Klein 5000 SERIES Operation And Maintenance Manual

SERIES 5000 SONAR

SYSTEM

Operations and Maintenance Manual

P/N 11210060, Rev. 16

11 Klein Drive

Salem, NH 03079-1249

U.S.A.

Tel: (603) 893-6131

Fax: (603) 893-8807

www.KleinMarineSystems.com

ii

This document contains proprietary information, and such information may not be

disclosed to others for any purpose or used for any manufacturing purpose without

expressed written permission from Klein Marine Systems, Inc. (KMS). The

information provided is for informational purposes only and is subject to change

without notice. KMS assumes no responsibility or liability for any errors,

inaccuracies or omissions that may be present in this document.

The SonarPro software program may be used or copied only in accordance with

the terms of the Software License Agreement.

©

Copyright 2007–2016 by Klein Marine Systems, Inc. All rights reserved.

SonarPro® is a registered trademark of Klein Marine Systems, Inc.

K-Wing® and K-Wing II® are a registered trademarks of Klein Marine Systems,

Inc.

Intel® and Pentium®are registered trademarks of Intel Corporation.

Windows® is a registered trademark of Microsoft Corporation.

vxWorks® is a registered trademark of Wind River Systems, Inc.

Kevlar® is a registered trademark of the DuPont Company.

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

WARNING

Klein Marine Systems recommends all troubleshooting be done by

a trained technician. Some circuits in the Sonar Transceiver and

Processing Unit have voltages as high as 240 volts, and some

circuits in the sonar towfish have 1500 volts. You should

familiarize yourself with the location of these voltages before you

attempt any troubleshooting. Failure to observe these warnings

could result in injuries to personnel.

CAUTION

Serious damage to the sonar electronics may occur if the sonar

towfish is operated out of the water for periods longer than 15

minutes. Let the sonar cool 15 minutes or longer between

operations. Protect the sonar towfish from direct exposure to the

sun prior to and during operation in high temperature climates.

iii

CAUTION

The depth rating on the transducers is 200 meters (656 feet).

Operations at depths greater than 200 meters may damage the

transducers.

STANDARDS

SAFETY: EN 60950

EMC: EN 60945

iv

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Sonar System Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

What Is Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Conditions Of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Changes, Errors And Ommissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Software License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

What’s in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Note, Warning, Caution, and Shock Hazard Notices . . . . . . . . . . . . . . . xx

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

CHAPTER 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Multibeam Sonar Instrumented Towfish . . . . . . . . . . . . . . . . 1-1

1.1.2 Transceiver and Processing Unit (TPU) . . . . . . . . . . . . . . . . . 1-1

1.1.3 Computer Display and Control Unit . . . . . . . . . . . . . . . . . . . . 1-2

1.1.4 Tow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.1 Surface Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.2 Subsurface Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.2 Towfish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.3 Transceiver and Processing Unit . . . . . . . . . . . . . . . . . . . . . . 1-8

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

CHAPTER 2: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Sonar System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Sonar Transceiver and Processing Unit (TPU) . . . . . . . . . . . . . 2-2

2.2.1 TPU Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Input/Output Ports (I/O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.3 Trigger Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.4 Trigger Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.5 RS-232 COM 1 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.6 RS-232 COM 2 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.7 LAN Input/Output Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.8 Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.9 Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Computer Display and Control Unit . . . . . . . . . . . . . . . . . . . . . 2-3

v

2.4 Ethernet Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5 Towfish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.2 Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.3 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.4 Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.5 A/D Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.6 Multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.7 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.8 Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.9 Heading Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5.10 Pitch and Roll Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5.11 Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 Tow Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6.1 Lightweight Tow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6.2 Steel Tow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7.1 Towfish Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7.2 Tow Cable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

vi

CHAPTER 3: Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Unpacking the TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Unpacking the Computer Display and Control

Unit (Computer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.3 Unpacking the Towfish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.4 Unpacking the Tow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Mechanical Installation of the TPU and Computer . . . . . . . . . . 3-2

3.2.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.3 Isolating from Shock and Vibration . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.1 Connecting Cables and Power Cords . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 Power Line Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.3 Towfish Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4 Towfish Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.1 General Rigging Notes and Cautions . . . . . . . . . . . . . . . . . . . 3-5

3.4.2 Tow Cable Electrical Connection . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.3 Towfish and Optional Depressor Connection . . . . . . . . . . . . 3-7

3.4.4 Tow Cable Disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.5 Quick Start Installation and Operating Guide . . . . . . . . . . . . . . 3-9

3.5.1 Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.5.2 Deck Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.5.3 At-Sea Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

CHAPTER 4: Equipment Maintenance . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Maintenance General Comments . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Maintenance Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Daily Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.2 Weekly Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.3 Long Term Maintenance Checklist . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Replacing the Fixed Tail Cone Assembly . . . . . . . . . . . . . . . . . 4-3

4.4 Removing the Fixed Tail Cone Assembly . . . . . . . . . . . . . . . . . 4-6

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

vii

CHAPTER 5: Splashproof TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Venting the Splashproof TPU . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.2 External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.3 Operator Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . 5-4

5.1.4 Functional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.2 Setting up and Connecting the Splashproof TPU . . . . . . . . . . . 5-9

5.2.1 Included Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.2.2 Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.3 Activating the Splashproof TPU . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.5 Splashproof TPU Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

APPENDIX A: Sample Towing Characteristics . . . . . . . . . . . . . . . . A-1

APPENDIX B: Notes on Handling Tow Cables . . . . . . . . . . . . . . . . B-1

B.1 Unreeling Tow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 Uncoiling Tow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.3 Cable Kinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.3.1 Cause of Cable Kinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.3.2 Effect of Cable Kinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.3.3 Result of Cable Kinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

APPENDIX C: TPU Software Interface and Control . . . . . . . . . . . . C-1

C.1 Control Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.2 Startup Script . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.3 Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

C.4 Snapshots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

C.5 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-15

C.5.1 Status Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-15

C.5.2 Heartbeat Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

C.5.3 Sensor Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

viii

C.6 Towfish Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-17

C.6.1 5000 System MUX Commands . . . . . . . . . . . . . . . . . . . . . . C-17

C.6.2 5000 System Transmitter Commands . . . . . . . . . . . . . . . . . C-18

C.6.3 System 5000 Actuator Commands . . . . . . . . . . . . . . . . . . . . C-19

C.6.4 3000 System Multiplexer Commands . . . . . . . . . . . . . . . . . C-19

C.6.5 Auxiliary and Compass Commands . . . . . . . . . . . . . . . . . . . C-19

C.6.6 System 5900 MUX Commands . . . . . . . . . . . . . . . . . . . . . . C-20

C.6.7 System 5900 DSP Commands . . . . . . . . . . . . . . . . . . . . . . . C-21

C.6.8 System 5900 Transmitter Commands . . . . . . . . . . . . . . . . . C-21

C.6.9 System x000 Sub-Bottom Profiler (SBP) Commands. . . . . C-22

C.6.10 Datalogger On/Off commands . . . . . . . . . . . . . . . . . . . . . . . C-23

APPENDIX D: General Setup, Configuration and

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

D.1 Basic System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

D.2 Basic System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

D.3 Installing SonarPro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

D.4 Configuring the LAN Connection . . . . . . . . . . . . . . . . . . . . . . D-5

D.4.1 Windows NT LAN Configuration Setup . . . . . . . . . . . . . . . D-5

D.4.2 Windows 2000 LAN Configuration Setup . . . . . . . . . . . . . D-11

D.4.3 Windows XP LAN Configuration Setup . . . . . . . . . . . . . . D-16

D.5 T PU LAN Configuration Setup . . . . . . . . . . . . . . . . . . . . . . . D-24

D.6 D ifferent Cable Lengths and the Startup.ini File . . . . . . . . . . D-29

D.6.1 Tow Cable Considerations . . . . . . . . . . . . . . . . . . . . . . . . . D-30

D.6.2 Measuring Cable Insertion Loss . . . . . . . . . . . . . . . . . . . . . D-31

D.6.3 Spare Tow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-32

D.7 Transceiver and Processing Unit . . . . . . . . . . . . . . . . . . . . . . D-32

D.7.1 Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-33

D.7.2 Towfish Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-34

D.7.3 TPU Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-34

D.7.4 TPU Internal Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-34

D.7.5 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-35

D.7.6 TPU Power up and Test Sequence . . . . . . . . . . . . . . . . . . . D-36

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

ix

D.8 Towfish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-39

D.8.1 Testing the Towfish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-40

D.8.2 Checking the Telemetry Link to the Towfish . . . . . . . . . . . D-40

D.8.3 Checking the Transmitters before Deployment . . . . . . . . . D-41

D.8.4 Checking the Receivers before Deployment . . . . . . . . . . . D-41

D.8.5 Standard Transducer Configuration

Trouble Shooting Chart D-42

D.8.6 Towfish Bottle Electronics . . . . . . . . . . . . . . . . . . . . . . . . . D-43

D.8.7 Removing the Towfish Electronics . . . . . . . . . . . . . . . . . . D-43

D.8.8 Towfish Telemetry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-46

D.8.9 Setting up for Testing the Electronics . . . . . . . . . . . . . . . . D-46

D.8.10 Checking the Multiplexer Board . . . . . . . . . . . . . . . . . . . . D-47

D.8.11 Checking the Transmitter Board . . . . . . . . . . . . . . . . . . . . D-48

D.8.12 Checking the Receiver Boards . . . . . . . . . . . . . . . . . . . . . . D-48

D.8.13 Checking the DSP Board . . . . . . . . . . . . . . . . . . . . . . . . . . D-49

D.8.14 Checking the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-50

D.8.15 Calibrating the Optional Temperature Probe . . . . . . . . . . . D-51

D.8.16 Towfish Power Supply Pinouts . . . . . . . . . . . . . . . . . . . . . D-51

D.8.17 Calibrating the Compass . . . . . . . . . . . . . . . . . . . . . . . . . . D-52

D.8.18 Series 5000 Sonar System Towfish Commands . . . . . . . . . D-53

D.9 Software Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . D-54

D.10 Terminating an Optical Fiber . . . . . . . . . . . . . . . . . . . . . . . . . D-54

D.11 Problem Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-55

D.11.1 Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . D-56

D.11.2 Spare Boards and Components . . . . . . . . . . . . . . . . . . . . . . D-57

D.12 Cable Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-58

D.13 NMEA 0183 Formats and Information . . . . . . . . . . . . . . . . . D-59

APPENDIX E: Drawings and Parts Lists . . . . . . . . . . . . . . . . . . . . . E-1

x

List of Figures

Figure 1-1: TPU—Shown With Access Panel Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-2: Towfish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1-3: Towfish Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-4: Towfish Connector—at Towfish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Figure 1-5: TPU Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Figure 1-6: TPU Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Figure 1-7: AC Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-8: COM1 and COM2 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-9: PARALLEL Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 3-1: Towfish Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 4-1: Towfish Tail with Rear Center Pin in Place . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-2: Tail Cone being Aligned and Attached to Towfish . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-3: Tail Cone Being Tightened with Hex Key . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-4: Crossbar Used to Secure Tail Cone Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-5: Tail Cone Being Tightened With Screwdriver and Key . . . . . . . . . . . . . . . . 4-5

Figure 4-6: Tail Fins being Inserted into Tail Cone . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-7: Tail Fins being Secured to Tail Cone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 5-1: Splashproof TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Figure 5-2: Splashproof TPU Vent Closed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-3: Splashproof TPU Vent Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-4: Splashproof TPU Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-5: Front Panel of VME Chassis inside Splashproof TPU . . . . . . . . . . . . . . . . 5-5

Figure 5-6: VME Backplane and Power Supply Connections inside

Splashproof TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Figure A-1: Cable Length vs. Towfish Depth Graph 1 . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Figure A-2: Cable Length vs. Towfish Depth Graph 2 . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Figure A-3: Cable Length vs. Towfish Depth Graph 3 . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

xi

Figure A-4: Cable Length vs. Towfish Depth Graph 4 . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Figure A-5: Cable Length vs. Towfish Depth Graph 5 . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Figure B-1: Correct Methods to Unreel Tow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Figure B-2: Spooling Real to Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Figure B-3: Cable Loop and Kink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-4: Damaged Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure C-1: Multibeam Basic System Setup Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Figure C-2: Multibeam System Setup Diagram with Acoustic Positioning System . . . . . C-4

Figure C-3: Sample Plot of Tow Cable Characteristics . . . . . . . . . . . . . . . . . . . . . . . . C-31

Figure C-4: Setup for Measuring Tow Cable Characteristics using a Function

Generator, Terminator and Oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . C-31

Figure C-5: The Transceiver and Processing Unit (TPU) . . . . . . . . . . . . . . . . . . . . . . . C-32

Figure C-6: TPU Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-33

Figure C-7: AC Connector, Voltage Switch and Fuse on the Rear Panel

of the TPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-33

Figure C-8: TPU Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-34

Figure C-9: Measuring the 200 VDC Output to the Towfish . . . . . . . . . . . . . . . . . . . . . C-35

Figure C-10: Location of D9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-36

Figure C-11: Towfish with Standard Transducer Configuration . . . . . . . . . . . . . . . . . . . C-39

Figure C-12: Towfish with Bathymetry Transducer Configuration . . . . . . . . . . . . . . . . . C-40

Figure C-13: Towfish Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-40

Figure C-14: Transmit Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-41

Figure C-15: Image in Sonar Viewer Window During a Rub Test . . . . . . . . . . . . . . . . . C-42

Figure C-16: Towfish Bottle Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-43

Figure C-17: Push/Pull Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-43

Figure C-18: Jacking Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-44

Figure C-19: Towfish Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-45

Figure C-20: The Towfish Telemetry Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-46

Figure C-21: Towfish Electronics Ready for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . C-47

xii

Figure C-22: The Multiplexer Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-48

Figure C-23: Multiplexer Board Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-49

Figure C-24: Sample Transmit Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-50

Figure C-25: Image in Sonar Viewer Window for Display Test Pattern #1 . . . . . . . . . . C-50

Figure C-26: The Sensor Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-51

Figure C-27: The Towfish Power Supply Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-51

Figure C-28: Cable Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-58

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

xiii

List of Tables

Table 1-1: Towfish Connector—at Towfish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-2: TOWFISH Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-3: AC Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Table 1-4: COM1 and COM2 Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Table 1-5: PARALLEL Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Table 1-6: System Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Table 3-1: TPU Power Cord Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Table 5-1: List of Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Table C-1: Troubleshooting Chart—1P or 1S Connections . . . . . . . . . . . . . . . . . . . . . . . C-42

Table C-2: Troubleshooting Chart—2P or 2S Connections . . . . . . . . . . . . . . . . . . . . . . . C-43

Table C-3: TPU Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-57

Table C-4: Towfish Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-57

Table C-5: Multiplexer Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-57

Table C-6: Transmitter Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-58

Table D-1: List of Drawings and Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

xiv

Sonar System Warranty

What Is Covered

LIMITED WARRANTY Subject to the conditions set forth below, equipment

sold by Seller is warranted against defects in materials and workmanship, and

Seller will repair or exchange any parts proven to be malfunctioning under normal

use for one year (12 months) from the date of Delivery as follows:

a) SONAR and other associated manufactured products, with the following

exceptions:

b) All third party accessories, winches, magnetometers, Sonar Laptops or PCs, and

peripherals/accessories and third party software packages related to the Sonar

Product Line are limited to the warranty provided by original manufacturer.

c) This warranty does not apply to tow cables. If applicable, the manufacturer’s

warranty will be forwarded with the equipment.

EQUIPMENT NOT MANUFACTURED BY SELLER Carries only its

vendor’s warranty, which is hereby incorporated by reference.

SERVICE WORK BY SELLER Warrants that ALL service work performed by

Seller’s technical and engineering employees will be performed in a good and

workmanlike manner, but its liability under this warranty is limited to the

obligation to remedy at Seller’s expense any such service work not performed

satisfactorily, upon receipt of written notice within ninety (90) days of the date of

performance of the work.

For authorized onsite service (excluding Side Scan Sonar category referenced as a.

SONAR) in which Seller has to travel to the installed equipment, travel costs (auto

mileage and tolls) up to 100 round trip highway miles and travel time of 2 hours,

will be allowed by Seller. The Overtime premium labor portion of service of

normal working hours is not covered by this Warranty. On-site warranty service is

capped at (4) hours per failure. Travel costs other than auto mileage, tolls and two

(2) hours travel time are specifically excluded on all products and services.

Travel costs which are excluded from coverage of this warranty include, but are

not limited to: taxi, launch fees, aircraft rental, airfare, subsistence, customs,

shipping, communication charges, etc.

During the warranty period, Seller will repair or, at its option, replace any

equipment that proves to be defective. Such repair or replacement is Buyer’s

exclusive right and remedy, and our only obligation, with respect to any defective

equipment.

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

Conditions Of Warranty

a) Seller’s warranty policy does not apply to equipment which has been subjected to

accident, abuse, or misuse, shipping damage, alterations, incorrect and/or nonauthorized service or equipment on which the serial number plate has been

altered, mutilated or removed.

b) A suitable proof of purchase, such as, a paid commercial invoice, an installation

certificate signed by Seller or an authorized agent must be made available to

Seller or Seller’s authorized servicing agent at the time of the Warranty Service.

c) The warranties stated herein are in lieu of all other warranties, expressed or

implied, and of all other obligations or liabilities on the part of Seller. Seller

neither assumes nor authorizes any other person to assume for it any other

liability. The Buyer expressly waives any right, claim or cause of action that

might otherwise arise out of the purchase and use of Seller’s products or service.

d) Warranty is not transferable and only applies to the original Buyer.

e) Warranty does not cover equipment that has been repaired or modified other than

by Seller, or equipment that has been subjected to misuse or to negligent or

accidental mishandling.

xv

f) Except where Seller has performed the installation of specific equipment, Seller

assumes no responsibility for damage incurred during installation of equipment or

by damage caused by no fault of the Seller.

g) This warranty does not cover routine system checkouts or alignment/calibration,

unless required by replacement of part(s) in the area being aligned.

h) Consumable items are specifically excluded from this Warranty.

i) Buyer is responsible for the prepayment of all freight charges, insurance,

customs, imposts, duties, etc., to return defective equipment to Seller and for

Seller to return the repaired or replaced equipment to buyer.

j) Equipment returned for warranty service must be packed to best commercial

standards to prevent shipping damage.

k) Warranty shall be void and Seller shall be released from all obligations u nder this

warranty if the equipment is operated with components other than those sold or

authorized by Seller.

l) This warranty is strictly limited to the terms and indicated herein, and no other

warranties or remedies shall be binding on Seller including, without limitation,

any warranties of merchantability or fitness for a particular purpose.

m) Repairs and replacements under warranty have the same warranty as the original

product for the remaining balance of the warranty period for the original product

existing prior to notice of the warranty claim.

xvi

Any failure to meet the foregoing conditions of warranty will automatically void

this limited warranty. This warranty gives Buyer specific legal rights, and Buyer

may also have other rights, which vary from State to State, Province to Province or

Country to Country.

DISPUTES Seller and Buyer agree that all disputes in any way relating to, arising

under, connected with, or incident to this agreement, and over which the federal

courts have subject matter jurisdiction, shall be litigated, if at all, exclusively in the

United States District Court for the State of Delaware, and if necessary, the

corresponding appellate courts. Seller and Buyer further agree that all disputes in

any way relating to, arising under, connected with or incident to this contract, and

over which the federal courts do not have subject matter jurisdiction, shall be

litigated, if at all, exclusively in the Courts of the State of Delaware, and if

necessary, the corresponding appellate courts. Seller and Buyers expressly submit

themselves to the personal jurisdiction of the State of Delaware. Before resorting

to litigation, Seller and Buyer agree to enter into negotiations to resolve the

dispute. If Seller and Buyer are unable to resolve the dispute by good faith

negotiation, either Seller or Buyer may refer the matter to litigation.

LIMITATION OF LIABILITY TO THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, SELLER SHALL NOT BE LIABLE UNDER ANY

THEORY AT LAW, IN EQUITY OR OTHERWISE FOR ANY SPECIAL,

EXEMPLAR Y, PUNITIVE, INCIDENT AL, INDIRECT , OR CONSEQUENTIAL

DAMAGES (EVEN IF SELLER HAS BEEN ADVISED OF SAME)

INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR REVENUES,

THE ENTIRE LIABILITY OF SELLER FOR ANY CLAIM, LOSS, OR

DAMAGES UNDER ANY THEORY AT LAW, IN EQUITY, OR OTHERWISE,

INCLUDING, BUT NOT LIMITED TO CONTRACT, TORT, (INCLUDING

INTELLECTUAL PROPERTY INFRINGEMENT , AND NEGLIGENCE), AND

STRICT LIABILITY, ARISING OUT OF THIS AGREEMENT OR ANY

INDEMNIFICATION OBLIGATION THEREOF, THE PERFORMANCE OR

BREACH THEREOF, OR THE SUBJECT MATTER SHALL NOT IN ANY

EVENT EXCEED THE SUM OF PAYMENTS ACTUALLY MADE BY BUYER

TO SELLER PURSUANT TO THIS AGREEMENT , ANY ACTION AGAINST

SELLER MUST BE BROUGHT WITHIN ONE (1) YEAR AFTER THE CLAIM

AROSE.

Changes, Errors And Ommissions

Klein Marine Systems, Inc. reserves the right to make changes to the design or

specifications at any time without incurring any obligation to modify previously

delivered sonar systems. In addition, while considerable effort has been made to

ensure that the information in this manual is accurate and complete, Klein Marine

Systems, Inc. assumes no liability for any errors or omissions.

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

Software License Agreement

This Software License Agreement is provided by Klein Marine Systems, Inc.

(KMS) for end users of SonarPro© software for the KMS Series 3000, UUV-3500,

3900, 4900, 5000, 5000 V2, 5900, HydroChart 3500, HydroChart 5000, and

D3500TF Sonar Systems.

YOU SHOULD CAREFULLY READ THE FOLLOWING TERMS AND

CONDITIONS BEFORE USING THIS PRODUCT. IT CONTAINS

SOFTWARE, THE USE OF WHICH IS LICENSED BY KMS, TO ITS

CUSTOMERS FOR THEIR USE ONLY, AS SET FORTH BELOW. IF YOU DO

NOT AGREE T O THE TERMS AND CONDITIONS OF THIS AGREEMENT,

DO NOT USE THE SOFTWARE. USING ANY PART OF THE SOFTWARE

INDICATES THA T YOU ACCEPT THESE TERMS.

LICENSE: KMS grants you a nonexclusive license to use the accompanying

software programs(s) (the "Software") subject to the terms and restrictions set

forth in this License Agreement. You are not permitted to lease, rent, distribute or

sublicense the Software or to use the Software in a time-sharing arrangement or in

any other unauthorized manner. Further, no license is granted to you in the human

readable code of the Software (source code). Except as provided below, this

License Agreement does not grant you any rights to patents, copyrights, trade

secrets, trademarks, or any other rights in respect to the Software.

xvii

The Software is licensed to be used on any workstation or any network server

owned by or leased to you, provided that the Software is used only in connection

with one KMS Series 3000, UUV-3500, 3900, 4900, 5000, 5000 V2, 5900,

HydroChart 3500, HydroChart 5000, or D3500TF Sonar System. You may

reproduce and provide authorized copies only of the Software and supporting

documentation for each such workstation or network server for this equipment on

which the Software is used as permitted hereunder. Otherwise, the Software and

supporting documentation may be copied only as essential for backup or archive

purposes in support of your use of the Software as permitted hereunder. You must

reproduce and include all copyright notices and any other proprietary rights

notices appearing on the Software and the supporting documentation on any copies

that you make.

NO ASSIGNMENT; NO REVERSE ENGINEERING: You may not transfer

or assign the Software and/or this License Agreement to another party without the

prior written consent of KMS. If such consent is given and you transfer or assign

the Software and/or this License Agreement, then you must at the same time either

transfer all copies of the Software as well as the supporting documentation to the

same party or destroy any such materials not transferred. Except as set forth above,

you may not transfer or assign the Software or your rights under this License

Agreement.

Modification, reverse engineering, reverse compiling, or disassembly of the

Software is expressly prohibited. You may not translate or create derivative works

of the software or the supporting documentation.

xviii

BATHYMETRIC PROCESSING A TTRIBUTION: Bathymetric processing

derived from DGA/GESMA publication in IEEE OCEAN'S 05 Europe

Conference Proceedings: "Bathymetric Sidescan Sonar: a System Dedicated to

Rapid Environment assessment, ref: 10.1109/OCEANSE.2005.1511695.

EXPORT RESTRICTIONS: You agree that you will not export or re-export the

Software or accompanying documentation (or any copies thereof) or any products

utilizing the Software or such documentation in violation of any applicable laws or

regulations of the United States or the country in which you obtained them.

TRADE SECRETS; TITLE: You acknowledge and agree that the structure,

sequence and organization of the Software are the valuable trade secrets of KMS.

You agree to hold such trade secrets in confidence. You further acknowledge and

agree that ownership of, and title to, the Software and all subsequent copies thereof

regardless of the form or media are held by KMS.

UNITED STATES GOVERNMENT LEGEND: All technical data and

Software are commercial in nature and developed solely at private expense. The

Software is delivered as Commercial Computer Software as defined in DFARS

252.227-7014 (June 1995) or as a commercial item as defined in F AR 2.101(a) and

as such is provided with only such rights as are provided in this License

Agreement, which is KMS's standard commercial license for Software. Technical

data is provided with limited rights only, as provided in DFAR 252.227-7015

(Nov. 1995) or FAR 52.227-14 (June 1987), whichever is applicable. You agree

not to remove or deface any portion of any legend provided on any licensed

program or documentation delivered to you under this License Agreement.

TERM AND TERMINATION: This license will terminate immediately if you

fail to comply with any term or condition of this License Agreement. Upon such

termination you agree to destroy the Software and documentation, together with all

copies and merged portions in any form. You may terminate it at any time by

destroying the Software and documentation together with all copies and merged

portions in any form.

GOVERNING LAW: This License Agreement shall be governed by the laws of

the State of New Hampshire, USA. You agree that the United Nations Convention

on Contracts for the International Sales of Goods (1980) is hereby excluded in its

entirety from application to this License Agreement.

LIMITED WARRANTY; LIMITATION OF LIABILITY: All warranties and

limitations of liability applicable to the Software are as stated in the product

manual accompanying the Software. Such warranties and limitations of liability

are incorporated herein in their entirety by this reference.

SEVERABILITY: In the event any provision of this License Agreement is found

to be invalid, illegal or unenforceable, the validity, legality and enforceability of

any of the remaining provisions shall not in any way be affected or impaired and a

valid, legal and enforceable provision of similar intent and economic impact shall

be substituted therefore.

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

Preface

xix

ENTIRE AGREEMENT : This License Agreement sets forth the entire

understanding and agreement between you and KMS supersedes all prior

agreements, whether written or oral, with respect to the Software, and may be

amended only in a writing signed by both parties.

The Series 5000 Sonar System is a towed multibeam sonar comprising a towed

underwater platform and a topside system.

What’s in This Manual

This operations and maintenance manual provides information pertaining to the

setup and deployment, operation, general maintenance, and troubleshooting of the

Series 5000 Sonar System. The manual is divided into the following five main

chapters and five appendices:

Chapter 1: Overview. Presents an overview of the Series 5000 Sonar

System components, including both functional and physical descriptions of the

system.

Chapter 2: Specifications. Provides detailed physical and performance

specifications for the main components of the system, including the acoustic

transducers, the environmental and navigation sensors, and the available tow

cables.

Chapter 3: Preparation for Use. Provides instructions for unpacking and

setting up the Series 5000 Sonar System components. It also includes a

pre-survey checkout procedure.

Chapter 4: Equipment Maintenance. Provides checklists for daily,

weekly , and long term inspection and service, and includes instructions on how

to replace the fixed tail cone assembly.

Chapter 5: Splashproof TPU. Provides a functional description and setup

and operating instructions for the optional Splashproof TPU.

Appendix A: Sample Towing Characteristics. Provides towing

characteristics charts which are helpful when planning survey equipment

requirements.

Appendix B: Notes on Handling Tow Cables. Contains information on

tow cable handling.

Appendix C: TPU Software Interface and Control. Describes the various

control and initialization procedures for the system.

xx

Appendix D: General Setup, Configuration and Troubleshooting.

Includes basic setup and configuration information and information that is

useful for system troubleshooting.

Appendix E: Drawings and Parts Lists. Provides drawings and parts lists

for reference and troubleshooting purposes.

Note, Warning, Caution, and Shock Hazard Notices

Where applicable, note, warning, caution, and shock hazard notices are included

throughout this manual as follows:

NOTE Recommendations or general information that is particular to the

material being presented or a referral to another part of this manual or to

another manual.

WARNING Identifies a potential hazard that could cause personal injury

or death to yourself or to others.

CAUTION Identifies a potential hazard that could be damaging to

equipment or could result in the loss of data.

SHOCK HAZARD Identifies a potential electrical shock hazard that could

cause personal injury or death to yourself or to others.

Customer Service

KMS technical support can be contacted using any of the following means:

Mail

Klein Marine Systems, Inc.

11 Klein Drive

Salem, NH 03079

Email

Klein.Mail@KleinMarineSystems.com

Telephone

(603) 893-6131

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

xxi

Facsimile

(603) 893-8807

For more information about KMS and our products, please go to our Web site at

www.KleinMarineSystems.com.

CHAPTER 1: OVERVIEW

The Series 5000 Sonar System displays sonar data on a high resolution monitor

and will store data on both the hard disk drive and a CD for high capacity storage.

Many optional accessories may be added to the basic system for special situations

or applications. This sonar equipment provides the capability for precision swath

imaging of the sea floor.

1.1 Equipment

The Series 5000 Sonar System equipment consists of a multibeam sonar

instrumented towfish, a Transceiver and Processing Unit (TPU), and a Windows

Computer Display and Control Unit (computer), along with a tow cable and

various interconnect cables.

1-1

1.1.1 Multibeam Sonar Instrumented Towfish

The towfish electronics perform all the sonar data processing prior to digital

transmission to the sonar TPU. This minimizes the system’s susceptibility to

externally induced electronic noise. Processing includes transmit/receive

functions, time varied gain (TVG) amplification, digitalization, and multiplexing

of the sonar uplink data. Timing and sonar data are bidirectionally multiplexed on

a single conductor coaxial cable. Use of a low noise preamplifier design ensures

maximum range performance. The ability to operate with a fiber-optic cable is

available as an option for very long cable (deep tow) operations or installations

requiring electrical isolation in severe noise environments.

An electro-mechanical termination is provided on the towfish end of the tow cable

for connection to the towfish. A tow shackle provides a strong, reliable,

mechanical termination to the towfish tow bracket. An underwater connector on a

pigtail connects the tow cable electrically to an underwater jumper cable on the

towfish.

1.1.2 Transceiver and Processing Unit (TPU)

The TPU contains the electronics for sonar data demultiplexing and data

processing.

1-2 CHAPTER 1 Overview

1.1.3 Computer Display and Control Unit

The Computer Display and Control Unit (computer) supports the PC based

Windows operating system as the display and control interface. This provides for

an easy to use familiar graphical user interface and simple expansion capabilities

to a wide assortment of equipment. The software is set up in a client-server fo rmat,

allowing for flexible and expandable system configurations with multiple

computers connected over a TCP/IP fast Ethernet network, all sharing the sonar

data.

1.1.4 Tow Cable

Coaxial or optional fiber-optic, double-armored, steel tow cable is used to transmit

data bidirectionally from the towfish to the TPU.

1.2 Features

The Series 5000 Sonar System has the following capabilities:

• High speed, high resolution, multibeam side scan sonar

• 12-bit digital multiplexer for transmission of sonar and control

data over a single coaxial cable

• Integrated attitude and ancillary sensors

• Easy to use graphical user interface (GUI)

• Data can be stored on the hard disk drive or on a CD

• Flexible and expandable system configurations

1.3 Physical Description

The Series 5000 Sonar System consists of two major subsystems: the surface

equipment and the subsurface equipment.

1.3.1 Surface Equipment

The surface subsystem comprises the TPU, the Computer Display and Control

Unit (computer), and the Ethernet Hub.

Transceiver and Processing Unit (TPU). The front panel of the TPU is

shown in Figure 1-1. The main power switch is located on the lower right

corner of the access panel. The TPU is rack mountable in a standard 48.26 cm

(19 inch) rack and contains electronics for receiving sonar data, downlink

multiplexing of control signals to the towfish, and uplink demultiplexing of

sonar and auxiliary sensor signals.

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

Physical Description 1-3

Figure 1-1: TPU—Shown With Access Panel Open

Computer Display and Control Unit (computer). Most operator functions

are accomplished through the use of the computer which supports the PC based

Windows operating system as the display and control interface for the sonar

signals. For a physical description of the computer, refer to the manufacturer's

manual.

Ethernet Hub. The Ethernet Hub is used to connect the computer and the

TPU. For a physical description of the Ethernet Hub, refer to the

manufacturer's manual.

1.3.2 Subsurface Equipment

The subsurface equipment comprises the towfish, as shown in Figure 1-2, and a

tow cable.

Towfish. The Towfish consists of a negatively buoyant tow body containing

port and starboard sonar transducers, processing and control electronics for

sonar operation, a downlink demultiplexer for control signals, and an uplink

multiplexer for sonar and auxiliary sensor data.

Tow Cable. The tow cable is a complete assembly consisting of a coaxial tow

cable with a copper conductor, an electro-mechanical termination on the

towfish end, and an electrical underwater connector . The tow cable is available

1-4 CHAPTER 1 Overview

in either a lightweight polyurethane jacketed Kevlar reinforced design or a

double armored steel design. The lightweight design is used for operations

with cable lengths of 300 meters and under . The double armored design is used

for cable lengths longer than 300 meters.

Figure 1-2: Towfish

1.4 Theory of Operation

This section provides a detailed functional description of the Series 5000 Sonar

System operation.

1.4.1 Introduction

The Series 5000 Sonar System is a simultaneous multiple swath-forming,

side-looking sonar intended for high speed, high resolution survey use. The two

primary drawbacks of conventional side-looking sonars, along-track resolution

and towing speed limitation, have been addressed by simultaneously forming

multiple dynamically focused beams per side, per ping. This allows greater towing

speeds without the usual loss of bottom coverage, while maintaining high

resolution. Also, the formed swaths are focused dynamically with across-track

range, thereby offering an inherently improved along-track resolution over

unfocused systems.

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

Theory of Operation 1-5

The Series 5000 departs from previous multibeam systems in that the swath

forming process is implemented digitally using digital signal processing (DSP),

rather than analog delay lines, phase shifters, or multipliers and adders. The

primary advantage of this technique is a reduction in the size and weight of the

towfish. This affords a concomitant reduction in the size of the required survey

vessel and ancillary equipment, such as a winch and crane. Other advantages

include more flexibility in the swath processing, allowing software control of

operating parameters. Previously this would have required hardware changes.

The Series 5000 architecture is composed of the towfish, the tow cable, the

computer, and the TPU. The towfish contains the transducer arrays and electronic

subsystems for transmission, reception and data acquisition, and telemetry. The

towfish also includes standard and optional sensors for the monitoring of towfish

position and motion dynamics, pressure, depth and altitude (acoustically

measured), temperature, and other pertinent information.

The tow cable is simply a coaxial cable that provides power transfer and duplex

communications between the towfish and the TPU.

The TPU processes the data from the towfish, producing multiple simultaneously

focused swaths. The TPU outputs this data via a proprietary parallel port. Sonar

processor control of the TPU is done via the local area network (LAN).

1.4.2 Towfish

The towfish is composed of the towfish housing, which has external brackets for

cable attachment, the transducer arrays (one for each side), the nose cone, the tail

section, and a pressure housing containing attitude and environmental sensors and

electronics. In a typical operation the towfish is towed behind the survey vessel by

means of the tow cable. The depth at which the towfish runs below the surface of

the water is a function of both the length of the deployed cable and the tow speed.

NOTE The transducers are side specific and are not interchangeable.

The two transducer arrays are each composed of 12 piezoelectric ceramic

sub-arrays that operate as both transmit and receive elements. Each set of

12 sub-arrays is arranged into a continuous line array spanning an overall aperture

of 1.2 meters.

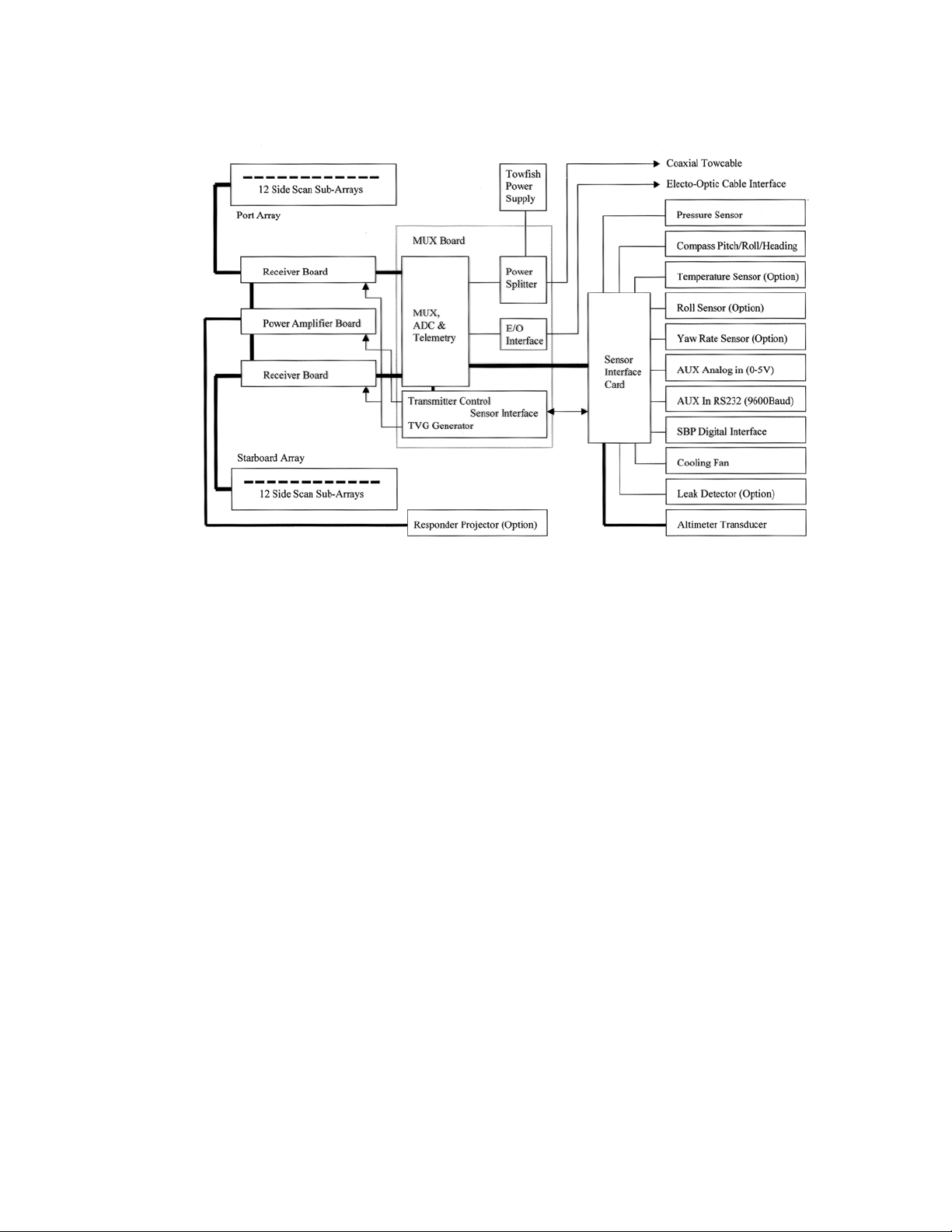

The towfish electronics is divided into five individual boards: a T ransmitter board,

two Receiver boards, a Sensor Interface board, and a Multiplexer board. A block

diagram of the towfish is shown in Figure 1-3.

1-6 CHAPTER 1 Overview

Figure 1-3: Towfish Block Diagram

Transmitter board.

The Transmitter board produces a transmit pulse, at the

start of a swath, that illuminates the sea floor over a defined footprint. The

pulse length is nominally 100 µs. The Transmitter board is composed of six

individual transmitting channels, each of which is connected to two sub-arrays

of both the port and starboard transducer. The six transmitters operate at a

center frequency of 455 kHz while independently providing phase modulation

to reduce coherence in the transmit pulse to mitigate the effects of speckle in

the received data. The transmitters are Class-D switching types coupled

through a double tuned transformer to the transducer sub-arrays.

The Transmitter board also contains two additional auxiliary transmitters, one

for an optional externally mounted responder and one for the downward

looking altimeter.

Receiver boards. The Receiver boards process the backscatter information

by applying fixed gain, time varied gain (TVG) and frequency filtering to the

input voltage signals received from the individual sub-arrays in the transducer

arrays. There are two Receiver boards, one for the port array and one for the

starboard array.

The Receiver boards first process the transducer data by isolating the input

preamplifier electronics from the high voltage transmit signal via a

transmit/receive (T/R) switch. The T/R switch is automatic and requires no

intelligent control. After the transmit waveform has decayed, the switch closes

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

Theory of Operation 1-7

to allow the receive signals to enter a fixed gain low noise preamplifier stage.

The output of the preamplifier is input to a voltage controlled amplifier (VCA)

which performs the TVG function. The gain versus time relationship, TVG,

that is applied identically to all channels is digitally synthesized from a

predefined curve stored in a PROM on the Multiplexer board. Provision has

been made for the storage of alternate TVG curves but in practice it has been

found that the use of these has been limited to test procedures.

Each of the receiver channels is bandpass filtered with tightly matched filters

providing a -3dB bandwidth of 20 kHz, centered at 455 kHz. The filtered

signal is then output to the Multiplexer board for subsequent sampling.

Sensor Interface board. The Sensor Interface board conditions sensor data

from the compass board, depth pressure sensor, altimeter, and optional devices

for subsequent multiplexing and transmission to the TPU.

Multiplexer board. The Multiplexer board digitizes the signals from each of

the transducer sub-array channels along with the signals from the sensors,

encodes the data, and transmits a high baud rate digital data stream to the TPU

via the tow cable. The Multiplexer board also receives the trigger signal and

command messages which instruct the T rans mitte r board to fire the arrays and

configure aspects of towfish operation. The Multiplexer board also acts as a

motherboard for the other boards providing the connections and distributing

power.

The Multiplexer board uses a proprietary sampling scheme that preserves the

phase of the individual channel signals, but only requires a single A/D

converter, thereby reducing cost and power consumption while eliminatin g the

phase mismatch between converters of alternate dual converter schemes. The

output of the A/D is input to the data encoder and converted to serial data for

subsequent transmission up the tow cable.

A full duplex hybrid allows data transmission up the cable while

simultaneously receiving the FSK trigger signals and power. The downlink

signals are input to FSK demodulators, and the baseband outputs are routed to

the Transmitter board, indicating when to fire the main array, and to a micro

controller that handles towfish configuration.

Towfish connector. The towfish connector pinouts are shown in Table 1-1,

and the connector is shown in Figure 1-4. Only two pins are used.

Table 1-1: Towfish Connector—at Towfish

PIN NO. LABEL FUNCTION

1

2 Shield Power and data return

Power/Data +200 VDC power and multiplexed data

1-8 CHAPTER 1 Overview

Figure 1-4: Towfish Connector—at Towfis h

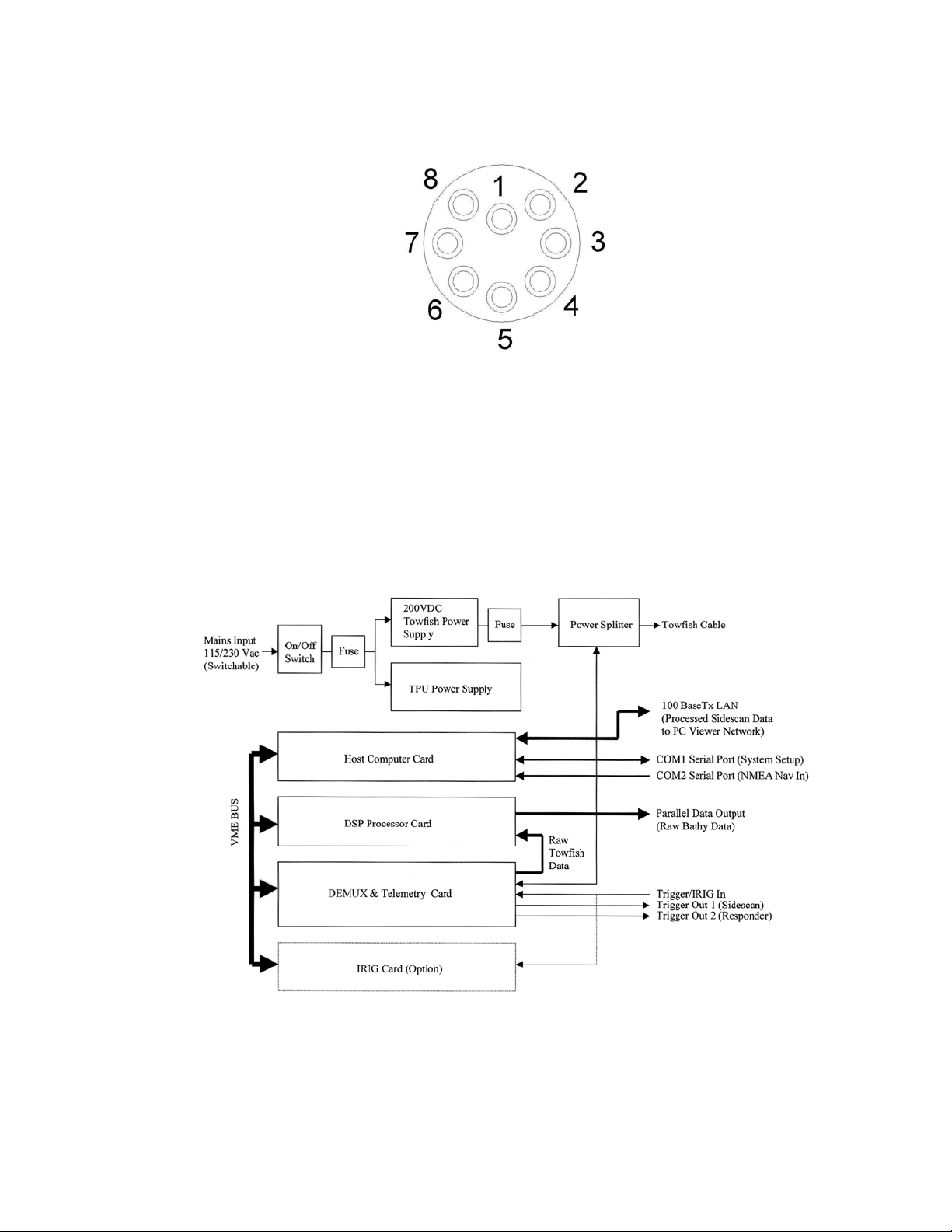

1.4.3 Transceiver and Processing Unit

The TPU provides signal processing along with the system control and data

telemetry functions. The TPU is composed of three circuit boards: an embedded

CPU board, a Demultiplexer board, and a Digital Signal Processor (DSP) board.

The TPU also contains a 200-volt towfish power supply and a TPU power supply.

A block diagram of the TPU is shown in Figure 1-5.

Figure 1-5: TPU Block Diagram

Series 5000 Sonar System Operations and Maintenance Manual P/N 11210060, Rev. 16

Loading...

Loading...