Page 1

TROUBLESHOOTING

Page 2

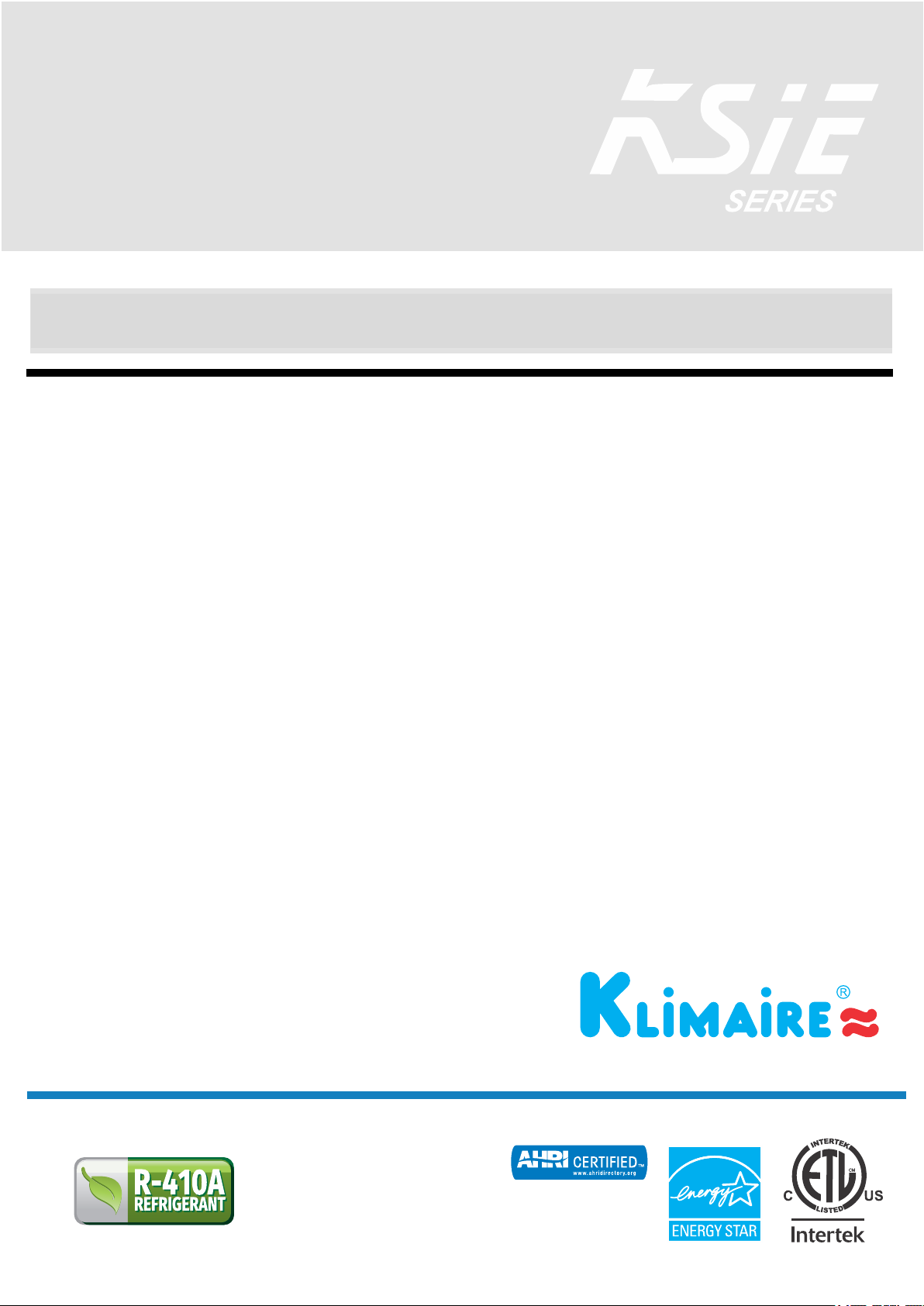

9. Troubleshooting

Safety

Electricity power is still kept in capacitors even the power supply is shut off. Do not forget to discharge the electricity

power in capacitor.

Electrolytic Capacitors

(HIGH VOLTAGE! CAUTION!)

For other models, please connect discharge resistance (approx.100Ω 40W) or soldering iron (plug) between +, -

terminals of the electrolytic capacitor on the contrary side of the outdoor PCB.

Note: The picture above is only for reference. The plug of your side may be different.

1

Page 3

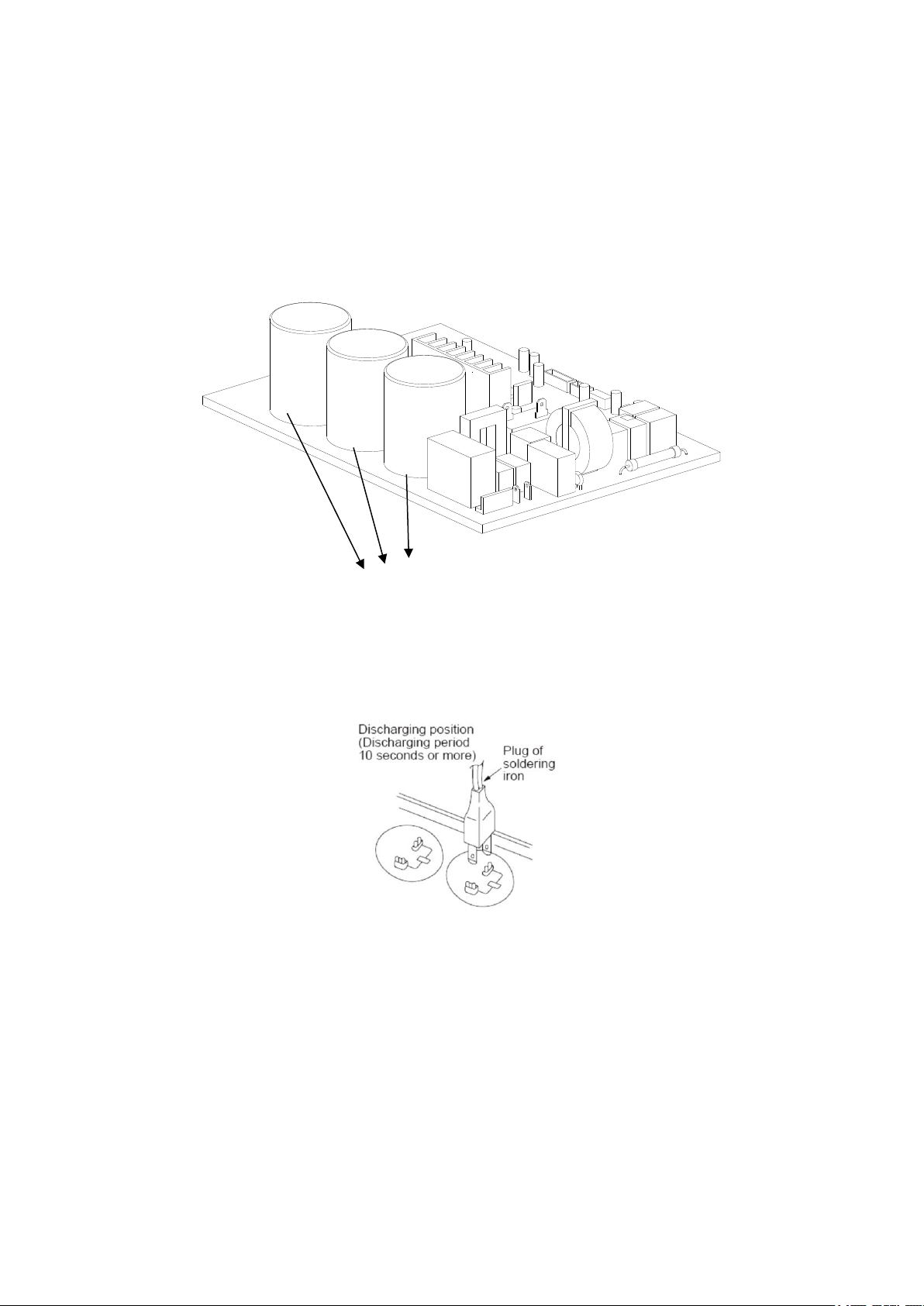

9.1 Indoor Unit Error Display

Operation

lamp

Timer lamp

Display

LED STATUS

☆ 1 time

X

E0

Indoor unit EEPROM parameter error

☆ 2 times

X

E1

Indoor / outdoor units communication error

☆ 3 times

X

E2

Zero-crossing signal detection error

☆ 4 times

X

E3

Indoor fan speed has been out of control

☆ 5 times

X

E4

Indoor room temperature sensor T1 open circuit or short

circuit

☆ 6 times

X

E5

Evaporator coil temperature sensor T2 open circuit or

short circuit

☆ 7 times

X

EC

Refrigerant leakage detection

☆ 1 times

O

F0

Overload current protection

☆ 2 times

O

F1

Outdoor ambient temperature sensor T4 open circuit or

short circuit

☆ 3 times

O

F2

Condenser coil temperature sensor T3 open circuit or

short circuit

☆ 4 times

O

F3

Compressor discharge temperature sensor T5 open

circuit or short circuit

☆ 5 times

O

F4

Outdoor unit EEPROM parameter error

☆ 6 times

O

F5

Outdoor fan speed has been out of control

☆ 1 times

☆

P0

IPM malfunction or IGBT over-strong current protection

☆ 2 times

☆

P1

Over voltage or over low voltage protection

☆ 3 times

☆

P2

High temperature protection of compressor top

diagnosis and solution(only for 9k,12k models)

☆ 4 times

☆

P3*

Outdoor ambient temperature too low.

☆ 5 times

☆

P4

Inverter compressor drive error

☆ 6 times

☆

P5

Indoor units mode conflict (multi-zone ONLY)

O(light) X(off) ☆(flash)

*P3

1) In heating mode, when the outdoor temperature is lower than -25 for 1 hour, the indoor unit display error

code P3.

2) If the OUTDOOR temperature is higher than -22c for 10 minutes and compressor stop for 1 hour OR outdoor

temperature is higher than -5C for 10 minutes, then the unit will return to work.

2

Page 4

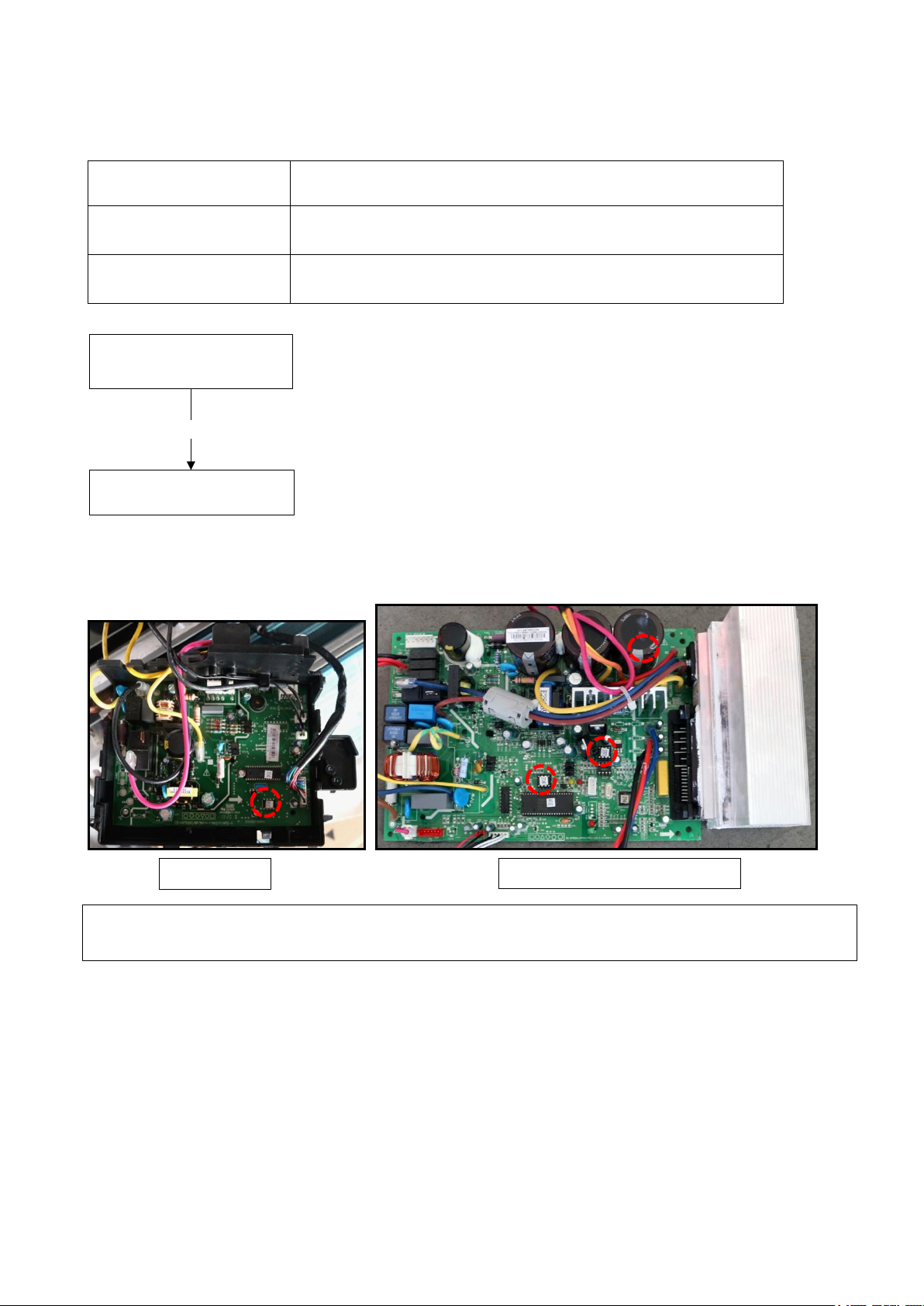

9.2 Outdoor unit error display(TBD)

Error Code

E0/F4

Malfunction decision

conditions

Indoor or outdoor PCB main chip does not receive feedback

from EEPROM chip.

Supposed causes

● Installation mistake

● PCB faulty

Yes

Replace the indoor/outdoor

main PCB.

Power off, then restart the

unit 2 minutes later.

Indoor PCB

Outdoor PCB

Note: The two photos above are only for reference, it’s may be not same totally with the ones on

your side.

9.3 Diagnosis and Solution

9.3.1 EEPROM parameter error diagnosis and solution(E0/F4)

Trouble shooting:

EEPROM: a read-only memory whose contents can be erased and reprogrammed using a pulsed

voltage. For the location of EEPROM chip, please refer to the below photos.

3

Page 5

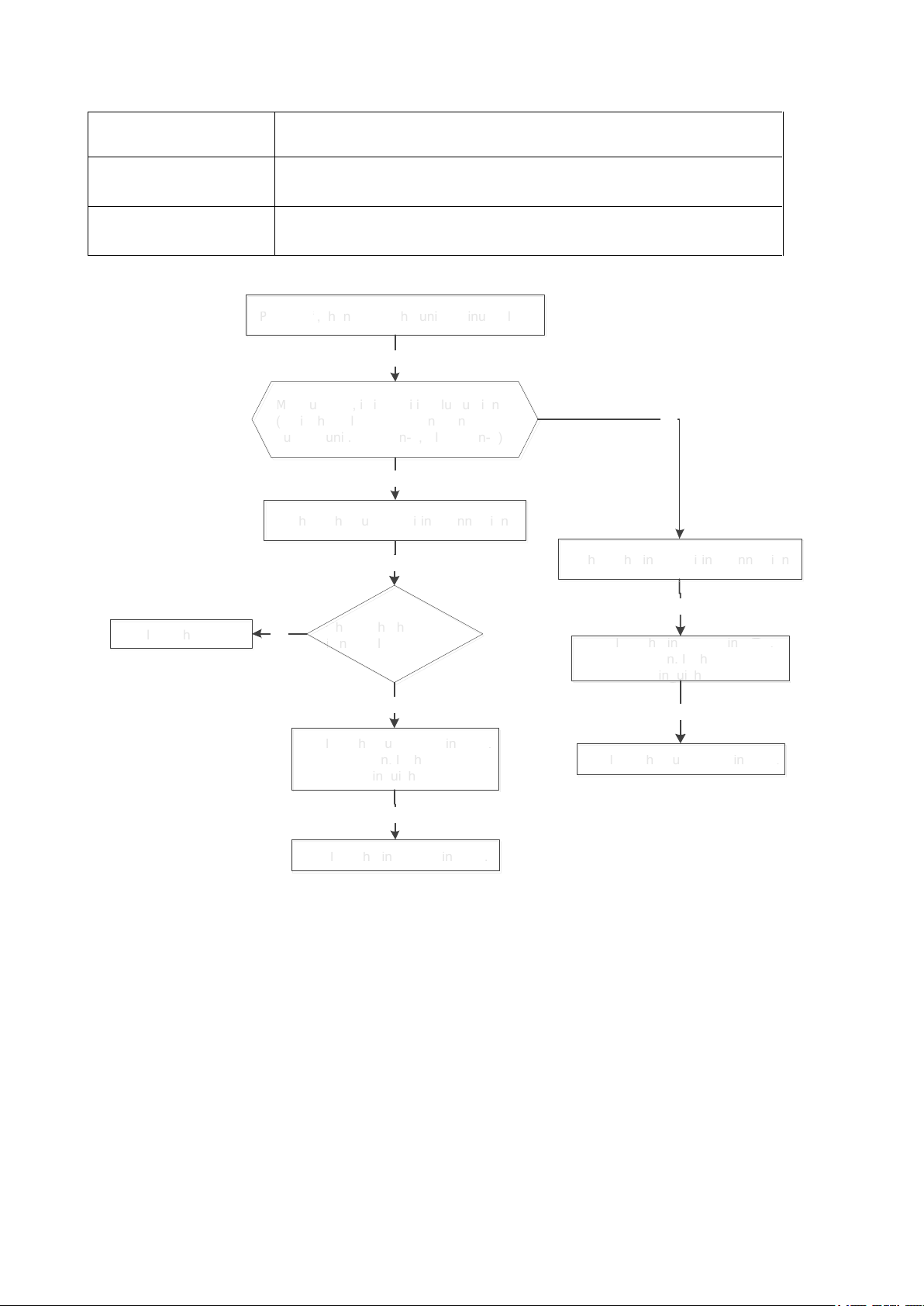

9.3.2 Indoor / outdoor unit’s communication diagnosis and solution(E1)

E1

Indoor or outdoor PCB faulty

M

eas

ureVs

V

w

Measure Vs, is it positive fluctuation?

(Vs is the voltage between 2 and 3 of

outdoor unit. Red pan-3, Black pan-2)

Yes

w

Power off, then restart the unit 2 minutes later

No

w

x

Replace the outdoor main PCB.

Power on. Is the error

extinguished?

Check the outdoor wiring connection

Replace the indoor main PCB.

Power on. Is the error

extinguished?

Yes

Replace the outdoor main PCB.

No

Replace the indoor main PCB.

No

w

Check the indoor wiring connection

Yes

Yes

Check whether reactor

is normal?

Yes

Replace the reactor No

Error Code

Malfunction decision

conditions

Indoor unit does not receive the feedback from outdoor unit during

110 seconds and this condition happens four times continuously.

Supposed causes ● Wiring mistake

●

Trouble shooting:

*

* Vs is the voltage between S and N ( for 115V 2014 models)

*Vs is the voltage between 2 and 3 ( for 2015 models)

4

Page 6

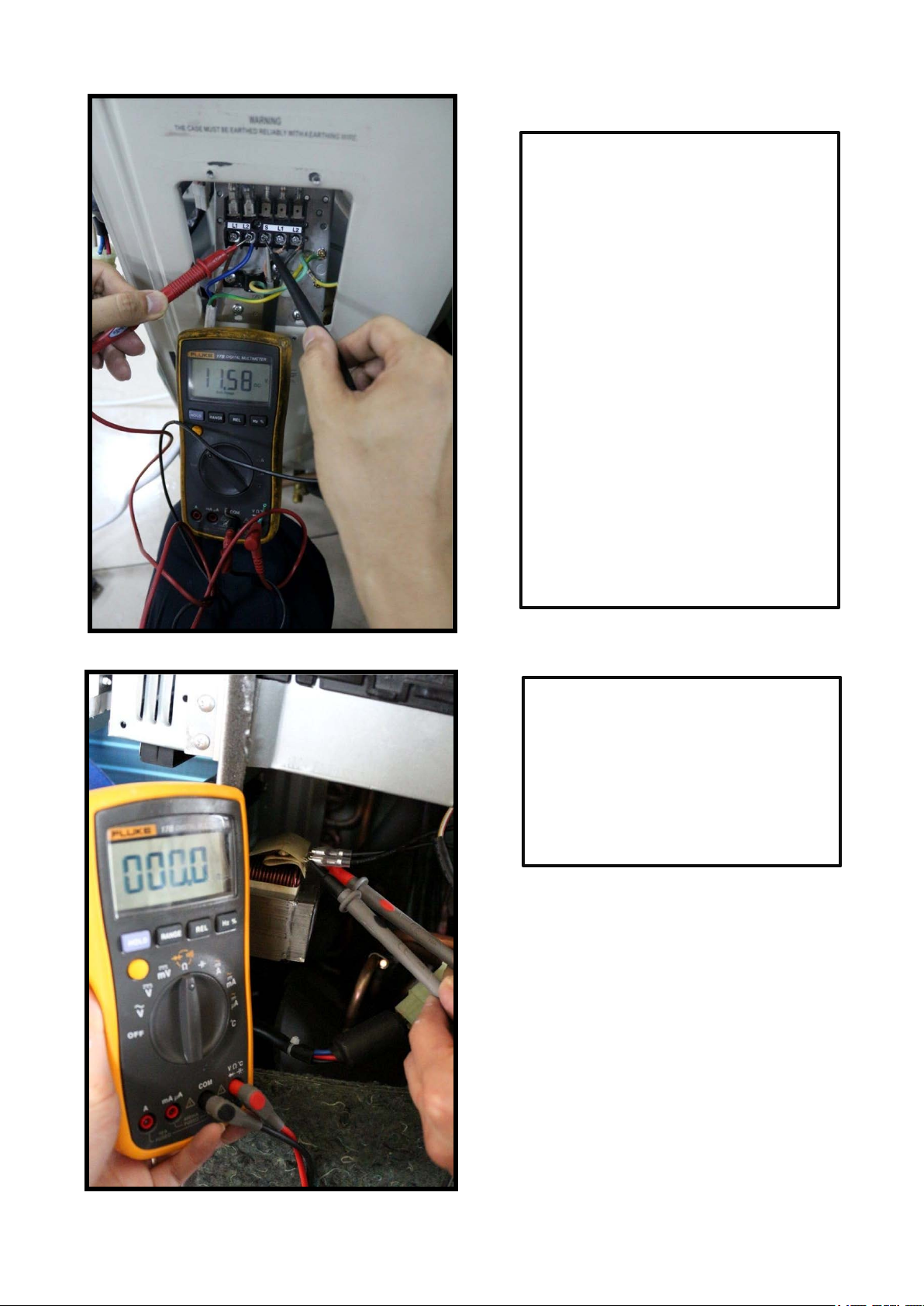

Remark:

Use a multimeter to test the DC voltage

between 2 port and 3 port of outdoor unit.

The red pin of multimeter connects with 2

port while the black pin is for 3 port.

When AC is normal running, the voltage

will move alternately between -50V to

50V.

If the outdoor unit has malfunction, the

voltage will move alternately with positive

value.

While if the indoor unit has malfunction,

the voltage will be a certain value.

Remark:

Use a multimeter to test the resistance

of the reactor which does not connect

with capacitor.

The normal value should be around zero

ohm. Otherwise, the reactor must have

malfunction and need to be replaced.

5

Page 7

9.3.3 Zero crossing detection error diagnosis and solution (E2)

Error Code

E2

Malfunction decision

conditions

When PCB does not receive zero crossing signal feedback for 4

minutes or the zero crossing signal time interval is abnormal.

Supposed causes

● Connection mistake

● PCB faulty

Check if the connections and

power supply is normal?

Correct the connections. Turn on the

unit when the power supply is good.

No

Yes

Indoor main PCB is

defective. Replace indoor

main PCB.

Trouble shooting:

6

Page 8

9.3.4 Fan speed has been out of control diagnosis and solution(E3)

Error Code

E3

Malfunction decision

conditions

When indoor fan speed keeps too low (300RPM) for certain time,

the unit will stop and the LED will display the failure.

Supposed causes

● Wiring mistake

● Fan ass’y faulty

● Fan motor faulty

● PCB faulty

Power off, then restart the

unit 2 minutes later

Shut off the power supply,

Rotate the fan by hand.

The unit operates normally.

Find out the cause and have

it solved

Check the wiring of fan

motor

No

Yes

No

Correct the connections.

No

NoReplace the fan motor

Yes

Yes

Measure the voltage for the

fan motor from the main

PCB

Yes

Replace the main PCBNo

Trouble shooting:

7

Page 9

Index 1:

NO.

Color

Signal

Voltage

1

Red

Vs/Vm

280V~380V

2

---

---

---

3

Black

GND

0V

4

White

Vcc

14-17.5V

5

Yellow

Vsp

0~5.6V

6

Blue

FG

14-17.5V

NO.

Color

Signal

Voltage

1

Red

Vs/Vm

140V~190V

2

---

---

---

3

Black

GND

0V

4

White

Vcc

14-17.5V

5

Yellow

Vsp

0~5.6V

6

Blue

FG

14-17.5V

1:Indoor or Outdoor DC Fan Motor(control chip is in fan motor)

Power on and when the unit is in standby, measure the voltage of pin1-pin3, pin4-pin3 in fan motor

connector. If the value of the voltage is not in the range showing in below table, the PCB must has

problems and need to be replaced.

DC motor voltage input and output(voltage: 220-240V~)

DC motor voltage input and output(voltage :115V~)

2. Outdoor DC Fan Motor (control chip is in outdoor PCB)

Power on ,and check if the fan can run normally, if the fan can run normally, the PCB must has

problems and need to be replaced, If the fan can’t run normally, measure the resistance of each two

pins. If the resistance is not equal to each other, the fan motor must have problems and need to be

replaced, otherwise the PCB must has problems and need to be replaced.

3. Indoor AC Fan Motor

Power on and set the unit running in fan mode at high fan speed. After running for 15 seconds,

measure the voltage of pin1 and pin2. If the value of the voltage is less than 100V(208~240V power

supply)or 50V(115V power supply), the PCB must has problems and need to be replaced.

8

Page 10

9.3.5 Open circuit or short circuit of temperature sensor diagnosis and solution(E5)

Error Code

E4/E5/F1/F2/F3

Malfunction decision

conditions

If the sampling voltage is lower than 0.06V or higher than 4.94V,

the LED will display the failure.

Supposed causes

● Wiring mistake

● Sensor faulty

Check the connection

between temperature

sensor and PCB.

Correct the connectionNo

Yes

Replace indoor or outdoor

main PCB

Measure the resistance

value of the sensor

Repalce the sensorNo

Yes

Trouble shooting:

9

Page 11

9.3.6 Refrigerant Leakage Detection diagnosis and solution(EC)

Error Code

EC

Malfunction decision

conditions

Define the evaporator coil temp.T2 of the compressor just starts

running as Tcool.

In the beginning 5 minutes after the compressor starts up, if T2

<Tcool-2°C(Tcool-35.6°F) does not keep continuous 4

seconds and this situation happens 3 times, the display area will

show “EC” and AC will turn off.

Supposed causes

● T2 sensor faulty

● Indoor PCB faulty

● System problems, such as leakage or blocking.

Check cool air blowing out

from indoor air outlet

Yes

Yes

Check if T2 sensor

No

Check leakage of system

No

Power off, then restart the

unit 2 minutes later.

Replace indoor PCB.

Yes

Repair the leakage and

recharge the refrigerant.

Yes

check blockIng of system and

clear the blocking

Trouble shooting:

10

Page 12

9.3.6 Overload current protection diagnosis and solution(F0)

Error Code

F0

Malfunction decision

conditions

An abnormal current rise is detected by checking the specified

current detection circuit.

Supposed causes

● Power supply problems.

● System blockage

● PCB faulty

● Wiring mistake

● Compressor malfunction

Check the power supply

Che ck the conne c tions and

wires

Stop the unit

No

Yes

No

Correct the connections or

replace the wires.

Yes

Replace the outdoor unit

Yes

Check the reactor

No

Replace outdoor main PCB

Check the blockage of system

Yes

No Clear the blockage

Check the compressor

resistance values

Yes

No Replace the compressor

11

Page 13

9.3.7 IPM malfunction or IGBT over-strong current protection diagnosis and solution(P0)

Error Code

P0

Malfunction decision

conditions

When the voltage signal that IPM send to compressor drive chip

is abnormal, the display LED will show “P0” and AC will turn off.

Supposed causes

● Wiring mistake

● IPM malfunction

● Outdoor fan ass’y faulty

● Compressor malfunction

● Outdoor PCB faulty

Check the wiring between main PCB

and compressor

Correct the connection or replace

the wires and connectors.

Yes

No

Check the IPM No

Yes

Replace the IPM board or replace

the main PCB

Check the outdoor fan and the

outdoor unit ventilation

No

Please refer to the solution of 【Fan

Speed Has Been Out Of Control】

malfunction

Yes

Check the compressor resistance

values

No

Replace the compressor.

Yes

Replace the outdoor main PCB

Trouble shooting:

12

Page 14

For example:

P-U

P-V

side.

Note: The photos below are only for reference, it’s may be not same totally with the ones on your

13

Page 15

P-W

N-U

14

Page 16

N-V

N-W

15

Page 17

9.3.8 Over voltage or too low voltage protection diagnosis and solution(P1)

Error Code

P1

Malfunction decision

conditions

An abnormal voltage rise or drop is detected by checking the

specified voltage detection circuit.

Supposed causes

● Power supply problems.

● System leakage or block

● PCB faulty

Check the power supply

Che ck the conne c tions and

wires

Stop the unit

No

Yes

No

Correct the connections or

replace the wires.

Yes

Replace the reactor

Yes

No

Replace the IPM board

Check the voltage between P

and N

Check the reactor

Yes

No

Replace outdoor main PCB

Remark:

Measure the DC voltage

between P and N port. The

normal value should be

around 310V.

P

N

Trouble shooting:

16

Page 18

9.3.9 High temperature protection of compressor top diagnosis and solution(P2)

Error Code

P2

Malfunction decision

conditions

If the sampling voltage is not 5V, the LED will display the failure.

Supposed causes

● Power supply problems.

● System leakage or block

● PCB faulty

Check the air flow system

of indoor and outdoor units

Clear up the air inlet and outlet or the heat

exchanger of indoor and outdoor units.

Yes

No

Yes

Yes

Power off, then restart the unit 10

minutes later

Check if the temperature

of compressor

No

Check refrigerant system

Yes

Check the overload

protector

Correct the connection.No

Measure the resistance

between the two ports of

the OLP. Is it zero?

Yes

Replace the OLP.

No

Replace the outdoor control PCB.

Yes

Trouble shooting:

17

Page 19

9.3.10 Inverter compressor drive error diagnosis and solution(P4)

Error Code

P4

Malfunction decision

conditions

An abnormal inverter compressor drive is detected by a special

detection circuit, including communication signal detection,

voltage detection, compressor rotation speed signal detection

and so on.

Supposed causes

● Wiring mistake

● IPM malfunction

● Outdoor fan ass’y faulty

● Compressor malfunction

● Outdoor PCB faulty

Check the wiring between main PCB

and compressor

Correct the connection or replace

the wires and connectors.

Yes

No

Check the IPM No

Yes

Replace the IPM board or replace

the main PCB

Check the outdoor fan and the

outdoor unit ventilation

No

Please refer to the solution of 【Fan

Speed Has Been Out Of Control】

malfunction

Yes

Check the compressor resistance

values

No

Replace the compressor.

Yes

Replace the outdoor main PCB

Trouble shooting:

18

Page 20

Main parts check

1. Temperature sensor checking

Disconnect the temperature sensor from PCB, measure the resistance value with a tester.

Temperature sensors.

Room temp.(T1) sensor,

Indoor coil temp.(T2) sensor,

Outdoor coil temp.(T3) sensor,

Outdoor ambient temp.(T4) sensor,

Compressor discharge temp.(T5) sensor.

Measure the resistance value of each winding by using the multi-meter.

19

Page 21

The Klimaire logo is a registered Trademark of Klimaire Products Inc.

Copyright 2016 Klimaire Products Inc.

2190 NW 89 Place, Doral, FL 33172 - USA

Tel: (305)593-8358

www.klimaire.com

The design and specifications are subject to change without prior notice for product

improvement. Consult with the sales agency or manufacturer for details.

Fax (305) 675-2212

sales@klimaire.com

Loading...

Loading...