Page 1

Instructions for the Proper Use and Care of Klein®

Lineman’s Body Belts and Positioning Straps

Para español, vaya a la página 13.

Pour le français, allez à la page 25.

Introduction

This instruction manual explains how to use,

inspect and maintain Klein lineman’s body belts

and positioning straps.

Klein manufactures a full line of lineman’s body belts

and positioning straps, designed to meet OSHA

criteria for positioning applications.

Note: Klein’s lineman’s body belts are for positioning applications only and should not be used

alone as a personal fall-arrest system, as defined

under Subpart M of OSHA standard 1926.

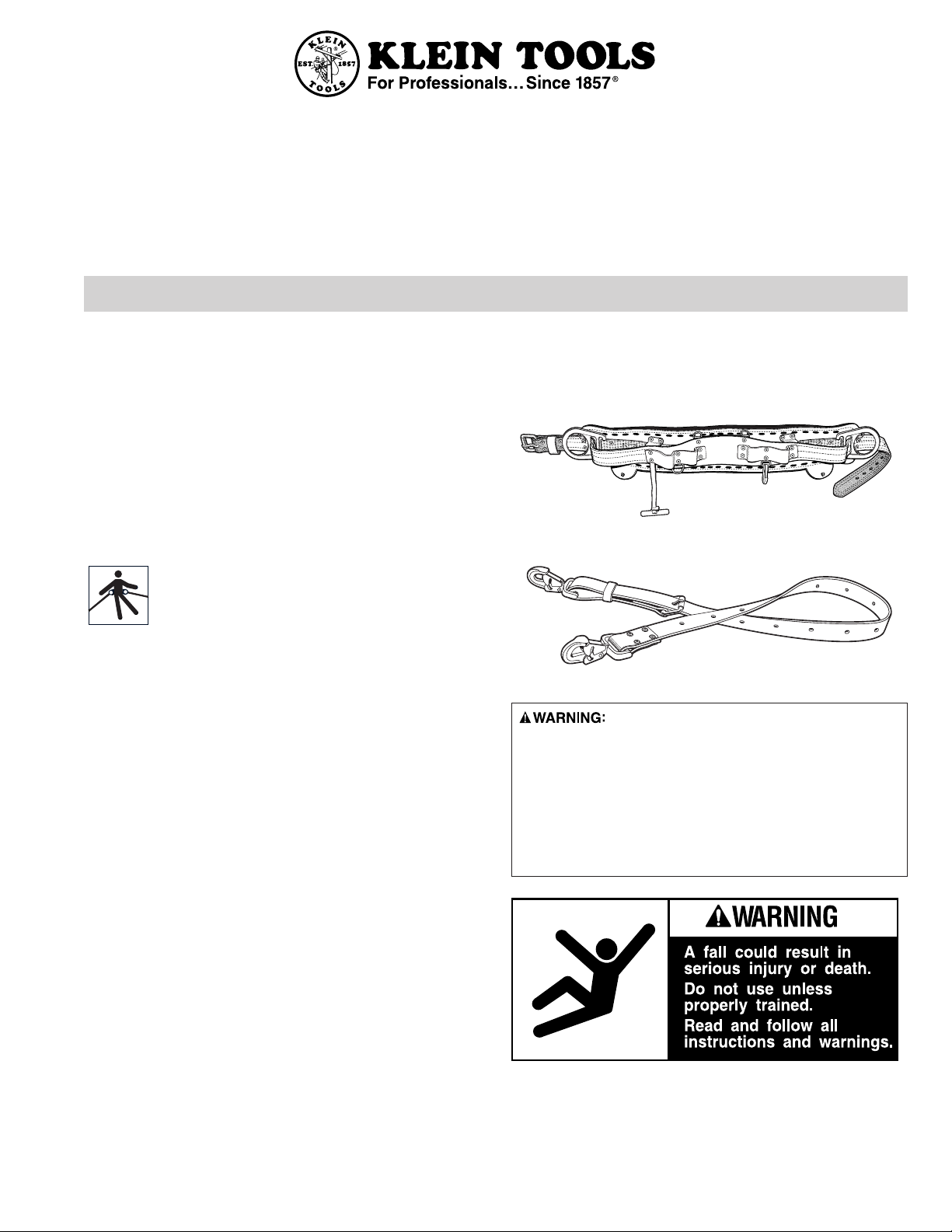

The positioning symbol shown in Figure 1

appears on warning tags attached to each

body belt. This symbol identifies the belt’s

Figure 1

Klein lineman’s body belts are available in full-floating,

semi-floating, or fixed styles. They combine the features of an OPE (occupational protective equipment)

positioning belt with a specialized tool belt. They

meet or exceed all OSHA regulations, which apply to

positioning device systems, for power utilities (OSHA

1926.959) and telecommunications (OSHA 1910.268

and 1910.269). They also meet or exceed standards

ASTM F 887, CSA Z259.1 and CSA Z259.11. Each

belt is affixed with a permanent tag, which identifies model number, serial number, size, and date of

manufacture.

OPE function.

Note: For clarity, illustrations in this instruction

booklet do not show any warning tags or labels,

which are attached to each product.

Save these instructions. This equipment

must not be used by anyone who has not read,

understood and followed all the instructions and

inspection procedures contained in this booklet.

Failure to read, understand and follow all instructions may result in serious injury or death. Training

and instruction review should be repeated at regular

intervals by the user and his or her employer.

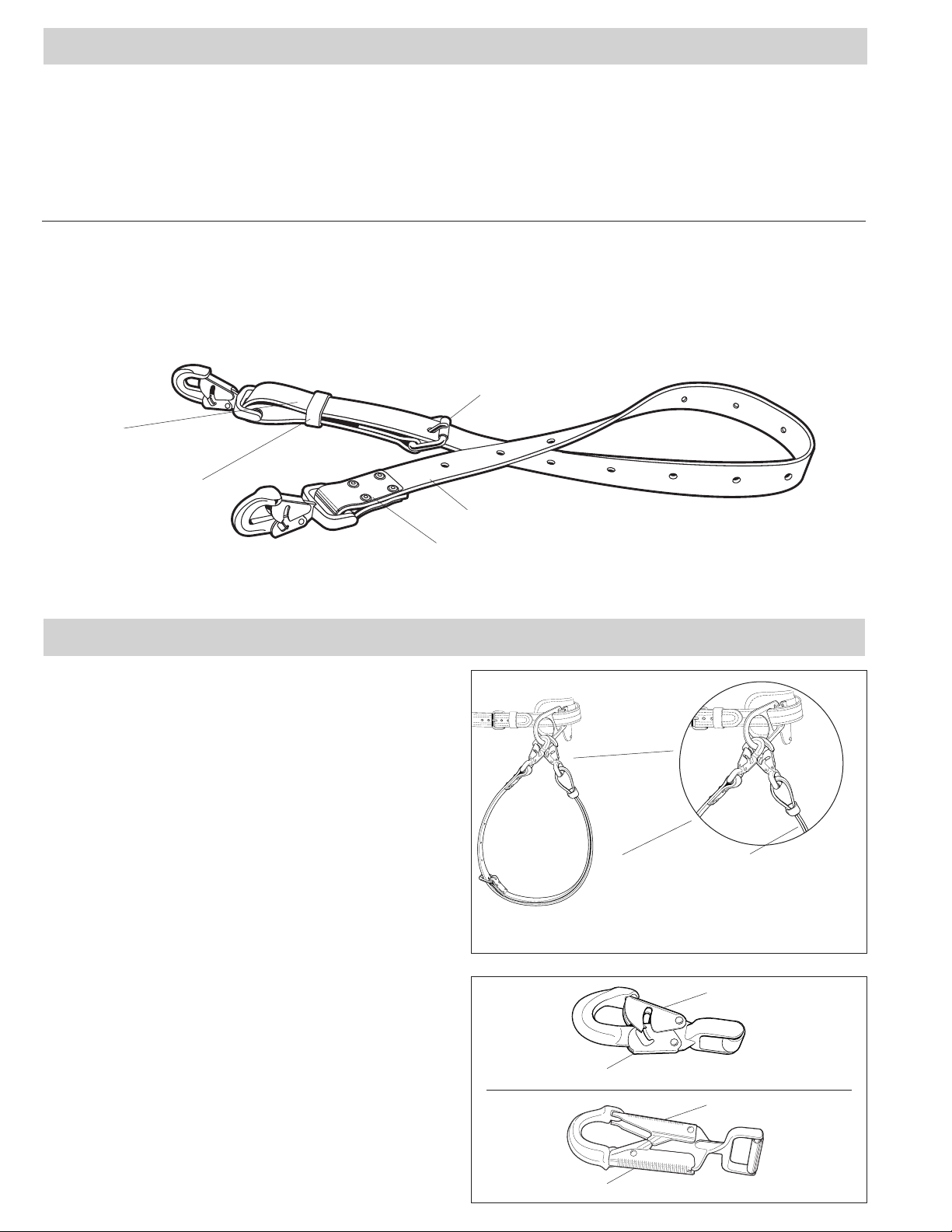

Klein positioning straps are available in the following lengths: 5'8" (1.7 m), 6' (1.8 m), 6'6" (2.0 m), 7'

(2.1 m), and 8' (2.4 m). They are designed to conform with OSHA standards 1910.268, 1910.269 and

1926.959.

All individuals who use Klein lineman’s body belts

and positioning straps must be instructed in how to

use that equipment correctly. Also, they must read,

understand and follow all instructions and warnings

contained in this booklet or packed with the product

before each use.

Page 2

Materials Used in Lineman’s Body Belts & Positioning Straps

Klein-Kord

The load-bearing material in Klein positioning straps

is our exclusive Klein-Kord, an exceptionally strong,

multi-ply filament nylon fabric that is neopreneimpregnated, folded, and vulcanized.

Klein-Kord is abrasion-resistant, non-conductive,

virtually free from stretch, and flexible for ease of use

and durability. It has excellent chemical resistance,

and is virtually unaffected by creosote and other poletreatment chemicals. In addition, its properties and

wear characteristics remain essentially unchanged

at temperatures up to 250°F (121°C).

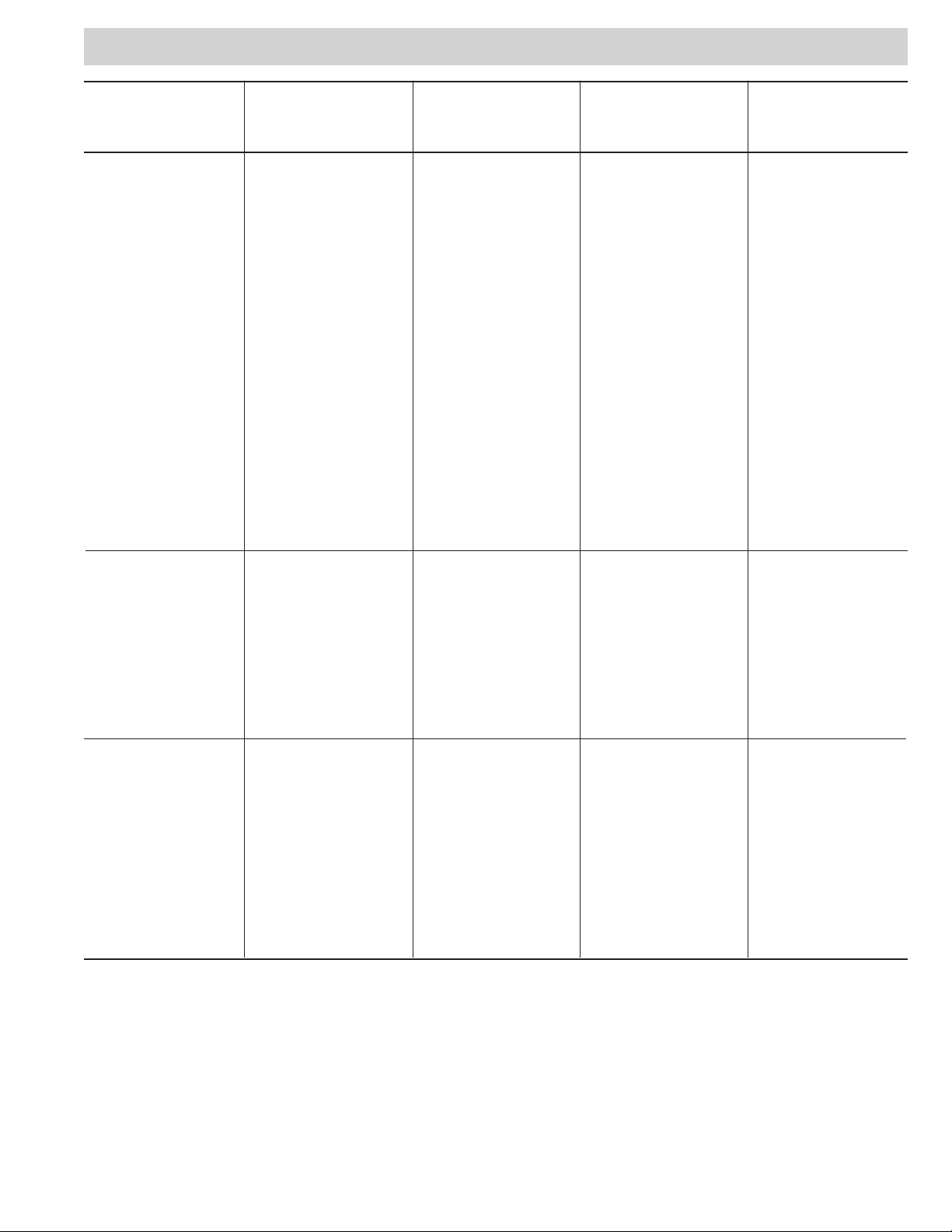

Shown below is Klein's six-ply Klein-Kord, which is

1-3/4" (44 mm) wide. The center plies of Klein-Kord

are red at the core. When the red plies appear,

remove the strap from use immediately and replace

it. This “early warning” feature is yet another safety

measure provided by Klein Tools.

Note: The red center plies may become discolored

in use. Therefore, visual inspection for wear before

each use is mandatory.

®

Six-ply Klein-Kord with red center plies

Buckles and Billets

Klein lineman’s belts have drop-forged, singletongue buckles. Belt straps and billets are made

of Klein-Kord. On top-of-the-line belts, straps are

covered with harness leather.

Klein strongly recommends using fall-

arrest protection when working at any elevated

position. Therefore, independent fall-arrest equipment

should be used in addition to Klein's body belts

and positioning straps unless a competent person,

as defined by OSHA, has determined that such fallarrest equipment is not necessary or appropriate.

Klein’s lineman’s body belts and posi-

tioning straps are designed for positioning purposes

only, and are not to be used for any other OPE function (such as fall arrest, suspension, or retrieval).

Klein strongly recommends that only

Klein components be used with any Klein lineman’s

equipment. Klein components should NOT be

interchanged with other components made by other

manufacturers, because Klein cannot guarantee

that components made by other manufacturers are

properly designed or are free of defects in materials

or workmanship.

Drop-Forged Steel

Klein D-rings and tongue buckles are made of dropforged steel with a corrosion-resistant finish. All

Klein hardware is tested to meet or exceed applicable OSHA standards.

Nylon Webbing

Klein uses a high-quality, commercial-grade nylon.

The nylon webbing is impregnated with latex or resin

for extra durability and abrasion resistance.

Leather

Rolled-edge, chrome-tanned leather is used for

cushioning in all Klein lineman’s belts. These cushions have sponge-rubber cores for added comfort.

Other components, such as tool loops, are made

of harness leather. Body pads are made of latigo

leather, hand laced and stitched to the belt cushion.

2

Page 3

Physical Properties of Materials*

Type of Material

Exposure to

Excessive Heat

Exposure to

Chemicals

Exposure to

Molten Metal or

Flame

Exposure to

Paints or Solvents

Nylon Poor resistance.

Becomes brittle,

has a shriveled

brown appearance. Fibers will

break when flexed.

Weakens at 300°F

(149°C).

Klein-Kord

®

Similar to nylon;

however, neoprene

will protect nylon

fabric for a period

of time.

Generally good

resistance except

around strong acids

and phenolic compounds (phenol

is present in coal

tar and wood tar),

which cause it to

become brittle.

Excellent resistance

to hydrocarbons

as used in wood

treatment, due to

neoprene.

Poor resistance.

Strands fuse

together and form

hard shiny spots.

Has hard and brittle

feel. Will not support combustion.

Similar to nylon;

however neoprene

helps protect nylon

fabric from welding

splatter.

Generally offers

good resistance.

However, paint

can penetrate into

the weave and dry.

This can cause

webbing to become

hard and brittle

and can eventually

break the fibers.

Some solvents

may affect fibers

(see “Exposure to

Chemicals”).

Excellent resistance;

however, some

strong solvents

could soften

neoprene and

attack nylon.

Leather Poor resistance.

Excessive heat

destroys strength.

Will burn at 330°F

(165°C). Dry leather slowly at room

temperature.

* This chart shows the general physical qualities of

the materials used in Klein lineman’s body belts and

positioning straps. Due to the wide variety of conditions in the workplace, this information should only

be considered as a general guide, and a qualified

person should evaluate the specific applications and

hazards to which the materials will be exposed.

Generally poor

resistance.

Chemicals tend to

dry leather out.

Will burn; however,

chrome leather is

excellent protection

against welding

splatter.

If you need more information, call Klein Tools at

1-800-553-4676.

Generally poor

resistance.

Chemicals tend to

dry leather out.

3

Page 4

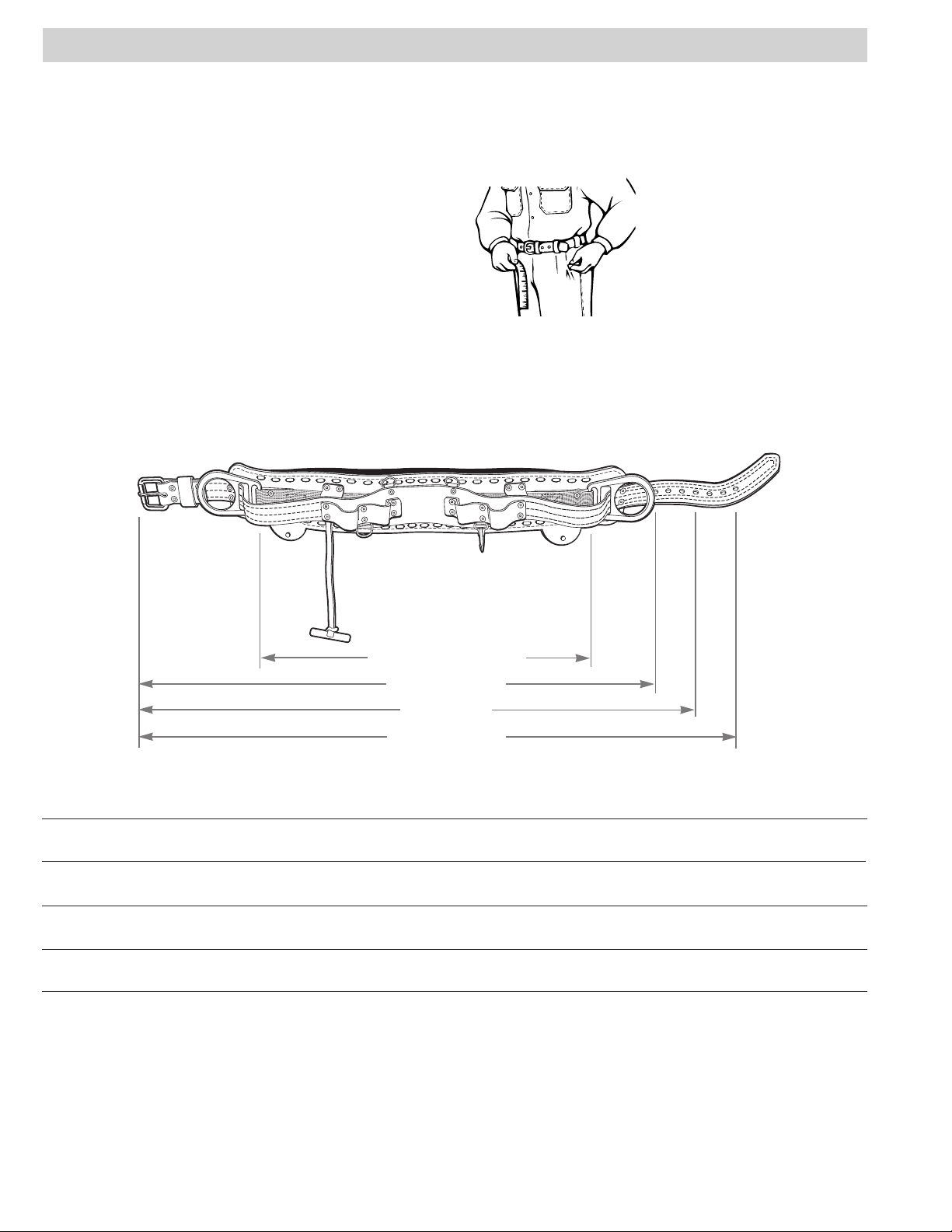

How to Select a Lineman’s Body Belt

Maximum Length

Center Hole

Minimum Length

D-to-D size:

Hipbone to Hipbone + 2"

1. Know the job and regulations governing per-

formance requirements for the equipment needed.

2. Select the belt style. Klein lineman’s body belts

are available in a choice of fixed, semi-floating and

full-floating styles, and feature the choice of belt pad

size. All Klein lineman’s body belts have chrometanned leather cushions for greater comfort. Fullfloating belts allow lateral movement of the D-rings

during use. Semi-floating belts only allow lateral

movement prior to wearing. Fixed-style belts are

lightweight and the most economical.

3. Select the proper belt size. The comfort of a

lineman’s belt depends on the construction of the

belt and the location of the D-rings. The D-rings should

be located about 1" (25 mm) in front of the hip bones.

Never order Klein lineman’s body belts by waist

size. Always order Klein lineman’s body belts by

the desired distance between D-rings.

Figure 1

Size your body belt using

a tape measure (Figure 1).

To obtain the correct D-to-D

(D-ring to D-ring) size, measure from hipbone to hipbone,

and then add 2" (51 mm).

The Lineman’s Belt Sizing

Table (shown below) contains

more information on selecting the proper belt size. For

non-standard sizes, please call the Klein Tools Sales

Department at 1-800-553-4676.

Lineman’s Belt Sizing Table*

D-to-D 18D 19D 20D 21D 22D 23D 24D 25D 26D 27D 28D 29D 30D

Distance** (46) (48) (51) (53) (56) (58) (61) (64) (66) (69) (71) (74) (76)

Minimum Length 32 33 34 36 37 38 40 41 42 44 45 46 47

(81) (84) (86) (91) (94) (97) (102) (104) (107) (112) (114) (117) (119)

Center Hole 36 37 38 40 41 42 44 45 46 48 49 50 51

Distance (91) (94) (97) (102) (104) (107) (112) (114) (117) (122) (124) (127) (130)

Maximum Length 40 41 42 44 45 46 48 49 50 52 53 54 55

(102) (104) (107) (112) (114) (117) (122) (124) (127) (132) (135) (137) (140)

* All measurements are listed in inches and (cm). This table shows the maximum and minimum lengths and center-hole

distances for the full range of standard D-to-D measurements. A belt sized for the proper D-to-D size will fit correctly

with buckle tongue engaged in the center hole.

** The following D-to-D sizes can be special ordered: 19" (48 cm), 25" (64 cm), 27" (69 cm) and 29" (74 cm).

4

Page 5

How to Use a Lineman’s Body Belt

1. These belts are for use only by individuals who

have been properly trained and who are qualified to

use this positioning equipment.

2. Read all the warning labels and instructional mate-

rials provided with Klein’s lineman’s belts and related

OPE equipment. They provide important information

on usage and care. Leave all affixed labels in place,

and keep all instructions for future reference.

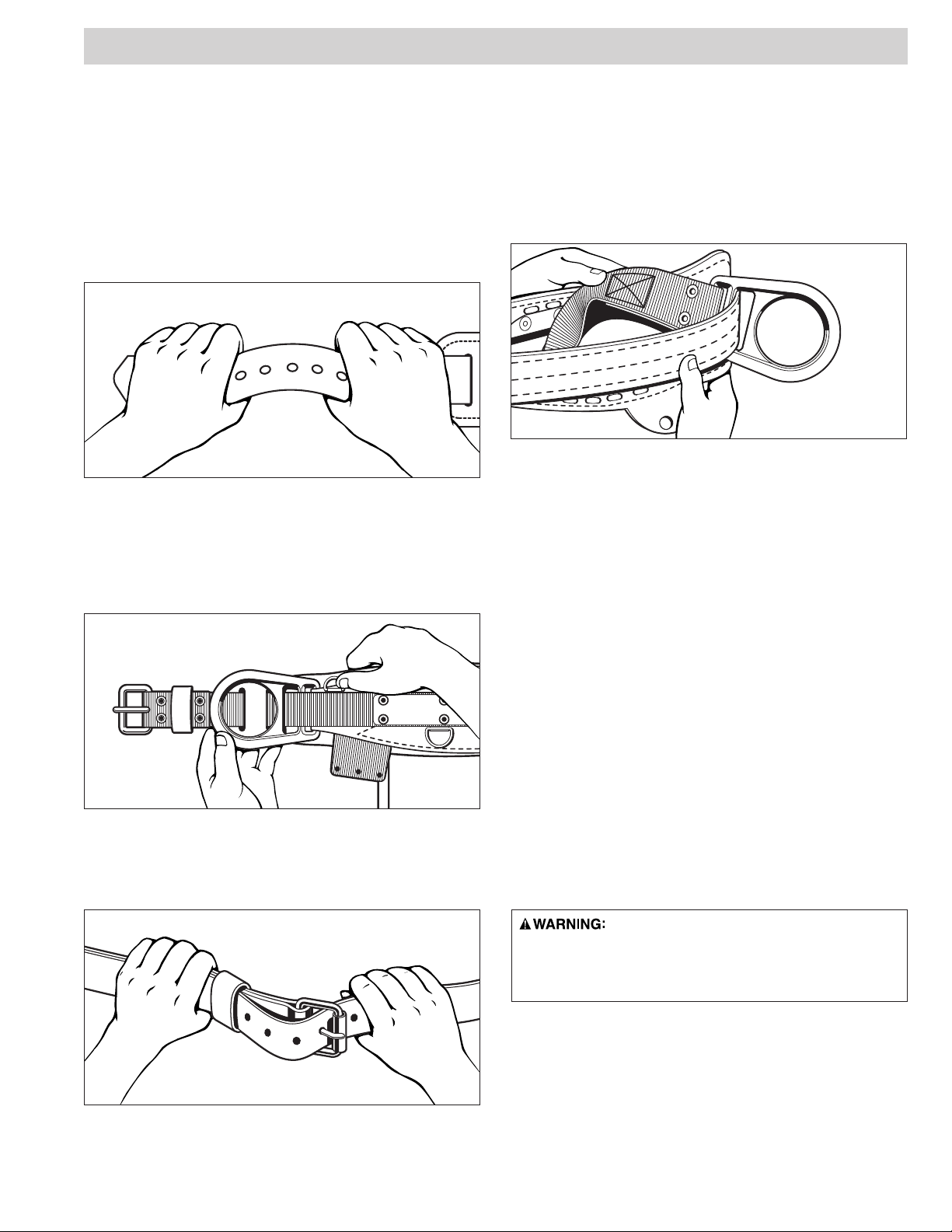

3. Buckle the belt securely around the waist. Be

sure the buckle is fully closed, and the belt tab is in

its keeper. A lineman’s belt should fit snugly around

the waist. If you cannot achieve a snug fit, replace

the belt with one that fits properly.

4. When using a lineman’s belt, positioning

D-rings should be equally spaced on either side of

the lineman’s body.

5. Attach one end of the positioning strap (or other

positioning connecting device) to one of the positioning D-rings.

6. Pass the positioning strap around the pole (the

positioning anchorage), and then attach the other end

of the strap to the other positioning D-ring.

7. Make sure by visual inspection that both snap

hooks freely engage the positioning D-rings and that

both keepers are closed completely.

8. When properly connected, the positioning strap

will not be twisted, and both snap hooks will face

outward.

9. Do not connect any tools, wires, or other snap

hooks to the positioning D-rings.

Note: See pages 6-7 for complete information on

how to use a Klein positioning strap.

5

Page 6

How to Select a Lineman’s Positioning Strap

Depending on your application, choose a positioning

strap that allows you to work at arms’ length from the

pole you’ll be working on.

Cat. No.

Klein-Lok® Series

KL5295L

KL5295-6L

KL5295-6-6L

KL5295-7L

KL5295-8L

double end

of positioning strap

leather keeper

Cat. No.

Klein-Gard™ Series

KG5295L

KG5295-6L

KG5295-6-6L

KG5295-7L

KG5295-8L

Maximum

Length

5'8" (1.7 m)

6' (1.8 m)

6' 6" (2.0 m)

7' (2.1 m)

8' (2.4 m)

Lineman’s positioning straps are available in five sizes

and with two snap-hook styles: 5'8" (1.7 m), 6' (1.8 m),

6'6" (2.0 m), 7' (2.1 m), and 8' (2.4 m). For more information, see the following chart.

Minimum

Length

3'10" (1.17 m)

4' (1.2 m)

4'3" (1.3 m)

4'6" (1.35 m)

5'6" (1.7 m)

adjusting buckle

single end of positioning strap

Adjustable

Range

1'10" (0.5 m)

2' (0.6 m)

2'3" (0.7 m)

2'6" (0.8 m)

2'6" (0.8 m)

metal clip

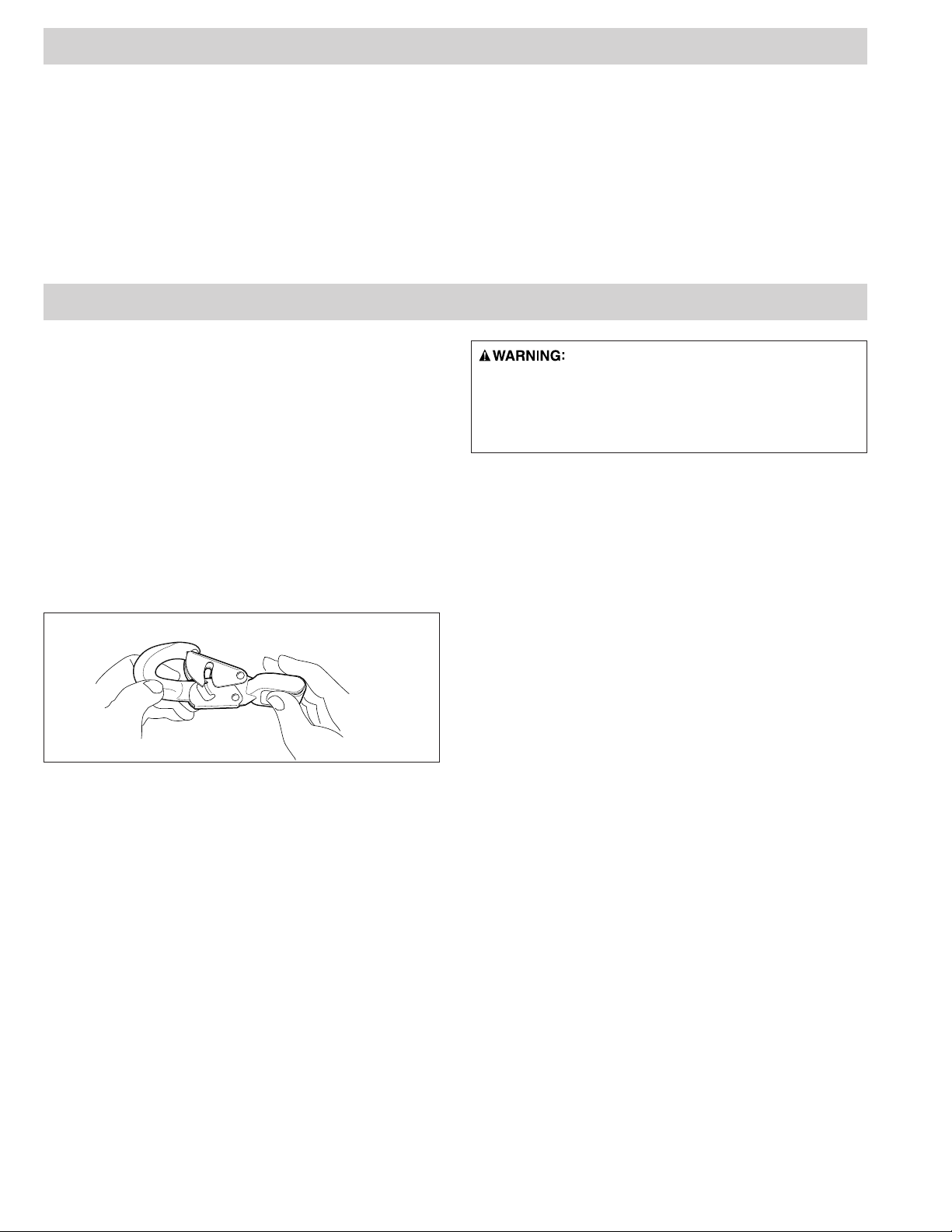

How to Use a Lineman’s Positioning Strap

Note: The following instructions apply to

right-handed people.

1. These positioning straps are for use only by

individuals who have been properly trained and who

are qualified to use this positioning equipment.

2. Before climbing a pole, make sure that both lock-

ing snap hooks of the positioning belt are attached to

the left D-ring of the body belt.

Note: The snap hook closest to the body should

be the snap hook on the positioning strap’s

double end. That snap hook should be engaged

so that the keeper faces outward. The outer snap

hook will be the snap hook on the positioning strap’s

single end. That snap hook should be engaged so

that the keeper faces inward (see Figure 2).

Note: To engage or release the locking snap hook,

depress both the keeper and the lock at the same

time. This can easily be done with one free hand (see

Figure 3).

Figure 2

Figure 3

KL Series

KG Series

Single end of

positioning strap,

with keeper

facing inward

lock

Double end of

positioning strap,

with keeper

facing outward

keeper

keeper

6

lock

Page 7

How to Use a Lineman’s Positioning Strap (continued)

3. Upon reaching working position, plant both gaffs

firmly into the pole, and hold onto the pole with

both hands.

4. Unsnap the outer snap hook whose keeper faces

inward (that is, the snap hook on the single end of the

positioning strap) with the left hand, while grasping

the pole with the right hand.

5. Pass the single end of the strap around the back

of the pole to the right hand, while maintaining a firm

grip on the pole.

6. Carry the positioning strap to the right D-ring with

the right hand, and fasten the snap hook so that the

keeper faces outward.

7. Make sure the positioning strap lies flat without

twists against the pole, and that the buckle tongue is

turned outward.

8. Before placing your full weight on the positioning

strap, visually check that each locking snap hook

freely engages the D-ring and that the keepers are

completely closed. Never rely solely on the feel or

sound of a snap hook engaging.

10. With the right hand, unfasten the snap hook

on the single end of the positioning strap from the

right D-ring.

11. Pass the single end of the positioning strap

around the back of the pole with the right hand until

the strap can be grasped by the left hand.

12. Now grasping the pole with the right hand, fasten

the snap hook of the single end of the positioning

strap to the left D-ring with the keeper facing in

(above the snap hook that’s already engaged).

13. When the positioning strap is not being used

for support, both ends should be fastened to the left

D-ring (see Figure 2 on page 6).

9. Removing the positioning strap (before descend-

ing the pole). Grasp the pole with the left hand and

release tension on the positioning strap by moving

the body slightly toward the pole.

7

Page 8

Maintenance Procedures

A written log of all service and inspection dates for this

equipment should be maintained by the company

safety officer or other competent individual.

1. Clean and maintain equipment as recommended.

Wash in warm water and mild detergent. Avoid harsh

chemical agents such as degreasing compounds, turpentine, paint thinner, gasoline, and other solvents.

General Inspection Procedures

1. Check for wear and deterioration. Before each

use, carefully inspect your OPE equipment for signs

of wear or deterioration or evidence of impact loading. Visually inspect for loose threads, pulled rivets,

burns, cuts, abrasions, or evidence of chemical or

physical deterioration that may have weakened the

material or assembly.

2. Inspect hardware for malfunctions and cracks,

including belt buckles, D-rings, and positioning-strap

snap hooks. Check that snap hooks are not distorted

or cracked and that the keepers are free of burrs,

functioning properly, clean, and not bent.

2. Inspect and lubricate all snap hooks after

cleaning to make sure they operate properly and

close securely. Use an all-purpose spray lubricant

or light motor oil.

3. Maintain leather parts with Neat’s-foot oil, saddle

soap or equivalent to help prolong life. Let leather

dry slowly at room temperature.

Should any unusual conditions be

noted during the inspection which are not specified here, do not use the suspect equipment

until a qualified individual has made a decision

on its usability.

KL Style Shown

3. Destroy and replace all worn or

damaged equipment. Immediately destroy and

replace any OPE system component which does not

pass inspection.

8

Page 9

Inspection of Belts & Straps

1. Straps, stitching and webbing. Check entire

length of the strap for excessive wear. Inspect the

tongue or billet end carefully. This end is subject to

considerable wear as a result of repeated buckling

and unbuckling of the belt. Also, check for torn or

excessively enlarged buckle-tongue holes. Check

stitching for broken, cut or pulled stitches. Check

webbing for broken strands, which appear as tufts

on the surface.

2. D-rings. Check all D-rings for distortion. Check

D-ring attachment points for unusual wear or damaged fibers. Badly pitted D-rings could indicate

chemical corrosion, and the equipment should be

replaced immediately.

4. Stitching or rivets at hardware attachment

points. For stitching-attachment points, check that

stitching is not broken, burned, cut or pulled. For riveted attachment points, check all rivets for tightness,

especially those at D-ring wear pads. Badly-pitted

rivets indicate chemical corrosion, and equipment

should be replaced immediately.

5. Destroy and replace all worn or damaged

OPE equipment. If any evidence of excessive

wear, deterioration, or mechanical malfunction is

observed, replace equipment immediately. Never

work with worn or damaged OPE equipment.

Using damaged or worn equipment can cause

serious injury or death.

3. Tongue buckles. Check tongue buckles for

distortion, sharp edges and cracks. The tongue

should move freely and overlap the frame. Rollers

should not be distorted and should roll freely.

6. The inspector is the most important part of any

inspection procedure. Check all equipment thoroughly

and follow all safety procedures and guidelines.

Do not take any shortcuts.

Important Note: OSHA specifies that all employers

covered by the Occupational Safety and Health Act

are responsible for inspection and maintenance of all

tools and equipment used by employees — whether

owned by the employees or by the company.

Personal-protective equipment should be inspected

before each use, and immediately removed from

service if any sign of wear or damage is found.

If you note any unusual conditions dur-

ing the inspection that are not specified here, do

NOT use the suspect equipment until a qualified

individual has made a decision on its usability.

9

Page 10

Lineman’s Equipment Warning Tags

For Positioning Use Only

■ Use this product for positioning only, NOTfor fall arrest.

■ If possible, the use of fall arrest equipment is highly

recommended in addition to this belt.

■ Assume the responsibilityfor determiningthat your belt is in

good condition at all times.

■ Do NOT use connecting devices made of leather

or

manila rope.

■ Neveruse side D-rings for fall arrest.

■ Positioning anchoragesmust support your

weight

plus any additional job related load.

■ Never allow belt to come in contact with edged or

pointed

tools; or come near a radiator, steam pipe, stove,

heater, engine exhaust pipe or other heat source.

C1b1.

997

Read

Other

Side

Read

Next

Tag

WARNINGS

W

ARNINGS

■ For use by properly trained professionals only.

■ Only use locking snap hooks.

■ OPE equipment must only be used for the

specific purpose for which it is designed and

intended.

■ OPE equipment must be destroyed if subjected

to impact loading.

■ Always visually check that all buckles are

properly

closed before each use.

■ Never allow a positioning strap to become twisted

before engaging D-ring.

■ Always visually check that: 1) each snap hook

freely engages D-ring or anchor point, 2) keeper is

completely closed with each use. Never rely solely

on the feel or sound of a snap hook engaging.

■ Before each use check that: 1) fabric or belt strap

is free

of burns, cuts, broken stitches or excessive

wear, 2) rivets are not bent, loose or missing, 3) buckles and

D-rings are

not distorted or cracked,

4) if tongue buckle,

tongue does not bind on buckle and buckle holes are

not

damaged. 5) Remove from service, destroy and discard

belt or harness if it fails inspection and replace

immediately.

B1-2 1

007

Read

Other

Side

Read

Next

Tag

INSTRUCTIONS

INSTRUCTIONS

■ For personal use only. NOT for towing or hoisting.

■ Snap hooks attached to D-rings must have

less than 3/4" (19mm) throat opening. Never attach

ladder or r

ebar hooks onto D-rings.

■ Never attach multiple snap hooks onto a D-ring.

■ Never punch additional holes in or alter any belt or

harness in any way.

■ Never work without independent fall arrest

protection if

there is danger of a fall.

■ NOT for recreational or sporting use.

■ Employer— instruct employee as to proper use and

warnings

before use of equipment.

■ Read, understand and follow all instructions and

cautions attached to and/or packed with this and

all occupational protective equipment before each use.

■ Klein strongly

recommends that Klein components

NOT be inter

changed with other components made by

other manufacturers,

because Klein cannot guarantee that

other manufacturers’ components are free of defects in

materials or workmanship.

B1-2 2.

007

Read

Other

Side

Read

Next

Tag

INSTRUCTIONS

INSTRUCTIONS

Klein permanently attaches highly durable warning

and instruction tags to its lineman’s body belts and

positioning straps.

If any of these tags become unattached, lost, or

damaged, call Klein Tools, toll-free at 1-800-553-4676,

for information on how to have the tags replaced

free of charge.

Tags for Lineman’s Body Belts

Klein strongly recommends using fallarrest protection when working at any elevated

position. Therefore, independent fall-arrest equipment

should be used in addition to Klein’s body belts

and positioning straps unless a competent person,

as defined by OSHA, has determined that such

fall-arrest equipment is not necessary or appropriate.

10

Page 11

Lineman’s Equipment Warning Tags (continued)

For Positioning Use Only

■ Always attach snap hooks to positioning

D-rings on both sides of the belt or harness with

keepers facing outward.

■ Never attach multiple snap hooks onto a D-ring.

■ Never allow a positioning strap to become

twisted before engaging D-ring.

■ Never attach multiple positioning straps

together.

■ Never attach a positioning strap back onto

itself.

■ Assume the responsibility for determining that your positioning strap is in good

condition at all times.

■ Never allow positioning strap to come in

contact with edged or pointed tools, welding;

or near a radiator, steam pipe, stove, heater, engine

exhaust pipe, or other heat source.

■ Never use a positioning strap which has worn to

the point of showing the red-colored

interior plies.

C6b 1

997

Read

Other

Side

Read

Next

Tag

WARNINGS

W

ARNINGS

■ For human support only, NOTfor towing or

hoisting material.

■ Never disable locking keeper on hook, punch holes

in or alter a positioning strap in any way

.

■ Use only with positioning belt or harness with

positioning D-rings meeting government

standards

for

intended use.

■ Klein strongly r

ecommends that Klein components

NOT be inter

changed with other components made by

other manufacturers, because Klein cannot guarantee that

other manufacturers’ components are free of defects in

materials or workmanship.

■ Before

each use check that: 1)

unit is free

of

burns, cuts, abrasions, kinks, knots, broken strands

and excessive wear, 2) hooks, buckle (and D-rings, if

any) are not distorted or cracked, 3) hook keepers are

free of burrs, functioning properly, clean, and not

bent, 4) positioning strap has not worn

to the point of

showing the red-colored interior plies, 5)Remove

from

service, destroy and discard unit if it does not

pass this inspection and replace immediately.

C6b2

007

Read

Other

Side

Read

Next

Tag

WARNINGS

WARNINGS

Copy A

( Klein recomienda enfáticamente que

los componentes Klein NO se intercam-

bien con otros componentes hechos

por otros

fabricantes, ya que Klein no

puede garantizar que los componentes

de otros fabricantes estén libres de

defectos de materiales o de fabricación.

Copy B

( Nunca deje que una correa de posi-

cionamiento se retuerza antes de

acoplarse al anillo en D.

Copy C

( Klein strongly

recommends that Klein

components NOT be interchanged with

other components made by other man

-

ufacturers, because Klein cannot guar-

antee that other manufacturers’

compo-

nents are

free of defects in materials or

workmanship.

Copy D

( Never allow a positioning strap to

become twisted before engaging D-ring.

■ For use by properly trained professionals only.

■ OPE equipment must only be used for the

specific purpose for which it is designed and intended.

■ Connecting devices must be destroyed if subjected

to impact loading.

■ Always visually check that: 1) each snap hook

freely engages D-ring or anchorage, 2) keeper is

completely closed with each use. Never rely solely

on the feel or sound of a snap hook engaging.

■ Make sure

each hook is positioned so that its keeper is

never load bearing.

■ Never join two snap hooks together. They are NOT

intended to be used that way, and could twist apart.

■ Never work without independent fall arrest pro-

tection if there is danger of a fall.

■ Employer — instruct employee as to proper use

and warnings

before use of equipment.

■ Read, understand and followall instructions

and

cautions attached to and/or packed with this and all occupational protective

equipment before each use.

C6b3.

997

Read

Other

Side

Read

Next

Tag

WARNINGS

WARNINGS

Klein permanently attaches highly durable warning

and instruction tags to its lineman’s body belts and

positioning straps.

If any of these tags become unattached, lost, or

damaged, call Klein Tools, toll-free at 1-800-553-4676,

for information on how to have the tags replaced

free of charge.

Tags for Lineman’s Positioning Straps

Klein strongly recommends using fallarrest protection when working at any elevated

position. Therefore, independent fall-arrest equipment

should be used in addition to Klein’s body belts

and positioning straps unless a competent person,

as defined by OSHA, has determined that such

fall-arrest equipment is not necessary or appropriate.

11

Page 12

Notes / Notas

12

Page 13

Para profesionales… desde 1857

®

Instrucciones para el uso y cuidado apropiados

de los cinturones de cuerpo y las correas de

posicionamiento Klein® para reparador de líneas

Introducción

En este manual de instrucciones se explica cómo utilizar,

inspeccionar y mantener los cinturones de cuerpo y las

correas de posicionamiento Klein® para reparador de

líneas.

Klein fabrica una línea completa de cinturones de cuerpo y

correas de posicionamiento para reparador de líneas, diseñada

para cumplir con los criterios de OSHA para aplicaciones de

posicionamiento.

Nota: Los cinturones de cuerpo Klein® para reparador de

líneas están diseñados solamente para aplicaciones de

posicionamiento y no deben utilizarse solamente como

un sistema personal de detención de caídas, tal como se

define en la Subparte M de la norma OSHA 1926.

El símbolo de posicionamiento que se muestra

en la Figura 1 aparece en las etiquetas de

advertencia sujetadas en el cinturón de cuerpo.

Figura 1

Los cinturones de cuerpo Klein para reparador de líneas están

disponibles en estilos de flotación completa, semiflotación

o fijos. Combinan las características de un cinturón de

posicionamiento de equipo de protección laboral (EPL) con

un cinturón especial para herramientas. Los cinturones de

cuerpo Klein para reparador de líneas cumplen o superan

todas las normas de OSHA que se aplican a los sistemas

de dispositivos de posicionamiento para empresas de

servicios públicos de energía eléctrica (OSHA 1926.959) y

telecomunicaciones (OSHA 1910.268 y 1910.269). También

cumplen o exceden las normas ASTM F 887, CSA Z259.1

y CSA Z259.11. Cada cinturón tiene colocada una etiqueta

permanente, que identifica el número de modelo, número de

serie, tamaño y fecha de fabricación.

Las correas de posicionamiento Klein son ajustables

y vienen en las siguientes longitudes: 1.73, 1.83, 1.98, 2.13

y 2.44 metros (5-2/3, 6, 6-1/2, 7 y 8 pies). Están diseñadas

para cumplir con las normas OSHA 1910.268, 1910.269 y

1926.259.

Este símbolo identifica la función del cinturón, un

equipo de protección laboral.

Nota: Para mayor claridad, en las ilustraciones de este

manual de instrucciones no se muestran los rótulos o

etiquetas de advertencia que están colocados en cada

producto.

ADVERTENCIA: Guarde estas instrucciones. Este equipo

no debe ser utilizado por ninguna persona que no haya

leído, entendido y seguido todas las instrucciones y procedimientos de inspección contenidos en este manual. Si no se

leen, entienden y siguen todas las instrucciones, el resultado

podría ser lesiones graves o la muerte. El usuario y su

empleador deben repetir con regularidad la capacitación y la

revisión de las instrucciones.

Una caída podría causar

lesiones graves o la muerte.

No utilice el cinturón a menos

que haya recibido capacitación

adecuada. Lea y siga todas las

instrucciones y advertencias.

Todas las personas que utilicen los cinturones de cuerpo y las

correas de posicionamiento Klein para reparador de líneas

deben recibir instrucciones sobre cómo utilizar correctamente

ese equipo. Además, antes de cada uso, deben leer,

entender y seguir todas las instrucciones y advertencias

contenidas en este manual y todas las advertencias o

instrucciones empaquetadas con el producto.

13

Page 14

Materiales utilizados en los cinturones de cuerpo y las correas de posicionamiento para reparador de líneas

Klein-Kord

El material de soporte de cargas de las correas de

posicionamiento Klein es nuestro Klein-Kord exclusivo, una

tela de nylon de filamentos multicapa excepcionalmente

fuerte que está impregnada con neopreno, plegada y

vulcanizada.

Klein-Kord es resistente a la abrasión, no conductor, flexible y

prácticamente inestirable para brindar fácil uso y durabilidad.

Tiene excelente resistencia a los productos químicos y

prácticamente no es afectado por la creosota y otros

productos químicos que se usan en el tratamiento de postes.

Además, sus propiedades y características de desgaste

permanecen esencialmente inalteradas a temperaturas de

hasta 121°C (250°F).

A continuación se muestra el material Klein-Kord de seis

capas de Klein, que tiene 44 mm (1-3/4 pulgada) de ancho.

Las capas centrales de Klein-Kord son rojas en el núcleo.

Cuando aparezcan las capas rojas, retire inmediatamente de

servicio la correa y reemplácela. Esta característica de “aviso

anticipado” es otra medida de seguridad proporcionada por

Klein Tools.

Nota: Las capas centrales rojas pueden descolorarse con

el uso. Por lo tanto, la inspección visual para comprobar

si existe desgaste es obligatoria antes de cada uso. Es

decir, vea y asegurese personalmente que no haya capas

desgastadas.

®

Hebillas y correas de cinturón

Los cinturones Klein para reparador de líneas tienen hebillas

de un solo clavillo forjadas en caliente. Las correas de

cinturón están hechas de Klein-Kord. En los cinturones de

calidad superior, las correas están cubiertas con cuero para

arneses.

ADVERTENCIA: Klein recomienda enfáticamente la

utilización de protección de detención de caídas cuando

se trabaje en cualquier posición elevada. Por lo tanto,

debe utilizarse equipo independiente de detención

de caídas además de los cinturones de cuerpo y las

correas de posicionamiento Klein, a menos que una

persona competente, según la definición de OSHA, haya

determinado que dicho equipo de detención de caídas no

es necesario o apropiado.

ADVERTENCIA: Los cinturones de cuerpo y las correas

de posicionamiento para reparador de líneas Klein están

diseñados para propósitos de posicionamiento solamente

y no deben utilizarse para ninguna otra función de equipo

de proteccion laboral (como por ejemplo detención de

caídas, suspensión o recuperación).

ADVERTENCIA: Klein recomienda enfáticamente que

sólo se utilicen componentes Klein con todo equipo para

reparador de líneas Klein. Los componentes Klein NO

deben intercambiarse con otros componentes fabricados

por otros fabricantes, ya que Klein no puede garantizar

que los componentes fabricados por otros fabricantes

estén diseñados apropiadamente ni que estén libres de

defectos de materiales o de fabricación.

Klein-Kord de seis capas con capas centrales rojas

Acero forjado en caliente

Los anillos en D y las hebillas con clavillo Klein están hechos

de acero forjado en caliente con un acabado resistente a la

corrosión. Todos los herrajes Klein se someten a pruebas

para asegurarse de que cumplan o superen las normas

OSHA pertinentes.

Malla de nylon

Klein utiliza nylon de grado comercial de alta calidad. La

malla de nylon está impregnada con látex o resina para dar

más durabilidad y resistencia a la abrasión.

Cuero

Se utiliza cuero de borde laminado curtido al cromo para

acojinar en todos los cinturones para reparador de líneas

Klein. Estos cojines tienen núcleos de goma esponjosa para

brindar comodidad adicional. Otros componentes de cuero,

como por ejemplo los bucles para herramientas, están

hechos de cuero para arneses. Las almohadillas de cuerpo

están hechas de cuero de látigo, unidas a mano y cosidas al

cojín de la correa.

14

Page 15

Propiedades físicas de los materiales*

Tipo de material

Nylon

Klein-Kord

®

Exposición a calor

excesivo

Mala resistencia.

Se vuelve quebradizo,

tiene un aspecto

marrón arrugado.

Las fibras se rompen

cuando se doblan.

Se debilita a 149°C

(300°F).

Parecido al nylon; sin

embargo, el neopreno

protegerá la tela de

nylon durante un

período de tiempo.

Exposición a

productos químicos

Generalmente,

buena resistencia,

excepto en presencia

de ácidos fuertes y

compuestos fenólicos

(el fenol está presente

en la brea de carbón

y la brea de madera),

los cuales hacen que

se vuelva quebradizo.

Excelente resistencia

a los hidrocarburos

que se usan en el

tratamiento de la

madera; debido al

neopreno.

Exposición a metal

fundido o llamas

Mala resistencia. Las

hebras se funden

entre sí y forman

puntos brillantes

duros. Tiene una

sensación al tacto

dura y quebradiza. No

resiste la combustión.

Similar al nylon; sin

embargo, el neopreno

ayuda a proteger la

tela de nylon contra

las salpicaduras de

soldadura.

Exposición a

pinturas o solventes

Generalmente, ofrece

buena resistencia. Sin

embargo, la pintura

puede penetrar en el

ligamento y secarse.

Esto puede hacer que

la malla se vuelva

dura y quebradiza,

y en última instancia

puede romper las

fibras. Algunos

solventes pueden

afectar las fibras

(consultar “Exposición

a productos

químicos”).

Resistencia excelente;

sin embargo, algunos

solventes fuertes

podrían ablandar el

neopreno y atacar el

nylon.

Cuero Mala resistencia.

El calor excesivo

destruye la resistencia.

Se quema a 165°C

(330°F). Seque el

cuero lentamente a

temperatura ambiente.

* En este cuadro se muestran las cualidades físicas generales

de los materiales utilizados en los cinturones de cuerpo y las

correas Klein para reparador de líneas. Debido a la amplia

variedad de condiciones que pueden existir en el lugar de

trabajo, esta información debe considerarse solamente

como una guía general, y una persona calificada debe

evaluar las aplicaciones y peligros específicos a los que los

materiales estarán expuestos.

Generalmente, mala

resistencia. Los

productos químicos

tienden a secar el

cuero.

Se quema; sin

embargo, el cuero

curtido al cromo

es una protección

excelente contra

las salpicaduras de

soldadura.

Si necesita más información, llame a Klein Tools al

1-800-553-4676.

Generalmente, mala

resistencia. Los

productos químicos

tienden a secar el

cuero.

15

Page 16

Cómo seleccionar un cinturón de cuerpo para reparador de líneas

Longitud máxima

Agujero central

Longitud mínima

Hueso de la cadera a hueso de la cadera + 2 pulg.

Tamaño de D a D:

1. Conozca el trabajo y las normas que rigen los

requisitos de rendimiento del equipo necesitado.

2. Seleccione el estilo de cinturón. Los cinturones de

cuerpo Klein para reparador de líneas están disponibles en

varios estilos fijos, semiflotantes y completamente flotantes,

con diversas características de cinturón, como tamaño de

la almohadilla. Todos los cinturones de cuerpo Klein para

reparador de líneas tienen cojines de cuero curtido al cromo

para brindar mayor confort. Los cinturones completamente

flotantes permiten el movimiento lateral de los anillos en

D durante el uso. Los cinturones semiflotantes permiten

solamente el movimiento lateral antes de ponérselos. Los

cinturones de estilo fijo son livianos y los más económicos.

3. Seleccione el tamaño de cinturón adecuado. La

comodidad de un cinturón para reparador de líneas depende

de su construcción y de la ubicación de sus anillos en D.

Los anillos en D deben estar ubicados aproximadamente a

1 pulgada (25 mm) delante de los huesos de la cadera.

Nunca pida cinturones de cuerpo Klein para reparador

de líneas por el tamaño de la cintura. Los cinturones

de cuerpo Klein para reparador de líneas deben pedirse

siempre por la distancia deseada entre los anillos en D.

Figura 1

aparece en esta página) contiene más información sobre la

selección del tamaño de cinturón apropiado. Para tamaños

que no sean estándar, tenga la amabilidad de llamar al

Departamento de Ventas de Klein Tools al 1-800-553-4676.

Mida el tamaño de su cinturón de

cuerpo utilizando una cinta para

medir (Figura 1). Para obtener el

tamaño correcto de D a D (anillo

en D a anillo en D), mida de hueso

de la cadera a hueso de la cadera

y añada 2 pulgadas (51 mm).

La tabla de tamaños de cinturón

para reparador de líneas (que

Tabla de tamaños de cinturón para reparador de líneas

*

Distancia de 18D 19D 20D 21D 22D 23D 24D 25D 26D 27D 28D 29D 30D

D a D** (46) (48) (51) (53) (56) (58) (61) (64) (66) (69) (71) (74) (76)

Longitud mínima 32 33 34 36 37 38 40 41 42 44 45 46 47

(81) (84) (86) (91) (94) (97) (102) (104) (107) (112) (114) (117) (119)

Distancia al 36 37 38 40 41 42 44 45 46 48 49 50 51

agujero central (91) (94) (97) (102) (104) (107) (112) (114) (117) (122) (124) (127) (130)

Longitud máxima 40 41 42 44 45 46 48 49 50 52 53 54 55

(102) (104) (107) (112) (114) (117) (122) (124) (127) (132) (135) (137) (140)

* Todas las medidas están en pulgadas y los centímetros están entre paréntesis. Esta tabla muestra las longitudes máximas

y mínimas y la distancia al agujero central para la gama completa de medidas estándar de D a D. Un cinturón con la medida

para el tamaño de D a D apropiado quedará ajustado correctamente con el clavillo de la hebilla acoplado en el agujero central.

** Los siguientes tamaños de D a D pueden ordenarse a pedido especial: 19" (48 cm), 25" (64 cm), 27" (69 cm), y

29" (74 cm).

16

Page 17

Cómo utilizar un cinturón de cuerpo para reparador de líneas

1. Estos cinturones están diseñados para ser utilizados

solamente por personas que hayan recibido entrenamiento

apropiado y que estén calificadas para utilizar este equipo

de posicionamiento.

2. Lea todas las etiquetas de advertencia y materiales

instructivos que se proporcionan con el cinturón Klein

para reparador de líneas y el equipo de protección laboral

relacionado. Proporcionan información importante sobre el

uso y cuidado. Deje puestas todas las etiquetas que estén

colocadas y guarde todos los materiales instructivos para

referencia futura.

3. Abroche firmemente con la hebilla el cinturón alrededor

de la cintura. Asegúrese de que la hebilla esté completamente cerrada y de que la lengüeta del cinturón esté en su

fijador. Un cinturón para reparador de líneas debe quedar

perfectamente ajustado alrededor de la cintura. Si no puede

lograr un ajuste perfecto, reemplace el cinturón con uno que

quede ajustado apropiadamente.

4. Cuando utilice un cinturón para reparador de líneas, los

anillos en D de posicionamiento deben estar separados por

igual en los dos lados del cuerpo del reparador de líneas.

5. Acople un extremo de la correa de posicionamiento (u

otro dispositivo de conexión de posicionamiento) en uno de

los anillos en D de posicionamiento.

6. Pase la correa de posicionamiento alrededor del poste

(el anclaje de posicionamiento) y luego acople el otro

extremo de la correa al otro anillo en D de posicionamiento.

7. Asegúrese mediante inspección visual de que los dos

ganchos de presión se acoplen libremente en los anillos

en D de posicionamiento y de que ambos fijadores estén

cerrados completamente.

8. Cuando esté conectada apropiadamente, la correa de

posicionamiento no estará retorcida y ambos ganchos de

presión estarán orientados hacia afuera.

9. No conecte ninguna herramienta, alambre u otros

ganchos de presión a los anillos en D de posicionamiento.

Nota: Vea las páginas 18 y 19 para obtener información

completa sobre cómo utilizar una correa de posicionamiento Klein.

17

Page 18

Cómo seleccionar una correa de posicionamiento para reparador de líneas

Dependiendo de la aplicación deseada, seleccione una

correa de posicionamiento que le permita trabajar a una

distancia del poste en el que vaya a trabajar que sea igual a

la longitud del brazo.

No. de cat.

Serie Klein-Lok

KL5295L

KL5295-6L

KL5295-6-6L

KL5295-7L

KL5295-8L

extremo doble de

la correa de posicionamiento

fijador de cuero

No. de cat.

®

Serie Klein-Gard™

KG5295L

KG5295-6L

KG5295-6-6L

KG5295-7L

KG5295-8L

Longitud

máxima

5'8" (1.7 m)

6' (1.8 m)

6' 6" (2.0 m)

7' (2.1 m)

8' (2.4 m)

Las correas posicionadoras de instalador de líneas están

disponibles en cinco tamaños y con dos estilos de ganchos

de presión: 1.73, 1.83, 1.98, 2.13 y 2.44 metros (5-2/3, 6,

6-1/2, 7 y 8 pies). Para obtener más información, consulte el

siguiente cuadro.

Longitud

mínima

3'10" (1.17 m)

4' (1.2 m)

4'3" (1.3 m)

4'6" (1.35 m)

5'6" (1.7 m)

hebilla ajustable

extremo sencillo de la correa de posicionamiento

Intervalo

ajustable

1'10" (0.5 m)

2' (0.6 m)

2'3" (0.7 m)

2'6" (0.8 m)

2'6" (0.8 m)

clip metálico

Cómo utilizar una correa de posicionamiento para reparador de líneas

Nota: Las siguientes instrucciones tienen aplicación a

personas diestras.

1. Estas correas de posicionamiento están diseñadas para

ser utilizadas solamente por personas que hayan recibido

capacitación apropiada y que estén calificadas para utilizar

este equipo de posicionamiento.

2. Antes de subir a un poste, asegúrese de que los dos

ganchos de presión de fijación del cinturón de posicionamiento estén acoplados al anillo en D izquierdo del cinturón

de cuerpo.

Nota: El gancho de presión más cercano al cuerpo debe

ser el gancho de presión que está en el extremo doble de la

correa de posicionamiento. Ese gancho de presión debe estar

acoplado de manera que el fijador esté orientado hacia afuera.

El gancho de presión exterior será el gancho de presión que

está en el extremo sencillo de la correa de posicionamiento.

Ese gancho de presión debe estar acoplado de manera que el

fijador esté orientado hacia adentro (vea la Figura 2).

Nota: Para acoplar o soltar el gancho de presión de fijación,

oprima el fijador y el cierre simultáneamente. Esto puede

hacerse fácilmente con una mano libre (vea la Figura 3).

Figura 2

Extremo sencillo

de la correa de

posicionamiento,

con el fijador

orientado hacia

adentro

Figura 3

Serie KL

cierre

Serie KG

Extremo doble

de la correa de

posicionamiento,

con el fijador

orientado hacia

afuera

fijador

fijador

18

cierre

Page 19

Cómo utilizar una correa de posicionamiento para reparador de líneas (cont.)

3. Cuando llegue a la posición de tra¸bajo, plante firmemente

los dos garfios en el poste y agárres¸e del poste con las dos

manos.

4. Desacople el gancho de presión exterior, cuyo fijador está

orientado hacia adentro (es decir, el gancho de presión que

está en el extremo sencillo de la correa de posicionamiento)

con la mano izquierda, mientras agarra el poste con la mano

derecha.

5. Pase el extremo sencillo de la correa alrededor de la

parte de atrás del poste hasta la mano derecha, mientras

mantiene un agarre firme del poste.

6. Lleve la correa de posicionamiento hasta el anillo en D

derecho con la mano derecha y sujete el gancho de presión

de manera que el fijador esté orientado hacia afuera.

7. Asegúrese de que la correa de posicionamiento esté

plana y sin torceduras contra el poste, y de que el clavillo de la

hebilla esté girado hacia afuera.

8. Antes de poner todo su peso en la correa de posiciona-

miento, asegúrese visualmente de que cada gancho de

presión de fijación se acople libremente en el anillo en D y

de que los fijadores estén completamente cerrados. Nunca

confíe únicamente en la sensación o el sonido de un

gancho de presión al acoplarse.

9. Remoción de la correa de sujeción (antes de bajar

del poste). Agarre el poste con la mano izquierda y reduzca

la tensión de la correa de posicionamiento moviendo el cuerpo

ligeramente hacia el poste.

10. Con la mano derecha, suelte el gancho de presión que

está en el extremo sencillo de la correa de posicionamiento

del anillo en D derecho.

11. Pase el extremo sencillo de la correa de posicionamiento

alrededor de la parte de atrás del poste con la mano derecha

hasta que la correa pueda agarrarse con la mano izquierda.

12. Ahora, agarrando el poste con la mano derecha, sujete

el gancho de presión que está en el extremo sencillo de la

correa de posicionamiento al anillo en D izquierdo con el fijador

orientado hacia adentro (encima del gancho de presión que ya

está acoplado).

13. Cuando la correa de posicionamiento no se esté utilizando

para obtener soporte, los dos extremos deben sujetarse al

anillo en D izquierdo (vea la Figura 2 en la página 18).

19

Page 20

Procedimiento de mantenimiento

El jefe de seguridad de la compañía u otra persona

competente debe mantener un registro escrito de todas las

fechas de servicio e inspección de este equipo.

1. Limpie y mantenga los equipos de acuerdo con la

práctica recomendada. Lávelos con agua templada y un

detergente suave. Evite los agentes químicos fuertes, como

por ejemplo compuestos desengrasadores, aguarrás, diluyente de pintura, gasolina y otros solventes.

Procedimientos de inspección general

1. Compruebe si hay desgaste y deterioro. Antes de cada

uso, inspeccione cuidadosamente su equipo de protección

laboral para ver si muestra indicios de desgaste o deterioro,

o evidencia de carga por impactos. Inspeccione visualmente

si hay roscas flojas, remaches arrancados, quemaduras,

cortes, abrasiones o evidencia de deterioro físico o químico

que puedan haber debilitado el material o el ensamblaje.

2. Inspeccione los herrajes para comprobar si

funcionan correctamente y si tienen grietas, incluyendo

las hebillas del cinturón, los anillos en D y los ganchos de

presión de la correa de posicionamiento. Compruebe que los

ganchos de presión no estén distorsionados ni agrietados,

y de que los fijadores no tengan quemaduras, funcionen

apropiadamente, estén limpios y no estén doblados.

2. Inspeccione y lubrique todos los ganchos de presión

después de realizar limpieza para asegurarse de que

funcionan apropiadamente y se cierran firmemente. Utilice

un lubricante de rociada de uso general o aceite ligero para

motores.

3. Mantenga las partes de cuero con aceite para

acondicionar el cuero (Neat’s-foot oil), jabón para silla de

montar o equivalente para ayudar a prolongar la duración. Deje

que el cuero se seque lentamente a temperatura ambiente.

ADVERTENCIA: Si se observa alguna situación irregular

durante la inspección, que no esté especificada en este

manual, no utilice el equipo sospechoso hasta que una

persona calificada haya tomado una decisión respecto a

su grado de utilización.

Estilo KL mostrado

3. Destruya y reemplace todos los equipos desgastados

o dañados. Destruya y reemplace inmediatamente todo

componente del sistema del equipo de protección laboral

(EPL) que no pase la inspección.

20

Page 21

Inspección de cinturones y correas

1. Correas, costuras y malla. Verifique la correa en

toda su longitud para ver si está desgastada. Inspeccione

cuidadosamente el extremo donde se acopla el clavillo

de la hebilla o sujeción. Este extremo está sometido a

un desgaste considerable como resultado de abrochar y

desabrochar repetidamente el cinturón. Además, compruebe

si los agujeros para el clavillo de la hebilla están desgarrados o excesivamente agrandados. Compruebe si las

costuras están rotas, cortadas o levantadas. Compruebe si

la malla tiene hebras rotas que aparecen como mechones

en la superficie.

2. Anillos en D. Verifique todos los anillos en D para saber

si tienen distorsión. Verifique los puntos de sujeción de los

anillos en D para saber si hay fibras desgastadas o dañadas

de forma irregular. Los anillos en D con picaduras fuertes

podrían indicar corrosión química y, en ese caso, el equipo

debe reemplazarse inmediatamente.

4. Costuras o remaches en el punto de sujeción de

los herrajes. Para los puntos de sujeción de las costuras,

compruebe si la costura no está rota, quemada, cortada o

levantada. Para los puntos de sujeción de los remaches,

compruebe si todos los remaches están apretados,

especialmente los que están en las almohadillas de desgaste

de los anillos en D. Los remaches con picaduras fuertes

indican corrosión química y, en ese caso, el equipo debe

reemplazarse inmediatamente.

5. Destruya y reemplace todos los equipos de protección

laboral desgastados o dañados. Si se observa evidencia

de desgaste excesivo, deterioro o funcionamiento mecánico

defectuoso, reemplace el equipo inmediatamente. Nunca

trabaje con equipo de protección laboral desgastado o

dañado. La utilización de equipo desgastado o dañado

puede causar lesiones graves o la muerte.

6. El inspector es el elemento más importante de todo

procedimiento de inspección. Verifique minuciosamente

todo el equipo y siga todos los procedimientos y normas de

seguridad. No omita nada.

3. Hebillas con clavillo. Verifique si las hebillas con

clavillo están distorsionadas, tienen bordes afilados o están

agrietadas. El clavillo debe moverse libremente y superponerse a la montura de la hebilla. Los rodillos no deben

estar distorsionados y deben rodar libremente.

Nota importante: OSHA especifica que todos los

empleadores afectados por la Ley de Seguridad y Salud

Laboral de los EE.UU. son responsables de la inspección

y el mantenimiento de todas las herramientas y equipos

utilizados por sus empleados — tanto si pertenecen a los

empleados como si pertenecen a la compañía. El equipo de

protección personal debe inspeccionarse antes de cada uso

y retirarse de servicio inmediatamente si se encuentra algún

indicio de desgaste o daño.

ADVERTENCIA: Si se observa alguna situación irregular

durante la inspección, que no esté especificada en este

manual, no utilice el equipo sospechoso hasta que una

persona calificada haya tomado una decisión respecto a

su grado de utilización.

21

Page 22

Para uso de posicionamiento solamente

■ Use este producto para posicionamiento solamente, NO para

detener caídas.

■ Si es posible, el uso de equipo de detención de caídas se

recomienda enfáticamente además de este cinturón.

■ Asuma la responsabilidad de determinar si el cinturón está en

buenas condiciones en todo momento.

■ NO utilice dispositivos de conexión hechos de cuero o

cuerda de cáñamo.

■ Nunca utilice los anillos en D laterales para detener caídas.

■ Los anclajes de posicionamiento deben soportar su peso

más toda carga adicional relacionada con el trabajo.

■ Nunca deje que el cinturón entre en contacto con

herramientas con bordes afilados o puntiagudas, ni que se

acerque a un radiador, tubería de vapor, estufa, calentador, tubo

de escape de motor u otra fuente de calor.

S-C1b1.

007

Lea el

otro

lado

Lea la

próxima

etiqueta

ADVERTENCIAS

ADVERTENCIAS

■ Para uso sólo por profesionales con capacitación

apropiada.

■ Use sólo ganchos de presión de fijación.

■ El equipo de protección laboral debe utilizarse

solamente para el propósito específico para el que está

diseñado y destinado.

■ El equipo de protección laboral debe destruirse si se

somete a carga por impactos.

■ Verifique siempre visualmente si todas las hebillas están

cerradas apropiadamente antes de cada uso.

■ Nunca deje que una correa de posicionamiento se

retuerza antes de acoplarse al anillo en D.

■ Asegúrese siempre visualmente de que: 1) cada gancho de

presión se acople libremente al anillo en D o al punto de anclaje,

2) el fijador esté completamente cerrado con cada uso. Nunca

confíe solamente en la sensación o el sonido de un gancho de

presión al acoplarse.

■ Antes de cada uso, asegúrese de que: 1)la tela o la correa del

cinturón no tenga quemaduras, cortes, costuras rotas ni desgaste

excesivo, 2) los remaches no estén doblados o sueltos, ni falten, 3) las

hebillas y los anillos en D no estén distorsionados ni agrietados, 4) si

alguna hebilla tiene clavillo, el clavillo no se atasque ni enganche en la

hebilla y los agujeros de hebilla no estén dañados. 5)Retire de

servicio, destruya y tire el cinturón o el arnés si no pasa la

inspección y reemplácelo inmediatamente.

S-B1-2 1

007

Lea el

otro

lado

Lea la

próxima

etiqueta

INSTRUCCIONES

INSTRUCCIONES

■ Para uso personal solamente. No es para remolcar

ni elevar.

■ Los ganchos de presión acoplados a los anillos en D

deben tener menos de 3/4" (19 mm) de abertura de

garganta. Nunca acople ganchos de escaleras o de barras

de refuerzo en los anillos en D.

■ Nunca acople varios ganchos de presión a un anillo

en D.

■ Nunca perfore agujeros adicionales en ningún cinturón

o arnés ni realice ninguna alteración.

■ Nunca trabaje sin protección independiente de detención de

caídas si existe peligro de caída.

■ NO es para uso recreativo ni deportivo.

■ Empleador: instruya al empleado en el uso apropiado

y las advertencias antes de utilizar el equipo.

■ Lea, entienda y siga antes de cada uso todas las

instrucciones y precauciones colocadas en este equipo

y en todos los equipos de protección laboral o

empaquetadas con ellos.

■ Klein recomienda enfáticamente que los componentes

Klein NO se intercambien con otros componentes hechos

por otros fabricantes, ya que Klein no puede garantizar

que los componentes de otros fabricantes estén libres de

defectos de materiales o de fabricación.

S-B1-2 2.

007

Lea el

otro

lado

Lea la

próxima

etiqueta

INSTRUCCIONES

INSTRUCCIONES

Etiquetas de advertencia del equipo para reparador de líneas

Klein coloca permanentemente etiquetas de advertencia e

instrucciones muy duraderas en sus cinturones de cuerpo y

correas de posicionamiento para reparador de líneas.

Si alguna de estas etiquetas se desprende, pierde o daña,

póngase en contacto con Klein Tools, llamando gratuitamente

al 1-800-553-4676, para obtener información sobre cómo

hacer que se reemplacen las etiquetas sin tener que pagar

ningún cargo.

Etiquetas para los cinturones de cuerpo para

reparador de líneas

ADVERTENCIA: Klein recomienda enfáticamente la

utilización de protección de detención de caídas cuando

se trabaje en cualquier posición elevada. Por lo tanto,

debe utilizarse equipo independiente de detención de

caídas además de los cinturones de cuerpo y las correas

de posicionamiento Klein, a menos que una persona

competente, según la definición de OSHA, haya determinado que dicho equipo de detención de caídas no es

necesario ni apropiado.

22

Page 23

Etiquetas de advertencia del equipo para reparador de líneas (cont.)

Para uso de posicionamiento solamente

■ Acople siempre los ganchos de presión a los anillos en D

de posicionamiento en ambos lados del cinturón o del arnés con

los fijadores orientados hacia afuera.

■ Cuando se esté usando, nunca acople más de un gancho de

presión a un anillo en D.

■ Nunca deje que una correa de posicionamiento se retuerza

antes de acoplarse al anillo en D.

■ Nunca acople juntas varias correas de posicionamiento.

■ Nunca acople una correa de posicionamiento de vuelta en

ella misma.

■ Asuma la responsabilidad de determinar si la correa de

posicionamiento está en buenas condiciones en todo

momento.

■ Nunca deje que la correa de posicionamiento entre en

contacto con herramientas con bordes afilados o puntiagudas,

o soldadura, ni que esté cerca de un radiador, tubería de

vapor, estufa, calentador, tubo de escape de motor u otra

fuente de calor.

■ Nunca use una correa de posicionamiento que se haya

desgastado hasta el punto de mostrar las capas interiores de

color rojo.

S-C 6b1

007

Lea el

otro

lado

Lea la

próxima

etiqueta

ADVERTENCIAS

ADVERTENCIAS

■ Sólo para soporte de seres humanos, NO es para

remolcar o elevar material.

■ Nunca desactive el fijador de sujeción en el gancho,

perfore agujeros en una correa de posicionamiento ni la altere

de ninguna manera.

■ Utilice la correa solamente con un cinturón o arnés de

posicionamiento con anillos en D que cumplan con las

normas gubernamentales para el uso previsto.

■ Klein recomienda enfáticamente que los componentes Klein

NO se intercambien con otros componentes hechos por otros

fabricantes, ya que Klein no puede garantizar que los

componentes de otros

fabricantes estén libres de defectos de

materiales o de fabricación.

■ Antes de cada uso, asegúrese de que: 1) la unidad no tenga

quemaduras, cortes, abrasiones, enredos, nudos, hebras rotas ni

desgaste excesivo, 2) los ganchos, la hebilla (y los anillos en D, si

los hay) no estén distorsionados ni agrietados, 3) los fijadores de

los ganchos no tengan quemaduras, funcionen apropiadamente,

estén limpios y no estén doblados, 4) la correa de posicionamiento

no se haya desgastado hasta el punto de mostrar las capas

interiores de color rojo, 5) Retire de servicio, destruya y tire la

unidad si no pasa esta inspección y reemplácela

inmediatamente.

S-C6b2

007

Lea el

otro

lado

Lea la

próxima

etiqueta

ADVERTENCIAS

ADVERTENCIAS

■ Para uso sólo por profesionales con capacitación

apropiada.

■ El equipo de protección laboral debe utilizarse

solamente para el propósito específico para el que se

diseñó y destinó.

■ Los dispositivos de conexión deben destruirse si

están sometidos a carga por impactos.

■ Asegúrese siempre visualmente de que: 1) cada

gancho de presión se acople libremente al anillo en D o al

anclaje, 2) el fijador esté completamente cerrado con cada uso.

Nuncaconfíe únicamente en la sensación o el sonido de un

gancho de presión al acoplarse.

■ Asegúrese de que cada gancho esté posicionado de manera

que su fijador nunca esté soportando cargas.

■ Nunca junte dos ganchos de presión. NO están diseñados

para utilizarse de esa manera y podrían retorcerse y separarse.

■ Nunca trabaje sin protección independiente de detención

de caídas si existe peligro de caída.

■ Empleador: instruya al empleado en el uso apropiado y

las advertencias antes de utilizar el equipo.

■ Lea, entienda y siga antes de cada uso todas las

instrucciones y precauciones colocadas en este equipo y en

todos los equipos de protección laboral o empaquetadas

con ellos.

S-C6b3.

007

Lea el

otro

lado

Lea la

próxima

etiqueta

ADVERTENCIAS

ADVERTENCIAS

Klein coloca permanentemente etiquetas de advertencia e

instrucciones muy duraderas en sus cinturones de cuerpo y

correas de posicionamiento para reparador de líneas.

Si alguna de estas etiquetas se desprende, pierde o daña,

póngase en contacto con Klein Tools, llamando gratuitamente

al 1-800-553-4676, para obtener información sobre cómo

hacer que se reemplacen las etiquetas sin tener que pagar

ningún cargo.

Etiquetas para correas de posicionamiento para

reparador de líneas

ADVERTENCIA: Klein recomienda enfáticamente la

utilización de protección de detención de caídas cuando

se trabaje en cualquier posición elevada. Por lo tanto,

debe utilizarse equipo independiente de detención de

caídas además de los cinturones de cuerpo y las correas

de posicionamiento Klein, a menos que una persona

competente, según la definición de OSHA, haya determinado que dicho equipo de detención de caídas no es

necesario ni apropiado.

23

Page 24

Notes / Notas

24

Page 25

Pour technicians professionnels … depuis que 1857

Instructions pour l'emploi et l'entretien corrects

des ceintures de travail et des courroies de

positionnement Klein® pour les poseurs de lignes

Introduction

Ce mode d'emploi explique comment utiliser, inspecter et

entretenir les ceintures de travail et les courroies de positionnement Klein pour les poseurs de lignes.

Klein fabrique une gamme complète de ceintures de travail et

de courroies de positionnement pour poseurs de lignes conçues

pour satisfaire aux critères de l'OSHA pour les applications

de positionnement.

Remarque : les ceintures de travail Klein pour poseurs

de ligne ne doivent être utilisées que pour les applica-

tions de positionnement et ne doivent pas être

employées seules pour servir de dispositif

anti-chute, conformément à la définition de la

sous-section M de la norme 1926 de l'OSHA

Figure 1

Le symbole de positionnement de la Figure 1 apparaît sur les

étiquettes d'avertissement qui sont apposées sur chaque ceinture

de travail. Ce symbole identifie la fonction d'équipement de protection individuelle professionnel (EPP) de la ceinture.

Les ceintures de travail Klein pour poseurs de lignes sont disponibles en styles complètement flottant, semi-flottant ou fixe.

Elles combinent les caractéristiques d'une courroie de positionnement EPP et celles d'une ceinture porte-outils spécialisée.

Elles respectent ou dépassent toutes les stipulations de l'OSHA

qui s'appliquent aux systèmes de dispositifs de positionnement

pour les entreprises de distribution d'électricité (OSHA 1926.959)

et de télécommunications (OSHA 1910.268 et 1910.269). Elles

respectent ou dépassent également les normes ASTM F 887,

ACNOR Z259.1 et ACNOR Z259.11. Chaque ceinture est

pourvue d'une étiquette permanente, qui identifie le numéro de

modèle, le numéro de série, la taille et la date de fabrication.

Les courroies de positionnement Klein sont disponibles dans les

longueurs suivantes : 5 pi 8 po (1,7 m), 6 pi 6 po (2,0 m), 7 pi

(2,1 m) et 8 pi (2,4 m). Elles sont conçues pour se conformer aux

normes OSHA 1910.268, 1910.269 et 1926.959.

Toutes les personnes qui utilisent des ceintures de travail et

des courroies de positionnement Klein pour poseurs de lignes

doivent recevoir une formation leur apprenant à utiliser ces

équipements de la façon correcte. Elles doivent également lire,

comprendre et appliquer avant chaque utilisation toutes les

instructions et tous les avertissements contenus dans ce livret ou

accompagnant le produit.

(États-Unis).

Remarque : pour des raisons de clarté, les illustrations

de ce livret d'instructions ne montrent pas les étiquettes

ou vignettes d'avertissement qui sont apposées sur

chaque produit.

Avertissement : conservez ces instructions. Ces équipements

ne doivent pas être utilisés par quiconque n'aurait pas lu, compris et

appliqué toutes les instructions et procédures d'inspection contenues

dans ce livret. Toute personne n'ayant pas lu, compris et appliqué

toutes les instructions court le risque d'être grièvement blessée ou

même tuée. Les instructions doivent être relues à intervalles réguliers

par l'utilisateur et son employeur, ce dernier devant aussi assurer la

répétition de la formation à intervalles réguliers.

AVERTISSEMENT

Une chute pourrait causer une

blessure grave ou même la mort.

N'utilisez pas ces équipements sans

avoir reçu la formation appropriée.

Lisez et suivez toutes les instructions et tous les avertissements.

25

Page 26

Matériaux utilisés pour fabriquer les ceintures de travail et

courroies de positionnement pour poseurs de lignes

Klein-Kord

Le matériau porteur dans les courroies de positionnement Klein

est un matériau exclusif de Klein, Klein-Kord, fait de nylon à filaments multi-plis d'une robustesse exceptionnelle qui est imprégné de néoprène, plié et vulcanisé.

Klein-Kord est un matériau non conducteur résistant à l'abrasion

qui ne s'étire pratiquement pas et est assez flexible pour assurer

une grande convivialité et durabilité. Sa résistance chimique est

excellente et il n'est pratiquement pas affecté par la créosote et

les autres produits chimiques utilisés pour traiter les poteaux.

De plus, ses propriétés et ses caractéristiques d'usure restent

essentiellement inchangées aux températures inférieures à

250 °F (121 °C).

On peut voir ci-dessous un exemple de matériau Klein-Kord à six

plis de Klein, qui a une largeur de 1 3/4 po (44 mm). Les plis centraux du matériau Klein-Kord sont de couleur rouge. Lorsque les

plis rouges sont visibles, cessez immédiatement d'utiliser la courroie et remplacez-la. Cette caractéristique d'« alerte précoce »

est une autre mesure de sécurité fournie par Klein Tools.

Remarque : les plis centraux de couleur rouge peuvent se

décolorer au bout d'un certain temps. Il est donc indispensable

d'effectuer une inspection visuelle de l'état d'usure des équipements avant chaque emploi.

®

Boucles et billettes

Les ceintures Klein pour poseurs de lignes ont des boucles

en acier matricé à ardillon unique. Les sangles et les billettes

des ceintures sont faites de matériau Klein-Kord. Sur les ceintures haut de gamme, les sangles sont recouvertes de cuir

à harnachement.

Avertissement : Klein recommande vivement l'emploi de dispositifs

anti-chute en cas de travail à hauteur élevée. Par conséquent, un dispositif anti-chute indépendant doit être utilisé en plus des ceintures de

travail et des courroies de positionnement Klein, sauf si une personne

compétente, conformément à la définition de l'OSHA, a déterminé

qu'un tel dispositif anti-chute n'est pas nécessaire ou est inapproprié.

Avertissement : les ceintures de travail et les courroies de positionnement Klein pour poseurs de lignes sont conçues exclusivement

dans un but de positionnement, et elles ne doivent pas être utilisées

dans un quelconque autre but d'EPP (par exemple, comme dispositif

de protection contre les chutes, ou à des fins de suspension ou

de récupération).

Avertissement : Klein recommande vivement de n'utiliser que des

composants Klein avec les équipements Klein pour poseurs de lignes.

Il ne faut PAS remplacer des composants Klein par des composants

fabriqués par d'autres sociétés parce que Klein ne pourrait alors pas

garantir que les composants fabriqués par d'autres sociétés sont conçus de façon appropriée pour ses équipements ou ne comportent pas

de défauts de matériau ou de fabrication.

Matériau Klein-Kord à six plis avec plis centraux rouges

Acier matricé

Les anneaux en D et les boucles à ardillon Klein sont fabriqués

en acier matricé avec une finition résistant à la corrosion. Tout le

matériel métallique Klein est testé pour respecter ou dépasser les

normes applicables de l'OSHA.

Sangles croisées en nylon

Klein utilise un nylon commercial de qualité élevée. Les sangles

croisées en nylon sont imprégnées de latex ou de résine pour

assurer une longévité et une résistance à l'abrasion supérieure.

Cuir

Du cuir tanné au chrome et à bords laminés est utilisé pour

rembourrer toutes les ceintures Klein pour poseurs de lignes. Ce

rembourrage a un centre en caoutchouc éponge pour plus de

confort. D'autres composants, tels que les boucles porte-outils,

sont fabriqués en cuir à harnachement. Les coussinets sont faits

de cuir latigo tressé à la main et cousu sur le rembourrage de

la ceinture.

26

Page 27

Propriétés physiques des matériaux*

Exposition à une

Type de matériau

Nylon Résistance

chaleur excessive

inadéquate. Devient

cassant et prend une

apparence brune et

racornie. Les fibres se

briseront si elles sont

fléchies. S'affaiblit à

300 °F (150 °C).

Exposition

aux produits

chimiques

Résistance

généralement

satisfaisante, sauf

au contact d'acides

forts et de composés

phénoliques (le

phénol est présent

dans le goudron de

houille et le goudron

de bois), qui le

rendent cassant.

Exposition aux

flammes ou aux

métaux en fusion

Résistance

inadéquate. Les brins

fondent et collent les

uns aux autres, et ils

forment des taches

dures et brillantes.

Donne l'impression

d'être dur et cassant.

Ne résistera pas à la

combustion.

Exposition à

la peinture ou

aux solvants

Offre généralement

une résistance

satisfaisante.

Cependant, de la

peinture risque

de pénétrer dans

l'armure et y sécher.

Ceci peut rendre les

sangles croisées

dures et cassantes,

ce qui peut briser

les fibres. Certains

solvants peuvent

affecter les fibres

(voir « Exposition aux

produits

chimiques »).

Klein-Kord

Cuir Résistance

®

Similaire au nylon ;

cependant, le

néoprène protégera le

tissu en nylon pendant

un certain temps.

inadéquate. Une

chaleur excessive

détruit sa robustesse.

Brûlera à 330 °C

(165 °C). Séchez le

cuir lentement à la