Page 1

cooking collection

Instructions for use and warranty details

Free Standing Oven

Model No.: OMFFS9010

Page 2

Congratulations on the purchase

of your new Kleenmaid appliance.

Your new Kleenmaid appliance has been

designed and manufactured to give you

years of reliable performance.

For best results, carefully read the

instructions on how to install your new

appliance. Correct installation will avoid

delays and unnecessary service call costs.

Once installation is complete, please read

this entire instruction manual carefully and

get to know the controls and the features

of your new Kleenmaid appliance.

Again, congratulations and thank you for

choosing Kleenmaid.

Page 3

RECORD HERE FOR EASY REFERENCE

Model Colour

Serial Number Installation Date

Dealer's Name and Address

GENERAL INFORMATION

ENVIRONMENTAL WARNING

Waste packaging

Do not throw the packaging of your appliance into the dustbin,

but pick out the different materials (for instance foil, paperboard,

polystyrene) according to the local rules for rubbish elimination.

This appliance must only be used for the purpose of domestic

cooking.

WHEN YOU CALL FOR SERVICE

When you call for service or order parts for your unit, be

sure to give:

1. MODEL

2. SERIAL NUMBER

3. COLOUR

4. PART NAME and/or description of problem

5. YOUR FULL NAME, ADDRESS, and HOME TELEPHONE

NUMBER and BUSINESS TELEPHONE NUMBER IF

APPROPRIATE.

Cooker' s ratings are written on the data plate sealed inside the

front appliance drawer *.

Getting to know your new cooker

Thank you for choosing one of our products.

Our cookers are of simple, rational design. They are

constructed to the best standards to ensure good

service and outstanding safety.

Please read this manual carefully; it will provide all the

advice needed to allow you to obtain the best results

from the very first day.

ATTENTION:

- Before using the appliance, do not forget to remove the

plastic protective film from

WARNING -Accessible parts will become hot when in use.

To avoid burns and scalds children should be kept away.

- WARNING -

In order to prevent accidental tipping of the appliance, for example

by a child climbing onto the open oven door, the stabilizing means

must be installed.

- WARNING

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

Children should be supervised to ensure that they do not play

with the appliance.

Young children and infirm persons should not be left

unsupervised in the vicinity.

- WARNING

Before you use the appliance for the first time, check that the

plastic films protecting some parts (fascia panel, parts in stainless

steel, etc.) have been removed.

- WARNING:

A steam cleaner is not to be used cleaning this appliances.

- WARNING

DO NOT place inflammable materials or plastic utensils in the

warming drawer.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE

WHILE IT IS IN OPERATION.

Not for use in marine craft, caravans or mobile homes

unless each burner is fitted with a flame safeguard.

WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT

OR IN CARAVANS, IT SHALL NOT BE USED AS A SPACE

HEATER

DO NOT MODIFY THIS APPLIANCE.

parts of the appliance.

Servicing shall be carried out only by authorised personnel.

SECTION FOR THE QUALIFIED TECHNICIAN

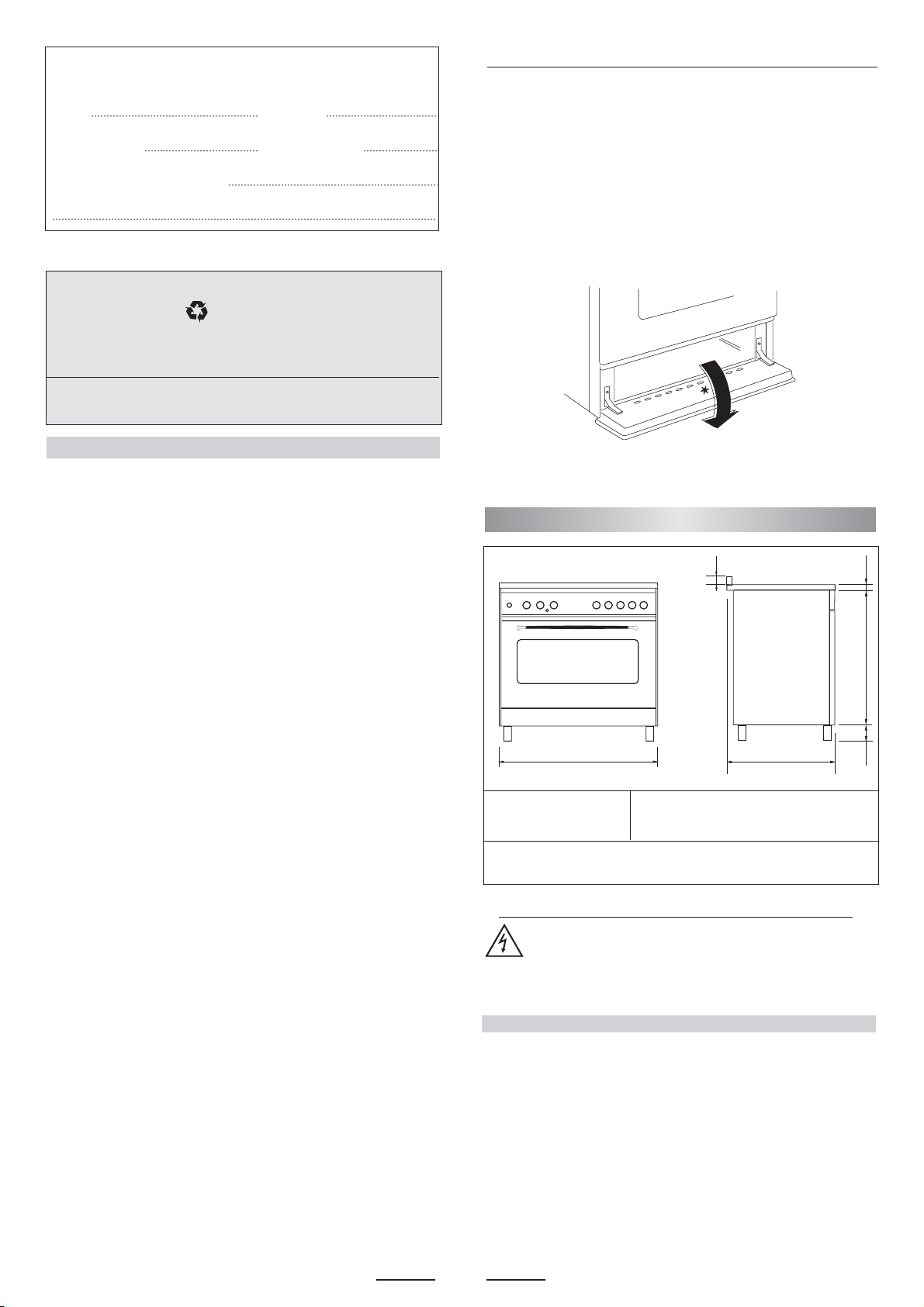

OVERALL DIMENSIONS

60

895

B =

Adjustable height 115/165 mm -

1st SECTION FOR THE QUALIFIED TECHNICIAN

INSTALLATION INSTRUCTIONS

These instructions address appropriate installers and serve as

a guide for installation, adjustment and maintenance in conformity

with the laws and regulations in force.

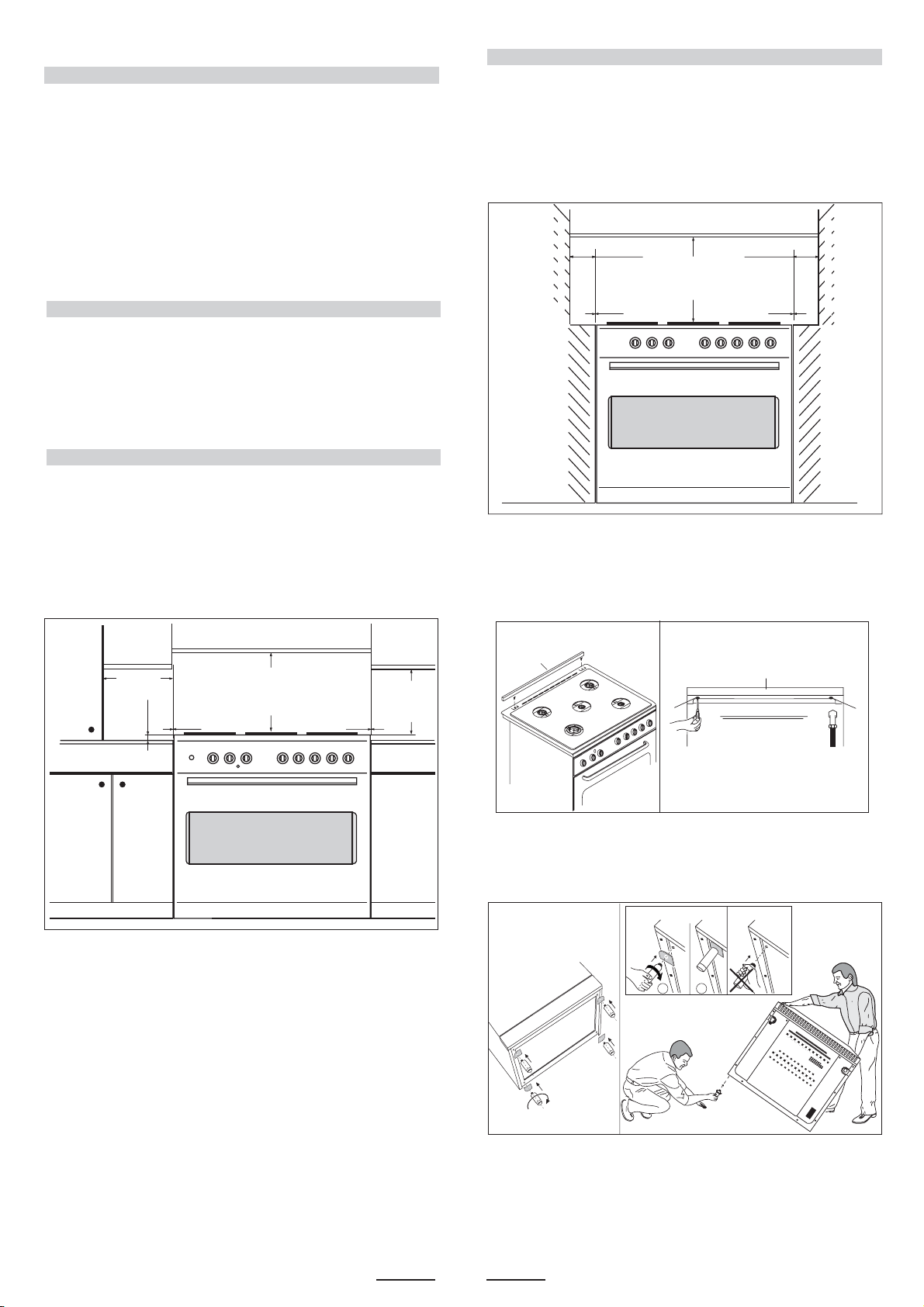

POSITIONING

If the range is placed on a base, ensure measures are taken

to prevent the product slipping off the base

Make sure that the wall surface behind the Cooker is noncombustable (will not catch fire). A plastered or tiled wall is ideal.

Where a painted surface is adjacent, a fire retardent paint surface

is recommended. Wallpaper, wood, or fabric should not be used

behind or next to the cooker.

Any adjoining wall surface situated within 200mm from the edge

of any hob burner must be suitable non-combustible material for

a height of 150mm for the entire length of the hob. Any combustible

construction above the hotplate must be at least 650mm above

the maintop.

600

30

725

B

3

Page 4

INSTALLATION

PROVISION FOR VENTILATION

The room where the Cooker is installed should have permanent

ventilation as follows:

Ventilation must be in accordance with AS5601/AG 601 - Gas

Installations. In general, the appliance should have adequate

ventilation for complete combustion of gas, proper flueing and to

maintain temperature of immediate surroundings within safe limits.

- Do not install in a bed-sitting room, a bathroom or shower room.

If there is another fuel burning appliance in the same room, a

higher level of ventilation will be required, you should consults

" the safety requirements".

In addition to the above, during prolonged use, opening a window

in the same room is recommended. This will avoid the build up

of excessive moisture and condensation.

POSITIONING

Important: Fix the chain located next to the gas connection on

both sides of the cooker to the wall to prevent the cooker from

tilting. Both chains must be securely fixed.

Make sure that the wall surface behind the Cooker is noncombustable (will not catch fire).

Where a painted surface is adjacent, a fire retardent paint surface

is recommended. Wallpaper, wood, or fabric should not be used

behind or next to the cooker.

Clearances to combustible materials

Any adjoining wall surface (side or rear) situated within 200mm

of any hob burner must be a suitable non-combustible material

from the edge for a height of 150mm for the entire length

of the cooker.

Any combustible construction above the cooker must be at least

650mm above the maintop. Ensure that a power and gas supply

are nearby. The Cooker should be located carefully so that the

heat produced by it has plenty of space to escape. The diagram

below shows an ideal configuration.

Clearances to non- combustible materials

If the cooker is being fitted next to cupboards or adjoing wall

surfaces, which are within 200mm from the edge of the hob

burner and of a suitable non-combustible material as specified

in AS5601, then ensure that a distance of at least 6cm is left

between the edge of the cooker and the non-combustible

material. This gap is to allow plenty of space for the heat

produced by the cooker to escape on each side of the cooker.

min "60" mmmin "60" mm min "60" mm

"0" mm "0" mm

non- combustible materials

min. 650 mm

non- combustible materials

Note:

the cooker is fitted with a metallic rear hob protecting

profile (F, see fig. 1) which must be assembled in

following way:

- put the profile (F) on the rear part of the cooker as in fig.

1, and screw the delivered screws (V) as in fig. 1A.

min.100 mm

min. 650 mm

"0" mm "0" mm

min.10 mm

min. 400 mm

No part of any adjoining wall surface can be made of combustible

materials. The protection of combustible materials

required by Clause 5.12.1.1 of AS5601-2004 is the fixing of 5 mm

thick ceramic tiles to the surface or attaching fire resistant

material to the surface and covering with sheet metal with a minimum

thickness of 0.4 mm.

F

F

Fig. 1

V

BACK SIDE

Fig. 1A

V

Note:

The cooker is fitted with 4 legs for an eventual alignment in height

with the furniture

Fig. 1 B

( fig. 1 B ).

OK

2

1

NO

WARNING: This appliance is not suitable to be installed on

a base

4

Page 5

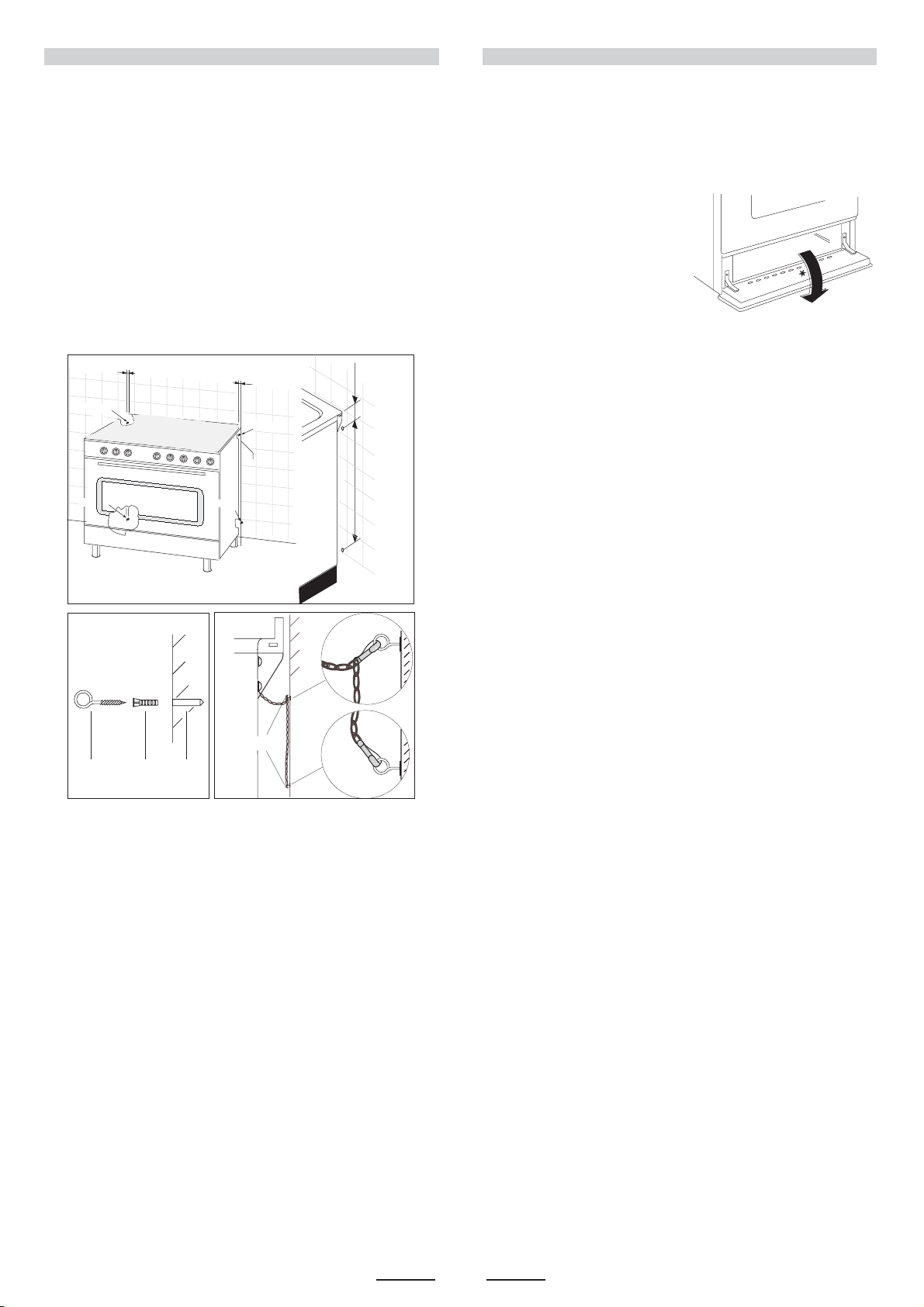

TO FIX THE COOKER TO THE REAR WALL

WARNING - For safety reasons and to prevent tipping of the appliance,

these stabilizing means must be installed.

The cooker is equipped with 2 chains fixed on each side at the rear of

the cooker near the top (see Fig. A). The chains are fitted with spring

clips which must be clipped to the screw eyes provided with the cooker.

Install the screw eyes as follows :

1. Drill four 6mm holes (position 1 - 2 - 3 - 4) in the wall

as in Fig. A.

2. Insert part R into the holes then screw in the screw eyes part

G see Fig. B.

Note: If the part provided is not suitable for the wall material please

use an appropriate device to ensure secure holding of the screw

eyes to the wall.

3. Bring the cooker near the wall and clip the chains on the

screw eyes as in Fig. C.

IMPORTANT: If the cooker is moved for any reason

(e.g. maintenance) resulting in the cooker being unclipped from the

wall, the cooker must be re-clipped to the wall at the completion of

the task.

55 mm

Position

2

Position

3

Fig. A

Fig. B

G R Hole

wall

Position

4

Fig. C

55 mm

Position

1

chain

G

wall

76 mm550 mm

GAS CONNECTION

Should conform to gas utility regulations e.g. AS5601 Gas

installations; also refer to rangehood manufacturers

recommendations.

Check gas pressure, note the correct setting from the data plate

sealed inside the front appliance drawer .

This appliance can be connected with rigid pipe as specified in

*

AS5601 table 3.1 or with a

Plumbezy Flexible hose, AGA

Approval number 6196, 10mm

ID, class D and between 1-1.2m

long in accordance with AS5601

for a 'high level connection'.

Ensure that the chain prevents

stress on the hose assembly

when the cooker is moved out

of its normal operating position.

This appliance from the factory suitable for NATURAL gas but, if

necessary, can be adjusted for U-LPG by authorised person.

For the adjustments to U-LPG please operate as specified in the

paragraph GAS CONVERSION AND ADJUSTMENT (pag 4).

The Gas Connection is male 1/2" BSP and is situated at the right

hand rear of the appliance, approximately 40mm from the side

and 695mm from the floor (depends on adjustment of feet).

The appliance shall be installed by an authorized person in

accordance with the manufacturers installation instructions,

relevant local fitting regulations, municipal building regulations,

the AS5601 code for gas burning appliances and equipment and

other relevant statutory code band regulations. If you have some

doubts, please contact the authorities for confirmation concerning

the characteristics of the gas and electricity output.

The appliance is generally preset for natural gas (so no other

adjustment is necessary) ensure regulator is fitted for N.G.

Ensure that all foreign matter has been cleared from the gas

supply line and also purge all air from the gas system. Connect

to regulator, tighten and check the installation to ensure no gas

leaks occur.

IT IS RECOMMENDED THAT A SERVICE TAP AND UNION BE

FITTED ADJACENT TO THE APPLIANCE INLET TO FACILITATE

FUTURE SERVICING.

5 burner models: set the burner pressure to 1kPa for Natural Gas

and 2.75kPa for U-LPG with the wok burner operating a full rate.

For commissioning of the appliance with the Oara 97

regulator for Natural Gas, the test point pressure should

be 1.00kPa with all burners operating on HIGH.

Apply a manometer to the test nipple and reset the regulator if

necessary. Do not forget to replace the test nipple screw and to

leave the instructions book with the user.

VERY IMPORTANT FOR THE INSTALLER

Do not attempt to turn or stress threaded elbow of the manifold:

you risk damage to this part of the gas appliance which may void

the manufacturers warranty.

Before Leaving - Check all connections for gas leaks with soap

and water. DO NOT use a naked flame for detecting leaks. Ignite

all burners to ensure correct operation of gas valves, burners and

ignition. Turn gas taps to low flame position and observe stability

of the flame.

When satisfied with the cooker, please instruct the user on the

correct method of operation.

In case the appliance fails to operate correctly after all checks

have been carried out, refer to the authorised service provider in

your area.

GAS CONVERSION AND ADJUSTMENT

When used with natural gas all burners have been preset at our

factory and further adjustment should not be necessary. Conversion

kits to other gases are available from the place of purchase. Do

not attempt to fit the conversion kit yourself. Conversion to U-LPG

gas should only be carried out by an authorized technician.

5

Page 6

GAS ADJUSTEMENTS

- change the injectors

- adjust the minimum flow

When converting from Natural Gas to U-LPG ensure that

the NG regulator is removed and replaced with the Test Point

Assembly. A gas regulator suitable for a supply pressure of 2.75kPa

should be part of the gas tank supply and should be adjusted with

the wok burner operating at maximum.

REPLACEMENT OF THE INJECTORS

When required to operate on other gas replace the injectors in

accordance with information referred to in chart below.

TA B. 1

Gas Type kPa

Jet mm Ø Burners Power MJ/h

0.90 Auxiliary 4.0

Natural Gas 1.00 kPa

1.20 Semi-rapid

1.50 Rapid 11.0

1.63

Triple Crown

7.1

12.7

NG Regulator

Gas Type kPa

Jet mm Ø Burners Power MJ/h

0.53 Auxiliary 3.7

U - LPG 2.75 kPa

0.73 Semi-rapid 7.0

0.95 Rapid 11.7

1.00

LP Test point

adaptor

Triple Crown

12.7

SPECIAL NOTE

After installation or any servicing operation, always ensure that

the appliance is gas sound and that the components are now

operating correctly. Items removed during servicing should be

replaced in the reverse order to their

removal.

In order to change the work-top injectors,

it is necessary to act as follows:

- remove the grids

- remove burners

and flame-spreaders.

- change the injector (see Fig. C) and replace it with another one

suitable for the new type of gas (see tab. 1)

Fig. C

MINIMUM FLOW ADJUSTMENT FOR HOB-TOP TAPS

In order to adjust the minimum flame setting proceed as follows:

switch the burner on, and set the knob at the minimum position

. Remove the knob from the tap, place a small bladed screwdriver

down the centre of the tap shaft (fig. 2A).

Attention: on taps with a security valve, the minimum adjusting

screw «Z» is on the body of the gas tap (fig. 2B).

Z

Fig. 2BFig. 2A

Unscrew the adjusting screw in order to increase the flow or screw

it to decrease the flow.

The correct adjustment is obtained when the flame has a length

of about 3 or 4 mm.

For butane/propane gas, the adjusting screw must be screwed

in thigt.

Make sure that the flame does not go out turning quickly from the

max. flow to the minimum flow .

Refit the knob again.

ELECTRICAL CONNECTION

ELECTRICAL CONNECTION

The appliance must be installed by a suitably qualified person in

accordance with these instructions and with the requirements of

the Australian Wiring Rules AS/NZS 3000.

Fixed wired installations are to be provided with suitable isolation

means in accordance with the said rules.

Any plug socket installed for the purpose of connecting the

appliance to supply must be readily accessible when the appliance

is installed.

Before making the connection, make sure that:

1) the safety circuit-breaker and the electrical system are able to

withstand the load of the appliance

(see nameplate).

2) the power supply system has an earth connection in good

working order in accordance with the regulations in force;

IMPORTANT

The wires in the mains lead are coloured in accordance with the

following code:

GREEN & YELLOW .........................................................EARTH

BLUE...........................................................................NEUTRAL

BROWN ...............................................................................LIVE

Electric power........1,5 mm

2

core cable (15 amp. Fuse required)

Should conform to local authority requirements.

Also refer to rangehood manufacturers recommendations.

This appliance is supplied with a plug & cord, simply plug into a

3 pin household socket outlet witch is properly earthed.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The flexible mains lead and plug must not be in contact with hot

surfaces.

In order to avoid hazard, any electrical work performed on this

equipment or its associated wiring, should only be done by persons

authorised by the supplier or similarly qualified persons.

6

Page 7

2nd SECTION FOR THE USER

WARNING:

Children should be kept away while the oven or grill is in use since

accessible parts become hot.

- WARNING -

During use, the appliance becomes hot.

Care should be taken to avoid touching heating elements inside

the oven.

LED PROGRAMMER

Features

24 hours clock with automatic programme and minutes counter.

Functions

Cooking time, cooking end time, manual position, clock,

minutes counter, times to be set up to 23 hours 59 minutes.

Display

4-figures, 7-segments diplay for cooking times and time of day.

Cooking time and manual function = saucepan symbol

Automatic function = AUTO

Minutes counter = bell symbol

The symbols light up when the corresponding functions are selected.

1

Minute timer

2

A

U

T

O

123456

3

4

5

6

Cooking time

Cooking end

Manual

Subtract time

Add time

- Do not use oven base panel as a shelf, make use of the oven

shelves.

- To avoid splattering and smoke, position collecting tray under

the grill with some water in it.

- Always turn pan handles to the side or to the back of the hob.

If they are left out into the room they can easily be hit or reached

by children, this knocking the pan off the hob.

- Dont let children sit down or play with the oven door. Do not

use the drop down door as a stool to reach above cabinets.

- Once your cooking is over make sure to close the main gas

supply.

Setting

To set, press and release the desired function, and within 5 seconds

set the time with 5 and 6 buttons.

+ and - buttons (5 and 6).

The 5 and 6 buttons increase or decrease the time at a speed

depending on how long the button is pressed.

Setting the time

Press the manual button (4) at the same time 5 or 6 button to set

the desired time. This deletes any previously set programme. The

contacts are switched off .

Manual use

By pressing the manual button the relay contacts switch on, the

AUTO symbol switches off and the saucepan symbol lights up.

Manual operation can only be enabled after the automatic

programme is over or it has been cancelled.

Automatic use

Press the cooking time (2) or end time button (3) to switch

automatically from the manual to the automatic function.

Semi-automatic use with cooking time setting

Press the cooking time button (2) and set the desired time with or +. The AUTO and cooking time symbols light up continuously.

The relay switches on immediately. When the cooking end time

corresponds to the time of day, the relay and cooking time symbol

switch off, the sound signal rings and the AUTO symbol flashes.

Semi-automatic use with end time setting

Press the end time button (3). The time of day appears on the

display. Set the cooking end time with 6 button. The AUTO and

cooking time symbols light up continuously. The relay contacts

switch on. When the cooking end time corresponds to the time of

day, the relay and the cooking time symbol switch off. When the

cooking time is up, the AUTO symbol flashes, the sound signal

rings and both the relay and the cooking time button switch off.

Automatic use with cooking time and end time setting

Press the cooking time button (2) and select the length of the

cooking time with 5 or 6 button. The AUTO and cooking time

symbols light up continuously. The relay switches on. By pressing

the cooking end time button (3) the next cooking end time appears

on the display. Set the cooking end time with 6 button. The relay

and the cooking time symbol switch off.

7

Page 8

The symbol lights up again when the time of day corresponds to

the cooking start time. When the cooking time is up, the AUTO

symbol flashes, the sound signal rings, the cooking time symbol

and the relay switch off.

Start programme and check

The programme starts 4 seconds after it has been set.

The programme can be checked at any time by pressing the

corresponding button.

Minutes counter

Press the minutes counter button (1) and set the cooking time

with 5 or 6 button.

The bell symbol lights up when the minutes counter is operating.

When the set time is up, the sound signal rings and the bell symbol

switches off.

Sound signal

The sound signal starts at the end of a programme or of the

minutes counter function and it lasts for 15 minutes.

To stop it, push any one of the functions buttons.

- 1 Minute Tour -

Be safe

Please read the rest of the instruction book which contains

important information to help you use the appliance safely and

efficiently.

Gas and Electricity on

Make sure that the gas supply is turned on and that the appliance

is plugged in and switched on. The ignitor needs electricity.

In case there is no electric current, the burner can also be lighted

using a match.

Setting error

A setting error is made if the time of day on the clock falls within

the cooking start and end times.

To correct the setting error, change the cooking time or cooking

end time.

The relays switch off when a setting error is made.

Cancelling a setting

To cancel a setting, press the cooking time button (2) and then

press the button (5) until 00 00 appears on the display.

A set programme will automatically cancel on completion.

Automatic electric ignition

To turn on a burner, press the knob corresponding to the

selected burner and turn it anticlockwise to the maximum

position. Keeping the knob pressed, the electric automatic

ignition of the burner will be started up. In case there is not

electric current, the burner can also be lighted using a match.

It is recommended that pans suitable to the size of the burner

should be used as follows:

BURNERS PANS

fl min. fl max

AUXILIARY 80 mm 160 mm

SEMI-RAPID 120 mm 200 mm

RAPIDE 200 mm 230 mm

TRIPLE CROWN 230 mm 260 mm

Always use pans with a flat base diameter, which are well balanced

and stable in use, a pan which overhangs the hotplate should not

be used. Avoid using old, misshapen pans, or pans which are

unstable when placed on a flat surface. Do not use split pans

as they are inherently unstable.

To save gas, always position pans centrally over the burners and

adjust the flames so that they do not lick up the sides of the pan

and only the base is heated. Always put lids on saucepans and

boil only the amount of liquid you use. When the liquid has boiled

adjust the setting to maintain a simmer. Do not light the burner

until the pan is in position and turn off the burner before removing

the pan. In hard water areas, descale kettles regularly. For safety,

keep saucepan handles turned to a safe position so they are out

of reach of small children and cannot be accidentally knocked.

To tunr the burner OFF, turn the control knob clockwise to the

OFF setting (marked with a dot )

The small flame indicates the low position.

Turn the knob to it after the contents of a pan have boiled.

The smaller burners are for smaller pans and simmering. Make

sure flames are under the pans. Using a lid will help the contents

boil more quickly.

WARNING

It is not recommended to press push button for ignition if all the

burners are not located in the proper positions. The burner heads,

burner skirts and pan supports are removable for better cleaning:

Always ensure that the burner skirts and heads are replaced

correctly so that the burners function safely and correctly.

During the use of the appliance pay attention that water or any

liquid does not enter into the appliance through the holes of the

burners or around the rods of the valves or the push button

electronic lighter.

Water or juice will produce dangerous short-circuits and can

seriously damage the working of the Hotplate.

8

Page 9

HOW TO USE YOUR ELECTRIC OVEN

- Before cooking in the first time we reccommend that the oven

should be operated at 200° C for 30 minutes to remove any

manufacturing greases and odours.

- Do not place items or pan directly on to the oven botton.

- Foil should only be used to cover food and not oven shelves or

party of the oven. When used improperly will obstruct the air

circulation causing problems in cooking and/or harmful accidents.

MULTIFUNCTIONAL OVEN

The oven is fitted with:

a lower heating element;

an upper heating element;

a circular heating element surrounding the fan.

N.B.: Always set the temperature on the thermostat knob before

selecting any of the functions.

Oven thermostat knob (fig. 3)

To obtain an oven temperature between 60°C and MAX°C, turn the

knob clockwise.

When you turn the control knob to this position, the light will be on

for all the following operations.

Defrosting with fan

The air at ambient temperature is distributed inside the oven for

defrosting food very quickly and without proteins adulterations.

Natural convection

Both the lower and upper heating elements operate together.

This is the traditional cooking, very good for roasting joints, ideal

for biscuits, baked apples and crisping food.

You obtain very good results when cooking on a shelf adjusting

the temperature between 60 and MAX°C.

Oven commutator knob (fig. 3A)

Depending on the type of oven, it is possible to select one of the

following functions turning the commutator knob clockwise.

max

60

80

100

125

225

200

175

150

Fig. 3 Fig. 3A

Note:

All the functions mentioned above switch the oven internal light on.

A warning light on the control panel will stay lit until the temperature

is reached; after it will light up intermittently.

Always use the oven with the oven door closed.

Use of the oven

Note: ovens with separate thermostat and commutator.

When the functions are used, place the thermostat knob

between 180 ÷ 200°C as maximum temperature.

ATTENTION:

The temperature shown on the control panel corresponds to the

temperature in the oven centre only when the functions selected

are or .

Fan oven

Both the fan and the circular heating element operate together.

The hot air adjustable between 60 and MAX°C is evenly distributed

inside the oven. This is ideal for cooking several types of food

(meat, fish) at the same time without affecting taste and smell.

It is indicated for delicate pastries.

Medium grill

It is indicated for grilling and gratinating small quantities of traditional

food.

The thermostat knob must be placed on the maximum position.

Total grill

It is indicated for grilling and gratinating traditional food.

Turn the thermostat control knob to the 200°C position.

Fan assisted total grill

The air which is heated by the grill heating element is circulated

by the fan which distributes the heat on the food.

The fan assisted grill replaces perfectly the turnspit. You can obtain

very good results also with large quantities of poultry, sausage,

red meat. Turn the thermostat control knob to the 200°C position.

Air forced lower heating element

The air which is heated by the lower heating element is circulated

by the fan which distributes the heat on the food.

This function can be used to sterilize food. This function can be

used between 60 and MAX°C

9

Page 10

GENERAL INSTRUCTION

may boil over (e.g. fruit pies) on a baking tray to prevent spillage

burning onto the oven base. Foil used improperly is frequent cause

used to cover food and cooking dishes. Always place items which

Warning: remember ovens get hot; some parts naturally become

very hot, notably the glass oven door and the protective strip. Keep

children away from oven at all times and warn them about the

danger.

GUIDE FOR CONVENTIONAL COOKING

(Outer ring of upper electric element and lower electric element

ON) The following Cooking Guides give the recommended shelf

positions (counted from the bottom), thermostat settings and

of oven problems and painful accidents. Avoid letting grease

deposit collect around the upper heating element: it will cause

smoking and may start a fire.

Remember do not place pan or items directly onto the oven base.

Never leave unit unattended at hight heat settings. Boil over causes

smokingand greasy spill over that may start a fire.

If a grease fire should occur in a pan put out the flame by placing

a lid on the pan. Do not throw water on a grease fire.

approximate cooking times for a range of baked items, using the

conventional oven, using one tray only. Cooking results are a

matter of personal preference and may easily be adjusted to suit

individual requirements by slight adjustment of the temperature

and or cooking time. Preheating of the oven is recommended for

10-15 minutes or until the oven thermostat indicator light switches

off to show the selected temperature has been reached.

When using a baking tray it should be placed centrally on the oven

shelf with the short sides of the tray parallel to the sides of the

oven. Do not use trays, tins or dishes larger than 380 mm (15")

long, 356 mm (14") wide, as cooking results may be impaired.

GUIDE FOR FORCED CONVECTION COOKING

(Back rolled electric element with fan)

The accessories provided with the oven can be slotted in at 5

positions: the following guide concerns cooking times and thermostat

settings using N. 2 shelves on the same time (in position N. 2 and

N. 4). Cooked results are a matter of personal preference and may

easily be adjusted to suit individual requirements by slight adjustment

of the temperature and/or cooking time, or when using more or

less shelves in the same time. Preheating of the oven is

recommended for 10-15 minutes or until the oven thermostat

Food Thermostat Shelf Position Cooking Time

setting °C

Small cakes (12 on tray) 195 3 20 - 30 mins.

Victoria sandwich 190 3 25 - 35 mins.

(2x7"/180mm)

Swiss roll or whisked sponge 200 3 20 - 25 mins.

Fruit cake (8"/205mm) 155 2 2 - 3 hours.

Scones 260 3 10 - 20 mins.

Meringues 95 2 2 - 3 hours.

Shortcrust Pastry 210 3 25 - 45 mins. depending

Puff or Flaky Pastry 220 2 20 - 35 mins. upon

Choux Pastry 220 3 25 - 35 mins. dish

Biscuits 200/220 3 15 - 25 mins. depending upon type

Bread 250 2 30 - 40 mins.

Milk pudding 165 2 1 H - 2 hours.

Pizza 270 3 25 mins.

Lasagne 170 3 75 mins.

Oven noodles 160 3 75 mins.

BEEF on bone & crusty 270 rare 3 12 mins. per 1/b (500 g) plus 12 mins.

(rare) 220 °C 3 15 mins. per 1/b (500 g) plus 15 mins.

(medium) 220 °C 3 20 mins. per 1/b (500 g) plus 20 mins.

(well done) 180 °C 3 25 mins. per 1/b (500 g) plus 15 mins.

LAMB on bone 220 °C 3 20 mins. per 1/b (500 g) plus 20 mins.

170 °C 3 27 mins. per 1/b (500 g) plus 27 mins.

Boned and rolled 220 °C 3 25 mins. per 1/b (500 g) plus 25 mins.

170 °C 3 35 mins. per 1/b (500 g) plus 20 mins.

PORK on bone 220 °C 3 25 mins. per 1/b (500 g) plus 25 mins.

Boned and roller 180 °C 3 30-35 mins. per 1/b (500 g) plus 35 mins.

VEAL on bone 220 °C 3 25 mins. per 1/b (500 g) plus 25 mins.

Boned and roller 220 °C 3 30 mins. per 1/b (500 g) plus 30 mins.

CHICKEN 220 °C 3 20 mins. per 1/b (500 g) plus 20 mins.

170 °C 3 25 mins. per 1/b (500 g) plus 25 mins.

TURKEY 220 °C 3 20 mins. per 1/b (500 g)

170 °C 3 25 mins. per 1/b (500 g)

DUCK 220 °C 3 20 mins. per 1/b (500 g)

170 °C 3 25 mins. per 1/b (500 g)

GOOSE 220 °C 3 20 mins. per 1/b (500 g) plus 20

(Counted from Bottom)

indicator light switches off to show the selected temperature has

been reached.

When using a baking tray it should be placed centrally on the oven

shelf with the short sides of the tray parallel to the sides of the

oven. Do not use trays, tins or dishes larger than 380mm (15")

long, 356 mm (14") wide, as cooking results may be impaired.

Food Thermostat setting °C Cooking Time

Small cakes (12 on tray) 175 15-25 mins.

Victoria sandwich 170 20-30 mins.

(2x7"/180mm)

Swiss roll or whisked sponge 180 15-20 mins.

Fruit cake (8"/205mm) 135 1 H - 2 H hours.

Scones 210 8-15 mins.

Meringues 80 1 H - 2 H hours.

Shortcrust Pastry 190 20-40 mins. depending

Puff or Flaky Pastry 200 15-30 mins. upon

Choux Pastry 200 20-30 mins. dish

Biscuits 170/180 10-20 mins. depending upon type

Bread 200/220 25-35 mins.

Milk pudding 150 1 H - 2 hours.

Pizza 250 20 mins.

Lasagne 165 60 mins.

Oven noodles 150 60 mins.

BEEF on bone 230 rare & crusty 9 mins. per 1/b (500 g) plus 9 mins.

BEEF on bone 190 °C (rare) 15 mins. per 1/b (500 g) plus 8 mins.

Boned and rolled 190 °C (rare) 20 mins. per 1/b (500 g) plus 10 mins.

LAMB on bone 190 °C 20 mins. per 1/b (500 g) plus 10 mins.

Boned and rolled 190 °C 25 mins. per 1/b (500 g) plus 14 mins.

PORK on bone 200 °C 25 mins. per 1/b (500 g) plus 14 mins.

Boned and roller 160 °C 30-35 mins. per 1/b (500 g) plus 18 mins.

VEAL on bone 200 °C 25 mins. per 1/b (500 g) plus 14 mins.

Boned and roller 200 °C 30 mins. per 1/b (500 g) plus 14 mins.

CHICKEN 200 °C 20 mins. per 1/b (500 g) plus 10 mins.

PLATE WARMING

Ovenproof plates and dishes may be warmed in the oven on a

TURKEY 200 °C 18 mins. per 1/b (500 g) plus 14 mins.

low temperature setting. Remember do not place items directly

into the oven base.

DUCK 200 °C 18 mins. per 1/b (500 g)

Warning: do not use foil to cover the oven shelves, or any part

of the oven interior including the oven base. Foil should only be

GOOSE 180 °C 18 mins. per 1/b (500 g) plus 20 mins.

190 °C (medium) 20 mins. per 1/b (500 g) plus 10 mins.

160 °C (well done) 25 mins. per 1/b (500 g) plus 8 mins.

190 °C (medium) 25 mins. per 1/b (500 g) plus 15 mins.

160 °C (well done) 30 mins. per 1/b (500 g) plus 8 mins.

155 °C 27 mins. per 1/b (500 g) plus 14 mins.

155 °C 25 mins. per 1/b (500 g) plus 14 mins.

155 °C 25 mins. per 1/b (500 g) plus 13 mins.

155 °C 23 mins. per 1/b (500 g)

155 °C 23 mins. per 1/b (500 g)

10

Page 11

USE OF THE ELECTRIC GRILL

USlNG THE GRILL

Turn the oven knob to the right and place it on the grill position

.

The grill pan should be located on the top oven shelf position.

Some models are provided with two detachable grill pan handles

which are engaged over the front edge of the pan between the

indentations provided. A wire grid is supplied. The grill pan handles

should be removed from the grill pan during the grilling operation

and only fitted for removal or insertion of the grill pan particularly

when hot. Always preheat the grill on full for 3-5 minutes before

inserting the food.

The user can change the shelves, depending on his personal

whishes and on the different food.

Geat the oven 5 minutes before introducing the food.

Warning:

Do not place fatty foods too close to the grill and never leave the

grill unattended. If fatty foods are grilled, or roasting has been

cooked in the oven at a high temperature the grill element may

smoke. This is not dangerous and the smoke is caused by the fat

burning off when the grill element is hot. Leave the grill element

on until the smoking has stopped t-hen use as normal. If a grease

fire should occur in a pan put out the flame by placing a lid on the

pan. Do not throw water on a grease fire.

CLEANING

Before cleaning the appliance, close the gas stopcock and unplug

appliance or disconnect power at the main circuit breaker of the

electrical system.

Do not clean the appliance surfaces when still hot.

Always clean off spillage as quickly as possible to prevent burning

on which will make removal more difficult. Wash with a clean cloth

soaked in hot soapy water, rinse and dry with a soft cloth.

DO NOT USE ABRASIVES. CAUSTIC PASTES OR SPRAYS.

COARSE CLEANING PADS OR POWDERS. DO NOT USE

EXCESSIVE WATER WHEN CLEANING YOUR OVEN IN ORDER

TO AVOID WATER PRESSING THROUGH CLEFTS INTO THE

BACK OF CONTROLS PANEL OR OF THE UNIT.

NOTE: A steam cleaner is not to be used for cleaning this

appliance .

Pan supports and burners

The burner heads can be removed for cleaning.

NB Do not drop hot burner caps in cold water.

Because of the rapid cooling they might get damaged.

Lift off and soak for about 10 minutes in hot water with a little

detergent. After having cleaned and washed them, dry them

carefully.

Make sure that no burner holes are clogged.

Clean the burners once a week or more frequently if necessary.

Make sure you have reassembled the burners correctly.

Pan supports can be washed by hand or in a dishwasher.

Remember to remove rubber feet (if fitted) prior to washing.

Refit them afterwards.

burner cap

locating pegs

notch for electrode

in burner head

electrode

Oven Shelves

The shelves are designed with stop-locks so when placed correctly

on the shelf supports, they will stop before coming completely

out of the oven and will not tilt when you are removing food from

them or placing food on them.

When placing cookware on a shelf, pull the shelf out to the bump

on the shelf support. Place the cookware on the shelf, then slide

the shelf back into the oven. This will eliminate reaching into the

hot oven.

To remove the shelves from the oven, pull them forward you,

tilt front end upward and pull them out.

To replace, ct in the opposite manner as before.

Bump

For a triple crown burner, make sure head C and covers A

and B are properly placed on their seats as figure 4C and not

off-centered as in figure 5.

A

B

A

B

C

Daily

Regular wiping down directly after use prevents dirt from burning

on. Clean the appliance with water and a detergent or all purpose

cleaner.

Avoid using too much water to prevent it entering the burner or

ventilation openings.

Oven accessories (shelves, trays etc) should be washed in mild

detergent solution and should not be treated with abrasives. The

oven interior panels should be cleaned with mild detergent solution,

mild cream cleaners or a moist soap pad.

Fig. 4C

B

Fig. 5

A

Install shelves by locating them in the horizontal guide rails on

the oven walls. The raised portion of the shelf is to be facing the

rear wall of the oven.

11

Page 12

Interior: the oven shelf

carriers and the back

fan cover can be

removed for easier

cleaning. To do this,

remove all the shelves

and spring off the side

carriers (Fig. 6 - 7).

Replace in a similar

manner.

Fig. 6

Fig. 9

Fig. 9A

B

A

C

Fig. 7

IMPORTANT

Do not use excessive water when cleaning the oven and avoid

water passing through the fan grill or ducts in the oven back .

Avoid letting grease deposit collect around the upper heating

element: it will cause smoking and may start a fire.

The interior glass of the oven

The interior glass of the oven door can be removed:

with the door in a semi-open position, remove the screws A and

B and the profime C

as shown in fig. 9

Use both hands to remove the glass as shown in figures 9A.

After cleaning, refit the glass by proceeding in reverse order.

Removal of oven door

In-depth cleaning of the oven becomes more convenient if the

door is removed following the instructions below:

1 open the oven door completely.

2 flip the hinge hooks "A" outwards (see fig. 9B).

3 shut the oven door slowly until it reaches hooks "A", making

sure these are locked into slots "B" of the oven door, as shown

in fig. 9C. Remove the glass FIg. 9A (

only for models where

present).

4 Using both hands, push the oven door lightly inwards, toenable

the door hinges "C" to come away from the slots "D" (see fig.

9D) and pull the door towards you until it is released from the

oven.

After cleaning it, reposition it correctly following the abovesteps

in the reverse order and flipping hooks "A" inwardsbefore you

shut the oven door (fig. 9E).

A

Fig. 9B

C

D

Fig. 9D

A

B

AA

Fig. 9C

A

Fig. 9E

WARNINGS

Before performing any repair or operation, switch the

appliance off and close the gas tap.

The manufacturer declines all responsibility for any damage to

persons, animals or things caused by failure to observe the rules

indicated above. In case it is necessary to repair or replace the

inside components, act as follows:

WARNINGS

Isolate the cooker from the electricity supply before attempting

to replace the oven lamp.

The oven lamp used is of a special type withstanding high

temperatures. To replace it, act as follows: disassemble the

protecting glass (A) and replace the burnt lamp with one of the

same type (Type E14 threaded clear lamp 230/240 V. 25 watt

T 300°C). Reassemble the protecting glass.

CAUTION:

Do not use rough or abrasive materials or sharp metal scrapers

to clean the glass doors of the oven since they may scratch the

surface and cause the glass to break.

A

12

Page 13

Disassembly of the worktop must only be done by a qualified

service technician.

DISASSEMBLE OF WORK-TOP

In case it is necessary to repair or replace the inside components,

act as follows:

Remove the grids, remove burners and flame-spreaders (see

fig. 13), unscrew the visible screws V placed on the work-top

(see fig. 14). Disassemble the work-top by unscrewing the rear

screws A (see fig. 15A). In this way it is possible to lift the worktop and to reach the inside components.

V

Fig. 13

Fig. 14

A

Fig. 15 A

SOME SAFETY POINT

Do not use the appliance as a space heater.

If you smell gas

Open a window. Do not use any electrical switches.

Immediately extinguish naked flames. Isolate appliance from

gas mains supplies via the isolation stopcock. Contact local

gas authority or emergency services as appropriate. In the

event of food fire. Isolate appliance from electric / gas mains

supplies if safe to do so. Try to extinguish flames with the

appropriate equipment (fire blanket or extinguishing foam).

Do not use water on cooking fat / oil fires.

If in difficulty call emergency services.

Do not store or use flammable products or aerosol containers

near the hotplate or burners.

Never flambe under an extractor - even if the ventilator is

switched off.

The high flames can cause fire.

For your safety and that of your children

Do not store items that are attractive to children above or near

the appliance.

Keep children well away from the appliance:

do not forget that some parts of the appliance or of the pans

become very hot and dangerous during use, and will take time

to cool down.

When cooking, do not use clothes that could catch fire and

cause serious injury.

Some Wok cooking pots are unstable. Check with the

manufacturer before purchasing.

Avoid using unstable and misshapen pans which may tilt easily

and pans with a very small base diameter, e.g. milk pans, single

egg poachers. The minimum pan diameter recommended is

125mm (5"). Smaller pans will be unstable.

Very large pans may cause walls or knobs to overheat. Using

pans which are too big may deform the control knobs or discolour

the walls. This is not covered by the guarantee.

Carefully place all pans centrally over the burners.

Always position pan handles safely away from the front of the

hotplate and out of danger, particularly from small children.

Never leave a chip pan unattended.

Pans and kettles with down turned base rims should not be

used.

Simmering aids such as asbestos or mesh mats are NOT

recommended. They will reduce burner performance and could

damage the pan supports.

Commercially available foil spillage aids are unnecessary on

this hotplate.

13

Page 14

PROBLEM SOLVER

Any of the following are considered to be abnormal operation

and may require servicing:

Yellow tipping of the hob burner flame.

Sooting up of cooking utensils.

Burners not igniting properly.

Burners failing to remain alight.

Burners extinguished by oven door.

Gas valves, which are difficult to turn.

Your Installer should be contacted if you have any problems with

the installation.

Before you call a service engineer please check if the problem

is something you could fix yourself. The cause of the problem is

often a simple one.

THINGS TO TRY BEFORE CALLING FOR AN ENGINEER

Burner does not burn well

Is the burner dirty or damp? Try cleaning and/or drying the burner.

Appliance not suitable for your gas type? Check the identification

plate on the hotplate base.

Burner does not ignite

Do the burners spark when you press the ignition button? If not

is the power on? See Checking the power supply section further

on. If the power supply is OK then there is probably something

wrong with the ignition system.

Are the electrode or burner slots blocked by debris?

Is the burner dirty or damp? Try cleaning and/or drying the burner.

Is the burner trim correctly located?

Are the burner caps correctly located?

Check that there is not a problem with your gas supply. You can

do this by making sure that other gas appliances you may have

are working.

Pan supports

Aluminium pans may cause a metallic marking on the pan supports

which does not affect the durability of the enamel and may be

cleaned off with a metal cleaner such as Brasso.

Checking the power supply

First check the socket by trying out another piece of electrical

equipment in it.

If that works, renew the fuse in the hotplate plug. Use a 10 amp

fuse. If the fuse blows again there is a fault on the hotplate. Do

not use a fuse with a higher rating. Do not carry out other electrical

work. Unplug the hotplate and tell your installer.

OVEN DOES NOT WORK AT ALL

First, when the oven is equipped with timer, check appliance is

not programmed to turn on later. If it is, turn to manual setting (i.e.

hand symbol). If the button or scale on the timer remains in the

automatic position after use, the power supply to the oven will be

interrupted. Also, check your appliance is switched on at the

mains. Next check for an unexpected power strike by switching

on adjacent lights etc. Finally, check fuses and plug wiring. If all

these prove satisfactory, call engineer.

LIGHT BULB DOESNT COME ON

Check bulb for looseness or burned out bulb.

Note: bulb replacement is not covered by your guarantee.

SMOKE COMING FROM OVEN

If oven is still relatively new, this problem is invariably due to

protective oil on elements. Otherwise, the answer may be oil or

fat which has become deposited on the elements during cooking.

In either event, continued use should burn away the residues. On

future occasions, try to shield food with foil or keep it further away

from element, particularly when grilling.

CLOCK/TIMER DOES NOT WORK

Check to be sure range cord is plugged into outlet completely.

Check for a blown fuse or tripped circuit breaker. Check for power

outage. Check step by step operating Instructions on previous

pages.

If, after checking through this section, you cannot resolve

your problem please call the number on the data plate fixed

to the front cover of these instructions for service and spare

parts.

When ordering please quote the appliance name, the colour

variant and serial number.

This information can be found on the data plate sealed inside

the front appliance drawer.

Power Failure

In the event of a failure in the electrical supply the hotplate burners

may be lit using a match.

Ventilation

The use of a gas cooking appliance results in the production of

heat and moisture in the room in which it is installed. Ensure that

the kitchen is well ventilated: keep natural ventilation holes open

or install a mechanical ventilation device, (mechanical extractor

hood). Prolonged intensive use of the appliance may call for

additional ventilation, for example opening a window, or more

effective ventilation, for example increasing the level of mechanical

ventilation where present. For more detail see the Installation

Instructions.

Maintenance schedule:

To ensure the appliance continues to operate at peak performance, we recommend

a routine service call every 2 years for the life of the appliance.

14

Page 15

Warranty and Service

Domestic Warranty – Full two year warranty

In addition to all statutory rights which you, the Purchaser, have under relevant laws in respect of this

appliance, during the first two years of ownership as the original purchaser of this Kleenmaid appliance,

Compass Capital Services trading as Kleenmaid guarantee that any fault caused by defective material

or workmanship becoming apparent will be rectified free of charge with reference to parts and labour,

provided that all service is performed during normal working hours by Kleenmaid or their designated

Agents. Where the appliance is installed outside the normal servicing area of the above, the Purchaser

must pay for the cost of transporting the appliance to and from the Agent or the Agent’s travel cost to

and from the purchaser’s home.

Commercial Warranty – One year warranty

When this appliance is installed in a commercial application, in addition to all statutory rights which

you, the Purchaser, have under relevant laws in respect of this appliance, during the first one year of

ownership as the original purchaser of this Kleenmaid appliance, Compass Capital Services trading as

Kleenmaid guarantee that any fault caused by defective material or workmanship becoming apparent

will be rectified free of charge with reference to parts and labour, provided that all service is performed

during normal working hours by Kleenmaid or their designated Agents. Where the appliance is installed

outside the normal servicing area of the above, the Purchaser must pay for the cost of transporting the

appliance to and from the Agent or the Agent’s travel cost to and from the purchaser’s home.

What these warranties do not cover

Compass Capital Services trading as Kleenmaid is not responsible for any damage or malfunction

unless caused by a defect in material or workmanship. This includes but is not limited to abuse,

misuse, improper installation and transportation damage. Compass Capital Services trading as

Kleenmaid is not responsible for consequential damages from any malfunction.

This warranty does not cover consumable items, replacement of light globes or glass breakage due

to impact. In case of fractured glass do not use your appliance.

Purchaser’s responsibility

The Purchaser must make the appliance available for servicing and shall bear any costs incurred

for any de-installation and/or re-installation required to make the appliance available for servicing.

Compass Capital Services trading as Kleenmaid is not liable for any consequential damage incurred

during de-installation or re-installation.

Warranty registration and Proof of Purchase.

Please complete warranty details below and retain together with your proof of purchase document.

When requesting service under this warranty the Purchaser agrees that Proof of Purchase of their

Kleenmaid appliance will be necessary in order to make the warranty valid. Inability to provide Proof

of Purchase even though this warranty is in place will not bind Compass Capital Services trading as

Kleenmaid to repair the appliance at no charge under this warranty and will require the Purchaser to

pay for the service costs in full.

Model Number Date of purchase

For service assistance visit

www.kleenmaid-appliances.com.au

Page 16

Other products available in the

Kleenmaid range of appliances

|

Washing machines

|

Clothes dryers

|

Dishwashers

|

Ovens

|

Cooktops

|

Steam ovens

|

Microwave ovens

|

Built in espresso

coffee machines

|

Rangehoods

|

Freestanding ranges

|

|

Sinks

Taps

Compass Capital Services Pty Limited

trading as Kleenmaid

ABN 96138214525

Level 29, Chifley Tower,

2 Chifley Square,

Sydney NSW, 2000

E: help@kmaid.com.au

www.kleenmaid-appliances.com.au

538861

Loading...

Loading...