Page 1

7

®

These instructions apply to gaffs for Klein pole

climbers (Cat. No. 1972AR Series and 1986AR

Series) and gaffs for Klein tree climbers (Cat. No.

1907AR Series).

are available for Klein pole and

tree climbers and can be installed in the field. Many

companies now replace all gaffs as they become dull

When resharpening becomes necessary (for those

companies or users who elect not to replace worn

gaffs), use only the Klein Cat. No. KG-1 gaff gauge,

which is available separately or in the Klein gaff-

sharpening kit, Cat. No. KG-2.

To assure proper sharpening, follow the instructions

in this booklet exactly. For your protection, we

original gaff and two replacement gaffs have been

used on the climbers.

essential to prevent serious injury or death.

para postes de Klein (garfios No. de cat. serie

1972AR y serie 1986AR) y a los trepadores

para árboles de Klein (garfios No. de cat. serie

1907AR).

disponibles para los

trepadores para postes y árboles de Klein y pueden

instalarse en el campo de operacíon. Muchas

compañías reemplazan ahora todos los garfios

cuando se desafilan, en lugar de correr el riesgo de

o usuarios que opten por no reemplazar los garfios

desgastados), utilice únicamente el calibre de garfios

separado o en el juego de afilado de garfios No. de

catálogo KG-2 de Klein.

siga exactamente las instrucciones que aparecen

en este folleto. Para su protección, recomendamos

que los trepadores se reemplacen cuando el garfio

original y dos garfios de repuesto se hayan utilizado

en los trepadores.

apropiados son esenciales para evitar lesiones

graves o la muerte.

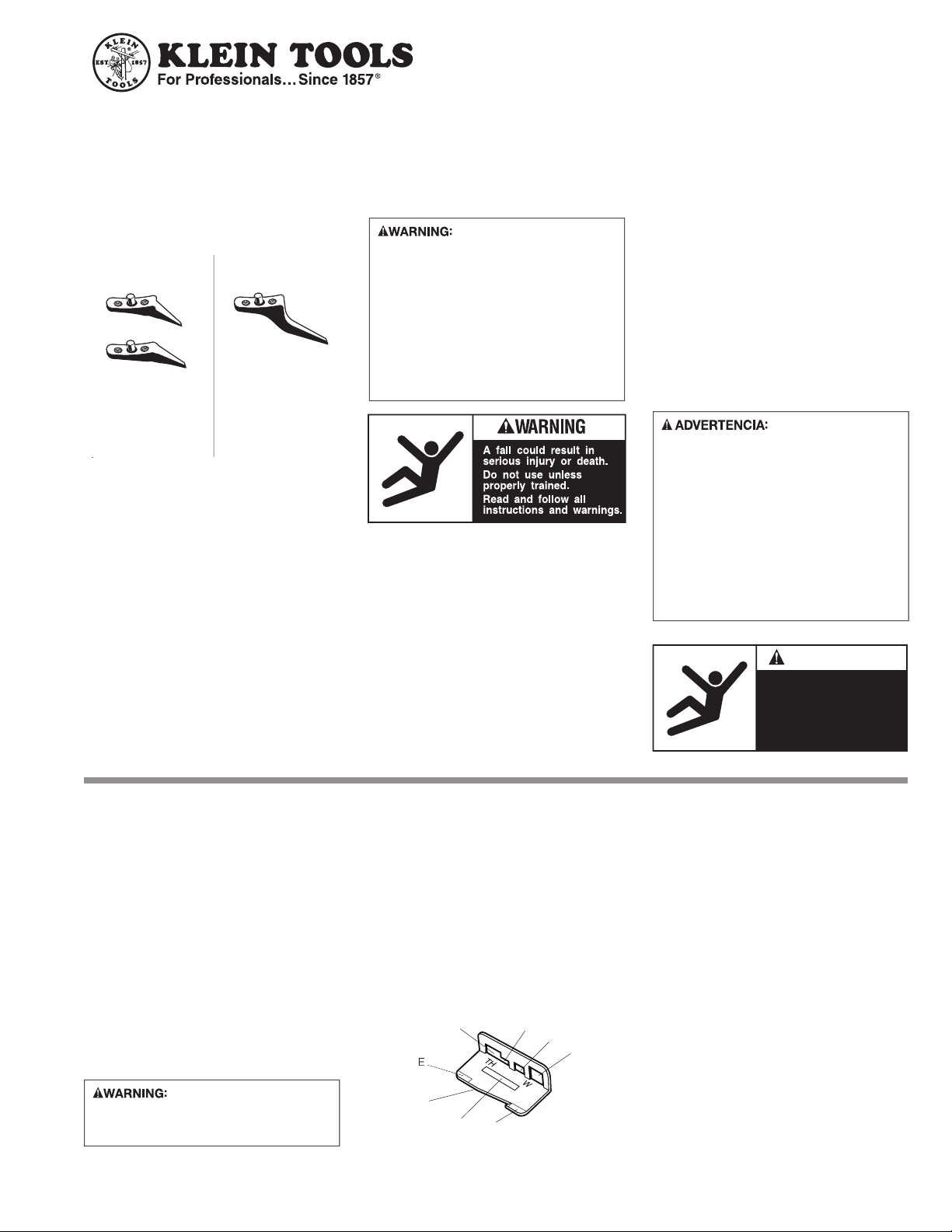

Tree Climber Gaff

Garfios de trepador para

árboles

Garfios de trepador para

postes

postes

Cat. No. 72

Cat. No. 86

Cat. No. 07

ADVERTENCIA

Una caida podria causar lesiones

General Description

critically-accurate dimensions and configuration to

function properly and to assure maximum protection

from the possibility of “cut-outs” or tip breakage

that could cause serious injury or death from a fall.

Although pole-climber gaffs are shorter than tree-

climber gaffs (see Figures 1 and 2), their points are

sharpened to identical configurations.

The Klein gaff gauge precisely measures both

gaff types, to accurately determine if gaffs need

to be sharpened, even in the field. See the “Gaff

specific

instructions on inspecting pole and tree-

climber gaffs.

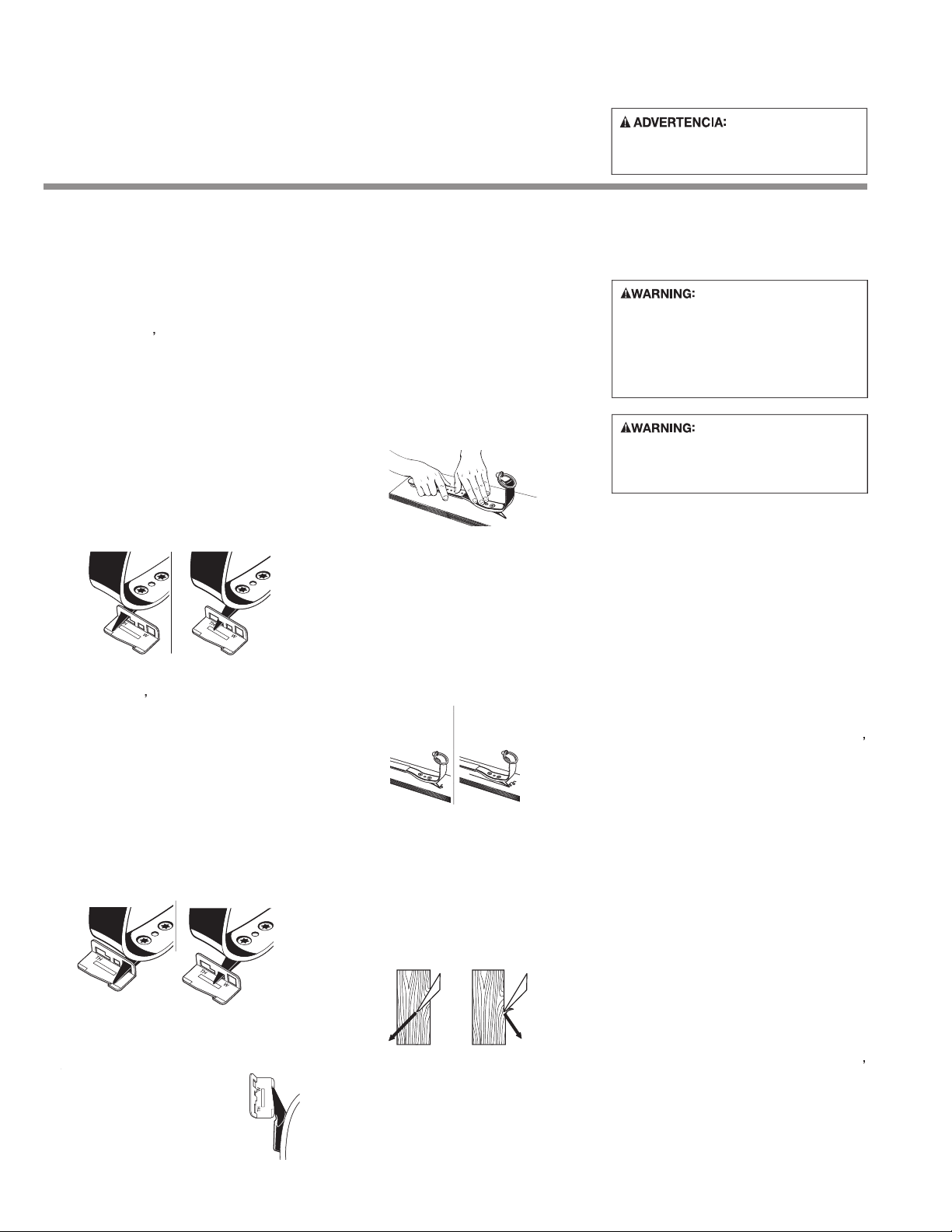

This gauge has openings and calibration marks for

precisely measuring gaff width, thickness, and point

profile (see Figure 3).

A

(pole gaffs only)

Slot to measure thickness 1/2" (12.7 mm) from tip

C.

Slot to measure width 1/2" (12.7 mm) from tip

Slot to measure width 1" (25.4 mm) from tip

(pole gaffs only)

Proper length-limit marks when measuring

thickness or width 1" (25.4 mm) from tip

Proper length-limit marks when measuring

thickness or width 1/2" (12.7 mm) from tip

G.

Template for determining proper tip profile

deben afilarse con unas dimensiones y una

configuración de precisión crucial para funcionar

correctamente y garantizar la máxima protección

contra la posibilidad de “deslizar y salirse” o de

graves o la muerte como resultado de una caída.

Aunque los garfios de trepador para postes son más

cortos que los garfios de trepador para árboles (vea

las Figuras 1 y 2), sus puntas están afiladas con

configuraciones idénticas.

ambos tipos de garfios, para determinar con

exactitud si es necesario afilar los garfios, incluso en

el campo de operacíon. Vea la sección de este folleto

“Procedimientos de inspección de los garfios” para

obtener instrucciones específicas.

The Klein Gaff Gauge

(Continúa en la página siguiente)

A

C

G

Save the se i nstruct ions.

This instruction booklet covers only the proper

use of the Klein gaff gauge and proper gaff-

sharpening instructions. Complete pole and tree

climber instructions are sent with each set of

climbers. Pole and tree climbers must not be used

without first reading, understanding, and following

installation, operation, inspection, maintenance,

and gaff sharpening instructions. Failure to read,

understand and follow all instructions may result

in serious injury or death. Training and instruction

the user and his or her employer.

Guarde estas instrucciones.

utilización correcta del calibre de garfios de Klein

y las instrucciones de afilado correcto de garfios.

para postes y para árboles se envían con cada

juego de trepadores. Los trepadores para postes

y para árboles no deben utilizarse sin primero leer,

entender y seguir las instrucciones de instalación,

utilización, inspección, mantenimiento y afilado de

garfios. Si no se leen, entienden y siguen todas las

instrucciones, el resultado podría ser una lesión

grave o la muerte. El usuario y su empleador deben

original gaff and two replacement gaffs have been

used on the climbers.

graves o la muerte.

No utilice este dispositivo a menos

que haya recibido capacitacion

adecuada.

Lea y siga todas las instrucciones

y-advertencias.

Page 2

(El calibre tiene aber turas y marcas de calibración

para medir con precisión la anchura, el grosor y el

perfil de la punta de los garfios (vea la Figura 3 en

la pagina 1).

A.

Ranura para medir el grosor a 1 pulgada (25,4

mm) de la punta (garfios para postes solamente).

Ranura para medir el grosor a 1/2 pulgada (12,7

mm) de la punta.

C.

Ranura para medir la anchura a 1/2 pulgada

(12,7 mm) de la punta.

Ranura para medir la anchura a 1 pulgada (25,4

mm) de la punta (garfios para postes solamente).

Marcas de límite de longitud apropiada cuando

se mide el grosor o la anchura a 1 pulgada (25,4 mm)

de la punta.

Marcas de límite de longitud apropiada cuando

se mide el grosor o la anchura a 1/2 pulgada (12,7

mm) de la punta.

G.

Plantilla para determinar el perfil apropiado de la

punta.

Carefully inspect the entire gaff before each use.

Check gaffs.

Check that gaffs are free of dents, gouges, or

scratches.

Check gaff thickness with Klein Gaff Gauge.

pole gaffs

only

,

inser t the gaff as far as

possible through the large opening in the gauge

marked “TH” (Figure 4). Make sure the top ridge is

flush against the gauge base. The point of the gaff

should fall within the limits formed by the last line and

the edge of the gauge, as shown. If it does, the gaff

is the proper thickness, as measured approximately

pole and tree gaffs,

insert the gaff as far as

possible through the small opening in the gauge

marked “TH” (Figure 5). Make sure the top ridge

is flush against the gauge base. The point should

fall within the center two lines, as shown. If it does,

the gaff is the proper thickness, as measured

approximately 1/2" (12.7 mm) from the point.

3.

Check gaff width with Klein Gaff Gauge.

pole gaffs

only

,

insert gaff as far as possible

through the large square opening in the gauge

marked “W” (Figure 6). Make sure the top ridge is

flush against the gauge base. The point should fall

within the limits formed by the last line and the edge

of the gauge, as shown. If it does, the gaff is the

proper width, as measured approximately 1" (25.4

mm) from the point.

pole and tree gaffs

through small opening in the gauge marked “W”

(Figure 7). Make sure the top ridge is flush against

the gauge base. The point should fall within the

center two lines, as shown. If it does, the gaff is the

proper width, as measured approximately 1/2" (12.7

mm) from the point.

Check gaff profile/contour with Klein Gaff

Gauge.

pole and tree gaffs,

place the

side of gaff along the front edge of

the gauge with gaff point resting in

the notch. The point should follow the

configuration of the gauge to assure

proper “rounding off” of the tip within

Minimum safe length for a pole-climbing gaff is

1-7/16" (37.5 mm), measured on the underside of

gaff. Minimum safe length for a tree-climbing gaff

is the greater of the following: (a) 2-1/4" (57 mm),

measured on the underside of the gaff, or (b) long

enough to penetrate the core of the tree.

Before

climbing, always test the penetration of tree gaffs at

the base of the tree to be sure gaffs extend through

the bark and properly penetrate the wood.

5.

Check gaff sharpness with the “plane test”.

Step 1:

Place climber with gaff pointing downward

and upper strap loop resting against a horizontal

board or pole. Hold the leg iron parallel to the wood

surface, with the stirrup vertical. Push the climber

horizontally in the direction of the gaff without any

downward pressure except the weight of the climber

(see Figure 9).

Step 2:

The gaff is properly sharpened if it buries

itself in the wood within a few inches of its starting

position and can no longer be moved forward (see

merely slips, slides, or plows a shallow groove in the

wood (see Figure 11). In this case, either replace

the gaff following the “Gaff Assembly and Ordering

“Gaff Sharpening Instructions”, both contained in

this booklet. A resharpened gaff must be tested for

proper width, thickness, and point profile, and it must

also pass the “plane test” before use.

The “plane test” reveals possible penetration

problems not noticeable to the naked eye. Figure

12 shows how a properly sharpened gaff cuts its

way into the pole for proper support. Figure 13

shows how an improperly sharpened gaff can

“cut-out”.

6.

Destroy and replace all worn or damaged OPE

equipment.

mechanical malfunction is observed, replace the

equipment immediately.

Never work with worn or

damaged OPE equipment. Using damaged or worn

equipment can cause serious injury or death.

7.

The inspector is the most important part of

any inspection procedure.

Check all equipment thoroughly and follow all safety

procedures and guidelines. Do not take shortcuts.

Inspeccione minuciosamente todo el garfio antes

de cada uso.

Compruebe los garfios.

Asegúrese de que los garfios no tengan

indentaciones, acanaladuras ni arañazos.

Compruebe el grosor de los garfios con el

calibre de garfios de Klein.

garfios de poste

solamente

,

introduzca el garfio tanto como sea posible a través

de la abertura grande que está en el calibre marcada

con las letras “TH” (Vea la figura 4). Asegúrese de

que la cresta superior esté al ras contra la base

del calibre. La punta del garfio debe caer dentro

de los límites formados por la última línea y el

borde del calibre, de la manera que se muestra en

la ilustración. Si lo hace, el garfio tiene el grosor

adecuado, según se mide aproximadamente a 1

pulgada (25,4 mm) de la punta.

garfios de poste y de árbol,

introduzca el garfio tanto como sea posible a través

de la abertura pequeña que está en el calibre

marcada con las letras “TH” (Vea la figura 5).

Asegúrese de que la cresta superior esté al ras

contra la base del calibre. La punta debe caer dentro

de las dos líneas centrales, de la manera que se

muestra en la ilustración. Si lo hace, el garfio tiene el

grosor adecuado, según se mide aproximadamente

a 1/2 pulgada (12,7 mm) de la punta.

3.

Compruebe la anchura de los garfios con el

calibre de garfios de Klein.

garfios de poste

solamente

,

introduzca el garfio tanto como sea posible a través

de la abertura cuadrada grande que está en el

calibre marcada con la letra “W” (Vea la figura 6).

Asegúrese de que la cresta superior esté al ras

contra la base del calibre. La punta debe caer

dentro de los límites formados por la última línea y

el borde del calibre, de la manera que se muestra

en la ilustración. Si lo hace, el garfio tiene el grosor

cuando el garfio original y dos garfios de repuesto

se hayan utilizado en los trepadores.

(continuacion)

Gaff Inspection Procedures

z

AA

- Correcto

- Incorrecto

BB

- Correcto

- Incorrecto

de los garfios

2

OSHA specifies that all employers

covered by the Occupational Safety and Health

Act are responsible for inspecting and maintaining

all tools and equipment used by employees —

whether owned by the employees or by the

company. Personal-protective equipment should

be inspected before each use and removed from

service if signs of wear or damage are found.

Should any unusual conditions

be noted during inspection that are not specified

here, do not use the suspect equipment until an

individual considered by OSHA to be qualified

makes a decision on its usability.

Page 3

adecuado, según se mide aproximadamente a 1

pulgada (25,4 mm) de la punta.

garfios de poste y de árbol,

introduzca el garfio tanto como sea posible a través

de la abertura pequeña que está en el calibre

marcada con la letra “W” (vea la Figura 7 en la pagina

2). Asegúrese de que la cresta superior esté al ras

contra la base del calibre. La punta debe caer dentro

de las dos líneas centrales, de la manera que se

muestra en la ilustración. Si lo hace, el garfio tiene el

grosor adecuado, según se mide aproximadamente

a 1/2 pulgada (12,7 mm) de la punta.

Compruebe el perfil o el contorno de los

garfios con el calibre de garfios de Klein.

garfios de poste y de árbol,

coloque

el lado del garfio a lo largo del borde delantero del

calibre de manera que la punta del garfio descanse

en la muesca. La punta debe seguir la configuración

del calibre para garantizar el “redondeado” adecuado

de la punta hasta 1/4 de pulgada (6,4 mm) de la

punta (vea la Figura 8 en la pagina 2).

trepar postes es 1-7/16 de pulgada (37,5 mm)

medidas en la cara inferior del garfio. La longitud

segura mínima para un garfio para trepar árboles

es la mayor de las siguientes: (a) 2-1/4 de

pulgada (57 mm), medidas en la cara inferior del

garfio, o (b) lo suficientemente larga como para

penetrar en el interior del árbol.

Antes de trepar,

compruebe siempre la penetración de los garfios de

árbol en la base del árbol con el fin de asegurarse

de que los garfios atraviesan la corteza y penetran

adecuadamente en la madera.

5.

Compruebe la agudeza de los garfios con la

“prueba de acepillado”.

Coloque el trepador con el garfio orientado

hacia abajo y con el bucle de la correa superior

descansando contra una tabla o un poste horizontal.

Sujete la pieza de hierro para la pierna paralela a

la superficie de madera, con el estribo en posición

vertical. Empuje el trepador horizontalmente en

dirección hacia el garfio sin ninguna presión hacia

abajo, excepto el peso del trepador (vea la Figura 9

en la pagina 2).

El garfio está afilado correctamente si se

incrusta en la madera a unas pocas pulgadas de su

posición de comienzo y ya no puede moverse hacia

adelante (vea la Figura 10 en la pagina 2). El garfio

no está afilado correctamente si meramente resbala,

se desliza o hace una ranura poco profunda en la

madera (vea la Figura 11 en la pagina 2). En este

caso, reemplace el garfio siguiendo las “Instrucciones

de montaje y pedido de garfios’ o reafile el garfio

siguiendo las “Instrucciones de afilado de garfios”.

Ambas instrucciones se encuentran en este folleto.

para verificar si tiene la anchura, el grosor y el perfil

de la punta apropiados, y también debe pasar la

“prueba de acepillado” antes de utilizarse.

problemas de penetración que no pueden ser

observados por el ojo humano. En la Figura 12

en la pagina 2

se muestra cómo un garfio afilado

correctamente corta abriéndose camino en el

poste para lograr un soporte adecuado. En la

se muestra cómo un

garfio afilado incorrectamente puede “deslizar

y salirse”.

6.

Destruya y reemplace todo equipo de

protección laboral (EPL) desgastado o dañado.

Si se observa evidencia de desgaste excesivo,

deterioro o mal funcionamiento mecánico, reemplace

inmediatamente el equipo. Nunca trabaje con equipo

de protección laboral desgastado o dañado. La

utilización de equipo dañado o desgastado puede

causar lesiones graves o la muerte.

El inspector es la parte más importante de la

inspección.

Compruebe minuciosamente todo el equipo y siga

todos los procedimientos y directrices de seguridad.

alguna situación inusual durante la inspección,

que no se especifique aquí, no utilice el equipo

bajo sospecha hasta que una persona que OSHA

considera calificada tome una decisión sobre su

utilizabilidad.

OSHA especifica que

todos los empleadores cubiertos por la Ley de

Seguridad y Salud Laboral son responsables de

inspeccionar y mantener todas las herramientas

y equipos utilizados por los empleados, tanto si

pertenecen a los empleados como si pertenecen

a la compañía. El equipo de protección personal

debe ser inspeccionado antes de cada uso y ser

desgaste o daños.

de los garfios

(continuacion)

Clean and maintain gaffs as recommended.

Make sure all metal parts are clean and free of

foreign material.

Wipe metal parts dry with a clean

cloth.

C.

Maintain or replace gaffs as explained in this

booklet to preserve proper width, thickness, point

profile, and sharpness.

2.

Reinspect all equipment after maintenance.

all maintenance procedures to determine if the

maintenance was done properly and effectively.

Limpie y mantenga los garfios de acuerdo con

las recommendaciones.

A.

Asegúrese de que todas os garfios estén limpias

y libres de material extraño.

Limpie y seque

los garfios con un paño limpio.

C.

Mantenga o

en este folleto para preservar la anchura, el grosor,

el perfil de la punta y la agudeza apropiados.

2.

Reinspeccione todo el equipo después del

mantenimiento.

para determinar si dicho mantenimiento se realizó

de forma adecuada y eficaz.

Always use a fine-tooth file.

which will alter the temper of the gaff and make it

dangerous to use. A proper file is contained in the

2.

File gaff from heel to point.

as shown in Figure 14, so that you can file from the

heel to the point of the gaff as shown by the arrow in

good point. Never cross file. Cross-filing weakens the

point, and under load it may cause tip breakage.

3.

Remove any file marks by honing.

Work the honing stone in the same direction as

the file (as shown by the arrow in Figure 15.) A

compatible honing stone is included in the KG-2 kit.

4.

Do not make a needle point.

file both side slopes to obtain straight edges. The top

straight from the tip back at least 1" (25.4 mm) and

should not be altered. Deep nicks, dents, or scratches

along the top ridge require gaff replacement. The final

point must always be in the top ridge of the gaff.

5.

Maintain proper shape on underside of gaff.

The underside of the gaff should be perfectly straight

(flat) to within 1/4" (6.35 mm) of the point, then

on a radius of 1/4" (6.35 mm) (see Figure 15). At

a distance of 1/16" (1.59 mm) back from the point,

the width should be a minimum of 3/32" (2.38 mm)

measured on the underside of the gaff (see Figure

perfectly straight (see Figure 15).

6.

Replace gaffs when necessary.

should not be used after the underside

of the gaffs are worn or filed to 1-7/16" (37 mm) long.

Tree climbers

should not be used after the underside

of gaffs are worn or filed to 2-1/4" (57 mm) long.

When bark thickness measures more than 2-1/2"

(64 mm), make sure the gaff has adequate

length to

properly penetrate the wood under the bark.

When climber gaffs measure less than the above

limits, they should be replaced with a new pair. For

your protection, Klein recommends that climbers be

gaffs have been used on the climbers.

7.

Check final result after sharpening.

Gaff Sharpening Instructions

and the use of pole or tree climbers for purposes

other than specified here can result in serious

injury or death.

- Wrong

- Incorrecto

Sharp Cutting Edges

Bordes de corte afilados

3/32"

Cross Section View

of Point

Vista de una sección

transversal de la

punta

of Gaff

Side Slope

Top

3

Page 4

Utilice siempre una lima dulce.

amolar, ya que se generará calor, lo cual alterará

el templado del garfio y hará que sea peligroso

utilizarlo. El juego KG-2 de Klein contiene una lima

adecuada.

Lime el garfio desde el talón hacia la punta.

Coloque el trepador en un tor nillo de carpintero

de mandíbulas lisas con el garfio de la manera

que se muestra en la Figura 19, para que pueda

limar desde el talón hacia la punta del garfio de

la manera mostrada por la flecha en la Figura 19.

Quite solamente suficiente material como para hacer

una buena punta. Nunca lime transversalmente. El

limado transversal debilita la punta y bajo carga

puede hacer que la punta se rompa.

3.

Quite todas las marcas de lima mediante

rectificado.

la lima (de la manera mostrada por la flecha en la

4.

No haga una punta de aguja.

Con el fin de no hacer una punta de aguja (vea la

laterales para obtener bordes rectos. La cresta

superior del garfio (vea la Figura 17 en la pagina 3)

debe ser perfectamente recta desde la punta hacia

atrás al menos 1 pulgada (25,4 mm) y no debe

alterarse. Las muescas, indentaciones o arañazos

profundos a lo largo de la cresta superior requieren

el reemplazo del garfio. La punta final debe estar

siempre en la cresta superior del garfio.

5.

Mantenga la forma adecuada de la cara

inferior del garfio.

la punta y luego estar redondeada ligeramente

hacia la cresta superior del garfio en un radio de

una distancia de 1/16 de pulgada (1,59 mm) hacia

atrás desde la punta, la anchura debe ser de 3/32

de pulgada (2,38 mm) como mínimo, medida en la

cara inferior del garfio (vea la Figura 17 en la pagina

3). El resto de la cara inferior debe mantenerse

perfectamente recto (vea la Figura 19).

6.

Reemplace los garfios cuando sea necesario.

no deben utilizarse

después de que la cara inferior de los garfios esté

desgastada o limada hasta 1-7/16 de pulgada (37

mm) de longitud.

no deben utilizarse después de que la cara inferior

de los garfios esté desgastada o limada hasta

2-1/4 de pulgada (57 mm) de longitud. Cuando el

grosor de la corteza mida más de 2-1/2 pulgadas

(64 mm), asegúrese de que el garfio tenga la

longitud adecuada para penetrar apropiadamente en

la madera que está debajo de la corteza.

Cuando los garfios de trepador midan menos que los

límites que anteceden, deben reemplazarse con un

par nuevo. Para su protección, Klein recomienda que

los trepadores sean reemplazados cuando el garfio

original y dos garfios de repuesto se hayan utilizado

en los trepadores.

Compruebe el resultado final después de

afilar el garfio.

calibre.

Talón

Cara

inferior

del garfio

Cresta

superior

garfios

Gaff Assembly

Attach gaff with locator pin (B) to

middle hole of leg iron.

Thread longer screw (C) into

bottom hole (nearest gaff point). Do

not seat screw.

3.

Thread shorter screw (A) through

flat portion of gaff.

Alternate tightening of both screws until seated.

Gaff Ordering.

Gaffs are supplied in pairs with

TORX® screws and wrench. No. 72 gaffs, No. 86

gaffs, and No. 07 gaffs are interchangeable and fit all

Cat. No. Description

72

Pair of 1-1/2" (38 mm) gaffs.

climbers only.

86

Pair of 1-9/16" (40 mm) gaffs.

climbers only.

07

Pair of 2-3/4" (70 mm) gaffs.

climbers only.

Montaje del garfio (vea las Figura 20 y 21)

Sujete el garfio con el pasador posicionador (B)

en el agujero central de la pieza de hierro para la

pierna.

2.

Enrosque el tornillo más largo (C) en el agujero

inferior (más próximo a la punta del garfio). No

asiente el tornillo.

3.

Enrosque el tornillo más corto (A) a través de la

porción plana del garfio.

4.

Alterne el apriete de los dos tornillos hasta que

estén asentados. No sobrepase 24 pies-libra de par

de torsión en el tornillo.

Los garfios se suministran en

pares con tornillos TORX

®

y una llave de tuerca.

trepadores con garfios intercambiables de Klein.

No de cat. Descripción

Par de garfios de 1-1/2 pulgadas (38

mm).

solamente.

86

Par de garfios de 1-9/16 de pulgada

(40 mm).

postes solamente.

07

Par de garfios de 2-3/4 de pulgada

(70 mm).

Para trepadores para

árboles solamente.

Gaff Assembly and Ordering

The e mpl oyer an d us er are

solely r esponsible fo r obtaining and correctl y

using th e pr oper climbe rs, gaffs, a nd o ther

occupa tio nal pro tective equipm ent. Use only

approved equi pme nt.

The use of occupational protective

The use of occupational protective

equipment without proper instructional materials

and training could result in serious injury or death.

materials, warnings tags, or will answer questions

on any piece of Klein occupational protective

equipment free of charge. Call Klein Tools, Inc. at

A

C

e instrucciones de pedido

7200 McCormick Blvd., P.O. Box 599033, Chicago, IL 60659-9033

7200 McCormick Blvd., P.O. Box 599033, Chicago, IL 60659-9033

© 2002 Klein Tools, Inc.

garfios y el uso de los trepadores para postes o

para árboles con fines que no sean los que se

especifican aquí pueden causar lesiones graves

o la muerte.

son los únicos responsables de obtener y utilizar

correctamente los trepadores, los garfios y otros

equipos de protección laboral apropiados. Utilice

solamente equipos aprobados.

protección laboral sin los materiales instructivos

apropiados y la capacitación adecuada podría

causar lesiones graves o la muerte. Klein Tools

proporcionará materiales instructivos y etiquetas de

advertencia adicionales, o responderá gratuitamente

a todas las preguntas sobre cualquier unidad de

equipo de protección laboral de Klein. Llame a Klein

Tools, Inc., al 1-800-553-4676.

Loading...

Loading...