Klimosz Combi NG 15, Combi NG 20, Combi NG 25, Combi NG 32, Combi NG 42 Technical Data Manual

...

Operation and installation manual 2013.03.06

1 o

Operation and installation manual part 2. 2015.10.08

2

ORIGINAL MANUAL part 2/2

KLIMOSZ COMBI B boilers are supplied in parts on pallet, which provides easy transport to the boiler room.

Advantages of the boiler:

• Automatic, simple and quick boiler operation and maintenance;

• possibility of installing an automatic pellet lighter;

• possibility of burning wood and large grade coal in an extra grate;

• cost-effective operation;

•

a low level of noxious substances in flue gas (tests in accordance with EN 303-5);

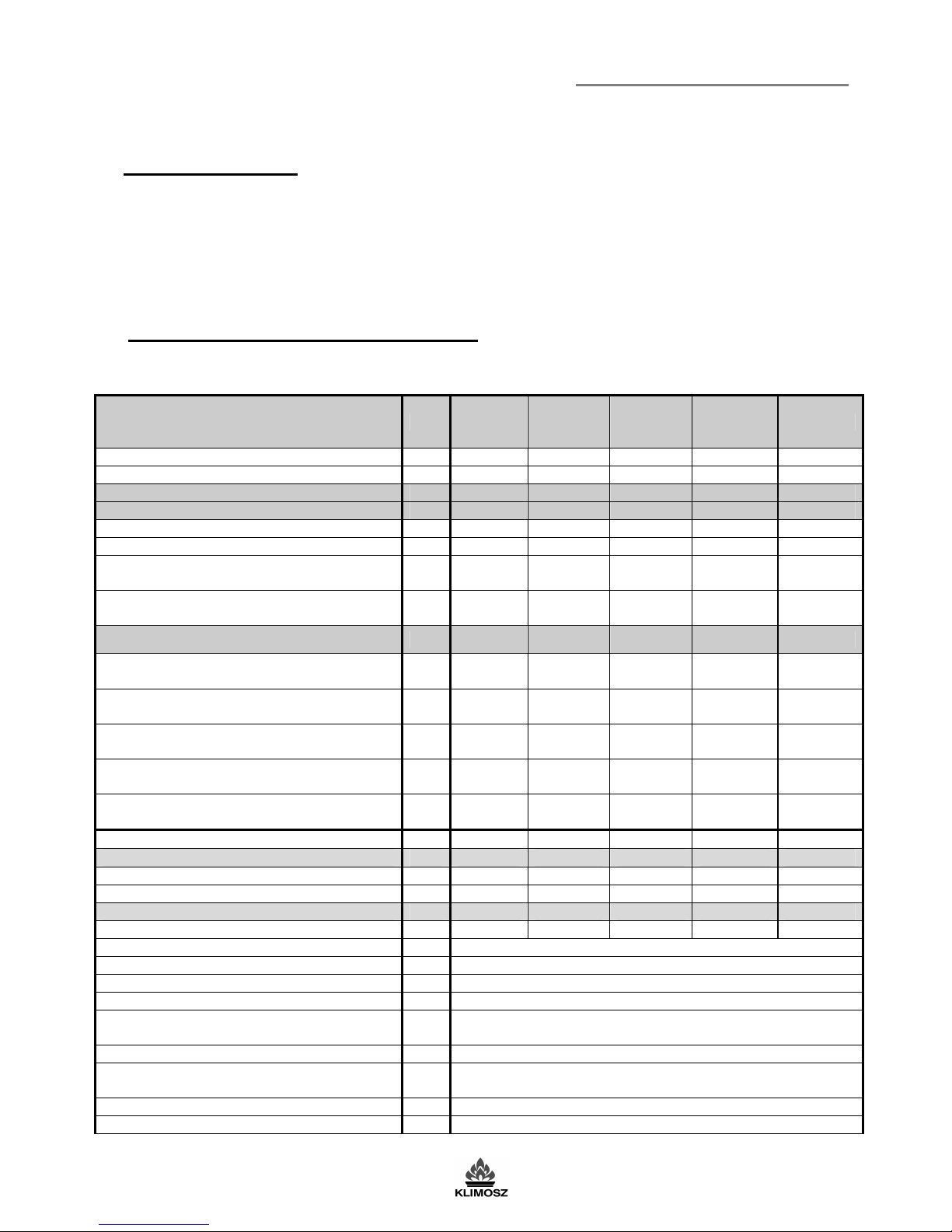

1. Technical Data for KLIMOSZ COMBI

Table 1a. Dimensions and technical parameters of the KLIMOSZ COMBI boiler.

Parametr SI

Klimosz

Combi

NG 15

Klimosz

Combi

NG 20

Klimosz

Combi

NG 25

Klimosz

Combi

NG 32

Nominal power - pea coal kW 15 20 25 32

- pellets kW 15 20 20 20

Efficiency - pea coal % 83 80 80 81,5

Efficiency - pellets % 84 78 78 82,5

Power regulation scope - pea coal kW 5,0 ÷ 15,0 6,0 ÷ 20,0 7,5 ÷ 25,0 9,6 ÷ 32,0

- pellets kW 5,0 ÷ 15,0 6,0 ÷ 20,0 6,0 ÷ 20,0 6,0 ÷ 20,0

Use of fuel at nominal power – continuous

heating - pea coal 27,5 MJ/kg

kg/h 2,5 3,3 4,1 5,1

- pellets 18 MJ/kg

kg/h 3,8 5,1 5,1 4,8

Storage bin volume dm

3

230 230 230 230

Approximate combus

tion time at nominal power

- pea coal 27MJ/kg

days 8,5 6,0 5,0 4,0

- pellets 16MJ/kg

days 4,5 3,5 3,5 3,5

Flow of fumes in the smoke conduit - pea coal

- nominal power

g/s 14,50 15,31 17,68 20,06

Flow of fumes in the smoke conduit - pellets

- nominal power

g/s 14,70 16,7 16,7 13,83

Recommended working temperature for heating

water

°C 100 ÷ 250 100 ÷ 250 100 ÷ 250 100 ÷ 260

Boiler class - 4 3 3 3

Mass kg 470 490 510 530

Heating area of the boiler m

2

- - - -

Water volume dm3 35 36 40 50

Diameter of fumes outlet mm 156 156 156 156

Chimney draught Pa 10 ÷ 15 10 ÷ 20 10 ÷ 20 10 ÷ 20

Water maximal working pressure bar 4,0

Water minimal working pressure bar Water maximal trial pressure bar 5,9

Fluid group - 2 – wather

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the

boiler

°C

50

Maximal permitted level of heating material m 30

Safety valve bar 4,0

Operation and installation manual part 2. 2015.10.08

3

Noise level dB < 65 (A)

Connections of the boiler - heating and returning

water

2 ” or 6/4” GZ

Resistance of water flow through the boiler ∆t =

20oC

mbar 0,4 ÷ 20

Electric energy consumption (fan / motor) - 230V / 50 Hz

Electric energy consumption (shot light-option) W 180 / 80

Electric insulation - IP 40

Table 1b. Dimensions and technical parameters of the KLIMOSZ COMBI boiler.

Parametr SI

Klimosz Combi

NG 42

Klimosz Combi

NG 49

Nominal power - pea coal kW 42 49

- pellets kW 36,3 43,3

Efficiency - pea coal % 80 80

Efficiency - pellets % 80 80

Power regulation scope - pea coal kW 12,6 ÷ 42 14,7 ÷ 49

- pellets kW 10,9 ÷ 36,3 13 ÷ 43,3

Use of fuel at nominal power – continuous

heating - pea coal 27,5 MJ/kg

kg/h 6,9 8,0

- pellets 18 MJ/kg

kg/h 9,1 10,8

Storage bin volume dm

3

230 230

Approximate combustion time at nominal power

- pea coal 27MJ/kg

days 3,0 2,5

- pellets 16MJ/kg

days 2,0 1,6

Flow of fumes in the smoke conduit - pea coal

- nominal power

g/s 24 30,3

Flow of fumes in the smoke conduit - pellets

- nominal power

g/s 25 28

Recommended working temperature for heating

water

°C 120 ÷ 260 120 ÷ 260

Boiler class - 3 3

Mass kg 613 630

Heating area of the boiler m

2

- Water volume dm3 60 65

Diameter of fumes outlet mm 156 156

Chimney draught Pa 15 ÷ 20 15 ÷ 20

Water maximal working pressure bar 2,0

Water minimal working pressure bar Water maximal trial pressure bar 3,0

Fluid group - 2 – wather

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the

boiler

°C

50

Maximal permitted level of heating material m 30

Safety valve bar 4,0

Noise level dB < 65 (A)

Connections of the boiler - heating and returning

water

2 ” or 6/4” GZ

Resistance of water flow through the boiler ∆t =

20oC

mbar 0,4 ÷ 20

Electric energy consumption (fan / motor) - 230V / 50 Hz

Electric energy consumption (shot light-option) W 250 / 80

Electric insulation - IP 40

Operation and installation manual part 2. 2015.10.08

4

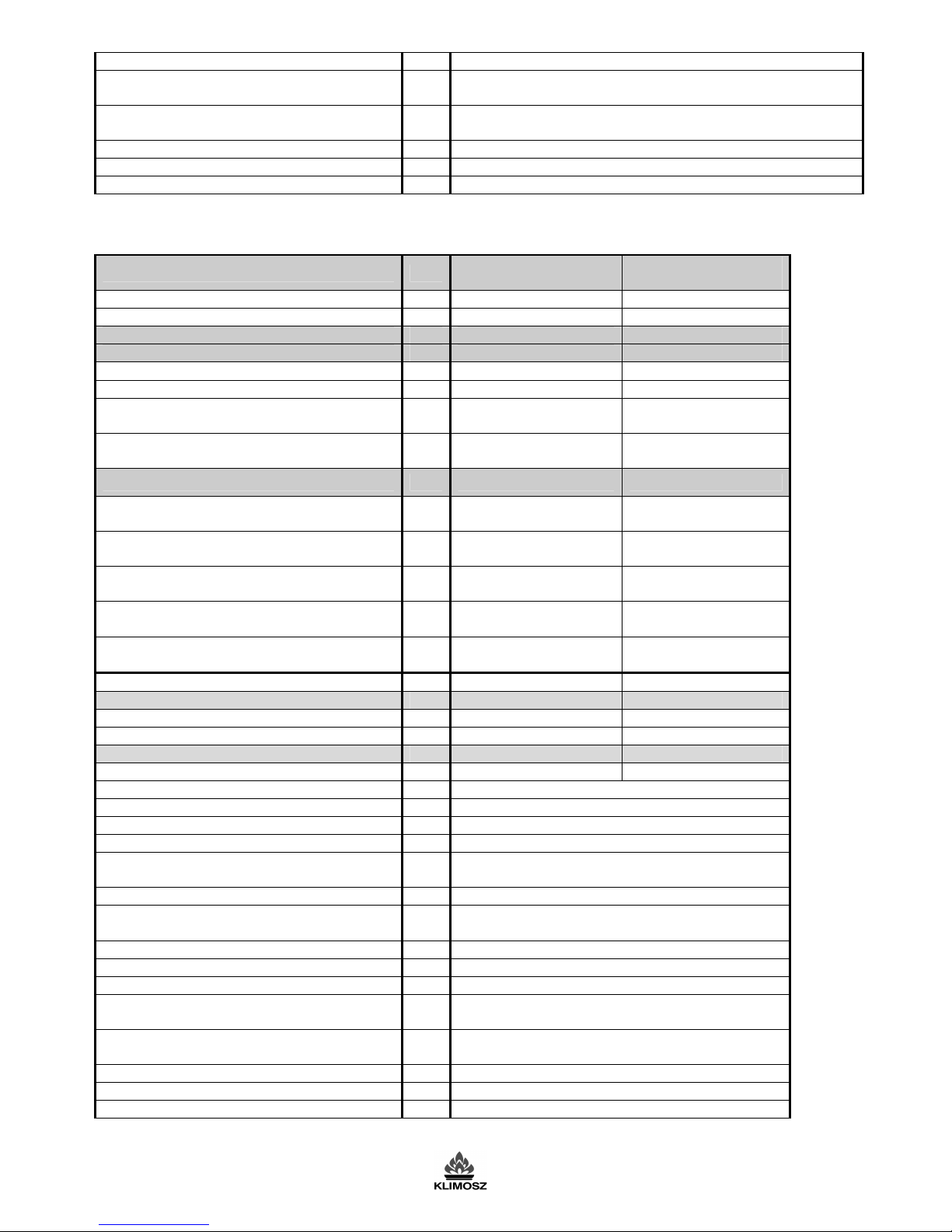

2. Technical Data for KLIMOSZ COMBI B

Table 2. Dimensions and technical parameters of the KLIMOSZ COMBI B boiler.

Parametr SI

Klimosz

Combi B

15

Klimosz

Combi B

20

Klimosz

Combi B

32

Klimosz

Combi B

35

Nominal power - pea coal kW 15 20 32 35

- pellets kW 15 20 20 25

Efficiency - pea coal % 81 80 81,5 81

Efficiency - pellets % 80 78 82,5 81

Power regulation scope - pea coal kW 5,0 ÷ 15,0 6,0 ÷ 20,0 9,6 ÷ 32 10,5 ÷ 35

- pellets kW 5,0 ÷ 16,0 6,0 ÷ 20,0 6,0 ÷ 20,0 7,5 ÷ 25

Use of fuel at nominal power – continuous

heating - pea coal 27,5 MJ/kg

kg/h 2,5 3,3 5,1 5,7

- pellets 18 MJ/kg

kg/h 3,8 5,1 4,8 6,4

Storage bin volume dm

3

230 230 230 230

Approximate combustion time at nominal power

- pea coal 27MJ/kg

dni 8,0 6,5 4,0 3,5

- pellets 16MJ/kg

dni 4,5 3,5 3,5 3

Flow of fumes in the smoke conduit - pea coal

- nominal power

g/s 11,2 15,31 17,68 18,9

Flow of fumes in the smoke conduit - pellets

- nominal power

g/s 12,4 16,7 16,7 18,1

Recommended working temperature for heating

water

°C 100 ÷ 250 100 ÷ 260 100 ÷ 260 100 ÷ 260

Boiler class - 3 3 3 Mass kg 460 475 490 525

Heating area of the boiler m

2

- - - Water volume dm3 31 40 50 60

Diameter of fumes outlet mm 156 156 156 156

Chimney draught Pa 10 ÷ 15 10 ÷ 20 10 ÷ 20 15 ÷ 20

Water maximal working pressure bar 4,0

Water minimal working pressure bar Water maximal trial pressure bar 8,0

Fluid group - 2 – woda

Recommended working temperature for heating

water

°C

65 ÷ 80

Maximal working temperature for heating water °C 90

Minimal temperature of water returning to the

boiler

°C

50

Maximal permitted level of heating material m 30

Safety valve bar 4,0

Noise level dB < 65 (A)

Connections of the boiler - heating and returning

water

2 ” lub 6/4” GZ

Resistance of water flow through the boiler ∆t =

20oC

mbar 0,4 ÷ 20

Electric energy consumption (fan / motor) - 230V / 50 Hz

Electric energy consumption (shot light-option) W 180 / 80

Electric insulation - IP 40

Operation and installation manual part 2. 2015.10.08

5

• Fuel parameters:

•

calorific value

kgMJQ

r

i

/15>

;

•

ash content

%12<

r

A

;

•

moisture content coal pellets

%15<

r

W

,

wood

%20<

r

W

;

•

volatile matter content

%28>

r

V

;

•

ash fusion point

Ct

o

A

1200>

;

•

caking properties

20

<

RI

(max 30);

•

low swelling

ATTENTION!!! The KLIMOSZ heating boilers are not intended for burning waste and no substances other

than those recommended by the manufacturer can be burnt in them.

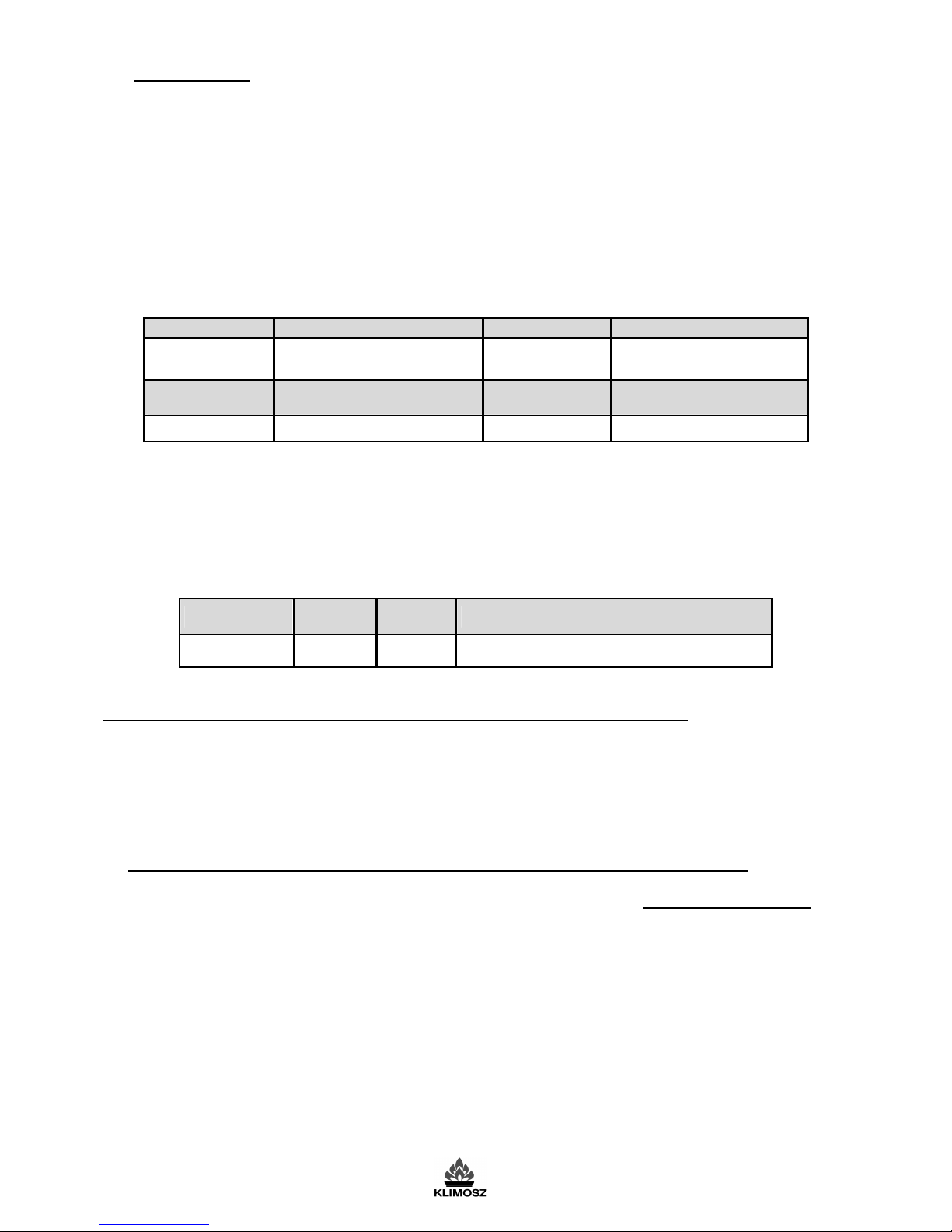

Table 3. Recommended fuel for burning in automatic mode.

Main fuel Fuel type Granulation [mm] Calorific value [MJ/kg]

Hard coal pea grade coal

Gr II 8 ÷ 20

(max 30)

24 ÷ 28 *

Substitute

fuel

Fuel type Granulation [mm] Calorific value [MJ/kg]

Biomass pellets ** Φ 6 ÷ 8 16 ÷ 18

*) Non-caking, non-coking

**) Sawdust granulate (pellets) should be at least hard enough for it to be impossible to crush

a few fuel granules in a clenched fist, preventing the feeder from getting jammed. Light colour grades are

recommended, without bark, which can cause deposit formation in the burner.

Table 4. Recommended fuel for burning in manual mode (emergency combustion chamber of the

KLIMOSZ COMBI and KLIMOSZ COMBI B boiler).

Fuel Unit Size non-coking, non-caking hard coal

Wood (mm) 200 O I [40 ÷ 80]; Ko II [63 ÷ 125]

ATTENTION!!! MOISTURE CONTENT IN FUEL MUST NOT EXCEED 15%. USING MOIST FUEL

RESULTS IN A CONSIDERABLE REDUCTION IN THE BOILER'S POWER CAPACITY (EVEN BY AS

MUCH AS 50%) AND REDUCTION IN THE LIFE-SPAN OF THOSE PARTS OF THE BOILER WHICH ARE

IN CONTACT WITH MOIST FUEL. USING IMPROPER QUALITY OR MOIST FUEL RESULTS IN LOSING

WARRANTY RIGHTS WITH RESPECT TO THE PARTS EXPOSED TO CONTACT WITH SUCH FUEL.

3. Construction of the KLIMOSZ COMBI, KLIMOSZ COMBI B boiler

The KLIMOSZ COMBI and KLIMOSZ COMBI B automatic boiler is not maintenance-free; it is

therefore recommended that the user should carefully read the principles of its operation, regulation and

maintenance in order to avoid any problems related to its work. Construction of the KLIMOSZ COMBI boiler

makes it possible to use solid fuels in the automatic or traditional mode as well as to use liquid fuels. The boiler

has been constructed on the base of a cast-iron exchanger of the multi-purpose VIADRUS U22 boiler. The castiron part of the boiler, which is called the upper combustion chamber, can be used for burning coal, coke or wood

as substitute fuel after manual fuel loading. KLIMOSZ COMBI boilers can be installed in a closed system up to

working pressure 4,0 bar.

Under the water grate of the boiler heat exchanger of a U22 boiler, there is an added steel combustion

chamber, with (W version) or without (S version) a water jacket. There are the following cast-iron parts in the

Operation and installation manual part 2. 2015.10.08

6

lower combustion chamber: a round grate, a round deflector above the grate, an elbow or retort, and a steel

chamber of the air mixer. Fuel burning (pea grade coal, pellets) in automatic mode takes place in the lower

chamber. Inside the fuel feeding retort there are holes which regulate the pressure of air needed for burning, which

prevents flames from reaching the fuel feeder during the burning process. Under the combustion chamber there is

an ash pan.

Next to the boiler, there is a fuel storage bin with a feeder screw at the bottom. The ash pan capacity is

suited to the capacity of the fuel bin, i.e. the ash pan should be filled with ash after the entire fuel from the bin has

been burnt. There is a water tank behind the fuel bin for emergency extinguishing (when pea grade coal is used as

fuel) or a place for installing a thermostatic valve (required when pellets are used as fuel) – a protective device in

case flame gets to the fuel bin.

The fan which supplies air for combustion is situated before the fuel bin and is connected to the mixer.

The amount of air is controlled electronically by the boiler regulator.

The inlet and outlet of heating water is situated at the back part of the boiler. At the back of the boiler there

is a smoke conduit, which carries flue gas to the chimney.

The exchanger is insulated with mineral wool, which reduces heat loss during combustion. The steel

casing is protected with high quality powder paint.

3.1 Hand-fired furnace of the KLIMOSZ COMBI and KLIMOSZ COMBI B boiler

The KLIMOSZ COMBI and KLIMOSZ COMBI B boiler provides the possibility for burning solid

fuels in the traditional mode. After manual loading, wood and coal, as substitute fuel, can be burnt in the upper

part of the exchanger, called the "upper combustion chamber". The upper combustion chamber is an emergency

chamber, in which burning throughout the heating season is not recommended due to the lower power capacity

achieved as compared to the maximum power capacity of the boiler. For burning in the upper chamber to run

properly, some conditions for chimney draught have to be met.

Operation and installation manual part 2. 2015.10.08

7

4. Boiler dimensions

Fig. 1. Dimensions boilers KLIMOSZ COMBI NG.

S L H S1 S2 L1 L2 L3 H1 H2 Z1 Z2 P1 P2 U1 U2

T

Y

P

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

15

1180 795 1555 550 600 630 30 710 1150 1271 250 275 450 275 430 180

20

1180 795 1555 550 600 725 82 710 1150 1271 250 275 630 275 - -

25

1180 795 1555 550 600 725 82 710 1150 1271 250 275 450 275 430 180

32

1180 900 1555 550 600 822 82 710 1150 1271 250 275 450 275 430 180

42

1180 996 1555 600 610 918 95 710 1150 1271 100 100 450 290 50 100

49

1180 1092 1555 600 610 1014 95 710 1150 1271 290 290 450 290 50 100

Operation and installation manual part 2. 2015.10.08

8

Fig. 2. Dimensions boilers KLIMOSZ COMBI B.

S L H S1 S2 L1 L2 L3 H1 H2 Z1 Z2 P1 P2

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

15

1200 655 1410 550 600 470 185 745 1150 1300 95 272 450 275

20

1200 765 1410 550 600 580 185 745 1150 1300 95 272 450 275

32

1200 860 1410 550 600 728 185 745 1150 1300 95 272 450 275

35

1200 950 1410 550 600 813 185 745 1150 1300 95 272 450 275

Operation and installation manual part 2. 2015.10.08

9

Fig. 3. Dimensions of the additional combustion chamber.

5. Boiler description

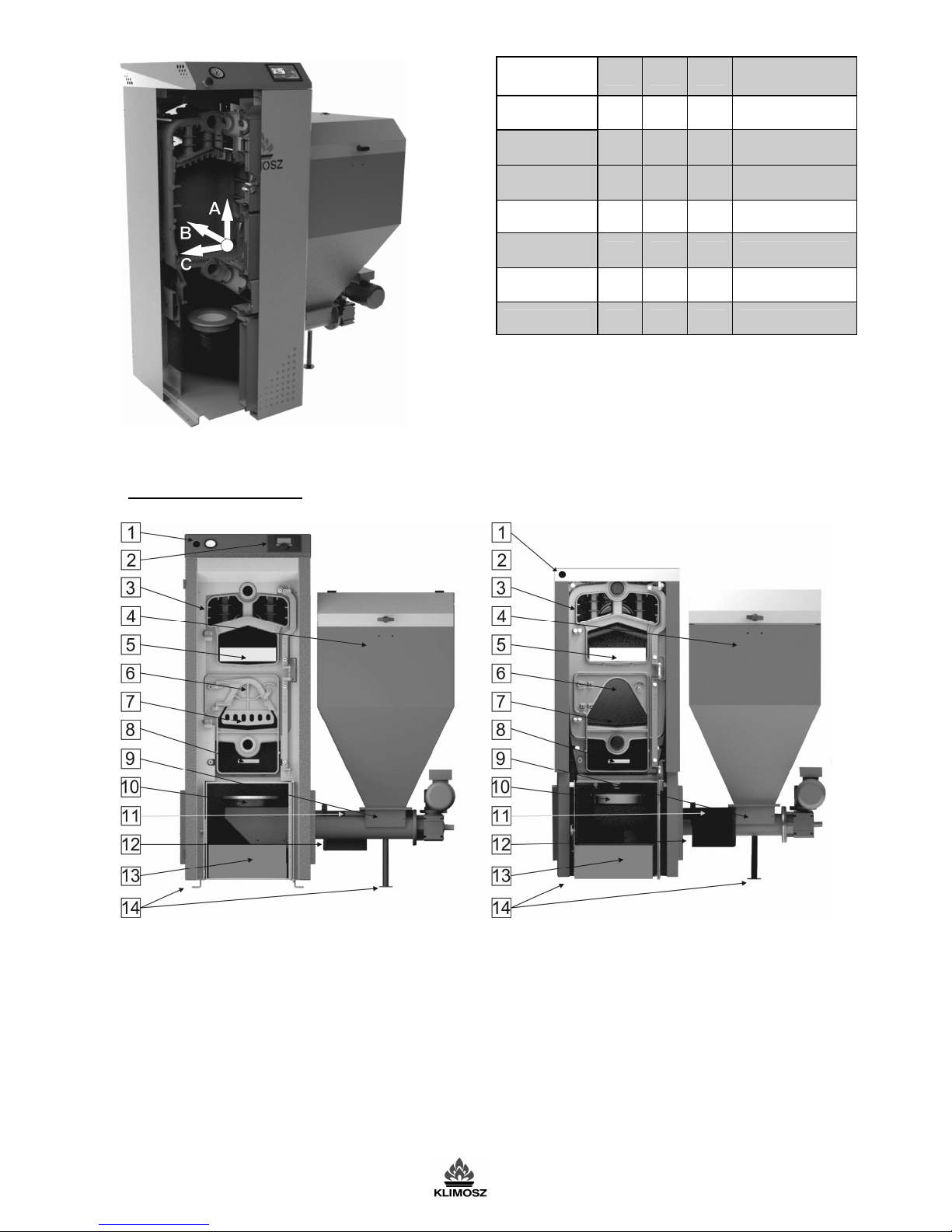

Fig. 4. Description of the KLIMOSZ COMBI and KLIMOSZ COMBI B boilers.

1. Flue gas thermometer (optional); 2. Boiler controller; 3. Boiler cleaning hole; 4. Storage bin; 5. Chamotte

plate; 6. Upper combustion chamber; 7. Inspection hole with the fire grate; 8. Cast- iron deflector. 9. Storage bin

cleaning hole; 10. Retort burner; 11. Measuring hole of feeding pipe ; 12. Fan; 13. Ashpan; 14. Boiler feet.

A B C

Combustion

chamber

[mm] [mm] [mm] [dm3]

COMBI 15

COMBI B 15

410 230 350 33

COMBI 20

COMBI B 20

410 340 350 48,8

COMBI 25

410 340 350 48,8

COMBI 32

COMBI B 32

410 435 350 51,7

COMBI 42

COMBI B 35

410 530 350 76,1

COMBI 49

410 625 350 89,7

Operation and installation manual part 2. 2015.10.08

10

NOTE No alterations in the furnace chamber may be made which could negatively affect the life-span of the

boiler or flue gas emission.

1: Fan connector

2: Air mixer

3: Retort grate

4: Screw feeding channel

5: Anti-smoke holes

6: Retort elbow

Fig. 5. Schematic diagram of a retort furnace in coal

burning.

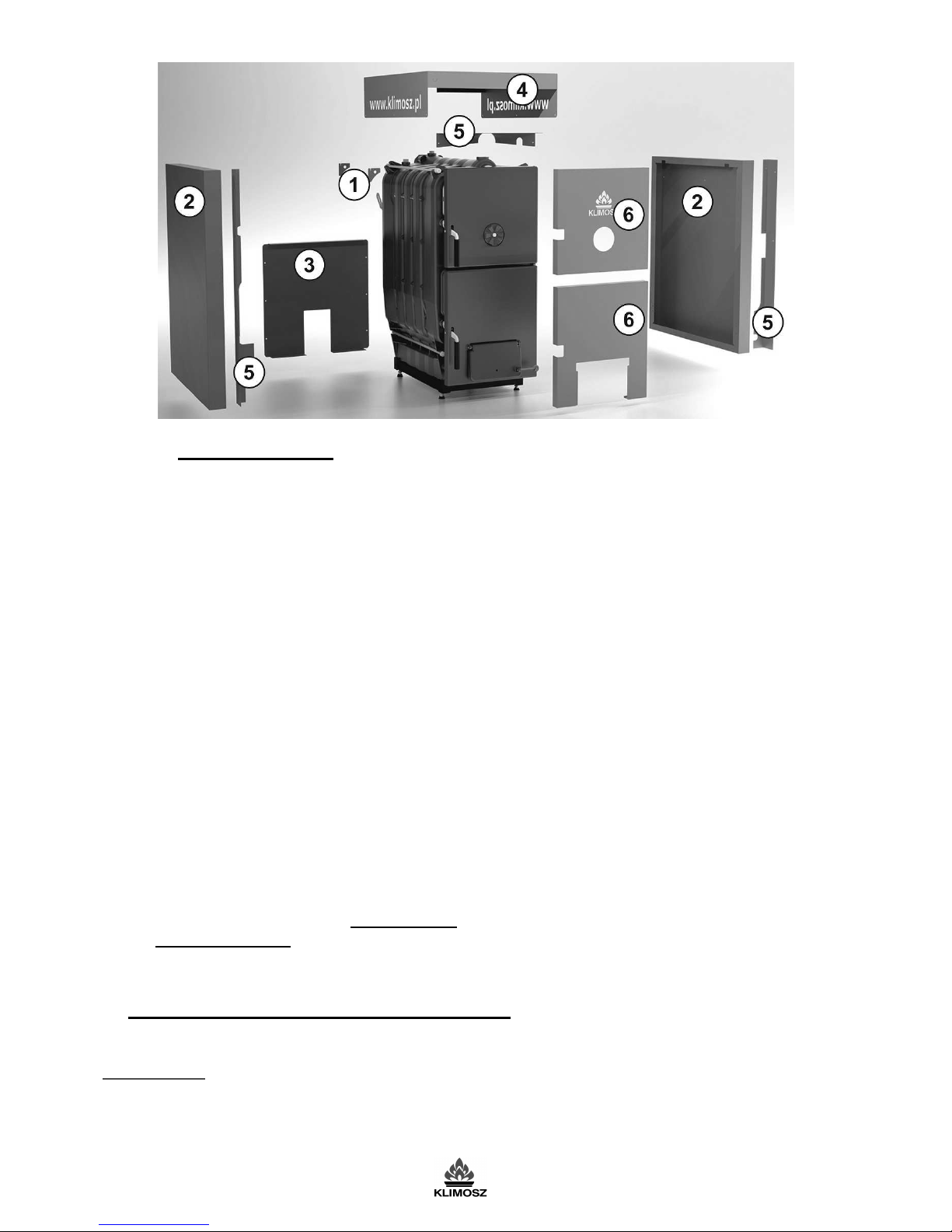

5.1 Delivery and installation KLIMOSZ COMBI B boilers

KLIMOSZ COMBI B boilers are supplied in parts on pallet, which provides easy transport to the boiler

room. On the pallet is: cast-iron VIADRUS U22 boiler (1), Steel base with a retort burner (2), feeding tube (3),

motoreducer (6), feeding screw (5), feet (4), fan (7), storage bin (8), controller (to order), chamotte plate, set of

screw.

Fig. 6. KLIMOSZ COMBI B boiler components.

Operation and installation manual part 2. 2015.10.08

11

5.2 Boiler accessories

Standard: On request:

• Installation and Operation Manual part 1;

• Installation and Operation Manual part 2;

• Regulator Operation Manual;

• screws - hardness class 8.8 (as cotter pins of the

feeder screw) - 2 items;

• cast-iron deflector above the burner of the

KLIMOSZ COMBI boiler - 1 item;

• chamotte plates in the upper furnace in

KLIMOSZ COMBI, KLIMOSZ COMBI B (see

table Number of chamotte plates in the Klimosz

Combi boiler);

• protective plate (covers the retort burner when the

upper combustion chamber is used) 15 ÷ 49 kW–

1 item;

• emergency extinguishing tank – “fire fighter”

only in KLIMOSZ COMBI.

• paraffin fuse - 1 item only in KLIMOSZ COMBI;

Required when biomass is used as fuel:

• protecting valve, e.g. STS Watts

(instead of the "fire fighter”)- required for all

boilers 55 ÷ 75 kW;

• limit switch of the storage bin.

• regulator of boiler;

• emergency extinguishing tank – “fire

fighter” for KLIMOSZ COMBI B.

• paraffin fuse - 1 item for KLIMOSZ

COMBI B;

• room thermostat;

• manual 4-way mixer (e.g. ESBE);

• mixer actuator (e.g. ESBE);

• domestic water heater (e.g. DRAŹICE);

• automatic pellet lighter (up to 35 kW);

• flue gas temperature sensor (option aimed to

activate the information that it is necessary to

clean the boiler).

6. Installation of the fire-resistant catalyst

ATTENTION! The boiler must not be operated without deflector in the retort furnace, as it leads to

accelerated depositing of soot on the boiler due to incomplete burning, and to quicker wearing of the

boiler’s steel parts.

Operation and installation manual part 2. 2015.10.08

12

Table 5. Number of catalysts (chamotte) in a KLIMOSZ COMBI and KLIMOSZ COMBI B boiler.

Boiler Plate [mm]

KLIMOSZ COMBI, COMBI B Chamotte plate

Klimosz Combi NG 15, Combi B 15 2 pc.

Klimosz Combi NG 20, Combi B 20 3 pc.

Klimosz Combi NG 25 3 pc.

Klimosz Combi NG 32, Combi B 32 4 pc.

Klimosz Combi NG 42, Combi B 35 5 pc.

Klimosz Combi NG 49 6 pc.

Fig. 8. Position of ceramic catalyst on the exchanger shelves in a KLIMOSZ COMBI and KLIMOSZ COMBI B

boiler.

7. Checking the leak-tightness of the grate

In order to achieve complete burning of fuel in the grate, it is important to maintain leak-tightness between the

grate and the retort burner and absence of any blocking of the nozzles which supply air flow

as well as the cleanliness of the mixer. It may be necessary

to seal the grate and clean the burner when:

- fuel does not burn completely in the grate and

incompletely burnt fuel is removed to the ash pan;

- the heat exchanging area of the heat exchanger gets

soiled quicker than usual;

- the flame is short and irregular when the boiler is being

heated up;

- fuel burns unevenly in the burner grate.

NOTE: The burner grate should be fixed such that

a false draught should not leak out from under it. It should be fixed tightly, with no possibility of turning.

Burner maintenance procedure:

Remove the cast-iron ring to seal the grate. The grate surface on which sealing will be applied should be

cleaned thoroughly to ensure good contact of the material with the sealing. The parts should be sealed with

fireplace silicon with a working temperature of greater than 1200oC, which should be applied evenly around the

grate perimeter.

Put the grate with silicon slowly onto the other part of the burner. Another obligatory action is to clean the

mixer of any impurities which may have got there during the installation or dismantling of the grate.

8. Notes about hand-firing the fuel in the upper combustion chamber

Operation and installation manual part 2. 2015.10.08

13

8.1 Types of fuel

Klimosz boilers are equipped with another emergency combustion chamber, which is used mainly for the

occasional burning of solid unsorted fuels. Wood used as fuel should not have more than a 20% moisture

content. The recommended fuel is wood, wooden waste, non-caking briquettes with granulation of 30 to 80 mm.

When lighting a fire in a boiler and when the chimney is cold, it is recommended that the chimney should

be heated up with wooden firelighter. After the boiler has been lit, and when some fuel has been burnt, the embers

in the grate should be stirred. The procedure should be interrupted when glowing fuel drops to the ash pan. The

operation is performed with a hook through the door of the upper combustion chamber. After completing the

procedure, top up the fuel without extinguishing the boiler. Fuel can be added only when the blow-in fan is

switched off. Larger unburnt pieces of fuel from the ash pan can be thrown back into the furnace.

Air inflow for combustion is regulated with a controller which regulates the fan operation and/or by

a flap on the fan. In prolonged hand-firing, it is recommended that all the fuel (pea grade coal or pellets)

should be removed from the fuel bin, feeding screw pipe and the retort burner. In this case, the protective

plate should also cover the retort burner hole. This prevents soiling of the retort burner.

8.2 Lighting the boiler

The boiler may be operated only by adults,

who know the principles of its operation,

and who follow this

Operation Manual.

The following should be done before the boiler is lit:

• check whether there is enough water in the central heating and domestic water systems;

• check whether the grate, ash pan and flue conduits are clean;

• remove the ceramic catalysts from the retort furnace chamber;

• put the protective plate on the retort burner (this prevents lighting the fuel in the retort burner as a result of

embers falling down from the upper grate to the ash pan);

• when burning in the upper chamber in the hand-firing mode, remove fuel from the retort in order to properly

supply air for combustion. When burning is continued for more than two weeks, fuel should also be removed

from the bin;

• switch on the hand-firing mode – “hand firing” in the burning type options on the regulator.

Put firelighter (paper) and wood through the charging door over the entire grate area. Light the firelighter

through the door of the combustion chamber. Close the door and open slightly the ash pan door, providing air

supply to the combustion chamber. Put a layer of fuel onto the burning wood. After lighting the fire, switch the

regulator to the hand-fire mode, set the desired temperature and close the ash pan door. When the fuel is burning

well, stoke the fire by putting in another portion of fuel (switch off the blow-in fan on the regulator when loading

in fuel) Attention!!! No flammable liquids can be used and the boiler cannot be overheated when lighting the

fire. No flammable materials can be left near the boiler.

8.3 Boiler operation

Fuel should be topped up as needed and in accordance with the intensity of burning. Fuel should be added

evenly so that it does not form a pyramid. Ash and slag should be removed from the grate only when it starts to

hinder combustion. The procedure should be interrupted when, during the grate cleaning with a hook, embers start

to fall down to the ash pan.

In the evening, before burning in the boiler during the night, the grate should be cleaned thoroughly. In the

morning, after night burning, remove caked coal with a hook to clear the air supply. Put some fuel onto the embers

and do not remove ash and caked fuel from the grate until the fuel is burning. Then add fuel until the combustion

Operation and installation manual part 2. 2015.10.08

14

chamber is full. Each time you check the amount of fuel in the combustion chamber and each time before stoking

the fire, switch off the fan on the regulator (preferably by switching off the regulator) and delay opening the

loading door until the fan stops; the door is leak-tight and you should first loosen it slightly, wait until pressure in

the combustion chamber equalises and only then can you open the door fully. This will prevent hot flue gas from

being blown out into the boiler room. The lower door of the furnace, the door of the lower combustion chamber

and the loading door must be tightly closed during the boiler operation.

NOTE: When opening any of the boiler's doors, stand in such a way as to prevent any hot gas from the boiler from

causing harm to you or to anyone standing nearby.

Adding more fuel – switch off the fan first (preferably by switching off the regulator). After the fan is

switched off and stopped, open the lower door of the boiler. Open the upper door of the boiler after a while,

unsealing it first, and put in a layer of fuel. After the upper and lower door is closed, switch on the fan by pressing

the button (as above). The boiler is now in normal operation mode. Do not add too much fuel as it may cause the

boiler to overheat quickly and it negatively affects the boiler's parameters as well as the parameters of emission of

hazardous substances in flue gas.

8.4 Boiler maintenance

Remove ash to non-flammable, closed containers with increased resistance to corrosion (for example zincplated). The boiler can be cleaned only after it has been extinguished and cooled down!!! Cleaning the walls

of the upper combustion chamber can be easily done through the open upper door. Cleaning the smoke conduits is

done through the inspection hatch under the casing (the same as cleaning in automatic mode). The boiler can be

cleaned with the cleaning tools supplied with it. A boiler that has been soiled with tarry substances should be

cleaned in two steps. First, tarry deposits should be burnt out with suitable agents (for example Sadpal), and then

the heat exchange areas should be cleaned with a brush. Cleaning semi-liquid tarry deposits results in damage to

the brush and is ineffective, resulting only in spreading the tar over the boiler surface.

After the boiler surface and smoke conduits have been cleaned, close the inspection hatch tightly.

NOTE: Avoid accumulation of tarry deposits and soot on the heat exchanger areas and in smoke conduits. This

reduces the boiler’s efficiency and poses a serious hazard of soot and tar ignition in the chimney duct, which

usually results in damaging the chimney and even the building walls and in fire.

Take care to make the boiler leak-tight (combustion chamber door, ash pan door, mixer cleaning hole, fuel

bin cover, etc.) in order to avoid flue gas being expelled from the boiler into the boiler room.

If the boiler is not in use for more than 2 days (for example, after the heating season), it must be cleaned

and the fuel bin and the fuel feeding system emptied of fuel. Leave the boiler with the doors and inspection

hatch covers open to enable its ventilation and to avoid moisture condensation on the steel surfaces of the

boiler.

Loading...

Loading...