Page 1

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 1

Manufacturer

ait-deutschland GmbH

Industriestraße 3

95359 Kasendorf

Germany

T +49 9228 9977 0

F +49 9228 9977 149

E info@kkt-chillers.com

W www.kkt-chillers.com

Representative in the US and Service Center

KKT chillers, Inc.

1280 Landmeier Road

Elk Grove Village

IL 60007

T +1 847 734 1600

F +1 847 734 1601

TF +1 866 517 6867

YOUR LOCAL SERVICE CONTRACTOR IS:

COMPANY NAME:

PHONE NUMBER: FAX NUMBER:

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 2

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 2

Contents

1 General Remarks ................................................................................................................................................... 4

1.1 Warranty .................................................................................................................................................5

1.2 Safety Warnings ......................................................................................................................................5

2 General Description ............................................................................................................................................... 6

2.1 Drawings ...............................................................................................................................................10

2.1.1 KPC 108-L-U/S Outdoor Model .................................................................................................................... 10

3 Brief operating instructions .................................................................................................................................. 11

3.1 Installing, maintenance and repair .........................................................................................................11

3.2 Linking to power supply .........................................................................................................................11

3.3 Filling the unit with cooling medium .......................................................................................................11

3.4 EMC Compatibility and Grounding ..........................................................................................................11

3.5 Draining air from the unit .......................................................................................................................13

3.6 Switch settings of main chiller functions (exfactory settings) ...................................................................13

4 Technical Specifications ...................................................................................................................................... 15

4.1 Data sheet ............................................................................................................................................15

5 Transport ............................................................................................................................................................. 16

6 Installing the industrial cooler .............................................................................................................................. 17

7 Notes on the cooling medium connections ........................................................................................................... 21

8 Power supply ....................................................................................................................................................... 24

9 Operating instructions .......................................................................................................................................... 25

9.1 Switching ON the Industrial Cooler .........................................................................................................25

9.2 High/low pressure control ......................................................................................................................25

9.3 Electronic controls .................................................................................................................................26

9.4 Regulating refrigerating capacity ............................................................................................................26

9.5 Condenser pressure regulation ..............................................................................................................26

9.6 Safety functions to protect components of cooling water circuit ..............................................................26

9.7 Collective alarm .....................................................................................................................................26

9.8 Flow switch ............................................................................................................................................26

9.9 Dirt trap .................................................................................................................................................26

10 Preventiv Maintenance ........................................................................................................................................ 27

11 TROUBLE SHOOTING ............................................................................................................................................ 29

12 Description of the individual parts ....................................................................................................................... 31

12.1 Compressor ...........................................................................................................................................31

12.2 Condenser .............................................................................................................................................59

12.2.1 Built-in Condenser....................................................................................................................................... 60

12.3 Fans ......................................................................................................................................................61

12.4 Evaporator .............................................................................................................................................67

12.5 Electronic temperature controller ...........................................................................................................67

12.6 Frequency Inverter .................................................................................................................................73

12.7 Pressure limiter .....................................................................................................................................78

12.7.1 Low pressure switch.................................................................................................................................... 78

12.7.2 High pressure switch ................................................................................................................................... 78

12.8 Pressure Transmitter .............................................................................................................................81

12.9 Sight glass .............................................................................................................................................85

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 3

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 3

12.10 Filter drier ..............................................................................................................................................86

12.11 Thermo-Expansion valve ........................................................................................................................87

12.12 Drier + Core ...........................................................................................................................................88

12.13 Liquid receiver .......................................................................................................................................89

12.14 Water pump ..........................................................................................................................................90

12.15 Flow switch (Type KPC 108-L-U/S) ........................................................................................................101

12.16 Water heater (Type KPC 108-L-U/S) .....................................................................................................106

12.17 Air vent ................................................................................................................................................108

12.18 Membrane safety valve ........................................................................................................................109

12.19 Expansion vessel .................................................................................................................................110

12.20 Flow control valve ................................................................................................................................111

12.21 Dirt trap ...............................................................................................................................................112

12.22 Manometers ........................................................................................................................................112

13 Switch gear ........................................................................................................................................................ 113

13.1 Remote control panel ..........................................................................................................................113

13.1.1 Collective alarm ........................................................................................................................................ 113

14 Safety notes ....................................................................................................................................................... 113

14.1 Notes for refrigerant ..............................................................................................................................113

14.1 Instructions regarding machine oil .......................................................................................................114

15 Wiring diagram ................................................................................................................................................... 115

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 4

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 4

1 General Remarks

Industrial coolers Type KPC 108-L-U/S,

Manufacturer: ait-deutschland GmbH

Industriestraße 3

95359 Kasendorf

Germany

T +49 9228 9977 0

F +49 9228 9977 149

E info@kkt-chillers.com

W www.kkt-chillers.com

After-sales: ait-deutschland GmbH

Industriestraße 3

95359 Kasendorf

Germany

T +49 9228 9977 7190

F +49 9228 9977 7474

E service@kkt-chillers.com

W www.kkt-chillers.com

Refrigerant R134a

Total filling weight 7,0 kg outdoor model

Permitted working pressure: 19 bar

Cooling medium 62/38 % water/glycol mixture outdoor model

CAUTION! Ethylene glycol must be added at the rate of 38 % of the cooling medium volume anytime –

otherwise warranty void!

Do not use automotive antifreeze.

Never install automatic water refill system.

After the connect the refrigerant circuit –check the valve of the low pressure manometer.

IN CASES OF EMERGENCY TURN OFF THE AGGREGATE BY THE MASTER SWITCH !

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 5

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 5

1.1 Warranty

The unit is supplied finished, tested and ready to work. The unit warranty will be void if any modification to the

unit is carried out without written agreement of KKT.

For warranty purposes, the following conditions must be satisfied:

The initial start of the unit must be carried out by trained personnel from an Authorized KKT Service Partner.

Maintenance must be carried out at least twice a year by properly trained personnel.

Only genuine KKT spare parts must be used.

For KPC108-L-U/S: Ethylene glycol must be added to the rate of 38Vol%.

The manual (this document) must not remove from the chiller.

All the scheduled maintenance operations detailed in this manual must be performed at the specified

times. Please use a higher amount of services if the local conditions require it.

The “Warranty Registration” has to be send return to KKT chillers

Failure to satisfy any of these conditions will automatically void the

warranty.

1.2 Safety Warnings

-Cooling water circuit is pressurized.

Switch off the chiller and depressurize before servicing the cooling water circuit.

-Drain water from pipes and spare parts before shipment.

-Nominal static filling pressure when Chiller has been switched off: 1,5bar. The pressure of the expansion tank is

without counter pressure from the “water / glycol – side” = 1,0 bar.

-Don`t handle valves while the Chiller is running

-Ethylene glycol must be added at the rate of 38% of the volume of water anytime otherwise warranty void.

-The rate depends not on the local ambient temperature.

-Don’t use automotive antifreeze.

-Voltage continuous to be present at the terminals, even after the medical device has been switched off.

-Parts in the refrigerant circuit are hot, even the Chiller has been switched off.

Warranty void if manual removed from chiller.

OBSERVE THE SAFETY RULES

Before commencing work on the unit, switch the plant to voltage-free

IN CASES OF EMERGENCY TURN OFF THE AGGREGATE BY THE MASTER SWITCH !

Caution! Work on electric and refrigerant circuits should only be performed by qualified operatives

Observe the safety rules!

Wear safety gloves and glasses when working on unit to avoid injury.

Wear long sleeve shirt and pants when working on unit.

No loose clothing items allowed to avoid injury.

Please read the manual.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 6

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 6

Cooling block Type KPC 108 - L - U/S 60 Hz

air-cooled design for outdoor use

2 General Description

The industrial coolers of the KPC series are fully assembled, factory inspected and tested, and suitable for fullyautomatic operation.

The industrial cooler of the KPC series consists of the refrigerant circuit, the cooling medium circulation, the transfer

station, the switch box and the remote control panel.

The refrigerant circuit includes compressor, primary side of the heat exchanger, air cooled condenser, necessary

equipment for liquid and gaseous refrigerant, safety and control device.

The cooling medium circulation includes secondary side of the heat exchanger with automatic air vent, medium heating

(electrical), circulation pump, expansion receiver, pressure relief valve, necessary equipment for cooling medium,

safety and control device.

The transfer station includes supply and return connections with shut-off valves, necessary equipment for cooling

medium, filling and draining cocks.

The refrigerant circuit and the cooling medium circulation are designed as a cooling block with built in switch box

The control elements are integrated in the front of the switch box. The remote control panel includes control switch,

lamp “run” as a status massage and lamp “fault” as a general fault massage.

The temperature set on the controller is kept automatically.

The cooling medium is constantly circulated by the pump.

The process heat is being transmitted from the cooling medium to the heat exchanger (evaporator of the refrigerant

circuit) and used for refrigerant evaporating (cooling). The compressor raises the gaseous refrigerant to a higher

pressure so that the warmth can be released via the condenser to the surrounding air. Consequently good air supply

and escape are vital for the proper running of the plant.

The cooling medium supply temperature can be changed from +7 °C to +12 °C by the temperature controller in front

of switch box.

Attention! Changes in the settings should only be made by qualified operatives.

The housing with stable welded, galvanized framework-construction, lateral cover-plates with drawer-edges made of

galvanized steel plate with ventilating nozzles worked into the top plate.

Framework-construction and top-plates are powder-coated on the inside and outside. All outer fastening screws rustproof, inspection-caps at the front easily removable for maintenance using casement-fastener caps.

Compressor, refrigerant and cooling medium mountings, additionally sound and rain-proofed using a galvanized coverplate.

Condenser axial-fans, pressure switch controlled condenser pressure dependent. Ventilators equipped with protectivegrating on the delivery side of the pump.

Laterally mounted condenser heat exchanger made of copper-aluminum with covering galvanized framework,

enameled fully in black.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 7

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 7

Compressor-unit, consisting of:

Stable base-frame construction made of steel-profiles, powder-coated. Vibration-absorbing-mounted fully hermetic

SCROLL compressor with motor and suction-gas cooling. Complete special shut-off valves placed at the pressure and

suction side. Refrigerant power-inputs of flexible design. Refrigerant circuit with collector, filter-dryer, inspection glass

and moisture indicator, solenoid valve, service-valves as well as the complete internal copper-pipe work with refrigerant

and special oil filling.

Thermostatic expansion-valve and plumb high-capacity copper-brazed plate heat exchanger – evaporator. The plates

with optimized profile for efficiency heat transfer.

Evaporator and suction-side pipe work with diffusion-seal insulation.

Safety pack, consisting of:

Crankcase heater, high / low pressure switches as well as protective motor relay.

Shut-off ball valve at the cooling medium entry, dirt absorber, expansion tank, feeder and safety valves. High-pressure

centrifugal-pump adjusted to the overall system, filling and drainage valves with piping terminal, automatic air vent,

manometers and machine-thermometers in forward and return flow. Quantity balancing-valve, connection piece for

computer terminal in cooling medium supply.

Temperature control as hot gas by-pass control with solenoid valve.

Electronic digital temperature controller with control range limitation for set point and actually temperature.

Condenser fan control via pressure transmitter in refrigerant circuit and frequency inverter.

The high pressure pressostat (pressure switch) for system safety.

Internal cooling medium copper-brazed piping with diffusion-seal insulation.

All necessary block and clip angles used for refrigerant und cooling medium construction are made of rust-proof and

powder-coated material.

Switch-box with front door integrated in cooling block, system of protection IP 54, wired according to VDE-regulations

with a main switch, supply-check indicator lamp, phase monitoring relay and Siemens components such as, overload

release, sliding-panel, motor safety-switch, control-switch and indicator lamps.

A pump post-relay for the safety of the vaporizer as well as pot. proof contacts for "supply-control" and "collective fault

messages". It is still possible to connect a remote board.

The switch box of the outdoor version contains a switch box heater and a switch box ventilator.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 8

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 8

Overview of outdoor industrial cooler KPC Series

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 9

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 9

KPC 108-L-U/S

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 10

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 10

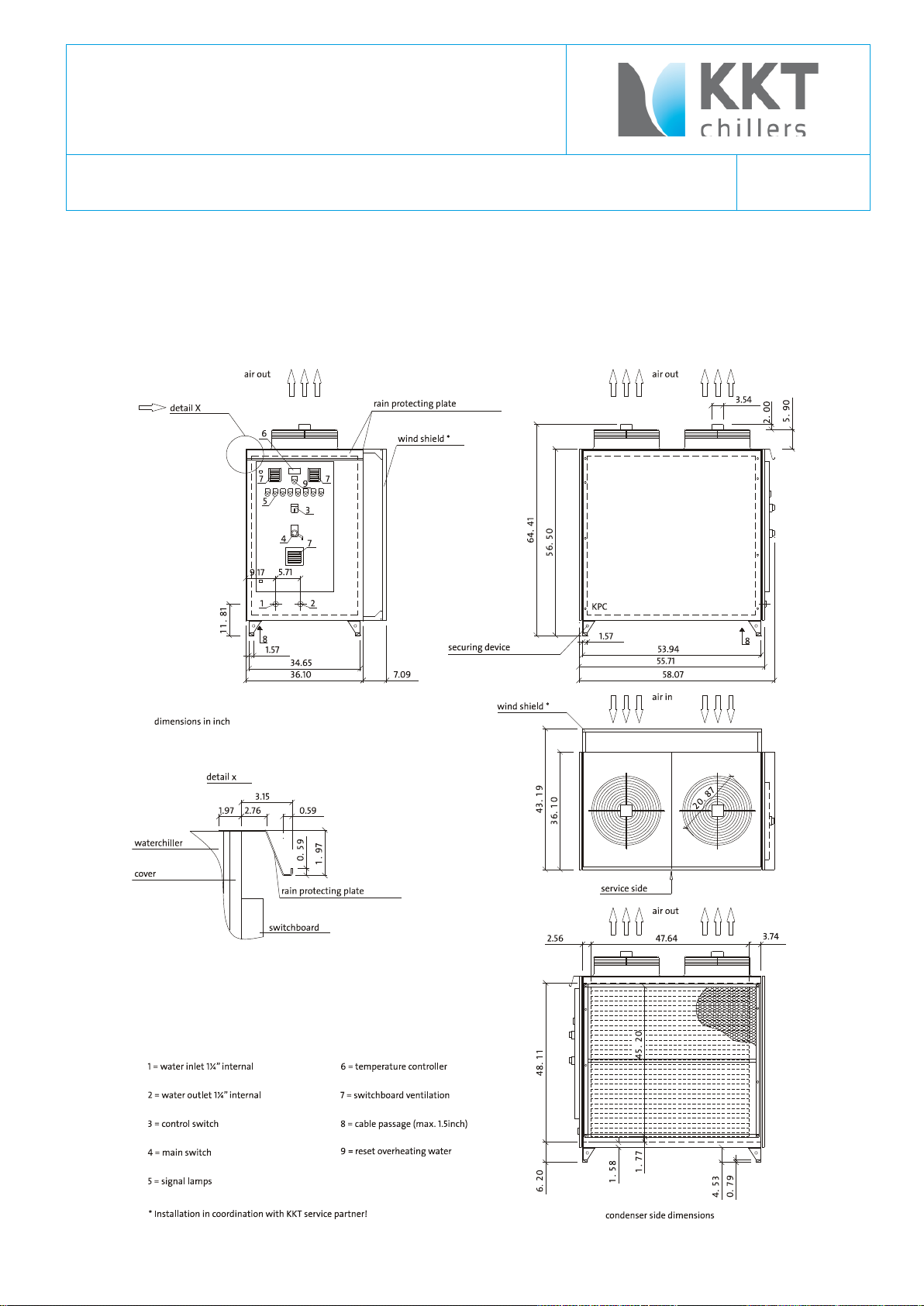

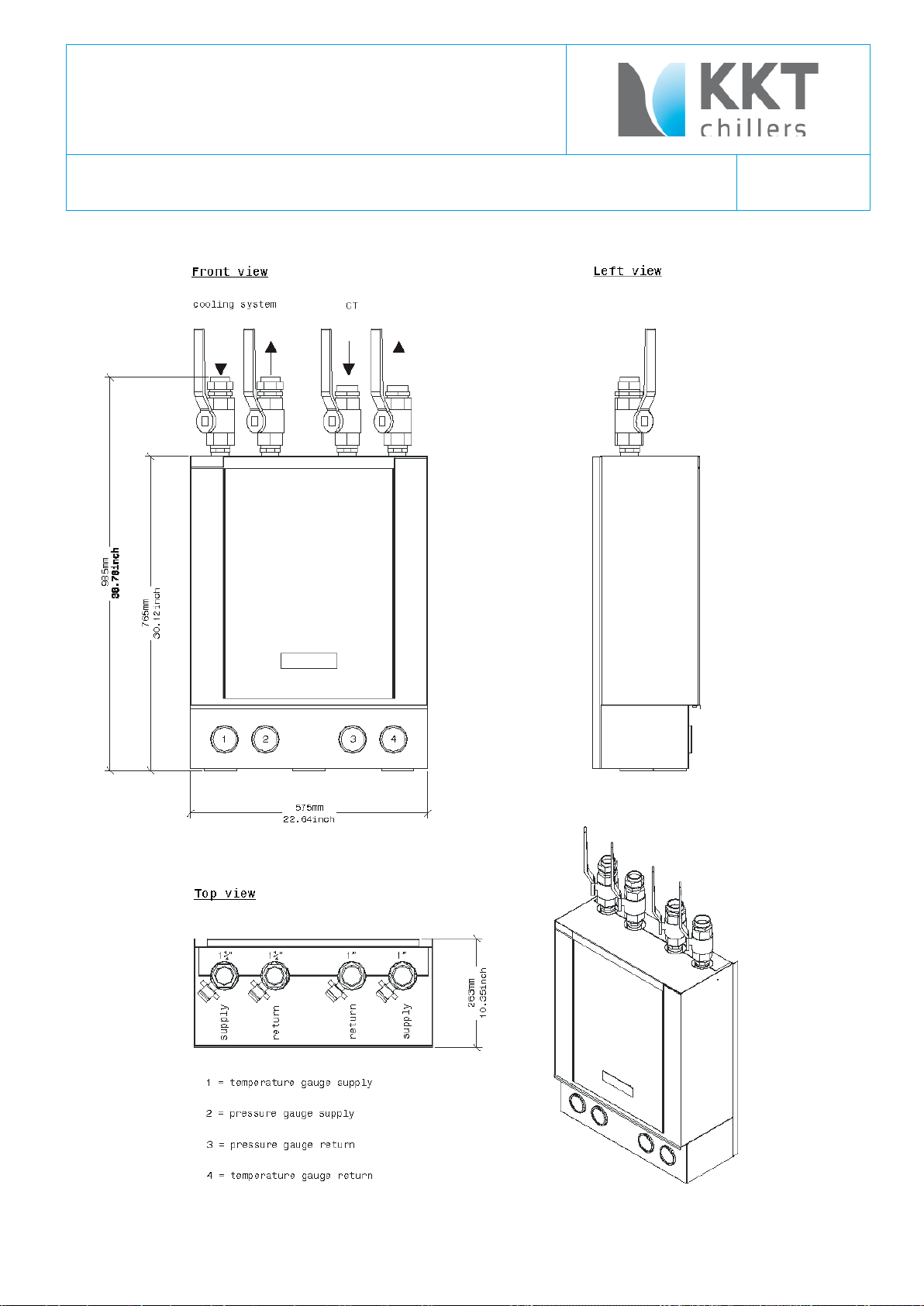

2.1 Drawings

2.1.1 KPC 108-L-U/S Outdoor Model

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 11

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 11

3 Brief operating instructions

3.1 Installing, maintenance and repair

Only qualified operatives with the requisite knowledge, equipment and facilities should maintenance and repair the

industrial cooler.

If its necessary to change the filling weight of the refrigerant circuit, please note:

Fill only with the refrigerants listed on the manufacturer name plate, and only up to the indicated filling weight.

OBSERVE THE SAFETY RULES

Before work on the industrial cooler, switch the plant to voltage-free and make sure against unauthorized switching

ON.

3.2 Linking to power supply

The size of the connection cable had to be conform to the local regulations. For current values and power input see

Switch Gear.

The industrial coolers of the KPC series are generally designed for a main supply of 480V 3Ph 60 Hz.

The connection L1, L2, L3, PE is performed via the terminal block in the switch box.

The cooling block is switched on via the master switch .

3.3 Filling the unit with cooling medium

The cooling circulation will be filled with cooling medium (mixture of 62 % clean water – drinking water quality – and

38 % glycol).

Open front panel and fill to a pressure of 1,5 bar via the feed cock.

After filling, check all connections for leakage.

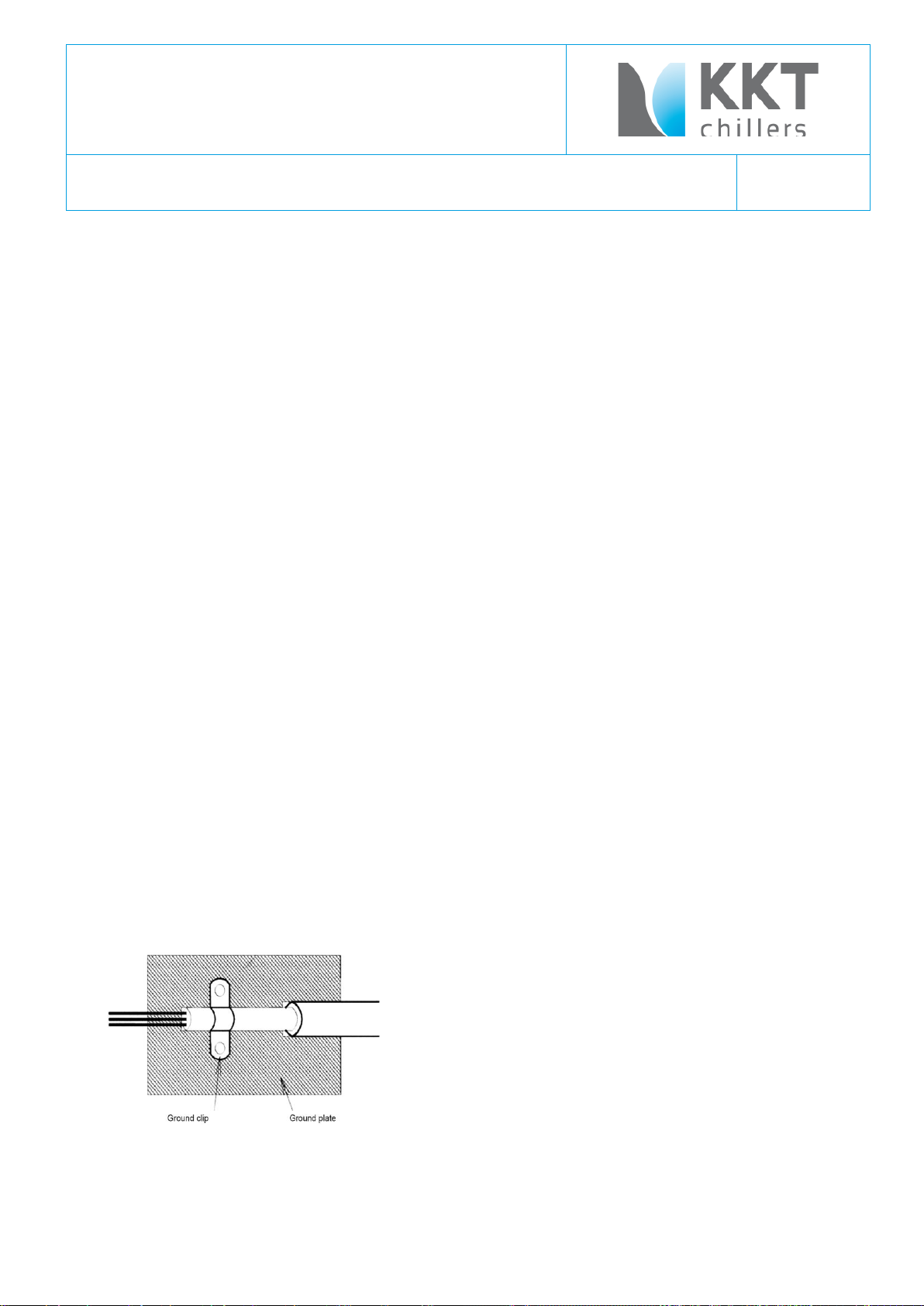

3.4 EMC Compatibility and Grounding

This comments are compiled to help the field electrician to install the grounding of the power supply and to get a EMC

Compatibility.

All electrical equipment produces radio and line-borne interference at various frequencies. The cables pass this on to

the environment like an aerial.

The basic countermeasures are isolation of the wiring of control and power components, proper grounding and

shielding of cables.

A large contact area is necessary for low-impedance grounding of HF interference. The use of grounding straps

instead of cables is therefore definitely advisable.

Moreover, cable shields must be

connected with purpose-made ground

clips.

The grounding surface must be highly

conductive bare metal. Remove any

coats of varnish and paint.

The width of the grounding wire must be min. 16mm² (AWG 6) or of the same width of the power supply.

The grounding must be an isolated ground and must connected on the ground terminal (X1) in the switch cabinet.

The ground resistance must be less than 10 Ohm.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 12

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 12

Metal cable conduits are not allowed for grounding.

The piping of the chiller (supply and return) have to be grounded too.

Do not share the ground wire with other devices.

Always use a ground wire that complies with technical standards on electrical equipment and minimize the length of

the ground wire.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 13

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 13

remote control panel

main switch

control switch

"0"

"1"

"0"

"1"

"0"

"Auto"

"Hand"

standard

operation: pump

runs, compressor

and condenser fan

are running on

demand (water

temp. higher than

8°C), water heater

works on demand

(water temp. below

4°C),

overheating

protection: pump

switches of if water

temp. Is longer

than 30 minutes

higher than 30°C)

X X X

X

(or no

remote

control

connected

with chiller)

X

X

When using more than one Inverter, be careful not to loop the ground wire.

(e.g. a CT-Chiller KPC108-L-U/S stands near an Avanto-Chiller KCC215-L-U/S)

3.5 Draining air from the unit

The KPC 108 includes a cooling medium circulation.

In case air gets out of the system the cooling medium pressure drops down. If that happens you have to check the

cooling medium pressure and if its to low you have to refill the cooling medium circulation as shown in 3.3

The procedure should be repeated until no more air is in the cooling medium circulation.

After all these steps, turn both switches to position "1". If all the prerequisites for operation have been met, the

industrial cooler will start after 1 minute.

In case of malfunction: search for faults taken note of TROUBLE SHOOTING in this manual.

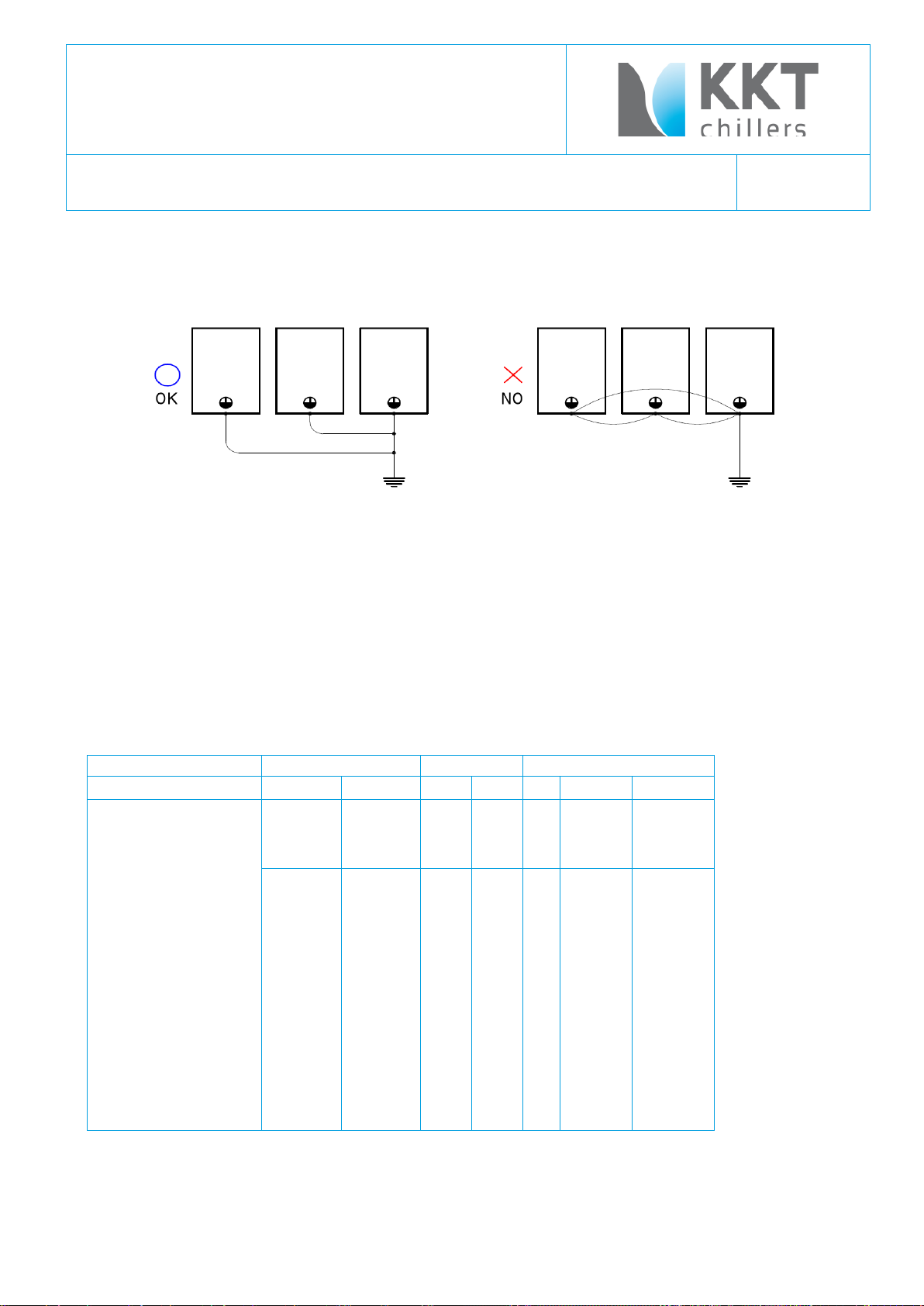

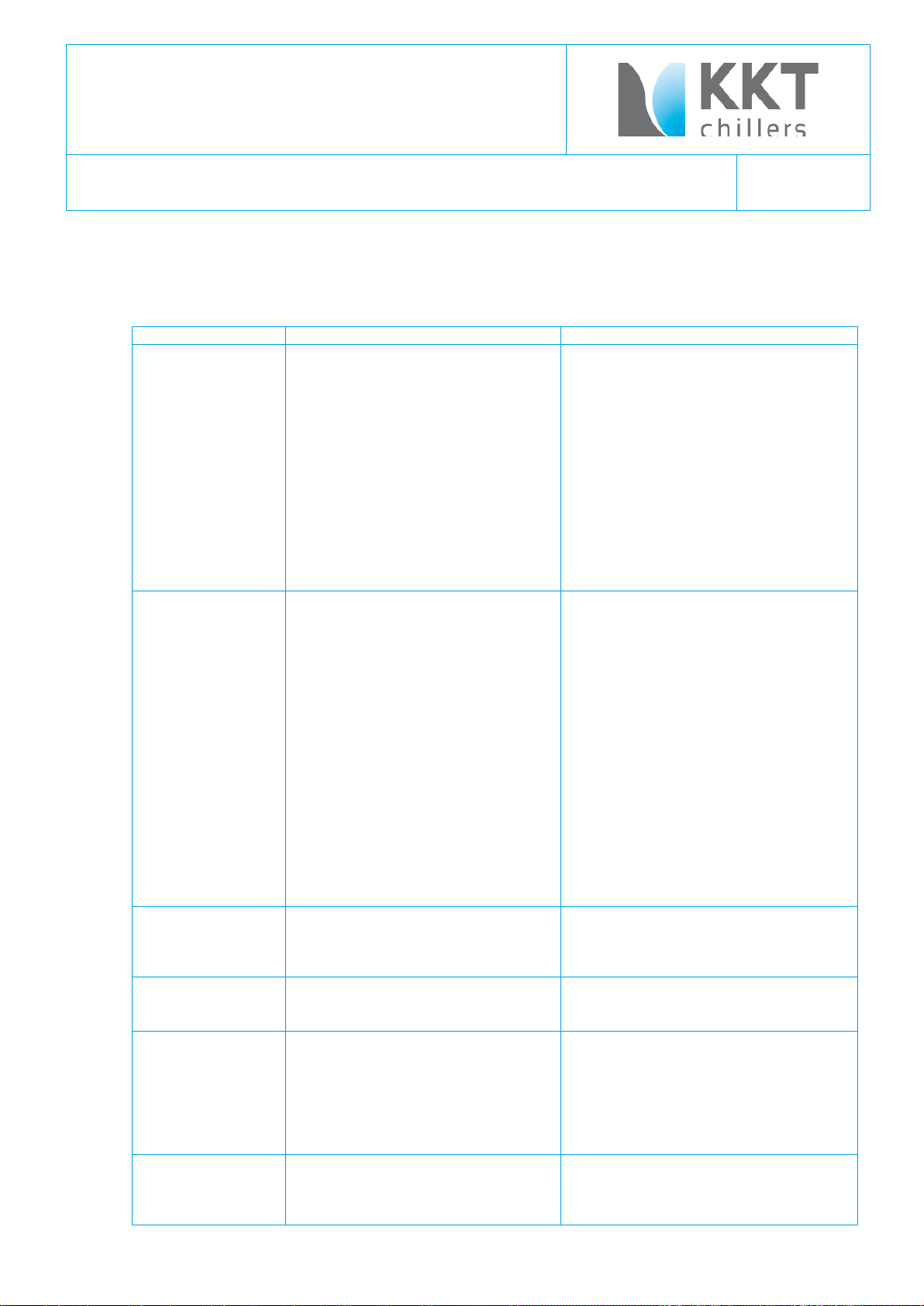

3.6 Switch settings of main chiller functions (exfactory settings)

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 14

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 14

stand by mode:

refrigerant circuit is

"switched off",

pump and heater

are running on

demand (water

temp. below 4°C),

X

(or no

remote

control

connected

with chiller)

X X

X X X

X

X

switched off:

no function (switch

cabinet is not

under voltage)

position without effect

X position without effect

remark: with the position "Auto" on the control switch is the remote control panel active.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 15

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 15

4 Technical Specifications

4.1 Data sheet

Outdoor

Dimensions Depth 962 mm

Breadth 1,410 mm

Height 1,620 mm

Weight without refrigerant load 540 kg

Weight with refrigerant load 7.0 kg

Number of fans 2

Quantity of air 18,000

Refrigerant R134a

Required quantity of refrigerant 7 kg

Low-pressure switch see testreport

High-pressure switch 19 bar

Water connection inlet 1 1/4“ inside

Water connection outlet 1 1/4“ inside

Cold water temperature outlet min. 7 °C +/-0,5 K

Cold water temperature outlet max. 12 °C

Primary water pump type CR3-6

Rated water capacity max. 4.1 m³/h

Rated water pressure 3.0 bar

Ambient temperature min. -20 °C

max. +48 °C

Cooling capacity 15,0 kW

Rated cold water outlet temperature 11 °C

temperature of surroundings 40 °C

Exactitude of temperature ±0.5 K

Main supply 480 V/3Ph/60 Hz

Control voltage 24 V

Fluctuations in main voltage max. ±5 %

Fluctuations in output max. ±5 %

Power input max. 9 kW

Noise level at 5m 65 db(A) -

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 16

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 16

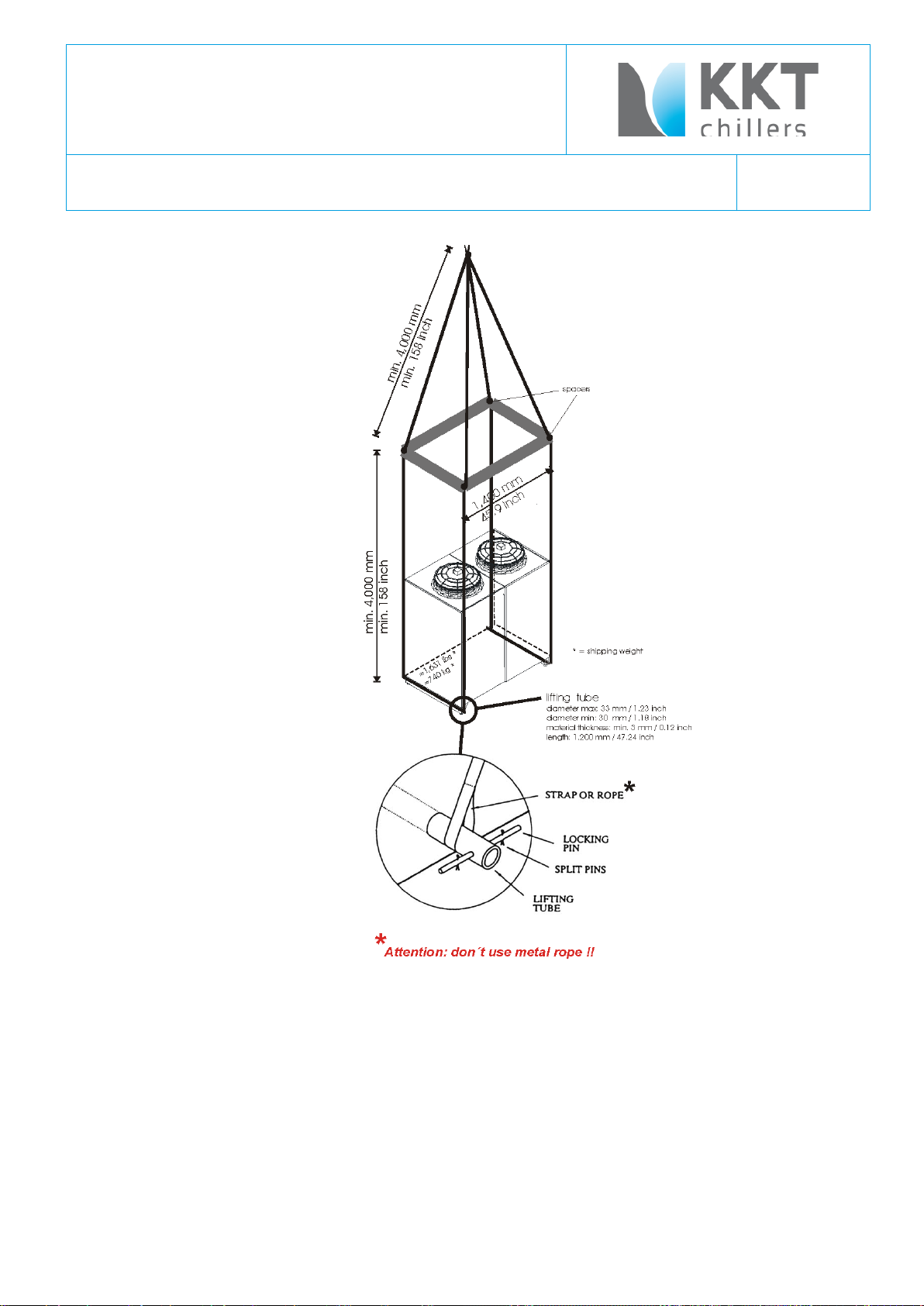

5 Transport

Transport on company premises may be done with a forklift truck. The appliance must however be kept in an upright

position and on no account tipped to the side. A visual inspection should be made on delivery to check for any damage.

Complaints should be made immediately to the haulage contractor and the insurance company must be notified at

once.

When transporting by crane,

please ensure that the housing is not subjected to pressure at the sides.

Place the lifting tubes in the holes in the feet at the base of the chiller. Lock the ends of the tubes in position with

locking pins and split pins as shown.

The capacity of the lifting gear must be adequate to lift the load in question. Check the weight of the unit, the capacity

of the lifting gear and ropes and there condition.

Check the suitability of the aforementioned equipment.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 17

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 17

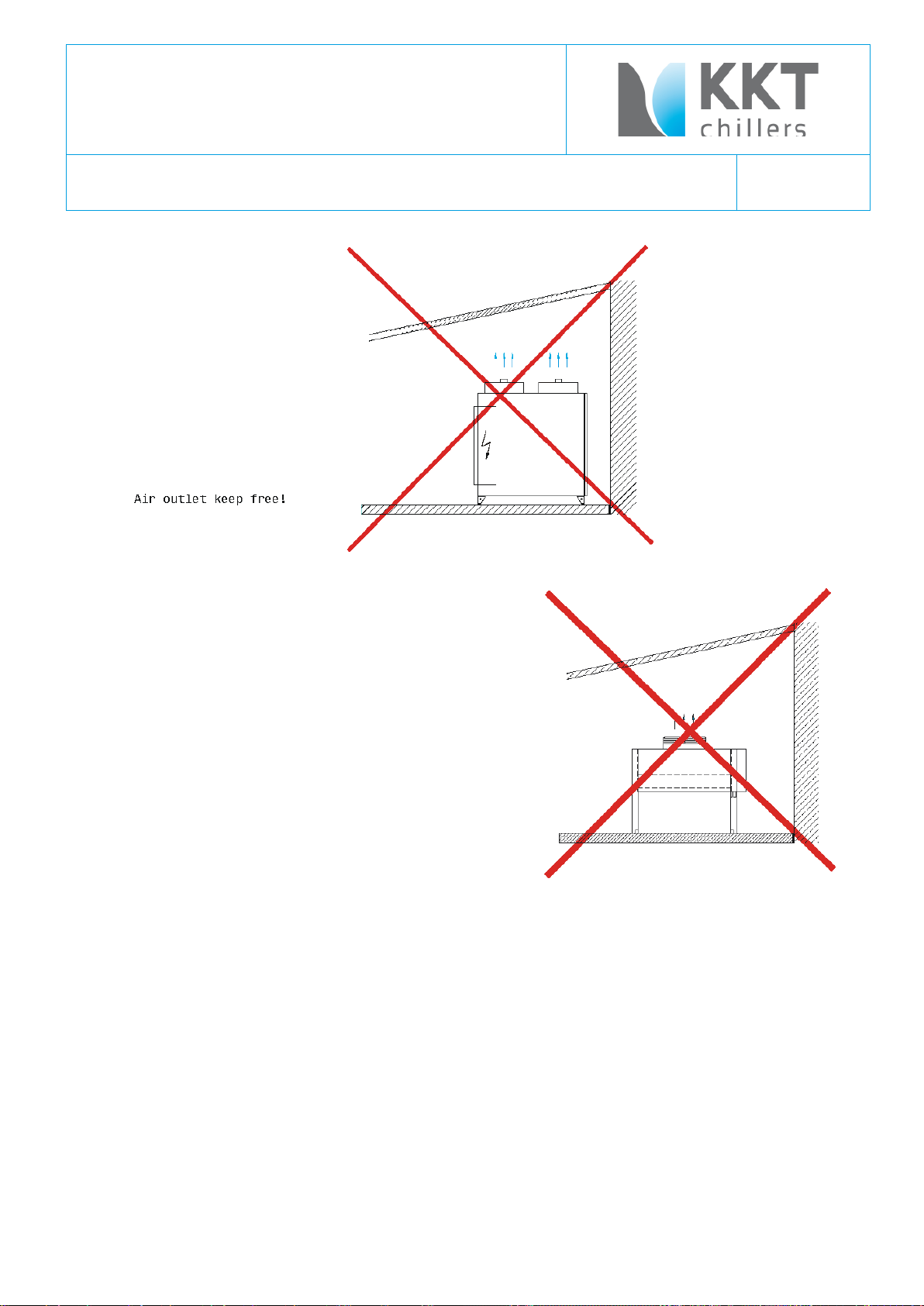

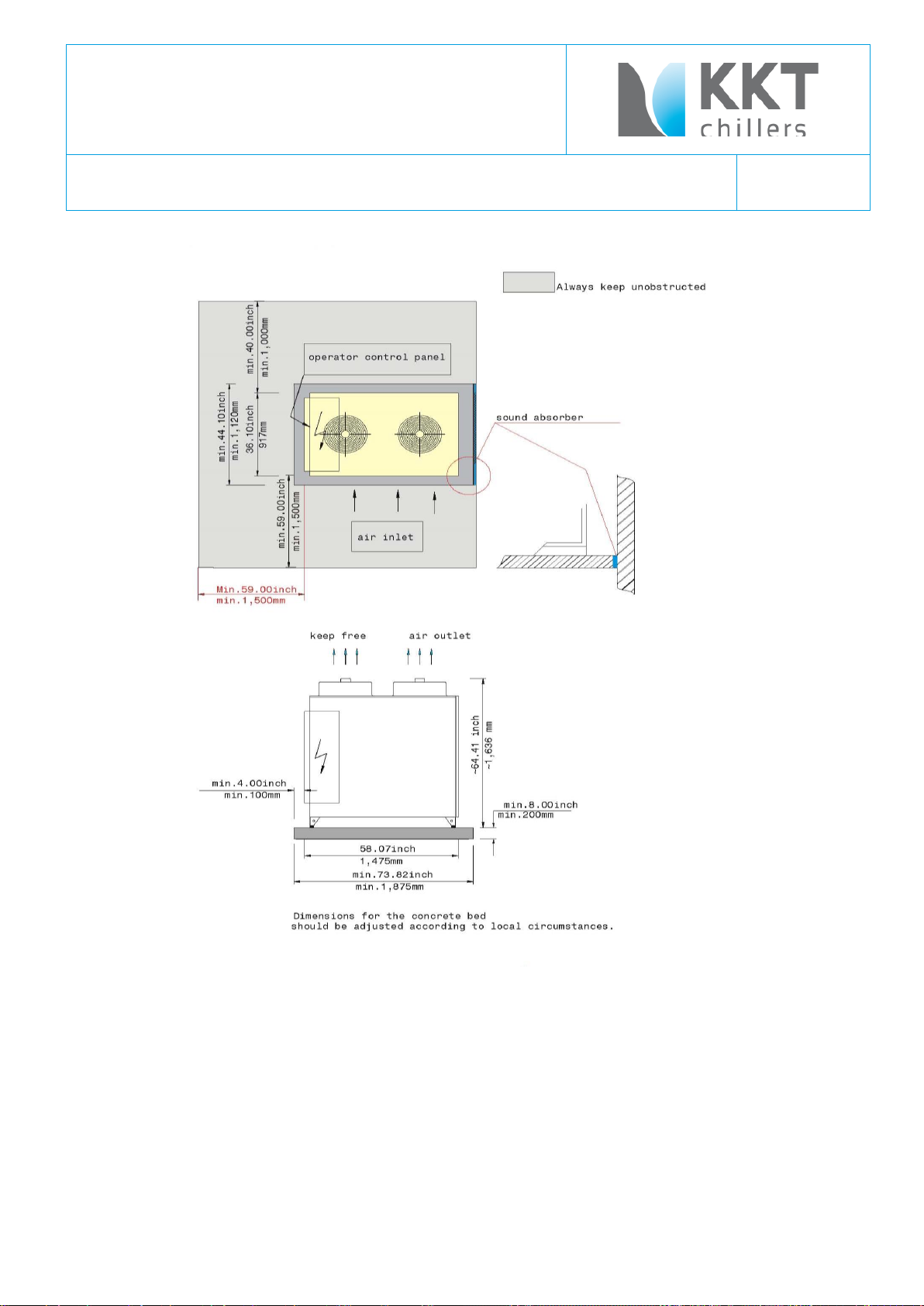

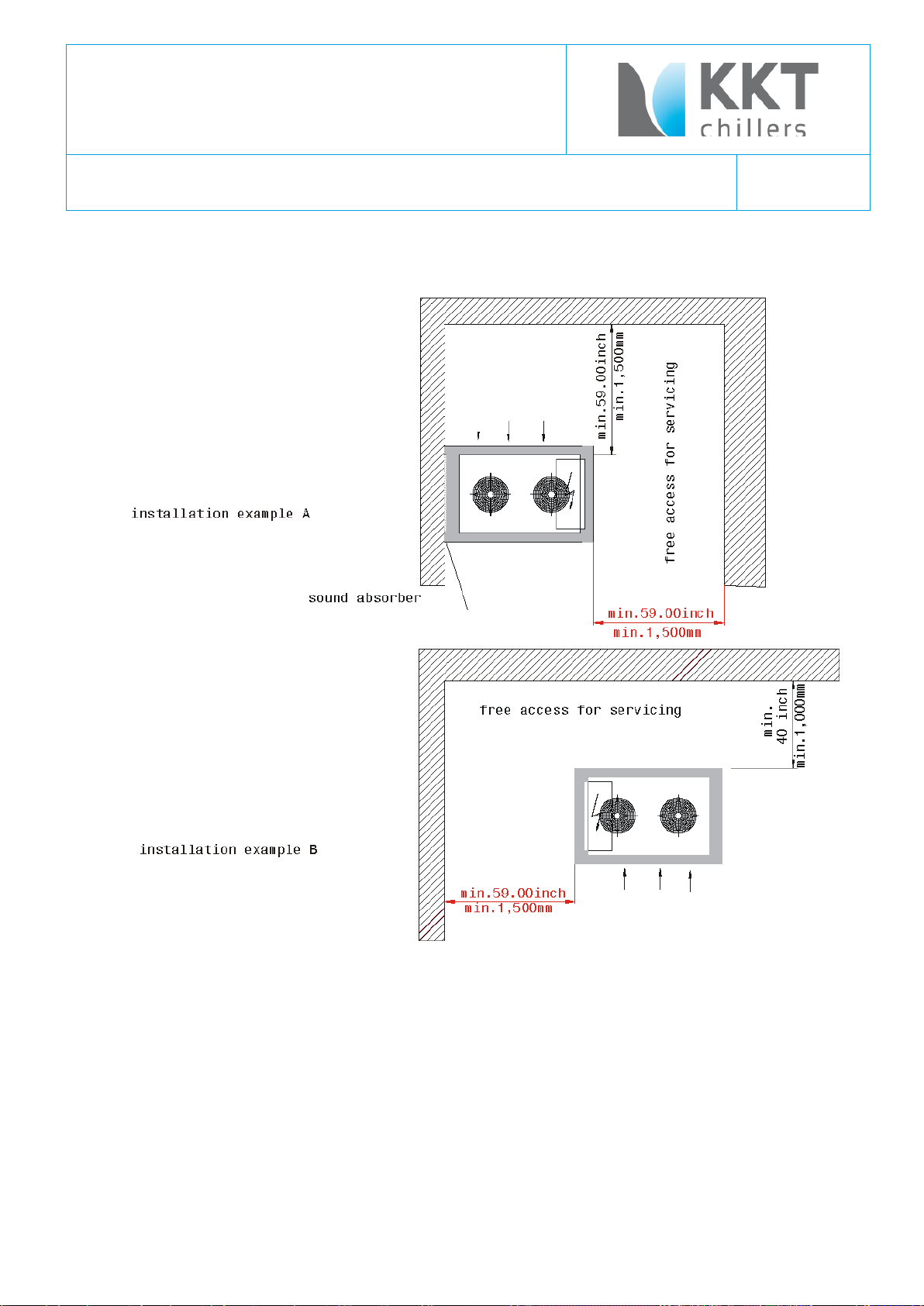

6 Installing the industrial cooler

The plant should be mounted in an upright position on a stable foundation.

(Weight with load: see technical specifications).

A distance of approx. 1 m should be kept free on all sides to allow sufficient access for operation and maintenance.

A space of 1,5 m must be left above the apparatus to ensure that air exhaust can leave freely by the outdoor model.

Further details can be found in the following installation plans.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 18

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 18

Type KPC 108-L-U/S Outdoor Unit

A distance of approx. 1 m should be kept free on all sides to allow sufficient access for operation and maintenance.

Picture is only to explain and not guilty for measurement.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 19

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 19

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 20

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 20

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 21

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 21

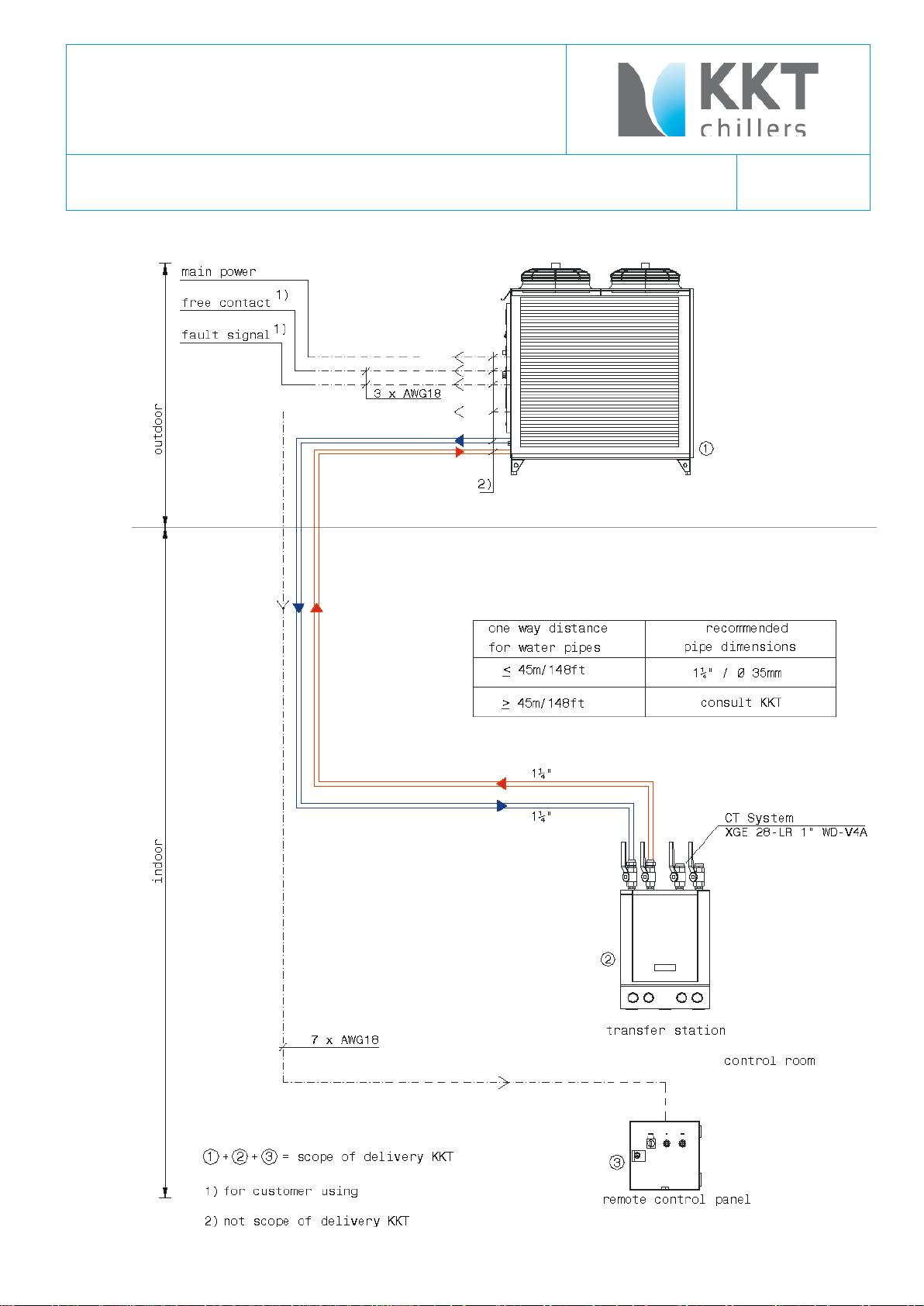

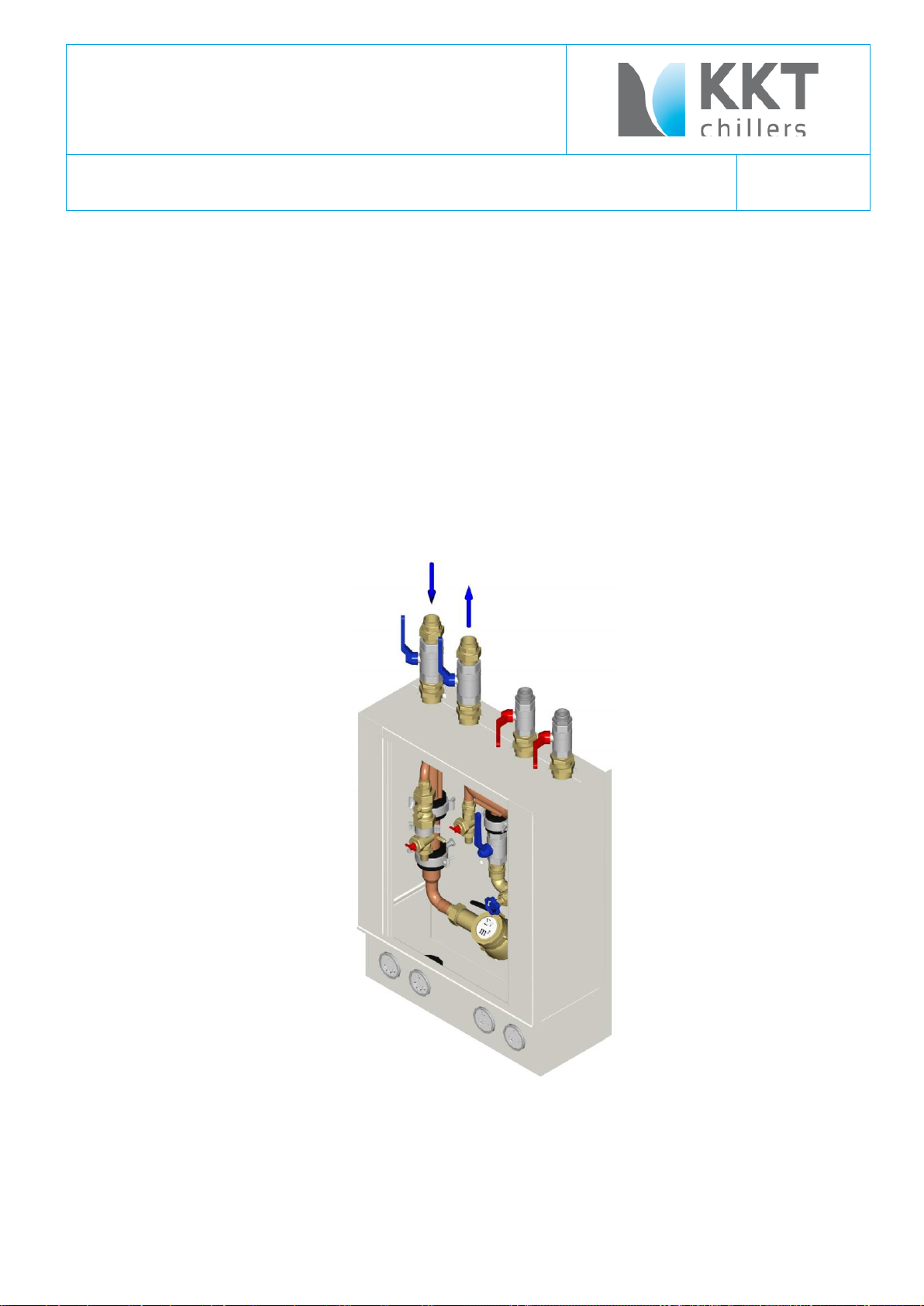

7 Notes on the cooling medium connections

The cooling medium connections between industrial cooler of the KPC series and the transfer station can be made of

steel, copper or plastic. The nominal widths of the piping for distances of up to approx. 45 m should match at least the

dimensions of the fittings on the appliance (see technical specifications).

The proper way to seal the European fittings can be done with any of following steps.

Pipe sealing cord. There are a number of brands available, however we use Loctite 55

Teflon Tape and a Anaerobic sealant.

Teflon Tape an Nylog sealant.

As with any sealant, the application instruction must be followed for proper use.

Reductions in diameter should be avoided. In case of longer pipelines, the pump pressure should be tested. When

choosing the pipe materials, ensure that no electrochemical series are created.

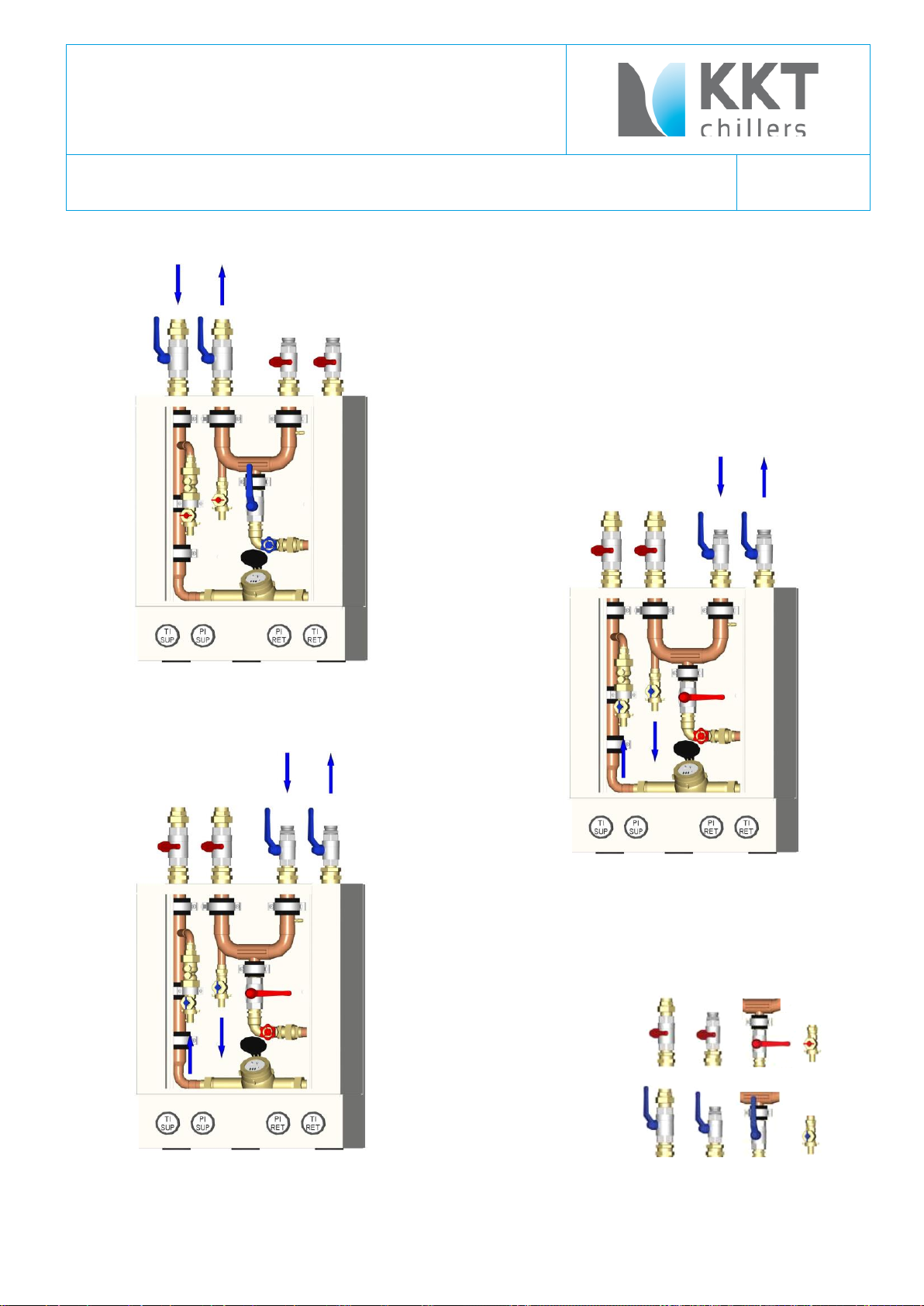

Transfer station

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 22

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 22

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 23

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 23

1.) regulation phase

2.) in operation

3. ) emergency cooling

Closed:

Open:

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 24

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 24

8 Power supply

The power supply is wired to the terminal block in the junction box of the transformer (see technical specifications).

The layout of the main cable must comply with the current values and the regulations of the local electricity company.

The Type KPC 108 L-U/S (Outdoor-Version) must be run with fuses of no less than 35 A in size ( see nameplate).

The supply voltage must be 480V / 3ph / 60 Hz.

The master and control switches must be in the "OFF" position when the plant is connected.

The supply line is attached to the terminal PE, L1 L2, L3,

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 25

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 25

9 Operating instructions

9.1 Switching ON the Industrial Cooler

The cooling medium circulation must be completely filled and all air must be removed.

Turn the “main switch” switch “ON” - to the position “1”

(For additional information about the switch settings please see chapter 3.8 “Swithch settings of main chiller functions

(exfactory settings).

Turn the control switch “ON” this means to “Automatik” if the remote control panel is installed otherwise to position

“HAND”.

The cold water pump starts.

The flow switch protection cuts off the compressor during start-up, if the water circuit has not enough water pressure.

The pressure on the pump supply side rises directly with the system pressure. If not: – the plant has either a leak or

insufficient cooling medium.

A flow switch acts to prevent freezing of the evaporator if and when water volumes drop.

The compressor switches on when the water becomes to warm.

The refrigeration compressor keeps running as long as cooling is required and the reference value for the water

temperature has not been reached. The fine adjustment is performed by hot gas by-pass solenoid valve.

The cooling medium pump remains in constant operation.

The compressor is switched off during circulation in cases of low or high pressure in the refrigerant circuit (fault

massage), or when the cooling is not required (normal).

When switched off in the normal way, the overload protection provides the compressor restart switching lag.

9.2 High/low pressure control

The high-pressure pressostat reacts by shutting off the compressor, when the refrigerant pressure after compressor is

higher then 19 bar.

Cause of this include - failure of condenser fans,

- high outdoor temperatures,

- a dirty condenser heat exchanger.

The compressor can only be put back in operation when the pressure has dropped and the reset switch on the high

pressure pressostat is activated.

An automatic start has not been provided for you have to do a reset on the high – pressure pressostat.

The low-pressure pressostat reacts by shutting off the compressor, when the refrigerant pressure before compressor

sinks to the magnitude mentioned in test report (Settings, Low-pressure-switch, different).

When the pressure rises to high enough, the compressor will switch on again automatically.

The start-up switching lag amount to the adjusted value in the testreport.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 26

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 26

9.3 Electronic controls

The control system consists of a 2-step controller. The reference value is set value see testreport for the outlet

temperature. The sensor for the controller is installed on the outlet side.

9.4 Regulating refrigerating capacity

The exact regulation of the leaving temperature is achieved by means of 2-step controllers and hot gas by-pass

injectors with solenoid valves. The setting is based on approx. 50% of each machine’s refrigerating capacity.

9.5 Condenser pressure regulation

the condenser-pressure is regulated with help of the Frequency Inverter.

– see caption “Frequency Inverter”

9.6 Safety functions to protect components of cooling water circuit

When the refrigerant cycle is failure the water pump heats up the cooling medium.

To prevent the components in the cooling circuit, there is a safety function which switches off the pump if the water

temperature is longer than 30 minutes over 30 °C.

When this function has worked, the lamp (7H3 – in switch gear) on the switch box lights and the water pump has

stopped.

The lamp is labelled “reset overheating water”.

When the problem in the refrigerant circuit is solved, you have to pull down the button “reset overheating water”. This

is the requirement that the pump can run again.

9.7 Collective alarm

The red warning lamp in the door of the switch box lights up when one of the safety sensors has been triggered. The

cause of the error can be identified more exactly by means of the LEDs in the switch box. For the purpose of external

evaluation of the error signal, the collective alarm message can be accessed, potential-free, from the terminal. (See

also circuit diagram)

9.8 Flow switch

Monitors the water flow volume through the evaporator and shuts the device down completely if the min. water

quantity is reached.

9.9 Dirt trap

The dirt trap is fully installed (see Shema in the appendix) and protects the evaporator from dirt.

As a matter of principle the plant is to be operated with clean water. With that regular servicing of the filter is

unnecessary.

Caution! Work on electric and refrigerant circuits should only be performed by qualified operatives.

Observe the safety rules!

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 27

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 27

10 Preventiv Maintenance

Caution! Work on electric and refrigerant circuits should only be performed by qualified operatives.

Observe the safety rules!

Service and maintenance should always be carried out by skilled technician and, where possible, under a maintenance

contract. Nevertheless, certain routine work can be effectively carried out by non-specialists and may become

important factor in preventing future damage to the plant.

Weekly Check

1. Check the working of the compressor:

Look out for too high head temperatures or suspicious noises.

2. Check the R134a through the sight-glass

3. Check that fans are rotating normally and not making unusual noises

4. Check that the temperatures is within the accepted limit.

If it is not, check that all the separate elements of the unit are working, by switching them on individually.

If they are not, see the “ Trouble shooting”

Two –monthly Check

a. The air conditioner unit:

1. Check the air filter and replace it if necessary

2. Check the air circulation fans and check that the bearings are not heating up

3. Check that the heating elements work, by switching them to “MAN”

4. Switch cooling system to “MAN” and check that it is in full working order

5. Check the compressor temperature.

6. Check there is no ice accumulations on the evaporator.

7. Check that the warning lights on the display panel are working properly.

8. Check the main voltage between all the phases

9. Check the principal and secondary circuits thoroughly, inspect the overload cut-outs and thermal

relays.

10. Pull out the fuses to check that the safety system works.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 28

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 28

b. The condenser

1. Air cooled units:

Make sure that the fan motor and the condensing coil are working efficiently, if necessary clean the

coil.

c. Electric heater

1. Check the heater coil

2. Check the overheating protection switch in the head of the heater

3. Check the fuses

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 29

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 29

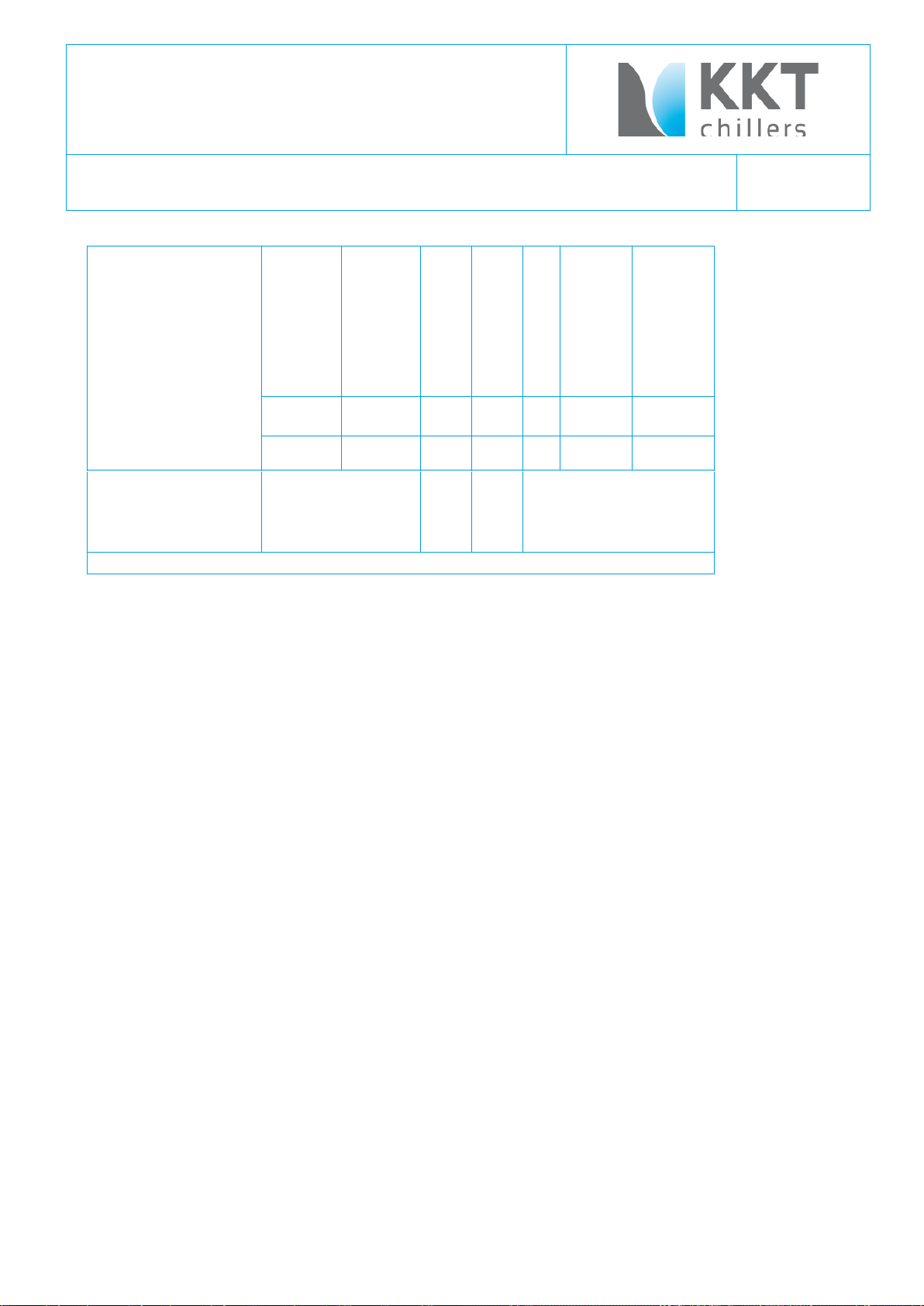

KIND OF TROUBLE

CAUSE

ELIMINATION

malfunction of

plant/system

1. power failure

2. feeler of temperatur controller

defective

3. feeler malfunction

- check mains connection

- check feeler:

clamp feeler and measure the resistance

- check thermostat:

bridge controller the thermostat relay

should shut and the compressor should

start

- check feeler:

clamp feeler and measure the resistance

- replace feeler ( sensor ) is defect.

malfunction of pump

1. main switch not switched on

2. control switch on 'OFF'

3. main fuse defective

4. fuse for control current defective

5. pump motor defective

6. flow controller responded

7. shortage of water

8. lamp “overheating water reset” lights

- switch on main switch

- switch control switch to 'AUTO'

- replace fuse

- replace fuse

- replace motor

- check water quantity

- check system pressure, clean strainer

- check the refrigerant circuit – see capture

“Water pump”

still malfunction of

pump

1. overload trip of pump protection

interrupted control circuit

- main switch to '0', push in overload trip

pump makes

gurgling noise

1. circuit is not completely vented

- vent and fill up with water

compressor stops

1. Klixon tripped

2. Klixon defective

- wait until compressor cooled down;

perhaps clean condenser or provide fresh

air supply

- replace Klixon

malfunction of

refrigerating machine

1. control thermostat stopped machine,

return temperature too cold

- to check function, level down adjustments,

wait until return temperature rised

11 TROUBLE SHOOTING

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 30

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 30

KIND OF TROUBLE

CAUSE

ELIMINATION

still malfunction of

refrigerating machine

1. low pressure in refrigerant circuit

- plant looses refrigerant

- dryer in liquid pipe dirty

- pressure relief valve defective

- solenoid valve in liquid pipe defective

2. high pressure in refrigerant circuit

- condenser dirty

- fan defective

- outside temperature too high

- condenser control pressostate

defective

- find leak, seal, refill circuit

- replace dryer

- replace pressure relief valve

- replace solenoid valve

- clean condenser

- put right electric cause;

check fuses

- spray condenser with water

- replace pressostate

refrigerating machine

starts and stops

short-termed

1. not enough fresh air supply for

condenser;

high pressure pressostate tries to

protect refrigerating machine against

overload

2. not enough pressure of refrigerant

circuit;

refrigerant partly escaped; diminished

pressure switch shut down compressor

- provide enough fresh air supply and fresh

air removal;

get rid of short-circuit across fresh air and

exhaust air

- find leak, seal, refill circuit

not enough

refrigeration power

1. air in water circuit

2. fallen below minimum water agitation

quantity

3. not enough fresh air supply for

condenser

4. not enough refrigerant in circuit

- vent system

- design cross-section of water pipe right;

perhaps open check valve in water circuit

completely, increase pipe cross-section

- provide enough fresh air supply and fresh

air removal;

get rid of short-circuit across fresh air and

exhaust air

- find leak, seal, refill circuit

electrical heater in

water circuit does

not work

1. the electrical heating box becomes

more than 266°F (130°C)

=> the safety temperature limiter

breaks the contact

2. control the pressure from the water

circuit

3. control the Parameter of the

temperature controller witch switches

the heater.

- the reset (is under the cover of the heater)

must be reset manually

- if necessary: prepare the cause of water

lack and fill the water circuit

- if necessary: set the right Parameter in the

temperature controller (which switches the

electrical heater)

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 31

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 31

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

12 Description of the individual parts

12.1 Compressor

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 32

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 32

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 33

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 33

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

Technical Data

Accessories

Crankcase Heater: 220 – 240 V 50 – 60 Hz

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 34

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 34

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

Z R 90K 3 E - TWD

-

561

1 2 3 4 5 6 7

7,2 °C

evaporating temperature

8,3 K

liquid sub cooling

54,4 °C

condensing temperature

35 °C

ambient temperature

11 K

suction gas superheat

Introduction

Scroll Compres sors in the ra nge fro m ZR 90 K3 * to ZR 38 0 KC* are characterized by the pilot duty motor

protection system that uses internal sensors and an external electronic module to protect the compressor

against motor overheating and excessive discharge temperature. For additional information, please refer to the

Copeland website at www.ecopeland.com.

Safety Instructions

Only qualified personnel should install and repair COPELAND compressors.

• Refrigerant compressors must be employed only for the use they are made for.

• Only approved refrigerant and refrigerating oils must be used.

• Do not start the compressor until it is charged with refrigerant.

• Correctly used, the compressor and the pressure line piping may reach temperatures that may cause burning if

touched.

• Wear safety goggles when working on open systems.

• If the refrigerant needs to be removed from the system, do not disperse it in the environment, use the correct

equipment & method of removal.

• Trained electrical personnel must connect the compressor and its accessories.

• All valid standards for connecting electrical and refrigeration equipment must be observed.

• Limit values for the supply voltage of the unit may not be exceeded.

• It is not allowed to run a test without the compressor being connected to the s ystem and without refrigerant.

It is of vital importance that the discharge stop valve has been fully opened before the compressor is

started. If the discharge stop valve is closed or partly closed an unacceptable pressure with accordingly high

temperatures may develop in the cylinder head. When operating with air the so called diesel effect may occur,

i.e. the air sucked in is mixed with oil gas and can explode due to the high temperature in the cylinder head, and

thereby destroy the compressor.

Model Designation

1 - compressor family: Z = Scroll

2 - application range: R = high/medium temperature

3 - nominal capacity [BTU/h] @ 60 Hz and ARI conditions (*see below) using multipliers "K" for 1000 and

4 - model variation

5 - oil type: E = POE oil

6 - motor version: TWD (400V/460V/3/50/60 Hz)

7 - bill of material number: 561: Rotalock connection, 24 V AC module (ZR90K3* to ZR19M3*)

*ARI-Conditions:

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

"M" for 10 000

Page 35

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 35

Qualified Refrigerant

R134a has been qualified for the models ZR 90 K3E…ZR 380 KCE.

Lubrication and Oil Removal

The compressor is supplied with an initial oil charge. The standard oil charge for use with refrigerants R134a is a

polyolester (POE) lubricant Copeland 3MAF (32 cSt). In the field the oil level could be topped up with ICI Emkarate RL

32 CF or Mobil EAL Arctic 22 CC, if 3MAF is not available.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 36

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 36

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

The crankcase heater must be mounted below the oil removal valve located on the

bottom shell.

The crankcase heater must remain energized during compressor off cycles.

The crankcase heater must be turned on a minimum of 12 hours prior to starting

the compressor. This will prevent oil dilution and bearing stress on initial start up.

If it is not feasible to turn on the crankcase heater 12 hours in advance of starting

the compressor, then use one of the techniques listed below to prevent possible

flooded-start damage to the compressor:

If oil is charged into a system it is recommended to charge systems with POE containing no more than 50 ppm moisture

content. If the moisture content of the oil in a refrigeration system reaches unacceptable high levels, corrosion and copper

plating may occur. The system should be evacuated down to 0.3 mbar or lower. If there is uncertainty, as to the moisture

content in the system, an oil sample should be taken and tested for moisture. Sight glass/moisture indicator will just

show the moisture contents of the refrigerant. The actual moisture level of POE would be higher than the sight glass

specifies. This is a result of the high hygroscopicity of the POE oil. Oil samples would have to be taken from the system

and analyzed to determine the actual moisture content of the lubricant.

Crankcase Heater (240 V, 70 W)

1) Direct a 500 watt heat lamp or other safe heat source (do not use torch) at the lower shell of the compressor for

approximately 30 minutes to boil off any liquid refrigerant prior to starting; or

2) Bump start the compressor by manually energizing the compressor contactor for about one second. Wait five

seconds and again manually energize compressor for one second. Repeat this cycle several times until the liquid in

the shell has been boiled off and the compressor can be safely started and run continuously.

Discharge Temperature Protection

A thermistor with a nominal response temperature of 140 °C is located in the discharge port of the fixed scroll. Excessive discharge

temperature will cause the electronic protector module to trip. The discharge gas sensor is wired in series with the motor

thermistor chain.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 37

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 37

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

Electronic Motor Protection

The electronic motor protection system as used in all ZR 90 K3* ... ZR 380 KC* models is identified by a “W” as the

center letter in the motor code. This system utilizes the temperature dependent resistance of thermistors (also called

PTC resistances) to read the winding temperature. A chain of four thermistors connected in series is embedded in the

motor windings so that the temperature of the thermistors can follow the winding temperature with little inertia. An

electronic module is required to process the resistance values and trip a control relay depending on the thermistor

resistance. The resistance curve can be designed for different operating points, the nominal response

temperature (NAT), e.g. 80 °C, 130 °C, 140 °C and must comply with the tolerances laid out in the standard DIN 44081.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 38

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 38

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

Module

For protection in case of blocked rotor one thermistor for each phase is embedded in the winding heads on the upper

(suction gas) side of the compressor motor (NAT 100 °C). A fourth thermistor is located in a winding head at the lower end

of the motor (NAT 140 °C). A fifth sensor is located in the discharge port of the fixed scroll to control discharge gas

superheat (NAT 140 °C). The entire chain is internally led to the fusite from where it is connected to the module connections S1

and S2. When any resistance of the thermistor chain reaches the tripping value, the module interrupts the control line

and causes the compressor to switch off. After the thermistor h as cooled sufficiently, its resistance drops to the

reset value but t h e modu l e itse lf res e t s a fter a t ime de lay of 3 0 minutes and restarts the compressor.

Protector Functional Check and Failure Detection

Prior to start-up of the compressor a functional check shall be carried out:

- Switch off power!

- Disconnect one terminal either S1 or S2 of the electronic module. If the compressor is now switched on, the motor should not start.

- Switch off power.

- Reconnect the disconnected thermistor line. If the compressor is now switched on the motor must start.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 39

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 39

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

Protector Fault Diagnosis:

If the motor does not start-up during the functional check, this indicates a disturbance in operation:

- Switch off power.

- Check the connection of the thermistor leads in the termin al box and at the protection module for possible

loose connections and check the connection cable for possible breakage.

- The resistance of the thermistor chain shall be measured in a cold condition, i.e. after the motor has sufficiently

cooled down.

Caution: Use maximum measuring voltage of 3 V!

In doing so, the thermistor leads at terminals S1 and S2 of the module shall be disconnected and measured between the leads.

Resistance must be between 150 and 1250 ohms.

If the thermistor chain has a higher resistance (2750 Ohms or greater) the motor temperature is still too high and it

has to be allowed to cool.

If the resistor is 0 Ohms, the compressor has to be exchanged due to shorted sensor circuit. - Ohms indicates an

open sensor circuit and the compressor has to be replaced.

If no defect is located in the thermistor chain or there is no loose contact or conductor breakage, the module shall be

checked. Then the control connections at M1 and M2 have to be removed (Caution! Switch off voltage supply

first!) and check the switching conditions by an ohm-meter or signal buzzer:

- short-cut the already disconnected thermistor contactors S1 and S2 and switch on the voltage supply; the relay must

switch; connection established between contactors M1 and M2

- remove the jumper between S1 and S2, the relay must switch off; no connection between contactors M1 and M2

- short-cut the contactors S1 and S2 again, the relay remains switched off; no connection between contactors M1 and

M2

- switch off the voltage supply for approximately 4 sec and switch it on again, the relay must switch on now; connection

between contactors M1 and M2

If one of the above conditions is not met, the module is defective and has to be exchanged.

Note: The power should be switched off between the tests, in order to avoid short circuits and accidental touching of

contacts. The function of the module should be tested each time the fuse in the control circuit breaks the power supply.

This makes sure that the contacts did not stick.

Starting

During the very brief start-up, a short metallic sound is audible, resulting from initial contacting of the spirals and is

normal. Due to the design of the Copeland Scroll, the internal compression components always start unloaded even if

system pressures are not balanced. In addition, since internal compressor pressures are always balanced at start-up,

low-voltage starting characteristics are excellent for Copeland Scroll compressors.

Deep Vacuum Operation

Copeland Scroll compressors should never be used to evacuate a refrigeration or air conditioning system. The scroll

compressor can be used to pump down refrigerant in a unit as long as the pressures remain within the operating envelope.

Low suction pressures will result in over-heating of the scrolls and permanent damage to the compressor drive bearing.

An internal protection device un-loads and stops the compressor pumping when the pressure ratio exceeds approximately 10.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 40

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 40

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

Shell Temperature

Certain types of system failures, such as condenser or evaporator fan blockage or loss of charge, may cause the top shell and

discharge line to briefly but repeatedly reach temperatures above 175 °C as the compressor cycles on its internal

protection devices. Care must be taken to ensure that wiring or other materials, which could be dam-aged by these

temperatures, do not come in contact with these potentially hot areas.

Brief Power Interruptions

No time delay is required on three phase models to prevent reverse rotation due to power interruptions. The torque of the motor is

strong enough to assure proper rotation under all starting circumstances.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 41

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 41

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

Compressor Functional Check

A functional compressor test with the suction service valve closed to check how low the compressor will pull

suction pressure is not a good indication of how well a compressor is performing. Such a test will damage a scroll

compressor. The following diagnostic procedure should be used to evaluate whether a Copeland Scroll compressor is working

properly.

1. Proper voltage to the unit should be verified.

2. The normal checks of motor winding continuity and short to ground should be made to determine if an internal motor short or

ground fault has developed. If the protector has opened, the compressor must be allowed to cool sufficiently to

allow it to reset.

3. Proper indoor and outdoor blower/fan operation should be verified.

4. With service gauges connected to suction and discharge pressure fittings, turn on the compressor. If suction

pressure falls below normal levels, the system is either low on charge or there is a flow blockage in the system.

5. If suction pressure does not drop and discharge pressure does not rise to normal levels, reverse any two of the

compressor power leads and reapply power to make sure compressor was not wired to run in reverse direction.

If pressures still do not move to normal values, either the revers ing valve (if so equipped) or the compressor is

faulty. Reconnect the compressor leads as originally configured and use normal diagnostic procedures to check

operation of the reversing valve.

6. To test if the compressor is pumping properly, the compressor current draw must be compared to published

compressor performance curves using the operating pressures and voltage of the system. If the average measured

current deviates more than ±15% from published values, a faulty compressor may be indicated. A current

imbalance exceeding 15% of the average on the three phases may indicate a voltage imbalance and should be

investigated further.

7. Before replacing or returning a compressor: Be certain that the compressor is actually defective. More than onethird of compressors returned to Copeland were misdiagnosed in the field as being defective.

Unbrazing System Components and Service Brazing Procedure

Caution! Before opening a system it is important to remove all refrigerant from both the high and low side. If the

refrigerant charge is removed from a scroll-equipped unit by bleeding the high side only, it is possible for the scrolls to seal,

preventing pressure equalization through the compressor. This may leave the low side shell and suction line tubing

pressurized. If a brazing torch is then applied to the low side while the low side shell and suction line contains

pressure, the pressurized refrigerant and oil mixture could ignite when it escapes and contacts the brazing flame. It is

important to check both the high and low side with manifold gauges before unbrazing. If compressor removal is

required, the compressor should be cut out of system rather than unbrazed.

Copeland Scroll compressors have copper plated steel suction and discharge tubes. Due to the different thermal

properties of steel and copper, brazing procedures may have to be changed from those commonly used. It is

important to flow nitrogen through the system while brazing all joints during the system assembly process. Nitrogen

displaces the air and prevents the formation of copper oxides in the system. The copper oxide flakes can be swept through the

system and block screens such as those protecting capillary tubes, thermal expansion valves, and accumulator oil

return holes. The blockage is capable of doing damage resulting in compressor failure.

The copper-coated steel tubes on scroll compressors can be brazed in approximately the same manner as any copper tube.

Recommended brazing materials: Any silfos material is recommended, preferably with a minimum of 5% silver. However, 0%

silver is acceptable.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 42

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 42

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx K3E-TWD-561

Rotation Direction

Scroll compressors will only compress in one rotational direction. Three phase compressors will rotate in either direction

depending upon phasing of the power. Since there is a 50-50 chance of connecting power in such a way as to cause

rotation in the reverse direction, it is important to include notices and instructions in appropriate loca tions on

the equipment to ensure proper rotation direction when the system is installed and operated.

Observing that suction pressure drops and discharge pressure rises when the compressor is energized makes

verification of proper rotation direction. There is no negative impact on durability caused by operating three phase

Copeland Scroll compressors in the reversed direction for a short period of time (under one hour) but oil may be lost. Oil loss can be

prevented during reverse rotation if the tubing is routed at least 15 cm above the compressor. After several minutes of

operation in reverse, the compressor's protection system will trip due to high motor temperature. The systems operator

will notice a lack of cooling. However, if allowed to repeatedly restart and run in reverse without correcting the situation, the

compressor will be permanently damaged.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 43

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 43

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 44

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 44

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 45

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 45

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

Attention: Motorcode 650 need Molded Plug for Re power connection!

4.2 Electrical installation

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 46

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 46

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 47

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 47

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 48

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 48

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 49

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 49

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 50

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 50

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 51

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 51

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 52

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 52

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 53

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 53

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 54

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 54

Single-Stage Hermetic Compliant SCROLL Motor -Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 55

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 55

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 56

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 56

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 57

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 57

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 58

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 58

Single-Stage Hermetic Compliant SCROLL Motor-Compressor

Type ZR xx KCE-TFD-650

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 59

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 59

12.2 Condenser

The condenser is a refrigerant / air heat exchanger consisting of copper pipes with aluminum fans. The process heat is

transmitted here to the surrounding air.

In order to guarantee optimal heat transmission, the condenser must be kept constantly clean and the fans must be

protected from damage.

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 60

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 60

Condenser coil

Type 2510 C 46 T 2 R 1210 A 3,0 P 12 NC

12.2.1 Built-in Condenser

Built-in Condenser coil only for KPC 108-L-U/S and -Plus

Two Fans Ziehl-ABEGG Type FE 050 VDD 4.I.P

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 61

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 61

Axial Fan FE-Series

Technical Description

12.3 Fans

The industrial cooler Type KPC 108-L-U/S is fitted with 2 fans.

The axial flow-fans suck the surrounding air through the condenser package and blow the warm air out at the top.

The fans are controlled by the Frequency Inverter.

The fans are fitted internally with a full motor protector (Klixon).

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 62

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 62

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 63

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 63

Axial Fan FE-Series

Technical Description

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 64

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 64

Axial Fan FE-Series

Technical Description

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 65

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 65

Axial Fans

Operating Instructions

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 66

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 66

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 67

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 67

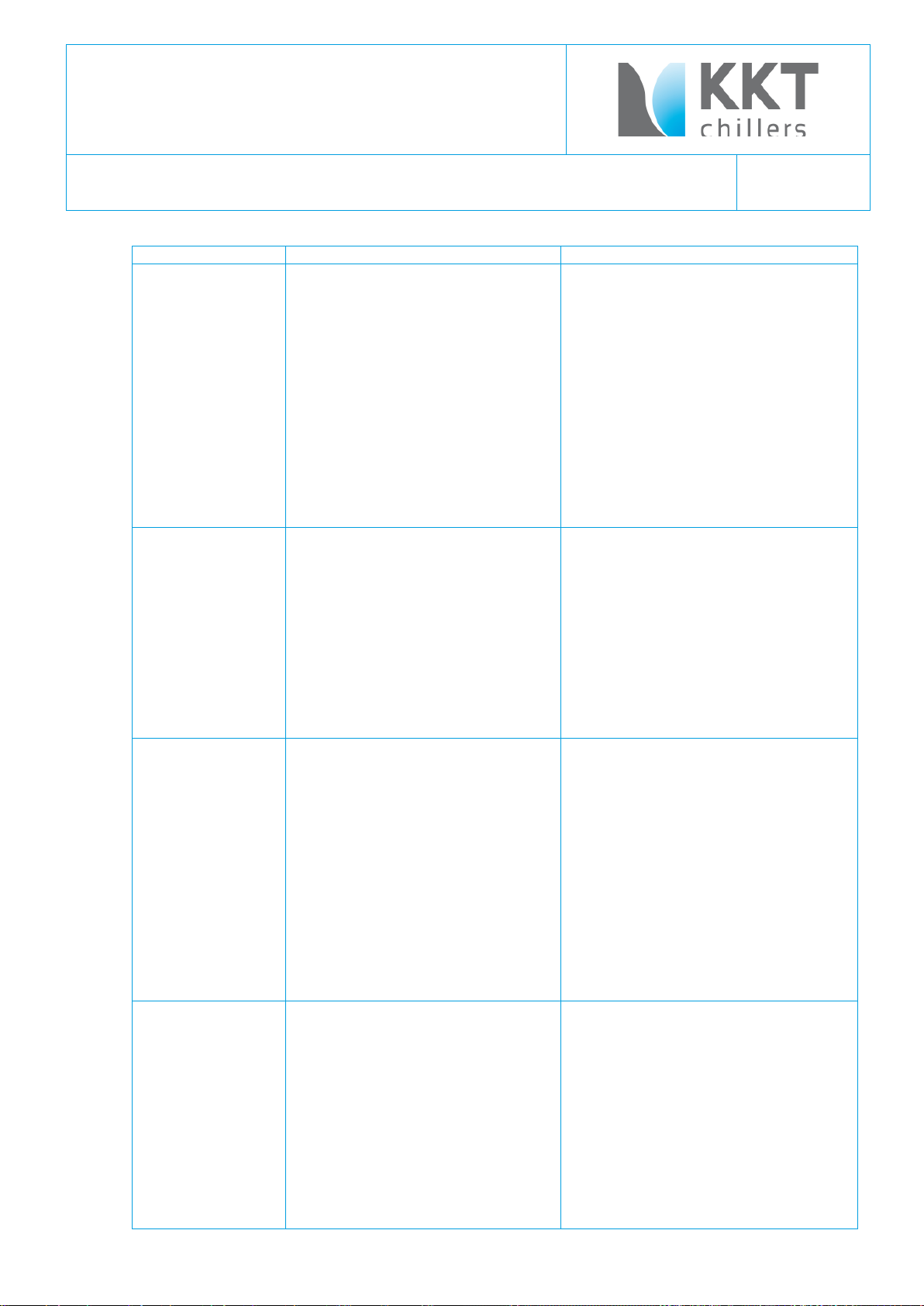

GEA EcoflexGmbH

Brazed Plate Heat Exchangers Model 25

No. of plates

[N]

L

[mm / in]

Weight empty

[kg / lbs]

Volume (prim / sec)

[liters]

Connections

R

Soldered Connections

[mm / in]

24

73.7 / 2.9

7.6 / 16.7

1.32 / 1.44

R1"

35 / 1.4

40

117.9 / 4.6

11.0 / 24.1

2.28 / 2.40

R1"

35 / 1.4

Plates

W.-1.4401, AISI 316

Solder

Copper 99.9 %

Max work pressure

(prim / sec) [bar]

Work temperature

(min / max) [o C]

25 / 30

-160 / 200

12.4 Evaporator

In the form of a brazed plate heat exchanger.

Industrial cooler Type KPC 108-L-U/S Indoor Model: GEA Ecoflex Model 25 Type M25-40

Dimensions:

Material:

Operating conditions:

12.5 Electronic temperature controller

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Page 68

83003702.K Operating Instruction

Type KPC 108-L-U/S

page 68

Six-stage temperature controller ST710-PWHVM.26

After switching-on the mains voltage the display shows

“OFF” if standby mode is activated and the actual value if

the controller is not in standby mode.

The LEDs have the following functions:

“°C” = temperature display in °C (upper LED),

“bar” = pressure display in bar (middle LED) ,

“%” = power display in % (lower LED).

Key UP

Pressing this key you can increase the parameter or parameter value or scroll the parameter list.

Key DOWN

Pressing this key you can decrease the parameter or parameter value or scroll the parameter list.

At alarm the buzzer can be switched off with this key.

Key Display

Shortly pressing this key shows the other value (“C”, “bar”) of the actual display for 3 seconds.

Pressing it for more than 5 seconds switches over to power display or back to temperature display.

The LEDs indicate the actual display value.

Key SET

While SET key is pressed, the set-point is indicated.

In addition, the SET key is used for setting parameters.

Key Standby

This key puts the controller into standby mode. Pressing the key a second time, restarts the unit.

The key can be deactivated.

Temperature regulation is attended by the temperature controller installed in the switch cabinet. It controls the leaving

temperature of the medium and switches the refrigeration compressors and/or the capacity reducing valve (hot gas

solenoid valve) on or off.

The digital temperature gauge shows the actual readings of the initial medium temperature.

The reference value is shown by pressing the SET button.

Settings for the parameter values – see chapter “temperature controller settings” (Main set point ).