Page 1

International

Bottom Freezer

Refrigerator

Owner's Manual

BX521VE BX521VW

Keep these instructions for future reference. Be sure this

manal stays with refrigerator .

Page 2

ongratulations on the purchase of your new appliance. This appliance

has been designed and manufactured to give you years of reliable

C

install your new appliance. Correct installation will avoid delays and

unnecessary service calls.

Once installation is complete, read this booklet carefully and get to know the

controls and the features of your new appliance.

We reserve the right to alter the specifications with no influence on the

operation of the appliance. This instruction manual cannot be reason for

claim.

performance. For best results, carefully read the instructions on how to

For appliance please phone

1300 652 100

Kleenmaid St George Store

131308

Page 3

Contents

!

!

Parts and Accesories.................................................................... 2

Electrical Requirements ................................................................ 2

Model Identification........................................................................ 2

Service ......................................................................................... 2

Proper Disposal of Y our Refriger ator.............................................. 3

Space Requirements..................................................................... 3

Instructions for Installation............................................................. 4

T o Remov e Doors and Hinges .................................................. 4

T o Replace Doors ..................................................................... 4

Connect Ice Maker Water Supply Line (some models)............... 5

Leveling Refrigerator ..................................................................... 6

Installation Checklist ..................................................................... 7

Controls ........................................................................................ 8

Fresh Food and Freezer Controls ............................................. 8

Setting Controls......................................................................... 8

Fresh Food Features .................................................................... 8

Fresh Food Shelves.................................................................. 8

Beverage Organizer.................................................................. 8

Adjustable Deli Drawer

Garden Fresh

Chiller Fresh

Storage Rack (some models)...................................................10

Covered Storage Bucket (some models)..................................10

Dairy Center (some models) .................................................... 10

Door Buckets ........................................................................... 11

T all P ackage Retainer .............................................................. 11

Door Shelves ...........................................................................11

Adjustable Divider (some models) ............................................11

Bottle Holder ............................................................................11

Freezer Features.........................................................................12

Frost-Free System...................................................................12

Automatic Ice Maker (some models) ........................................12

Ice Service Rack (some models) .............................................12

Slideout Shelf (some models) ................................................... 12

V ertical Shelf Divider (some models) ........................................12

Fixed Wire Shelf (some models)...............................................12

Wire Basket (some models) .....................................................13

Ice Bin (some models) .............................................................13

Vertical Basket Divider .............................................................1 3

Tilt-Out Bin (some models).......................................................13

Pullout Drawer Baskets (some models)....................................13

Ice Shield (some models) .........................................................13

Care and Cleaning .......................................................................14

General Cleaning .....................................................................14

Stainless Steel Cleaning ...........................................................1 4

Adhesives ................................................................................14

Door Gaskets .......................................................................... 14

Condenser Coils ......................................................................14

Glass Shelves..........................................................................14

Odor Removal..........................................................................14

Light Bulb Replacement ............................................................15

Vacation Tips................................................................................1 5

Energy Tips..................................................................................15

Normal Operating Sounds ............................................................16

Before Calling For Service............................................................17

Note: T r anslation may sometimes cause variations in meaning. In all

cases where meaning varies, the most accurate meaning will be the

English version of this document.

TM

TM

Recognize this symbol as a safety precaution.

TM

Crisper ............................................................ 9

System (some models) ..................................... 9

(some models)................................... 9

Parts and Accessories

Purchase replacement parts and additional accessories

(e.g. refrigerator shelves) over the phone. To order

accessories for your product, call 1-800-843-0304 inside

U.S.A. or 319-622-5511 outside U.S.A., or contact us on

the internet at www.amana.com.

Electrical Requirements

WARNING

To avoid electrical shock which can cause severe

personal injury or death do not cut or remove the round

grounding prong from the plug. Refrigerator must be

grounded at all times. Do not remove warning tag from

power cord.

Do not use a two-prong adapter. Do not use an

extension cord.

This refrigerator is equipped with a three-prong

(grounding) plug for protection against possible

shock hazards. If a two-prong wall receptacle

is encountered, contact a qualified

electrician and have the two-prong wall

receptacle replaced with a properly grounded

three-prong wall receptacle in accordance

with the National Electrical Code.

Refrigerator is designed to operate on a separate 230

volt, 10 amp., 50 Hz line.

Model Identification

Thank you for purchasing this Amana® refrigerator. Please

read this Owner's Manual thoroughly. This manual

provides proper maintenance information. Any questions,

call the Consumer Affairs Department at 1-800-843-0304

inside U.S.A. and 1-319-622-5511 outside the U.S.A., or

contact us on the internet at www.amana.com.

When contacting Amana , provide product information.

Product information is on the serial plate, located on the

ceiling of fresh food section. Record the following

information.

Model Number: _________________________

Manufacturing Number: _________________________

S/N or Serial Number: _________________________

Date of Purchase: _________________________

Dealer's name and address: ________________________

________________________________________________

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. Any questions or to

locate an authorized servicer, call 1-800-NAT-LSVC

(1-800-628-5782) inside U.S.A. 319-622-5511 outside

U.S.A. Warranty service must be performed by an

authorized servicer. Amana also recommends contacting

an authorized servicer if service is required after warranty

expires.

2

Page 4

!

DANGER

!

Proper Disposal of Your Refrigerator

IMPORTANT: Child entrapment and suffocation

are not problems of the past. Junked or abandoned

refrigerators are still dangerous-even if they will sit for "just a few days." If you

discard an old refrigerator, please follow the

instructions below to help prevent accidents.

BEFORE BEFORE

BEFORE

BEFORE BEFORE

REFRIGERAREFRIGERA

REFRIGERA

REFRIGERAREFRIGERA

• Take off the doors.

• Leave the shelves in place so that children may

not easily climb inside.

YY

OU OU

THRTHR

OO

Y

OU

THR

YY

OU OU

THRTHR

TT

OR OR FREEZER:OR OR FREEZER:

T

OR OR FREEZER:

TT

OR OR FREEZER:OR OR FREEZER:

O

OO

W AW A

W A

W AW A

WW

W

WW

AA

A

AA

Y Y

Y

Y Y

YY

Y

YY

OUR OLDOUR OLD

OUR OLD

OUR OLDOUR OLD

Space Requirements

WARNING

Keep flammable materials and vapors, such as

gasoline, away from refrigerator. Failure to do so can

result in death, explosion, fire, or burns.

• To ensure proper ventilation for your refrigerator, allow

for a 1"(2.5 cm) for 33" wide models, or ½"(1.3 cm) for

30" wide models, at the top of your refrigerator.

• If your refrigerator has an ice maker, make sure you

leave some extra space at the back to allow for the

water line connection. The refrigerator can be flush with

the back wall if you do not have an ice maker installed.

• If you are installing your refrigerator next to a fixed wall,

leave 2 ½" minimum on hinge side (depending on your

model) to allow for the door to swing open 90°.

NOTE: Do not install the refrigerator near an oven,

radiator, or other heat source. Do not install the

refrigerator in a location where the temperature will fall

below 55°F (13° C).

3

Page 5

!

Instructions for Installation

Proper installation will ensure this

refrigerator operates most efficiently.

Amana cannot be held responsible for

improper installation.

Tools Required

Putty knife

Masking tape ¼" hex nut driver

3

/8" hex nut driver Phillips screwdriver

IMPORTANT:

• Save all screws for reuse.

• For plug removal requiring use of flat blade screwdriver

or putty knife, blade of tool must be covered with

masking tape to avoid damage to refrigerator

finish. For plugs using a screwdriver or nut driver style

head, use appropriate tool to avoid damage to plugs.

5

/16" hex nut driver

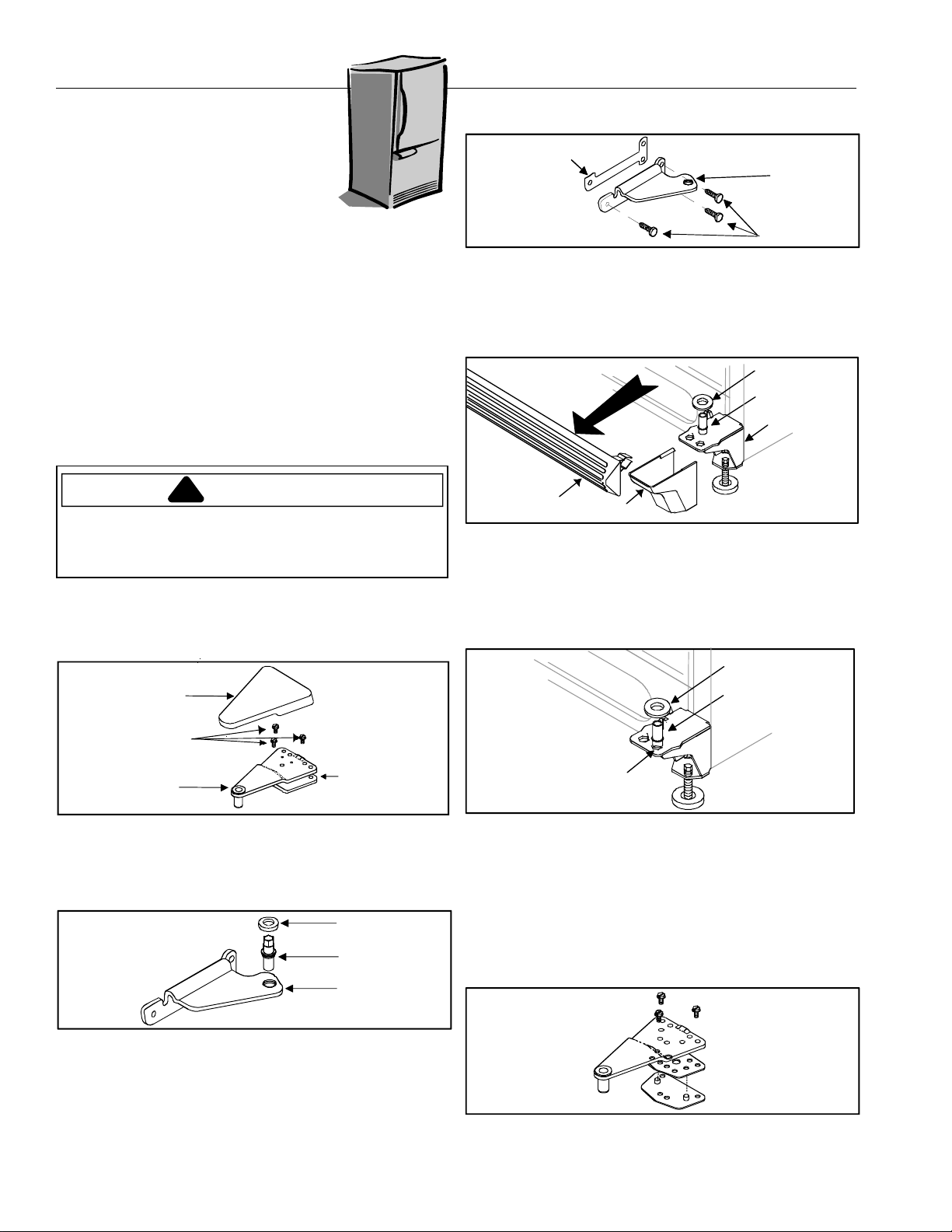

To Remove Doors and Hinges

Some installations may require door and hinge removal to

transport unit to final location.

WARNING

To avoid electrical shock which can cause severe

personal injury or death, disconnect power to

refrigerator before removing doors. After replacing

doors, connect power.

(A)

1. Remove top hinge cover

off. While supporting refrigerator door, remove top

(B)

hinge

remove screws

and shim

(D)

(C)

.

. Top hinge cover snaps

using 5/16" hex nut driver to

5. Remove center hinge bracket

(C)

removing screws

using Phillips screwdriver.

(A)

and shim

(B)

by

B

A

C

6. Remove toe grille

snap off.

7. Remove bottom hinge

driver. Remove hinge pin

round washer shims

A

(A)

and bottom hinge cover

and shim

(D)

(E)

, if present.

(C)

. Remove and retain all

B

(B)

with 3/8" hex nut

E

D

C

To Replace Doors

1. Replace bottom hinge and shims with 3/8" hex nut

screws from hinge removal.

(A)

2. Replace bottom hinge pin

(B)

hole

shims

toward outside of cabinet. Replace all washer

(C–some models)

in hinge bracket

.

C

. Both

A

D

C

B

2. Lift refrigerator door off center hinge.

3. While supporting freezer door, remove center hinge pin

(A)

from center hinge bracket

driver. Remove and retain all round washer shims

some models)

.

(B)

with 5/16" hex nut

(C–

C

A

B

4. Remove freezer door by lifting door off bottom hinge.

A

B

3. Replace center hinge and shims with Phillips screws

from hinge removal.

4. Place freezer door on bottom hinge pin.

5

5. Replace center hinge pin with

Make sure fit is tight. Replace all washer shims

(some models)

6. Assemble top hinge, hinge shim, and positioning

shim together. Attach loosely to opposite side of

cabinet to allow for door clearance.

.

/16" hex nut driver.

4

Page 6

7. Place refrigerator door on center hinge. Tighten down

!

!

top hinge to securely hold door.

8. Use a dime at top to space door

cabinet. Handle side of door should be approximately

1

/8" (3 mm) higher than hinge side. Door will become

level when it is loaded with food.

11

/16"(18 mm) from

1/8"

(3 mm)

11/16"

(18 mm)

9. Replace hinge cover.

Note: If automatic ice maker water supply is

required, procede to

Supply Line

Leveling Refrigerator

. If not, procede to section entitled

Connect Ice Maker Water

.

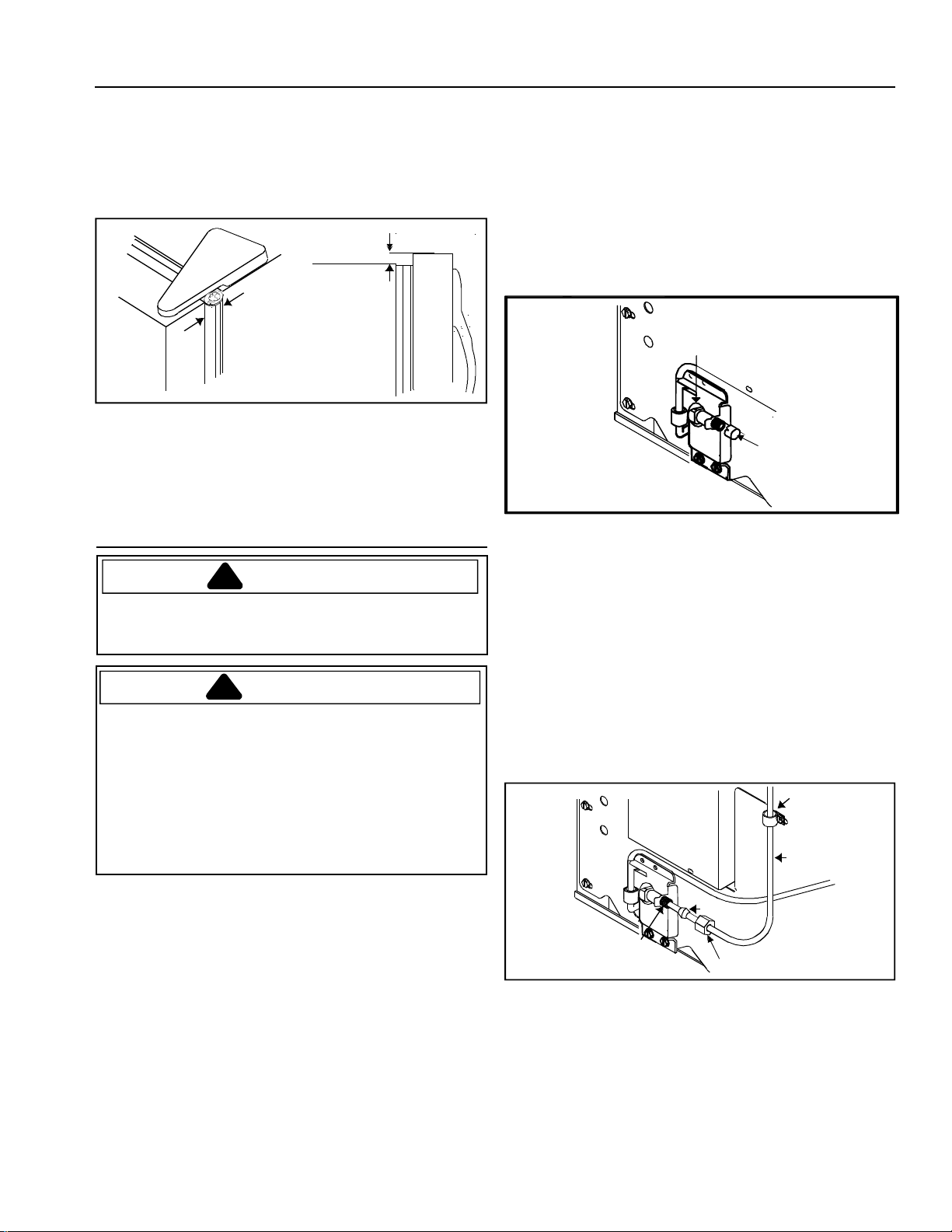

Connect Ice Maker Water Supply Line

(some models)

DANGER

To avoid electrical shock which can cause severe

personal injury or death. Disconnect power to

refrigerator before connecting water supply.

CAUTION

Observe the following to avoid property damage:

• Raise stabilizing leg before moving unit.

• Make sure water pressure to water valve is

between 20 and 100 pounds per square inch.

• Tighten adapter fitting and nuts with pliers and

wrenches. Do not overtighten.

• Check for water leaks and correct if necessary

before returning refrigerator to normal location. After

24 hours check again for leaks.

Important

• Before connecting water supply, contact a plumber to

connect coper tubing to household plumbing in

compliance with local codes and ordinances.

• DO NOT use piercing type or

Both reduce water flow, become clogged with time and

in addition, may cause leaks if repair is attempted. The

correct type–a shut-off valve–requires a ¼" hole to be

drilled in the water supply pipe before valve attachment.

3

/16" saddle valves!

Materials Required

¼" O.D. (6 mm) flexible copper tubing

½" open end wrench

Length of copper tubing must reach from water supply

connection to water valve inlet port on back of

refrigerator, plus additional 8 ft. (2 m) of tubing for a

service loop. A service loop will allow refrigerator to be

pulled away from the wall without disconnecting tubing.

Procedure

1. Remove plastic cap

(A)

from water valve inlet port

B

A

2. Place brass nut

tubing

(C)

literature packet.). Insert copper tubing into water

valve inlet port

tubing to water valve inlet port. Make sure copper

tubing is secure by pulling on copper tubing.

3. Turn on water supply to refrigerator and check for

leaks. Correct any leaks at connection. Be careful not

to overtighten connection.

4. Create a service loop using extreme care to avoid

kinks. Secure copper tubing to refrigerator cabinet

with a "P" clamp

tubing to refrigerator to avoid leaks when pushing

refrigerator back into opening.

(A)

and brass sleeve

(Brass nut and sleeve are found in your

(D)

. Connect brass nut on copper

(E)

. It is important to secure copper

(B)

on copper

E

C

B

D

A

5. Proceed to

placement.

Leveling Refrigerator

for final refrigerator

(B)

.

• Do not install copper tubing in area where temperatures

drop below 32°F (0°C).

5

Page 7

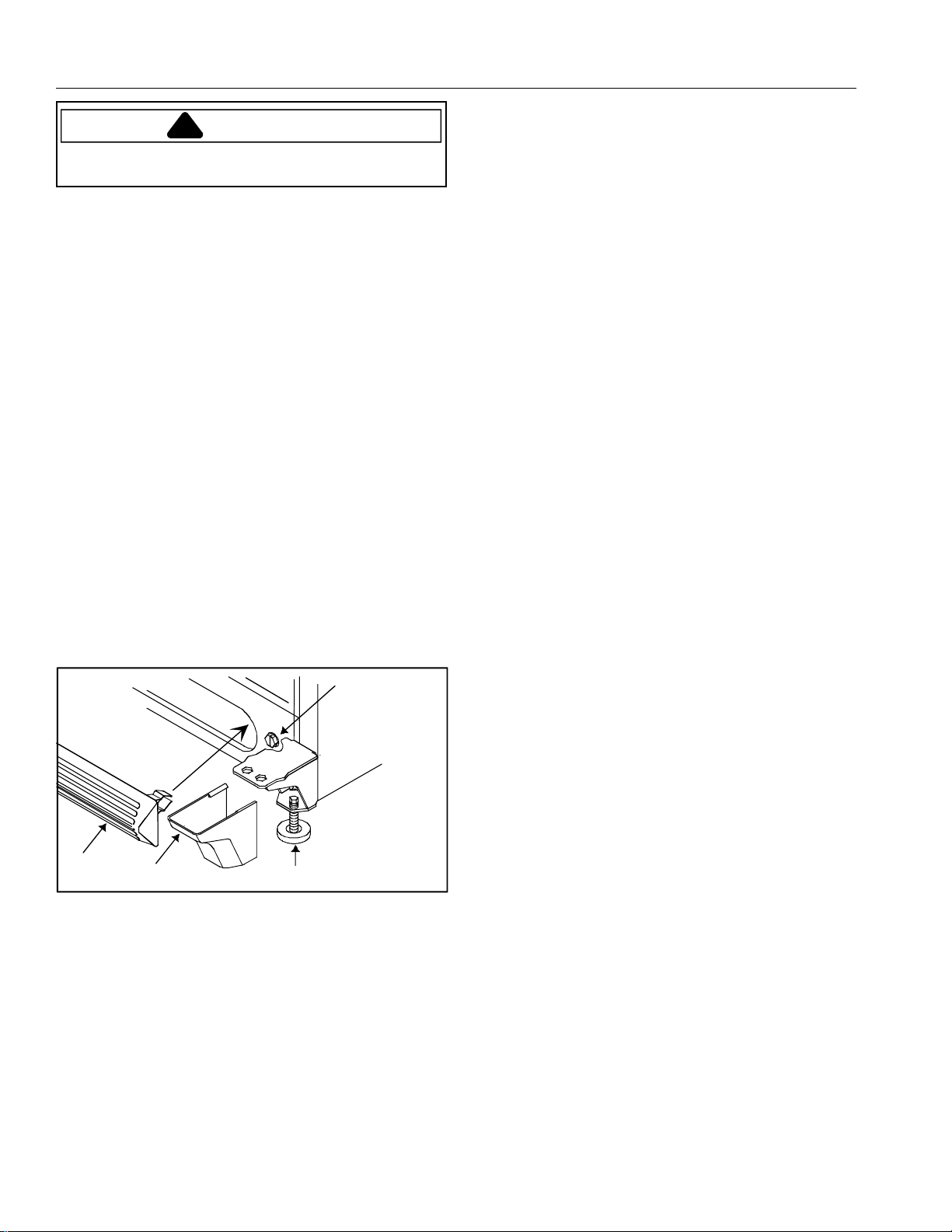

Leveling Refrigerator

!

CAUTION

Protect soft vinyl or other flooring with cardboard, rugs

or other protective material to avoid property damage.

If your refrigerator requires an ice maker water supply

connection, proceed to

section before lev eling your refrigerator.

1. Plug in power cord.

2. Move refrigerator into final location.

3. Level refrigerator using a level placed on top of the

refrigerator.

• Remove toe grille

cover

(B)

.

• T urn roller adjustment screws

refrigerator cabinet. F ront of refrigerator must be

¼" (6 mm), or ½ bubble on your level, higher than

the back of your refrigerator .

• Make sure refrigerator cabinet is level from side to

side by adjusting left and right roller adjustment

screw

(C)

.

• T urn stabilizing leg

floor.

4. Replace toe grille

markings on inside of toe grille to insure proper

placement.

• Snap top portion into place first. Press down on

lower part of grille until bottom portion snaps into

place.

Connect ice maker water supply

(A)

. Remove bottom hinge

(C)

to raise or lower

(C)

clockwise until firmly against

(A)

and bottom hinge cover

(B)

. See

A

5. Review

consumer.

B

Installation Checklist

C

D

in Owner's Manual with

6

Page 8

Installation Checklist

This checklist is for personal records only.

Consumer Installer

Doors

Handles are solidly attached to doors.

Handle side of door is 1/8" (3 mm) higher than hinge side. (Door lowers when

loaded with food.)

Doors seal completely to refrigerator cabinet.

Leveling

Refrigerator is tilted 1/4" (6 mm) from front to rear.

T oe grille is properly attached to refrigerator .

Product Literature

Owner's manual is reviewed including the following information.

• product registration card

• Fresh f ood and freezer controls

• Humidity-controlled crispers

• normal operating sounds

Notes

Consumer's Signature

Installer's Signature

DateInstaller's Company Name/Phone Number

7

Page 9

Controls

!

!

This refrigerator is designed to operate at normal

household temperatures of 55° to 110°F (13° to 43°C).

CAUTION

Fresh Food and Freezer Controls

Fresh food control is located on upper rear wall of fresh

food section.

4

3

5

2

Freezer control is located on left front ceiling of freezer

section.

Cold Coldest

4

6

7

1

Deepfreeze Control

Handle tempered glass shelves carefully to avoid

personal injury or property damage. Shelves ma y

break suddenly if nicked, scratched, or exposed to

sudden temperature change.

• Remove shelves

hooks

(B)

from metal track

(A)

by lifting up shelf front,releasing

(C),

then pulling out.

• Replace shelves by inserting hooks into metal track

and lowering front of shelf.

C

A

B

Easy Glide™ shelves pull forward for easy access to

items in back.

Setting Controls

When freezer control is set to OFF, neither refrigerator nor

freezer sections will cool. Initially, set both controls to 4.

Wait 24 hours for refrigerator and freezer sections to

stabilize temperatures. After 24 hours, adjust controls,

one number at a time, as desired. One is warmest setting

and seven is coldest.

Set controls precisely using a household thermometer

with a temperature range between -5° to 50°F

(-21° to 10°C).

Put thermometer snugly between frozen packages in

freezer section. Wait 5–8 hours. If freezer temperature is

not 0° to 2°F (-17° to -16°C), adjust freezer control one

number at a time. Check again after 5–8 hours.

Put thermometer in a glass of water in middle of fresh

food section. Wait 5–8 hours. If fresh food temperature is

not 38° to 40°F (3° to 4°C), adjust fresh food control one

number at a time. Check again after 5–8 hours.

Fresh Food Features

Fresh Food Shelves

Shelves adjust to meet individual storage needs. Some

models feature Spillsaver TM Shelves and Easy Glide TM

shelves. Spillsaver TM Shelves hold minor spills for easier

cleaning.

Beverage Organizer (some models)

The beverage organizer slides out from underneath the

glide-out shelf. This may hold 12 cans or other desired

beverages.

• Before removing organizer, empty contents.

(A)

• Remove organizer

it catches on grooves

front and pull out.

• To replace, guide organizer

forward movement is stopped by groove

organizer front and ease organizer toward back of unit.

by pulling organizer forward until

(B)

in shelf rail

(A)

(C)

. Lift organizer

into shelf rails

(B)

(C)

. Lift

until

B

C

CAUTION

Make sure shelf is secure before replacing items on

shelf to avoid property damage.

C

A

8

Page 10

!

Adjustable Deli Drawer™ (some models)

!

• Refer to instructions entitled Spillsaver ™ Shelves for

removing and replacing shelf.

• Remove drawer and sleeve by lifting and pulling out.

• Replace drawer by sliding into place.

Garden Fresh™ Crispers

Garden Fresh ™ crispers keep produce fresh longer. Wrap

produce tightly. Do not wash produce before placing in

crispers. Excess moisture could cause produce to spoil

prematurely. Do not line crispers with paper towels. Paper

towels retain moisture.

Garden Fresh ™ crisper control is located below front

shelf trim. Control adjusts humidity in crisper drawers.

Slide control to high for produce with leaves such as

lettuce,spinach or cabbage. Slide control to low for

produce with skins such as cauliflower, corn or tomatoes.

To remove or clean crisper drawer assembly for 33"

wide units:

1. Remove crisper drawer on handle side of unit.

CAUTION

Handle tempered glass shelves carefully to avoid

personal injury or proper ty damage. Shelves may

break suddenly if nicked, scratched, or exposed to

sudden temperature change.

2. Remove glass crisper top by gently pushing up from

underneath. Tilt one end up and pull out.

6. Replace crispers and shelves by performing steps

2 through 5 in reverse order.

Note: Be sure to hook shelf frame over notch on top

of support post when replacing shelf frames.

7. Slide crisper glass into place.

To remove or clean crisper drawer assembly for 30"

wide units:

1. Open refrigerator door as wide as possible and

remove crisper drawers.

CAUTION

Handle tempered glass shelves carefully to avoid

personal injury or proper ty damage. Shelves may

break suddenly if nicked, scratched, or exposed to

sudden temperature change.

2. Remove glass crisper top by gently pushing up from

underneath. Tilt one end up and pull out.

2

2

1

3. Lift front of crisper shelf frame and remove.

4. Lift front of remaining crisper assembly and remove

support post from center of refrigerator floor.

3

4

5. To avoid interference with door, move remaining

crisper assembly to opposite wall and remove.

1

3. Raise front of crisper frame free of refrigerator cabinet

rail assembly and pull out of unit.

3

4. Replace crispers and shelf by performing steps 2

through 3 in reverse order.

5. Slide crisper glass into place.

Chiller FreshTM System (some models)

The Chiller FreshTM System features a drawer inside a

sleeve. Freezer air circulates between drawer and sleeve.

This systems keeps food fresh longer and up to 5°F (3°C)

colder than refrigerator temperature.

5

9

Page 11

Chiller FreshTM control

Control adjusts amount of air circulating around drawer.

Slide control to

and to

form on drawer or food on

entering the Chiller Fresh

refrigerator temperature. Fresh food control may need to

be adjusted to a lower number to compensate for colder

air.

Chiller Fresh

right side of the refrigerator compartment to accomodate

different storage needs.

To install on left side, see Figure 1. To install on right

side, see Figure 2

1. Remove drawer

2. Remove plastic cap

3. Rotate boot

4. Insert plastic cap in hole

5. Replace shelf by inserting hooks into metal track and

6. Replace drawer by sliding in. Make sure boot fits

COLDER

TM

drawer can be moved from the left to the

(C)

shelf

metal track

section by placing a knife covered with masking tape

underneath cap and pulling forward.

food section. Confirm cap is snugly in place. Cold air

may cause food to freeze if cap is not replaced.

lowering the front. Use slots 4 though 6 only.

snugly over air inlet in back wall.

by lifting from front, releasing hooks from

(A)

is located below front shelf trim.

COLD

for normal refrigerator temperature

for colder temperature. Ice crystals may

COLDER

TM

drawer can decrease

(B)

by lifting and pulling out. Remove

(D)

, then pulling out.

(E)

from back wall of fresh food

(F)

180° to opposite side.

setting. Cold air

(G)

opposite side of fresh

D

Storage Rack (some models)

Storage rack

bottle, eggs, etc.

• Hang rack by hooking over side of shelf.

(A)

provides convenient storage for a large

A

Covered Storage Bucket (some models)

The covered storage bucket has a lid and removable egg

tray. When tr ay is removed, b uc k et will accept standard

egg carton, ice, etc.

C

1

F

G

E

Dairy Center (some models)

A

D

B

G

E

F

C

The dairy center provides convenient storage for b utter,

cheese, etc.

• Remove dairy center by lifting door

tabs

(B)

of shelf down on both sides, and pulling out.

(A)

, pushing

• Replace dairy center by sliding in until tabs lock

into place, then lower door .

2

B

A

A

B

10

Page 12

Door Buckets

Door buckets adjust to meet individual storage needs.

• Remove door buckets by pushing tabs

sides of shelves toward center and pulling bucket

out.

• Replace door buckets by sliding in until tabs lock

into place.

A

(A)

on both

Tall Package Retainer (some models)

T all pac kage retainer

fits on front edge of any refrigerator door bucket or door

shelf.

(A)

keeps tall items secure. Retainer

Adjustable Divider (some models)

Adjustable divider keeps items in place and adjusts to

meet individual storage needs. Divider fits in any door

bucket or door shelf.

Bottle Holder (some models)

Bottle holder keeps items in place and adjusts to meet

individual storage needs. Bottle holder fits in any door

bucket or door shelf.

A

Door Shelves

• Remove door shelves by lifting ends and pulling

out.

• Replace door shelves by placing shelf on glides

and sliding down.

A

(A)

11

Page 13

!

Freezer Features

Frost-Free System

The fresh food and freezer sections are completely frostfree. Defrosting is automatic under normal conditions.

Automatic Ice Maker (some models)

• Make sure ice bucket is in place and ice maker arm

is down

• After freezer section reaches normal temperature, the

ice maker fills with water and begins operating. For

optimum ice production, it is recommended that freezer

section be at least half full. Allow 24–48 hours after

installation before first harvest of ice. Ice maker

produces 7 to 9 harvests of ice in a 24-hour period

under ideal conditions.

• After ice is formed, ice maker drops ice cubes into ice

storage bucket. During ice production, ice maker arm

raises and lowers. When ice storage bucket is full, ice

maker arm turns ice maker off

Note: Discard first 3 harvests of ice so any impurities left

in the water line after installation are not consumed.

• If you wish to stop automatic ice production lift ice

maker arm

position is reached. Ice maker arm will remain in that

position until pushed down.

(C)

.

C

(A)

.

(A)

. A definite click is heard when proper

B

(B)

A

(B)

Slideout Shelf (some models)

Slide out shelf pulls forward for easy access to items in

back.

• Remove slideout shelf by sliding forward until ball

(B)

point

groove.

• Grasp shelf by center rail, pull up, and remove.

• Slide in until ball point falls into molding groove.

beneath center rail

(A)

catches in molding

A

B

Vertical Shelf Divider (some models)

Install vertical shelf divider by completing the following

steps:

1. Slide prongs of shelf divider beneath desired grill

work, slightly off-center from center rail.

2. Press top of divider down and slide hook assembly

beneath center rail.

2

1

Ice Service Rack (some models)

Install ice service rack

washers

(B)

and sliding down.

(A)

by placing ice service rack on

B

A

CAUTION

Make sure shelf is secure before placing items on

shelf to avoid property damage.

Fixed Wire Shelf (some models)

• Remove wire shelf by pulling out. A sharp tug may

be necessary.

• Replace wire shelf by sliding in until back locks in

place.

12

Page 14

Wire Basket

Wire basket

back.

• Remove wire basket by lifting and pulling out.

• Replace wire basket by sliding in.

(A)

slides out for easy access to items in

A

Ice Bin (some models)

Ice bin

(A)

sits below the ice service rack on the wire

freezer shelf.

A

Tilt-Out Bin (some models)

The tilt-out bin

food items in freezer door and tilts forward for easy

access of those items.

(A)

provides convenient storage for frozen

A

Pullout Drawer Baskets (some models)

(Door assembly of drawer removed from illustration for

visual clarity)

To remove and replace top basket:

• Remove basket by pulling basket out to its full

extension and lift out.

• Replace basket by sliding into upper compartment of

freezer.

To remove and replace bottom basket:

• Remove basket by lifting basket from rail guides.

• Replace basket by placing into rail guides.

Vertical Basket Divider

Install vertical basket divider

following steps:

1. Align clips on side of divider with rungs in basket

wall.

2. Press top of divider down until divider meets bottom

of basket

To remove divider:

1. Grasp top of divider and pull straight up.

A

(A)

by completing the

Ice Shield (some models)

The ice shield is mounted at the back of the pullout

drawer to prevent ice from falling behind the basket

assemblies.

To remove and replace ice shield:

• Slide ice shield to the right to release hooks

vertical wire rungs.

(B)

• To replace, slide tab

B

13

into place as shown.

A

(A)

from

Page 15

!

!

Care and Cleaning

!

!

WARNING

Disconnect power to refrigerator before cleaning to

avoid electrical shock which can cause severe

personal injury or death. After cleaning, restore power .

CAUTION

Read and follow all manuf acturer’s cleaning directions

to avoid personal injury or property damage.

General

See section on Stainless Steel Cleaning if doors are

stainless steel.

1. Wash surfaces with 4 tablespoons baking soda

dissolved in 1 quart warm water and a soft, clean

cloth.

2. Rinse surfaces with warm water. Dry surfaces with a

soft, clean cloth.

• Do not use the following items:

- abrasive or harsh cleaners, ammonia,

chlorine bleach, etc.

- concentrated detergents or solvents

- metal scouring pads

These items can scratch, crack and discolor

surfaces.

• Do not place buck ets, shelves, etc. in dishwasher.

Stainless Steel Cleaning

Damage to stainless steel finish due to improper use

of cleaning products, or using non-recommended

cleaining products, is not covered under warranty .

For Amana recommended products, call our Consumer

Affairs division at 1(800) 843-0304, or contact us on the

internet at www.amana.com.

1. Wash surfaces with warm soapy w ater and a soft,

clean cloth or sponge.

2. Rinse surfaces with warm water. Dry surfaces with a

soft, clean cloth.

• Do not use the following harsh cleaners:

- abrasive or acidic cleaners(ammonia, chlorine

bleach, vinegar-based product, etc.

- citrus-based cleaners

- scouring pads(metal, textured plastic, etc.)

These items can scratch, discolor, or permanently

tarnish surfaces.

3. Follow up rinsing by immediately drying with a soft,

clean cloth. This will av oid water spotting on

stainless steel finish.

Adhesives

1. Remove adhesive residue from refrigerator surfaces

by rubbing toothpaste into adhesive with fingers until

adhesive loosens.

2. Rinse surface with warm water. Dry surface with a

soft, clean cloth.

Door Gaskets

1. Clean door gaskets every 3 months according to

General Cleaning instructions. Clean any spills

immediately .

Condenser Coil

Clean condenser coil behind toe grille every 3 months to

ensure maximum performance of refrigerator .

Accumulated dust and lint may cause the following:

• reduced cooling performance

• increased energy usage

• premature part failure

1. Remove toe grille by holding ends and pulling away

from refrigerator.

2 . Clean front surface of condenser coil with a vacuum

cleaner hose nozzle.

3. Replace toe grille by inserting clips in holes and

snapping in. See

4. Raise stabilizing legs (some models) by turning

counterclockwise.

Leveling Refrigerator

section.

CAUTION

Protect soft vinyl or other flooring with cardboard, rugs

or other protective material to avoid property damage.

5. Pull refrigerator away from wall. Run a vacuum

brush across grille on back of refrigerator.

Glass Shelves

CAUTION

Handle tempered glass shelves carefully to avoid

personal injury or property damage. Shelves ma y

break suddenly if nicked, scratched, or exposed to

sudden temperature change.

Remove shelf by lifting front, releasing hooks from metal

track then pulling out. Place shelf on a towel. Allow shelf

to adjust to room temperature before cleaning.

Clean crevices by completing the following:

1. Dilute mild detergent and brush solution into crevices

using a plastic bristle brush. Let sit for 5 minutes.

2. Spray warm water into crevices using faucet spray

attachment.

3. Dry shelf thoroughly and replace shelf by inserting

hooks into metal track and lowering it from the front.

Odor Removal

1. Remove all food and disconnect power to refrigerator .

2. Clean all interior surfaces including ceiling, floor, and

walls according to General Cleaning instructions

above. Pay special attention to corners, crevices, and

grooves. Include all drawers, shelves, and gaskets.

3. Connect power to refrigerator and return food to

refrigerator. W ash and dry all containers. Wrap foods

in tightly sealed containers to prevent further odor .

14

Page 16

After 24 hours, check if odor has been eliminated.

!

!

Complete steps 4–9 if odor has not been eliminated.

4. With unit unplugged, place crispers on top shelf of

refrigerator section. P ack refrigerator and freezer

sections, including doors, with crumpled sheets of

newspaper.

5. Place charcoal briquettes randomly throughout

newspaper.

6. Close doors and let stand 24–48 hours.

7. Remove charcoal briquettes and newspapers.

8. Complete steps 2–3.

If odor is still not eliminated, contact a customer service

representative with the number located in the Model

Identification section.

Light Bulb Replacement

WARNING

Disconnect power to refrigerator before replacing light

bulb to avoid electrical shock which can cause severe

personal injury or death. After replacing light bulb ,

restore power .

CAUTION

Observe the following to avoid personal injury or

property damage.

• Allow light bulbs to cool

• Wear gloves when replacing light bulb .

Fresh Food Light

• Remove light bulb cover

screws

than 25 watts.

• Replace light bulb cover by replacing ¼" hex nut

screws.

(A)

. Replace with appliance bulb no greater

(B)

by removing ¼" hex nut

A

Freezer Light

• Remove light bulb cover

screws

than 25 watts.

• Replace light bulb cover by replacing ¼" hex nut

screws.

(A)

. Replace with appliance bulb no greater

(B)

by removing ¼" hex nut

A

B

Vacation Tips

Complete the following steps f or short vacations.

1. Remove perishable foods.

2. If an ice maker is installed, move ice maker arm to

Off

position. (See “Automatic Ice Maker” section)

Complete the following steps for long vacations.

1. Empty refrigerator and freezer sections.

2. Unplug refrigerator .

3. Clean refrigerator and door gaskets according to

General Cleaning instructions in “Care and Cleaning”

section.

4. Prop doors open, so air can circulate inside.

5. If an ice maker is installed, turn off water supply to

refrigerator and move ice maker arm to

position. (See “Automatic Ice Maker” section page 12)

Off

Energy Tips

This refrigerator is designed to be one of the most energy

efficient refrigerators available. Reduce energy use by

observing the following.

• Operate in household temperatures of 55° to 110°F (13°

B

to 43°C) away from heat sources and direct sunlight.

• Set refrigerator, freez er, and temperature controlled

meat drawer system controls no colder than necessary .

• Keep freez er section full.

• Keep door gask ets clean and pliable. Replace gask ets

if worn.

• Keep condenser coils clean.

15

Page 17

Normal Operating Sounds

This new refrigerator may be replacing a differently

designed, less efficient or smaller refrigerator. T oda y’ s

refrigerators have new features and are more energy

efficient. As a result, certain sounds may be unf amiliar.

These sounds are normal and will soon become familiar

to you. They also indicate refrigerator is operating and

performing as designed.

1. Freezer control clicks when starting or stopping

compressor.

2. Freezer fan air rushes and whirs.

3. Sealed system (evaporator and heat exchanger)

refrigerant flow gurgles, pops or sounds like boiling

water.

4. Defrost heater sizzles, hisses or pops.

8

5. Defrost timer sounds like an electric clock and

snaps in and out of defrost cycle.

6. Condenser fan air rushes and whirs.

7. Compressor has a high pitched hum or pulsating

sound and cycles on and off.

8. Ice cubes from ice maker (some models) drop into

ice bucket.

9. Ice maker water valve hookup (some models)

buzzes when ice maker fills with w ater. This occurs

whether or not refrigerator is connected to water

supply . If refrigerator is not connected to w ater

supply, stop sound by raising ice mak er arm to

position. Ice maker water valve hookup is located

behind condenser fan in back of refrigerator .

Note: Foam insulation is very energy efficient and

has excellent insulating capabilities. How ev er , f oam

insulation is not as sound absorbent as

previously used fiberglass insulation.

Off

1

6

5

2

3

4

7

16

Page 18

Before Calling For Service

Problem Solution

Refrigerator does not

operate.

Refrigerator still will not

operate.

Food temperature appears

too warm.

Chiller Fresh™ System

temperature is too warm.

Food temperature is too

cold.

Refrigerator runs too

frequently.

•

Make sure freezer control is on.

• Make sure refrigerator is plugged in. If not, firmly plug the cord into a live outlet

with proper voltage.

• Check fuse or circuit breaker. Plug in another item at that wall outlet. If outlet

does not work, replace the fuse or reset the circuit.

• If freezer control is on, light works but 2 fans and compressor are not

operating, refrigerator may be in defrost cycle. Wait 40 minutes to see if

refrigerator restarts.

• Unplug refrigerator. Transfer food to another refrigerator or place dry ice in

freezer section to preserve food. Call for service.

• See above sections.

• Allow time for recently added warm food to reach refrigerator or freezer

temperature. Adding food warms the refrigerator. It can take a few hours for the

refrigerator to return to normal temperature.

• Check gaskets for proper seal. Gaskets should seal tightly to cabinet.

• Clean condenser coil. See “Condenser Coil” instructions in “Care and

Cleaning” section.

• Adjust refrigerator and or freezer control. See “Setting Controls” instructions in

“Controls” section.

• Freezer or refrigerator light stays on. If light stays on, call service.

• Return air vents behind crisper are blocked restricting airflow. Locate return air

vent behind crispers and remove any debrisis that blocks vents or restricts

airflow.

• Slide control to colder setting.

• Adjust freezer control to colder setting. See “Setting Controls” instructions of

“Controls” section.

• Verify Chiller Fresh™ System cap has been moved if drawer has been moved

from left to right side of cab inet. See “Chiller Fresh™ System” section.

• Clean condenser coil. See “Condenser Coil” instructions in “Care and Cleaning

section.

• Adjust refrigerator control. See “Setting Controls” instructions in “Controls”

section.

• Adjust freezer control to warmer setting. See “Setting Controls” instructions in

“Controls” section. Allow several hours for temperature to adjust.

Verify plastic cap is in place near Chiller Fr esh™ System. See “Chiller Fresh™

•

System” section.

•

It may be normal to maintain constant temperature.

• Doors have been opened frequently or for an extended period of time. When

the door is opened warm humid air is allowed into the refrigerator. The more

the door is opened the more warm air the refrigerator must cool.

Allow time for recently added warm food to reach refrigerator or freezer

•

temperature. It can take a few hours for the refrigerator to return to normal

temperature.

• Clean condenser coil. See “Condenser Coil” instructions in “Care and

Cleaning” section.

• Adjust freezer control. See “Setting Controls” instructions in “Controls” section.

• Check gaskets for proper seal. Gaskets should seal tightly to cabinet.

• Freezer light stays on. If light stays on, call service

• Make sure refrigerator is level. See “Leveling Refrigerator” section of

Installation Instructions.

17

Page 19

Pro b le m Solu tio n

Water droplets form on inside of

refrigerator.

•

It is normal during high humidity periods or if doors have been opened

frequently.

•

Wrap food tightly and wipe off damp containers prior to storing in the

refrige ra to r to av o id moisture a c c u mulation .

Water droplets form on outside

of refrigerator.

• Check door seals for proper seal. Gaskets should seal tightly to cabinet.

• It is normal during high humidity periods or if doors have been opened

frequently.

Chille r F re s h ™ Sys te m or

crisper drawer does not close

freely (some models).

• Check for a package that may prevent drawer from closing properly.

• Con firm draw e r is in p roper position.

• Clean drawer channels with warm, soapy water. Rinse and dry thoroughly.

• Apply a thin layer of petroleum jelly to drawer channels.

• Con firm refrigera to r is le v e l.

Refrigerator has an odor. •

Refrig e ra to r makes u n fa miliar

See “Odor Removal” instructions in “Care and Cleaning” section.

• It may be normal. See “Normal Operating Sounds” section.

sounds or seems too loud.

Ice cubes have an odor.

• See “Odor Removal” instructions in “Care and Cleaning” section.

•

Ice maker w a s re c e n tly in s ta lle d . D is c a rd firs t fe w b a tc h e s o f ic e to a v o id

disc o lo re d o r off-fla v o re d ic e .

• Food has not been wrapped tightly in either refrigerator or freezer

compartment. Rewrap foods since odors may migrate to the ice if food is not

wrapped properly.

• Discard ice and clean ice bucket or trays more frequently. Ice cubes are

porous and absorb odors easily.

• Water supply contains minerals such as sulfur. In some situations a filter ma y

need to be installed to eliminate taste and odor problems.

Ice cubes stick together or

“shrink”.

Ice maker is not producing ice.

•

Empty ice cube bucket or trays more frequently. If used infrequently, ice cubes

may stick together or shrink.

• Wa te r p re s s u re may be to lo w o r h ig h . Ic e maker re q u ire s a w a te r p re s s u re o f

20-100 psi to function properly.

• Con firm ice m a k e r a rm is down. See “Autom a tic Ic e Maker” s e c tio n .

• Con firm household water supply is reaching water valve. Make sure the water

valve shut off is fully turned on.

• Piercing type or

and may become clogged with time. Replace these valves with correct type of

saddle valve requiring ¼” hole to b e drille d in water supply pipe prior to valve

attachment.

•

Con firm ice m a k e r wiring ha rn e s s is in s e rte d co mpletely in p roper holes.

• Check for kinks in copper or plastic tubing. Remove kinks or replace tubing.

• Che c k e le c tric a l c onnections to water valve coil and connector block on

refrigerator cabinet.

•

If a wa te r filte r h a s been installed on the water line outside the refrigerator,

che c k th e filte r fo r c log s o r improper installation of the filter.

Ice maker is not producing

enough ice.

• Ice maker has just recently been installed or a large amount of ice has just

been used. Wait 24 hours for ice production to begin and for ice maker to

resto c k a fte r e mptied.

• Con firm household water supply is reaching water valve. Make sure the water

valve shut off is fully turned on.

• Piercing type or

and may become clogged with time. Replace these valves with correct type of

saddle valve requiring ¼” hole to b e drille d in water supply pipe prior to valve

attachment.

• Check for kinks in copper or plastic tubing. Remove kinks or replace tubing

• Con firm freeze r s e c tio n is operating at proper temperature and that freezer is,

at lea s t, h a lf-fu ll. F re e z e r must be c o ld enough to produce ice. See ‘Setting

Con tro ls ” s e c tio n .

Ice forms in inlet tube to ice

maker.

•

Che c k water pre s s u re. L o w water p re s s u re c a u s e s v a lv e s to le a k .

•

Piercing type or

and may become clogged with time. Replace these valves with correct type of

saddle valve requiring ¼” hole to b e drille d in water supply pipe prior to valve

attachment.

3

/16” saddle valve was used for hookup. Both reduce water flow

3

/16” saddle valve was used for hookup. Both reduce water flow

3

/16” saddle valve was used for hookup. Both reduce water flow

18

Page 20

WARRANTY AND SERVICE

DOMESTIC WARRANTY- FULL FIVE YEAR WARRANTY

In addition to all statutory rights which you, the Consumer, have under the relevant laws in

respect of this appliance, during the first five years of ownership as the original purchaser of

this Kleenmaid appliance, we guarantee that any fault caused by faulty material or

workmanship becoming apparent will be rectified free or charge for parts and labour,

provided that all service is performed during normal working hours by Kleenmaid or their

designated Agents. Where the appliance is installed outside the normal servicing area of the

above, the Purchaser must pay for the cost of transporting the appliance to and from the

Agent or the Agent’s travelling cost to and from the Purchaser’s home.

COMMERCIAL WARRANTY - ONE YEAR WARRANTY

When this appliance is installed in a commercial application, in addition to all statuory rights

which you, the Consumer, have under the relevant laws in respect of this appliance, during

your first one year of ownership as the original purchaser of the Kleenmaid appliance, we

guarantee that any fault caused by faulty material or workmanship becoming apparent, will

be rectified free of charge for parts and labour, provided that all service is performed during

normal working hours by Kleenmaid or their designated Agents. Where the appliance is

installed outside the normal servicing area of the above, the Purchaser must pay for the cost

of transporting the appliance to and from the Agent or the Agent’s travelling cost to and from

the Purchaser’s home.

WHAT THESE W ARRANTIES DO NOT COVER

We are not responsible for any damage or malfunction unless caused by a defect in material

or workmanship. This includes but is not limited to abuse, misuse, improper installation and

transportation damage. We are not responsible for any consequential damages from any

malfunction.

WARRANTY DOES NOT COVER REPLACEMENT OF LIGHT

GLOBES OR GLASS BREAKAGE DUE TO IMP ACT

In case of fractured glass do not use your appliance.

WARRANTY REGISTRA TION

Please complete the enclosed warranty card and retain it together with your proof of

purchase document. These documents will need to be viewed by our service

representative should you request in warranty service.

SERVICE ASSIST ANCE

T o assist you when phoning our After Sales Service number to arrange a service call please

complete the following details and have them ready when you call.

Model Number:........................................................... Date of purchase:....................................

Kleenmaid Store purchased from:............................... Date of installation:.................................

Your Postcode

:...................................................

Page 21

Other products in Kleenmaid St George

range of world’s best appliances:

Washers

Dryers

Dishwashers

Ovens

Cooktops

Rangehoods

Sinks

Waste Disposals

Taps

Cookware

Refrigerators

Freezers

Vacuum Cleaners

For sales information on the full range of quality kitchen and laundry

appliances, phone 13 13 08.

For service related enquires, phone 1300 652 100

Loading...

Loading...