Page 1

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Manufacturer

Manufacturer

ManufacturerManufacturer

ait-deutschland GmbH T +49 9228 9977 0

Industriestraße 3 F +49 9228 9977 149

95359 Kasendorf E info@kkt-chillers.com

Germany W www.kkt-chillers.com

Representative in the US and Service Center

Representative in the US and Service Center

Representative in the US and Service CenterRepresentative in the US and Service Center

KKT chillers, Inc. T 847 734 1600

1280 Landmeier Road F 847 734 1601

Elk Grove TF 866 517 6867

IL 60007 E support@kkt-chillersusa.com

YOUR LOCAL S

YOUR LOCAL SERVICE CONTRACTOR IS:

YOUR LOCAL SYOUR LOCAL S

COMPANY NAME:

PHONE NUMBER: FAX NUMBER:

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

ERVICE CONTRACTOR IS:

ERVICE CONTRACTOR IS:ERVICE CONTRACTOR IS:

U/S

U/SU/S

page

page 1111von

page page

von39

39

vonvon

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 2

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

Contents

Contents

ContentsContents

I Technical Data ..................................................................................................................... 4

I. Basics .................................................................................................................................. 5

II. Installation site .................................................................................................................. 7

a) Ambient temperatures ................................................................................................. 7

b) Clearance ...................................................................................................................... 7

c) Servicing and repair access ......................................................................................... 7

d) Air flow .......................................................................................................................... 7

e) Load capacity of the base............................................................................................ 7

III. Transport route/transport ............................................................................................. 10

a) Transport measurements ......................................................................................... 10

b) Transport weight ....................................................................................................... 10

c) Transport safety locks ............................................................................................... 10

d) Crane transport ......................................................................................................... 10

e) Dimensions in inch .................................................................................................... 12

f) Dimensions in mm ..................................................................................................... 13

g) Weights ...................................................................................................................... 14

IV. Power supply/electrical connection ............................................................................ 14

a) Follow local regulations ............................................................................................ 14

b) Voltage, frequency, tolerances ................................................................................. 14

c) Type of cable .............................................................................................................. 14

d) Length and cable width ............................................................................................ 14

e) Strain relief ................................................................................................................ 14

f) Clamps ........................................................................................................................ 15

g) Fuse ............................................................................................................................ 16

h) Phase sequence ........................................................................................................ 16

i) EMC Compatibility and Grounding ............................................................................ 17

j) Data cable ................................................................................................................... 18

V. Interface filter panel (IFP) .............................................................................................. 20

Scope of IFP supply: ...................................................................................................... 21

Installation of IFP ........................................................................................................... 21

VI. Water connection .......................................................................................................... 22

a) Pipe material ............................................................................................................. 22

b) Relation of pipe diameter to distance between chiller and IFP ............................. 22

c) Dimensions of the connections ................................................................................ 22

d) Inflow and outflow ..................................................................................................... 22

e) Water quality ............................................................................................................. 22

f) Glycol........................................................................................................................... 23

g) Filling .......................................................................................................................... 23

h) Vents and air chambers............................................................................................ 23

VII. Initial start-up ............................................................................................................... 27

VIII. SPS Settings ............................................................................................................... 28

IX. Control ............................................................................................................................ 31

a) Pump .......................................................................................................................... 31

page

page 2222von

page page

von39

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 3

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

b) Water pressures ........................................................................................................ 31

c) Compressor ................................................................................................................ 31

d) Vents .......................................................................................................................... 31

e) Refrigerant pressures ............................................................................................... 31

f) Temperatures ............................................................................................................. 31

X Overview water chiller and IFP ....................................................................................... 32

XI Trouble Shooting ............................................................................................................ 33

XII. Maintenance ................................................................................................................ 38

XIII. Warranty ...................................................................................................................... 38

XIV. Safety Warnings ......................................................................................................... 38

page

page 3333von

page page

von39

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 4

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

I

I Technical Data

Technical Data

I I

Technical DataTechnical Data

Model Outdoor

Dimensions Depth 940 mm

Width 3040 mm

Height 1850 mm

Weight without refrigerant load ca. 1066 kg

Weight with load ca. 1090 kg

Shipping weight ca. 1600 kg

Weight total refrigerant load 24.0 kg

Quantity of air 2x 18000 m³/h

Number of fans 4

Refrigerant R134a

Required quantity of refrigerant 2x12kg

High-pressure switch 19 bar

Water connection inlet internal 2“ G" female thread

Water connection outlet internal 2“ G" femalethread

Cold water temperature outlet min. 19-22 °C ±0.5 K

Cold water temperature inlet max. 30 °C

Primary water pump type 60Hz CR 10 - 05

Primary water pump type 50Hz CR 10 - 07

Rated water capacity min. 7.8 m³/h

Rated water pressure 6.5 bar

Ambient temperature min.-20 °C

max.+48 °C

Cooling capacity 60.0 kW

Rated cold water outlet temperature 20 °C

Temperature of surroundings 48 °C

Main supply 380-480 V / 3Ph / 50-60 Hz

Control voltage 24 VDc

Fluctuations in main voltage max. -14+10 %

Fluctuations in frequency max. ±1 Hz

Power input max. 29 kW

Noise level at 5 m max.68 db(A)

at max cooling capacity and max. ambient temperature

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 4444von

page page

von39

39

vonvon

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 5

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 5555von

page page

I. Basics

I. Basics

I. BasicsI. Basics

Scope of Chiller supply:

-KSC215-L-…

-Installing Instruction inside the switch cabinet

-Manual inside the switch cabinet

-Data transfere cable 50m (164feet) in a box near the pump

-Short data transfere cable in a box near the pump

-Grounding in a box near the pump

-Overvoltage protection in a box near the pump

-Spare parts in a box near the pump

-Brass fittings for the connection Chiller inlet/outlet and piping (on the pump)

-Stainless steel fittings for the connetion piping and IFP (on the pump)

Carefully read the operating instructions located in the control cabinet before beginning

installation.

Check the equipment for damage on arrival and report any defects immediately.

Claims submitted later cannot be honored.

Please observe the following notes and warnings.

1. Removing the operating instructions from the cooling block voids the warranty!

von39

39

vonvon

3939

2. The volume of the water circulation system of the cooling block is approx. 17 liters

(~4.5 gal) Please consider this by filling the water system with water ethylene

glycol mixture.

3. Always operate the water circulation system at a volume of 35-38% ethylene

glycol.

This is regardless of the ambient temperature.

Non-compliance voids the warranty.

Use of automobile anti-freeze and propylene glycol is prohibited.

Fill with clean water (potable water quality) with Ethylene-glycol at the rate of min.

35% to max. 38%.

Use ethylene-glycol of only one manufacturer.

(e.g.: DOWTHERM SR1-Dow Chemical, Safeflow EG-Clariant)

Do not mix two ore more different manufacturer for one water-ethylene-glycol

circuit.

Open front panel and fill to a pressure of min.1,5 bar via the feed cock when the

pump is off.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 6

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

After filling, check all connections for leakage.

4. With the pump turned off, fill the system to a static water pressure of 1.5 bar

(21.75 psi) by Avanto an Chiller at the same level. (Also see Table 1 page24)

(Also see Table 1 page24)

(Also see Table 1 page24) (Also see Table 1 page24)

5. The cooling block operates completely independently of the MR system.

6. Voltage is still present in the KSC control cabinet when the MR system is turned

off. Risk of death!

Risk of death!

Risk of death!Risk of death!

7. Even with the cooling block turned off, high surface temperatures can cause

burns. Risk of death!

Risk of death!

Risk of death!Risk of death!

Only trained and qualified personnel are permitted to install, start up, and repair the

cooling block.

page

page 6666von

page page

von39

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 7

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

II. Installation site

II. Installation site

II. Installation siteII. Installation site

a) Ambient temperatures

a) Ambient temperatures

a) Ambient temperaturesa) Ambient temperatures

The chiller is designed to operate at ambient temperatures between –20°C (-4°F)

minimum and +48°C (+118.4°F) maximum.

Malfunctions can occur outside these specifications.

If the chiller is used at high ambient temperatures (higher than 40°C = 104°F) the the

If the chiller is used at high ambient temperatures (higher than 40°C = 104°F) the the

If the chiller is used at high ambient temperatures (higher than 40°C = 104°F) the the If the chiller is used at high ambient temperatures (higher than 40°C = 104°F) the the

chiller should be installed that the

chiller should be installed that the switch cabinet is not fully exposed to the sun

chiller should be installed that the chiller should be installed that the

radiation when the maximum ambient temperature is prevent. If th

radiation when the maximum ambient temperature is prevent. If this is not possible

radiation when the maximum ambient temperature is prevent. If thradiation when the maximum ambient temperature is prevent. If th

please install a sun protection!!

please install a sun protection!!

please install a sun protection!! please install a sun protection!!

Support from KKT

Support from KKT chillers

Support from KKTSupport from KKT

”

” ”

chillers could be requested.

chillerschillers

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

could be requested.

could be requested.could be requested.

U/S

U/SU/S

switch cabinet is not fully exposed to the sun

switch cabinet is not fully exposed to the sun switch cabinet is not fully exposed to the sun

is is not possible

is is not possible is is not possible

page

page 7777von

page page

von39

vonvon

39

3939

b) Clearance

b) Clearance

b) Clearanceb) Clearance

Maintain at least 100 cm (39.4 in.) around all four sides of the chiller for air intake and

servicing/repair.

Under no circumstances install a roof above the chiller.

c) Servicing and repair access

c) Servicing and repair access

c) Servicing and repair accessc) Servicing and repair access

See Clearance

d) Air flow

d) Air flow

d) Air flowd) Air flow

Never obstruct the air intake to the condensers on the upper third of the chiller.

The diameter of the tubes may not be smaller than the size specified.

e) Load capacity

e) Load capacity of the base

e) Load capacitye) Load capacity

Verify that the installation surface has sufficient load capacity.

A concrete foundation or sectional steel construction is recommended.

A concrete foundation needs to be 200 mm (7.8 in.) wider and 200 mm (7.8 in.) longer

than the cooling block. Final dimensions: approx. 3,200 mm (10.5 feet) long by 1,100

mm (3.6 ft) wide.

The operating weight of the chiller is approx. 1,100 kg (2,425 lbs.).

The operating weight of the chiller is approx. 1,100 kg (2,425 lbs.).

The operating weight of the chiller is approx. 1,100 kg (2,425 lbs.).The operating weight of the chiller is approx. 1,100 kg (2,425 lbs.).

It is important that the cooling block be installed on a level surface.

of the base

of the baseof the base

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 8

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 8888von

page page

von39

39

vonvon

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 9

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 9999von

page page

von39

39

vonvon

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 10

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

III. Transport r

III. Transport route/transport

III. Transport rIII. Transport r

a) Transport measurements

a) Transport measurements

a) Transport measurementsa) Transport measurements

Length: approx. 3,200 mm (126 inches)

Width: approx. 1,100mm (43.3 inches)

Height: approx. 2,150mm (approx. 84.65 inches)

You also need to add the height of the transport equipment, such as pallets, lift truck,

transport rollers, etc.

”

” ”

oute/transport

oute/transportoute/transport

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 10

10von

page page

1010

von39

39

vonvon

3939

b) Transport weight

b) Transport weight

b) Transport weightb) Transport weight

Weight: approx. 1,600 kg (approx. 3,528 lbs.)

c) Transport safety locks

c) Transport safety locks

c) Transport safety locksc) Transport safety locks

There are no transport safety locks to remove.

d) Crane transport

d) Crane transport

d) Crane transportd) Crane transport

If a crane will be used to transport the chiller, note the following:

Lift the chiller only from its base. Insert two steel rods through the holes in the base.

The rods must be specifically designed for this purpose and able to support the weight

(1,100 kg./2,425 lbs.).

Secure the rods with locking pins to prevent shifting.

Use only straps or rope for lifting from the rods.

The straps or ropes must be held in place with a frame to keep them from pressing into

the side walls, gutters, and condenser body. (Refer to the following graphic).

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 11

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 11

page page

11von

von39

1111

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 12

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

e)

e) Dimensions in inch

Dimensions in inch

e) e)

Dimensions in inchDimensions in inch

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 12

page page

12von

von39

1212

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 13

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

f)

f) Dimensions in mm

Dimensions in mm

f) f)

Dimensions in mmDimensions in mm

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 13

page page

13von

von39

1313

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 14

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

g) Weights

g) Weights

g) Weightsg) Weights

Net weight: 1,060 kg. (2,337 lbs.)

Operating weight: approx. 1,100 kg. (2,425 lbs.)

Transport weight: approx. 1,600 kg (3,527.4 lbs.)

Refrigerant: approx. 2 X 12 kg. (26.45 lbs.) R 134a

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 14

page page

14von

von39

1414

vonvon

39

3939

IV. Power supply/ele

IV. Power supply/electrical connection

IV. Power supply/eleIV. Power supply/ele

a) Follow local regulations

a) Follow local regulations

a) Follow local regulationsa) Follow local regulations

Strictly adhere to the regulations of the local power company and authorities. Only

trained, authorized persons are permitted to connect the power.

b) Voltage, frequency, tolerances

b) Voltage, frequency, tolerances

b) Voltage, frequency, tolerancesb) Voltage, frequency, tolerances

Voltage range: 380 - 480 Volt –14%+10%

Frequency range: 50 – 60Hz +/-1Hz

c) Type of cable

c) Type of cable

c) Type of cablec) Type of cable

Make sure to use appropriately designed and approved cables when routing.

d) Length and cable width

d) Length and cable width

d) Length and cable widthd) Length and cable width

A cable width of at least 16mm² per phase is required for cables up to 50 meters (164

ft.) in length.

Therefore, a 5 x 16mm² cable is required.

ctrical connection

ctrical connectionctrical connection

e) Strain relief

e) Strain relief

e) Strain reliefe) Strain relief

The input cable must be fitted on both sides with a strain relief.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 15

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 15

page page

f) Clamps

f) Clamps

f) Clampsf) Clamps

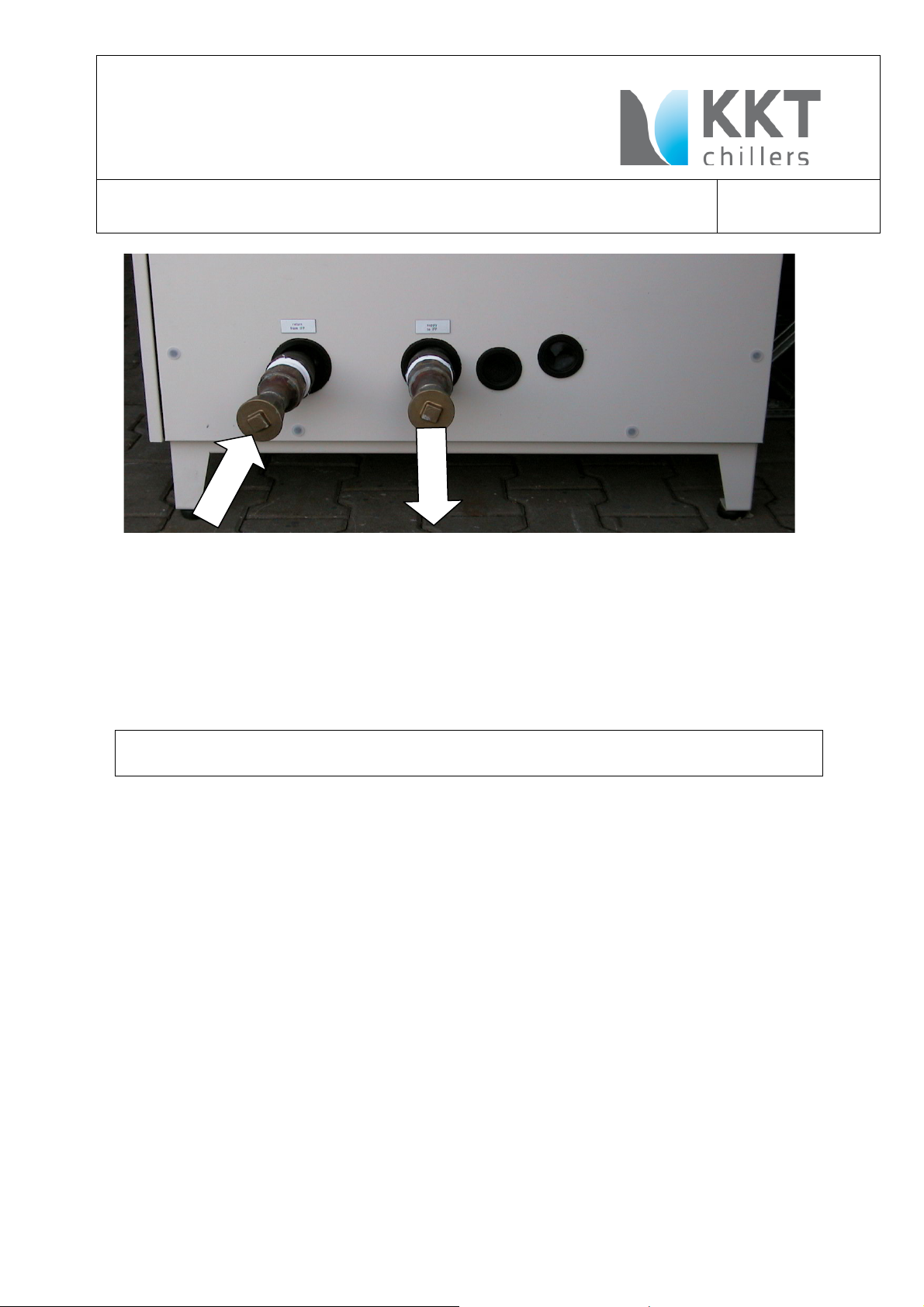

Insert the input cable through the cable feed-through (see photograph) next to the

water connections. Route it into the control cabinet through the cable channel installed

on the back of the control cabinet.

15von

von39

1515

vonvon

39

3939

Use the clamps to secure the routed cable (see photograph).

Attention!!

Do not pass the power supply line across the switch cabinet!!

Use cable opening in the lower right hand side of cabinet!!

Drilling holes into and running cables into the cabinet can cause interferences with the

regulation electronics!!

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 16

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 16

page page

g) Fuse

g) Fuse

g) Fuseg) Fuse

Maximum 60 A slow-blowing fuse for pre-fusing.

Maximum overcurrent of 200 A for 50 msec.

h) Phase sequence

h) Phase sequence

h) Phase sequenceh) Phase sequence

Observe the correct phase sequence when routing the wires, otherwise the cooling

block will not start. A phase sequence relay (5A1) is installed for this purpose.

The monitoring relay has ist own power supply, measured voltage = supply voltage.

The relay monitors the phase sequence an the phase failureof one of the three phases

in a 3-phase network. No settings are necessary.

When the line voltage is switched on, the green LED lights up. IF the correct phase

sequence is applied to the terminals L1-L2-L3, the output relay picks up.

If the wrong phase sequence is applied, the red LED blinks an the output relay does not

pick up. If a phase failure occurs, the red LED lights up an the output relay drops out.

Attention: The red LED is an error diagnosis indicator an does not show the current

state of the relay.

16von

von39

1616

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 17

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 17

page page

i) EMC Compatibility and Grounding

i) EMC Compatibility and Grounding

i) EMC Compatibility and Groundingi) EMC Compatibility and Grounding

This comments are compiled to help the field electrician to install the grounding of the

power supply and to get a EMC Compatibility.

All electrical equipment produces radio and line-borne interference at various

frequencies. The cables pass this on to the environment like an aerial.

The basic countermeasures are isolation of the wiring of control and power components,

proper grounding and shielding of cables.

A large contact area is necessary for low-impedance grounding of HF interference. The

use of grounding straps instead of cables is therefore definitely advisable.

Moreover, cable shields must be

connected with purpose-made ground

clips.

The grounding surface must be highly

conductive bare metal. Remove any

coats of varnish and paint.

The width of the grounding wire must be min. 16mm² (AWG 6) or of the same width of the

power supply.

The grounding must be an isolated ground and must connected on the ground terminal

(X1) in the switch cabinet. The ground resistance must be less than 10 Ohm.

Metal cable conduits are not allowed for grounding.

The piping of the chiller (supply and return) have to be grounded too.

Do not share the ground wire with other devices.

Always use a ground wire that complies with technical standards on electrical equipment

and minimize the length of the ground wire.

When using more than one Inverter, be careful not to loop the ground wire.

(e.g. a CT-Chiller KPC108-L-U/S stands near an Avanto-Chiller KSC215-L-U/S)

17von

von39

1717

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 18

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

j) Data cable

j) Data cable

j) Data cablej) Data cable

Attach the “X8 Chiller” end of the 16-pin data cable (included) to the green connector

(see photograph) at the top right of the control cabinet.

page

page 18

18von

page page

1818

von39

39

vonvon

3939

Power plug

A separate feed-through for the power plug is located on the right wall of the control

cabinet (see photograph).

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 19

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

Feed-through

• Run the cable from the chiller to the MR electronic cabinets.

• Connect the lightning arrester with the 164 ft / 50 m data cable.

• Connect the short data cable with the lightning arrester.

• Attach the other end of the short data cable on the electronics cabinet ACC X81 of

the MR system.

• Connect the grounding wire.

page

page 19

19von

page page

1919

von39

39

vonvon

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 20

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 20

page page

20von

von39

2020

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

.

Page 21

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Interface filter panel (IFP)

Scope of IFP supply:

Scope of IFP supply:

Scope of IFP supply:Scope of IFP supply:

Data transfer cable (164 ft / 50 m)

Lightning arrester

Short data cable

Grounding wire

Power cable (IFP – compressor)

Water hoses (IFP – compressor)

Dummy plugs

Installation of IFP

Installation of IFP

Installation of IFPInstallation of IFP

To Chiller

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

Air bleeder

page

page 21

page page

21von

von39

2121

vonvon

39

3939

From Chiller

Attach the IFP to the wall. Contact the project manager for the location provided.

The outflow port of IFP to the MR electronic cabinet and the inflow port from the MR

electronic cabinet can be closed with dummy plugs.

The dummy plugs allows filling the chiller and the IFP with water/ethylene glycol mixture

without MR electronic cabinets connected to IFP.

Water hoses from IFP to the MR electronic cabinets are delivered with the MR system.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 22

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

VI. Water connection

VI. Water connection

VI. Water connectionVI. Water connection

a) Pipe material

a) Pipe material

a) Pipe materiala) Pipe material

Use only the following materials for the pipes:

1. Copper is recommended

2. Stainless steel

3. PE or PVC – ensure that the appropriate steps are taken to protect the pipe along its

length.

The proper way to seal the European fittings can be done with any of following steps.

1. Pipe sealing cord. There are a number of brands available, however we use Loctite

55

2. Teflon Tape and a Anaerobic sealant.

3. Teflon Tape an Nylog sealant.

As with any sealant, the application instruction must be followed for proper use.

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 22

page page

22von

von39

2222

vonvon

39

3939

b) Relation of pipe diameter to distance between chiller and IFP

b) Relation of pipe diameter to distance between chiller and IFP

b) Relation of pipe diameter to distance between chiller and IFPb) Relation of pipe diameter to distance between chiller and IFP

Use 2” (R2, DN 50 or 54-mm copper) for up to 25 meters (82 ft.) of straight pipe.

Use 2 ½” (R21/2, DN 65 or 64-mm copper) for up to 45 meters (147.6 ft.) of straight

pipe.

For distances exceeding 45 meters (147.6 ft.) of straight pipe, e-mail the

actual pipe length, the difference in height, and the required pipe elbows to

KKT: info@kkt-chillers.com

)

c) Dimensions of the connections

c) Dimensions of the connections

c) Dimensions of the connectionsc) Dimensions of the connections

Both the coolant return (water/ethylene glycol mix) from the IFP and the coolant supply

(water/ethylene glycol) to the IFP need to have a 2” internal thread.

To connect them, use a crossover with a 2” external screw thread or preferably a fitting

with a 2” external screw thread (two crossovers are attached to the pump).

d) Inflow and outflow

d) Inflow and outflow

d) Inflow and outflowd) Inflow and outflow

Verify that the inflow and outflow pipes are attached correctly (do not confuse).

The inflow is FROM the IFP.

The outflow is TO the IFP.

The connections are labeled (see photograph).

On the Chiller inflow and outflow use the brass-fittings.

On the IFP use the stainless steel fittings.

e) Water quality

e) Water quality

e) Water qualitye) Water quality

Use only distilled water to fill the system

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 23

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 23

page page

23von

von39

2323

vonvon

39

3939

f) Glycol

f) Glycol

f) Glycolf) Glycol

For transport the chiller is empty. The volume which is to consider for the water

ethyleneglycol mixture is approx. 17 liters (~4.5 gal.).

35-38% of the whole volume of watercircuit must be filled with ethylene glycol..

Never use automobile anti-freeze or propylene glycol.

The contractor who fills the water circuit has to supply 30 liters (7.9 gal.) of

The contractor who fills the water circuit has to supply 30 liters (7.9 gal.) of distilled

The contractor who fills the water circuit has to supply 30 liters (7.9 gal.) of The contractor who fills the water circuit has to supply 30 liters (7.9 gal.) of

water

water----ethylene glycol mixture (

waterwater

ethylene glycol mixture (35

ethylene glycol mixture (ethylene glycol mixture (

35----38

3535

38% ethylene glycol) for service.

% ethylene glycol) for service.

3838

% ethylene glycol) for service. % ethylene glycol) for service.

distilled

distilled distilled

Fill with clean water (distilled water quality) with Ethylene-glycol at the rate of min. 35%

to max. 38%.

Use ethylene-glycol of only one manufacturer.

(e.g.: DOWTHERM SR1-Dow Chemical, Safeflow EG-Clariant)

Do not mix two ore more different manufacturer for one water-ethylene-glycol circuit.

Open front panel and fill to a pressure of min.1,5 bar via the feed cock when the pump

is off.

After filling, check all connections for leakage.

g) Filling

g) Filling

g) Fillingg) Filling

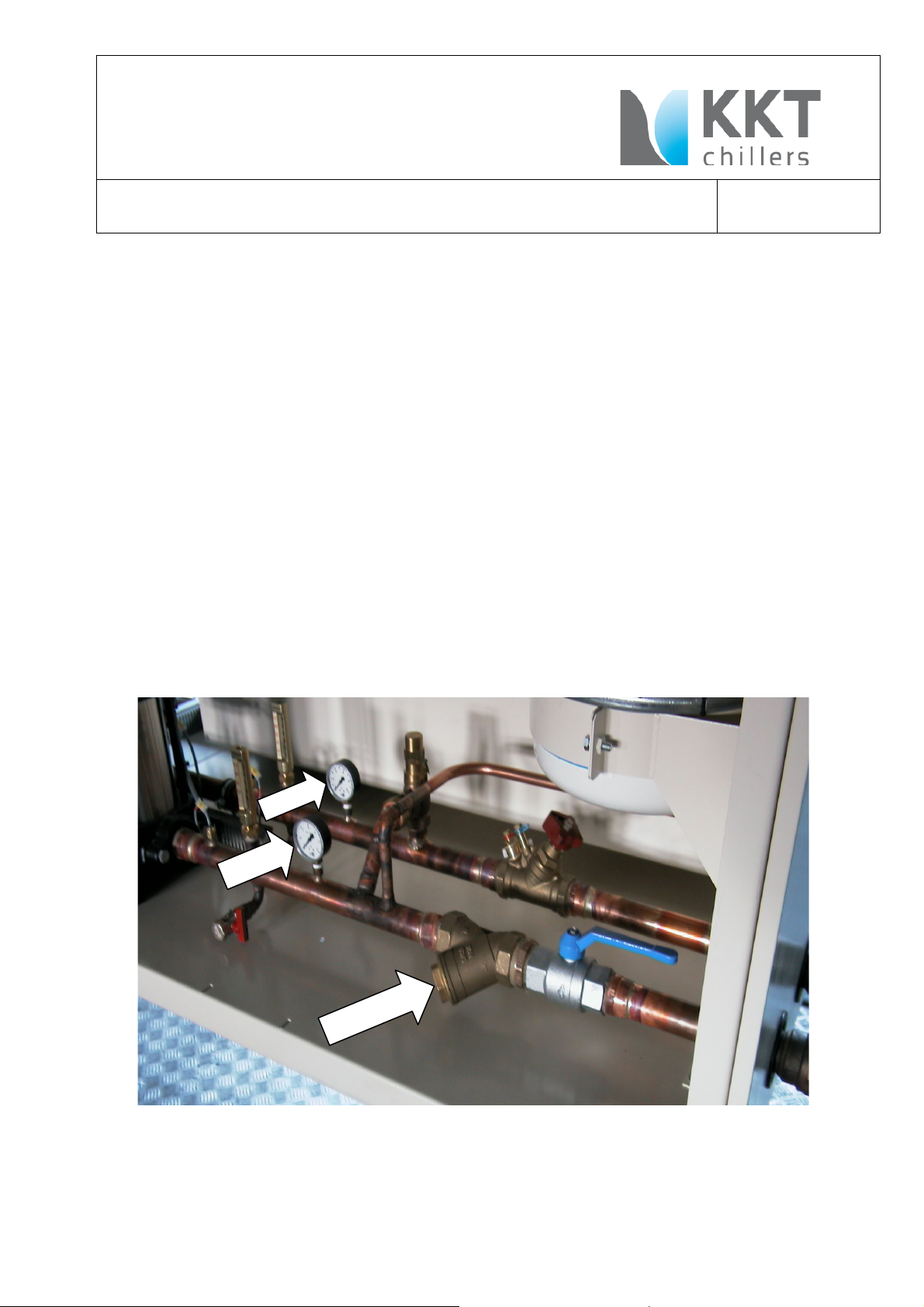

For filling, use the fill and drain valve near the pump.

It is best to fill the circulation system completely for the air to escape most easily (refer

to the following item).

open the valves on the IFP

h) Vents and air chambers

h) Vents and air chambers

h) Vents and air chambersh) Vents and air chambers

Be sure to avoid air pockets when routing the pipes.

Air chambers or automatic vents must be attached at the highe

Air chambers or automatic vents must be attached at the highest point to ensure the

Air chambers or automatic vents must be attached at the higheAir chambers or automatic vents must be attached at the highe

most simple and reliable venting procedure

most simple and reliable venting procedure.

most simple and reliable venting proceduremost simple and reliable venting procedure

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

st point to ensure the

st point to ensure the st point to ensure the

Page 24

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

Perform and repeat the following steps until all the air has been bled from the system.

This steps have to be done during the first start up and after

This steps have to be done during the first start up and after each

This steps have to be done during the first start up and afterThis steps have to be done during the first start up and after

components with

components with water inside also Siemens components.

components with components with

water inside also Siemens components.

water inside also Siemens components.water inside also Siemens components.

each replacement of

replacement of

eacheach

replacement of replacement of

page

page 24

24von

page page

2424

von39

39

vonvon

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 25

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

1. From the lowest point possible, fill the pipe with water/ethylene glycol mixture until

no more air escapes from the vent (at the highest point).

Fill the centrifugal pump with the water/ethylene glycol mixture and vent. Close the

vent.

2. Continue filling until the pressure on the water circulation manometers display 1.5

bar (21.75 PSI) with the pump OFF

OFF.

OFFOFF

3. Turn on the pump for 15 seconds and turn it off again.

4. Open the vents on the air chambers and the pump and vent off the remaining air.

The pressure on the manometers drops.

5. Fill again until the pressure on the manometers with the pump OFF

OFF reaches 1.5 bar

OFF OFF

(21.75 PSI).

6. Repeat starting with step 3 until no more air escapes from the vents and the static

pressure with the pump off does not drop below 1.5 bar (21.75 PSI).

7. Clean the filter during the next-to-the-last pass.

8. If the pressure remains constant for 60 – 90 minutes of operation, the coolant

circulation system is full and no air remains.

page

page 25

25von

page page

2525

von39

39

vonvon

3939

Figure

Figure 1111

Figure Figure

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 26

Installing Instruction

System configuration

System configurationSystem configuration

System configuration

Fill pressure

Fill pressure Fill pressure

Fill pressure

Warnung level setting:

Warnung level setting: Warnung level setting:

Warnung level setting:

MR_system & Chiller are at the same

MR_system & Chiller are at the same MR_system & Chiller are at the same

MR_system & Chiller are at the same

0.1 -

0.5 bar

Warning level =0.1 bar

Example:

Example: Example:

Example:

0.5 bar (overpressure)

Warning level =

Example:

Example: Example:

Example:

0.5 bar (overpressure)

Warning level =

MR_system & Chiller &

MR_system & Chiller & MR_system & Chiller &

MR_system & Chiller &

0.1 -

0.5 bar

0.4 bar

MR_system is higher than Chiller

MR_system is higher than Chiller MR_system is higher than Chiller

MR_system is higher than Chiller

0.1 -

0.5 bar

0.4 bar

Example.

Example.Example.

Example.

0.5 bar (overpressure)

0.4 bar

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

level and

level and

level andlevel and

Pipe routing is highe

Pipe routing is higher than the

Pipe routing is highePipe routing is highe

MR_system

MR_system

MR_systemMR_system

or

or

oror

Chiller above MR_system

Chiller above MR_system

Chiller above MR_system Chiller above MR_system

Chiller or pipe routing

Chiller or pipe routing is 10m above

Chiller or pipe routing Chiller or pipe routing

MR_system

MR_system

MR_systemMR_system

Length of piping 20m

Length of piping 20m

Length of piping 20mLength of piping 20m

r than the

r than the r than the

is 10m above

is 10m above is 10m above

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

at Chiller manometer

at Chiller manometer

at Chiller manometerat Chiller manometer

Chiller is off

Chiller is off

Chiller is offChiller is off

(overpressure)

+ 0.1 bar / m (difference

in level)

+ 10m * 0.1 bar/m

(difference in level)

= 1.5 bar (fill pressure)

U/S

U/SU/S

page

page 26

26von

page page

2626

SeSo/Magnet & Cooling/

SeSo/Magnet & Cooling/

SeSo/Magnet & Cooling/ SeSo/Magnet & Cooling/

ACS/Water Pressure Return

ACS/Water Pressure Return

ACS/Water Pressure ReturnACS/Water Pressure Return

(overpressure)

+ 0.01 bar/ m (flow resistance)

+ 0.1 bar/m (difference in level)

0.1 bar + 0.01 bar/m * 20m +

0.1 bar/m *10m

= 1.3 bar

von39

39

vonvon

3939

Chiller and MR_system are on the same

Chiller and MR_system are on the same

Chiller and MR_system are on the same Chiller and MR_system are on the same

llllevel.

evel.

evel.evel.

Pipe routing is 5m above the MR_system

Pipe routing is 5m above the MR_system

Pipe routing is 5m above the MR_systemPipe routing is 5m above the MR_system

Pipe length is 20m

Pipe length is 20m

Pipe length is 20mPipe length is 20m

Pi

Pipe routing on same level

pe routing on same level

PiPi

pe routing on same levelpe routing on same level

Chiller is 5 m below MR System

Chiller is 5 m below MR System

Chiller is 5 m below MR SystemChiller is 5 m below MR System

Table

Table 1111

TableTable

+ 5m * 0.1 bar/m

(difference in level)

= 1.0 bar (fill pressure)

(overpressure)

(overpressure)

+ 0.1 bar/m (difference in

level)

+ 5m * 0.1 bar/m

(difference in level)

= 1.0 bar (fill pressure)

0.1 bar + 0.01 bar/m * 20m +

0.1 bar/m *5m

= 0.5 bar

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 27

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

VII. Initial start

VII. Initial start----up

VII. Initial startVII. Initial start

up

upup

1. Turn on main switch 5Q1.

5Q1

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 27

page page

27von

von39

2727

vonvon

39

3939

The display needs approx. 15 seconds to activate.

2. The flow meter is bypassed for 15 seconds after the pump starts.

Press reset, if necessary. (Black button on the control cabinet door

button on the SPS display).

button on the SPS display).

button on the SPS display).button on the SPS display).

(Black button on the control cabinet door and

(Black button on the control cabinet door (Black button on the control cabinet door

and ACK

andand

ACK

ACK ACK

3. The compressor begins running when the water temperature reaches 18.5°C after

30 seconds.

4. When the compressor is running the two condenser vents are released. They are

reactivated once the pressure in the condenser reaches approx. 13 bar. The stop

light on the frequency converter stays lit as long as the vents are off.

5. Vents regulate themselves gradually and independently of the SPS in accordance

with the set condenser pressure.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 28

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

6. Without MR, the IFP is set to Bypass (open magnet valves with no current). In this

operating state, there is only approx. 3 m³/h (13.2 gal/min) of coolant in

circulation.

VIII. SPS Settings

VIII. SPS Settings

VIII. SPS SettingsVIII. SPS Settings

Setting the clock on the operation panel OP73

Remark: The function of the button F1, F2. F3 and F4 will shown above the buttons at

the screen.

The following steps are to be used:

1. Switch on the main switch 5Q1

2. Now the chiller is running in autarc.

3. If the date and time displayed are incorrect, change them using the following

steps.

4. If the display shows any failure please press back till the display looks like figure

2

page

page 28

28von

page page

2828

von39

39

vonvon

3939

Abbildung

Abbildung 2222 figure 2

Abbildung Abbildung

figure 2

figure 2figure 2

5. Than press „F4“.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 29

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 29

page page

29von

von39

2929

vonvon

39

3939

6. Than press „F2“

day month

7. Press “Enter” and the “left arrow” and “right arrow” to set the cursor for change

the values with the “up arrow”, “down arrow”. Close with “Enter”.

8. Than change the cursor with up arrow to the date.

With left arrow” and “right arrow” change the possition of the cursor wihtin the

date and with the “up arrow”, “down arrow” change the values. Close with

“Enter”

9. Press F2 for setting.The black sign show that the time will be set in the opertion

panel.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 30

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 30

page page

30von

von39

3030

vonvon

39

3939

10.With “Back” you go to System

11.With another “Back” you will go to the first picture.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 31

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

Do not remove the memory chip in the SPS with voltage present.

The pump begins to run approx. 30 seconds after it is switched on. Press reset, if

necessary.

IX. Control

IX. Control

IX. ControlIX. Control

a) Pump

a) Pump

a) Pumpa) Pump

Check the direction of rotation of the pump.

Check any noises the pump makes while running.

Check the power consumption.

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 31

page page

31von

von39

3131

vonvon

39

3939

b) Water pressures

b) Water pressures

b) Water pressuresb) Water pressures

Suction pressure must be between 1.0 bar (14.5 PSI) and 1.5 bar (21.75 PSI).

High pressure must be between 6.5 bar (94.3 PSI) and 7.0 bar (101.5 PSI).

c)

c) Compressor

Compressor

c) c)

CompressorCompressor

Check the power consumption.

d) Vents

d) Vents

d) Ventsd) Vents

Check the power consumption.

e) Refrigerant pressures

e) Refrigerant pressures

e) Refrigerant pressurese) Refrigerant pressures

The low-pressure side must be between 3.0 bar (43.5 PSI) and 5.0 bar (72.5 PSI).

The high-pressure side must be between 8.0 bar (116 PSI) and 15.0 bar (217.5 PSI).

f) Temperatures

f) Temperatures

f) Temperaturesf) Temperatures

Outflow water temperatures should be between 19°C (66.2°F) and 22°C (71.6°F).

Inflow water temperatures should be between ~21°C (69.8°F) and ~27.7°C (81.9°F),

depending on the operating state of the MR system.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 32

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

X Overview wate

X Overview water chiller and IFP

X Overview wateX Overview wate

r chiller and IFP

r chiller and IFPr chiller and IFP

U/S

U/SU/S

page

page 32

page page

32von

von39

3232

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 33

Installing Instruction

KIND OF TROUBLE

KIND OF TROUBLEKIND OF TROUBLE

KIND OF TROUBLE

CAUSE

CAUSECAUSE

CAUSE

ELIMINATION

ELIMINATIONELIMINATION

ELIMINATION

•

malfunction of

1. power failure, phase sequence or

check mains connection and

•

malf

unction of

1. main switch 5Q1 not switched on

switch on main switch 5Q1

•

still malfunction

1. overload trip 17

Q1 of pump

main switch to '0', push in

•

pump makes

1. circuit is not completel

y vented

vent and fill up with

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

XI Trouble Shooting

XI Trouble Shooting

XI Trouble ShootingXI Trouble Shooting

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 33

page page

33von

von39

3333

vonvon

39

3939

plant/system

pump 17M1

phase failure

2. temperature sensor defective

3. simatic 8N1, 8A1, 8A2, 8A3 an

8A4 malfunction

4. chiller “not ok”

2. main fuse 5Q1 defective

3. fuse for control current defective

4. pump motor 17M1 defective

5. flow switch responded 10B1

6. shortage of water

-

relay 5A1

-

check sensor 9B1

clamp feeler and measure the

resistance

-

check MMC-Card

check power supply 24VDC

7U1and

fuses 7F1 and 7F2

-

check fuse 24F1

-

data transfere cable

-

check overvoltage protection

-

-

replace fuse 5Q1

-

replace fuse

-

replace motor 17M1

-

check water flow

-

check system pressure, clean

strainer

of pump

gurgling noise

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

protection interrupted control

circuit

-

overload trip

-

water/Ethylene glycol

Page 34

Installing Instruction

KIND OF TROUBLE

KIND OF TROUBLEKIND OF TROUBLE

KIND OF TROUBLE

CAUSE

CAUSECAUSE

CAUSE

ELIMINATION

ELIMINATIONELIMINATION

ELIMINATION

•

compressor

1. Klixon/INT69 tripped 18

A1 and

Check Fuses 18Q1 and 21

Q1

•

malfunction of

1. simatic stopped machine, return

to check function, level down

•

still malfunction

1. low pressure in refrigerant circuit

•

refrigerating

1. not enough fresh air supply for

provide enough fresh air supply

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 34

page page

34von

von39

3434

vonvon

39

3939

18M1 and

21M1 stops

refrigerating

machine

of refrigerating

machine

21A1

2. Klixon/INT69 18A1and

21A1defective

temperature too cold

-

plant looses refrigerant

-

dryer in liquid pipe dirty

-

pressure relief valve defective

2. high pressure in refrigerant circuit

-

condenser dirty

-

fan defective

-

outside temperature too high

-

pressure sensor 20B1 and 23B1

for condenser control defective

-

Frequency inverter defective

-

-

wait until compressor cooled

down; perhaps clean condenser

or provide fresh air supply

-

replace Klixon/INT69

-

adjustments, wait until return

temperature rised

-

find leak, seal, refill circuit

-

replace dryer

-

replace pressure relief valve

-

clean condenser

-

put right electric cause;

check fuses 20Q1 and 23Q1

-

spray condenser with water

-

replace pressostat

-

replace frequency inverter

20U1and 23U1

machine starts

and stops shorttermed

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

condenser;

high pressure pressostat tries to

protect refrigerating machine

against overload

2. not enough pressure of

refrigerant circuit;

refrigerant partly escaped;

diminished pressure switch shut

down compressor

-

and fresh air removal;

get rid of short-circuit across

fresh air and exhaust air

-

find leak, seal, refill circuit

Page 35

Installing Instruction

KIND OF TROUBLE

KIND OF TROUBLEKIND OF TROUBLE

KIND OF TROUBLE

CAUSE

CAUSECAUSE

CAUSE

ELIMINATION

ELIMINATIONELIMINATION

ELIMINATION

•

not enough

1. air in water circuit

vent system

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 35

page page

35von

von39

3535

vonvon

39

3939

refrigeration

power

2. fallen below minimum water

agitation quantity

3. not enough fresh air supply for

condenser

4. not enough refrigerant in circuit

-

-

design cross-section of water

pipe right;

perhaps open check valve in

water circuit completely,

increase pipe cross-section

-

provide enough fresh air supply

and fresh air removal;

get rid of short-circuit across

fresh air and exhaust air

-

find leak, seal, refill circuit

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 36

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 36

page page

36von

von39

3636

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 37

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 37

page page

37von

von39

3737

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Page 38

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

XII. Maintenance

XII. Maintenance

XII. MaintenanceXII. Maintenance

The cooling block must be serviced at least twice a year by a Chiller company. (e.g., KKT

chillers or SBT)

XIII.

XIII. Warranty

XIII. XIII.

The unit is supplied finished, tested and ready to work. The unit warranty will be void if

any modification to the unit is carried out without written agreement of KKT chillers.

For warranty purposes, the following conditions must be satisfied:

Warranty

WarrantyWarranty

Failure to satisfy any of these conditions will automatically void the

Failure to satisfy any of these conditions will automatically void the

Failure to satisfy any of these conditions will automatically void the Failure to satisfy any of these conditions will automatically void the

warranty.

warranty.

warranty.warranty.

”

” ”

• The initial start of the unit must be carried out by trained personnel from an

Authorized KKT chillers Service Partner.

• Maintenance must be carried out by properly trained personnel.

• Only genuine KKT chillers spare parts must be used.

• For KSC215-L-U/S: Ethylene glycol must be added to the rate of 35-38Vol%.

• The manual (this document) must not remove from the chiller.

• All the scheduled maintenance operations detailed in this manual must be

performed at the specified times. Please use a higher amount of services if

the local conditions require it.

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

page

page 38

page page

38von

von39

3838

vonvon

39

3939

XIV.

XIV. Safety Warnings

XIV. XIV.

-Cooling water circuit is pressurized.

Switch off the chiller and depressurize before servicing the cooling water circuit.

-Drain water from pipes and spare parts before shipment.

-Nominal static filling pressure when Chiller has been switched off: 1,5bar. The pressure

of the expansion tank is without counter pressure from the “water / glycol – side” = 1,0

bar.

-Don`t handle valves while the Chiller is running

-Ethylene glycol must

otherwise warranty void.

-The rate depends not on the local ambient temperature.

-Don’t use automotive antifreeze.

-Voltage continuous to be present at the terminals, even after the medical device has

been switched off.

-Parts in the refrigerant circuit are hot, even the Chiller has been switched off.

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Safety Warnings

Safety WarningsSafety Warnings

Ethylene glycol must be added at the rate of 35-38% of the volume of water anytime

Ethylene glycol mustEthylene glycol must

Page 39

Installing Instruction

Installing Instruction

Installing InstructionInstalling Instruction

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC Series

Healthcare chiller of the KSC SeriesHealthcare chiller of the KSC Series

Version „Revision 0

Version „Revision 05555”

Version „Revision 0Version „Revision 0

”

” ”

Type KSC 215

Type KSC 215----LLLL----U/S

Type KSC 215Type KSC 215

U/S

U/SU/S

Warranty void if manual removed from chiller.

OBSERVE THE SAFETY RULES

OBSERVE THE SAFETY RULES

OBSERVE THE SAFETY RULESOBSERVE THE SAFETY RULES

Before commencing work on the unit, switch the plant to voltage-free

IN CASES OF EMERGENCY TURN OFF THE AGGREGATE BY THE MASTER SWITCH !

IN CASES OF EMERGENCY TURN OFF THE AGGREGATE BY THE MASTER SWITCH !

IN CASES OF EMERGENCY TURN OFF THE AGGREGATE BY THE MASTER SWITCH !IN CASES OF EMERGENCY TURN OFF THE AGGREGATE BY THE MASTER SWITCH !

Caution!

Caution!

Caution!Caution!

qualified operatives

Work on electric and refrigerant circuits should only be performed by

Observe the safety rules!

page

page 39

page page

39von

von39

3939

vonvon

39

3939

U:\KSC 215 L\03_Dokumente\Installationsanleitung\KKT_chillers_Installing_Instruction_engl_Vers05.doc

Loading...

Loading...