Page 1

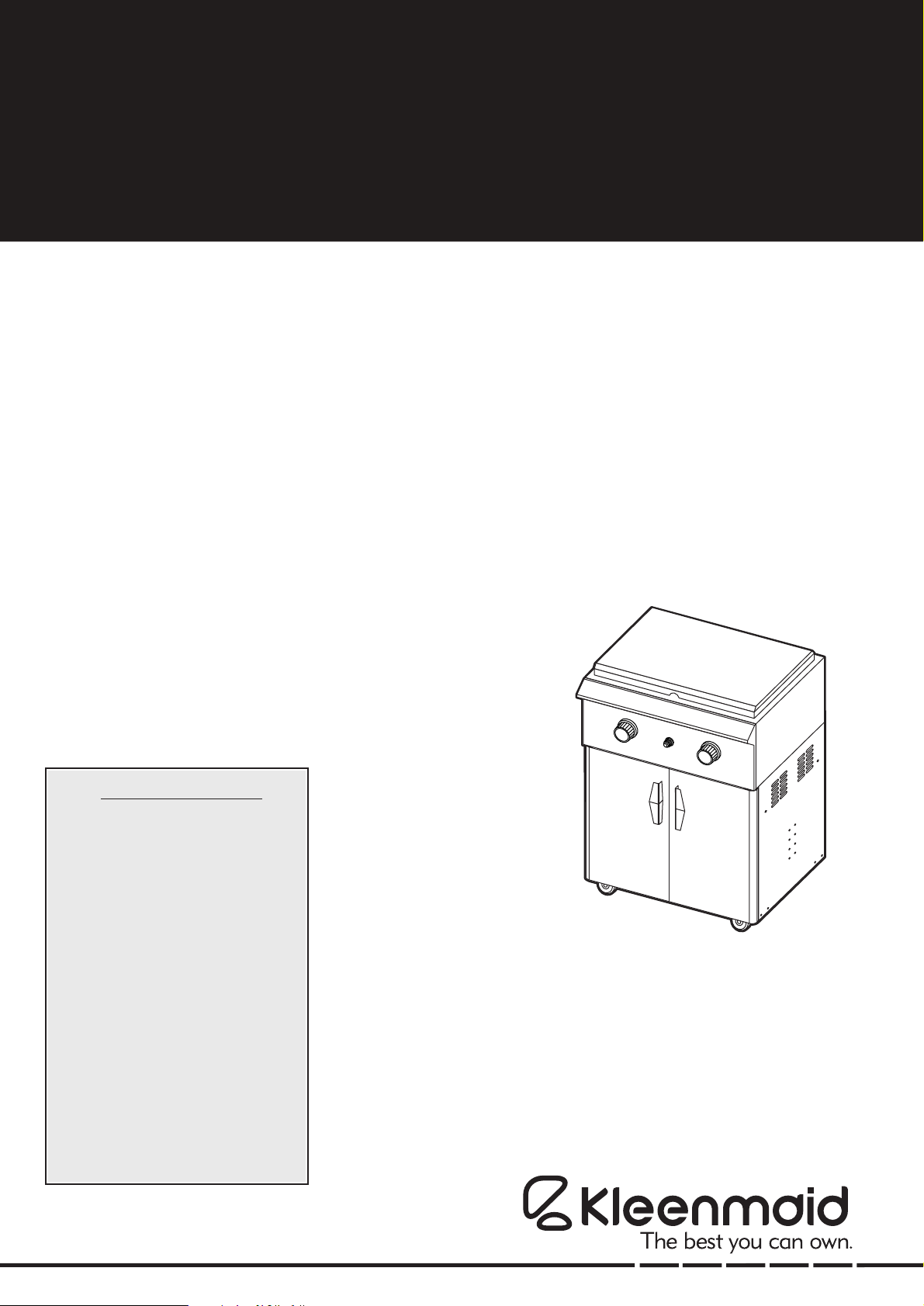

Outdoor

Cooking Centres

Operating and assembly instructions

warranty details

Teppanyaki plate and wok burner

barbecue and pedestal

Only to be used outdoors.

FOR YOUR SAFETY

.

1. If you smell gas:

Shut off gas to the

appliance, if possible.

Extinguish any open flame.

Open lid.

If odour continues,

immediately call your gas

supplier or fire department.

2. Do not store or use

petrol or other flammable

vapours and liquids in the

vicinity of this or any other

appliance.

3. A gas cylinder not

connected for use must not

be stored in the vicinity of

this or any other appliance.

Model OCCTWB / OCCTWBNG

Page 2

the best you can own.

Congratulations on the purchase of your new Kleenmaid outdoor cooking centre. This

appliance has been designed and manufactured to give you years of reliable performance.

the kleenmaid story.

More than one million Australians enjoy using Kleenmaid appliances daily. Selected because of

their unique design, outstanding performance, excellent quality and unquestionable reliability,

each one is value-for-money, 100 per-cent guaranteed and at the top of its class.

attention to detail.

We are proud of our reputation for product innovation and service excellence. By dealing direct, we

can ensure that you consistently receive a high standard of customer service.

Free delivery, dedicated customer and after-sales service plus free kitchen design including

planning seminars are just a few of the ways we are setting new benchmarks for customer service

and experience.

satisfaction guaranteed.

Your new outdoor cooking centre is covered by a written five-year parts and labour warranty,

no lemon guarantee and a unique best value guarantee.

best results.

For best results, carefully read the enclosed instructions on how to assemble your new barbecue.

Correct assembly will avoid delays and unnecessary service calls.

This booklet provides you with comprehensive information to help you get to know the controls and

the features of your new outdoor cooking centre.

congratulations

Page 3

GENERAL INFORMATION

3

3

The following minimum clearances from combustible materials must be

maintained when the appliance is in use:

top – 1000 mm, rear – 450 mm, sides – 250 mm.

Openings at the rear and sides of the appliance provide air for

combustion and must not be obstructed.

CLEARANCES

Height – lid closed 990 mm, lid open 1290 mm

Width – 665 mm

Depth – lid closed 585 mm, lid open 710 mm

OVERALL DIMENSIONS

Appliance specifications can be found on the data label attached to the

side panel of the appliance body.

SPECIFICATIONS

Appliances for use with bottled gas are labelled ‘Universal LPG’ or

‘Propane’. Appliances for use with natural gas are labelled ‘Natural Gas’

and must be installed by an authorised person. Check the gas type sticker

attached to the appliance.

Your Outdoor Range barbecue is preset at the factory to operate on

bottled gas only, unless specified otherwise.

• FAILURE TO COMPLY WITH THESE

INSTRUCTIONS COULD RESULT IN A

FIRE OR EXPLOSION WHICH COULD

CAUSE SERIOUS BODILY INJURY,

DEATH OR PROPERTY DAMAGE.

• ACCESSIBLE PARTS MAY BE

VERY HOT.

• KEEP YOUNG CHILDREN AWAY.

• ANY MODIFICATION OF THIS

APPLIANCE MAY BE DANGEROUS.

• DO NOT MOVE THIS APPLIANCE

DURING USE.

• TURN OFF THE GAS SUPPLY AT THE

GAS CYLINDER AFTER USE.

• READ THE INSTRUCTIONS BEFORE

USING THE APPLIANCE.

• PARTS SEALED BY THE

MANUFACTURER MUST NOT BE

ALTERED IN ANY WAY.

• THIS APPLIANCE IS ONLY TO BE

USED OUTDOORS.

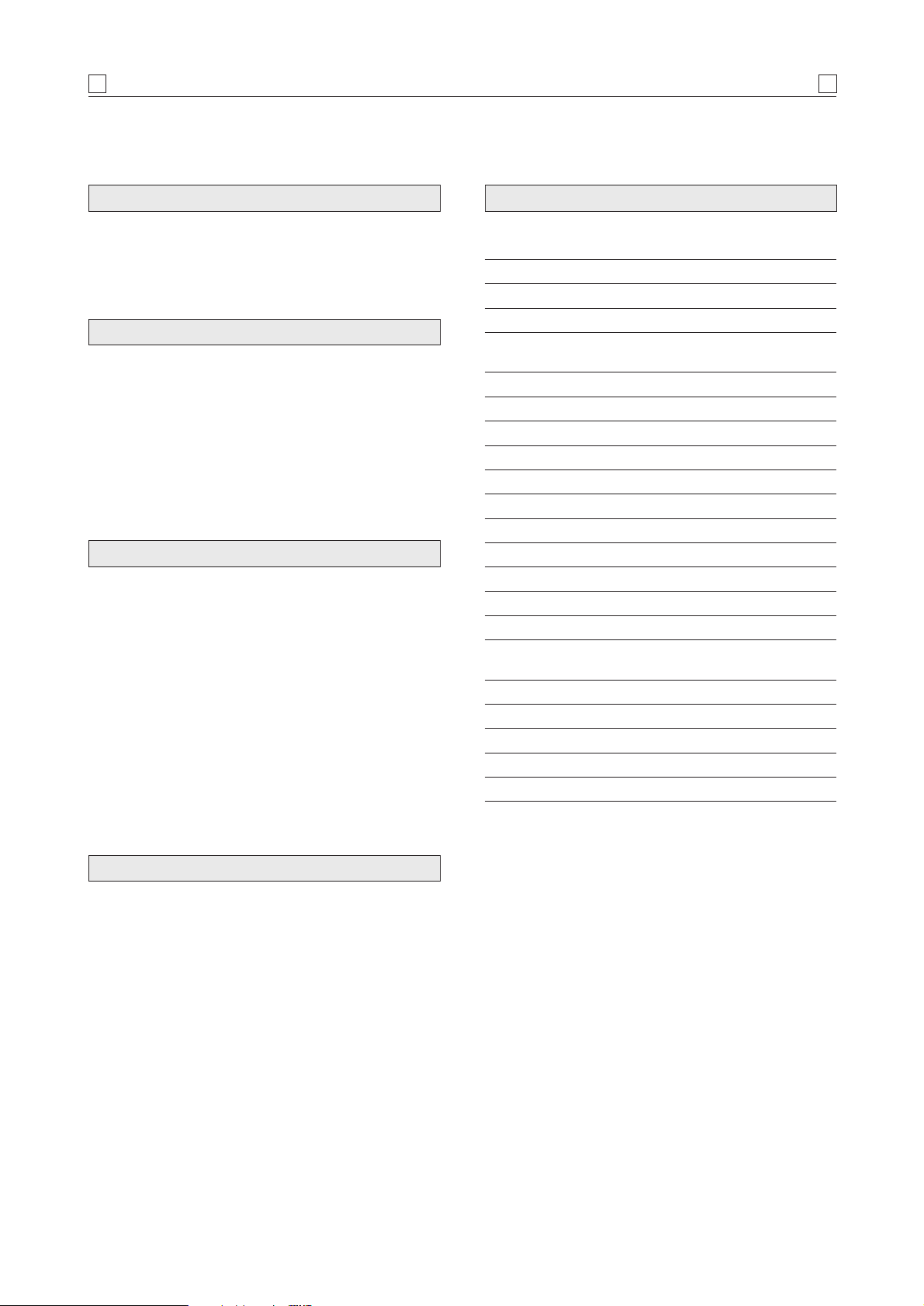

Purchased from

Date purchased

Serial No.

NOTE: Sales docket must be kept as proof of purchase date.

FOR CUSTOMER REFERENCE

(Record and file in a safe place)

General Information 3

Safety 4-5

Outdoor Areas 6

Pre-Assembly 7

Assembly 8-10

Inspection 11

Assembly – General 12-13

Operation 14

Fault Finding 15

Maintenance 16-17

Parts Diagram/List 18-19

TABLE OF CONTENTS

The regulator and hose assembly supplied with the appliance are suitable

for use with bottled gas.

This regulator is adjusted to have an outlet pressure of 2.75 kPa for

connection to a gas cylinder only. The regulator and hose assembly supplied

with the appliance must be used. Replacement regulator and hose

assemblies must be those specified by the appliance manufacturer.

When connecting the hose and regulator assembly to the gas cylinder,

take care to avoid unnecessary twisting of the flexible hose. Also, take

care to avoid a loose connection with the gas cylinder. After the assembly

has been secured, turn on the gas and check for leaks by brushing a

soap and water solution over all visible and accessible gas line connections.

Include checking those connections which were made by your supplier.

The presence of bubbles will indicate a gas escape. DO NOT TEST FOR

GAS ESCAPES WITH AN OPEN FLAME. If you are unable to correct the

leak by tightening the connections, turn off the gas and contact your place

of purchase immediately.

Always ensure the appliance is kept away from flammable materials

and the gas cylinder clear of any heat source. When changing over from

an empty gas cylinder to a full one, make sure this procedure is carried

out in a flame free atmosphere.

Inspect the gas hose assembly when exchanging the gas cylinder,

or at least once a year, whichever is more frequent. If the ‘O-Ring’ or PVC

hose is cracked, cut, abraded or damaged in any way, the appliance must

not be operated. The complete assembly must be replaced if damaged

and when statutory conditions require it. Contact your place of purchase

if uncertain.

HOSE AND REGULATOR SAFETY

NEVER OPERATE THIS APPLIANCE

WITHOUT A REGULATOR.

This appliance is certified to AS 4557 by the Australian Gas Association.

Refer to data label on the appliance for certificate number.

This appliance must be used in accordance with the installation

requirements of your local gas supply authority, and the appropriate

installation standard AS5601.

GAS INSTALLATION CODES

Page 4

SAFETY

4

4

FOR YOUR SAFETY:

• DO NOT STORE OR USE PETROL OR

OTHER FLAMMABLE VAPOURS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

• DO NOT STORE EMPTY OR FULL SPARE

GAS CYLINDERS UNDER OR NEAR THIS

OR ANY OTHER APPLIANCE.

• KEEP THE GAS HOSE AWAY FROM HOT

SURFACES. PROTECT GAS HOSE FROM

DRIPPING GREASE.

AVOID UNNECESSARY TWISTING OF

HOSE. VISUALLY INSPECT HOSE PRIOR TO

EACH USE FOR CUTS, CRACKS, EXCESSIVE WEAR OR OTHER DAMAGE.

REPLACE HOSE, IF NECESSARY.

• NEVER TEST FOR GAS LEAKS WITH A LIT

MATCH OR OPEN FLAME.

• NEVER LIGHT APPLIANCE WITH LID

CLOSED.

• NEVER LEAN OVER COOKING

SURFACE WHILE LIGHTING APPLIANCE.

• USE GOOD QUALITY INSULATED OVEN

MITTS WHEN OPERATING APPLIANCE.

• NEVER ALTER OR MODIFY THE

REGULATOR OR GAS SUPPLY ASSEMBLY.

• THIS APPLIANCE MUST NOT BE USED

INDOORS.

DANGER – IF YOU SMELL OR HEAR

THE HISS OF ESCAPING GAS FROM

THE GAS CYLINDER:

• KEEP CLEAR OF THE GAS CYLINDER.

• TURN ALL CONTROLS ON THE

APPLIANCE TO ‘OFF’.

•

EXTINGUISH ANY OPEN FLAME.

•

REMOVE LID OR OPEN HOOD.

•

IF ODOUR CONTINUES, IMMEDIATELY

CALL YOUR GAS SUPPLIER OR FIRE

DEPARTMENT.

READ CAREFULLY BEFORE

ASSEMBLING AND OPERATING

YOUR OUTDOOR RANGE BARBECUE.

NEVER CONNECT AN UNREGULATED

GAS CYLINDER TO THIS APPLIANCE.

• NEVER STORE YOUR

GAS CYLINDER INDOORS.

• FOR STORAGE AND CYLINDER

EXCHANGE, DISCONNECT HOSE AT THE

CYLINDER ONLY –

DO NOT DISCONNECT HOSE FROM

THE APPLIANCE.

DO NOT use this appliance in garages, porches, breezeways, sheds or

other enclosed areas. The Outdoor Range barbecue is to be used

OUTDOORS ONLY. Refer to page 6. It is not intended to be installed in

or used on recreational vehicles and/or boats and should not be placed

under any surface that will burn. Do not obstruct the flow of combustion

and ventilation air around the appliance housing while in use.

LOCATION OF YOUR OUTDOOR RANGE

Keep children away from this appliance during use and until it has cooled

after you are finished. Do not allow children to operate appliance or to

swing on handle.

PROTECT CHILDREN

The gas cylinder should be filled by a reputable gas dealer, or exchanged at

a reputable gas cylinder exchange outlet. Gas cylinders should be

visually inspected and re-qualified periodically.

Always keep gas cylinder in an upright position. Always close the

cylinder valve when the appliance is not in use.

Do not subject the gas cylinder to excessive heat.

If you store this appliance indoors, ALWAYS disconnect and remove gas

cylinder FIRST, and store gas cylinder safely outside. Gas cylinders

must be stored outdoors in a well ventilated area out of reach of children,

and must not be stored in a building, garage or any other enclosed area.

This is a low pressure appliance and must only be used with the hose and

regulator supplied.

This appliance is designed for use with a 9 kg gas cylinder. Ensure

gas cylinder conforms to Australian Standard AS2469 and is less than 10

years old.

DO NOT CONNECT THIS APPLIANCE TO A GAS

CYLINDER LESS THAN OR EXCEEDING THIS CAPACITY.

GAS CYLINDER USE AND APPLIANCE SAFETY

SERVICING

ANY OF THE FOLLOWING SIGNS MAY

INDICATE THAT THE APPLIANCE IS NOT

OPERATING PROPERLY AND MAY NEED

SERVICING:

• EXCESSIVE YELLOW FLAME.

• IRREGULAR SIZE OF FLAME

ACROSS BURNER.

•‘POPPING’ OF FLAME.

• SOOTING.

• ABNORMAL NOISE(S).

• HISSING SOUND.

NOTE:

Before requesting service,

please refer to page 15 ‘Fault Finding’.

NEVER TEST FOR LEAKS WITH A FLAME.

Prior to first use, and at the beginning of each new season (or, if using

bottled gas, whenever gas cylinder is changed), you must check for gas

leaks. Follow these steps:

1. Make soap solution by mixing one part liquid detergent and one

part water.

2. Turn burner control(s) to

‘OFF’, then turn on gas at source.

3. Apply the soap solution to all visible and accessible gas connections

including the gas cylinder. Bubbles will appear in the soap solution

if connections are not properly sealed. Tighten or rectify as necessary.

Refer to page 5 for further details.

4. If you have a gas leak you cannot rectify, turn off the gas at the

source. Contact the manufacturer for assistance.

Refer to back cover.

CHECKING FOR GAS LEAKS

Page 5

SAFETY

5

5

NEVER CHECK FOR LEAKS WITH

A FLAME.

IF YOU HAVE A GAS LEAK YOU

CANNOT RECTIFY, TURN OFF THE GAS

AT THE SOURCE. CONTACT THE

MANUFACTURER.

WHEN CHANGING THE GAS HOSE FOR

ANY REASON, ALWAYS CHECK THE

CONNECTION TO THE MANIFOLD FOR

GAS LEAKS BEFORE OPERATING THE

APPLIANCE.

ALWAYS CHECK FOR GAS LEAKS EACH TIME

YOU USE YOUR OUTDOOR RANGE BARBECUE.

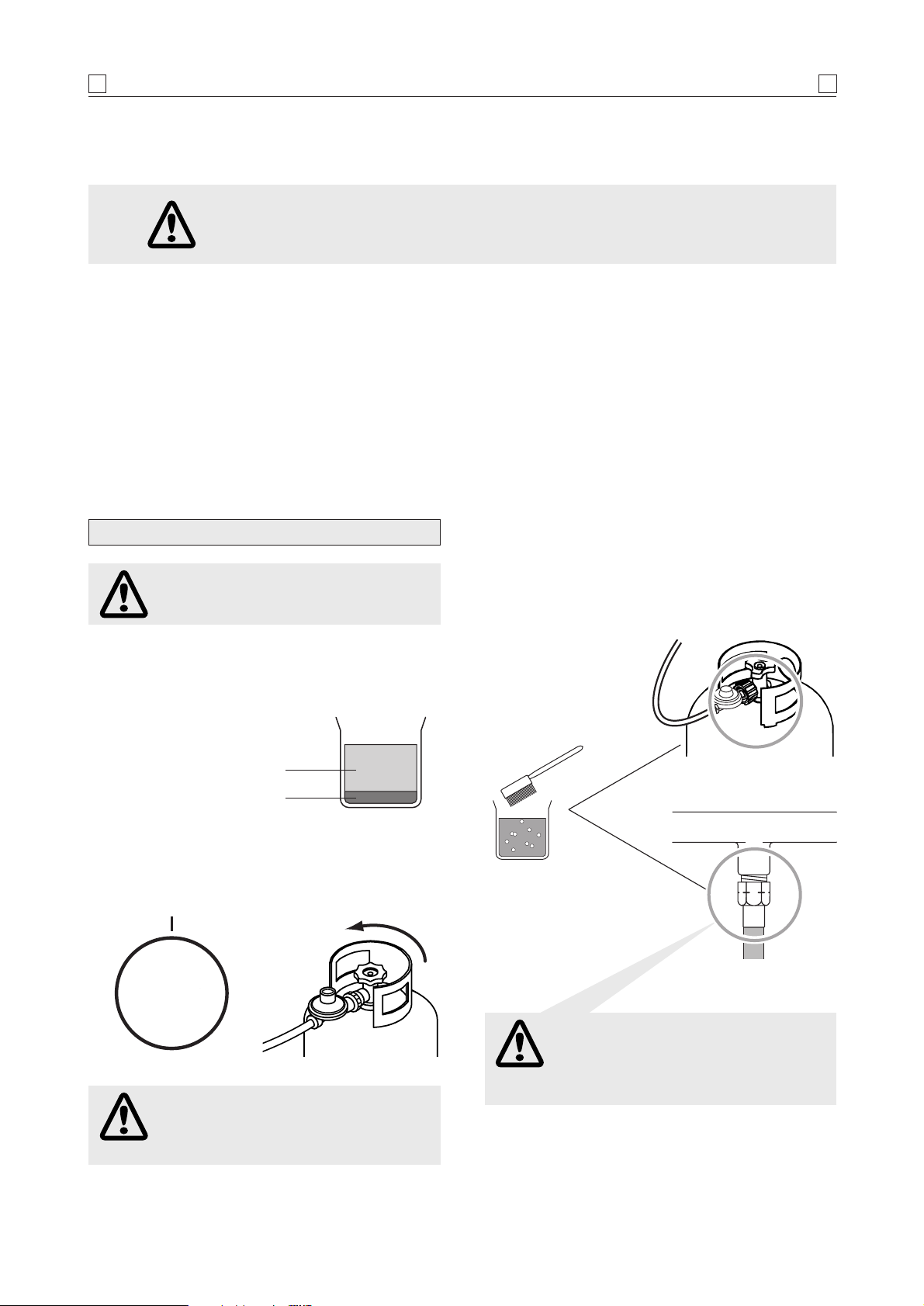

1. Make liquid detergent solution by mixing one (1) part liquid

detergent and four (4) parts water.

2. Turn burner control knob(s) to

‘OFF’, then turn on gas at

source.

CHECKING FOR GAS LEAKS

You should follow this procedure after any of the following:

• Not having used the appliance for an extended period of time,

• Initial assembly of the appliance,

• Any disconnection and reconnection of hose assembly,

• Changing gas cylinder,

• Upon re-connecting gas cylinder after it has been disconnected for storage.

4 parts water

Gas cylinder connection

Manifold connection

Open

1 part liquid

detergent

3. Apply the liquid detergent solution to all visible and accessible

gas connections, including the connection to the gas cylinder.

Bubbles will appear in the liquid detergent solution if

connections are not properly sealed. Tighten or rectify as

necessary.

OFF

LO

IGN

HI

Page 6

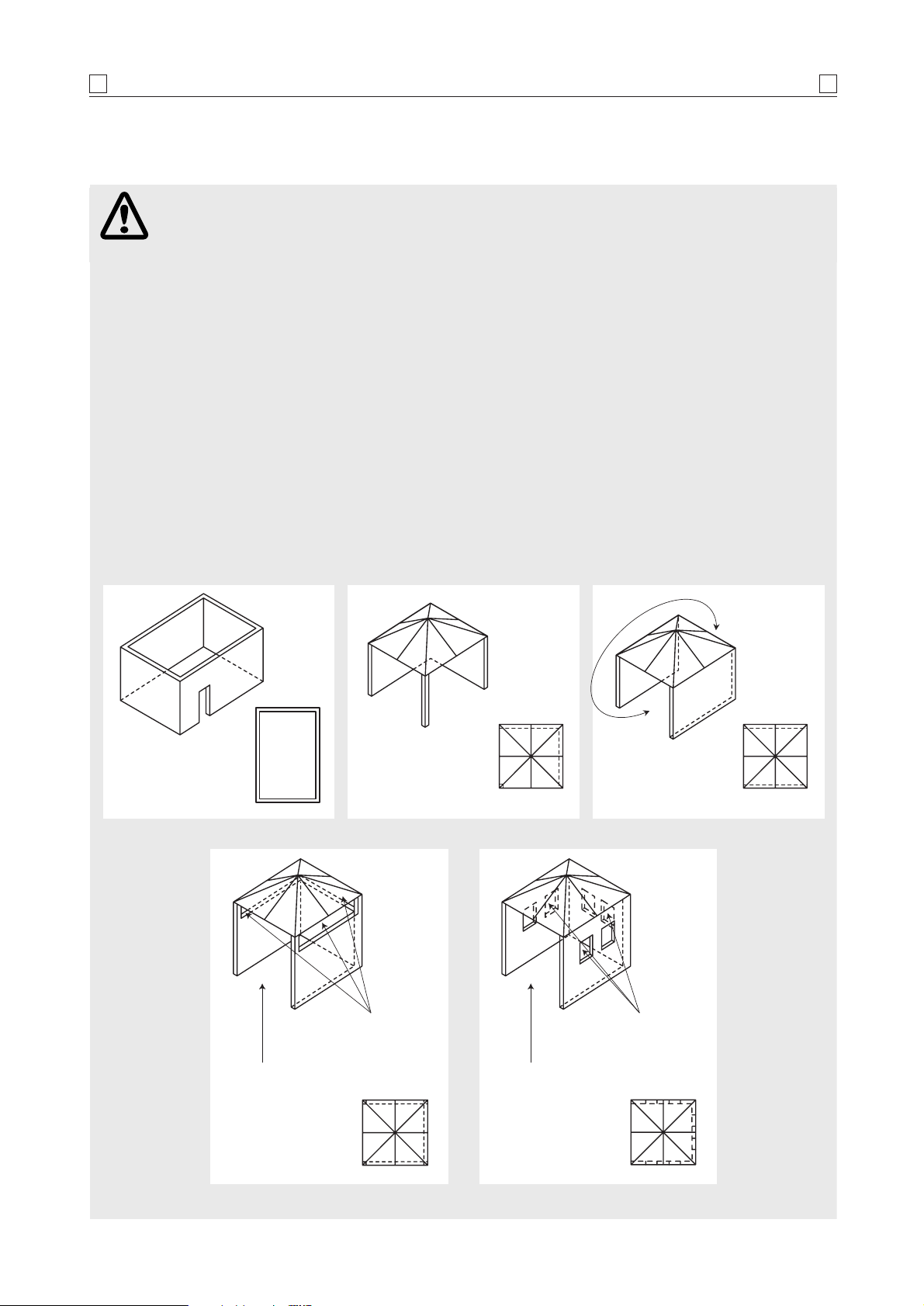

The following diagrams are examples of outdoor areas.

These same principles apply to canopy or shaded cloth areas.

THIS APPLIANCE SHALL ONLY BE USED IN AN ABOVE GROUND OPEN AIR SITUATION WITH NATURAL

VENTILATION, WITHOUT STAGNANT AREAS, WHERE GAS LEAKAGE AND PRODUCTS OF COMBUSTION

ARE RAPIDLY DISPERSED BY WIND AND NATURAL CONVECTION.

ANY ENCLOSURE IN WHICH THE APPLIANCE IS USED SHALL COMPLY WITH ONE OF THE FOLLOWING:

OUTDOOR AREAS

6

6

• AN ENCLOSURE WITH WALLS

ON ALL SIDES, BUT AT LEAST

ONE PERMANENT OPENING AT

GROUND LEVEL AND NO

OVERHEAD COVER

• WITHIN A PARTIAL

ENCLOSURE THAT INCLUDES

AN OVERHEAD COVER AND NO

MORE THAN TWO WALLS

• WITHIN A PARTIAL

ENCLOSURE THAT INCLUDES

AN OVERHEAD COVER AND

MORE THAN TWO WALLS, THE

FOLLOWING SHALL APPLY:

(i) AT LEAST 25% OF THE TOTAL

WALL AREA IS COMPLETELY

OPEN: AND

(ii) AT LEAST 30% OF THE

REMAINING WALL AREA IS

OPEN AND UNRESTRICTED

• IN THE CASE OF BALCONIES,

AT LEAST 20% OF THE TOTAL

OF THE SIDE, BACK AND FRONT

WALL AREAS SHALL BE AND

REMAIN OPEN AND

UNRESTRICTED

• DO NOT USE THIS APPLIANCE IN

GARAGES, PORCHES, BREEZEWAYS, SHEDS OR OTHER

ENCLOSED AREAS.

THIS APPLIANCE IS TO BE

USED OUTDOORS ONLY.

Refer below.

• THE APPLIANCE IS NOT

INTENDED TO BE INSTALLED IN

OR USED ON RECREATIONAL

VEHICLES AND/OR BOATS AND

SHOULD NOT BE PLACED

ADJACENT TO OR UNDER ANY

SURFACE THAT WILL BURN.

• DO NOT OBSTRUCT THE FLOW

OF COMBUSTION AND

VENTILATION AIR AROUND

THE APPLIANCE HOUSING

WHILST IN USE.

Both ends

open

30% or more in total of

the remaining wall area

is open and unrestricted

30% or more in total of

the remaining wall area is

open and unrestricted

Open side at

least 25% of total

wall area

Open side at

least 25% of total

wall area

Page 7

PRE-ASSEMBLY

7

7

Standard Phillips-head screwdriver.

Adjustable spanner

(open-end shifter).

TOOLS YOU WILL NEED

Description Qty

Trolley side panel – right 1

Trolley side panel – left 1

Trolley rear panel 1

Castor seat

– 1 x left rear, 1 x left front, 1 x right rear, 1 x right front

4

Castors 4

Bottom shelf 1

Trolley bracket – front 1

Gas cylinder pull-out tray 1

Body support bracket 2

Trolley separation panel 1

Doors 2

Body assembly 1

Hardware pack 1

Hot plate 1

Pot support 1

Door hinge

– 1 x top left, 1 x top right

2

Door guide 1

Grease tray 1

Grease drain tube 1

Towel rack 1

Spice rack 1

CARTON CONTENTS

Before attempting to assemble your barbecue, check that all the

necessary parts have been included using the parts list opposite.

Inspect barbecue and trolley parts as you proceed.

Contact your place of purchase for assistance regarding

replacement of any damaged or missing parts. Supplier contact

details are on the back cover of the instruction manual.

Do not assemble or operate a barbecue that appears damaged.

Check that the barbecue supplied is correct for the gas type

being used. There is a label on the side panel of the barbecue

above the gas connection. Barbecues for use with gas cylinders

are labelled

‘Universal LPG’. Barbecues for use with natural gas

are labelled

‘Natural Gas’.

CHECK BARBECUE FOR ANY DAMAGE

While it is possible for one person to assemble the barbecue,

we recommend asking for the assistance of another person when

manoeuvring some of the larger or heavier pieces.

GENERAL

1. Flatten cardboard packaging and use this as a protective

work surface to assemble upon.

2. Some protective coating may need to be removed from

components prior to assembly.

3. Tighten screws and nuts unless otherwise specified.

4. Pre-screwing of connection points for securing the side

shelves will assist in securing shelves smoothly.

ASSEMBLY TIPS

Page 8

ASSEMBLY

8

8

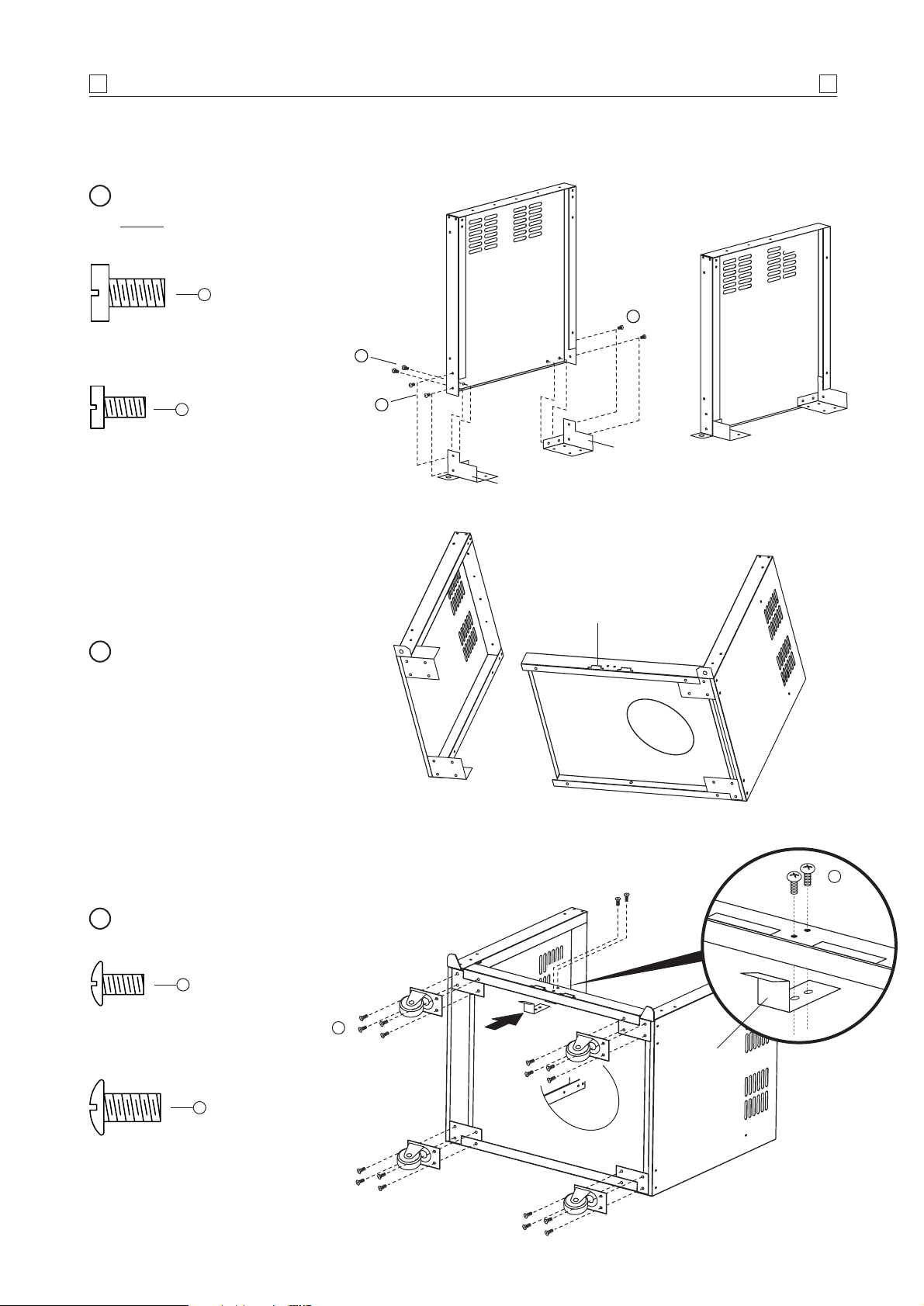

LEFT

SIDE

Phillips flat-head screw 1/4" x 1/2"

Qty: 4

Phillips flat-head screw 3/16" x 3/8"

Qty: 4

Attach side panels to bottom shelf.

2

Phillips-head screw 1/4" x 1/2"

Qty: 16

Attach castor seats to side panels.

NOTE: Castor seats are labelled for

correct location

Repeat for right side.

1

A

B

Door magnets

to front

LF

B

RF

Attach castor wheels to castor seat.

Attach door guide

3

Phillips-head screw 3/16" x 3/8"

Qty: 2

Door guide

A

B

A

B

B

A

Page 9

ASSEMBLY

9

9

Phillips-head screw 3/16" x 3/8"

Qty: 12

Flange nut 3/16"

Qty: 12

Phillips-head screw 1/4" x 1/2"

Qty: 4

Rear panel

Attach the trolley bracket front and rear panel.

4

Attach gas cylinder tray.

TIGHTEN ALL SCREWS.

5

RIGHT

SIDE

Phillips-head screw

3

/16" x 3/8"

Qty: 6

Flange nut 3/16"

Qty: 6

Screw

Attach body support brackets and trolley

separation panel.

6

Trolley bracket front.

NOTE:

Door magnets to bottom

Nut x3

Door hinge bracket,

top left

Door hinge bracket,

top left

Page 10

A S S E M B L Y

10

10

Phillips-head screw 1/4" x 13/16"

Qty. 4

Attach barbecue body to trolley.

NOTE:

Release regulator from underneath the

body by cutting the cable tie. Feed regulator

through the hole in the trolley separation panel.

After assembly is complete close the hatch

(located underneath) around the gas hose.

Refer to page 13 for installation of grease tray and grease

tube.

8

Phillips-head screw

3

/16" x 1/4"

Qty: 4

Phillips-head screw

3

/16" x 3/8"

Qty: 4

Attach top right and left door hinges / doors. Insert the bottom

door hinge pin into the lower door hinge bracket holes.

Depress the spring loaded top door hinge pin and line up

with the top hinge bracket holes, and release the pin.

Attach door handles and towel rack to the inside panel

of the left door.

7

A

B

A

A

B

Towel rack

Locate spice rack into

slots inside left door

Note: Change of screws for securing Towel Rack:

4 x self tapping screws have been attached to original hardware

pack to replace original 4 x metal threaded 3/16” screws. Please

use self tappers to secure towel rack. Original screws may still

be enclosed in hardware pack and will remain after assembly.

Page 11

INSPECTION

11

11

Ensure gas source is turned off or is disconnected and all burner

control knobs are set to

‘OFF’. Open the lid and remove the hot

plate. Push the electronic igniter. You should hear a ‘clicking’

sound. You should see a blue spark within the gas collector

box. If a spark is present the electrode tips are properly positioned.

If no spark is seen, the spark gap needs to be

adjusted as follows:

• Using an adjustable spanner, loosen the inside nut until the

gas collector box can be turned upward. If the gap between

the spark electrode tip and receiver is more than 4 - 5 mm use

long nose pliers to gently squeeze the gas collector box to

narrow gap. Return the gas collector box to its original

position, secure the inside nut and try the electrode check

again.

• CHECK PERFORMANCE OF

BURNERS PRIOR TO INSTALLING

HOT PLATE COMPONENTRY.

Refer to page 14 for lighting instructions.

• DO NOT SMOKE WHEN ATTEMPTING

TO IGNITE APPLIANCE.

• NEVER USE VOLCANIC ROCK,

HEAT BEADS OR OTHER MATERIAL.

• ALWAYS USE PROTECTIVE GLOVES

WHEN HANDLING HOT COMPONENTS.

• Open pot burner lid.

• Push electronic ignition button. Look for a spark between tip

of electrode and burner.

• If you don't see a spark from pot burner electrode, adjust

gap between electrode and burner surface to 4 - 5 mm.

ELECTRODE CHECK – POT BURNER

This test will ensure the spark electrode tips are correctly positioned

so the appliance lights easily and properly.

ELECTRODE CHECK – HOT PLATE BURNER

+

-

4-5 mm

spark gap

Gas collector

box

Spark

electrode tip

Spark

receiver

Inside

nut

• Unscrew igniter cap from control panel.

• Place supplied AA battery into the igniter slot with positive

pole facing you.

• Position the cap and spring over the AA battery and tighten

onto control panel.

INSTALL IGNITER BATTERIES

AA

battery

Spring

Igniter

cap

Contact

Page 12

ASSEMBLY– GENERAL

12

12

TEST FOR LEAKS WITH A

SOAP SOLUTION, NEVER WITH AN

OPEN FLAME (Refer to pages 4 and 5).

CONNECTING TO, AND DISCONNECTING

FROM GAS SOURCE

CONNECTING TO GAS SOURCE

1. Place gas cylinder into the gas cylinder tray and face the

gas cylinder valve to the left rear corner. Secure with

wing bolt.

2. Attach cylinder connection

device of regulator and hose

assembly to cylinder

valve outlet.

Tighten firmly.

3. Open gas cylinder

valve fully to allow

gas to flow.

4. Leak test all accessible

connections thoroughly

using a soapy water

solution prior to lighting the appliance.

Refer to Safety information, pages 4 and 5.

5. If a leak is found, turn gas cylinder valve off and do not use

appliance until repairs or replacement can be made.

DISCONNECTING FROM GAS SOURCE

1. Turn burner control ‘OFF’.

2. Turn gas cylinder valve off fully.

3.

Detach regulator assembly from gas cylinder

valve.

This appliance is also certified for use on natural gas. Contact

the manufacturer for advice in relation to using this appliance on

natural gas.

Refer to back cover.

Appliances for use on natural gas must be installed by an

authorised person.

NATURAL GAS INSTALLATION

IMPORTANT:

Before connecting and disconnecting

appliance to gas source, ensure burner controls are

in ‘OFF’ position.

NOTE:

The ‘OFF’ position on the control panel is

identified by either a small black dot / a short vertical

black line / or the word ‘OFF’.

When the marking, or the word ‘OFF’ printed on

the control knob, aligns with the printed marking on

the control panel, then the burner is in the fully off

position.

CAUTION:

When the appliance is not in use, the gas

must be turned off at the gas cylinder

.

Familiarise yourself with the general information and safety

guidelines located at the front of this booklet. Check to see that

gas cylinder is filled and that end of each burner tube is properly

located over each valve orifice. Set burner controls to

‘OFF’

position.

ENSURING BURNER CONTROLS ARE OFF

• DISCONNECT AND REMOVE GAS

CYLINDER WHEN MANOEUVRING

APPLIANCE OVER UNEVEN SURFACES

OR CARRYING UP AND DOWN STAIRS.

• IF THIS INFORMATION IS NOT

FOLLOWED EXACTLY, A FIRE

CAUSING DEATH OR SERIOUS INJURY

MAY OCCUR!

• DO NOT STORE A SPARE GAS

CYLINDER UNDER OR NEAR THIS

APPLIANCE.

• THIS APPLIANCE IS ONLY TO BE

USED OUTDOORS.

Direction for

tightening

Page 13

Before first use and at the beginning of each season:

1. Please read Safety, Lighting and Operating instructions

carefully.

2. Check gas valve orifices, burner tubes and burner ports for

any obstructions.

eg. spiders, webs, insects.

3. Check and ensure gas cylinder is full.

4. Ensure all connections are securely tightened.

Check for gas leaks.

Refer to pages 4 and 5.

NOW YOUR OUTDOOR RANGE APPLIANCE

IS READY TO USE

ASSEMBLY– GENERAL

13

13

NOTE: Side shelves are supplied separately.

The side shelves may be installed to any of the Modular Outdoor

Kitchen modules, Modular barbecue, Outdoor Range module and

Sink / Workstation module, depending on the configuration

preferred.

Refer to the instructions included in the ‘Side Shelf’ pack.

INSTALL SIDE SHELVES

• Slide grease tray into position as shown in diagram.

• Remove the hot plate and position

the grease tube in the slot at the

front of the fire box.

INSTALL GREASE TRAY AND GREASE TUBE

Grease tube

Page 14

‘HI’ setting – Use this setting only for warm up, for searing

steaks and chops, and for burning food residue from the grill

plates after the cooking is over. Rarely, if ever, do you use the

‘

HI’ setting for extended cooking.

‘MED’ setting (mid-way between ‘HI’ and ‘LO’). Use this setting

for most grilling, and for cooking hamburgers and vegetables.

‘LO’ setting – Use this setting when cooking very lean cuts such

as fish.

Actual cooking surface temperatures vary with outside temperature

and the wind conditions.

COOKING TEMPERATURES

If igniters fail to produce a spark at the electrode, burners can be

lit with a match.

1.

HOT PLATE BURNER

Turn right burner control to ‘HI’ position then position

match into lighting tube provided at the rear of cooking surface.

The burner will light immediately.

2.

POT BURNER

Turn left burner control to ‘HI’ position then light burner

directly with a match.

MANUAL LIGHTING

NOTE: Burners are fitted with a thermal shut-off

feature. After ignition, the control knob must continue

to be depressed at the ‘HI’ position. Refer to step 5.

1. Open the lid before attempting to

light burners.

2. Set burner control knobs to

‘OFF’

and open the gas cylinder valve.

3. Push and turn required burner control

knob to

‘IGN’.

4. Push the control knob in and hold to

ignite the burner.

5. Once the burner is ignited,

continue to depress the control

knob and rotate to

‘HI’ position.

Hold for 10 seconds to bypass the

thermal shut-off.

6. If burner does not light, turn burner

control knob to

‘OFF’, wait 5 minutes

for gas to clear, then retry.

7. Adjust burner control knobs to

the

desired cooking temperature.

8. If ignition cannot be achieved, perform electrode check

procedure.

Refer to page 11.

HOT PLATE / POT BURNER IGNITION

• THE POT BURNER IS DESIGNED FOR

USE WITH A WOK UP TO 360 mm

DIAMETER AND COOKING POTS UP TO

200 mm DIAMETER.

• USE OF VERY LARGE POTS MAY

RESULT IN DISCOLOURATION OF THE

SURFACE FINISH, OR CAUSE POOR

COMBUSTION.

Match

OPERATION

14

14

• THE LID MUST BE IN THE OPEN

POSITION FOR LIGHTING.

• DO NOT SMOKE AT ALL TIMES

WHEN ATTEMPTING TO IGNITE THE

APPLIANCE.

• CAUTION:

DO NOT MOVE TROLLEY

WHILE APPLIANCE IS IN OPERATION.

• CAUTION:

DO NOT LEAVE THIS

APPLIANCE UNATTENDED WHEN

BURNER/S IS ALIGHT.

LIGHTING PROCEDURES

BURN-OFF

Before cooking on your Outdoor Range for the first time, burn-off

any residual oils or foreign matter from the cooking plate.

ENSURE THE LID IS OPEN, and operate at ‘HI’ setting for

approximately 15 minutes. Allow to cool then wash plate thoroughly

with soap suds and scrubbing brush. Rinse thoroughly and

wipe clean with a cloth. Your plate is ready to use.

PREHEATING

It is necessary to preheat the plate before cooking. Operate the

burner under the cooking surface to be used at

‘HI’ for approximately

10 minutes before cooking.

OPERATING PROCEDURE

Lighting

tube

OFF

IGN

LO

HI

IGN

HI

LO

OFF

Page 15

FAULT FINDING

15

15

• SHOULD A FLASHBACK FIRE OCCUR

IN OR AROUND BURNER TUBES,

FOLLOW THE INSTRUCTIONS BELOW.

FAILURE TO COMPLY WITH THESE

INSTRUCTIONS COULD RESULT IN

• A FIRE OR EXPLOSION THAT COULD

CAUSE SERIOUS BODILY INJURY,

DEATH, OR PROPERTY DAMAGE.

• SHUT OFF GAS SUPPLY TO

APPLIANCE.

• TURN THE CONTROL KNOBS TO OFF

POSITION.

• OPEN THE APPLIANCE LID.

PUT OUT ANY FLAME WITH A FIRE

EXTINGUISHER.

• ONCE THE APPLIANCE HAS COOLED

DOWN, CLEAN THE BURNER TUBES

AND BURNERS ACCORDING TO THE

CLEANING INSTRUCTIONS IN THIS

OPERATION MANUAL.

1. Turn gas off at source and turn burner control knobs to

‘OFF’. Wait at least five (5) minutes for gas to clear, then

retry.

2. If your Outdoor Range barbecue still fails to light, check gas

supply and connections.

3. Repeat lighting procedure. If the appliance still fails to

operate, turn the gas off at source, turn the control knobs to

‘OFF’, then check the following:

•

MISALIGNMENT OF BURNER TUBES

OVER ORIFICES

Correction: Reposition burner tubes over orifices.

•

OBSTRUCTION IN GAS LINE

Correction: Remove fuel line from appliance. Do not

smoke! Open gas supply for one second to clear any

obstruction from fuel line. Close off gas supply at source

and reconnect fuel line.

•

PLUGGED ORIFICE

Correction: Remove burners. Carefully lift each burner up

and away from gas valve orifice. Remove the orifice from

gas valve and gently clear any obstruction with a fine wire.

Then reinstall all orifices, burners and cooking components.

If an obstruction is suspected in gas valves or manifold,

contact your place of purchase or manufacture.

•

OBSTRUCTION IN BURNER TUBES

Correction: Follow burner tube cleaning procedure on page 18

of this operation manual.

•

MISALIGNMENT OF IGNITER ON BURNER

Correction: Check for proper position of electrode tip as

shown on page 11. The gap between spark electrode tip

and spark receiver should be approximately 4 - 5 mm.

Adjust if necessary. With gas supply closed and all control

knobs set to

‘OFF’ press the electric igniter cap and check

for the presence of a spark at electrode.

•

DISCONNECTED ELECTRIC WIRES

Correction: Inspect the igniter junction box found behind the

control panel. Connect loose electric wires to junction box

and try to light appliance.

•

WEAK AA BATTERY

Correction: Unscrew igniter cap and replace battery.

IF THIS APPLIANCE FAILS TO LIGHT

CAUTION:

If burners go out during operation, close

gas supply at source, and turn all gas valves off.

Open lid and wait 5 minutes before re-attempting to

light (this allows accumulated gas fumes to clear).

CAUTION:

Should grease fire occur, close gas supply

at source, turn off all burners and remove food until

fire is out.

KEEP THE VENTILATION OPENINGS OF THE

CYLINDER ENCLOSURE FREE AND CLEAR FROM

DEBRIS.

Page 16

MAINTENANCE

16

16

Before initial use and periodically, wash the cooking plates in a mild

soap and warm water solution. You can use a wash cloth or

vegetable brush to clean the cooking plates.

It is recommended cooking plates be coated with a thin layer

of cooking oil on a regular basis to prevent rusting. Slight rusting

can be removed with a scrubbing brush before use.

CLEANING THE COOKING PLATE

Proper care and maintenance will keep your Outdoor Range in top

operating condition and prolong its life. Follow these cleaning

procedures on a timely basis and your Outdoor Range will stay

clean and operate with minimum effort.

CAUTION: Be sure your Outdoor Range is off and

cool before cleaning.

CLEANING AND MAINTENANCE

Before initial use and periodically thereafter we suggest you wash

your Outdoor Range using a mild soap and warm water solution.

You can use a wash cloth or sponge for this process. Do not use

a stiff wire or brass brush. These will scratch stainless steel and

chip painted surfaces

(varies by model) during the cleaning

process.

CLEANING EXTERIOR SURFACES

To reduce the chance of fire, the grease receptacle should be

visually inspected before each appliance use. Remove any

grease and wash grease receptacle with a mild soap and warm

water solution.

NOTE: Grease fires are not covered by warranty.

CLEANING THE GREASE TRAY RECEPTACLE

FAILURE TO READ AND FOLLOW THE

‘USE AND CARE INSTRUCTIONS’ COULD

RESULT IN A FIRE OR EXPLOSION

THAT COULD CAUSE SERIOUS BODILY

INJURY, DEATH OR PROPERTY

DAMAGE.

Stainless steel over time will be affected by ‘tea staining’ (the

brown discolouration of some stainless steel)

.

Tea staining can be reduced by washing the surface with

mild detergent and warm water and then rinsing with clean cold

water. We recommend the surface be wiped dry with a clean

cloth.

CARE FOR STAINLESS STEEL

IN COASTAL AREAS, FREQUENT

CLEANING AND THE USE OF A COVER

IS RECOMMENDED TO PROLONG THE

LIFE OF THE APPLIANCE.

SALTY AIR WILL ADVERSELY AFFECT

EXPOSED PARTS.

DO NOT USE OVEN CLEANER TO CLEAN

THE OUTDOOR RANGE.

SOME PROPRIETORY BARBECUE

CLEANERS MAY AFFECT / DAMAGE

SOME OF THE SURFACE COATINGS

USED ON THIS APPLIANCE.

READ THE CLEANER INSTRUCTIONS

CAREFULLY.

IT IS RECOMMENDED TO TEST FIRST IN

AN INCONSPICUOUS PLACE.

GENERALLY WE RECOMMEND ONLY

WARM SOAPY WATER FOR CLEANING

THIS APPLIANCE.

Page 17

• KEEP APPLIANCE AREA CLEAR AND

FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE AND OTHER FLAMMABLE

VAPOURS AND LIQUIDS.

• DO NOT OBSTRUCT FLOW OF AIR FOR

COMBUSTION AND VENTILATION.

• KEEP VENTILATION OPENINGS OF

CYLINDER ENCLOSURE CABINET FREE

AND CLEAR OF DEBRIS.

• VISUALLY CHECK BURNER FLAMES

OCCASIONALLY TO ENSURE PROPER

FLAME PATTERN AS SHOWN BELOW.

• FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN A

HAZARDOUS SITUATION WHICH, IF

NOT AVOIDED, MAY RESULT IN

INJURY.

Magnified view

of burner flame

through lighting

hole

General cleaning of the Outdoor Range barbecue will keep it

ready for instant use, however, depending on how much it is

used you must thoroughly clean the entire appliance to minimise

risk of grease fire and keep the appliance in top condition.

Follow

these steps:

1. Turn all burner valves to full ‘OFF’ position.

2. Turn LP gas cylinder valve to full

‘OFF’ position.

3. Disconnect regulator from gas cylinder. Inspect hose with

regulator assembly for cracking, cuts or any other damage,

and replace as necessary.

Refer to Parts List in this operation

manual, pages 20 - 21.

4. Remove and clean cooking plates and burners.

5. Cover each gas valve orifice with aluminum foil.

6. Brush inside and bottom of the Outdoor Range barbecue

with a fibre pad or nylon brush and wash with a mild soap

and warm water solution. Rinse thoroughly and let dry.

7. Remove aluminum foil from orifices and check each orifice

for obstruction.

8. Check each spark electrode, adjusting as needed. The

space between the spark electrode tip and spark receiver

should be approximately 4 - 5 mm.

9. Replace the burner and adjust the gas collector box. The

edge of collector box should be overlapping the burner port.

10. Reconnect gas source and observe burner flame for correct

operation.

11. Replace flame tamers and cooking plates.

ANNUAL CLEANING OF THE

APPLIANCE INTERIOR

MAINTENANCE

17

17

• BEWARE OF SPIDERS.

BURNER TUBES SHOULD BE

INSPECTED AND CLEANED

PERIODICALLY.

• SPIDERS AND SMALL INSECTS CAN

OCCASIONALLY SPIN WEBS OR MAKE

NESTS IN BURNER TUBES.

THESE WEBS CAN LEAD TO A GAS

FLOW OBSTRUCTION WHICH COULD

RESULT IN A FIRE IN AND AROUND

THE BURNER TUBES.

• THIS TYPE OF FIRE IS KNOWN AS

‘FLASH-BACK’ AND CAN CAUSE

SERIOUS DAMAGE TO APPLIANCE AND

CREATE AN UNSAFE OPERATING

CONDITION FOR THE USER.

• ALTHOUGH AN OBSTRUCTED BURNER

TUBE IS NOT THE ONLY CAUSE OF

‘FLASH-BACK’ IT IS THE MOST

COMMON CAUSE AND FREQUENT

INSPECTION AND CLEANING OF THE

BURNER TUBES IS NECESSARY.

We recommend that you minimise the exposure of the Outdoor

Range to the elements.

High moisture content in the air (rain, mist, salt spray etc.)

can affect metal components and lead to material breakdown. If

left in an area subjected to high moisture content, we strongly

recommend that you observe the cleaning procedure on a regular

basis and cover the appliance whilst not in use.

Material breakdown from high moisture conditions can be

avoided if the appliance is well protected from the weather and

regular cleaning is performed.

STORAGE

Page 18

Gas valve assembly Orifice Burner tube

To reduce risk of FLASHBACK FIRE you must clean the burner

tubes as follows at least once a month in summer and autumn or

whenever spiders are active in your area, and if the appliance has

not been used for an extended period of time.

1. Turn all burner valves to full

‘OFF’ position.

2. Turn LP gas cylinder valve to full

‘OFF’ position.

3. Detach LP gas regulator assembly from gas cylinder.

4. Remove cooking plates and grease tray.

5. Remove screw from rear of each burner using a Phillips-head

screwdriver.

6. Carefully lift each burner up and away from gas valve orifice.

7. Check and clean burner/venturi tubes for insects and insect

nests. A clogged tube can lead to a fire beneath the appliance.

8. Refer to diagram 1 and perform one of these three cleaning

methods:

METHOD 1: Bend a stiff wire or wire coat hanger into a small

hook as shown and run the hook through burner tube and inside

burner several times to remove debris.

METHOD 2: Use a bottle brush with a flexible handle and run

through the burner tube and inside burner several times to

remove any debris.

METHOD 3: Use an air hose to force air through each burner tube.

The forced air should pass debris or obstructions through burner

and out the ports.

Regardless of which burner cleaning procedure you use, we

recommend you also complete the following steps to help prolong

burner life.

1. Use a fibre pad or nylon brush to clean the entire outer surface

of each burner until free of food residue and dirt.

2. Clean any clogged ports with a stiff wire, such as an open

paper clip.

3. Inspect each burner for damage

(cracks or holes) and if

such damage is found, order and install a new burner. After

installation, check to ensure the gas valve orifices are correctly

placed inside the ends of the burner tubes. Also check position

of your spark electrode.

CLEANING BURNER TUBES

AND BURNER PORTS

FOR SAFE OPERATION ENSURE GAS

VALVE ASSEMBLY ORIFICE IS INSIDE

BURNER TUBE BEFORE USING YOUR

APPLIANCE. See diagram.

IF ORIFICE IS NOT INSIDE BURNER

TUBE, LIGHTING THE BURNER MAY

CAUSE EXPLOSION AND / OR FIRE

RESULTING IN SERIOUS BODILY

INJURY AND / OR PROPERTY DAMAGE.

Diagram 1.

To clean burner tube, insert hook as indicated by

the arrow.

MAINTENANCE

181819

Page 19

19

Page 20

This diagram is provided to assist you identify

parts if replacement is necessary.

Contact the place of purchase or manufacture

to enquire about parts, availability and / or service.

Items included in Outdoor Range barbecue

specification may differ from parts list, depending

on region or specific dealer specification.

7

8

13

16

17

20

22

59

23

24

26

25

27

21

15

6

14

28a

24

34

35

38

45

48

50

51

1

2

3

3

10

11

9

4

5

19

12

18

28

29

31

32

33

36

37

39

47

46

55

54

53

35b

40

41

58

43

49

61

60

44

56

56

42

52

56

58

57

58

PARTS DIAGRAM

20

20

Page 21

PARTS LIST

21

21

Ref Description Part # Qty Ref Description Part # Qty

1 Lid P0014605AY 1

1a Lid bracket P03304030C 2

2 Hot plate P05702020E 1

3 Hot plate handle P00203021H 2

4 Hot plate burner P02008027B 1

5 Hot plate burner mounting bracket P03327031C 1

6 Side burner body P01106040B 1

7 Grease tube P02721042B 1

8 Side burner frame P01903003B 1

9 Hot plate frame P0071325FC 1

10 Hot plate bracket P03328041C 4

11 Lighting tube P05507004A 1

12 Bowl panel – top P0073941DC 1

13 Pot support P00815013D 1

14 Side burner P02004036B 1

15 Side burner cap P02013057E 1

16 Side burner bracket P03327032C 1

17 Bowl panel – left P0072075DC 1

18 Bowl panel – right P0072175DC 1

19 Bowl panel – rear P0072575DC 1

20 Control panel bracket – left P03328039C 1

21 Control panel bracket – right P03328040C 1

22 Control panel – upper P02907871S 1

23 Control panel – lower, with screen print P02907886A 1

24 Control knob P03419413J 2

25 Control knob seat P03415014S 2

26 Electric igniter – 2P P02502172C 1

27 Manifold heat shield assembly –

LP Y0060396 1

27 Manifold heat shield assembly – NG Y0060422 1

27a Manifold P05001292G 1

27b Gas valve heat shield P03007163B 1

27c Jet – main burner, propane P06525004A 1

Jet – main burner, NG P06525005A 1

27d Jet – side burner, propane P06525006A 1

Jet – side burner, NG P06525007A 1

27e

Hot plate burner gas valve – LP, without jet

P03218111A 1

Hot plate burner gas valve – NG, without jet

P03218113A 1

27f Side burner gas valve – LP, without jet P03218110A 1

Side burner gas valve – NG, without jet P03218112A 1

28 Side burner electrode P02606016A 1

28a Electric wire set – 2 contact P02615104A 1

29 Gas collector box – with wire P02610036A 1

31 Thermocouple for hot plate burner P05305013A 1

32 Thermocouple for side burner P05305020A 1

33 Regulator P03603004A 1

34 Grease draining tray P02717447C 1

35 Grease tray handle P00213011B 1

35b Wheel for grease tray P05354002A 4

36 Trolley panel – top P01001054L 1

37 Trolley panel cap P05535003P 1

38 Bowl support bracket – left P01301007B 1

39 Bowl support bracket – right P01302007B 1

40 Door top support P01303006B 1

41 Door support bracket – upper left P03302033A 1

42 Door support bracket – upper right P03302034A 1

43 Castor seat – left front P05327021T 1

44 Castor seat – right front P05327023T 1

45 Trolley side panel – left P07614011A 1

46 Trolley side panel – right P07615011A 1

47 Trolley side panel – rear P07701048A 1

48 Door panel – left P04302043A 1

49 Door panel – right P04303043A 1

50 Door handle P00214004A 2

51 Spice rack P05204011B 1

52 Towel rack P05212003B 1

53 Trolley bottom shelf P01006006C 1

54 Castor seat – right rear P05327024T 1

55 Castor seat – left rear P05327022T 1

56 Castor 21/2" P05110004D 4

57 Door guide plate P05510024A 1

58 Door magnet P05523001K 4

59 Name plate P00410040G 1

60 Gas cylinder pull-out tray Y0340048 1

61 Wing bolt S233G05591 1

Hardware pack P06003072A 1

Page 22

22

22

Page 23

Warranty Period

Kleenmaid Professional Series Outdoor Cooking Centres

emitefiLStainless Steel Frames

emitefiLsrenruB leetS sselniatS

sraeY 5sevlaV

sraeY 5 metsyS noitingI

sraeY 5strap rehto llA

emitefiLRoasting Hood

emitefiL

Pedestal

Should any part fail due to defective workmanship or faulty

materials within the specified period from the date of purchase,

Kleenmaid will repair or replace the defective part free of charge.

LP Gas Tank

The cylinder manufacturer is responsible for the materials,

workmanship and performance of the cylinder. Contact your

dealer or the cylinder manufacturer.

Warranty Administration

Warranty is administered by Kleenmaid.

Domestic Warranty

In addition to all statutory rights which you, the consumer, have

under the relevant laws in respect to this appliance, during the first

five years of ownership as the original purchaser of this Kleenmaid

appliance, we guarantee that any fault caused by faulty material

or workmanship becoming apparent will be rectified free of charge

for parts and labour, provided that all service is performed during

normal working hours by Kleenmaid or their designated agents.

Storage

Exposure of the barbecue appliance to the elements should be

minimised. Once the unit has cooled and is cleaned, store the

barbecue under cover. Polyester/Vinyl covers are an optional

accessory that will ensure years of trouble free operation.

This warranty does not cover the purchaser or any other person for damage, malfunction or loss due to the following:

• Commercial use of the barbecue.

• Lack of maintenance, abuse, neglect, misuse, accident or improper installation of this appliance.

• Scratches, dents, corrosion or discolouring caused by heat, abrasive or chemical cleaners or chipping on porcelain parts.

• Corrosion or damage caused by exposure to the elements, grease fires, insects, weather or hail. Barbecues must be covered when not in use.

• Cleaning and normal wear and tear. Service calls of this nature are chargeable.

• Cooktops must be covered when not in use.

• Unauthorised repairs during the warranty period.

• Removal or re-installation costs.

• We are not responsible for any consequential damages from any malfunction.

Conditions of Warranty

Service Assistance

1. The consumer, must make the appliance available for servicing and shall bear any costs incurred for any de-installation and /or re-installation

required to make the appliance available for servicing. Kleenmaid are not liable for any consequential damage incurred during

de-installation and/or re-installation.

2. The appliance is delivered to the Kleenmaid service department or authorised service agent and freight charges both ways are paid

by the owner. No liability is accepted for loss or damage during transit.

3. The appliance is installed by a qualified person and operated and maintained in accordance with the instructions supplied.

Repairs or service must be carried out by an authorised person.

4. Installation must conform to the standards laid down by the local codes or, in the absence of local codes, with

AGA code AG:601 AS:5601:2002

5. No alterations or repairs have been carried out without obtaining Kleenmaid’s prior consent. Such repair or any replacement does not

extend the warranty period.

6. Where this warranty is inconsistent with any state laws, the statutory rights or the purchaser shall prevail.

7. Parts installed from other manufacturers products will nullify this warranty.

To assist you when phoning our After Sales Service Number to arrange a service call, please complete the following details and

have them ready when you call.

Model Number Serial Number

Kleenmaid store purchased from

Date of Purchase

Gas type: LPG NG

KLEENMAID AFTER SALES SERVICE: 1300 652 100

Date of Installation

TERMS OF WARRANTY

23

23

Page 24

appliances available

in the Kleenmaid range

P80140160A 02/2007

the best products we can find.

We search the globe for products that meet our high standards of functionality, style and quality and

are proud of our innovative range sourced from countries throughout the world.

This outstanding appliance from our professional series is proudly handed crafted in Italy.

Washing Machines

Dryers

Dishwashers

Ovens

Cooktops

Outdoor Cooking Centres

Built-In Coffee Machines

Rangehoods

Freestanding Ovens and Cooktops

Sinks

Waste Disposals

Taps

Cookware

Refrigerators

Wine Cellars

Vacuum Cleaners

To find your nearest Kleenmaid Showroom

telephone 13 13 08.

Technical specifications and product sizes can be varied

by the manufacturer without notice.

Any cutouts for appliances should only be physical

measurements. Drawings are not to scale.

All information supplied is for general reference purposes

only and is on the understanding that Kleenmaid Pty

Limited will not be liable for any loss, liability or damage

whatsoever arising as a result of reliance of such

information.

Loading...

Loading...