Page 1

HEAT ACTIVATED SWITCH KIT

REACT TO THE

TEMPERATURE WITH THIS

ESSENTIAL INFORMATION

BUILD INSTRUCTIONS

CHECKING YOUR PCB & FAULT-FINDING

MECHANICAL DETAILS

HOW THE KIT WORKS

Version 2.1

Page 2

Heat Activated Switch Essentials

www.kitronik.co.uk/2113

Build Instructions – Cold activated

Before you start, take a look at the Printed Circuit Board (PCB). The components go in the side with the writing on

and the solder goes on the side with the tracks and silver pads.

Start with the resistor:

The text on the PCB shows where R1, go.

Ensure that you put the resistors in the right place.

PCB Ref

Value

Colour Bands

R4

220Ω Red, red, brown

Now place the two transistors. They should be placed into Q1 and Q2. It is important that they are

inserted in the correct orientation. Ensure the shape of the device matches the outline printed on the

PCB. Once you are happy solder the devices into place.

Place the variable resistor into R1. It will only fit in the holes in the board when it is the correct way

around.

Solder the thermistor in to the circle indicated by the text R2. This is next to the ‘cold’ text. It does

not matter which way around it is inserted.

Connecting power

There are two power terminals on the PCB to allow power to be connected. These are identified by the text ‘power’

on the PCB.

• The positive power connection should be connected to the terminal indicated by the text ‘+’ and ‘red’

• The negative power connection should be connected to the terminal indicated by the text ‘-’ and ‘black’

Connecting an LED

The circuit can be used to turn on a LED. The LED should be soldered into the LED1 on the PCB. A current limit

resistor must also be placed in the R3 on the PCB. The value of R3 will depend on the LED used and the supply

voltage. For a standard LED and a 5V supply voltage a 220Ω would be

suitable. Connecting an external circuit to the boards output

The circuit can be used to control another device. To do this the device

that is to be controlled should be connected to the terminals labelled

output. When the circuit is activated the output turns on and can be

used to turn on the device to which it is connected.

Note: This output will be around 0.9V lower that that connected to the PCB.

PLACE

THE

RESISTORS

1

Place the Transistors

2

Place the variable resistor

3

Plac

e the

thermistor

4

External

Circuit

Output +

Output –

Page 3

Heat Activated Switch Essentials

www.kitronik.co.uk/2113

Build Instructions – Heat activated

Before you start, take a look at the Printed Circuit Board (PCB). The components go in the side with the writing on

and the solder goes on the side with the tracks and silver pads.

Start with the resistor:

The text on the PCB shows where R1, go.

Ensure that you put the resistors in the right place.

PCB Ref

Value

Colour Bands

R4

220Ω Red, red, brown

Now place the two transistors. They should be placed into Q1 and Q2. It is important that they are

inserted in the correct orientation. Ensure the shape of the device matches the outline printed on the

PCB. Once you are happy solder the devices into place.

Solder the thermistor in to the circle indicated by the text R1. This is next to the ‘hot’ text. It does

not matter which way around it is inserted.

Place the variable resistor into R2. It will only fit in the holes in the board when it is the correct way

around.

Connecting power

There are two power terminals on the PCB to allow power to be connected. These are identified by the text ‘power’

on the PCB.

• The positive power connection should be connected to the terminal indicated by the text ‘+’ and ‘red’

• The negative power connection should be connected to the terminal indicated by the text ‘-’ and ‘black’

Connecting an LED

The circuit can be used to turn on a LED. The LED should be soldered into the LED1 on the PCB. A current

limit resistor must also be placed in the R3 on the PCB. The value of R3 will depend on the LED used and the

supply voltage. For a standard LED and a 5V supply voltage a 220Ω would be suitable.

Connecting an

external circuit to the boards output

The circuit can be used to control another device. To do this the

device that is to be controlled should be connected to the terminals

labelled output. When the circuit is activated the output turns on

and can be used to turn on the device to which it is connected.

Note: This output will be around 0.9V lower that that connected to the PCB.

PLACE

THE

RESISTORS

1

Place the Transistors

2

Place the

thermistor

3

Place

the variable resistor

4

External

Circuit

Output +

Output –

Page 4

Heat Activated Switch Essentials

www.kitronik.co.uk/2113

Checking Your Heat Activated Switch Board

Check the following before you connect power to the board:

Check the bottom of the board to ensure that:

• All these leads are soldered

• Pins next to each other are not soldered together

Check the top of the board to ensure that:

• The body of the two transistors match the outline on the PCB

Testing the PCB

Cold activated circuit

• Turn the variable resistor R1 fully clockwise (high resistance = 47KΩ). At this point the output should be off

(and the LED if fitted).

• Now turn the variable resistor R1 anti-clockwise until the output turns on (and the LED if fitted).

• Turn the variable resistor R1 back clockwise. Note the point at which the output (and the LED if fitted) turns

back off. This is the trip point for the current temperature.

• If you want the circuit to trip at a lower temperature then adjust R1 forward in the clockwise direction.

• If you want the circuit to trip at a higher temperature then adjust R1 back in the anti-clockwise direction.

• Some experimentation maybe required to set the correct trip point.

Heat activated circuit

• Turn the variable resistor R2 fully clockwise (high resistance = 47KΩ). At this point the output should be on

(and the LED if fitted).

• Now turn the variable resistor R2 anti-clockwise until the output turns off (and the LED if fitted).

• Turn the variable resistor R2 back clockwise. Note the point at which the output (and the LED if fitted) turns

back on. This is the trip point for the current temperature.

• If you want the circuit to trip at a lower temperature then adjust R2 forward in the clockwise direction.

• If you want the circuit to trip at a higher temperature then adjust R2 back in the anti-clockwise direction.

• Some experimentation maybe required to set the correct trip point.

Page 5

Heat Activated Switch Essentials

www.kitronik.co.uk/2113

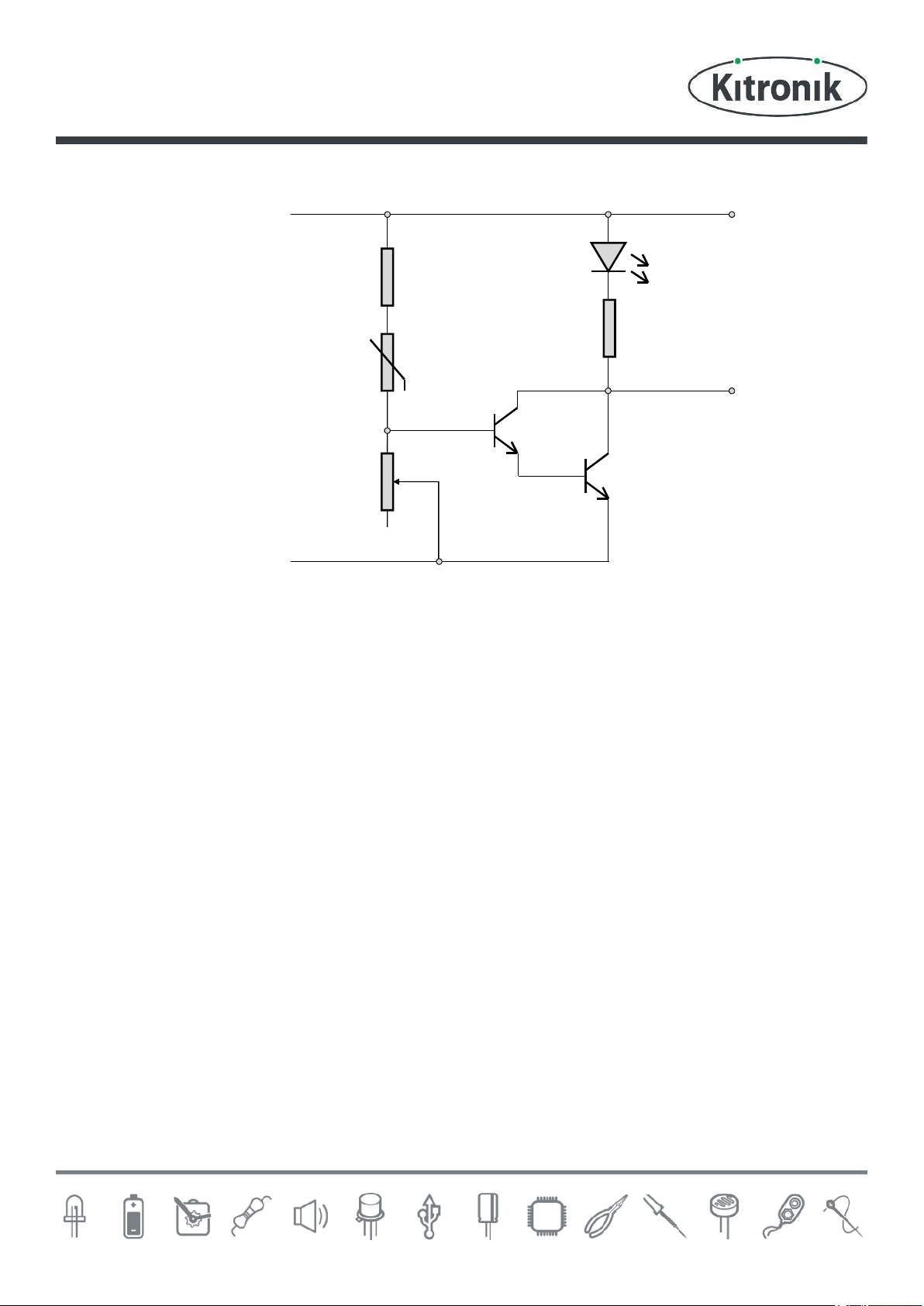

How the heat activated switch works – Cold activated

The circuit operation is very simple. When the input to the transistor Q1, which is fed from the connecting point of

R1 and R2, is greater than 1.4V the output is turned on. The voltage at the join of R1 and R2 is determined by the

ratio of the two resistors. This is known as potential divider.

Voltage at the join of R1 and R2 = The supply Voltage x (R1/(R1+R2))

Normally it requires 0.7V to turn on a transistor but this circuit uses two transistors in a Darlington Pair meaning it

requires 2 x 0.7V = 1.4V to turn on both transistors.

It is also worth noting that the output, when turned on, will be around 0.9V lower than the supply voltage V+. This is

because of the voltage drop across the collector and emitter pins of the Darlington Pair of transistors. Therefore if

the supply voltage is 5V then the output voltage will be around 4.1V.

R4 is present to protect the transistor should the variable resistor be set to zero.

Adjusting the trigger level

The point at which the circuit is triggered is set by the 47KΩ variable resistor. By varying the value of this resistor the

ratio of the resistance of R1 and R2 can be varied to a point where a centre voltage (trip point) of 1.4V is achieved at

the desired light level.

LED (if fitted)

If LED1 and R3 are fitted the LED will light at this point. The value of R3 should be selected for the relevant supply

voltage on LED used. A standard LED would require around 10mA (0.01A) producing a normal brightness. As stated a

5V supply would give 4.1V across LED1 and R3. The LED1 would use 1.9V leaving around 2.2V (4.1V-1.9V) across R3.

Using R = V/I R3 = 2.2 / 0.01 R3 = 220Ω

V+

LED1

R4

220

Transistor

Q2

Transistor

Q1

R1

47K

R2

Thermistor

0V

R3

+

-

Output

Page 6

Heat Activated Switch Essentials

www.kitronik.co.uk/2113

How the heat activated switch works – Heat activated

The circuit operation is very simple. When the input to the transistor Q1, which is fed from the connecting point of

R1 and R2, is greater than 1.4V the output is turned on. The voltage at the join of R1 and R2 is determined by the

ratio of the two resistors. This is known as potential divider.

Voltage at the join of R1 and R2 = The supply Voltage x (R1/(R1+R2))

Normally it requires 0.7V to turn on a transistor but this circuit uses two transistors in a Darlington Pair meaning it

requires 2 x 0.7V = 1.4V to turn on both transistors.

It is also worth noting that the output, when turned on, will be around 0.9V lower than the supply voltage V+. This is

because of the voltage drop across the collector and emitter pins of the Darlington Pair of transistors. Therefore if

the supply voltage is 5V then the output voltage will be around 4.1V.

Note: R4 is only present to protect the transistor in the cold activated version (when the variable resistor is set to

zero).

Adjusting the trigger level

The point at which the circuit is triggered is set by the 47KΩ variable resistor. By varying the value of this resistor the

ratio of the resistance of R1 and R2 can be varied to a point where a centre voltage (trip point) of 1.4V is achieved at

the desired light level.

LED (if fitted)

If LED1 and R3 are fitted the LED will light at this point. The value of R3 should be selected for the relevant supply

voltage on LED used. A standard LED would require around 10mA (0.01A) producing a normal brightness. As stated a

5V supply would give 4.1V across LED1 and R3. The LED1 would use 1.9V leaving around 2.2V (4.1V-1.9V) across R3.

Using R = V/I R3 = 2.2 / 0.01 R3 = 220Ω

V+

LED1

R4

220

Transistor

Q2

Transistor

Q1

R2

47K

0V

R3

+

-

Output

R1

Thermistor

Page 7

Heat Activated Switch Essentials

www.kitronik.co.uk/2113

Applications

Heat activated fan/cooler

By using a temperature activated

board built in the heat activated

option and the addition of motor it

is possible to make a heat

activated fan (shown right). The

fan can be set up to come on at a

desired temperature by adjusting

the variable resistor.

Parts list to build 100 heat activated fans:

Part no. Description Qty

2113 Temperature activated switch 100

2234-25 3 x AA battery cage with clip, pack of 25 4

2238-25 PP3 Battery clip lead, pack of 25 4

2501 Pack of 10 motors 10

2503 Pack of 10 motor clips 10

2201-40 Zinc Chloride AA batteries, box of 40 8

Babies bath over temperature indicator

By using a temperature activated board built in the heat activated option it is possible to make a simple

babies bath too hot indicator. The ‘too hot’ state can be indicated by an LED that light by the addition of

the 150Ω resistor (in R3) and red LED (in LED1).

The thermistor should be mounted on separate flying leads as the PCB should not be immersed in water.

Parts list to build 100 babies bath over temperature indicators:

Part no. Description Qty

2113 Temperature activated switch 10

2234-25 3 x AA battery cage with clip, pack of 25 4

2238-25 PP3 Battery clip lead, pack of 25 4

3003-150R 150ohm resistor, pack of 100 1

3504 Red 5mm LED, pack of 50 2

2201-40 Zinc Chloride AA batteries, box of 40 8

Page 8

Online Information

Two sets of information can be downloaded from the product page where the kit can also be reordered from. The

‘Essential Information’ contains all of the information that you need to get started with the kit and the ‘Teaching

Resources’ contains more information on soldering, components used in the kit, educational schemes of work and so

on and also includes the essentials. Download from:

www.kitronik.co.uk/2113

Every effort has been made to ensure that these notes are correct, however Kitronik accept no responsibility for

issues arising from errors / omissions in the notes.

Kitronik Ltd - Any unauthorised copying / duplication of this booklet or part thereof for purposes except for use

with Kitronik project kits is not allowed without Kitronik’s prior consent.

This kit is designed and manufactured in the UK by Kitronik

Loading...

Loading...