Page 1

Gas Furnace

Installation Operation & Service Manual

80 % AFUE

GM80S Series

Page 2

THIS BOOKLET CONTAINS

IMPORTANT INFORMATION

INSTALLER: USE THE INFORMATION IN THIS BOOKLET

TO INSTALL THE APPLIANCE AND AFFIX THIS

BOOKLET ADJACENT TO THE APPLIANCE

AFTER INSTALLATION.

USER: KEEP THIS BOOKLET OF INFORMATION FOR

FUTURE REFERENCE.

SERVICER: USE THE INFORMATION IN THIS BOOKLET

TO SERVICE THE APPLIANCE AND AFFIX

THE BOOKLET ADJACENT TO THE APPLI ANCE AFTER SERVICING.

“NOTE: Please read all instruction in the manual and

retain all manuals for futrue reference. ”

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury death

or property damage.

— Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

— Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

NOTE: Do not use this furnace if any part has been under water. A flood-damaged furnace is extremely dangerous.

Attempts to use the furnace can result in fire or explosion. A qualified service agency should be contacted

to inspect the furnace and to replace all gas controls, control system parts, electrical parts that have been

wet or the furnace if deemed necessary.

GD Midea Heating & Ventilating Equipment Co., Ltd.

Penglai Industry Road, Beijiao, Shunde, Foshan

Guangdong, P.R.China

Page 3

Installation Start-up Operating and Service and Maintenance Instructions

CONTENTS PAGE

птНЯЪЫМЗ ЭСТНЧЬЫОЯМЧСТНтттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттто

от ЧТМОСЬЛЭМЧСТттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттл

нтЭСЬЫН ЯТЬ НМЯТЬЯОЬНттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

нтп Н¿º»¬§тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

нто Щ»²»®¿´ Ч²-¬¿´´¿¬·±² тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

нтн Э±³¾«-¬·±² ¿²¼ К»²¬·´¿¬·±² Я·® тттттттттттттттттттттттттттттттттттттттттттттттттттттк

нтм Ь«½¬ Н§-¬»³-тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

нтл Я½±«-¬·½¿´ Ф·²·²¹ ¿²¼ Ъ·¾®±«- Щ´¿-- Ь«½¬ттттттттттттттттттттттттттттттттттттттк

нтк Щ¿- Р·°·²¹ ¿²¼ Щ¿- Р·°» Р®»--«®» М»-¬·²¹ттттттттттттттттттттттттттттттттттттк

нтй Ы´»½¬®·½¿´ Э±²²»½¬·±²- тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

нти Ы´»½¬®·½¿´ Р±©»® Н«°°´§ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

нтз К»²¬·²¹тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

мт ЫФЫЭМОСНМЯМЧЭ ЬЧНЭШЯОЩЫ шЫНЬч РОЫЭЯЛМЧСТН РОСЭЫЬЛОЫ ттттттк

лт ФСЭЯМЧСТ ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттй

кт ЧТНМЯФФЯМЧСТ ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттт и

ктп Л°º´±© Ч²-¬¿´´¿¬·±²ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттти

кто Ь±©²º´±© Ч²-¬¿´´¿¬·±²ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттти

ктн Ш±®·¦±²¬¿´ Ч²-¬¿´´¿¬·±²тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпр

ктм Ъ·´¬»® Я®®¿²¹»³»²¬тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпо

ктл Я·® Ь«½¬-ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпо

йт КЫТМ НЗНМЫУттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпм

йтп К»²¬ Э±²²»½¬·±²- тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпм

йто К»²¬·²¹тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпм

йтн К»²¬·²¹ Ч²¬± Я² Ы¨·-¬·²¹ Э¸·³²»§ ттттттттттттттттттттттттттттттттттттттттттттттпм

йтм Я·® Ъ±® Э±³¾«-¬·±² ¿²¼ К»²¬·´¿¬·±²ттттттттттттттттттттттттттттттттттттттттттттпм

йтл Я·® Н«°°´§ С°»²·²¹- ¿²¼ Ь«½¬-тттттттттттттттттттттттттттттттттттттттттттттттттттпл

йтк К»²¬·´¿¬»¼ Э±³¾«-¬·±² Я·®ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпл

йтй К»²¬ ¿²¼ Н«°°´§ шС«¬-·¼»ч Я·® Н¿º»¬§ Э¸»½µ

Р®±½»¼«®»ттттттттттттттпл

и ЩЯН НЛРРФЗ ЯТЬ РЧРЧТЩттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпк

итп Щ»²»®¿´ тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпк

ито Ш·¹¸ Я´¬·¬«¼» Ь»®¿¬»ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпй

итн Р®±°¿²» Щ¿- Э±²ª»®-·±²тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпи

итм Щ¿- Р·°·²¹ Э±²²»½¬·±²-ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпи

итл Щ¿- Р·°·²¹ Э¸»½µ-тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпз

з ЫФЫЭМОЧЭЯФ ЭСТТЫЭМЧСТНтттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттор

зтп пплК Й·®·²¹ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттор

зто Ы´»½¬®·½¿´ Э±²²»½¬·±² М± Цу¾±¨ тттттттттттттттттттттттттттттттттттттттттттттттттор

зтн Р±©»® Э±®¼ Ч²-¬¿´´¿¬·±² Ч² Ъ«®²¿½» Цу¾±¨ттттттттттттттттттттттттттттттттттоп

зтм Ю¨ Э¿¾´» Ч²-¬¿´´¿¬·±² Ч² Ъ«®²¿½» Цу¾±¨ттттттттттттттттттттттттттттттттттттттоп

зтл омК Й·®·²¹ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттоп

зтк Я½½»--±®·»- шЪ·»´¼ Н«°°´·»¼чтттттттттттттттттттттттттттттттттттттттттттттттттттттоп

зтй Щ®±«²¼·²¹тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттоп

прт НМЯОМуЛРф ЯЬЦЛНМУЫТМф ЯТЬ НЯЪЫМЗ ЭШЫЭХ тттттттттттттттттттттттттттон

пртп Щ»²»®¿´ ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттон

прто Н¬¿®¬уЛ° Р®±½»¼«®»-тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттон

пртн Ъ«®²¿½» Н¬¿®¬у«°тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттон

пртм Н»¯«»²½» ±º С°»®¿¬·±²тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттом

пртл Щ¿- У¿²·º±´¼ Р®»--«®» У»¿-«®»³»²¬ Я²¼

Я¼¶«-¬³»²¬ттттттттттол

пртк Щ¿- Ч²°«¬ О¿¬» У»¿-«®»³»²¬ шТ¿¬«®¿´ Щ¿- С²´§чтттттттттттттттттттол

пртй М»³°»®¿¬«®» О·-» тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттол

прти Э·®½«´¿¬±® Ю´±©»® Н°»»¼ Я¼¶«-¬³»²¬ттттттттттттттттттттттттттттттттттттттток

пп СРЫОЯМЧСТЯФ ЭШЫЭХНттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттток

по НЯЪЫМЗ ЭЧОЭЛЧМ ЬЫНЭОЧРМЧСТтттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

п отп Щ»²»®¿´тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

пото Ч²¬»¹®¿¬»¼ Э±²¬®±´ У±¼«´»тттттттттттттттттттттттттттттттттттттттттттттттттттттттой

потн Р®·³¿®§ Ф·³·¬тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

потм О»ª»®-» Ъ´±© Н©·¬¸тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

потл О±´´±«¬ Ф·³·¬-ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

потк Р®»--«®» Н©·¬½¸»-тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

потй Ъ´¿³» Н»²-±®тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

пн МОСЛЮФЫНШССМЧТЩттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

пнтп Ы´»½¬®±-¬¿¬·½ Ь·-½¸¿®¹» шЫ-±ч Р®»½¿«¬·±²-тттттттттттттттттттттттттттттой

пнто Ь·¿¹²±-¬·½ Э¸¿®¬тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

пнтн О»-»¬¬·²¹ Ъ®±³ Ф±½µ±«¬тттттттттттттттттттттттттттттттттттттттттттттттттттттттттой

пм НЫОКЧЭЫ ЯТЬ УЯЧТМЫТЯТЭЫ РОСЭЫЬЛОЫНттттттттттттттттттттттттттттттттттттттнр

пмтп Я²²«¿´ Ч²-°»½¬·±²тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттнр

пмто Ъ·´¬»®-тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттнр

пмтн ЧТЬЛЭЫЬ ЬОЯЪМ ЯТЬ ЭЧОЭЛФЯЧТЩ ЮФСЙЫО УСМСОНттттттттттнр

пмтм ЪФЯУЫ НЫТНСО шПЛЯФЧЪЧЫЬ НЫОКЧЭЫО СТФЗчттттттттттттттттттттттнр

пмтл Ю«®²»®-тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттнр

пмтк Э´»¿²·²¹ Ш»¿¬ Ы¨½¸¿²¹»®тттттттттттттттттттттттттттттттттттттттттттттттттттттттнп

пмтй Ю»º±®» Ф»¿ª·²¹ Я² Ч²-¬¿´´¿¬·±²тттттттттттттттттттттттттттттттттттттттттттттттно

пмти О»°¿·® Я²¼ О»°´¿½»³»²¬ Р¿®¬-тттттттттттттттттттттттттттттттттттттттттттттно

плт ЙЧОЧТЩ ЬЧЯЩОЯУНттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттнн

ISO 9001:2008

NOTE: Read the entire instruction manual before starting the

installation.

Portions of the text and tables are reprinted from NFPA 54/ANSI

Z223.1-2006©, with permission of National Fire Protection

Association, Quincy, MA 02269 and American Gas Association,

Washington DC 2000l. This reprinted material is not the complete

and official position of the NFPA or ANSI on the referenced subject,

which is represented only by the standard in its entirety.

WARNING

FIRE OR EXPLOSION HAZARD

The furnace is designed and approved for use with Natural Gas

and (LP) Propane Gas ONLY. DO NOT BURN ANY LIQUID

FUEL OR SOLID FUEL IN THIS FURNACE.

Burning any unapproved fuel will result in damage to the furnace

heat exchanger, which could result in Fire, Personal Injury, and/or

Property Damage.

I&O manual

I&O manual

ï

ï

Page 4

пт НЯЪЫМЗ ЭСТНЧЬЫОЯМЧСТН

WARNING

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to identify

unsafe practices which may result in minor personal injury or product

and property damage. NOTE is used to highlight suggestions which

will result in enhanced Installation, reliability, or operation.

FIRE, EXPLOSION, ELECTRICAL SHOCK,

AND CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous operation, serious injury, death or property damage. Improper

installation adjustment alteration service maintenance

or use could cause carbon monoxide poisoning explosion

fire electrical shock or other conditions which may cause

personal injury or property damage. Consult a qualified service

agency local gas supplier, or your distributor or branch for

information or assistance. The qualified service agency must

use only factory-authorized and listed kits or accessories when

modifying this product.

CAUTION

FURNACE RELIABILITY HAZARD

Improper installation or misapplication of furnace may require

excessive servicing or cause premature component failure.

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate, air

temperature rise, unit leveling, and unit sizing.

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts and servicing furnaces.

Improper installation, adjustment, alteration, service, Maintenance, or

use can cause explosion, fire, electrical shock, or other conditions

which may cause death, personal injury, or property damage. Consult

a qualified installer, service agency, or your distributor or branch for

information or assistance. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this product.

Refer to the individual instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing, and

work gloves. Have a fire extinguisher available. Read these instructions thoroughly and follow all warnings or cautions include in

literature and attached to the unit. Consult local building codes the

current editions of the National Fuel Gas Code (NFGC) NFPA

54/ANSI Z223.1 and the National Electrical Code (NEC) NFPA 70.

In Canada, refer to the current editions of the National Standards of

Canada CAN/CSA-BI49.1 and .2 Natural Gas and Propane Installation Codes, and Canadian Electrical Code CSA C22.1

Recognize safety information. This is the safety-alert symbol . When

you see this symbol on the unit and in instructions or manuals, be alert

to the potential for personal injury. Understand the signal words

DANGER, WARNING, and CAUTION. These words are used with the

safety-alert symbol.

Use only with type of gas approved for this furnace. Refer to the

furnace rating plate.

Install this furnace only in a location and position as specified in

the "Location" section of these instructions.

Provide adequate combustion and ventilation air to the furnace

space as specified in "Air for Combustion and ventilation" section.

Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in the

"Venting" section of these instructions.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks

to check all connections, as specified in the "Gas Suppy and

Piping" section.

Always install furnace to operate within the furnace's intended

temperature-rise range with a duct system which has an external

static pressure within the allowable range, as specified in the

"Start-Up, Adjustments, and Safety Check" section. See furnace

rating plate.

When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by duct(s) sealed to

the furnace casing and terminating outside the space containing

the furnace. See "Air Ducts" section.

A gas-fired furnace for installation in a residential garage must be

installed as specified in the warning box in the "Location" section.

The furnace may be used for construction heat provided that the

furnace installation and operation complies with the first CAUTION

in the LOCATION section of these instructions.

These multipoise Gas-Fired Furnaces are CSA (formerly A.G.A.

and C.G.A). design-certified for use with natural and propane

gases (see furnace rating plate) and for installation in alcoves

attics, basements, closets, utility rooms, crawlspaces, and

garages. The furnace is factory-shipped for use with natural gas.

A CSA listed accessory gas conversion kit is required to convert

furnace for use with propane gas.

The furnaces must be kept free and clear of insulating materials.

Inspect surrounding area to ensure insulation material is in safe

distance when installing furnaces or adding insulation materials.

Insulation materials may be combustible.

See Fig. 2 for required clearances to combustible construction.

Maintain a 1 in. (25 mm) clearance from combustible materials to

supply air ductwork for a distance of 36 in. (914 mm) horizontally

from the furnace. See NFPA 90B or local code for further requirements.

These furnaces SHALL NOT be installed directly on carpeting,

tile, or any other combustible material other than wood flooring. In

downflow installations, factory accessory floor base MUST be

used when installed on combustible materials and wood flooring.

Special base is not required when this furnace is installed on

manufacturer's Coil Assembly .

I&O manual

I&O manual

î

î

Page 5

See Fig Instruction of lighting/ shutdown operation. Should the

gas supply fail to shut off or if overheating occurs, shut off the

gas valve to the furnace before shutting of the electrical supply.

Before heating season begins, exame the furnace to determine

that:

a. All flue gas carrying areas external to the furnace (i.e.

chimney, vent connector) are clear and free of obstructions.

b. The vent connector is in place, slopes upward and is

physically sound without holes or exccessive corrosion.

c. The return-air duct connection(s) is physically cound, is

sealed to the furnace casing, and terminates outside the space

containing the furnace.

Cover old lighting instructions with this label. Note: Rating plate must be left visible for future reference.

d. The physical support of the furnace is sound without sagging,

cracks, gaps, etc around the base so as to provide a seal

between the support and the base.

e. There are no obvious sign of deterioration of the furnace.

f. The burner flames are in good adjustment (by comparison with

pictorial sketches of the main burner flame (see Fig 31).

Furnace operation needs air for combustion and ventilation.

Do not block or obstruct air openings on furnace or spacing

arroud furnace required for supplying sufficient combustion air

and ventilation.

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING

A.

This appliance does not have a pilot. it is equipped with an

ignition device which automatically lights the burner.

Do not try to light the burner by hand.

BEFORE OPERATING smell all around the appliance

B.

area for gas. Be sure to smell next to the floor because

some gas ls heavier than air and will settle on the floor.

If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

FOR YOUR SAFETY

“WHAT TO DO IF YOU SMELL GAS”

any phone in your building.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this

label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

SWITCH SHOWN IN

THE “OFF” POSITION

neighbors phone. Follow the gas suppliers

Instructions.

fire department.

Use only your hand to turn the gas control switch. Never use

C.

call a qualified service technician. Force or attempted repair

may result in a fire or explosion.

Do not use this appliance if any part has been under water.

D.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

5. Remove control access panel.

6. Wait five (5) minutes to clear out any gas. if you

then smell gas, STOP! Follow “B” in the safety

gas, go to the next step.

7. Push gas control switch to “ON”.

NOTE: Do not force.

8. Replace control access panel.

9.Turn on all electric power to the appliance.

10.Set thermostat to desired setting

11.If the appliance will not operate, follow instructions

“To Turn Off Gas To Appliance” and call your

service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if

service is to be performed.

3. Remove control access panel.

4. Push gas control to “OFF”. Do not force.

5. Replace control access panel.

I&O manual

I&O manual

í

í

Page 6

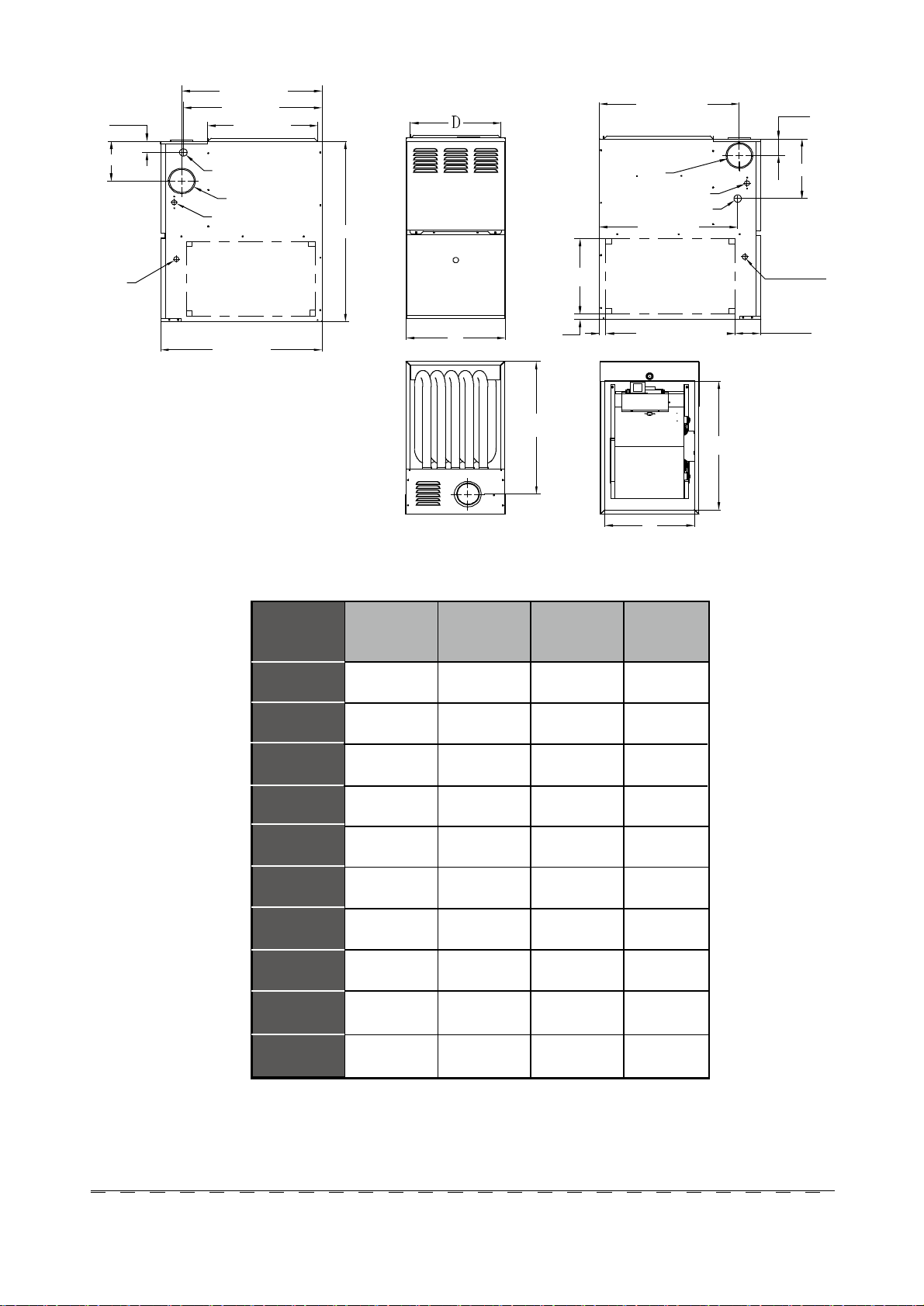

2-1/8”(54mm)

24-13/16”(630mm)

24-1/2”(622mm)

19-1/2”(495mm)

24-13/16”(630mm)

3-1/8”(79mm)

7-7/16”(189mm)

DIA.THERMOSTAT

WIRE ENTRY

7/8”(22mm)

1-1/2”(38mm)

DIA.JUNCTION BOX LOCATION

7/8”(22mm)

RIGHT SIDE RETURN AIR

28-1/2”(724mm)

Table 1 - Dimensions

33-3/4”(857mm)

14”(355mm)

A

1-1/16”(27mm)

24-13/16”(630mm)

Fig. 1 - Dimensional Drawing

DIA.LEFT VENT OUTLETDIA.RIGHT HAND GAS ENTRY

4-3/4”(120.7mm)

DIA.JUNCTION BOX LOCATION

DIA.LEFT HAND GAS ENTRY

1-3/16”(30mm)

7/8”(22mm)

1-1/2”(38mm)

24-1/2”(622mm)

LEFT SIDE RETURN AIR

22-13/16”(580mm)

E

24”(610mm)

11-3/16”(284mm)

DIA.THERMOSTAT

WIRE ENTRY

7/8”(22mm)

4-1/2”(114mm)

A

FURNACE SIZE

FURNACE SIZE

50A3A

70A3A

80B4A

80C4A

90B4A 145

100C5A

100D5A

110C5A

120D5A

135D5A

CABINET WIDTH

IN. (MM)

14.5

(368)

14.5

(368)

17.5

(445)

21

(533)

17.5

(445)

21

(533)

24.5

(622)

21

(533)

24.5

(622)

24.5

(622)

D

SUPPLY-

AIR WIDTH

IN. (MM)

13

(330)

13

(330)

16

(406)

19.5

(495)

16

(406)

19.5

(495)

23

(584)

19.5

(495)

23

(584)

23

(584)

E

RETURN-

AIR WIDTH

IN. (MM)

12-27/32

(326)

12-27/32

(326)

15-27/32

(402)

19-13/32

(493)

15-27/32

(402)

19-13/32

(493)

22-27/32

(580)

19-13/32

(493)

22-27/32

(580)

22-27/32

(580)

SHIP WT (lbs)

123

128

145

152

161

167

161

172

176

I&O manual

I&O manual

ì

ì

Page 7

от ЧТМОСЬЛЭМЧСТ

This series 4-way multipoise Category I fan-assisted furnace is CSA

design-certified. A Category I fan-assisted furnace is an appliance

equipped with an integral mechanical means to either draw or force

products of combustion through the combustion chamber and/or heat

exchanger. The furnace is factory-shipped for use with natural gas.

This furnace is not approved for installation in mobile homes,

recreational vehicles, or outdoors. This furnace is designed for

minimum continuous return-air temperature of 60°F (16°C) db or

intermittent operation down to 55°F (13°C)db such as when used with

WARNING

AVERTISSEMENT

FIRE, EXPLOSION, ASPHYXIATION HAZARD RISQUE

D’INCENDIE, D’EXPLOSION ET ASPHYXIE

Improper adjustment, alteration, service,

maintenance, or installation can cause serious

injury or death.

Read and follow instructions and precautions in

User's Information Manual provided with this

furnace. Installation and service must be performed

by a qualified service agency or the gas supplier.

Une réglage, une modification, un reparation, un

enretien ou une installation incorrect puet entraîner

des blessures graves ou la mort.

Suivre les instructions et les consignes qui figurent

dans la notice d'utilisation qui accompagne ce

générateur d'air chaud. L'installation et I'entretien

doivent être effecturés par un réparateur qualifié

ou par Ie foumisseur de gaz.

CAUTION

MISE EN GARDE

Check entire gas assembly for leaks after lighting

this appliance.

Vérifier tous les éléments à gaz pour rechercher

les fuites après avoir allumé cet appareil.

INSTALLATION

1.This fumace must be installed in accordance with

the manufacturer's instructions and local codes. In

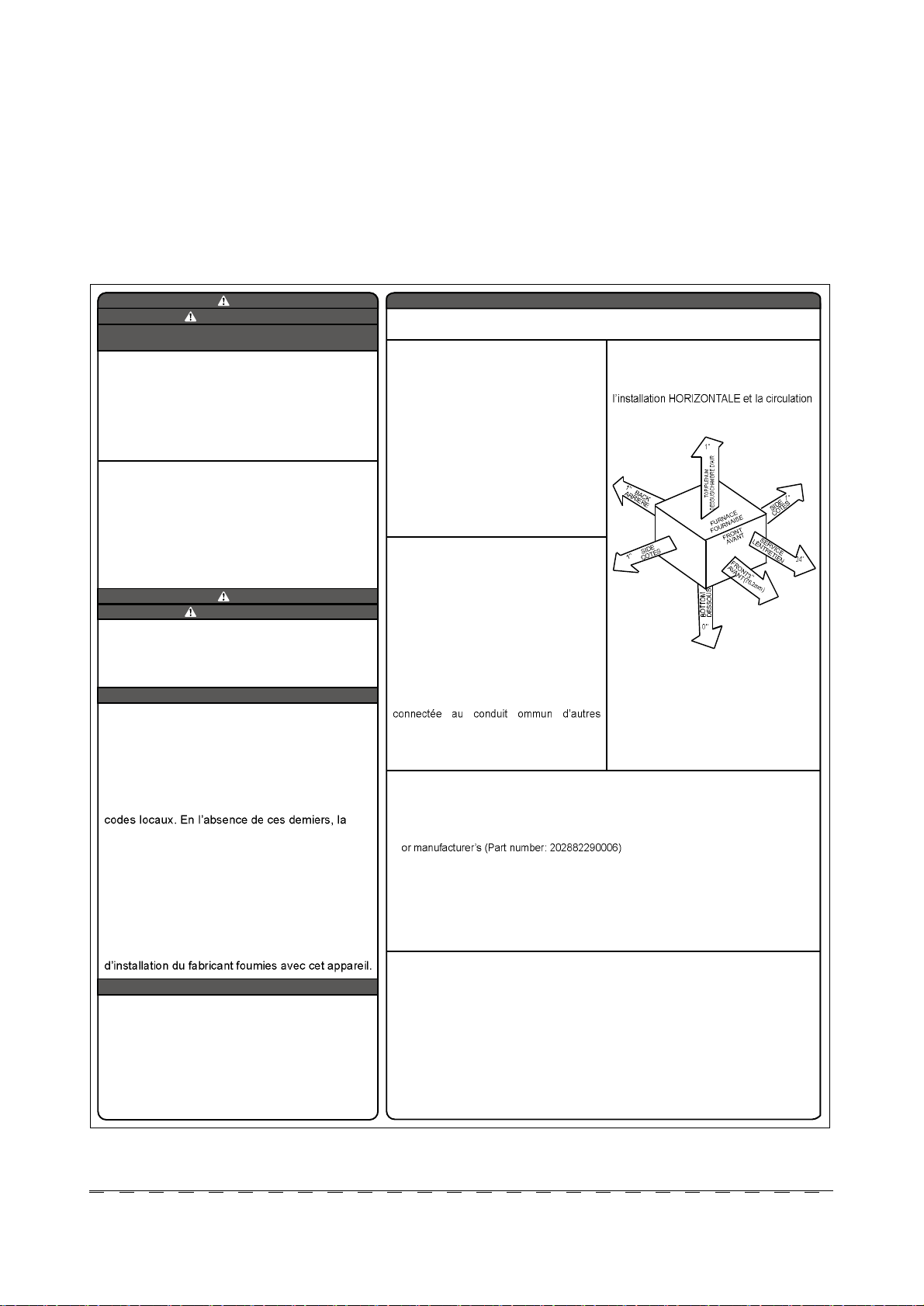

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

DISTANCE MINIMALE EN POUCES AUX CONSTRUCTIONS COMBUSTIBLES

An accessory kit, supplied by the

manufacturer, shall be used to convert to

propane gas use or may be required for

some natural gas applications.

This fumace is for indoor installation in a

building constructed on site.

This fumace may be installed on combustible

flooring in alcove or closet at minimum

clearance as indicated by the diagram from

combustible material.

This furnace may be used with a Type B-1

Vent and may be vented in common with

other gas fired appliances.

Utiliser une trousse de conversion, foumie

par Ie fabricant, pour passer au gaz propane

ou pour certaines installations au gaz naturel.

Cette foumaise est prévue pour être

installée dans un bâtiment construit sur

place.

Cette foumaise peut être installée sur un

pIanctler combustible dans une aIdôve ou

dans un garde-robe en respedant Ie

minimum d'espace libre des matériaux

combustibles, tel qu'indiqué sur Ie

diagramme.

Cette foumaise peut être utilisée avec un

oondutt d'évacuation de Type B-1 ou

appareils à gaz.

the absence of local codes, follow the National Fuel

Gas Code ANSI Z223.1/ NFPA54 or CSA B-149. 1

Gas Installation Code.

Ce foumaise á air chaud doit être installé

conforrnément aux instructions du fabricant et aux

norme. ANSI Z223.1/NFPA54 intitulée National Fuel

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

DOWNFLOW POSITIONS:

Installation on non-combustible floors only.

†

For Installation on combustible flooring only when installed on sub-base provided by installer

Gas Code ou Ies code d'installation CSAB149.1.

18 inches front dearanre required for alcove.

2.This fumace must be installed so there are

provisions for combustion and ventilation air. See

manufacturer's installation information provided with

this appliance.

Ce foumaise á air chaud doit être installé de

manière à ce qu'iIyait ait suffisamment d'air de

Ø

HORIZONTAL INSTALLATION IN ATTIC

Indicates supply or return sides when furnace is in the horizontal position. Line contact only

*

permissible between lines formed by intersections of the Top and two Sides of the furnace

jacket, and building joists, studs or framing.

A special base is required (refer to “Horizontal Installation” section in Manual)

ventilation et combustion. Consulter Ies instructions

OPERATION

This fumace is equipped with manual reset limit

swich(es) in bumer compartment to protect against

overheat conditions that can result from inadequate

combustion air supply or blocked vent conditions,

1. Do not bypass limit switches.

2. If a limit opens, call a quallified serviceman to

correct the condition and reset limit switch.

†

POUR LA POSITION COURANT DESCENDANT:

Pour I'installation sur pIancher non combustible seuIement.

Ø

Pour I'installation sur un pIancher combustible seulement quand on utilise Ia base spéciale

Dans une aloôve, on doit maintenir un dégagement à I'avant de 18 po (450mm).

*

La poistion indiquée conceme Ie côté d' entrée ou de retour quand la foumaise est dans la

position horizontale.

Le contact n'est permis qu'entre Ies lignes formées par les intersections du dessus et des

deux côtés de Ia cherrise de Ia foumaise et Ies soIives, montant sous cadre de charpente.

a night setback thermostat. Return-air temperature must not exceed

85°F (29°C) db. Failure to follow these return-air temperature limits

may affect reliability of heat exchangers, motors, and controls. (See

Fig. 3).

For accessory installation details, refer to the applicable instruction

literature.

NOTE: Remove all shipping brackets and materials before

operating the furnace.

INSTALLATION

This fumace is approved for UPFLOW,

DOWNFLOW and HORIZONTAL

installations.

Cette foumaise est approuvée pour

d 'air VERS LE HAUT et VERS LE BAS.

Clearance arrows

do not change with

fumace

orientation.

Les fléches de dégagement ne change pas

(25.4mm)

avec I 'orientation de

Ia foumaise.

*

Ø

†

Clearance in inches

Dégagement (po).

Vent Clearance to combustibles:

For Single Wall vents 6 inches (6 po),

For Type B-1 vent type 1 inch (1 po).

Dégagement de I'é vent avec combustibles:

Pour oondurt d'évacuation à paroi simple 6 po (6

inches).

Pour oonduit d'évacuation de Type B-1 1 PO (1

inch).

DÉGAGEMENT MINIMUM EN POUCES AVEC ÉLÉMENTS

DE CONSTRUCTION COMBUSTIBLES

*

(609.6mm)

MI

Fig. 2 - Clearances to Combustibles

I&O manual

I&O manual

ë

ë

Page 8

нт ЭСЬЫН ЯТЬ НМЯТЬЯОЬН

Follow all national and local codes and standards in addition to these

instructions. The installation must comply with regulations of the

serving gas supplier, local building, heating, plumbing, and other

codes. In absence of local codes, the installation must comply with

the national codes listed below and all authorities having jurisdiction.

In the United States and Canada, follow all codes and standards for

the following:

íòï Í¿º»¬§

USA: National Fuel Gas Code (NFGC) NFPA 54-2006/ANSI

Z223.1-2006 and the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI/NFPA 90B

íòë ß½±«-¬·½¿´ Ô·²·²¹ ¿²¼ Ú·¾®±«- Ù´¿-- Ü«½¬

US and CANADA: current edition of SMACNA and NFPA 90B as

tested by UL Standard 181 for Class I Rigid Air Ducts

íòê Ù¿- з°·²¹ ¿²¼ Ù¿- з°» Ю»--«®» Ì»-¬·²¹

US: NFPA 54/ANSI Z223.1-2006 Chapters 5,6, 7, and 8 and

National Plumbing Codes.

CANADA: CAN/CSA-B149.1-05 Parts 4, 5, and 6 and

Appendices A, B, E, and H.

íòé Û´»½¬®·½¿´ ݱ²²»½¬·±²-

US: National Electrical Code (NEC) ANSI/NFPA 70-2008.

CANADA: CSA B149.1-05 National Standard of Canada Natural

Gas and Propane Installation Codes (CAN/CSA-B149.1-05)

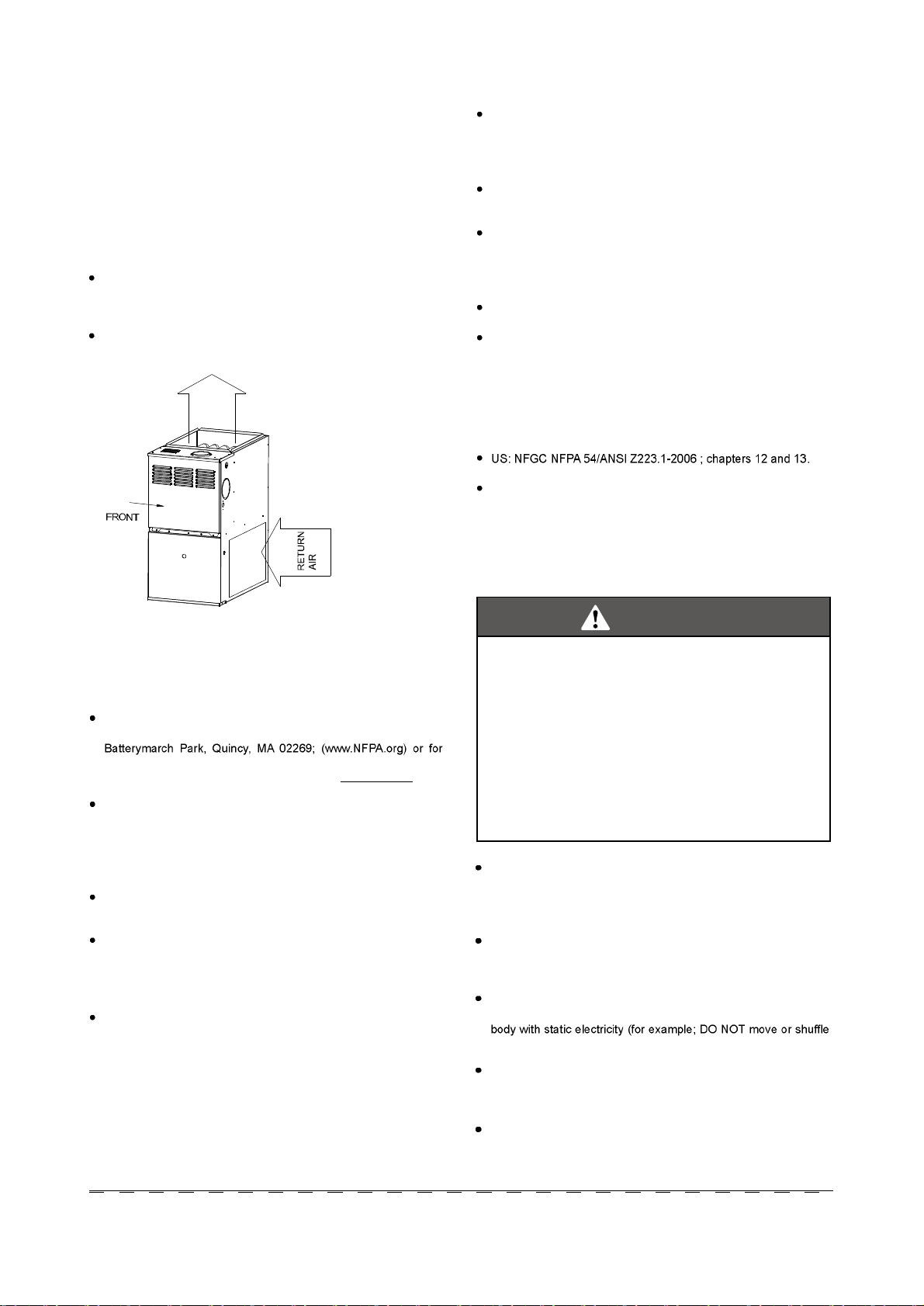

OUTLET

AIR

Max 850F/290C

Min 600F/160C

Fig. 3 - Return Air Temperature

íòî Ù»²»®¿´ ײ-¬¿´´¿¬·±²

US: Current edition of the NFGC and the NFPA 90B. For copies,

contact the National Fire Protection Association Inc.,

only the NFGC, contact the American Gas Association, 400 N.

Capitol Street, N.W., Washington, DC 20001 (www.AGA.org).

CANADA: CAN/CSA-B149.1-05. For a copy, contact Standard

Sales, CSA International, 178 Rexdale Boulevard, Etobicoke

(Toronto), Ontario, M9W 1R3 Canada.

CANADA: Canadian Electrical Code CSA C22.I.

íòè Û´»½¬®·½¿´ °±©»® -«°°´§

Voltage: ANSI C84.1-2006 (104-127 volt)

íòç Ê»²¬·²¹

CANADA: CAN/CSA-B149.1-05 Part 8 and Appendix C.

мт ЫФЫЭМОСНМЯМЧЭ ЬЧНЭШЯОЩЫ шЫНЬч

РОЫЭЯЛМЧСТН РОСЭЫЬЛОЫ

CAUTION

FURNACE RELIABILITY HAZARD

Improper installation or service of furnace may cause premature furnace component failure.

Electrostatic discharge can affect electronic components.

Follow the Electrostatic Discharge Precautions Procedure

listed below during furnace installation and servicing to protect

the furnace electronic control. Precautions will prevent electrostatic discharges from personnel and hand tools which are held

during the procedure. These precautions will help to avoid

exposing the control to electrostatic discharge by putting the

furnace, the control, and the person at the same electrostatic

potential.

íòí ݱ³¾«-¬·±² ¿²¼ Ê»²¬·´¿¬·±² ß·®

US: Section 9.3 of the NFGC, NFPA 54/ANSI Z223.1-2006 Air for

Combustion and Ventilation.

CANADA: Part 8 ofCAN/CSA-B149.1-05, Venting Systems and

Air Supply for Appliances.

íòì Ü«½¬ ͧ-¬»³-

US and CANADA: Air Conditioning Contractors Association

(ACCA) Manual D, Sheet Metal and Air Conditioning Contractors

National Association (SMACNA), or American Society of Heating,

Refrigeration, and Air Conditioning Engineers (ASHRAE) 2001

Fundamentals Handbook Chapter 34 or 2000 HVAC Systems

and Equipment Handbook Chapters 9 and 16.

I&O manual

I&O manual

ê

ê

Disconnect all power to the furnace. Multiple disconnects maybe

required. DO NOT TOUCH THE CONTROL OR ANY WIRE

CONNECTED TO THE CONTROL PRIOR TO DISCHARGING

YOUR BODY'S ELECTROSTATIC CHARGE TO GROUND.

Firmly touch the clean, unpainted, metal surface of the furnace

chassis which is close to the control.Tools held in a person's hand

during grounding will be satisfactorily discharged.

After touching the chassis, you may proceed to service the control

or connecting wires as long as you do nothing to recharge your

your feet, do not touch ungrounded objects, etc.).

If you touch ungrounded objects (and recharge your body with

static electricity), firmly touch a clean, unpainted metal surface of

the furnace again before touching control or wires,

Use this procedure for installed and un installed (ungrounded)

furnaces.

Page 9

Before removing a new control from its container, discharge your

body's electrostatic charge to ground to protect the control from

damage. If the control is to be installed in a furnace, follow items 1

through 4 before bringing the control or yourself in contact with the

furnace. Put all used and new controls into containers before

touching ungrounded objects.

An ESD service kit (available from commercial sources) may also

be used to prevent ESD damage.

лт ФСЭЯМЧСТ

ëòï Ù»²»®¿´

This multipoise furnace is shipped in packaged configuration. Some

assembly and modifications are required when used in any of the

four applications . This furnace must:

Be installed so the electrical components are protected from

water.

Not be installed directly on any combustible material other than

wood flooring (refer to SAFETY CONSIDERATIONS).

Downflow installation and horizontal installation in atttic have

additional requirements. See Section 6 Installation.

Be located as close to the chimney or vent and attached to an air

distribution system. Refer to Air Ducts section.

Be provided ample space for servicing and cleaning. Always

comply with minimum fire protection clearances shown on the

furnace clearance to combustible label.

If air is exposed to the following substances, it should not be used for

combustion air, and outdoor air may be required for combustion:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine based swimming pool chemicals

Water softening chemicals

De-icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

All fuel-burning equipment must be supplied with air for fuel

combustion. Sufficient air must be provided to avoid negative

pressure in the equipment room or space. A positive seal must be

made between the furnace cabinet and the return-air duct to prevent

pulling air from the burner area and from draft safeguard opening.

Also see Section 6.4.

The following types of furnace installations may require OUTDOOR

AIR for combustion due to chemical exposures:

Commercial buildings

Buildings with indoor pools

Laundry rooms

Hobby or craft rooms, and

Chemical storage areas

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or

death, and unit component damage.

Corrosive or contaminated air may cause failure of parts

containing flue gas, which could leak into the living space. Air

for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide, and

iodide. These elements can corrode heat exchangers and

shorten furnace life. Air contaminants are found in aerosol

sprays, detergents, bleaches, cleaning solvents, salts, air

fresheners, and other household products. Do not install

furnace in a corrosive or contaminated atmosphere. Make sure

all combustion and circulating air requirements are met, in

addition to all local codes and ordinances.

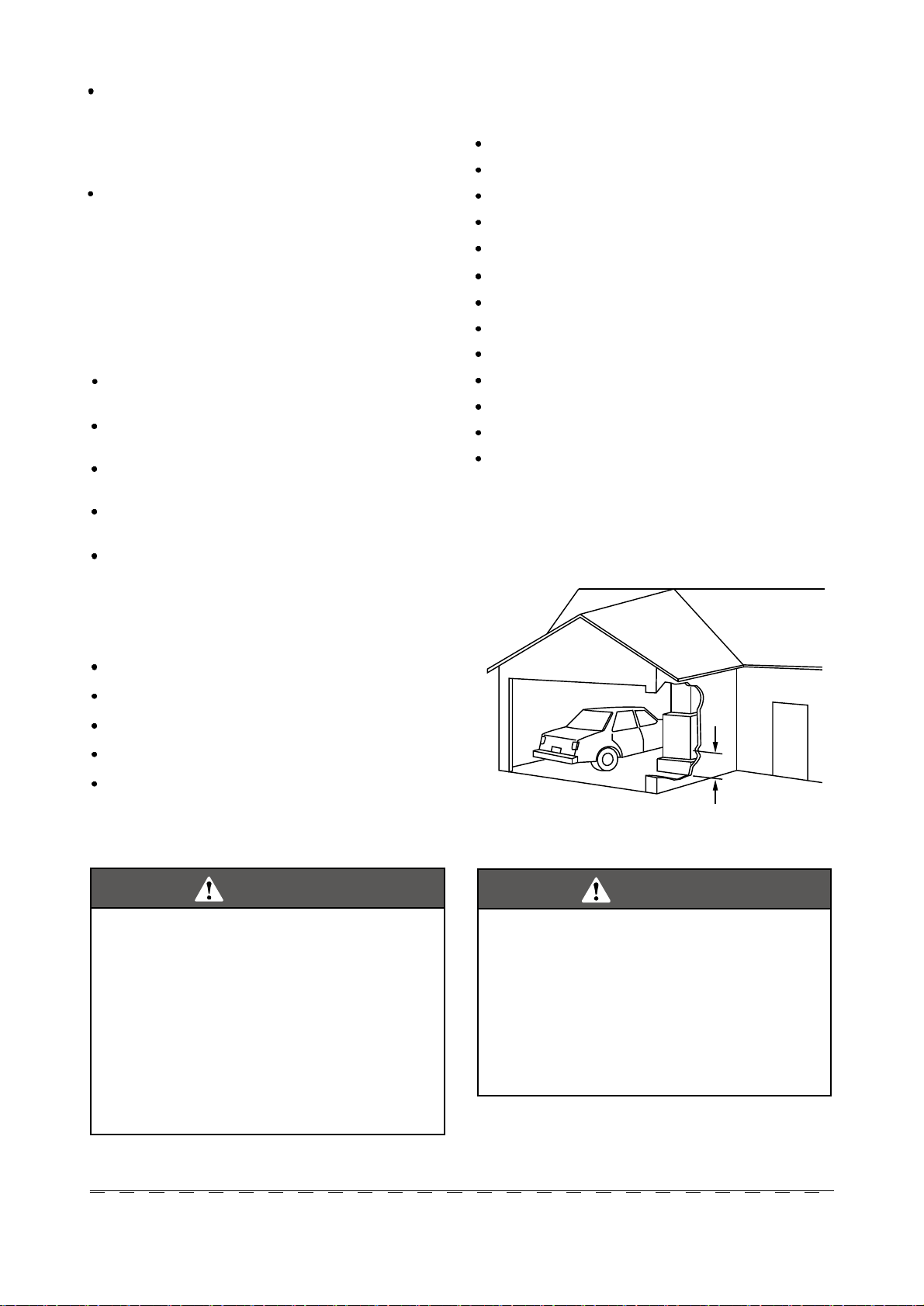

18-IN. (457.2 mm)

MINIMUM TO BURNERS

Fig. 4 - Installation in a Garage

WARNING

FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

When the furnace is installed in a residential garage, the

burners and ignition sources must be located at least 18 inches

(457 mm) above the floor. The furnace must be located or

protected to avoid damage by vehicles. When the furnace is

installed in a public garage, airplane hangar, or other building

having a hazardous atmosphere, the furnace must be installed

in accordance with the NFGC or CAN/CSA - B149 .1-05. (See

Fig. 4).

I&O manual

I&O manual

é

é

Page 10

CAUTION

PERSONAL INJURY AND/OR PROPERTY DAMAGE

HAZARD

Improper use or installation of this furnace may cause premature furnace component failure.

This gas furnace may be used for heating buildings under

construction provided that:

- The furnace is permanently installed with all electrical wiring,

piping, venting and ducting installed according to these installation instructions. A return air duct is provided, sealed to the

furnace casing, and terminated outside the space containing

the furnace. This prevents a negative pressure condition as

created by the circulating air blower, causing a flame rollout

and/or drawing combustion products into the structure.

- The furnace is controlled by a thermostat. It may not be "hot

wired" to provide heat continuously to the structure without

thermostatic control.

-Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and other

construction materials. It also prevents the entrainment of

drywall dust into combustion air, which can cause fouling and

plugging of furnace components.

- The temperature of the return air to the furnace is maintained

between 60°F (16°C) and 85°F (29°C), with no evening setback

or shutdown. The use of the furnace while the structure is under

construction is deemed to be intermittent operation per our

installation instructions.

- The air temperature rise is within the rated rise range on the

furnace rating plate, and the gas input rate has been set to the

nameplate value.

- The filters used to clean the circulating air during the construction process must be either changed or thoroughly cleaned

prior to occupancy.

- The furnace, ductwork and filters are cleaned as necessary to

remove drywall dust and construction debris from all HVAC

system components after construction is completed.

- Verify proper furnace operating conditions including ignition,

gas input rate, air temperature rise, and venting according to

these installation instructions.

кт ЧТНМЯФФЯМЧСТ

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. This panel MUST be in place when

only side return air is used.

NOTE: Side return-air openings can be used in UPFLOW and

most HORIZONTAL configurations. Do not use side return-air

openings in DOWNFLOW configuration.

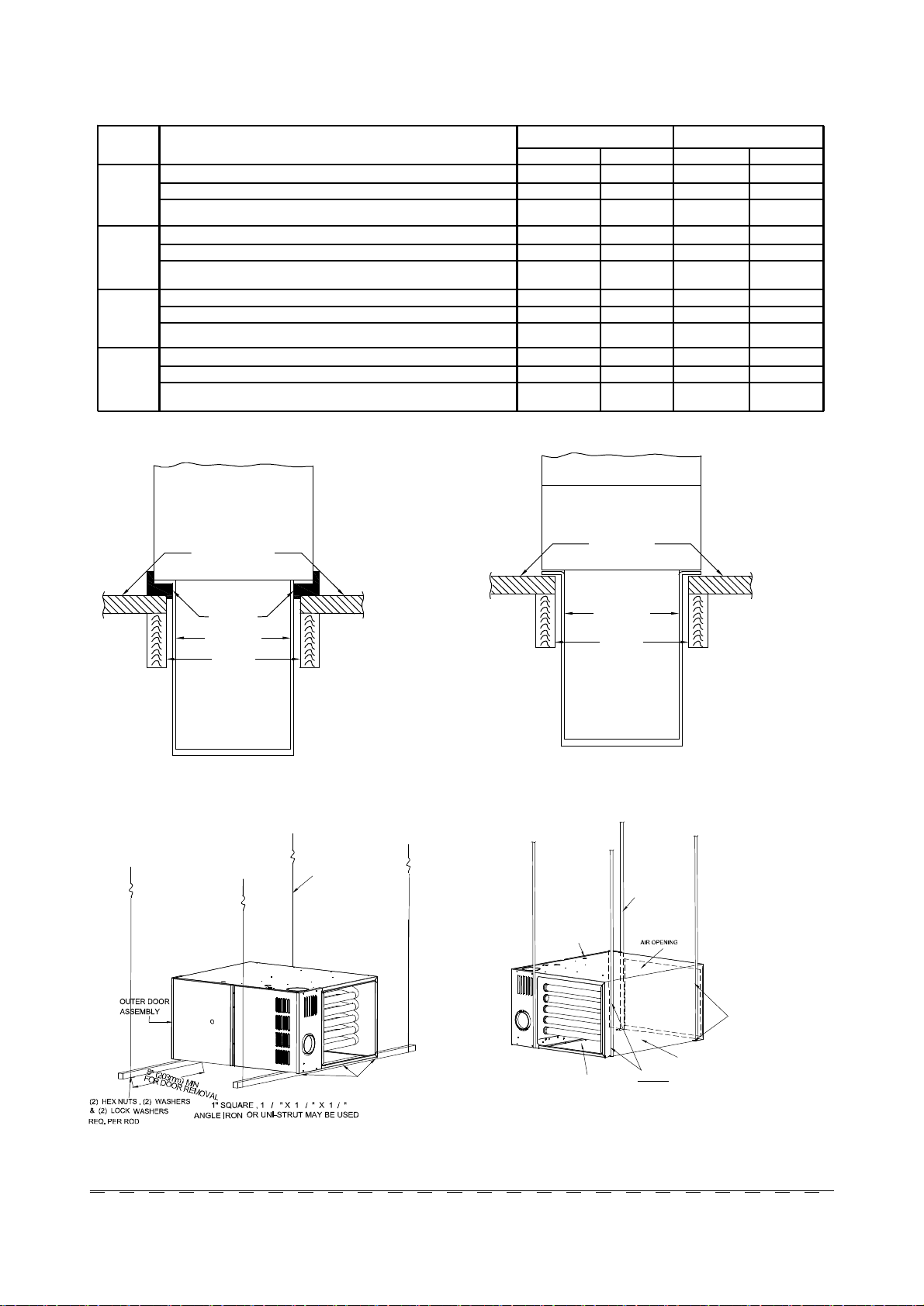

êòî ܱ©²º´±© ײ-¬¿´´¿¬·±²

NOTE: For downflow applications, this furnace is approved for use

on combustible flooring when anyone of the following 3 accessories

are used:

Special Base

Cased Coil Assembly

Coil Box

Determine application being installed from Table 2.

1.

Construct hole in floor per Table 2 and Fig. 6.

2.

Construct plenum to dimensions specified in Table 2 and Fig. 6.

3.

If down flow subbase is used, install as shown in Fig. 7. If Coil

4.

Assembly or Coil Box is used, install as shown in Fig. 8.

NOTE: It is recommended that the supply-air duct flanges be

completely folded over or removed from furnace when installing the

furnace on a factory-supplied cased coil or coil box.

To remove the supply-air duct flange, use wide duct pliers or hand

seamers to bend flange Be careful of sharp edges.

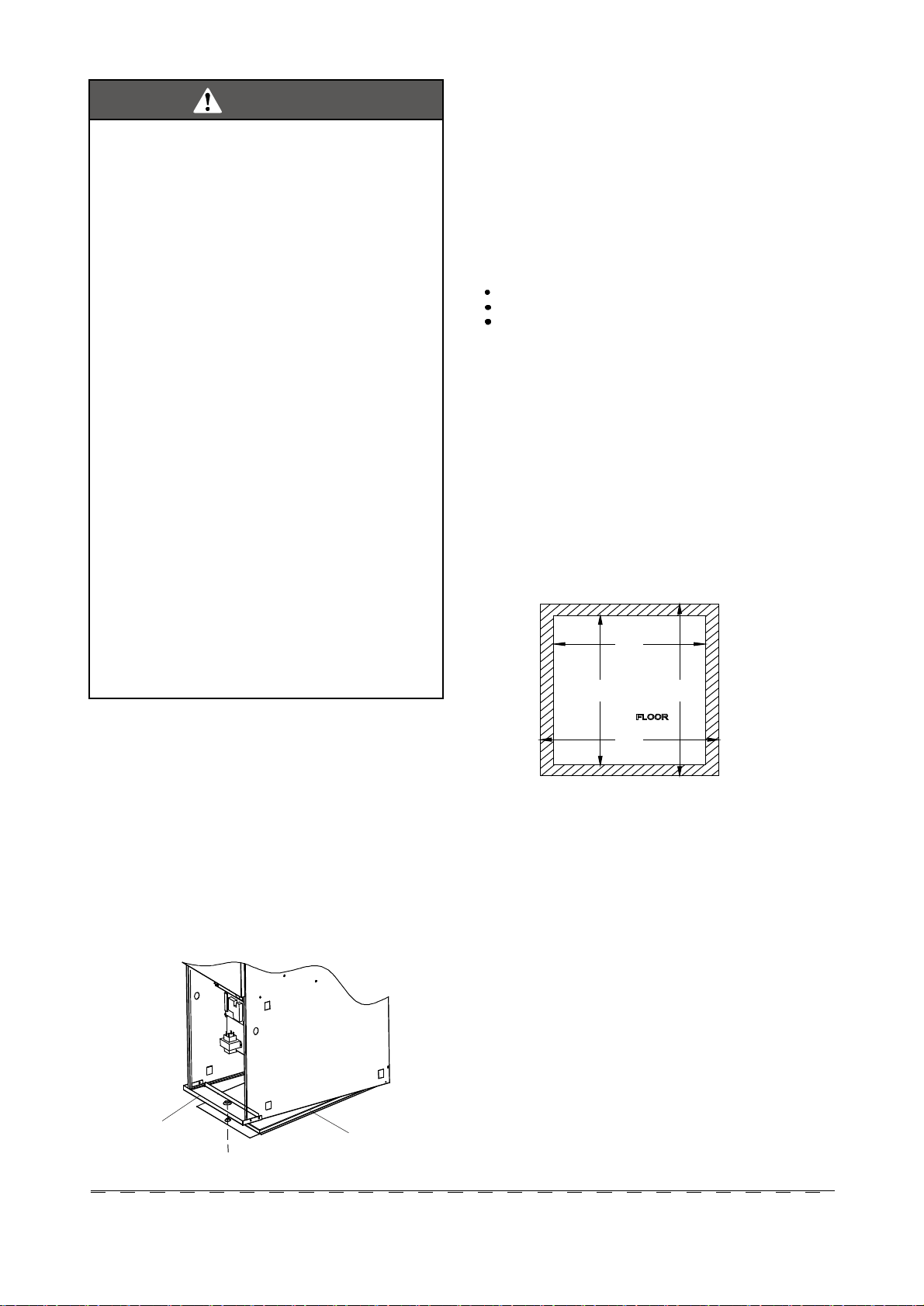

Bottom Return Air Inlet

Do not use side return openings in downflow configuration.

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. Remove and discard this panel when

bottom return air is used. See 6.1 and Fig. 5 for bottom closure

removal.

A

PLENUM

OPENING

B D

FLOOR

OPENING

C

This furnace can be installed for upflow, downflow and horizonal

positions (see Fig 12-18).

êòï Ë°º´±© ײ-¬¿´´¿¬·±²

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel, perform

the following:

Tilt or raise furnace and remove the screw holding bottom

1.

filler panel. (See Fig. 5.)

Remove bottom closure panel.

2.

BOTTOM FILLER

PANEL

I&O manual

I&O manual

è

è

Fig. 5 - Removing Bottom Closure Panel

SCREW

BOTTOM CLOSURE PANEL

Fig. 6 - Floor and Plenum Opening Dimensions

Page 11

TABLE 2 - OPENING DIMENSIONS - IN. (MM)

C

E

G

H

T

FURNA

CASIN

WIDT

14-1/2

(368)

17-1/2

(445)

21

(553)

24-1/2

(622)

APPLICATION

PLENUM OPENING FLOOR OPENING

A B C D

Downflow Applications on Noncombustible Flooring 13-3/16(335) 19-11/16(500)13-13/16(350) 20-5/16(516)

Downflow Applications on Combustible Flooring Using special base 12-3/16(311) 19(483) 13(331)

Downflow Applications on Combustible Flooring with Manufacturer

Supplied Coil Assembly or Coil Box

Downflow Applications on Noncombustible Flooring

Downflow Applications on Combustible Flooring Using special base

Downflow Applications on Combustible Flooring with Manufacturer

Supplied Coil Assembly or Coil Box

Downflow Applications on Noncombustible Flooring

Downflow Applications on Combustible Flooring Using special base

Downflow Applications on Combustible Flooring with Manufacturer

Supplied Coil Assembly or Coil Box

Downflow Applications on Noncombustible Flooring

Downflow Applications on Combustible Flooring Using special base

Downflow Applications on Combustible Flooring with Manufacturer

Supplied Coil Assembly or Coil Box

FURNACE

(OR COIL CASING

WHEN USED)

COMBUSTIBLE

FLOORING

13-3/16(335)

16-3/16(411) 19-11/16(500)16-13/16(427)

15-3/16(385)

16-3/16(411)

19-11/16(500)

18-11/16(474) 19(483) 19-1/2(495)

19-11/16(500)

23-3/16(589)

22-3/16(563)

19-11/16(500)

19-3/16(487)

13-13/16(351) 19-13/16(503)

19(483) 16(406)

19-3/16(487)

16-13/16(427)

19-11/16(500)20-5/16(516) 20-5/16(516)

19-3/16(487)

20-5/16(516)

19-11/16(500)20-5/16(516) 23-13/16(605)

19(483)

19-3/16(487)

FURNACE

APPROVED

COIL ASSEMBLY

OR

COIL BOX

COMBUSTIBLE

FLOORING

23(584)

20-5/16(516)

19-3/4(503)

20-5/16(516)

19-3/4(503)

19-13/16(503)

19-3/4(503)

19-13/16(503)

19-3/4(503)

19-13/16(503)

DOWNFLOW

SUBBASE

SHEET METAL

PLENUM

FLOOR

OPENING

Fig. 7 - Furnace, Plenum, and Subbase Installed on a

Combustible Floor

1/4" (6mm) THREADED

ROD 4 REQ

4

1

4

SECURE ANGLE

IRON TO BOTTOM

OF FURNACE WITH

3 #8 X / " SCREWS

4 1

1

8

TYPICAL FOR 2 SUPPORTS

SHEET METAL

PLENUM

(B, Ref Fig 6)

FLOOR

OPENING

(D, Ref Fig 6)

Fig. 8 - Furnace, Plenum, and Coil Assembly or

Coil Box Installed on a Combustible Floor

22 GAUGE GALVANIZED

STRAPS TYPICAL

FOR 4 STRAPS

OUTER DOOR

ASSEMBLY

METHOD 2

USE (4) #8 X 3/4 (19mm) SHEE

METAL SCREWS FOR EACH

STRAP . THE STRAPS

SHOULD BE VERTICAL

AGAINST THE FURNACE

BACK OF

AIR OPENING

3

FURNACE

METHOD 1

FOLD ALL STRAPS UNDER

FURNACE AND SECURE WITH

(4) #8 X 3/4 (19MM) SHEET METAL SCREWS

(2 SCREWS IN SIDE AND 2 SCREWS

IN BOTTOM) .

SIDES AND NOT PULL AWAY

FROM THE FURNACE

SIDES.

Fig. 9 - Horizontal Unit Suspension Fig. 10 - Horizontal Suspension with Straps

I&O manual

I&O manual

ç

ç

Page 12

Supply Air

LINE CONTACT ONLY PERMISSIBLE BETWEEN

LINES FORMED BY INTERSECTIONS OF

THE TOP AND TWO SIDES OF THE FURNACE

JACKET AND BUILDING JOISTS ,

STUDS , OR FRAMING.

SEDIMENT

TRAP

Sheet metal in front of furnace

combustion air Openings is

Recommended

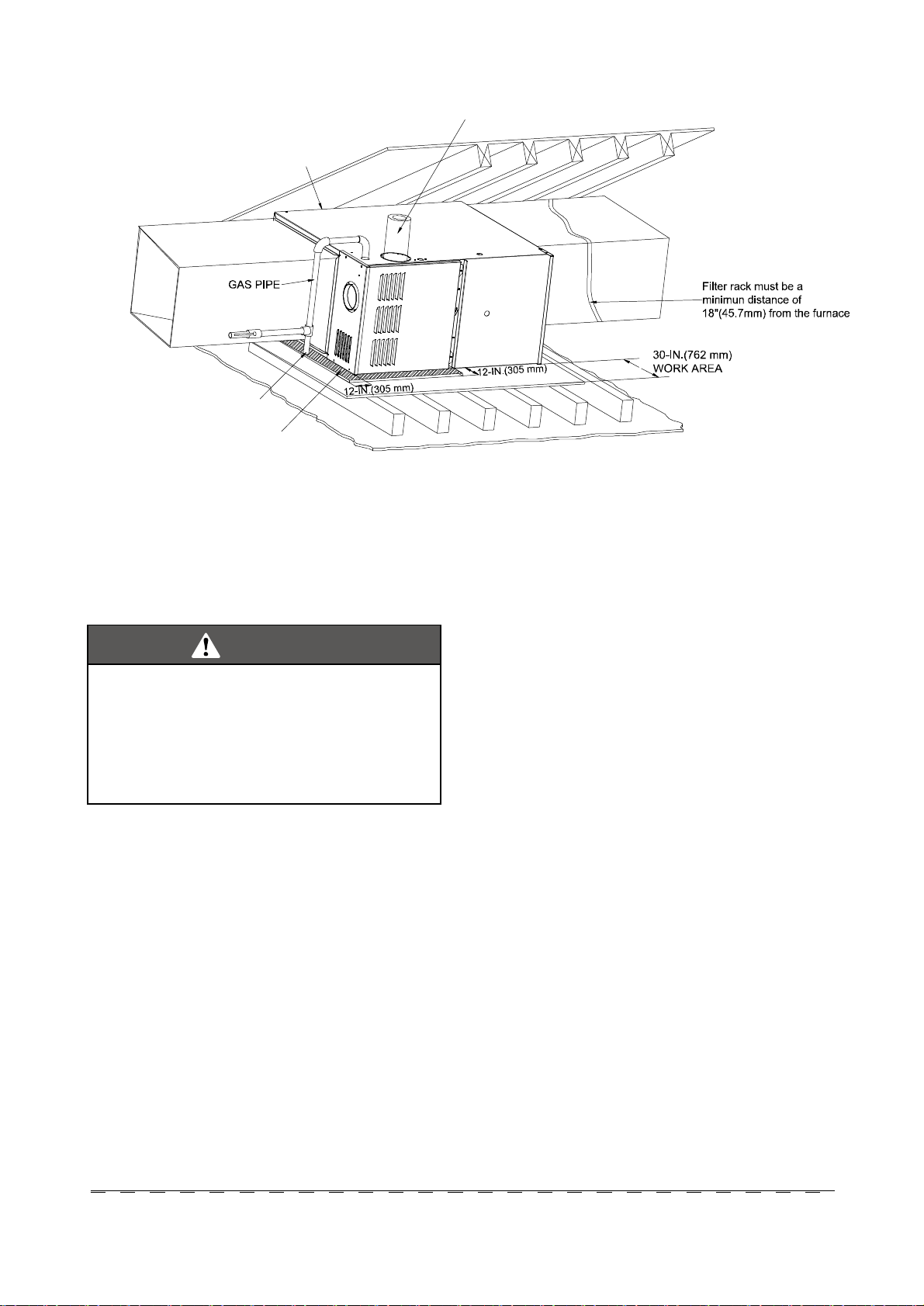

Fig. 11 - Typical Attic Installation

VENT(Maintain required clearances to

combustibles)

Return Air

êòí ر®·¦±²¬¿´ ײ-¬¿´´¿¬·±²

WARNING

FIRE, EXPLOSION, AND CARBON MONOXIDE

POISONING HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Do not install the furnace on its back or hang furnace with

control compartment facing downward. Safety control operation

will be adversely affected. Never connect return-air ducts to the

back of the furnace.

The furnace can be installed horizontally in an attic or crawl space

on bottom or either the left-hand (LH) or right-hand (RH) side. The

furnace can be hung from floor joists, rafters or trusses or installed

on a non-combustible platform, blocks, bricks or pad.

Suspended Furnace Support

The furnace may be supported under each end with threaded rod,

angle iron or metal plumber's strap as shown. (See Fig. 9 and 10.)

Secure angle iron to bottom of furnace as shown. Heavy-gauge

sheet metal straps (plumber's straps) may be used to suspend the

furnace from each bottom corner. To prevent screws from pulling out,

use 2 #8 x 3/4-in. screws into the side and 2 #8 x 3/4-in. screws in

the bottom of the furnace casing for each strap. (See Fig. 9 and 10.)

If the screws are attached to ONLY the furnace sides and not the

bottom, the straps must be vertical against the furnace sides and not

pull away from the furnace sides, so that the strap attachment

screws are not In tension (are loaded in shear) for reliable support.

Platform Furnace Support

Construct working platform at location where all required furnace

clearances are met. (See Fig. 2 and 11.) For furnaces with 1-in.

clearance requirement on side, set furnace on noncombustible

blocks, bricks or angle iron. For crawl space installations, if the

furnace is not suspended from the floor joists, the ground

underneath furnace must be level and the furnace set on blocks or

bricks.

Roll-Out Protection

Provide a piece of sheet metal for flame roll-out protection in front of

burner area for furnaces closer than 12-in. (305 mm) above the

combustible deck or suspended furnaces closer than 12-in. (305

mm) to joists. The sheet metal MUST extend underneath the furnace

casing by 1-in. (25 mm) with the door removed.

The bottom closure panel on furnaces of widths 12in. (305 mm) and

larger may be used for flame roll-out protection when bottom of

furnace is used for return air connection. See Fig. 11 for proper

orientation of roll-out shield.

I&O manual

I&O manual

ïð

ïð

Page 13

Vent the furnace with the appropriate connector as shown in Fig. 12-18.

Fig. 12 - Downflow Application- Vent Elbow Up then Left

Fig. 14 -Horizontal Left Application-Vent Elbow Up

Fig. 13- Downflow Application- Vent Elbow Up then Right

Fig. 15 -Horizontal Right Application-Vent Elbow Up

Fig. 16 -Upflow Application-Vent

Elbow Left

Fig. 17 -Upflow Application-Vent

Elbow Up

Fig. 18 -Upflow Application-Vent

Elbow Right

I&O manual

ïï

Page 14

êòì Ú·´¬»® ß®®¿²¹»³»²¬ êòë ß·® Ü«½¬-

General Requirements

WARNING

CARBON MONOXIDE AND POISONING HAZARD

Failure to follow this warning could result in personal injury, or

death.

Never operate a furnace without a filter or with filter access door

removed.

FILTER SIZE

See recommended filter size and type in Table 4.

One of the most common causes of a problem in furnace is a blocked

or dirty filter. The filter must be inspected monthy for dirt accumulation

and replace it if neccessarily.

FILTER TYPE

Air velocity through throwaway filters may not exceed 300 feet per

minute (91.4m/min). All velocities over this require the use of hight

velocity filters. If a normal speed desposable filter is used and air

speed exceeds 300 feet per minute(FPM), two side returns or one

side return and the bottom return may be needed. For airflow, refer to

Table 3.

If disposable filters are used air throw away passage through filters

should be increased to twice the size of original air opening by using

a transition duct or using two filters in V shap in normal duct size.

SIDE RETURN

Locate the 4 cutout locations. These indicate the size of the cut-out

to be made in the furnace side panel. Refer to Fig 19, "Side Return

Cutout Markings".

Frontof

Furnace

Corner

Markings

Fig. 19 Side Return Cutout Markings

Install the side filter rack followi ng the instructions provided with that

accessory. If a filter(s) is provided at another location in the return air

system, the ductwork may be directly attached to the furnace side

panel.

IMPORTANT:

pleated media may require a larger side opening. Follow the instructions supplied with that accessory for side opening requirements.

Downflow Filters

Downflow furnaces typically are inst alled with the filters located above

the furnace, extending into the re turn air plenum or duct. Any branch

duct (rectangular or round duct) attached to the plenum must attach to

the vertical plenum above the filter height.

Filter(s) may be located in the duct system external to the furnace using

an external duct filter box attached to the furnace plenum or at the end

of the duct in a return filter grille(s). The use of straps and/or supports is

required to support the weight of the external filter box.

I&O manual

Some accessories such as electronic air cleaners and

The duct system should be designed and sized according to accepted

national standards such as those published by: Air Conditioning

Contractors Association (ACCA), Sheet Metal and Air Conditioning

Contractors National Association (SMACNA) or American Society of

Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) or

consult The Air Systems Design Guidelines reference tables available

from your local distributor. The duct system should be sized to handle

the required system design CFM at the design external static

pressure. The furnace airflow rates are provided in Table 6-AIR

DELIVERY -CFM (Without Filter).

When a furnace is installed so that the supply ducts carry air

circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by duct(s) sealed to the

furnace casing and terminating outside the space containing the

furnace.

Secure ductwork with proper fasteners for type of ductwork used.

Seal supply and return-duct connections to furnace with code

approved tape or duct sealer.

NOTE: Flexible connections should be used between ductwork and

furnace to prevent transmission of vibration. Ductwork passing

through unconditioned space should be insulated and sealed to

enhance system performance. When air conditioning is used, a

vapor barrier is recommended.

Maintain a I-in. (25 mm) clearance from combustible materials to

supply air ductwork for a distance of 36 in. (914 mm) horizontally

from the furnace. See NFPA 90B or local code for further

requirements.

Ductwork Acoustical Treatment

NOTE: Metal duct systems that do not have a 90 degree elbow and

10 ft. (3 M) of main duct to the first branch take-off may require

internal acoustical lining. As an alternative, fibrous ductwork may be

used if constructed and installed in accordance with the latest edition

of SMACNA construction standard on fibrous glass ducts. Both

acoustical lining and fibrous ductwork shall comply with NFPA 90B

as tested by UL Standard 181 for Class 1 Rigid air ducts.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct shall

be provided with a removable access panel. This opening shall be

accessible when the furnace is installed and shall be of such a size

that the heat exchanger can be viewed for possible openings using

light assistance or a probe can be inserted for sampling the

airstream. The cover attachment shall prevent leaks.

Upflow and Horizontal Furnaces

Connect supply-air duct to flanges on furnace supply-air outlet. Bend

flange upward to 90° with wide duct pliers. The supply-air duct must

be connected to ONLY the furnace supply-outlet-air duct flanges or

air conditioning coil casing (when used). DO NOT cut main furnace

casing side to attach supply air duct, humidifier, or other

accessories. All accessories MUST be connected to duct external to

furnace main casing.

NOTE: For horizontal applications, the top-most flange may be bent

past 90 degrees to allow the evaporator coil to hang on the flange

temporarily while the remaining attachment and sealing of the coil

are performed.

Downflow Furnaces

Connect supply-air duct to supply-air outlet on furnace. Bend flange

inward past 90° with wide duct pliers. The supply-air duct must be

connected to ONLY the furnace supplyoutlet or air conditioning coil

casing (when used). When installed on combustible material,

supply-air duct must be connected to ONLY the accessory subbase

or a factory approved air conditioning coil casing. DO NOT cut main

furnace casing to attach supply side air duct, humidifier, or other

accessories. All accessories MUST be connected to duct external to

furnace casing.

ïî

Page 15

Table 3 - Air Delivery - CFM (Without Filter)

#

*

**

FURNACE

SIZE

50A

70A

80B

80C

90B

100C

110C

100D

120D

135D

RETURN-AIR

INLET

Bottom or

Sides

Bottom or

Sides

Bottom or

Sides

Bottom or

Sides

Bottom or

Sides

Bottom or

Sides

Bottom or

Sides

Bottom or

Sides

Bottom or

Sides

Bottom or

Sides

SPEED

H

H-M

M-L

**

L

H

H-M

**

M-L

L

H

H-M

**

M-L

L

H

H-M

**

M-L

L

H

H-M

**

M-L

L

H

H-M

**

M-L

L

H

H-M

**

M-L

L

H

H-M

**

M-L

L

H

H-M

**

M-L

L

H

H-M

**

M-L

L

0.1

1460

1210

1080

780

1415

1145

1015

740

1880

1680

1440

1190

1863

1625

1351

1096

1880

1680

1440

1190

2180

1760

1570

1410

2180

1760

1570

1410

2360

1800

1560

1360

2320

1790

1550

1360

2271

2265

1727

1516

0.2

1420

1170

1050

760

1355

1100

975

710

1810

1620

1390

1150

1816

1583

1315

1062

1810

1620

1390

1150

2070

1710

1540

1370

2070

1710

1540

1370

2280

1760

1540

1340

2240

1750

1520

1350

2188

2188

1677

1477

0.3

1370

1140

1010

730

1300

1050

930

680

1730

1560

1340

1110

1763

1534

1281

1041

1730

1560

1340

1110

1960

1660

1490

1340

1960

1660

1490

1340

2200

1720

1500

1330

2160

1700

1490

1330

2112

2101

1620

1436

EXTERNAL STATIC PRESSURE (IN.WC)

0.4

1320

1090

960

700

1240

1000

885

645

1650

1500

1290

1070

1709

1479

1246

1012

1650

1500

1290

1070

1890

1600

1440

1310

1890

1600

1440

1310

2120

1670

1460

1290

2060

1660

1450

1310

2016

2006

1568

1386

0.5

1260

1030

960

670

1165

940

840

605

1580

1430

1240

1020

1645

1428

1200

968

1580

1430

1240

1020

1810

1520

1380

1250

1810

1520

1380

1250

2020

1600

1420

1250

1980

1610

1430

1280

1939

1917

1513

1335

0.6

1200

970

870

630

1100

880

785

555

1500

1350

1170

950

1569

1356

1142

919

1500

1350

1170

950

1720

1460

1310

1200

1720

1460

1310

1200

1920

1530

1360

1210

1890

1540

1360

1220

1837

1832

1442

1268

0.7 0.8

1120

910

810

580

1010

820

730

500

1430

1270

1080

870

1483

1288

1071

841

1430

1270

1080

870

1620

1360

1240

1130

1620

1360

1240

1130

1810

1460

1300

1150

1780

1460

1300

1160

1737

1732

1368

1195

1040

840

750

510

935

750

660

430

1330

1160

970

750

1381

1190

970

738

1330

1160

970

750

1500

1260

1150

1040

1500

1260

1150

1040

1700

1360

1210

1070

1670

1360

1210

1070

1628

1622

1263

1095

0.9

950

760

670

390

850

670

575

345

1210

1020

810

640

1234

1059

831

638

1210

1020

810

640

1370

1140

1040

940

1370

1140

1040

940

1600

1240

1090

920

1540

1220

1110

960

---

---

---

---

1.0

860

780

550

---

750

565

475

240

990

800

640

530

1059

849

695

566

990

800

640

530

1230

1130

910

810

1230

1130

910

810

1460

1030

890

760

1360

1060

960

830

---

---

---

---

A filter is required for each return -air Inlet. Airflow performance Included 3/4-ln. (19 mm) washable filter media such as contained In

*

factory-authorized accessory filter rack. To determine airflow performance with this filter, assume an additional 0.1 in. wc available external static

pressure.

Manufacturer default speed tap for heating.

**

# CSA tested at Max. external static pressure 0.5 in W.C.

Table 4 - Filter Size Information - In. (mm)

FURNACE CASING WIDTH

14-1/2(368)

17-1/2(445)

21(533)

24.5(622)

FILTER SIZE

SIDE RETURN BOTTOM RETURN

16X25

(406X635)

16X25

(406X635)

16X25

(406X635)

16X25

(406X635)

14X25

(356X635)

16X25

(406X635)

20X25

(508X635)

24X25

(610X635)

FILTER TYPE

High Velocity (600 FPM)

High Velocity (600 FPM)

High Velocity (600 FPM)

High Velocity (600 FPM)

I&O manual

ïí

Page 16

й КЫТМ НЗНМЫУ

éòï Ê»²¬ ݱ²²»½¬·±²-

Fig. 20 , “Combustion Air Inducer” shows the furnace as it is shipped

from the factory. To convert to a horizontal or downflow position,

remove the four screws that secure the inducer assembly and rotate 90

being careful not to damage the gasket. Reinstall screws. Remove cap

from appropriate vent outlet location on the cabinet cut insulation in

cabinet to same size as the hole provided and reinstall cap in the hole in

the top panel.

IMPORTANT

In downflow applications, do not block the combustion air inlet.

The furnace must be installed on a coil cabinet or subbase to

allow combustionair to enter the burner compartment.

éòí Ê»²¬·²¹ ײ¬± ß² Û¨·-¬·²¹ ݸ·³²»§

This furnace may not be connected to any masonry chimney. However,

an existing masonry chimney may be used on as a chase through which

the metal vent pipe passes.

éòì ß·® Ú±® ݱ³¾«-¬·±² ¿²¼ Ê»²¬·´¿¬·±²

йтмтп Я³¾·»²¬ Э±³¾«-¬·±² Я·® Н«°°´§

This type installation will draw the air required for combustion from

within the space surrounding the appliance and from areas or rooms

adjacent to the space surrounding the appliance. This may be from

within the space in a non-confined location or it may be brought into

the furnace area rom outdoors through permanent openings or ducts.

A single, roperly sized pipe from the furnace vent connector to the

outdoors must be provided. For upflow models combustion air is

brought into the furnace through the unit top panel opening.

90

Flue Transition

90

(Do Not Remove)

Mounting Screw (Remove)

Fig . 20

Combustion Air Inducer

ЭЯМЫЩСОЗ п у млр Ът УЯИт КЫТМ МЫУРт

The venting system must be installed in accordance with Section 5.3

Air for combustion and Ventilation, of the National Fuel Gas Code

Z223.1/NFPA 54 (latest edition), or Sections 7.2, 7.3 or 7.4 of CSA

B149.1, National Gas and Propane Codes (latest edition) or applicable

provisions of the local building code and these instructions.

̸» º«®²¿½» -¸¿´´ ¾» ½±²²»½¬»¼ ¬± ¿ ¬§°» Þ ª»²¬ ½±²²»½¬±®ô ̸» º«®²¿½» -¸¿´´ ²±¬

¾» ½±²²»½¬»¼ ¬± ¿ ½¸·³²»§ º´«» -»®ª·²¹ ¿ -»°¿®¿¬» ¿°°´·¿²½» ¼»-·¹²»¼ ¬± ¾«®²

-±´·¼ º«»´ò Í·²¹´»ó©¿´´ ª»²¬ °·°» ·- ²±¬ ¿´´±©»¼ò

It is recommended that the appliance is installed in a location where the

space temperature is 32 °F( 0 °C) or higher. If the appliance is installed

in a location where the temperature is below 32 °F (0 °C) , the combustion

byproducts could condense causing damage to the appliance heat

exchanger.

This appliance may be common vented with another gas appliance for

residential installations as allowed by the codes and standards listed in

these instructions.

éòî Ê»²¬·²¹

Category I venting consists of vertically venting one or more appliances

in B-vent or B-vent connectors. Type B-vent system extends in a general vertical direction and does not contain offsets exceeding 45° .

A vent system having not more than one 60° offset is permitted.

Gas

Attic

TopAbove

Insulation

Outlet

Air(a)

Vent

Soffit

Vent

Gable

Vent

Ventilated

Attic

TopAbove

Insulation

Soffit

Vent

Gable

Vent

Optional

Inlet(a)

Ventilated

Combustion Air

Fig. 21: Combustion Airflow Path Through The Furnace Casing to

the Burner Box

WARNING

This type of installation requires that the supply air to the appliance(s) be of a sufficient amount to support all of the appliance(s) in

the area. Operation of a mechanical exhaust, such as an exhaust

fan, kitchen ventilation system, clothes dryer or fireplace may create conditions requiring special attention to avoid unsatisfactory

operation of gas appliances. A venting problem or a lack of supply air will result in a hazardous condition, which can cause the appliance to soot and generate dangerous levels of CARBON MINOXIDE, which can lead to serious injury, property damage and I or

death.

An

«²½±²º·²»¼ -°¿½»

(0.2928 kW) input rating for all of the appliances installed in that area.

Rooms communicating directly with the space containing the appliances

through openings not furnished with doors, are considered a part of the

unconfined space.

In unconfined spaces (see definition below) in buildings, infiltration may

be adequate to provide air for combustion ventilation and dilution of flue

gases. However, in buildings of tight construction (for example, weather

stripping, heavily insulated, caulked, vapor barrier, etc.), additional air

may need to be provided using the methods described in “An confined

space” section.

An

½±²º·²»¼ -°¿½»

Btu/hr (0.2928 kW) input rating for all of the appliances installed in that

area. The following must be considered to obtain proper air for combustion and ventilation in confined spaces.

Gas

Vent

is not less than 50 cu.ft (1.42m3) per 1,000Btu/hr

is an area with less than 50 cu . ft (1.42m3) per 1,000

Gas

Vent

Outlet

Air(b)

Outlet

Air(a)

I&O manual

ïì

Gas

Water

Heater

Ventilated

CrawlSpace

Gas

Inlet

Air(b)

Water

Heater

Fig. 22 Outside and Ambient Combustion Air

Inlet

Air(a)

Inlet

Air(b)

Gas

Water

Heater

Inlet

Air(a)

Page 17

WARNING

When a Category I furnace is removed or replaced, the original

venting system may no longer be correctly sized to properly vent

the attached appliances.

An improperly sized vent system can cause CARBON MONOXIDE

to spill into the living space causing personal injury, and or death.

Û¯«·°³»²¬ Ô±½¿¬»¼ ·² ݱ²º·²»¼ Í°¿½»-æ

a) All air from inside the building:

The confined space shall be provided with two permanent openings

communicating directly with an additional room(s) of sufficient volume

so that the combined volume of all spaces meets the criteria. The total

input of all gas utilization equipment installed in the combined space

shall be considered in making this determination. Each opening shall

have a minimum free area of 1 square inch per 1,000BTU per hour of

the total input rating of all gas utilization equipment in the confined sp ace. One opening shall be within 12 inches of the top and one within

12 inches of the bottom of the enclosure (See Table 5).

Table 5 : Minimum Area in Square Inch Required for Each Opening

BTUH Input Rating

50,000

70,000

80,000

90,000

100,000

110,000

120,000

135,000

Minimum Free Area in Square Inch

Required for Each Opening

50 in (322 cm

70 in (450 cm

80 in (516 cm

90 in (580 cm

100 in (645 cm

110 in (708 cm

120 in (742 cm

135 in (871 cm

2 2

)

2 2

)

2 2

)

2

2

)

2

2

)

2

2

)

2

2

)

2

2

)

a. 1 square in per 3000 Btu per hour (734 mm2/kW) of the total

input rating of all equipment located in the enclosure.

b.Not less than the sum of all vent connectors in the confined

3.The duct shall be least the same

space.

cross-sectional area as the free

area of the air supply inlet opening to which it connects.

4.The blocking effects of louvers, grilles and screens must be given

consideration in calculating free area. If the free area of a specific

louver aor grille is not known. Refer to Table ,“Estimated Free

Area” to estimated free area.

Table 7 : Estimated Free Area

Wood or Metal

Louvers or Grilles

Screens +

Wood 20-25%

Metal 60-70%

1/4” (0.635cm)

mesh or larger 100%

5.An opening may be used in lieu of a duct to provide to provide the

outside air supply to an appli ance unless otherwise permitted by

the authority having jurisdiction. The opening shall be located

within 12” (30.5 cm) horizontally from the burner level of the appliance. Refer to “COMBUSTIO N AIR SOURCE FROM OUTDOORS

and VENT AND SUPPLY AIR SAFETY CHECK” in these instructions for additional informati on and safety check procedure.

éòê Ê»²¬·´¿¬»¼ ݱ³¾«-¬·±² ß·®

The ventilated attic space or a crawl space from which the combustion

air is taken must comply with the requirements specified in “

Air Source from Outdoors

” in this instruction or in Section 7.4, Air

for Combustion and Ventilation of the National Fuel Gas Code, ANSI

Z223.1 (latest edition). This type in stallation requires two properly sized

pipes. One brings combustion air from

a properly ventilated attic space

or crawl space and a second pipe that extends from the furnace vent

connection (top right of unit) to the exterior of the building.

Combustion

b) All air from outdoors:

Table 6 : Minimum Free Area Required for Each Opening

Minimum Free Area Required for Each Opening

BTUH Input

Rating

50,000

70,000

80,000

90,000

100,000

110,000

120,000

135,000

Horizontal Duct

(2,000 BTUH)

25 in 2 (129 cm 2 )12.5 in 2 (81 cm 2 )

35 in 2 (226 cm )

40 in 2 (258 cm 2 )20 in 2 (129 cm 2 )

45 in 2 (290 cm ) 2 22.5 in 2 (145 cm 2 )

50 in 2 (323 cm 2 )25 in 2 (161 cm 2 )

55 in 2 (355 cm )

60 in 2 (387 cm 2 )30 in

70 in 2 (452 cm )

Vertical Duct or

Opening to Outside

(4,000 BTUH)

2

2

2

2

17.5 in

2

27.5 in

2

35 in 2 (226 cm 2 )

(113 cm 2 )

(178 cm 2 )

(194 cm 2 )

Round Duct

(4,000 BTUH)

4” (10 cm)

5” (13 cm)

5” (13 cm)

6” (15 cm)

6” (15 cm)

7” (18 cm)

7” (18 cm)

7” (18 cm)

EXAMPLE: Determining Free Area.

Appliance 1 Appliance 2 Total Input

100,000 +30,000 = (130,000 4,000) = 32.5 Sq. In. Vertical

Appliance 1 Appliance 2 Total Input

100,000 +30,000 = (130,000 2,000) = 65 Sq. In. Horizontal

éòë ß·® Í«°°´§ Ñ°»²·²¹- ¿²¼ Ü«½¬-

1.Two permanent openings, one within 12 in (305 mm) of the top

and one within 12 in (305 mm) of bottom of the confined space,

Two permanent openings, shall communi cate directly or by means

of ducts with the outdoors, crawl spaces or attic spaces.

2.One permanent openings, commencing within 12 in (305 mm)of

the top of the enclosure shall be permitted where the equipment

has clearances of at least 1 in (25.4 mm) from the sides and back

and 6 in (152.4 mm) from the front of the appliance. The opening

shall communicate directly with the outdoors and shall have a minimum free area of:

éòé Ê»²¬ ¿²¼ Í«°°´§ øÑ«¬-·¼»÷ ß·® Í¿º»¬§ ݸ»½µ Ю±½»¼«®»

For Category I furnaces, vent installations shall be in accordance with

Parts 7 and 11 of the National Fuel Gas Code, ANSI Z223.1/NFPA 54

and or Section 7 and Appendix B of the CAS B 149.1, Natural Gas and

Propane Installation Codes, the local building codes, furnace and vent

Multi-story or common venting systems are permitted and must be

installed in accordance with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and / or the CSA B 149.1, Natural Gas and

Vent connectors serving Category I furnaces shall not be connected

into any portion of mechanical draft systems operating under positive

pressure.

I&O manual

ïë

Page 18

Horizontal portions of the venting system shall be supported to prevent sagging using hangers or perforated straps and must slope upwards

not less than 1/4” per foot (0.635 cm/m) from the furnace to the vent terminal.

It is recommended that you follow the venting safety procedure below. This procedure is designed to detect an inadequate ventilation system

that can cause the appliances in the area to operate improperly causing unsafe levels of Carbon Monoxide or an unsafe condition to occur.

WARNING

ЭЯОЮСТ УСТСИЧЬЫ РСЧНСТЧТЩ ШЯЖЯОЬ

Failure to follow the steps outlined below for each appliance connected to the venting system being placed into operation could result in carbon

-monxide poisoning or death. The following steps shall be followed for each appliance connected to the venting system being placed into operation, while all other appliances connected to the venting system are not in operation:

1. Inspect the venting system for proper size and horizontal pitch. Determine that there is no blockage, restriction, leakage, corrosion or other

deficiencies, which could cause an unsafe condition

2. Close all building doors and windows and all doors.

3. Turn on clothes dryers and TURN ON any exhaust fans, such as range hoods and bathroom exhausts, so they shall operate at maximum

speed. Open the fireplace damper. Do not operate a summer exhaust fan.

4. Follow the lighting instructions. Place the appliance being inspected in operation. Adjust thermostat so the appliance shall operate

continuously.

5. Test each appliance (such as a water heater) equipped with a draft hood for spillage (down-draft or no draft) at the draft hood relief opening

after 5 minutes of main burner operation. Appliances that do not have draft hoods need to be checked at the vent pipe as close to the

appliance as possible. Use a combustion analyzer to check the CO2 and CO levels o each appliance. Use a draft gauge to check for a

downdraft or inadequate draft condition.

6. After it has been determined that each appliance properly vents when tested as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas burning appliance to their normal condition.

7. If improper venting is observed during any of the above tests, a problem exists with either the venting system or the appliance does not

have enough combustion air (Supply Air from outside) to complete combustion. This condition must be corrected before the appliance can

function safely.

NOTE: An unsafe condition exists when the CO reading exceeds 40 ppm and the draft reading is not in excess of -0.1 in. W.W.(-25 kPa) with

all of the appliance(s) operating at the same time.

8. Any corrections to the venting system and / or to the supply (outside) air system must be in accordance with the National Fuel Gas Code

Z223.1 or CAN/CGA B149.1 Natural Gas and Propane Installation Code (latest editions). If the vent system must be resized, follow the

appropriate tables in Appendix G of the above codes or for this appliance.

и ЩЯН НЛРРФЗ ЯТЬ РЧРЧТЩ

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Never purge a gas line into a combustion chamber. Never test

for gas leaks with an open flame. Use a commercially available

soap solution made specifically for the detection of leaks to

check all connections.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.