Page 1

Compact-Line

Operating Instructions

cBoxX 30

cBoxX 40

cBoxX 50

cBoxX 60

cBoxX 70

cBoxX 80

cBoxX 90

cBoxX 100

cBoxX 120

cBoxX 160

cBoxX 180

cBoxX 200

Page 2

2 / 89 83000102.Ki

Table 1: Contact details

Manufacturer

ait-deutschland GmbH

Industriestraße 3

95359 Kasendorf

Germany

T +49 9228 9977 0

F +49 9228 9977 149

E info@kkt-chillers.com

W www.kkt-chillers.com

Service

ait-deutschland GmbH

Industriestraße 3

95359 Kasendorf

Germany

T +49 9228 9977 7190 *

F +49 9228 9977 7474

E service@kkt-chillers.com

W www.kkt-chillers.com*

Service USA

KKT chillers, Inc.

1280 Landmeier Road

Elk Grove Village

IL 60007

T +1 847 734 1600

F +1 847 734 1601

TF +1 866 517 6867 *

E support@kkt-chillersusa.com *

Page 3

3 / 89 83000102.Ki

Introduction

These operating instructions have been drawn up by KKT chillers on the basis of the Machinery

Directive 2006/42/EC. They contain all important information and instructions for the installation

and safe operation of the refrigerating machine (chiller). It also contains advice on how to prevent

or correct faults.

Please allow yourself sufficient time to read through these instructions carefully and to digest all

the information this document contains. If you have any further questions, please contact the

KKT chillers Service Team using the contact details provided.

If properly used for its intended use and correctly maintained, the chiller ensures sustained, faultfree operation. The methods and procedures described in these instructions should help you to

detect problems early and to take appropriate countermeasures.

If you keep to the maintenance programme described you ensure the reliability and safety of the

machine. You also keep the operating costs low and at the same time increase the life of the

components.

To ensure that the performance of your chiller is not impaired, we recommend that you only use

original spare parts purchased from KKT chillers. In this way you ensure the reliability and quality

of the machine.

KKT chillers reserves the right to change technical details without prior notice. The illustrations in

this document are not to scale!

As the Compact-Line units can be adapted to specific projects, this document only contains

information that is generally valid for all units in the series.

All project-specific data is enclosed with the unit in separate summary documentation.

▪ Machine configuration

▪ Parameter list

▪ P&I diagram

▪ Pump characteristic curve(s)

▪ Circuit diagram

▪ All other project specific details

ATTENTION! A black exclamation mark on a yellow background in a triangle indicates

important information and instructions to which you must pay particular attention and

must always follow.

Page 4

4 / 89 83000102.Ki

Contents

Introduction ............................................................................................................................................. 3

1. Product description ................................................................................................................... 8

1.1. Intended use ...................................................................................................................... 8

1.2. Elements ........................................................................................................................... 11

1.3. Explanation of terms ........................................................................................................ 12

2. Function and main components ............................................................................................. 13

2.1. Compressor ...................................................................................................................... 13

2.2. Evaporator ........................................................................................................................ 14

2.3. Condenser ........................................................................................................................ 14

2.4. Expansion valve ............................................................................................................... 14

2.5. Refrigerant ........................................................................................................................ 14

2.6. Oil ...................................................................................................................................... 15

2.7. Filter dryer ........................................................................................................................ 15

2.8. Pressure sensors ............................................................................................................. 15

2.9. Temperature sensors....................................................................................................... 15

2.10. Control unit/ main circuit board ...................................................................................... 15

2.11. Display .............................................................................................................................. 15

2.12. Control cabinet ................................................................................................................. 16

2.13. Pump ................................................................................................................................. 16

2.14. Fan .................................................................................................................................... 16

2.15. Cold water cycle ............................................................................................................... 16

2.16. Materials used in the water circuit ................................................................................. 17

2.17. Water quality .................................................................................................................... 19

2.18. Permitted cooling media ................................................................................................. 20

3. Options and accessories ......................................................................................................... 20

3.1. Version without tank, with pump .................................................................................... 20

3.2. Version without tank, without pump ............................................................................... 20

3.3. Version with water cooled condenser ............................................................................. 21

3.4. Heater for compressor and control cabinet ................................................................... 21

3.5. Insulation of the cold pipes and the pump(s) ................................................................ 21

3.6. Tank heater with thermostatic pump start ..................................................................... 22

3.7. Overflow valve for standby mode .................................................................................... 22

3.8. Higher pressure pump ..................................................................................................... 22

3.9. Second consumer circuit ................................................................................................. 23

3.10. Additional evaporator pump ............................................................................................ 23

3.11. Automatic water feed ....................................................................................................... 23

3.12. Water circuit in non-ferrous metal-free version ............................................................. 23

3.13. DI package ........................................................................................................................ 23

3.14. Special voltage ................................................................................................................. 23

3.15. Phase monitoring ............................................................................................................. 24

3.16. Hot gas bypass for output control <1K........................................................................... 24

3.17. High-temperature package .............................................................................................. 24

3.18. Special paint finish .......................................................................................................... 24

Page 5

5 / 89 83000102.Ki

3.19. Air filter mat (accessories) ............................................................................................... 24

3.20. Levelling feet (accessories) ............................................................................................. 24

3.21. Level package (accessories) ........................................................................................... 25

3.22. Filter assembly group coolant circuit (accessories) ....................................................... 25

3.23. Filter assembly group cooling water circuit (accessories) ............................................. 25

3.24. MultiplexX connection group (accessories) .................................................................... 26

3.25. Refill cartridge R410A (accessories) .............................................................................. 26

3.26. Anybus-Gateway (accessories) ........................................................................................ 26

3.27. Remote Control Panel (accessories)............................................................................... 27

3.28. Special languages (accessories) ..................................................................................... 27

3.29. Wooden Crate (accessories) .......................................................................................... 27

3.30. Seaworthy crate packaging (accessories) ...................................................................... 27

3.31. Water Pump Redundancy ................................................................................................ 27

3.32. Closed Water Loop ........................................................................................................... 27

4. Safety........................................................................................................................................ 29

4.1. General information ......................................................................................................... 29

4.2. Hazard warnings .............................................................................................................. 29

4.3. Residual energy................................................................................................................ 32

4.4. Safety devices, guards and safeguards ......................................................................... 33

4.4.1. High-pressure limiter ................................................................................................ 33

4.4.2. High-pressure monitoring ........................................................................................ 34

4.4.3. Low-pressure monitoring ......................................................................................... 34

4.4.4. Flow monitoring ........................................................................................................ 34

4.4.5. Personal protective equipment when operating the machine .............................. 34

4.5. Personal protective equipment for servicing work ........................................................ 35

4.6. Airborne sound emissions ............................................................................................... 35

4.7. Notes on reducing noise and vibration ........................................................................... 36

4.7.1. Noise ......................................................................................................................... 36

4.7.2. Vibration .................................................................................................................... 36

4.8. Residual risks ................................................................................................................... 37

4.8.1. Electrical ................................................................................................................... 37

4.8.2. Mechanical ............................................................................................................... 37

4.8.3. Chemical ................................................................................................................... 37

4.8.4. Other ......................................................................................................................... 37

4.9. Dangerous substances .................................................................................................... 37

4.9.1. Refrigerant R410A ................................................................................................... 37

4.9.2. Oil POE 160SZ .......................................................................................................... 39

4.10. Reasonably foreseeable misuse ..................................................................................... 40

4.11. Information for emergencies ........................................................................................... 41

5. Handling and storage .............................................................................................................. 41

5.1. Dangerous goods ............................................................................................................. 41

5.2. Transport .......................................................................................................................... 41

5.2.1. Forklift truck ............................................................................................................. 42

42

5.2.2. Crane ......................................................................................................................... 43

Page 6

6 / 89 83000102.Ki

5.3. Unpacking ......................................................................................................................... 44

5.4. Storage ............................................................................................................................. 44

6. Installation ............................................................................................................................... 45

6.1. Overview ........................................................................................................................... 45

6.2. Installation site ................................................................................................................. 45

6.2.1. General information ................................................................................................. 45

6.2.2. Minimum room volume ............................................................................................ 45

6.2.3. Ambient temperature ............................................................................................... 46

6.2.4. Effect of surrounding air flow .................................................................................. 46

6.2.5. Minimum clearances ............................................................................................... 46

6.2.6. External attachments ............................................................................................... 46

6.2.7. Process level ............................................................................................................. 47

6.2.8. Surface and foundation ........................................................................................... 47

6.2.9. Stability ..................................................................................................................... 48

6.2.10. Levelling .................................................................................................................... 48

6.2.11. Vibration isolation .................................................................................................... 48

6.2.12. Installation ................................................................................................................ 49

6.2.13. Hydraulic installation ............................................................................................... 49

6.2.14. Frost protection measures ...................................................................................... 50

6.2.15. Flushing the cold water circuit ................................................................................ 50

6.2.16. Filling ......................................................................................................................... 50

6.2.17. Venting ...................................................................................................................... 52

6.2.18. Electrical installation ................................................................................................ 53

7. Commissioning ........................................................................................................................ 54

7.1. Installation checklist ........................................................................................................ 54

8. Operation.................................................................................................................................. 55

8.1. Switching on ..................................................................................................................... 55

8.2. Selecting the operating mode ......................................................................................... 55

8.3. External release ............................................................................................................... 55

8.4. Control .............................................................................................................................. 55

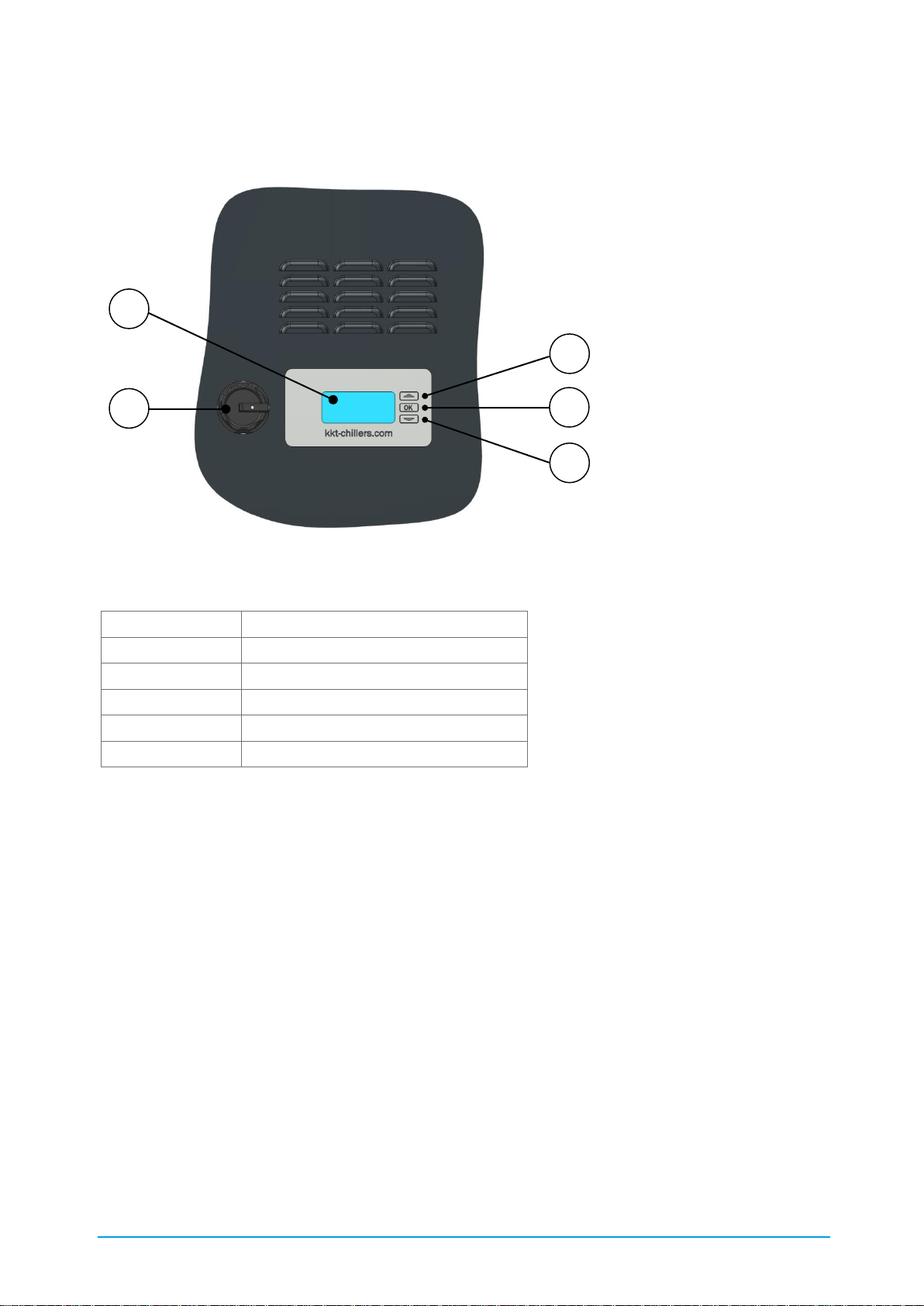

8.5. Control panel .................................................................................................................... 56

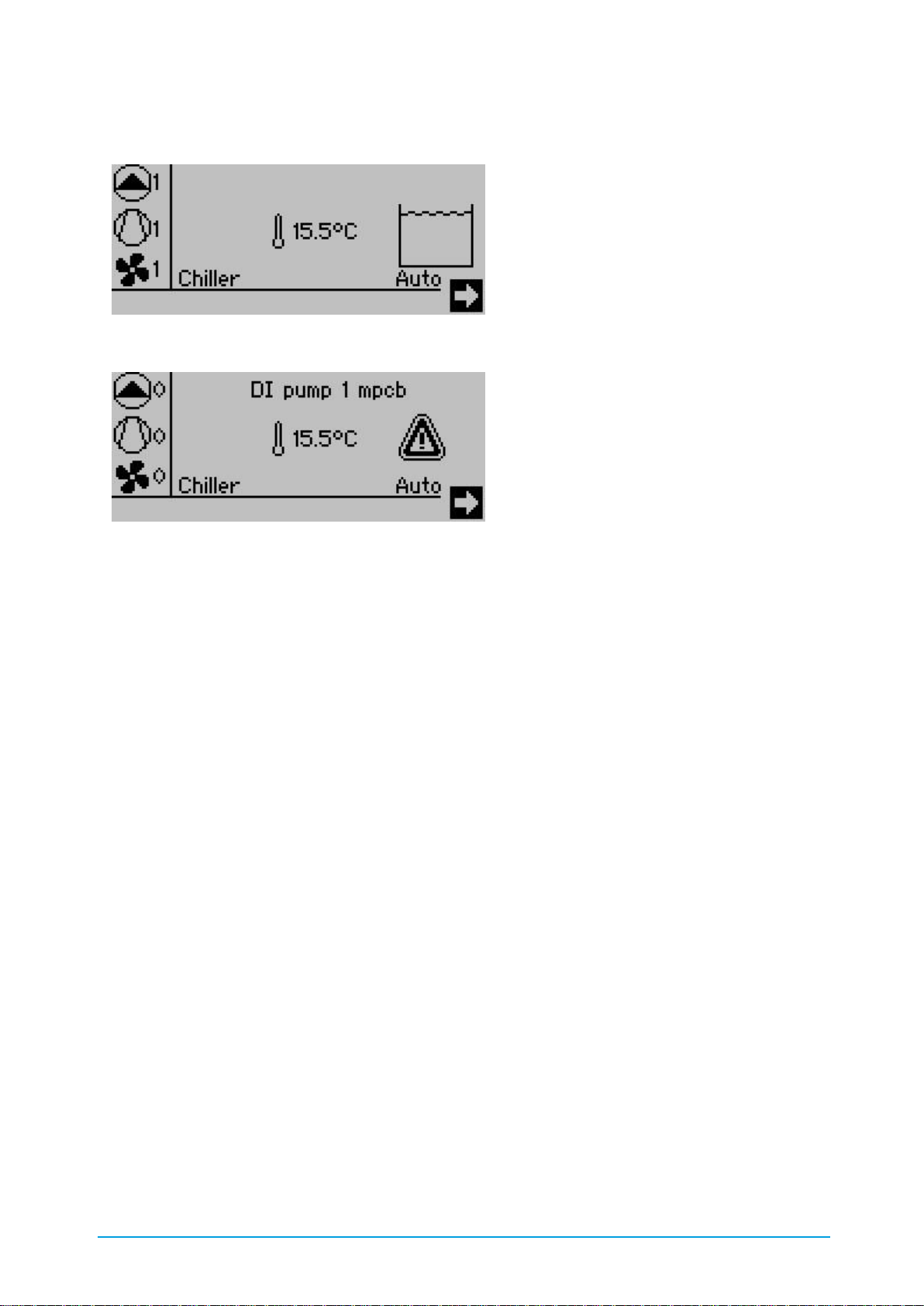

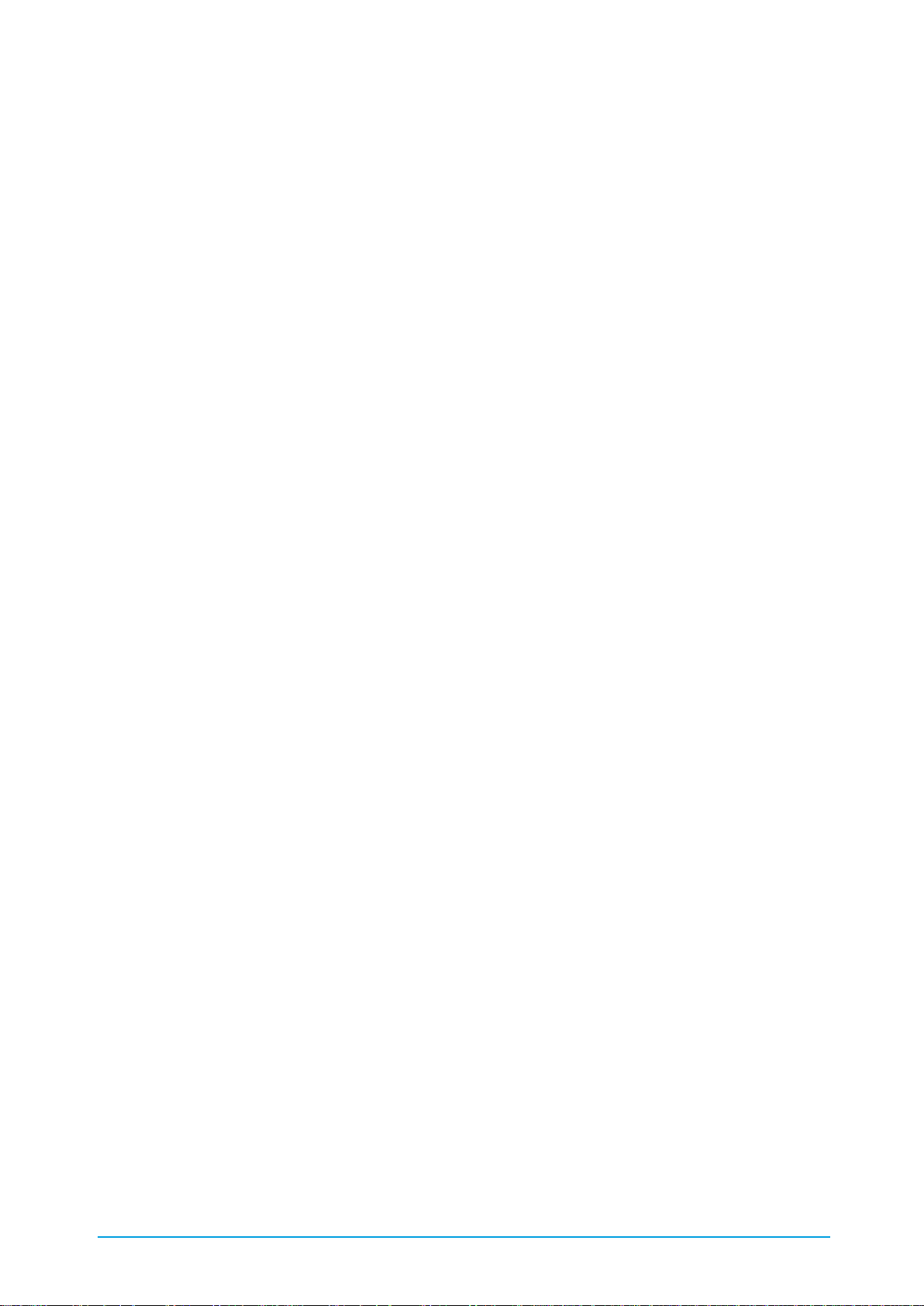

8.5.1. Start screen .............................................................................................................. 57

8.5.2. Main menu ................................................................................................................ 58

8.5.3. Information ............................................................................................................... 58

8.5.4. Settings ..................................................................................................................... 60

8.5.5. Alarm menu .............................................................................................................. 60

8.6. Parameters ....................................................................................................................... 61

8.7. Controller description ...................................................................................................... 62

8.7.1. Electronic level monitoring ...................................................................................... 62

8.7.2. Switching the chiller On/off ..................................................................................... 62

8.7.3. Cold water flow temperature control ...................................................................... 63

8.7.4. Compressor control .................................................................................................. 64

8.7.5. Fan speed control .................................................................................................... 64

8.7.6. Electronic expansion valve control .......................................................................... 65

8.7.7. Temperature limit monitoring .................................................................................. 65

Page 7

7 / 89 83000102.Ki

8.7.8. Group fault alarm ..................................................................................................... 65

8.8. Operating modes .............................................................................................................. 65

8.8.1. ECO mode ................................................................................................................. 65

8.8.2. Comfort mode ........................................................................................................... 65

9. Cleaning ................................................................................................................................... 66

9.1. Air filter mat ...................................................................................................................... 66

9.2. Condenser ........................................................................................................................ 66

9.3. Water filter ........................................................................................................................ 66

9.4. Complete cleaning of the cold water circuit ................................................................... 66

10. Service ...................................................................................................................................... 67

10.1. Maintenance .................................................................................................................... 67

10.2. Fault correction ................................................................................................................ 67

10.3. Spare parts ....................................................................................................................... 67

11. Taking out of service ............................................................................................................... 68

11.1. Draining ............................................................................................................................ 68

12. Recycling .................................................................................................................................. 69

13. Products, solutions and services ............................................................................................ 69

14. Lists .......................................................................................................................................... 70

14.1. List of illustrations............................................................................................................ 70

14.2. List of tables ..................................................................................................................... 70

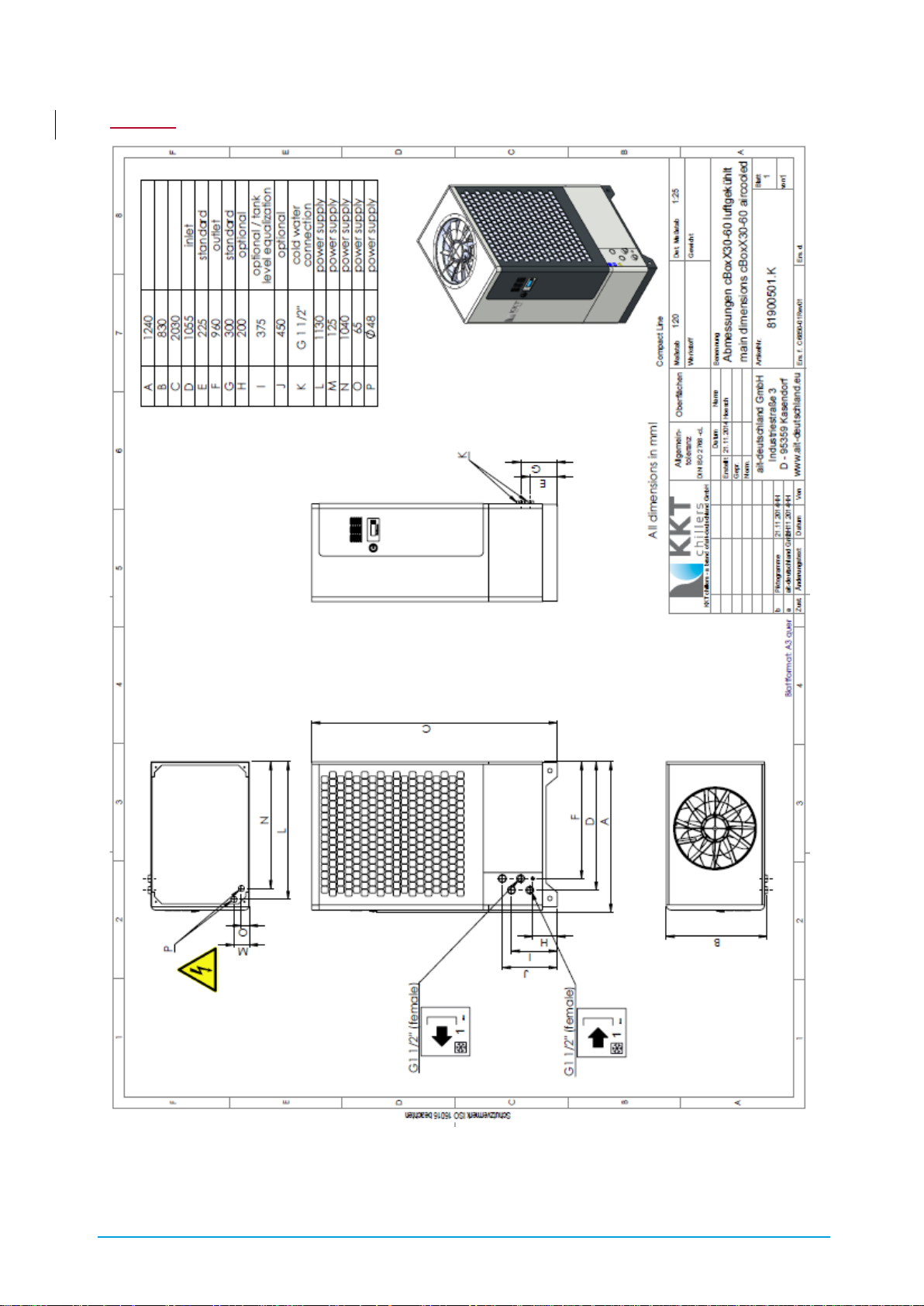

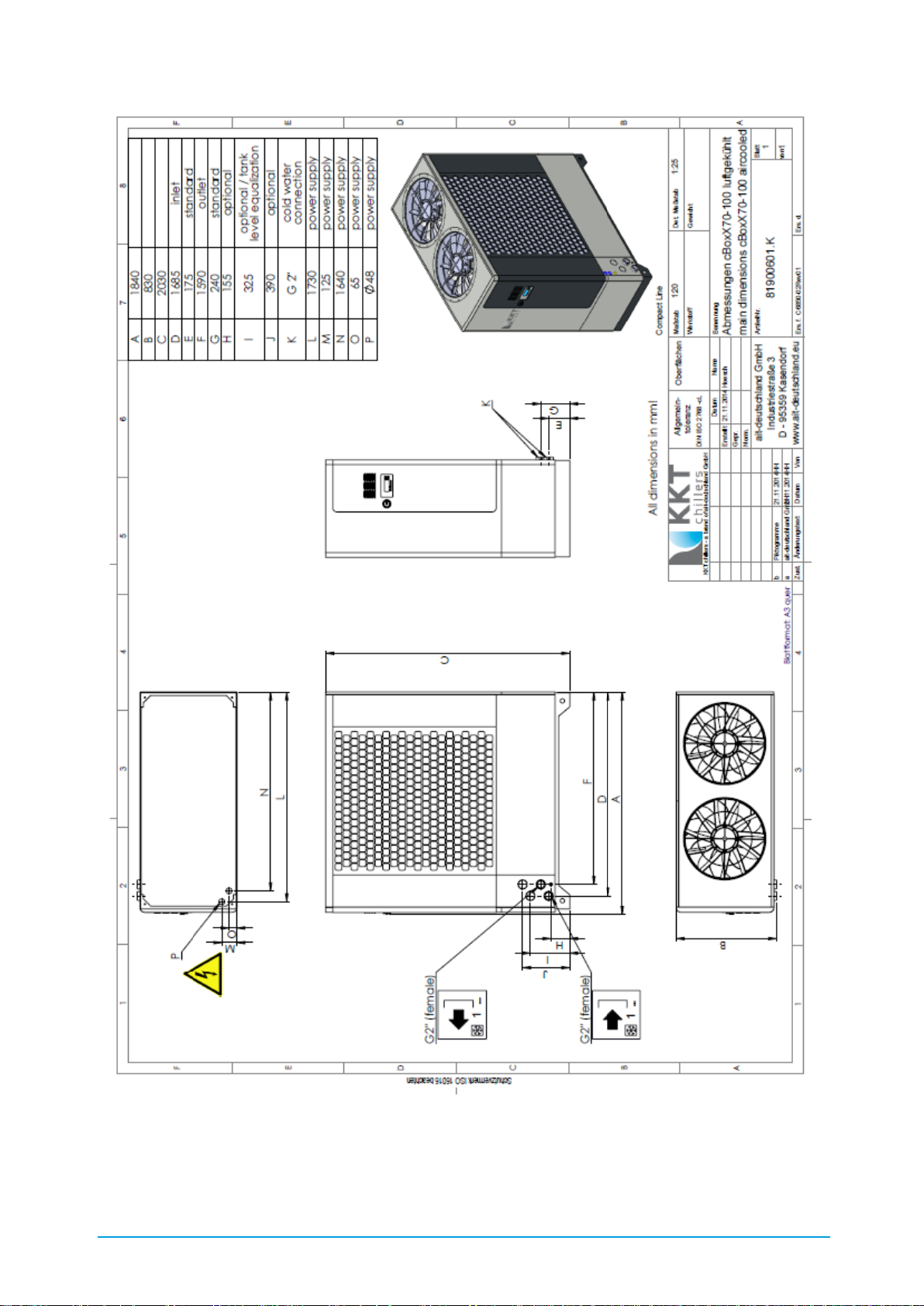

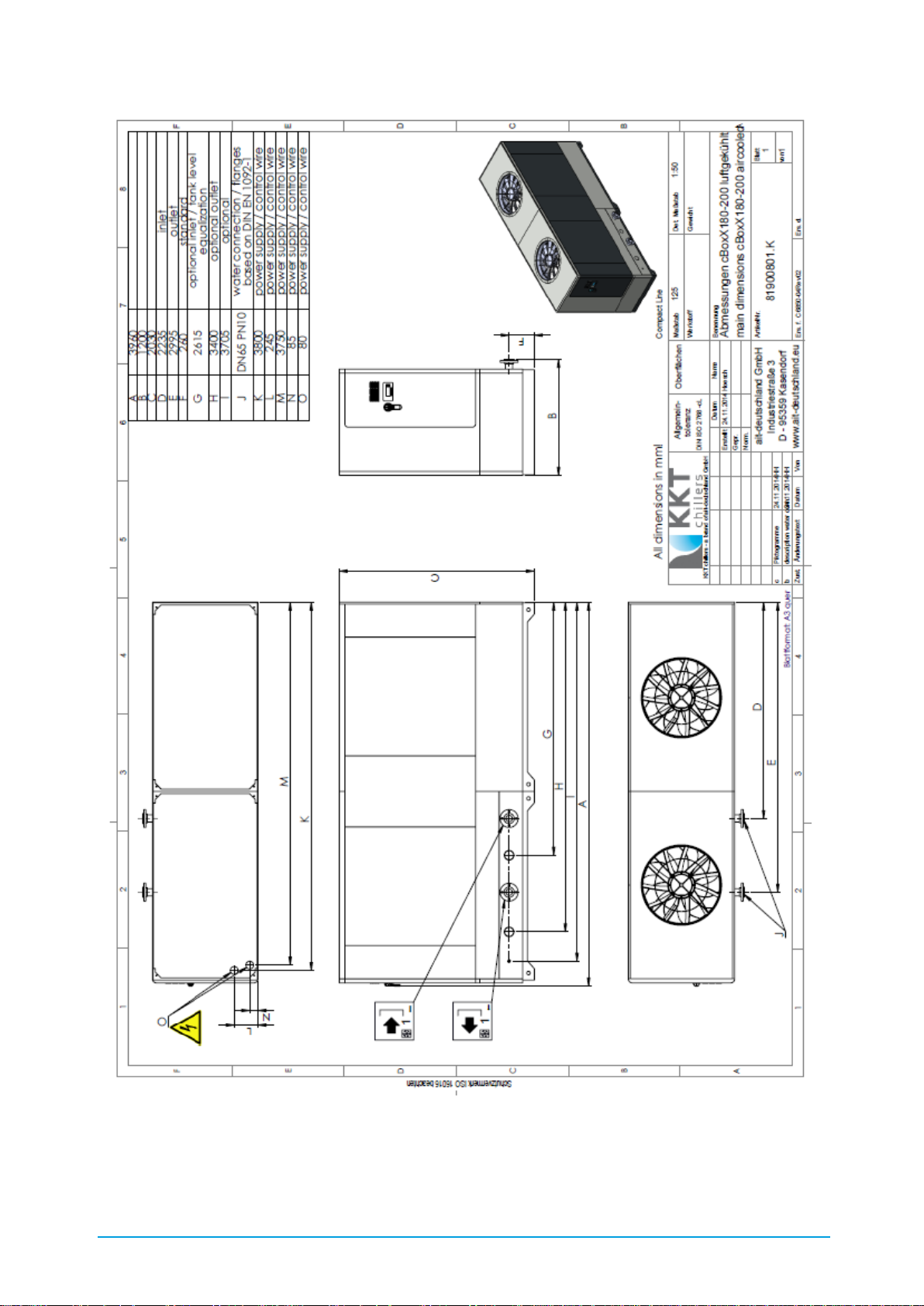

I. Main dimensions ..................................................................................................................... 72

II. Installation instructions ........................................................................................................... 76

III. Troubleshooting ....................................................................................................................... 80

IV. Maintenance intervals in accordance with the VDMA ........................................................... 85

V. Product Registration ................................................................................................................ 88

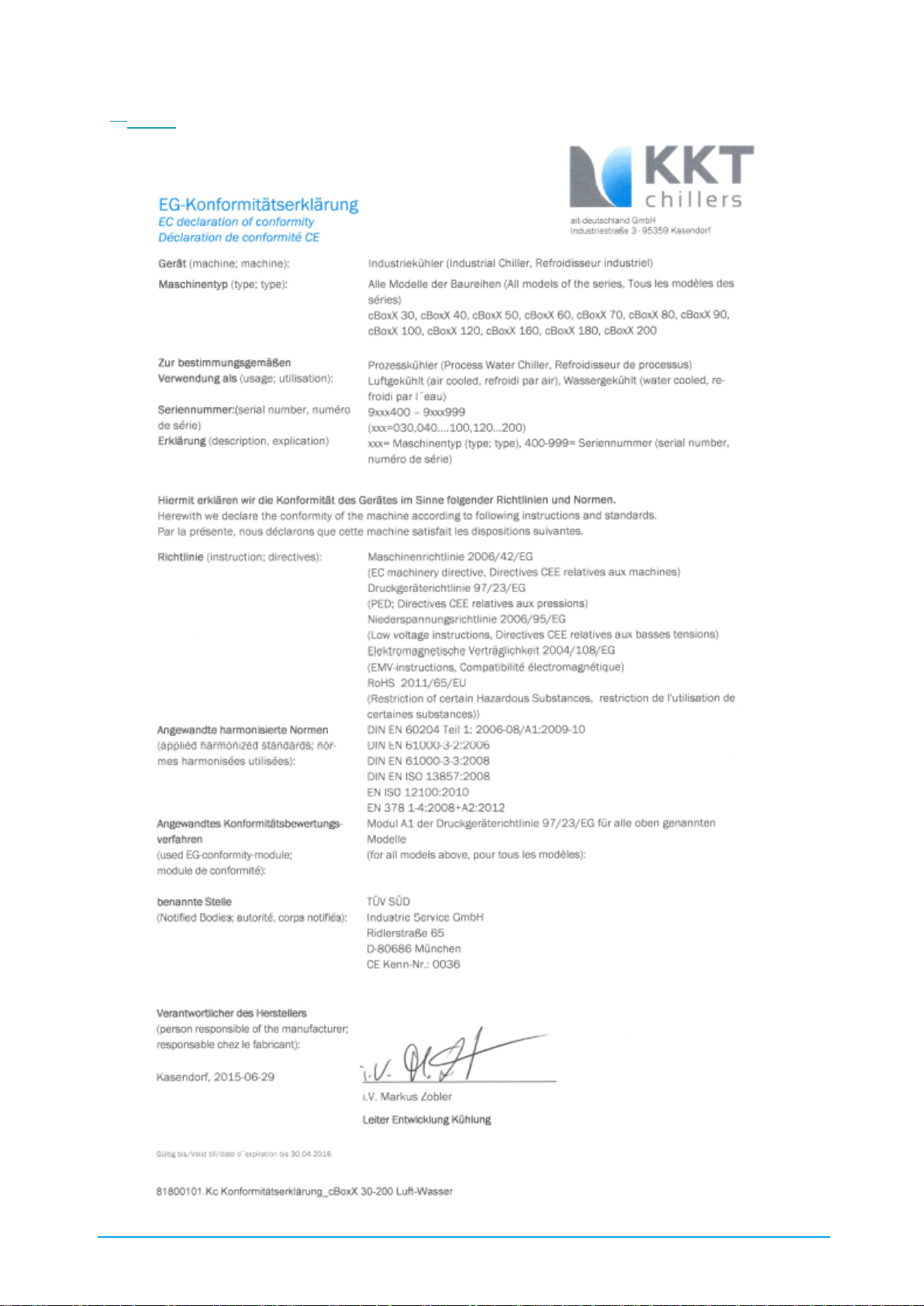

VI. EC Declaration of Conformity .................................................................................................. 89

Page 8

8 / 89 83000102.Ki

1. Product description

Please read all the points in these operating instructions before starting up the machine. You

should pay particular attention to the points on safety, commissioning/startup and operation. If

you have further questions about your machine, please contact the KKT chillers Service Team

(see Table 1: Contact details).

1.1. Intended use

The cBoxX is a factory-tested, fully automatic compressor chiller. The machine is solely for cooling

liquids (fluids) in accordance with EN 378-1. An adequate supply of cooling air must be provided.

Only approved liquids may be used. The cBoxX corresponds to protection class IP 54 (when the

housing is closed) and is suitable for both indoor and outdoor installation (note the options

packages).

The operator is responsible for complying with the specified operating, servicing and maintenance

conditions according to these operating instructions.

The owner of the chiller, not the manufacturer, is responsible and liable for all personal injuries

and damage to property caused by improper use of the unit (misuse).

Table 2 shows the general safety instructions of the chiller. These are attached to the machine in

a clear and readily visible position. A complete description of all hazard warnings is given in

Chapter 4.2 Hazard warnings.

Table 2: Safety instructions

Note and follow the instructions for use!

Before opening the machine it must be disconnected from the power supply!

After disconnecting the machine from the power supply, always wait for at least

5 minutes before opening it.

Danger! High voltage! If the machine is only switched off at its main switch,

dangerous electrical voltage is still present at several terminals in the control

cabinet.

Page 9

9 / 89 83000102.Ki

Technical data

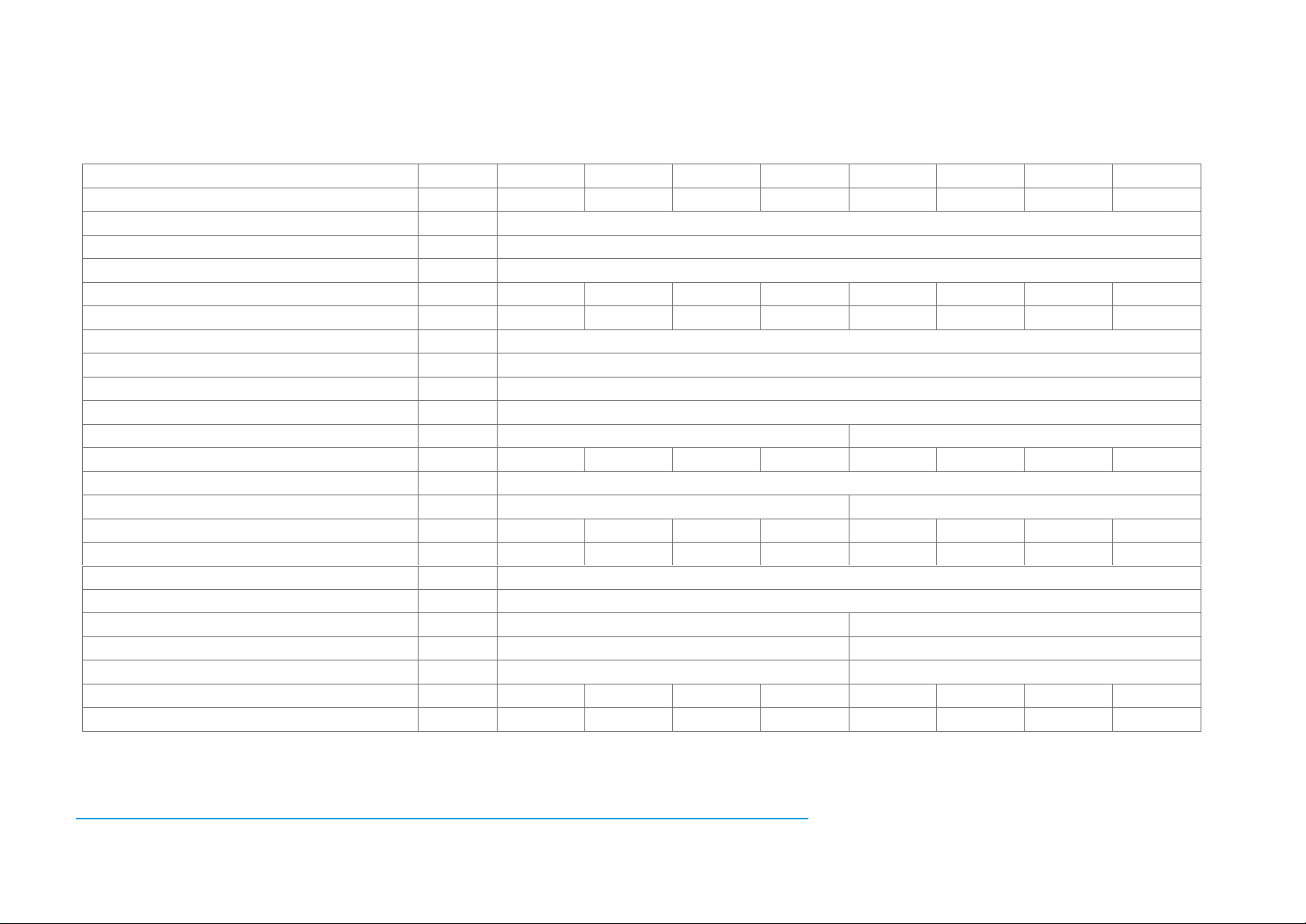

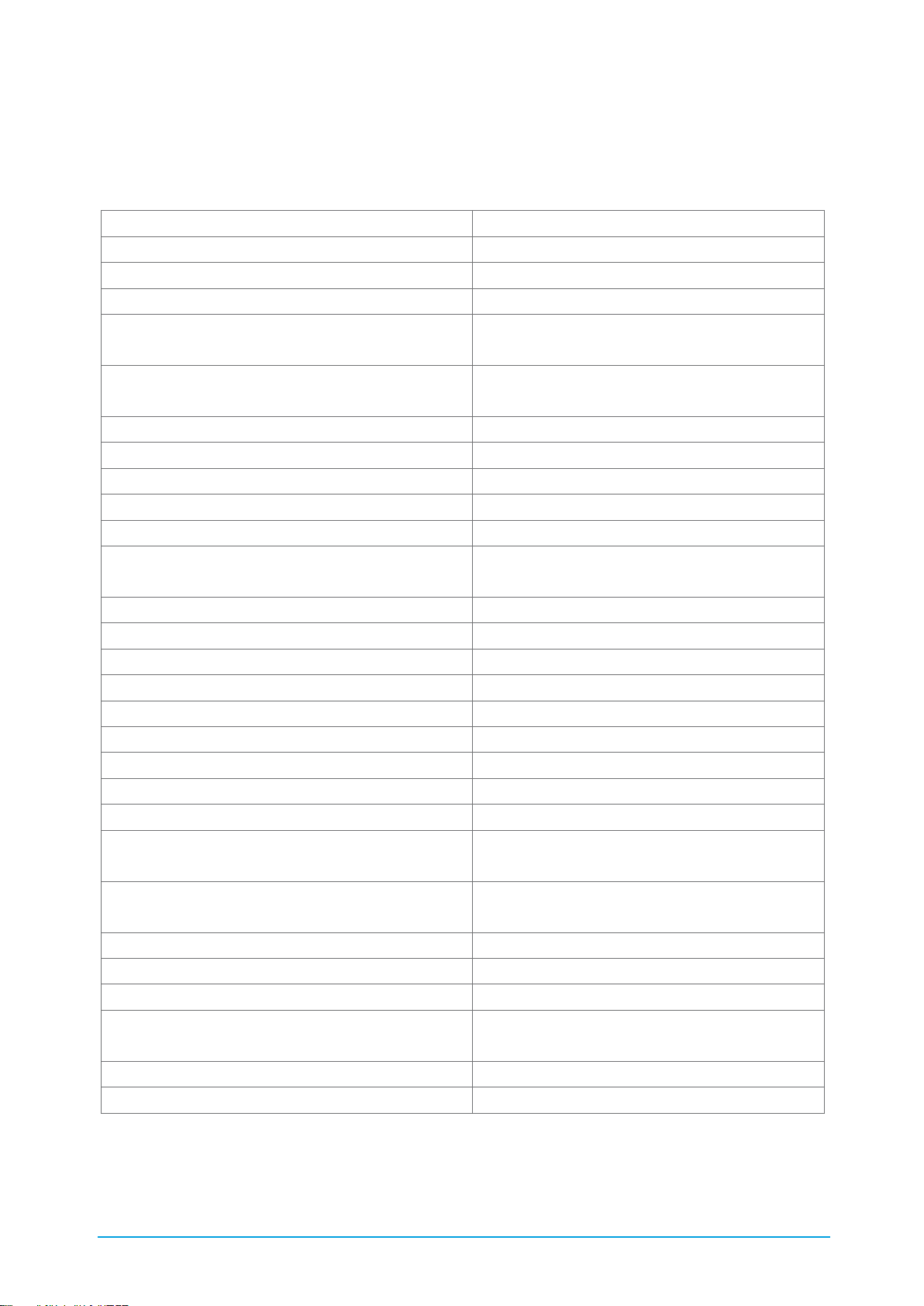

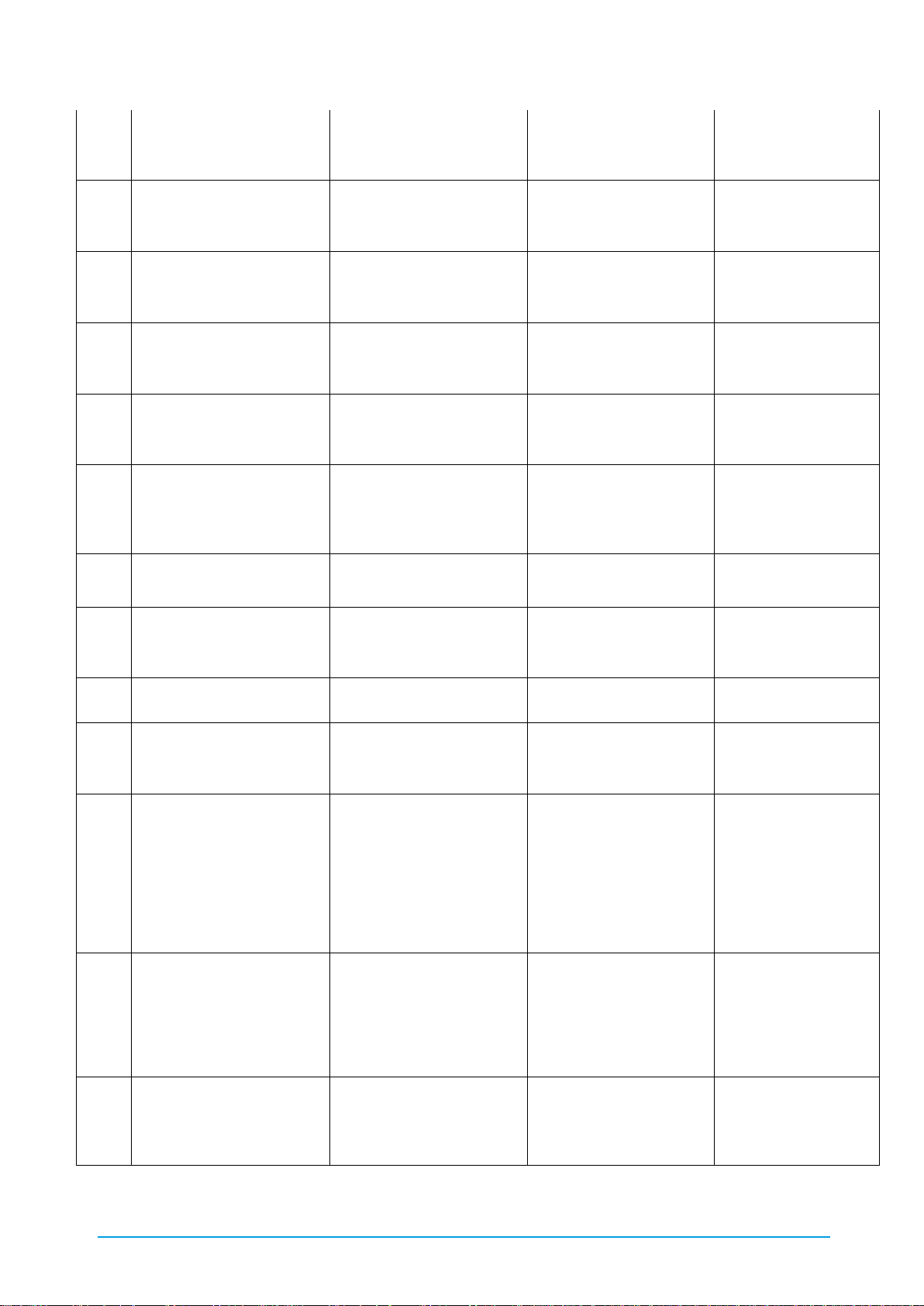

Table 3: Technical data

Compact-Line

-

cBoxX 30

cBoxX 40

cBoxX 50

cBoxX 60

cBoxX 70

cBoxX 80

cBoxX 90

cBoxX 100

Refrigerating capacity @ tw2=20°C / tu=32°C

kW

34

43

55

68

78

87

95

105

Refrigeration circuit hermetically tight

no

Refrigerant

-

R410A

GWP

2088

Refrigerant capacity

kg 6 6 6 7 8 8 8 8

CO2 equivalent

t CO2

12,5

12,5

12,5

14,6

16,7

16,7

16,7

16,7

Cooling medium (liquid/secondary refrigerant)

-

Water or water / glycol

Ambient temperature range

°C

+5 to +45 (optionally -25 to +50°C)

Liquid feed temperature

°C

+8 to +30 (optionally to -10)

Target constancy

K

+/-1

Tank volume

l

300

500

Coolant circulation, nominal (dt = 5K)

m³/h

5.5

7.2

9.2

11.1

12.4

14.3

16.1

18.2

Free pump pressure (standard)

bar

3

Water connection, nominal size

RP

11/2"

2"

Air flow rate (max.)

m³/h

9350

9350

12600

20000

23270

23270

23270

23270

Sound pressure level at 5 m distance

dBA

62

62

55

69

59

59

59

59

Operating voltage (standard)

V/Ph/Hz

400/ 3/ 50

Protection class

-

IP54

Height

mm

2030

2030

Width

mm

830

830

Length

mm

1240

1840

Net weight

kg

540

540

550

620

650

650

700

720

Gross weight

kg

840

840

850

920

1150

1150

1200

1220

Page 10

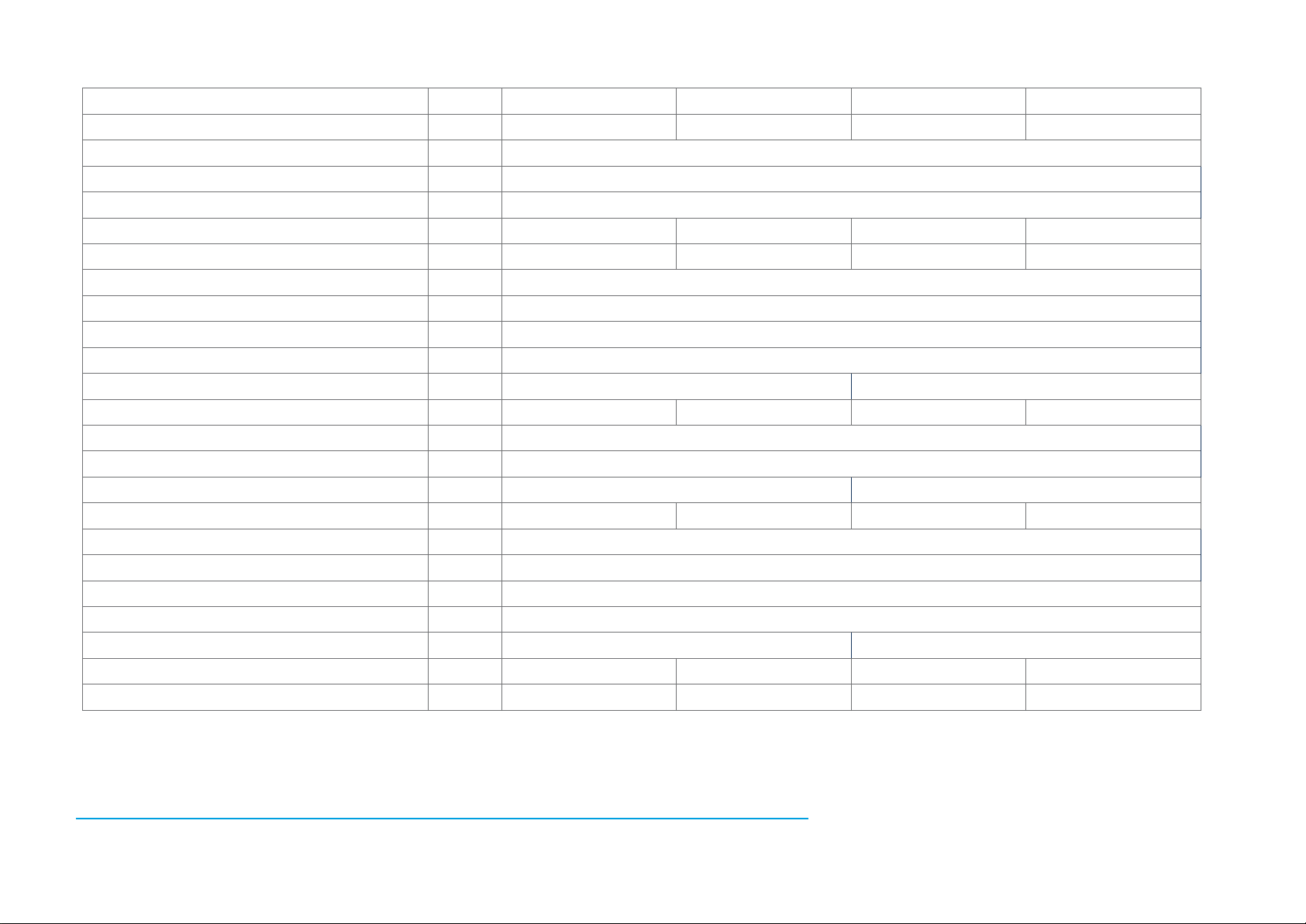

10 / 89 83000102.Ki

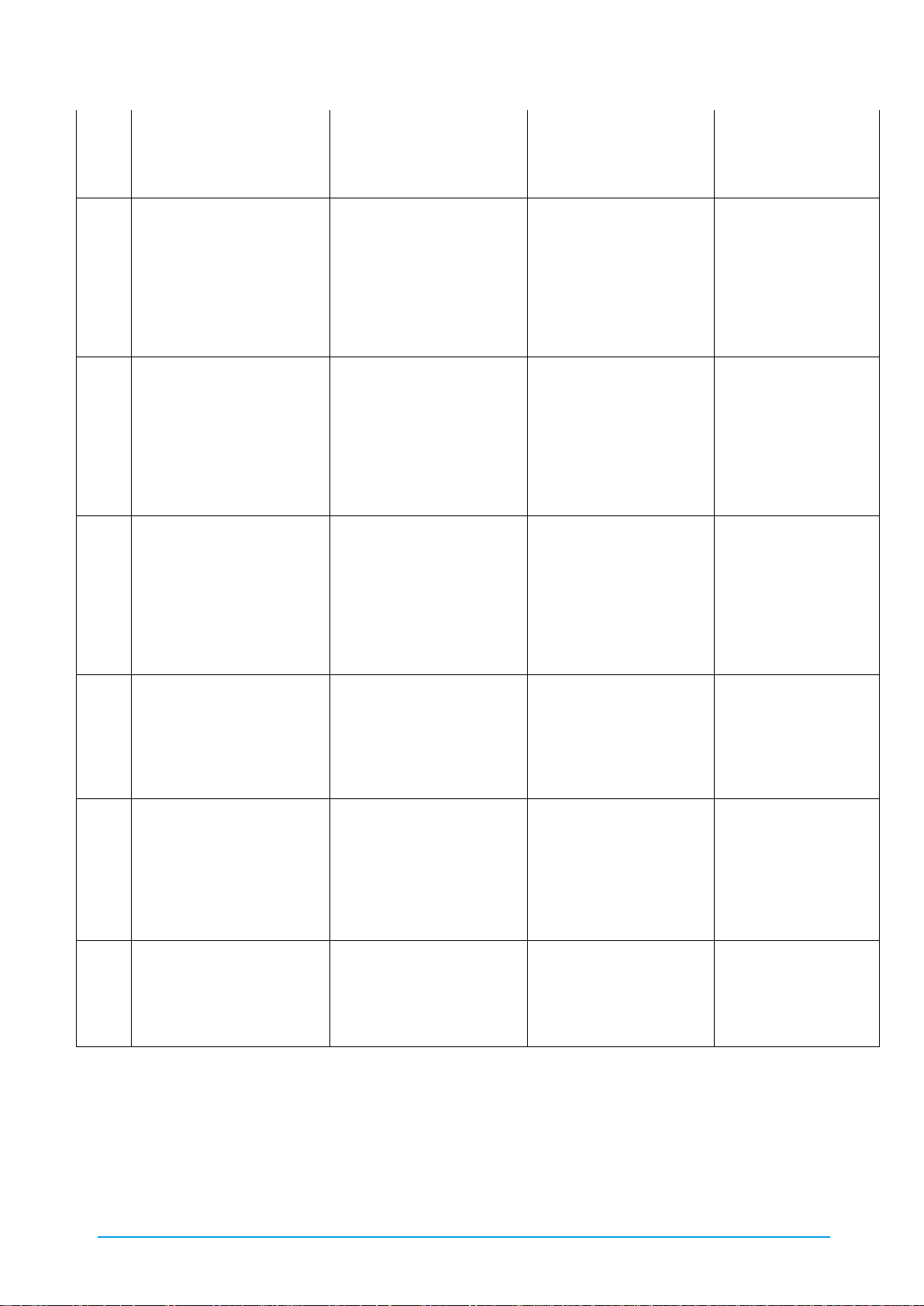

Compact-Line

-

cBoxX 120

cBoxX 160

cBoxX 180

cBoxX 200

Refrigerating capacity @ tw2=20°C / tu=32°C

kW

135

166

194

210

Refrigeration circuit hermetically tight

no

Refrigerant

-

R410A

GWP

2088

Refrigerant capacity

kg

17

17

23,5

23,5

CO2 equivalent

t CO2

35,5

35,5

49,1

49,1

Cooling medium (liquid/secondary refrigerant)

-

Water or water / glycol

Ambient temperature range

°C

+5 to +45 (optionally -25 to +50°C)

Liquid feed temperature

°C

+8 to +30 (optionally to -10)

Target constancy

K

+/-1

Tank volume

l

700

900

Coolant circulation, nominal (dt = 5K)

m³/h

21,5

27,2

32,2

35,4

Free pump pressure (standard)

bar

3

Water connection, nominal size

RP

DN65 PN10 EN1092

Air flow rate (max.)

m³/h

45550

49100

Sound pressure level at 5 m distance

dBA

67

67

67

67

Operating voltage (standard)

V/Ph/Hz

400/ 3/ 50

Protection class

-

IP54

Height

mm

2030

Width

mm

1200

Length

mm

2665

3965

Net weight

kg

1100

1200

1300

1400

Gross weight

kg

1800

1900

2200

2300

Page 11

11 / 89 83000102.Ki

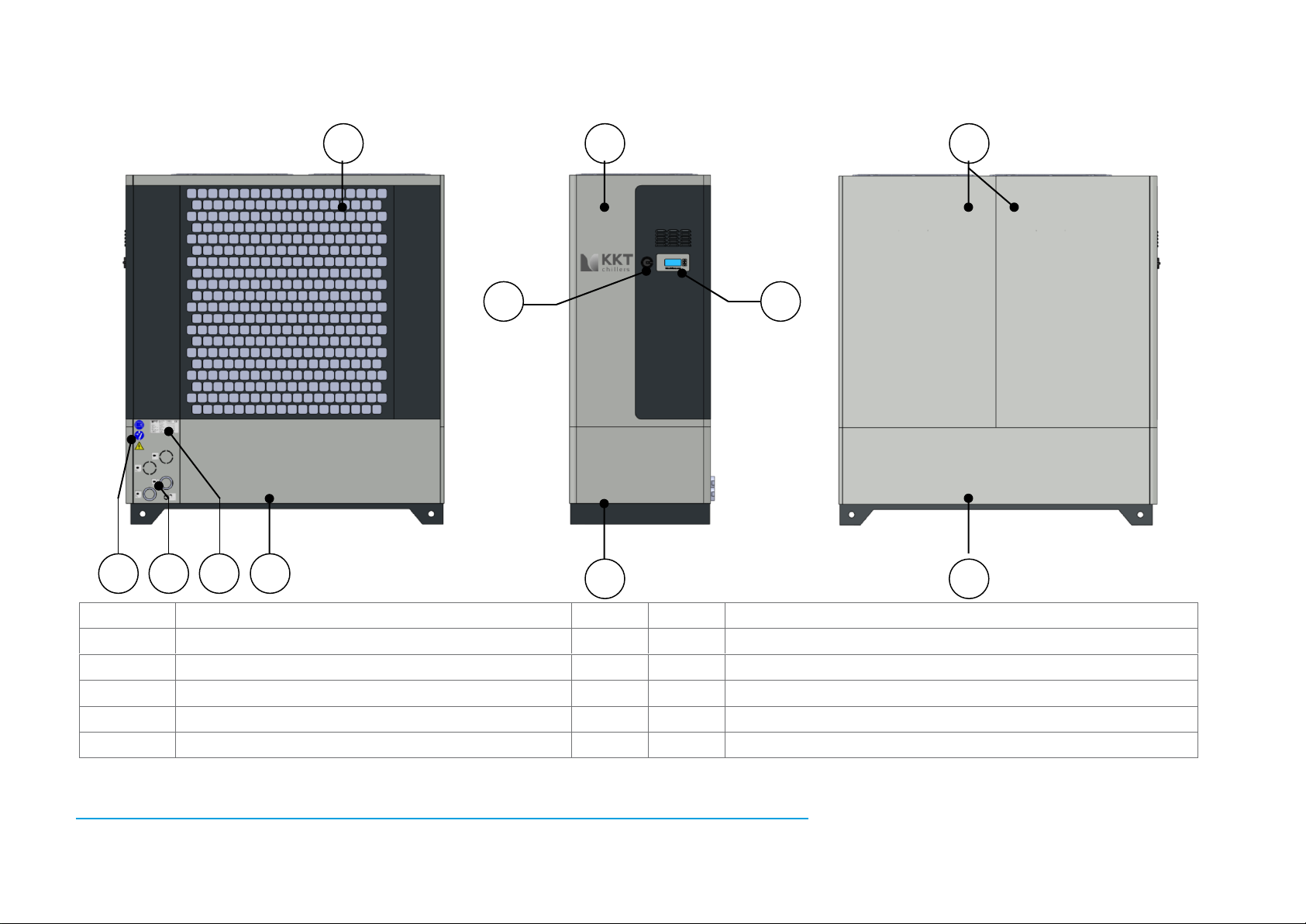

1.2. Elements

1

Metal cladding, top, operator side

a

Safety instructions

2

Metal cladding, bottom, operator side

b

Water connections

3

Metal cladding, top, service side

c

Rating plate

4

Metal cladding, bottom, service side

d

Display

5

Metal cladding, condenser protective grating

e

Main switch

6

Cladding, hydraulics

1 2 3 4 5 6 a b c d e

Page 12

12 / 89 83000102.Ki

1.3. Explanation of terms

A few important terms which appear in this document are briefly explained here for improved

understanding.

Table 4: Explanation of terms

Term

Explanation

Application

The heat source connected hydraulically with the chiller.

Process circuit

Application and piping to the chiller.

Cold water cycle

The process circuit and chiller in hydraulic piping.

Cold water

Cooling medium in the cold water circuit.

Cooling air

Ambient air drawn through the machine, which absorbs the heat.

Net weight

Ready to operate machine without cold water.

Gross weight

Ready to operate machine including cold water.

Page 13

13 / 89 83000102.Ki

2. Function and main components

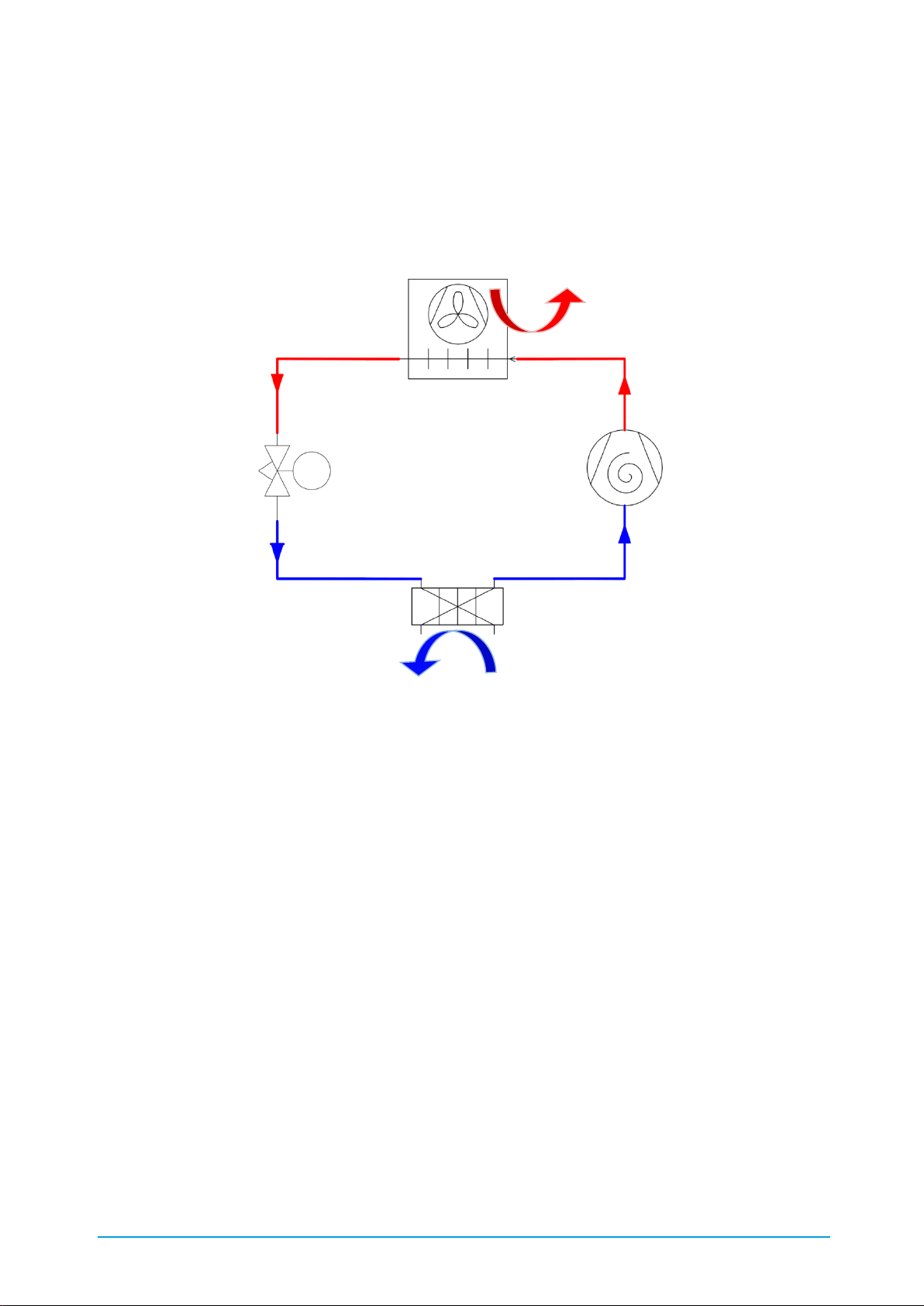

The chiller consists of the main components: compressor, condenser, expansion valve and

evaporator, which are arranged in a circuit (Figure 1). Refrigerant circulates in this circuit (cycle).

It absorbs heat from the cold water in the evaporator and gives it up to the ambient air in the

condenser.

Figure 1: C6848 refrigeration diagram

In addition, diverse pressure and temperature sensors, a control unit, a high-pressure switch, one

or more pumps and one or more fans are also installed for control and operation of the chiller.

2.1. Compressor

The compressor generates the pressure difference between the heat sink and heat source in the

refrigerant circuit needed for evaporation and condensing. Coolant vapor from the evaporator is

drawn in and compressed to the condensing pressure in the compressor.

The compressors used operate according to the scroll principle. Scroll compressors are

maintenance-free, quiet and have a very high efficiency.

The flow temperature is controlled by switching on or off one or more compressors (see 8.7.4

Compressor control). Sequential changeover ensures that all compressors are loaded uniformly.

Compressor

Condenser and fan

Evaporator

Expansion

valve

Heat

Cold

Page 14

14 / 89 83000102.Ki

2.2. Evaporator

The evaporator is a plate heat exchanger which transfers heat from the cold water to the

refrigerant. In order for the heat transfer to take place, the refrigerant in the evaporator has a

lower temperature than the cold water and when it absorbs heat it changes its physical state from

liquid to gaseous.

If the cold water is contaminated, deposits can form on the transfer surfaces of the evaporator.

These impair the heat transfer to the refrigerant and reduce the refrigerating capacity of the

machine. For this reason, always ensure the specified water quality and do not use any other

additives than those specified.

2.3. Condenser

The condenser is a microchannel heat exchanger which transfers heat from the refrigerant to the

ambient air. In order for the heat transfer to take place, the refrigerant in the condenser has a

higher temperature than the ambient air drawn in and when it gives off heat its physical state

changes from gaseous to liquid.

Contaminated cooling air can cause deposits to form on the surface of the condenser over time.

This impairs heat transfer to the refrigerant which restricts the operating limit of the machine and

reduces the machine's refrigerating capacity. Please refer to Chapter 9: Cleaning for a description

of how to clean the condenser. If you operate your chiller in an environment containing dust or oil

vapour, use the optionally available air filter mat (see 3.19 Air filter mat).

In case that there already is an existing house water system and the warm condensing air has to

be avoided, the chiller can also be specified with a water cooled condenser (see 3.3 Version with

water cooled condenser)

2.4. Expansion valve

The expansion valve controls the admission of liquid refrigerant to the evaporator and at the

same time restricts the pressure of the refrigerant before it enters the evaporator. With this

restriction the refrigerant cools to the evaporation temperature.

The expansion valve used in your machine is controlled electronically. The electronic control

ensures that the evaporator is always optimally supplied with refrigerant. This improves the COP

(Coefficient of Performance) and reduces pressure fluctuations in the refrigeration circuit.

2.5. Refrigerant

The refrigerant R410A circulates in the refrigeration circuit. It conveys heat from the evaporator to

the condenser and at the same time continuously changes its physical state.

R410A is a fluorinated greenhouse gas consisting of the zeotropic mixture of 50% R32 and 50%

R125 with virtually negligible temperature glide. R410A has a very high volumetric refrigerating

capacity and has no ozone depletion potential (ODP=0). A corresponding safety data sheet can be

obtained from our KKT chillers Service Team (see Table 1: Contact details).

Page 15

15 / 89 83000102.Ki

2.6. Oil

The components of the compressor subject to friction are lubricated by oil, which is added to the

refrigerant in the factory. The polyolester-160SZ is used for this. The oil is soluble in the

refrigerant and is distributed with it throughout the refrigeration circuit. The total oil quantity of

the respective unit is given in the technical data. A corresponding safety data sheet can be

obtained from our KKT chillers Service Team (see Table 1: Contact details).

2.7. Filter dryer

The task of the filter dryer is to absorb any contamination or moisture from the refrigerant circuit.

Both refrigerant and oil are hygroscopic. When the refrigeration circuit is installed the oil can

absorb moisture. This moisture can cause corrosion and has a negative effect on the cooling

process. The filter dryer bonds this moisture and also has a mechanical filter effect. If work is

carried out on the refrigeration circuit requiring it to be opened, the filter dryer (cBoxX 30 –

cBoxX100) respectively the filter cartridge (cBoxX 120 – cBoxX 200) must be replaced.

2.8. Pressure sensors

The pressure sensors used are compact pressure transmitters with piezoresistive measuring cell.

The sensors register the system pressure continuously in different places within the refrigerant

and cold water circuit. The values are used to control the system and for visualisation at the

controller display.

2.9. Temperature sensors

The temperature sensors used are equipped with a platinum measuring cell. The sensors register

the temperature continuously in different places within the refrigerant and cold water circuit. The

values are used to control the system.

2.10. Control unit/ main circuit board

The control unit is programmed in the factory. All system readings and information come together

on it. In addition, the electrical components are controlled via algorithms.

2.11. Display

The display is used to visualise the information required by the operator and the system

processes. It is also possible to make entries at it. The display communicates with the control

unit. Further information on operation is given in Chapter 8.5 Control panel).

Page 16

16 / 89 83000102.Ki

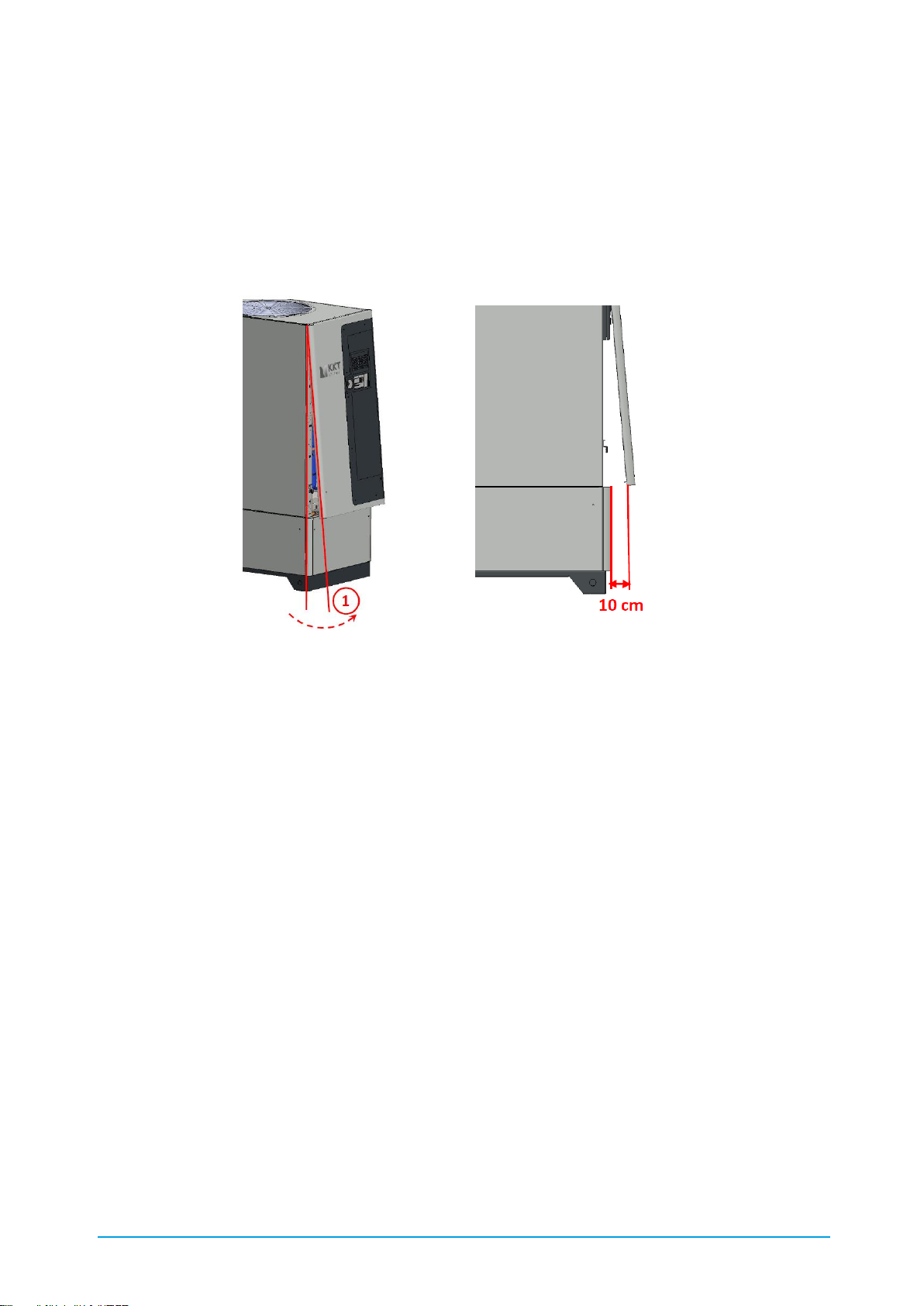

2.12. Control cabinet

The control cabinet conforms to the requirements of EN 60204 and contains the electrical and

electronic components for controlling the chiller. After removing the operator control panel the

control cabinet is accessible and can be opened using a standard two-way key. In order to avoid a

damage of the main switch while demounting the side panel, the side panel has to be tipped

10cm on the bottom side. A circuit diagram is supplied with the unit.

Figure 2: Demounting the side panel of the switch cabinet

2.13. Pump

The chiller's pump ensures the necessary circulation of the cold water. The water is drawn out of

the chiller's internal tank and is pumped through the process circuit. Optionally, the units can also

be designed as a continuous flow cooler without tank, with pump or without tank, without pump

(see Chapter 3.1 Version without tank, with pump, and Chapter 3.2 Version without tank, without

pump).

2.14. Fan

The fan draws the cooling air from the surroundings through the condenser and blows out the

heated air upwards out of the chiller. To prevent injuries, the fan is protected against accidental

contact by protective grilles. The fan's speed is variable and is controlled by the main printed

board. The speed of the fan is essentially controlled by the condensing pressure. The fan is

protected against thermal overload. In units with two fans the speed of fan 1 is always the same

as the speed of fan 2.

2.15. Cold water cycle

The cold water is drawn out of the chiller's internal tank by the internal pump and is pumped

through the process circuit. Optionally, the units can also be designed as a continuous flow cooler

without tank, with pump or without tank, without pump (see Chapter 3.1 Version without tank,

with pump, and Chapter 3.2 Version without tank, without pump). In the process circuit the cold

Page 17

17 / 89 83000102.Ki

water absorbs heat. The circuit closes when the cold water is pumped back into the chiller. It

flows through the evaporator, in which it gives off heat. The cold water then passes back into the

tank. The cycle begins again.

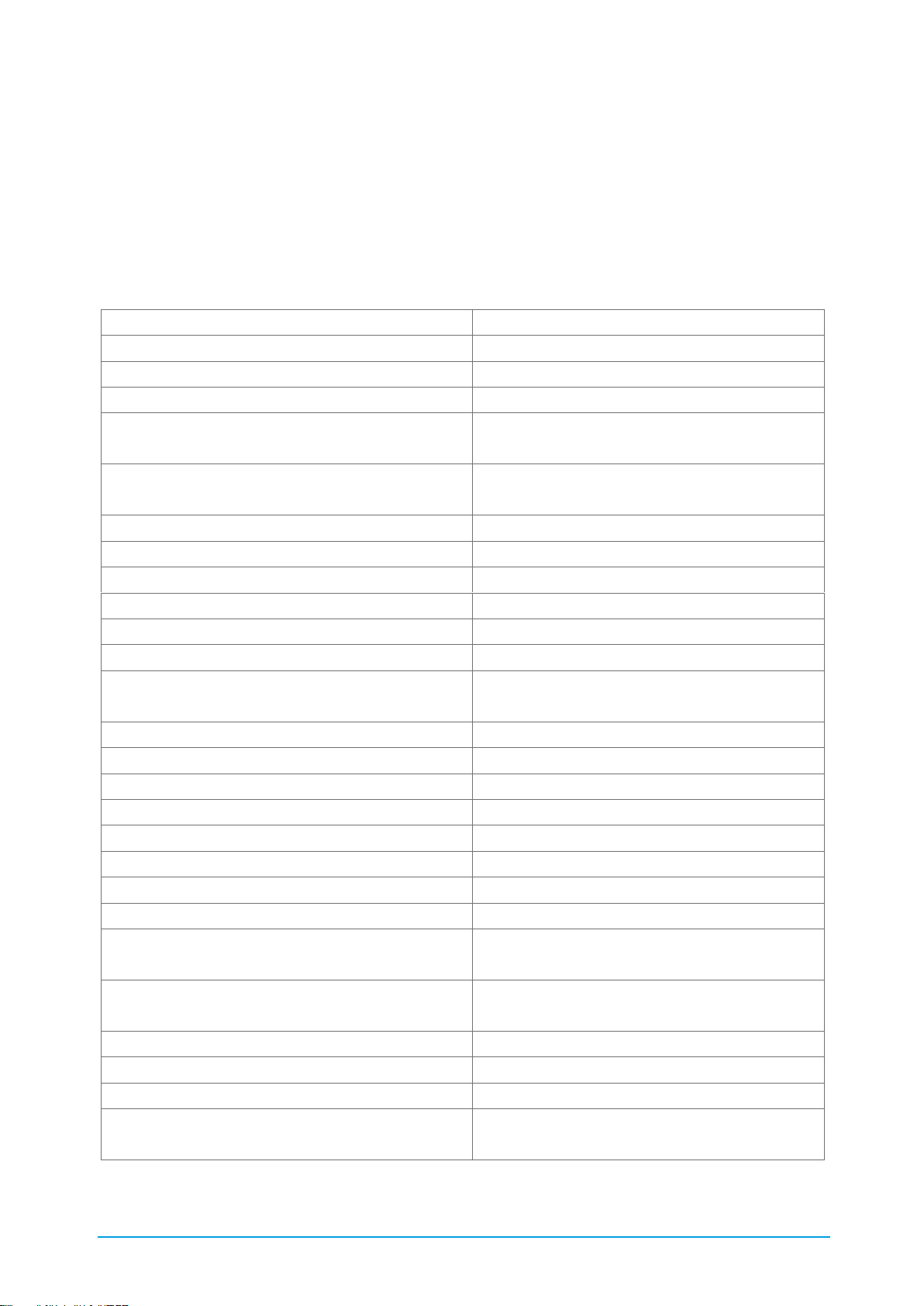

2.16. Materials used in the water circuit

The material composition of the standard equipment is shown in Table 5:

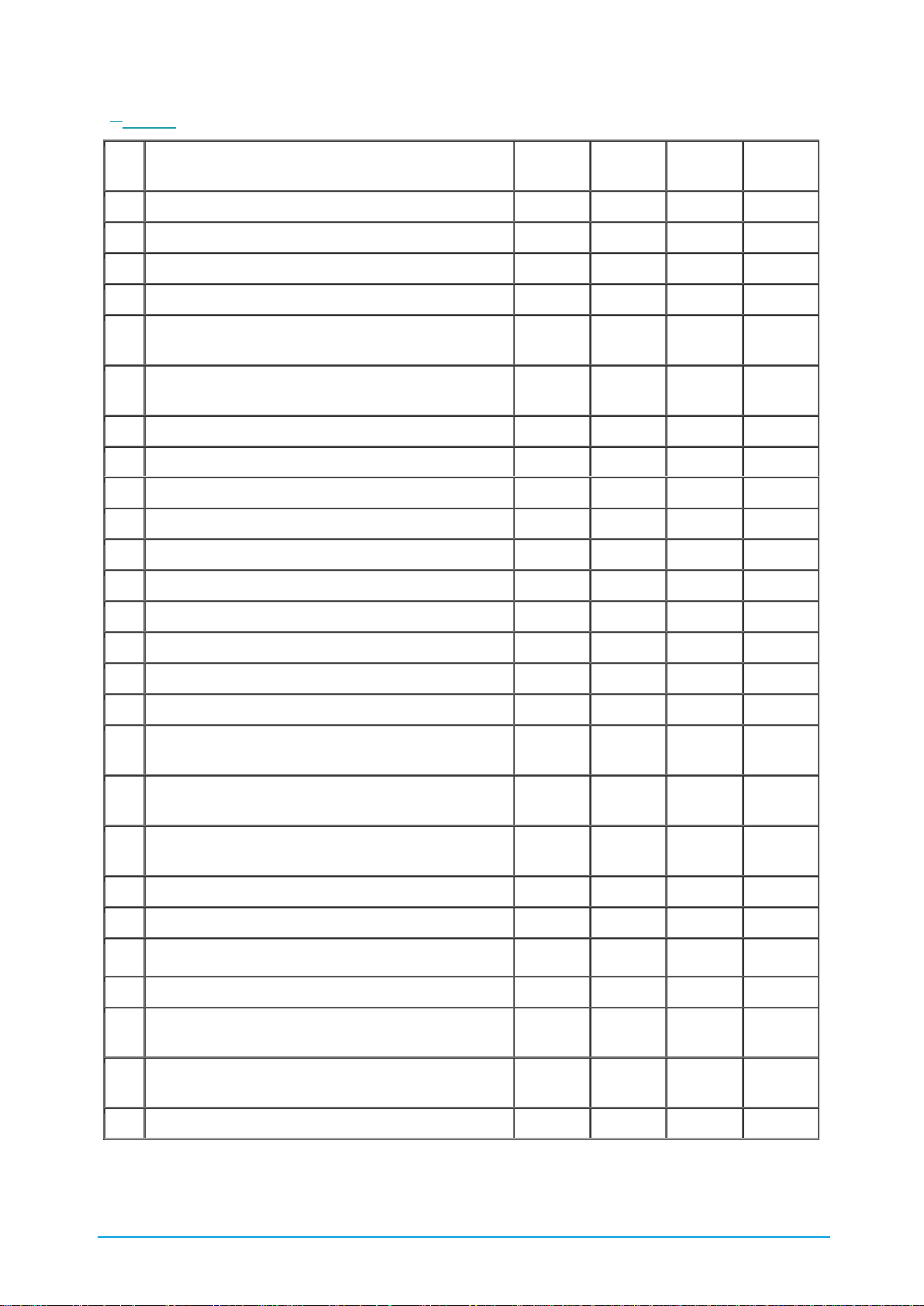

Table 5: Materials used - standard version

Component

Material (cBoxX 30 – cBoxX 100)

Unit connections

V2A 1.4305

Hose

Synthetic rubber

Evaporator

V2A 1.4301 and copper (99.9%)

Tank

Tank ports/connection sockets

V2A 1.4301

V4A 1.4571

Pump

Mechanical seal

Grey cast iron and V2A 1.4301

EPDM

Sealing plugs, yellow

Polyamide PA 6

Sealing plugs, black

Polyoxymethylene (POM)

Filling and drain cock

Nickel-plated brass

Bends, tees, couplings

Gunmetal CC499K

Fittings

V4A 1.4408

Hose nozzles

Nickel-plated brass

Swivelling elbow threaded coupling

(level indicator)

PVC and nickel-plated brass

Temperature sensor PT1000

V2A 1.4301

Pressure sensor XSK AC10I-U188

V2A 1.4301

Overflow valve (optional)

Gunmetal

Tank heater (optional)

Nickel-chrome-iron alloy 825

Component

Material (cBoxX 120 – cBoxX 200)

Unit connections

ABS

Piping and fittings

ABS

evaporator

V2A 1.4301 and copper (99,9%)

Tank

Tank ports/connection sockets

V2A 1.4301

V4A 1.4571

Pump

Mechanical seals

Grey cast iron and V2A 1.4301

EPDM

Sealing plugs, yellow

Polyamide PA 6

Sealing plugs, black

Polyoxymethylene (POM)

Filling and drain cock

Nickel-plated brass

Swivelling elbow threaded coupling

(level indicator)

PVC and nickel-plated brass

Page 18

18 / 89 83000102.Ki

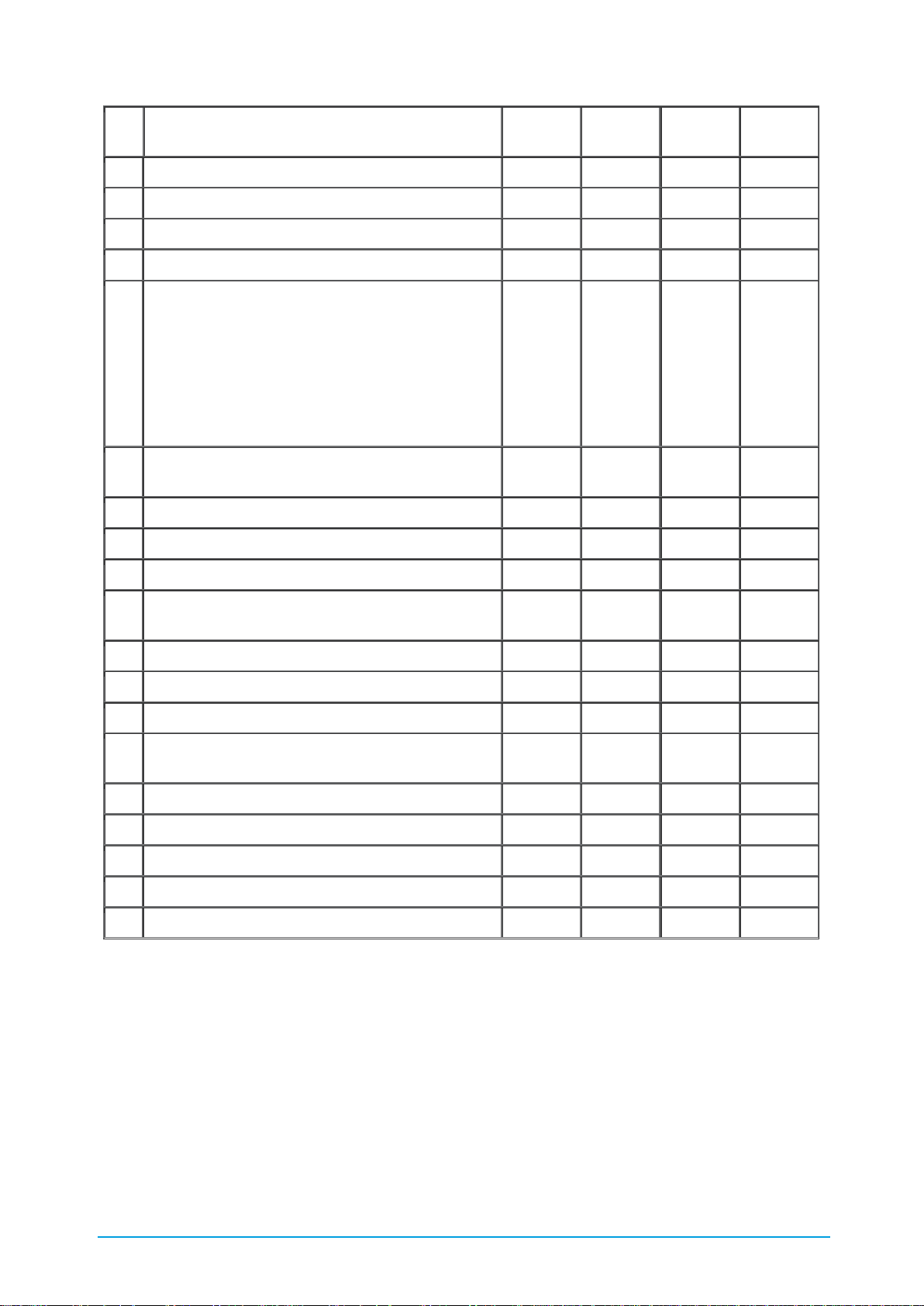

If equipped with the optional Water circuit in non-ferrous metal-free version the material

composition is as shown in Table 6:

Table 6: Materials used for the non-ferrous metal-free version

Component

Material (cBoxX 30 – cBoxX 100)

Unit connections (rotating parts)

V2A 1.4305

Hose

Synthetic rubber

Evaporator

V2A 1.4301

Tank

Tank ports/connection sockets

V2A 1.4301

V4A 1.4571

Pump

Mechanical seal

V2A 1.4301

EPDM

Sealing plugs, yellow

Polyamide PA 6

Sealing plugs, black

Polyoxymethylene (POM)

Filling and drain cock

V4A 1.4401

Fittings

V4A 1.4408

Hose nozzles

V4A 1.4408

Elbow threaded couplings

(level indicator)

PVC and polyoxymethylene (POM)

Hose (level indicator)

PE natural

Temperature sensor PT1000

V2A 1.4301

Pressure sensor XSK AC10I-U188

V2A 1.4301

Overflow valve (optional)

V2A 1.4301

Tank heater (optional)

Nickel-chrome-iron alloy 825

Component

Material (cBoxX 120 – cBoxX 200)

Unit connections

ABS

Piping and fittings

ABS

evaporator

V2A 1.4301

Tank

Tank ports/connection sockets

V2A 1.4301

V4A 1.4571

Pump

Mechanical seals

V2A 1.4301

EPDM

Sealing plugs, yellow

Polyamide PA 6

Sealing plugs, black

Polyoxymethylene (POM)

Filling and drain cock

V4A 1.4401

Swivelling elbow threaded coupling

(level indicator)

PVC und polyoxymethylen (POM)

Hose for level indicator

PE nature

Temperature sensor PT1000

V2A 1.4301

Page 19

19 / 89 83000102.Ki

2.17. Water quality

The following limits must be maintained for safe operation of the equipment:

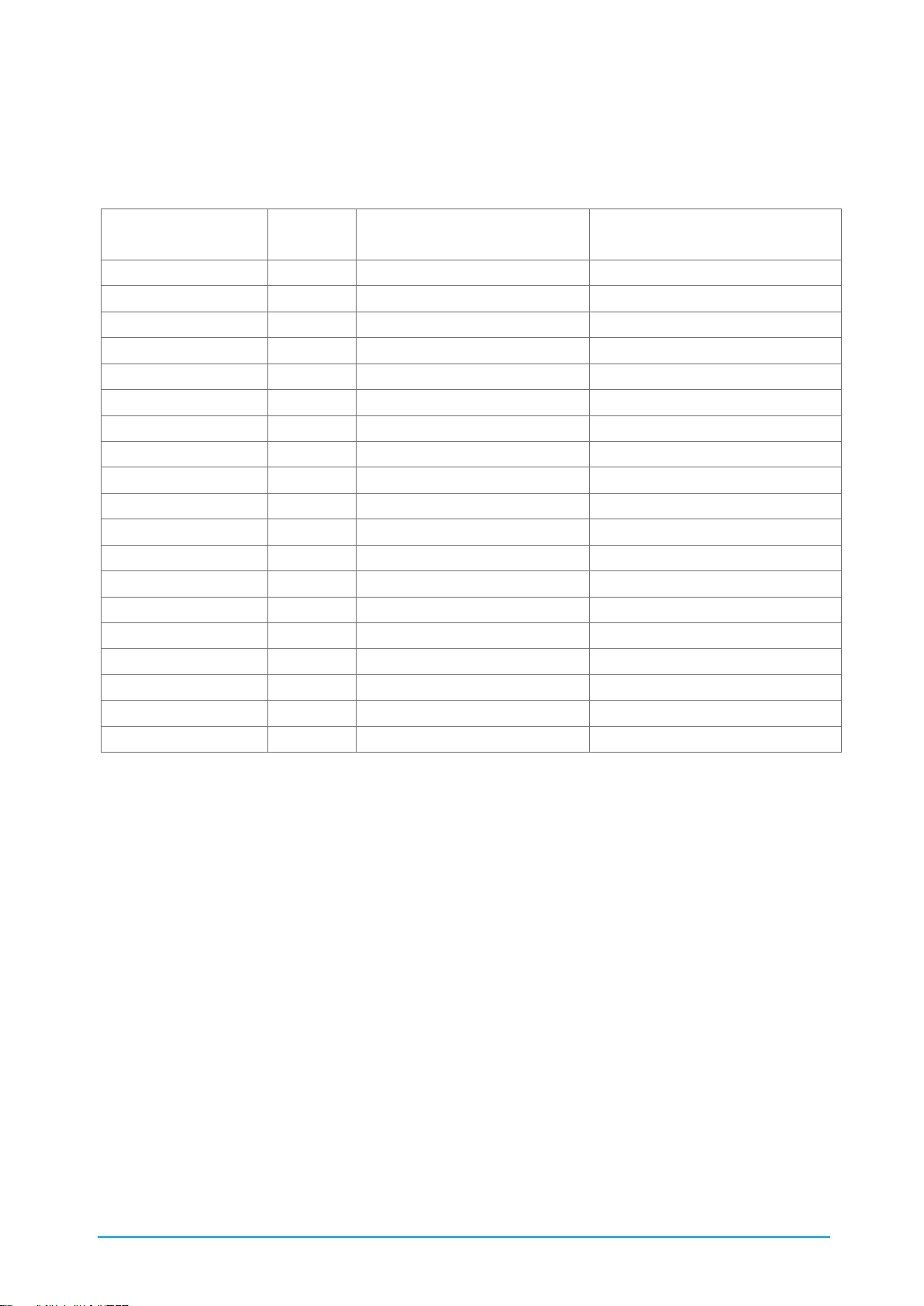

Table 7: Water quality

Property /

components

Unit

Value range

Standard version

Value range

Non-ferrous metal-free version

pH value (20 °C) - 7-9

6-9

Saturation index

-

-0.2 < 0 < +0.2

-0.2 < 0 < +0.2

Conductivity

µS/cm

80-500

5-500

Water hardness

°dH

<5.6

<5.6

Carbonate hardness

mol/m³

<0.5

<0.5

Total plate count

K/ml

<10,000

<10,000

Grain size

µm

< 250

< 250

Glycol fraction (AFN)

% by vol

20-40

20-40

Oil fraction

% by vol

0

0

Chloride (Cl-)

mg/l

<50

<50

Sulphate

mg/l

<50

<50

Nitrate

mg/l

<100

<100

Copper

mg/l

<0.1

<0.1

Iron

mg/l

<0.2

<0.2

Free carbonic acid

mg/l

<20

<20

Manganese

mg/l

<0.1

<0.1

Ammonia

mg/l

<2

<2

Free chloride

mg/l

<0.5

<0.5

Sulphide

mg/l

<0.03

<0.03

In order to avoid a restriction of the plate heat exchanger the above listed limit values have to be

guaranteed imperatively.

Furthermore mucilage bacteria are not allowed in the cooling water. If that is not possible, KKT

chillers can recommend an accordant inhibitor based on a biologic water analysis.

Page 20

20 / 89 83000102.Ki

2.18. Permitted cooling media

Water and mixtures of water / Antifrogen N (AFN) or water / Antifrogen L (AFL) according to the

details given in Chapter 2.17 Water quality. The following table shows the requirements for the

mix ratio of water with the antifreezes AFN or AFL. To maintain the performance of your machine

and prevent damage to components, these values must be maintained as precisely as possible.

Table 8: AFN and AFL mix ratios (or equivalent)

Setting

Frost-free at

t-environment to

AFN mix ratio

AFL mix ratio

Glycol 20 - 25 %

-10°C

20-25 %

25-30 %

Glycol 30 - 35 %

-15°C

30-35 %

32-37 %

Glycol 40 %

-25 °C

40 %

42 %

3. Options and accessories

The chiller can be equipped in the factory with the options described in the following.

The items marked "accessories" are enclosed with the unit, unattached, and can be reordered at

any time using the appropriate product number. The installer of the machine is responsible for

installing the accessories. You can also ask our KKT chillers Service Team to arrange for this

installation (see Table 1 Contact details).

Details of your machine's equipment are given in the separate summary documentation.

3.1. Version without tank, with pump

The Compact-Line units are also optionally available as continuous flow chillers. In this case the

units are delivered without an internal tank. The temperature sensor is then located in the

chiller's return line. If a tank open to the atmosphere is integrated on site, it is necessary to

ensure that the tank is not installed at a lower level than the chiller. Additional pressure losses

between the tank on site and integrated pump must be avoided (dp

max

=0.3bar)

3.2. Version without tank, without pump

The Compact-Line units are also optionally available as continuous flow chillers. In this case the

units are delivered without an internal tank and without pump. The temperature sensor is then

located in the chiller's return line. The cold water is then circulated via the evaporator by a pump

to be installed on site. This must at least be designed to the pressure loss of the overall system.

ATTENTION! Do not mix different antifreezes. This can cause unwanted chemical

reactions and silting up.

Page 21

21 / 89 83000102.Ki

3.3. Version with water cooled condenser

Whereas the basic versions of the Compact-Line is specified with an air cooled condenser, the

units are also available with an water cooled condenser.

Thereby the condenser is a plate heat exchanger with copper brazed stainless steel plates. The

3way valve is mounted in the cooling water outlet and is adjusted by an actuator depending on

the condensing pressure. The operation mode can be switched from the 3way operation to a

2way operation by closing the pre mounted bypass valve. The cooling water temperature is

measured by an additional temperature sensor in the cooling water inlet and is shown at the

controller display.

The project specific data as well as the adapted hydraulic scheme and the dimension sketch can

be found in the additional short documentation.

3.4. Heater for compressor and control cabinet

The oil sump heater prevents refrigerant from becoming deposited in the oil of the compressor at

low ambient temperatures. When the compressor is started up this refrigerant would be liberated

from the oil as gas and make the oil foam up. Under these basic conditions the lubrication of

components in the compressor subject to friction would be poor and the compressor could be

damaged.

The control cabinet heating is controlled thermostatically and, at low ambient temperatures, it

prevents moisture from the ambient air drawn in condensing on the electrical and electronic

components of the cabinet thereby damaging them.

For both heaters to be active, the chiller must not be disconnected from the power supply (8.2

Selecting the operating mode).

3.5. Insulation of the cold pipes and the pump(s)

To prevent condensation on cold chiller pipes, where high temperature differences exist between

the surroundings and cold water flow and taking into account the relative humidity the option of

insulation of the cold pipes must be specified.

The water quality shown in Table 7: Water quality has to be guaranteed imperatively –

the manufacturer does not assume liability for damages caused by other water

qualities.

Page 22

22 / 89 83000102.Ki

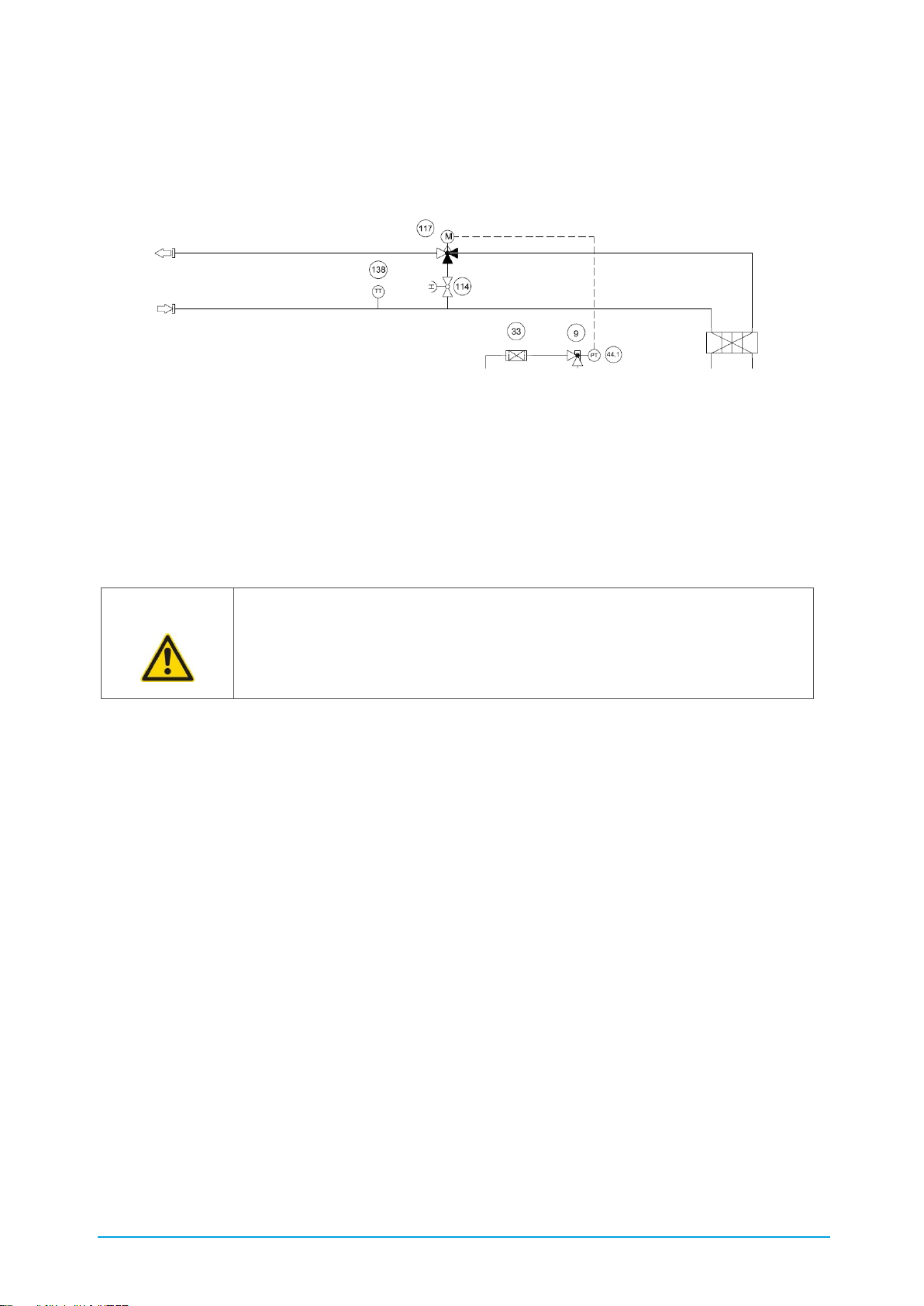

3.6. Tank heater with thermostatic pump start

The tank heater maintains a minimum temperature in the tank. The pump circulates the cold

water, while the tank heater controls the temperature in the system. We recommend a hydraulic

installation as shown in Figure 3. Any bypass valves must therefore always be installed frost-free.

For the heater to be active, the chiller must not be disconnected from the power supply. Even if

the external release (8.3 External release) is deactivated, the pump remains active.

Figure 3: C6856 thermostatic pump start with overflow valve (recommended installation)

3.7. Overflow valve for standby mode

The optional overflow valve should be installed if it is possible for the flow of the cold water to

reduce sharply or be completely prevented while the unit is running. The internal overflow valve

ensures the minimum volumetric flow through the chiller and therefore prevents the pump from

switching off. Figure 4 shows the position of the internal overflow valve.

Figure 4: C6863 overflow valve for standby mode

3.8. Higher pressure pump

The standard Compact-Line units have a 3 bar pump, which is designed for the nominal

volumetric flow of the respective unit. Optionally the units can also be built with higher pressure

pumps, within the limits of the minimum or maximum volumetric flow (1.2 Technical data). The

pump characteristic curve of the pump(s) used in your unit is enclosed with the unit.

cBoxX

Frost-free area

Application

Application

cBoxX

Page 23

23 / 89 83000102.Ki

3.9. Second consumer circuit

The standard Compact-Line units have a 3 bar pump, which is designed for the nominal

volumetric flow of the respective unit. If several consumers with different water specifications are

to be cooled with one unit, the unit can also be supplied with an optional second cold water

circuit. Ask your KKT chillers contact.

3.10. Additional evaporator pump

The evaporator is optimised for the nominal volumetric flow rate of cold water. The nominal

volumetric flow rate is given in Table 3 Technical data.

If the operating volumetric flow rate of the cold water is more than 50 % smaller, an evaporation

pump must be installed. The evaporator pump circulates the cold water internally and keeps the

storage water at feed temperature. A second pump supplies the process circuit with cold water.

3.11. Automatic water feed

Any leaks and evaporation can cause the quantity of cold water available for the chiller function to

reduce during the course of operation of the chiller. The Automatic water feed option provides the

possibility of topping up the cold water circuit automatically. The tank contents are monitored

continuously and if necessary topped up until it has again reached the optimum level. In this case

the operator only has to connect the chiller to the building's water system via the feed connection

(see Figure 5). The inlet pressure must lie between 1 bar and 10 bar.

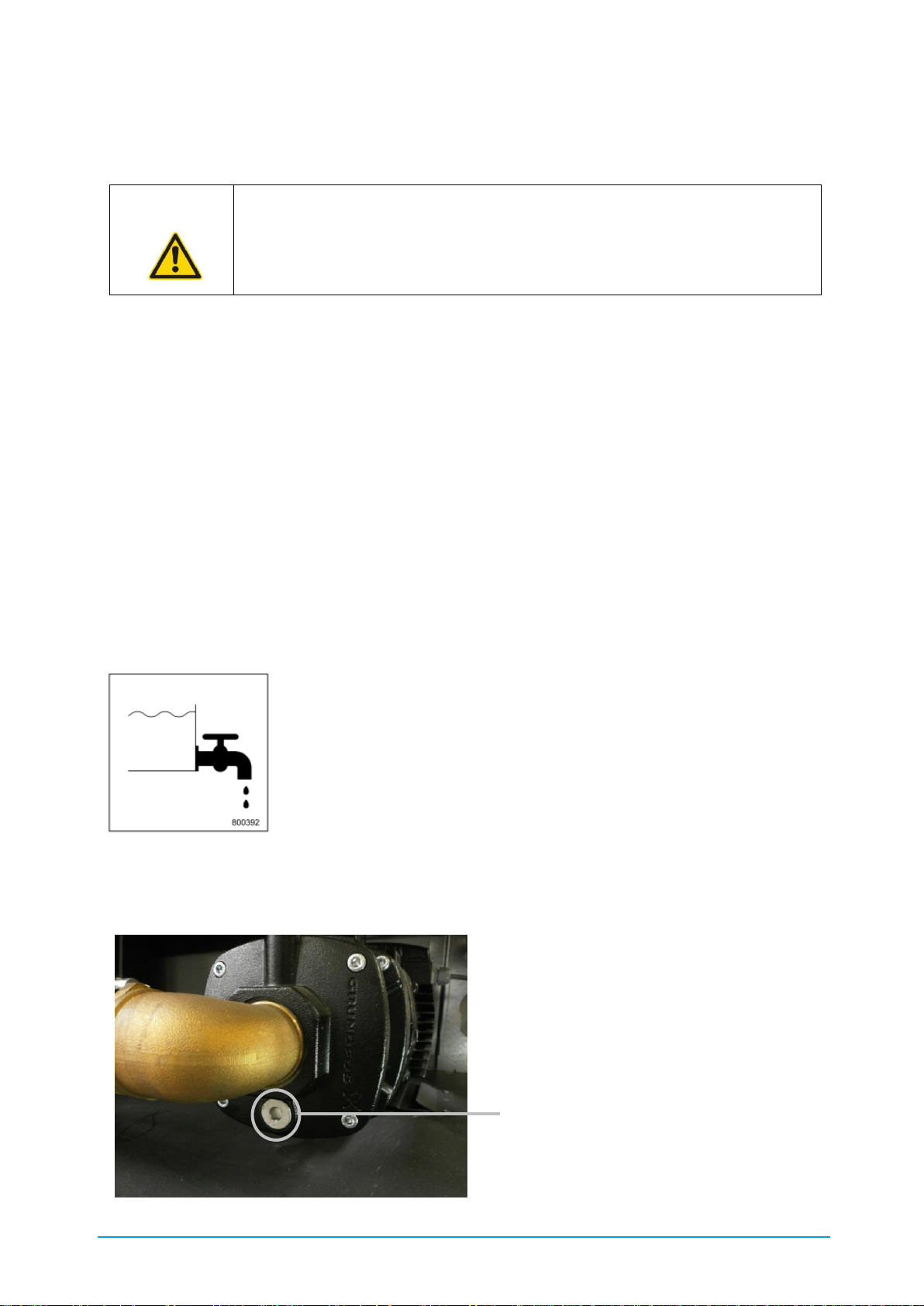

Figure 5: Top-up connection

If you operate your chiller with a mixture of water / glycol and top up only with pure water, you

must check the glycol content of the circuit water at regular intervals and if necessary adjust it.

3.12. Water circuit in non-ferrous metal-free version

If your machine is a non-ferrous metal-free version, all parts of the chiller's cold water circuit in

contact with the media are free from non-ferrous metals. Certain components such as the

evaporator and pump are suitably modified. The materials used in the water circuit are listed in

Table 6.

3.13. DI package

The DI package contains the non-ferrous metal-free option for the water circuit (see chapter,

3.12) and a replaceable DI cartridge with conductivity monitoring and control.

3.14. Special voltage

The special voltage option describes the use of the aggregate outside the voltage supply of 400V

(±10%)/3phases/50Hz. Here alternative components (e.g. compressors, pumps or fans) as well

as an autotransformer (integrated or unattached) can be used.

Page 24

24 / 89 83000102.Ki

For chillers with an integrated autotransformer sizes cBoxX 30 to cBoxX100, the transformer is

located in an additional flanged-mounted housing; for sizes cBoxX 120 to cBoxX 200 it is located

in the existing housing. For exact specifications, please refer to the circuit diagram. Please get in

touch with your KKT chillers contact person for further information on implementing this option.

3.15. Phase monitoring

The Compact-Line units can be equipped with optional phase monitoring. This monitors the phase

sequence, phase failure, undervoltage and asymmetry and covers a voltage range of 200-690V. If

the respective predefined limits are exceeded the system switches off and protects the electrical

components installed in the unit.

3.16. Hot gas bypass for output control <1K

If a more precise target constant than ±1 Kelvin is required, the chiller can be equipped with an

output control. In this case the output of the refrigeration circuit is adjusted to the cooling

demand by an electronically controlled valve. Unlike the standard control by switching

compressors on or off, a higher target constant is achieved by the continuous regulation of the

valve.

3.17. High-temperature package

In principle, the units must be operated within the given ambient temperature range (see

Table 3). If the high-temperature package is selected, the unit can be operated at an ambient

temperature of up to 50 °C without high-pressure faults.

3.18. Special paint finish

While the condenser's protective grille is always painted in RAL 7015 anthracite black, the

cladding panels (1.3 Elements) can also be optionally finished in special colours.

3.19. Air filter mat (accessories)

If the chiller is operated in surroundings with dust or oil vapour the condenser should be

protected with the air filter mat. The filter is fixed using the Velcro tapes attached in the

condenser protective grille. The filter is cleaned by removing it and washing it with water or a

slightly alkaline solution. Heavily-contaminated filters must be replaced by new ones. Please

contact the KKT chillers Service Team (see Table 1 Contact details).

3.20. Levelling feet (accessories)

The levelling feet are used for vibration isolation and for height adjustment. They consist of a

threaded rod and a grey cast iron shell with an elastic element attached. The threaded rod

enables the height to be adjusted and compensates for floors sloping by up to 5°. The elastic

element has a slip-resistant covering. Figure 6 and Figure 7 show the installed machine foot – the

technical drawing is given in the appendix.

Page 25

25 / 89 83000102.Ki

Figure 6: Machine base (foot) – outside view

Figure 7: Machine base (foot) - mounting on the baseplate

3.21. Level package (accessories)

The level package is used if the application is to be installed more than 500 mm above or below

the chiller (see also Chapter 6.2.7 Process level). This option is delivered uninstalled and consists

of an electronically controlled valve and a non-return valve. The electronically controlled valve

must be installed at the unit inlet, the non-return valve at the unit outlet. The electronically

controlled valve is installed electrically in the control cabinet as shown in the circuit diagram.

3.22. Filter assembly group coolant circuit (accessories)

The water filter protects the coolant circuit against dirt. The set, consisting of a filter, fitting and

two shut off valves, is enclosed with the chiller in a separate pack and must be fitted onto the

cold water inlet of the chiller from the outside when the chiller is installed.

3.23. Filter assembly group cooling water circuit (accessories)

The water filter protects the cooling water circuit against dirt. The set, consisting of a filter, fitting,

two shut off valves and two pressure gauges for displaying the cooling water inlet- and outlet

pressure is enclosed with the chiller in a separate pack. The installation can be either mounted

for shutting of the filter group or for shutting of the complete cooling water circuit.

Page 26

26 / 89 83000102.Ki

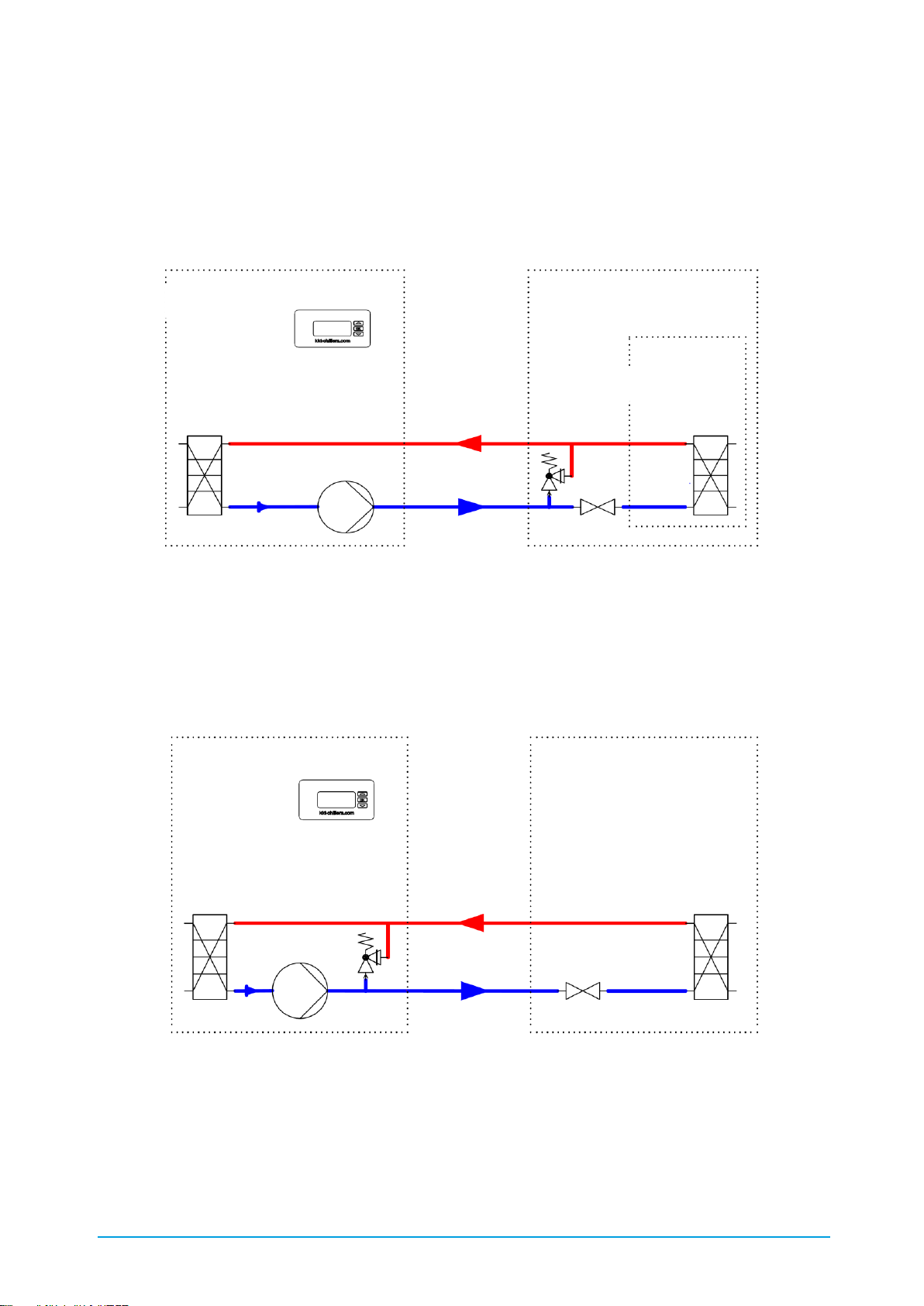

3.24. MultiplexX connection group (accessories)

If the refrigerating capacity of a chiller is not sufficient, several units of the same type can be

combined in the version with tank and pump. A MultiplexX connection group can be ordered for

this purpose and consists of the level package (3.21 Level package) and a corresponding

connection kit for the flow balance between the tanks. The refrigerating capacity of the individual

units can then be added together. Please contact your KKT chillers contact to arrange the

appropriate project planning for this option.

3.25. Refill cartridge R410A (accessories)

Chillers with refrigerant capacity >12kg must be declared as dangerous goods in accordance with

UN2857 (5.1 Dangerous goods). The optional R410A refill cartridge is available for units with

refrigerant capacities >12kg (cBoxX 120- CBoxX 200) so that you do not incur any additional

logistics costs. Following the performance check in the factory, a quantity of refrigerant is filled in

a certified refrigerant cylinder so that the 12kg limit is kept to in the unit. The refill cartridge is

then delivered together with the unit. The refrigerant quantity drained for transport can be

returned to the system as part of the commissioning using the summary description provided with

the refill cartridge.

3.26. Anybus-Gateway (accessories)

The Anybus-Gateway is ready mounted in the switch cabinet and can be used as an interface for

processing all chiller signals. Therefore the following processing protocols are available

depending on the customer specification:

▪ Modbus

▪ Profibus

▪ CANopen

▪ Profinet

▪ Devicenet

▪ EtherNet

▪ EtherCAT

▪ ControlNet

▪ CC-Link

A Modbus TCP communication is already included on the display pcb as a standard feature. An

Anybus gateway is not required.

Page 27

27 / 89 83000102.Ki

3.27. Remote Control Panel (accessories)

For the case that the chiller shall be operated not from the machine itself but from a different

operating place the chiller can be delivered with a remote control panel. Thereby the same display

is mounted together with the operating voltage supply in one miniature housing. The remote

control panel is connected to the chiller with clips and takes over the complete function of the

controller in the main device. By switching the accordant bridge integrated in the control cabinet,

the required operating place can be chosen.

(in = internally installed control / out = outward leading control)

3.28. Special languages (accessories)

These instruction manuals are provided in German, English, French and Spanish. Other languages

are available on request.

3.29. Wooden Crate (accessories)

Whereas the chillers of the Compact-Line are delivered on a wooden palette with Styrofoam

corners stretched in the foil as a standard, the chillers can be also ordered in a wooden crate.

There the chillers are protected additionally by a wooden crate with IPPC-Label according ISPM

15.

3.30. Seaworthy crate packaging (accessories)

Seaworthy crates for the Compact-Line are produced according to International Standards for

Phytosanitary Measures with packaging made of solid wood (ISPM 15). This means that the

crates are made of heat-treated solid wood which has been stripped of its bark. Only wood-based

materials, such as OSB boards, are used. In addition, all crates are marked with the IPPC logo

and registration number. The units are fixed in the crate with the help of coach bolts, ring nuts

and polyester straps and are packed in a sea air consistent foil with desiccant. The components

used to pack the units can be dismantled using a cross-head screwdriver.

3.31. Water Pump Redundancy

Depending on the optional configuration, the cboxX (water chiller) can be equipped with a dual

water pump for redundancy and increased life time of the pump itself. The operating hours of the

pumps are programmable and can be shared by both pumps (f. e. 24h switch on/off between

both pumps). In case of a pump defect, an automatic switch to the pump redundant, ensures the

continuation of the water chiller and the operation of the end customers application.

3.32. Closed Water Loop

The water chiller is designed as a closed water loop system with an expansion tank. The

expansion tank is pressurized in accordance with the volume of the entire system volume

(including installation). The expansion tank balances temperature swings and related system

pressure of the water loop. In case the coolant temperature rises the expansion tank takes in the

expanded volume of the coolant and if the coolant temperature falls the stored volume will be

released back into the loop again.

Advantages of a closed water loop system are:

Page 28

28 / 89 83000102.Ki

- No top up or refill required, due to no evaporation of the coolant

- No dirt or algues in the coolant

- No cleaning required of the tank

- Reduces weight of the chiller

Page 29

29 / 89 83000102.Ki

4. Safety

Provided it is used as intended, the chiller is designed to operate safely, provided also that the

instructions concerning transport, installation, commissioning/startup and maintenance given in

these operating instructions are complied with. The machine conforms to the safety standards in

accordance with the EC Declaration of Conformity (see Appendix III).

4.1. General information

The chiller contains a high-pressure circuit. The maximum pressure that occurs is 45 bar. Even

when inactive or disconnected from the power supply the circuit is still under pressure.

4.2. Hazard warnings

A number of warning labels are applied to the machine. Keep these warnings clean at all times.

Damaged or missing warnings must be replaced.

Page 30

30 / 89 83000102.Ki

Table 9: Definition of the safety symbols

Note and follow the instructions for use!

Before opening the machine it must be disconnected from the power supply!

After disconnecting the machine from the power supply, always wait for at

least 5 minutes before opening it.

Danger! High voltage! If the machine is only switched off at its main switch,

dangerous electrical voltage is still present at several terminals in the control

cabinet.

Wear foot protection!

Wear hand protection!

Wear eye protection!

Wear protective clothing!

Warning! Hot surface!

Warning! Cold surface!

ATTENTION!

Contains pressurised gas!

Page 31

31 / 89 83000102.Ki

In particular, the following hazard warnings apply to the machine:

Table 10: Hazard warnings

ATTENTION! Work on the chiller must be carried out by properly qualified,

competent personnel!

The surfaces of pipes and components of the refrigerant and cold water

circuit and electrical equipment can be very hot during operation and even

for a while after.

The surfaces of pipes and components of the refrigerant and cold water

circuit and electrical equipment can be very cold during operation and even

for a while after.

ATTENTION! Pipes and components of the refrigerant and cold water circuit

are pressurised.

ATTENTION! Do not undo the system parts. Risk of injury on contact.

ATTENTION! Only use the specified liquids!

WARNING! The device frame as well as the housing have not been designed

for additional loads, which is why it is not permitted to enter or place any

additional loads on the components!

Do not enter No additional loads

Page 32

32 / 89 83000102.Ki

4.3. Residual energy

Even if all the hazard warnings in the chapter above are taken into account, the following residual

energy situations can result in a hazard:

▪ Rotational energy of the decelerating fan

o Despite the installed protective grille, hair or pieces of clothing can still be drawn

in and caught.

▪ Hot surfaces on machine parts

o Especially the compressor head and the hot gas pipe and the condenser can still

be very hot for some time after the machine has been switched off. Temperatures

within the range from 60°C to 90°C are possible.

▪ Dangerous electrical voltage in the control cabinet despite the switched off main switch

o If the machine is only switched off at its main switch, dangerous electrical voltage

is nonetheless still present at several terminals in the control cabinet. In

particular, these are the main supply terminal and the input terminals of the main

switch.

▪ Refrigeration circuit is pressurised

o Provided it is not damaged the refrigeration circuit is closed. Therefore, a hazard

is not to be assumed.

Note:

After switching off the unit at the main switch, if you wait for 5 minutes before opening the unit

risks due to rotational energy and electrical power can be reduced. In this case only the residual

thermal energy must be considered.

Page 33

33 / 89 83000102.Ki

4.4. Safety devices, guards and safeguards

4.4.1. High-pressure limiter

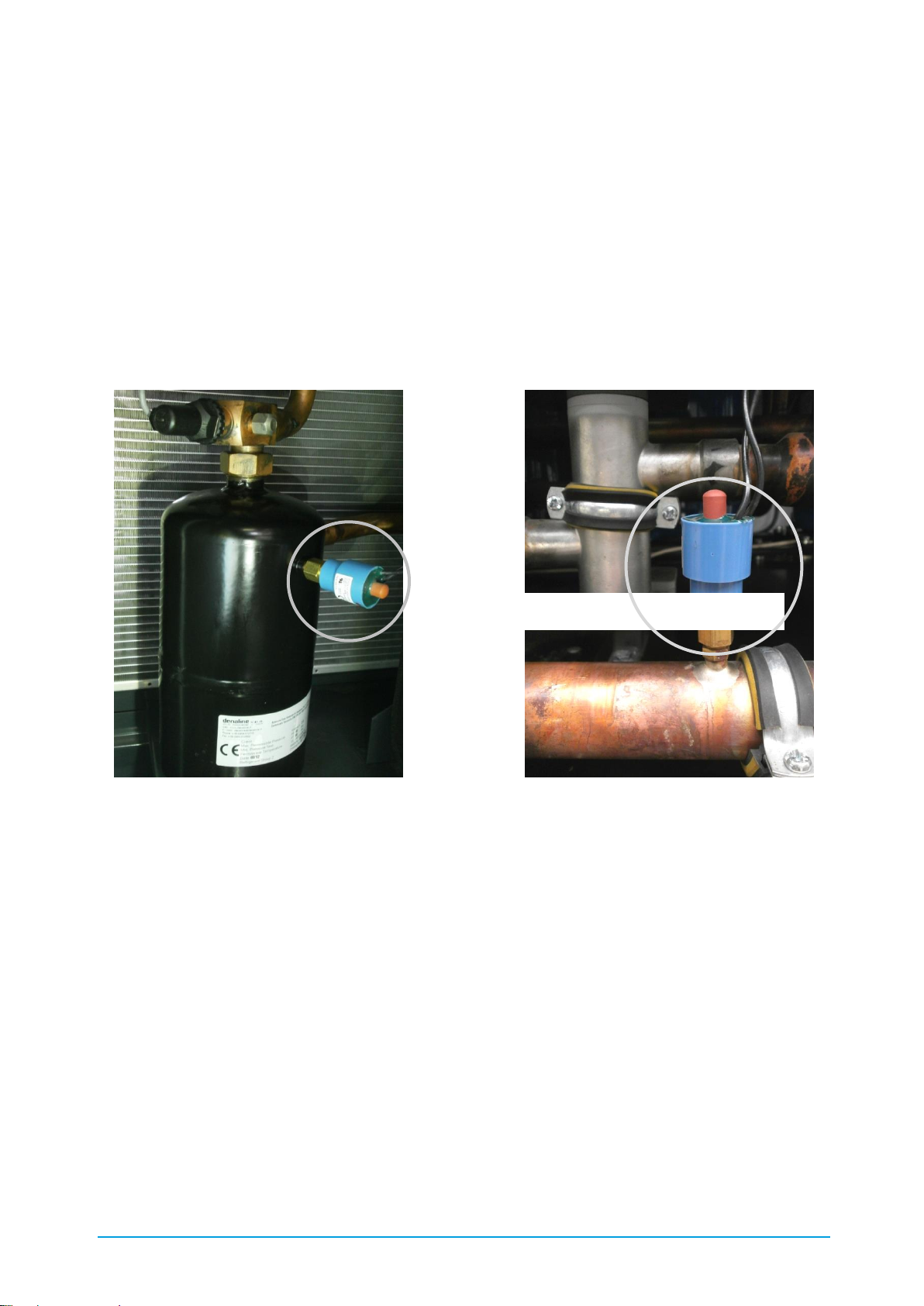

The high-pressure limiter (PZH) is a pressure switch with manual reset. The PZH limits the

condensing pressure and switches off all compressors via their load contactors when the

maximum permitted system operating pressure is reached. It is part of the safety chain. The PZH

is installed on the refrigerant collector for the chiller types cBoxX 30 – cBoxX 200 and on the fluid

pipe for the chiller types cBoxX 120 – cBoxX 200 (see Figure 8: Position of the high-pressure

limiter (PZH)). If the PZH has triggered, a message appears at the operator control terminal. In

this case, please follow the instructions in the Troubleshooting chapter (see Appendix 0).

High pressure limiter (PZH) High pressure limiter (PZH)

cBoxX 30 – cBoxX 100 cBoxX 100 – cBoxX 200

Figure 8: Position of the high-pressure limiter (PZH)

High-pressure limiter (PZH)

Page 34

34 / 89 83000102.Ki

4.4.2. High-pressure monitoring

If the high pressure in the refrigeration circuit of your machine increases to a maximum value, the

compressors are switched off via the High-pressure limiter (see Chapter 4.4.1 High-pressure

limiter). A manual reset is required. The high-pressure monitoring on the other hand reduces the

compressor output before the PZH's switch-off value is reached. This is done by successive

switching off of one or more compressors. A message appears at the control panel. When the

high pressure has reduced to a minimum value of 31.5 bar, the compressors are released once

more. In most cases partial shutdown of the compressors enables operation of the chiller to be

maintained with reduced output. If the high-pressure monitor has triggered, please follow the

instructions in the Troubleshooting chapter (see Appendix 0).

4.4.3. Low-pressure monitoring

If the low-pressure in the refrigeration circuit of your system is too low for the specified cooling

medium there is a risk of freezing. For this reason the low pressure is monitored continuously and

if it falls below a minimum value, one or more compressors are switched off successively. A

message appears at the control panel. If the low pressure has increased to a minimum value the

compressors are released once more. In most cases partial shutdown of the compressors

enables operation of the chiller to be maintained with reduced output.

If the low-pressure monitor has triggered, please follow the instructions in the Troubleshooting

chapter (see Appendix 0).

4.4.4. Flow monitoring

If the volumetric flow of the cold water which is pumped through the evaporator is too low, there

is a risk of freezing. For this reason the flow through the evaporator is monitored continuously. If

the volumetric flow rate is only around 50 % of the nominal volumetric flow rate, the message

"Flow warning" appears.

If the rate falls below the minimum value of 20 % the compressors are switched off and the

message "Flow stop“ appears. In this case, please follow the instructions in the Troubleshooting

chapter (see Appendix 0).

4.4.5. Personal protective equipment when operating the machine

Operating the machine involves making settings at the control panel. During operation of the

machine its cladding panels are installed, the machine is completely enclosed. No protective

equipment is needed.

We recommend ear protectors be worn by persons with jobs that require them to be continuously

in the immediate vicinity of the chiller. Please refer to the sound emission information included in

the technical data.

Page 35

35 / 89 83000102.Ki

4.5. Personal protective equipment for servicing work

Servicing work on the machine includes all work for which the machine is opened and one or

more cladding panels are dismantled. In particular, this includes cleaning work in accordance

with Chapter 9 Cleaning and maintenance work in accordance with Chapter 10 Service. Before

work is carried out on the chiller the protective equipment described in Table 9: Definition of the

safety symbols must be used.

Table 11: Personal protective equipment for servicing work

Wear foot protection!

Wear hand protection!

Wear eye protection!

Wear protective clothing!

4.6. Airborne sound emissions

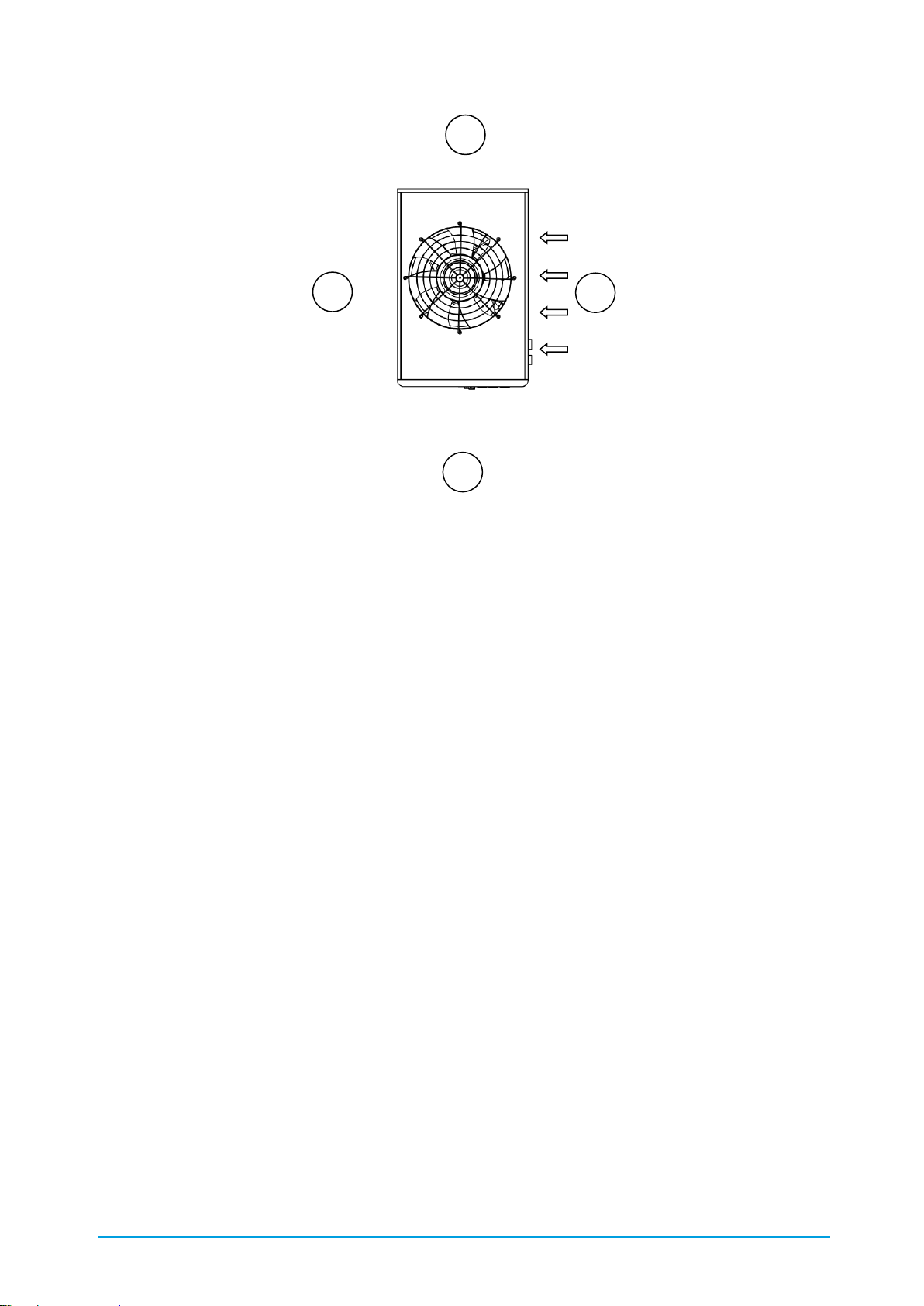

The airborne sound emissions data is given as the sound pressure level, measured at a distance

of five metres without reflection. Its maximum value is shown in the technical data. This only

occurs at the highest fan speed at the air intake side of the chiller (Figure 9, measuring point [1]).

The emissions in [2] to [4] are generally around 10 % lower than [1].

Page 36

36 / 89 83000102.Ki

Figure 9: Airborne sound emissions

In partial load mode or under favourable ambient conditions (see Chapter 4.7.1 Noise) the fan

speed and therefore the sound emissions reduce automatically.

4.7. Notes on reducing noise and vibration

4.7.1. Noise

Details of your chiller's airborne sound emissions are given in Chapter 4.6.

To reduce noise pollution caused by airborne sound emissions it is advisable to install the chiller

out of doors and out of the range of workplaces.

If this is not possible we recommend that when the unit is installed attention is paid to ensuring

that the air intake side is not pointed directly at a workplace/workstation.

High ambient temperatures mean high fan speeds and this increases the noise levels produced.

It is advisable not to expose the chiller to direct sunlight or to install it in rooms with high air

temperature. Further information is given in Chapter 6.2 Installation site.

4.7.2. Vibration

The chiller is designed so that the vibrations caused by the compressor are largely isolated by the

chiller's frame.

To minimise the effect of vibration still further it is possible to install the chiller with optionally

available levelling feet (3.20 Levelling feet ). These are fitted with damping elastomers.

1 2 3

4

Page 37

37 / 89 83000102.Ki

4.8. Residual risks

4.8.1. Electrical

If all safety provisions are complied with there is no risk.

4.8.2. Mechanical

If all safety provisions are complied with there is no risk.

Mechanical damage to components or pipes of the refrigerant circuit can cause refrigerant to

leak. Leaking refrigerant can cause cold burns.

4.8.3. Chemical

4.8.4. Other

4.9. Dangerous substances

4.9.1. Refrigerant R410A

First aid measures:

▪ After inhaling: remove victim to fresh air, ensuring your own safety, and keep the person

at rest in a comfortable position. Get medical attention. If the person stops breathing,

give artificial respiration.

▪ Following skin contact: leave clothing that has fused with the skin. Rinse areas damaged

by cold with lukewarm water (never use hot water). Do not rub! Cover with sterile

dressing. Ensure medical treatment is provided.

ATTENTION! Toxic and caustic products are produced by the thermal

decomposition of the R410A refrigerant.

ATTENTION! Do not install in rooms with naked flames or smoke.

ATTENTION! Risk of suffocation if the chiller is installed in a room that is too

small. Please note and follow Chapter 6.2.2.

ATTENTION! In the EU you must follow the provisions of EN378-3. Please also

note and follow the local installation regulations and provisions, especially the

Ordinance on handling water pollutant substances and BGR500 Chapter 2.35.

Page 38

38 / 89 83000102.Ki

▪ Following eye contact: rinse the eyes with clean water or eyewash solution for at least 15

minutes with the eyelids open. Consult an eye specialist.

▪ After swallowing: swallowing is not considered to be a likely risk as the refrigerant in the

surroundings is gaseous.

Notes for the doctor: do not give the patient catacholamine or adrenalin ephedrine preparations.

Fire-fighting measures:

▪ Suitable extinguishing agents: The product itself does not burn. Match the extinguishing

measures to the surrounding fire. Cool containers with sprayed water.

▪ Particular hazards due to the substance, its combustion products or gases formed:

forms toxic and caustic gases and fumes on decomposition.

▪ Special protective equipment for fire-fighting: self-contained or air-line breathing

apparatus and acid-resistant protective suit for deployment in immediate vicinity.

▪ Further information: The effect of fire can cause bursting or explosion of the container.

Ignitable gas-air mixtures possible under certain conditions.

Measures in case of accidental release:

▪ Environmental protection measures: where possible do not allow the product to get into

the environment.

▪ Cleaning procedure: leave the product to evaporate.

Handling and storage:

▪ Handling: fire and explosion protection: heating results in increased pressure and a risk

of bursting. Cool containers at risk with water. Open the containers slowly and carefully.

Personal protective equipment:

▪ Respiratory protection: not necessary if adequate ventilation available. Self-contained or

air-line breathing apparatus within enclosed rooms, if insufficient oxygen supply

available, in case of substantial or uncontrollable release. Only use breathing apparatus

in accordance with the international / national standards. Only use breathing apparatus,

no filtering devices.

▪ Hand protection: chemical-resistant protective gloves. Recommended material: Polyvinyl

alcohol.

▪ Eye protection: close-fitting safety glasses/goggles.

General protection and hygiene measures:

▪ Do not inhale fumes / aerosols.