | 6

K-Line Ag ©

Decal

Part Number

A.

9WD-W022

B.

9WD-C023

C.

9WD-W05

D.

9WD-D04

E.

9WD-D01V

F.

9WD-D01H

G.

9WD-W021

H.

9WD-C04

I.

9WD-I01

J.

9WDW-T5

K.

9WDD-T3

L.

9WD-W024

M.

9WD-W10

N.

9WD-W01

H.

J.

I.

K.

L.

M.

Safety Alert

N.

___________________________________________________________________

Page | 7

K-Line Ag ©

Figure 2

Safety Alert

Australia: K-Line Agriculture

PO Box 340

74 Young Rd

Cowra NSW 2794

Email: sales@k-line.net.au

Freecall: 1800 194 131

___________________________________________________________________

Safety Sign Care

Keep safety signs clean and legible at all times

Replace safety signs that are missing or have become illegible

Replaced parts that displayed a safety sign should also display the current sign.

To order Safety Decals contact:

USA: K-Line Agriculture

PO Box 567

700 Division Avenue S

Cavalier ND 58220

Email: sales@k-lineag.com

Freecall: 1800 445 6882

How to Install Safety Signs:

Be sure that the installation area is clean and dry.

Decide on the exact position before you remove the backing paper.

Remove the smallest portion of the split backing paper.

Align the decal over the specified area and carefully press the small portion with the

exposed sticky backing in place.

Slowly peel back the remaining paper and carefully smooth the remaining portion of

the decal in place.

Safe Operation In field and

Transport/Roading

Read and understand your manual

Take time to familiarize yourself with the operation of

this machine, particularly the safety signs and

devices fitted to this machine.

good serviceable condition. Failure to heed may result in serious personal injury or

death. Escaping hydraulic fluid under pressure can penetrate the skin causing serious

injury. Avoid the hazard by relieving the pressure before disconnecting lines or

performing work on the system. Make sure hydraulic fluid connections are tight and all

hydraulic hoses and lines are in good condition before applying pressure to the system.

Use a piece of paper or cardboard, NOT BODY PARTS, to check for suspected leaks.

Wear protective gloves and safety glasses or goggles when working with hydraulic

systems. DO NOT DELAY! If an accident occurs, see a doctor familiar with this type of

injury immediately. Any fluid injected into the skin or eyes must be treated within a few

hours or gangrene may result.

Page | 8

Hydraulic fluid escaping under pressure can have sufficient

force to cause injury. Keep all hoses and connections in

K-Line Ag ©

OIL under high pressure COULD result in

serious injury or death

Figure 4

Figure 3

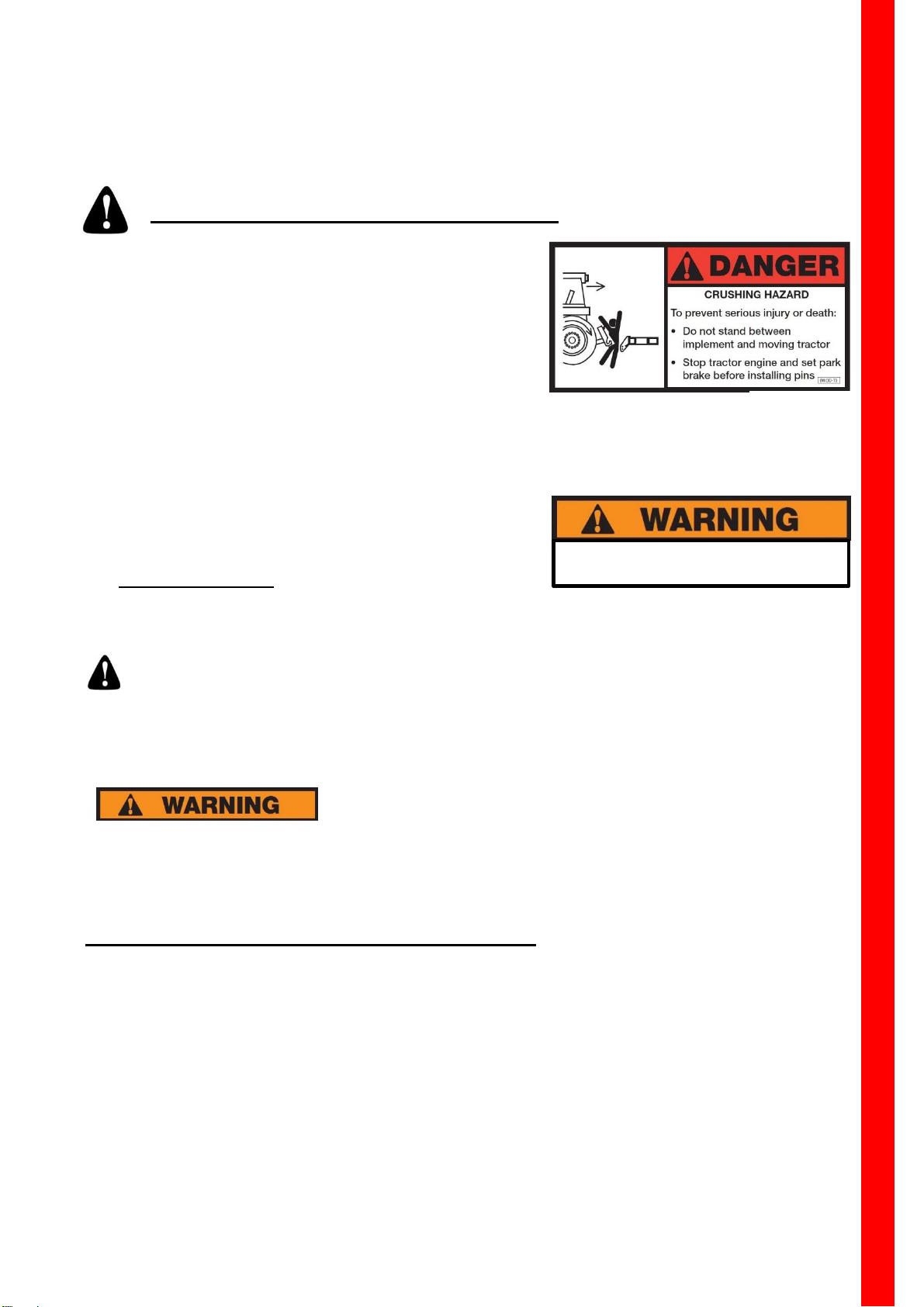

Safe Operation

___________________________________________________________________

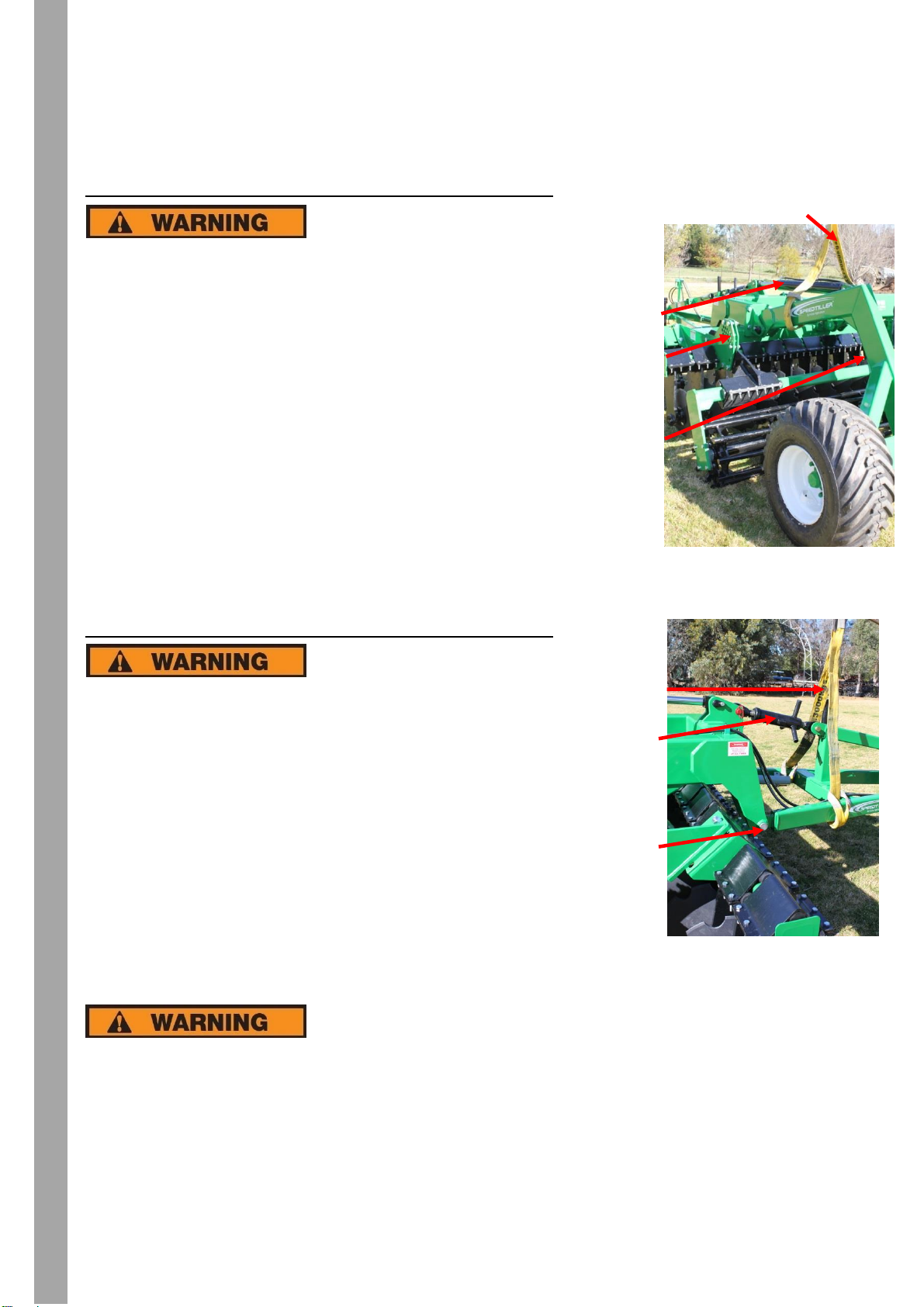

Hitching and Un-hitching (3PL) Mode

1. Keep well clear when backing up to machine. (see

figure 3)

2. Shut down tractor.

3. Secure all 3 Point Linkage safety locks & lock

drawbar pin in place.

4. Lock up 3 Point Linkage anti sway stabiliser system

on tractor.

5. Both Linkage arms must be set level

6. Plug in electrical lead to tractor connection (if

provided)

Hydraulic models

1. Clean all hydraulic couplings.

2. Hoses are coded according to function. (Page 10)

3. Beware of high pressure fluid. (see figure 4)

4. Release pressure from system before disconnecting.

5. Plug in hoses to respective remote ports.

6. Check hydraulic cylinders are fully primed to avoid

serious injury or death. (Page 10) for priming hydraulic

system

Hitching and Un-hitching (Trailing Mode)

1. Keep well clear when backing up to machine. (see

figure 3)

2. Shut down tractor.

3. Secure & lock drawbar pin in place.

4. Install safety chain by crossing the chains under the

tongue and secure to the drawbar hitch frame of the

tractor.

5. Clean all hydraulic couplings.

Page | 9

K-Line Ag ©

Extend

Retract

Hose Grip color codes

Color

Function

Red

Wheel lift

Figure 8

Figure 7

Figure 6

Figure 5

Safe Operation

Figure 9

___________________________________________________________________

6. Hoses are coded according to function. (Page 10)

7. Check tire pressure and wheel tension

8. Beware of high pressure fluid. (see figure 6)

9. Release pressure from system before

disconnecting.

10. Plug in hoses to respective remote ports.

11. Plug in electrical lead to tractor connection

12. Release implement jack & store

13. Jack must be securely locked in place when

disconnecting.

If implement jack is damaged DO NOT USE, replace

immediately, or severe bodily harm may result. See Figure

7.

14. Check hydraulic cylinders are fully primed to avoid

serious injury or death. (Page 24) for priming

hydraulic system

Hydraulic Hose Hook up (Accessory)

For ease of hook up, hose grip handles

are color coded.

The same color is used for both hoses on

each circuit

To distinguish between EXTEND and

RETRACT grips are marked according

to Figure 8

Electrical Connection Hook up

(Accessory)

Ensure tractor and machine electrical connections are compatible

Plug lead into tractor terminal

Test lighting prior to road travel (power not required for field work)

Page | 10

K-Line Ag ©

Figure 11

Sway Hazard:

IN DEATH OR SERIOUS INJURY.

Figure 10

Lift cylinder

Safe Operation

Figure 12

___________________________________________________________________

Wheel Lift safety locks

Lift cylinder lock channel type. (See figure 10)

Fully extend lift cylinder/s

Remove from storage point

Secure lock channel on cylinder/s shaft, with

lynch pins provided.

To release lock channel from cylinder/s, lift

hydraulics

When not in use always place lock channel

in storage point provided.

Transporting/Roading 3PL Mode

1. Check the tractor manufacturer specifications

for weight and suitability of rear mounted

implements

2. lock up 3 Point Linkage anti sway stabiliser

safety lock

channel

system on tractor

3. Ensure tractor tires are correctly inflated

4. Ensure safety locks and pins are engaged.

5. Keep brake pedals latched together at all times

6. Plan your route to avoid heavy traffic

7. Observe bridge load ratings

Transporting/Roading Trailing Mode

8. Ensure towing unit weight is the same as or greater

than the towed unit.

9. Lockout tractor drawbar swing mechanism

10. Ensure tires are inflated to see page 25

11. Check wheel nut tension see page 25

*NB(see page 25 for wheel nut re-tensioning

sequence).

Lock out draw bar swing mechanism.

FAILURE TO COMPLY COULD RESULT

12. Ensure safety locks are engaged

13. Ensure safety chains are attached to towing unit.

Page | 11

K-Line Ag ©

Figure 14

Figure 13

Safe Operation

___________________________________________________________________

14. Drawbar must be in fixed position, not swinging.

(figure 13)

15. Keep brake pedals latched together at all times

16. Plan your route to avoid heavy traffic

17. Observe bridge load ratings

TIP OVER HAZARD this is an unbraked implement. Use

extreme caution when turning and on steep terrain.

Maximum towing speed is 20mph (32km/hr).

DO NOT EXCEED AT ANY TIME.

(figure 13)

Never transport machine on public roads

without complying with Federal and State laws

and local regulations governing the safe

movement of farm machinery.

Comply with state law warning light regulations.

POWER LINES CAN ARC AND ELECTROCUTE WITHOUT

COMING IN DIRECT CONTACT!!!

Consult electricity authorities and all relevant energy

companies to determine safe working distances from

overhead power lines etc. BEFORE operation of this

machine.

Ensure all operators are familiar with this manual

and all safety devices and features of the

machine.

Take every reasonable precaution as is

commonly expected in this industry and in the

operation of the machine.

Maintain the machine at all times in a condition

that is safe to operate, and ensure it complies

with any relevant safety acts of parliament,

government authorities and regulations.

Page | 12

K-Line Ag ©

Safe Operation

___________________________________________________________________

In the event of hydraulic system failure or hydraulic hose rupture,

you must follow the steps set out below.

Escaping Hydraulic fluid is dangerous and can cause serious injury or death.

Step 1: Prepare for shutdown.

Immediately return hydraulic leaver to neutral position.

Stop operating machine.

Step 2: Shutdown the equipment.

Use hydraulic leaver to lower machine to ground (if in raised position).

Step 3: Isolate the equipment.

Freely operate remote levers to release residual pressure from system.

If tractor so equipped place levers in float position.

Shut down tractor

Step 4: Apply the lockout / tagout device.

Disconnect all hydraulic hoses from tractor remotes.

Place lockout or out of service tags on all hoses.

Step 5: Control the stored energy.

Ensure no hydraulic pressure remains in system, slowly release bleed tap (if

equipped), or slightly loosen one hydraulic connection on each circuit to allow

any remaining fluid under pressure to be released.

Step 6: Verify isolation of equipment.

Double check the steps and verify that the equipment has been shut down and has

the lock and tag labels evident. Have repairs carried out and defective parts

replaced. Do not re-connect to tractor or other hydraulic power source, until system

has been fully tested.

Page | 13

K-Line Ag ©

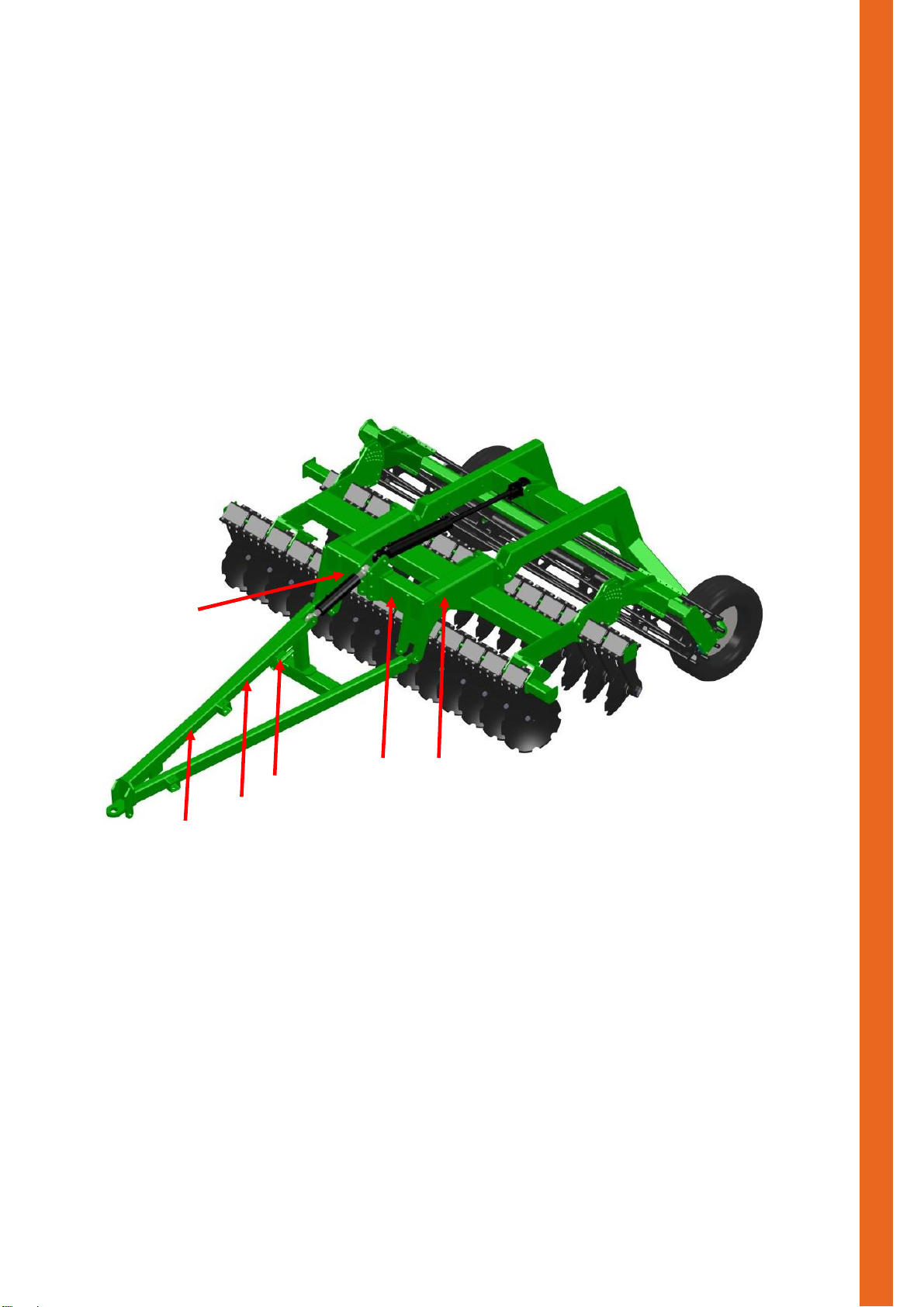

Depth Control

Regulates depth via rear roller

Fore & Aft Tilt

Controls Tracking in line and

affects ground disturbance.

Front Disc Gang

Lateral positioning

Controls ground disturbance.

Side Coulter

adjustment

Controls furrow filling and levelling.

Four Main Adjustments

Machine Adjustments

___________________________________________________________________

MACHINE OPERATION

The Speedtiller® is a high performer in a wide range of conditions, but you will need to

know how to set up your new machine to gain the full benefits.

Adjustments

Tables

First Start-Up –

What do you need your Speedtiller® to do? -

Problem Solving-

SETTINGS & ADJUSTMENTS

Support machine on suitable jack stands or,

Lower machine to ground level.

Shut down engine.

Speed range

5-9 mph (8-15 km/hr).

Speed variable to suit conditions.

Greater activity occurs at higher speeds.

Before adjusting in the field YOU MUST:

Page | 14

To work deeper adjust roller upwards.

Insert pin in

requirement

Figure 15

Machine Adjustments

Fore and Aft

tilt adjuster

Figure 16

To work shallower adjust roller downwards.

For initial depth setting start shallow.

Operate machine for short distance and stop.

Adjust depth control in small increments to

Ensure both wing modules operate at same

Fore and Aft or tilt level affects how machine

tracks, straight tracking in line gives superior

ground disturbance, better trash flow and more even

disc wear.

In general, start with front row of discs working ¾”

(20mm) higher than back row of discs.

After initial setting run machine at normal operating

speed and stop.

Stand behind machine to check if machine is tracking

correctly. If adjustment is needed see figure 16

To adjust Fore and Aft Tilt (Trailing mode)

Rotate tilt adjustment to suit and lock See figure….

After initial setting run machine at normal operating

speed and stop.

Stand behind machine to check if machine is tracking

correctly. If adjustment is needed follow figures 17 &

18 on following page

To adjust Fore and Aft Tilt (Linkage mode)

K-Line Ag ©

___________________________________________________________________

Depth Control

Rear roller controls depth,

achieve required depth.

depth. (folding wing models)

hole

according to

depth

Fore and Aft, Tilt & tracking in line

IMPORTANT

To adjust Fore and Aft Tilt (Trailing mode)

See Page 16 to adjust for correct tracking in line

Turn top link to adjust

Page | 15

K-Line Ag ©

Tracking to the left

Lower front of module or machine

Tracking to the Right

Lift front of module or machine

Figure 18

Figure 17

*NB Ensure both wing modules are the same depth

Rear module tilt has greater effect on the tracking

in line

Right

Hand Side

Left

Hand Side

Left

Right

Hand Side

Hand Side

Left

Right

Hand Side

Hand Side

Machine Adjustments

___________________________________________________________________

*NB for tracking in line both wing modules must be

set at the same depth (folding wing models)

Page | 16

K-Line Ag ©

B

Direction of travel

Figure 19 Top View

A

A

Adjustable

Move front

Move front

B.

Ridge

Figure 20 Rear View

Adjust so the

Adjustable

Front Gang

Fixed

A

Machine Adjustments

___________________________________________________________________

Front Disc Gang Lateral Positioning

*NB- Be sure machine is tracking in line before attempting to make this adjustment page 19-

20.

The Disc positioning system is used for maximum

soil disturbance and reduced ridging. Adjustment can

be made for more precise weed control, soil

disturbance and to compensate for disc wear.

Start with factory settings

Test run at normal operating speed and stop

quickly.

Check for ridges of undug soil. (follow ridge into

machine)

For ridges where front and rear discs throw away

from each other see figure 19 at point (A), front

gang should be adjusted to the right. Figure 20

shows correct adjustment to remove ridge.

For ridges where front and rear discs throw

towards each other see figure 19 at point (B),

front gang should be adjusted to the left.

Only adjust in small increments ½” or 12mm

Re-check in hard soils as jump arms tend to flex

more.

Remember, Full ground disturbance starts at 2

½” 60mm

gang left to

remove

ridges at

Front Gang

gang right to

remove

ridges at A.

See figure 20

Page | 17

discs on

Rear

Gang

rear disc cuts

just down on

the side of the

front disc cut

discs on

K-Line Ag ©

Height adjustment

Fore & Aft

adjustment

Angle

adjustment

Slide adjuster

linkage

Right

Left

Slide

Bolts

Figure 21

Figure 22

Machine Adjustments

___________________________________________________________________

To Adjust Lateral disc gang position

Loosen main retaining bolts on slide mechanism

(See Figure 21)

Turn slide adjusting linkage to adjust to right or

left (see figure 21)

Lock slide adjusting linkage and tighten main

retaining bolts (380ft lb / 500nm)

Side Coulter Adjustment

Series of holes are provided for height adjustment –

(see Figure 22)

Adjust coulter on left hand side of module for

optimum furrow filling.

For excessive trash conditions

Move coulter forward and angle outwards

Raise coulter.

Move coulter to the outside of supporting angle

for more clearance.

setting

Page | 18

K-Line Ag ©

Comments

Pg

Before starting

Set machine on level surface

Ensure both Tractor 3 Point

Linkage arms are correctly

adjusted for level working.

Adjust roller 1” or 25mm above

surface.

Preliminarily adjust tilt

approximately ¾” or 20mm higher

at front.

Run at operating speed & check

adjustments in this order.

Tracking in line.

Lateral front disc adjustment

Depth (adjust deeper gradually).

Side coulter setting

15

15/16

15/16

17

15

18

Comments

Pg

Mulch in trash for humus

building

Shallower and faster better for

mulching.

Shallower gives more trash flow.

May have to go slower if trash

content is heavy.

Adjust side coulter if necessary

15

18

Full ground disturbance for

better weed control, trash

flow & seed bed

preparation.

Pay Specific attention to settings &

operating conditions

Full ground disturbance starts at 2

½” 60mm

Cross working 15° off line is best to

level soil and give better trash flow.

Soil moisture & conditions.

What do you need your Speedtiller® to do?

First Start-up

Machine Adjustments

___________________________________________________________________

Page | 19

K-Line Ag ©

Depth setting- ensure both wing

modules are the same depth. This

can affect tracking in line.

Tracking in line (tilt)

Lateral disc gang adjustment.

Side coulter settings.

15

15/16

17/18

18

Work Soil Deeper

Gradually lower depth settings.

Slower operating speed.

15

14

Comments

Pg

Need more disturbance &

weed control

Check these adjustments in sequence-

Tracking in line.

Lateral disc gang adjustment.

Lower depth control settings

(gradually).

15/16

17/18

15

Machine Blocking in loose

soil with heavy trash

Work at an angle 15° off line.

Lift front disc gang to work

shallower, ensuring rear disc gang

is operating deep enough to drive in

the soil.

Slow down to allow time for trash to

move through machine.

Adjust side coulter (common reason

for blockage).

Coulter Adjustment alternatives-

Lift up.

Move forward.

Angle coulter outwards.

Move coulter to outside of support

member to give better to give better

clearance for trash flow.

18

18

Plugging in Wet Soils

Raise working depth

Increase speed

Give soil more time to dry out.

15

Problem Solving

Cont…

Machine Adjustments

___________________________________________________________________

Page | 20

K-Line Ag ©

Disc bolts –

hours

Figure 23

Figure 24

Disc Arm Locating Bolts –

Performing Maintenance

Front Row

Left Hand

Back Row

Right Hand

Figure 25

Figure 26

___________________________________________________________________

Daily maintenance check for

optimum performance

Before Starting Work:

1. Check wheel nut tension & tire pressure page 25

2. Check all pivot pins are fastened and anchor

bolts are correctly tensioned. Follow tension

specification on Pages 31-32

3. Check discs and disc bolt tension to specified

torque 250ft lb / 340nm

4. Check for damaged, worn and fatigued parts.

Have machine repaired if necessary.

5. Ensure all appropriate safety decals are securely

attached to machine – Refer to Pages 5-8

6. Check hydraulic system is fully primed – see

Page 23

7. Check all safety mechanisms are in place and

operating correctly

8. Lubricate rear roller bearings – Refer to Page 24

9. Instruction manual has been read, understood

and stored with machine.

*NB All steps set out in MACHINE OPERATION (page 14-18) must be performed

after replacing discs.

check first 10

Disc Arm Identification (Rear view)

Page | 21

Top

plate bolt tension

200ft lb / 280nm

Disc bolt tension

250ft lb / 340nm

check first 10hrs of operation

TO CONVERT FROM TRAILING MODE TO 3PL MODE

Main lift

ram

Attachment

pins

Rear

assembly

Tilt

Link

Sling

Attachment

Pins

Sling

Performing Maintenance

Figure 25

Figure 26

TO CONVERT FROM 3PL MODE TO TRAILING MODE

ARE BEING LIFTED INTO PLACE! SERIOUS INJURY MAY

OCCUR IF SAFETY PRECAUTIONS ARE NOT FOLLOWED.

K-LINE AGRICULTURE carries no responsibility for any personal injury, machine

damage, excessive wear, and failure of parts, related to improper use, adjustment or

lack of routine maintenance, as set out in this Operators Manual.

Any warranty given is at the sole discretion of K-LINE AGRICULTURE.

K-Line Ag ©

___________________________________________________________________

- Failure to observe instructions could result in serious

injury or death

1. Lower machine to ground.

2. Release oil pressure from system (using tractor hydraulics.)

i.e. rear wheels to rest only under their own weight on the

ground.

3. Ensure implement jack is installed correctly.

4. Remove tilt adjust link, see figure 8.

5. Remove lift ram & hoses. Store.

6. Attach sling to front drawbar as shown in figure 8.

7. Using suitable lifting equipment, remove pins as shown in

figure 8.

8. Remove drawbar. Store.

9. Attach sling to rear wheel assembly as shown in figure 9

10. Using suitable lifting equipment, remove pins as shown in

figure 9.

11. Store wheel assembly.

12. Check all bolts are tensioned correctly and pins are in place.

13. Machine is now converted and ready to be used as 3PL mode.

wheel

- Failure to observe instructions could result in serious

injury or death

1. Set machine on ground

2. Attach sling to front drawbar as shown in figure 26

3. Using suitable lifting equipment, set drawbar in place and

install attachment pins

4. Attach implement jack to front of drawbar

5. Attach tilt adjustment link. See figure 26

6. Attach sling to rear wheel assembly as shown in figure 25.

7. Using suitable lifting equipment, set rear wheel assembly in

place and insert attachment pins

8. Install lift ram as shown in figure 25

9. Attach hydraulic hoses to mounting cleats

10. Check all bolts are tensioned correctly and pins are in place.

11. Machine is now converted & ready to be used in trailing

mode.

KEEP WELL CLEAR OF

MACHINE PARTS AS THEY

Page | 22

Adjust

K-Line Ag ©

Performing Maintenance

___________________________________________________________________

Performing Maintenance

Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

- Make sure maintenance area has plenty of ventilation. Beware exhaust fumes may

cause asphyxiation.

Prior to commencing work, IDENTIFY ALL HAZARDS! Use control measures to

eliminate these dangers.

Use blocks to support frame of machine on level area free of obstruction.

Always use a safety support and chock the wheels.

Never use an implement jack to support the machine.

Never work under raised machine unless all components are securely positioned and

locked.

Engage all safety transport locks, chock wheels and front drawbar for temporary

service if machine is in free standing mode.

A fire extinguisher and first aid kit should be kept readily accessible while performing

maintenance on this equipment.

Follow the torque chart in this manual when tightening bolts and nuts.

Refer to bolt torque chart for head identification marking.

Always replace bolts with specified grades.

Where replacement parts are necessary for periodic maintenance and servicing,

genuine factory replacement parts must be used to restore your equipment to original

specifications.

If equipment has been altered in any way from original design, the manufacturer does

not accept any liability for warranty or personal injury.

Replace all shields and guards after servicing before moving.

After servicing, be sure all tools, parts and service equipment are removed.

The machine is identified by the serial number on the metal plate on the machine.

When requesting spare parts or maintenance service, please indicate the model and

number of your equipment to ensure prompt and efficient attention.

K-Line Agriculture spare parts and accessories have been specifically designed and

developed for the machines produced. We would call your attention to the fact that

non-genuine parts and accessories are not recommended by K-Line. Use of nongenuine parts and accessories releases K-Line from all liability and makes the

warranty void. The installation and/or use of non-genuine parts may, because of

technical characteristics of construction, may modify or influence the performance of

the machine negatively.

Hydraulic fluid escaping under pressure can have sufficient force to cause

injury. Keep all hoses and connections in good serviceable condition.

Failure to heed may result in serious personal injury or death. Escaping

hydraulic fluid under pressure can penetrate the skin causing serious

injury. Avoid the hazard by relieving the pressure before disconnecting

lines or performing work on the system. Make sure hydraulic fluid

Page | 23

K-Line Ag ©

Figure 28

Figure 27

- Always cage tires before seating

Failure to comply could result in serious injury or

Tire pressure

35PSI / 250KPA

Wheel nut tension

500lbs / 677nm

Performing Maintenance

___________________________________________________________________

connections are tight and all hydraulic hoses and lines are in good

condition before applying pressure to the system. Use a piece of paper or

cardboard, NOT BODY PARTS, to check for suspected leaks. Wear

protective gloves and safety glasses or goggles when working with

hydraulic systems. DO NOT DELAY! If an accident occurs, see a doctor

familiar with this type of injury immediately. Any fluid injected into the skin

or eyes must be treated within a few hours or gangrene may result.

Priming Hydraulic System

Fully extend and retract hydraulic cylinders

Repeat 3-4 times and hold lever extended each way for 10 to

15 seconds to release air from the system.

Lubrication of Rear Roller Bearings

Standard Rear Roller Bearings:

One point is provided for each bearing. Two pumps

of grease every 20 hours of operation.

Tire Safety & Pressures

Always cage tires before seating beads. (see

figure 27 & 28)

Never exceed a stated pressures when seating

beads.

Do not attempt to mount a tire unless you have

the suitable equipment and experienced

personnel.

Inflating tires can be dangerous. Always stand to

the side when inflating. (27 & 28)

Load ratings of replacement tires should meet or

exceed weight requirements.

Correct pressure is 35PSI / 250KPA

Before mounting wheel to machine, check all hub

and rim contact surfaces are undamaged and

free of paint, dirt and grease.

Lubricate wheel stubs with standard viscosity oil.

Tension wheel nuts to 500ft lbs / 677nm.

For field operation: Re-tension after first, fifth,

then every fifty hours of operation.

For road travel re-tension first 3miles (5kms),

10miles (15kms), and thereafter at 25miles

(40kms) intervals

beads.

- Never exceed stated pressures when

seating beads

Page | 24

K-Line Ag ©

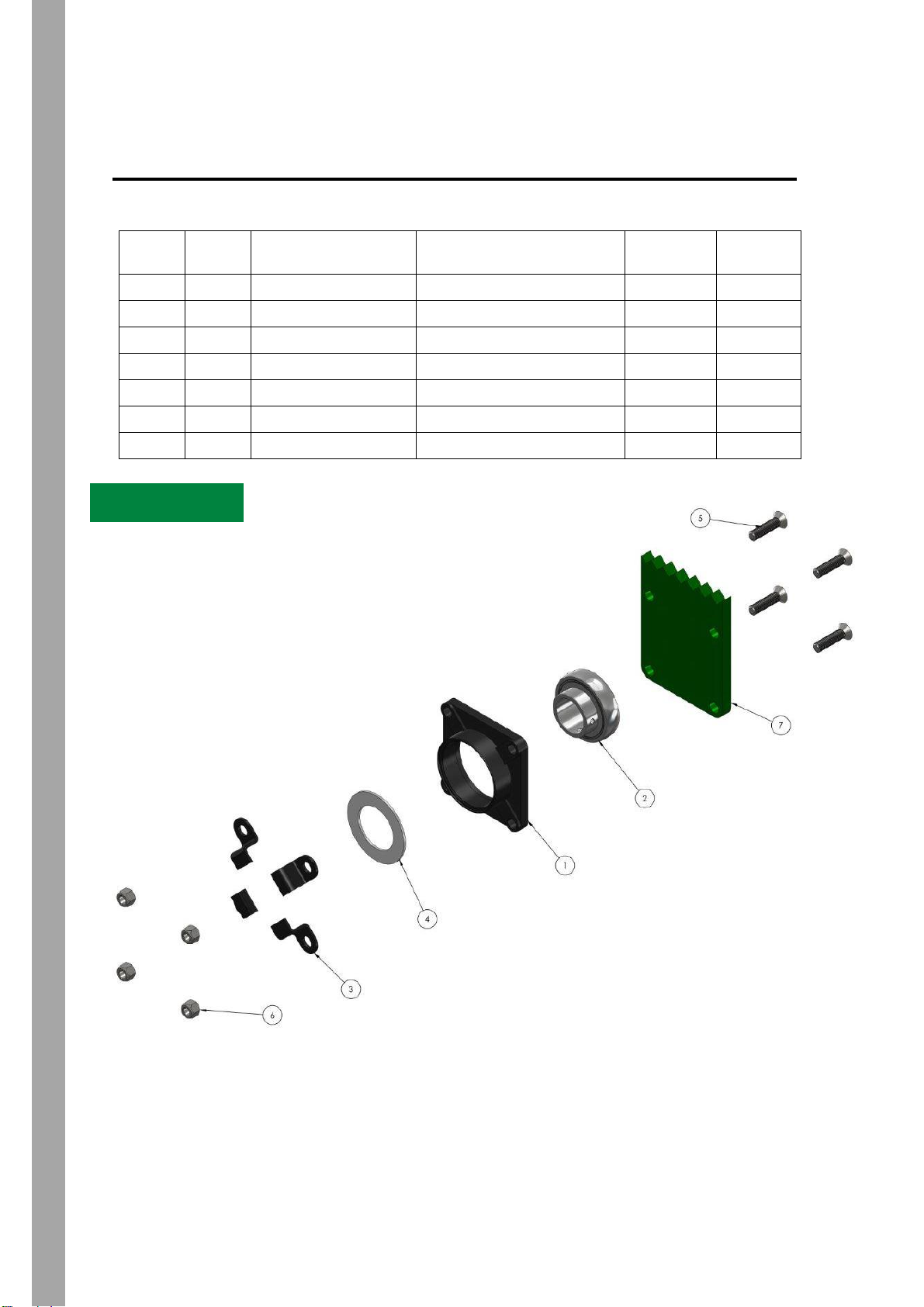

Item

QTY.

Part

Current Part No.

Weight

(kg)

1

1

Complete Jump Arm Back (shown)

29000JAAR1

44.95

1 1 Complete Jump Arm Front

29000JAAF1

44.95

2

Jump Arm only Back

29000JAWR1

36.75

2

Jump Arm only Front

29000JAWF1

36.75

3

1

2900 Torsion Rubber (Requires Set of

4)

29000JAX23

0.58

4 1 2900 Jump arm Top Hat

29000THP08

4.78

5

6

2900 Jump Arm Bolt Kit - 6 x M12 Set

screw with conelok nut

29000JABK

0.54

5

1

2900 Jump Arm Bolt Kit - 1 x M12 Set

screw with conelok nut

29000JABK

0.09

6

4

2900 Disc Bolt Kit - 4 x Plough bolt with

nut and spring washer

29000PLBK

0.24

6

1

2900 Disc Bolt Kit - 1 x Plough bolt with

nut and spring washer

29000PLBK

0.06

7 1 18" x 5mm Scalloped Disc

9SD1805S

9.8

7 1 20" x 5mm Scalloped Disc

9SD2005S

10

7 1 22" x 5mm Scalloped Disc

9SD2205S

10.21

7 1 22" x 6mm Scalloped Disc

9SD2206S

10.9

7 1 24" x 6mm Scalloped Disc

9SD2406S

12.5

Performing Maintenance

Figure 29

Diagram F81

___________________________________________________________________

Attaching Jump Arm to Machine

Lift jump arm into position

Loosely attach top clamp plate with rear clamp plate bolt &

conelock nuts. (Just start by a few threads only & leave arm hanging loosely)

Slide in torsion rubbers

Loosely attach front clamp bolts & conelock nuts

Check positioning

Tension all clamp bolts with conelock

nuts provided.

Back Jump Arm - front view

Page | 25

K-Line Ag ©

ITEM

NO.

QTY.

PART NUMBER

DESCRIPTION

WEIGHT

RRP

1 1 9BHF212

F212 Bearing housing

2.33

$ 144.00

2 1 9UC2123LS

UC212 Bearing

2.2

$ 110.00

3 4 9RBCO1

Bearing clip

0.13

$ 7.60

4 1 9PWMO4

Poly washer

0.03

$ 16.00

5 4 9M16065Z8CS

M16 x 65mm Socket Screw

0.1

$ 3.42

6 4 9M16CLZ

M16 Prevailing Torque Nut

5.605

$ 0.65

7

1

NA

NA

Rear Roller Bearing and dust protector- (Standard equipment)

Diagram F84

Figure 30

___________________________________________________________________

Page | 26

K-Line Ag ©

Item

QTY.

DESCRIPTION

PART NUMBER

RRP

1 1 2900 Jump arm bearing housing

29000JAM02

2 1 M85 Bearing housing cap

29000JAM05

$15.00

3 1 2900 Bearing Spacer

29000JAM03

$7.90

4 1 M40 Locking Washer

9MB08

$12.50

5 1 M40 Locking Nut

9KM08

$14.80

6 1 2900 Jump arm Seal

9SS508011ML

$15.00

7

1

6208 Bearing

9B62082RS

$10.00

8 1 DAC 4080 Bearing

9DAC4080

$20.00

9

1

MRV2090 Seal

MRV2090

$9.00

10 1 2900 Disk stub

29000JAW02

$65.00

Diagram F82

*NB- Spindle

torque tension

360ft lb / 500nm

Exploded View of Disc Arm Bearing

Performing Maintenance

Figure 31

___________________________________________________________________

Page | 27

K-Line Ag ©

ITEM

NO.

QTY.

PART NUMBER

DESCRIPTION

WEIGHT

RRP

1 1 2900LSSWM1

2900 Spray Stopper Mount

7.97

$185.00

2 1 2900LSSWA1

2900 Spray Stopper Angle

6.09

$105.00

3 1 2900LSSWS1

2900 Spray Stopper Shaft

1.78

$ 26.00

4 1 29000SSWM1

2900 Spray Stopper Hub

0.97

$ 78.00

5 1 29000JAX215

2900 Short Rubber

1.2

$ 16.00

6 1 29000SSWT1

2900 Spray Stopper Top Hat

3.32

$ 36.00

7

1

9CD2405HT

24" Coulter

7.61

$ 82.00

8 1 9SW62-40-1.6

ISC gal seal protector

0.02

$ 7.00

9 1 9MW50M4011

ISC Seal spacer

0.06

$ 4.20

10 1 9SW67.8-52-1.5

IDC bearing spacer

0.02

$ 7.50

11 1 29000SSPO1

Coulter hub cover

0.21

$ 14.00

12 1 9DRT396837

Bearing

0.18

$ 28.00

13-15 1 29000SSBKD

2900 Spray Stopper disc

bolt Kit

0.33185

$ 6.00

16-24 1 29000SSBK1

2900 Spray Stopper Mount

bolt kit

55.66998

$ 13.83

25 1 29000BWP01

Bearing washer

0.13

$ 5.10

26 1 9M16040Z8SS

M16 x 40mm Set screw

0.25414

$ 2.10

27

1

9TC50-65-8_50x65x8 oil seal

Oil Seal

0.12

$ 3.13

Performing Maintenance

Exploded View of Side Coulter

Diagram F83

Figure 32

___________________________________________________________________

Page | 28

K-Line Ag ©

Figure 41

Figure 33

Performing Maintenance

___________________________________________________________________

Page | 29

K-Line Ag ©

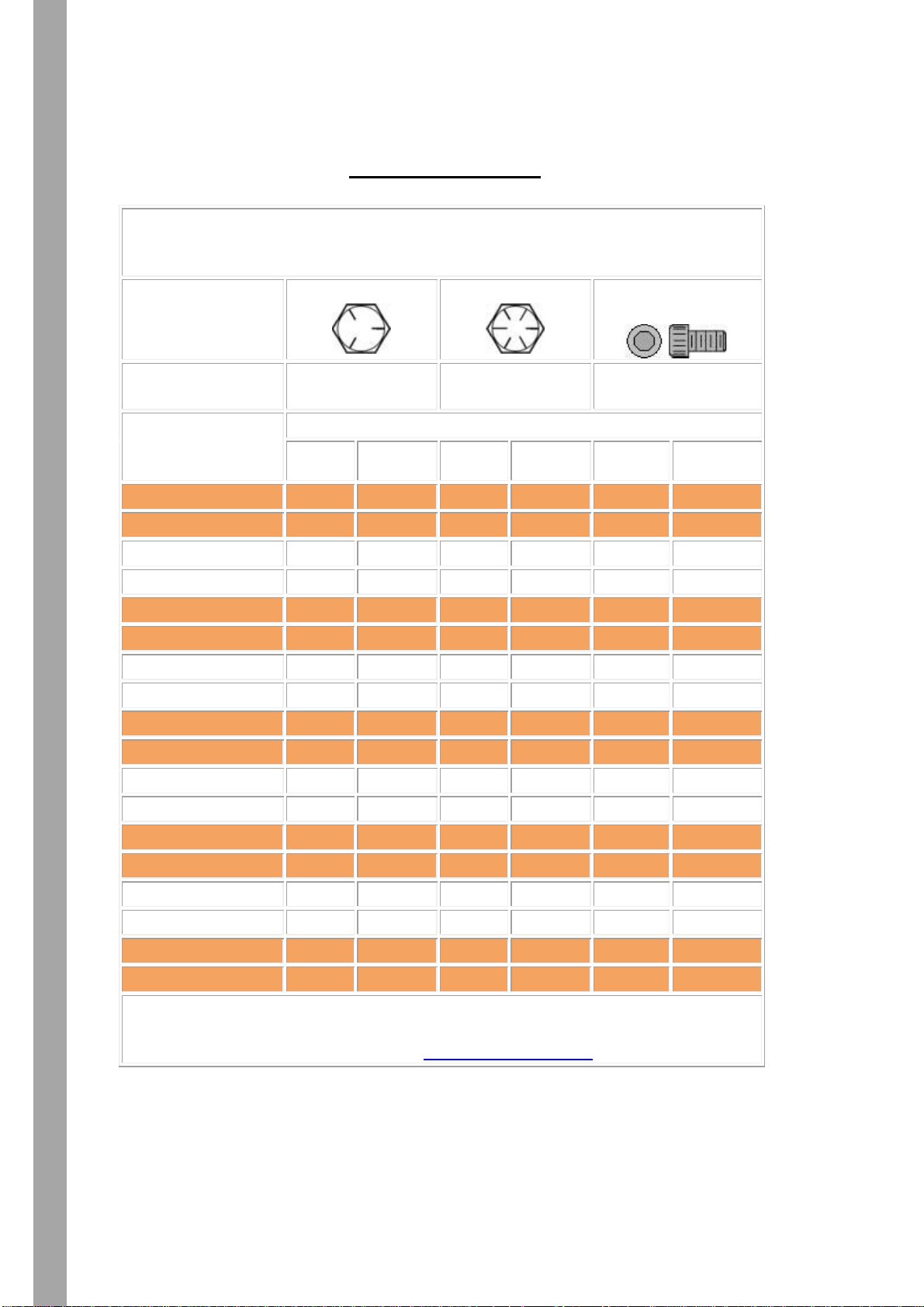

Bolt Torque Table

Estimated with clamp load as 75% of proof load

as specified in SAE J429 and ASME 574

Steel Grade

SAE 5

SAE 8

Socket Head

Cap Screws

Minimum Tensile

Strength PSI

120,000

150,000

1/4-1/2" 180,000

5/8-1" 170,000

Nominal Dia.

and

Thread Pitch

Bolt Torque Specs in Foot Pounds or (Inch Pounds)

Dry

Lubed

Dry

Lubed

Dry

Lubed

1/4-20

(101)

(76)

(143)

(107)

(168)

(120)

1/4-28

(116)

(87)

(147)

(123)

(192)

(144)

5/16-18

(209)

(157)

(295)

(221)

(348)

(264)

5/16-24

(231)

(174)

(327)

(245)

(384)

(288)

3/8-16

(372)

(276)

44

33

51

38

3/8-24

(420)

(312)

49

37

58

43

7/16-14

49

37

70

52

81

61

7/16-20

55

41

78

58

91

68

1/2-13

75

57

106

80

124

93

1/2-20

85

64

120

90

140

105

5/8-11

150

113

212

159

238

179

5/8-18

170

127

240

180

270

202

3/4-10

267

200

376

282

423

317

3/4-16

297

223

420

315

472

354

7/8-9

429

322

606

455

682

511

7/8-14

474

355

669

502

752

564

1-8

644

483

909

681

1022

767

1-12

722

542

1020

765

1147

860

Lubed means cleaned dry bolts lubricated with a standard medium viscosity

machine oil. Lubricate all contact areas of the bolts and washers. Lubricating

the bolts is the suggested method. Thread Engagement

Figure 34

Bolt Torque table

Performing Maintenance

___________________________________________________________________

Page | 30

K-Line Ag ©

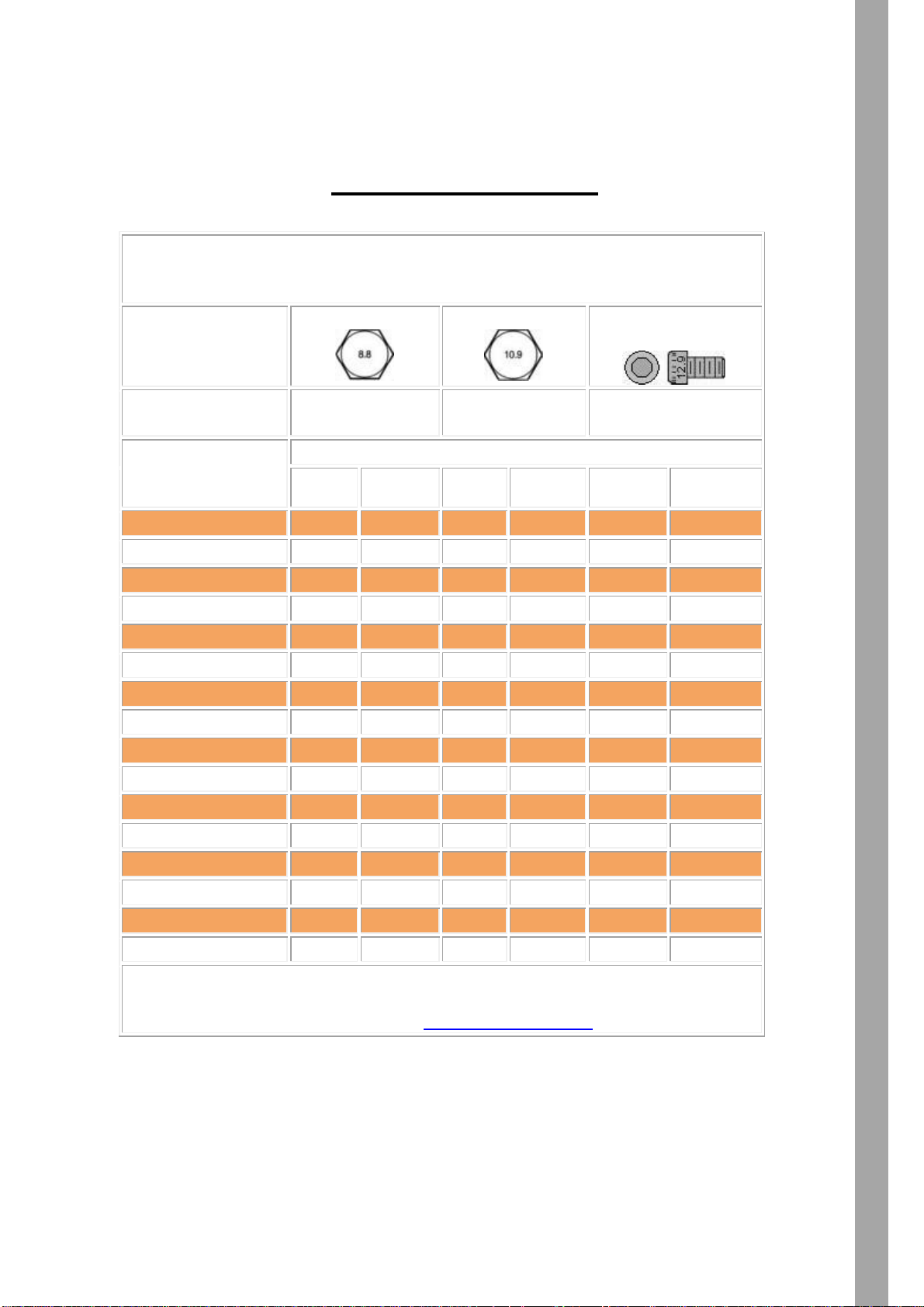

Metric Bolt Torque Table

Estimated with clamp load as 75% of proof load

as specified in ISO 898-1

Property

Class

8.8

10.9

12.9 Socket Head

Cap Screw

Minimum Tensile

Strength MPa

M6 - M16: 800

M20 - M30: 830

1040

1220

Nominal Size

and

Thread Pitch

Bolt Torque Specs in Foot Pounds or (Inch Pounds)

Dry

Lubed

Dry

Lubed

Dry

Lubed

M5 x 0.80

(54)

(41)

(78)

(59)

(91)

(68)

M6 x 1.00

(92)

(69)

(133)

(99)

(156)

(116)

M7 x 1.00

(156)

(116)

(222)

(167)

(260)

(195)

M8 x 1.25

(225)

(169)

(333)

(242)

(377)

(284)

M10 x 1.50

37

28

53

40

62

47

M12 x 1.75

65

49

93

69

108

81

M14 x 2.00

104

78

148

111

173

130

M16 x 2.00

161

121

230

172

269

202

M18 x 2.50

222

167

318

238

372

279

M20 x 2.50

314

235

449

337

525

394

M22 x 2.50

428

321

613

460

716

537

M24 x 3.00

543

407

776

582

908

681

M27 x 3.00

796

597

1139

854

1331

998

M30 x 3.50

1079

809

1543

1158

1804

1353

M33 x 3.50

1468

1101

2101

1576

2455

1842

M36 x 4.00

1886

1415

2699

2024

3154

2366

Lubed means cleaned dry bolts lubricated with a standard medium viscosity

machine oil. Lubricate all contact areas of the bolts and washers. Lubricating

the bolts is the suggested method. Thread Engagement

Figure 35

Metric Bolt Torque table

Performing Maintenance

__________________________________________________________________

Page | 31

K-Line Ag ©

2918U

2925U

2930U

Operating Width

(approx.)

5.7ft (1.75m)

8.2ft (2.5m)

9.8ft (3.0m)

Total overall

width

6.6ft (2.05m)

9.1ft (2.8m)

10.7ft (3.3m)

Number of discs

14

20

24

Disc cut spacing

5 inches

(125mm)

5 inches

(125mm)

5 inches

(125mm)

Adjustable disc

positioning

Variable to suit

conditions

Variable to suit

conditions

Variable to suit

conditions

Standard disc

size

22” x 6 gauge

(560 x 5mm)

22” x 6 gauge

(560 x 5mm)

22” x 6 gauge

(560 x 5mm)

Disc options

22” x ¼ (560 x

6mm)

24” x ¼ (610 x

6mm)

22” x ¼ (560 x

6mm)

24” x ¼ (610 x

6mm)

22” x ¼ (560 x

6mm)

24” x ¼ (610 x

6mm)

Speedtiller

approximate

weight

depending on

rollers etc.

4190lbs

(1900kg),

6505lbs

(2950kg),

7056lbs

(3200kgs)

Tractor Power

range

Transport Width

6.7ft (2.1m)

9.2ft (2.8m)

10.8ft (3.3m)

Tractor Hydraulic

remote

requirements

1 hydraulic

wheel lift

1 hydraulic

wheel lift

1 hydraulic

wheel lift

Hydraulic

Pressure

2800 PSI /

19000 KPA

Performing Maintenance

__________________________________________________________________

Specifications

Page | 32

K-Line Ag ©

2935U

2940U

Operating Width

(approx.)

11.5ft (3.5m)

13.1ft (4.0m)

Total overall

width

12.4ft (3.8m)

14ft (4.6m)

Number of discs

28

32

Disc cut spacing

5 inches

(125mm)

5 inches

(125mm)

Adjustable disc

positioning

Variable to suit

conditions

Variable to suit

conditions

Standard disc size

22” x 6 gauge

(560 x 5mm)

22” x 6 gauge

(560 x 5mm)

Disc options

22” x ¼ (560 x

6mm)

24” x ¼ (610 x

6mm)

22” x ¼ (560 x

6mm)

24” x ¼ (610 x

6mm)

Speedtiller

approximate

weight depending

on rollers etc.

7497lbs

(3400kgs)

7938lbs

(3600kgs)

Tractor Power

range

Transport Width

8.2ft (2.5m)

8.2ft (2.5m)

Transport Height

12.5ft (3.8m)

14.1ft (4.3m)

Tractor Hydraulic

remote

requirements

1 hydraulic

wheel lift

1 hydraulic

wheel lift

Hydraulic

pressure

2800 PSI /

19000 KPA

2800 PSI /

19000 KPA

Performing Maintenance

__________________________________________________________________

Specifications

Page | 33

K-Line Ag ©

Risk Management

__________________________________________________________________

RISK MANAGEMENT

Risk management is the process of finding out what may cause an injury, deciding what

may happen as a result, and doing something about it.

The steps of risk management are:

Identify the hazards to workplace health and safety arising from work activities

Assess the risks

Determine and implement control measures to reduce risk

Monitor and review the effectiveness of the control measures

IDENTIFYING HAZARDS

Prior to commencing work, all hazards related to the work tasks should be identified.

The selection of the appropriate work procedure(s) will depend on the type of work

procedure(s) and hazards involved. Regular safety inspections will also identify hazards

and ensure that control measures are in place.

RISK ASSESSMENT

Risk assessment allows appropriate control measures to be developed. Once hazards

have been identified, they should be assessed in terms of their potential to do harm. To

assess risk, consideration should be given to probability and consequences. SEE RISK

ASSESSMENT MODEL.

RISK CONTROL

Risk control is the process of eliminating or reducing risk factors. Control measures

should be chosen and implemented to eliminate or reduce risk as far as practicable.

When deciding on the most appropriate measures to use, practicality and acceptance of

the control measures should be considered. Safe Working Procedures will be developed

for all high – medium risk hazards.

MONITOR AND REVIEW CONTROL MEASURES

The risk identification, assessment and control process requires regular monitoring to

ensure the implemented control measures perform as originally intended and continue

to prevent or adequately control the risk of injury or incident. Control measures should

also be checked carefully to ensure that new hazards are not created, directly or

indirectly, by the original control measures.

Page | 34

K-Line Ag ©

Risk Management

AT ALL TIMES COMPLY WITH RECOMMENDATIONS

__________________________________________________________________

RISK ASSESSMENT MODEL

AND REQUIREMENTS OF THE MANUFACTURER AND

THE ENVIRONMENTAL PROTECTION AUTHORITY

Page | 35

K-Line Ag ©

CODE

HAZARDS

RISK

SCORE

CONTROL

REVISED

RISK SCORE

1(A).

Crushing – when adjusting

and cleaning, as machine

may drop without warning

1

Adjusting & cleaning must only be done when machine is

lowered or in transport position and only after all chains and

bolts have been checked for tightness & wear in the lower

position.

5

1(B).

Crushing - improper use of

jack

1

Ensure jack is installed correctly & jack receives regular

maintenance. Keep feet and body clear when operating.

5

1(C).

Crushing - when hitching

tractor

2

Ensure no personnel are between tractor & harrow bar when

hitching to tractor.

5

1(D).

Crushing - prior to priming

hydraulic system, as

machine may drop without

warning

1

Machine must be lowered into working position using suitable

lifting equipment before priming is effected by slightly

loosening fitting/s into cylinders and operating tractor

hydraulics to achieve full uninterrupted travel of cylinder

several times. Then retighten hydraulic tine fittings.

5

1(E).

Sudden lift of drawbar

causing severe injury, if

machine becomes

unhitched

1

Ensure all three jacks are correctly positioned and taking

weight before removing drawbar pin. Stickers warn operator.

5

2(A).

Penetration of oil - broken

or badly maintained

hydraulic lines

2

Maintain regular checks on hydraulic system for wear &

check all fittings are secure.

5

2(B).

Rupture of oil lines by over

pressure when machine

comes to sudden stop

before fully lowered to

working position

2

Ensure tractor oil flow is limited to reduce falling speed or do

not interrupt machine falling until machine is fully in lowered

position

5

3.

Collision – hydraulics

accidentally lowered when

machine is being operated

in transport

1

Safety pins must be put in place as soon as machine is put in

transport position and if travelling on public roads to

disconnect hydraulics from tractor.

5

Risk Management

__________________________________________________________________

K-LINE AGRICULTURE RISK ASSESSMENT

ALL HAZARDS & RISKS ARE CONTROLLED THROUGH SAFE WORKING

Page | 36

PROCEDURES & ADEQUATE SIGNAGE

K-Line Ag ©

__________________________________________________________________

WARRANTY

K-LINE AGRICULTURE has been known over the last 22 years for supplying an

ever expanding range of quality agricultural machinery.

K-LINE AGRICULTURE warrants the products it manufactures and distributes to be

free of defective materials and workmanship for a period of twelve months from date

of purchase, to the first owner.

Any part of the goods manufactured and distributed by K-LINE AGRICULTURE that

proves to be defective material, will be replaced or repaired by K-LINE

AGRICULTURE when returned to K-LINE AGRICULTURE at cost to purchaser and

at purchaser’s risk.

Goods sold shall only have the benefit of this warranty if the purchaser has complied

with the manufacturer’s instructions in relation to the maintenance and operation of

the said goods. All conditions and warranties implied by Law or Statute are hereby

expressly excluded and negative so far as legally permissible.

K-LINE AGRICULTURE is not otherwise liable for any direct, indirect or

consequential loss or damage howsoever arising or occurring, whether founded in

tort, contract, and statute or otherwise.

This warranty must be read as subject to the General Terms and Conditions and

does not cover misuse, neglect or negligence.

ANY CLAIM FOR WARRANTY IS ALSO SUBJECT TO THE FOLLOWING

CONDITIONS:

Machine has not been subject to misuse.

The speed limit of 20mph (32kmh) has been observed at all times.

The machine has not been used for custom or hire work.

Equipment must be handled, assembled, operated, maintained and stored

correctly in accordance with the manufacturer’s instructions by competent

personnel.

Warranty registration form must be signed by reseller and purchaser and

returned to K-LINE AGRICULTURE within 14 days of invoice. Warranty is not

valid unless registered.

Normal wear and tear, routine maintenance costs and accidental damage are

NOT covered by this warranty.

Any alteration of equipment or negligence in maintenance including the use of

non-genuine parts, renders this warranty null and void.

K-LINE AGRICULTURE will not authorize or reimburse expenses without a

warranty request form filled out to K-LINE AGRICULTURE satisfaction.

Signed on behalf of K-LINE AGRICULTURE

Page | 37

K-Line Ag ©

_______________________________________________________________________

THIS PAGE IS LEFT

INTENTIONALLY BLANK

Page | 38

Reseller:

Client First Name:

Client Last Name:

Salesman:

Trading Name:

Address:

Address:

Phone:

Phone:

Date of

Invoice:

Email Address:

Invoice No:

Start- Up Date:

Machine

Make &

Type:

Serial No:

Signed:

Signed:

WARRANTY REGISTRATION FORM

Conduct comprehensive risk assessment of machine with consideration for use

and maintenance

Ensure machine is delivered as per purchase order including options

All pins and lynch pins are in place

Hydraulic system is primed and operating properly (if applicable).

Check gearboxes for oil (if applicable).

Check belts for tightness (if applicable).

Instruction manual is supplied and explained.

It is the responsibility of the purchaser to:

Maintain in as new condition all warning and safety signs and devices at all times.

Ensure all operators are familiar with this manual and all safety devices and features

of the machine.

Maintain the machine at all times in a condition that is safe to operate, and ensure it

complies with any relevant safety acts of parliament, government authorities and

regulations.

Take every reasonable precaution as is commonly expected in this industry and in

the operation of the machine.

Before mounting, check with manufacturer of machine or consult engineer to ensure

strength and balance of machine is adequate to accommodate the K-Line products

you have purchased.

You must conduct a risk assessment, taking all risks into consideration before

commissioning machine for use.

To confirm registration for warranty, please return this page (signed) to

F :( 02) 6342 6913 or E: sales@k-line.net.au

K-Line Ag ©

________________________________________________________________________

THIS PAGE IS LEFT

INTENTIONALLY BLANK

Page | 40

WARRANTY REQUEST FORM

RESELLER: _______________________ CLIENT:

______________________

ADDRESS: _______________________ _____________________________

PHONE: _________________________ _____________________________

MACHINE MAKE & TYPE: ____________________________________________

SERIAL NO: ______________________ CUSTOMER ORDER NO: _______

INVOICE NO: _____________________ DATE OF INVOICE: ___________

FULL DESCRIPTION: ________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

CAUSE:

____________________________________________________________

___________________________________________________________________

___________________________________________________________________

DATE OF FAILURE: _______________ HOURS WORKED:

_____________

DATE OF REPAIR: ________________ HECTARES WORKED: _________

I AGREE:

1. That in accordance with the warranty given by K-LINE AGRICULTURE, I have

taken every reasonable precaution as is commonly expected in this industry

in the operation of the machine.

2. This claim is not due to negligence, lack of maintenance, routine wear & tear

or accidental damage & no unauthorised alteration has been made to this

machine.

OPERATOR: SIGNATURE ________________________________ DATE:

_____________________________________________

OWNER: SIGNATURE _________________________________ DATE:

_____________________________________________

OFFICE USE ONLY:

ACCEPTED: YES/NO DENIED: YES/NO

DATE: ___________________________________ DATE:

_____________________________

GOODS REPAIRED/ REPLACED/ REFUNDED FOR REASON FOR DENIAL:

_______________

CREDIT? (CIRCLE) ___________________________________

REFUND OR REIMBURSEMENT REQUIRED? ___________________________________

CHQ NO/ ADJUSTMENT NOTE NO: ___________ CHANGE REQUIRED? (CIRCLE)

SHIPPING DETAILS: _______________________ DESIGN

APPROVED BY: ___________________________ WORK METHOD

ACTION TAKEN: ___________________________ SUPPLIED PRODUCT

_________________________________________ REFER TO SUPPLIER

CLIENT SATISFIED YES/NO RECALL REQUIRED

FILE CLOSED BY: _________________________ DATE: _____________________________

K-Line Ag ©

________________________________________________________________________

THIS PAGE IS LEFT

INTENTIONALLY BLANK

Page | 42

K-Line Ag ©

_______________________________________________________________________

NOTES

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

Page | 43

K-Line Ag ©

_______________________________________________________________________

NOTES

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

Page | 44

K-Line Ag ©

_______________________________________________________________________

NOTES

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

Page | 45

THIS PAGE IS LEFT

INTENTIONALLY BLANK

THIS PAGE IS LEFT

INTENTIONALLY BLANK

K-Line Ag ©

K-Line Agriculture

PO Box 567

700 Division Avenue S

Cavalier ND 58220

Email: sales@k-lineag.com

K-Line Agriculture

PO Box 340

72-80 Young Rd

Cowra NSW 2794

Email: sales@k-line.net.au

002

__________________________________________________________________

DESIGNERS AND

MANUFACTURERS OF

QUALITY

AGRICULTURAL

MACHINERY

Speedtiller, Speed Tiller, Speedbuster, TrackAttack, Seed Commander, Crop-

Registered trademarks of K-Line Agriculture, Include:

Commander, Crop Commander, Aus-Cut, Scimitar, Carers of the Land.

TOLL FREE PHONE NUMBER:

USA- 1800 556 6882

AUS- 1800 194 131

Page | 48

Loading...

Loading...