Page 1

INSTRUCTIONS FOR USE

IMPORTANT – PLEASE READ THESE INSTRUCTIONS BEFORE USING THIS APPLIANCE

Page 2

I M P O R TANT USER INFORMAT I O N

These notes are provided in the interest of safety. You must read them before installing or

using the appliance.

– This tumble dryer is intended for NORMAL DOMESTIC USE ONLY.

– Please note it is not recommended that the dryer be placed directly next to ovens or

cookers, as the performance of the dryer may be affected.

– Any electrical work required to install the appliance should be carried out by a qualified

person.

– It is important to clean the lint filter after each drying cycle and the condenser every

three or four months or the restrictions to airflow will extend drying times and could

cause the safety cut-out to trip.

– Do not stack the tumble dryer on top of any other appliances without the correct stacking

kit.

– Under no circumstances should anything other than the recommended articles be

placed in the tumble dryer.

– The tumble dryer should be serviced by an appointed service organisation and only

genuine parts used.

– It is dangerous to alter or modify the product in any way other than fitting authorised

accessories.

– We recommend that the appliance is unplugged each time after use. It should always

be disconnected from the electricity supply if it is to be left unattended for long periods

(i.e. weekends, holidays etc.)

– The rear of the dryer gets quite hot during use. Position the dryer so that the back is not

accessible while in operation, but the sides have a space available to allow air flow.

– It is important to clean fluff from the window of the dryer and around the door seal after

each drying cycle. Failure to do so could result in water leaking.

– DO NOT use a two-way adaptor, or extension lead. The dryer must be connected to its

own socket.

– DO NOT block the air inlets at the front and back of your dryer.

– DO NOT allow fluff to accumulate around the tumble dryer.

– DO NOT exceed the recommended maximum load.

– DO NOT allow children to tamper with the controls and keep them away from the dryer

when it is in operation.

– DO NOT place articles in the dryer if anything other than a water solution has been used

in the cleaning process.

– DO NOT attempt to dry dripping wet articles or items containing foam rubber or rubber-

like materials.

– DO NOT use the tumble dryer if you suspect that it is damaged in any way. Under no

circumstances should you attempt to repair the appliance yourself. Repairs carried out

by inexperienced persons may cause serious injury. Consult your local appointed

service engineer and insist on genuine spare parts.

THIS APPLIANCE MUST BE EARTHED

Page 3

I N S TA L L AT I O N

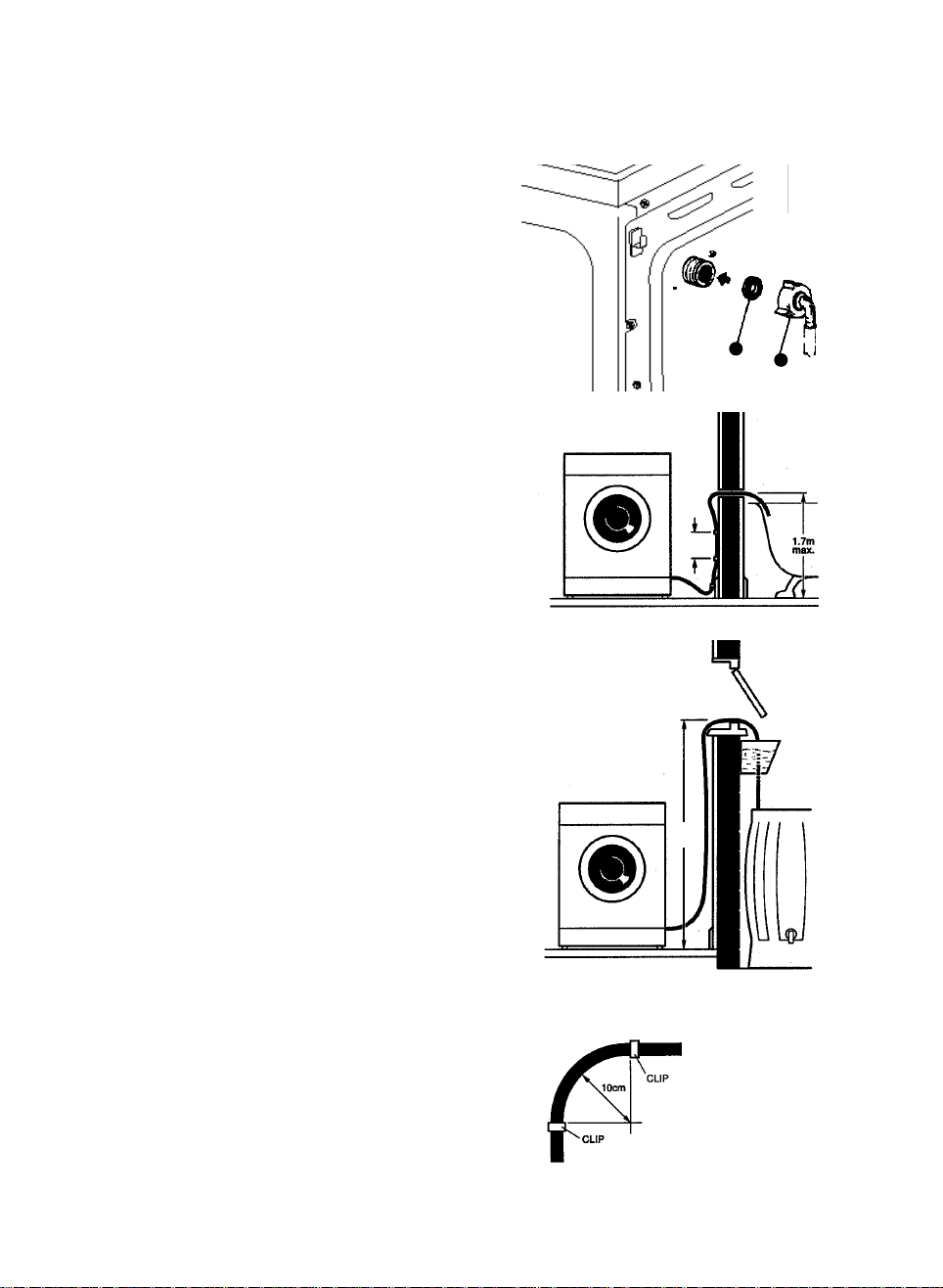

Connecting the Drain Kit

1. Unscrew the plastic nut J from the connector at

the top, rear of the machine. Keep the rubber

washer K.

3. Push the free end of the hose through the

threaded end of the nut and pull through so that

the flange of the plastic elbow, at the other end of

the hose is seated against the inside of the nut.

4. Insert the rubber washer K.

5. Screw the nut onto the connector on the back of

the machine and position the elbow ensuring the

nut is tight.

Your dryer does not need to be installed

adjacent to a drain.

It can be positioned up to 4m from the drain using the

kit provided (this can be extended using additional

hose if required). The small bore flexible outlet pipe

can easily run behind existing units or along a skirting

board.

If in doubt, consult an experienced plumber.

Figure 1

Figure 2

50cm

K

J

The outlet drain hose may be routed

through a wall, window or door frame.

(The water can be re used if collected) see

figures 1 and 2.

Caution: When discharging during cold periods

ensure that the hose is protected from freezing in

areas where the temperature will drop below 4˚C. The

hose must NOT be submerged in the discharged

water a gap of at least 10cm must be left between the

hose end and the surface of the water.

1. A 12mm hole can be drilled through the wall,

window or door frame, not more than 1.5m from

the dryer base. Check for pipes and wires

before commencing drilling.

2. Feed outlet hose through the hole.

3. Fix outlet hose to the wall or skirting board with

the clips supplied at 50cm intervals. When fixing

outlet hose around corners, ensure a minimum

radius of 10cm and fit two clips as shown in

Figure 3.

4. Cut outlet hose to the length required.

5. Check that the pipe is not kinked.

Figure 3

1.5m

max.

Page 4

Drain your dryer into a sink or bucket, see

Figure 4.

1. Fix outlet hose to the wall or skirting board if

required with the clips supplied at 50cm intervals.

When fixing outlet hose around corners, ensure a

minimum radius of 10cm and fit two clips as

shown in Figure 3.

2. Cut outlet hose to the length required.

Connect your dryer to an unused sink

drain outlet, see Figure 5.

If a blanking cap or plug is provided:

1. Remove cap/plug (1) and fit connector (2a) (not

supplied).

2. Connect elbow (not supplied) (3a) to connector

(2a).

3. Cut dryer hose (4) to length and insert into hole in

plug.

4. After the first run check the installation for leaks.

5. If water appears under your dryer, check that

the outlet hose is not kinked, blocked or

frozen.

Connect your dryer to a sink drain already

connected to a washing machine or

dishwasher, see Figure 6.

1. Remove washing machine/dishwasher drain

connector (1).

2. Fit elbows (2b & 2c) (not supplied).

3. Connect elbow (3a) (not supplied).

4. Cut dryer hose (4) to length and connect to elbow

(3a) (not supplied).

5. Reconnect washing machine/dishwasher drain (1).

6. After the first run check the installation for leaks.

If water appears under your dryer, check that

the outlet hose is not kinked, blocked or

frozen.

Figure 4

Figure 5

Figure 6

2a

3a

2c

Connect your dryer to a washing machine

standpipe, see Figure 7.

40mm standpipe

1. Cut the drain hose (4) to the length required and

insert into the standpipe alongside the washing

machine hose.

2. After the first run check the installation for leaks.

If water appears under your dryer, check that

the outlet hose is not kinked, blocked or

frozen.

3a

4

2b

Page 5

Figure 7

4

1.5m

max

FINAL INSTALLATION

Push the filter into its operating position as shown in the diagram.

If you wish to change the side on which your door opens, see the

instructions on the back page.

Remove any dust by wiping the drum and door with a damp cloth.

Any initial smell from the heater should disappear after the first

period of heating.

Page 6

T H E C O N T R O L S

A. THE TIMER

Select the required dryer time based on

the recommendations on the control panel.

B. HEAT SWITCH(ES)

Select the required heat setting based on

the recommendations on the control panel.

P R E PA R AT I O N

Check care labels inside the garments.

CARE LABELS YOU MAY FIND ON YOUR FABRICS

Suitable for tumble drying

Tumble dry using full heat

Tumble dry using half heat

AB

Do not tumble dry

Do not tumble dry woollen or wool mixture articles unless the article is labelled to be suitable due

to a possibility of shrinkage.

Roll dripping wet articles in a towel to remove excess water.

Place delicate articles e.g. tights, scarves, inside a pillowcase.

To avoid the need to iron easycare polyester/cotton items it is better to only dry small loads (i.e

half fill drum).

It is better to dry small and large articles together.

We suggest a fabric conditioner to be used to reduce static electricity.

Do not overload the dryer or dry large bulky items such as duvets or sleeping bags as it is

important that the airflow through the dryer is not obstructed.

Do not place items contaminated with inflammable substances in the dryer, such as petrol,

cleaning solvents, cooking oil, fat, or hair lacquer. These can cause fires. For the same reason,

do not dry rubber, foam rubber, plastic or paper.

Page 7

O P E R AT I O N

Open the door.

Load clothes loosely into the drum.

Load sheets first, starting with one corner.

Close the door.

Dry your hands.

Check that the timer is in the ‘0’ p o s i t i o n .

Plug in the machine.

Select correct heat position (see programme chart on control panel for recommendations).

Set the timer to the required time setting (see programme chart on control panel for

r e c o m m e n d a t i o n s ) .

The drum will begin rotating. Reversing drum models will stop every few minutes to rotate in the

reverse direction for a short time.

Should the clothes become dry before the cycle has finished, or if an excessive programme time

has been selected, the drum will continue to rotate while the thermostat will automatically switch

the heater off to prevent over-drying and save energy.

There is an automatic 12 minute cool down period at the end of every cycle, during which the heater

is switched off. This helps to minimise creasing.

NEVER SWITCH THE DRYER OFF AND LEAVE A HOT LOAD IN THE DRUM.

When drying large items such as sheets, we suggest you periodically stop the dryer to

redistribute the load.

To stop the machine during the middle of the programme simply open the door; the drum will

stop rotating automatically and restart when you close the door.

To lengthen or shorten a timed programme, reset the timer knob.

AFTER REMOVING THE DRIED CLOTHES:

ALWAYS CLEAN THE FILTER. Failure to do so could cause the safety cut-out to operate.

– Pull the filter upwards and away from the appliance.

– Remove any threads or fluff by hand or with a soft brush.

– Slide the filter back.

– Wash the filter occasionally in detergent solution using a soft

brush to remove small particles.

Page 8

T H E C O N D E N S E R

The condenser and ducting should be cleaned 3 or 4 times a year or more frequently if the dryer is

in constant use. See “CLEANING THE CONDENSER” opposite.

NOTE: The condenser will discolour through use.

REMOVING THE

CONDENSER

– Slide the condenser grille catch to the left.

– Firmly pull the condenser out.

RE-INSTALLING

THE CONDENSER

– Carefully push the condenser back into the machine,

until it is pushed fully home and a “click” is heard.

– Ensure all lint and fluff is removed from around the

grille seal before closing or water may leak.

– IMPORTANT: The dryer may leak if the condenser is

not correctly re-installed.

CLEANING THE CONDENSER

CAUTION: For maximum efficiency, the plates are made

from very thin aluminium and are easily damaged. Do not

try to poke anything between the plates or use a hard

object or tool for cleaning. At all times, handle the

condenser carefully and avoid crushing the plates.

– Remove the condenser (see opposite).

– Flush the fluff from between the plates under running

water and carefully shake off excess water.

– Whilst the condenser is removed, clean as much fluff

as possible from inside the ducting by reaching a hand

into the machine. In particular, keep the passage from

the fan clear (on the right hand side of the condenser

duct).

– After cleaning, re-install the condenser (see opposite).

Page 9

REVERSING THE DOOR OPENING

Your dryer is supplied with a reversible door. To change the direction of opening proceed

as follows for your type of door.

Dryers fitted with hinge cover:-

Open the door. Undo screw (A)

remove switch strike (B) and

replace screw. Undo screw (J) and

remove buff e r. Remove screws (C)

and latch plate (D). Remove hinge

cover screw (E). Close the door.

Pull the hinge cover (F)

forwards to remove it.

Remove two outer screws

(G). Remove door. Fit latch

plate (D) with screws (C).

Fit screw (E) to secure hinge

cover. Remove screw (H) at

top of door and refit switch

strike (B) as shown. Refit

buffer (J).

Dryers fitted without hinge cover:-

Open the door. Undo screw (A)

remove switch strike (B) and

replace screw. Undo screw (J) and

remove buffer. Remove screws (C)

and latch plate (D). Remove hinge

block screws (E). Remove door

from hinge blocks.

Remove hinge screws (F)

and hinge (G) and refit to

opposite side as shown.

Reverse door and fit to dryer

in closed position. Refit

screws (G) and hinge cover

(F). Open the door.

Refit latch plate (D) with

screws (C). Remove screw

(H) at top of door and refit

switch strike (B) as shown.

Refit buffer (J). Fit door to

hinge blocks and secure with

screws (E).

Page 10

A D D I T I O N A L I N F O R M AT I O N

ANY PROBLEMS

If the clothes are not dry after normal drying time:

– Check that you used the correct heat setting.

– Check that you have not set the timer within a cool down period.

– Check that the lint filter has been cleaned. Ablocked filter will restrict the airflow.

– Check that the condenser unit and associated duct work are clean. If blocked these will

restrict the airflow.

– Check that your dryer is heating - below the door to the left side, should feel warm to the

touch after the first 10-15 minutes of its programme. Failure to heat may indicate the safety

cut-out has operated. To reset, simply press the red button at the rear of the machine. If it

has operated then a sharp “click” will be heard. This cut-out only operates if the airflow is

severely restricted so make sure the filter is clean and that all other restrictions are

removed before re-starting.

If the cut-out continues to operate after checking the above points, you should contact your

service agent.

If your machine does not work check the following before calling a service engineer:

– Check that there is a supply of electricity.

– Check that the door has been properly closed and the machine is switched on.

– Check that the condenser has been pushed back into the machine.

– Check the plug internal connections.

TECHNICAL DATA

OVERALL DIMENSIONS:

Height: 85 cm

Width: 59.5 cm

Depth: 58 cm

MAXIMUM DRY WEIGHT LOADS:

Cotton 6kg

(for minimum creasing 2kg)

Delicates 2kg

For electrical ratings see plate on back of dryer.

For Model No. see serial plate inside door (needed when requesting service).

Room temperature range 5˚C to 30˚C.

Your washing machine should have a spin speed of not less than 800rpm.

Loading...

Loading...