Klimosz Combi NG 15, Combi NG 20, Combi NG 25, Combi NG 32, Combi NG 42 Technical Data Manual

...

Operation and installation manual 2013.03.06

1 o

Operation and installation manual part 2. 2015.10.08

2

ORIGINAL MANUAL part 2/2

KLIMOSZ COMBI B boilers are supplied in parts on pallet, which provides easy transport to the boiler room.

Advantages of the boiler:

• Automatic, simple and quick boiler operation and maintenance;

• possibility of installing an automatic pellet lighter;

• possibility of burning wood and large grade coal in an extra grate;

• cost-effective operation;

•

a low level of noxious substances in flue gas (tests in accordance with EN 303-5);

1. Technical Data for KLIMOSZ COMBI

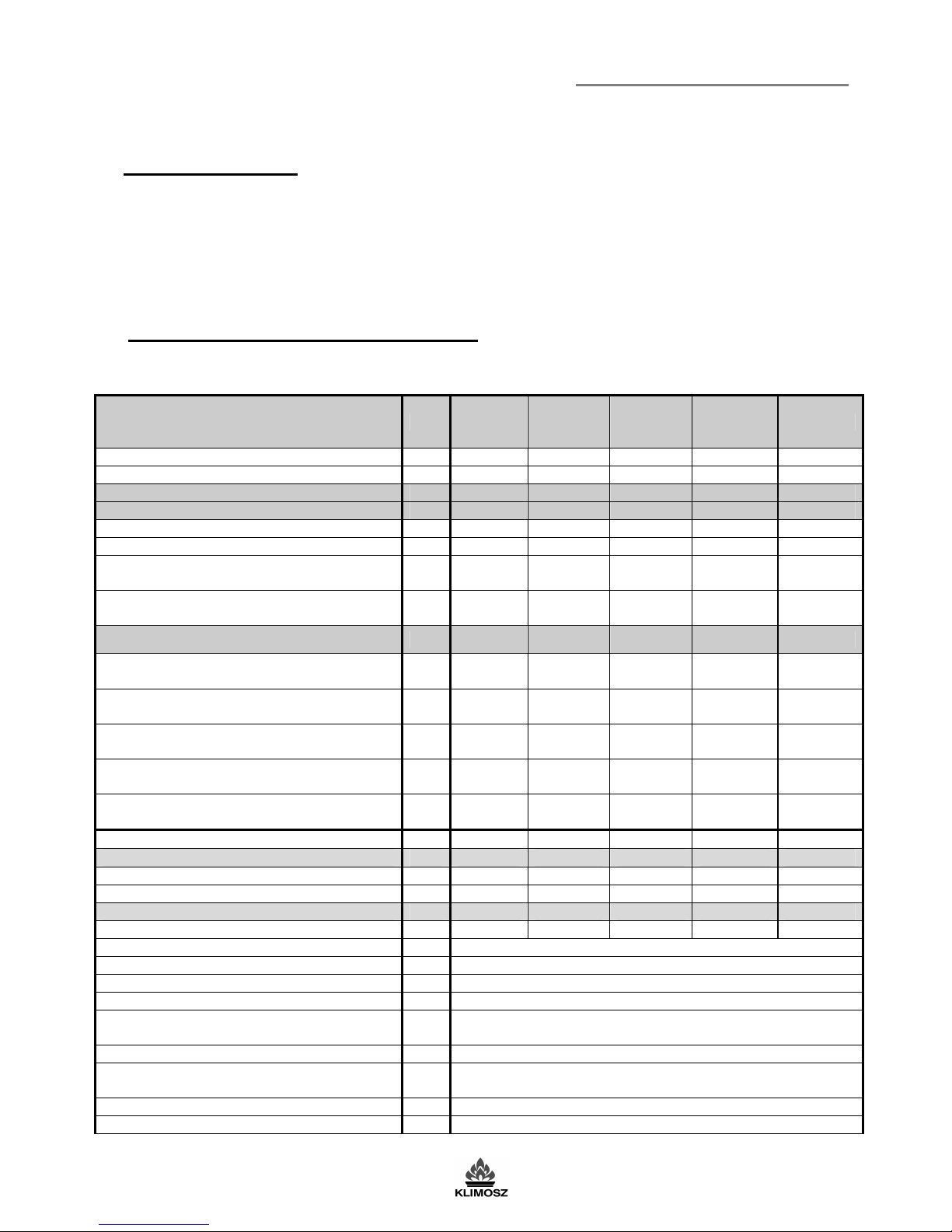

Table 1a. Dimensions and technical parameters of the KLIMOSZ COMBI boiler.

Parametr SI

Klimosz

Combi

NG 15

Klimosz

Combi

NG 20

Klimosz

Combi

NG 25

Klimosz

Combi

NG 32

Nominal power - pea coal kW 15 20 25 32

- pellets kW 15 20 20 20

Efficiency - pea coal % 83 80 80 81,5

Efficiency - pellets % 84 78 78 82,5

Power regulation scope - pea coal kW 5,0 ÷ 15,0 6,0 ÷ 20,0 7,5 ÷ 25,0 9,6 ÷ 32,0

- pellets kW 5,0 ÷ 15,0 6,0 ÷ 20,0 6,0 ÷ 20,0 6,0 ÷ 20,0

Use of fuel at nominal power – continuous

heating - pea coal 27,5 MJ/kg

kg/h 2,5 3,3 4,1 5,1

- pellets 18 MJ/kg

kg/h 3,8 5,1 5,1 4,8

Storage bin volume dm

3

230 230 230 230

Approximate combus

tion time at nominal power

- pea coal 27MJ/kg

days 8,5 6,0 5,0 4,0

- pellets 16MJ/kg

days 4,5 3,5 3,5 3,5

Flow of fumes in the smoke conduit - pea coal

- nominal power

g/s 14,50 15,31 17,68 20,06

Flow of fumes in the smoke conduit - pellets

- nominal power

g/s 14,70 16,7 16,7 13,83

Recommended working temperature for heating

water

°C 100 ÷ 250 100 ÷ 250 100 ÷ 250 100 ÷ 260

Boiler class - 4 3 3 3

Mass kg 470 490 510 530

Heating area of the boiler m

2

- - - -

Water volume dm3 35 36 40 50

Diameter of fumes outlet mm 156 156 156 156

Chimney draught Pa 10 ÷ 15 10 ÷ 20 10 ÷ 20 10 ÷ 20

Water maximal working pressure bar 4,0

Water minimal working pressure bar Water maximal trial pressure bar 5,9

Fluid group - 2 – wather

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the

boiler

°C

50

Maximal permitted level of heating material m 30

Safety valve bar 4,0

Operation and installation manual part 2. 2015.10.08

3

Noise level dB < 65 (A)

Connections of the boiler - heating and returning

water

2 ” or 6/4” GZ

Resistance of water flow through the boiler ∆t =

20oC

mbar 0,4 ÷ 20

Electric energy consumption (fan / motor) - 230V / 50 Hz

Electric energy consumption (shot light-option) W 180 / 80

Electric insulation - IP 40

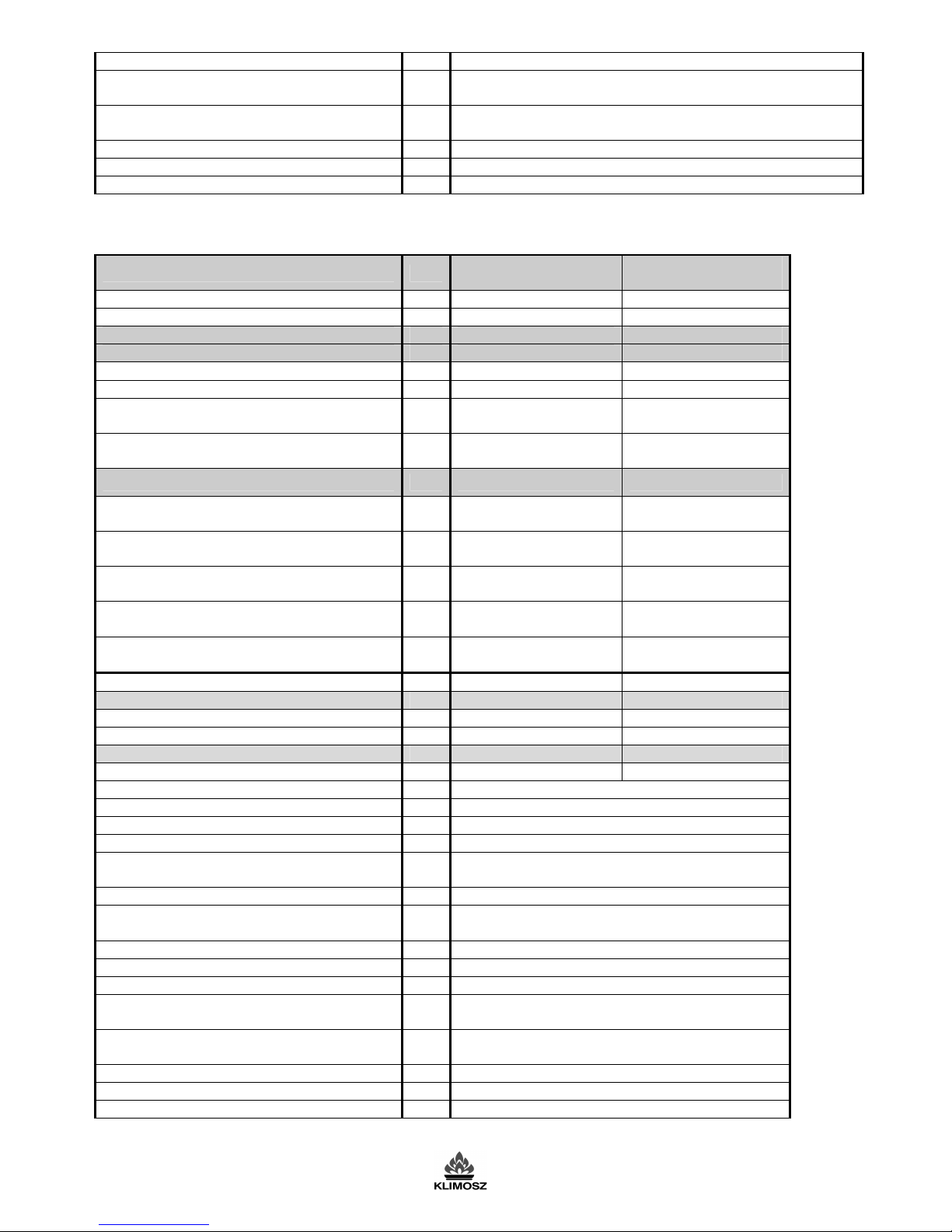

Table 1b. Dimensions and technical parameters of the KLIMOSZ COMBI boiler.

Parametr SI

Klimosz Combi

NG 42

Klimosz Combi

NG 49

Nominal power - pea coal kW 42 49

- pellets kW 36,3 43,3

Efficiency - pea coal % 80 80

Efficiency - pellets % 80 80

Power regulation scope - pea coal kW 12,6 ÷ 42 14,7 ÷ 49

- pellets kW 10,9 ÷ 36,3 13 ÷ 43,3

Use of fuel at nominal power – continuous

heating - pea coal 27,5 MJ/kg

kg/h 6,9 8,0

- pellets 18 MJ/kg

kg/h 9,1 10,8

Storage bin volume dm

3

230 230

Approximate combustion time at nominal power

- pea coal 27MJ/kg

days 3,0 2,5

- pellets 16MJ/kg

days 2,0 1,6

Flow of fumes in the smoke conduit - pea coal

- nominal power

g/s 24 30,3

Flow of fumes in the smoke conduit - pellets

- nominal power

g/s 25 28

Recommended working temperature for heating

water

°C 120 ÷ 260 120 ÷ 260

Boiler class - 3 3

Mass kg 613 630

Heating area of the boiler m

2

- Water volume dm3 60 65

Diameter of fumes outlet mm 156 156

Chimney draught Pa 15 ÷ 20 15 ÷ 20

Water maximal working pressure bar 2,0

Water minimal working pressure bar Water maximal trial pressure bar 3,0

Fluid group - 2 – wather

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the

boiler

°C

50

Maximal permitted level of heating material m 30

Safety valve bar 4,0

Noise level dB < 65 (A)

Connections of the boiler - heating and returning

water

2 ” or 6/4” GZ

Resistance of water flow through the boiler ∆t =

20oC

mbar 0,4 ÷ 20

Electric energy consumption (fan / motor) - 230V / 50 Hz

Electric energy consumption (shot light-option) W 250 / 80

Electric insulation - IP 40

Operation and installation manual part 2. 2015.10.08

4

2. Technical Data for KLIMOSZ COMBI B

Table 2. Dimensions and technical parameters of the KLIMOSZ COMBI B boiler.

Parametr SI

Klimosz

Combi B

15

Klimosz

Combi B

20

Klimosz

Combi B

32

Klimosz

Combi B

35

Nominal power - pea coal kW 15 20 32 35

- pellets kW 15 20 20 25

Efficiency - pea coal % 81 80 81,5 81

Efficiency - pellets % 80 78 82,5 81

Power regulation scope - pea coal kW 5,0 ÷ 15,0 6,0 ÷ 20,0 9,6 ÷ 32 10,5 ÷ 35

- pellets kW 5,0 ÷ 16,0 6,0 ÷ 20,0 6,0 ÷ 20,0 7,5 ÷ 25

Use of fuel at nominal power – continuous

heating - pea coal 27,5 MJ/kg

kg/h 2,5 3,3 5,1 5,7

- pellets 18 MJ/kg

kg/h 3,8 5,1 4,8 6,4

Storage bin volume dm

3

230 230 230 230

Approximate combustion time at nominal power

- pea coal 27MJ/kg

dni 8,0 6,5 4,0 3,5

- pellets 16MJ/kg

dni 4,5 3,5 3,5 3

Flow of fumes in the smoke conduit - pea coal

- nominal power

g/s 11,2 15,31 17,68 18,9

Flow of fumes in the smoke conduit - pellets

- nominal power

g/s 12,4 16,7 16,7 18,1

Recommended working temperature for heating

water

°C 100 ÷ 250 100 ÷ 260 100 ÷ 260 100 ÷ 260

Boiler class - 3 3 3 Mass kg 460 475 490 525

Heating area of the boiler m

2

- - - Water volume dm3 31 40 50 60

Diameter of fumes outlet mm 156 156 156 156

Chimney draught Pa 10 ÷ 15 10 ÷ 20 10 ÷ 20 15 ÷ 20

Water maximal working pressure bar 4,0

Water minimal working pressure bar Water maximal trial pressure bar 8,0

Fluid group - 2 – woda

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the

boiler

°C

50

Maximal permitted level of heating material m 30

Safety valve bar 4,0

Noise level dB < 65 (A)

Connections of the boiler - heating and returning

water

2 ” lub 6/4” GZ

Resistance of water flow through the boiler ∆t =

20oC

mbar 0,4 ÷ 20

Electric energy consumption (fan / motor) - 230V / 50 Hz

Electric energy consumption (shot light-option) W 180 / 80

Electric insulation - IP 40

Operation and installation manual part 2. 2015.10.08

5

• Fuel parameters:

•

calorific value

kgMJQ

r

i

/15>

;

•

ash content

%12<

r

A

;

•

moisture content coal pellets

%15<

r

W

,

wood

%20<

r

W

;

•

volatile matter content

%28>

r

V

;

•

ash fusion point

Ct

o

A

1200>

;

•

caking properties

20

<

RI

(max 30);

•

low swelling

ATTENTION!!! The KLIMOSZ heating boilers are not intended for burning waste and no substances other

than those recommended by the manufacturer can be burnt in them.

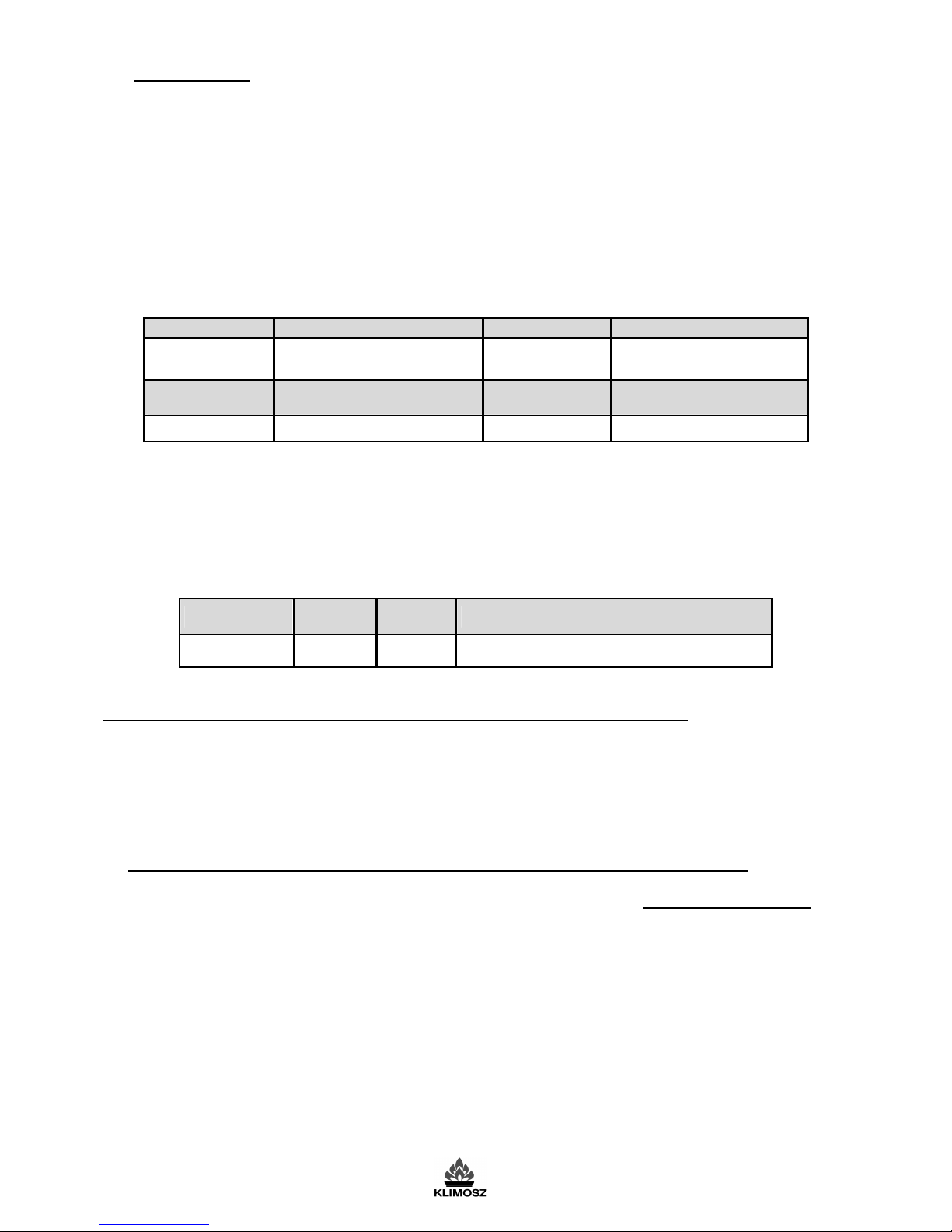

Table 3. Recommended fuel for burning in automatic mode.

Main fuel Fuel type Granulation [mm] Calorific value [MJ/kg]

Hard coal pea grade coal

Gr II 8 ÷ 20

(max 30)

24 ÷ 28 *

Substitute

fuel

Fuel type Granulation [mm] Calorific value [MJ/kg]

Biomass pellets ** Φ 6 ÷ 8 16 ÷ 18

*) Non-caking, non-coking

**) Sawdust granulate (pellets) should be at least hard enough for it to be impossible to crush

a few fuel granules in a clenched fist, preventing the feeder from getting jammed. Light colour grades are

recommended, without bark, which can cause deposit formation in the burner.

Table 4. Recommended fuel for burning in manual mode (emergency combustion chamber of the

KLIMOSZ COMBI and KLIMOSZ COMBI B boiler).

Fuel Unit Size non-coking, non-caking hard coal

Wood (mm) 200 O I [40 ÷ 80]; Ko II [63 ÷ 125]

ATTENTION!!! MOISTURE CONTENT IN FUEL MUST NOT EXCEED 15%. USING MOIST FUEL

RESULTS IN A CONSIDERABLE REDUCTION IN THE BOILER'S POWER CAPACITY (EVEN BY AS

MUCH AS 50%) AND REDUCTION IN THE LIFE-SPAN OF THOSE PARTS OF THE BOILER WHICH ARE

IN CONTACT WITH MOIST FUEL. USING IMPROPER QUALITY OR MOIST FUEL RESULTS IN LOSING

WARRANTY RIGHTS WITH RESPECT TO THE PARTS EXPOSED TO CONTACT WITH SUCH FUEL.

3. Construction of the KLIMOSZ COMBI, KLIMOSZ COMBI B boiler

The KLIMOSZ COMBI and KLIMOSZ COMBI B automatic boiler is not maintenance-free; it is

therefore recommended that the user should carefully read the principles of its operation, regulation and

maintenance in order to avoid any problems related to its work. Construction of the KLIMOSZ COMBI boiler

makes it possible to use solid fuels in the automatic or traditional mode as well as to use liquid fuels. The boiler

has been constructed on the base of a cast-iron exchanger of the multi-purpose VIADRUS U22 boiler. The castiron part of the boiler, which is called the upper combustion chamber, can be used for burning coal, coke or wood

as substitute fuel after manual fuel loading. KLIMOSZ COMBI boilers can be installed in a closed system up to

working pressure 4,0 bar.

Under the water grate of the boiler heat exchanger of a U22 boiler, there is an added steel combustion

chamber, with (W version) or without (S version) a water jacket. There are the following cast-iron parts in the

Loading...

Loading...