Page 1

Instructions for Use

KFL850

Washing machine

Page 2

Thank you for your condence in purchasing our

3

washing machine, and congratulations on the

excellent choice.

Your new washing machine meets the requirements

of modern treatment of laundry. It is rational in the

consumption of energy, water and washing agents.

Our appliances are friendly to the environment.

Some of the materials may be recycled, others

deposited or decomposed. To avoid pollution

on the environment, once your appliance is no

longer useful, take it to your local authorised waste

appliance dealer.

Description of washing machine .....................3

Cautions ............................................................. 4

Installation and connection.............................. 6

Operation ........................................................ 10

Tips for washing and saving energy .............19

Cleaning and maintenance............................. 21

Failures............................................................. 24

Tables ...............................................................27

2

Page 3

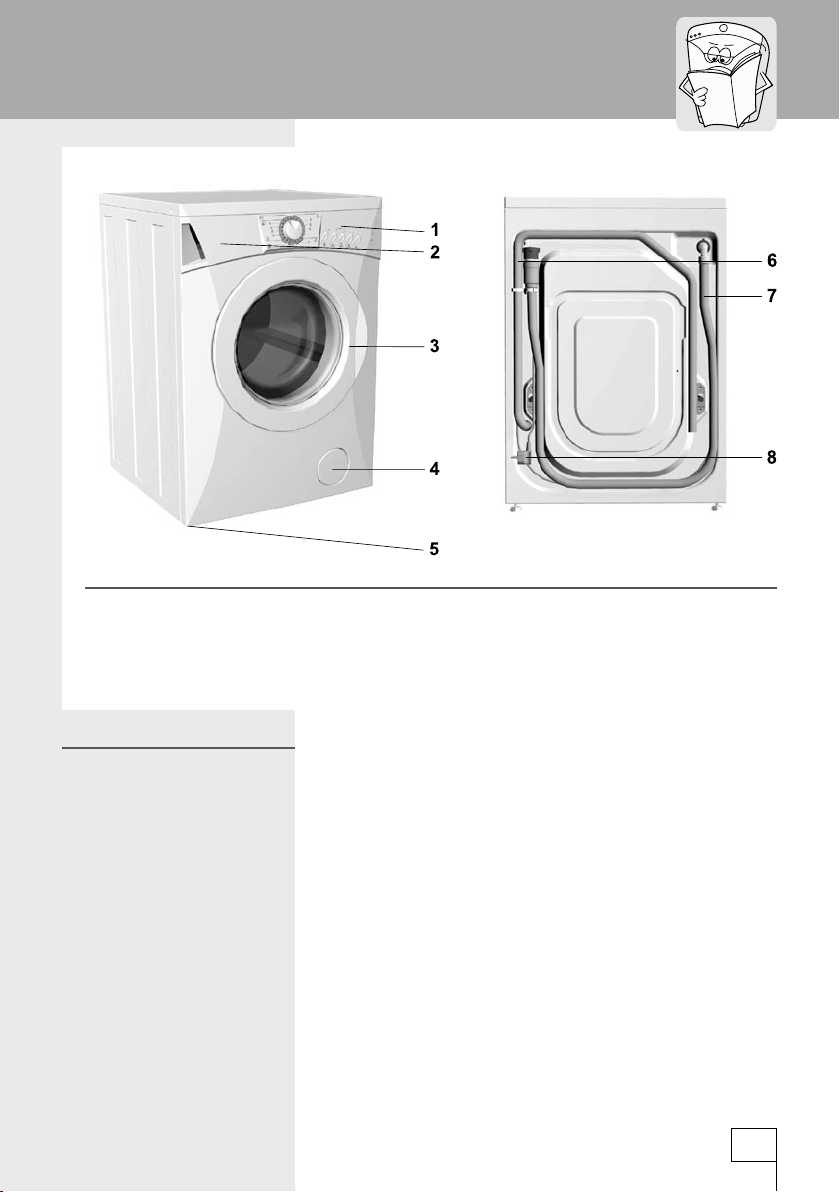

Description of washing machine

1. Front panel

2. Detergent dispenser

3. Door

4. Filter lid

Technical information

5. Adjustable legs

6. Water outlet hose

7. Water inlet hose

8. Mains power cable

Dimensions (w x d x h):

600 mm x 600 mm x 850 mm

Depth with door open: 106 cm

Weight (net): 77 kg

Nominal voltage: 240 V, 50 Hz

Power: 2300 W

Max. load: 6.5 kg

Power socket: (240 V, 50 Hz, 10 A)

Water pressure: min. 0,05 MPa, max. 0,8 MPa

Fuse: 10 A

3

Page 4

5

Cautions

Be sure to remove transport brackets prior

•

to rst use of the appliance. Attempted

operation of the blocked machine may result in

irreparable damage which is not covered by the

manufacturer’s warranty!

When connecting your washing machine to water

•

supply, be sure to use brand new water inlet hose

and appropriate sealing gaskets (attached).

Do not locate the machine in a room with

•

temperature below 0°C. Parts of the machine may

be damaged if frozen.

Install the washing machine in a perfectly

•

horizontal position, on solid at concrete oor.

Follow the instructions for correct installation and

•

water and mains connections.

Never immerse the end of the drain hose into the

•

draining water.

Prior to starting the washing cycle lock the door

•

by pressing them at the designated spot.

Door may not be opened during the washing

•

cycle.

Use only detergents and softeners for

•

machine wash. Manufacturer may not assume

responsibility for any damage and eventual

discoloring of gaskets and plastic components as

a consequence of incorrect use of bleach and/or

colouring agents.

For removal of lime residues use such agents

•

with added anti-corrosion agents. Follow the

manufacturer’s instructions. Finish the lime

removal by multiple rinsing to remove completely

eventual acid residues.

Never use detergents containing solvents, as

•

there is a danger of creating toxic gasses which

may damage the machine and result in ignition or

explosion.

Upon completion of washing operation close the

•

water tap.

4

Page 5

Before any transport, block the machine by

•

inserting at least one transport blocking rod. Prior

to this operation disconnect the appliance from

the mains power!

Rating plate with basic information is located

•

above the opening of the machine.

The symbol on the product or on its

packaging indicates that this product

may not be treated as household waste.

Instead it shall be handed over to the

applicable collection point for the recycling

of electrical and electronic equipment.

By ensuring this product is disposed of

correctly, you will help prevent potential

negative consequences for the environment

and human health, which could otherwise

be caused by inappropriate waste

handling of thisproduct. For more detailed

information about recycling of this product,

please contact your local city ofce, your

household waste disposal service or the

shop where you purchased the product.

This appliance is not intended for use by

young children or inrm persons unless

they have been adequately supervised by a

responsible person to ensure that they can

use the appliance safely.

Young children should be supervised

to ensure that they do not play with the

appliance.

5

Page 6

7

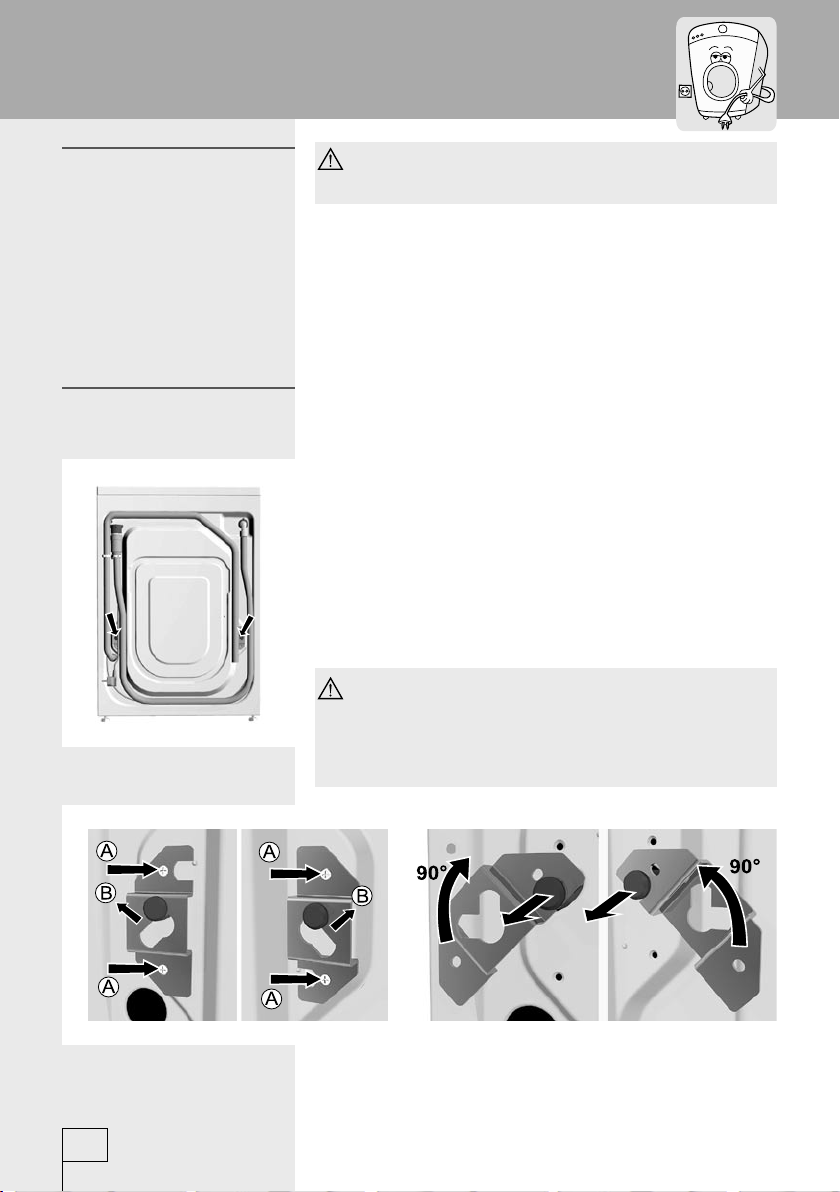

Installation and connection

Package removal

Removal of transport

brackets

In removing the wrapping, be careful not to

damage the appliance with a sharp object.

Our appliances are packed in environmentally

•

friendly materials which may be recycled,

deposited or decomposed without any threat to

the environment.

To this end all wrappings are marked accordingly.

•

Move the hoses.

•

Loosen screws A at the rear of the machine

•

(Fig. 1).

Remove the brackets B (Fig. 1) and slide them

•

into the groove on the blocking rod (Fig. 2) - the

right one should be turned around.

Use the brackets to rotate blocking rods for 90°

•

and pull them out.

Close the openings with attached plastic pegs.

•

Save transport brackets for eventual later use.

Be sure to remove the transport brackets

prior to rst use, otherwise the appliance

may be permanently damaged. In such

cases the warranty conditions are void.

Fig. 2

Fig. 1

6

Fig. 2

Page 7

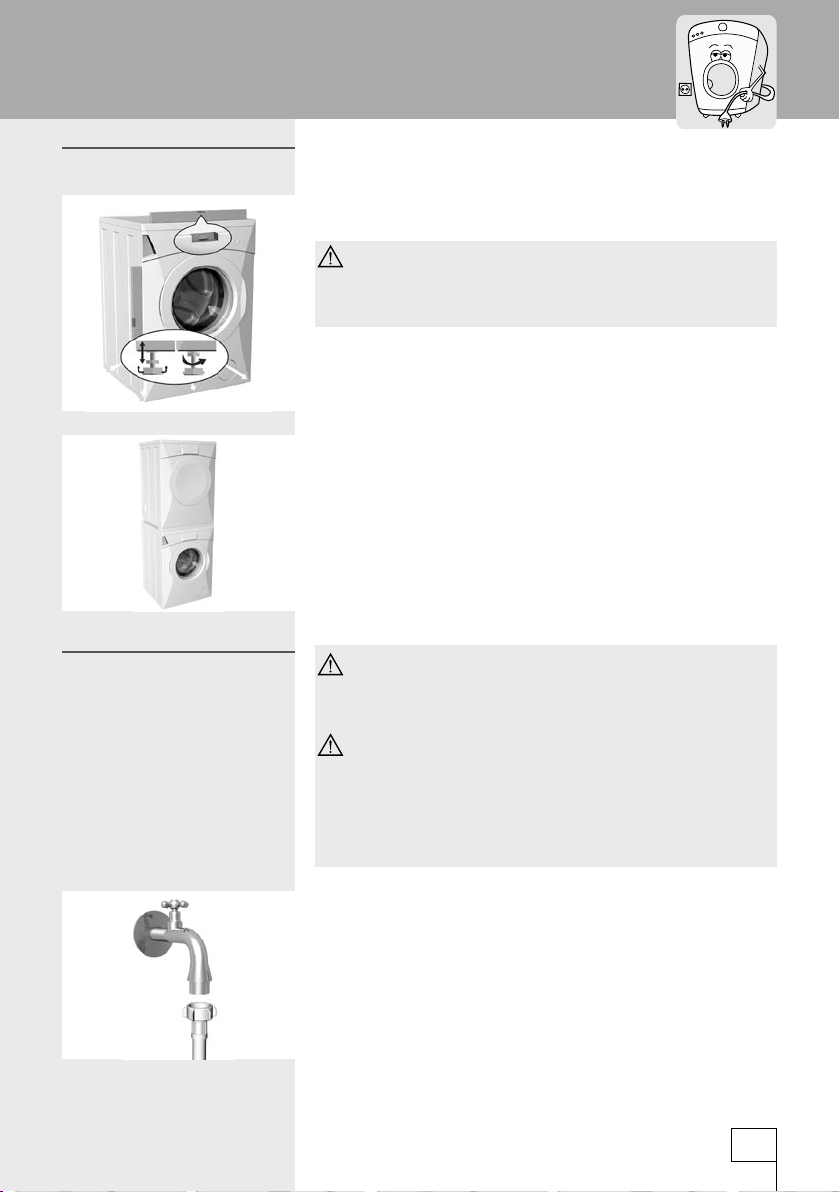

Levelling the appliance

Water inlet connection

Put the appliance in a horizontal position by

•

turning the adjustable legs.

The legs are adjustable up to +/- 1 cm.

The oor below the appliance must be dry

and clean, otherwise the appliance may

slide.

If you have a tumble dryer of the same

•

dimensions, you can place it on top of the

washing machine.

To ensure correct operation of the

appliance, water pressure inlet must be

between 0,05 and 0,8 MPa.

Minimum water pressure can be

established by measuring the quantity of

poured out water. 3 litres of water must be

poured out from completely opened tap in

15 seconds.

Insert the gasket with screen into the water inlet

•

hose thread. Screw the hose thread to the water

faucet.

In case of hot and cold water connection, connect

•

one hose to cold and the other to the hot water

faucet marked at the rear of the appliance (letters C

and H) (C - cold; H - hot).

7

Page 8

9

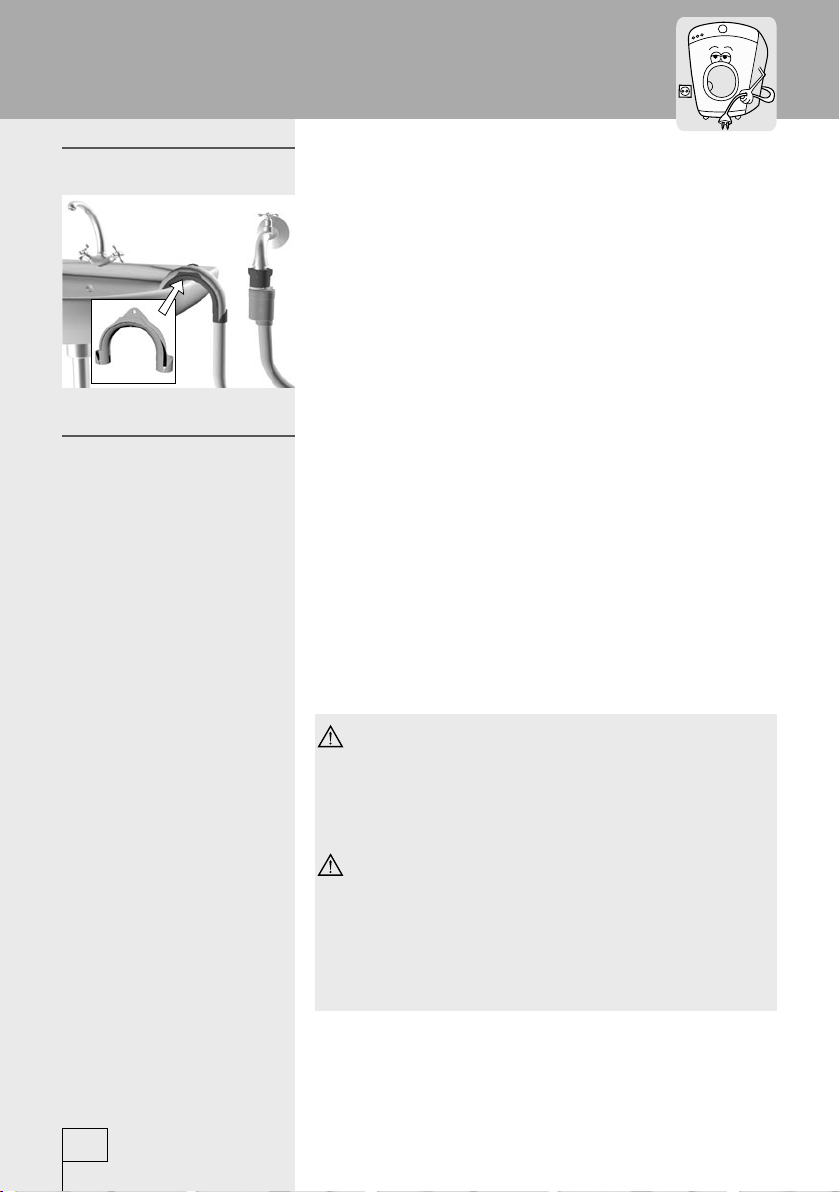

Water outlet connection

Fix the outlet hose to the wall drain outlet

•

(diameter min. 4 cm).

Wall drain must be installed properly and must

•

enable occasional cleaning.

Fasten the outlet hose support with a piece of

•

rope fed through the hose elbow to prevent the

hose from slipping to the oor.

The end of the outlet hose should be placed

between minimum 60 cm and maximum 100 cm

above the oor level.

Connection to Power

Supply

Connect the appliance to the power supply with the

cord provided.

A three pin, switched, earthed power point less than

1500mm from the back of the machine is required.

Rated voltage, frequency and other data are listed

on the rating plate on the back of the machine.

Check that the supplied electrical voltage is the

same as on the rating sticker.

Your washing machine should be earthed and

connected to the power supply according to local

electricity supplier regulations and standards.

If the supply cord of this appliance is

damaged, it must be replaced by the special

cord, part no. G 360440, available from your

nearest spare parts centre (refer to guarantee

and service guide).

CAUTION: If this appliance is supplied

from a cord extension set or electrical

portable outlet device, the cord extension

set or electrical portable outlet device must

be positioned so that it is not subject to

splashing or ingress of moisture.

8

Page 9

9

Page 10

11

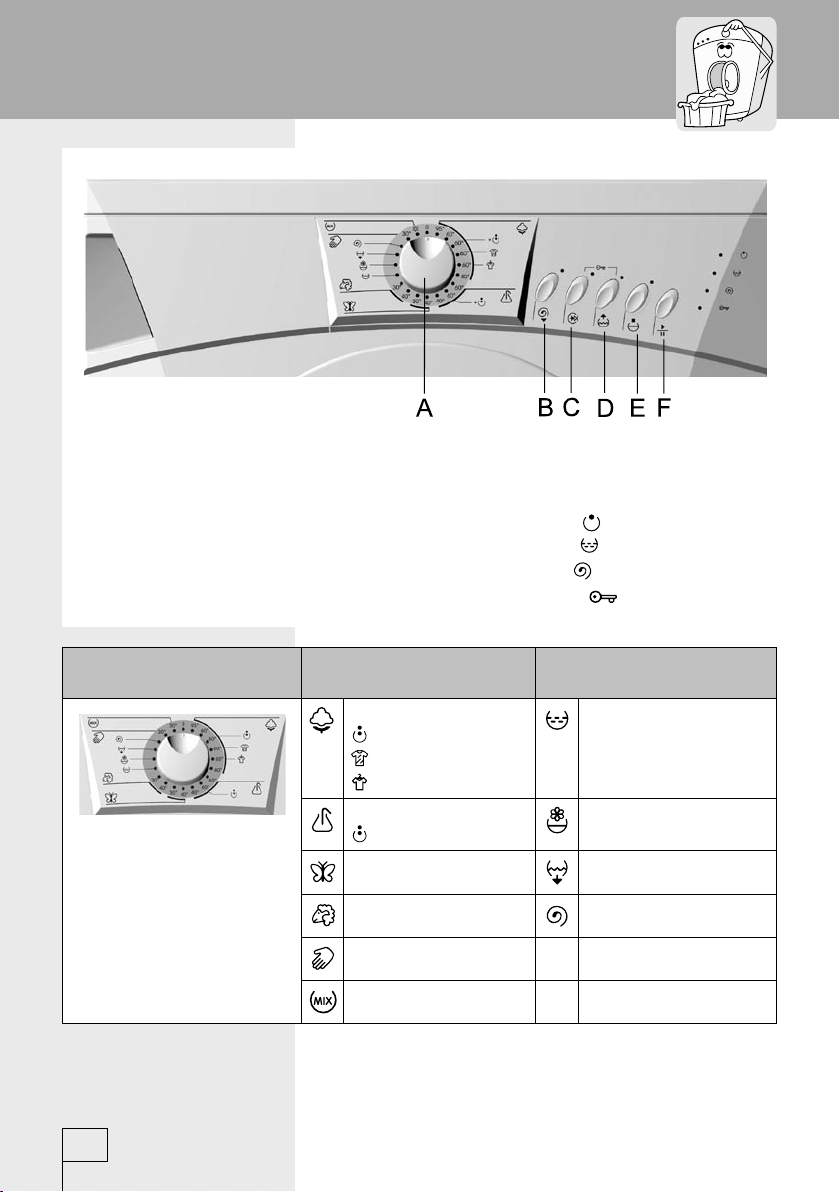

Operation

A - program selector

B - Spin speed reduction

C - Quick

D - Water plus

E - Rinse hold

F - START/PAUSE knob

Program selector

Signal LED’s:

- washing program stages

wash

•

rinse

•

spin

•

- Child lock

Basic programs

Cotton

Pre-wash

Intensive

Easy ironing

Synthetics

Pre-wash

Delicate Drain

Wool Spin

Hand wash

Mix

Partial programs

Rinse

Conditioning

10

Page 11

Washing procedure

- Open the door of the machine.

Door is opened by pulling the handle (lever) on

the right hand side of the door towards you.

Sort the laundry by the type of fabrics.

•

Load the laundry into the drum.

•

Close the door.

•

Open the water inlet tap.

•

Push the ON/OFF button and select the program.

•

Add washing and treatment agents (detergent and

•

softener).

Start the operation by pushing the START knob (F).

•

Do up buttons and zippers, tie strings and

pull out pockets.

Very delicate laundry should be put in a

special protective laundry bag.

It is suggested to load the drum with items

of different sizes.

Pay attention to the labels on clothes

which indicate the recommended washing

mode (see table of textile treatment

symbols on the last page of these

instructions).

Washing machine

operation

Program is selected by turning the program selector

(A) from the “0” position to the desired washing

program. The ON/OFF signal LED indicating

particular washing stage for the chosen program

starts ashing. The program selector (A) may

be turned in both directions, and the appropriate

program selected according to the type of laundry

washed and the required washing temperature (see

Program Chart for help). You may select basic or

partial programs.

Select additional functions by pressing their relevant

knobs.

11

Page 12

- Selection of basic programs ( , , , , , )

13

Basic programs represent integral programs

containing all washing stages, including softening

and spinning (see Program Chart Page 27).

Programs are selected by turning the program

selector (A) to the appropriate position.

Cottons: whites/coloured

Normally stained cotton and ax bed linen

underwear, table cloths, bathroom towels, top

garments, etc.

For heavily stained permanent press use the heavy

duty program, or program with a pre-wash .

If you wish the laundry not to be excessively

creased at the end of washing, use the easy ironing

program .

Synthetics - Permanent Press

Normally stained shirts, blouses and other polyester

and polyamide garments, or a mixture of these

fabrics with cotton.

For heavily stained permanent press use program

with pre-wash .

Delicates

This program is for delicate fabrics (dresses, skirts,

blouses) and curtains.

12

Wool

Especially gentle program for washing wool and

garments made from a mixture of other fabrics with

wool, appropriately marked for machine washing.

Hand wash

Very gentle program concluded with a short gentle

spin (max. 400 RPM).

It is suitable for washing fabrics from ax, silk, wool

or viscose, marked accordingly for hand wash.

Page 13

Mix

Special program for washing normally stained

coloured laundry made from various resistant fabrics

at 30°C.

- Selection of additional function

( , , , )

Additional functions alter the basic washing cycle

procedure. Particular function is switched on

by pressing the relevant knob. The selection is

conrmed with sound signal and switching on the

signal LED above the selected function. If certain

function is not available for the selected program,

signal LED will not illuminate.

The function is switched off by pressing the same

button again - signal LED goes off.

Select the particular function after the

selection of the basic program, but prior

pressing the START button (F).

Rinse hold (E)

This function is switched on after the selection of

•

a basic program by pressing the knob (E). It may

also be switched on during the operation, prior to

the last rinse. Indicator LED above the washing

cycle symbol is lit.

The program stops at the end of last rinse, prior

•

to spinning: laundry remains soaked in water and

prevents creases, if you are unable to remove

laundry from the drum immediately after the end

of the washing cycle.

Indicator LED above the knob is ashing.

•

The selected program is completed by pushing

•

the START button (F), but you may also apply

partial programs (pumping or spinning), but you

must rst return the program selector (A) to the “0”

position for at least one second, prior to selecting

any of the partial programs.

When program continues, indicator LED above

•

13

Page 14

the knob goes off.

15

Water plus (D)

For a better rinse, which is important for skin extra

•

sensitive to detergents.

For washing heavily stained laundry.

•

Quick program (C)

Convenient for washing less stained laundry.

•

Washing time is reduced (see Program chart).

•

Spin speed reduction (B)

Reduction of spin RPM depends on program

•

selection and maximum RPM for particular type of

machine.

Basic programs Spin speed - RPM

max. reduced

Cotton 800 500

Synthetics , Mix 800 600

Delicate 700 0

Wool 600 0

Hand wash 400 0

- Selection of partial programs ( , , , )

These are independent programs and may be used

when you do not need the entire washing program.

In case you would like to use more additional

programs in a sequence, you must turn off the

appliance prior any new program selection (turn the

program selector to “0” for at least one second).

14

Rinse

Independent program for rinsing delicate laundry,

without intermediate spinning and with short nal

spin. You may use it for rinsing hand washed

delicate laundry.

You may engage the reduced spin RPM knob.

Page 15

Conditioning

This program is intended for softening, bleaching or

impregnating washed laundry. It is completed with

an aggressive spin at high RPM.

You may engage the reduced spin RPM knob.

Drain

Use when the washing program was interrupted or

if the rinse hold function was engaged, and you only

wish to pump the water out of the drum, without

spinning.

Spin

Aggressive spinning for non-delicate laundry at high

spin RMP.

You may engage the reduced spin RPM knob.

- Adding washing and softening agents

(see Tips for washing and energy saving)

pre-wash compartment

•

main wash compartment

•

softener compartment

•

If you do not select a program which includes the

pre-wash feature, you may add washing detergent

directly into the drum, using the measuring vessel.

When adding softener, be careful to ll the

dispenser only up to the marked level.

Be sure to close the detergent dispenser

when opening/closing the appliance door.

15

Page 16

17

Start the operation

Push the START button (F). Sound signal

•

conrms the start, and the LED indicating

particular washing stages stops ashing. The

machine starts operating after a few seconds. If

the door is not properly closed after starting the

operation, the washing stage indicator LED starts

ashing again after a few seconds. When you

close the door, the machine initiates the selected

program.

As each washing stage is completed the relevant

•

washing stage indicator LED goes off and the

subsequent one goes on.

In case you would like to alter the washing

•

program after the initiated washing operation,

turn the program selector for one second to the

position “0”, followed by the selection of a new

program. Switching the machine off deletes any

previously selected additional functions (i.e. Rinse

hold), so they have to be reactivated.

Upon switching OFF, all additional pre-

selected functions are deleted; therefore

they must be switched-ON again.

If a power failure occurs during the

washing program, when the power is

restored the machine will resume the

execution of a program where it had been

interrupted.

16

- End of operation

Flashing LED’s for particular washing stages

indicate that the program has completed.

Sound signal indicates that you may now open

•

the door of the machine.

Extract the laundry from the drum and remove

•

any alien objects from the door gasket.

Leave the door ajar to allow the interior to dry.

•

Close the water inlet tap.

•

Switch the machine off by turning the program

•

selector to position “0”.

Page 17

Interruptions

By the user

•

Selecting RINSE HOLD function

Program is stopped when it comes to the RINSE

HOLD stage (drum door remains closed all the

time). Indicator LED above the knob (E) starts

ashing. Washing procedure is continued by

pressing the START knob (F).

Own (physical) interruption

You may stop the program by turning the program

selector to the position “0”. If there is water in the

drum select one of additional programs (drain, spin)

to empty the water and terminate the program.

PAUSE knob

By pressing the PAUSE knob (F) program may

be suspended at any time. After certain time you

may open the door if there is no water in the drum,

otherwise this is not possible. Program is continued

by pressing the START knob (F).

Failures

•

Program is suspended in case a failure occurs.

Signal LED’s are ashing and sound signal is

heard (see Failures page 24).

Power failure

•

If a power failure occurs the washing program is

interrupted, and when the power is restored. The

program is automatically resumed where it was

interrupted.

If a power failure occurs when the drum is

still full of water, be careful not to open the

door before you pump the water out.

17

Page 18

19

Special functions

Child lock

•

- It is switched on by simultaneously pressing

the water plus (D) and Quick program knob

(C) for at least 3 seconds. Selection is

conrmed by the sound signal and illuminated

signal LED. The function is switched off

following the same procedure.

- As long as the child lock function is engaged

you may not alter the program or additional

functions. You may merely switch off the

machine by turning the program selector (A) to

the position “0”. Child lock remains active even

after the appliance is switched off, and you

have to disengage it if you want to select a new

washing program.

Setting the sound signal

•

The appliance has the possibility of setting

stronger sound signal. Press the spin speed

reduction knob and switch the machine on. The

selection of the function is conrmed by the sound

signal. The function is disengaged following the

same procedure.

18

Page 19

Tips for washing and energy saving

Before washing sort out the laundry according

•

to the type, degree of dirtiness and colour

resistance.

Prior to selecting the washing program consult

•

the laundry tab of the germent with information on

washing of the garment (see Maintenance Chart

on Page 29).

Wash separately new coloured textile products

•

when washing for the rst time.

Wash heavily soiled laundry in small quantities

•

and add more detergent.

Treat stubborn stains with special stain remover. It

•

will save energy.

With lightly stained laundry select a washing

•

program without a pre-wash. Use a short program

and select lower washing temperature. This way

you can save up to 50% of energy.

Avoid washing too little quantities of laundry

•

because of energy saving and for better

performances of the appliance.

The largest allowed quantity of dry laundry is

•

indicated in the Program chart.

Before washing empty pockets, close zips

•

fasteners, and remove any metal fasteners or

badges that might clog the drain or damage the

laundry or drum interior.

Loosen stacked laundry prior inserting it into the

•

drum.

Use only detergents for front load machine wash.

•

Add powder or liquid detergents according to the

•

manufacturer’s instructions.

In case of hard water it is recommended to use

•

water softeners.

19

Page 20

21

Hardness

scale

1 - Soft 0-7 0-1,3 0-12 0-120

2 - Medium 7-14 1,3-2,5 12-25 120-250

3 - Hard 14-21 2,5-3,8 25-37 250-370

4 - Extra hard >21 >3,8 >37 >370

In case of hard water add detergent according to the Chart for

degree 1 and add appropriate quantity of water softener (see

manufacturer’s instructions).

If you do not select a program which includes the

•

pre-wash feature, you may add washing detergent

directly into the drum.

If you use thick liquid softener it is recommended

•

to dilute it with water, to prevent clogging of

dispenser compartment ducts.

Washing machine is equipped with the dispenser

•

partition gate, so you may pour liquid detergent

also into the central compartment. If you use

powder detergent the gate is lifted up, and in case

of liquid detergent it is slid down.

Liquid detergents are intended for main wash

•

only, without pre-wash.

Insert particularly delicate linen (stockings,

•

delicate underwear, etc.) into a special laundry

bag.

High spin RPM leaves less moisture in the

•

laundry which dries out much quicker in a tumble

dryer, thereby saving energy.

Degree of hardness

°dH(°N) m mol/l °fH(°F) p.p.m.

20

Do not put large clumps of detergent into

the soap dispenser as the tube in the

washing machine may clog.

Page 21

Cleaning and maintenance

Disconnect the washing machine from the

mains before cleaning!

The casing should be cleaned with a soft cloth

•

and mild detergent.

The interior of the drum and the door gasket is

•

cleaned by washing at 60°C without laundry and

adding half quantity of detergent.

If necessary, clean the detergent dispenser. Pull it

•

out from its casing completely by pressing the ap

(see Fig.).

If necessary, clean the cover of the bung under

•

running water.

21

Page 22

Wash under running water using a brush, and

23

•

then dry. Remove any leftover dried detergent

from the bottom of the casing.

Clean the water inlet hose screen frequently

•

under running water.

After each wash wipe the rubber door gasket. This

•

will prolong its useful life.

Open the lter lid using a at screwdriver or

•

similar tool.

22

The lter needs occasional cleaning, especially

•

following heavily linted or old laundry. Before

cleaning, drain any water from the machine via

the drain hose.

Page 23

Turn in an anti-clockwise direction, pull out and

•

clean under running water.

Insert the lter back as shown in the picture

•

(arrow and pointer), and tighten by turning in a

clockwise direction.

23

Page 24

25

Failures

The washing machine automatically monitors the

execution of particular functions during the operation,

and reports any detected failures. In such cases

both signal LED’s start ashing in certain sequence,

accompanied by the audible signal, sounding in the

same sequence as the indicator LED’s ash. The

ashing sequence changes in accordance with the

nature of the detected failure.

In some cases you may attempt removing certain

failures yourself.

The machine signals failures immediately after

detecting them and stops the program, except for

heater failure, where the machine completes the

washing program without heating water.

Failures

In certain cases you may remove the failure yourself.

If the WASH LED ashes twice check the door is

closed correctly.

Before calling for service check the following

troubleshooting charts on Page 25 & 26 of the

manual. If you are still unable to remedy the fault call

your nearest authorised service centre on

1300 652 100.

24

Service calls resulting from any failure arising due to

customer error or not checking the troubleshooting

chart are not covered by warranty and any repair

expenses are to be paid by the customer.

LED’s continue ash until the machine is switched off.

Interferences from the ambient (for example electrical

wiring) could induce signalization of different faults. In

such cases:

- switch the appliance off, and wait for a few seconds;

- switch the appliance back on and repeat the

washing program.

If the fault repeats, call authorized service shop.

Page 25

Failure Possible cause Remedy

The machine does not

work (indicator LED’s

are not illuminated).

Washing program

does not start (WASH

LED ashes twice).

Water does not enter

the machine (after

approx. 8 min the

machine reports

failure).

Water is leaking from

the machine.

The machine moves

during operation.

The machine vibrates

during the spin.

Excessive foaming

during washing.

Water is poorly

pumped out or not at

all (machine reports

failure).

Machine is not powered. Check if:

• power in the socket,

• the fuse is OK,

• plug is in the socket.

Door is not properly closed. Push it towards the machine.

Disturbed water inlet. Check if:

• the water tap is open,

• inlet hose lter is clean.

Push the START button.

Filter is not tightly screwed in.

Inlet hose is not tightly screwed

to the machine or to the water

tap.

Outlet hose has dislodged.

The machine is not properly

levelled.

Transport brackets are not

removed.

Unevenly distributed laundry,

especially with very small

quantities.

Excessive measure of detergent. Use washing powder according to

Water outlet is clogged. Check if:

Tighten the lter properly.

Tighten the inlet hose.

Afx the outlet hose to the drain.

Level the machine with the adjustable

legs.

Remove transport brackets.

This is normal, the machine will

reduce the RPM if vibrations are too

strong.

Wash larger quantity of laundry.

the manufacturers instructions and

according to water hardness and the

amount of soiling of the laundry.

Use only detergents for machine

washing.

• the lter is clean,

• outlet hose is not jammed,

• outlet hose is positioned higher than

1 m.

Push START again.

Laundry is not

properly spun.

No failure is reported.

The machine switched on the

UKS* function. Because of

uneven laundry balance, the

machine has automatically

reduced the spin RPM.

The machine operates normally.

Wash large and small pieces of

laundry together.

25

Page 26

27

Failure Possible cause Remedy

Greasy wads appear

on the laundry.

Laundry is stained

after washing.

Too little detergent (laundry was

very greasy).

You used liquid detergent or

detergent for coloured laundry

which does not contain whitener.

Wash the laundry again.

Add more detergent for such soiled

laundry, or use liquid detergent.

Use the detergent containing

whitener.

White powdery

residues on the

laundry.

Detergent residues in

the dispenser.

Softener is not

completely rinsed,

or water is left in the

dispenser dish.

Washing time is

longer than usual.

* UKS: universal stability control - this function prevents excessive vibrations during spinning.

It is not the consequence of bad

rinsing, but because of neophosphate detergents containing

non soluble components

(zeolites) for water softening.

Such substances may be

deposited upon the laundry.

Low water ow pressure.

Some detergents may stick to

the dispenser. Clean dispenser

regularly.

Cover is not correctly positioned

or is clogged.

• The UKS* function has been

activated because of uneven

laundry load.

• Power failure has occurred.

Immediately rinse the laundry once

again.

• Use liquid detergents which do not

contain zeolites.

• Try removing the residues with the

brush.

• Clean the inlet hose lter.

• In case of low water pressure

increase water level.

• Wipe the dispenser prior loading

detergent.

Clean the dispenser and rmly x the

cover in place.

• Washing program time may be

prolonged for 10 minutes and the

machine still functions perfectly.

• Time is prolonged for the power

failure period.

In case you were not successful in repairing the

malfunctions in spite of the above troubleshooting

chart call your nearest authorised service centre

on 1300 652 100. Service calls resulting from any

failure arising due to customer error or not checking

the troubleshooting chart are not covered by

warranty and any repair expenses are to be paid by

the customer.

26

Page 27

Tables

Program chart

Programs

Dispenser

Type of laundry

Max. load (kg)

Temp. (°C)

Cottons - white 6,5 95

Cottons - colour 6,5 60

Cotton with prewash 6,5 60

Cottons - intensive 6,5 60

800

Cottons - easy ironing 3 60

Cottons - colour 6,5 40

Synthetics / Permanents Press 3 60

Synthetics with prewash 3 60

800

Synthetics 3 40

Delicates 2,5 40

Delicates 2,5 30

Wool 2 40

Wool 2 30

700

600

Handwash 1,5 30 400

Mix 3 30 800

cold water

cold and hot water

* Testing program by EN 60456 with the selection of max. spin

RPM.

Additional

functions

Spin (RPM)

l l l l

l l l l

l l l

l l l

l l l l

l l l l

l l l l

l l l

l l l l

l l l l

l l l l

l l l l

l l l l

l l l l

l l l l

Duration (min.)

Water cons.

136 62

120 57

145 62

137 57

120 55

118 57

112 43

137 50

100 40

59 58

53 58

51 42

46 42

50 57

75 45

(L/cycle)

27

Page 28

29

Program chart/

Additional functions

Program

Basic programs

Cotton-white

Cotton-colour

Cotton with pre-wash

Cotton heavy

Cotton for easy ironing

Cotton

Synthetics

Synthetics with pre-wash

Delicate

Wool

Manual wash

Mix

Partial Programs

Rinse

Softening

Pumping water

Spinning

l possibility

Rinse hold

l l l l

l l l l

l l l

l l l

l l l l

l l l l

l l l l

l l l

l l l l

l l l l

l l l

l l l l

Water plus

Ouick

Spin speed

reduction

l

l

l

28

Page 29

Maintenance chart

Normal wash

Delicate wash

Whitening

Ironing Hot iron max.

Dry cleaning Dry cleaning in all

Drying Place on

Max.

washing

temp. 95°C

Whitening in cold water

200°C

solvents

Hang wet Hang

at surface

Max.

washing

temp.

60°C

Max.

washing

temp.

40°C

Hot iron max.

150 °C

Perchlorin-

etyhlene

R11, R113,

Kerosene

Max.

washing

temp.

30°C

Hot iron max.

110 °C

Dry cleaning in

kerosene, in pure

alcohol and in

R 113

High

temperature

Low

temperature

Manual

washing

Whitening not allowed

Washing

not

allowed

Ironing not

allowed

Dry cleaning not

allowed

Tumble drying

not allowed

29

Page 30

30

Page 31

WARRANTY AND SERVICE

DOMESTIC WARRANTY - FULL FIVE YEAR WARRANTY

In addition to all statutory rights which you, the Consumer, have under the relevant laws in respect

of this appliance, during the rst ve years of ownership as the original purchaser of this Kleenmaid

appliance, we guarantee that any fault caused by faulty material or workmanship becoming apparent

will be rectied free of charge for parts and labour, provided that all service is performed during normal

working hours by Kleenmaid or their designated Agents. Where the appliance is installed outside the

normal servicing area of the above, the Purchaser must pay for the cost of transporting the appliance

to and from the Agent or the Agent’s travelling cost to and from the Purchaser’s home.

COMMERCIAL WARRANTY - ONE YEAR WARRANTY

When this appliance is installed in a commercial application, you, the Consumer, have under the

relevant laws in respect of this appliance, during your rst one year of ownership as the original

purchaser of this Kleenmaid appliance, we guarantee that any fault caused by faulty material or

workmanship becoming apparent, will be rectied free of charge for parts and labour, provided that all

service is performed during normal working hours by Kleenmaid or their designated Agents. Where the

appliance is installed outside the normal servicing area of the above, the Purchaser must pay for the

cost of transporting the appliance to and from the Agent or the Agent’s traveling cost to and from the

Purchaser’s home.

WHAT THESE WARRANTIES DO NOT COVER

We are not responsible for any damage or malfunction unless caused by a defect in material or

workmanship. This includes but is not limited to abuse, misuse, improper installation and transportation

damage. We are not responsible for any consequential damages from any malfunction.

The Consumer must make the appliance available for servicing and shall bear any costs incurred

for any de-installation and/or re-installation required to make the appliance available for servicing.

Kleenmaid is not liable for any consequential damage incurred during de-installation or re- installation.

WARRANTY DOES NOT COVER REPLACEMENT OF LIGHT

GLOBES OR GLASS BREAKAGE DUE TO IMPACT

In case of fractured glass do not use your appliance.

WARRANTY REGISTRATION

Please complete warranty details below and retain together with your proof of purchase document

These documents will need to be viewed by our Service Representative should you request in warranty

service.

SERVICE ASSISTANCE

To assist you when phoning our After Sales Service number to arrange a service call please complete

the following details and have them ready when you call.

Model Number Date of purchase

Kleenmaid Store purchased from Date of installation

KLEENMAID AFTER SALES SERVICE

1300 652 100

Page 32

Other products available in the Kleenmaid

Range of appliances

Washers

Dryers

Dishwashers

Ovens

Cooktops

Outdoor Cooking Centres

Built In Espresso Coffee Machines

Rangehoods

Freestanding Ranges

Sinks

Waste Disposals

Taps

Cookware

Refrigerators

Freezers

Wine Cellars

Vacuum Cleaners

For sales information on the full range of quality appliances

Phone 13 13 08

PS PG2 KLE 130714/en (10-05)

Loading...

Loading...