KITO ER2, ER2SP, ER2M, ER2SG Owner's Manual

OM-ER2ZZZ-MGE-00

ER2 Series Electric Chain Hoist

Owner's Manual

Hook Suspended Type (hoist only) : ER2

Motorized Trolley Type : ER2M

Manual Trolley Type : ER2SP/ER2SG

(125kg to 5t)

To Customer

• Thank you for purchasing KITO Electric Hoist (ER2).

• Operators and maintenance engineers are requested to read this manual.

After reading, please keep this manual at hand for future use.

• This product is designed considering the environment protection. The product contains none of six hazardous

substances specified by European RoHS Directives nor asbestos.

Table of Contents

Introduction ............................................................................................2

Safety Precautions ................................................................................4

Chapter 1 Handling the Product ..........................................................7

Chapter 2 Inspection ..........................................................................63

Chapter 3 Troubleshooting ................................................................93

Appendix ............................................................................................119

Warranty .............................................................................................162

Introduction

This electric hoist ER2 is designed and manufactured for the purpose to lift and lower a load within a normal

work environment. The motorized trolley MR2 and the manual trolley are designed and manufactured for the

purpose to move the lifted load laterally with the combination with the electric hoist.

Movement of a load in a 3D direction such as up/down, forward/backward and right/left is also enabled by

combining with a crane.

This Owner's Manual is intended for those operating the KITO electric hoist ER2 and maintenance engineers

(* pesonnel with expertise).

Other than this manual, Disassembly/Reassembly Manual and Parts List are also available for the maintenance

engineers. Assign the maintenance engineers and use these materials for inspection and repair. Please contact

the nearest distributor or KITO for these materials.

■Disclaimer

●

KITO shall not be liable for any damage incurred thereof due to natural disaster such as fire, earth quake

and thunderbolt, conduct by third party, accident, willful conduct or negligence by customer, erroneous use

and other use exceeding the operational condition.

●

KITO shall not be liable for any incidental damage due to the use or non-use of the product such as the loss

of business profit, suspension of business and damage of the lifted load.

●

KITO shall not be liable for any damage arising from negligence of the contents in the Owner's Manual and

the use of the product exceeding the scope of its specification.

●

KITO shall not be liable for any damage arising from the malfunction due to the combination of the product

with other devices in which KITO is not concerned.

●

KITO shall be indemnified from any loss of life, bodily injury and property damage due to the use of our

product for which it has passed 10 years since its delivery.

●

KITO shall not be liable to supply the spare parts for the product for which it has passed for 15 years since

the discontinue of the product.

2

■Restriction on Use

●

The product described herein is not designed or manufactured for transporting people. Do not use the

product for that purpose.

●

The product described herein is designed for the materials handling work such as lifting/lowering and

traveling the load under ordinary operational condition. Do not use the product for the work other than

materials handling work.

●

Do not assemble the product into machinery not for materials handling, as a part of it.

■Operators

●

Read carefully this Owner’s Manual and the instruction manuals of related products, fully understand their

contents, and the use and operate the product.

●

Be sure to ware the proper clothing and protective equipment when using and operating the product.

■Laws and Standards

Carry out installation, inspections, operations, maintenance management in accordance with the laws and

standards of the country and region where the product is used.

An application before installation or a test before beginning usage may be required. Furthermore, the tester

may be required to have specific qualifications. Be sure to check the laws and standards of the corresponding

country and region before using the product.

3

Safety Precautions

Improper use of electric chain hoist causes danger such as drop of lifted load. Read this Owner’s

Manual carefully before installation, operation and maintenance. Use the product after understanding the

product knowledge, safety information and precautions.

This Owner’s Manual classifies the safety information and precautions into two categories of “DANGER”

“WARNING” and “CAUTION”.

Also read the instruction manual of the device associated with electric chain hoist, and follow the

described contents.

Description of Signal Words

DANGER

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

WARNING

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

CAUTION

Further, the event described in CAUTION may result in serious accident depending on the situation. Both DANGER and CAUTION

describe important contents. Please follow the instruction.

After reading, please keep this manual at hand for future use by the user.

injury. It may also be used to alert against unsafe practices.

Description of Safety Symbols

Means “Prohibited” or “You must not do”.

Prohibited action is shown in the circle or described near the circle.

Prohibited

Mandatory

This Owner’s Manual uses

Means “Mandatory Action” or “You must do”.

Required action is shown in the circle or described near the circle.

This Owner’s Manual uses

as the general prohibition.

as the general instruction.

■General Matters on Handling and Control

DANGER

• This product shall not be disassembled and repaird by personnel other than maintenance engineers.

Other than this manual, Disassembly/Assembly Manual and Parts List are provided for the maintenance engineers.

Prohibited

Mandatory

4

Per form the disassembling and repair by the maintenance engineer in accordance with these materials for

maintenance.

• Do not modify the product and its accessories.

Failure to comply with these instructions may result in death or serious injury.

• Understand the contents of the Owner’s Manual sufficiently. Then operate the Electric chain hoist.

• Warning label is affixed to each part of the product. Follow the instruction described in the warning label.

Failure to comply with these instructions may result in death or serious injury.

CAUTION

• Do not drag or drop the product when carrying.

Otherwise it causes damage or flaw of the electric chain hoist, bodily injury or loss of property due to the drop of the

Prohibited

Mandatory

lifted load.

• When discarding the product, disassemble it not to be used and discard in accordance with the

ordinances of local government or the rules specified by the business entity.

Ask the local government or the relevant section for the details.

Refer to “Disassembly/Assembly Manual” for disassembling, or contact KITO.

(This product uses oil. We prepare MSDS (Materials Safety Data Sheet) for the oil. Contact KITO for it.)

• Carry out daily inspection by user.

• Carry out inspection (monthly, annual) by maintenance engineer.

• Keep the record of the inspection.

Failure to comply with these instructions causes bodily injury or loss of property.

■General Matters on Handling of Dual Speed VFD Model

The dual speed VFD model electric chain hoist is controlled by VFD for important items related to safety such as

operation, braking and emergency stop. Be sure to follow the safety precautions below as well as the above safety

precautions.

Prohibited

DANGER

• Do not change parameters.

When parameters need to be changed, ask distributor or KITO.

• Do not carry out the work such as maintenance and inspection within 5 minutes after power off.

Wait for the completion of discharging of the capacitor inside the VFD.

• Do not touch the controller cover as it becomes hot during operation.

Do not touch the controller cover until about 30 minutes elapsed after the stop of operation.

• USE KITO genuine VFD.

The VFD requires the special specification for KITO. Be sure to use genuine VFD.

• Do not change the connection of the VFD.

When the wires were removed for any reason, connect them again correctly checking the wiring diagram inside the

controller cover.

• Do not carry out withstand voltage test and insulation resistance measurement of a circuit by megger

while the VFD is connected.

• Do not turn off the power while operating.

Failure to comply with these instructions may result in death or serious injury and the damage of VFD.

5

6

Chapter 1

Handling the Product

This chapter describes mainly how to use, assemble and install, and the check

after installation. It also describes the daily inspection items before use.

For Operators and Maintenance Engineers

●

Type and Names of Each Part ..........................................................8

Opening the Package ......................................................................11

Product Specication and Operational Environment ..................16

How to Use ......................................................................................19

● Daily Inspection of Electric Chain Hoist (Hook Suspended Type)

● Daily Inspection of Motorized Trolley (MR2) .............................25

● Daily Inspection of Manual Trolley (TSG/TSP) ..........................26

● How to Operate the Push Button Switches ...............................28

● Operation ......................................................................................31

● Speed Change of Dual Speed VFD Model .................................34

● How to Sling the Load Properly .................................................34

● How to Suppress the Swinging of a Load .................................34

● Precautions After Work ...............................................................35

20

For Maintenance Engineers and Installars

●

Work Flow of Assembling and Installation....................................36

Assembling ......................................................................................37

● Assembling Parts to Electric Chain Hoist .................................37

● Combination with the Trolley ......................................................41

● Checking Power and Power Cable .............................................52

● Connecting Cables ......................................................................54

Installation ........................................................................................57

● Connecting Power and Power cable ..........................................57

● Installing the Hook suspended Type (hoist only).........................57

● Installing the Trolley Combined Model .......................................58

Check after Installation ...................................................................61

7

Chapter 1 Handling the Product

Type and Names of Each Part

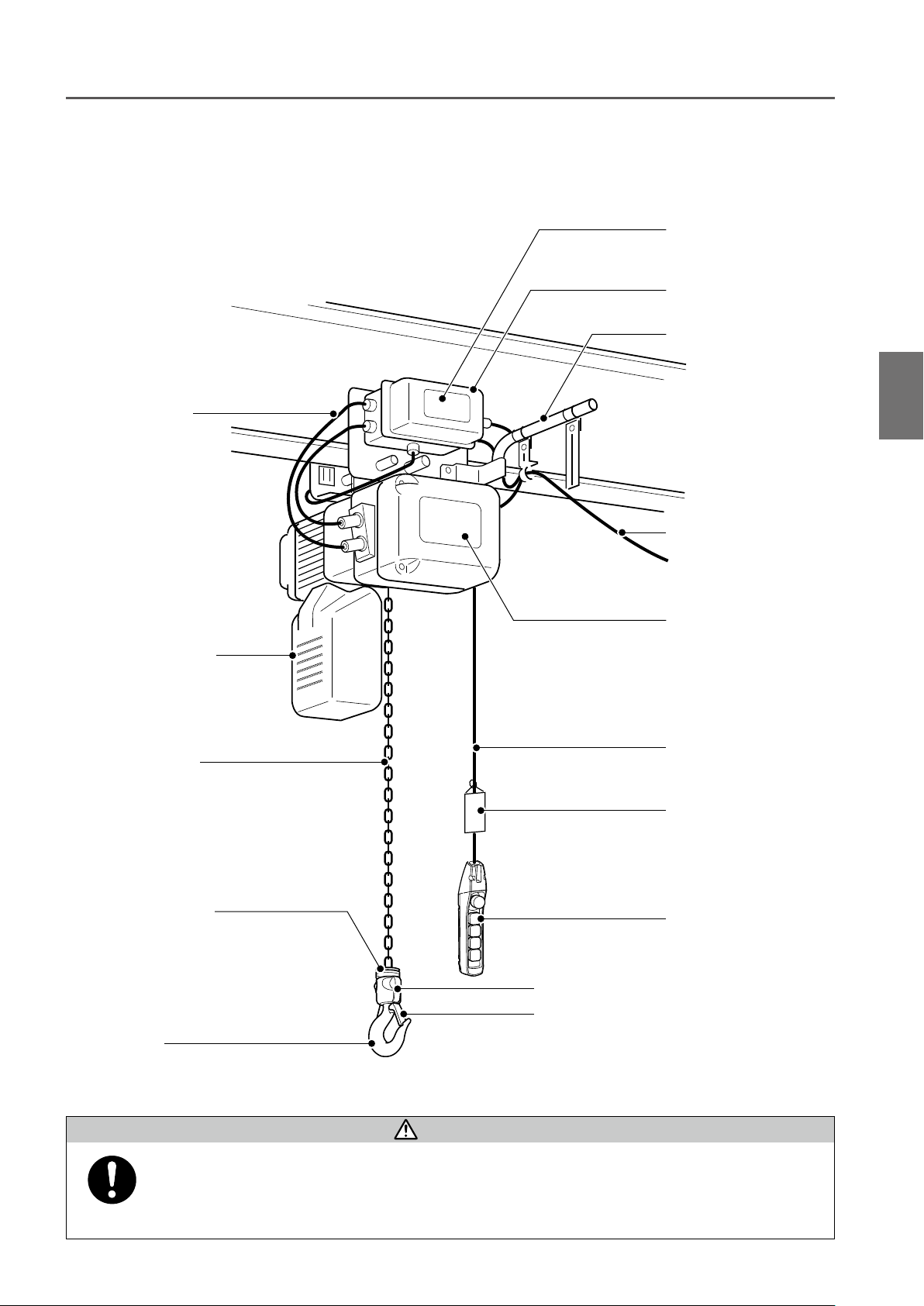

■Hook Suspended Type (ER2)

●

Electric chain hoist dedicated for elevation

Type and Names of Each PartHook Suspended Type (ER2)

1

Electric Chain hoist

name plate

Chain Container

Push Button

Switch Cord

Top Hook

Body

Load Chain

Cushion Rubber

(Chain spring and end plate for the

model of rated load 2 t or more)

Bottom Yoke

Warning Tag

Mandatory

Hook Latch

Bottom Hook

Push Button Switch

DANGER

• Warning labels are affixed to each part other than above. Be sure to follow the instructions in the label.

Failure to comply with the contents of the label may result in death or serious injury.

8

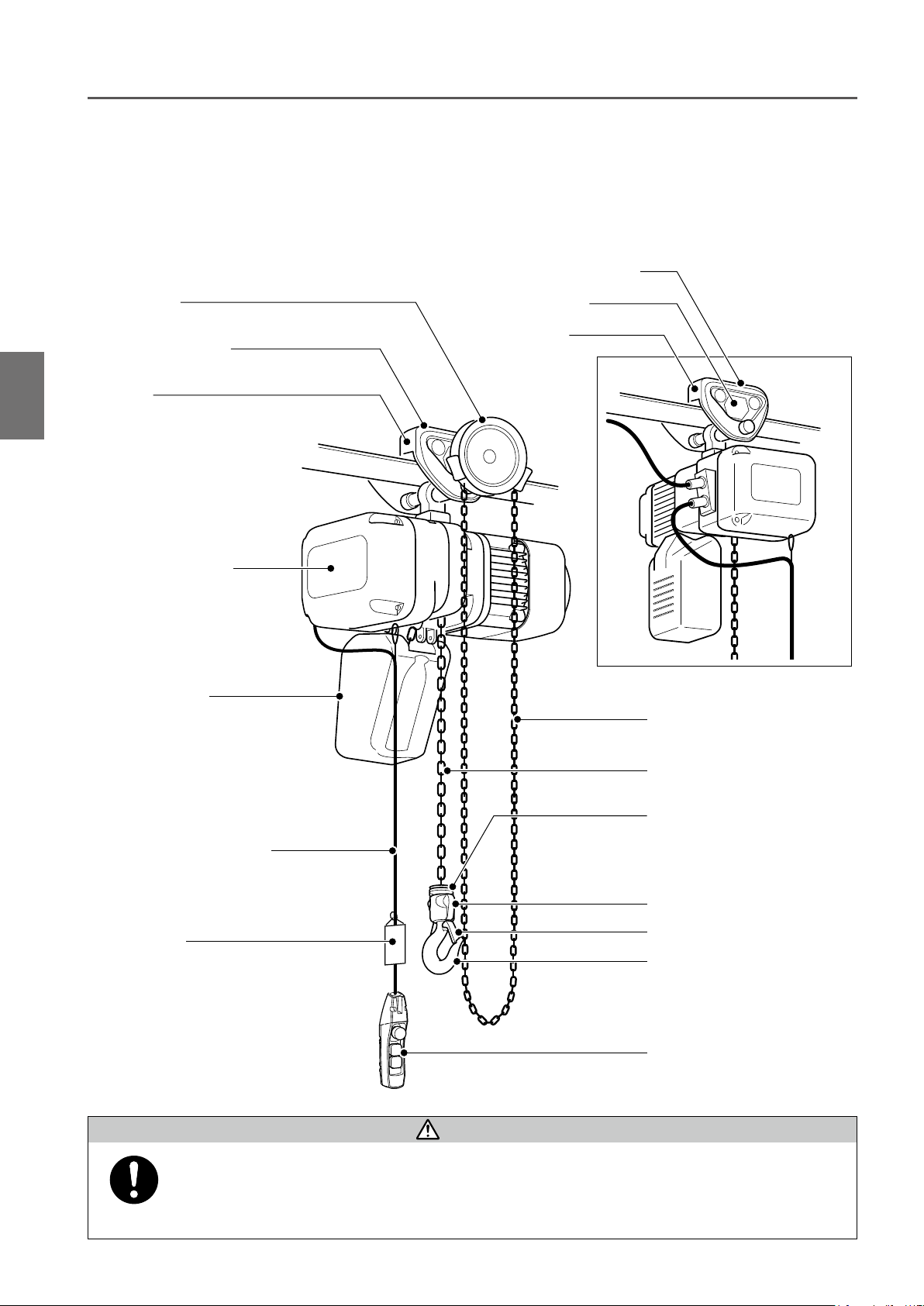

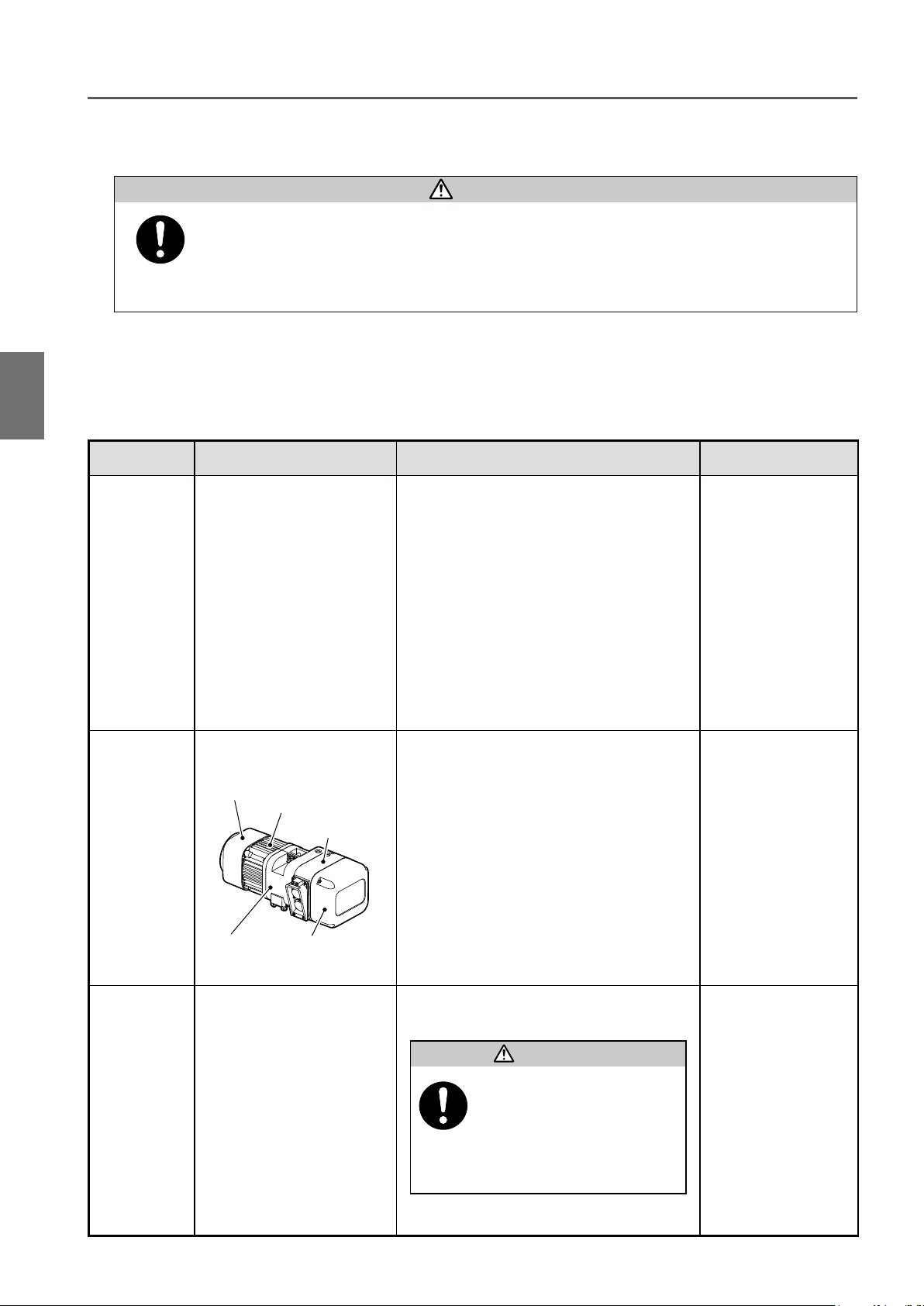

■Motorized Trolley Type (ER2M)

●

Electric Chain Hoist combined with motorized trolley (MR2) for elevation and traveling motion

Motorized trolley

nameplate

Connection Box

Cable Support Bar

Type and Names of Each Part Motorized Trolley Type (ER2M)

Relay Cable

Chain Container

Load Chain

1

Power Cable

Electric chain hoist

nameplate

Push Button

Switch Cord

Warning Tag

Cushion Rubber

(Chain spring and end plate for the

model of rated load of 2 t or more)

Bottom Hook

• Warning labels are affixed to each part other than above. Be sure to follow the instructions in the label.

Failure to comply with the contents of the label can result in serious bodily injury or death.

Mandatory

DANGER

Bottom Yoke

Hook latch

Push Button Switch

(to be continued)

9

Chapter 1 Handling the Product

Chain Container

Electric chain hoist

nameplate

Push Button Switch Cord

Warning Tag

Load Chain

Cushion Rubber

(Chain Spring and End Plate for the

model of rated load 2 t or more)

Hand Chain

Bottom Yoke

Hook Latch

Bottom Hook

Push Button Switch

Geard Trolley (TSG)

Bumper

Hand Wheel

Type and Names of Each Part (continued)

■Manual Trolley Type (ER2SG/ER2SP)

●

ER2SG : The electric chain hoist equipped with the geared trolley (TSG) enabling fine

adjustable lateral motion of the load by pulling the hand chain.

●

ER2SP : The electric chain hoist equipped with the plain trolley (TSP) enabling lateral motion by moving the

load manually. For light work.

Plain Trolley (TSP)

Nameplate

Type and Names of Each PartManual Trolley Type (ER2SG/ER2SP)

1

Bumper

Mandatory

DANGER

• Warning labels are affixed to each part other than above. Be sure to follow the instructions in the label.

Failure to comply with the contents of the label can result in serious bodily injury or death.

10

Opening the Package

■Checking the Product

●

Make sure that the indication on the package and the product coincide with your order.

●

Make sure that the product is not deformed and damaged due to the accident during transportation.

■Packaging

■Packaging

For the customer's convenience, the main parts of our product are packaged individually and delivered.

Electric chain hoist main

unit packaging

Equipped with

Top Hook

ER2

Equipped with

Connection Yoke

Accessory set

3-Push

Button

Switch set

Power

Cable set

Trolley packaging

TSP Plain Trolley

Applicable model

Hook Suspended

Model

Plain Trolley

Combined Model

Geared Trolley

Combined Model

Opening the Package Checking the Product / Packaging

1

ER2SP,

ER2SG

Equipped with

Suspender

ER2M

* Power Cable longer than 10 m is available as an optional part.

5-Push

Button

Switch set

Button

Switch set

TSG Geared Trolley

Model MR2

Motorized Trolley

■Parts packaged with the Electric Chain Hoist

Plastic or canvas

Chain Container (option)

Owner's Manual

Option

Power *

Cable

Power *

Cable

Load Chain

Grease Tube

Motorized Trolley

Type

Crane

Control Box7-Push

(to be continued)

11

Chapter 1 Handling the Product

Opening the Package (continued)

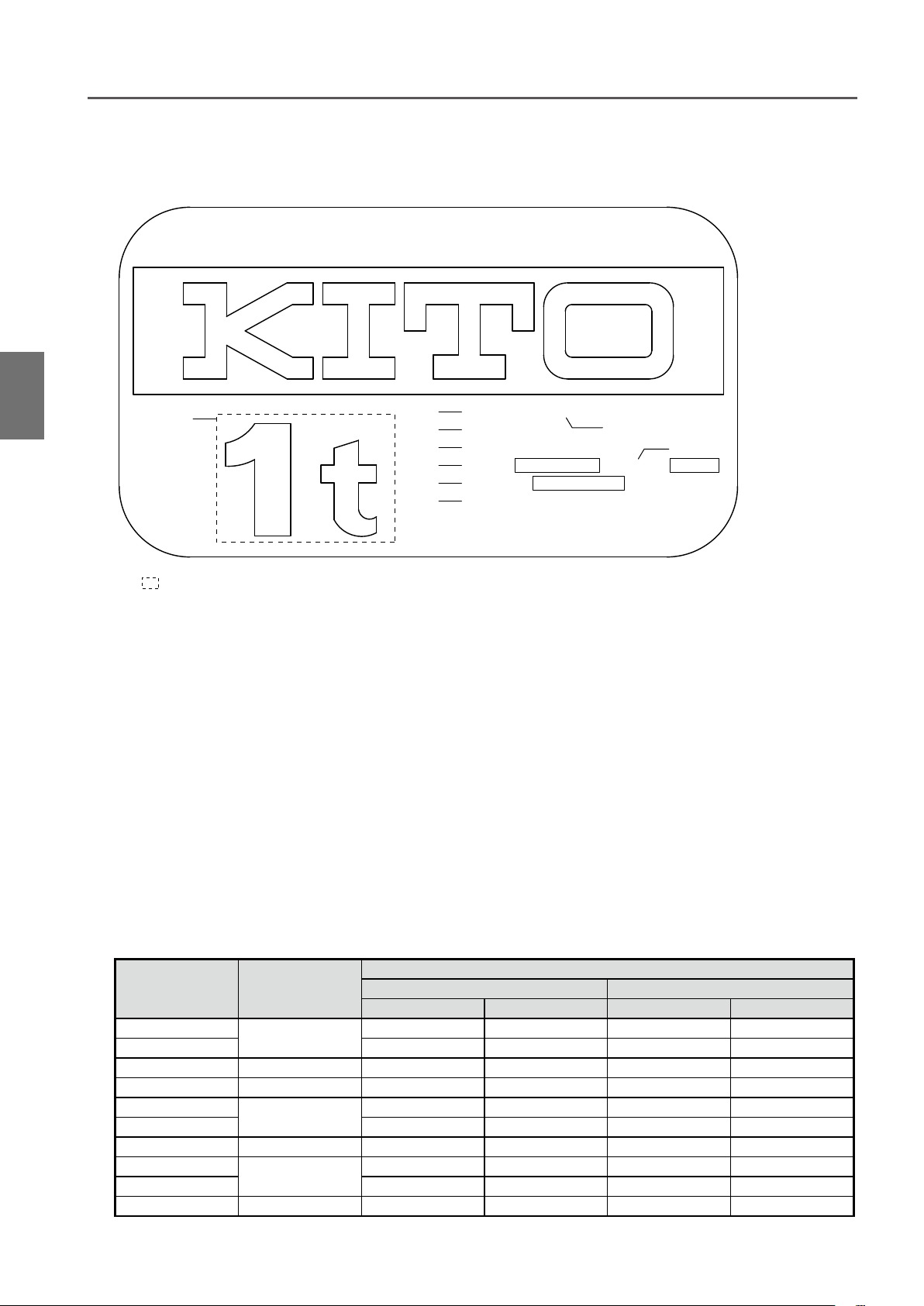

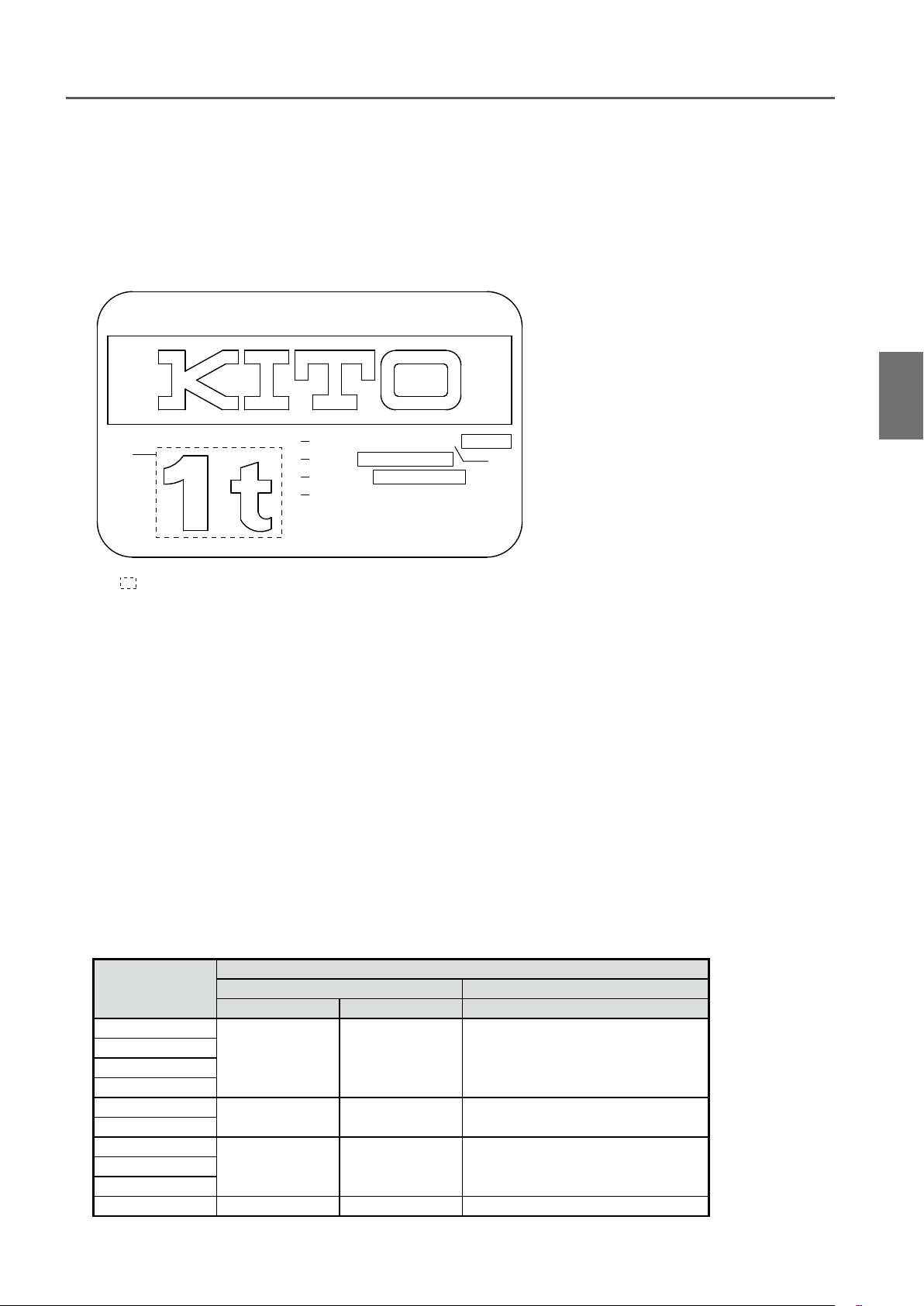

■Nameplate and Product Model

■Nameplate Indication of Electric Chain Hoist

Opening the PackageNameplate and Product Model

1

1

· · · Capacity Ex. 1t, 500kg

1

Th e maximu m mass of the lo ad that can be

imposed on the product. The mass of the hook is

excluded.

SIZE…Body size Ex. Body size C, ER2-C

2

Th e si z e of the electric chain hois t bo d y to

support the load. Five models of B, C, D, E and F

are provided.

GRADE Ex. M4, M5

3

The grade of an electric chain hoist specified by

ISO standard. A guidepost of durability.

CODE…Product model Ex. ER2-005S

4

A code to indicate the model No. of the product,

capacity and lifting speed.

CHAIN SIZE…Load Chain size

5

Ex. T-7.7×21.4mm

The alphabet and the figures indicate the JIS

2

4

5

6

8

9

SIZE: ER2-D GRADE: M5

CODE: ER2-010S

CHAIN SIZE: T-7.7×21.4mm

LOT No: MFG.YEAR

SERIAL No:

LIFTING SPEED: 0.118 m/min 50Hz

grade, wire diameter and chain pitch respectively.

LOT No.

6

Manufacture No. to identify the time of manufacture

and the production lot.

MFG. YEAR…Manufacture year

7

SERIAL No.

8

Serial number to indicate the manufacturing sequence

of the product.

LIFTING SPEED

9

Single speed model and dual speed VFD model

are provided. Variable speed range and its set

value are indicated for the dual speed VFD model.

3

: 0.142 m/min 60Hz

7

12

■Code of ER2

Capacity Body Size

125kg

250kg ER2-003S (ER2-003H)* ER2-003IS/SD (ER2-003IH/HD)*

500kg ER2-C ER2-005S ER2-005L ER2-005IS/SD ER2-005IL/LD

1t ER2-D ER2-010S ER2-010L ER2-010IS/SD ER2-010IL/LD

1.5t

2t ER2-020S ER2-020L ER2-020IS/SD ER2-020IL/LD

2.5t ER2-F ER2-025S — ER2-025IS/SD —

2.8t

3t ER2-030S — ER2-030IS/SD —

5t ER2-F ER2-050S — ER2-050IS/SD —

* Hight Speed Type

ER2-B

ER2-E

ER2-E

CODE

Single speed model Dual speed model

Standard speed Low speed Standard speed Low speed

— (ER2-001H)* — (ER2-001IH/HD)*

ER2-015S — ER2-015IS/SD

ER2-028S — ER2-028IS

■Nameplate Indication of Motorized Trolley

CODE: MR2-010S MFG.YEAR

1

· · · Capacity Ex. 1t, 500kg

1

The maximum mass of the load that can be imposed on the

product. The mass of the hook is excluded.

CODE · · · Product model Ex. MR2-010S

2

A code to indicate the model No. of the product, capacity and

traveling speed.

MFG. YEAR…Manufacture year

3

LOT No.

4

Manufacture No. to identify the time of manufacture and the

quantity of a production unit.

SERIAL No.

5

Serial number to indicate the manufacturing sequence of the

product.

TRAVELING SPEED

6

Single speed model and dual speed VFD model are provided.

Variable speed range and its set value are indicated for the

dual speed VFD model.

2

LOT No:

4

SERIAL No:

5

TRAVELING SPEED:

6

0.333 m/min 50Hz

0.400 m/min 60Hz

3

Opening the Package Nameplate and Product Model

1

■Code of MR2

Capacity

125kg

250kg

500kg

1t

1.5t

2t

2.5t

3t

5t MR2-050S MR2-050L MR2-050IS/SD

CODE

Single speed model Dual speed model

Standard speed Low speed Standard speed

MR2-010S MR2-010L MR2-010IS/SD

MR2-020S MR2-020L MR2-020IS/SD

MR2-030S MR2-030L MR2-030IS/SD2.8t

(to be continued)

13

Chapter 1 Handling the Product

Opening the Package (continued)

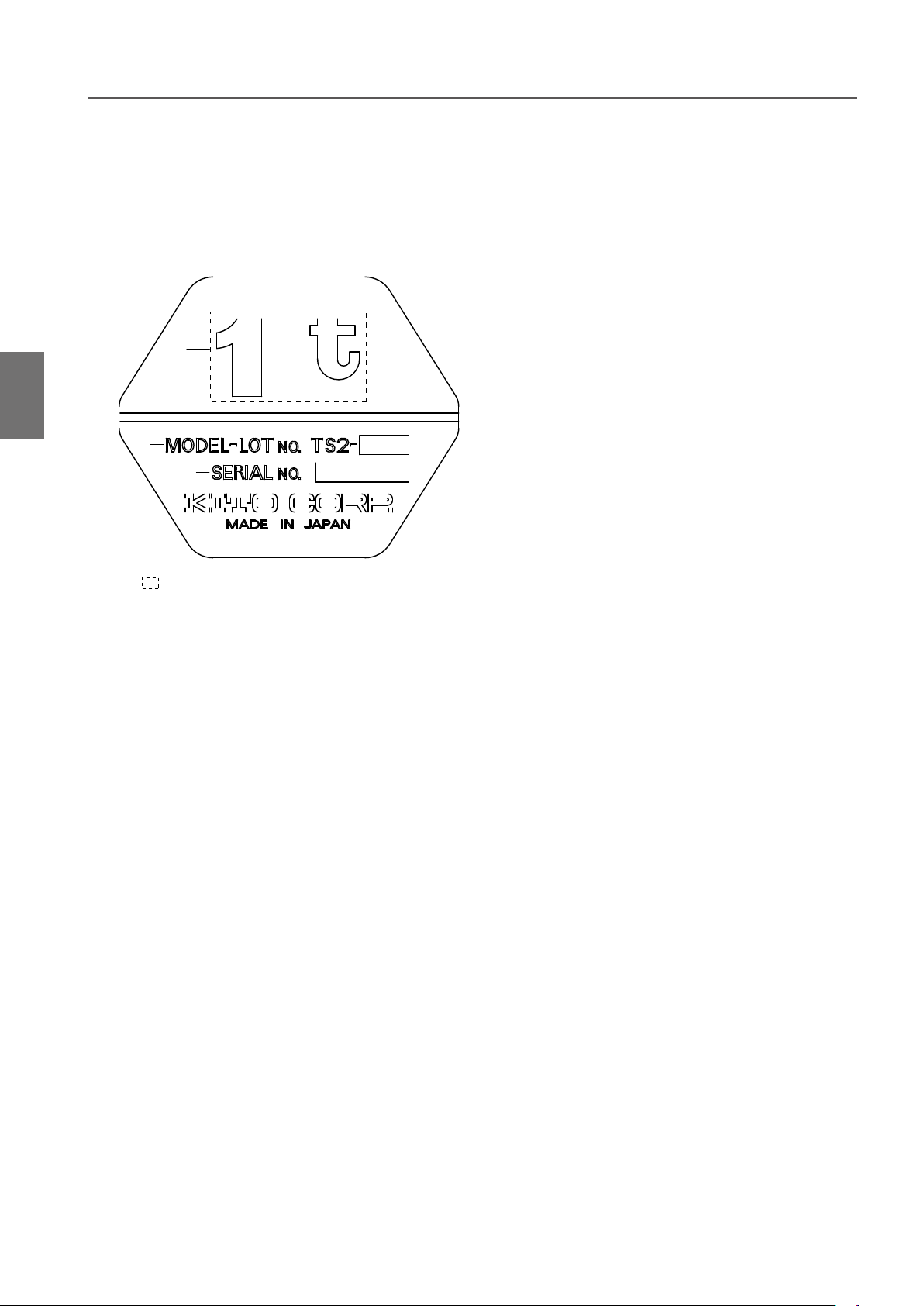

■Nameplate Indication of Manual Trolley

Opening the PackageNameplate and Product Model

1

1

2

3

· · · Capacity Ex. 1t, 500kg

1

The maximum mass of the load that can be imposed on the

product. The mass of the hook is excluded.

LOT No.

2

Manufacture No. to identify the time of manufacture and the

production lot.

SERIAL No.

3

Serial number to indicate the manufacturing sequence of the

product.

14

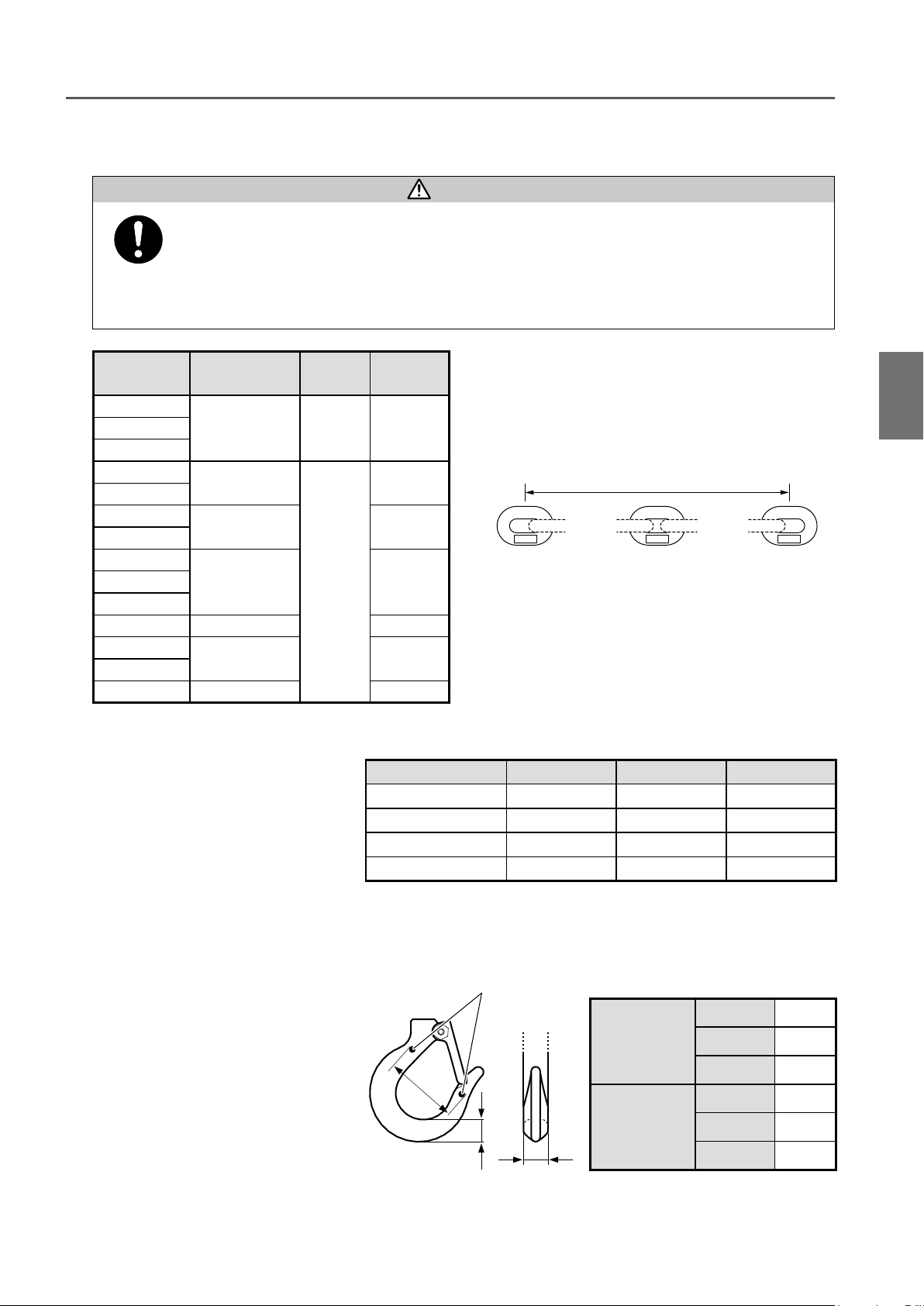

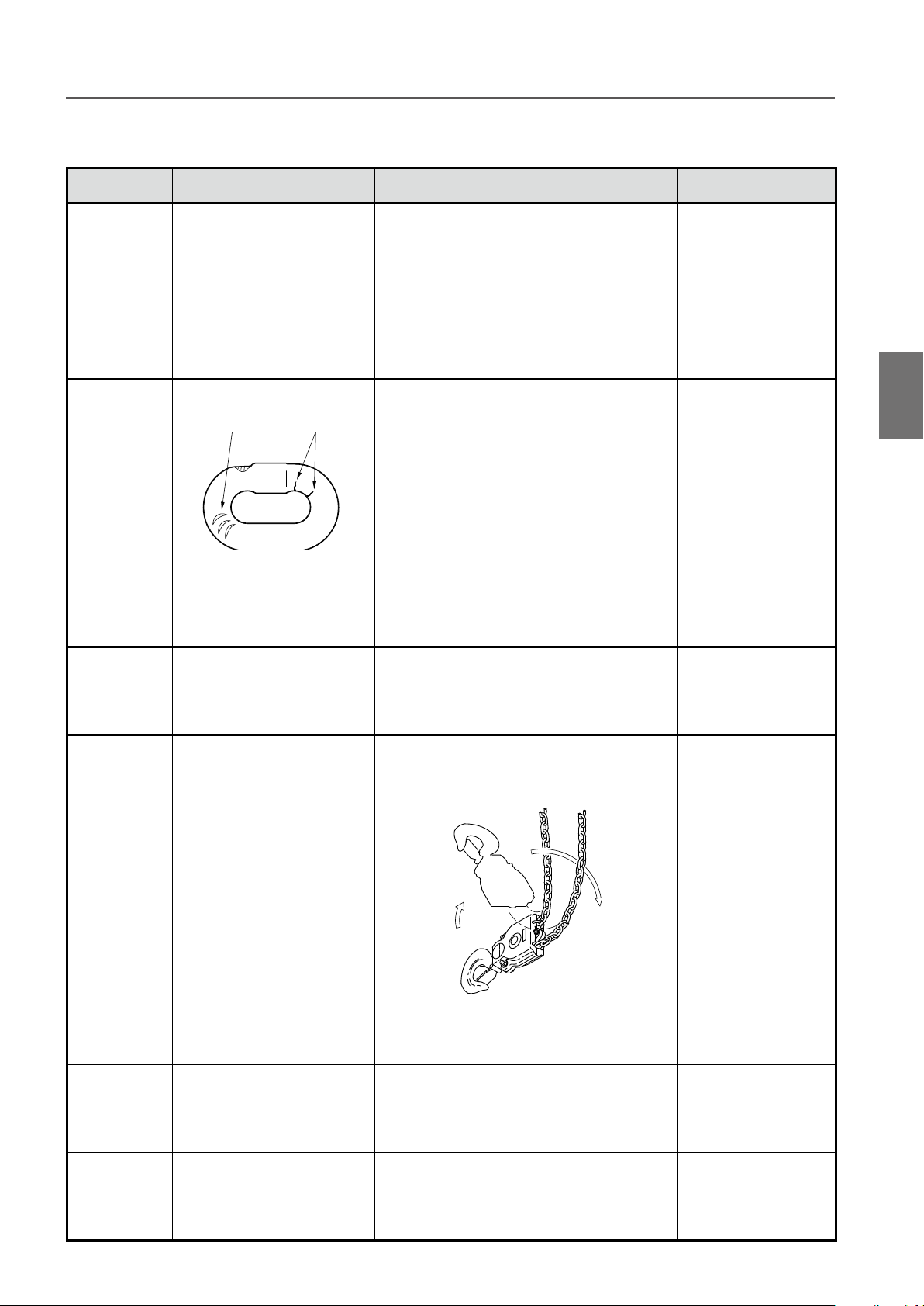

■Checking the Marks

• Be sure to check that the Load Chain has "RH-DAT " or "FT-DAT" mark on it and the chain size is

appropriate for the ER2 model you are using. (See the following table.) The Load Chain of other models

(such as model ES or ER) or different rating cannot be used.

Mandatory

Use of the Load Chain of other model or other rating may result in death or serious injury due to the drop of the lifted

load.

Opening the Package Checking the Marks / Recording the Product No. / Recording the Initial Value

DANGER

The mark (RH-DAT) to indicate the model of the Load

Chain is indicated on it at an equal spacing. Make sure

that the Load Chain is of a chain size (wire diameter)

appropriate for ER2 referring to the table in the left.

RH-DAT 0000 RH-DAT

Front side : RH-DAT

or

FT-DAT

Back side : H-23

Code

ER2-001H/IH/HD

ER2-003H/IH/HD

ER2-003S/IS/SD

ER2-005L/IL/LD

ER2-005S/IS/SD

ER2-010L/IL/LD

ER2-010S/IS/SD

ER2-015S/IS/SD

ER2-020L/IL/LD

ER2-020S/IS/SD

ER2-025S/IS/SD

ER2-028S/IS

ER2-030S/IS/SD

ER2-050S/IS/SD

Load Chain size :

diameter (mm)

4.3 FT-DAT 24 Links

6.0

7.7 20 Links

10.2 16 Links

11.2 12 Links

10.2 16 Links

11.2 12 Links

Mark Mark pitch

RH-DAT

20 Links

■Recording the Product No.

● Fill in the table in the right with

product's Lot No., Serial No.

(described in the product nameplate),

date of purchase and the name of the

sales shop where you purchased the

product.

* When requesting repair or ordering

a chain hoist part, please inform us of these pieces of information together.

Lot No.

Serial No.

Date of purchase

Name of the sales shop

Item

Electric chain hoist

1

Mark pitch

First markSecond mark Second mark

Front side : Original Lot No. of the

Load Chain (4 digits)

Back side : KITO

Motorized trolley Manual trolley

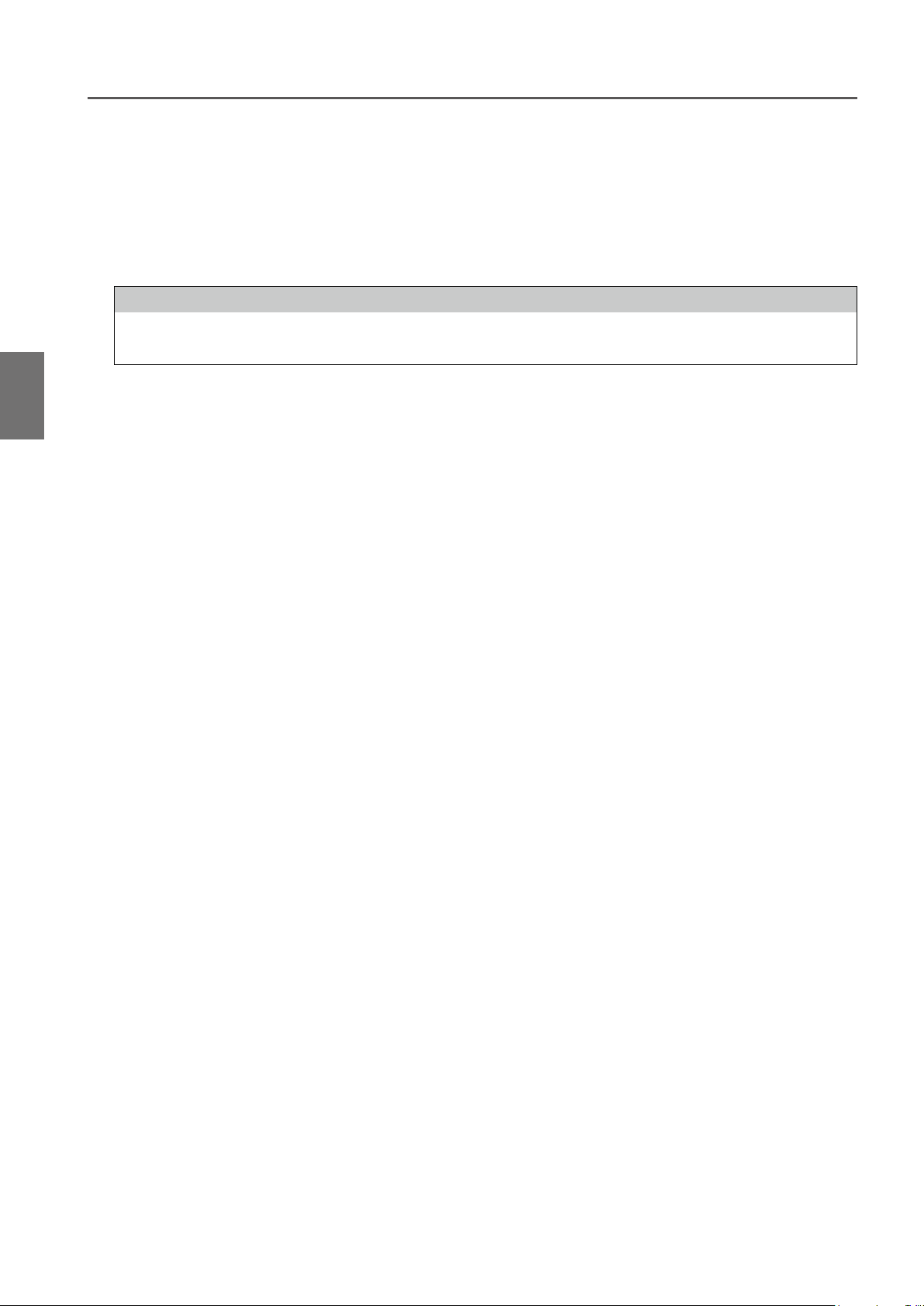

■Recording the Initial

Value

● When opening the package, fill in

the table in the right with the opening

dimension "a" between embossed

marks on the Bottom Hook, the width

of the hook "b" and the thickness of

the hook "c". (These values are used

for checking. Record the value for the

top hook of ER2 when it is used individually.)

Embossed marks

a

Dimensions when the package was opened

Dimension a

Top Hook

(For ER2 only)

c

b

Bottom Hook

Dimension b

Dimension c

Dimension a

Dimension b

Dimension c

mm

mm

mm

mm

mm

mm

15

1

Chapter 1 Handling the Product

Product Specification and Operational Environment

The operational environment of the electric chain hoist and motorized trolley is as follows:

■Standard Specification

Short time ratings : ER2 series(Capacity 100 %) : Single speed model — 60 min.

: MR2 series(Capacity 100 %) : Single speed model — 30 min.

Intermittent ratings : ER2 series(63 % of the capacity) : Single speed model — 60 % ED (at 360 rev/h)

: MR2 series(63 % of the capacity) : Single speed model — 40 % ED (at 240 rev/h)

Product Specication and Operational Environment

Grade * 1 : ISO-M6, M5 or M4, FEM-3m, 2m or 1Am, ASME-H4

Protection : Hoist IP55, Push button IP65

Operation Push button switch operation / 3-Push Button Switch set for hoist only and Manual trolley type / 5- or

7-Push Button Switch set for motorized trolley combined model

Power supply method....Power supply through cabtyre cable

Color...............................KITO Yellow (Equivalent to Munsell 7.2YR6.5/14.5)

Noise level : ER2, single speed 75dB or less (A scale: measured at 1 m away from the Electric chain hoist)

: ER2, dual speed VFD model 80dB or less (A scale: measured at 1 m away from the Electric chain hoist)

: MR2 85dB or less (A scale: measured at 1 m away from the Electric chain hoist)

Braking capacity : 150% of the capacity or more

Other...............................Power Cable length 5 m/10 m (Standard)

Dual speed VFD model (high speed/low speed) — 30/10 min.

Dual speed VFD model (high speed/low speed) — 30/10 min.

Dual speed VFD model (high speed/low speed) — 40/20 % ED

(120/240 rev/h)

Dual speed VFD model (high speed/low speed) — 27/13 % ED

(78/162 rev/h)

Product category

230V Class B

Standard Specication

400V Class F

500V Class B 500V 575V

230/460V Class B

• Operate the electric chain hoist with the rated voltage.

• Do not use the electric chain hoist exceeding the short time ratings and the intermittent ratings.

* Grade

Capacity (kg or t)

125 ER2-001H ER2-001HD

250

500

1

1.5 ER2-015S ER2-015IS/SD

2

2.5 ER2-025S ER2-025IS/SD

2.8 ER2-028S ER2-028IS

3 ER2-030S ER2-030IS/SD

5 ER2-050S ER2-050IS/SD

* For 125kg - 500kg dual speed VFD type equipped with friction clutch with mechanical brake, the grade is ISO M5

16

and FEM 2m.

Motor Insulation

Class

Voltage range

50Hz 60Hz

220V 220V

230V 230V

380V 380V

400V 440V

415V —

208-230V

415-460V

Operating

Voltage

24V

(24V~26.4V)

110V

(110V~121V)

NOTE

Code GRADE Code GRADE

Single speed Dual speed ISO ASME FEM Dual speed ISO ASME FEM

ER2-001IH

ER2-003H ER2-003HD ER2-003IH

ER2-003S ER2-003SD ER2-003IS

ER2-005L ER2-005LD ER2-005IL

ER2-005S ER2-005SD ER2-005IS

ER2-010L ER2-010IL/LD

ER2-010S ER2-010IS/SD

ER2-020L ER2-020IL/LD

ER2-020S ER2-020IS/SD

M5 H4 2m

M4 H4 1Am

M6 H4 3m

●

ISO

ISO 4301 specifies the total operating hour (service life) of gears and bearings according to the loading status. For

example, the total operating hour (service life) of the mechanism when it is constantly applied with the capacity is

1,600 hours for M5. The total operating hour is 6,300 hours when operated with a medium load.

Product Specication and Operational Environment

Loading status

Light M4 M5 M6

Medium M4 M5 M6

Heavy M4 M5 M6

Ultra heavy M4 M5 M6

* Rate of loading

Light : A case where the capacity is rarely applied. Usually the hoist is used with a light load.

Medium : A case where the capacity is applied considerably frequently. Usually the hoist is used with a medium

Heavy : A case where the capacity is applied considerably frequently. Usually the hoist is used with a heavy load.

Ultra heavy : A case where the capacity is applied constantly.

●

ASME HST

Hoist duty class Typical areas of application

H2

H3

H4

• The grade symbols are identical to those of ASME HST-1M. (Performance standard for Electric Chain Hoist)

*

load.

Light machine shop fabricating,

service,and maintenance; loads and

utilization randomly distributed; capacitys

infrequently handled.

General machine shop fabricating,

assembly, storage, and warehousing;

loads and utilization randomly distributed.

High volume handing in steel warehouses,

machine shops, fabricationg plants and

mills, and foundries; manual or automatic

cycling operations in heat treating

and plating; loads at or near capacity

frequently handled.

800 1600 3200 6300 12500 25000

Total operating hour h

Operation time ratings at K=0.65

Unlformly distributed

work periods

Max. on

time, min / hr

7.6 (12.5%) 75 15 100

15 (25%) 150 30 200

30 (50%) 300 30 300

Max. No.

starts / hr

Max. on time from

cold start, min

work periods

Infrequent

Max. No.

of starts

1

Standard Specication

●

FEM

Relation between ISO-and FEM-Denominations

1 Dm 1 Cm 1 Bm 1 Am 2 m 3 m 4 m 5 m

M 1 M 2 M 3 M 4 M 5 M 6 M 7 M 8

Class of operation time

Load

spectrum

1 L1 K

2 L2 0.50<K

3 L3 0.63<K

4 L4 0.80<K

• The grade symbols are identical to those of FEM 9.511.

(Rules for Design of Serial Lifting Equipment: Classification of Mechanisms)

Cubic

mean value

V0.06 V0.02 V0.25 V0.5 V1 V2 V3 V4 V5

T0 T1 T2 T3 T4 T5 T6 T7 T8

Average operation time per day in hours

0.12 0.25 0.5 1 2 4 8 16>16

0.50 – – 1 Dm 1 Cm 1 Bm 1 Am 2 m 3 m 4 m

0.63 – 1 Dm 1 Cm 1 Bm 1 Am 2 m 3 m 4 m 5 m

0.80 1 Dm 1 Cm 1 Bm 1 Am 2 m 3 m 4 m 5 m –

1.00 1 Cm 1 Bm 1 Am 2 m 3 m 4 m 5 m – –

Class of

operating

time

V0.06 T0 0.12 200

V0.12 T1

V0.25 T2

V0.5 T3

V1 T4

V2 T5

V3 T6

V4 T7

V5 T8 >16 50,000

Average

operating

time per day

(in hours)

0.25 400

0.5 800

Calculated

total operating

time

(in hours)

1 1,600

2 3,200

4 6,300

8 12,500

16 25,000

(to be continued)

17

Chapter 1 Handling the Product

Product Specification and Operational Environment (continued)

■Operational Environment

Ambient temperature : -20°C — +40°C

Gradient of rail : No gradient in travel rail (for the hoist with trolley)

Ambient humidity : 85 % or less (no condensation)

Explosion-proof construction : Not applicable to the work environment with explosive gases or explosive vapor

Non-conforming environment : A place with organic solvent or volatile powder, and a place with a plenty of powder

and dust of general substances

: A place with considerable amount of acids and salts

NOTE

Product Specication and Operational Environment

When installing the electric chain hoist outdoors or to the place where the hoist is exposed to direct rain, wind and

snow, shade the hoist with roof to protect it from rain, wind and snow.

1

Operational Environment

18

How to Use

ER2 Series Electric Chain Hoist has two models: single speed model and dual speed VFD model. Other than them,

such products are provided that can travel/traverse when combined with a trolley or a crane. Their push button switches

for operation differ in the size and the operating method. Check the product model of the hoist and use it properly.

Prohibited

Mandatory

Prohibited

DANGER

• Do not use the Hook without a Hook Latch or damaged Hook.

• Do not use the Load Chain with heavy elongation, abrasion or deformation.

• Do not cut, extend, or weld the Load Chain.

• Do not use the Load Chain with the Bottom Hook without smooth motion.

• Do not use the Load Chain when its brake does not function securely even without load, or when the

stopping distance is too long.

• Do not use the product if it moves oppositely to the direction indicated on the push button switch.

Failure to comply with these instructions may result in death or serious injury.

• Carry out daily inspection before operation.

(When any abnormality was found during inspection, turn off the power, indicate “FAILURE" and ask the maintenance

engineer for repair.)

• Check the slinging devices for no abnormality.

Failure to comply with these instructions may result in death or serious injury.

CAUTION

• Do not use the product with an illegible nameplate or warning label affixed to the body size.

Failure to this instruction may result in the injury or the property damage.

How to Use

1

Mandatory

• When using the product for the first time, affix the labels indicating East, West, North and South on the push

button switches.

• Check the contents of the work and make sure that the electric chain hoist has proper performance for the load

and lift.

• Check the contents of the work and operate the electric chain hoist at a place enabling to look out the operating

area without hindrance.

• When looking out the operating area is difficult, arrange the monitor near the place for safety.

• Operate the electric chain hoist at a place with firm foothold without danger of falling, stumbling, slipping or

over turning.

• Before moving the load, warn all the surrounding people.

• Even if the crane or the electric chain hoist is permanently installed and used for the same purpose repeatedly,

check the contents of the work and make sure that the work does not exceed the capacity on each occasion.

• Appoint the maintenance engineer or competent personnel among the qualified personnel for operation of

cranes and electric chain hoists. Indicate the name of the personnel on a place with legibility.

• The maintenance engineers shall check the result of daily inspection.

• When informed of abnormality of the electric chain hoist, the maintenance engineers shall take immediately

any necessary measures such as prohibition of use and repair.

• When carrying out inspection and repair, secure the environment for safe work without electric shock and

falling.

Failure to comply with these instructions may result in bodily injury or property damage.

(to be continued)

19

Chapter 1 Handling the Product

Body

Fan cover

Motor frame

Gear case

Controller cover

How to use (continued)

■Daily Inspection of Electric Chain Hoist (Hook Suspended Type)

DANGER

• Carry out daily inspection before use.

(When any abnormality was found during inspection, turn off the power, indicate “FAILURE" and ask the maintenance

Mandatory

engineer for repair.)

Neglecting to carry out daily inspection may result in death or serious injury.

1

How to UseDaily Inspection of Electric Chain Hoist (Hook Suspended Type)

Refer to the technical material attached in Appendix (P122) for the structure of the product and the name

●

of each part.

■Appearance

Item Check method Criteria When failed

Indication of

nameplates

and labels

Deformation

and damage

of body size

and each part

• Check visually. • No peel off. Indication can be seen clearly.

• Check visually. • Noapparentdeformation,damage,awand

crack

Carry out cleaning, repair

or replace with new

nameplate or label.

When replacing with a

new nameplate or label

is required, please inform

KITO of the description

in “Record of the Product

No." (P17) such as Lot

No. and Serial No.

Replace the parts with

deformation, damage,

flaw or crack.

20

Loosened

or fallen off

bolts, nuts

and split pins

• Check visually or using

tools.

• Bolts, nuts and split pins are fastened

securely.

DANGER

• Even fallen off of a bolt causes

for the body size to drop. Be

Mandatory

sure to check.

Fallen off of a bolt may result in death

or serious injury.

Fasten bolts, nuts and

split pins securely.

■Load Chain

Item Check method Criteria When failed

Elongation of

Pitch

Abrasion

of Wire

Diameter

Deformation,

Flaw,

Entanglement

Rust,

Corrosion

• Check visually • No apparent elongation Refer to Load Chain

(P69) of Chapter 2,

Frequent inspection.

• Check visually • No apparent abrasion Refer to Load Chain

(P69) of Chapter 2,

Frequent inspection.

• Check visually

Flaw

• Check visually for no foreign

matter such as attached

sputter.

• Check visually • No apparent rust and corrosion Replace the Load

Crack

• No deep notch

• No deformation such as twist

• No attached sputter

• No entanglement

• No crack

Replace the Load

Chain.

Chain.

How to Use Daily Inspection of Electric Chain Hoist (Hook Suspended Type)

1

Twist • Check visually • No capsized link at Bottom Hook of double

type Load Chain

Lubrication • Check visually • To be oiled adequately Apply oil.

Mark • Check visually • Check the mark pitch and the indication. (Refer

to “Checking the Marks" (P17).)

Untwist the Load

Chain.

Replace the Load

Chain.

(to be continued)

21

Chapter 1 Handling the Product

How to use (continued)

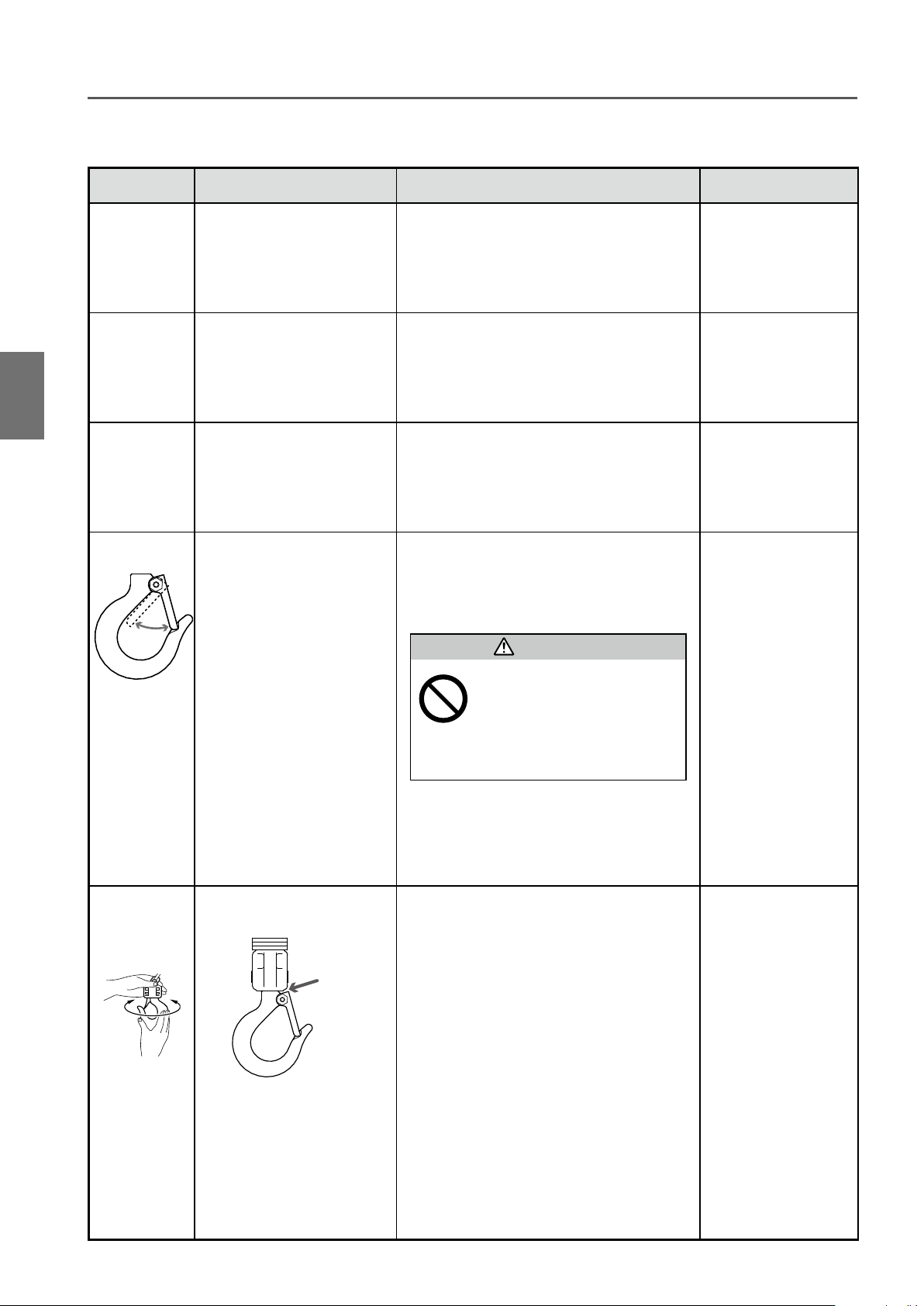

■Top Hook/Bottom Hook

Item Check method Criteria When failed

1

How to UseDaily Inspection of Electric Chain Hoist (Hook Suspended Type)

Opening of

the Hook

Abrasion • Check visually • No apparent abrasion

Deformation,

Flaw,

Corrosion

Hook Latch • Check visually and check

• Check visually • No apparent opening of the Hook

• Check visually • Noapparentdeformation,awandcorrosion

• The Hook Latch is mounted securely inside

the movement of the Hook

Latch.

the Hook opening.

• No deformation. The Hook Latch moves

smoothly.

DANGER

Carry out the

inspection item of Top

and Bottom Hook (P70)

of Frequent inspection.

Carry out the

inspection item of Top

and Bottom Hook (P70)

of Frequent inspection.

Carry out the

inspection item of Top

and Bottom Hook (P70)

of Frequent inspection.

Replace the Hook

Latch.

Hook

movement

(Rotation)

• Check visually and rotate

the Hook by hand.

Neck

• Do not use the Hook without

the Hook Latch.

Prohibited

• No apparent gap between the Bottom Yoke

and the shank (at the neck).

• The Bottom Yoke rotates in both directions

equally.

• The Bottom Yoke rotates smoothly.

Use of the Hook without the Hook

Latch may result in death or serious

injury.

Replace the Hook.

22

Item Check method Criteria When failed

Movement

of the Idle

Sheave

Bottom Yoke • Check visually. • No loosened bolt or nut

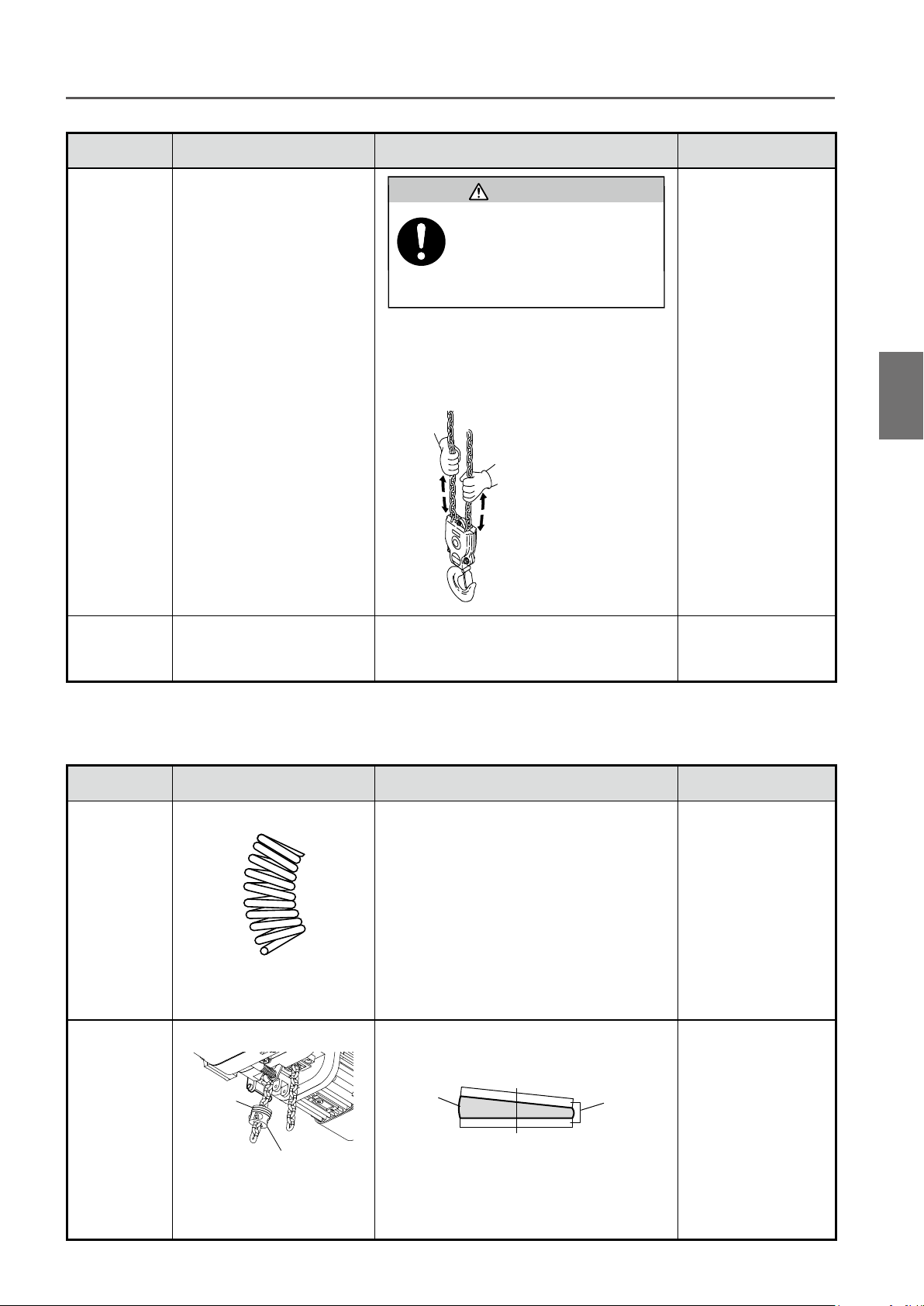

• Check the Idle Sheave by

moving

CAUTION

• When chec king, wear gloves

and be careful for your finger

Mandatory

• The Idle Sheave rotates smoothly.

* The Idle Sheave does not rotate smoothly

when bearing is damaged or sheave shaft is

deformed.

• The Load Chain moves smoothly.

not to be caught.

Otherwise it may result in injury.

Move the Load Chain

by hand.

Replace the bearing of

the Idle Sheave.

How to Use Daily Inspection of Electric Chain Hoist (Hook Suspended Type)

1

Attach the Bottom Hook to

the Load Chain securely.

■Peripheral parts of the body size

Item Check method Criteria When failed

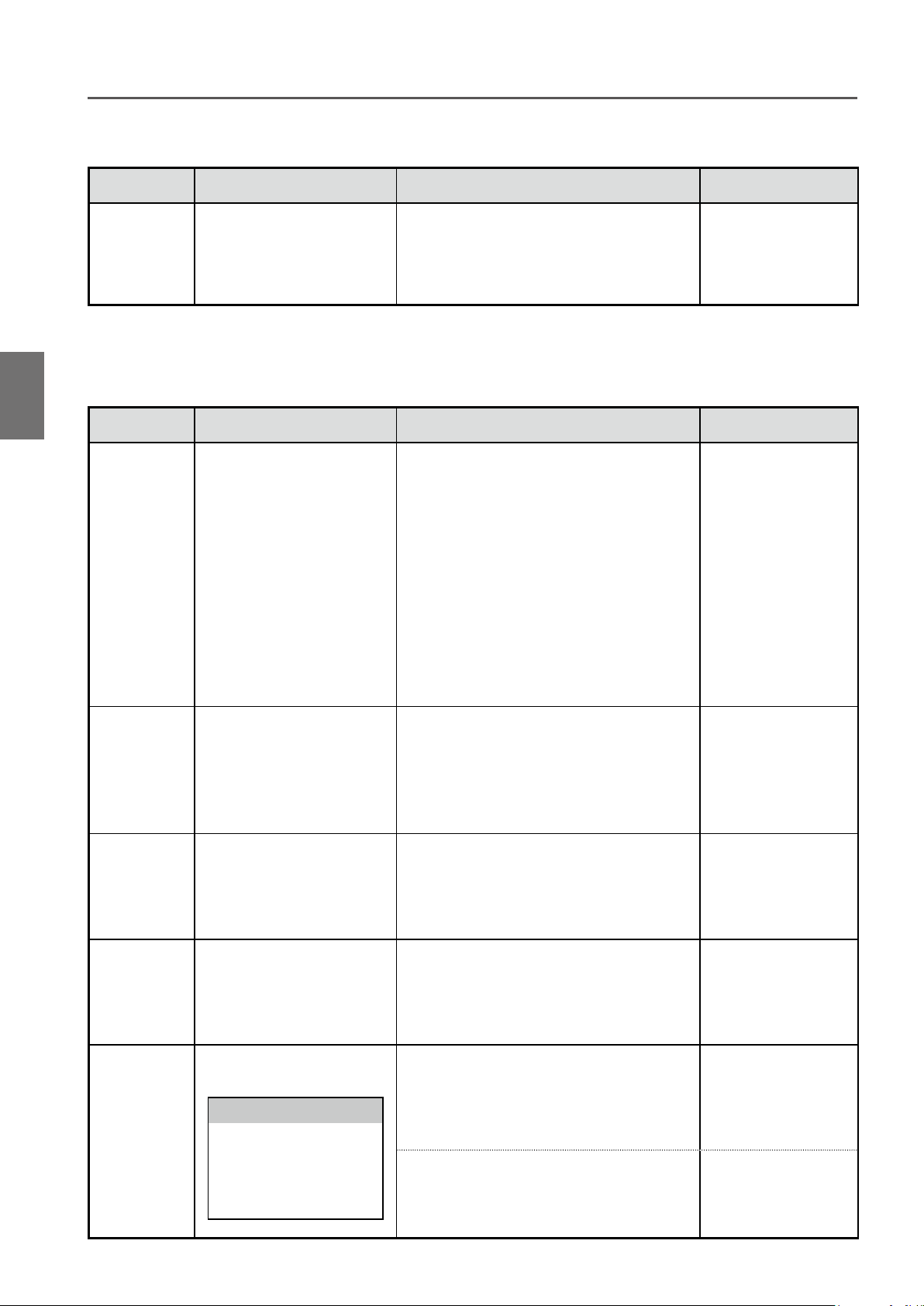

Chain Spring • Check visually • No apparent shrinkage or compression Carry out the

inspection item of

Chain Spring (P77) of

Periodic inspection.

Cushion

Rubber

• Check visually

Cushion

Rubber

Stopper

• No apparent shrinkage or compression

• No peel off, crack of deformation of rubber

Rubber

Steel plate

Replace the Cushion

Rubber.

(to be continued)

23

Chapter 1 Handling the Product

How to use (continued)

■Push Button Switch

Item Check method Criteria When failed

1

How to UseDaily Inspection of Electric Chain Hoist (Hook Suspended Type)

Switch body

size

• Check visually • No deformation, damage and no loosened

screw

• Label indication of the push button switch can

be seen clearly.

Clean and repair the

label or replace with

a new label. Affix the

label securely.

■Function and Performance

Check the following item with no load.

●

Item Check method Criteria When failed

Operational

Check

• Press the push button and

check each operation.

• The Load Chain can be wound smoothly.

• The Electric chain hoist moves in the same

direction as that of the push button operation.

• When the operation is stopped, the motor

stops immediately.

• When the Emergency Stop Button is pressed,

all hoist motions stop.

• When operating other push button while the

Emergency Stop Button is pressed, the hoist

does not start operation.

• When canceling the Emergency Stop Button,

the hoist operates normally.

Refer to Chapter 3

“Guidance on

Troubleshooting" (P94

to 97).

Brake • Press the push button and

check the operation of the

Brake.

Friction

Clutch with

Mechanical

Brake

Limit Switch • Press the push button and

Check for no

Abnormal

Sound

• Press the push button and

check the operation of the

Friction Clutch.

check the operation of the

Limit Switch.

• Press the push button and

check the operation.

NOTE

Sound is also an important

che c k point. A l w a y s be

careful for the noise of the

electric chain hoist.

• When stopping the operation, the Brake is

applied immediately and the Bottom Hook

shall stop immediately.

(Guideline: The travel of the Load Chain is

within 2 to 3 links.)

• When lifting, the sound of pawl clicks regularly.

(Forthefrictionclutchofstandardspecication

makes no pawl sound.)

• When the hoist is operated to the upper or

lower limit, the motor automatically stops.

• No abnormal sounds and vibrations Replace the abnormal

• No popping sound from the Load Chain. Check the Load Chain.

Carry out the inspection in

accordance with the items

in Chapter 2 “Periodic

inspection" Electromagnetic

Brake (P79).

Disassemble the

Friction Clutch and to

check.

Replace the Limit Switch.

Disassemble the actuator

of the Limit Switch to

clean.

part.

Apply oil on the Load

Chain.

(Refer to P21.)

24

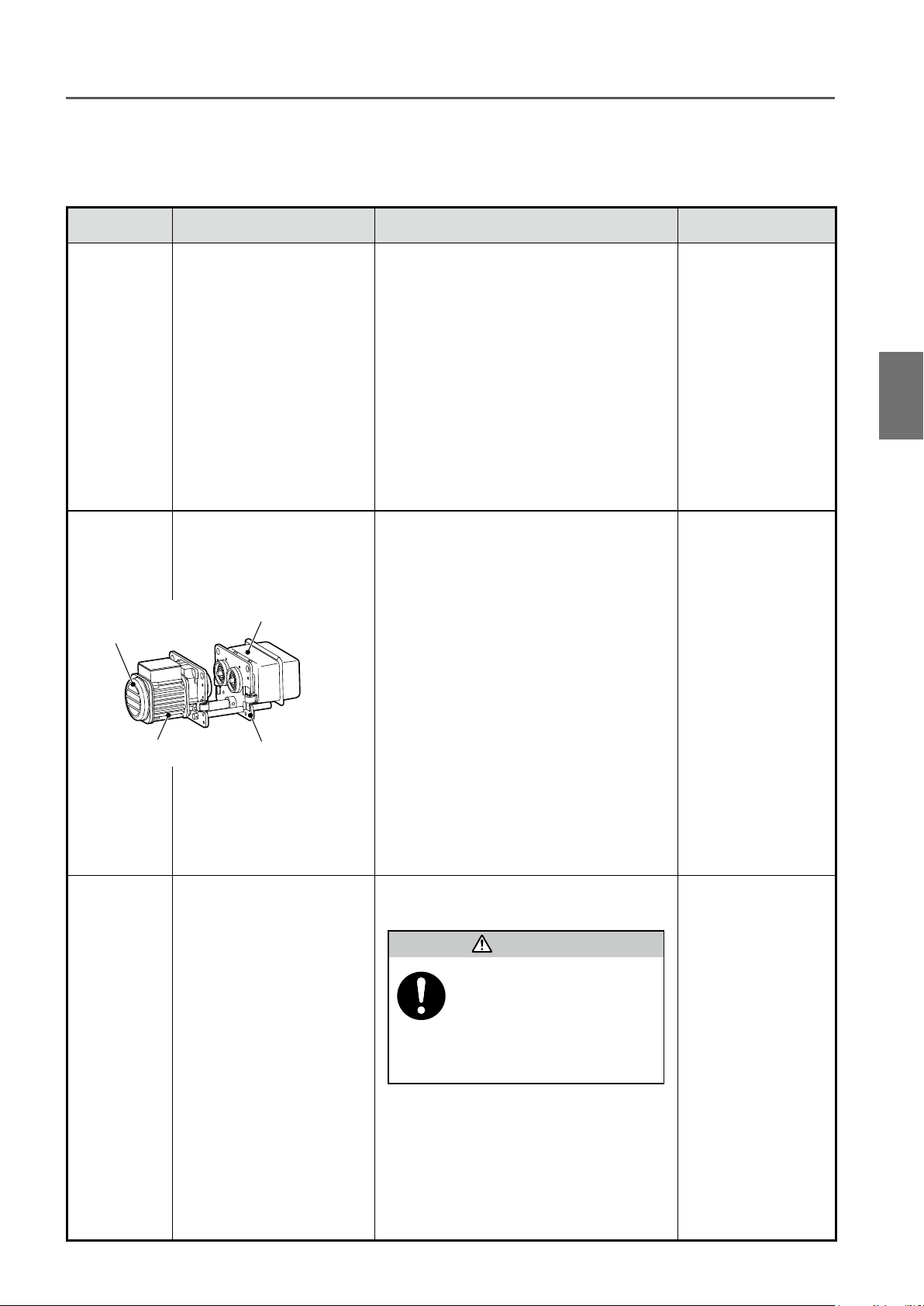

■Daily Inspection of Motorized Trolley (MR2)

■Appearance

Item Check method Criteria When failed

Indication of

Nameplates

and Labels

Deformation

and damage

of each part

Motor cover

• Check visually • No peel off. Indication can be seen clearly. Clean and repair the

label or replace with a

new label.

• Check visually • No apparent deformation, damage and

corrosion

Connection Box

Replace the deformed

or damaged part.

How to Use Daily Inspection of Motorized Trolley (MR2)

1

Loosened

or fallen off

bolts, nuts

and split pins

FrameMotor frame

• Check visually or using

tools.

• Bolts, nuts and split pins are fastened

securely.

DANGER

• Even a drop off of a split pin

may cause of drop of the body

Mandatory

size. Be sure to check it.

Drop off of split pin may result in death

or serious injury.

Fasten bolts, nuts and

split pins securely.

(to be continued)

25

Chapter 1 Handling the Product

How to use (continued)

■Function and Performance

Check the following item with no load.

●

Item Check method Criteria When failed

How to Use

1

Operational

Check

Brake • Press the push button to

• Press the push button to

check the operation.

check the operation of the

Brake.

• To travel smoothly. No meandering and

vibration.

• The electric chain hoist moves in the same

direction as that of the push button operation.

• When the operation is stopped, the motor

stops immediately.

• When the Emergency Stop Button is pressed,

all hoist motions stop.

• When operating other push button while the

Emergency Stop Button is pressed, the hoist

does not start operation.

• When canceling the Emergency Stop Button,

the hoist operates normally.

• When the operation is stopped, the Brake is

applied and the motor stops immediately.

■Daily Inspection of Manual Trolley (TSG/TSP)

Refer to Chapter 3

“Guidance on

Troubleshooting" (P94

to 97).

Carry out the inspection

in accordance with the

items in Chapter 2

“Periodic inspection"

Electromagnetic Brake

(P84).

■Appearance

Item Check method Criteria When failed

Indication of

Nameplates

and Labels

Deformation

and damage

of each part

Loosened

or fallen off

bolts, nuts

and split pins

Daily Inspection of Motorized Trolley (MR2) / Daily Inspection of Manual Trolley (TSG/TSP)

• Check visually • No peel off. Indication can be seen clearly. Clean and repair the

label or replace with a

new label.

• Check visually • No apparent deformation and corrosion

• No apparent deformation on the Frame

• Check visually or using

tools.

• Bolts, nuts and split pins are fastened

securely.

Replace the deformed

or damaged part.

Fasten bolts, nuts and

split pins securely.

DANGER

• Even a drop off of a split pin

may cause of drop of the body

Mandatory

size. Be sure to check it.

Drop off of split pin may result in death

or serious injury.

26

■Function and Performance

Check the following item with no load.

●

Item Check method Criteria When failed

Operational

Check

• Check the traveling motion

of the electric chain hoist by

moving it manually.

• To travel smoothly. No meandering and

vibration.

Carry out Chapter 2

"Periodic inspection".

How to Use Daily Inspection of Manual Trolley (TSG/TSP)

1

(to be continued)

27

Chapter 1 Handling the Product

How to use (continued)

■How to Operate the Push Button Switches

CAUTION

• Do not hang the Push Button Switch Cord on other object, or pull the cord strongly.

• Do not use the Push Button Switch if its button does not operate smoothly.

Prohibited

• Do not bundle or tie the cord for the adjustment of its length.

Failure to comply with this instruction causes bodily injury or loss of property.

How to UseHow to Operate the Push Button Switches

Mandatory

• When taking hand off the Push Button Switch after operation, do not throw it. Be careful not to hit other

worker with the Push Button Switch.

Failure to comply with this instruction causes bodily injury or loss of property.

1

If the Electric chain hoist is tripped due to overheat of the VFD, the VFD cannot be reset soon after the trip. Reset the VFD

after a while.

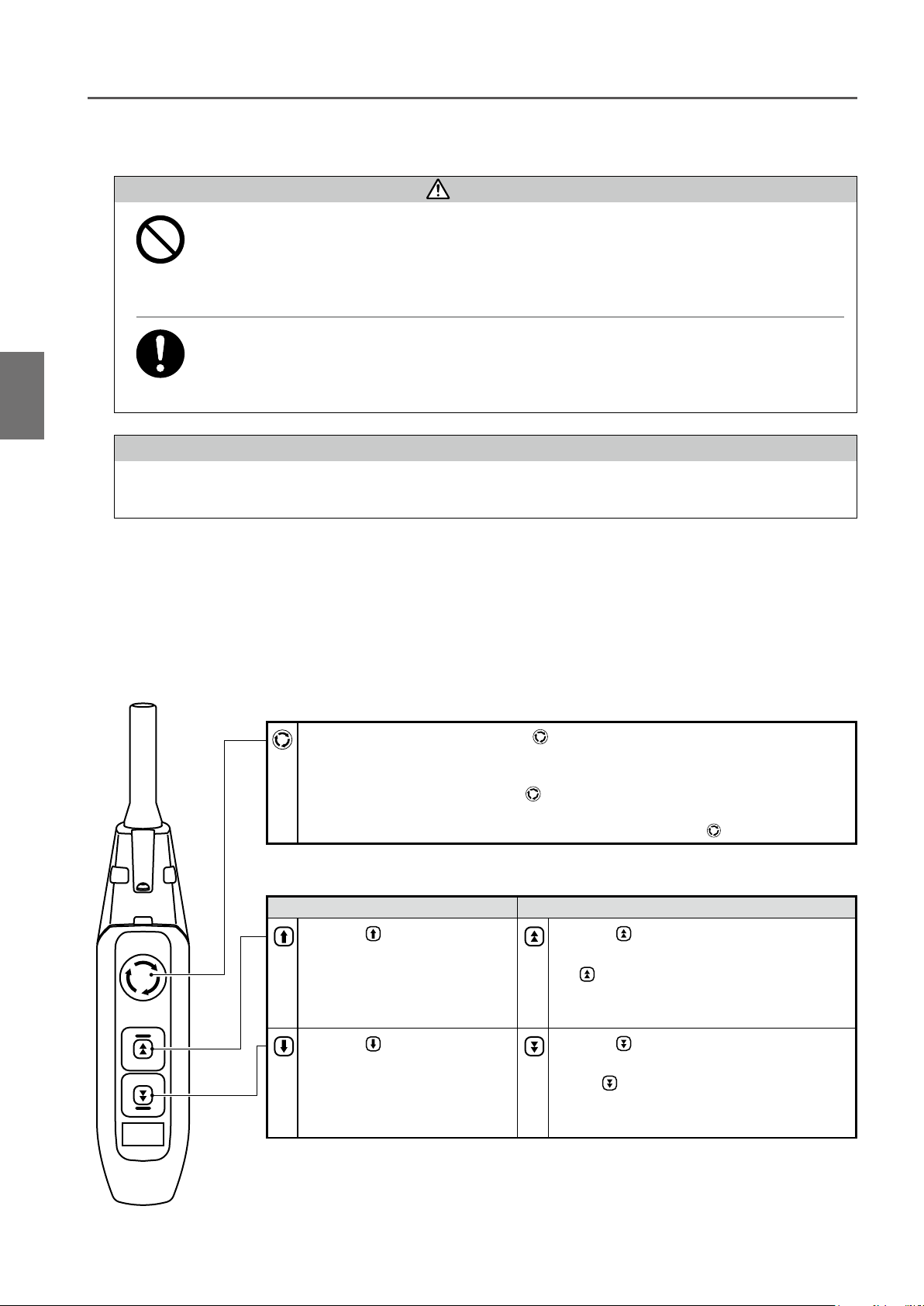

■3-Push Button Switch Set

3-Push Button Switch Set is equipped with a lock type emergency stop button (VFD reset button) and lift/lower push

buttons. One-step push button switch or two-step push button switch is mounted as Lift/lower push button switches

in accordance with the specification of single speed or dual speed VFD specification. Refer to the operation method

of the corresponding specification.

●

Emergency Stop Button (VFD Reset Button)

1) Press the Emergency Stop Button deeply when carrying out an emergency stop or

VFD reset.

• The button is locked at the pressed end.

2) Turn the Emergency Stop Button clockwise to cancel the lock.

• Press-locked button returns to the original position.

* When the electric chain hoist is not used, press the Emergency Stop Button

NOTE

deeply to the end.

28

●

Operation Button

● Lift/Lower Button

Single Speed Model Dual Speed VFD Model

1) Press button to lift the

load.

• The electric chain hoist stops

when the button is released.

1) Press button to lower the

load.

• The electric chain hoist stops

when the button is released.

1) Press button to lift the load.

2) When lifting the load at high speed, press the

button further to the end.

• The electric chain hoist stops when the button is

released.

1) Press button to lower the load.

2) When lowering the load at high speed, press

the

button further to the end.

• The electric chain hoist stops when the button is

released.

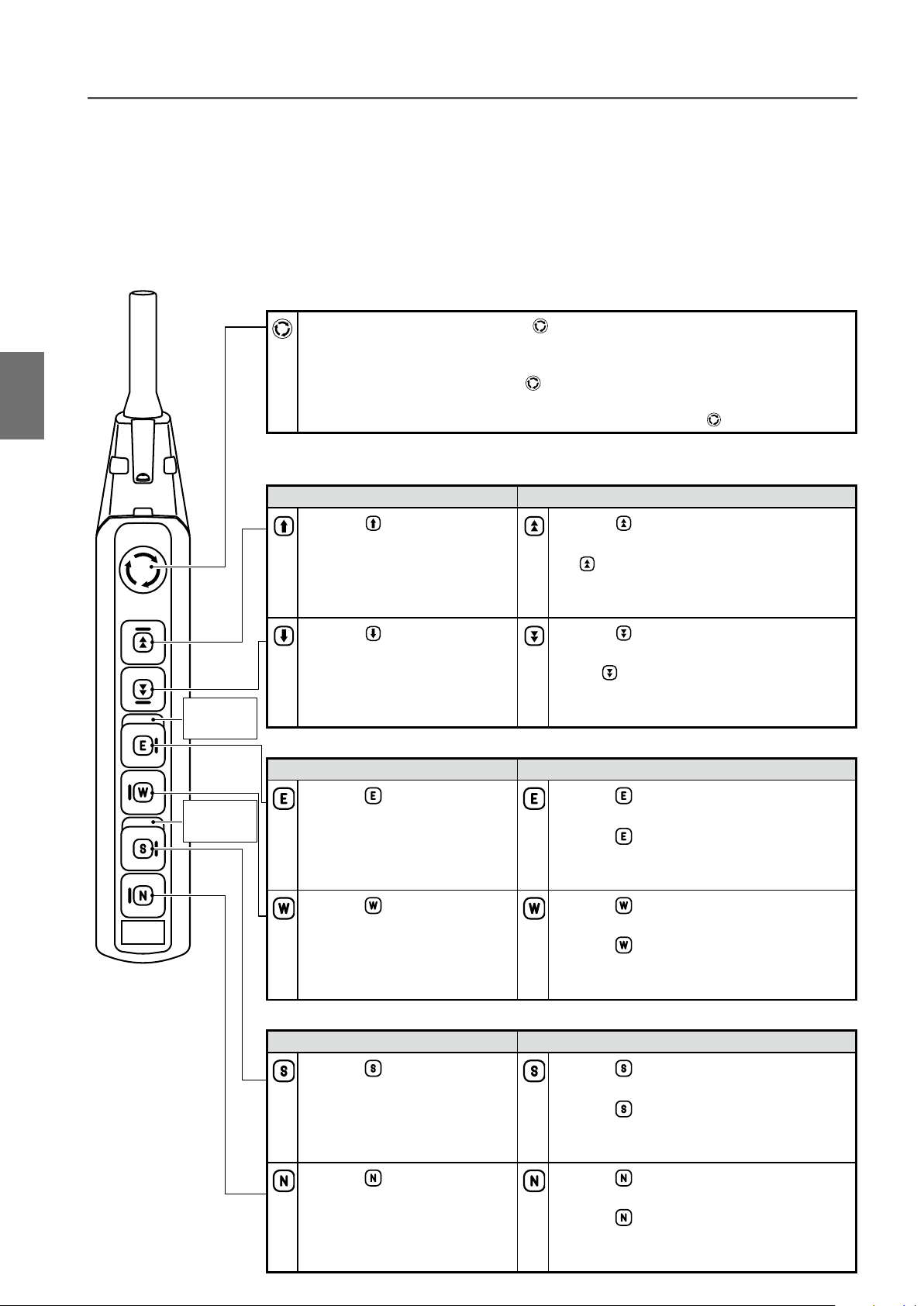

■5-Push Button Switch Set

5-Push Button Switch Set is equipped with a lock type emergency stop button (VFD reset button) and lift/lower push

buttons. One-step push button switch or two-step push button switch is mounted as Lift/lower push button switches

in accordance with the specification of single speed or dual speed VFD specification. Refer to the operation method

of the corresponding specification.

Moving direction of the trolley is expressed as East/West for traveling motion in the operational instruction of the

Push Button Switch Set.

●

Emergency Stop Button (VFD Reset Button)

1) Press the Emergency Stop Button deeply when carrying out an emergency stop or

VFD reset.

• The button is locked at the pressed end.

2) Turn the Emergency Stop Button clockwise to cancel the lock.

• Press-locked button returns to the original position.

* When the electric chain hoist is not used, press the Emergency Stop Button

●

Operation Button

● Lift/Lower Button

Single Speed Model Dual Speed VFD Model

deeply to the end.

How to Use How to Operate the Push Button Switches

1

Dual

No label for the

single speed

model

1) Press button to lift the

load.

• The electric chain hoist stops

when the button is released.

1) Press button to lower the

load.

• The electric chain hoist stops

when the button is released.

● Travel Button

Single Speed Model Dual Speed VFD Model

1) Press button to move the

trolley to the east.

• The trolley stops when the

button is released.

1) Press button to move the

trolley to the west.

• The trolley stops when the

button is released.

1) Press button to lift the load.

2) When lifting the load at high speed, press the

button further to the end.

• The electric chain hoist stops when the button is

released.

1) Press button to lower the load.

2) When lowering the load at high speed, press

the

button further to the end.

• The electric chain hoist stops when the button is

released.

1) Press button to move the trolley to the

east at low speed.

2) Press

button further to the end to move

the trolley to the east at high speed.

• The trolley stops when the button is released.

1) Press button to move the trolley to the

west at low speed.

2) Press

button further to the end to move

the trolley to the west at high speed.

• The trolley stops when the button is released.

(to be continued)

29

Chapter 1 Handling the Product

How to use (continued)

■7-Push Button Switch Set

7-Push Button Switch Set is equipped with a lock type emergency stop button (VFD reset button) and lift/lower push

buttons. One-step push button switch or two-step push button switch is mounted as Lift/lower push button switches

in accordance with the specification of single speed or dual speed VFD specification. Refer to the operation method

of the corresponding specification.

Moving directions of the trolley are expressed as East/West for traveling motion, and North/South for traversal

motion in the operational instruction of the Push Button Switch Set.

●

Emergency Stop Button (VFD Reset Button)

How to UseHow to Operate the Push Button Switches

1) Press the Emergency Stop Button deeply when carrying out an emergency stop or

VFD reset.

• The button is locked at the pressed end.

2) Turn the Emergency Stop Button clockwise to cancel the lock.

1

●

Operation Button

• Press-locked button returns to the original position.

* When the electric chain hoist is not used, press the Emergency Stop Button

● Lift/Lower Button

Single Speed Model Dual Speed VFD Model

1) Press button to lift the

load.

• The electric chain hoist stops

when the button is released.

1) Press button to lower the

load.

• The electric chain hoist stops

when the button is released.

Dual

No label for the

single speed

model

● Travel Button

Single Speed Model Dual Speed VFD Model

deeply to the end.

1) Press button to lift the load.

2) When lifting the load at high speed, press the

button further to the end.

• The electric chain hoist stops when the button is

released.

1) Press button to lower the load.

2) When lowering the load at high speed, press

the

button further to the end.

• The electric chain hoist stops when the button is

released.

30

Dual

No label for the

single speed

model

1) Press button to move the

trolley to the east.

• The trolley stops when the

button is released.

1) Press button to move the

trolley to the west.

• The trolley stops when the

button is released.

● Traverse Button

Single Speed Model Dual Speed VFD Model

1) Press button to move the

trolley to the south.

• The trolley stops when the

button is released.

1) Press button to move the

trolley to the north.

• The trolley stops when the

button is released.

1) Press button to move the trolley to the

east at low speed.

2) Press

button further to the end to move

the trolley to the east at high speed.

• The trolley stops when the button is released.

1) Press button to move the trolley to the

west at low speed.

2) Press

button further to the end to move

the trolley to the west at high speed.

• The trolley stops when the button is released.

1) Press button to move the trolley to the

south at low speed.

2) Press

button further to the end to move

the trolley to the south at high speed.

• The trolley stops when the button is released.

1) Press button to move the trolley to the

north at low speed.

2) Press

button further to the end to move

the trolley to the north at high speed.

• The trolley stops when the button is released.

Loading...

Loading...