Page 1

Introduction

Instructions for the Proper Use and Care

of Klein

®

Harnesses

These instructions explain how to use, inspect

and maintain Klein Harnesses.

Klein manufactures a full line of occupational

Protective Equipment (OPE).Each product is a specific component of an OPE system for fall protection.

As required by OSHA, Klein harnesses are designed

to arrest free falls and to distribute impact forces

over thighs, pelvis, waist, chest and shoulders. In

addition to fall-arrest protection, many Klein FullBody Harnesses feature additional OPE applications (such as positioning, suspension and retrieval)

in selectable integrated units.

Workers who use Klein OPE Harnesses must be

instructed on how to use them correctly. They must

also read, understand and follow all instructions and

warnings contained in this booklet and any warnings

or instructions attached to and/or packed with this

product and all other tools, devices and equipment

before each use.

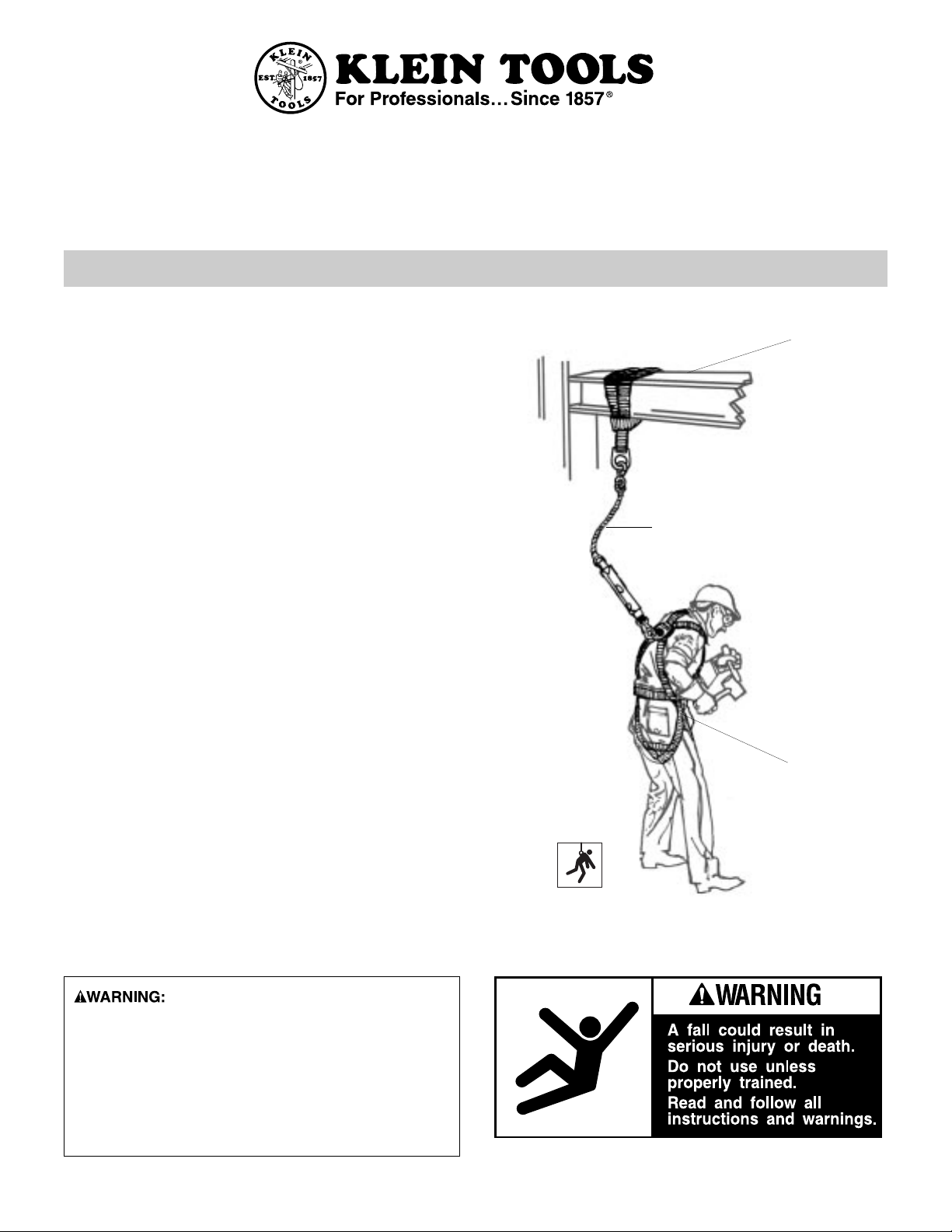

Remember the A-B-C Rule:

To be complete , an OPE system must include at

least one piece of equipment from each of the

A-B-C components (for an example,see Figure 1).

Some OPE systems may include more than one

piece of equipment in each component. Choosing

the proper equipment depends on the job-site and

the application. A competent person, as defined by

OSHA, must make these equipment decisions.

Figure 1

(A) Anchorage

(C) Connecting Device

(B) Body Wear

Klein harnesses must NOT be used

by anyone who has not read, understood and followed all the instructions and inspection procedures contained in this booklet. Failure to observe

these instructions and inspection procedures could

lead to serious injury or death. Training and

instruction review should be repeated at regular

intervals by the user and his or her employer.

Page 2

OPE Systems and The A-B-C Rule

An OPE system is more than just a combination of

equipment.To function properly, the system must be

custom designed for the specific application, environment and work-site requirements. Follow the

A-B-C Rule when assembling an OPE system. The

system must contain all of the following components:

(A) anchorage, (B)body wear , and (C)connecting device .

(A) Anchorage

OSHA defines anchorage as "a secure point of

attachment for lifelines, lanyards or deceleration

devices". Choosing the proper anchorage is determined by the type of fall protection needed (fall

arrest, or fall arrest combined with positioning, suspension and/or retrieval functions). The anchorage

must be identified and evaluated by a competent

person, as defined by OSHA, at the job-site before

the appropriate OPE equipment can be selected.

Typical anchorages could be an I-beam or other

structural members.

(B) Body Wear

The second component of an OPE system is body

wear (OPE harnesses and belts). To select the right

harness for the job-site requirements, a competent

person, as defined by OSHA, must determine the

type of fall protection needed (such as fall arrest, or

fall arrest combined with positioning, suspension

and/or retrieval capabilities).Whenever there is a risk

of a fall, fall-arrest protection must be used. OSHA

prohibits the use of a body belt for fall arrest.

(C) Connecting Device

The third component of an OPE system is the

connecting device. Examples include lanyards, rope

grabs and deceleration devices. As with anchorages

and body wear, choosing a proper connecting de vice

is dictated by other system components and job-site

requirements. Only use connecting devices

equipped with locking snap hooks. OSHA prohibits

the use of connecting devices without locking snap

hooks in any fall-protection system.

Introduction (continued)

How OPE Systems Are Used

Klein offers personal fall protection equipment in four

OPE system categories. Each system and its associated equipment is designed to help protect against

different kinds of risks. The risks which require the

use of OPE systems and the proper use of OPE

equipment must be fully understood. OPE equipment and systems must be used only for the specific

purpose for which they are designed and intended.

The following section introduces the basic kinds of

OPE systems: fall arrest or fall arrest combined with

positioning, suspension and/or retrieval functions.

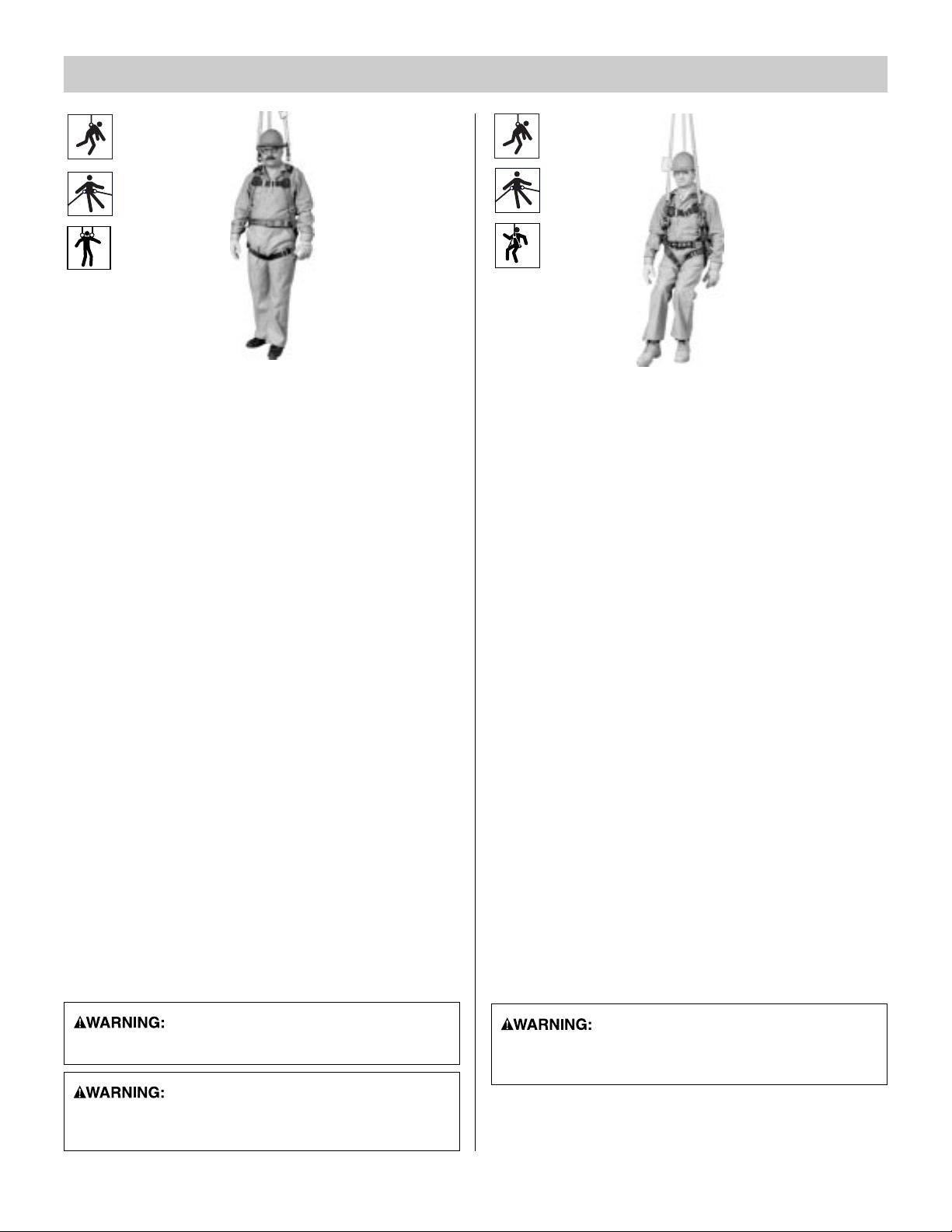

Personal Fall-Arrest System

A personal fall-arrest system is required if there

is any risk of a worker falling from an elevated position (generally, six feet or more). NOTE: Know the

specific OSHA regulations which pertain to your

industry.

OSHA defines a personal fall-arrest system as a

“system used to arrest an employee in a fall from a

working level.” It consists of (A) a fall-arrest anchorage capable of supporting at least 5,000 lbs. per

attached worker and independent of the worker’s

support; (B) a full-body harness designed to distribute the fall-arrest forces over thighs, pelvis, waist,

chest and shoulders and equipped with a circle

D-ring at the back for attaching a fall-arrest connect-

ing device, and (C) a fall-arrest connecting device

such as a lanyard, deceleration device, lifeline or a

combination of these devices equipped with locking

snap hooks.

A personal fall-arrest system is a passive protection

system which only comes into service when a fall

occurs, similar to a seat belt in a car which restrains

the wearer only upon impact.

For example, as shown in Figure 2, a fall-arrest system would be used by an ironworker bolting steel

beams together for a skyscraper. Following the

A-B-C Rule, this OPE system includes: (A) beam,

(B) full-body harness, and (C) lanyard.

Figure 2

(A) Beam

(B) Full Body Harness

(C) Rope Lanyard

2

Page 3

Personal Fall-Arrest System (continued)

The shaded area in Figure 3 shows the impact-force

distribution for a typical full-body fall-arrest harness.

OSHA requires that impact force in a fall NOT

exceed an 1,800 lbs.(8kN) limit with a harness. At a

given weight, the longer the free fall, the greater the

resulting impact force. To stay under the 1,800 lbs.

(8kN) limit, minimize slack in the fall-arrest connecting device or use a deceleration unit.

Remember, a personal fall-arrest system only

becomes active in a fall. If equipment is required to

help hold or place a worker in position, a separate

suspension or positioning system must be used in

addition to the fall-arrest system. A personal fallarrest system is designed only to aid a worker once

a fall occurs, and must be used whenever there is

danger of falling. When a worker may be in danger

of being killed or injured in a fall, equipment specifically designed for fall arrest must also be used.

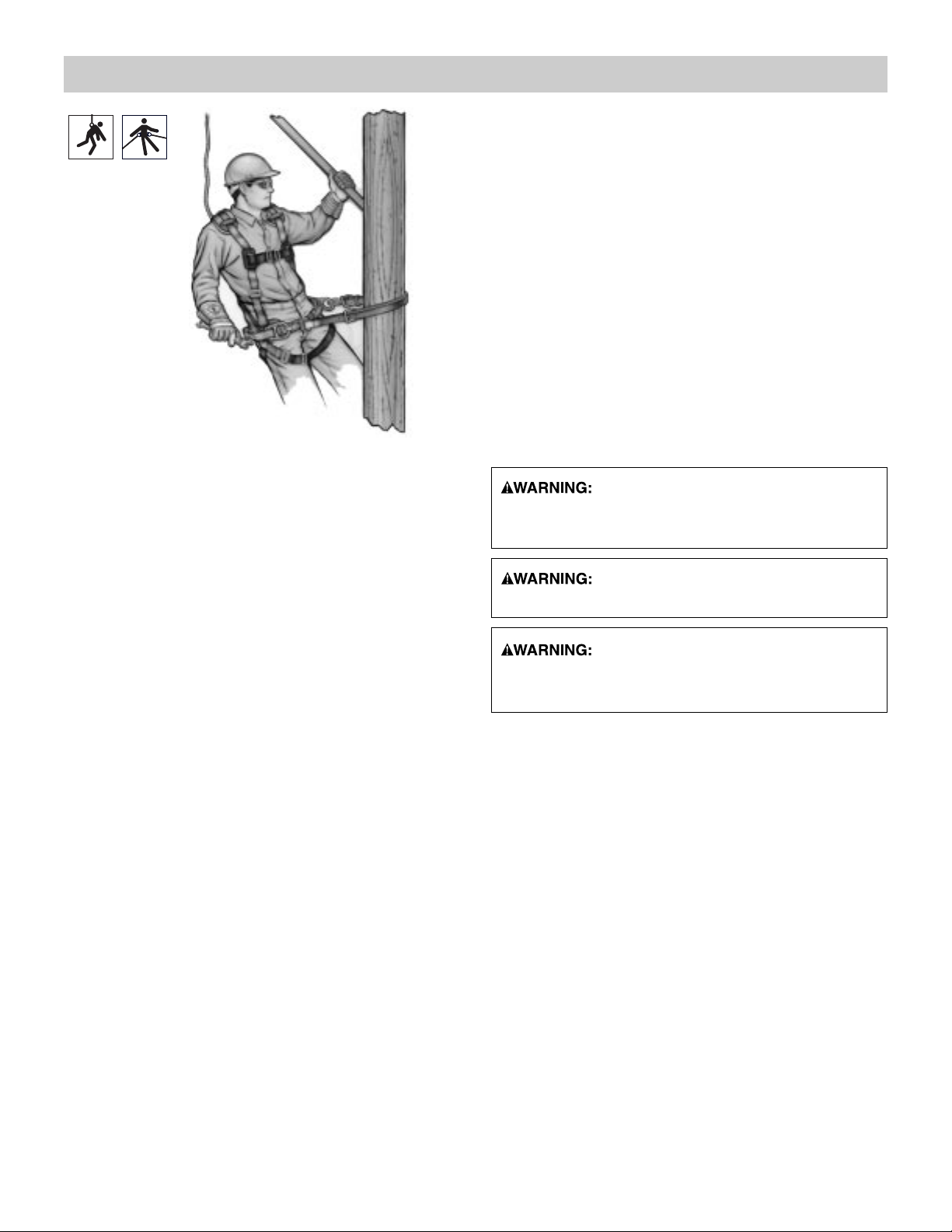

Personal Positioning System

A personal positioning system is required if a

worker must be held in place while his hands are

free to work. OSHA defines a positioning system as

“a body belt or harness system rigged to allow an

employee to be supported on an elevated vertical

surface, such as a wall, and work with both hands

free.” If there is risk of a worker falling from an elevated position, (generally, six feet or more), personal fall-arrest protection must also be used.

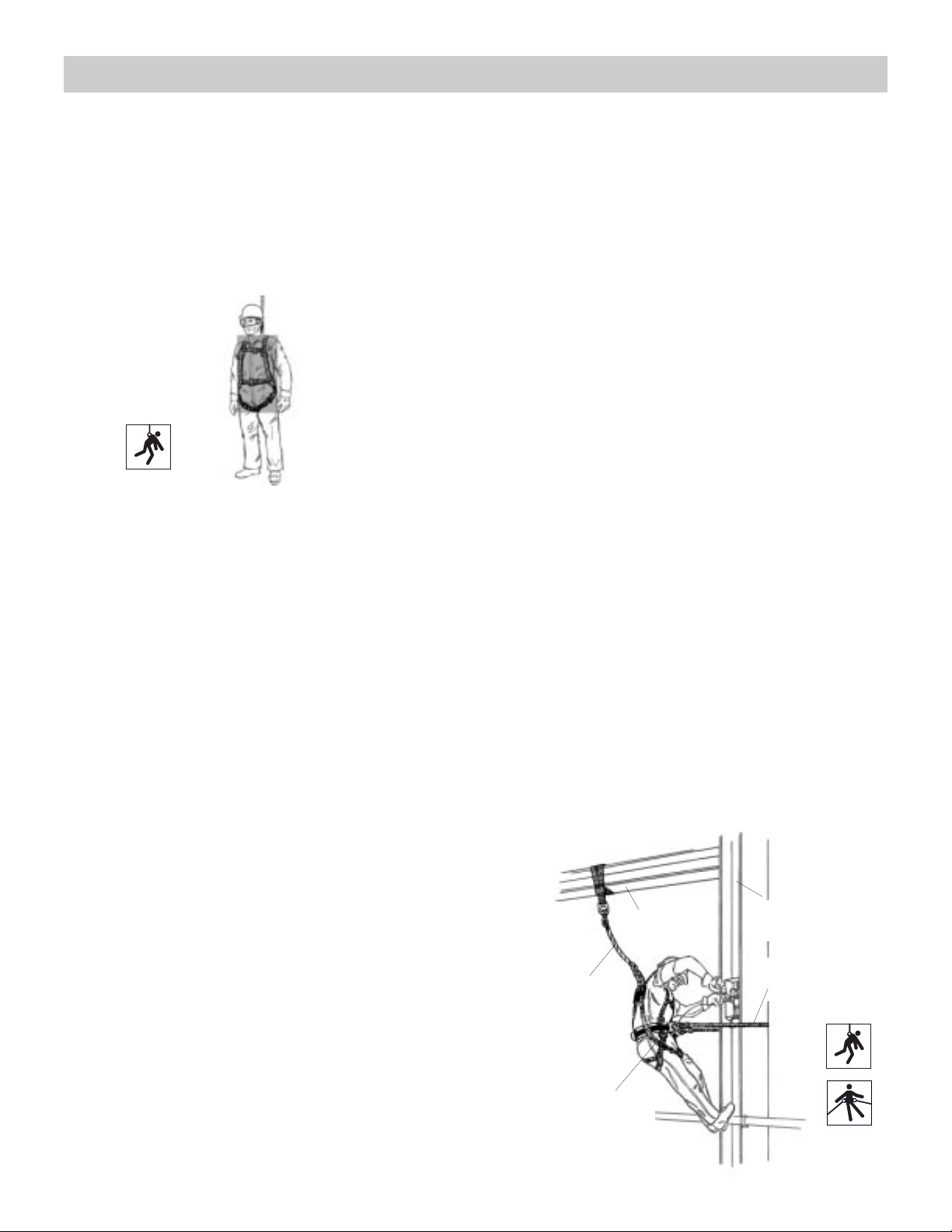

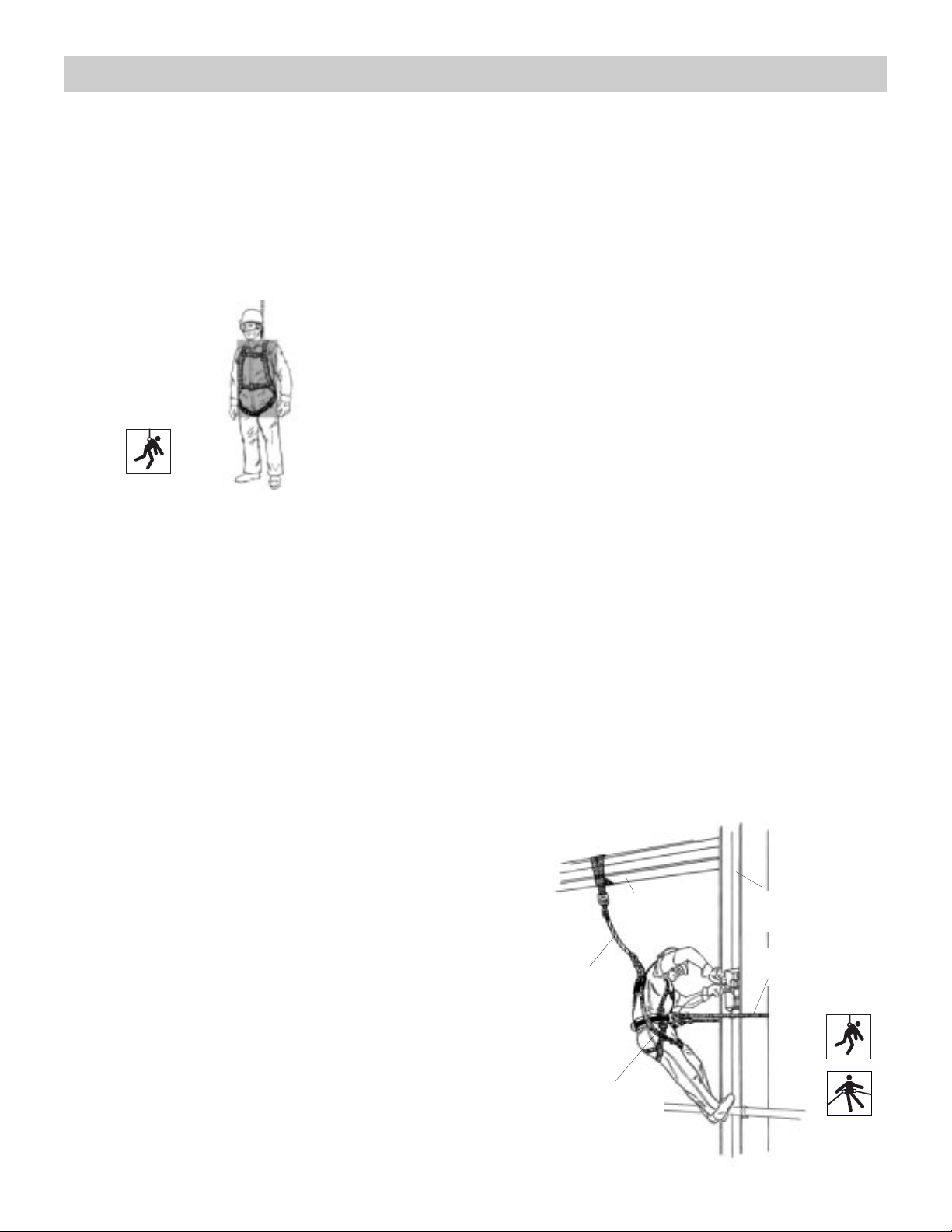

The ironworker in Figure 4 is using both a personal

positioning system and a personal fall-arrest system.

Each system has its own A-B-C components.

Since the worker’s job requires that both hands be

free, he is using a personal positioning system.The

(A) component is the vertical support beam that

serves as a positioning anchorage. Positioning

anchorages must be capable of supporting at least

twice the potential impact load of the worker’s fall or

3,000 lbs., whichever is greater. The (B) component

is the worker’s full-body harness, which is equipped

with a D-ring at each side for attaching a positioning

connecting device.

The (C) component is the positioning lanyard which

has a locking snap hook at each end.Rig positioning

connecting devices so that a worker cannot free fall

more than 2 feet.

Since the worker is at risk of falling, he is also using

a personal fall-arrest system.The (A) component is

the horizontal beam which serves as a fall-arrest

anchorage. Fall-arrest anchorages must be capable

of supporting at least 5,000 lbs. and must be independent of the worker’s support. The (B) component

is the worker’s full-body harness which is equipped

with a D-ring at the back for attaching a fall-arrest

connecting device. The (C) component is the fallarrest lanyard equipped with a locking snap hook at

each end.

In some cases, fall-arrest protection is not possible

when using a personal positioning system. For

example, a worker building highway pillars or similar

structures may have no overhead anchorages available. In these situations, alternative fall-arrest protection devices such as safety nets must be used.

A positioning system is an active system and is in

use whenever the w orker leans back.The positioning

body wear provides solid midriff support, leaving the

worker’s hands free to get the job done.

Remember, a positioning system is only designed to

help hold a worker in place while leaving his hands

free to work.When used with a fixed anchorage, this

system can help prevent a fall. However, positioning

equipment is never a replacement for fall-arrest protection. A positioning system must be used only for

the positioning assistance for which it was designed.

Do not rely upon a positioning system to provide fall

arrest or any other kind of protection.

Figure 3

Figure 4

(A) Vertical Support

(Positioning)

(C) Web Lanyard

(Positioning)

(A) Beam

(Fall-Arrest)

(B) Full-Body Harness

with Positioning Belt

(Fall Arrest and

Positioning)

(C) Rope Lanyard

Attached to

Choker Hitch

(Fall Arrest)

How OPE Systems Are Used (continued)

3

Page 4

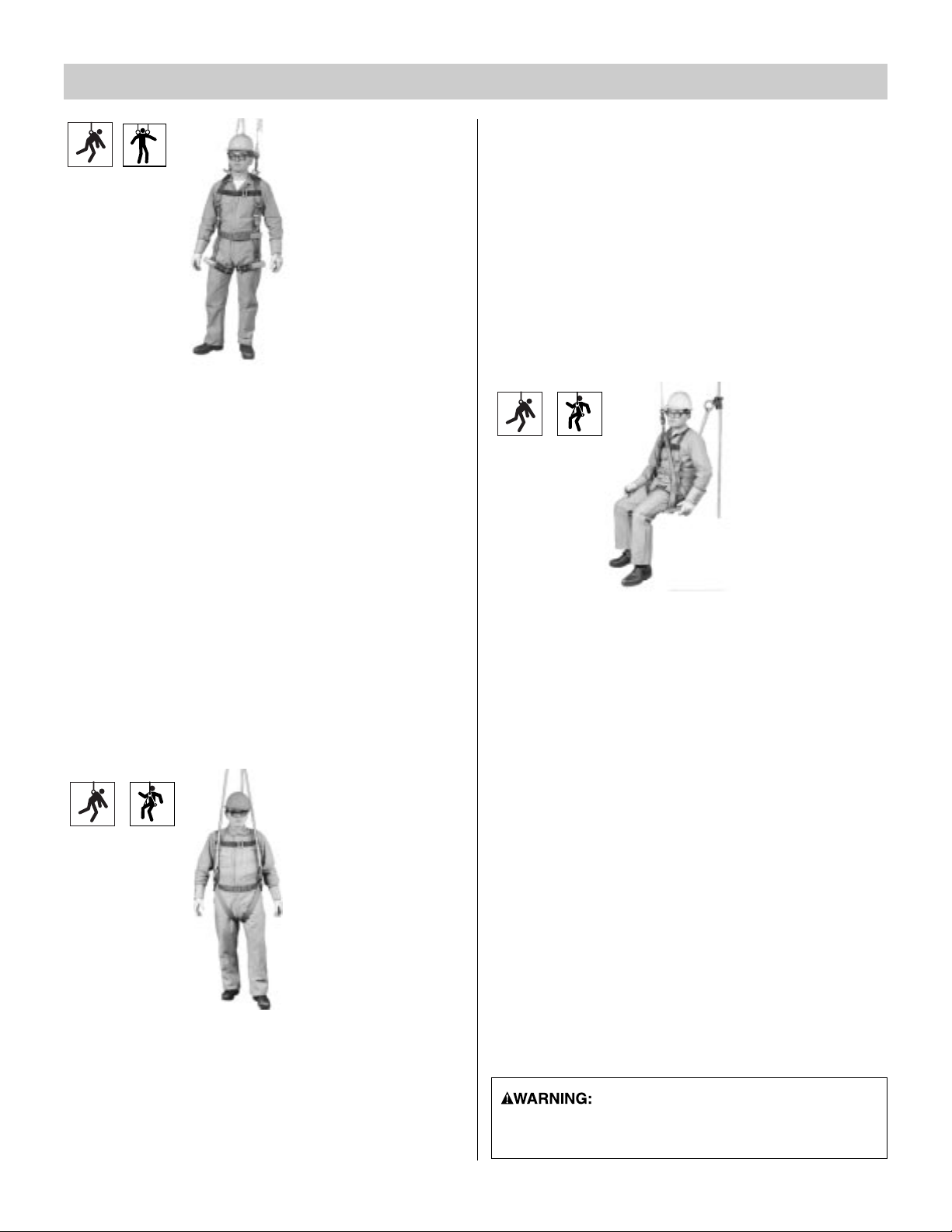

Personal Suspension System

A personal suspension system is required when it

is necessary to suspend and position a worker from

above.A typical system involves the use of a winch,

cable and either a Bosun’s chair or specially

designed suspension harness. A suspension system

is an active system (used constantly). Fall-arrest

protection must always be used with a suspension

system.

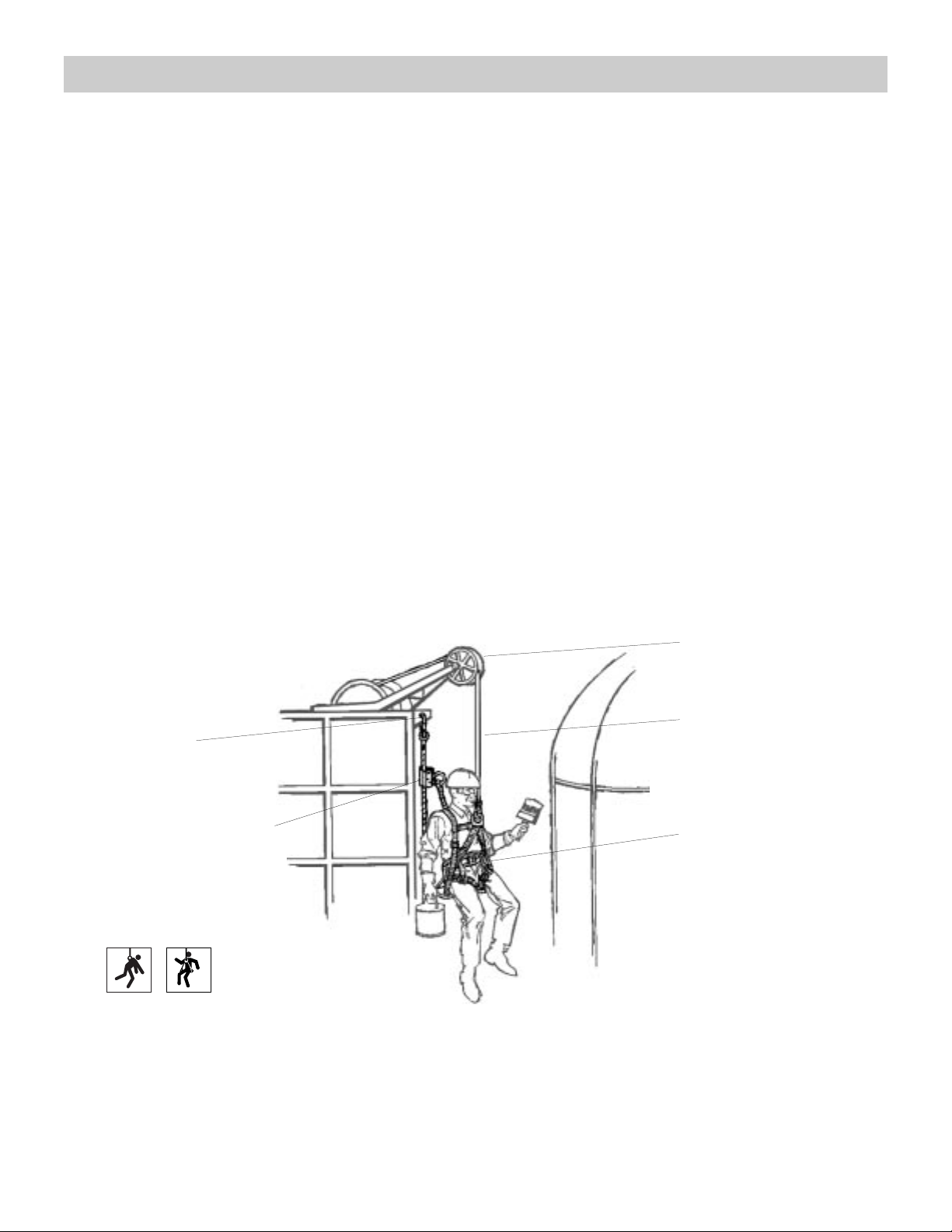

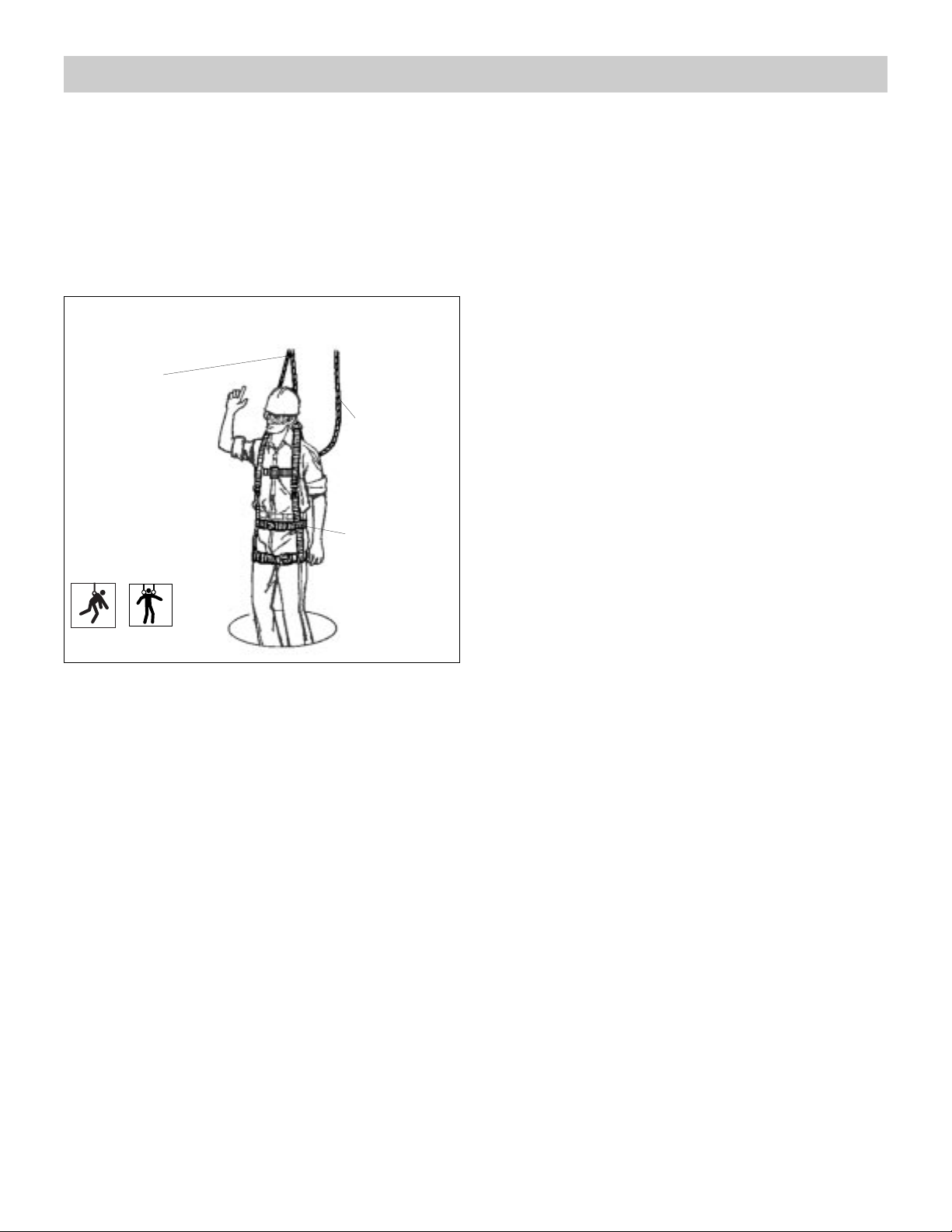

For example, the painter shown in Figure 5 is using

both a personal suspension system and a personal

fall-arrest system. Each system has its own A-B-C

components.

Since the worker must be suspended from above in

order to get to his work area, he is using a personal

suspension system.The (A) component is the winch

that serves as a suspension anchorage.Suspension

anchorages must be capable of supporting at least

twice the potential impact load of a worker’s fall or

3,000 lbs., whichever is greater.The (B) component

is the worker’s Bosun’s chair harness with a front

suspension D-ring. The (C) component is the winch

cable which is equipped with a locking snap hook.

Since the painter is at risk of falling, he is also using

a personal fall-arrest system.The (A) component is

the structural beam with the eye bolt which serves as

a fall-arrest anchorage. Fall-arrest anchorages must

be capable of supporting at least 5,000 lbs.and must

be independent of the worker’s support. The (B)

component is the worker’s Bosun’s chair harness

which is also equipped with a D-ring at the back for

attaching a fall-arrest connecting device. The (C)

component is the vertical lifeline equipped with a

locking snap hook.

Remember, a suspension system is designed to

lower, raise and suspend a worker at an

elevated work station. The suspension attachment

points on the harness, such as the front

D-ring or seat-strap D-rings, are NOT designed to

properly distribute the impact forces that result in

arresting a free fall. A suspension system cannot be

relied upon to provide fall-arrest protection. Always

use the fall-arrest features of a suspension harness.

NOTE: Klein suspension harnesses provide

a rear D-ring which must be used for fall-arrest

protection.

(A) Personnel Winch

(Suspension

Anchorage)

(A) Eye Bolt

(Fall-Arrest Anchorage)

(C) Winch Cable

(Suspension

Connecting Device)

(C) Rope Grab with Ver tical

Device (Fall-Arrest

Connecting Device)

(B) Full-Body Harness

with Bosun’s Chair

(Fall Arrest and

Suspension Bodywear)

Figure 5

How OPE Systems Are Used (continued)

4

Page 5

How OPE Systems Are Used (continued)

Personal Retrieval System

A personal retrieval system is required where

a worker may need to be rescued from a work

environment.

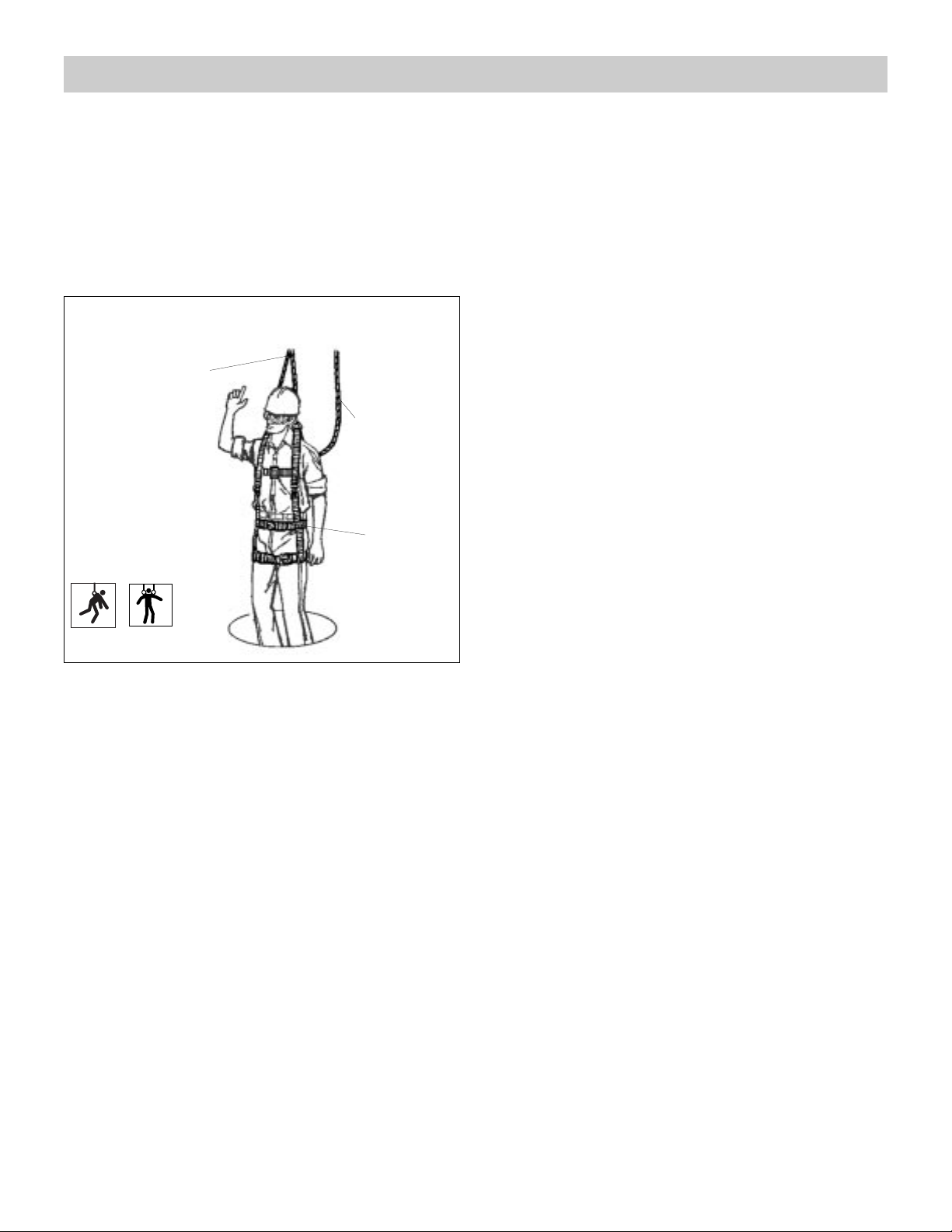

For example, the worker shown in Figure 6 is using

both a personal retrieval system and a personal fallarrest system. Each system has its own A-B-C

components.

Since this worker is in an area that may contain

potentially hazardous conditions, he is using a personal retrieval system. The (A) component (not

shown) is the personnel retrieval winch that serves

as part of the retrieval anchorage.

Retrieval anchorages must be capable of supporting

at least twice the potential impact load of worker’ s fall

or 3,000 lbs., whichever is greater. The (B) com-

ponent is the worker’s retrieval harness with shoulder

D-rings. The (C) component is a V-sling, which is

equipped with locking snap hooks.

Since the worker is at risk of falling, he is also using

a personal fall-arrest system. The (A) component

(which is not shown) could be any suitable fall-arrest

anchorage. Fall-arrest anchorages must be capable

of supporting a minimum of 5,000 lbs. and must be

independent of the worker’s support. The (B) compo-

nent is the harness which is also equipped with

aD-ring at the back for attaching a fall-arrest connecting device.The (C) component is the fall-arrest

lanyard which is equipped with a locking snap hook

at each end.

When used in accordance with OSHA 1910.146

Permit Required Confined Space procedures, the rear

fall-arrest D-ring may also be connected to retrieval

connecting devices that meet OSHA standards.

Like a fall-arrest system, a retrieval system is a passive system which only becomes active when the

worker needs to be removed from the work location.

Remember, a retrie v al system is designed to remov e

a worker from a work location, not to provide fallarrest protection. Therefore, the worker may also

need the fall-arrest and positioning functions.

The retrieval shoulder D-rings are NOT designed to

properly distribute impact forces caused by arresting

a free fall. Do not rely upon a retrieval system by

itself for fall-arrest protection. Always use the fallarrest features of a retrieval harness.

NOTE: Klein retrieval harnesses with shoulder

retrieval D-rings also provide a rear D-ring which

must be used for fall-arrest protection.

Always Use Fall Protection if There is

a Risk of a Fall

Although OSHA regulations generally require workers to use fall protection when exposed to a fall of six

feet or more, Klein strongly recommends using fallarrest protection when working at any elevated position. When in doubt, contact your regional OSHA

office. Also, OSHA regulations prohibit body belts

from being used alone as a fall-arrest system.

Know the appropriate regulations. Learn about the

types of protective equipment and systems which

must be used on the job. OSHA requires employers

to know and follow the OSHA regulations pertaining

to their industry and to provide a workplace free from

hazards that might cause injuries. OSHA provides

free consultation assistance to employers who need

help in training and implementation. If you have

questions or any doubt as to what regulations

apply to you or what safety equipment is

required, contact your regional OSHA office.

Figure 6

(C) V -Sling (Retrieval

Connecting Device)

(A) Personnel

Retrieval

Winch/Anchorage

(not shown)

(A) Suitable Fall-Arrest

Anchorage (not shown)

(C) Rope

Lanyard

(Fall-Arrest

Connecting

Device)

(B) Full-Body

Harness

(Fall Arrest

and

Retrieval

Bodywear)

5

Page 6

When selecting OPE equipment, employers must

understand the government regulations and the

purposes for which specific items are intended.They

need to know the specific working conditions and

how that equipment must be combined with an

anchorage to form a complete OPE system. Also,

employers must train their workers to identify,

maintain, and use OPE equipment correctly. The next

section explains the equipment selection process.

1.Understand the job. Are workers going where they

will need fall protection? Will positioning equipment

be needed to get the job done? Will it be necessary

for a person to be suspended from a structure? Does

the job environment require retrieval equipment?

Consider all potential risks. Understand and be prepared to follow rescue procedures. Do you need to

hold a job-site meeting before starting the work?

2. Identify the specific job requirements.

Determine suitable anchorages. In addition to personal fall protection, does the job require nets, hand

rails or other non-personal fall protection? Decide if

additional anchorages will be needed and/or if any

special engineering will be required to meet safety

regulations. If an engineered system for personal

fall-arrest protection is required, it shall be designed,

installed, and used under the supervision of a

qualified person, as defined by OSHA, and under

regulations set forth by OSHA.

3. Know the appropriate regulations. Learn about

the types of OPE equipment and systems which

must be used on the job.Know and follow state and

local regulations which pertain to your industry.

OSHA requires employers to kno w and follow OSHA

regulations pertaining to their industry and to provide

a workplace free from hazards that might cause

injuries.OSHA provides free consultation assistance

to employers who need help in training and implementation.If you hav e any questions or an y doubt as

to what regulations apply to you or what safety

equipment is required, contact your regional OSHA

office.

4. Determine which OPE system(s) are needed.

Based on job requirements and appropriate regulations, choose that fall-arrest system or f all-arrest system combined with positioning, suspension or

retrieval systems that will satisfy the specific requirements. Always follow the A-B-C Rule. Each system

must contain at least one (A) anchorage, one (B)

body wear, and one (C) connecting device.

5. Select the proper OPE equipment. The major

criteria for selecting OPE equipment is dictated by

the OPE system(s) required. In 1994, OSHA issued

its Final Rule of Fall Protection in the Construction

Industry. This Final Rule requires workers to use fall

protection when exposed to a risk of a fall of six feet

or more. It also mandates the use of fall-arrest harnesses and locking snap hooks.Therefore, fall-arrest

body belts and non-locking snap hooks can no

longer be used.

Types of OPE systems:

Fall-arrest system: Used to arrest an employee in a

fall from a working level. It consists of an (A) anchorage, (B) full-body harness, and (C) connecting

device. Fall-arrest protection is required if there is a

risk of falling (generally, six feet or more).

Positioning system: Allows an employee to be

supported on an elevated vertical surface while

working with both hands free, and rigged so that a

worker cannot free fall more than tw o f eet.It consists

of (A) anchorage, (B) full-body harness with a positioning belt, and (C) connecting device(s). If there

is risk of falling, fall-arrest protection must also be

provided.NO TE:Klein positioning harnesses also

provide a rear D-ring which m ust be used f or fallarrest protection.

Suspension system: Required when a worker must

be suspended from above.It consists of (A) anchorages, (B) full-body harness, and (C) connecting

device(s). Do not rely upon a suspension system

alone for fall-arrest protection;use an additional fallarrest system. NOTE: Klein suspension harnesses

also provide a rear D-ring which must be used

for fall-arrest protection.

Retrieval system: Required when a worker may

need to be rescued from a work environment. This

system consists of (A) anchorages, (B) full-body harness, and (C) connecting device(s).Do not rely upon

a retrieval system alone for fall-arrest protection.

If there is risk of a fall, a fall-arrest system must also

be used. NOTE: Klein retrieval harnesses also

provide a rear D-ring which m ust be used f or fallarrest protection.

How to Select OPE System Components

6

Page 7

6. Select the proper connecting device.Choose a

connecting device which is compatible with the OPE

system you wish to use. Also, OSHA’s Final Rule of

Fall Protection in the Construction Industry prohibits

the use of connecting devices with non-locking snap

hooks. Make sure your connecting devices are

equipped with locking snap hooks.

Some examples of connecting devices are:deceleration units, rope grabs, lanyards with wire pigtail,

nylon V -slings , nylon rope , cable or web bing lanyards.

The decision to use a particular connecting device or

a combination of connecting devices (such as one

for suspension, and another for fall arrest) in your

fall-protection system is based not only on the specific job, but also on your job-site environment.

Sharp-edged fall-arrest anchorages, such as

I-beams, may require a nylon lanyard with wire

pigtail; whereas exposure to welding splatter

requires a steel cable lanyard. Know the job before

selecting the connecting device.

7. Use Klein’s identifying symbols. These sym-

bols tell at a glance the intended purpose for each

piece of OPE equipment. Symbols help assure

selection of the proper equipment.

8. For technical product information, call the

Klein Tools Sales Department, toll free, at 1-800553-4676.

How to Select OPE System Components (continued)

Never attempt to repair or modify any

part or component of a har ness.

It is important that a competent person, as defined by OSHA, select OPE system

components to fit the specific job requirements.

Incorrect component choices can cause serious

injury or death.

Whenever there is a risk of a fall,

personal fall-arrest protection must be used.

Therefore, when working at an elevated position,

always attach the fall-arrest D-ring in the back of

the harness to an approved anchorage with a suitable lanyard or other connecting device.When not

possible, use alternative fall-arrest protection.

Fall Arrest Positioning

Suspension Retrieval

7

Page 8

Type of

Material

Nylon

Exposure to

Excessive Heat

Poor resistance.

Becomes brittle,

has a shriveled

brown appearance. Fibers will

break when

flexed.Weakens

at 300°F

(149°C).

Exposure to

Chemicals

Generally good

resistance,

except around

strong acids and

phenolic compounds, which

cause it to

become brittle.

Exposure to

Molten Metal

or Flame

Poor resistance.

Strands fuse

together and

form hard shiny

spots. Has hard

and brittle feel.

Will not support

combustion.

Exposure to

Paints

or Solvents

Generally offers

good resistance.

However, paint

can penetrate

into the weave

and dry. This can

cause webbing to

become hard

and brittle and

can eventually

break the fibers.

Some solvents

may affect fibers

(see “Exposure

to Chemicals”).

Exposure

Near Live

Electrical Lines

& Equipment

Poor protection

(no dielectric

strength).

Provides no

protection against

exposure to live

electrical lines

or equipment.

Polyester Poor resistance.

Fibers become

brittle and will

shrivel and turn

brown in color

and break when

flexed.Should

not be used

above 180°F

(82°C).

Good resistance

to most chemicals, including

hydrochloric acid,

aqueous alkalies,

and many solvents.Exposure

to incompatible

chemicals may

cause fibers to

change color and

texture, similar

to a brownish

smudge or smear.

Also will become

less elastic, with

transverse cracks

resulting from

bending.

Poor resistance.

Fiber strands

fuse together

and become

hard, brittle,

and shiny.

Generally offers

good resistance.

However, paint

can penetrate

into the weave

and dry. This can

cause webbing to

become hard

and brittle and

can eventually

break the fibers.

Some solvents

may affect fibers

(see “Exposure

to Chemicals”).

Poor protection

(no dielectric

strength).

Provides no

protection against

exposure to live

electrical lines

or equipment.

Nylon Webblng. Klein uses high-quality, commercial-grade nylon.The web is impregnated with latex or

resin for extra durability.

Polyester Webbing. Used in certain Klein lightweight harnesses.P olyester resists a wider v ariety of

chemicals than nylon does.

Softee™ Pads.These pads, which are stitched onto

many Klein belt components, are made of soft, nonabrasive nylon with rounded edges for comfort.

Ultra-Hyde™. This highly durable, leather-like material

with high density and a “tight”surface is used primarily

for belt linings and pads. It is well suited for severeservice environments. Klein does not use Ultra-Hyde

as the load-bearing material in OPE harnesses.

Drop-Forged Steel. Klein D-rings and snap hooks

are manufactured from drop-forged steel with a

corrosion-resistant finish and are tested to meet or

exceed applicable OSHA regulations.

Buckles. Klein Harnesses have single-tongue buckles ,

friction-style buckles and/or easy-connect buckles. All

buckles are made of steel that is tested to meet or

exceed applicable OSHA regulations. Adjustments to

single-tongue buckles are made through holes that are

reinforced with solid brass grommets. Friction-style

buckles provide a continuous range of adjustment.

Easy-connect buckles also have friction slide adjusters

which hold straps in place, so the user does not

need to readjust for each use.

Physical Properties

Materials Used in Klein Harnesses

8

Page 9

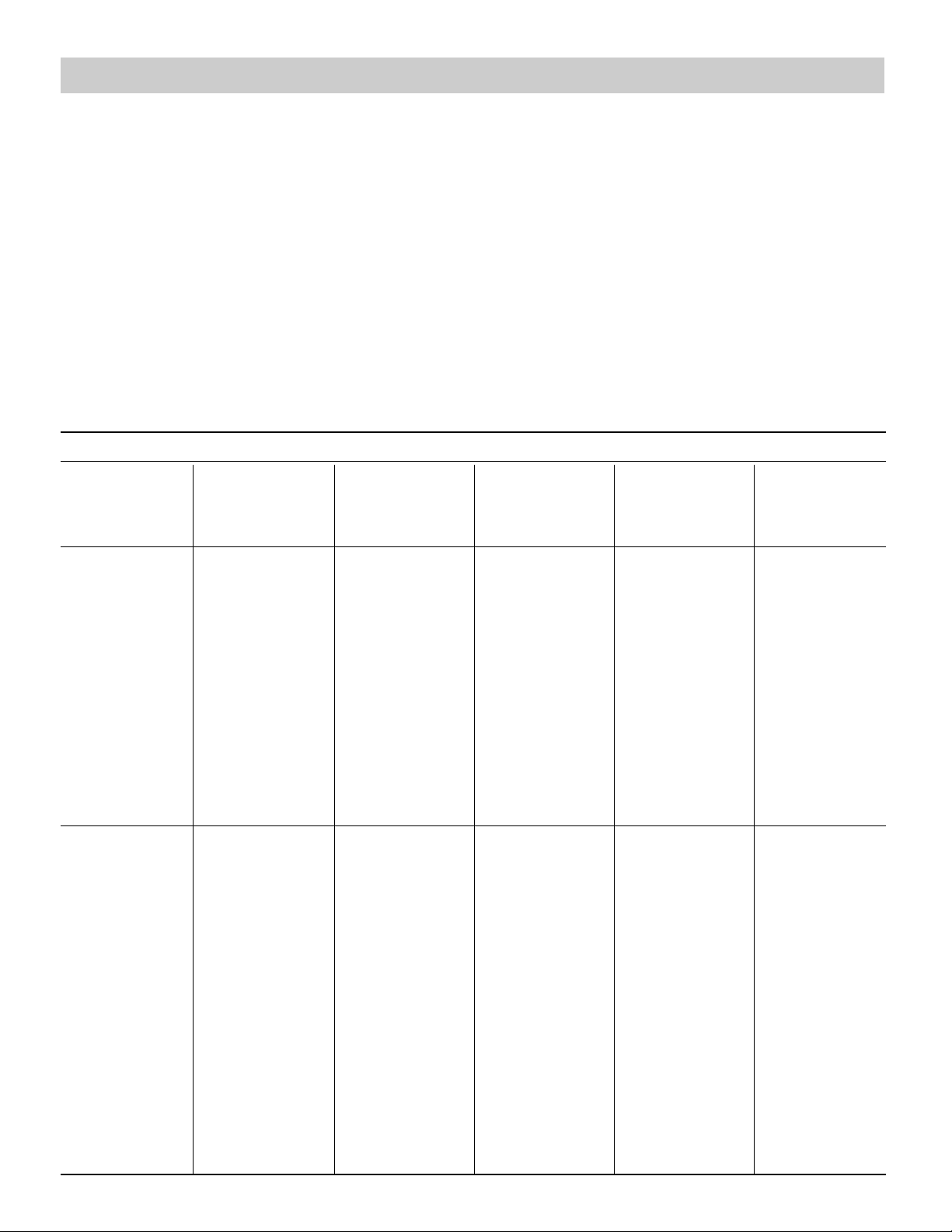

1. Fall-Arrest Harness has a fall-arrest D-ring

attached to the upper middle of the back.Klein offers

four styles of this full-body harness.

The 87020 style harnesses have seat, chest and leg

straps and a waist belt with friction-style buckle,

designed to distribute impact forces of a fall over

thighs, pelvis, waist, chest and shoulders.This harness can also provide a positioning function by

adding a Klein positioning belt, which inserts through

special belt loops on the harness backstraps.

The 87074 style harnesses are designed for workers

on transmission towers and other elevated sites.

They hav e an Ultra-Hyde lined waist belt and leg straps

designed to distribute impact forces of a fall over

thighs, pelvis, waist, chest and shoulders.The 87140

style harness has seat, chest and leg straps.The legs

straps have easy-connect hardware. It has lightweight

polyester webbing.* The 87141 style harness has seat,

chest and leg straps.The leg straps have tongue buckles.It has lightweight polyester webbing.*

When using a fall-arrest harness, only attach

connecting devices meeting government regulations

for fall arrest to the adjustable D-ring in the upper

middle of the harness back. The fall-arrest anchorage must support at least 5,000 lbs. (22.2kN) per

attached worker and be independent of worker support. OSHA also requires that impact forces in a fall

NOT exceed 1,800 lbs. (8kN) with a harness.To stay

under that limit, work with minimum slack in the

connecting device or use a deceleration unit.

In rigging a fall-arrest OPE system, you must also be

sure that, in the event of a fall, you won’t come in

contact with any structures below your work position.

The free-fall distance must not exceed 6 feet (1.8m).

If you are using a deceleration unit, add 3-1/2 feet to

the free-fall distance to allow for unit extension.

*other Klein harnesses have nylon webbing

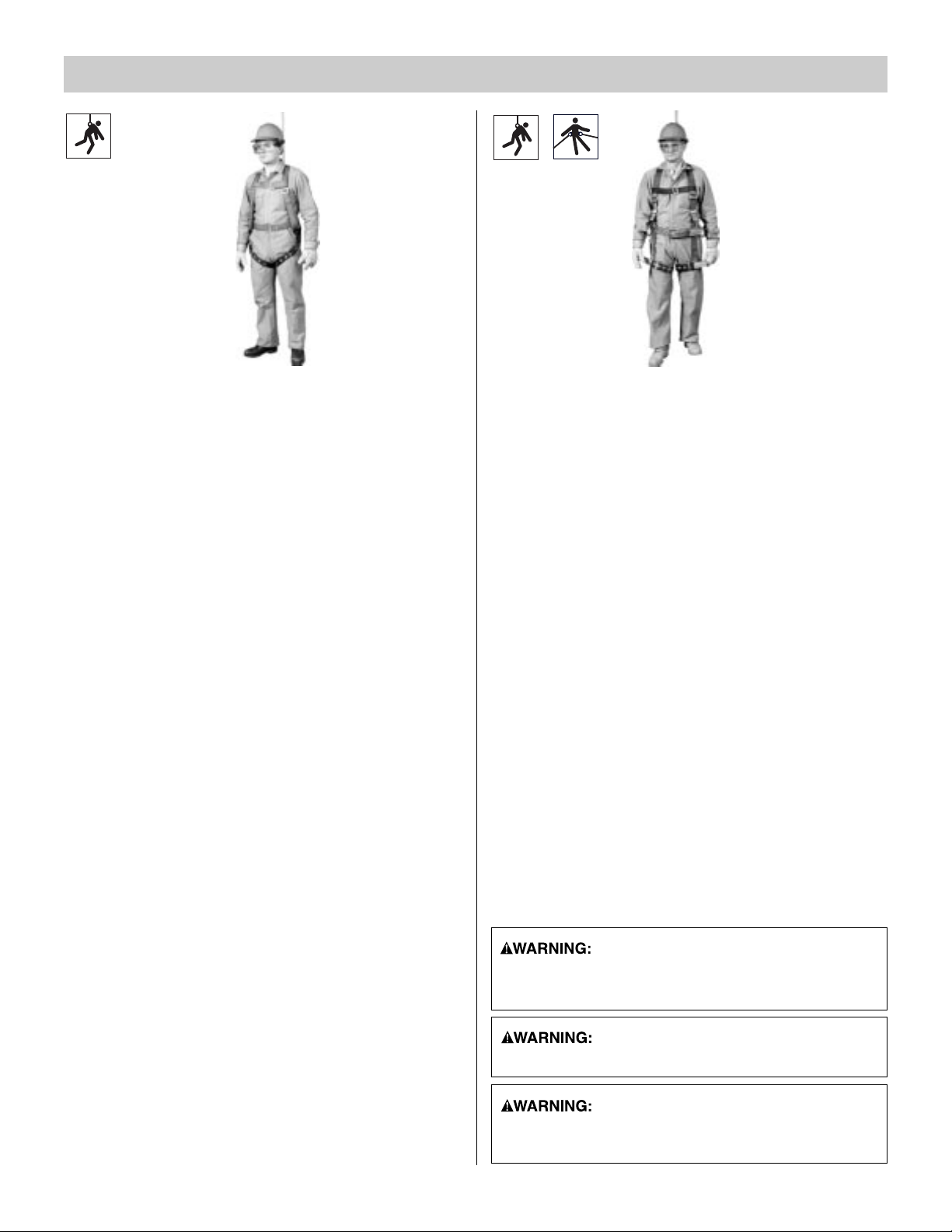

2. Fall-Arrest/Positioning Harness has a fall-arrest

D-ring attached to the upper middle of the back and

positioning D-rings attached to each side. Klein

offers five styles of this full-body harness. These

harnesses are designed to hold a worker in place

while leaving his hands free to work.

The 87810 style harnesses have seat, chest and leg

straps, a waist belt with a tongue buckle and a Softee

Pad.It also features an integral positioning tool belt.

The 87820 style harnesses have seat, chest and leg

straps, a waist belt with a friction buckle and a Softee

Pad. It also features an integral positioning tool belt.

The 87080 style har nesses have Ultra-Hyde lined leg

straps and an Ultra-Hyde lined waist belt with a tongue

buckle. It also features an integral positioning tool belt.

The 87144 style harness has seat, chest and leg

straps.The leg straps have easy-connect hardware.

It has lightweight polyester webbing.* The 87145

style harness has seat, chest and leg straps.The leg

straps have tongue buckles. It has lightweight polyester webbing.*

To use these harnesses: (1) Attach a fall-arrest connecting device to the fall-arrest D-ring in the upper

middle of the harness back. (2) Attach a positioning

connecting device to the side D-rings.

Onlyuseconnectingdevicesequipped

with locking snap hooks.

Never alter or modify a harness.

Always select a harness that fits properly without

modification.

Types of Klein Harnesses and General Rules for Proper Use

Fall-arrest anchorage must be independent of worker support and be able to support

a minimum of 5,000 lbs. per attached worker.

9

Page 10

3. Fall-Arrest/Retrieval Harness has a fall-arrest

D-ring (attached to the upper middle of the back) and

two retrieval D-rings (attached to the harness shoulder straps). Klein offers two styles of this full-body

harness.

The 87840 style harnesses have leg, seat, waist,

chest, and shoulder straps. These harnesses can

also provide a positioning function by adding a Klein

positioning belt, inserted through special belt loops

on the harness backstraps.The 87090 style harnesses

have an Ultra-Hyde lined waist belt and leg straps.

These harnesses are designed for retrieval of a

worker from a tank, manhole, shaft, tunnel, or other

confined or non-confined space.

When used in accordance with OSHA 1910.146

Permit Required Confined Space procedures, the rear

fall-arrest D-ring may also be connected to retrieval

connecting devices that meet OSHA standards.

4. Fall-Arrest/Suspension Harness has a fall-arrest

D-ring (attached to the upper middle of the back), and

two attached suspension D-rings (positioned in the

lower front portion of the harness). Klein's 87012

style har ness is a parachute-type, full-body harness

with leg, seat, waist, chest, and shoulder straps, and

it includes a V-sling suspension connecting device.

This harness keeps the worker in an upright position

when the V-sling is held taut. The V-sling and front

D-rings on the harness are for suspension purposes

only and are NOT to be used for fall-arrest.

To use this harness: (1) Attach the suspension

V-sling connecting device to the seat strap D-rings in

the lower front portion of the harness. (2) Attach a

fall-arrest connecting device to the fall-arrest D-ring

in the upper middle of the harness back.

5. Fall-Arrest Suspension Harness with Bosun’s

Chair features a fall-arrest D-ring (attached to the

upper middle of the back), a suspension D-ring

(attached in front), and an integral suspension chair

(Bosun’s chair) for extra comfort in normal use.

Klein's 87044 style harness has leg, waist, chest and

shoulder straps that distribute fall-arrest forces over

thighs, pelvis, waist, chest and shoulders.

To use this harness: (1) Attach the suspension connecting device to the top front D-ring on the Bosun’s

chair. (2) Attach the fall-arrest connecting device to

the fall-arrest D-ring in the upper middle of the

harness back.

Fall-arrest anchorage must be independent of worker support and be able to support

a minimum of 5,000 lbs. per attached worker.

Types of Klein Harnesses and General Rules for Proper Use

10

Page 11

Types of Klein Harnesses and General Rules for Proper Use

6. Fall-Arrest/Positioning/Retriev al Harness has a

fall-arrest D-ring (attached to the upper middle of the

back), two positioning D-rings (one attached to each

side), and two retrieval D-rings (one attached to

each of the harness shoulder straps). Klein's 87850

style har nesses have leg, seat, chest, and shoulder

straps, and an integral positioning/tool belt with

tongue buckle.

This harness allows for retrieval of workers from

tanks, manholes, or other areas where retrieval may

be required.

To use this harness: (1) Attach a fall-arrest connecting device to the fall-arrest D-ring in the upper middle of the harness back.(2) Attach a positioning connecting device to the side D-rings. (3) Attach a

retrieval connecting device to the shoulder D-rings.

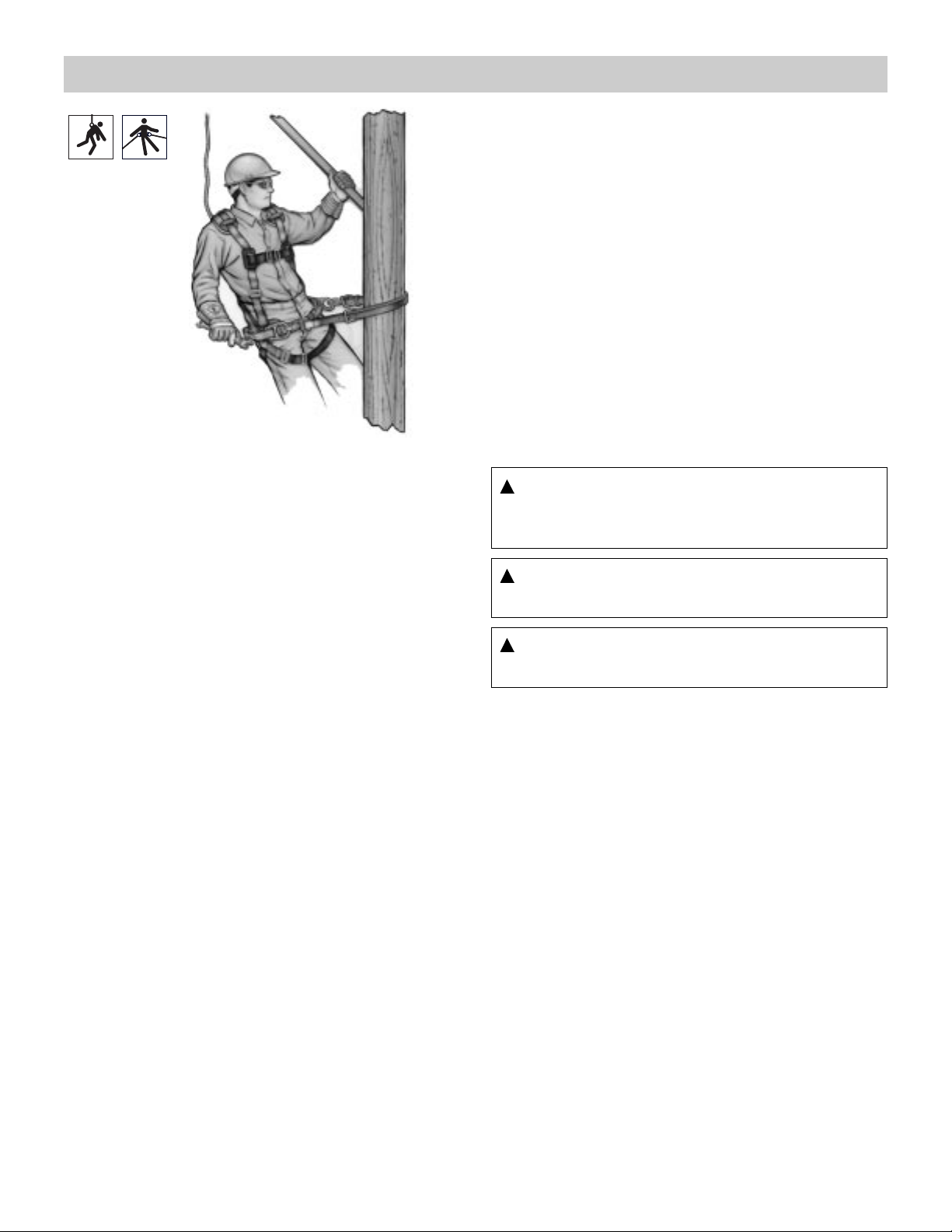

7. Fall-Arrest/Positioning/Suspension Tree Trimmer’ s

Harness features a fall-arrest D-ring (attached to the

upper middle of the back), two positioning D-rings

(one attached to each side of the belt), and two

upward-facing suspension D-rings (attached to each

side of the harness seat straps).

Klein's 87891 style saddle harness also features leg,

seat, chest and shoulder straps, an integral positioning/suspension saddle-style belt with tongue buckle,

and a Softee™ pad back and seat straps.

This specialized harness, designed for tree-trimming

professionals, meets ANSI Z-133.1.Know and follow

ANSI Z-133.1 guidelines before using this harness.

Fall-arrest anchorage must be independent of worker support and be able to support

a minimum of 5,000 lbs. per attached worker.

Only use connecting devices

equipped with lo cking snap hooks.

Never alter or modify a harness.

Always select a harness that fits properly without

modification.

11

Page 12

Types of Klein Harnesses and General Rules for Proper Use

8.The Lineman’s Harness (Fall Arrest/ Positioning)

is a special-order harness that has a permanentlyattached lineman’s body belt.

This harness has a fall-arrest D-ring attached to the

upper middle of the back. It also features leg, seat,

chest, and shoulder straps, easy-connect buc kles , and

detachable shoulder pads made of synthetic lamb’s

wool. The lineman’s body belt has positioning

D-rings attached to each side.

This harness is available with five different belts:

• The LH5278 style has a deluxe full-floating* body

belt, with a glove bag ring, two-wa y knif e snap , two

pocket tabs, four belt-suspender rings, a tape

thong, and leather hand stitching.

• The LH5249 style has a full-floating* body belt

with a glove bag ring, two-way knife snap, two

pocket tabs, four belt-suspender rings, a tape

thong and a tool area hood.

• The LH5282 style has a full-floating* body belt

with a glove bag ring, two-way knife snap, two

pocket tabs, four belt-suspender rings, and a tape

thong.

• The LH5266 style has a semi-floating* body belt

with a glove bag ring, two-way knife snap, two

pocket tabs, four belt-suspender rings, a tape

thong, and a No.5133 hand-line clip.

• The LH5268 style has a fixed-style* body belt with

a glove bag ring, two-way knife snap, two pocket

tabs, four belt-suspender rings, and a tape thong.

To use these harnesses: (1) Attach a fall-arrest connecting device to the fall-arrest D-ring in the upper

middle of the harness back. (2) Attach a lineman’s

positioning strap (or other positioning connecting

device) to the side D-rings on the belt.

NOTE:For information on proper use of the bod y

belt that’s attached to this harness, see the

Instructions for the Proper Use and Care of Klein

Lineman’s Body Belts and Positioning Straps, a

separate instruction sheet which is also packed

with this product. To get additional copies of this

instruction sheet, call Klein Tools toll-free at 1-800553-4676.

NOTE: For information on ordering the Lineman’s

Harness, call the Klein Tools Sales Depar tment, tollfree at 1-800-553-4676.

Only use connecting devices

equipped with l o cking snap hooks.

Never alter or modify a harness.

Always select a harness that fits properly without

modification.

Fall-arrest anchorage must be independent of worker support and be able to support

a minimum of 5,000 lbs. per attached worker.

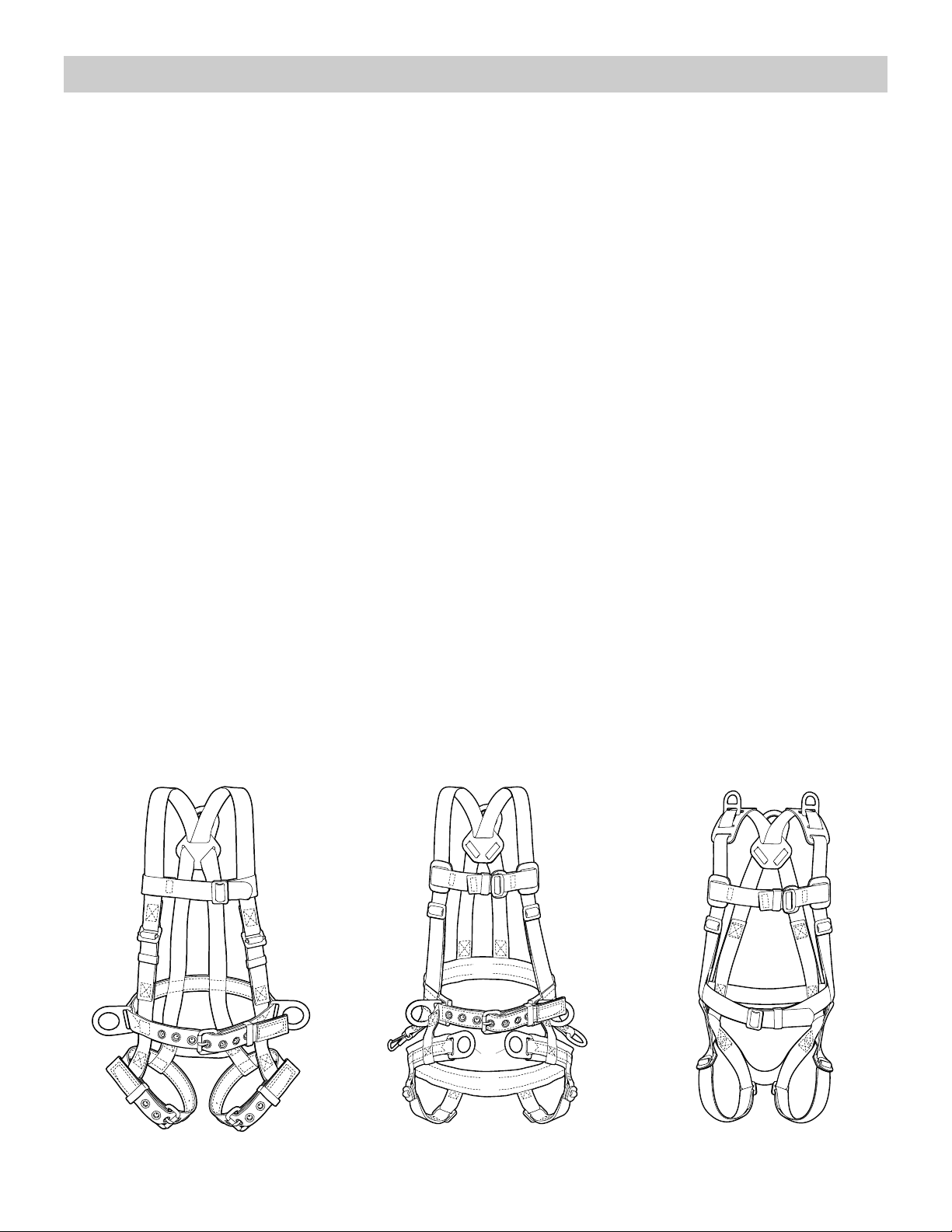

* Full-floating belts allow lateral movement of the D-rings during

use.Semi-floating belts only allow lateral movement prior to wearing. Fixed-style belts are lightweight and the most economical.

12

Page 13

① Fall-arrest D-ring: All Klein harnesses have an

adjustable D-ring attached to the upper back for

attaching a fall-arrest connecting device.

② Positioning D-rings: All Klein positioning

harnesses have two positioning D-rings, one on

each side of the harness.

③ Retrieval D-rings: All Klein retrieval harnesses

have two retrie val D-rings, one on each of the harness

shoulder straps.

④ Suspension D-rings: All Klein suspension har-

nesses have suspension D-ring(s) located in the low er

front of the harness, in an upward-facing position.

⑤ Softee™ Pads are made of soft, non-abrasive

nylon with rounded edges for maximum comfort

during prolonged use. Some Softee™ Pads overlap

the buckle assembly for added comfort.

⑥ Contrasting color construction helps identify

different parts of a harness to aid the user in putting

it on.

⑦ Buckles. Three types of forged-steel

buckles are used in Klein Harnesses:

a) Single-Tongue Buckles adjust easily and

securely over a range of sizes. Steel grommeted

holes assure durable and positive buckle connection.

b) Friction-Style Buckles allow adjustment over a

continuous range of sizes.

c) Easy-Connect Buckles attach quickly and eas-

ily; the user simply inserts one buckle through the

other.Friction slide adjusters hold straps in place so

the user does not need to readjust for each use.Belt

end holders secure the belt ends to reduce the

chance of the ends being caught on an object.

⑧ Seat strap adds extra comfort in normal use as

well as support after a fall.

⑨ Chest, waist and leg straps adjust fully to fit

most individuals and to add support after a fall.

Belt adjuster pads on some harnesses are used to

integrate waist belts to the harness while allowing

complete horizontal and vertical adjustment of the

belt for maximum comfort and a snug fit.

All Klein D-rings are made of forged steel with a

corrosion-resistant finish for strength and durability.

D-rings with rollers minimize friction and excessive

wear. All Klein D-rings are proof-loaded to meet

OSHA regulations.

Identity and Warning Tags (not illustrated here) are

reminders of the proper application and inspection

procedures. The Klein name, model, date of manufacture and OPE-system application symbol(s) are

permanently and clearly inscribed on each tag.

Nylon is high-quality, commercial-grade that is

impregnated with resin or latex for abrasion resistance and added durability.

Polyester is lightweight, and it resists a wider

variety of chemicals than nylon does.

Ultra-Hyde™, which lines waist belts and leg straps,

is a material that looks and feels like leather, yet is

virtually maintenance-free.

Fall Arrest/Positioning

Harness

Fall Arrest/Positioning /Suspension

Harness

Fall-Arrest/Retrieval

Harness

②

⑨

③

⑦

⑧

⑥

②

③

①

④

①

①

②

②

⑤

⑤

Construction of Klein Harnesses

13

Page 14

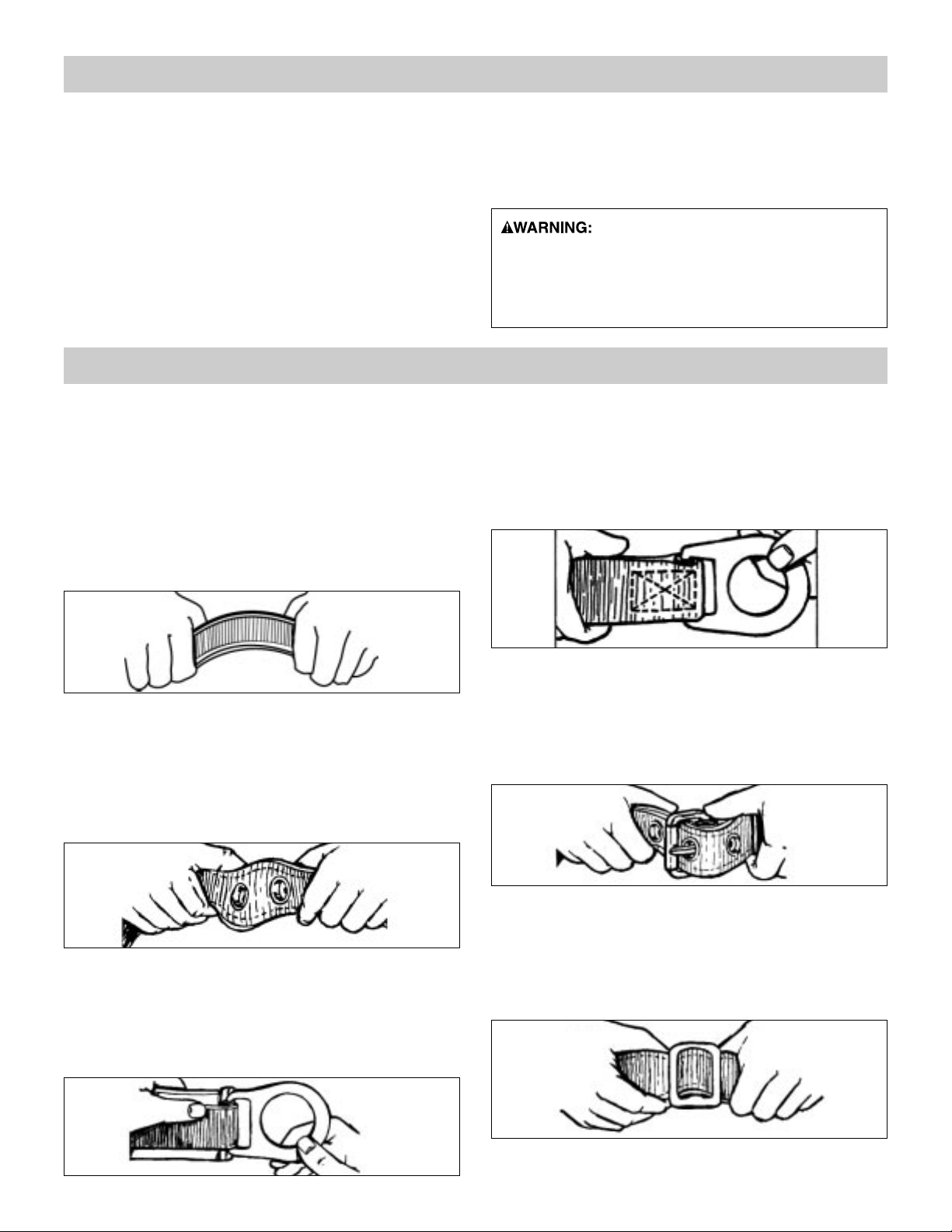

1. Inspect stitching and webbing.

Check stitching for broken, burned, cut or pulled

stitches. Broken strands appear as tufts on the

surface. To inspect, hold the webbing with your

hands six to eight inches apart. Bend the webbing in

an inverted “U” to cause surface tension, exposing

problem areas. Inspect all web areas. Damage from

cuts, abrasion, corrosives , heat, or chemicals should

be apparent.

2. Inspect buckle and belt ends.

Inspect the ends of all straps, which can wear from

repeated opening and closing. Enlarged or distorted

holes may indicate excessive wear or damage

through impact loading. Harnesses with unusually

enlarged or distorted holes should fail inspection.

3. Inspect D-Rings.

Check all D-rings for distortion. Check D-ring attachment points for unusual wear or damaged fibers.

Badly pitted D-rings indicate chemical corrosion, and

they should fail inspection.

4. Inspect stitching or rivets at hardware

attachment points.

For stitched attachment points, chec k that stitching is

not broken, burned, cut, or pulled. Check all riveted

attachment points for tightness. Badly-pitted rivets

indicate chemical corrosion, and should fail inspection.

5.

Inspect tongue buckles.

Check all tongue buckles for distortion, sharp edges,

and cracks. The tongue should move freely and

overlap the frame. Rollers should not be distorted

and should roll freely.

6. Inspect friction slide adjusters.

Check all friction slide adjusters for distortion, sharp

edges, and cracks.Make sure outer bars and center

bars are straight. Also check corners and attachment

points for wear and cracks.

1. Check for wear and deterioration.

Before each use, carefully inspect your harness for

signs of wear, deterioration, or evidence of impact

loading. Visually inspect for loose threads, pulled

rivets, burns, cuts, distortions, abrasions, or any other

evidence of chemical or physical deterioration that

may have weakened the material or assembly.

2.Inspect hardware for malfunctions and cracks.

Check all snap hooks, buckles, and D-rings.

3. Remove from service and replace all worn or

damaged equipment.

If any part does not pass inspection, immediately

remove the harness from service and destroy it.

Should any unusual condition be

noted during inspection which is not specified here,

do not use the suspect harness until a competent

person as defined by OSHA has made a decision

on its usability.

General Inspection Procedures

Harness Inspection Procedures

14

Page 15

Harness Inspection Procedures (continued)

7.

Inspect easy-connect buckles.

Check easy-connect buckles (square rings) for distortion, sharp edges, and cracks .F or stitched attachment points, check that stitching is not broken,

burned, cut, or pulled.

8.

Inspect friction-style buckles.

Check friction-style buckles for sharp edges, cracks,

and distortion. Make sure that outer bars and center

bar are straight. Also check corners and attachment

points for wear.

9. Inspect leather.

Leather should be soft and supple. Inspect leather

for cracks, tears, burns, brittleness, and other signs

of damage, age, or abuse. While the leather components of the system are not load bearing, damaged

leather is a sign that the entire harness MA Y NOT be

in acceptable condition. Re-inspect entire system.

Leather should both look and feel good.

10. Destroy or replace worn or damaged

harnesses.

If evidence of excessive wear, deterioration or

mechanical malfunction is found, the harness should

be destroyed. Never work with worn or damaged

equipment. Using worn or damaged equipment can

cause serious injury or death.

11. The inspector is the most important part of

any inspection procedure.

Check all equipment thoroughly and follow all safety

procedures and guidelines.Don't take any shortcuts.

Important Note: OSHA requires all employers

covered by the Occupational Safety and Health Act

to inspect and maintain all tools and equipment used

by employees — whether owned by the employees

or by the company. All OPE equipment should be

inspected before each use, and immediately

removed from service if equipment does not pass

inspection.

Note - Lineman’s Harness:

For information on inspection and maintenance

of the body belt that’s attached to the Lineman’s

Harness, see the Instructions for the Proper Use

and Care of Klein Lineman’s Body Belts and

Positioning Straps, a separate instruction sheet

which is also packed with this product.

To get additional copies of this instruction sheet, call

Klein Tools toll-free at 1-800-553-4676.

Maintenance Procedures

A written log of all servicing and inspection dates for

this equipment should be maintained by the company

safety officer or other competent individual.

Clean and maintain equipment in accordance with

recommended practice.Wash nylon and polyester in

warm water and mild detergent. Avoid harsh chemical agents such as degreasing compounds, turpentine, paint thinner , gasoline and other solvents.Allow

nylon and polyester objects to dry naturally. Do not

use heat to speed up the process.

Maintain leather parts with Neat’s-foot oil, saddle

soap or equivalent to help prolong life. Allow leather

to dry slowly at room temperature.

Inspect and lubricate all snap hooks after cleaning to

make sure they operate properly and close securely.

Use Klein Cinch

®

aerosol lubricant or light motor oil.

Klein strongly recommends that Klein

components NOT be interchanged with other components made by other manufacturers, because

Klein cannot guarantee that other manufacturers’

components are free of defects in materials or

workmanship.

A Klein Harness must be destroyed

or reconditioned by Klein if subjected to an impact

load.

On all harness straps with frictionstyle buckles, the strap end must extend a minimum of 3" (76 mm) beyond the buckle.

Remove from service any Klein harness that is torn, fray ed, or otherwise damaged and

destroy it.

15

Page 16

1. Read all warning tags and instructions provided

with the harness.They contain important information

on usage and care.Keep all tags and instructions for

future reference.

NOTE: Highly-durable warning and instruction tags

or labels are permanently attached to each Klein

Harness. If any of these tags or labels becomes

unattached, lost or damaged, call the Klein Tools

Sales Department, toll-free, at 1-800-553-4676 for

information on how to get new tags free of charge.

(Warning tags are not shown in the product illustrations in this instruction booklet for clarity.)

2. Use all the capabilities of your harness, including

the fall-arrest capability, when working at an elevated

position. When not possible, use alternative fall protection.

3. Be sure to inspect the entire harness before each

use (see pages 14-15 in this instruction booklet for

inspection procedures).

4. Hold the harness by the back or top of the har-

ness to help untangle it. Fit the harness across your

shoulders so the D-ring on the back of the harness

lies flat against the upper middle of your back.

Buckle all the straps securely around your waist,

chest and legs, and secure the ends through the belt

keepers, making sure they do not interfere with tool

access.

To connect the easy-connect buckle used on some

harnesses, insert the smaller square ring through

the large square ring at an angle. After inser tion, the

smaller square ring must lie flat against the larger

square ring for secure attachment. Use the friction

slide adjuster so that the strap fits snugly.

5. Attach a connecting device that meets govern-

ment regulations for fall arrest to the center back fallarrest D-ring on the harness. ONLY USE fall-arrest

connecting devices equipped with locking snap

hooks.When attaching the snap hook, make sure

the snap hook freely engages the harness D-ring

and that the keeper is closed completely after

each hookup. Also, have a co-worker check for

proper attachment.

6. Keep the fall-arrest anchorage at or above

shoulder height. Allow minimum slack in the fallarrest connecting device to reduce the impact force

from a fall.

Attach the free end of the fall-arrest connecting

device to a fall-arrest anchorage that meets OSHA

regulations. The fall-arrest anchorage must support

at least 5,000 lbs. (22.2kN) per attached worker and

must be independent of worker support.

Make sure by visual inspection that the snap

hook freely engages the anchorage and that the

keeper is closed completely after each hook-up.

Rig to avoid contact with structures below in a fall.

The free-fall distance must not exceed 6 feet (1.8m).

If using a deceleration unit, add 3-1/2 feet (1m) to the

free-fall distance to allow for unit extension.

7. To use the positioning function of a

harness, be sure the positioning D-rings are equally

spaced on either side of your body. Attach one end

of the positioning connecting device to one of the

positioning D-rings. Pass connecting device around

or through a positioning anchorage, and then attach

the free end of the device to the other positioning

D-ring.

Make sure by visual inspection that both snap

hooks of the positioning device freely engage

the positioning D-rings and that both keepers are

closed completely after each hook-up. Never

attach anything to the side D-rings other than the

locking snap hooks of a positioning connecting

device. Attaching another object to any D-ring may

prevent or falsely indicate snap hook engagement.

How To Use Klein Harnesses

16

Page 17

How To Use Klein Harnesses (continued)

8. To use the suspension function of a harness:

With a Tree-Trimmer’s Saddle – Attach a suspen-

sion connecting device only to the upward-facing

D-rings attached to the web seat. Never attach anything to the suspension D-rings other than the locking snap hooks of a V-sling (or other suspension

device meeting gov ernment and industry regulations

for tree-trimming professionals). Tree-trimmer’s saddle must only be used by tree-trimming professionals. Know and follow ANSI Z-133.1 regulations.

Make sure by visual inspection that the snap

hook(s) of the suspension device freely engage

the suspension D-ring(s) and that the keepers

are closed completely after each hook-up.

With a Web Seat – Attach a V-sling suspension

connecting device only to the upward-facing seatstrap D-rings. Never attach anything to the suspension D-rings other than the locking snap hooks of a

V-sling (or other suspension device meeting government regulations). Thread the V-sling locking snap

hooks through the shoulder clips, and attach them to

the upward-facing seat-strap D -r ings. Only attach the

eye of the V-sling to an anchorage connecting device

attached to man-rated hoist or winch. Make sure by

visual inspection that the snap hook(s) of the

suspension device freely engage the suspension

D-ring(s) and that the keepers are closed completely after each hook-up.

With a Bosun’s Chair – Attach suspension con-

necting device only to the front D-ring. Never attach

anything to the suspension D-ring other than the

locking snap hook of a suspension device. Make

sure by visual inspection that the snap hook(s)

of the suspension device freely engage suspension D-ring(s) and that the keepers are closed

completely after each hook-up.

9.To use the retrieval function of a harness, attach

the two locking snap hooks of a V-sling only to the

shoulder D-rings. Only attach eye of V-sling to a

retrieval device meeting OSHA standards.

Make sure by visual inspection that both snap

hooks of the retrieval device freely engage the

retrieval D-rings, and that both keepers are

closed completely after each hook-up. Never

attach anything to the retrieval D-rings other than the

locking snap hooks of a retrieval connecting device.

Attaching another object to any D-ring may prevent or

falsely indicate snap hook engagement.

10. Remember, if there is any risk of a worker fall in g

from an elevated position (generally, six feet or more),

personal fall-arrest protection must also be used.

Shoulder D-rings are for retrieval pur-

poses only, and are NOT to be used for fall arrest.

All system components must meet

government standards for intended job-site use as

determined by a competent person, as defined by

OSHA.

The attachment of another object to

any D-ring may prevent or falsely indicate snaphook engagement.

The use of Klein Harnesses without

the proper instructional materials and training

could result in serious injury or death. Klein Tools

will supply additional instruction materials, warnings tags, or will answer questions on any piece of

Klein occupational protective equipment free of

charge. Call the Klein Tools Sales Department,

toll-free at 1-800-553-4676.

In computing the total-fall distance,

add 3-1/2 feet (1m) to the free-fall distance to allo w

for deceleration-unit extension.

On all harness straps with frictionstyle buckles, the strap end must extend at least

3 inches (76mm) beyond the buckle.

Always check visually to assure that

buckles are fully closed, and that all tabs are

securely in their keepers before use.

17

Page 18

For Fall Arrest Use Only

DO NOT REMOVE THIS LABEL

Model: Size: Date:

■■

Read, understand and follow all instructions, cautions and warnings attached to and/or packed with

this and all other occupational protective equipment before each use.

■■

For use by properly trained professionals only.

■■

Harness must be worn so that the fall-arrest D-ring is centered in back.

■■

Fall-arrest anchorage must support a minimum of 5,000 lbs. (22.2kN) per attached worker and be

independent of worker support.

■■

Attach fall-arrest connecting devices that meet OSHA standards only to the rear fall-arrest D-ring.

■■

Rig to avoid contact with structures below in the event of a fall. The free-fall distance must not ex-

ceed 6 ft. (1.8m). If using a deceleration unit, add 3-1/2 ft. (1m) to free-fall distance to allow for unit extension.

■■

For fall arrest, always keep anchorage at or above shoulder height to minimize fall distance.

■■

For personal use only. NOT for towing or hoisting.

■■

NOT for recreational or sporting use.

■■

Harnesses must be properly sized and adjusted to fit user. Always wear harness snug to avoid injury.

■■

Only use locking snap hooks.

■■

OPE equipment must only be used for the specific purpose for which it is designed and intended.

■■

OPE equipment must be destroyed if subjected to impact loading.

■■

OSHA requires that impact force in a fall NOT exceed an 1,800 lb.. (8kN) limit with a harness. At a

given weight, the longer the free fall, the greater the resulting impact force. Therefore, minimize slack in

fall-arrest connecting device or use deceleration unit to stay under 1,800 lbs. (8kN).

QUESTIONS?

Call TOLL FREE

1-800-553-4676

Klein Tools, Inc.

OSHA 1910, 1915 & 1926.

ANSI A10.14, ANSI Z359.1 Made in U.S.A.

■■

Whenever there is risk of a fall, personal fall-arrest protection must be used. Therefore, when working at

an elevated position, always attach the fall-arrest D-ring in the back of the harness to an approved fallarrest anchorage with a suitable fall-arrest lanyard or other connecting device. Where not possible, use

alternative fall-arrest protection.

■■

Always visually check that: 1) each snap hook freely engages the intended D-ring or anchorage,

and 2) the snap-hook keeper (latch) is completely closed with each use. Have a co-worker visually check

to make sure that the locking snap hook attached to the fall-arrest D-ring (centered in the back of the

harness) is properly secured. Never rely solely on feel or sound in attempting to determine that a snap

hook is engaged.

■■

Always visually check that all buckles and connectors are properly closed before each use.

■■

Assume the responsibility for determining that your OPE harness and equipment are in excellent

condition at all times.

■■

Before each use check that: OPE equipment is free of burns, cuts, abrasions, broken strands or

stitches, kinks, knots or excessive wear, 2) rivets are not bent, loose or missing, 3) buckles, D-rings and

other hardware are not distorted or cracked, 4) buckle tongue does not bind on buckle and buckle holes

are not damaged, and 5) hook keepers are free of burrs, functioning properly, clean and not bent. If the

OPE equipment does not pass the inspection, it should be removed from service immediately and

destroyed or re-inspected by a competent person as defined by OSHA to determine its usability.

■■

Never punch additional holes in or alter any OPE equipment in any way.

■■

Never attach ladder or rebar hooks onto a D-ring.

■■

Never attach multiple snap hooks onto a D-ring.

■■

Never attach anything to a D-ring other than a single, locking snap hook. The existence of another

object attached to a D-ring may prevent or falsely indicate snap-hook engagement.

■■

Store your OPE equipment in a clean, dry area such as a tool chest or storage room.

■■

Employer –Before allowing the use of this equipment, instruct your employees as to its proper use

and alert them to these warnings.

■■

Klein strongly recommends that Klein components NOT be interchanged with other components made

by other manufacturers, because Klein cannot guarantee that other manufacturers' components are free of

defects in materials or workmanship.

T-126

998

READ BEFORE USE

READ BEFORE USE

QUESTIONS?

Call TOLL FREE at 1-800-553-4676

Klein Tools, Inc.

OSHA 1910, 1915 & 1926

ANSI A10.14, ANSI Z359.1 Made in U.S.A.

Klein-Lite®, Klein-Lok®, Klein-Kord®, Softee™, Ultra-Hyde™

139132

T-12 7

201

■ Read, understand and follow all instructions, cautions and warnings attached to and/or packed with this and all

other occupational protective equipment before each use.

■ For use by properly trained professionals only.

■ Employer – Before allowing the use of this equipment, instruct your employees as to its proper use and alert them

to these warnings.

■ Harness must be worn so that the fall-arrest D-ring is centered in back.

■ Fall-arrest anchorage must support a minimum of 5,000 lbs. (22.2kN) per attached worker and be independent of

worker support.

■ Attach fall-arrest connecting devices that meet OSHA standards only to the rear fall-arrest D-ring.

■ Attach positioning connecting devices that meet OSHA standards only to the side D-rings. Side D-rings are NOT for

fall arrest.

■ Positioning anchorages must support at least twice the potential impact load of an employee's fall or 3,000 lbs.

(13.3kN), whichever is greater.

■ Rig to avoid contact with structures below in the event of a fall. The free-fall distance must not exceed 6 ft. (1.8m).

If using a deceleration unit, add 3-1/2 ft. (1m) to free-fall distance to allow for unit extension.

■ For fall arrest, always keep anchorage at or above shoulder height to minimize fall distance.

■ OPE equipment must be destroyed if subjected to impact loading.

■ OSHA requires that impact force in a fall NOT exceed an 1,800 lb. (8kN) limit with a harness. At a given weight, the

longer the free fall, the greater the resulting impact force. Therefore, minimize slack in fall-arrest connecting device or

use deceleration unit to stay under 1,800 lbs. (8kN).

■ Whenever there is risk of a fall, personal fall-arrest protection must be used. Therefore, when working at an elevated

position, always attach the fall-arrest D-ring in the back of the harness to an approved fall-arrest anchorage with a

suitable fall-arrest lanyard or other connecting device. Where not possible, use alternative fall-arrest protection.

■ Always visually check that: 1) each snap hook freely engages the intended D-ring or anchorage, and 2) the snap-

hook keeper (latch) is completely closed with each use. Have a co-worker visually check to make sure that the locking snap hook attached to the fall-arrest D-ring (centered in the back of the harness) is properly secured. Never rely

solely on feel or sound in attempting to determine that a snap hook is engaged.

■ Always visually check that all buckles and connectors are properly closed before each use.

■ Before each use check that: OPE equipment is free of burns, cuts, abrasions, broken strands or stitches, kinks,

knots or excessive wear, 2) rivets are not bent, loose or missing, 3) buckles, D-rings and other hardware are not

distorted or cracked, 4) buckle tongue does not bind on buckle and buckle holes are not damaged, and 5) hook keepers

are free of burrs, functioning properly, clean and not bent. If the OPE equipment does not pass the inspection, it

should be removed from service immediately and destroyed or re-inspected by a competent person as defined by

OSHA to determine its usability.

■ Never allow this equipment to come in contact with fire, high-temperature surfaces, welding sparks, or other heat

sources.

■ Harnesses must be properly sized and adjusted to fit user. Always wear harness snug to avoid injury.

■ Only use locking snap hooks.

■ OPE equipment must only be used for the specific purpose for which it is designed and intended.

■ Never punch additional holes in or alter any OPE equipment in any way.

■ Never attach ladder or rebar hooks onto a D-ring.

■ Never attach multiple snap hooks onto a D-ring.

■ Never attach anything to a D-ring other than a single, locking snap hook. The existence of another object attached to

a D-ring may prevent or falsely indicate snap-hook engagement.

■ For personal use only. NOT for towing or hoisting.

■ NOT for recreational or sporting use.

■ Assume the responsibility for determining that your OPE harness and equipment are in excellent condition at all

times.

■ Store your OPE equipment in a clean, dry area such as a tool chest or storage room.

■ Klein strongly recommends that Klein components NOTbe interchanged with other components made by

other manufacturers, because Klein cannot guarantee that other manufacturers' components are free of defects in

materials or workmanship.

For Fall-Arrest and Positioning Use Only

DO NOT REMOVE THIS LABEL

Model: Size: Date:

READ BEFORE USE

READ BEFORE USE

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

Name of User _________________________________________________________________________

Date Into Service (Month/Year)___________________________________________________________

INSPECTION GRID

Competent person, as defined by OSHA, must inspect equipment every 6 months. Mark month of current

year if it passes. Remove from service if it is not inspected every 6 months; if it fails, remove and replace.

YEAR

20_____

20_____

20_____

20_____

20_____

Klein permanently attaches highly durable warning

and instruction tags and/or labels to its harnesses. In

the event any of these tags and/or labels become

unattached, lost, or damaged, contact the Klein Tools

Sales Department, toll-free at 1-800-553-4676 for

information on how to have the tags and/or labels

replaced free of charge.

Tag for Lightweight Fall-Arrest Harnesses

87140, 87141

Tag for Lightweight Fall-Arrest/Position. Harnesses

87144, 87145, LH5249 style, LH5266 style, LH5268

style, LH5278 style, LH5282 style

Klein Harness Warning Tags

18

Page 19

Klein permanently attaches highly durable warning

and instruction tags and/or labels to its harnesses. In

the event any of these tags and/or labels become

unattached, lost, or damaged, contact the Klein Tools

Sales Department, toll-free at 1-800-553-4676 for

information on how to have the tags and/or labels

replaced free of charge.

■ For use by properly trained professionals only.

■ For personal use only. NOT for towing or hoisting.

■ NOT for recreational or sporting use.

■ Harnesses must be properly sized and adjusted to fit

user. Always wear harness snug to avoid injury.

■ Only use locking snap hooks.

■ OPE equipment must only be used for the specific pur-

pose for which it is designed and intended.

■ OPE equipment must be destroyed if subjected to impact

loading.

■ Always visually check that: 1) each snap hook freely

engages the intended D-ring or anchorage, and 2) the

snap-hook keeper (latch) is completely closed with

each use. Have a co-worker visually check to make

sure that the locking snap hook attached to the fallarrest D-ring (centered in the back of the harness) is

properly secured. Never rely solely on feel or sound in

attempting to determine that a snap hook is engaged.

■ Always visually check that all buckles and connectors are

properly closed before each use.

B2 1

592

Read

Other

Side

Read

Next

Tag

WARNINGS

WARNINGS

■ Before each use check that: 1) OPE equipment is

free of burns, cuts, abrasions, broken strands or

stitches, kinks, knots or excessive wear, 2) rivets are not

bent, loose or missing, 3) buckles, D-rings and other

hardware are not distorted or cracked, 4) buckle tongue

does not bind on buckle and buckle holes are not dam-

aged, and 5) hook keepers are free of burrs, functioning properly, clean and not bent. If the OPE equipment does not

pass the inspection, it should be removed from service

immediately and destroyed or re-inspected by a competent person as defined by OSHA to determine its usability.

■ Assume the responsibility for determining that your

OPE harness and equipment are in excellent condition

at all times.

■ Whenever there is a risk of a fall, personal fall-arrest

protection must be used. Therefore, when working at

an elevated position, always attach the fall-arrest Dring in the back of the harness to an approved fall-arrest

anchorage with a suitable fall-arrest lanyard or other connecting device. Where not possible, use alternative fall-arrest

protection.

■ Never punch additional holes or alter any OPE equipment

in any way.

B2 2

592

Read

Other

Side

Read

Next

Tag

WARNINGS

WARNINGS

WARNINGS

■

Never attach ladder or rebar hooks onto a D-ring.

■ Never attach multiple snap hooks onto a D-ring.

■ Never

attach anything to a D-ring other than a single, locking snap hook. The existence of another

object attached to a D-ring may prevent or falsely indicate snap-hook engagement.

■

Store your OPE equipment in a clean, dry area such as

a tool chest or storage room.

■

Employer – Before allowing the use of this equipment,

instruct your employees as to its proper use and alert them

to these warnings.

■ Read, understand and follow all instructions, cau-

tions and warnings attached to and/or packed with this

and all occupational protective equipment before

each use.

■ Klein strongly recommends that Klein components

NOT be interchanged with other components made

by other manufacturers because Klein cannot guarantee that

other manufacturers’ components are free of defects in materials or workmanship.

B2 3.

592

Read

Other

Side

Read

Next

Tag

WARNINGS

■ AVERTISSEMENT: Ne pas réutiliser un harnais

ayant déjà interrompu la chute d’un utilisateur.

■ AVERTISSEMENT: Ajuster la sangle pec-

torale à mi-hauteur de la poitrine.

■ AVERTISSEMENT: Au cours d’une opération de

sauvetage, le ou les cordages ne devraient étre fixés

qu’à l’anneau simple monté à l’arrière ou aux deux

anneaux coulissants en forme de D montés sur les

épaules.

■ WARNING: Any unit harness which has seen

fall arresting service should not be used after such

service.

■ WARNING: The chest strap should be positioned at

the mid-chest level.

■ WARNING: During a rescue, the line or lines should

be attached only to the single-mounted back D-ring and/or

to both shoulder- mounted sliding D-rings.

CSA B2 1.

693

Read

Other

Side

Read

Next

Tag

HOMOLOGU

É

CSA

CSA CERTIFIED

HARNAIS DE SÉCURITÉ

Z259.10 ANSI Z359.1

FULL-BODY HARNESS

Z259.1 ANSI Z359.1

KLEIN TOOLS INC., CHICAGO, IL USA LM91642

KLEIN TOOLS INC., CHICAGO, IL USA LM91642

General T ags for Harnesses

87012, 87020, 87021, 87022, 87023, 87044, 87074,

87075, 87076, 87080, 87081, 87082, 87090, 87091,

87092, 87093, 87810, 87811, 87812, 87813, 87814,

87820, 87821, 87822, 87823, 87824, 87829, 87830,

87831, 87832, 87840, 87841, 87842, 87850, 87851,

87852, 87853, 87854, 87890, 87891, 87892, 87893,

87962, 87963, 87964, 87965

Klein Harness Warning Tags (continued)

19

Page 20

Klein permanently attaches highly durable warning

and instruction tags and/or labels to its harnesses. In

the event any of these tags and/or labels become

unattached, lost, or damaged, contact the Klein Tools

Sales Department, toll-free at 1-800-553-4676 for

information on how to have the tags and/or labels

replaced free of charge.

For Fall-Arrest Use Only

■ Harness mustbe worn so that the fall-arrest

D-ring is centered in back.

■ Fall-arrest anchorage must support a minimum of

5,000 lbs. (22.2kN) per attached worker and be independent of worker support.

■ Attach fall-arrest connecting devices that

meet OSHA standards only to the rear fall-arrest

D-ring.

■ Rig to avoid contact with structures below

in the event of a fall. The free-fall distance must

not exceed 6 ft. (1.8m). If using a deceleration

unit, add 3-1/2 ft. (1m) to the free-fall distance to allow

for unit extension.

■ For fall-arrest, always keep anchorage at or above

shoulder height to minimize fall distance.

C2a 1

592

Read

Other

Side

Read

Next

Tag

WARNINGS

WARNINGS

■ OSHA requires that impact force in a fall

NOT exceed an 1,800 lb. (8kN) limit with a harness. At a given weight, the longer the free fall,

the greater the resulting impact force. Therefore,

minimize slack in fall-arrest connecting device

or use deceleration unit to stay under 1,800 lbs.

(8kN).

WARNINGS

C2a 2.

592

Read

Next

Tag

For Fall-arrest and Positioning Use Only

■

Harness must be worn so that the fall-arrest

D-ring is centered in back.

■

Attach fall-arrest connecting devices that meet

OSHA standards only to the rear fall-arrest D-ring.

■

Attach positioning connecting devices that

meet OSHA standards only to the side D-rings.

Side D-rings are NOT for fall-arrest.

■

Fall-arrest anchorage must support a mini-

mum of 5,000 lbs. (22.2kN) per attached worker

and be independent of worker support.

■

Positioning anchorage must support at least twice the

potential impact load of an employee’s fall or 3,000 lbs.

(13.3kN), whichever is greater.

■ For fall-arrest, always keep anchorage at or

above

shoulder height to minimize fall distance.

C2ab 1

592

Read

Other

Side

Read

Next

Tag

WARNINGS

WARNINGS

WARNINGS

C2ab 2.

592

Read

Next

Tag

■

Rig to avoid contact with structures below

in the event of a fall. The free-fall distance

must not exceed 6 ft. (1.8m). If using a deceleration unit, add 3-1/2 ft. (1m) to the free-fall distance to allow for unit extension.

■

OSHA requires that impact force in a fall NOT

exceed an 1,800 lb. (8kN) limit with a harness. At a

given weight, the longer the free fall, the greater the

resulting impact force. Therefore, minimize slack in fall

-arrest connecting device or use deceleration unit to

stay under 1,800 lbs. (8kN).

Specific Tags for Fall Arrest Harnesses

87020, 87021, 87022, 87023,

87074, 87075, 87076

Specific Tags for Fall Arrest/Position Harnesses

87080, 87081, 87082, 87810, 87811, 87812, 87813,

87814, 87820, 87821, 87822, 87823, 87824, 87829,

87830, 87831, 87832, 87962, 87963, 87964, 87965

Klein Harness Warning Tags(continued)

20

Page 21

For Fall-Arrest and Retrieval Use Only

■ Harness must be worn so that the fall-arrest

D-ring is centered in back.

■ Attach retrieval V-sling connecting devices that meet

OSHA standards only to the shoulder D-rings. Shoulder D-rings are NOT for fall-arrest.

■ Attach fall-arrest connecting devices that

meet OSHA standards only to the rear fall-arrest

D-ring.

■ Fall-arrest anchorage must support a

minimum of 5,000 lbs. (22.2kN) per attached

worker and be independent of worker support.

■ To use the retrieval function of this harness, attach