Klimawent WP-11/Ex Use And Maintenance Manual

1

04.06.2019 explosion-proof duct fan WP-11/Ex

Use and Maintenance Manual

Explosion-proof duct fans

WP-11/Ex

Contents:

1. Introductory Remarks ......................................................................................................... 2

2. Application........................................................................................................................... 3

3. Reservations of Producer ................................................................................................... 3

4. Technical Data ..................................................................................................................... 4

5. Structure and Function ....................................................................................................... 5

6. Assembly and Start-up ....................................................................................................... 5

7. Operational Use ................................................................................................................... 8

8. Troubleshooting Guide ....................................................................................................... 9

9. Maintenance ........................................................................................................................ 9

10. Occupational Health and Safety ....................................................................................... 10

11. Transport and Storage ...................................................................................................... 10

12. Terms of warranty ............................................................................................................. 10

13. Sample of the Declaration of Conformity ........................................................................ 11

888W40

WP-11/Ex

04.06.2019/EN

2

explosion-proof duct fan WP-11/Ex 04.06.2019

1. Introductory Remarks

The purpose of the present Use and Maintenance Manual is to supply User with directions within the range of application, installation, start-up and the use of the WP-11/Ex explosion-proof

duct fans.

Installing, start up and operational use are exclusively admissible after getting acquaintted with the contents of the Use and Maintenance Manual.

With regard to continuity of work carried on improvement of our products, we reserve for oursel-

ves the revision possibility of the draft and technological changes improving their functional fea-

tures and safety.

Construction of the WP-11/Ex explosion-proof duct fans meets the requirements of the current

state of technology as well as the safety and health assurances included in:

2006/42/EC Machinery Directive of the European Parliament and of the Council of May 17th,

2006 on machinery – amending the 95/16/EC (recast) /Journal of Laws EC L157 of 09.06.2006, page 24/

2014/35/EC Directive of the European Parliament and of the Council of February 26th, 2014

on the harmonisation of the laws of the Member States relating to the making available on the

market of electrical equipment designed for use within certain voltage limits.

/Journal of Laws EC L96 of 29.03.2014/

2014/34/EC ATEX Directive of the European Parliament and of the Council of February 26th

2014 on the harmonisation of the laws of Member States relating to equipment and protective

systems intended for use in potentially explosive atmospheres.

/ Journal of Laws EC L96 of 29.03.2014 /

Additionally, the appliance meets following harmonized standard:

●

EN ISO-12100:2012

–

“Safety of machinery – Basic concepts, general principles

for design. Risk assessment and risk reduction”.

●

EN 60204-1:2018-12

–

“Safety of machinery – Electrical equipment of machines.

Part 1: General requirements”.

●

EN ISO 13857:2010

–

“Safety of machinery – Safe distances to prevent hazard

zones being reached by upper and lower limbs”.

●

EN 80079-0:2013/A11:2014

–

“Electrical appliances in areas of gas explosion risk. Part 0:

General requirements”.

●

EN 60079-7:2016-02

–

“Electrical appliances for areas of gas explosion hazard.

Part 7: Increased safety construction “e”.

●

EN 1127-1:2011

–

“Explosive atmospheres. Explosion prevention and protec-

tion. Basic terminology and methodology”.

●

EN ISO 80079-36:2016-07

–

“Explosive atmospheres – Part 36: Non-electrical equip-

ment for explosive atmospheres. Methodology and requi-

rements.

●

EN ISO 80079-37:2016-07

–

“Explosive atmospheres – Part 37: Non-electrical equip-

ment for explosive atmospheres. Non-electrical types of

protection. Constructional safety “c”, supervised ignition

“b”, immersion in a liquid “k”.

●

EN 14986:2017-02

–

“Designing of fans applied in areas of explosion hazard”

●

ISO 14694:2003+AMD1:2010

–

“Industrial fans – Guidelines on the quality of balancing

and the vibration level.

●

ISO 14695:2008/AC:2017-10

–

“Industrial fans – Methods of measurements of vibration

of fans.

3

04.06.2019 explosion-proof duct fan WP-11/Ex

2. Application

Duct fans are designed for general ventilation of the rooms, where explosive atmosphere, (i.e.

mixture of flammable substances in form of gas and vapour with the air, whereby after their

ignition – in atmospheric conditions – the burning mass would expand within the whole nonburning mixture) is likely to occur.

the whole non-burning mixture) is likely to occur.

The appliances are meant for installing inside the rooms (indoor application), directly in the

system of round ventilation ducts. They have been constructed for application within temperature range -20 up to 40C.

The forwarded air must be of dustiness not exceeding 0,3 g/m3, without viscous pollutants and

without aggressive compounds, and maximum temperature 60C.

According to the 1914/34/EC ATEX Directive and EN ISO 80079-36 the device carries the level

of protection: “HIGH” – as a device classified for Group II, Category 2, and it can work in areas

where explosive atmospheres are likely to occur. The fan can be applied in zones 1, 2 (G).

Specification of the operational zones and the knowledge on hazards caused by atmosphere of explosion risk in those zones – belongs to operator of the appliance.

The appliance is marked on the nominal data plate:

II 2 G c Ex eb IIB T3

Marking of the operational conditions of the device: group / category / hazard / class.

marking for explosion proof properties of the appliance,

group II – the device is designed for on-ground work, in factories, in areas of explosion

hazard, but this cannot be methane (firedamp) hazard neither carbon dust occurrence,

category 2 – the device is designed for application in areas where explosive atmospheres are likely to occur,

gas hazard G,

“c” – category of protection against the ignition – constructional protection,

Ex – mark of the electrical device – constructed and tested according to the European Stan-

dards for work in areas of explosion hazard,

execution “e” – type of construction of the motor (a motor of increased safety)

“b” – protection by means of controlling the ignition sources,

gas explosion group IIB – occurring in on-ground factories – the fans are constructed according to the PN-EN 14986:2009, whereby they can be applied for gases in explosion groups

IIA and IIB and hydrogen,

temperature class T3 – the surface temperature of any part of the appliance should not ex-

ceed 200ºC (during the normal operation). The device can be used safely in explosive atmospheres belonging to temperature classes T1, T2, T3.

3. Reservations of Producer

A.

Manufacturer accepts no liability for any consequences following from the operational use

that is in contradiction to the purpose of application.

B.

Installing of any additional elements not belonging to the normal device structure (or acces-

sory set) is not acceptable.

C.

Do not undertake any structural changes or constructional modifications on the device on

one’s own.

D.

Protect the appliance’s housing from mechanical damage.

E.

Prior to installing check the load carrying capacity of the building structure where the device

will be mounted. Unsure mounting could cause hazard to personnel/people in vicinity and

effect in damage of the device.

4

explosion-proof duct fan WP-11/Ex 04.06.2019

F.

Do not use the fan for conveying the air containing viscous impurities that

could deposit (build up) on the device surface, especially on the impeller.

G.

Neither use it for forwarding the air with aggressive pollutants which

will destructively effect the device structure.

H.

During operation, the maximum impeller rotations should not exceed the nominal rotations.

I.

Manufacturer is not responsible for wounds, injuries, body laceration experienced

by User or personnel during the improper operational use.

4. Technical Data

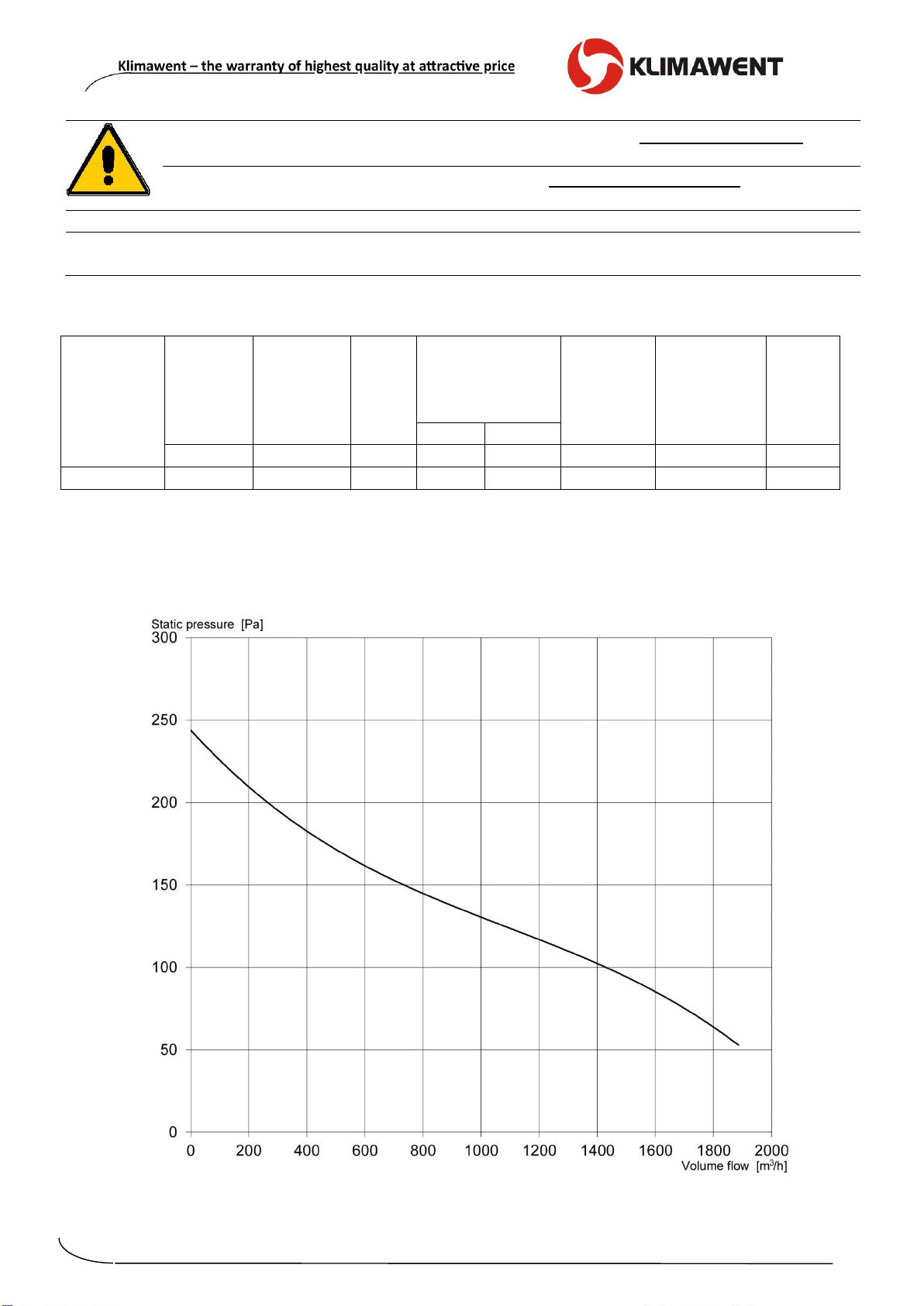

Table No.1

Type

Rotations

Supply

voltage

Motor

rate

Acoustic

pressure level

[dB(A)] from

distance

Maximum

volume

flow

Maximum

vacuum

Weight

1m

5m

[r.p.m.]

[V]

[W]

1m

5m

[m3/h]

[Pa]

[kg]

WP-11/Ex

1320

3 x 400

120

47,4

33,4

1885

245

6,5

1. ingress protection of the motor: IP 44

2. operational temperature range: -20

o

C ÷ 40

o

C

3. explosion group: II

4. explosion zone: 1 and 2

5. temperature class: T3

Fig. No.1 – WP-11/Ex – Flow chart

Loading...

Loading...