KLA 482-22-0800 User Manual

Accura°C

User Manual

°SensArray

47451 Fremont Blvd.

Fremont, CA 94538

510-360-5600

Fax 510-360-5601

info@sensarray.com

www.sensarray.com

Copyright © 2003 by °SensArray® Corporation. All rights reserved.

UM-ACC-A 2003.02

This manual applies to the 3.0.6 version of Thermal MAP software.

°SensArray reserves the right to modify, change, or improve any or all specifications

published in this document without notice.

Important Notices

Warranty

Thermal MAP Software

SensArray Corporation warrants that (a) Thermal MAP software (Software) will perform

substantially in accordance with the accompanying written materials for a period of 12 months after

shipment, and (b) the medium on which the Software is recorded will be free from defects in

materials and workmanship under normal use and service for a period of 12 months after shipment.

Faults caused by unauthorized modification, misuse or abuse of products, or problems due to

software not supplied by SensArray, are not covered by this Warranty. During the Warranty Period,

the purchaser may return failed Software to SensArray for repair or replacement, at SensArray’s

option. SensArray does not warrant that the operation of the Software shall be uninterrupted or

error free. The purchaser will first notify SensArray of the nature of the problem and obtain a

Returned Materials Authorization [RMA] number. The purchaser will pay the costs of shipping

returned Software to SensArray; SensArray will pay the cost of shipping repaired/replaced

Software to the purchaser. No other warranty is expressed or implied. SensArray specifically

disclaims the implied warranty of merchantability and fitness for a specific application.

The Thermal MAP Software Documentation Materials (“Documentation”) are subject to revision

and change without notice. SensArray agrees to make a best effort attempt to keep the purchaser

advised of changes to the Documentation.

Accura°C System Hardware

SensArray Corporation warrants that the Accura°C Systems (“Products”) sold will be free from

defects in material and workmanship, and perform to SensArray’s applicable published

specifications for a period of 12 months after shipment. The liability of SensArray hereunder shall

be limited to replacing or repairing, at its option, any defective Products that are returned F.O.B. to

SensArray’s plant in Fremont, CA. In no case are Products to be returned without the purchaser

first obtaining SensArray’s permission and Returned Materials Authorization [RMA] number. In no

event shall SensArray be liable for any consequential or incidental damages. Products that have

been subject to abuse, misuse, accident, alteration, neglect, or unauthorized repair or installation are

not covered by this warranty. SensArray will make the final determination as to the existence and

cause of any alleged defect. SensArray is not responsible for maintaining or supplying any

consumable materials used in conjunction with this hardware and SensArray is not liable for

expendable items such as fuses, lamps, paper, ink, etc. No warranty is made with respect to any

customized equipment or Products supplied with Accura°C systems where produced to Purchaser’s

specifications except as specifically stated in writing by SensArray in the contract for such

Products. The purchaser will pay the shipping costs of returned materials to SensArray; SensArray

will pay the cost of shipping repaired/replaced material to Purchaser. This Warranty is the only

warranty made by SensArray with respect to the Product delivered hereunder and may be modified

only by a written instrument that is signed by a duly authorized officer of SensArray and accepted

by Purchaser. Except as provided above, SensArray makes no warrantees, expressed or implied,

including any warranty of merchantability for a particular purpose.

Software License Agreement

The Software is owned by SensArray Corporation and is protected by United States copyright laws

and international treaty provisions. Therefore, you must treat the Software like any other

copyrighted material. Under the Copyright Laws, the Thermal MAP Software, or accompanying

written materials, may not be copied, photo-copied, reproduced, translated, in whole or in part,

without the prior written permission of SensArray.

You may make one copy of the Software solely for backup or archival purposes.

You may make 10 copies of the written materials accompanying the SensArray Corporationproduced Software provided that such copies are solely for use by personnel using Thermal MAP.

All rights not expressly granted to you in this Agreement are reserved to SensArray Corporation.

Third-Party Software

Licenses for any software which was provided but not produced by SensArray Corporation are

granted solely and only by the original supplier or manufacturer and solely and only with the

supplier’s limitations and rights. Copying restrictions for such software are governed solely and

only by the original supplier or manufacturer’s license or any other supplier-approved agreements,

as applicable.

Trademarks

°SensArray®, Thermal MAP®, and Accura°C are trademarks of SensArray Corporation.

Windows and Excel are trademarks or trade names of Microsoft Corporation.

Any other terms mentioned in this document that are known to be trademarks or service marks have

been appropriately capitalized. Use of a term in this document should not be regarded as affecting

the validity of any trademark or service mark.

FCC Compliance Statement:

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

CAUTION: Changes or modifications not expressly approved by the manufacturer

responsible for compliance could void the user’s authority to operate the equipment.

Important Note: To comply with FCC RF exposure compliance requirements, the antenna

used for this transmitter must be installed to provide a separation distance of at least 20cm from al

persons and must not be co-located or operating in conjunction with any other antenna or

transmitter.

European Union Notice

This system has been tested for conformance with CE radio spectral, EMC and safety requirements.

Chapter 1

Overview

The Accura°C system is a unique robot loadable temperature measurement system

designed for advanced track systems with two or more robot arms. The Accura°C system

consists of a Process Probe 1880 thin film RTD hybrid wafer in combination with an

advanced battery powered, disk-shaped, intelligent sensor interface system (DISIS),

which is the same diameter and weight of a process wafer. The data collected by the

system is sent to a laptop computer running Thermal MAP software via a Bluetooth

wireless connection for later analysis.

The Accura°C User Manual is designed as a quick reference document to setup and use

the Accura°C system in conjunction with the Thermal MAP software. For more detailed

information on using the Thermal MAP software, please refer to the Thermal MAP 3

User Manual or the help file. A PDF version of the manual may be found in the

C:\Sensarray\Documents folder on the laptop hard drive.

This chapter discusses the features of the Accura°C system.

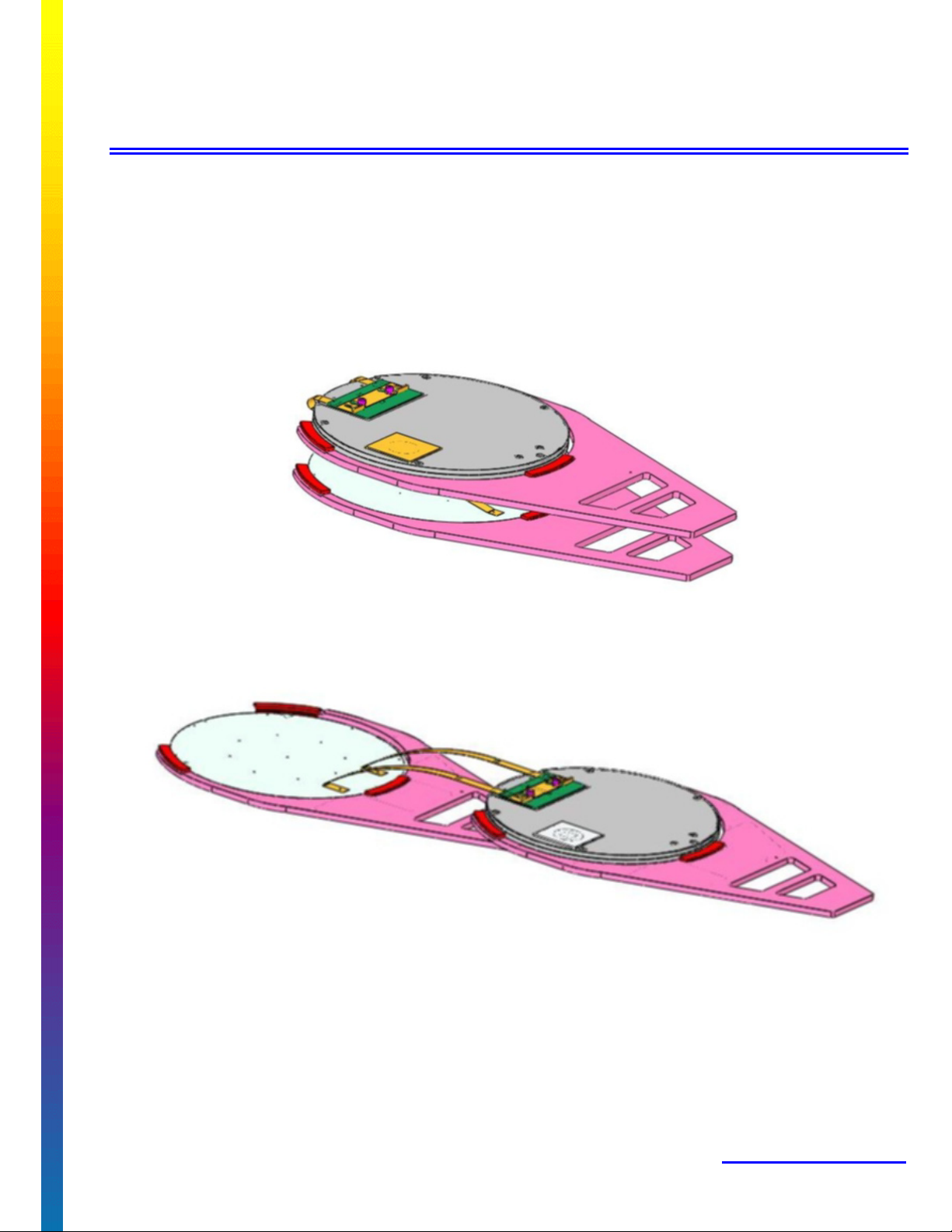

The Accura°C System

The wafer and the DISIS are connected using two specially developed polyimide flat

cables and placed on the lower and upper robot arms respectively. The robot arm holding

the Process Probe 1880 wafer extends at half the normal speed to place the instrumented

wafer on the hotplate. The system is now ready to make measurements. The Accura°C

system can be setup to follow the exact movement of a product wafer to measure the

transient temperature conditions on the wafer during both transportation and thermal heat

up and cool down.

Figure 1. Accura°C System on Retracted Robot Pincers

Measurements taken by the sensors are converted from analog to digital signals within

the DISIS module, which are then exported via Bluetooth RF link and received by the

Bluetooth antenna at the laptop computer. The Thermal MAP software on the computer is

triggered to collect data from the antenna, which is then processed, analyzed and

displayed.

°SensArray 1-1 Accura°C User Manual

Chapter 1 Overview

Acquiring Data

The Thermal MAP software acquires and logs the data collected by the Accura°C system.

With the Thermal MAP data acquisition features, you can simultaneously view and log

wafer temperature sensor data. The data is observed on the strip charts and digital

readouts during the acquisition.

The software allows the user to determine how often and for how long the data points

will be collected. The user may chose which temperature scale the data will be calculated

in, or display the direct resistance output of each sensor on the wafer.

Thermal MAP measures the uncorrected sensor signals, applies corrections for sensor and

data acquisition system calibration offsets, then converts the readings to temperature. The

data is saved to the laptop hard disk for later analysis.

Analyzing Data

Previously logged data files may be analyzed using a powerful graphic interface to view

XY graphs, contour maps, surface maps, animations, and data tables. The logged data is

stored in a data table. Thermal MAP Analysis graphics can be viewed directly without

opening the data table. Or the data can be viewed and evaluated in table form, if desired.

A row in the table is called a sample or a single-timed sampling of all of the sensors on

the wafer and system inputs. You use the sample number to identify the table row of

measurements collected at the sample time.

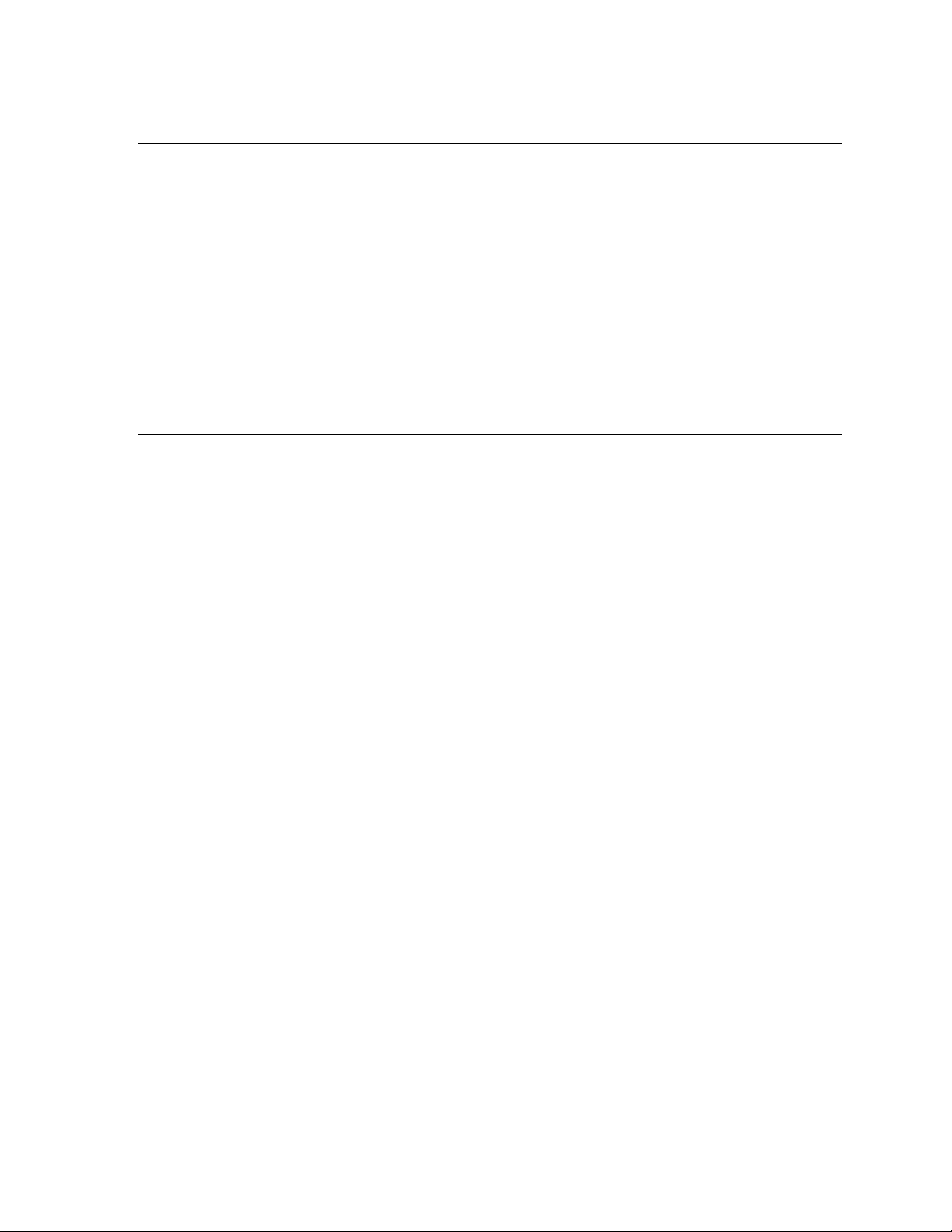

The first column in the table is the sample number. The second column is the elapsed

time at which the sample was acquired. For example, as shown in Figure 2, Sample# 0

has a time of zero. The remaining columns in the table are the temperatures of the

individual RTD sensors within the wafer. Additional columns of data can be present if

system sensors, digital, and/or calculated values have been logged.

In addition to the data within the table, the data file stores other pertinent information—

including run date and time, operator’s name, and a description of the test—which you

enter before acquisition.

Accura°C User Manual 1-2 °SensArray

Chapter 1 Overview

Figure 2. Sample Data Table

During acquisition, Thermal MAP performs computations on acquired data, such as

determining the minimum, maximum, mean, range (max-min), and standard deviation of

all wafer sensor values for the sample, and logs the results in columns. These computed

values are referred to as calculated values.

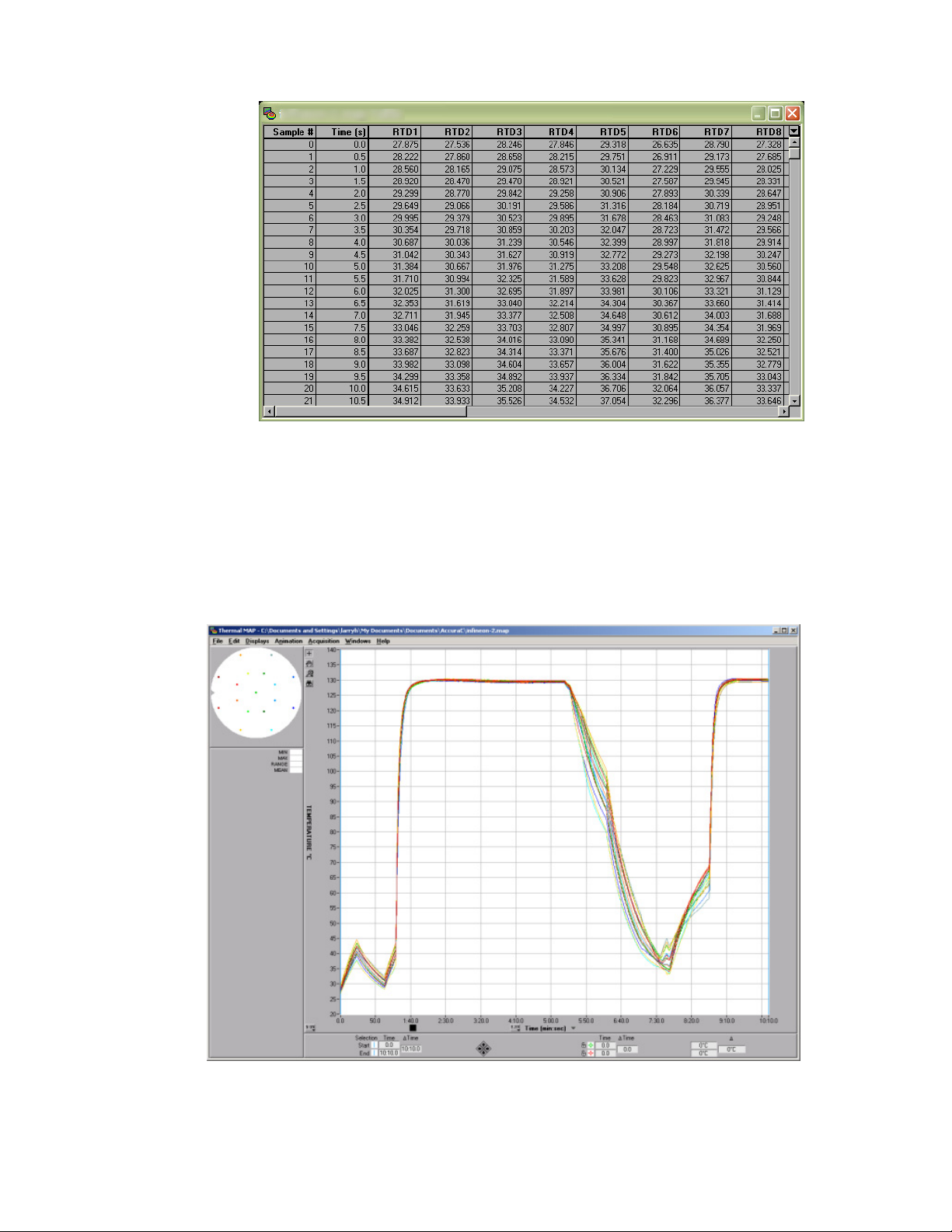

After acquiring, linearizing, and storing the sensor data, you can display or print the data

as a line plot graph, as shown in Figure 3. In addition, you can display data in a table or

as a wafer map.

Figure 3. Displaying Data on a Line Plot Graph

°SensArray 1-3 Accura°C User Manual

Chapter 1 Overview

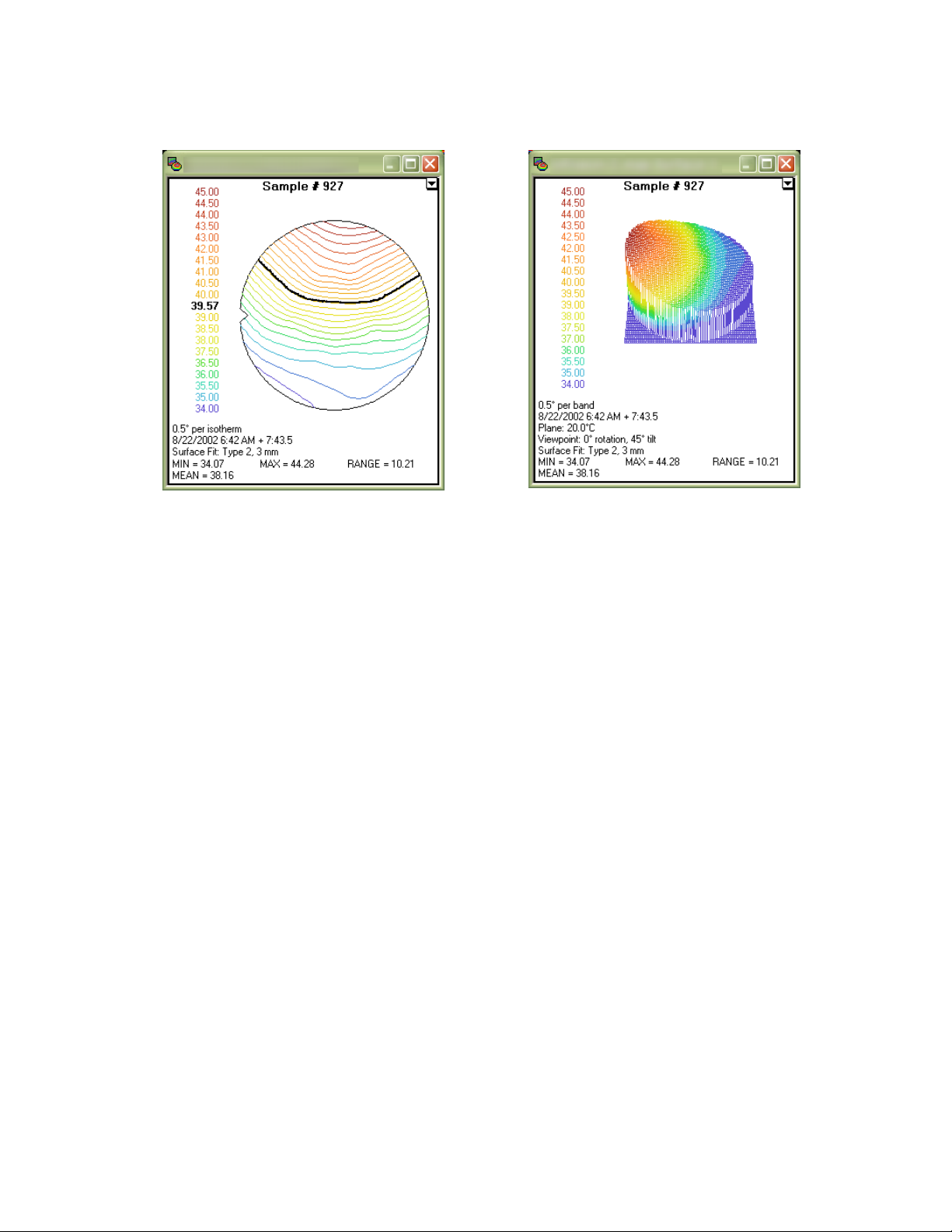

You can also display a 2-dimensional color contour map as shown in Figure 4 or a 3dimensional surface map as shown in Figure 5.

Figure 4. Two-Dimensional Color Contour Map Figure 5. Three-Dimensional Surface Map

With the Animation feature, an animation of the acquired data can be created. The

animation can be set for a particular range of the acquired data, saved to a standard AVI

file, and replayed at any time. The AVI file can be sent to other computers not running

the Thermal MAP software and played using the Windows Media Player

With the Derived Files Feature, statistical data can be generated for selected periods of an

acquisition run. In addition, the differences in selected sensor readings between two

different acquisition runs may be compared.

Data may also be exported to a spreadsheet program, edited in the spreadsheet, and

loaded back to Thermal MAP for further analysis.

Accura°C User Manual 1-4 °SensArray

Chapter 2

System Setup and Operation

Before you can begin working with the Accura°C system, you need to unpack the system

components, prepare the equipment for transfer to the cleanroom, and connect the system

cables.

Connecting the System

Before shipping, SensArray assembles and tests the Accura°C system. The Thermal MAP

software is preinstalled and configured. To setup the system, you only need to connect

the cable from the wafer to the DISIS unit and install the Bluetooth module to the laptop.

Do not load any additional software on the system hard drive. All required

software is loaded and tested prior to shipping.

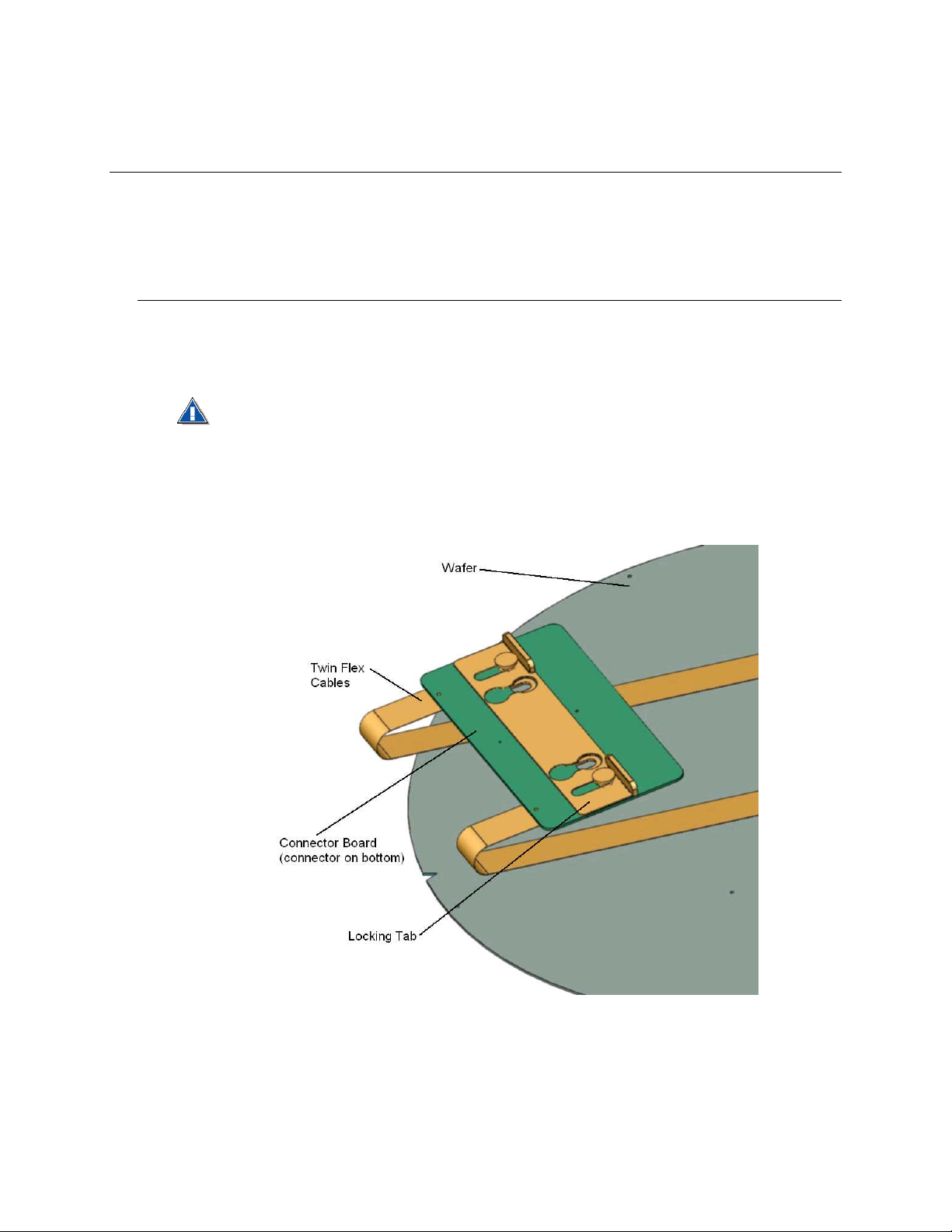

Connecting the Wafer to the DISIS

To connect wafer and DISIS unit, complete the following instructions.

1. Slide the locking tab on the wafer connector forward to unlock the connector.

Figure 1. Connector Board Components

2. Place the DISIS unit and the wafer so that the twin cable and connector face each

other as shown in Figure 2.

°SensArray 2-1 Accura°C User Manual

Loading...

Loading...