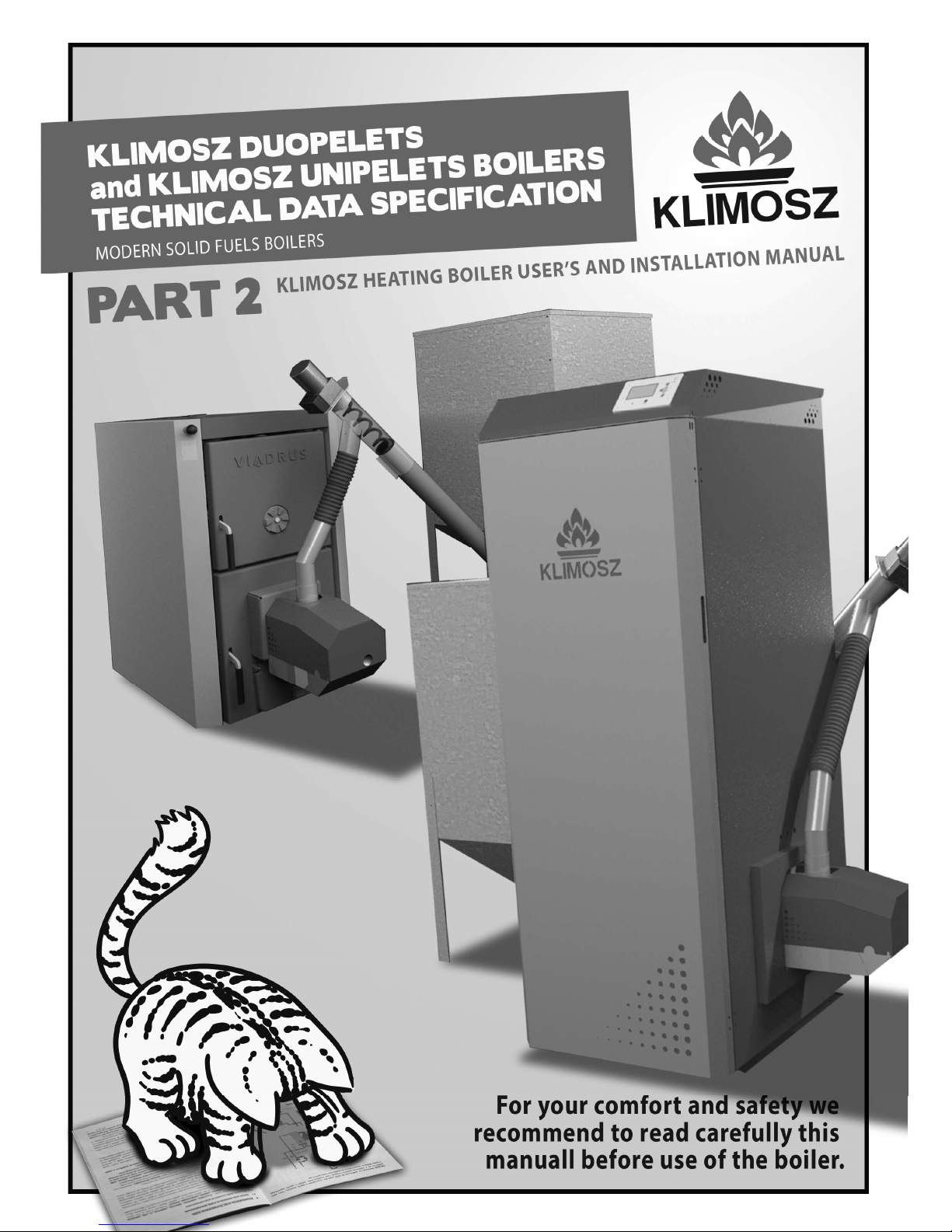

Klimosz DUOPELET 15, DUOPELET 45, DUOPELET 25, DUOPELET 55, DUOPELET 75 User And Installation Manual

...

Operation and installation manual 2015.12.07

1

Operation and installation manual 2015.12.07

2

Boilers KLIMOSZ DUOPELET are delivered ready to instal in the hydraulic system. Boilers KLIMOSZ

DUOPELET, KLIMOSZ UNIPELET requires regulation by the authorized service.

Boilers KLIMOSZ UNI PELET requires montage of the steel jackets and the fuel tank.

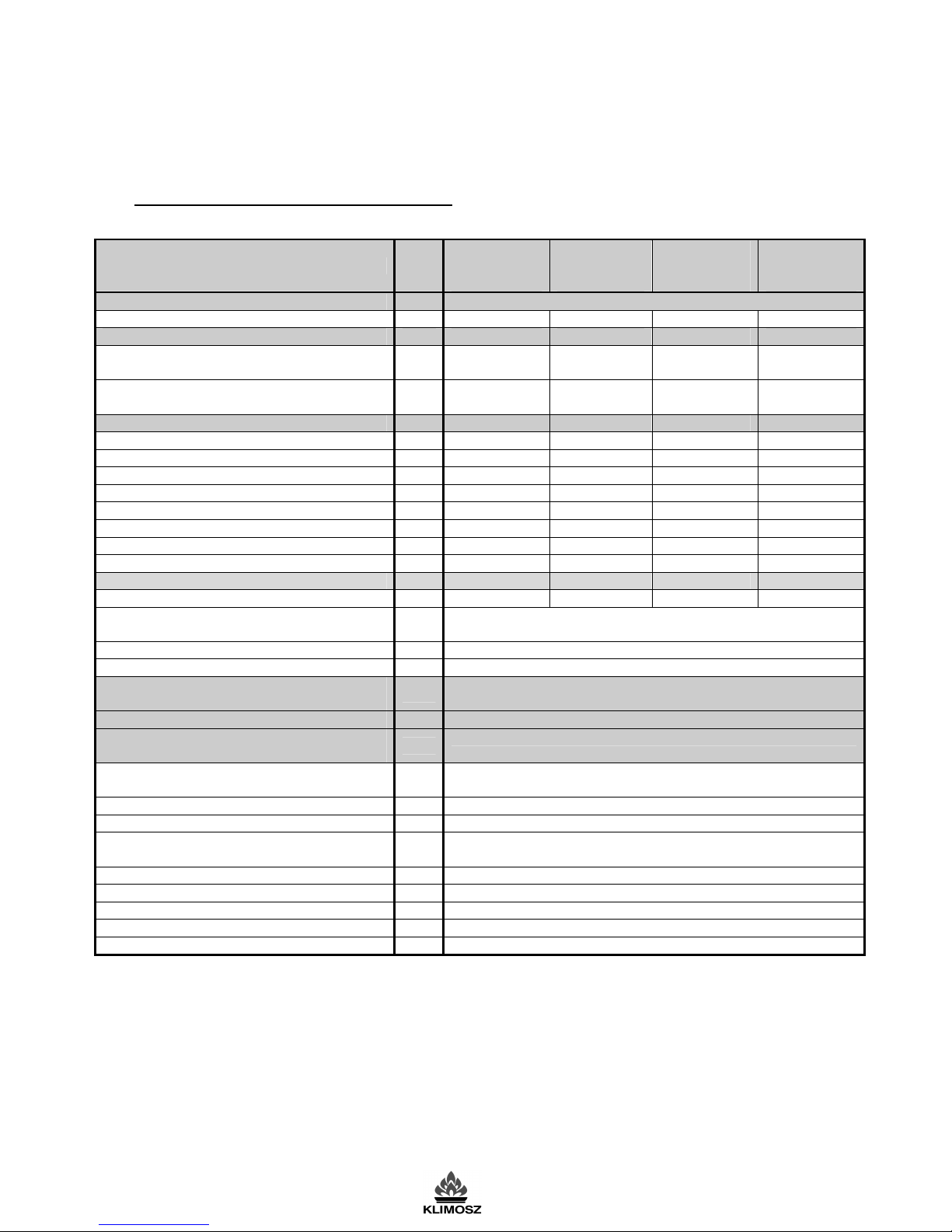

1 Technical Data for KLIMOSZ DUOPELET

Tab. 1. Technical parameters of the KLIMOSZ DUOPELET NG 15 – 45 and DUOPELET B 15 - 35.

Parametr SI

KLIMOSZ

DUOPELET

15

KLIMOSZ

DUOPELET

25

KLIMOSZ

DUOPELET

35

KLIMOSZ

DUOPELET

45

AUTOMATIC MODE

Nominal power – pellets (max / nominal) kW 15 / 15 25 / 25 35 / 27 45 / 42

Efficiency - pellets % 90,1 91 91 89,8

Fuel consumption at nominal power

- pelety 18MJ/kg

kg/h 3,3 5,5 7,1 10,0

Approximate combustion time at nominal

power – pellets

h 81,8 49,1 38 28,4

Range of power – pellets kW 4,5 ÷ 15 7,5 ÷ 25 9,6 ÷ 32 13,5 ÷ 45

Flow of fumes - pellets – nominal power g/s 11 12 15 16

Fumes temperature °C 100 ÷ 170 100 ÷ 170 100 ÷ 200

Boiler class - 5 5 5 4

Approximate combustion time – Wood h 2 2 2 2

Mass: DuoPelet NG / DuoPelet B kg 380 / 320 450 / 375 480 / 390 560

Heating area of the boiler m

2

2,1 3,1 3,5 4,4

Water volume dm3 70 92 105 115

Diameter of fumes outlet mm 160 160 160 160

Chimney draught Pa 10 ÷ 15 10 ÷ 20 10 ÷ 20 10 ÷ 20

Capacity of the fuel tank dm3 260 260 260 260

Water maximal working pressure: DuoPelet NG

/ DuoPelet B

bar

2,0 / 1,5

Water minimal working pressure bar Water maximal trial pressure bar 4,5

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the

boiler

°C

50

Maximal permitted level of heating material:

DuoPelet NG / DuoPelet B

m

20 / 15

Noise level: DuoPelet NG / DuoPelet B bar 2,0 / 1,5

Poziom hałasu dB < 65 (A)

Connections of the boiler - heating and

returning water

1 1/2 ”

Resistance of water flow through the boiler mbar 1,4 / 0,4

Voltage 230V / 50 Hz

Electric energy consumption (fan / motor) W 50 / 45

Electric energy consumption (shot light-option) W 200

Electric insulation IP 40

Operation and installation manual 2015.12.07

3

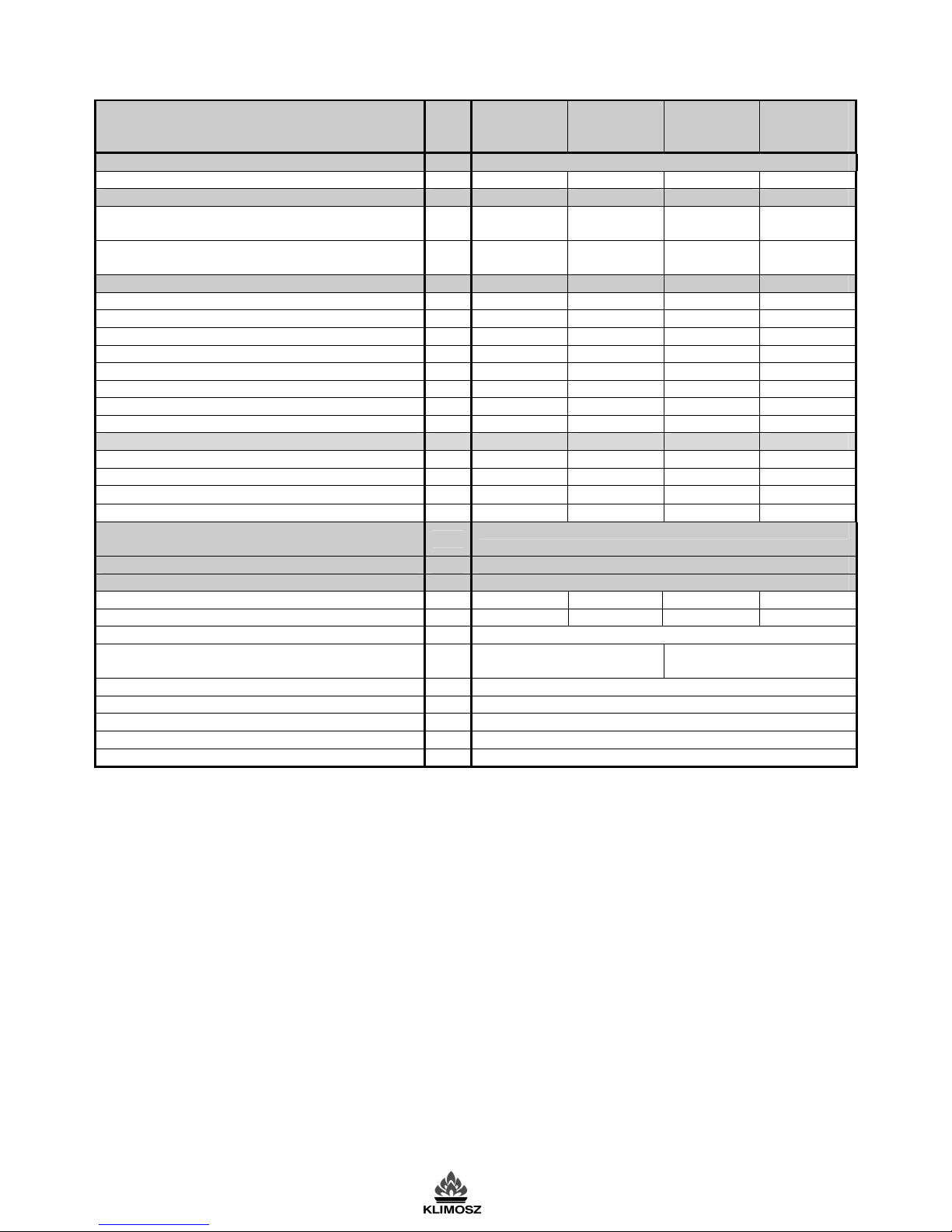

Tab. 2. Technical parameters of the KLIMOSZ DUOPELET NG.

Parameter SI

KLIMOSZ

DUOPELET

55

KLIMOSZ

DUOPELET

75

KLIMOSZ

DUOPELET

100

KLIMOSZ

DUOPE

LET

150

AUTOMATIC MODE

Nominal power – pellets (max / nominal) kW 50 / 47 75 / 62 97 / 90 140 / 120

Efficiency - pellets % 91 91,5 90,0 90,0

Fuel consumption at nominal power

- pelety 18MJ/kg

kg/h 11,0 16,8 21,8 29,8

Approximate combustion time at nominal power –

pellets

h 56,8 37,5 28,9 21,1

Range of power – pellets kW 15 ÷ 50 22,5 ÷ 75 29,1 ÷ 97 42 ÷ 140

Flow of fumes - pellets – nominal power g/s 17 19 21 22

Fumes temperature °C 100 ÷ 220 100 ÷ 220 100 ÷ 240 100 ÷ 240

Boiler class - 4 5 3 5

Approximate combustion time – Wood h 2 2 2 2

Mass kg 820 960 1415 1575

Heating area of the boiler m

2

5,8 8,1 11,1 15,2

Water volume dm3 148 195 260 360

Diameter of fumes outlet mm 200 200 200 200

Chimney draught Pa 20 ÷ 30 20 ÷ 30 20 ÷ 35 25 ÷ 35

Capacity of the fuel tank dm3 700 700 700 700

Water maximal working pressure bar 1,8 2,0 2,0 2,0

Water minimal working pressure bar - - -

Water maximal trial pressure bar 2,7 3,0 3,0 3,0

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the boiler °C 50

Maximal permitted level of heating material m 18 20 20 20

Noise level bar 1,8 2,0 2,0 2,0

Poziom hałasu dB < 65 (A)

Connections of the boiler - heating and returning

water

2” 2 1/2”

Resistance of water flow through the boiler mbar 1,4 / 0,4

Voltage 230V / 50 Hz

Electric energy consumption (fan / motor) W 50 / 45

Electric energy consumption (shot light-option) W 700

Electric insulation IP 40

Operation and installation manual 2015.12.07

4

2 Technical Data for KLIMOSZ UNIPELET

Tab. 3. Technical parameters of the KLIMOSZ UNI PELLETS boiler.

Parameter SI

KLIMOSZ

UNIPELET 15

KLIMOSZ

UNIPELET 25

KLIMOSZ

UNIPELET 35

AUTOMATIC MODE

Nominal power – pellets kW 15 25 32

Efficiency - pellets % 87 90 90

Fuel consumption at nominal power

- pelety 18MJ/kg

kg/h 3,4 5,6 8,0

Approximate combustion time at nominal

power – pellets

h 82 50 35

Range of power – pellets kW 4,5 ÷ 15 7,5 ÷ 25 9,6 ÷ 32

Flow of fumes - pellets – nominal power g/s 12 13 14

Fumes temperature °C 100 ÷ 200 100 ÷ 200 100 ÷230

Boiler class - 4 5 4

Maximal power – wood kW 20 25 35

Mass of the boilers without burner and fuel tank kg 268 304 384

Powierzchnia grzewcza kotła m

2

Water volume dm3 36 41 50

Diameter of fumes outlet mm 156 156 156

Chimney draught Pa 10 ÷ 15 10 ÷ 20 10 ÷ 20

Capacity of the fuel tank dm3 310 310 310

Water maximal working pressure bar 4,0

Water minimal working pressure bar Water maximal trial pressure bar 8,0

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the

boiler

°C

50

Maximal permitted level of heating material m 30

Noise level bar 4,0

Poziom hałasu dB < 65 (A)

Connections of the boiler - heating and

returning water

2” or 6/4” GZ

Resistance of water flow through the boiler mbar 1,2 / 0,4

Voltage 230V / 50 Hz

Electric energy consumption (fan / motor) W 50 / 45

Electric energy consumption (shot light-option) W 400

Electric insulation IP 40

Fuel parameters:

•

calorific value

kgMJQ

r

i

/15>

;

•

ash content

%3<

r

A

;

•

•

moisture content coal pellets

%15<

r

W

,

wood

%20<

r

W

;

ATTENTION!!! The KLIMOSZ heating boilers are not intended for burning waste and no substances other

than those recommended by the manufacturer can be burnt in them.

Tab.4. Recommended fuel for burning in automatic mode.

Main Fuel Granulation[mm]

Calorific value [MJ/kg]

Pelety z drewna** Φ 6 ÷ 8 16 ÷ 19

Substitute fuel Granulation [mm] Calorific value [MJ/kg]

Oats grain - 12 ÷ 14

Wood - 10 ÷ 14

Operation and installation manual 2015.12.07

5

Sawdust granulate (pellets) should be at least hard enough for it to be impossible to crush

a few fuel granules in a clenched fist, preventing the feeder from getting jammed. Light colour grades are

recommended, without bark, which can cause deposit formation in the burner.

3 Construction of a KLIMOSZ DUOPELET boiler

The KLIMOSZ DUOPELET automatic boiler is not maintenance-free and requires the user to carry out

some periodic maintenance activities; it is therefore recommended that the user should carefully read the principles

of its operation, regulation and maintenance in order to avoid any problems related to its working.

The main part of the boiler is a steel heat exchanger, made from 6-8mm internal sheet and 4mm external

sheet. KLIMOSZ DUO PELLES NG 15 ÷ 75 boilers can be installed in a closed system. KLIMOSZ DUO

PELLES NG 100 ÷ 150 and KLIMOSZ DUOPELET B 15 ÷ 35 boilers can be installed only in a open system. In

the lower chamber there is situated the automatic burner to combust pellets. In the automatic mode there is an

automatic ignition. After the ignition module thanks to the ventilator, automatic cleaning is activated. Below the

combustion chamber there is an ash tray situated.

Next to the boiler, there is a fuel storage bin with a feeder screw at the bottom. The fan which provides air

for combustion is situated below the automatic burner. The amount of air for combustion can be regulated by

changing the fan rotation speed on the boiler regulator (recommended) or by manual setting of the choking flap on

the fan.

The heating water inlet is situated on the back wall of the exchanger, in its bottom middle; the water outlet

is situated on the top left and right. In the back of the boiler there is a smoke conduit, which carries flue gas to the

chimney. The steel exchanger, its cover as well as lower and upper door, are covered with mineral insulation,

which reduces heat loss during combustion. The steel casing is protected with high quality powder paint.

Boiler is prepared t ochange the side of the fuel tank and the burner. Doors also can be opened on both

sides.

4 Construction of a KLIMOSZ UNI PELLETS boiler

The KLIMOSZ UNIPELET automatic boiler is not maintenance-free and requires the user to carry out

some periodic maintenance activities; it is therefore recommended that the user should carefully read the principles

of its operation, regulation and maintenance in order to avoid any problems related to its working.

The boiler drum consists of sections with the help of pressured boiler nipples and is secured with boiler screws.

The sections create burning and ash space, water space and a convective part. Heat water input and output are

situated at the back part of the furnace.

The back section of the furnace has a smoky chimney – pot and a heat water flange in the upper part, and a

returnable water flange with a socket for impregnating and clearing plug. Stoker and ash door and a firebox door

under them are fixed to the front section.

The whole boiler drum is isolated with a stifling, mineral isolation that reduces losses by sharing heat into the

surroundings. The steel jacket is fitted in colour with a quality comaxite paint

4.1 Hand-fired furnace of the KLIMOSZ DUOPELET boiler

The KLIMOSZ DUOPELET boiler provides the possibility for burning solid fuels in the traditional

mode. After manual loading, wood and coal, as substitute fuel, can be burnt in the upper part of the exchanger,

called the "upper combustion chamber". The upper combustion chamber is an emergency chamber, in which

burning throughout the heating season is not recommended due to the lower power capacity achieved as compared

to the maximum power capacity of the boiler. For burning in the upper chamber to run properly, some conditions

for chimney draught have to be met

.

Loading...

Loading...