Kleenmaid TX768A User Manual

model : TX768A

3

Contents

Pages

Unpacking your machine............................................................................ 4 & 5

Installing the machine ................................................................................ 5 & 6

Connecting up your machine .................................................................... 6 & 7

Fabric care symbols .................................................................................. 8

Sorting the washing.................................................................................... 9

Fabric care advice ...................................................................................... 9

Dealing with difficult stains ........................................................................ 10

Loading the laundry and the washing powder/liquid ................................ 11

Selecting a wash programme ....................................................................12 to 14

Automatic safety devices .......................................................................... 14

Programme examples ................................................................................ 15

Routine maintenance..................................................................................16 to 18

Possible incidents ...................................................................................... 19

Warranty and Service ................................................................................ 20

Before using your machine, carefully read these instructions which will

enable you to quickly become familiar with the way it works.

4

Unpacking your machine

BEFORE ATTEMPTING TO USE THE MACHINE, YOU MUST FOLLOW THE PROCEDURE

DESCRIBED BELOW

These operations involve removing the metal transit bracket and the blocks which

immobilise the tank of your machine during the transportation, as well as the supports

which hold up the hoses and the electric cable.

These operations, known as "unpacking", are necessary for your machine to

operate correctly and also for complying with current safety standards.

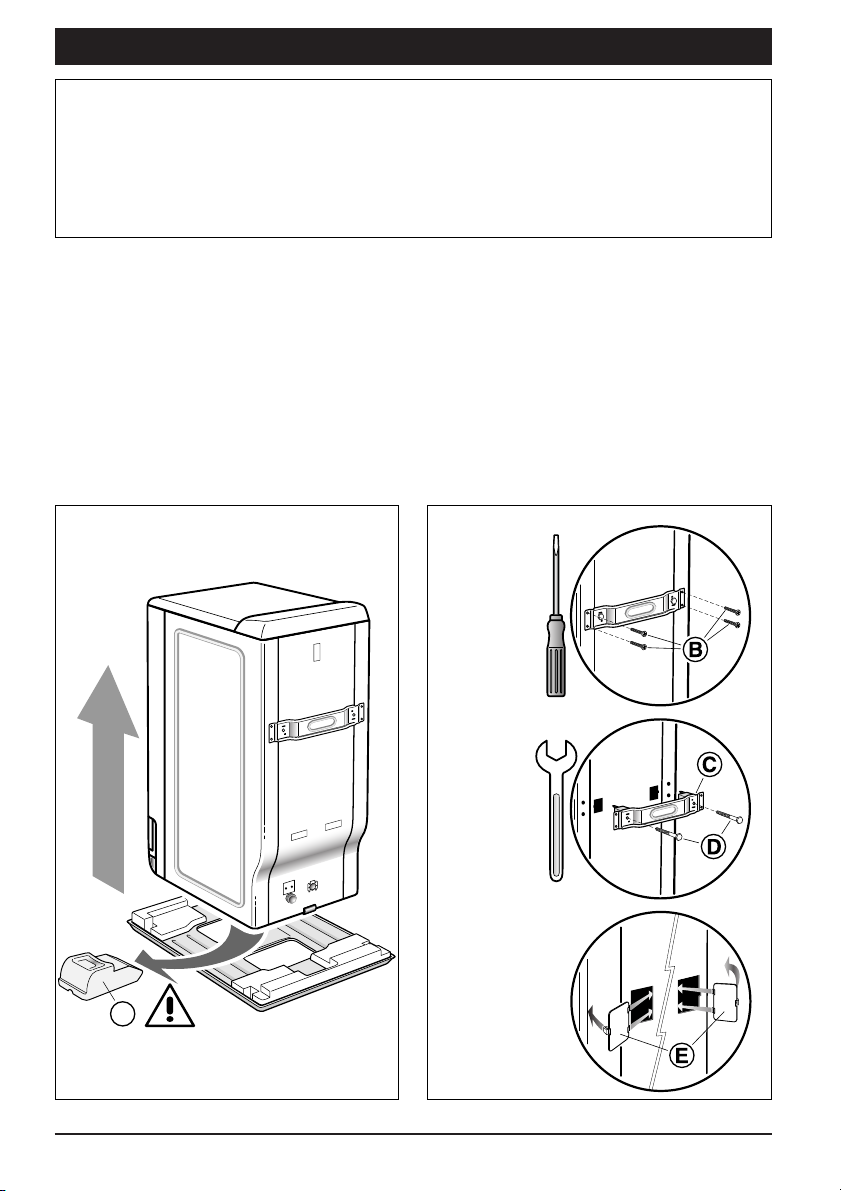

1 - Remove the washing machine from its

base (check that the block «A» that

retains the motor is not stuck under

the machine) (Diagram 1)

2 - Remove the four screws «B» with a

screwdriver (Diagram 2.1)

3 - Remove the bracket «C» by removing

the two bolts «D» with a 13 mm spanner

(Diagram 2.2)

(Make sure that the two plastic

spacers attached to the bar are

removed at the same time).

Replace screws «B» in their original

position.

4 - Blank off the two holes using the plugs

«E» (provided in bag of accessories)

(Diagram 2.3)

Diagram 1 Diagram 2.1

Diagram 2.2

Diagram 2.3

13

1

1

2

2

A

5

Unpacking your machine

Please keep all packing components as they must be replaced if the machine is

to be shipped elsewhere

All these parts and the components of your machine are made of recyclable

materials. Please bear this in mind when the time comes to dispose of your machine

Your machine was inspected before leaving the factory. You may therefore find traces

of water in the tank or in the detergent compartment

Installing the machine

We advise against installing your machine on a carpeted floor. If this is unavoidable,

take all precautions to avoid preventing air circulation at the base, to ensure that

the internal parts are well ventilated.

Machine location

If you locate your machine next to another

appliance or an item of furniture, you should

leave space between them to allow air to

circulate (Diagram 5).

Diagram 5

5 - Remove the block that immobilises the

drum and tub (Diagram 3).

To do this:

- raise the machine lid;

- if your machine comes with a packing

wedge «F», remove it;

- remove the block «G» by rotating it

through 90°;

- open the doors of the drum which are

locked in the low position, by pushing

both flaps at the same time.

6 - Lift up the hoses support clamps

➀

and

do not fall to block the holes using

plugs

➁

(provided in the accessories

bag) (Diagram 4).

Diagram 3

a

b

a

b

➀

➁

Diagram 4

F

G

6

Installing the machine

Connecting up your machine

Moving the machine

using the castors

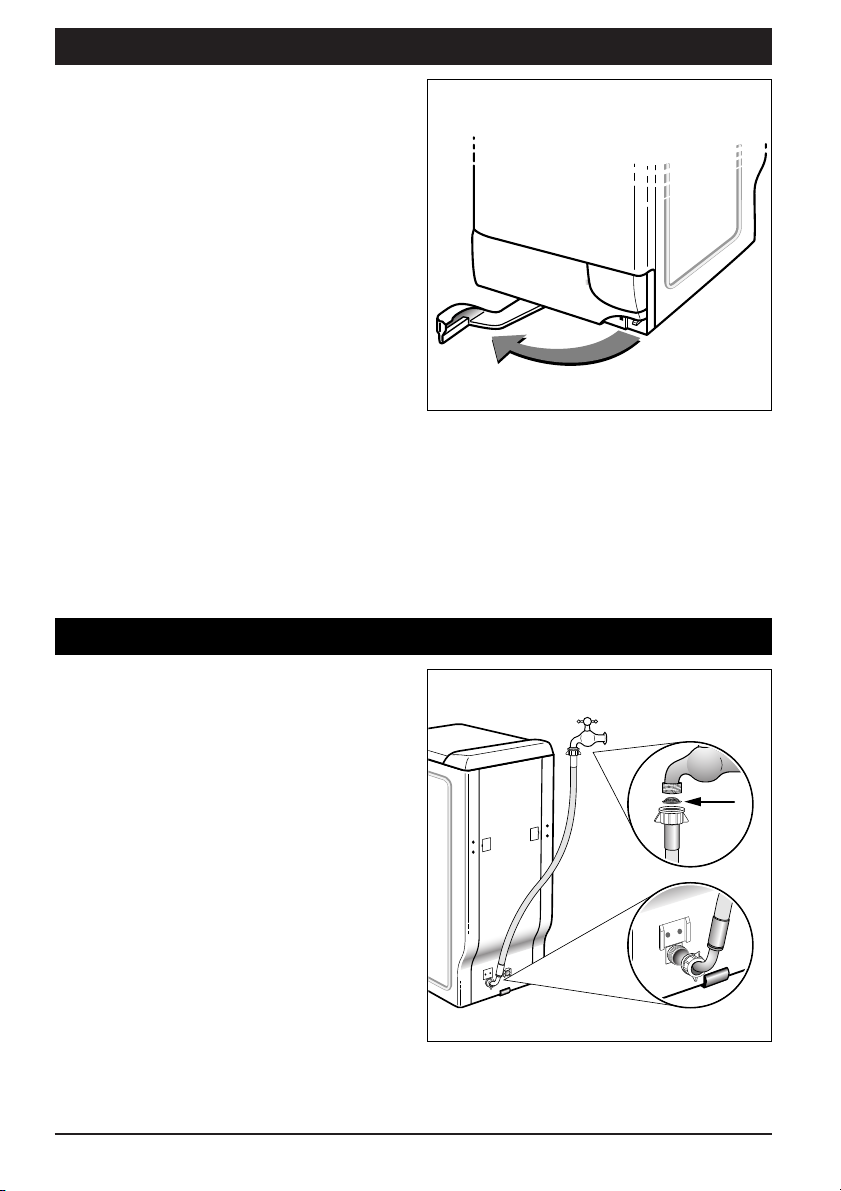

To extend the castors, move the lever at

the bottom of the machine from right to left

(Diagram 6).

The machine should not be used while

standing on its "front" castors: do not forget

to return the lever to its original position.

Levelling

Use a spirit level to check that the ground

is horizontal: the maximum allowable slope

is 2° which gives a difference in height of

about 1 cm across the width of the machine

and 1.5 cm from front to rear.

Cold water supply

Connect up the hose (Diagram 7):

- connect the 90° elbow end to the union

at the back of the machine;

- connect the other end to a tap fitted with

a threaded end diameter 3/4 BSP, not

forgetting to insert the filter washer

supplied in the bag of accessories.

Diagram 6

Diagram 7

Water inlet :

- Minimum water pressure: 70 kPa

- Maximum water pressure : 1000 kPa

Loading...

Loading...