Page 1

Frontload Washers

Model LTK95A*N3050

Installation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

FLW1518C

FLW1518C

Part No. 802116R1

May 2005

Page 2

Page 3

Table of

Contents

Replacement Parts.............................................................................. 3

Installation........................................................................................... 5

Dimensions and Specifications............................................................. 5

Before You Start................................................................................... 6

Tools ................................................................................................ 6

Electrical .......................................................................................... 6

Water................................................................................................ 6

Accessories Bag............................................................................... 6

Installing the Washer............................................................................ 7

Step 1: Position Washer Near Installation Area .............................. 7

Step 2: Connect Fill Hoses............................................................... 7

Step 3: Connect Drain Hose to Drain Receptacle............................ 8

Step 4: Position and Level the Washer ............................................ 11

Step 5: Remove the Shock Sleeves and Shipping Brace ................. 12

Step 6: Wipe Out Inside of Washer Drum ....................................... 12

Step 7: Plug In the Washer............................................................... 12

Step 8: Check Installation................................................................ 12

Moving Unit to a New Location...................................................... 13

Electrical Requirements........................................................................ 13

Earthing Instructions........................................................................ 14

Water Supply Requirements................................................................. 15

Water Temperature .......................................................................... 15

Water Pressure ................................................................................. 15

Risers................................................................................................ 16

Information for Handy Reference......................................................... 17

Installer Checklist................................................................ Back Cover

© Copyright 2005, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 5

Replacement Parts

If replacement parts are required, contact the source

from which you purchased your washer.

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Notes

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 7

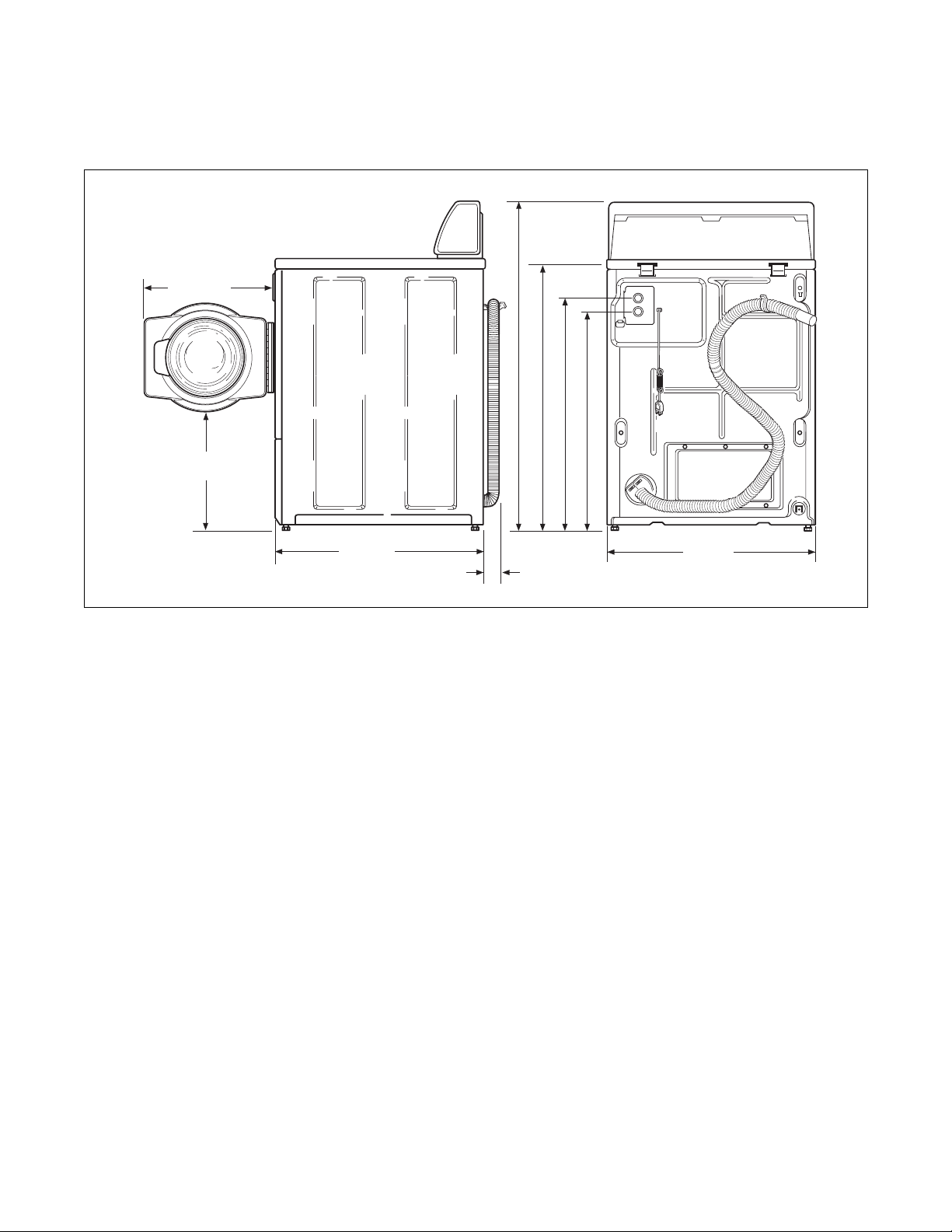

Installation

Dimensions and Specifications

47,5 cm

(18,7 in.)

36,3 cm

(14,3 in.)

109,2 cm (43 in.)

93 cm (36,6 in.)

79 cm (31,1 in.)

75,2 cm (29,6 in.)

71,1 cm

(28 in.)

5,1 cm

(2 in.)

68,3 cm

(26,9 in.)

FLW2050N

FLW2050N

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Installation

1

2

3

4

5

Before You Start

Tools

For most installations, the basic tools you will need

are:

D820I

1 Wrench

2 Screwdriver

3 Pliers

4 Socket Wrench

5 Level

Water

Washer needs two standard 19,1 mm (3/4 in.) water

supply faucets with a pressure between 138 and

827 kPa (20 to 120 pounds per square inch). For more

detailed information, refer to section on Water Supply

Requirements.

Accessories Bag

An accessories bag has been shipped inside your

washer. It includes:

● Two fill hoses with washers and filter screens.

Refer to step 2 of Installation.

● Four rubber feet. Refer to step 4 of Installation.

● Beaded tie-down strap. Refer to step 3 of

Installation.

● Installation instructions.

● Operating instructions.

● Use and Care Guide.

● Warranty bond.

● Bag for storing shipping materials.

Figure 1

Electrical

Refer to serial plate for specific electrical

requirements. For more detailed information, refer to

section on Electrical Requirements.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 9

Installation

Installing the Washer

NOTE: If the washer is delivered on a cold day

(below freezing), or is stored in an unheated room

or area during the cold months, do not attempt to

operate it until the washer has had a chance to

warm up.

Step 1: Position Washer Near Installation

Area

IMPORTANT: Install dryer before washer. This

allows room for attaching exhaust duct.

Move washer so that it is within 1,2 meters (4 feet) of

desired area of installation.

Step 2: Connect Fill Hoses

NOTE: Refer to section on Water Supply

Requirements before connecting fill hoses.

The appliance is to be connected to the water mains

using new hose-sets, and old hose-sets should not be

reused.

Turn on the water supply faucets and flush the lines for

approximately two minutes to remove any foreign

materials that could clog the filter screens in the fill

hoses, or the screens in the water mixing valve.

NOTE: When installing in newly constructed or

renovated building, it is very important to flush the

lines since build-up may have occurred during

construction.

Remove the two filter screens and the two plain rubber

washers from accessories bag, and install them

according to Figure 3.

IMPORTANT: Thread hose couplings onto valve

connections finger-tight, then approximately

1/4 turn with pliers. DO NOT cross thread or

overtighten couplings.

Figure 2

D772I

Turn water on and check for leaks. If leaks are found,

retighten the hose couplings. Continue tightening and

rechecking until no leaks are found.

IMPORTANT: Hoses and other natural rubber

parts deteriorate after extended use. Hoses may

develop cracks, blisters or material wear from the

temperature and constant high pressure they are

subjected to.

All hoses should be checked on a yearly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be

replaced immediately.

D772I

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Installation

1

2

3

4

5

FLW2008N

1

2

3

WATE R

MIXING

VALVE

4

1 Filter Screen (Screen must be facing

outward)

2 Fill Hose

3 Rubber Washer (Plain)

4 Install this end of hose (blue coupling) to

valve connections at rear of washer.

5 Install this end of hose (white coupling) to

water supply faucet.

Step 3: Connect Drain Hose to Drain

Receptacle

Remove the drain hose from its shipping position on

the rear of the washer by unhooking the hose from the

retainer clamp and by removing shipping tape.

Find the instructions, on the following pages, that are

appropriate for your type of drain receptacle

(standpipe, sink, wall, or laundry tub). Follow these

instructions to properly install the drain hose.

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 3,2 cm (1-1/4 inch) outside

diameter drain hose.

H091I

1

Figure 3

1 Water Supply Faucets

2 Cold Water Connection

3 Hot Water Connection

4 Fill Hoses

Figure 4

FLW2009N

1 Retainer Clamp

Figure 5

FLW2008N

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 11

Installation

1

2

3

Standpipe Installation

Place the drain hose into the standpipe.

Remove the beaded tie-down strap from accessories

bag and place around standpipe and drain hose and

tighten strap to hold hose to standpipe. This will

prevent the drain hose from dislodging from drain

receptacle during use.

FLW2010N

1 61 to 91,44 cm (24 to 36 in.) Recommended

Height

2 Standpipe – 5,08 cm (2 in.) or 4 cm

(1-1/2 in.) Diameter

3 Beaded Tie-Down Strap

Sink Installation

For this type of installation, use the beaded tie-down

strap (supplied in accessories bag) or use a large wire

tie (available from your local hardware store), and

secure the drain hose to the cabinet top hinge (refer to

Figure 7). This will prevent the drain hose from

dislodging during use.

1

2

FLW2011N

FLW2011N

1 Drain Hose

2 Tie-Down Strap (Wire tie or tape if

necessary)

Figure 6

Figure 7

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Installation

2

3

1

In-the-Wall Installation

For installations of this type, the drain hose MUST be

secured to one of the fill hoses using the beaded tiedown strap from accessories bag.

NOTE: End of drain hose must not be below 61 cm

(24 in.).

H023I

1 Drain Hose

2 Tie-Down Strap (Tape if necessary)

3 Fill Hoses

Laundry Tub Installation

For this type of installation, the drain hose MUST be

secured to the stationary tub to prevent hose from

dislodging during use. Use the beaded tie-down strap

(supplied in accessories bag) to secure hose.

1

2

FLW2012N

1 Drain Hose

2 Tie-Down Strap (Tape if necessary)

Figure 9

Figure 8

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 13

Installation

Washers elevated above floor level must be

anchored to that elevated surface, base or

platform. The material used to elevate the

washer should also be anchored to the floor

to ensure that the washer will not walk or

that the washer can not be physically

pulled, tipped or slid from its installed

position. Failure to do so may result in

conditions which can produce serious

injury, death and/or property damage.

W306

WARNING

Step 4: Position and Level the Washer

Place washer in position on a clean, firm and

reasonably level floor. Installing the washer on any

type of carpeting is not recommended.

Loosen 7/8 inch locknut and adjust the front and rear

leveling legs until the washer is level from side to side

and front to back (using a level). Washer should not

rock.

NOTE: Level must rest on raised portion of top

panel. Refer to Figure 10.

Tighten the locknuts securely against the washer

base using the 7/8 inch wrench. If the locknuts are not

tight, washer will move out of position during operation.

NOTE: DO NOT slide washer across floor if the

leveling legs have been extended, as legs and base

could become damaged.

NOTE: Use of the dispenser drawer or washer door

as a handle in the transportation of the washer may

cause damage to the dispenser or door.

Remove rubber feet from accessories bag and place on

all four leveling legs.

Verify that washer does not rock.

1

2

4

5

1 Leveling Leg

2 Washer Base

3 Level

4 Locknut

5 Rubber Foot

3

FLW2052N

FLW2052N

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 10

11

Page 14

Installation

Step 5: Remove the Shock Sleeves and

Shipping Brace

IMPORTANT: The shock sleeves and shipping brace

MUST be removed from the washer before operation.

Remove front access panel by removing the two screws.

Remove bolts and lockwashers from shipping brace

with 9/16 inch wrench and remove brace. Remove

shock sleeves by pulling on the yellow rope.

Remove label from front side of front access panel and

place on backside of front access panel.

IMPORTANT: The shipping brace, bolts,

lockwashers and shock sleeves should be saved and

MUST be reinstalled whenever the unit is moved

more than four feet. Do not lift or transport unit

from front or without shipping materials installed.

Store the shipping materials in the bag provided in the

accessories bag. Save materials for use whenever the

unit is moved.

IMPORTANT: The shipping materials MUST be

reinstalled whenever the unit is moved. Refer to

Moving Unit to a New Location section for proper

instructions on reinstalling the shipping materials.

Step 6: Wipe Out Inside of Washer Drum

Before using the washer for the first time, use an allpurpose cleaner, or a detergent and water solution, and

a damp cloth to remove shipping dust from inside the

drum.

FLW2053N

Figure 12

Step 7: Plug In the Washer

Refer to section on Electrical Requirements and plug

washer in.

Reinstall front access panel.

IMPORTANT: DO NOT tip washer more than

152,4 mm (6 inches) in any direction after shipping

brace has been removed. Shock absorbers may

separate and damage to washer may result. For

leveling purposes, the washer may be tilted a

maximum of 152,4 mm (6 inches) in any direction.

1

2

4

3

H336I

1 Shock Sleeves

2 Motor Mount

3 Bolts and Lockwashers

4 Hooked End of Shipping Brace

FLW2070N

Figure 13

Step 8: Check Installation

Refer to Installer Checklist on the back cover and

make sure that unit is installed correctly.

12

Figure 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 15

Installation

Moving Unit to a New Location

To prevent damage while moving the unit, the

shipping materials MUST BE reinstalled.

Reinstallation of Shipping Materials

Disconnect washer from electrical supply.

Remove front access panel by removing two screws.

Place the shock sleeves on all four shock absorbers.

Refer to Figure 14.

Insert hooked end of shipping brace into the open slot

of the motor mount. Attach with bolts and lockwashers.

Refer to Figure 14.

Reinstall front access panel.

1

2

4

3

H336I

1 Shock Sleeves

2 Motor Mount

3 Bolts and Lockwashers

4 Hooked End of Shipping Brace

Figure 14

Refer to step 5 for proper procedures whenever the

unit is moved.

Electrical Requirements

(240 Volt, 50 Hertz with 3-Prong Earthing Plug)

NOTE: The wiring diagram is located in the

control hood.

WARNING

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

earthing MUST abide with local electrical

codes. It is the customer’s responsibility to

have the wiring and fuses checked by a

qualified electrician to make sure the

laundry room has adequate electrical power

to operate the washer.

W246

DO NOT OVERLOAD

CIRCUITS

DO NOT USE AN

ADAPTER

DO NOT USE AN

EXTENSION CORD

D009I

Figure 15

The washer is designed to be operated on a separate

branch, polarized, three-wire, effectively earthed,

240 Volt, 50 Hertz, AC (alternating current) circuit

protected by a 10 Ampere fuse, equivalent fusetron or

circuit breaker.

The three-prong earthing plug on the power cord

should be plugged directly into a polarized three-slot

effectively earthed receptacle rated 240 Volts AC

(alternating current) 10 Amps. Refer to Figure 16 to

determine correct polarity of the wall receptacle.

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Installation

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the washer to the

electric power source.

W082

WARNING

WARNING

Improper connection of the equipmentearthing conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is properly

earthed.

W032

This unit is equipped with a three-prong

(earthing) plug for your protection against

shock hazard and should be plugged

directly into a properly earthed three-prong

receptacle. Do not cut or remove the

earthing prong from this plug.

W477

WARNING

240 VOLT

50 HERTZ

Earthing Instructions

The washer must be earthed. In the event of

malfunction or breakdown, earthing will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The washer is equipped

with a cord having an equipment-earthing conductor

and a 3-prong earthing plug. The plug must be plugged

into an appropriate outlet that is properly installed and

earthed in accordance with all local codes and

ordinances.

DO NOT modify the plug provided with the washer –

if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

NOTE: Have a qualified electrician check the

polarity of the wall receptacle. If a voltage reading

is measured other than that illustrated, the

qualified electrician should correct the problem.

240 VOLT

50 HERTZ

2

1

STANDARD 240 VOLT, 50 HERTZ, 3-WIRE

EFFECTIVELY EARTHED CIRCUIT

1 Power Cord

2 Earth (Ground) Prong

Figure 16

0 VOLT

FLW2069N

FLW2069N

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT. DO NOT OVERLOAD

CIRCUITS!

Do not operate both a washer and gas dryer on the

same circuit. Use separately fused 10 Amp circuits.

If the supply cord is damaged, it must be replaced by a

special cord or assembly available from the

manufacturer or its service agent.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 17

Water Supply Requirements

Under certain conditions, hydrogen gas may

be produced in a hot water system that has

not been used for two weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If the hot

water system has not been used for such a

period and before using the washer, turn on

all hot water faucets and let the water flow

from each for several minutes. This will

release any accumulated hydrogen gas. The

gas is flammable. Do not smoke or use an

open flame during this time.

W029

WARNING

Installation

NOTE: Water supply faucets must fit standard

3/4-14 BSP metric female couplings.

DO NOT USE SLIP-ON OR CLAMP-ON

CONNECTIONS.

NOTE: Water supply faucets should be readily

accessible to permit turning them off when washer

is not being used.

Water Temperature

Cold:

Recommended cold water temperature is 16° to

27° Celsius (60° to 80° Fahrenheit).

Hot:

Recommended hot water temperature is 49° to

60° Celsius (120° to 140° Fahrenheit).

Warm:

Mixture of hot and cold water. (Warm water

temperature is dependent upon the water temperature

and the pressure of both the hot and cold water supply

lines.)

1

4

1 Water Supply Faucets

2 Cold Water Connection

3 Hot Water Connection

4 Fill Hoses

Figure 17

2

WATE R

MIXING

VALVE

3

FLW2008N

FLW2008N

Water Pressure

Pressure must be a minimum of 138 to a maximum of

827 kPa (20 to 120 pounds per square inch) static

pressure measured at the faucet.

NOTE: For water pressure over 827 kPa

(120 pounds per square inch) we recommend the

installation of a pressure limiting valve (Part

Number PSL50DK). This item may be purchased

by calling 1300 652 100.

NOTE: Water pressure under 138 kPa (20 pounds

per square inch) will cause an extended fill time in

the washer and may not properly flush out the

detergent dispenser.

IMPORTANT: Turn off water supply faucets after

check-out and demonstration. Owner should turn

off water supply whenever there will be an

extended period of non-use.

NOTE: A longer fill hose is available (as optional

equipment at extra cost) if the hose (supplied with

the washer) is not long enough for the installation.

Order hose as follows:

Part Number 1010102 – 2,5 m Fill Hose

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Installation

W005I

Risers

Risers (or air cushions) may have to be installed if the

pipes knock or pound when flow of water stops. The

risers are more efficient when installed as close as

possible to the water supply faucets (refer to

Figure 18).

2

1

W005I

1 Water Supply Faucets

2 Risers (Air Cushions)

Figure 18

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 19

Installation

Information for Handy Reference

Date Purchased

Model Number Serial Number

Store Name

Store Address Phone Number

Service Agency

Service Agency Address Phone Number

NOTE: Record the above information and keep your sales slip. Model and serial numbers are located on

the nameplate.

Customer Care Centre and

Information:

1300 652 100

802116

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Notes

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802116

Page 21

Page 22

Installer Checklist

• Position Washer

Near

Installation

Area.

CHECK

1

D772I

W520I

• Connect Fill

Hoses.

CHECK

2

W520I

• Connect

Drain Hose

to Drain

Receptacle.

CHECK

3

FLW2010N

• Position and

Level the

Washer.

CHECK

4

FLW2052N

Fast Track for Installing the Washer

(Refer to the manual for more detailed information)

• Remove the

5

Shock Sleeves

and Shipping

Brace.

D772I

H336I

CHECK

• Wipe Out

6

Inside of

Washer

Drum.

FLW2053N

FLW2053N

CHECK

• Plug In the

7

Washer.

FLW2010N

FLW2070N

FLW2070N

CHECK

FLW2052N

Loading...

Loading...