Page 1

Instructions for Use

and Warranty Details

Gas Cooktops CH24 - 60cm White

CH25 - 60cm Stainless Steel

CH26 - 60cm Black

CH35 - 90cm Stainless Steel

CH84

W

- 60cm White - Flame Failure

CH85S - 60cm Stainless Steel - Flame Failure

CH86B - 60cm Black - Flame Failure

CH95S - 90cm Stainless Steel - Flame Failure

Page 2

• 2 •

ongratulations on the purchase of your new

Kleenmaid appliance. This appliance has been

designed and manufactured to give you years of

reliable performance. For best results, carefully

read the instructions on how to install your

new appliance. Correct installation will avoid delays and

unnecessary service calls.

Once installation is complete, read this booklet and get to

know the controls and the features of your new appliance.

If you need further information call our

Customer Call Centre

1 800 072 144.

We reserve the right to alter the specifications with no

influence on the operation of the appliance. This instruction

manual cannot be reason for a claim.

Page 3

• 3 •

CAUTION:

✓ This appliance must be installed in accordance with

these installation instructions and the requirements of

the local gas authority or the appropriate installation

code issued by the A.L.P.G.A. and A.G.A. (Refer to

AG601 Code), or the Building Authority requirements.

✓ This appliance shall only be serviced by authorized

personnel.

WARNING:

✓ This appliance is to be installed only by an authorised

person.

✓ This appliance must be used only for the task it has

explicitly been designed for, that is for cooking

foodstuffs. Any other form of usage is to be

considered as inappropriate and therefore dangerous.

✓ Do NOT place combustible materials or products on

this appliance at any time.

✓ Do NOT spray aerosols in the vicinity of this

appliance while it is in use.

Natural Gas LPG

Test Point

1.0 2.75

Pressure (kPa)

Burner Injector Orifice Gas Consumption Injector Orifice Gas Consumption

[mm] [MJ/h] [mm] [MJ/h]

Simmer 0.70 2.4 0.47 2.9

Semi-rapid no.1 0.90 4.0 0.60 4.7

Semi-rapid no.2 1.15 6.5 0.76 7.5

Rapid 1.35 9.3 0.83 9.0

Wok burner 1.45 11.0 0.90 10.4

Fish warmer 1.45 11.0 0.90 10.4

(Note: Gas type sticker and data plate are attached to the underside of the base of the appliance.)

NOMINAL GAS CONSUMPTION AND INJECTOR SIZES (Table 1):

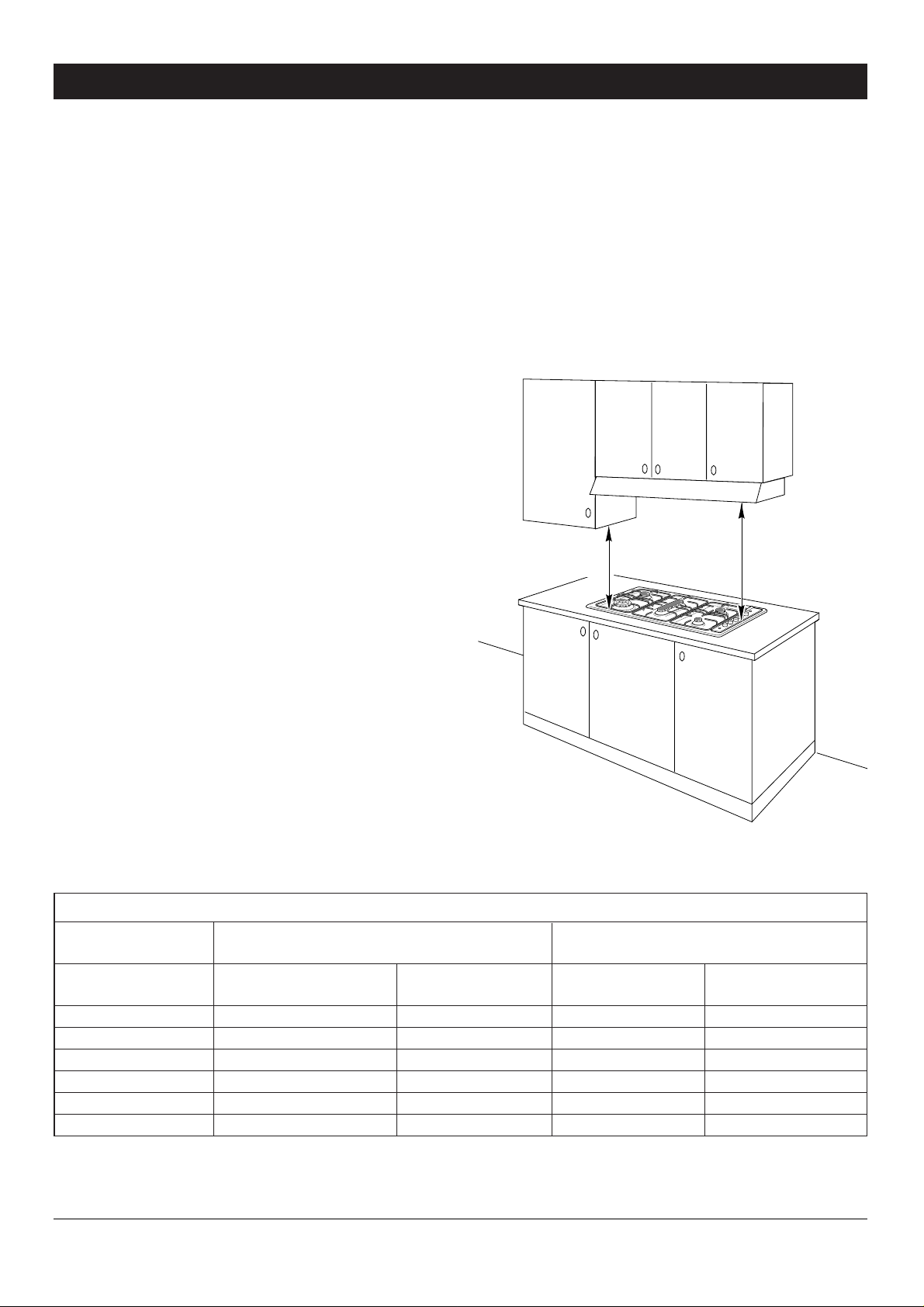

CLEARANCES:

Installation clearances and protection of combustible

surfaces shall comply with section 5.12 of AG 601 - 1995.

Figure 1

650 mm

450 mm

INSTALLATION

Page 4

• 4 •

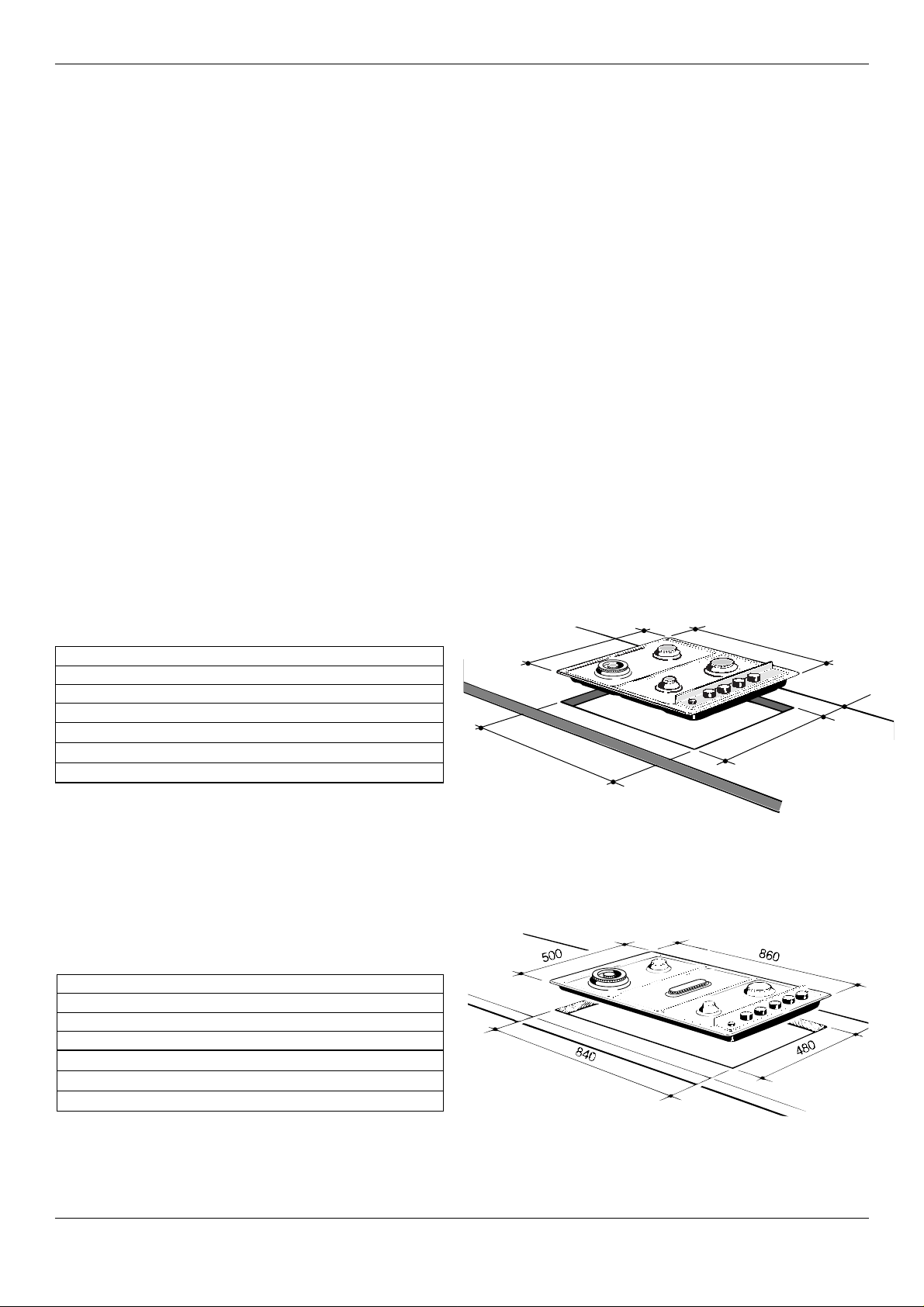

DIMENSIONS (Table 3):

Models: CH35 - CH95S

(Note: Also refer to Figure 3 side)

General Dimensions

Width 860 mm

Depth 500 mm

Depth Below Mounting Surface 30 mm

Cut-out Dimensions

Width 840 mm

Depth 480 mm

Figure 3

General Dimensions

Width 580 mm

Depth 500 mm

Depth Below Mounting Surface 30 mm

Cut-out Dimensions

Width 560 mm

Depth 480 mm

Figure 2

The installation shall comply with the dimensions in

Figures 2 and 3, bearing in mind that:

✓ A minimum clearance of 20 mm has to be kept

between the bottom of the cooking hob and the top

of an appliance or a shelf.

✓ A partition between the base of the hob and the

cupboard below should be fitted 100 mm below the

workbench surface if the cupboard is to be used for

storage.

✓ Overhead clearances - In no case shall the clearance

between the highest part of the hob and a range hood

be less than 600 mm, or for an overhead exhaust fan,

750 mm. Any other downward facing combustible

surface less than 600 mm above the highest part of the

hob shall be protected for the full width and depth of

the cooking surface area in accordance with Clause

5.12.1.2 of AG 601. However, in no case shall this

clearance to any surface be less than 450 mm.

✓ Side clearances - Where the dimension from the

periphery of the nearest burner to any vertical

combustible surface is less than 200 mm, the surface

shall be protected in accordance with Clause 5.12.1.2

of AG 601 to a height of not less than 150 mm above

the hob for the full dimension (width or depth) of the

cooking surface area.

✓ Protection of combustible surfaces - AG 601 Clause

5.12.1.2 specifies that where required protection shall

ensure that the surface temperature of the combustible

surface does not exceed 50 °C above ambient. The

fixing of 5 mm thick ceramic tiles to the surface or

attaching fire resistant material to the surface and

covering with sheet metal with minimum thickness of

0.4 mm would satisfy this requirement.

DIMENSIONS (Table 2):

Models: CH24 - CH25 - CH26

CH84W - CH85S - CH86B

(Note: Also refer to Figure 2 side)

560

500

580

50

480

Page 5

• 5 •

INSTALLATION

(Refer to Figures 4 and 5):

1. Spread out the gasket “C” over the workbench at the

edge of the cut out taking care to overlap the gasket

at the corners.

2. Slot in the cooking hob into the cut out of the

workbench and locate it correctly.

3. Adjust the clamps “A” and tighten the screws “B” until

the hob is firmly secured.

4. Using a sharp tool, trim any excess gasket which

protrudes from the edge of the hob.

5. Assemble the three piece burners. Take care to

properly locate the assembled burner on the burner

base.

B

C

A

Figure 4

20 mm min.

40 mm max.

B

C

A

GAS SUPPLY:

✓ This appliance is suitable for use with Natural Gas or

LPG. (Check the “gas type” sticker attached to the

appliance).

✓ For Natural Gas models the gas supply is connected to

the pressure regulator which is supplied with the

appliance. Adjust the regulator to obtain a test point

pressure of 1 kPa with the two largest burners

operating.

✓ For LPG models connect the gas supply directly to the

appliance inlet connection and ensure that the supply

pressure is regulated to 2.75 kPa.

✓ Do NOT force the “elbow” rotation prior to

loosening the nut.

✓ Do NOT over tighten the nut at the “elbow”.

1. After connecting the gas supply, check the piping and

connections for leaks using a soap and water solution.

The presence of bubbles indicates a leak, tighten or

replace connections as appropriate.

2. Adjust the test point pressure or supply pressure to

the value which is appropriate for the gas type.

3. Turn on the appliance gas controls and light each

burner. Check for a well defined blue flame without

any yellow tipping. If any abnormality is evident then

check that the burner cap is located properly and the

injector nipple is aligned correctly.

4. Check the minimum burner setting by quickly rotating

the gas control knob from the maximum to the

minimum position, the flame must not go out. If

adjustment is required carry out the “minimum burner

setting adjustment" procedure described below.

5. If satisfacfory performance cannot be obtained isolate

the appliance and contact the local gas authority for

advice and assistance.

Figure 5

20 mm min.

40 mm max.

Page 6

• 6 •

INJECTOR REPLACEMENT:

This appliance is suitable for use with Natural Gas or

LPG. (Check the “gas type” sticker attached to the

appliance.) The nominal gas consumption and injector size

details are provided in Table 1 on page 3.

To replace injectors

1. Remove the knobs and ignition push button

2. Unscrew the “A” screw in Figure 6

3. Remove the control panel “B” in Figure 6

4. With a wrench “C” replace the injectors “J” with

those suitable for the gas to be used (see Figure 7).

A

B

Figure 7

Figure 6

C

J

J

MINIMUM BURNER SETTING

ADJUSTMENT:

To regulate the flame follow the instructions below:

• Light the burner

• Set the cock valve to minimum

On gas valves provided with adjustment screw in

the centre of the shaft (fig. 8a):

• Using a screwdriver with max. diameter 3 mm, turn the

screw inside the tap until the correct setting is

obtained.

On gas valves provided with adjustment screw on

the valve body (fig. 8b):

• Turn the screw “A” to the correct setting with a

screwdriver.

Figure 8b

Figure 8a

A

Page 7

• 7 •

ELECTRICAL REQUIREMENTS:

WARNING:

✓ THIS APPLIANCE MUST BE EARTHED.

CAUTION:

✓ Ensure that the power outlet is properly earthed

before connecting the appliance.

✓ Disconnect power before servicing the appliance.

The appliance is provided with a standard 240VAC three

pin plug and power cable (3X0.75 mm2).

The wires in the power cable are coloured in accordance

with the following code: Green/Yellow = Earth, Blue =

Neutral, Brown = Active.

If the colours of the wires in the power cable to the

appliance do not correspond with the coloured markings

identifying the terminals in the junction terminal, proceed

as follows:

1. The wire which is coloured green and yellow must be

connected to the terminal marked E (Earth) or

coloured Green.

2. The wire which is coloured blue must be connected to

the terminal marked N (Neutral) or coloured Black.

3. The wire which is coloured brown must be connected

to the terminal marked L (Live) or A (Active) or

coloured Red.

WIRING DIAGRAM:

IGNITION

MODULE

240 VAC

50 Hz

0.5 VA

DANGER 240 VAC

Ignition

Switch

To Electrodes

A

N

E

CH24 - CH25 - CH26

CH84W - CH85S - CH86B

CH35 - CH95S

Figure 9

Figure 10

REPLACEMENT OF IGNITION

MODULE/ELECTRODES/GAS COCKS:

1. Turn off and disconnect gas supply and electricity.

2. Lift off trivets and burner heads, and pull off igniter

and control knobs.

3. Undo the screws “B” and remove the clamps “A”

shown in Figure 4 and remove the hob.

4. Remove screws securing the top of the hob to the

base pan and lift it off.

5. To replace the electrode, unhook the locking spring

and remove the electrode and cable.

6. To remove the igniter module, disconnect the

electrodes, power and igniter switch wires, undo the

two retaining screws and remove the module.

7. To remove the gas cock undo the two screws which

secure it to the gas manifold. On re-assembly ensure

that the injectors are aligned with the burner venturi.

8. Reassemble in reverse order

9. Check all connections for gas leaks with soapy water

(including gas cocks if they have been removed).

GAS COCK LUBRICATION:

1. Turn off gas supply and disconnect electricity.

2. Remove the knobs and ignition push button

3. Unscrew the “A” screw in Figure 6

4. Remove the control panel “B” in Figure 6

5. Unscrew the two screws on top of the gas cock

6. Lift out the valve cone, clean it with solvent and regrease it with high temperature grease

7. Replace the valve cone, move it around and remove

excess grease. Remove it once again and check that

internal holes or galleries are not blocked.

8. Replace and reassemble in reverse order.

9. Check for gas leaks with soapy water.

Ignition

Switch

A

N

E

DANGER 240 VAC

IGNITION

MODULE

240 VAC

50 Hz

0.5 VA

To Electrodes

Page 8

• 8 •

CAUTION:

✓ This appliance must be used only for the task it has

explicitly been designed for, that is for cooking

foodstuffs. Any other form of usage is to be

considered as inappropriate and therefore dangerous.

Do not use this appliance as a space heater.

✓ Do NOT place combustible materials or products on

this appliance at any time.

Operates right rear burner

Operates left rear burner

Operates middle burner

Operates left front burner

Operates right front burner

Ignition

Semi rapid

burner no. 1

Semi rapid

burner no. 1

Wok

burner

Wok

burner

Fish

warmer

Simmer

burner

Simmer

burner

Semi rapid

burner no. 2

Semi rapid

burner no. 2

Figure 12

CH35 - CH95S

Operates right rear burner

Operates left rear burner

Operates left front burner

Operates right front burner

Ignition

Figure 11

CH24 - CH25 - CH26

CH84W - CH85S - CH86B

✓ Do NOT spray aerosols in the vicinity of this appliance

while it is in use.

✓ Before using for the first time, clean the cooktop with

warm soapy water.

✓ Use the coffee pot support to ensure that small

cooking utensils are stable.

USE and CARE

Page 9

• 9 •

✓ Check that the electricity is switched on to allow

spark ignition.

✓ Make sure that all controls are turned to zero.

✓ The gas flow to the burner is controlled by a knob

operating on a safety tap. You control the flow by

turning the knob indicator to line up with the following

symbols:

symbol ● : Off

symbol : full on (nominal rate)

symbol : reduced rate

✓ To ignite automatically, simply push the required knob

down and turn it to maximum, then press ignition

continuously until the burner lights. When the flame is

lit, you can control the temperature by the knob.

✓ To switch off, turn the knob clockwise until you hear

the safety click.

✓ Note that, if you are using a burner at the minimum

setting, you turn the knob clockwise past the maximum

setting before reaching the off position.

COOKING HINTS FOR GAS HOBS

✓ The burners are different sizes, and can be used in

different ways.

✓ The largest can be used for boiling, to seal meat or

foods that are cooked quickly, and the smallest for

stews and sauces.

✓ Always ensure that you use the correct size of

saucepan.

✓ For fast boiling, make sure the flame just reaches the

edge of the pan. Flames going up the side of the pan

means wasted heat and the contents of the pan will

take longer to boil.

Figure 13

CORRECT USE OF DOUBLE-RING

BURNER

✓ The flat-bottomed pans are to be placed directly onto

the pan-support.

✓ To use the WOK you need to place the proper stand

in order to avoid any faulty operation of the wok

burner.

WRONG

Figure 14

Figure 15

CORRECT

To ignite the burners with flame failure device:

1. Turn the knob counter-clockwise to the “full on” position,

then maintain this pressure

2. Press ignition continuously until the burner lights.

3. Wait for about 10 seconds after the gas burner has been lit

before letting go of the knob (security valve activation

delay)

4. You can control the temperature by the knob.

If the burner flame should go out for same reason, the safety

valve will automatically stop the gas flow.

Page 10

• 10 •

CLEANING AND MAINTENANCE

GENERAL ADVICE

✓ It is advisable to clean when the appliance is cold and

especially when cleaning the enamelled parts.

✓ Avoid leaving alkaline or acidic substances (lemon juice,

vinegar, etc.) on the surfaces.

✓ Avoid using cleaning products with a chlorine or acidic

base.

ENAMELLED PARTS

✓ All of the enamelled parts must be washed only with a

sponge and soapy water or with non-abrasive products.

Dry, preferably, with a soft cloth or chamois.

STAINLESS STEEL

✓ Clean with a suitable product. Always dry fully with a

soft cloth or chamois.

BURNERS AND RACKS

✓ These parts may be removed and washed with suitable

products.

✓ The burners and their caps must be well dried after

cleaning and put back perfectly into their slots. It is

very important to verify the positioning of the burnercaps because a misplacing in their slots can cause

serious damage.

✓ In the appliances with electrical ignition for the

burners, verify that the electrode is always cleaned well

to permit a regular spark.

SERVICE AND MAINTENANCE

If the ignition spark fails to operate or does not light the

gas check the following items before calling the authorized

service agent:

✓ Burner is reassembled and located correctly.

✓ Spark electrode and white ceramic are clean and dry.

✓ 240 VAC power supply is connected.

Contact the local gas utility or the authorized service

agent if:

✓ You can smell gas when all burners are turned on.

✓ The burners do not remain alight at the minimum

marked setting

✓ The burner flame is yellow or emits an unusual odour

Note that a bi-annual inspection of the appliance by an

authorized service agent or your local gas utility will

ensure many years of trouble free operation of your

appliance.

Page 11

• 11 •

WARRANTY AND SERVICE

DOMESTIC WARRANTY - FULL FIVE YEAR WARRANTY

In addition to all statutory rights which you, the Consumer, have under the relevant laws in respect of this appliance,

during the first five years of ownership as the original purchaser of this Kleenmaid appliance, we garantee that any fault

caused by faulty material or workmanship becoming apparent will be rectified free of charge for parts and labour, provided

that all service is performed during normal working hours by Kleenmaid or their designated Agents. Where the appliance

is installed outside the normal servicing area of the above, the Purchaser must pay for the cost of transporting the

appliance to and from the Agent or the Agent’s travelling cost to and from the Purchaser’s home.

COMMERCIAL WARRANTY - ONE YEAR WARRANTY

When this appliance is installed in a commercial application, you, the Consumer, have under the relevant laws in respect

of this appliance, during your first one year of ownership as the original purchaser of the Kleenmaid appliance, we

garantee that any fault caused by faulty material or workmanship becoming apparent, will be rectified free of charge for

parts and labour, provided that all service is performed during normal working hours by Kleenmaid or their designated

Agents. Where the appliance is installed outside the normal servicing area of the above, the Purchaser must pay for the

cost of transporting the appliance to and from the Agent or the Agent’s travelling cost to and from the Purchaser’s home.

WHAT THESE WARRANTIES DO NOT COVER

We are not responsible for any damage or malfunction unless caused by a defect in material or workmanship. This

includes but is not limited to abuse, misuse, improper installation and transportation damage. We are not responsible for

any consequential damages from any malfunction.

WARRANTY DOES NOT COVER REPLACEMENT OF LIGHT GLOBES OR GLASS

BREAKAGE DUE TO IMPACT

In case of fractured glass do not use your appliance.

WARRANTY REGISTRATION

Please complete the enclosed warranty card and post it to us or phone our Customer Call Centre.

SERVICE ASSISTANCE

To assist you when phoning our Customer Call Centre number to arrange a service call please complete the following

details and have them ready when you call.

Model Number:.................................................................................... Date of purchase:.....................................................

Kleenmald Store purchased from:.................................................. Date of installation:..................................................

KLEENMAID CUSTOMER CALL CENTRE

CONTACT NUMBER

1 800 072 144

Page 12

• Ed. 2 - 1101156.1 •

ß8

Loading...

Loading...