KKT chillers cBoxX 60, cBoxX 70 Installation Manuallines

cBoxX SERIES

INSTALLATION GUIDELINES

cBoxX 60

cBoxX 70

830.013.02.K_Installation Guidelines (USA ONLY!) - cBoxX (Version 1.3).docx

KKT chillers, Inc.

Model:

cBoxX 60

cBoxX 70

Net (Empty / Dry) Weight:

1,367 lb. (620kg)

1,433 lb. (650kg)

Gross (Operating / Wet) Weight:

1.477 lb. (670kg)

1.543 lb. (700kg)

Fig. 1 - Machine base (foot) – outside view

Fig. 2 - Machine base (foot) – inside view

Installation Guidelines

See KKT chillers Installation and Operation Manual for further details

1. Foundation, dimensioning and transport

1.1 Concrete Foundation:

Verify that the installation surface has sufficient load capacity

(see chart below)

A level concrete foundation is recommended.

A concrete foundation needs to be 8 in. (200mm) wider and 8

in. (200mm) longer than the chiller cabinet.

Leveling feet (Fig. 1 & 2) are used for vibration

isolation and height adjustment.

Rooftop curbing to be installed per your local building code

specifications.

1.2 Minimum Pad Dimensions:

• cBoxX 60: Approx. 57in. (1448mm) long by 41 in. (1041mm)

wide.

• cBoxX 70: Approx. 81in. (2057mm) long by 41 in. (1041mm)

wide.

cBoxX 60 cBoxX 70

1.3 Chiller weights:

830.013.02.K_Installation Guidelines (USA ONLY!) - cBoxX (Version 1.3).docx

1 | Page

Transport. (Crated) Weight:

1720 lbs. (780kg)

1863 lbs. (845kg)

830.013.02.K_Installation Guidelines (USA ONLY!) - cBoxX (Version 1.3).docx

2 | Page

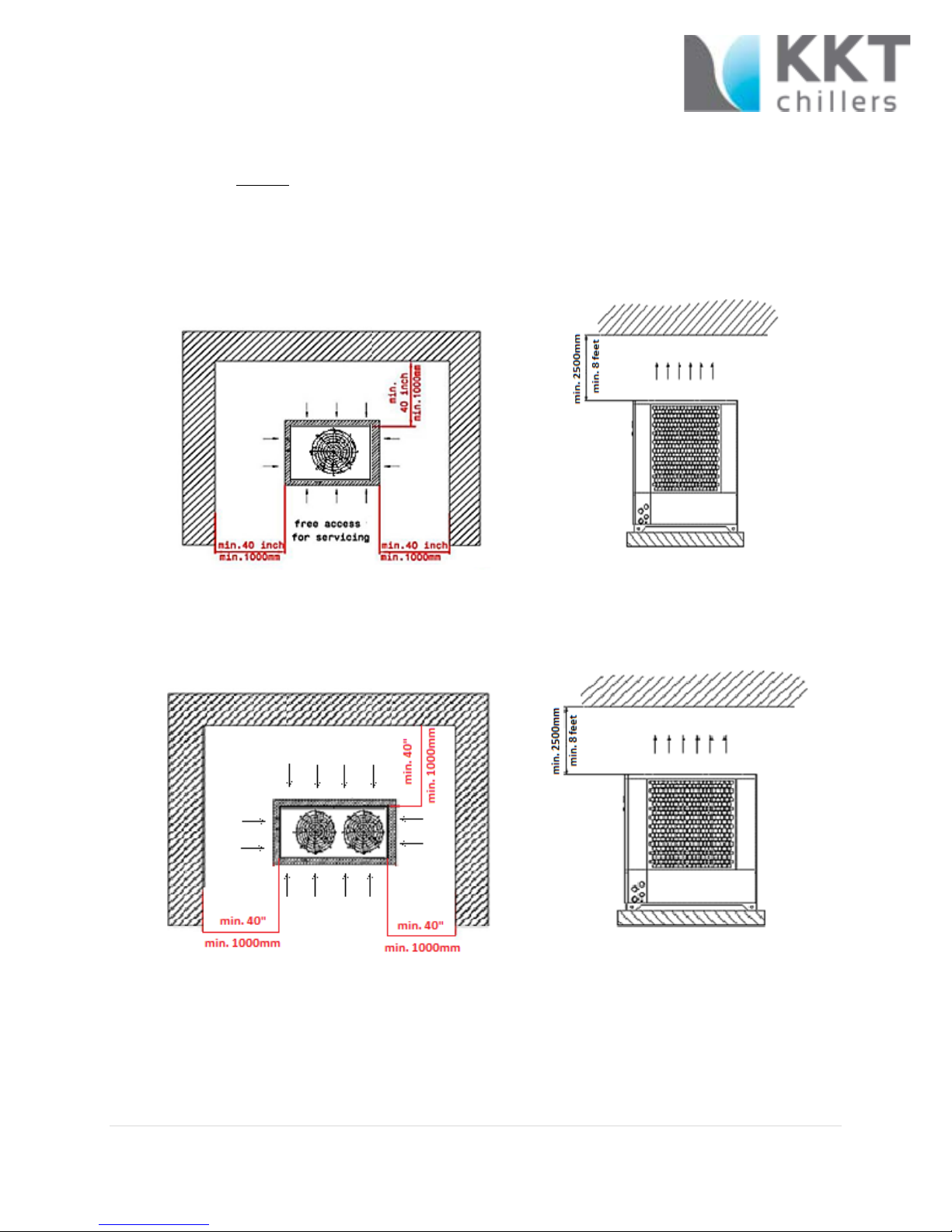

1.4 Installation Clearance:

Maintain at least 40 in. (1000mm) around all four sides of the chiller for air circulation and

servicing.

Maintain at least 8 feet clearance (2500mm) above the chiller to allow proper discharge of

warm air from the chiller.

cBoxX 60:

cBoxX 70:

830.013.02.K_Installation Guidelines (USA ONLY!) - cBoxX (Version 1.3).docx

3 | Page

37 in.

37 in.

37 in.

37 in.

1 in.

2 in.

1 in.

2,6 in.

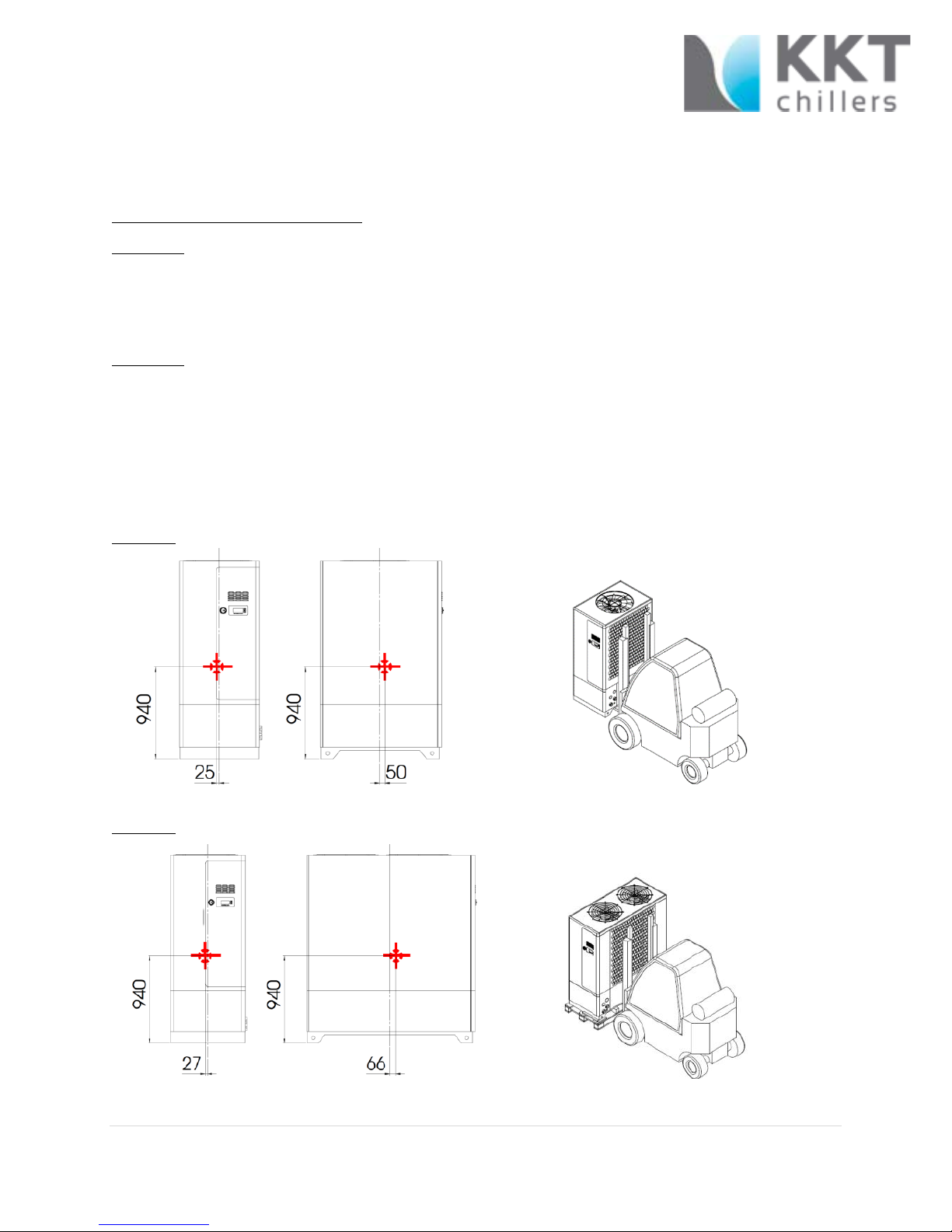

1.5 Transporting and Rigging

Transport (Crated) Measurements:

cBoxX 60:

Length: Approx. 56 in. (1430 mm).

Width: Approx. 41 in. (1030 mm).

Height: Approx. 88 in. (2230 mm).

cBoxX 70:

Length: Approx. 80 in. (2030 mm).

Width: Approx. 41 in. (1030 mm).

Height: Approx. 88 in. (2230 mm).

You will also need to consider the height of the transport equipment

(pallets, lift truck, transport rollers, etc.)

cBoxX60

cBoxX70

830.013.02.K_Installation Guidelines (USA ONLY!) - cBoxX (Version 1.3).docx

4 | Page

118 in.

, 3,94 in.

, 0,2 in.

, 1,2-2 in.

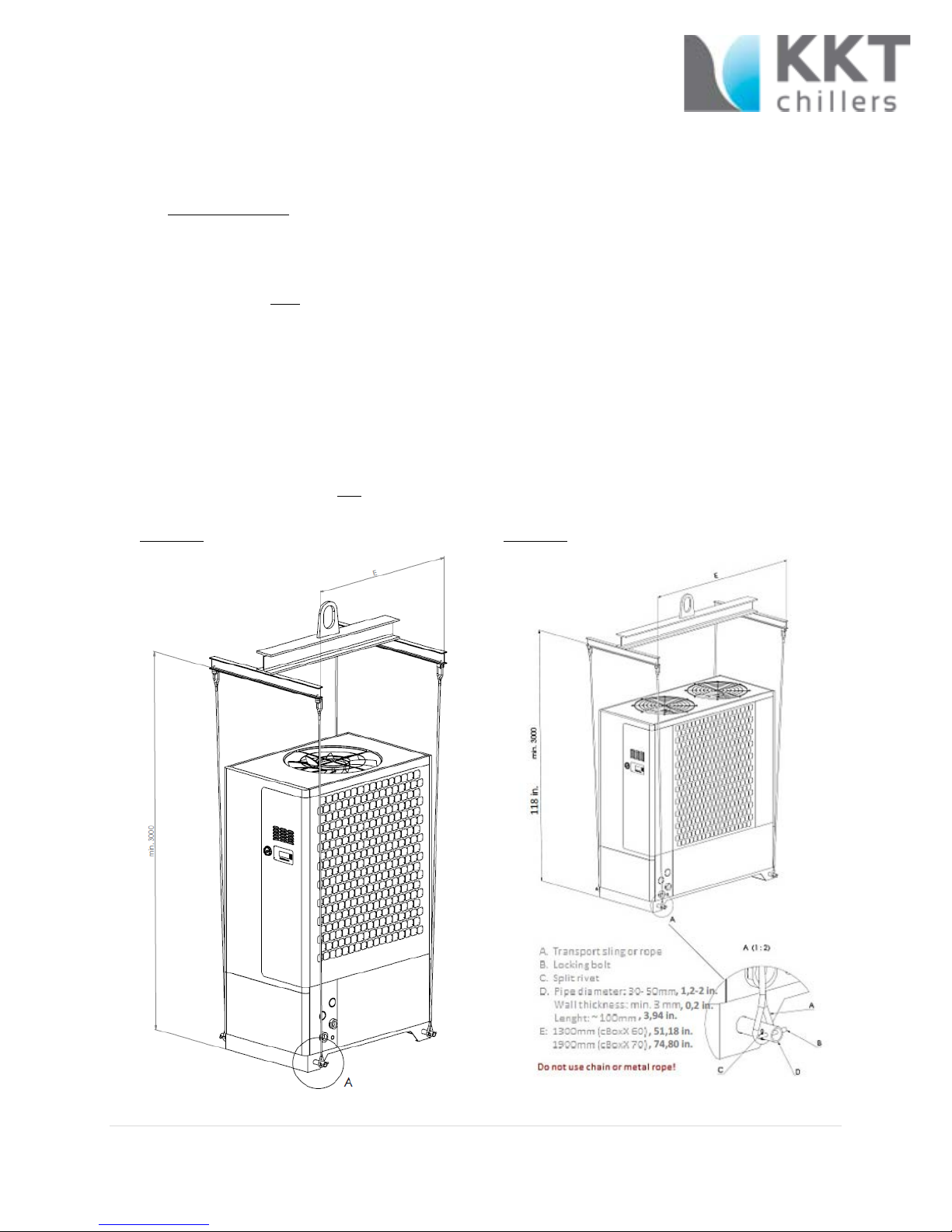

1.6 Crane Transport:

If a crane will be used to transport the chiller, please note the following:

Lift the chiller only from its base. Insert two steel rods through the holes in the base. Rods

must be specifically designed for this purpose, and able to support the weight of the unit (see

chart).

Secure the rods with locking pins to prevent shifting. Use only lifting straps or rope for lifting

from the rod

The straps or ropes must be held in place with a frame to keep them from pressing into the

side walls, gutters, and condenser body. (Refer to the following graphic).

Metal rope or chains, must

not

be used!

cBoxX60 cBoxX70

830.013.02.K_Installation Guidelines (USA ONLY!) - cBoxX (Version 1.3).docx

5 | Page

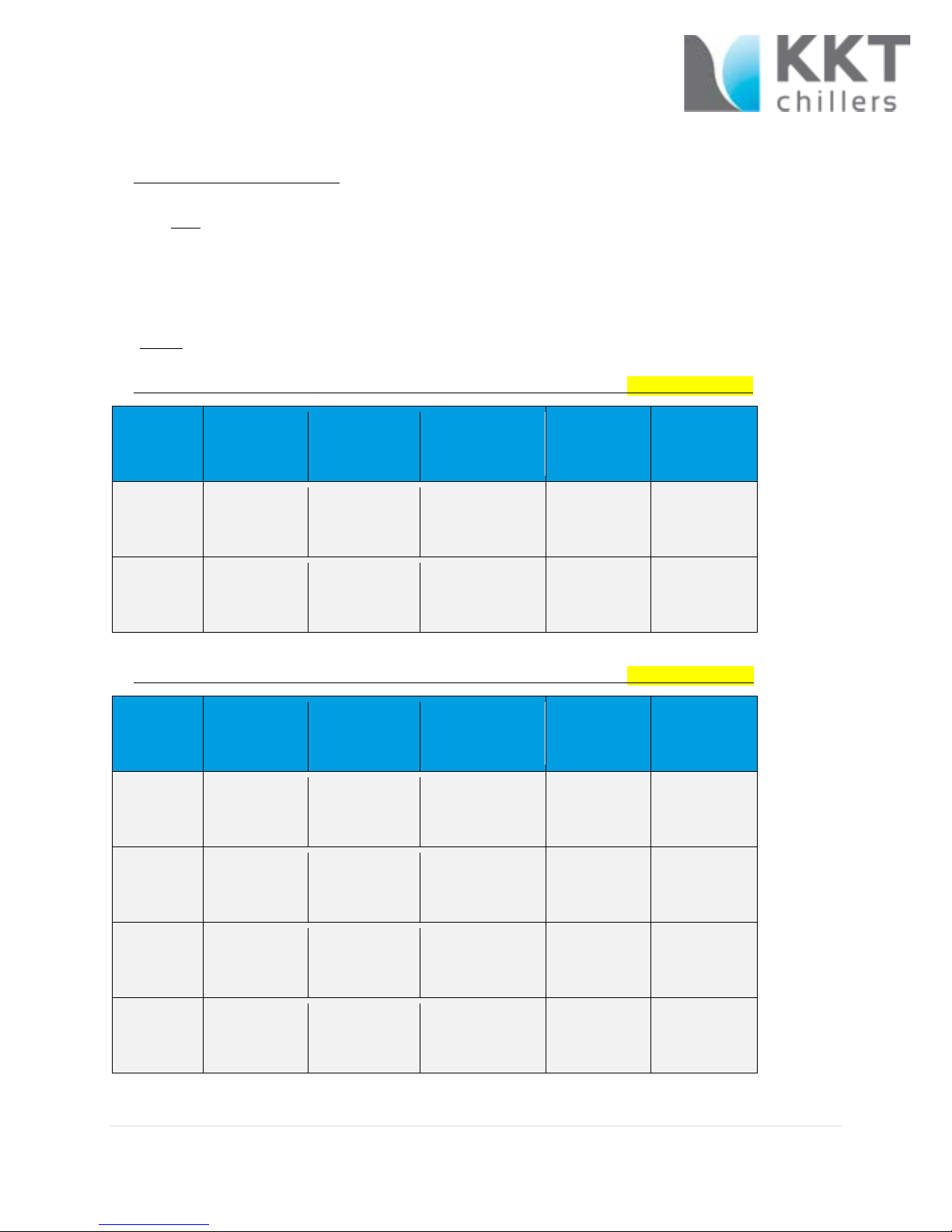

Max Allowed

Level

Max Long

Elbows

10 long

20 round trip)

10 long

20 round trip)

Max Allowed

Level

Max Long

Elbows

10 long

20 round trip)

10 long

20 round trip)

10 long

20 round trip)

10 long

20 round trip)

2. Piping and Installation

2.1 Piping Materials Allowed

Use only the following materials for the pipes:

1. Copper is recommended

2. Stainless steel

3. PE or PVC – ensure that the appropriate steps are taken to protect the pipe along its length.

Never

use galvanized piping!

2.2 Relation of Pipe Diameter to Distance between Chiller and CIP

KKT Chiller

cBoxX 60

US-Version

cBoxX 70

US-Version

Elevation

above Sea

2000 1-1/2” RP

2000 2” RP

Connections at

Chiller (metric)

Max Allowed One

Way Piping

<=50M (164’) @

1-1/2” Pipe

0-100M (328’) @

1-1/2” Pipe;

radius elbows

radius elbows

/ Chiller below MRI

Radius 90

Degree

one way (or

one way (or

Glycol

(35% to 50%)

35% to 50%

35% to 50%

2.3 Relation of Pipe Diameter to Distance between Chiller and CIP

KKT Chiller

cBoxX 60

US-Version

cBoxX 60

US-Version

cBoxX 70

US-Version

cBoxX 70

US-Version

Elevation

above Sea

2000 1-1/2” RP

2000 1-1/2” RP

2000 2” RP

2000 2” RP

Connections at

Chiller (metric)

Max Allowed One

Way Piping

<=50M (164’) @

1-1/2” Pipe

<=100M (328’)

@ 2” Pipe

<=50M (164’) @

1-1/2” Pipe;

<=100M (328’)

@ 2” Pipe;

radius elbows

radius elbows

radius elbows

radius elbows

/ Chiller above MRI

Radius 90

Degree

one way (or

one way (or

one way (or

one way (or

Glycol

(35% to 50%)

35% to 50%

35% to 50%

35% to 50%

35% to 50%

830.013.02.K_Installation Guidelines (USA ONLY!) - cBoxX (Version 1.3).docx

6 | Page

Loading...

Loading...