Page 1

Arrow

saddle b

ends.

Star Point

Angle Marks

situations

Conduit Bender Guide

Center

of Bend Rim

Notches

Klein Tools

1-¼”

EMT: #56211

Klein Tools

Conduit Bending Basics:

The line of Klein Tools conduit benders have been designed for performance and durability exceeding

the expectations of today’s professional. It is recommended to familiarize yourself with bending

concepts, techniques and learn the bender’s functionality to provide you a positive experience while

greatly improving the overall outcome of your project.

Conduit come in two types, EMT and Rigid conduits and can be found in various sizes. Klein Tools

provides conduit benders for EMT in ½”, ¾”, 1” and 1-¼” conduit and ½”, ¾”, and 1” Rigid conduit.

To aid bending when performing a ground or air bend, the benders are marked with different alignment

symbols to help the operator create the bends necessary to accomplish any project. The symbols found

on the Klein Tools benders are the arrow, the teardrop, the star point and angle markings. These

markings are found on various sides of the bender head.

Ductile Iron Series:

½” EMT: #56203

¾

” EMT: #56204

1” EMT: #56205

Uses: Locates the center of a

saddle bend.

Aluminum Series:

½” EMT: #56206

¾” EMT: #56207

Uses: Stub-up, Offset

and outer marking of

Stub Height

Uses: Number to use

for bender take-up.

The 4 most common bends to know how to make are the 90° Stub-Up, Back to Back, Offset and the 3

Point Saddle bends. It is common to use a combination of the bender markings when making certain

tube profiles. Knowing the proper technique and method of making the bends will allow you to

accomplish most projects efficiently.

Things to remember while bending:

1. A proper bend is made by rolling the conduit about the bender in the conduit’s cradle using all foot pressure.

2. Use the correct size bender for the conduit size being bent.

3. Some over bending may be required to allow for spring back of the conduit. The resting condition of the conduit is to be at

the final angle desired.

4. Measure and properly mark your conduit using the tables and information provided.

5. Floor bending: Make sure conduit is secure so it does not slide prior to bending. Apply ample foot pressure to the benders

heel while minimizing the use of the handle as a lever but more of a guide.

6. Air Bending: Make sure handle’s hilt is secure on ground and is reinforced by your foot so it does not slide out. Make sure

you are balanced and apply force close to the tool and your body controlling the tubing as you bend it around the bender’s

cradle making sure the conduit does not slide in the bender head.

7. To prevent injury, always wear protective gear and do not over exert.

Uses: Back bends.

Uses: Offset, saddle bends

and various installation

1

Page 2

90° Stub-Up Bend:

½”

EMT

5”

¾” EMT

6” 1” EMT

8”

1-¼” EMT

11”

The stub bend is made by bending a piece of conduit into an L shape or 90° bend by placing the free end

(short end) of the tube to a predetermined length as indicated in the diagram below. This is the most

common bend and is a building block for other bends. Common uses for this bend are: Running conduit

into electrical boxes, running conduit up or down walls, running conduit into walls through floors and

ceilings and making inner and outer corner turns.

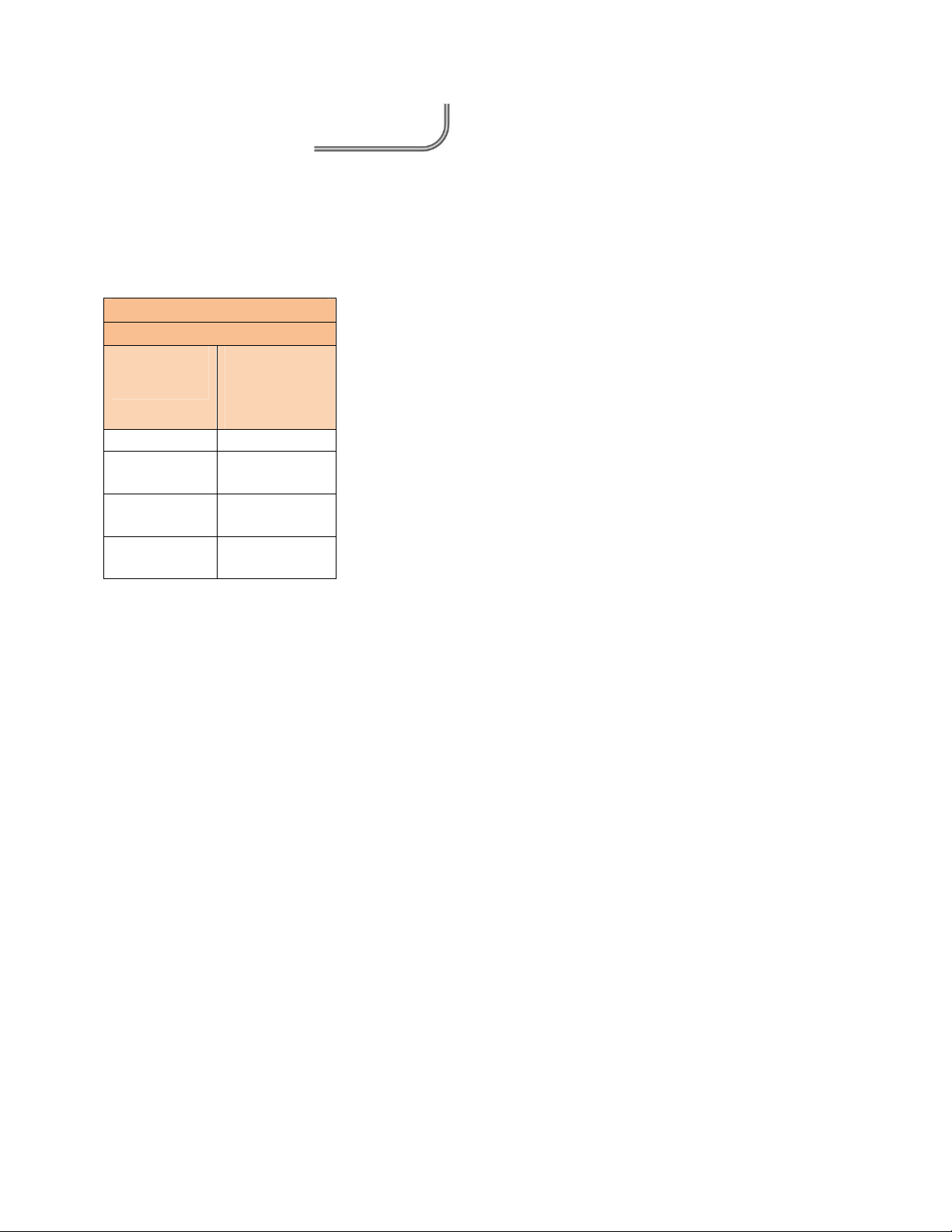

Bender Take Up Table

90° Stub-Up Bend

Conduit

Size

and ½” Rigid

and ¾” Rigid

and 1” Rigid

1. Determine the overall free end height of the conduit you want after the bend.

2. From the overall free height, subtract the stub height listed in the Bender Take-Up Table for the

conduit size you are bending. Klein Tools has provided the correct stub height on each bender head.

3. On the conduit, measure from the free end to be bent up the calculated number and mark the

conduit.

Stub

Height

Amount to subtract

from Measurement

As an example, to bend 3/4” EMT conduit have a free end height

of 8.5”, the table indicates to subtract 6” from the 8.5” which

leave 2.5” from the end to bend up to make the mark.

Advanced benders can lay a tape measure next to the conduit and perform the

bending operations if the bend does not call for high degree of accuracy.

4. Always use the proper size conduit bender for the conduit size being

bent. The conduit will not bend properly and/or will be damaged if a

mismatch of bender and conduit size is used. Place the bender onto the

tubing with the hook pointed towards the free end to be bent upwards.

Make sure the conduit is resting properly in the bender’s hook and

lineup the arrow symbol with the mark you placed on the tubing.

Tip:

2

Page 3

5. Keeping the conduit flat, apply ample foot pressure to the bender’s heel minimizing the use of

the handle as a lever, rolling up the free end into the 90° position checking the degree with a

level. When done properly the free end will be at the desired height and the arrow will be at

the stub height as indicated.

In some installations there will be a need to cut down the

unbent side of the conduit to another desired length to fit

the installation. Use a tube cutter for smooth precise

cutting and burr removal to ensure the safety of the

electrical wiring when pulled through. A hacksaw can be

substituted as long as the tubing’s cut edge is prepared

properly.

Klein Tools Tube Cutter: #88975 & 88977

K

lein Tools Hacksaw: #701-10, 701 -12 &701 -S

Klein Tools Level: #931-6RE & 931-7RE

3

Page 4

Back to Back Bends:

The back to back bend is the next style of bend that is needed while running electrical conduit. In reality

the concept is formulated by the need to know the distance from the back edge of a 90° bend to a fixed

point down the conduit to mark for other bend operations to meet the installation requirement. As you

will see it builds on the 90° stub bend and when done the most common use of this bend will look like

an elongated U.

You will need to know this bend method when you want to fit conduit between two parallel surfaces

such as two walls or joists while keeping the U’s outer edges of the legs touching the two surfaces. This

allows for proper anchoring and a nice clean appearance.

1. Determine the distance between

the two parallel surfaces to get the

dimension for back to back bend.

2. The first bend for the back to back bend is the 90°

stub-up bend. Follow the steps from the 90° StubUp section to create the ideal bend for the

connection on the first side.

3. From the back edge of the 90° stub-up bend,

measure the distance found in step 1 and make

your mark on the conduit.

4. Place the bender on the conduit with the bender’s hook facing the free end of the tube to be

bent opposite the original bend side. Make sure the conduit is resting properly in the bender’s

cradle and lineup the Star Point Symbol with the mark you placed on the tubing.

4

Page 5

5. Keeping the conduit flat, apply ample foot pressure to the bender’s heel, with minimal use of

the handle as a lever, rolling up the free end into the 90° position checking the degree with a

level. It is very important to keep the first 90° bend in the same plane as the new bend. If not

the two legs of the U will be skewed and will not produce the desired shape. If this happens,

some correcting can be done to properly align the legs depending on how out of shape they are.

When the bend is done properly the conduit will lay flat and will fit inside the two surfaces

measured.

In some installations there will be a need to cut down the unbent side of the conduit to another desired length to fit the installation. Use a tube

cutter for smooth precise cutting and burr removal to ensure the safety of the electrical wiring when pulled through. A hacksaw can be

substituted as long as the tubing’s cut edge is prepared properly.

Klein Tools Tube Cutter: #88975 & 88977

K

lein Tools Hacksaw: #701-10, 701 -12 &701 -S

Klein Tools Level: #931-6RE & 931-7RE

If the back to back distance is short (a tight U) so the bender has problems fitting to make the

second bend, you may compensate by subtracting the stub height from the measured distance to fit

the gap then follow step 3 to mark the calculated number on the conduit. But this time you would

put the bender on the conduit with the hook facing the first bend and line up the Arrow Symbol as

demonstrated in the Stub-Up section, step 5, with the conduit mark and proceed to make the bend

as in step 5 rolling up the previously bent end up into the 90° position giving you the desired

dimension.

the operator as the second bend is made.

Caution should be taken when creating the second bend. With this technique the first bend will be coming at

5

Page 6

Offset Bends:

Angle of

Constant

Shrink Per

10° X 10°

6

1/16

= .063

22½° X

2.6 3/16

= .188

30° X 30°

2.0 1/4 = .250

45° X 45°

1.4 3/8 = .375

60° X 60°

1.2 1/2 = .500

Angle of

Constant

Shrink Per

45° X 45°

1.4 3/8 = .375

An offset bend is a style of bend that is built independently of the 90° stub and the Back to Back

bend and is an important bend to know when running conduit. It is common to shift the conduit a

certain distance while continuing to run parallel in the same direction as the pre-shift portion of the

conduit. There are many situations that call for an offset bend. The most common uses of this bend

are: staggered joists, running tight on a wall and offset into an electrical box and changes in

elevation.

Offset Formula Table

Bend

Multiplier

Inch of Offset

22½°

1. Determine/measure the offset distance necessary to clear the obstacle and how far away the

offset will need to be bent from the end of the conduit.

2. Decide what angle you wish to make the offset bend and determine the proper values from the

Offset Formula Table. Calculate the proper values to mark on the conduit to clear the obstacle

and fit in the gap measured.

Offset Formula Table

Bend

Multiplier

Inch of Offset

As an example, the offset distance of the obstacle is 6” and

the distance to obstacle is 20”. The installation allows for

a 45° X 45° offset bend. Note: The choice of degree is

usually the installer’s choice and most of the time the

installation location will determine what degree will fit.

6

Page 7

3. From the table use the 45° X 45° offset row for the values to calculate the series of markings

necessary to make the proper bend. To find out where to place the first mark on the conduit,

multiply the measured Offset Distance to clear the obstacle by the tables Shrink/Inch that will

occur to the conduit after all the bends are made due to that offset distance or:

(Offset Distance) X (Shrink/Inch) = Total Shrink.

Example: 6” X .375 = 2.25” of total shrink.

This value is then added to the measured Distance to Obstacle number or:

(Distance to Obstacle) + (Total Shrink) = First Mark Distance.

Example: 20” + 2.25” = 22.25” to make first mark.

To calculate the second mark needed on the conduit, multiply the measured Offset Distance by

the Constant Multiplier of the table or:

(Offset Distance) X (Constant Multiplier) = Second Mark Distance (Distance between Marks).

Example: 6” X 1.4 = 8.4” between 1

st

& 2nd mark.

This calculated value is how far apart to make your marks from each other on the conduit and

where to make your 45° bends.

4. Using the technique to align the

bender on the conduit as

described under the Stub-Up

Section 5, Place the bender on

the conduit with the hook

facing away from the second

mark and line up the Arrow

Symbol up with the first mark.

7

Page 8

6. Keeping the bender and conduit together flip the

two parts upside down and put the bender’s handle

hilt on the floor, balancing the conduit in the air,

allow the conduit to rotate 180° in the cradle. Slide

the conduit down so the first bend is moving away

from the bender head, aligning the second mark as

outlined before using the Arrow Symbols (See StubUp section, note 5).

5. Keeping the conduit flat, apply ample foot

pressure to the bender’s heel minimizing the use

of the handle as a lever, smoothly rolling up the

free end until the 45° mark is reached. When

done properly the free end will be at a 45° angle

from the original plane

Note: Some over bending may be required to allow for

spring back of the conduit. The resting condition of the

conduit is to be at the final angle desired.

.

7. The second bend of the offset is

accomplished by performing an air-bend. Make

sure the handle hilt is secure on ground and is

reinforced by your foot so it does not slide out.

Make sure you are balanced and apply force close

to the tool and your body controlling the tubing as

you bend it around the bender’s cradle. Bend the

free end until the 45° mark is reached.

It is very important to keep the first 45° bend in the same plane as the new bend will be. If not, the two

legs of the offset will be skewed and will not produce the desired shape. If this happens, some

correcting can be done to properly align the legs depending on how out of shape they are. When the

bend is done properly the conduit will lay flat and fit inside the measured distance to and clear the

obstacle.

In some installations there will be a need to cut down

the unbent side of the conduit to another desired

length to fit the installation. Use a tube cutter for

smooth precise cutting and burr removal to ensure the

safety of the electrical wiring when pulled through. A

hacksaw can be substituted as long as the tubing’s cut

edge is prepared properly.

Klein Tools Tube Cutter: #88975 & 88977

Klein Tools Hacksaw: #701-10, 701 -12 &701 -S

8

Page 9

Three Point Saddle Bend:

Every inch Add:

3/16” 2-1/2” 1/4” 2”

1” 3/16”

2-

1/2” 1/4”

2” 2”

3/8”

5”

1/2”

4” 3”

9/16”

7-

1/2” 3/4”

6” 4”

3/4”

10” 1” 8” 5” 15/16”

12-

1/2”

1-

1/4” 10”

6” 1-1/8” 15” 1-1/2” 12”

The three point saddle bend is a variant of the offset bend since it is an offset bend that returns to the

original in-line run after clearing an obstacle. This bend is intended to bridge over obstacles such as

existing conduit or plumbing running perpendicular to the intended conduit installation.

1. Determine/measure the offset distance necessary to clear the obstacle and how far away the

saddle bend will need to be from the edge of the conduit. Unlike the offset bend you must

measure to the center of the obstacle to bridge over.

2. Choose the angle that will be used for the center bend. The other two return bends will be 1/2

the center angle chosen. If the center angle is 45°, the two return bends will be 22.5°. Use the

table to calculate the distance between bends and how much shrink is to occur to the conduit

due to the bends.

Degree of

Bend:

Obstruction

Height

3 Point Saddle Bend Table

45° Center

60° Center

Bend

22.5° Return Bends

Shrink

Amount

Distance off

Center Mark

30° Return Bends

Shrink

Amount

Bend

Distance off

Center Mark

Example:

distance of an obstacle is 2” and the

distance to obstacle’s center point is 20”.

The installation allows for a 45° saddle

bend. Note: The choice of degree is usually

the installer’s choice and most of the time

the installation location will determine what

degree will fit.

As an example, the offset

3. Calculate the value needed to place your first mark on the conduit. This number is determined

by the Measured Distance to Center Point of the obstacle plus the Shrink from the 3 Point

Saddle Bend Table that will occur.

(Measured Distance to Center Point) + (Shrink) = Center Mark

Example: 20” + 3/8” = 20-3/8”

9

Page 10

4. Using the Distance off Center Mark values found in the table to clear a 2” obstacle, simply mark

30° 45°

60°

that distance from the center line in both directions or subtract this number from the center

mark value for the first return bend mark and add that number to the center mark value to

obtain the second return bend mark distance.

(Center Mark) – (Distance off Center Mark) = 1

st

Return Bend Mark

Example: (20-3/8”) – 5” = 15-3/8”

(Center Mark) + (Distance off Center Mark) = 2nd Return Bend Mark

Example: (20-3/8”) + 5” = 25-3/8”

5. Mark the conduit accordingly.

6. Place the bender on the conduit and

position the appropriate Center of

Bend Rim Notch on the center mark in

the orientation shown.

10

Page 11

7. Keeping the conduit flat, apply ample foot

pressure to the bender’s heel minimizing the

use of the handle as a lever, smoothly rolling

up the free end until the 45° mark is reached.

Note: Some over bending may be required to allow for spring

back of the conduit. The resting condition of the conduit is to

be at the final angle desired.

Note: Some over bending may be required to allow for spring back of the conduit. The resting condition of the

conduit is to be at the final angle desired.

9. The second bend of the saddle bend is

accomplished by performing an air-bend.

Make sure handle hilt is secure on ground

and is reinforced by your foot so it does

not slide out. Make sure you are

balanced and apply force close to the tool

and your body controlling the tubing as

you bend it around the bender’s cradle.

Bend the free end until the 22.5° mark is

reached.

8. Keeping the bender and conduit together, flip

the two parts upside down and put the bender’s

handle hilt on the floor, balancing the conduit in the

air, allow the conduit to rotate 180° in the cradle.

Slide the conduit down so the first bend is moving

away from the bender head, aligning the 1st return

bend mark with the Arrow Symbol (See Stub-Up

section, note 5).

11

Page 12

10. Remove bender and place it back on the

conduit on the other side of the center bend with the

hook facing the center bend as before aligning Arrow

Symbol (See Stub-Up section, note 5). On the 2

nd

return bend mark.

Note: Some over bending may be required to allow for spring back

of the conduit. The resting condition of the conduit is to be at the

final angle desired

11. The last bend of the saddle bend

is made again by performing an airbend. Make sure handle hilt is secure

on ground and is reinforced by your foot

so it does not slide out. Make sure you

are balanced and apply force close to

the tool and your body controlling the

tubing as you bend it around the

bender’s cradle. Bend the free end until

the 22.5° mark is reached.

It is very important to keep all the bends in the same plane. If not, the offset will be skewed and will

not produce the desired shape. If this happens some correcting can be done to properly align the legs

depending on how out of shape they are. When the bend is done properly the conduit will lay flat and

will fit the measured distance to obstacle, clear the object and return to the original line continuing the

run as desired.

In some installations there will be a need to cut down the unbent side of the conduit to another desired length to fit the installation. Use a tube

cutter for smooth precise cutting and burr removal to ensure the safety of the electrical wiring when pulled through. A hacksaw can be

substituted as long as the tubing’s cut edge is prepared properly.

Klein Tools Tube Cutter: #88975 & 88977

Klein Tools Hacksaw: #701-10, 701 -12 &701 -S

12

Loading...

Loading...