Page 1

HYDROCHART 5000 SONAR

SYSTEM

Operations and Maintenance Manual

P/N 11210080, Rev. 02

11 Klein Drive

Salem, NH 03079-1249

U.S.A.

Tel: (603) 893-6131

Fax: (603) 893-8807

www.KleinMarineSystems.com

Page 2

ii

This document contains proprietary information, and such information may not be

disclosed to others for any purpose or used for any manufacturing purpose without

expressed written permission from Klein Marine Systems, Inc. (KMS). The

information provided is for informational purposes only and is subject to change

without notice. KMS assumes no responsibility or liability for any errors,

inaccuracies or omissions that may be present in this document.

The SonarPro software program may be used or copied only in accordance with

the terms of the Software License Agreement.

©

Copyright 2010–2019 by Klein Marine Systems, Inc. All rights reserved.

SonarPro® is a registered trademark of Klein Marine Systems, Inc.

Intel® and Pentium®are registered trademarks of Intel Corporation.

Windows® is a registered trademark of Microsoft Corporation.

vxWorks® is a registered trademark of Wind River Systems, Inc.

Kevlar® is a registered trademark of the DuPont Company.

\HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 3

WARNING

Klein Marine Systems recommends all troubleshooting be done by

a trained technician. Some circuits in the Transceiver and

Processing Unit (TPU) have voltages as high as 240 volts, and

some circuits in the sonar Sonar Head Unit have 1500 volts. You

should familiarize yourself with the location of these voltages

before you attempt any troubleshooting. Failure to observe these

warnings could result in injuries to personnel.

CAUTION

Serious damage to the sonar electronics may occur if the Sonar

Head Unit is operated out of the water for periods longer than

15 minutes. Let the sonar cool 15 minutes or longer between

operations. Protect the Sonar Head Unit from direct exposure to the

sun prior to and during operation in high temperature climates.

iii

CAUTION

The depth rating on the transducers is 200 meters (656 feet).

Operations at depths greater than 200 meters may damage the

transducers.

Page 4

iv

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Sonar System Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

What Is Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Conditions Of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Changes, Errors And Omissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Software License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

What’s in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Note, Warning, Caution, and Shock Hazard Notices . . . . . . . . . . . . . xvii

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

CHAPTER 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Sonar Head Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.2 TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.3 SonarPro Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.4 Deck Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Surface Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Subsurface Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Technical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.5.1 Sonar Head Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.5.2 TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

CHAPTER 2: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Sonar System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Topside System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.1 System Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.3 SonarPro Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 5

2.3 Sonar Head Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.2 Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.3 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.4 Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.5 A/D Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.6 Multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.7 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.8 Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 SonarPro Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Deck Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6.1 Sound Velocity Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

v

2.6.2 Motion Reference Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

CHAPTER 3: Preparation for Deployment . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Unpacking the TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Unpacking the SonarPro Workstation . . . . . . . . . . . . . . . . . . 3-2

3.1.3 Unpacking the Sonar Head Unit and Deck Cable . . . . . . . . . 3-2

3.2 Locating the Topside System Components . . . . . . . . . . . . . . . . 3-2

3.3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.1 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 TPU and SonarPro Workstation Circuit Breakers . . . . . . . . . 3-3

3.4 Sonar Head Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.5 Motion Reference Unit Installation . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6 Topside System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6.1 TPU Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6.2 SonarPro Workstation Connections . . . . . . . . . . . . . . . . . . . . 3-8

3.7 Connecting the Topside System Components . . . . . . . . . . . . . . 3-8

3.8 Topside System Controls and Indicators . . . . . . . . . . . . . . . . . 3-11

3.8.1 TPU Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.8.2 SonarPro Workstation Controls and Indicators . . . . . . . . . . 3-13

Page 6

vi

3.9 Predeployment Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.10 Bathymetric System Calibration and Patch Test . . . . . . . . . . . 3-15

3.10.1 Static Position Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.10.2 Latency Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.10.3 Pitch Bias Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.10.4 Yaw Bias Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.10.5 Roll Bias Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

CHAPTER 4: Equipment Maintenance . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Maintenance General Comments . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Maintenance Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Daily Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.2 Weekly Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.3 Long Term Maintenance Checklist . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Disassembling and Reassembling the Sonar Head Unit . . . . . . 4-3

4.3.1 Disassembling the Sonar Head Unit . . . . . . . . . . . . . . . . . . . . 4-3

4.3.2 Reassembling the Sonar Head Unit . . . . . . . . . . . . . . . . . . . 4-10

APPENDIX A: General Setup, Configuration and

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.1 Basic System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.2 Basic System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.3 Installing SonarPro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.4 Sonar Head Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.4.1 Checking the Telemetry Link to the Sonar Head Unit . . . . . A-4

A.4.2 Checking the Transmitters before Deployment . . . . . . . . . . A-4

A.4.3 Checking the Receivers before Deployment . . . . . . . . . . . . A-5

A.4.4 Setting up for Testing the Electronics . . . . . . . . . . . . . . . . . A-5

A.4.5 Checking the Multiplexer Board . . . . . . . . . . . . . . . . . . . . . A-5

A.4.6 Checking the Transmitter Board . . . . . . . . . . . . . . . . . . . . . A-7

A.4.7 Checking the Receiver Boards . . . . . . . . . . . . . . . . . . . . . . . A-8

A.4.8 Sonar Head Unit Power Supply Pinouts . . . . . . . . . . . . . . . . A-8

A.5 Spare Boards and Components . . . . . . . . . . . . . . . . . . . . . . . . A-9

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 7

vii

A.6 Cable Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

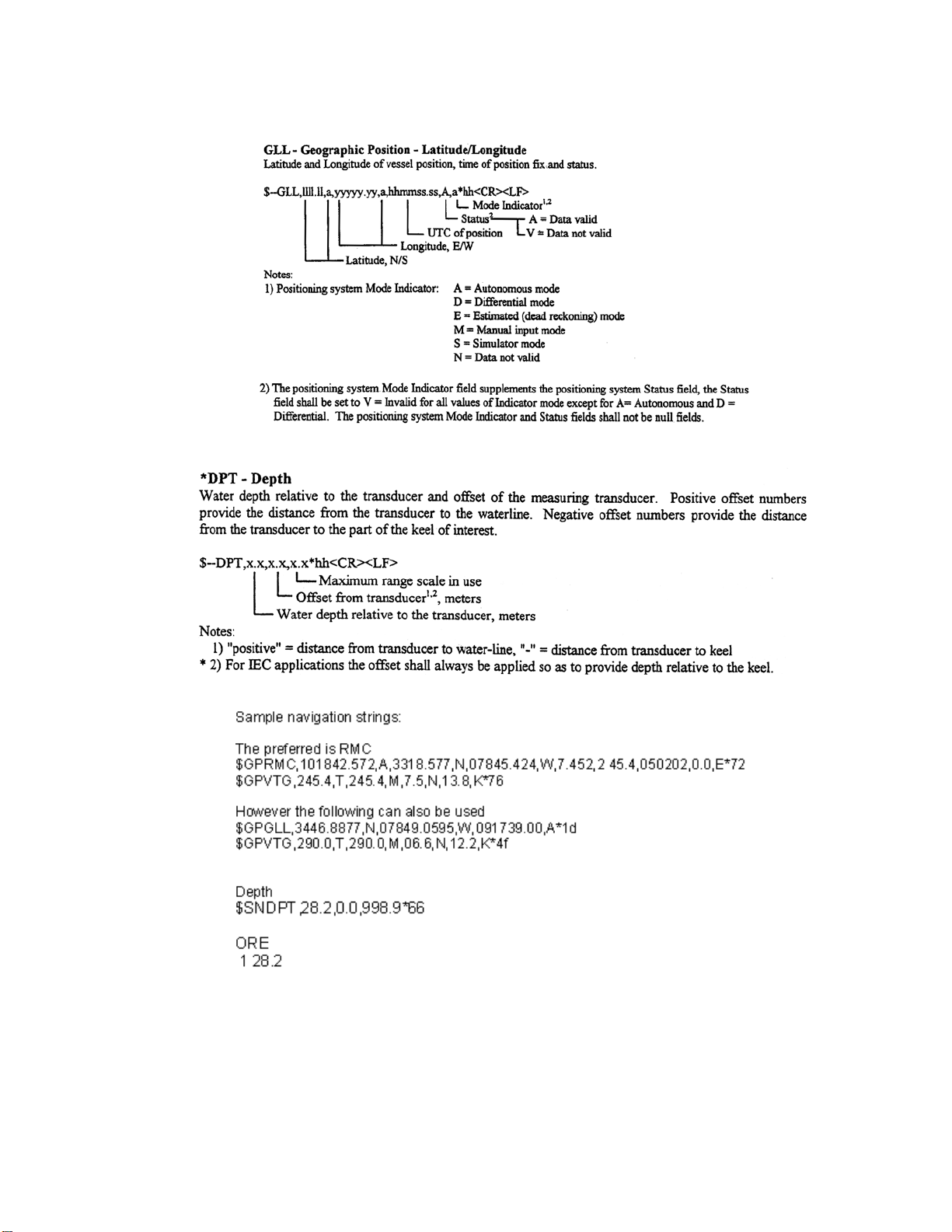

A.7 NMEA 0183 Formats and Information . . . . . . . . . . . . . . . . . A-10

APPENDIX B: Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Page 8

viii

List of Figures

Figure 1-1: HydroChart 5000 Sonar System Topside System Main Components . . . . . . 1-4

Figure 1-2: HydroChart 5000 Sonar System Sonar Head Unit . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-3: HydroChart 5000 Sonar System Sonar Head Unit Block Diagram . . . . . . . 1-7

Figure 1-4: Deck Cable Connector—at Sonar Head Unit . . . . . . . . . . . . . . . . . . . . . . . 1-8

Figure 1-5: HydroChart 5000 Sonar System TPU Electronics Block Diagram . . . . . . . 1-9

Figure 1-6: HydroChart 5000 Sonar System TPU Electronics Chassis . . . . . . . . . . . . 1-10

Figure 3-1: Sonar Head Unit Mounting Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-2: FWD and Arrow Labels on the Sonar Head Unit Mounting Flange . . . . . . 3-4

Figure 3-3: Sonar Head Unit Eye Rings and Handles . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-4: TPU Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-5: SonarPro Workstation Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-6: TPU Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-7: SonarPro Workstation Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 4-1: Removing the Phillips Head Screws from the Top of the Fairing . . . . . . . . 4-3

Figure 4-2: Removing the Skid Plates from the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-3: Removing the Phillips Head Screws from the Bottom of the Fairing . . . . . . 4-4

Figure 4-4: Removing the Socket Head Cap Screws that Secure the Transducers to the

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-5: Fairing Halves Separated from the Frame . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-6: Disconnecting the Cables from the Sonar Electronics End Cap . . . . . . . . . 4-6

Figure 4-7: Sonar Electronics Housing with all the Cables Disconnected . . . . . . . . . . . 4-6

Figure 4-8: Removing the Altimeter Transducer from the Frame . . . . . . . . . . . . . . . . . . 4-7

Figure 4-9: Removing the Socket Head Cap Screw that Secures the Sonar Electronics

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Figure 4-10: Sliding the Sonar Electronics Housing out of the Frame . . . . . . . . . . . . . . . 4-8

Figure 4-11: Sonar Head Unit Fully Disassembled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-12: Tightening the Socket Head Cap Screws in the Electronics Housing

Connector End Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 9

ix

Figure 4-13: Inserting the 7-inch, 1/2 x 13 threaded rod into the Connector End cap . . . 4-9

Figure 4-14: Pulling the Sonar Electronics Chassis out of the Sonar Electronics

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4-15: Aligning and Installing the Connector End Cap . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4-16: Sonar Electronics Chassis Installed in Frame with the Jumper and

Altimeter Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 4-17: Sonar Electronics Housing Connector End Cap Connectors . . . . . . . . . . 4-12

Figure 4-18: Sonar Head Unit Fully Assembled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Figure A-1: HydroChart 5000 Sonar System Basic System Setup Diagram . . . . . . . . . . A-3

Figure A-2: Sonar Head Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

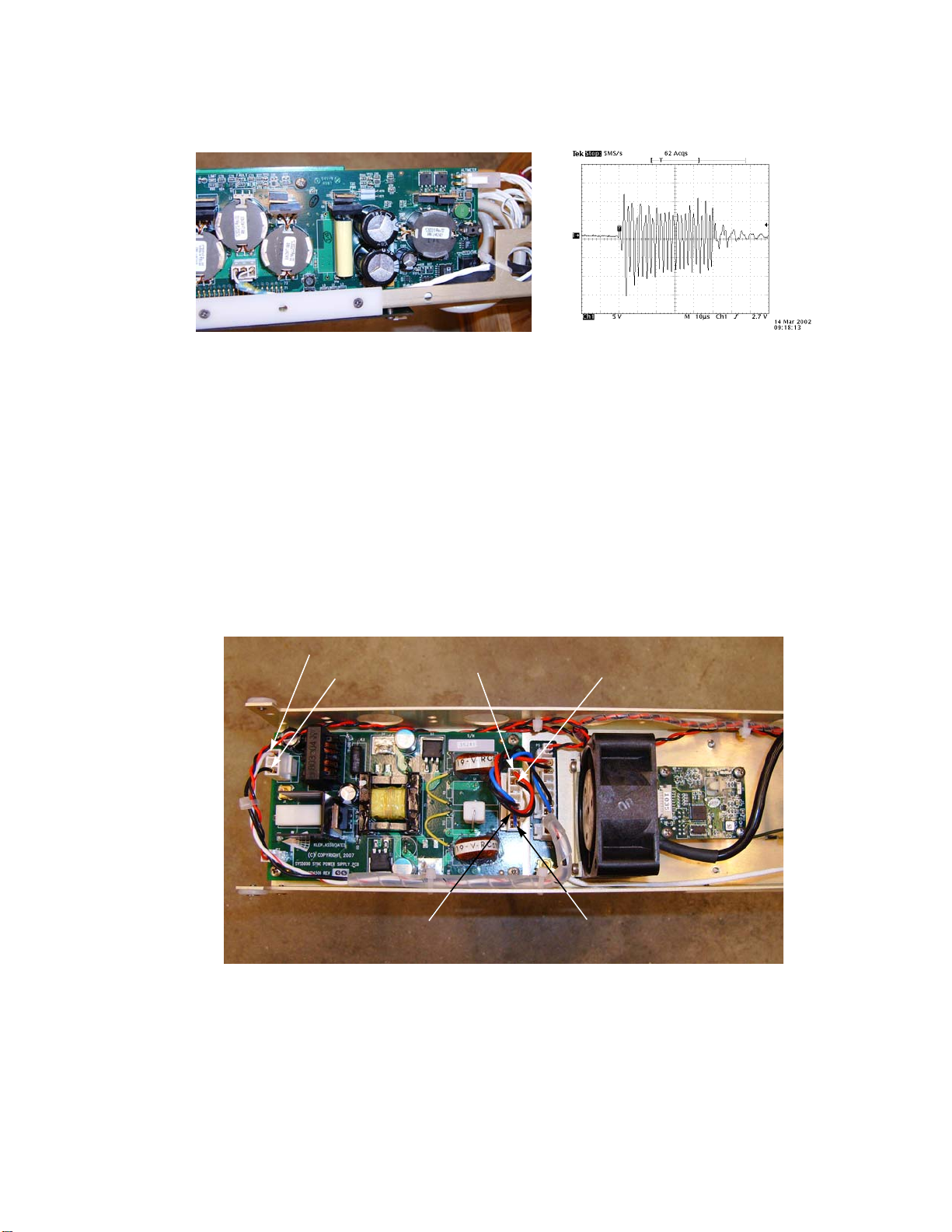

Figure A-3: Transmit Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

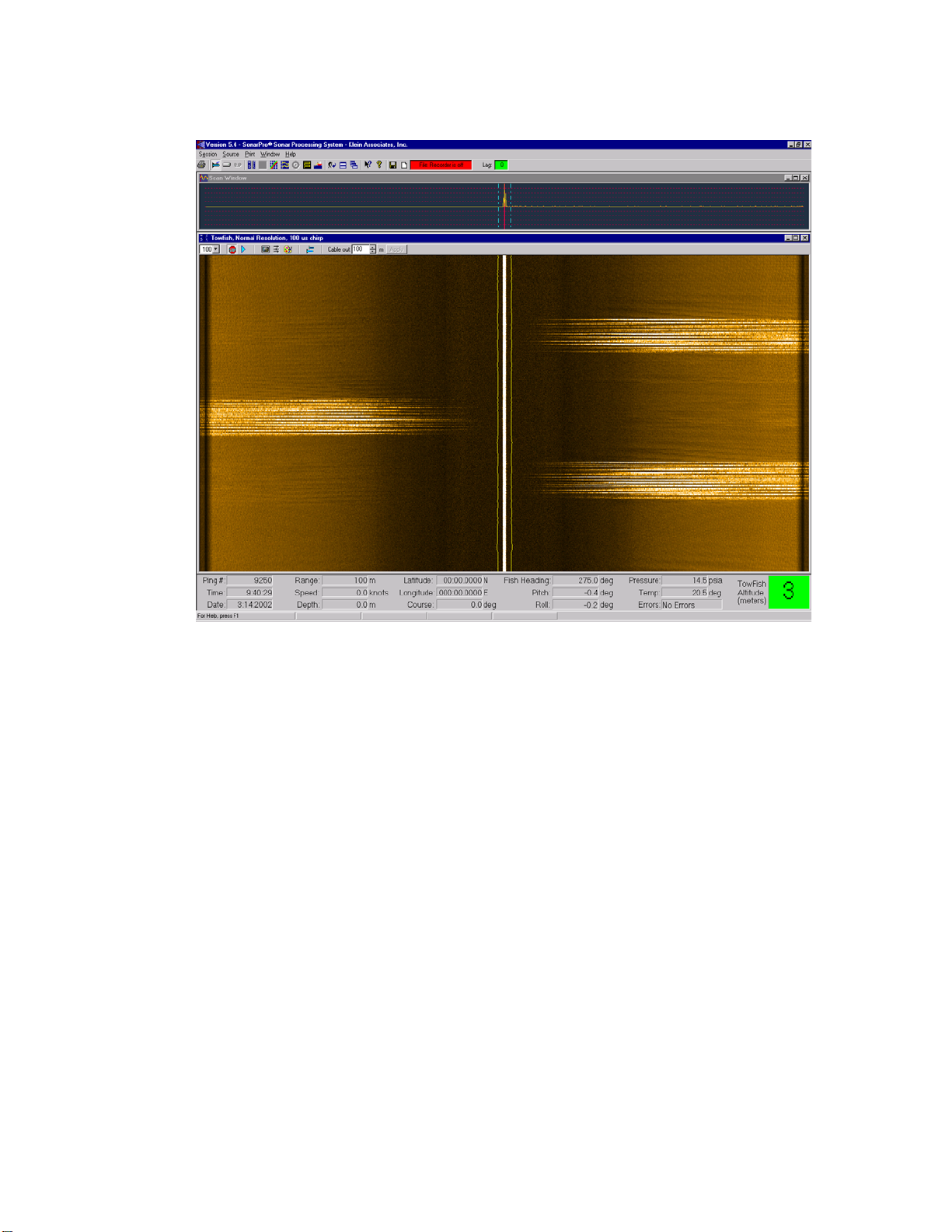

Figure A-4: Image in Sonar Viewer Window During a Rub Test . . . . . . . . . . . . . . . . . . A-6

Figure A-5: Multiplexer Board Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Figure A-6: Sample Transmit Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Figure A-7: The Sonar Head Unit Power Supply Pinouts . . . . . . . . . . . . . . . . . . . . . . . . A-8

Figure A-8: Cable Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Page 10

x

List of Tables

Table 1-1: Deck Cable Connector—Sonar Head Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Table 3-1: TPU Power Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Table A-1: TPU Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Table A-2: Sonar Head Unit Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Table B-1: List of Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 11

Sonar System Warranty

What Is Covered

LIMITED WARRANTY Subject to the conditions set forth below, equipment

sold by Seller is warranted against defects in materials and workmanship, and

Seller will repair or exchange any parts proven to be malfunctioning under normal

use for one year (12 months) from the date of Delivery as follows:

a) SONAR and other associated manufactured products, with the following

exceptions:

b) All third party accessories, winches, magnetometers, Sonar Laptops or PCs, and

peripherals/accessories and third party software packages related to the Sonar

Product Line are limited to the warranty provided by original manufacturer.

c) This warranty does not apply to tow cables. If applicable, the manufacturer’s

warranty will be forwarded with the equipment.

EQUIPMENT NOT MANUFACTURED BY SELLER Carries only its

vendor’s warranty, which is hereby incorporated by reference.

xi

SERVICE WORK BY SELLER Warrants that ALL service work performed by

Seller’s technical and engineering employees will be performed in a good and

workmanlike manner, but its liability under this warranty is limited to the

obligation to remedy at Seller’s expense any such service work not performed

satisfactorily, upon receipt of written notice within ninety (90) days of the date of

performance of the work.

For authorized onsite service (excluding Side Scan Sonar category referenced as a.

SONAR) in which Seller has to travel to the installed equipment, travel costs (auto

mileage and tolls) up to 100 round trip highway miles and travel time of 2 hours,

will be allowed by Seller. The Overtime premium labor portion of service of

normal working hours is not covered by this Warranty. On-site warranty service is

capped at (4) hours per failure. Travel costs other than auto mileage, tolls and two

(2) hours travel time are specifically excluded on all products and services.

Travel costs which are excluded from coverage of this warranty include, but are

not limited to: taxi, launch fees, aircraft rental, airfare, subsistence, customs,

shipping, communication charges, etc.

During the warranty period, Seller will repair or, at its option, replace any

equipment that proves to be defective. Such repair or replacement is Buyer’s

exclusive right and remedy, and our only obligation, with respect to any defective

equipment.

Page 12

xii

Conditions Of Warranty

a) Seller’s warranty policy does not apply to equipment which has been subjected to

accident, abuse, or misuse, shipping damage, alterations, incorrect and/or nonauthorized service or equipment on which the serial number plate has been

altered, mutilated or removed.

b) A suitable proof of purchase, such as, a paid commercial invoice, an installation

certificate signed by Seller or an authorized agent must be made available to

Seller or Seller’s authorized servicing agent at the time of the Warranty Service.

c) The warranties stated herein are in lieu of all other warranties, expressed or

implied, and of all other obligations or liabilities on the part of Seller. Seller

neither assumes nor authorizes any other person to assume for it any other

liability. The Buyer expressly waives any right, claim or cause of action that

might otherwise arise out of the purchase and use of Seller’s products or service.

d) Warranty is not transferable and only applies to the original Buyer.

e) Warranty does not cover equipment that has been repaired or modified other than

by Seller, or equipment that has been subjected to misuse or to negligent or

accidental mishandling.

f) Except where Seller has performed the installation of specific equipment, Seller

assumes no responsibility for damage incurred during installation of equipment or

by damage caused by no fault of the Seller.

g) This warranty does not cover routine system checkouts or alignment/calibration,

unless required by replacement of part(s) in the area being aligned.

h) Consumable items are specifically excluded from this Warranty.

i) Buyer is responsible for the prepayment of all freight charges, insurance,

customs, imposts, duties, etc., to return defective equipment to Seller and for

Seller to return the repaired or replaced equipment to buyer.

j) Equipment returned for warranty service must be packed to best commercial

standards to prevent shipping damage.

k) Warranty shall be void and Seller shall be released from all obligations u nder this

warranty if the equipment is operated with components other than those sold or

authorized by Seller.

l) This warranty is strictly limited to the terms and indicated herein, and no other

warranties or remedies shall be binding on Seller including, without limitation,

any warranties of merchantability or fitness for a particular purpose.

m) Repairs and replacements under warranty have the same warranty as the original

product for the remaining balance of the warranty period for the original product

existing prior to notice of the warranty claim.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 13

xiii

Any failure to meet the foregoing conditions of warranty will automatically void

this limited warranty. This warranty gives Buyer specific legal rights, and Buyer

may also have other rights, which vary from State to State, Province to Province or

Country to Country.

DISPUTES Seller and Buyer agree that all disputes in any way relating to, arising

under, connected with, or incident to this agreement, and over which the federal

courts have subject matter jurisdiction, shall be litigated, if at all, exclusively in the

United States District Court for the State of Delaware, and if necessary, the

corresponding appellate courts. Seller and Buyer further agree that all disputes in

any way relating to, arising under, connected with or incident to this contract, and

over which the federal courts do not have subject matter jurisdiction, shall be

litigated, if at all, exclusively in the Courts of the State of Delaware, and if

necessary, the corresponding appellate courts. Seller and Buyers expressly submit

themselves to the personal jurisdiction of the State of Delaware. Before resorting

to litigation, Seller and Buyer agree to enter into negotiations to resolve the

dispute. If Seller and Buyer are unable to resolve the dispute by good faith

negotiation, either Seller or Buyer may refer the matter to litigation.

LIMITATION OF LIABILITY TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, SELLER SHALL NOT BE LIABLE UNDER ANY

THEORY AT LAW, IN EQUITY OR OTHERWISE FOR ANY SPECIAL,

EXEMPLAR Y, PUNITIVE, INCIDENT AL, INDIRECT , OR CONSEQUENTIAL

DAMAGES (EVEN IF SELLER HAS BEEN ADVISED OF SAME)

INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR REVENUES,

THE ENTIRE LIABILITY OF SELLER FOR ANY CLAIM, LOSS, OR

DAMAGES UNDER ANY THEORY AT LAW, IN EQUITY, OR OTHERWISE,

INCLUDING, BUT NOT LIMITED TO CONTRACT, TORT, (INCLUDING

INTELLECTUAL PROPERTY INFRINGEMENT , AND NEGLIGENCE), AND

STRICT LIABILITY, ARISING OUT OF THIS AGREEMENT OR ANY

INDEMNIFICATION OBLIGATION THEREOF, THE PERFORMANCE OR

BREACH THEREOF, OR THE SUBJECT MATTER SHALL NOT IN ANY

EVENT EXCEED THE SUM OF PAYMENTS ACTUALLY MADE BY BUYER

TO SELLER PURSUANT TO THIS AGREEMENT , ANY ACTION AGAINST

SELLER MUST BE BROUGHT WITHIN ONE (1) YEAR AFTER THE CLAIM

AROSE.

Changes, Errors And Omissions

Klein Marine Systems, Inc. reserves the right to make changes to the design or

specifications at any time without incurring any obligation to modify previously

delivered sonar systems. In addition, while considerable effort has been made to

ensure that the information in this manual is accurate and complete, Klein Marine

Systems, Inc. assumes no liability for any errors or omissions.

Page 14

xiv

Software License Agreement

This Software License Agreement is provided by Klein Marine Systems, Inc.

(KMS) for end users of SonarPro© software for the KMS Series 3000, UUV-3500,

3900, 4900, 5000, 5000 V2, 5900, HydroChart 3500, HydroChart 5000, and

D3500TF Sonar Systems.

YOU SHOULD CAREFULLY READ THE FOLLOWING TERMS AND

CONDITIONS BEFORE USING THIS PRODUCT. IT CONTAINS

SOFTWARE, THE USE OF WHICH IS LICENSED BY KMS, TO ITS

CUSTOMERS FOR THEIR USE ONLY, AS SET FORTH BELOW. IF YOU DO

NOT AGREE TO THE TERMS AND CONDITIONS OF THIS AGREEMENT ,

DO NOT USE THE SOFTWARE. USING ANY PART OF THE SOFTWARE

INDICATES THA T YOU ACCEPT THESE TERMS.

LICENSE: KMS grants you a nonexclusive license to use the accompanying

software programs(s) (the "Software") subject to the terms and restrictions set

forth in this License Agreement. You are not permitted to lease, rent, distribute or

sublicense the Software or to use the Software in a time-sharing arrangement or in

any other unauthorized manner. Further, no license is granted to you in the human

readable code of the Software (source code). Except as provided below, this

License Agreement does not grant you any rights to patents, copyrights, trade

secrets, trademarks, or any other rights in respect to the Software.

The Software is licensed to be used on any workstation or any network server

owned by or leased to you, provided that the Software is used only in connection

with one KMS Series 3000, UUV-3500, 3900, 4900, 5000, 5000 V2, 5900,

HydroChart 3500, HydroChart 5000, or D3500TF Sonar System. You may

reproduce and provide authorized copies only of the Software and supporting

documentation for each such workstation or network server for this equipment on

which the Software is used as permitted hereunder. Otherwise, the Software and

supporting documentation may be copied only as essential for backup or archive

purposes in support of your use of the Software as permitted hereunder. You must

reproduce and include all copyright notices and any other proprietary rights

notices appearing on the Software and the supporting documentation on any copies

that you make.

NO ASSIGNMENT; NO REVERSE ENGINEERING: You may not transfer

or assign the Software and/or this License Agreement to another party without the

prior written consent of KMS. If such consent is given and you transfer or assign

the Software and/or this License Agreement, then you must at the same time either

transfer all copies of the Software as well as the supporting documentation to the

same party or destroy any such materials not transferred. Except as set forth above,

you may not transfer or assign the Software or your rights under this License

Agreement.

Modification, reverse engineering, reverse compiling, or disassembly of the

Software is expressly prohibited. You may not translate or create derivative works

of the software or the supporting documentation.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 15

xv

BATHYMETRIC PROCESSING A TTRIBUTION: Bathymetric processing

derived from DGA/GESMA publication in IEEE OCEAN'S 05 Europe

Conference Proceedings: "Bathymetric Sidescan Sonar: a System Dedicated to

Rapid Environment assessment, ref: 10.1109/OCEANSE.2005.1511695.

EXPORT RESTRICTIONS: You agree that you will not export or re-export the

Software or accompanying documentation (or any copies thereof) or any products

utilizing the Software or such documentation in violation of any applicable laws or

regulations of the United States or the country in which you obtained them.

TRADE SECRETS; TITLE: You acknowledge and agree that the structure,

sequence and organization of the Software are the valuable trade secrets of KMS.

You agree to hold such trade secrets in confidence. You further acknowledge and

agree that ownership of, and title to, the Software and all subsequent copies thereof

regardless of the form or media are held by KMS.

UNITED STATES GOVERNMENT LEGEND: All technical data and

Software are commercial in nature and developed solely at private expense. The

Software is delivered as Commercial Computer Software as defined in DFARS

252.227-7014 (June 1995) or as a commercial item as defined in F AR 2.101(a) and

as such is provided with only such rights as are provided in this License

Agreement, which is KMS's standard commercial license for Software. Technical

data is provided with limited rights only, as provided in DFAR 252.227-7015

(Nov. 1995) or FAR 52.227-14 (June 1987), whichever is applicable. You agree

not to remove or deface any portion of any legend provided on any licensed

program or documentation delivered to you under this License Agreement.

TERM AND TERMINATION: This license will terminate immediately if you

fail to comply with any term or condition of this License Agreement. Upon such

termination you agree to destroy the Software and documentation, together with all

copies and merged portions in any form. You may terminate it at any time by

destroying the Software and documentation together with all copies and merged

portions in any form.

GOVERNING LAW: This License Agreement shall be governed by the laws of

the State of New Hampshire, USA. You agree that the United Nations Convention

on Contracts for the International Sales of Goods (1980) is hereby excluded in its

entirety from application to this License Agreement.

LIMITED WARRANTY; LIMITATION OF LIABILITY: All warranties and

limitations of liability applicable to the Software are as stated in the product

manual accompanying the Software. Such warranties and limitations of liability

are incorporated herein in their entirety by this reference.

SEVERABILITY: In the event any provision of this License Agreement is found

to be invalid, illegal or unenforceable, the validity, legality and enforceability of

any of the remaining provisions shall not in any way be affected or impaired and a

valid, legal and enforceable provision of similar intent and economic impact shall

be substituted therefore.

Page 16

xvi

Preface

ENTIRE AGREEMENT : This License Agreement sets forth the entire

understanding and agreement between you and KMS supersedes all prior

agreements, whether written or oral, with respect to the Software, and may be

amended only in a writing signed by both parties.

The HydroChart 5000 Sonar System is a portable, high speed hydrographic survey

system comprising an over-the-side mounted sonar and a topside system.

What’s in This Manual

This operations and maintenance manual provides information pertaining to the

setup and deployment, operation, general maintenance, and troubleshooting of the

HydroChart 5000 Sonar System. The manual is divided into the following four

main chapters and two appendices:

Chapter 1: Overview. Presents an overview of the HydroChart 5000 Sonar

System components, including both functional and physical descriptions of the

system.

Chapter 2: Specifications. Provides detailed physical and performance

specifications for the main components of the system, including the acoustic

transducers, the environmental and navigation sensors, and the available tow

cables.

Chapter 3: Preparation for Use. Provides instructions for unpacking and

setting up the HydroChart 5000 Sonar System components. It also includes a

predeployment checkout procedure and information on how to perform a

system calibration and patch test.

Chapter 4: Equipment Maintenance. Provides checklists for daily,

weekly , and long term inspection and service, and includes instructions on how

to disassemble and reassemble the Sonar Head Unit.

Appendix A: General Setup, Configuration and Troubleshooting.

Includes basic setup and configuration information and information that is

useful for system troubleshooting.

Appendix B: Drawings. Provides drawings applicable to the HydroChart

5000 Sonar System.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 17

xvii

Note, Warning, Caution, and Shock Hazard Notices

Where applicable, note, warning, caution, and shock hazard notices are included

throughout this manual as follows:

NOTE Recommendations or general information that is particular to the

material being presented or a referral to another part of this manual or to

another manual.

WARNING Identifies a potential hazard that could cause personal injury

or death to yourself or to others.

CAUTION Identifies a potential hazard that could be damaging to

equipment or could result in the loss of data.

SHOCK HAZARD Identifies a potential electrical shock hazard that could

cause personal injury or death to yourself or to others.

Customer Service

KMS technical support can be contacted using any of the following means:

Mail

Klein Marine Systems, Inc.

11 Klein Drive

Salem, NH 03079

Email

TechSupport@KleinMarineSystems.com

Telephone

(603) 893-6131

Facsimile

(603) 893-8807

For more information about KMS and our products, please go to our Web site at

www.KleinMarineSystems.com.

Page 18

Page 19

CHAPTER 1: OVERVIEW

The HydroChart 5000 Sonar System is a portable, high speed hydrographic survey

system which has the ability to simultaneously collect IHO-quality bathymetry and

co-registered, high resolution multibeam side scan sonar data.

1.1 Equipment

The HydroChart 5000 Sonar System equipment consists of an instrumented Sonar

Head Unit, a Transceiver and Processing Unit (TPU) and a SonarPro Workstation,

along with a deck cable and various interconnect cables.

1.1.1 Sonar Head Unit

The Sonar Head unit has all of the necessary electronics and acoustic

instrumentation to perform all of the sonar data acquisition and processing prior to

digital transmission to the TPU. Processing includes transmit and receive

functions, time varied gain (TVG) amplification, digitalization, and multiplexing

of the sonar uplink data. Timing and sonar data are bidirectionally multiplexed on

a single conductor coaxial cable, and the use of a low noise preamplifier design

ensures maximum range performance. The Sonar Head Unit has a flange assembly

which easily mates with typical customer provided over-the-side mount pole or

ram configurations. A jumper cable connects from the sonar electronics in the

Sonar Head Unit to the deck cable, and the deck cable connects to the TPU to

provide the electrical power and data connections.

1-1

1.1.2 TPU

The TPU is housed in a 19-inch rack mountable 2U chassis and connects to the

Sonar Head Unit directly using a deck cable. The TPU receives and demultiplexes

the sonar and sensor data from the Sonar Head Unit and transfers the data to the

SonarPro Workstation over an Ethernet connection. The TPU can also input

standard National Marine Electronics Association (NMEA) 0183 message

sentence formats from a connected GPS, and a 1 PPS input is provided which

inputs 1 PPS (one pulse per second) signals from the GPS. This signal is used in

conjunction with a NMEA $ZDA message input to add an accurate time stamp to

the data. The TPU provides power and downlink commands to the Sonar Head

Unit by combining 200 VDC with FSK control signals for transmission over the

coaxial conductor in the tow cable. In addition, the TPU initiates each ping cycle

to the side scan sonar and provides a trigger signal simultaneously with the

responder trigger generated in the Sonar Head Unit for use with an acoustic

positioning system.

Page 20

1-2 CHAPTER 1 Overview

1.1.3 SonarPro Workstation

The SonarPro Workstation is an industrial grade Intel Pentium Dual Core

based computer housed in a 19-inch rack mountable 2U chassis that inputs

processed and time tagged sonar and sensor data from the TPU over an Ethernet

10/100/1000baseT connection. A SATA hard drive is included with the Microsoft

Windows 7 operating system and SonarPro installed. SonarPro is a comprehensive

Windows based software program that provides multiple displays of real-time or

saved sonar and sensor data and Sonar Head Unit status. SonarPro also allows you

to record all acquired sonar and sensor data. The SonarPro Workstation also

includes a high resolution 27-inch 2560 x 1440 monitor, a keyboard and a mouse.

1.1.4 Deck Cable

The deck cable is a Kevlar reinforced, polyurethane jacketed, coaxial cable that

provides power and data communication between the Sonar Head Unit and the

TPU.

1.2 Features

The HydroChart 5000 Sonar System has the following features and capabilities:

• High resolution multibeam side scan imagery

• High resolution IHO-quality swath bathymetry

• Co-registered geo-referenced swath bathymetry and side scan data

• Bathymetry coverage up to 12 times water depth

• 14-bit digital multiplexer for transmission of sonar and control

data over a single coaxial cable

• Easy to use graphical user interface (GUI)

• Flexible and expandable system configurations

• Altimeter

• Support for an optional sound velocity sensor to provide surface

sound velocity measurements

• Support for a motion reference unit (MRU), gyro heading sensor,

GPS, and CTD

• Operates with Klein Marine Systems SonarPro for operator

control, data acquisition and display

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 21

1.3 Surface Equipment

The surface subsystem comprises the TPU and the SonarPro Workstation. In

addition, an optional motion reference unit can be connected for measurement of

pitch, roll, yaw , and heave, as well as GPS for location, a heading sensor for ship’s

heading, and a CTD.

Transceiver and Processing Unit (TPU). The TPU is shown in Figure 1-1.

The main power switch is located on the lower right corner of the front panel.

The TPU is rack mountable in a standard 48.26 cm (19 inch) rack and contains

electronics for receiving sonar data, downlink multiplexing of control signals

to the Sonar Head Unit, and uplink demultiplexing of sonar and auxiliary

sensor signals.

SonarPro Workstation. The SonarPro Workstation is shown in Figure 1-1.

Most operator functions are accomplished through the use of the SonarPro

Workstation which supports the PC based Windows operating system and runs

SonarPro. SonarPro provides the operator interface to the HydroChart 5000

Sonar System. SonarPro is a comprehensive software package developed to

support survey planning; data visualization and quality control; target

management and data recording; and playback. SonarPro also performs the

side scan and bathymetry data processing. Data can be logged in SDF, GSF or

XYZ format. These formats are supported by most third party post-processing

software applications. In addition to processed data, raw stave data can be

logged together with all motion, navigation, and heading and sound velocity

data. This permits reprocessing of both side scan and bathymetry data in a

post-processing environment. For more information on the computer, refer to

the manufacturer's manual.

Surface Equipment 1-3

1.4 Subsurface Equipment

The subsurface equipment comprises the Sonar Head Unit, as shown in Figure 1-2

on page 1-5, and a deck cable. In addition, an optional sound velocity sensor can

be included for measurement of surface sound velocity.

Sonar Head Unit. The Sonar Head Unit is shown in Figure 1-2. It consists of

the sonar electronics, the transducers, the sonar altimeter, a support frame,

interconnect cables, and fairings. An optional sound velocity sensor and cable

can also be installed in the Sonar Head Unit.

Deck cable. The deck cable is a complete assembly consisting of a coaxial

cable in a Kevlar reinforced light weight Polyurethane jacket.

Page 22

1-4 CHAPTER 1 Overview

SonarPro Workstation

Transceiver and Processing Unit (TPU)

Figure 1-1: HydroChart 5000 Sonar System Topside System Main Components

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 23

Technical Description 1-5

Figure 1-2: HydroChart 5000 Sonar System Sonar Head Unit

1.5 Technical Description

The HydroChart 5000 Sonar System is a multiple swath forming, frequency

modulated (FM) chirp side looking sonar that provides high speed, high resolution,

extended range imagery and bathymetry. The two primary drawbacks of

conventional side-looking sonars, along-track resolution and towing speed

limitation, have been addressed by simultaneously forming multiple dynamically

focused beams per side, per ping. This allows greater side scan survey speeds

without the usual loss of bottom coverage while maintaining high resolution. In

addition, the formed swaths are focused dynamically with across-track range,

thereby offering an inherently improved along-track resolution over unfocused

systems. The interferometric bathymetry (also referred to as Phase Differencing)

component of the HydroChart 5000 Sonar System is not a multibeam sonar and

requires that speed and range settings be considered when operating the system for

100% bottom coverage.

1.5.1 Sonar Head Unit

The Sonar Head Unit consists of the sonar arrays together with the sonar

electronics in a lightweight frame assembly. The sonar electronics, which is

contained inside a waterproof housing, includes transmitters, receivers and digital

circuits that combine time-synchronized complex stave samples, ping trigger

timing and optional time-synchronized motion data from the vessel’s sensors. An

altimeter is included, and the system accommodates an optional sound velocity

sensor or a CTD. For hull mount configurations, the electronics bottle is located

inside the vessel’s hull, and an optional transducer mounting bracket is required.

The two transducer arrays are each composed of 12 piezoelectric ceramic

Page 24

1-6 CHAPTER 1 Overview

sub-arrays and three bathymetry sub-arrays that operate as receive elements. There

is also a separate transmit line array included that projects acoustic energy to the

seabed.

NOTE The transducers are side specific and are not interchangeable.

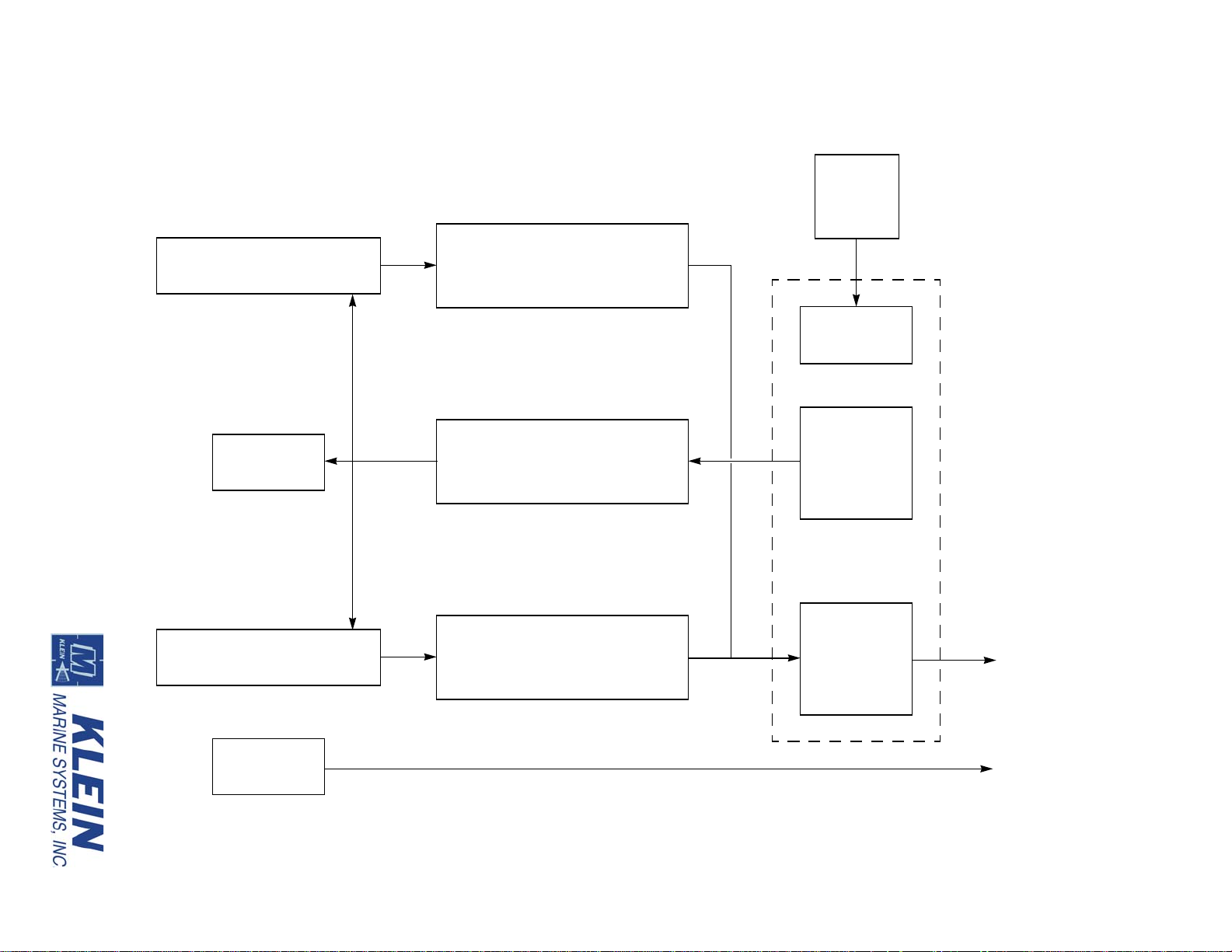

The Sonar Head Unit sonar electronics includes a T ransmitter board, two Receiver

boards and a Multiplexer board. A block diagram of the Sonar Head Unit is shown

in Figure 1-3.

Transmitter board. The Transmitter board produces a transmit pulse, at the

start of a swath, that ensonifies the sea floor over a defined footprint. The

Transmitter board is composed of two individual transmitting channels, one

connected to the port array and the other connected to the starboard array. The

transmitters operate at a center frequency of 455 kHz and support both CW and

chirp waveform transmission. The Transmitter board also contains transmit

and receive circuitry for the altimeter.

Receiver boards. The Receiver boards process the backscatter information by

applying fixed gain, time varied gain (TVG) and frequency filtering to the

input voltage signals received from the individual sub-arrays in the transducer

arrays. There are two Receiver boards, one for the port array and one for the

starboard array. Each of the receiver channels is bandpass filtered with tightly

matched filters providing a -3dB bandwidth of 20 kHz, centered at 455 kHz.

The filtered signal is then output to the Multiplexer board for sampling.

Multiplexer board. The Multiplexer board digitizes the signals from each of

the transducer sub-array channels along with the signals from the sensors,

encodes the data, and transmits a high baud rate digital data stream to the TPU

over the deck cable. The Multiplexer board also receives the trigger signal and

command messages which instruct the T ransmitter board to fire the arrays and

configure aspects of the sonar operation. In addition, the Multiplexer board

functions as a motherboard for the other boards providing the connections and

distributing power . The Multiplexer board uses a proprietary sampling scheme

that preserves the phase of the individual channel signals, but only requires a

single A/D converter, thereby reducing cost and power consumption while

eliminating the phase mismatch between converters of alternate dual converter

schemes. The output of the A/D is input to the data encoder and converted to

serial data for subsequent transmission over the deck cable. A full duplex

hybrid allows data transmission up the cable while simultaneously receiving

the FSK trigger signals and power. The downlink signals are input to FSK

demodulators, and the baseband outputs are routed to the Transmitter board,

indicating when to fire the main array, and to a micro controller that handles

the sonar configuration.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 25

Port Side Scan Transducer Array

Stbd Side Scan Transducer Array

Altimeter

Sound Velocity

Sensor

(Optional)

Receiver (port)

Transmitter

Receiver (starboard)

Power

Interface

Power

Supply

Transmitter

Control and

TVG Interface

Multiplexer,

ADC and

Telemetry

Deck Cable

to TPU

SVP Cable

Multiplexer

to TPU

Figure 1-3: HydroChart 5000 Sonar System Sonar Head Unit Block Diagram

Technical Description 1-7

Page 26

1-8 CHAPTER 1 Overview

A deck cable connector connects the Sonar Head Unit sonar electronics to the

TPU. The deck cable connector is shown in Figure 1-4, and the pinouts are shown

in Table 1-1. Only two pins are used.

Figure 1-4: Deck Cable Connector—at Sonar Head Unit

Table 1-1: Deck Cable Connector—Sonar Head Unit

PIN NO. LABEL FUNCTION

1

2 Shield Power and data return

Power/Data +200 VDC power and multiplexed data

1.5.2 TPU

A block diagram depicting the functional relationships of all of the printed circuit

boards in the TPU electronics is shown in Figure 1-5. These boards are located in

the TPU electronics chassis as shown in Figure 1-6 on page 1-10. The printed

circuit boards, along with their corresponding part numbers, are the following:

• Demultiplexer board 14105785

• CPU board 14105873

• 200V Power Supply board 11700098

• 200V Power Filter board 14104980

• Telemetry Interface board 14105841

• 12V Power Supply board 11700092

• 12V Power Filter board 14105397

• LED board 14105464

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 27

Figure 1-5: HydroChart 5000 Sonar System TPU Electronics Block Diagram

Technical Description 1-9

Page 28

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Topside Telemetry

board

CPU board

Demultiplexer

200V

Power Supply

200V Power

Filter board

12V Power

Filter board

12V Power

Supply board

LED board

board

board

1-10 CHAPTER 1 Overview

Figure 1-6: HydroChart 5000 Sonar System TPU Electronics Chassis

Page 29

Technical Description 1-11

Assembled into a single rack mountable 2U enclosure, the TPU connects to the

Sonar Head Unit. It also connects to the SonarPro Workstation over an Ethernet

connection and to customer supplied equipment, such as a GPS and an acoustic

positioning system.

Demultiplexer board. The Demultiplexer board demultiplexes the uplink

sonar and sensor data from the Sonar Head Unit and outputs FSK downlink

commands along with 200 VDC power to the Sonar Head Unit while providing

all of the external input and output signal and data connections for the TPU. It

also provides the required recovery of signal and clock, detects trigger inputs

and 1-PPS signals, generates the trigger outputs, inputs NMEA 0183 data, time

stamps all of the data, and outputs the data to the SonarPro Workstation over

the Ethernet connection. 200 VDC power is input to the Demultiplexer board

from the 200V Power Filter board, and 12 VDC power is input from the 12V

Power Filter board. The Demultiplexer board also provides front panel

indicator outputs which drive the front panel LEDs on the LED board.

CPU board. The CPU board functions as the command and data interface

between the SonarPro Workstation and the Sonar Head Unit. It executes a

real-time data server which outputs sonar and sensor data to and receives

commands from an external client, such as SonarPro.

200V Power Supply board. The 200V Power Supply board provides

200 VDC which is output to the Sonar Head Unit to power it.

200V Power Filter board. The 200V Power Filter board provides noise

filtering of the 200 VDC power for transmission to the Sonar Head Unit over

the coaxial tow cable. The filtered 200 VDC power is output to the

Demultiplexer board where it is combined with the FSK control signals and

output to the Sonar Head Unit.

Telemetry Interface board. The T e lemetry Interface board provides the cable

interface for the TPU. Specifically, the Tele metry Inter face board perf orms the

following functions:

• Separates the uplink data signals, the downlink command signals and the

Sonar Head Unit power.

• Acquires sonar and sensor data and reformats the data as required for the

Demultiplexer board.

• Generates command and timing signals for the Sonar Head Unit.

• Matches the time references at the Sonar Head Unit and the TPU.

12V Power Supply board. The 12V Power Supply board inputs 100–125 or

200–250 VAC and outputs 12 VDC to the 12V Power Filter board.

Page 30

1-12 CHAPTER 1 Overview

12V Power Filter board. The 12V Power Filter board provides noise filtering

of the 12V power supply for the Demultiplexer board.

LED board. The LED board contains all of the front panel LED indicators. It

mounts directly to the back of the front panel and connects to the

Demultiplexer board over a single cable.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 31

CHAPTER 2: SPECIFICATIONS

This chapter includes the physical and performance specifications for the main

components of the HydroChart 5000 Sonar System. The specifications are typical

and subject to change without notice.

2.1 Sonar System

Deployment method: Over the side or hull mount

Sonar channels: Multiple side scan sonar channels and

6 sensor/auxiliary channels

Sonar frequency: 500 kHz nominal (455 kHz actual)

Pulse length: 16 ms maximum (chirp)

2-1

Sonar data processing: Uncorrected

Range scale: 50, 75, 100, and 150 m; 50 and 75 m are

high resolution

Maximum range: Up to 150 m per side

Number of beams (side scan): 10 (5 per side)

Swath width (side scan): 500 m (250 m per side)

Maximum swath (bathymetry): 10–12 times water depth

Resolution along-track

(bathymetry):

Resolution across-track

(bathymetry):

Resolution along-track

(side scan):

0.4

0.5 m

cm @ 38 m

20 cm @ 75 m

36 cm @ 150 m

50 cm @ 250 m

Resolution across-track

(side scan):

3.75 cm

Depth limit: Up to 50 m

Operating temperature: -10–35C (14–95F)

Page 32

2-2 CHAPTER 2 Specifications

2.2 Topside System

The main topside components of the HydroChart 5000 Sonar System are the

Transceiver and Processing Unit (TPU) and the SonarPro Workstation.

2.2.1 System Power Requirements

The system power requirements are 100–125 or 200–250 VAC, 50–60 Hz at

100 watts for the TPU and the Sonar Head Unit together.

2.2.2 TPU

Size: 8.9 cm (3.5 in.) H

Weight: 7.6 kg (17 lb)

Chassis type: 2U, 19-inch rack mount

48.3 cm (19.0 in.) W

35.6 cm (14.0 in.) D

2.2.3 SonarPro Workstation

Size: 8.9 cm (3.5 in.) H

48.3 cm (19.0 in.) W

43.2 cm (17.0 in.) D

Weight: 22.8 kg (50 lb)

Chassis type: 2U, 19-inch rack mount

CPU: Intel Pentium Dual Core

Memory: 8 GB

Storage: SATA hard drive

DVDRW optical drive

I/O ports: (2) Ethernet 10/100/1000baseT

(6) USB 2.0

(2) RS-232

(1) VGA

(1) DVI (dual display support)

Operating system: Windows 7, 64 bit

Monitor: 21.5-inch diagonal

2560 x 1440 resolution

16:9 aspect ratio

Operator I/O: Keyboard and mouse

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 33

2.3 Sonar Head Unit

2.3.1 General

Electronics boards: Modular

2.3.2 Transducers

Type: Proprietary line array

Vertical beam angle: 40°

Depth limit: 200 m

2.3.3 Transmitter

Type: CW and chirp

Pulse width: 50 µs, 2 ms, 4 ms, 8 ms, 16 ms, and chirp

Sonar Head Unit 2-3

2.3.4 Receiver

Type: High gain, tuned preamplifier with TVG

Noise figure: 1 dB nominal

TVG range: 80 dB

2.3.5 A/D Converter

Type: Pipeline

Resolution: 14 bits

Quantization: Linear

Sample rate: Proprietary

2.3.6 Multiplexer

Modulation format: Pulse code modulation (PCM)

Multiplexing format: Time division multiplexing (TDM)

Number of channels: 32

Data rate: 29.12 Mbaud

Data format: NRZ

Bit error rate: Better than 1x10

-8

(before correction)

Page 34

2-4 CHAPTER 2 Specifications

2.3.7 Power

Input power: Powered from the TPU; no additional

2.3.8 Physical Characteristics

Body material: Stainless steel frame, plastic fairings,

Size: 162.8 cm (64.1 in.) long

Weight in air: 29.5 kg (65 lb)

Weight in water: 9.1 kg (20 lb)

power required

pressure case, and end cap

19.8 cm (7.8 in.) wide

15.5 cm (6.1) high (w/o mtg flange)

23.1 cm (9.1) high (w/ mtg flange)

2.4 SonarPro Workstation

For specifications on the SonarPro Workstation, refer to the manufacturer's

manual.

2.5 Deck Cable

Type: Polyurethane jacketed coaxial, Kevlar

Conductors: Coaxial copper

Diameter (OD): 1.16 cm (0.455 in.)

Breaking strength: 2270 kg (5000 lb)

Working load: 454 kg (1000 lb)

Operational length: 100 m maximum

Voltage rating: 600 VDC

Termination: Subconn underwater pigtail with locking

reinforced

sleeve

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 35

2.6 Options

The HydroChart 5000 Sonar System design provides the configuration flexibility

to meet your specific needs. The highly modular design of the equipment makes

this possible. This section provides information on the available optional

capabilities of the System.

2.6.1 Sound Velocity Sensor

The Sonar Head Unit can accommodate several third party sound velocity sensors.

This data is recorded along with the sonar data and can be used for surface sound

velocity measurements for post processing corrections.

2.6.2 Motion Reference Unit

The HydroChart 5000 Sonar System can interface with a variety of third party

motion reference units for correction and subsequent processing of bathymetric

data. Both Ethernet and high speed serial interfaces are supported.

Options 2-5

Page 36

Page 37

CHAPTER 3: PREPARATION FOR

DEPLOYMENT

This chapter provides instructions for unpacking and preparing the HydroChart

5000 Sonar System for deployment, including detailed instructions on the

following:

TPU and SonarPro Workstation setup. Guidelines for installing the TPU

and the SonarPro Workstation to optimize performance and equipment

lifetime.

Power and ground requirements. Power and ground requirements to

protect against over and under voltage and transient spikes.

Sonar Head Unit installation. How to install the Sonar Head Unit.

3-1

Connect the surface equipment. How to connect all of the surface

equipment, including an optional motion reference unit and a sound velocity

sensor.

Predeployment test. How to perform a predeployment test to verify that the

system is operational.

System calibration. Information on how to perform a patch test to account

for residual biases in the system installation.

3.1 Unpacking and Inspection

The HydroChart 5000 Sonar System is shipped in multiple shipping containers.

Before unpacking the containers, carefully inspect them for damage. If any

damage is found, immediately contact Klein Marine Systems, Inc. or your KMS

sales representative and report the damage to the freight carrier. Do not install or

operate any equipment that appears to be damaged.

3.1.1 Unpacking the TPU

Remove the TPU from the shipping container and set it on a sturdy, flat surface.

Inspect the TPU for signs of damage. If there is any damage or if any items are

missing, immediately contact Klein Marine Systems, Inc. or your KMS sales

representative. Record the serial number of the TPU; it can be found on a sticker

on the rear panel.

Page 38

3-2 CHAPTER 3 Preparation for Deployment

3.1.2 Unpacking the SonarPro Workstation

Remove the SonarPro Workstation from the shipping container, and set it on a

sturdy , flat surface. Inspect the So narPro Workstation for signs of damage. If there

is any damage or if any items are missing, immediately contact Klein Marine

Systems, Inc. or your KMS sales representative. Record the serial numbers of the

computer modules.

3.1.3 Unpacking the Sonar Head Unit and Deck Cable

The Sonar Head Unit and the deck cable are shipped in a reusable crate. Open the

crate and inspect the Sonar Head Unit for damage. If there is any damage or if any

items are missing, immediately contact Klein Marine Systems, Inc. or your KMS

sales representative. Record the serial number of the Sonar Head Unit. The serial

number can be found on the aft end of Sonar Head Unit mounting flange opposite

the FWD label.

3.2 Locating the Topside System Components

The TPU and the SonarPro Workstation should be located in an area that is

protected from weather and spray and where the temperatures are consistently

between 0°C and 35°C (32°F and 95°F). The location should also be near the

Sonar Head Unit or be adequately equipped with devices for communicating with

launch personnel. If separately mounting components in a 19-inch rack, ensure

that the rack is properly secured and that there is ample room behind it for

connecting the cables. A thick layer of foam should also be placed under the rack

for shock isolation, and the back of the rack should be left open for proper air flow .

Support the units inside the rack using appropriate mounting brackets, shelves or

slides as needed and secure the front panels to the front of the rack where possible

using standard 19-inch rack front panel mounting hardware.

3.3 Power Requirements

The TPU and the SonarPro Workstation require 100–125 or 200–250 VAC,

50–60 Hz power to operate. The HydroChart 5000 Sonar System is designed to

protect against over and under voltage and transient spikes. However, it is always

best to check the power source carefully using a voltmeter or oscilloscope before

operating the equipment.

CAUTION Application of improper AC power may damage the

HydroChart 5000 Sonar System. Do not turn the equipment on until the

supply voltage and frequency have been checked.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 39

Sonar Head Unit Installation 3-3

Since a variety of power connectors are in use throughout the world, it may be

necessary to use an adapter or to cut off the US-type plug on the AC power cable

and re-terminate it with a new plug. Should this modification be required, the

wires should be connected in accordance with Table 3-1.

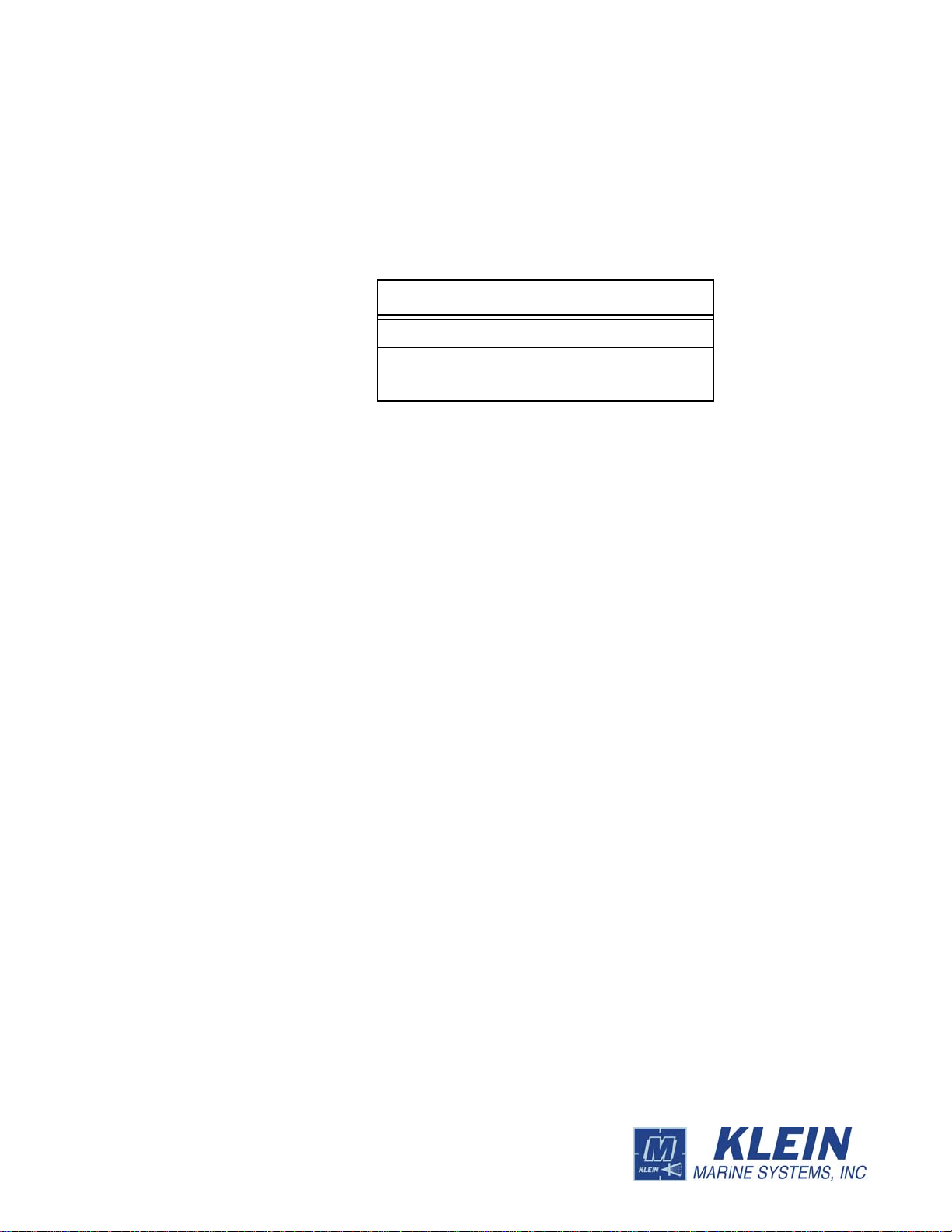

Table 3-1: TPU Power Cable Wiring

COLOR FUNCTION

Green Ground (earth)

Blue or white Neutral

Brown or black Hot

3.3.1 Grounding

It is important that the HydroChart 5000 Sonar System be well grounded to

minimize potential hazards to the operator and electrical interference from other

equipment. A good ground for the system is a low impedance, well conducted path

to sea water. Always check the quality of the electrical ground by verifying that the

AC power source ground has no voltage potential with respect to the vessel hull.

3.3.2 TPU and SonarPro Workstation Circuit Breakers

The main AC power input line is protected by a switch/circuit breaker in both the

TPU and the SonarPro Workstation. The one on the TPU is located on the front

panel on the far right as shown in Figure 3-6 on page 3-12. The one on the

SonarPro Workstation is located on the pack panel just to the right of the AC

INPUT connector as shown in Figure 3-5 on page 3-9. To reset a switch/circuit

breaker, switch it to ON.

3.4 Sonar Head Unit Installation

When installing the Sonar Head Unit, lightly grease the male pins of the

waterproof connectors before connecting them. The silicone grease serves an

important lubricating and corrosion protection function. Use a high quality,

nonconducting grease such as Dow Corning DC-4. Before connecting the deck

cable, make a general inspection of the Sonar Head Unit. Check that the fasteners

holding the Sonar Head Unit to the mounting platform are tight. Check that all

cables running from the Sonar Head Unit are secured. A safety cable should also

be attached to the Sonar Head Unit in the event that it breaks free.

Page 40

3-4 CHAPTER 3 Preparation for Deployment

Four 0.4-inch diameter holes

on a 5-inch bolt circle

6-inch diameter

mounting flange

CAUTION Always avoid putting excessive silicon grease on the Subcon

male pins. Apply a light coat of gr ease, and never put gr ease into the female

connectors.

NOTE When installing the Sonar Head Unit, r efer to Drawing 14605080 in

APPENDIX B: “Drawings.” for the outline dimensions of the Sonar Head

Unit.

The Sonar Head Unit is mounted to the survey vessel by attaching the mounting

flange at the top of Sonar Head Unit to a standard 6-inch pipe flange or other

mounting surface. A bolt pattern is provided on the mounting flange as shown in

Figure 3-1. For a typical, pole mount type over-the-side installation, this design is

well suited for attaching to the base of a pipe.

FWD on the neck of the mounting flange as shown in Figure 3-2. An arrow label is

also included.

Figure 3-2: FWD and Arrow Labels on the Sonar Head Unit Mounting Flange

Figure 3-1: Sonar Head Unit Mounting Flange

NOTE When attaching the Sonar Head Unit to the mounting surface, it is

important to ensure that the assembly is mounted correctly in the fore/aft

direction. The end of the Sonar Head Unit that faces the bow is labeled

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 41

Sonar Head Unit Installation 3-5

Handles (2)

Eye rings (2)

To install the Sonar Head Unit:

1. Align the bolt hole patterns and secure the mounting flange to the pipe flange

using stainless steel hardware. Be sure to maintain the long axis of the Sonar

Head Unit parallel to the keel at all times. However, offsets can be corrected

with a patch test as described in “Bathymetric System Calibration and Patch

Test” on page 3-15.

2. If your installation permits, it is suggested that you attach straps to the eye rings

or handles on the fore and aft portions of th e Sonar Head Unit an d secure them to

the bow and stern of the survey vessel to minimize any induced body motion. The

eye rings and handles are shown in Figure 3-3.

Figure 3-3: Sonar Head Unit Eye Rings and Handles

WARNING In all of the remaining steps, be sure that the power is turned

off and the TPU power cable is disconnected from the power source.

Failure to follow this practice may result in personal injury or damage to

the Sonar Head Unit or to the TPU electronics, or to both.

SHOCK HAZARD Do not connect or disconnect the deck cable from the

Sonar Head Unit or the TPU when the power is on. Failure to follow this

practice may result in personal injury and will damage the Sonar Head

Unit or the TPU electronics, or both.

3. Remove the dummy plug from the connector on the end of the Sonar Head Unit

jumper cable, and then apply a thin film of silicone grease to the pins of the

connector. Do not over grease. Align this connector with the female connector of

the deck cable and press the connectors firmly together. If necessary, use a slight

side to side rocking motion while pressing on the connectors, but do not bend the

pins. When properly inserted there should be no gap between the surfaces of the

two connectors. Screw the locking sleeves together to complete the connection.

4. Secure the deck cable to the Sonar Head Unit using tie-wraps.

Page 42

3-6 CHAPTER 3 Preparation for Deployment

5. If an optional sound velocity sensor is included, there will also be a cable

assembly included whose wet end should have been factory connected to the

sensor. Verify that this connector is properly seated and that the locking sleeves

are secure. Use tie-wraps to secure the cable to the Sonar Head Unit.

3.5 Motion Reference Unit Installation

The HydroChart 5000 Sonar System is capable of interfacing with several

industry-standard motion reference systems. These devices are critical to

measuring vehicle motion and correcting for its effect on the bathymetric data.

Connection and configuration of these devices is documented in the "HydroChart

5000 Motion Sensor Installation Guide" (P/N 11260086).

3.6 Topside System Connections

All of the topside system components connect together using the supplied cables.

User supplied cables are required for connecting to a GPS and to other equipment.

3.6.1 TPU Connections

All the connections to the TPU are made to connectors on the back panel which is

shown in Figure 3-4.The TPU connectors are the following:

LAN: RJ-45 connector that connects to the ETHERNET

connector on the SonarPro Workstation.

COM A (Debug): DB9 male RS-232 serial port connector that is for

factory use only.

COM B (Sound Velocity): DB9 male RS-232 serial port connector that inputs

sound velocity.

COM C (Motion

Reference Unit):

NAV: DB9 male RS-232 serial port connector that

EXT TRIG IN: Not supported for this system.

T/F TRIG: BNC connector that connects to an external sonar

DB9 male RS-232 serial port connector that inputs

motion reference unit data.

connects to a shipboard navigation system and

inputs NMEA 0183 message sentence formats.

system and is used to trigger the sonar of that system

at the start of each ping cycle. Provides a TTL

compatible, 100-µs wide output pulse.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 43

TOWFISH connector

NOTE: Connectors that are not

called out are not used or are

for factory use only.

NAV connector

AC INPUT connector

1 PPS connector

T/F TRIG connector

TRIG A connector

LAN connector

COM A (Debug) connector

COM B (Sound Velocity) connector

COM C (Motion Reference Unit) connector

Topside System Connections 3-7

Figure 3-4: TPU Back Panel

Page 44

3-8 CHAPTER 3 Preparation for Deployment

TRIG A:

BNC connector that connects to an ultra short

baseline navigation system (USBL). Provides a TTL

compatible, 100-µs wide output pulse with each

trigger of the optional responder.

1 PPS: BNC connector that connects a GPS and is used to

input 1 PPS (one pulse per second) signals.

TOWFISH: Type N coaxial connector that connects to the Sonar

Head Unit.

AC INPUT: IEC type connector that connects to the AC power

source.

3.6.2 SonarPro Workstation Connections

All the connections to the SonarPro Workstation are made to connectors on the

back panel which is shown in Figure 3-5.

The SonarPro Workstation connectors are the following:

USB: USB connectors (4, plus 2 on the front panel). Any

two connect to the keyboard and the mouse. The

front panel USB connectors are shown in Figure 3-7

on page 3-14.

DVI: DVI connector that connects to the monitor.

ETHERNET: RJ-45 connectors (2). Any one connects to the LAN

connector on the TPU.

AC INPUT: IEC type AC input connector that connects to the

AC power source.

3.7 Connecting the Topside System Components

The following cables are required to connect the TPU and the SonarPro

Workstation:

• Ethernet cable

• AC power cords (2)

• Deck cable

WARNING Before connecting the topside system components, verify that

the TPU is turned off and that its power cord is disconnected. Failure to

follow this practice may result in personal injury or damage to the Sonar

Head Unit or to the TPU electronics, or to both. For the location of the power

switches, refer to “Topside System Controls and Indicators” on page 3-11.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 45

ON/OFF switch

AC INPUT connector

ETHERNET connector (2)

USB connector (4)

NOTE: Connectors that are not

called out are not used or are

available for optional use.

DVI connector

and circuit breaker

Connecting the Topside System Components 3-9

Figure 3-5: SonarPro Workstation Back Panel

Page 46

3-10 CHAPTER 3 Preparation for Deployment

To connect the TPU and the SonarPro Workstation:

1. Connect the Ethernet cable to the LAN connector on the TPU and to either

one of the two the ETHERNET connectors on the SonarPro Workstation.

2. Connect the monitor to the DVI connector on the SonarPro Workstation and

connect the monitor power supply to the AC power source.

3. Connect the keyboard and the mouse to any two of the six USB connectors on

the SonarPro Workstation.

4. Connect a GPS to the NAV connector on the TPU. A user supplied RS-232

serial cable is required where one end is terminated with a DB9 female

connector and the other end is as required by the navigation system.

5. Verify that the GPS is outputting NMEA-0183 formatted data strings at

4800 baud, no parity , 8 data bits, and 1 stop bit. In addition, the GPS should be

outputting the following messages:

• GLL or GGA

•VTG

• RMC (optional)

NOTE If 4800 baud is not available from the GPS, contact KMS customer

service for instructions on how to reconfigure the system to accept a

different baud rate. Refer to “Customer Service” on page xvii for

information on how to contact KMS customer service.

6. Connect the deck cable to the TOWFISH connector on the TPU.

7. Connect an AC power cable to the AC INPUT connectors on the TPU and the

SonarPro Workstation and to the AC power source.

The following connections are optional:

8. Connect the 1 PPS connector on the TPU to the 1 PPS output of the shipboard

GPS. A user supplied BNC-to-BNC cable is required.

9. Connect the T/F TRIG connector on the TPU to the trigger input of an

external sonar system. A user supplied BNC-to-BNC cable is required.

10. Connect the TRIG A connector on the TPU to the trigger input of a USBL

system. A user supplied BNC-to-BNC cable is required.

11. Connect the COM B (Sound Velocity) connector to the sound velocity sensor

if installed on the Sonar Head Unit.

12. Connect the COM C (Motion Reference Unit) connector to the motion

reference unit if available.

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

Page 47

Topside System Controls and Indicators 3-11

3.8 Topside System Controls and Indicators

The TPU and the SonarPro Workstation include controls and indicators on the

front panels. The SonarPro Workstation also has its power switch on the back

panel.

3.8.1 TPU Controls and Indicators

All of the TPU controls and indicators are on the TPU front panel which is shown

in Figure 3-6.

The TPU controls and indicators are the following:

POWER switch: Rocker switch/circuit breaker that turns the TPU on

or off and provides AC input current protection.

Should the breaker trip, the switch/circuit breaker

will switch to the OFF position. To reset it, switch it

to the ON position.

POWER: Green LED that is on when the TPU is powered.

SYS READY: Green LED that will flash while the TPU and the

Sonar Head Unit are powering up and then remain

on when the TPU is ready to link with SonarPro on

the SonarPro Workstation.

T/F POWER: Blue LED that is on when power is being output to

the Sonar Head Unit.

TOWFISH AWAKE: Green LED that is on when the Sonar Head Unit is

powered and is acquiring data.

TOWFISH DOWNLINK: Green LED that is on when commands are being

transfered from the TPU to the Sonar Head Unit.

TOWFISH UPLINK: Green LED that is on when data are being transfered

from the Sonar Head Unit to the TPU.

STATUS TRIGGER: Yellow LED that flashes when the sonar on the

Sonar Head Unit transmits.

STATUS RESPONDER: Yellow LED that flashes when a responder trigger is

sent to the Sonar Head Unit.

STATUS ERROR: Red LED that flashes if system errors are detected.

Page 48

HydroChart 5000 Sonar Operations and Maintenance Manual P/N 11210080, Rev. 02

POWER indicator

SYS READY indicator

T/F POWER indicator

TOWFISH indicators

POWER switch

STATUS indicators

NOTE: Indicators that are not

called out are not used or are

available for optional use.

3-12 CHAPTER 3 Preparation for Deployment

Figure 3-6: TPU Front Panel

Page 49

Predeployment Test 3-13

3.8.2 SonarPro Workstation Controls and Indicators

Most of the SonarPro Workstation controls and indicators are on the SonarPro

Workstation front panel which is shown is Figure 3-7. Also shown is the location

of the DVDRW optical drive.

The SonarPro Workstation controls and indicators are the following:

ON/OFF switch: Rocker switch/circuit breaker that switches AC

power to the SonarPro Workstation and provides AC

input current protection. This switch/circuit breaker ,

which is on the back panel and is shown in