Page 1

Instructions for the Proper Use and Care of

Klein

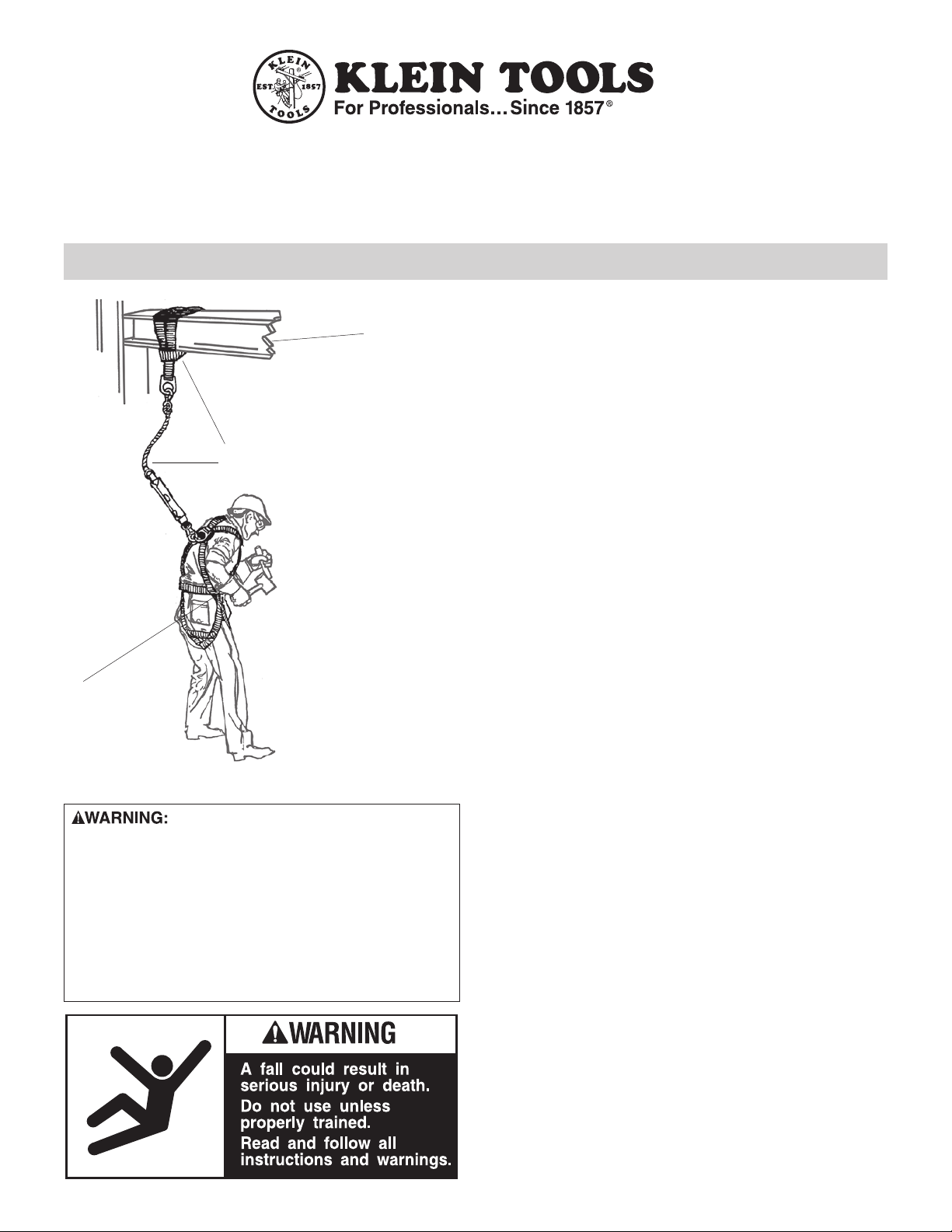

Introduction

(B) Body Wear

®

Occupational Protective Connecting Devices

(C) Connecting Devices

(A) Anchorage

These instructions apply to all Klein rope

lanyards, aircraft-cable lanyards, nylon webbing

lanyards, deceleration lanyards, deceleration

units, and V-sling harness attachments.

NOTE: For clarity, illustrations in this instruction

booklet do not show any warning tags or labels,

which are attached to each product. Warning

information for V-slings and all lanyards is printed on

a durable label wrapped around the product.

Klein makes a full line of Occupational Protective

Equipment (OPE). Each OPE product is part of an

OPE system for fall arrest, positioning, suspension,

retrieval, or combination application.

Follow the A-B-C Rule when assembling an OPE

system. All personal OPE systems are made up of

three (3) major components: (A) Anchorage,

(B) Bodywear (for example, a full body harness),

and (C) Connecting Device(s).

Klein’s Lanyard Connecting Devices are used to

attach the harness (the “B” component) to a suitable

anchorage (the “A” component) in order to provide

one of the four OPE functions (Fall Arrest, Positioning,

Suspension, and Retrieval).

Save these instructions. Klein

connecting devices must NOT be

used by anyone who has not read, understood and

followed all instructions and inspection procedures

contained in this booklet. Failure to observe these

warnings, instructions, and inspection procedures

could lead to serious injury or death. Training and

instruction review should be repeated at regular

intervals by the user and his or her employer.

Note: A personal fall-arrest system only becomes

active in a fall. If equipment is required to help hold

or place a worker in position, you must use other

OPE systems in addition to the fall-arrest system.

A personal fall-arrest system is designed only to aid

a worker once a fall occurs, and must be used

whenever there is a danger of falling. Where there is

a danger of being killed or injured from a fall, only

use equipment specifically designed for fall arrest.

Page 2

Introduction (continued)

When using any OPE system, you must be sure the

entire system meets OSHA regulations. Be sure the

primary anchorage is identified and evaluated by a

competent person, as defined by OSHA, at the job

site. A competent person must also determine that

the type of OPE connecting device and harness are

appropriate for the job.

Many connecting devices can be used properly in

more than one OPE system application. For example,

a Klein rope lanyard can be used as a component in

a positioning, suspension, or retrieval system. Other

connecting devices, such as deceleration lanyards

and deceleration units, can only be used for fall

arrest. All Klein OPE connecting devices meet or

exceed all pertinent OSHA regulatory requirements.

The symbols shown above indicate that a particular

Fall Arrest

Positioning

Suspension

Retrieval

connecting device is appropriate for use in one or

more of the following systems:

• in a fall-arrest system, where there is danger of

falling from an elevated position;

• in a positioning system, where it is necessary to

have your hands free while working on an elevated

surface;

• in a suspension system, where it is necessary to

be positioned and supported from above; or

• in a retrieval system, where it is necessary to

have a quick means of being lifted out of, or pulled

from, a working environment.

Double-check the intended function

of any Klein connecting device

before using it. Proper OPE system applications

are identified in the Klein OPE catalog and are

printed clearly on the warning tags, labels and

other literature provided with each product. Misuse

of a connecting device or any other piece of OPE

equipment can result in serious injury or death.

It is imperative that qualified

people select OPE system

components to fit the specific job requirements.

Incorrect component choices can cause serious

injury or death.

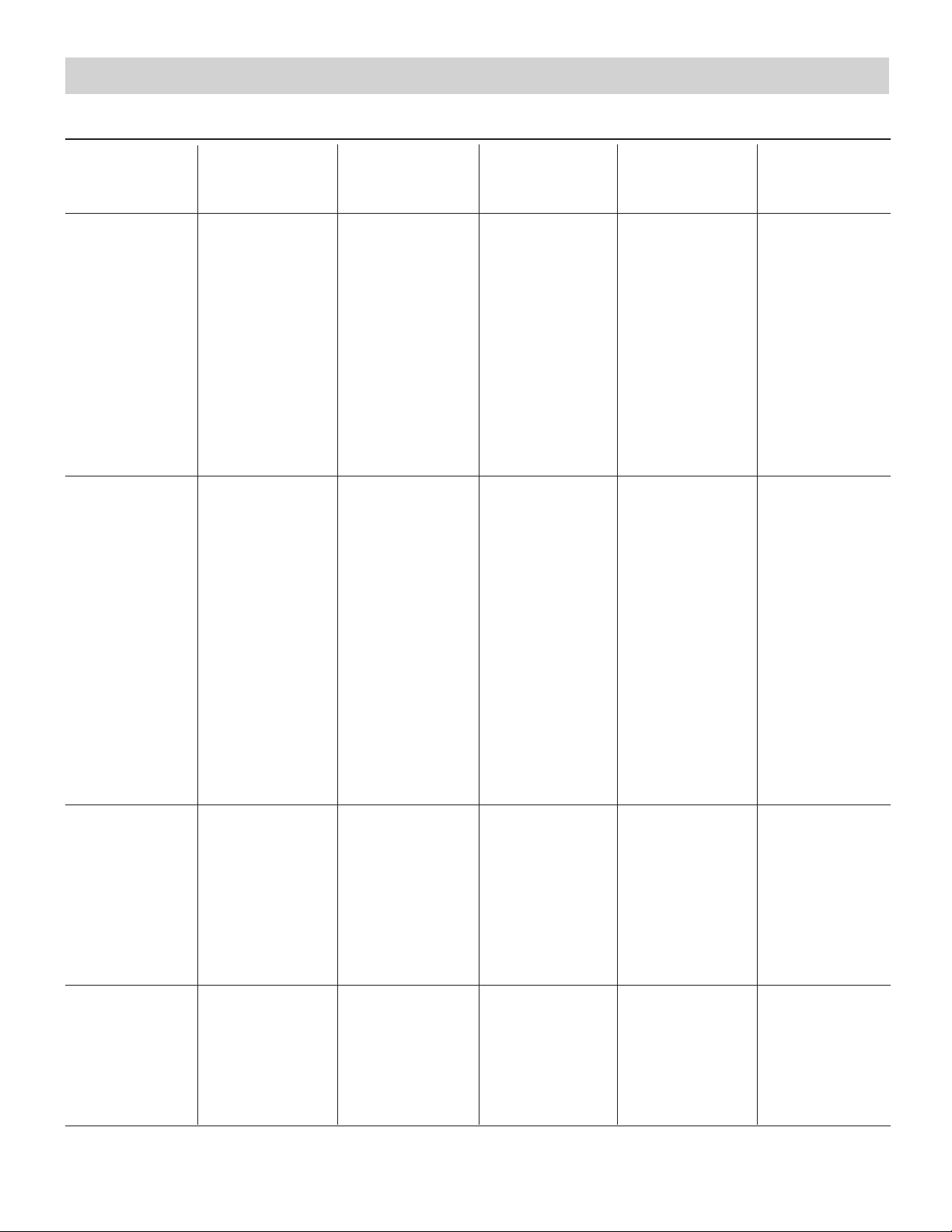

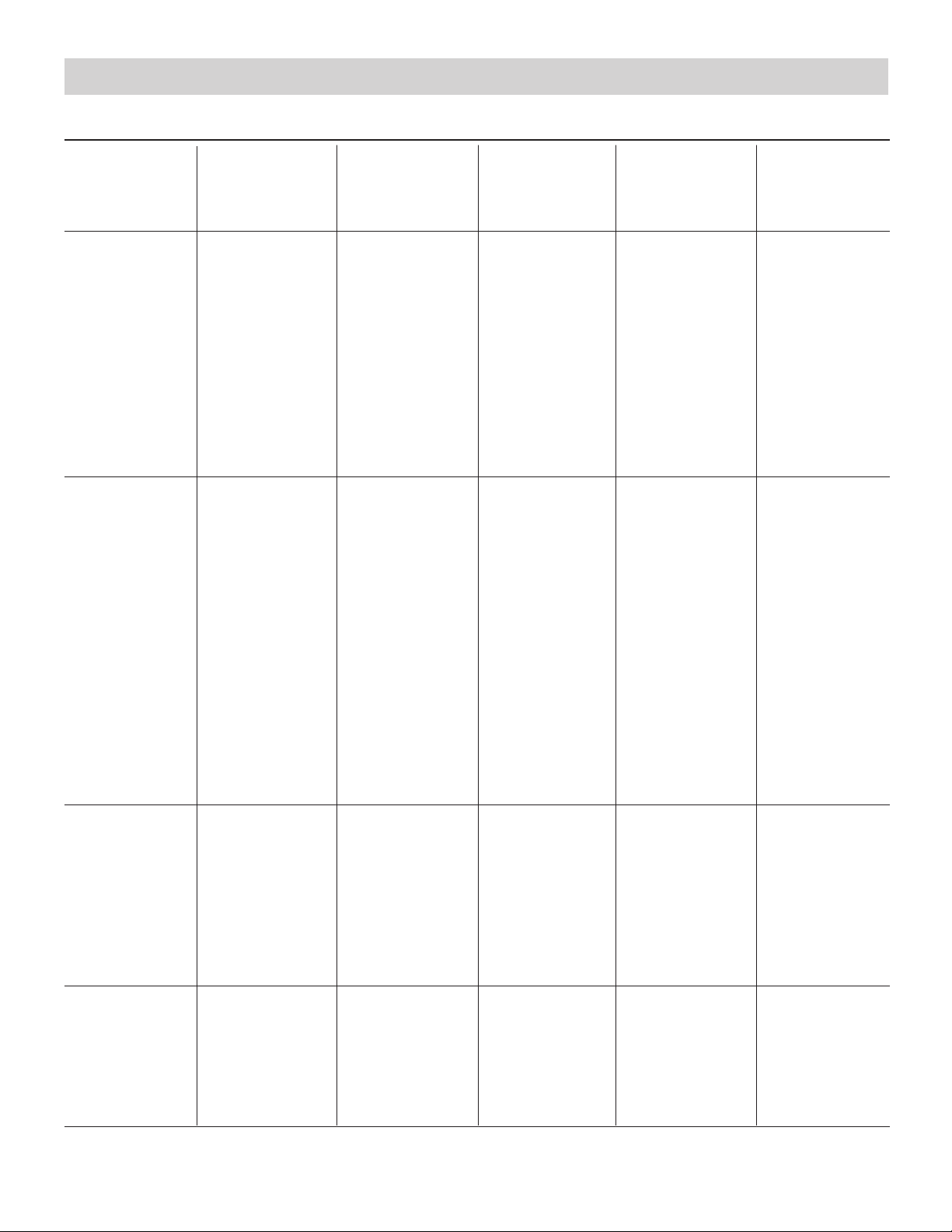

Note: This table lists working heights for which OSHA requires the use of a fall-arrest system.

Heights at Which Guarding or Fall Protection is Required by Federal OSHA:

Industry Height or Depth OSHA Standard

General Industry 4 feet 1910.23

1910.66 (Appendix C)

Construction

- Fall Protection 6 feet 1926.500-.503

- Scaffolding 10 feet 1926.450-.454

Steel Erection 15 - 30 feet 1926.750

Perimeters and Over Water 25 feet maximum at perimeter 1926.105

To measure height:

• Measure the distance from the working/walking surface to grade or lower level.

• The worst fall hazard should be considered in each particular application.

Page 3

Types of Klein OPE Connecting Devices

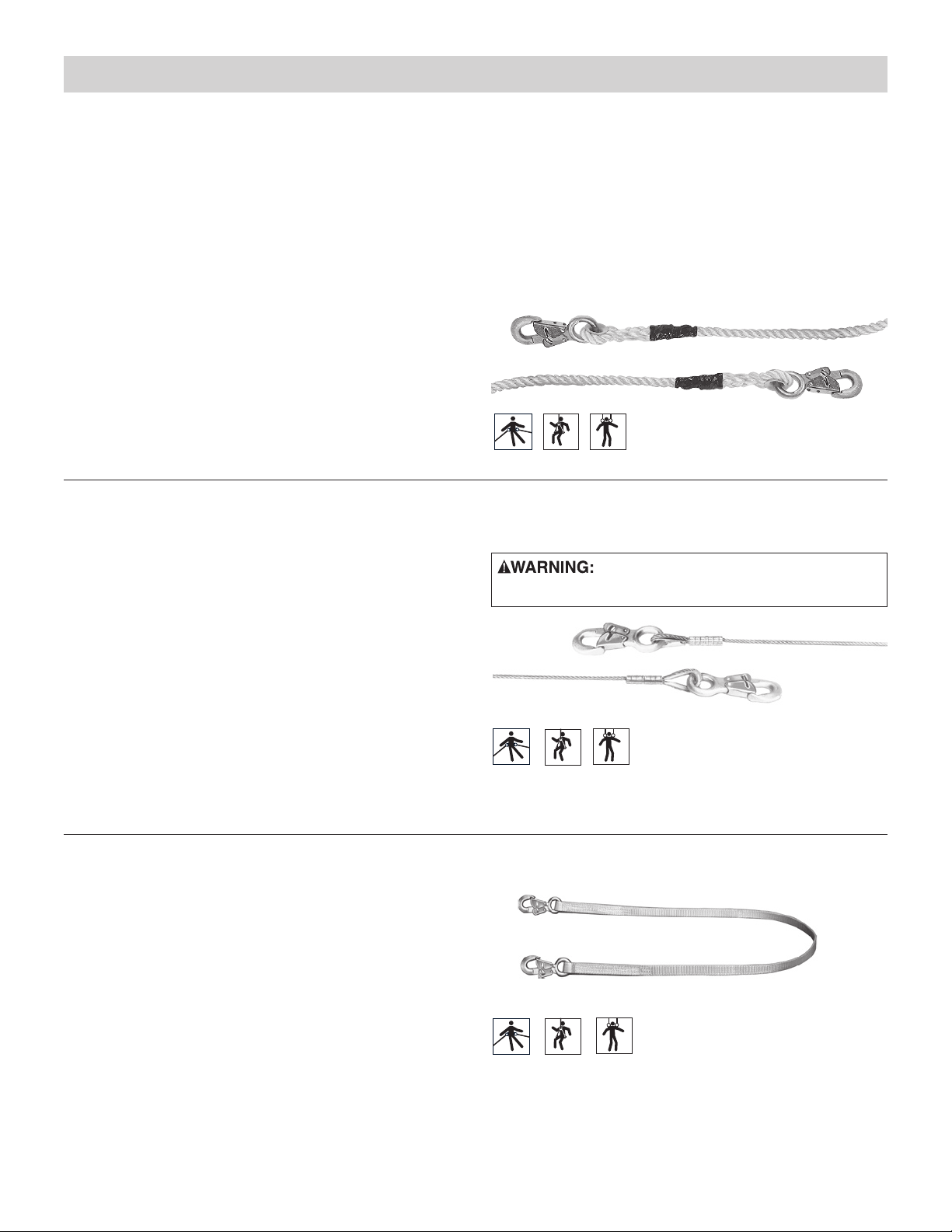

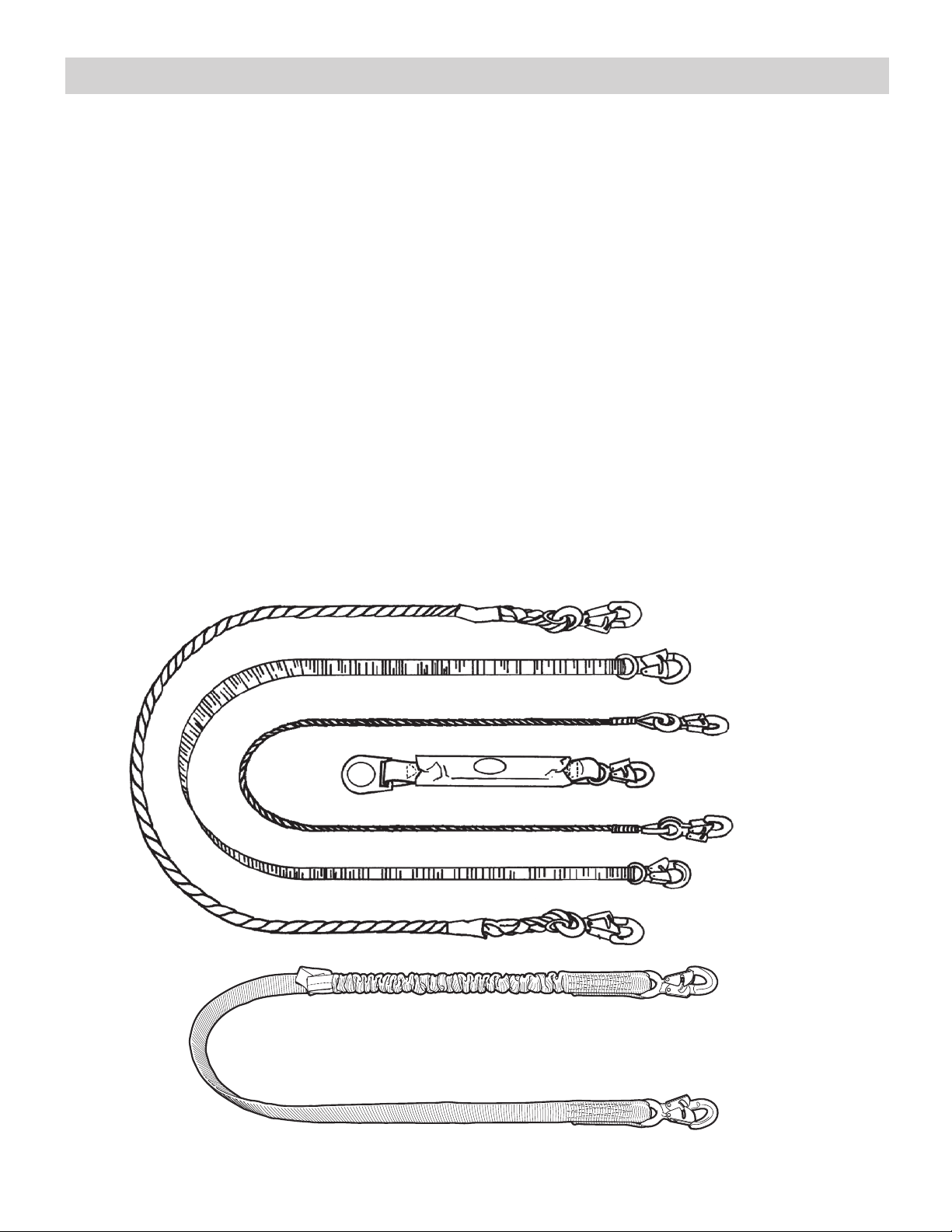

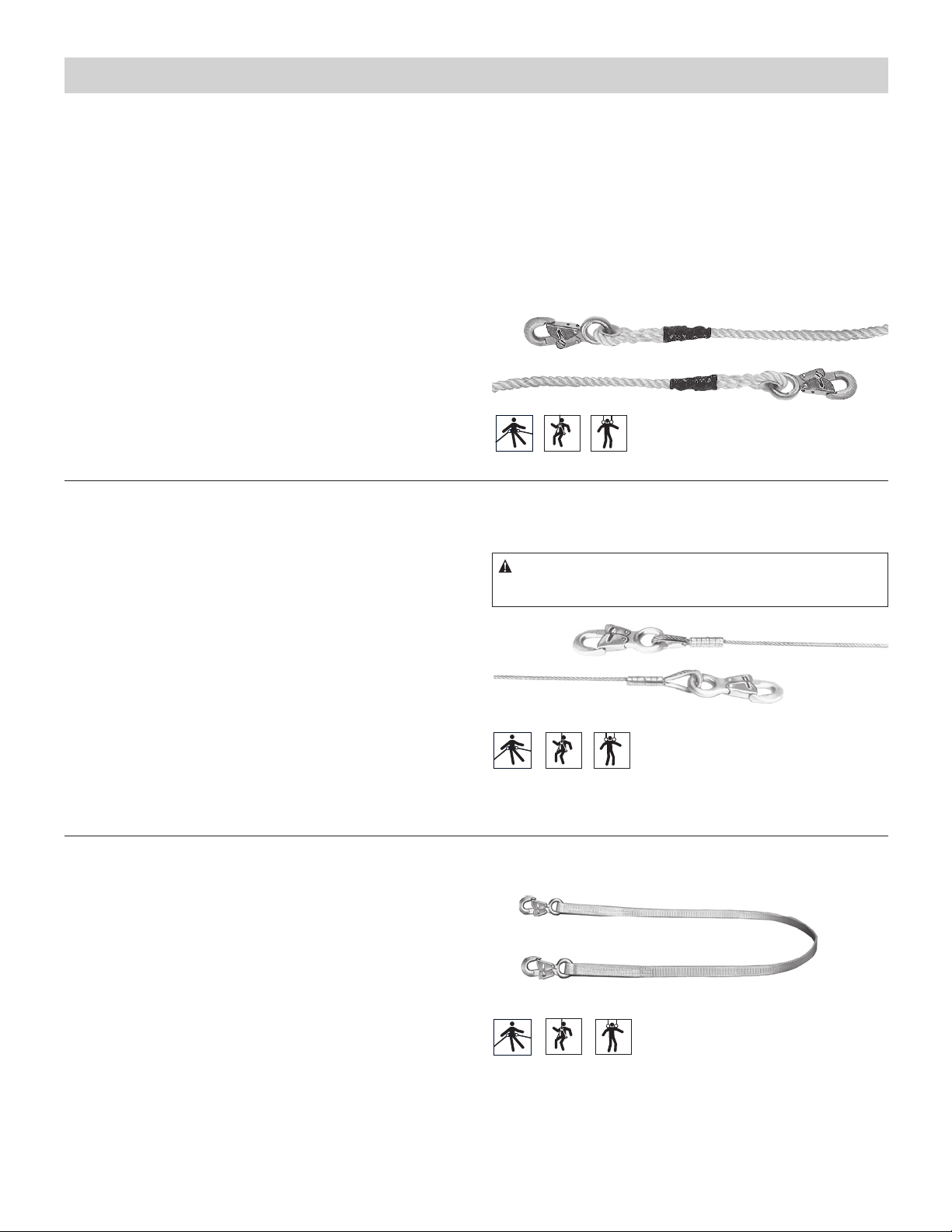

Rope Lanyards

Rope Lanyards are designed for use in positioning,

suspension, or retrieval systems. They are made of

long-filament nylon or safety-orange polypropylene

and are available in fixed or adjustable lengths. They

have locking snap hooks (Klein-Lok

attached at both ends. Special-length lanyards are

available through special order at your authorized

Klein distributor.

Nylon-Filament Rope Lanyards are designed for use

in positioning, suspension, or retrieval systems.

They have excellent elasticity. These lanyards also

have good abrasion resistance.

Polypropylene-Rope Lanyards are designed for use

in positioning, suspension, or retrieval systems.

Polypropylene has excellent dielectric properties and

®

) permanently

is ideal for use around live electrical lines, energized

equipment and other electrical OPE applications.

However, take care to keep metal snap hooks away

from live electrical lines or energized equipment.

Note: Rope lanyards can be used with a deceleration

unit for fall arrest.

Aircraft-Cable Lanyards

Aircraft-Cable Lanyards are designed for use in

positioning, suspension, or retrieval systems. They

are vinyl covered for protection from abrasion. They

have locking snap hooks (Klein-Lok

attached at both ends. Common users include

welders and others who must tie off on objects with

sharp edges.

Aircraft-cable lanyards must NOT be used around

live electrical lines or energized equipment. NEVER

use aircraft-cable lanyards alone for fall arrest.

Always use a deceleration unit with aircraft-cable

lanyards for fall arrest.

®

) permanently

Nylon-Webbing Lanyards

Nylon-Webbing Lanyards are designed for use in

positioning, suspension, or retrieval systems. They

are made of orange nylon webbing impregnated

with resin for greater durability. Locking snap hooks

are permanently attached at both ends. These

lanyards are available in fixed or adjustable

lengths.

Do not use aircraft-cable lanyards

near energized equipment.

Note: Nylon-webbing lanyards can be used with a

deceleration unit for fall arrest.

Page 4

Types of Klein OPE Connecting Devices (continued)

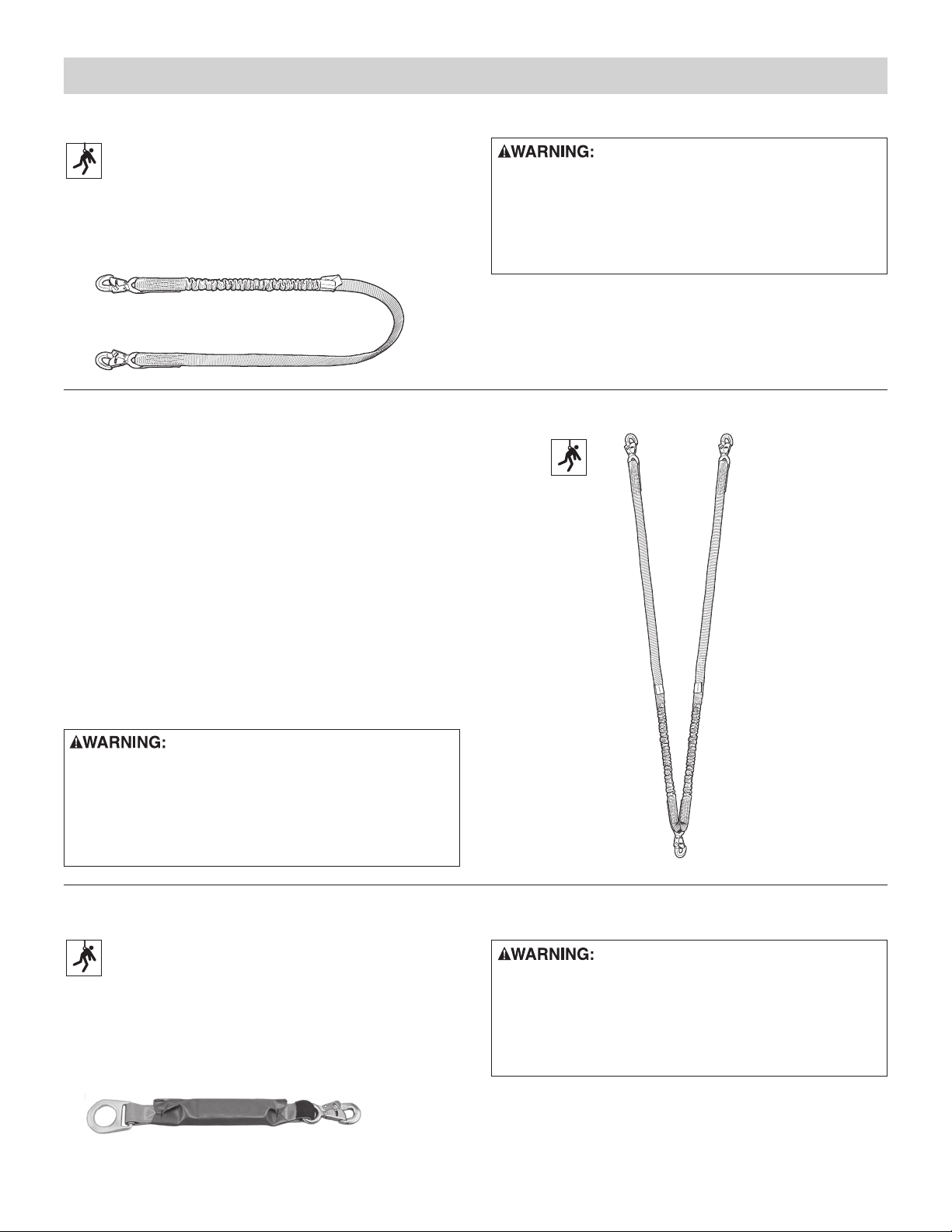

Deceleration Lanyard

The Deceleration Lanyard is designed solely

for use in fall-arrest systems. It features an

energy-absorbing inner core made of polyester,

protected by an outer shell made of orange tubular

nylon webbing. Locking snap hooks are permanently

attached at both ends.

Dual Deceleration Lanyard

The Dual Deceleration Lanyard is designed solely for

use in fall-arrest systems. This “two-legged” lanyard

can be used when 100% tie-off is required. It allows

the user to attach to a new fall-arrest anchorage with

one lanyard leg, while staying connected to the original

fall-arrest anchorage with the remaining lanyard leg.

The Dual Deceleration Lanyard has an energyabsorbing inner core made of polyester, surrounded by

an outer shell made of orange tubular nylon webbing.

Locking snap hooks are permanently attached at the

ends of both legs and at the deceleration end.

On Klein deceleration lanyards,

the uncovering of a red-lettered

warning label indicates that the unit was

subjected to a severe impact force; therefore,

the unit must not be used and must be disposed

of immediately.

On Klein dual deceleration

lanyards, the uncovering of a redlettered warning label indicates that the unit

was subjected to a severe impact force;

therefore, the unit must not be used and must

be disposed of immediately.

Deceleration Units

Deceleration Units are designed solely for use in

fall-arrest systems. They are made of overlapped

nylon webbing, heavily cross-stitched together

with nylon thread and sewn into a protective breakaway

jacket. Available separately or with permanentlyattached lanyards made of nylon rope, aircraft cable,

or nylon webbing.

On Klein deceleration units, the

uncovering of a red-lettered warning

label inside the leather jacket indicates that the

unit was subjected to a severe impact force;

therefore, the unit must not be used and must be

disposed of immediately.

Page 5

Types of Klein OPE Connecting Devices (continued)

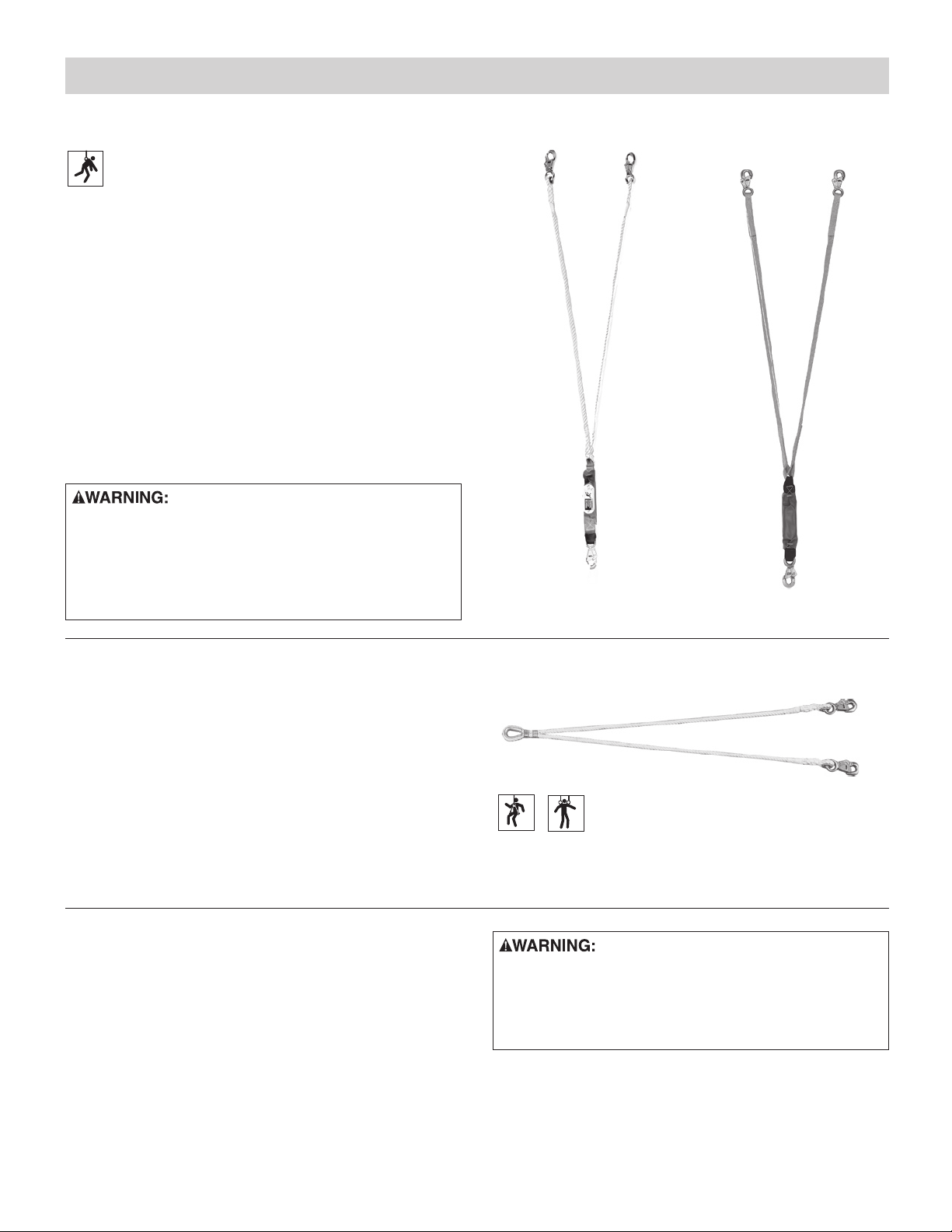

Deceleration Units with Dual Lanyards of Nylon Rope or Nylon Webbing

Deceleration units with dual lanyards are

designed solely for use in fall-arrest systems,

and they can be used when 100% tie-off is

required. They allow the user to attach to a new fallarrest anchorage with one lanyard, while still being

connected to the original fall-arrest anchorage with

the remaining lanyard.

The deceleration unit is made of overlapped nylon

webbing, heavily cross-stitched together with nylon

thread and sewn into a protective breakaway jacket.

Two lanyards are permanently attached to the

deceleration unit. Also, locking snap hooks are

attached to the free end of the deceleration unit and

to the free ends of both lanyards.

Available in either nylon rope or nylon webbing.

On Klein deceleration units, the

uncovering of a red-lettered

warning label inside the leather jacket indicates

that the unit was subjected to a severe impact

force; therefore, the unit must not be used and

must be disposed of immediately.

V-Slings

V-Slings are used in suspension and retrieval systems.

They include two permanently-attached, locking snap

hooks. These hooks connect to the shoulder D-rings of

retrieval harnesses or to the seat-strap D-rings of

suspension harnesses. Klein V-slings are made of

high-quality, nylon-filament rope.

V-slings are designed for retrieval and suspension

purposes only, and are NOT to be used for fall arrest.

Klein OPE connecting devices are constructed

according to OSHA system criteria for occupational

protective equipment.

NOTE: Other types of Klein connecting devices, not

shown here, include rope grabs, boom straps,

anchorage connectors, and retractable lifelines.

Information on their proper use and care is contained

in separate instruction booklets provided with each

product.

When working with a lanyard,

keep the amount of slack between

the anchorage and the fall-arrest harness at an

absolute minimum to reduce impact forces in

the event of a fall.

NOTE: Special-length lanyards are available.

Contact your authorized Klein distributor.

Page 6

Construction of Klein Connecting Devices

① Nylon rope used in Klein rope lanyards, deceleration

units, rope grabs and V-slings is a 1/2" (13 mm)

diameter filament-nylon type with long strands for

very high tensile strength, excellent elasticity and

good abrasion resistance.

② Polypropylene rope used in Klein rope lanyards is

a 9/16" (14 mm) diameter safety-orange type with

excellent dielectric characteristics, ideal for working

near live electrical lines and equipment. It also has

good elasticity.

③ Nylon webbing used in Klein webbing lanyards,

deceleration units, deceleration lanyards and boom

straps is a high-quality, commercial-grade nylon

sling webbing. It is impregnated with latex or resin

for extra durability, and it provides extra abrasion

resistance.

④ Polyester core used in Klein deceleration lanyards

resists a wider variety of chemicals than nylon

does.

⑤ Aircraft cable used in Klein aircraft-cable lanyards

and deceleration units is made of 7/32" (5.6 mm)

diameter galvanized steel cable that is vinyl covered

for protection against abrasion. Provides excellent

resistance to heat, chemicals, paints and solvents.

Also resists molten metal splatter and open flame,

although the vinyl coating may melt or char. It will not

resist the flame of a torch.

⑥ Drop-forged steel used in Klein connecting devices

has a corrosion-resistant finish. Examples of Klein

hardware include locking snap hooks and

D-rings. All Klein hardware meets or exceeds

applicable OSHA standards.

Quality Assurance

Thorough testing of all Klein connecting devices

assures durability and quality construction. Klein

connecting devices and accessories meet or exceed

all applicable regulatory requirements.

⑥

①

③

②

⑥

③

⑥

⑤

⑥

⑥

③

⑥

⑥

⑥

⑥

③

④

⑥

Page 7

Construction of Klein Connecting Devices (continued)

Physical Properties of Materials*

Exposure to

Paints or

Solvents

Generally offers

good resistance.

However, paint can

penetrate into the

weave and dry.

This can cause

webbing to become

hard and brittle and

can eventually

break the fibers.

Some solvents

may affect fibers

(see “Exposure to

Chemicals”).

Type of Material

Nylon

Exposure to

Excessive Heat

Poor resistance.

Becomes brittle,

has a shriveled

brown appearance.

Fibers will break

when flexed.

Weakens at 300°F

(149°C).

Exposure to

Chemicals

Generally good

resistance, except

around strong

acids and phenolic

compounds

(phenol is present

in coal tar and

wood tar), which

cause it to become

brittle.

Exposure to

Molten Metal

or Flame

Poor resistance.

Strands fuse

together and form

hard shiny spots.

Has hard and

brittle feel.

Will not support

combustion.

Exposure Near

Live Electrical

Lines and

Equipment

Poor protection (no

dielectric strength).

Provides no

protection to

exposure to live

electrical lines or

equipment.

Polyester

Polypropylene

Poor resistance.

Fibers become

brittle and will

shrivel, turn brown

in color, and break

when flexed.

Should not be used

above 180°F

(82°C).

Poor resistance.

Same as nylon,

except weakens at

230°F (110°C).

Good resistance to

most chemicals,

including

hydrochloric acid,

aqueous alkalies

and many solvents.

Exposure to

incompatible

chemicals may

change fiber color

and texture, similar

to a brownish

smudge or smear.

Also, fibers will

become less

elastic, with

transverse cracks

caused by bending.

Excellent

resistance to most

chemicals, but

is attacked by

chlorinated

hydrocarbons at

elevated

temperatures.

Poor resistance.

Fiber strands fuse

together and

become hard,

brittle, and shiny.

Poor resistance;

same as nylon.

Generally offers

good resistance.

However, paint can

penetrate into the

weave and dry.

This can cause

webbing to

become hard and

brittle and can

eventually break

the fibers.

Some solvents

may affect fibers

(see “Exposure to

Chemicals”).

Good resistance.

However, may

be attacked by

chlorinated

hydrocarbons.

Poor protection (no

dielectric strength).

Provides no

protection to

exposure to live

electrical lines or

equipment.

Good protection

(high dielectric

strength).Generally

provides good

protection, when in

dry, clean condition,

on exposure to live

electrical lines and

equipment.

Metal

(Aircraft Cable,

Vinyl Coated)

* Due to the wide variety of conditions in the workplace, this chart should only be considered as a general guide, and a qualified

person should evaluate the specific applications and hazards to which the material will be exposed. For more information,

call Klein Tools at 1-800-553-4676.

Excellent

resistance.

Excellent

resistance.

Good resistance.

However, coating

may melt or char.

Excellent

resistance.

Poor protection (no

dielectric strength).

Provides no

protection against

exposure to live

electrical lines or

equipment.

Page 8

Choose the Proper Length Lanyard for the Job

Note: Before choosing the proper length

connecting-device lanyard, you must determine the

distance between the work position and the

anchorage. This is true for all OPE system

applications, but accuracy is most important in fall-

arrest situations. (See “How to Size an OPE

Connecting Device”, on the next page.)

1. In fall-arrest applications, OSHA requires that

the free-fall distance must never exceed 6' (1.8m).

OSHA also requires the maximum impact force for

an OPE harness be under 1800 lbs.

The major factor affecting the severity of the impact

force is the free-fall distance. Therefore, when

choosing connecting devices, it is important to select

the correct length in order to minimize the slack and

thus limit the free-fall distance and impact force in a

fall. When multiple connecting-device components

are used, you must consider the total slack for all

connecting devices. (For greater user control of

length, Klein offers adjustable-length rope and

webbing lanyards in addition to fixed-length rope

and webbing lanyards.)

Another factor that influences the impact force is the

elasticity of the lanyard. The greater the elasticity,

the less the impact force. Other factors affecting

impact force are the age and material of the lanyard

and the rigidity of the anchorage.

2. In positioning applications, choose the correct

lanyard length to hold you at a comfortable distance

to perform the work.

3. In suspension applications, choose the lanyard

length that will vertically position you at the correct

height to perform the work.

4. In retrieval applications, choose the correct

lanyard length with minimum slack to allow your fast

removal in a potentially dangerous situation, while

not interfering with your ability to do the job.

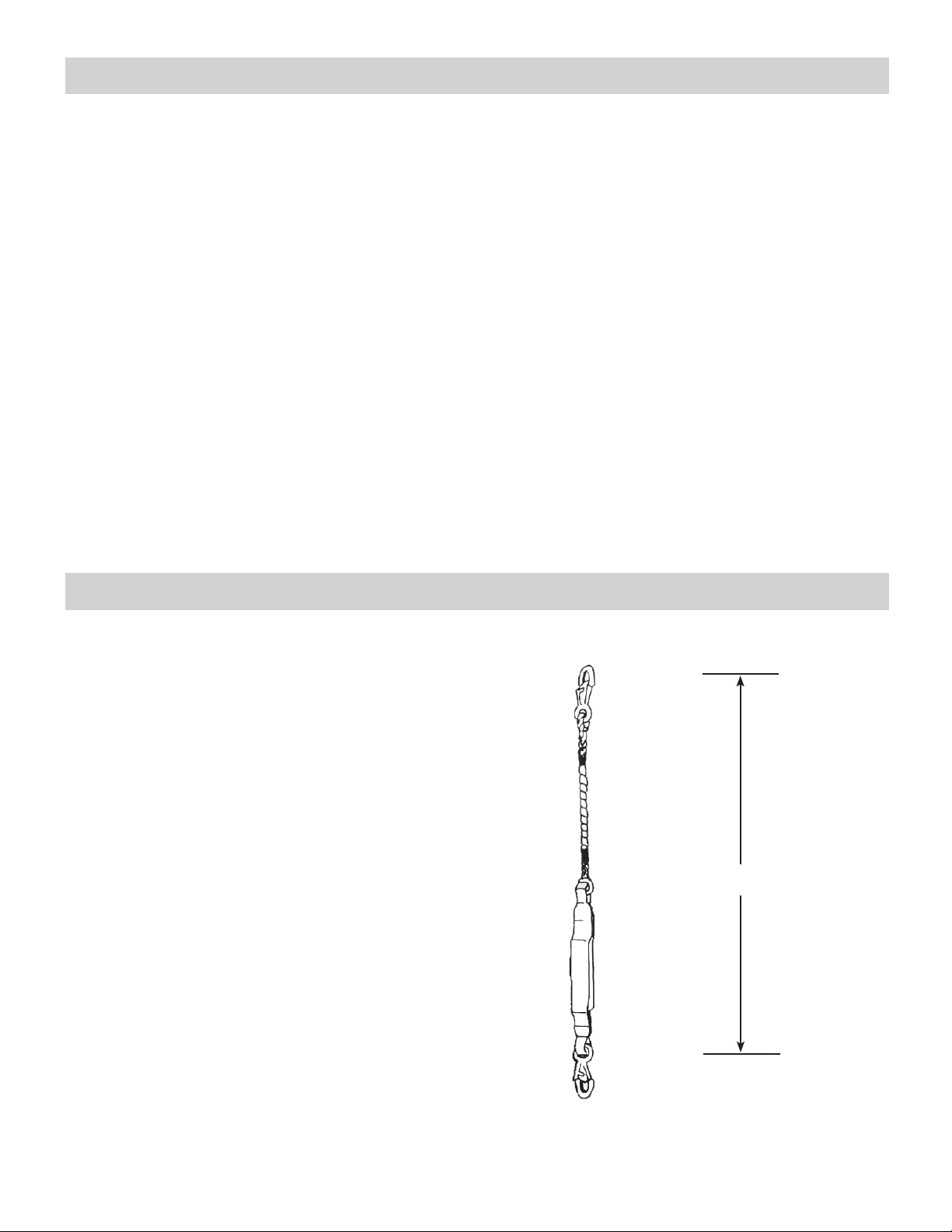

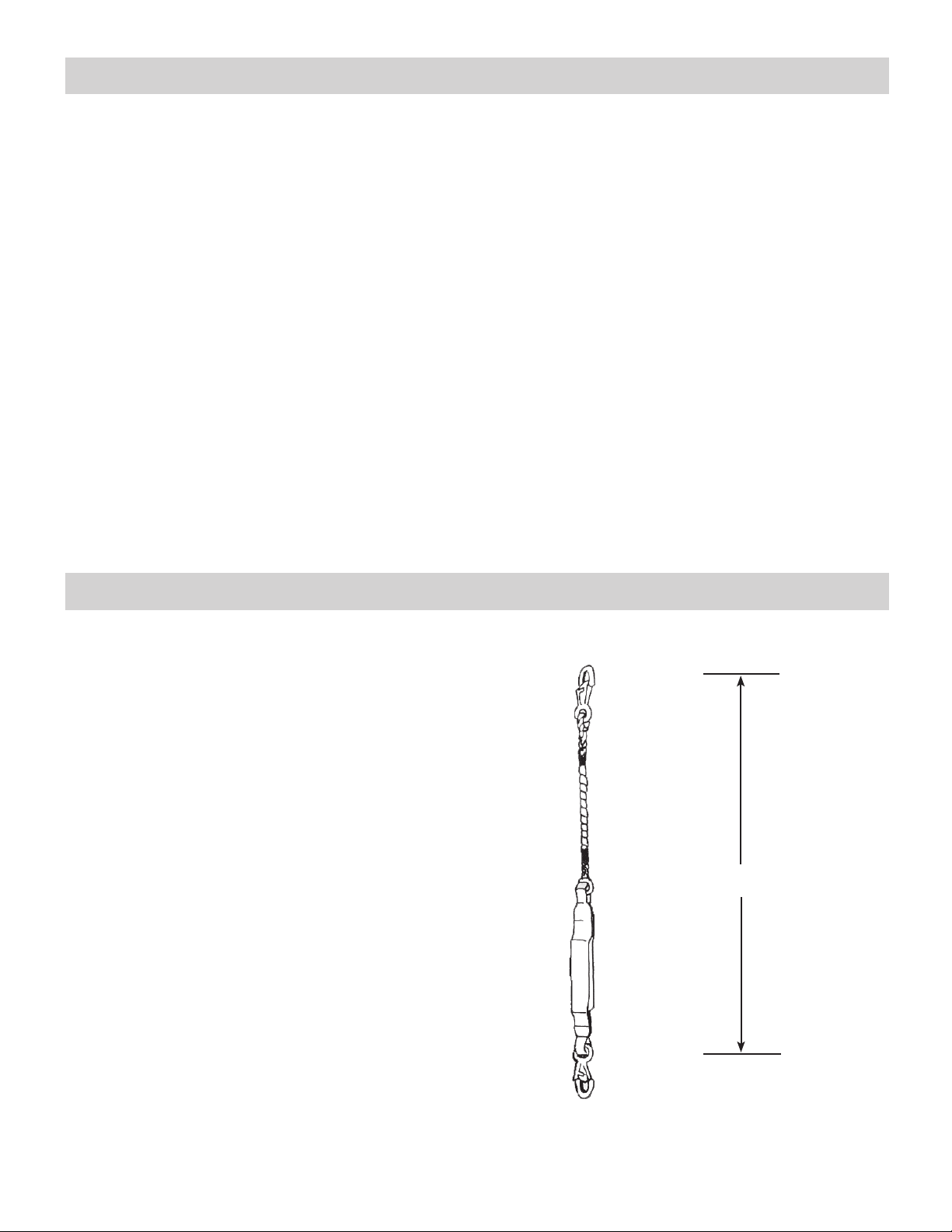

How to Size an OPE Connecting Device

Connecting devices are measured from bearing

point to bearing point (see Figure A on this page).

The undeployed length (or range of lengths, if the

connecting device is adjustable) is clearly printed on

the warning tag or label. This is the undeployed

connecting device length.

The distance between the harness bearing point (the

fall-arrest D-ring) and the anchorage connector

bearing point (the anchorage connector D-ring) must

be determined before choosing the proper length

connecting device (see Figure B on the next page).

This is true for all OPE applications, but accuracy is

most important in fall-arrest systems.

Always rig connecting devices so that you avoid

contact with structures below in a fall. As a general

rule, allow an additional 3.5 feet (1 m) to each fallarrest connecting device to account for the following

connecting-device extension factors:

• elasticity (stretch) upon impact or load (rope

or web lanyards)

Figure A

Length of undeployed

connecting device (Y)

• extension upon impact (deceleration units or

deceleration lanyards)

(Continued on the next page)

Page 9

How to Size an OPE Connecting Device (continued)

Any free-fall distance (slack in the connecting device)

must also be added to this 3.5 feet (1 m) connectingdevice extension factor to determine the minimum

distance to any structure below.

To determine the free-fall distance, subtract the

distance between the harness and anchorage

connector bearing points (X) from the undeployed

connecting device length (Y). In any situation, the total

free-fall distance must not exceed 6 feet (1.8 m).

For example, if the undeployed connecting device

length is 5 feet and the distance between the harness

and anchorage bearing points is 4 feet, the free-fall

distance is 1 foot (5 feet minus 4 feet equals 1 foot).

Thus, in this example, a minimum 4.5 feet must be

allowed as the distance between the support position

and any structure below (1 foot plus 3.5 feet equals

4.5 feet).

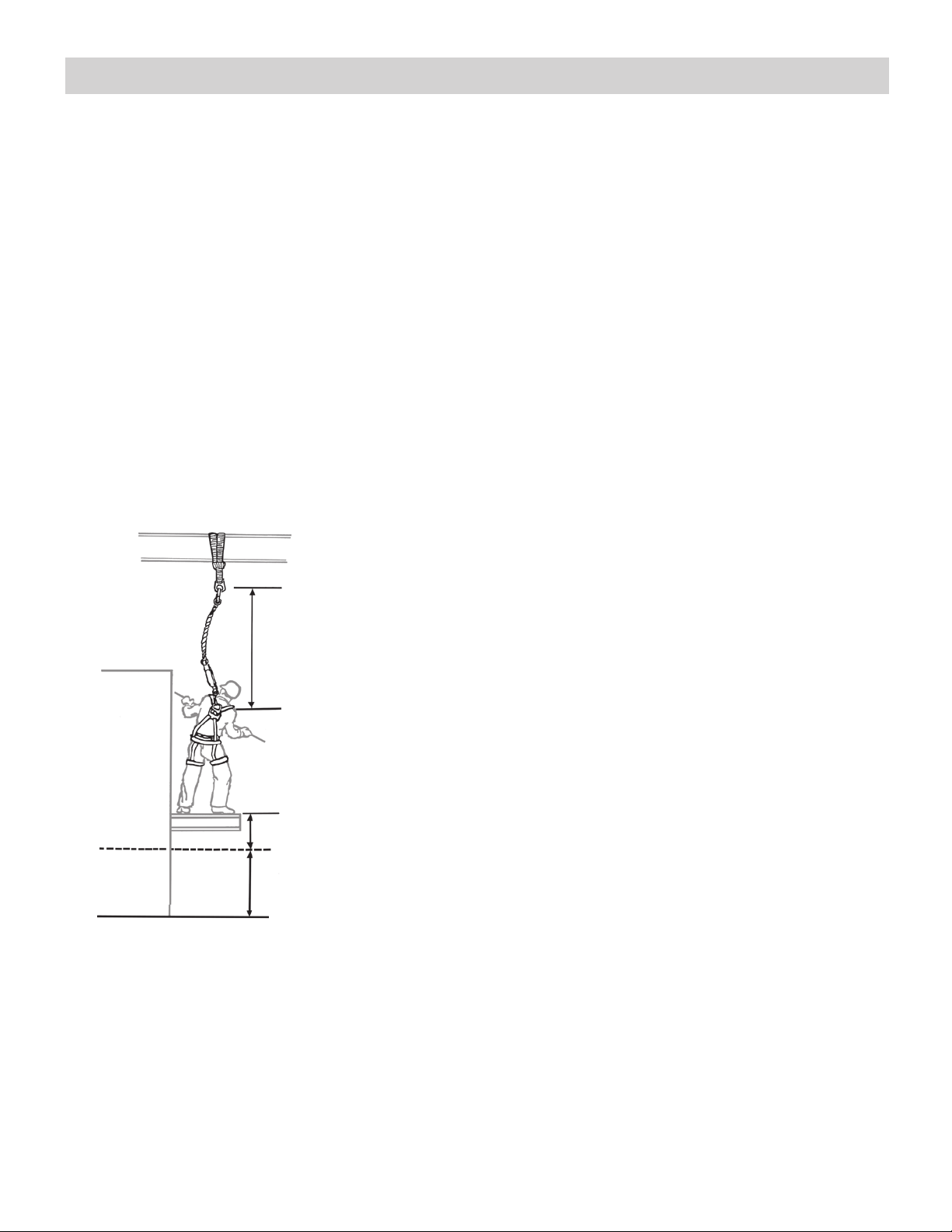

Figure B

Distance between anchorage

connector bearing point and

fall-arrest D-ring bearing

point (X)

Free-fall distance from

connecting device slack

Connecting device extension

factor of 3-1/2 feet (1 m)

Page 10

How to Use an OPE Connecting Device

1. Read all warning labels and instructions provided

with or attached to Klein connecting devices for

important information on use and care. Keep all this

material for future reference.

2. For fall-arrest applications, attach one end of

the connecting device to the fall-arrest D-ring on the

OPE harness. This D-ring is in the upper middle of a

harness wearer’s back.

For positioning applications, attach one end of

the connecting device to one of the side D-rings.

Then, properly engage the anchorage and attach

the loose end to the unused side D-ring.

For suspension applications, attach the

connecting device to the suspension D-rings(s). Be

sure to select the proper connecting device to fit the

harness, bosun’s chair, or other suspension

equipment.

For retrieval applications, attach the connecting

device to the retrieval D-rings, usually found on the

shoulders of the harness.

anchorages include approved pad eyes, bolt holes,

life lines, beams, pillars, or other approved structural

members.) In fall-arrest applications, keep the

anchorage above the rear fall-arrest D-ring or

overhead, and allow as little slack as possible to limit

the impact force of a fall. Rig to avoid contact with

structures below in case of a fall. Free fall distance

must not exceed 6 ft. (1.8 m). If using a deceleration

lanyard or a deceleration unit, add 3.5 ft (1 m) to the

free-fall distance to allow for unit extension.

When attaching any snap hook to the anchorage,

make sure by visual inspection that the snap

hook freely engages the anchorage and the

keeper is closed completely after each hookup.

Make sure each snap hook is positioned so that its

keeper is never load bearing.

4. Never connect anything to the fall-arrest,

positioning, suspension, or retrieval D-rings other

than the proper connecting device. Also, never

attach more than one connecting device to a single

anchorage.

For all applications, make sure by visual

inspection that all snap hooks engage freely and

that their keepers are closed completely after

each hookup.

3. Connect the other end of the connecting device

to a proper anchorage. (Examples of proper

General Inspection Procedures

1. Check for wear and deterioration.

Before each use, carefully inspect your complete

OPE system for signs of wear or deterioration, or

evidence of impact loading. Visually inspect for loose

threads, pulled rivets, burns, cuts, distortions,

abrasions, or other evidence of chemical or physical

deterioration that may have weakened the material

or assembly.

2. Inspect hardware for malfunctions or cracks.

Check all snap hooks, buckles, and D-rings. Check

that snap hooks are not distorted or cracked,

and that the keepers are free of burrs, functioning

properly, clean, and not bent.

5. In a fall-arrest application, where work position

changes, reposition the connecting device whenever

necessary to make sure the fall-arrest anchorage is

above the rear fall-arrest D-ring or overhead, and

allow as little slack in the connecting device as

possible. Failure to follow this procedure can result

in serious injury or death.

3. Destroy and replace all worn or damaged

equipment.

Immediately destroy and replace any component

which does not pass inspection.

Should any unusual conditions be

noted during the inspection which

are not specified here, do not use the suspect

equipment until a qualified individual has made

a decision as to its usability.

Always inspect your equipment

before using. Destroy and replace

all worn or damaged equipment immediately.

Page 11

Connecting Device Inspection Procedures

to the reverse twisting often seen in a telephone

handset cord. This can be caused by a repetitive

twisting movement such as normal hand rotation in

hooking and unhooking a lanyard dangling freely, or

by using the lanyard to suspend equipment.

1. Inspect stitching and webbing.

Check stitching for broken, burned, cut or pulled

stitches. Broken strands of webbing appear as tufts

on the webbing surface. To visually check for

damage caused by corrosives, heat, chemicals and

other conditions, hold the connecting device with

your hands six to eight inches apart. Bend the

webbing in an inverted “U” to cause surface tension

and to expose problem areas. Inspect entire length.

Preventative measures include: (1) never using a

lanyard for towing or hoisting, (2) inspecting and

smoothing out after each use, and (3) storing

neatly.

For deceleration units, check the stitching for

broken, burned, cut or pulled stitches, and the

breakaway jacket for cuts, tears, broken stitches,

stretch marks or other evidence of impact load.

Note: On Klein deceleration units, the uncovering

of a red-lettered warning label inside the leather

jacket indicates that the unit was subjected to a

severe impact force; therefore, the unit must not

be used and must be disposed of immediately.

For deceleration lanyards, check the stitching for

broken, burned, cut or pulled stitches, and/or other

evidence of impact load. Note: On Klein deceleration

lanyards, the uncovering of a red-lettered warning

label indicates that the unit was subjected to a

severe impact force; therefore, the unit must not

be used and must be disposed of immediately.

For aircraft-cable lanyards, check the full length

for breaks, burns, or cuts in the vinyl covering and

the aircraft cable.

2. Check for broken strands.

Inspect rope lanyards for broken strands by twisting

the rope slightly to undo the braiding. Inspect entire

lanyard in this manner. Lanyards with broken strands

must be discarded.

3. Inspect snap hooks, D-rings, and other metal

parts.

Check hardware for sharp edges and cracks. Rollers

should not be distorted in shape and should roll

freely. Check all parts, especially corners and

attachment points, for wear and cracks.

4. Destroy and replace all worn or damaged OPE

equipment.

If evidence of excessive wear, deterioration or

mechanical malfunction is observed, replace the

equipment immediately. Never work with worn or

damaged OPE equipment. Using damaged or

worn equipment can cause injury or death.

5. The inspector is the most important part of

any inspection procedure.

Check all equipment thoroughly and follow all safety

procedures and guidelines. Do not take any shortcuts;

they could result in injury or death.

Important Note: OSHA specifies that all employers

covered by the Occupational Safety and Health

Act are responsible for inspection and

maintenance of all tools and equipment used by

employees — whether owned by the employees or

by the company. Personal-protective equipment

should be inspected before each use, and immediately

removed from service if any sign of wear or damage

is found.

Note: Twisted rope, such as the nylon filament and

polypropylene rope used in Klein lanyards, is subject

to a condition known as “hockling”, which is similar

Page 12

Maintenance Procedures

A written log of all servicing and inspection dates for

this equipment should be maintained by the company

safety officer or other competent person.

Clean and maintain equipment in accordance with

recommended practice. Wash nylon and polyester

straps in warm water and mild detergent. Avoid

harsh chemical agents such as degreasing

compounds, turpentine, paint thinner, gasoline and

other solvents. Allow nylon and polyester objects to

dry naturally. Do not use heat to speed up the

process.

Inspect and lubricate all snap hooks after

cleaning to make sure they operate properly and

close securely. Use an all-purpose spray lubricant

or light motor oil.

Page 13

Warnings: Klein OPE Connecting Devices

The use of occupational protective

equipment without the proper

instructional materials and training could result

in serious injury or death. Klein Tools will

supply additional instructional material,

warning tags or labels, or will answer questions

on any piece of Klein occupational protective

equipment free of charge. Call Klein Tools, Inc.

toll-free at 1-800-553-4676.

Never work in a potential fall

situation without using separate

fall-arrest protection.

Understand and follow all

regulations, warnings, and safe

work practices pertaining to the job you are

performing and to the equipment or machinery

you are using or working near.

It is imperative that qualified

people select OPE system

components to fit the specific job requirements.

Incorrect component choices can cause serious

injury or death.

Never use an aircraft-cable lanyard

by itself for fall protection. Always

use a deceleration device with aircraft cable.

Never tie knots in lanyards. Knots

reduce the strength by 50%.

Always inspect your equipment

before using. Destroy and replace

all worn or damaged equipment immediately.

Snap hooks should only be

attached to an approved anchorage

capable of supporting at least 5,000 lbs. per

each attached worker.

OSHA requires that all personal

OPE equipment must be taken

out of service immediately after being subjected

to a fall impact.

Do not rely on the feel or sound of a

snap hook engaging. Always check

visually for proper engagement of the snap hook.

Double-check the intended

function of any Klein connecting

device before using it. Proper OPE system

applications are identified in the Klein OPE

catalog and are printed clearly on the warning

tags, labels and other literature provided with

each product. Misuse of a connecting device or

any other piece of OPE equipment can result in

serious injury or death.

Care should be taken to keep

metal snap hooks away from live

electrical lines or energized equipment.

Klein strongly recommends that Klein

components NOT be interchanged

with other components made by other manufacturers,

because Klein cannot guarantee that other

manufacturers’ components are free of defects in

materials or workmanship.

(Continued on the next page)

Page 14

Warnings: Klein OPE Connecting Devices (continued)

Read, understand and follow all information

contained on warning tags, labels and literature

furnished with all Klein OPE equipment.

• Connecting devices are for use by properly trained

professionals only.

• Employer — instruct employee as to proper use

and warnings before use of equipment.

• Use only locking snap hooks. The use of

connecting devices without locking snap hooks in

any fall protection system is strictly prohibited by

OSHA.

• OPE equipment must only be used for the specific

purpose for which it is designed and intended.

• Connecting devices must be destroyed if subjected

to impact loading.

• Always visually check that: 1) each snap hook

freely engages D-ring or anchorage, 2) the snaphook keeper (gate) is completely closed with each

use. Never rely solely on the feel or sound of a snap

hook engaging.

• Before each use check that: 1) unit is free of

burns, cuts, abrasions, kinks, knots, broken strands

and excessive wear, 2) hooks, D-rings and buckles

(if any) are not distorted or cracked, 3) hook keepers

are not bent, and are free of burrs, clean and

functioning properly, 4) breakaway jacket on

deceleration units has no broken stitches, tears,

stretch marks or other evidence of impact loading, 5)

for deceleration lanyards and deceleration units,

check that red-lettered warning label is not uncovered

(the uncovering of this label indicates that a severe

impact force has occurred), 6) Remove from service,

destroy, and discard unit if it does not pass this

inspection and replace it immediately.

• Make sure each snap hook is positioned so that its

keeper (gate) is never load bearing.

• Snap hooks attached onto D-rings must have less

than 3/4" (19 mm) throat opening. Never attach

ladder or rebar hooks onto D-rings.

• Only attach connecting devices that meet

government standards to D-rings.

• Do NOT attach a ladder or rebar hook to anything

larger than the diameter indicated on keeper, so

keeper can close properly.

• Always attach snap hook to proper anchorage for

the intended use or the proper D-ring of harness or

bosun’s chair. For fall arrest, use designated rear

D-ring. For positioning, use designated side D-rings.

For suspension, use designated seat strap or other

proper D-rings. For retrieval, use designated

shoulder or other proper D-rings.

• Never disable locking keeper on hook, punch holes

in, or alter a connecting device in any way.

• Never join snap hooks together. They are NOT

meant to be used that way, and could twist apart.

• Never attach multiple snap hooks onto a D-ring.

• Fall-arrest anchorages must support a

minimum of 5,000 lbs. (2,250 kg) per attached

worker and must be independent of worker support.

Positioning, suspension and retrieval anchorages

must support at least twice the potential impact load

of an employee’s fall or 3,000 lbs. (13.3kN), whichever

is greater.

• OSHA requires that impact force in a fall NOT

exceed an 1,800 lb. (8 kn) limit with a harness.

Minimize connecting-device slack or use a

deceleration unit to limit force.

• Rig to avoid contact with structures below in a

fall. Free-fall distance must not exceed 6 feet (1.8

m). To allow for deceleration unit or deceleration

lanyard extension, add 3-1/2 feet (1 m) to free-fall

distance.

• For personal use only; do NOT use for towing or

hoisting.

• NOT for recreational or sporting use.

• Positioning connecting devices must be rigged so

that a worker cannot free fall more than 2 feet.

• For fall arrest, always keep anchorage above the

rear fall-arrest D-ring and allow as little slack in the

lanyard as possible. If climbing above the anchorage,

attach to a new anchorage higher up.

(Continued on the next page)

Page 15

Warnings: Klein OPE Connecting Devices (continued)

• Never wrap a rope lanyard around a beam or other

sharp structure. The rope can be cut or damaged.

Instead, use an aircraft-cable lanyard or a webbing

lanyard.

• Never attach a lanyard back onto itself.

• Never allow a rope or webbing lanyard to contact

high-temperature surfaces, welding or other heat

sources. Use an aircraft-cable lanyard.

• Never attach multiple lanyards together.

• Never tie knots in lanyards. Knots can reduce the

strength of the lanyard up to 50%.

• Never work without independent fall-arrest

protection if there is danger of a fall.

• Do NOT use a lanyard made of aircraft cable near

electrical lines or equipment.

• Do NOT use aircraft-cable lanyards for fall arrest

unless used with shock-absorbing device such as a

deceleration unit.

• Never use deceleration units or similar fall-arrest

devices for positioning. If activated, you could fall.

• Never allow a V-sling to straddle a beam or any

other anchorage.

• Dual Deceleration Lanyards:

To ensure 100% tie-off of your fall-arrest protection

equipment, ALWAYS keep at least one lanyard-end

locking snap hook attached to a fall-arrest anchorage

as you change your work location. Start by securing

both lanyard-end locking snap hooks to separate

fall-arrest anchorages. To change your work location,

detach one lanyard-end locking snap hook, move to

the new location, and attach locking snap hook to

new fall-arrest anchorage. Establish your balance.

Detach the remaining lanyard-end locking snap hook

from your previous anchorage and attach to new fallarrest anchorage. Repeat these steps as you continue

to move.

• Never use a fall-arrest connecting device with non-

locking snap hooks on a horizontal lifeline. Movement

could disengage the non-locking hook.

Page 16

© 2002 Klein Tools, Inc.

Printed in U.S.A.

Mail: P.O. Box 599033, Chicago, IL 60659-9033 U.S.A.

Shipping: 7200 McCormick Blvd., Skokie, IL 60076-4038 U.S.A.

www.kleintools.com

139166

Page 17

Instrucciones para el uso y cuidado apropiados de los

Para profesionales... desde 1857

®

ADVERTENCIA:

dispositivos de conexión de protección laboral de Klein

Introducción

(B) Indumentaria

de cuerpo

Guarde estas instrucciones. Los

dispositivos de conexión Klein NO deben ser utilizados

por ninguna persona que no haya leído, entendido y

seguido todas las instrucciones y procedimientos de

inspección contenidos en este folleto. Si no se siguen

estas advertencias, instrucciones y procedimientos de

inspección, el resultado podría ser lesiones graves o la

muerte. El usuario y su empleador deben repetir con

regularidad la capacitación y la revisión de las

instrucciones.

(A) Anclaje

(C) Dispositivos de conexión

Una caída podría causar lesiones

graves o la muerte

No use el dispositivo a menos que

haya recibido capacitación adecuada

Lea y siga todas las instrucciones y

advertencias

®

Estas instrucciones se aplican a todos los acolladores de

cuerda, acolladores de cable para aviación, acolladores

de malla de nylon, acolladores de desaceleración,

unidades de desaceleración y aditamentos de arnés de

eslinga en V de Klein.

NOTA: Para mayor claridad, en las ilustraciones que

aparecen en este folleto de instrucciones no se muestra

ninguno de los rótulos o etiquetas de advertencia que

están colocados en cada producto. La información de

advertencia para las eslingas en V y para todos los

acolladores está impresa en una etiqueta duradera colocada

alrededor del producto.

Klein fabrica una línea completa de equipo de protección

laboral (EPL). Cada producto de EPL es parte de un

sistema de EPL de detención de caídas, posicionamiento,

suspensión, recuperación o aplicación combinada.

Siga la regla A-B-C cuando monte un sistema de EPL.

Todos los sistemas de EPL constan de tres (3) componentes

principales: (A) anclaje, (B) indumentaria de cuerpo (por

ejemplo, un arnés) de cuerpo completo y (C) dispositivo de

conexión.

Los dispositivos de conexión de acollador Klein se utilizan

para sujetar el arnés (el componente “B”) a un anclaje

adecuado (el componente “A”) con el fin de proporcionar

una de las cuatro funciones de EPL (detención de caídas,

posicionamiento, suspensión y recuperación).

Nota: Un sistema personal de detención de caídas sólo se

activa en una caída. Si se requiere equipo para ayudar a

sujetar o ubicar a un trabajador en una posición determinada,

se deben usar otros sistemas de EPL además del sistema

de detención de caídas.

Un sistema personal de detención de caídas está diseñado

solamente para ayudar a un trabajador una vez que se

produce una caída, y debe utilizarse siempre que exista

peligro de caída. En lugares donde exista peligro de morir

o resultar lesionado por causa de una caída, utilice

únicamente equipo diseñado específicamente para la

detención de caídas.

Page 18

Introducción (continuación)

ADVERTENCIA:

ADVERTENCIA:

Cuando utilice cualquier sistema de EPL, debe estar seguro

de que todo el sistema cumple con las normas de OSHA.

Asegúrese de que el anclaje primario sea identificado y

evaluado por una persona competente, de acuerdo con la

definición de OSHA, en el lugar de del trabajo. Una persona

competente debe determinar también si el tipo de dispositivo

de conexión de EPL y el arnés son apropiados para el

trabajo.

Muchos dispositivos de conexión pueden utilizarse

apropiadamente en más de una aplicación de sistema de

EPL. Por ejemplo, un acollador de cuerda de Klein puede

utilizarse como un componente en un sistema de detención

de caídas, posicionamiento, suspensión o recuperación.

Otros dispositivos de conexión, como por ejemplo acolladores

y unidades de desaceleración, sólo pueden utilizarse para

detención de caídas. Todos los dispositivos de conexión de

EPL de Klein cumplen o sobrepasan todos los requisitos

Detención

de caídas

Posicionamiento

Suspensión

Recuperación

normativos pertinentes de OSHA.

Los símbolos que se muestran arriba indican que un

dispositivo de conexión específico es apropiado para

utilizarse en uno o más de los sistemas siguientes:

• en un sistema de detención de caídas, en un lugar donde

haya peligro de caída desde una posición elevada;

• en un sistema de posicionamiento, en un lugar donde sea

necesario tener las manos libres mientras se trabaja en una

superficie elevada;

• en un sistema de suspensión, en un lugar donde sea

necesario ser posicionado y soportado desde arriba; o

• en un sistema de recuperación, en un lugar donde sea

necesario tener un medio rápido de ser elevado o extraído de

un medio de trabajo.

Compruebe dos veces la función

prevista de todo dispositivo de conexión Klein antes de

utilizarlo. Las aplicaciones apropiadas de los sistemas

de EPL están identificadas en el catálogo de EPL de Klein

y están impresas claramente en los rótulos y etiquetas

de advertencia y otros materiales impresos suministrados con cada producto. El uso incorrecto de un dispositivo de conexión o de cualquier otra unidad de equipo

de EPL puede ocasionar lesiones graves o la muerte.

Es imperativo que personal calificado

seleccione los componentes de los sistemas de EPL

para ajustarse a los requisitos específicos del trabajo.

La selección incorrecta de componentes puede causar

lesiones graves o la muerte.

Nota: Esta tabla indica las alturas de trabajo para las que OSHA requiere el uso de un sistema de detención de caídas.

Alturas a las que OSHA federal requiere protectores o protección contra caídas:

Industria Altura o profundidad Norma de OSHA

Industria general 4 pies (1,2 m) 1910.23

1910.66 (Apéndice C)

Construcción

- Protección contra caídas 6 pies (1,8 m) 1926.500-.503

- Andamios 10 pies (3 m) 1926.450-.454

Construcción de acero 15 pies (4,6 m) - 30 pies (9,1 m) 1926.750

Perímetros y sobre agua 25 pies (7,6 m) como 1926.105

máximo en el perímetro

Para medir la altura:

• Mida la distancia desde la superficie de trabajo o de paso hasta el nivel del piso o el nivel inferior.

• El peor peligro de caída debe considerarse en cada aplicación específica.

Page 19

Tipos de dispositivos de conexión de EPL de Klein

ADVERTENCIA:

Acolladores de cuerda

Los acolladores de cuerda están diseñados para utilizarse

en sistemas de posicionamiento, suspensión o recuperación.

Están hechos con nylon de filamentos largos o polipropileno de

color naranja de seguridad y están disponibles en longitudes

fijas o ajustables. Tienen ganchos de presión de fijación (Klein-

®

) sujetos permanentemente en ambos extremos. Hay

Lok

acolladores de longitud especial disponibles mediante pedido

especial a través de su distribuidor autorizado Klein.

Los acolladores de cuerda de filamento de nylon están

diseñados para utilizarse en sistemas de posicionamiento,

suspensión o recuperación. Tienen excelente elasticidad. Estos

acolladores también tienen excelente resistencia a la abrasión.

Los acolladores de cuerda de polipropileno están diseñados

para utilizarse en sistemas de posicionamiento, suspensión o

recuperación. El polipropileno tiene excelentes características

dieléctricas y es ideal para utilizarse alrededor de líneas

eléctricas con corriente, equipos con corriente y otras

aplicaciones eléctricas de EPL. Sin embargo, debe tenerse

cuidado de mantener los ganchos metálicos de presión alejados

de las líneas eléctricas con corriente o de los equipos con

corriente.

Nota: los acolladores de cuerda pueden utilizarse con una

unidad de desaceleración para detención de caídas.

Acolladores de cable para aviación

Los acolladores de cable para aviación están diseñados para

utilizarse en sistemas de posicionamiento, suspensión o

recuperación. Están recubiertos con vinilo para protegerlos

de la abrasión. Tienen ganchos de presión de fijación (Klein-

®

) sujetos permanentemente en ambos extremos. Los

Lok

usuarios habituales incluyen soldadores y otros trabajadores

que deben sujetarse a objetos con bordes afilados.

Los acolladores de cable para aviación NO deben utilizarse

alrededor de líneas eléctricas con corriente o equipos con

corriente. NUNCA utilice acolladores de cable para aviación

por sí solos para detención de caídas. Utilice siempre una

unidad de desaceleración con acolladores de cable para

aviación para detención de caídas.

Acolladores de malla de nylon

Los acolladores de malla de nylon están diseñados para

utilizarse en sistemas de posicionamiento, suspensión o

recuperación. Están hechos con malla de nylon naranja

impregnada con resina para aumentar su duración. Los

ganchos de presión de fijación están sujetos permanentemente

en ambos extremos. Estos acolladores están disponibles en

longitudes fijas o ajustables.

Nota: Los acolladores de malla de nylon pueden utilizarse

con una unidad de desaceleración para detención de caídas.

No utilice acolladores de cable para

aviación cerca de equipos con corriente.

Page 20

Tipos de dispositivos de conexión de EPL de Klein (continuación)

ADVERTENCIA:

ADVERTENCIA:

ADVERTENCIA:

Acollador de desaceleración

El acollador de desaceleración está diseñado

solamente para utilizarse en sistemas de detención

de caídas. Cuenta con un alma interior hecha de

poliéster que absorbe energía, esta alma está protegida por

un revestimiento exterior hecho de malla de nylon tubular

naranja. Los ganchos de presión de fijación están sujetos

permanentemente en ambos extremos.

Acollador de desaceleración doble

El acollador de desaceleración doble está diseñado

exclusivamente para utilizarse en sistemas de detención de

caídas. Este acollador de “dos tramos” puede utilizarse

cuando se necesita mantenerse atado a un punto de anclaje

100% del tiempo. Permite que el usuario se sujete a un nuevo

anclaje de detención de caídas con un tramo del acollador,

mientras se mantiene conectado al anclaje de detención de

caídas original con el tramo del acollador restante.

El acollador de desaceleración doble tiene un alma interior

hecha de poliéster que absorbe energía, rodeada por un

revestimiento exterior hecho de malla de nylon tubular

naranja. Los ganchos de presión de fijación están

permanentemente sujetos en los extremos de ambos tramos

y en el extremo de desaceleración.

En los acolladores de desaceleración

Klein, una etiqueta de advertencia con letras rojas que

esté descubierta indica que la unidad ha estado sometida

a una fuerza de impacto severa; por lo tanto, la unidad no

debe utilizarse y debe desecharse inmediatamente.

En los acolladores de desaceleración

dobles de Klein, una etiqueta de advertencia con letras

rojas que esté descubierta indica que la unidad ha estado

sometida a una fuerza de impacto severa; por lo tanto,

la unidad no debe utilizarse y debe desecharse

inmediatamente.

Unidades de desaceleración

Las unidades de desaceleración están diseñadas

solamente para utilizarse en sistemas de detención

de caídas. Están hechas con malla de nylon

superpuesta, fuertemente tejida de forma entrecruzada con

hilo de nylon y cosida a una chaqueta de separación

protectora. Estas unidades están disponibles por separado

o con acolladores sujetos permanentemente hechos de

cuerda de nylon, cable para aviación o malla de nylon.

En las unidades de desaceleración

Klein, una etiqueta de advertencia con letras rojas que

esté descubierta dentro de la chaqueta de cuero indica

que la unidad ha estado sometida a una fuerza de

impacto severa; por lo tanto, la unidad no debe

utilizarse y debe desecharse inmediatamente.

Page 21

Tipos de dispositivos de conexión de EPL de Klein (continuación)

ADVERTENCIA:

ADVERTENCIA:

Unidades de desaceleración con acolladores dobles de cuerda o malla de nylon

Las unidades de desaceleración con acolladores dobles

están diseñadas solamente para utilizarse en sistemas

de detención de caídas y pueden utilizarse cuando se

necesita mantenerse atado a un punto de anclaje 100% del

tiempo. Permiten que el usuario se sujete a un nuevo anclaje de

detención de caídas con un acollador, mientras se mantiene

conectado al anclaje de detención de caídas original con el

acollador restante.

La unidad de desaceleración está hecha con malla de nylon

superpuesta, fuertemente tejida de forma entrecruzada con hilo

de nylon y cosida a una chaqueta de separación protectora. Dos

acolladores están sujetos permanentemente a la unidad de

desaceleración. Además, los ganchos de presión de fijación

están sujetos al extremo libre de la unidad de desaceleración y

a los extremos libres de ambos acolladores.

Hay unidades disponibles con cuerda de nylon o malla de nylon.

En las unidades de desaceleración

Klein, una etiqueta de advertencia con letras rojas que

esté descubierta dentro de la chaqueta de cuero indica

que la unidad ha estado sometida a una fuerza de

impacto severa; por lo tanto, la unidad no debe

utilizarse y debe desecharse inmediatamente.

Eslingas en V

Las eslingas en V se utilizan en sistemas de suspensión y

recuperación. Incluyen dos ganchos de presión de fijación

sujetos permanentemente. Estos ganchos se conectan a los

anillos en D de los hombros de los arneses de recuperación

o a los anillos en D de las correas de asiento de los arneses

de suspensión. Las eslingas en V de Klein están hechas de

cuerda de filamento de nylon de alta calidad.

Las eslingas en V están diseñadas únicamente para fines de

recuperación y suspensión, y NO deben utilizarse para

detención de caídas.

Los dispositivos de conexión de EPL de Klein están

fabricados de acuerdo con los criterios de sistemas de

OSHA para equipos de protección personal laboral.

NOTA: Otros tipos de dispositivos de conexión Klein que no

se muestran aquí incluyen amarras de cuerda, correas de

pescante, conectores de anclaje y cuerdas de seguridad

retraíbles. La información sobre su uso y cuidado apropiados

está contenida en folletos de instrucciones aparte suministrados con cada producto.

NOTA: Hay acolladores de longitud especial disponibles.

Póngase en contacto con su distribuidor autorizado Klein.

Cuando trabaje con un acollador,

mantenga a un mínimo absoluto la cantidad de flojedad

entre el anclaje y el arnés de detención de caídas, para

reducir las fuerzas de impacto en caso de caída.

Page 22

Construcción de los dispositivos de conexión Klein

① La cuerda de nylon que se utiliza en los acolladores de

cuerda, unidades de desaceleración, amarras de cuerda y

eslingas en V de Klein es un tipo de nylon filamentoso de 1/2

pulgada (13 mm) de diámetro con hebras largas para brindar

una resistencia a la tensión muy alta, excelente elasticidad y

buena resistencia a la abrasión.

➁ La cuerda de polipropileno que se utiliza en los acolladores

de cuerda de Klein es del tipo naranja de seguridad de 9/16 de

pulgada (14 mm) de diámetro con excelentes características

dieléctricas, ideal para trabajar cerca de líneas eléctricas con

corriente y equipos eléctricos con corriente. También tiene

buena elasticidad.

③ La malla de nylon que se utiliza en los acolladores de malla,

unidades de desaceleración, acolladores de desaceleración y

correas de pescante de Klein es malla de eslinga de nylon de

grado comercial de alta calidad. Está impregnada de látex o

resina para brindar mayor durabilidad y proporciona resistencia

adicional a la abrasión.

④ El alma de poliéster que se utiliza en los acolladores de

desaceleración Klein resiste una variedad más amplia de

agentes químicos que el nylon.

⑤ El cable para aviación, que se utiliza en los acolladores y las

unidades de desaceleración de cable para aviación de Klein,

está hecho de cable de acero galvanizado de 7/32 de pulgada

(5,6 mm) de diámetro que está recubierto con vinilo para

contar con protección contra la abrasión. Proporciona

excelente resistencia al calor, los agentes químicos, las

pinturas y los solventes. También resiste las salpicaduras de

metales fundidos y las llamas al descubierto, aunque el

revestimiento de vinilo puede derretirse o carbonizarse. No

resiste la llama de un soplete.

⑥ El acero forjado en caliente que se utiliza en los dispositivos

de conexión Klein tiene un acabado resistente a la corrosión.

Ejemplos de herrajes Klein incluyen los ganchos de presión de

fijación y los anillos en D. Todos los herrajes Klein cumplen o

sobrepasan las normas pertinentes de OSHA.

Garantía de calidad

La realización minuciosa de pruebas de todos los dispositivos

de conexión Klein garantiza una construcción duradera y de

calidad. Los dispositivos de conexión y los accesorios Klein

cumplen o sobrepasan todos los requisitos normativos

pertinentes.

⑥

①

③

②

⑥

③

⑥

⑤

⑥

⑥

③

⑥

⑥

⑥

⑥

③

④

⑥

Page 23

Construcción de los dispositivos de conexión Klein (continuación)

Propiedades físicas de los materiales*

Exposición a calor

Tipo de material

Nylon

Poliéster Mala resistencia. Las

excesivo

Mala resistencia. Se

vuelve quebradizo, tiene

un aspecto marrón

rugoso. Las fibras se

rompen cuando se

doblan. Se debilita a

149 °C (300 °F).

fibras se vuelven

quebradizos, se pondrán

rugosas y marrones y

se romperán cuando se

doblen. No debe

utilizarse a más de

82 °C (180 °F).

Exposición a agentes

químicos

Generalmente, buena

resistencia, excepto en

presencia de ácidos

fuertes y compuestos

fenólicos (el fenol está

presente en la brea de

carbón y la brea de

madera), los cuales

hacen que se vuelva

quebradizo.

Buena resistencia a la

mayoría de los agentes

químicos, incluyendo

ácido clorhídrico, álcalis

acuosos y muchos

solventes. La exposición

a agentes químicos

incom pati bles puede

hacer que las fibras

cambien de color y

textura, par ec ido a una

mancha o marca de

color castaño. Además,

las fibras se volverán

menos elásticas y se

formarán grietas

transversales al

doblarse.

Exposición a metal

fundido o llamas

Mala resistencia. Las

hebras se funden entre

sí y forman puntos

brillantes duros. Tiene

una sensa ción al tacto

dura y quebradizo. No

resiste la combustión.

Mala resistencia. Las

hebras de fibra se

funden entre sí y se

vuelven duras,

quebradizos y brillantes.

Exposición a pinturas o

solventes

Generalmente, ofrece

buena resistencia. Sin

embargo, la pintura

puede penetrar en el

ligamento y secarse.

Esto puede hacer que la

malla se vuelva dura y

quebradizo, y en última

instancia puede romper

las fibras. Algunos

solventes pueden

afectar a las fibras

(consultar “Exposición a

agentes químicos”).

Generalmente, ofrece

buena resistencia. Sin

embargo, la pintura

puede penetrar en el

ligamento y secarse.

Esto puede hacer que la

malla se vuelva dura y

quebradizo, y en última

instancia puede romper

las fibras. Algunos

solventes pueden

afectar a las fibras

(consultar “Exposición a

agentes químicos”).

Exposición cerca de

líneas eléctricas y

equipos eléctricos con

corriente

Mala protección

(no tiene resistencia

dieléctrica). No

proporciona protección

contra la exposición a

líneas eléctricas o

equipos eléctricos con

corriente.

Mala protección

(no tiene resistencia

dieléctrica). No

proporciona protección

contra la exposición a

líneas eléctricas o

equipos eléctricos con

corriente.

Polipropileno Mala resistencia. Igual

que el nylon, excepto

que se debilita a 110 °C

(230 °F).

Metal

(cable para aviación

revestido con vinilo)

Resistencia excelente. Resistencia excelente. Buena resistencia. Sin

Excelente resistencia a

la mayoría de los

agentes químicos, pero

es atacado por los

hidrocarburos clorados

a temperaturas

elevadas.

Mala resistencia, igual

que el nylon.

embargo, el

revestimiento puede

derretirse o

carbonizarse.

Buena resistencia. Sin

embargo, puede ser

atacado por los

hidrocarburos clorados.

Resistencia excelente. Mala protección

Buena protección (alta

resistencia dieléctrica).

General mente,

proporcio na buena

protección, cuando está

en cond i ciones secas y

lim pias, al resultar

expuesto a líneas

eléctricas y equipos

eléctricos con corriente.

(no tiene resistencia

dieléctrica). No prop orciona protección contra

la exposición a líneas

eléctricas o equipos

eléctricos con corriente.

* Debido a la amplia variedad de condiciones existentes en el lugar de trabajo, este cuadro debe considerarse solamente como una guía general, y personal

calificado debe evaluar las aplicaciones y peligros específicos a los que el material estará expuesto. Para obtener más información, llame a Klein Tools al

1-800-553-4676.

Page 24

Seleccione el acollador apropiado para el trabajo

Nota: Antes de seleccionar el acollador de longitud apropiada

para el dispositivo de conexión, se debe determinar la

distancia entre la posición de trabajo y el anclaje. Esto es

necesario para todas las aplicaciones de sistemas de EPL,

pero la precisión es de importancia máxima en las situaciones

de detención de caídas. (Consulte la sección “Cómo determinar

el tamaño adecuado de un dispositivo de conexión de EPL”

que aparece en esta página.)

1. En aplicaciones de detención de caídas. OSHA requiere

que la distancia de caída libre nunca sobrepase 6 pies

(1,8 m). OSHA también requiere que la fuerza de impacto

máxima para un arnés de EPL sea inferior a 1800 lb (8 kN).

El factor principal que afecta la severidad de la fuerza de

impacto es la distancia de caída libre. Por lo tanto, cuando se

seleccionen dispositivos de conexión, es importante

seleccionar la longitud correcta con el fin de minimizar la

flojedad y por lo tanto limitar la distancia de caída libre y la

fuerza de impacto en una caída. Cuando se utilicen varios

componentes de dispositivos de conexión, se debe considerar

la flojedad total de todos los dispositivos de conexión. (Para

mayor control de la longitud por el usuario, Klein ofrece

acolladores de cuerda de longitud ajustable y acolladores de

malla de longitud ajustable, además de acolladores de cuerda

de longitud fija y acolladores de malla de longitud fija.)

Otro factor que afecta la fuerza de impacto es la elasticidad

del acollador. Cuanto mayor sea la elasticidad, menor será

la fuerza de impacto. Otros factores que afectan la fuerza

de impacto son la edad y el material del acollador y la

rigidez del anclaje.

2. En aplicaciones de posicionamiento, seleccione la

longitud correcta del acollador para sostenerlo a usted a una

distancia cómoda para realizar el trabajo.

3. En aplicaciones de suspensión, seleccione la longitud

del acollador que lo posicionará a usted verticalmente a la

altura correcta para realizar el trabajo.

4. En aplicaciones de recuperación, seleccione la longitud

correcta del acollador con una flojedad mínima que le permita

la recuperación rápida en una situación potencialmente

peligrosa, a la vez que no interfiera con su capacidad para

hacer el trabajo.

Cómo determinar el tamaño adecuado de un dispositivo de conexión de EPL

Los dispositivos de conexión se miden de punto de apoyo a

punto de apoyo (vea la Figura A en esta página). La longitud

sin desplegar (o gama de longitudes, si el dispositivo de

conexión es ajustable) está impresa claramente en el rótulo

o etiqueta de advertencia. Ésta es la longitud del dispositivo

de conexión sin desplegar.

La distancia entre el punto de apoyo del arnés (el anillo en D

de detención de caídas) y el punto de apoyo del conector de

anclaje (el anillo en D del conector de anclaje) debe

determinarse antes de seleccionar el dispositivo de conexión

de longitud apropiada (vea la Figura B en la página siguiente).

Esto es necesario para todas las aplicaciones de EPL, pero

la precisión es de máxima importancia en los sistemas de

detención de caídas.

Monte siempre los dispositivos de conexión de manera que

evite el contacto con las estructuras que estén debajo en una

caída. Como regla general, deje 3,5 pies (1 m) adicionales

por cada dispositivo de conexión de detención de caídas

para tener en cuenta los siguientes factores de extensión de

los dispositivos de conexión:

• la elasticidad (estiramiento) al producirse un impacto o

carga (acolladores de cuerda o de malla)

• la extensión al producirse un impacto (unidades de

desaceleración o acolladores de desaceleración)

Figura A

Longitud del dispositivo de

conexión sin desplegar (Y)

(Continúa en la página siguiente)

Page 25

Cómo determinar el tamaño adecuado de un dispositivo de conexión de EPL (continuación)

Toda distancia de caída libre (flojedad en el dispositivo de

conexión) también debe añadirse a este factor de extensión

del dispositivo de conexión de 3,5 pies (1 m) para determinar

la distancia mínima a cualquier estructura que esté debajo.

Para determinar la distancia de caída libre, reste la distancia

entre los puntos de apoyo del arnés y del conector de

anclaje (X) a la longitud del dispositivo de conexión sin

desplegar (Y). En cualquier situación, la distancia total de

caída libre no debe sobrepasar 6 pies (1,8 m).

Por ejemplo, si la longitud del dispositivo de conexión sin

desplegar es de 5 pies (1,5 m) y la distancia entre los puntos

de apoyo del arnés y del anclaje es de 4 pies (1,2 m), la

distancia de caída libre es de 1 pie (0,3 m) (5 pies menos 4

pies es igual a 1 pie [1,5 m menos 1,2 m es igual a 0,3 m]).

Por lo tanto, en este ejemplo debe dejarse un mínimo de 4,5

pies (1,3 m) como la distancia entre la posición de apoyo y

cualquier estructura que esté debajo (1 pie más 3,5 pies es

igual a 4,5 pies [0,3 m más 1 m es igual a 1,3 m]).

Figura B

Distancia entre el punto de apoyo del

conector de anclaje y el punto de

apoyo del anillo en D de detención de

caídas (X)

Distancia de caída libre correspondiente

a la flojedad del dispositivo de conexión

Factor de extensión del dispositivo

de conexión de 3,5 pies (1 m)

Page 26

Cómo usar un dispositivo de conexión de EPL

ADVERTENCIA:

ADVERTENCIA:

1. Lea todas las etiquetas de advertencia e instrucciones

suministradas con los dispositivos de conexión Klein o

colocadas en ellos para obtener información importante

sobre su uso y cuidado. Guarde todo este material para

referencia futura.

2. Para aplicaciones de detención de caídas, sujete un

extremo del dispositivo de conexión al anillo en D de detención

de caídas del arnés de EPL. Este anillo en D está en la parte

superior central de la espalda del usuario que emplea el arnés.

Para aplicaciones de posicionamiento, sujete un extremo del

dispositivo de conexión a uno de los anillos en D laterales.

Luego, acople apropiadamente el anclaje y sujete el extremo

suelto al anillo en D lateral no utilizado.

Para aplicaciones de suspensión, sujete el dispositivo de

conexión al anillo o anillos en D de suspensión. Asegúrese de

seleccionar el dispositivo de conexión apropiado para ajustarse

al arnés, el asiento colgante u otro equipo de suspensión.

Para aplicaciones de recuperación, sujete el dispositivo de

conexión a los anillos en D de recuperación, que generalmente

se encuentran en los hombros del arnés.

Para todas las aplicaciones, asegúrese mediante inspección

visual de que todos los ganchos de presión se acoplen

libremente y de que sus fijadores estén completa mente

cerrados después de realizar cada enganche.

3. Conecte el otro extremo del dispositivo de conexión a un

anclaje apropiado. (Ejemplos de anclajes apropiados incluyen

ojillos de platillo, agujeros para pernos, cuerdas de seguridad,

vigas, pilares u otros miembros estructurales aprobados.) En

aplicaciones de detención de caídas, mantenga el anclaje por

encima del anillo en D de detención de caídas trasero o por

encima de la cabeza, y deje tan poca flojedad como sea posible

para limitar la fuerza de impacto de una caída. Realice el

montaje de manera que se evite el contacto con las estructuras

que estén debajo en caso de caída. La distancia de caída libre

no debe sobrepasar 6 pies (1,8 m). Si está utilizando un

acollador de desaceleración o una unidad de desaceleración,

añada 3,5 pies (1 m) a la distancia de caída libre para tener en

cuenta la extensión de la unidad.

Cuando sujete cualquier gancho de presión al anclaje,

asegúrese mediante inspección visual de que el gancho

de presión se acople libremente en el anclaje y de que el

fijador esté completamente cerrado después de realizar

cada enganche. Asegúrese de que cada gancho de presión

esté posicionado de manera que su fijador nunca soporte

cargas.

4. Nunca conecte nada a los anillos en D de detención de

caídas, posicionamiento, suspensión o recuperación que no

sea el dispositivo de conexión apropiado. Además, nunca

sujete más de un dispositivo de conexión a un solo anclaje.

5. En una aplicación de detención de caídas, en la que la

posición de trabajo cambia, reposicione el dispositivo de

conexión siempre que sea necesario para asegurarse de que el

anclaje de detención de caídas esté por encima del anillo en D

de detención de caídas trasero o por encima de la cabeza, y deje

tan poca flojedad como sea posible en el dispositivo de

conexión. Si no sigue este procedimiento, el resultado puede

ser lesiones graves o la muerte.

Procedimientos generales de inspección

1. Compruebe si hay desgaste o deterioro.

Antes de cada uso, inspeccione cuidadosamente el sistema

de EPL completo para ver si presenta señales de desgaste

o deterioro, o evidencia de carga por impactos. Inspeccione

visualmente si hay hilos flojos, remaches desprendidos,

quemaduras, cortes, distorsiones, abrasiones u otra

evidencia de deterioro químico o físico que pueda haber

debilitado el material o el conjunto.

2. Inspeccione los herrajes para comprobar si funcionan

correctamente o si tienen grietas.

Compruebe todos los ganchos de presión, hebillas y anillos

en D. Compruebe que los ganchos de presión no estén

distorsionados ni agrietados, y que los fijadores estén libres

de rebabas, funcionen apropiadamente, estén limpios y no

estén doblados.

3. Destruya y reemplace todos los equipos desgastados

o dañados.

Destruya y reemplace inmediatamente todo componente

que no pase la inspección.

En caso de que se observe alguna

situación no usual durante la inspección, que no se

especifique aquí, no utilice el equipo bajo sospecha

hasta que una persona calificada haya tomado una

decisión en cuanto a su utilizabilidad.

Inspeccione siempre su equipo antes

de utilizarlo. Destruya y reemplace inmediatamente

todos los equipos desgastados o dañados.

Page 27

Procedimientos de inspección de los dispositivos de conexión

Nota: La cuerda trenzada, como el filamento de nylon y la

cuerda de polipropileno que se utilizan en los acolladores

Klein, está sometida a una condición conocida como “tendencia

a enredarse”, que es similar al retorcimiento inverso que se

produce a menudo en el cordón de un receptor de teléfono.

1. Inspeccione las costuras y la malla.

Compruebe si las costuras están rotas, quemadas, cortadas o

levantadas. Las hebras o mallas rotas aparecen como

mechones en la superficie de la malla. Para comprobar

visualmente si hay daños causados por agentes corrosivos,

calor, agentes químicos y otras condiciones, sostenga el

dispositivo de conexión con las manos separadas de seis a

ocho pulgadas (15 a 20 cm). Doble la malla en forma de U

invertida para causar tensión en la superficie y dejar al

descubierto las áreas problemáticas. Inspeccione toda la

longitud.

Para unidades de desaceleración, inspeccione las costuras

para comprobar si están rotas, quemadas, cortadas o

levantadas, y la chaqueta de separación para comprobar si

tiene cortes, rasgaduras, costuras rotas, marcas de

estiramiento u otra evidencia de carga por impactos. Nota: En

las unidades de desaceleración Klein, una etiqueta de

advertencia con letras rojas que esté descubierta dentro

de la chaqueta de cuero indica que la unidad ha estado

sometida a una fuerza de impacto severa; por lo tanto,

la unidad no debe utilizarse y debe desecharse

inmediatamente.

Para acolladores de desaceleración, inspeccione las

costuras para comprobar si están rotas, quemadas, cortadas

o levantadas, o si muestran alguna otra evidencia de carga por

impactos. Nota: En los acolladores de desaceleración Klein,

una etiqueta de advertencia con letras rojas que esté

descubierta indica que la unidad ha estado sometida a una

fuerza de impacto severa; por lo tanto, la unidad no debe

utilizarse y debe desecharse inmediatamente.

Para acolladores de cable para aviación, inspeccione toda

la longitud para comprobar si hay roturas, quemaduras o

cortes en el revestimiento de vinilo y el cable para aviación.

2. Compruebe si hay hebras rotas.

Inspeccione los acolladores de cuerda para comprobar si hay

hebras rotas, retorciendo la cuerda ligeramente para deshacer

el trenzado. Inspeccione todo el acollador de esta manera. Los

acolladores con hebras sueltas deben desecharse.

Esto puede ser causado por un movimiento repetitivo de

torsión, como la rotación normal de la mano al enganchar y

desenganchar un acollador que cuelgue libremente, o al

utilizar el acollador para suspender equipos. Las medidas de

prevención incluyen: (1) no utilizar nunca un acollador para

remolcar o izar, (2) inspeccionarlo y alisarlo después de cada

uso, y (3) almacenarlo ordenadamente.

3. Inspeccione los ganchos de presión y otras piezas

metálicas.

Inspeccione los herrajes para comprobar si tienen bordes

afilados y grietas. Los rodillos no deben estar distorsionados

y deben rodar libremente. Compruebe todas las piezas,

especialmente las esquinas y los puntos de sujeción, para ver

si hay desgaste y grietas.

4. Destruya y reemplace todos los equipos de EPL

desgastados o dañados.

Si se observa evidencia de desgaste excesivo, deterioro

o funcionamiento mecánico defectuoso, reemplace inmediatamente el equipo. Nunca trabaje con equipo de EPL desgastado

o dañado. La utilización de equipo dañado o desgastado

puede causar lesiones o la muerte.

5. El inspector es el factor más importante de todo

procedimiento de inspección.

Compruebe minuciosamente todo el equipo y siga todos los

procedimientos y directrices de seguridad. No omita nada. El

resultado podría ser lesiones o la muerte.

Nota importante: OSHA especifica que todos los empleadores

afectados por la Ley de Seguridad y Salud Laboral son

responsables de inspeccionar y mantener todas las

herramientas y equipos utilizados por los empleados, tanto

si pertenecieran a los empleados como si pertenecieran a la

compañía. Todo el equipo de protección personal debe

inspeccionarse antes de cada uso y retirarse inmediatamente

de servicio si se encuentra cualquier indicio de desgaste o

daños.

Page 28

Procedimientos de mantenimiento

El jefe de seguridad de la compañía u otra persona

competente debe mantener un registro escrito de todas las