Page 1

Global SVQQPSU SFSWJDFT (GSS) Knowledge Services

KLA-Tencor Confidential—Restricted Distribution

KT Automation User Guide

9022549‐000

AB

Page 2

KT Automation User Guide

Page Intentionally Blank

9022549-000 / AB

KLA-Tencor Confidential - Restricted Distribution

Page 3

KT Automation User Guide

is preliminary document is not complete. This document contains significant

omissions and inaccuracies. GSS Technical Publications distributes this

preliminary draft for review purposes only. Customers and KLA- Customer

Service Engineers should not use this document while installing, servicing, or

using the KT Automation System. Any input regarding the accuracy of the

content of this document is welcome and appreciated.

KLA-Tencor Corporation

One Technology Drive,

Milpitas, CA. 95035

KLA-Tencor Technical Publications

KLA-Tencor Confidential - Restricted Distribution

Page 4

Copyright

Copyright © 2016-2017 by KLA-Tencor. All rights reserved worldwide. No part of this publication may be

reproduced, modified, transmitted, transcribed, stored in retrieval systems, or translated into any human or computer

language, in any form or by any means, electronic, mechanical, magnetic, chemical, manual, or otherwise, without the

express written permission of KLA-Tencor, One Technology Drive, Milpitas, California 95035. KLA-Tencor may

revise this document at any time without notice.

Trademarks

KT Automation™ System, SensArray® Temperature Wafers, and Automation Metrology™ Wafers are trademarks of

KLA-Tencor Corporation. KLA-Tencor

Corporation. All other brand and product names may be trademarks of their respective companies.

®

and the KLA-Tencor logo are registered trademarks of the KLA-Tencor

Reprint Acknowledgements

This document contains excerpts from the following SEMI® Standards and/or Safety Guidelines: SEMI S1-0708E,

“Safety Guidelines for Equipment Safety Labels,” and SEMI S2-0709, “Environmental Health, and Safety Guidelines

for Semiconductor Manufacturing Equipment,” Copyright © Semiconductor Equipment and Materials International

2009. All Rights Reserved. Used by Permission. SEMI is a registered trademark of Semiconductor Equipment and

Materials International. www.semi.org

Original Instructions.

Send any comments to:

GSS.ECMSAdmin@kla-tencor.com

9022549-000 / AB Printed in Milpitas

KLA-Tencor Confidential - Restricted Distribution

Page 5

Preface

. 1.Introduction

1.1 KT Automation System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 KT Automation System Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 KT Automation Missions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Regulatory Compliance Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4.1 Prohibitions on Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.2 Class A Digital Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.3 Special Accessory Installation: Manual Use Laptop/FOUP cable . . . . . . 1-4

. 2.KT Automation System Hardware Components

2.1 KT Automation Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1.1 KT Automation Station Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1.2 KT Automation Station Indicator Panel LEDs . . . . . . . . . . . . . . . . . . . . . 2-6

2.1.3 KT Automation Station Indicator Panel Manual/Auto Button . . . . . . . . . 2-7

2.2 KT Automation FOUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.1 KT Automation FOUP Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.2 KT Automation FOUP Indicators and Controls . . . . . . . . . . . . . . . . . . . . 2-8

2.2.3 KT Automation FOUP Data Storage and Transfer . . . . . . . . . . . . . . . . . . 2-9

2.2.4 KT Automation FOUP Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.5 Option: Emulating Occupied KT Automation FOUP Slots . . . . . . . . . . 2-10

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution v

Page 6

TABLE OF CONTENTS

. 3.KT Automation Web UI

3.1 Logging In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3.2 Logging Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3.3 KT Automation Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.3.1 Equipment Coverage and Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3.3.2 Tool Mission Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.3.3 Connected FOUPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3.4 Tools Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3.5 Setup Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.5.1 Edit or Add Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.5.2 Edit or Add Tool Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3.5.3 Edit or Add Handler Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3.5.4 Edit or Add Wafer Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.6 History Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.7 Administration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

PRELIMINARY

3.8 Automation Metrology Wafer Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3.8.1 Edit or Add an Automation Metrology Wafer Mission Recipe . . . . . . . .3-26

3.8.2 Define and Execute an Automation Metrology Wafer User Mission. . . .3-29

Glossary

Revision History

vi KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 7

Manual Purpose

This User Guide describes:

• Hardware components of the KT Automation

instrumented test wafers

• Setting up the system for automatic missions

• Managing inventory

• Controlling the KT Automation System

• Launching user missions using SensArray® Temperature Wafers and

Automation Metrology™ Wafers

Preface

™

System for KLA-Tencor

Manual Structure

This manual consists of this preface, 4 sections, and a glossary. Each section is

briefly described below:

Preface

Introduces the manual.

Section 1: Introduction

This section provides an introduction to the KT Automation System.

Section 2: KT Automation System Hardware Components

This section describes the functions and controls of the KT Automation System

hardware components.

Section 3: KT Automation System Web UI

This section describes how to use the Web UI of the KT Automation System.

Glossary

Defines abbreviations and terms used in the manual.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 1

Page 8

Preface

WARNING

CAUTION

IMPORTANT

NOTE

Reference Documentation

The following table specifies documents referenced in this manual.

Document Number Title

9022547-000 CPG KT Automation System Safety Manual

9022552-000 KT Automation System GEM/SECS Reference Manual

Conventions Used in this Manual

Indicates danger to personnel.

Includes instructions needed to prevent any damage.

Indicates danger to Equipment.

Includes instructions needed to prevent any damage.

When either of the above symbols appear in this manual, follow the advice

given. Failure to do so may endanger yourself or others, and can result in

damage to the Equipment.

Indicates there is possibility for a failure.

Includes the instruction needed to prevent the failure.

Indicates there is additional information connected with the current subject.

Includes that information.

Special terms

Special terms (dialog box names, button names and any other unique term)

are in bold, as demonstrated in the example below:

File menu, Start button.

Hyperlinks

Hyperlinks to references in this document appear in blue (on screen).

Hyperlinks to web sites, or external documentation, are blue and underlined.

2 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 9

1.

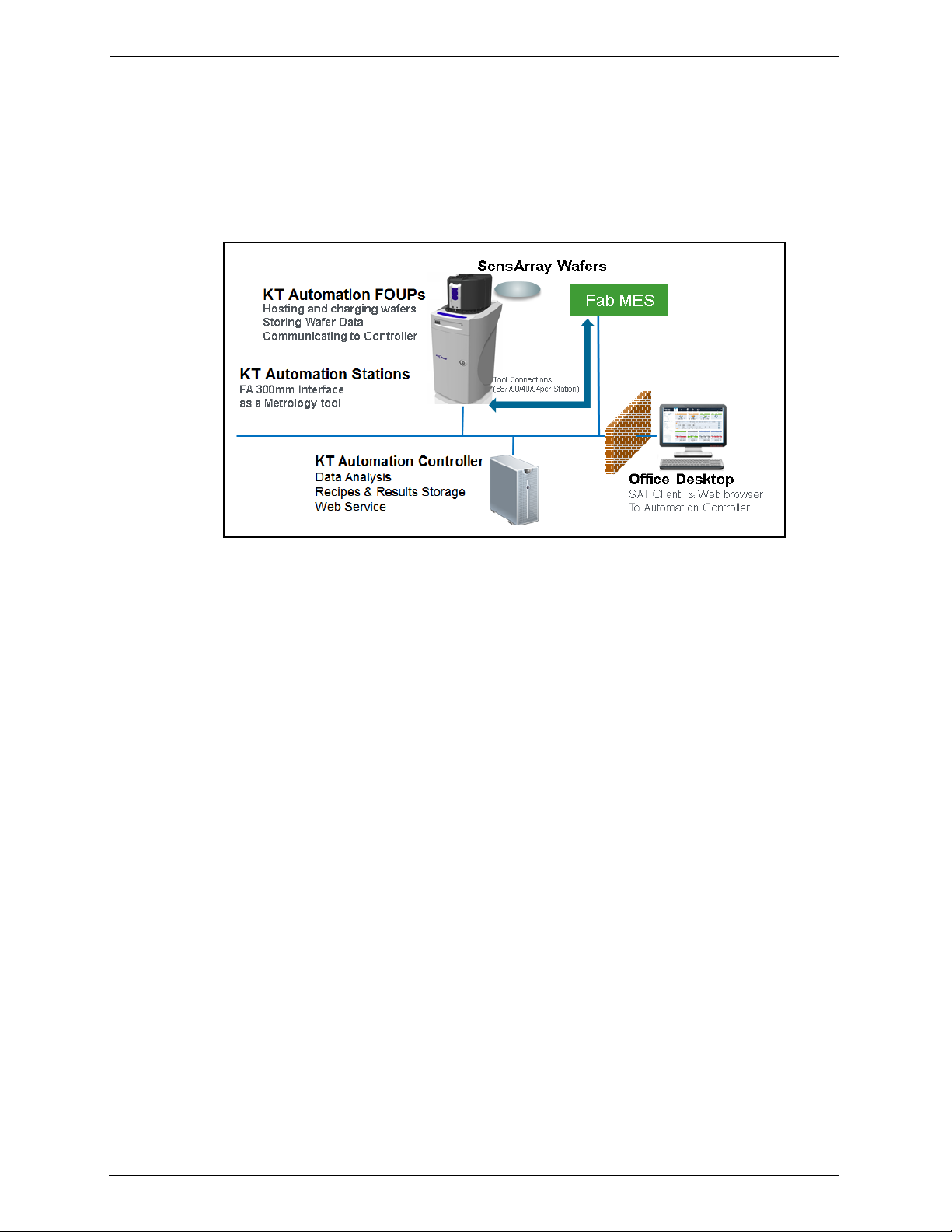

1.1 KT Automation System Overview

The KT Automation System provided by KLA-Tencor automates the use of

instrumented wafers in a semiconductor wafer fab. The KT Automation System

is used with SensArray temperature wafers and Automation Metrology motion

analysis wafers to enable real-time measurement and monitoring of

parameters that are critical to fab yield and productivity.

The KT Automation hardware consists of the following components:

• Battery-powered, instrumented wafers that perform the actual

measurements and reside in Automation FOUPs; examples are SensArray

Temperature Wafers and Automation Metrology Wafers (to measure motion

and humidity)

Introduction

• Battery-powered Automation FOUPs to transport and store instrumented

wafers, and to provide wafer charging and data communications (see

Section 2.2 for information about KT Automation FOUPs)

• KT Automation Stations that charge Automation FOUPs and provide the

communication between the FOUP and the fab host (see Section 2.1 for

information about KT Automation Stations)

• KT Automation Controller to control the system

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 1

Page 10

1. Introduction KT Automation System Operation

1.2 KT Automation System Operation

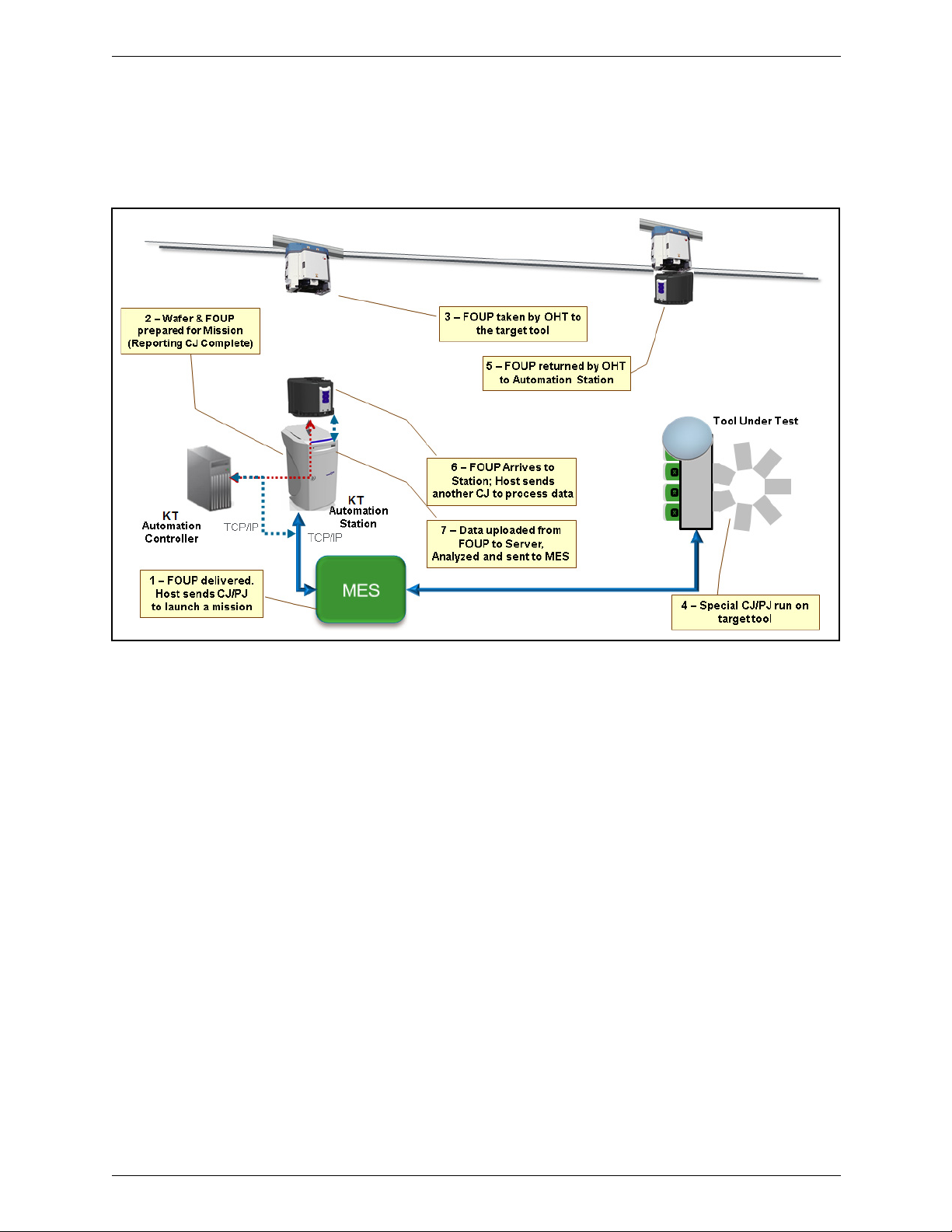

The KT Automation System provided by KLA-Tencor is used to deploy and

manage instrumented wafers

measurement and monitoring of parameters that are critical to fab yield and

productivity. Operation is completely automated (see Figure 1-1).

Figure 1-1: KT Automation System Topology

in a

semiconductor wafer fab to enable real-time

Measurement “missions” are executed automatically under control of the fab

manufacturing execution system (MES). The instrumented wafers are

transported by the fab OHT and automated material handling system (AMHS)

to and from the tool under test. Tests are executed on process tools without

removing them from full automated mode. Mission results are communicated

directly to the MES, plus results can be automatically available to engineers

inside and outside the fab through a web-based GUI and desktop analysis

software system.

Measurements are easy to accomplish without removing the process tools from

production use and without manual handling or recipe execution in the fab.

This enables KT metrology wafers to be used for in-line monitoring of process

and mechanical system parameters, preventing excursions that can cause yield

loss, and improving tool matching performance.

Examples of instrumented metrology wafers from KT that are supported by this

system are: the SensArray EtchTemp Wafer for monitoring etch temperature;

and the KT Automation Metrology Wafer for monitoring AMHS FOUP and

equipment front end wafer handling.

To create and launch a new mission (see Figure 1-2), the MES system sends

the instrumented wafer(s) in a KT Automation FOUP to the KT Automation

Station (1). The MES communicates with the KT Automation Station to initiate

the mission with a Control Job/Process Job (CJ/PC). If the correct wafers for

the mission are present in the FOUP with sufficient charge, the CJ/PJ is

completed (2). The FOUP is transported to the target tool under test by the

standard fab AMHS (3). The MES host system initiates the correct test recipe

on the target tool in full auto mode. When the test is complete, the Automation

FOUP is returned to the Automation Station (5). When the Automation FOUP

2 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 11

1. Introduction KT Automation Missions

arrives at the Automation Station, the host executes another CJ/PJ to process

the data (6). The mission results are uploaded to the KT Automation Controller

and the Go/No Go results are reported to the host from the Station, per the

metrology recipe in effect (7).

Figure 1-2: KT Automation System Mission Sequence

1.3 KT Automation Missions

There are 3 ways to launch and control KT Automation missions:

1. Automatic missions: controlled by fab MES via Factory Automation (as

described above); results are reported back to the MES (see

9022552-000, KT Automation System GEM/SECS Reference

Manual)

2. User missions: initiated by an operator via the KT Automation Web UI;

the Automation FOUP is carried manually to the target tool and back to the

station

3. Manual missions: initiated through the SA Tools software installed on a

laptop that is directly connected to the Automation FOUP and provides all

the required parameters for starting a mission; the Automation FOUP is

carried manually to the target tool and the mission is manually executed

on that tool

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 3

Page 12

1. Introduction Regulatory Compliance Statements

1.4 Regulatory Compliance Statements

1.4.1 Prohibitions on Modifications

Changes or modifications not expressly approved by KLA Tencor could void the

user's authority to operate the equipment.

1.4.2 Class A Digital Device

Note: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

1.4.3 Special Accessory Installation: Manual Use Laptop/FOUP cable

1. Verify SensArray Tools software is installed before connecting cable to

ensure appropriate communication settings.

2. Connect power supply to barrel connector in middle of manual use case

cable.

3. Connect manual use case RJ (Ethernet) connector to Ethernet port on

laptop.

4. Connect manual use case cable to FOUP magnetic connector on the back of

the FOUP to the left of the power switch. The factory provided ferrite must

be installed on the magnetic connector side of the manual use case cable.

4 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 13

2.

NOTE

KT Automation System Hardware

2.1 KT Automation Station

2.1.1 KT Automation Station Function

The KT Automation Station communicates with the KT Automation FOUP to

start missions and to extract the results after the missions are completed. The

KT Automation Station also recharges the KT Automation FOUP between

missions.

Figure 2-1 shows the KT Automation Station (including the optional signal

tower), with and without a KT Automation FOUP loaded on the station.

Components

Figure 2-1: KT Automation Station

If your system uses the optional signal tower, the signal tower is installed and

configured at the time the rest of the system is installed.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 5

Page 14

2. KT Automation System Hardware Components KT Automation Station

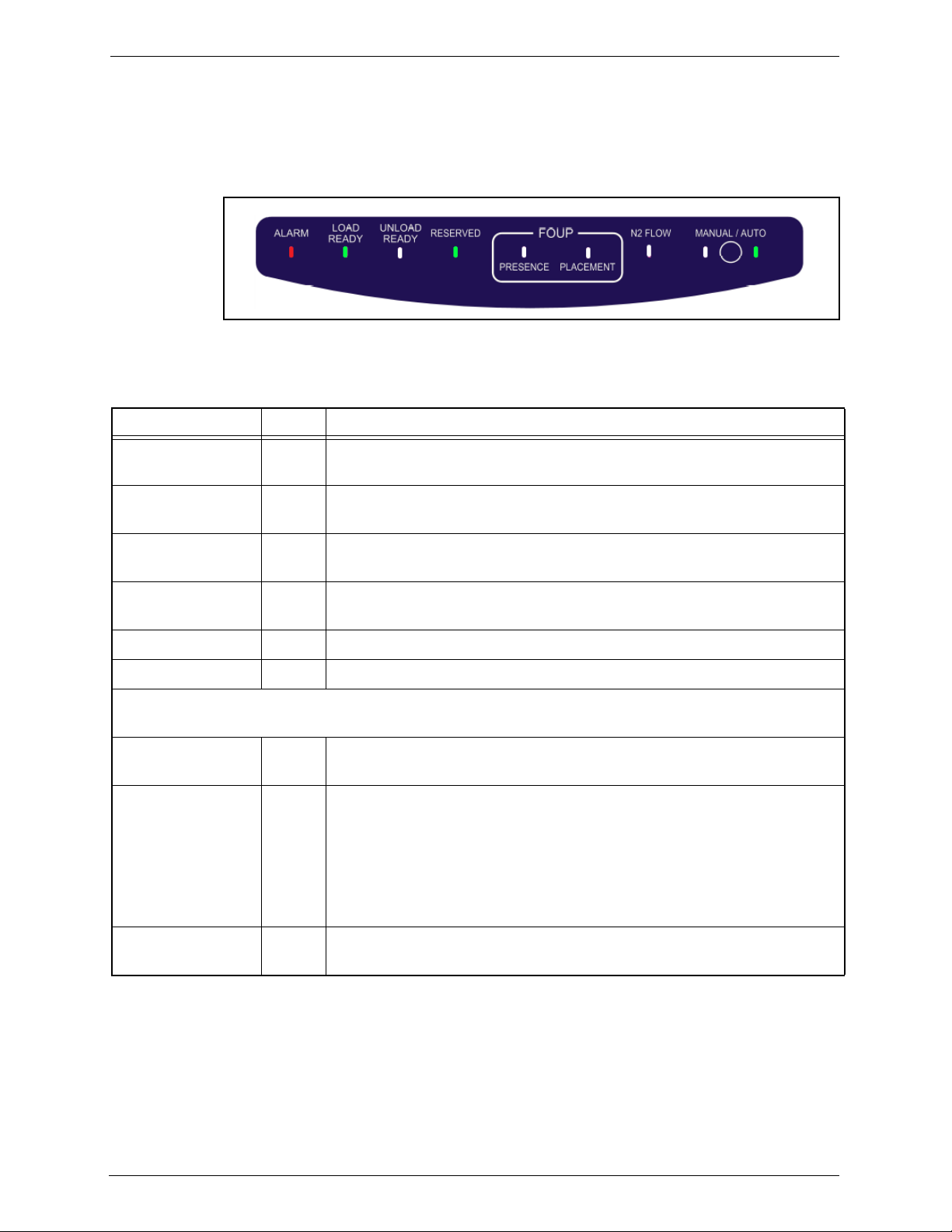

2.1.2 KT Automation Station Indicator Panel LEDs

The indicator panel at the front of the top cover (see Figure 2-2) contains all

the Automation Station LEDs, as well as the Manual/Auto control button.

Figure 2-2: KT Automation Station Indicator Panel

Table 2-1: KT Automation Station Indicator Panel LEDs

LED Name Color Description

ALARM Red Indicates a critical error (for example, application has stopped working)

that requires the operator to recover the Automation Station

LOAD READY Green Indicates the Automation Station is ready to receive a FOUP (there is

currently no FOUP on the Automation Station)

UNLOAD READY Green Indicates the FOUP can be unloaded from the Automation Station

(there is currently a FOUP loaded on the Automation Station)

RESERVED Green Indicates the Automation Station is reserved by the fab Host for a

mission

FOUP PRESENCE Green Indicates a FOUP is present on the Automation Station

FOUP PLACEMENT Green Indicates a FOUP is fully placed on the Automation Station

Important:

When a FOUP is seated properly, both the FOUP PRESENCE and the FOUP PLACEMENT LEDs are on.

N2 FLOW Indicates N2 is flowing from the Automation Station to the FOUP (in

systems that include the N2 option)

MANUAL Blinking MANUAL LED

Indicates the Automation Station is in the process of initializing and is

not yet ready for use

Steady MANUAL LED

Indicates the Automation Station is in Manual mode (user can manually

place or remove a FOUP)

AUTO Green Indicates the Automation Station is in Auto mode (controlled by the fab

Host and the OHT delivery system)

6 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 15

2. KT Automation System Hardware Components KT Automation FOUP

NOTE

The KT Automation FOUP configuration

must be updated when:

* The CID pill is written or replaced, or

* The network configuration or server

IP address has changed.

2.1.3 KT Automation Station Indicator Panel Manual/Auto Button

The Manual/Auto control button is located between the MANUAL and the AUTO

LEDs on the KT Automation Station Indicator Panel (see Figure 2-2).

The button has two functions:

1. Toggles between Auto mode and Manual mode

Press and hold the Manual/Auto control button for 5 seconds to toggle the

Automation Station between Auto mode and Manual mode, indicated by

the AUTO and MANUAL LEDs.

2. Operates the Automation Station (when the Automation station is in

Manual mode)

• When the FOUP is present on the Automation Station, press and release

the button to unclamp the FOUP and switch it to the UNLOAD READY

state (UNLOAD READY LED is green), which allows you to pick it up

manually.

• When the Automation Station is in the LOAD READY state (LOAD READY

LED is green):

• Manually place the FOUP on the Automation Station.

• Press and release the Manual/Auto control button to lock the FOUP

and connect it to the Automation Station.

2.2 KT Automation FOUP

2.2.1 KT Automation FOUP Function

The KT Automation FOUP transports the instrumented wafer to the equipment

during missions. It also charges the wafer, stores the wafer data, and

communicates the wafer data to the Automation Controller.

Figure 2-3: KT Automation FOUP

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 7

Page 16

2. KT Automation System Hardware Components KT Automation FOUP

2.2.2 KT Automation FOUP Indicators and Controls

All FOUP indicators and controls are on the rear of the KT Automation FOUP

(see Figure 2-4).

Figure 2-4: KT Automation FOUP Indicators and Controls

Table 2-2: KT Automation FOUP Indicators and Controls

Control or Indicator Color Comments

Wafer Charging LED Green Blinks when the applicable Wafer is charging

Steady when the applicable Wafer is present but not charging

(Wafer is fully charged)

Orange Steady when the applicable Wafer is absent

FOUP Charging LED Green Blinks when the FOUP is charging

Steady when the FOUP is powered On and at the Station but not

charging (FOUP is fully charged)

Orange Steady when the FOUP is powered On but is not at the Station

Reset button n/a To press the Reset button, insert a thin stylus or pen tip into the

hole

Important: Reset the FOUP only if it is an error state.

Manual power/

communication connector

ON/OFF button n/a To power down the FOUP, press and hold the ON/OFF button

n/a Used to connect a laptop to the FOUP in order to perform

manual missions, or provide power to a FOUP that has not been

at the Station for a long time

until the FOUP Charging LED turns off

8 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 17

2. KT Automation System Hardware Components KT Automation FOUP

NOTE

NOTE

2.2.3 KT Automation FOUP Data Storage and Transfer

• When the Wafer is back in the Automation FOUP, it automatically transmits

the data it collected during the mission to the Automation FOUP.

• When the Automation FOUP is placed on the Automation Station, the

Automation FOUP automatically transmits the data to the Automation

Controller to be stored in the centralized database.

• An Automation FOUP can store up to 10 hours of data.

2.2.4 KT Automation FOUP Battery

• When an Automation FOUP’s charge level goes down to 35%, an alarm is

sent to the host.

• The Automation FOUP goes into power-save mode:

• When the charge level goes down to 20%

• If it is not on a mission and has not been charged for 30 minutes

• When in power-save mode, the Automation FOUP can maintain its charge

for 6 months.

• To charge an Automation FOUP, place it on the FOUP Station and make sure

it is clamped (not in LOAD READY state), or use the manual

power/communication cable to connect it to a laptop.

If the Automation FOUP was powered off, placing it on the Automation Station

and clamping it will power it on automatically.

• When powered off, the Automation FOUP can maintain its charge for 12

months.

If the Automation FOUP loses its charge completely, please ask your KT service

representative to change the battery.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 9

Page 18

2. KT Automation System Hardware Components KT Automation FOUP

2.2.5 Option: Emulating Occupied KT Automation FOUP Slots

An available KT Automation FOUP option is a set of emulation fins for slots that

contain any electronics boxes. The fins cause load port wafer mappers to

identify those slots as occupied.

Figure 2-5: KT Automation System Topology

10 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 19

3.

3.1 Logging In

1. At the KT Automation login page, select your role (in this example,

Administrator is selected).

2. Enter your password.

3. Click Start to log in and go to the Home page (see Section 3.3).

KT Automation Web UI

3.2 Logging Out

1. From any page in the KT Automation Web UI, click Logout.

The display returns to the KT Automation login page.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 11

Page 20

3. KT Automation Web UI KT Automation Home Page

3.3 KT Automation Home Page

The Home page summarizes the current status of all KT Automation System

components, usage, and recent mission alerts. It is the first page that you see

after you log on.

1. To return to the Home page from any other KT Automation page, click

Home.

12 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 21

3. KT Automation Web UI KT Automation Home Page

3.3.1 Equipment Coverage and Usage

The Equipment Coverage & Usage area allows you to view information

about the Tools, KT Automation FOUPs, KT Wafers, and KT Automation

Stations in the system.

The color of the header for each equipment type shows the extent of usage:

• Green:High usage (>80%)

• Orange:Low usage

• Red:Not used

1. To select the time period for which you want to see coverage and usage

information, select the time period from the drop-down list in the top

right-hand corner.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 13

Page 22

3. KT Automation Web UI KT Automation Home Page

2. To view the statistics for the equipment type, hover the cursor over the

image.

Equipment Statistics Provided

Tools

KT Automation

FOUPs

KT Automation

Stations

KT Wafers

• How many configured

• How many online (as number)

• How many online (as percentage)

• How many hours purchased

• How many hours used (as number)

• How many hours used (as percentage)

3.3.2 Tool Mission Alarms

The Tool Mission Alarms area lists error messages and alerts received during

recent missions.

14 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 23

3. KT Automation Web UI KT Automation Home Page

3.3.3 Connected FOUPs

The Connected FOUPs area displays all KT Automation FOUPs (carriers) in

the system and their statuses.

For each FOUP, the following information is displayed:

1. Carrier ID

2. Carrier status

3. Wafer IDs

4. Battery level of KT Automation FOUP

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 15

Page 24

3. KT Automation Web UI Tools Page

NOTE

3.4 Tools Page

The Tools page displays information about all the tools that were set up in the

system (as described in Section 3.5.1 through Section 3.5.4).

To v ie w t h e Tools page, click Tools.

• shows that the last mission that ran on this tool was successful

• shows that the last mission that ran on this tool indicated a problem

1. You can group tools by:

•Tool Type

•Tool Location

• Mission Time (mission run date and time)

16 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 25

3. KT Automation Web UI Setup Page

IMPORTANT

IMPORTANT

3.5 Setup Page

Use the Setup page to add new or edit existing tools and mission recipes.

Mission recipes are added or edited for Automation Metrology Wafers only. See

Section 3.8.1 for details of adding or editing recipes.

1. To view the Setup page, click Setup.

3.5.1 Edit or Add Tool

Before you can add a new tool, the applicable tool type and handler type must

have been defined in the system (see Section 3.5.2 and Section 3.5.3).

1. In the Setup page, make sure Tools is selected (the default selection

when the Setup page opens).

2. Continue as follows:

• To edit an existing tool, click the Edit icon for the tool.

• To add a new tool, click + New Tool.

In either case, the Edit Tool window opens.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 17

Page 26

3. KT Automation Web UI Setup Page

NOTE

3

3. In the Edit Tool window, enter or select a value for every field.

If you are editing an existing tool, enter or select new values only for those

fields that you need to update.

4. Click Save to save the values and close the Edit Tool window.

3.5.2 Edit or Add Tool Type

1. In the Setup page, click Tool Type.

2. Continue as follows:

• To edit an existing tool type, click the Edit icon for the tool type.

• To add a new tool, click + New Tool Type.

In either case, the Tool Type Edit window opens.

18 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 27

3. KT Automation Web UI Setup Page

NOTE

IMPORTANT

If you are editing an existing tool type, enter or select new values only for

those fields that you need to update.

3. In the Tool Type Edit window, type a Tool Type Name.

Use an informative name that includes information that will be important for

operators to know about the tool.

4. Select the Tool Type Recipe.

5. Continue as follows:

If you want to... Then continue with...

Create a new Tool Type Sequence

Modify an existing Tool Type Sequence

step 6

step 11

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 19

Page 28

3. KT Automation Web UI Setup Page

NOTE

6. To create a new Tool Type Sequence from scratch, click +New.

Each location that wafers visit within a tool is called a tool station.

7. From the list of available stations, select the first station in the sequence.

8. Continue clicking +New and selecting stations until you have selected

every station in the sequence.

9. For the last station in the sequence (in this example, FOUP), click Finish

here to select that station and remove the option to select from the other

stations.

10. Click Save to save the new tool type and close the Tool Type Edit

window.

20 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 29

3. KT Automation Web UI Setup Page

11. You can modify an existing Tool Type Sequence in any of the following

ways:

• Change the station where the sequence finishes

• Delete a station from the sequence or replace it with a different station

• Add another station to the sequence

12. To change the station where the sequence finishes:

• Click to deselect the station.

Every station in the sequence then displays the option to select it.

•Click Finish here to select the new station where the sequence

finishes.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 21

Page 30

3. KT Automation Web UI Setup Page

NOTE

13. To delete a station from the sequence or replace it with a different station:

• Click for that station.

•Click Replace station.

• To delete the station, click Delete station.

• To replace the station, click the station from the list of available station.

The list contains those stations that are set up in the KT Automation System

but are not currently used in this Tool Type Sequence.

14. When you have made all the required changes to the Tool Type

Sequence, click Save to save the changes and close the Tool Type Edit

window.

22 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 31

3. KT Automation Web UI Setup Page

NOTE

IMPORTANT

3.5.3 Edit or Add Handler Type

The only parameter that is entered for a Handler Type is the Name.

1. In the Setup page, click Handler Types.

2. Continue as follows:

• To edit an existing handler type, click the Edit icon for the handler type.

• To add a new handler type, click + New.

3. Type the Name for the handler type.

Use an informative name that shows the robot type, the number of load ports,

and any other information that will be important for operators to know about

the handler type.

4. Click to save.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 23

Page 32

3. KT Automation Web UI Setup Page

NOTE

IMPORTANT

3.5.4 Edit or Add Wafer Sequence

The only parameter that is entered for a Chamber or Station is the Name.

1. In the Setup page, click Wafer Sequence.

2. Continue as follows:

• To edit an existing chamber or station, click the Edit icon for the

chamber or station.

• To add a new chamber, click + New Chamber.

• To add a new location, click + New Station.

3. Type the Name for the chamber or station.

Use an informative name that includes information that will be important for

operators to know about the chamber or station.

4. Click to save.

24 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 33

3. KT Automation Web UI History Page

NOTE

IMPORTANT

3.6 History Page

The History page displays information about missions that have run.

1. To view the History page, click History.

• shows that the mission ran successfully

• shows that the mission did not run successfully

3.7 Administration Page

The Administration page allows those with Administrator-level privileges to

remote-connect to KT Automation Stations to perform troubleshooting.

The Administration page is available only to those who log in with the role of

Administrator.

1. To view the Administration page, click Administration.

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 25

Page 34

3. KT Automation Web UI Automation Metrology Wafer Functions

3.8 Automation Metrology Wafer Functions

3.8.1 Edit or Add an Automation Metrology Wafer Mission Recipe

1. In the Setup page, click Recipes.

2. Click the folder where the recipe you want to edit or add is located.

3. Continue as follows:

If you want to... Then continue with...

Add a new folder

Edit an existing recipe or add a new recipe

4. To add a new folder:

•Click Folder.

• Type the Folder Name.

step 4

step 5

•Click Save.

26 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 35

3. KT Automation Web UI Automation Metrology Wafer Functions

NOTE

5. To edit an existing recipe or add a new recipe:

• Click the Edit icon for the recipe, or

•Click +New Recipe.

If you are editing an existing recipe, enter or select new values only for those

items that you need to update.

6. Type a Recipe Name.

7. Select a Recipe Type.

8. Select the recipe’s Start Trigger (the trigger to start data acquisition).

The following are available start triggers:

Trigger Description

Door Open FOUP door opens

Delay Data acquisition begins after specified delay (in seconds) from

start of mission

Wafer Leaves FOUP Wafer is picked from the FOUP at the start of a tool mission

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 27

Page 36

3. KT Automation Web UI Automation Metrology Wafer Functions

9. If you selected Delay in the previous step, enter the Delay (seconds).

10. Select the recipe’s Stop Trigger (the trigger to stop data acquisition).

The following are available stop triggers:

Trigger Description

Door Close FOUP door closes

Duration Data acquisition ends after the specified duration (in

seconds) of data acquisition

Wafer Return to FOUP Wafer is returned to the FOUP at the end of a tool mission

11. If you selected Duration in the previous step, enter the Duration

(seconds).

12. When you have entered all the values, click Save.

28 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 37

3. KT Automation Web UI Automation Metrology Wafer Functions

IMPORTANT

3.8.2 Define and Execute an Automation Metrology Wafer User Mission

The User Mission page allows you to define and execute an Automation

Metrology Wafer user mission.

Before you can define a mission, the applicable recipes, tools, and carrier IDs

must have been defined in the KT Automation system (see Section 3.5

Section 3.8.1).

1. To view the User Mission page, click User Mission.

and

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 29

Page 38

3. KT Automation Web UI Automation Metrology Wafer Functions

NOTE

2. Select the following:

• Tool ID of the target tool to be measured by the mission

Tool Type is populated automatically once Tool ID is selected.

• Tool Recipe to be executed by the tool when the FOUP is placed on the

tool

• Carrier ID of the FOUP that will execute the mission

• Wafer ID of the wafer that will execute the mission

• Mission Recipe that defines the mission’s start and stop parameters

• Analysis Recipe that defines the template used to analyze the raw

data and provide the results (SensArray wafers only)

• Chamber in which the recipe will be executed (optional)

30 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Page 39

3. KT Automation Web UI Automation Metrology Wafer Functions

3. If you want the results of the mission to be reported to the FA Host, click

Report to FA Host.

4. Type the Load Port Number of the load port on which the FOUP will be

loaded (if applicable to the selected recipe).

5. When you have set up all the mission parameters and loaded the FOUP on

the load port, click Execute.

Once the mission is completed and the FOUP has been returned to the station,

mission data is automatically uploaded to the Automation Controller and is

visible on the History page (see Section 3.6).

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 31

Page 40

This page was intentionally left blank

Page 41

Glossary

Term,

acronym,

abbreviation Description

CID Wafer Carrier ID (serial number contained in RF Pill of FOUP;

might also be Lot ID, if written by fab)

FA Factory Automation (software- and communications-based control

of a semiconductor fab)

FOUP Front-Opening Universal Pod (wafer container)

GEM Generic Model for Communications and Control of SEMI Equipment

GSS Global Support Services (KLA-Tencor Support organization).

HWID Hardware ID (serial number of the specified hardware component

such as SensArray Wafer)

KT KLA-Tencor Corporation

KTAF KT Automation FOUP (to charge, transport, and store KT in situ

test wafers)

KTAS KT Automation Station (charging and communication station for

Automation FOUPs)

MES Manufacturing Execution System (the fab Host)

Mission Execution of a single KT Automation job/cycle

OHT Overhead Transport system (fab automation system for FOUP

transportation)

UI User Interface

WID Wafer ID (T7 Mark on the bottom of the wafer)

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution 33

Page 42

This page was intentionally left blank

Page 43

Revision History

Revision

Date

10/2016 AA Initial Issue Avi Zaban Henry Lam

New Rev.

Level Changes Made Reviewer Approver

AB DCR T35533: Add Regulatory Compliance Statements

(Section 1.4); other minor edits

Avi Zaban Henry Lam

PRELIMINARY

9022549-000/AB KLA-Tencor Confidential - Restricted Distribution REV HISTORY-35

Page 44

PRELIMINARY

This page intentionally left blank.

REV HISTORY-36 KLA-Tencor Confidential - Restricted Distribution KT Automation User Guide

Loading...

Loading...