OM-CX1ZZZ-CEE-02

/005

Original Instruction

This equipment should not be installed,operated or

maintained by any person who has not read and

understood all the contents of this manual. Failure to

read and comply with the contents of this manual can

result in serious bodily injury or death, and/or property

damage.

Issued August, 2011. Revised November, 2019 (Revision 05)

Table of Contents

Introduction ........................................................................................................ 2

Intended Purpose .............................................................................................. 2

Safety precautions ............................................................................................ 3

Chapter 1 Operation ......................................................................................... 5

Chapter 2 Inspection ...................................................................................... 17

Chapter 3 Troubleshooting ............................................................................ 33

WARRANTY ...................................................................................................... 40

Introduction

This Instruction Manual is intended for those operating the KITO model CX chain hoist. Separate document;

Disassembly/Reassembly Manual is also available for the relevant person (Note). Please contact KITO or your dealer

for the material.

Note : A person who is authorized by the business entity as having thorough knowledge and expertise on the

structure and devices of a chain hoist, or a person with similar thorough knowledge and expertise and capable of

understanding periodic inspection, and Disassembly/Reassembly Manual.

When these conditions are not satisfied, consult KITO or your dealer, or request maintenance.

Intended Purpose

This manual chain hoist is designed and manufactured to lift and lower a load manually within a normal work

environment. Movement in the horizontal direction is also enabled by combining with a trolley.

- Reproduction of this document, in whole or in part, without prior consent is prohibited.

- This document is subject to change without prior notice.

- This document was prepared with the utmost care. However, the customer is kindly requested to inform us of

any question, error or unclear point included in the document.

2

Safety precautions

Improper use of this manual chain hoist may result in danger, such as falling of the lifted load. Before installation,

operation, maintenance and inspection, be sure to read this manual carefully, comply with its instructions and operate

the product correctly. Prior to operation, all the safety and operating information, and safety precautions must be fully

understood. In this manual, precautions are classified into three categories: "Danger", "Warning" and "Caution". In

addition, read the instruction manuals of the equipment (such as trolley) related to the operation of the manual chain

hoist, and follow the instructions.

Description of signal words

DANGER indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury.

However, even CAUTION situations may result in serious injury or death depending on circumstances.

Ensure all precautions are recognized as important and complied with. After reading this manual, ensure it

remains readily available for users.

Description of safety symbols

Means a "Prohibited" action or a thing "You must not do".

Prohibited

Mandatory

Specific prohibited actions are shown in the safety symbol or described near the same.

Means a "Mandatory Action" or "Do as indicated".

The specific required action is shown in the safety symbol or described near the same.

Disclaimer

- KITO shall not be liable for any damage incurred due to fire, natural disasters such as earthquake and lightning,

actions of a third party, other accidents, intentional or accidental improper operation or misuse by customer, and

operation under conditions exceeding the operating environmental conditions.

- KITO shall not be liable for any incidental damage incurred, due to the use or inability to use this product (loss of

business profit, interruption of business, and damage to the lifted load).

- KITO shall not be liable for any damage incurred due to negligence concerning the instructions in this manual, or

operation under a condition exceeding the range defined in the specifications.

- KITO shall not be liable for any damage arising from malfunction due to the combination of the chain hoist used

with other equipment, unrelated to KITO.

Restricted usage

- The product is intended for use only in the region or the country where it was purchased. Due to the differences in

regulations and standards, it is not for use outside of the region or the country where it was purchased.

- This product is not designed nor manufactured to transport people. Do not use the product to transport people.

- This product is designed and manufactured for the purpose of lifting and lowering a load manually under normal

operating environmental conditions. Do not lift or lower loads using electric power. Movement in a horizontal

direction is enabled by combining with a trolley. Decide on and judge the appropriateness of use in accordance

with the intended purpose of the product design and manufacture.

- Since this chain hoist is used under diverse conditions, the customer should judge whether the product would be

used appropriately by carrying out analysis and tests if necessary. Ensuring the product performance and safety

are the responsibility of the person who judges the appropriateness.

3

Operators

- Before operating the product, read this manual and that of related equipment thoroughly to understand the

contents.

- Be sure to wear the proper clothing and personal protective equipment when using and operating the product.

Handling & Maintenance

Do not handle the chain hoist in any of the following manners.

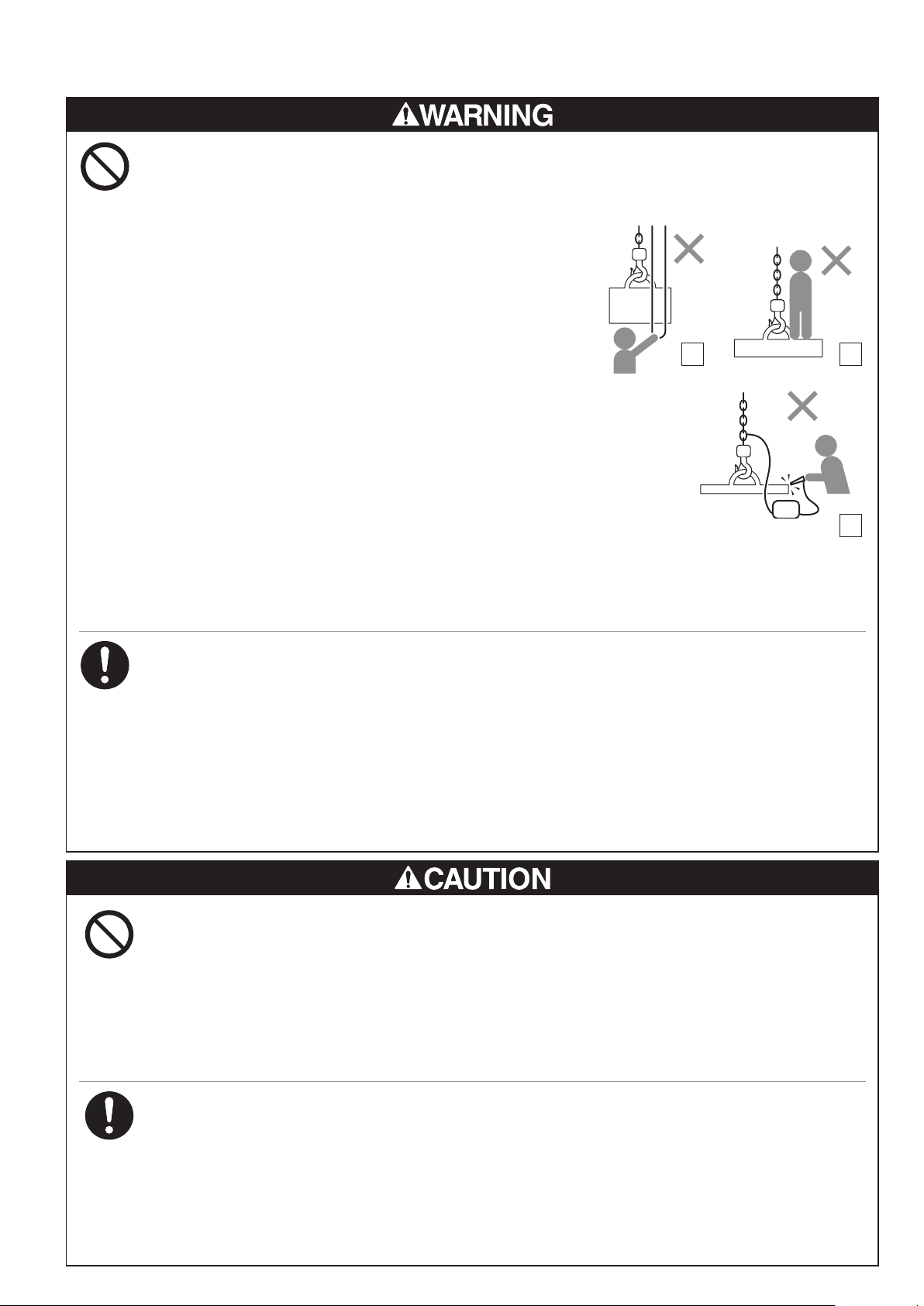

Handling the chain hoist in the manner described below may result in death or severe injury:

Prohibited

- Only suitably competent persons are allowed to disassemble or repair the chain hoist.

Separate document; Disassembly/Reassembly Manual is provided for such competent persons. Disassembly and repair shall

be carried out in accordance with the document and page 17 to 39.

- Do not enter into any area below a lifted load or moving range thereof. Do not transport a load over people or allow people to

enter into the moving range of a lifted load.

- Do not remodel the product and its accessories.

- Do not adjust or disassemble the Bottom Yoke and Overload Limiter (a device to prevent excessive overload).

Mandatory

Prohibited

Mandatory

Comply with the following instructions when handling the chain hoist.

Failure to comply with these instructions may result in death or severe injury:

- Before operating the product, fully understand the contents of this manual and the caution labels.

- Carry out daily inspection before operation.

- Request the competent person to carry out periodic inspection (monthly, annually), or ask KITO.

- Keep the record of the periodic inspections.

- When not in use of the chain hoist, store it at any place where appropriate for the weight and size.

Do not drag or throw the chain hoist when carrying.

The chain hoist may be broken or damaged and any fall of the lifted load during use may result in injury or physical damage to

property.

Follow the operating environmental conditions (refer to page 11) when using the chain

hoist.

Use of chain hoist beyond the conditions may result in injury or physical damage to property.

4

Mandatory

When discarding the product, disassemble it to ensure it is not reused, and discard in

accordance with locale government regulations and ordinances or the rules defined by

the business entity.

Contact your local government and related division for details.

Refer to Disassembly/Reassembly Manual for how to disassemble the chain hoist, or consult with KITO.

Chapter 1

Operation

Table of Contents

Safety precautions ............................................................................................ 6

Unpacking ........................................................................................................ 10

Main parts......................................................................................................... 10

Specifications .................................................................................................. 11

Operating environmental conditions ............................................................. 11

Installation ........................................................................................................ 11

Preoperational check ...................................................................................... 11

Operation .......................................................................................................... 12

Maintenance and storage ............................................................................... 13

Inspection classification ................................................................................. 14

Daily inspection ............................................................................................... 15

Parts list ........................................................................................................... 16

5

Safety precautions

Mounting

Avoid the following when mounting the chain hoist.

Failure to comply with these instructions may result in death or severe injury:

Prohibited

- Ensure that only trained or competent persons install the chain hoist.

- Do not install the chain hoist within the range of movement of other devices (equipment), such as a trolley.

Mandatory

Mandatory

Comply with the following instructions when installing the chain

hoist.

Failure to comply with these instructions may result in death or severe injury:

- Check that the structure for mounting the chain hoist has sufficient strength.

- Fix the Top Hook to the structure securely.

- Before using the chain hoist with a trolley, read the Instruction Manual of the trolley carefully

and install it by adjusting the rail width.

- Install a stopper at both ends of the traversing rail for the trolley.

Comply with the following instructions when installing the chain

hoist.

Failure to comply with these instructions may result in injury or damage to property:

- Install the chain hoist to avoid impeding the hoist.

- Install the Load Chain with sufficient length for lifting work.

- If the adjustment of the bottom of the hand chain between 500 mm and 1000 mm from the

ground is required, consult KITO.

Traversing rail

Trolley

Stopper

Lift

Before use

Mandatory

Mandatory

6

Before moving the load, warn all the surrounding people.

Failure to comply with these instructions may result in death or severe injury.

Check the following before using the chain hoist.

If a defect is found while checking the chain hoist, stop using it, place a notice indicating "failure/inspection in progress" and request

a competent person to carry out inspection and repair.

Failure to comply with these instructions may result in death or severe injury:

- Carry out daily inspection before operation (refer to page 15).

- Check to see whether there is any defect in the sling.

- Check to use a proper chain hoist for your purpose, capacity and lift.

- Check the work environment to see if the work area is secure to pull the hand chain vertically and to maintain a good view

without any obstacles to monitor the operation.

- Check to see if the footing is secure.

Operation

Do not use the chain hoist in the following manners.

Failure to comply with these instructions may result in death or severe injury.

Prohibited

<General>

<Slinging>

- The Load Chain is exclusively designed for this model of chain hoist. Do not use chains of other models of chain hoist.

Ensure that a competent person replaces the chain with an authorized part for this model, referring to Disassembly/Reassembly

Manual.

- Operate the chain hoist using only manual force.

- Do not leave a lifted load unattended for an extended period.

A

- Do not use a Hook without a Latch.

- Do not apply a load to the tip of the hook or latch.

<Fig. A>

- Do not use the load chain as a sling. <Fig. B>

- Do not operate the load chain while it is in contact with any

sharp edges, e.g. of a steel plate. <Fig. C>

B C

<Lifting>

- Do not lift more than the rated load. <Fig. D>

- Do not cause the load to come into contact with the load or

hand chains.

- Do not lift the load while holding the load chain.

- Do not swing the lifted load.

- Do not use the chain hoist without a straight line present

between the top and bottom hooks relative to the load direction. <Fig. E>

- Do not swing the load when lifting it off the ground. <Fig. F>

- In the situation where the chain hoist is to be used as a sling by connecting it to a crane, be

certain to convey the fact of this intended usage to KITO beforehand to confirm whether this

type of use is possible.

- Do not impede the hand chain with a lifted load or a member of the structure caught on the

chain.

Overload

D

E

F

- Do not use the chain hoist as a fulcrum. <Fig. G>

- When lifting off a load from a pallet, lift the load to avoid

exposing to shock, such as the load falling. <Fig. H>

- Do not lift or lower excessively.

- Before use, confirm the minimum distance between the

hook and load (minimum headroom) and lift in technical

data.

- Do not repeatedly operate the overload limiter (slipping action).

- If the overload limiter is activated, stop the lifting operation immediately and ensure that the chain hoist is in a no load state.

G

(Continued on the following page)

H

7

Operation

Do not use the chain hoist in the following manners.

Failure to comply with these instructions may result in death or severe injury.

Prohibited

<Transportation/Move>

<Post-lifting Work>

(continued from the previous page)

- Do not operate the chain hoist underneath the load or transport a load

over people. <Fig. I>

- Do not ride on a lifted load and do not use the chain hoist to support, lift,

or transport people. <Fig. J>

- Do not strike the stopper of the traversing rail or the structure with the

chain hoist or the trolley.

I J

- Do not execute welding or cutting work on a suspended steel plate.

- Do no use the load chain as the earth for welding work. <Fig. K>

- When repairing or disassembling, ensure that the chain hoist is placed down on the floor and

that only competent persons maintain the chain hoist.

- Ensure that the hand chain is pulled by a single person.

Mandatory

Prohibited

<Abnormality/failure>

- Do not use a damaged chain hoist or one generating abnormal sounds.

- Do not use the chain hoist if one of the following defects is found in the load chain.

Deformation, twists, kinks, flaws, cracks, adhesion of foreign matter, corrosion, and abnormal meshing.

- Heavy elongation or abrasion.

- Do not use the load chain hoist out of order or under repair.

Follow the instructions below when using the chain hoist.

Failure to comply with these instructions may result in death or severe injury:

- If any abnormality is detected during use, immediately stop using of the chain hoist, indicate "failure/repair in progress" and

request a competent person to perform maintenance and repair.

- When the manual force becomes excessive, stop operation immediately.

- Use sling appropriate for the weight and shape of a load. Improper slinging may result in an unsafe situation, such as the falling

of the lifted load.

- When any abnormality is observed during the operation, stop the operation immediately, indicate "FAILURE" and contact with

the maintenance engineers.

- When inspecting and repairing, be sure to indicate "INSPECTION" and carry out without lifting a load.

Do not use the chain hoist in the following manners.

Failure to comply with these instructions may result in death or severe injury:

- Do not operate the chain hoist as the hand chain is tangled or twisted.

- Do not expose the chain hoist to sparks from welding.

- Do not use an overload limiter for measuring the weight of the load.

- Do not apply a load to the hook tip or hook latch.

- Do not impede the lifted load or hand chain with other structures.

- If a load bounces up and down significantly when lowering the load, do not operate the chain hoist until the bouncing reduces.

K

Observe the following instructions when using the chain hoist.

Failure to comply with these instructions may result in death or severe injury:

Mandatory

- Unwind any twists in the load chain before lifting a load.

- If the load and hand chains are entangled or twisted, stop the operation immediately and reset the entangled or twisted chains.

- When lifting a load with two hoists, choose each hoist whose lifting capacity exceeds the load and operate the respective chain

hoist to keep the load lifted horizontal.

- There are risks of overheating of the braking system during prolonged lowering of loads.

If you are considering of the use under such condition, consult KITO.

8

Maintenance inspection / storage

Only competent persons are allowed to carry out maintenance inspection of the chain

hoist.

Mandatory

Mandatory

Failure to comply with these instructions may result in death or serious injury:

- The competent person should carry out maintenance inspection in accordance with page 17 to 39 and Disassembly/

Reassembly Manual.

- Do not cut, extend, or weld the load and hand chains.

- Do not apply oil to the braking part.

Comply with the following instructions when carrying out maintenance inspection and

storing the chain hoist.

Failure to comply with these instructions may result in injury or physical damage to property:

- To avoid misuse of the chain hoist under repair, apply a label indicating "failure/inspection in progress" on the chain hoist.

- When storing the chain hoist, wipe off dust and waterdrop, apply oil to the neck of the hook and load chain and store the hoist

indoors when not used for lifting loads.

- When replacing a part, use only an authorized part for the KITO model CX chain hoist.

Even though the part is an authorized one for KITO chain hoist, it may not be used for different model.

- Wear protection equipment such as protection goggles and gloves depending on the work contents. Especially, wear helmet

and safety belt when carrying the high lift work.

- Pay attention to work method, work procedure and work posture.

- Remove the oil or grease attached to the product or spilt on the floor.And keep the work area clean when disassembling the

product.

9

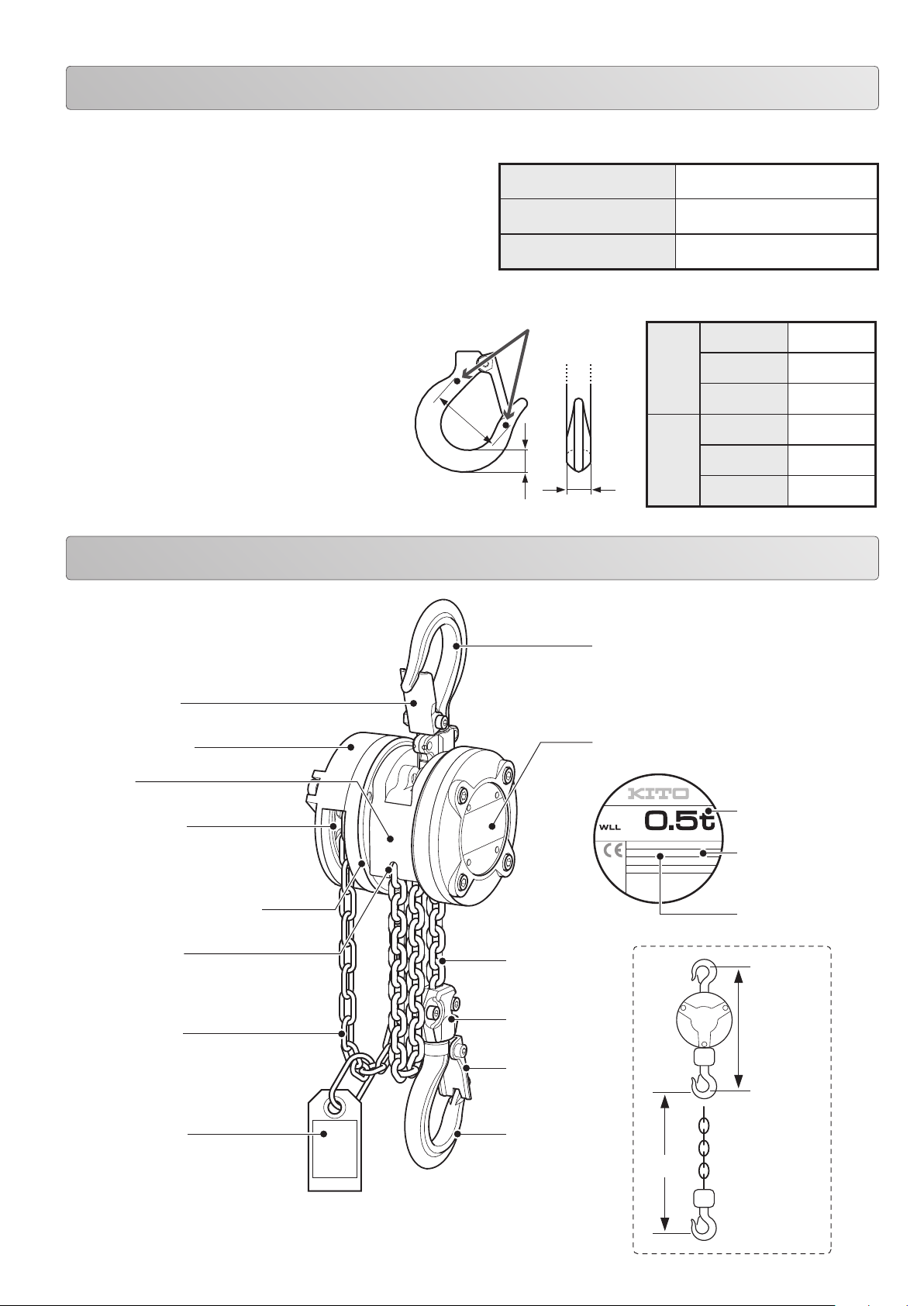

Unpacking

b

- Check that the information on the box and the product match the details of your order.

- Check to see whether the product has been deformed or damaged by an accident in transit.

- Fill in the blank provided in the right table with the Lot NO. (written

on the nameplate on the product), the date of purchase, and the

name of the store where you purchased the product.

* When requesting repair or ordering a chain hoist part, please

inform us of these pieces of information together.

Lot NO. CX1A-

Date of purchase

Store

- Fill in the spaces provided in the right table with

the distance "a" between embossed marks, the

hook width "b" and the thickness "c" for both the

top and bottom hook. (These figures are referred in

maintenance.)

Main parts

Hook latch

Wheel cover

Body

Hand wheel

Over load limiter (OLL)

built-in

Brake (built into the body)

Embossed mark

a

c

Top

hook

Bottom

hook

Top hook

Nameplate

(rating / warning)

Equipped with OVERLOAD LIMITER

CODE:

LOAD CHAIN:

LOT No: CX1A

SERIAL No:

MFG.YEAR:

Yamanashi 409-3853 Japan

MADE IN JAPAN

Dimensions when new

Dimension a

Dimension b

Dimension c

Dimension a

Dimension b

Dimension c

Rated load

(ex. of CX005)

LOT No.

Model

mm

mm

mm

mm

mm

mm

10

Load chain

Load chain end at no-load side

Hand chain

Warning tag

Load chain

Bottom yoke

Latch

Bottom hook

Minimum

Headroom

Lift

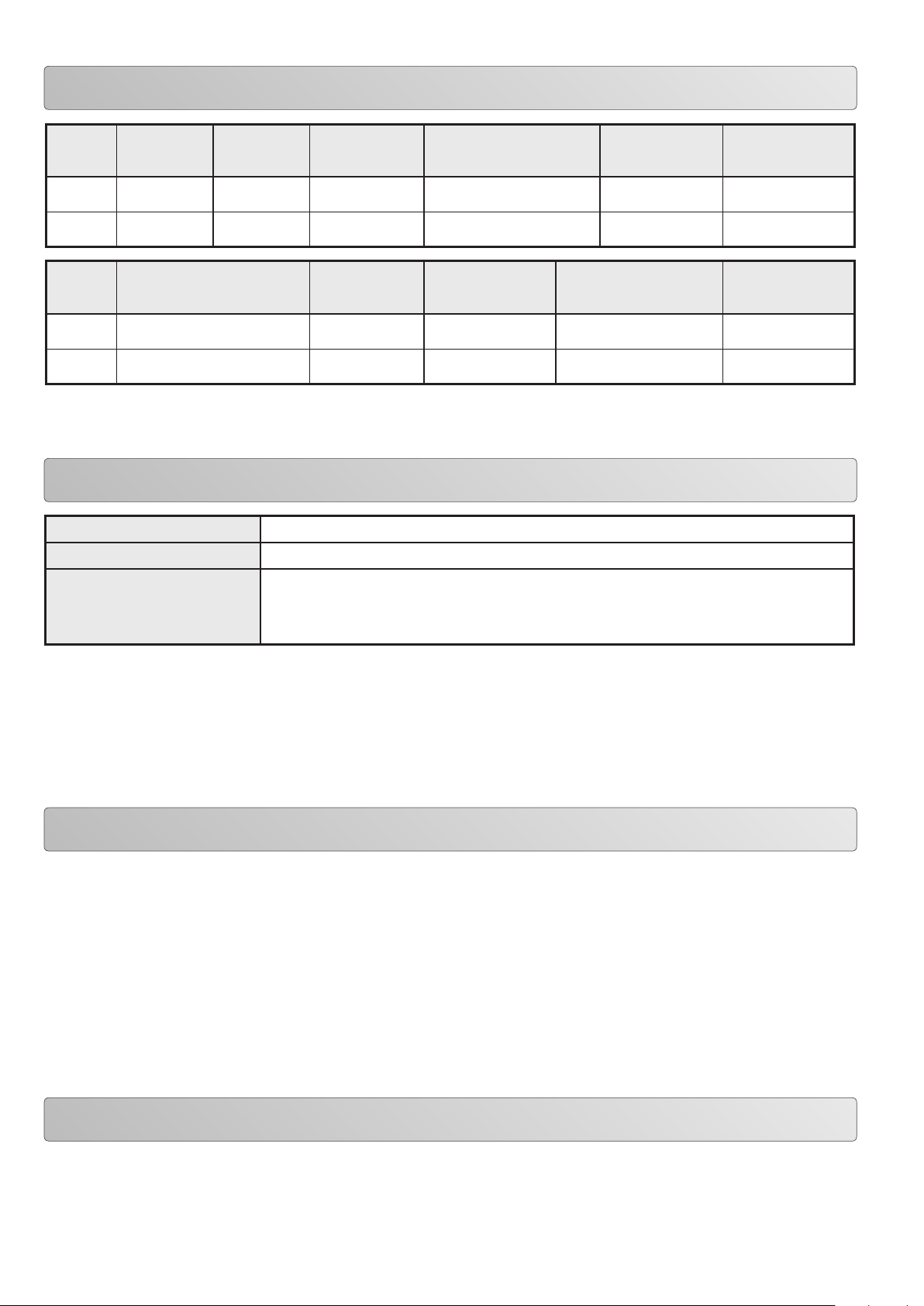

Specifications

Product

code

CX003 0.25 2.5 217 2 147[15] 33.8

CX005 0.5 2.5 260 2.5 187 [19] 42.8

Product

code

CX003 3.2 x 9.0 1 0.313 0.4 2.4

CX005 4.3 x 12.0 1 0.625 0.9 4.5

This device was tested according to the required static and dynamic load test provided on the European standard EN 13157.

Rated load

(t)

Load chain diameter x pitch

Standard lift

(m)

(mm)

Minimum

Headroom (mm)

Chain fall lines

Standard length of the hand

chain double fold (m)

Test Load

(t)

*1: Average hand pull to lift the rated load.

*2: Length of the hand chain necessary to lift a load 1m.

Weight for additional 1m

Pull to lift Load

(N) [kgf]

of lift (kg/m)

*1

Hand chain length

for 1m lifting*2 (m)

Operating environmental conditions

Operating temperature range -40°C to +60°C

Operating humidity range Use the hoist at under 100%RH. This product cannot be used in water.

Standard materials are used.

Materials

Special materials such as sparkless materials and asbestos are not used.

With regard to the environmental load substances, 6 substances defined in the

RoHS directives are not contained in this product.

Mass

(kg)

Do not use the chain hoist in the following environments:

- In an alkaline/acidic atmosphere

- In an organic solvent/explosive atmosphere

Incidentally, when you wish to use the chain hoist in environments other than the aforementioned normal use environments, such as one with a high

salt content, or in an environment where outdoor use in particular is extensive, it may be possible to use the chain hoist by carrying out maintenance

inspection frequently. In such cases, consult with KITO beforehand.

Installation

Read the "Safety precautions : Mounting" on page 6 carefully before use and follow the instructions.

- The safety factor of the chain hoist is 4:1. The hoist may lift and hold a load more than the rated load. Check that the structure for mounting the

chain hoist has sufficient strength.

- Only allow trained or competent persons to install the chain hoist.

- Do not install the chain hoist within the moving range of other devices (equipment), such as a trolley.

- Before using the chain hoist with a trolley, read the Instruction Manual of the trolley carefully and install it by adjusting the rail width.

Install a stopper at both ends of the traversing rail for the trolley.

- If the adjustment of the bottom of the hand chain between 500 mm and 1000 mm from the ground is required, consult KITO.

Note: KITO TS trolley (Models TSP005) can be connected to this hoist. When using the CX003 by connecting to a

trolley, change the capacity on the trolley nameplate to 250kg, corresponding to CX003. For details, contact

KITO.

Preoperational check

Read the "Safety precautions : Mounting" on page 6 and "Safety precautions : Maintenance" on page 9 carefully

before use and follow the instructions.

The user must carry out a daily inspection before operation.

Even if the chain hoist is permanently installed and used for the same purpose repeatedly, check all the works for the

day and check to ensure that it does not exceed the rated load on each occasion.

11

Operation

Read the "Safety precautions" Operation on pages 7 to 9 carefully before use and follow the instructions.

Correct way to lift a load

Hang on the axis of

the hook.

Avoid the dangerous hooking method shown in the following diagrams.

The holding object or

the sling is not hooked

in the correct position.

More than 60 degrees.

The angle is too wide.

60 degrees or less.

The hook latch does

not close.

Operation method

Wheel cover side

The load is applied at

the tip of the hook.

Lowering

When the hand chain on the left,

as viewed from the wheel cover

side, is pulled down (in a DN

direction), the load is lowered.

This product is designed for a rated load to be hoisted by pulling the hand chain with a force shown in the "Pull to lift

load" table below or less. If an excessive load is applied, the overload limiter will operate. In this situation, immediately

stop the operation and lighten the load.

Pull to lift load:

CX003 147 N (15kgf)

CX005 187 N (19kgf)

Lifting

When the hand chain on the right,

as viewed from the wheel cover

side, is pulled down (in an UP

direction), the load is lifted.

12

Overload limiter (OLL)

Do not adjust or disassemble Overload Limiter (OLL).

Failure to comply with these instructions may result in death or serious injury.

This product is equipped with an overload limiter (OLL: a device to prevent an excessive overload) as standard.

An excessive overload via the hand chain activates OLL which slips the hand wheel to prevent damage to the

product.

When OLL operates, the maximum load to the product is approximately 2.4 times of the rated load.

If OLL operates, reduce a load to less than the rated load. Also check that the structure for mounting the chain

hoist (including a trolley) has no damage.

Maintenance and storage

Read the "Safety precautions : Maintenance, inspection/storage" on page 9 carefully after use and follow the

instructions.

Care

- Do not drag or throw the chain hoist when carrying.

- Never apply oil to the braking part.

- Wipe off dust and moisture, and apply oil to the neck of hook and the load chain.

Storage

- When not in use, ensure that it does not encumber other works.

- Store the hoist in a dry area indoors.

- When installing outdoors, cover the hoist to avoid exposure to rain or store in a place with covering against rain.

- Before storing the hoist, pull the hand chain by about 10cm to lower the hook and ensure that the brake is released.

Tool

- To disassemble or reassemble the hoist, prepare for the following tools.

.

No

1 Hexagon wrench 4mm

2 Snap ring pliers For disassembling and reassembling the pawl and cam guide

Hexagon wrench

3

2.5mm

4 Hexagon wrench 3mm For disassembling and reassembling the bottom yoke and hook latch

Tool name Application

For disassembling and reassembling the frames A and B, gear case, and

wheel cover

For disassembling and reassembling the end pin

5 Wrench 7mm For disassembling and reassembling the bottom yoke and hook latch

6 Long nose pliers For the cam guide

7 Torque wrench For checking a tightening force

13

Inspection Classification

To maintain continuous and satisfactory operation, a regular inspection procedure must be initiated to replace worn or

damaged parts before they become unsafe.

INSPECTION Classification

Inspection intervals must be determined by individual application and are based on the type of service to which the hoist will be subjected and the

degree of exposure to wear, deterioration or malfunction of the critical components.

The type of service to which the hoist is subjected can be classified below.

- Normal Service – service that involves operation with randomly distributed loads within the rated load limit, or uniform loads less that 65% of

rated load for not more than 15% of the time.

- Heavy Service – service that involves operation within the rated load limit which exceeds normal service.

- Severe Service – service that involves normal or heavy service with abnormal operating conditions.

The three general classifications are herein designated as DAILY, FREQUENT and PERIODIC, with respective intervals between inspections as

defined below.

DAILY Inspection – visual examinations by the operator or other competent person before daily operation.

FREQUENT Inspection – visual examinations by the competent person with intervals per the following criteria:

- Normal service – monthly

- Heavy service – weekly to monthly

- Severe service – daily to weekly

Records are not required.

PERIODIC Inspection – disassembly/reassembly inspection by the competent person with intervals per the following criteria:

- Normal service – yearly

- Heavy service – semiannually – 6 months

- Severe service – quarterly – 3 months

Records are to be kept for continuing evaluation of the condition of the hoist.

14

Daily inspection

Inspections include the "Daily inspection" carried out by the operator, using the product before use, and a more

thorough "Frequent/Periodic inspection (page 17 to 31)" carried out by a competent person with sufficient knowledge,

who can disassemble the chain hoist.

- Be sure to carry out these inspections in order to use the chain hoist safely.

- Separate document; Disassembly/Reassembly Manual is also available for the competent person. Please contact KITO or your dealer for the

material.

Hook

- To ensure both the top/bottom hooks

have no deformation or flaws.

- For the neck part of both the top /

bottom hooks to rotate smoothly.

- To ensure no looseness in the bolts and

nuts fixing the bottom yoke.

Appearance

- For the nameplate to be fixed firmly and

for the displayed contents to be clear and

legible.

- No loosend or fallen-out bolts and nuts.

- To have no flaws and damages to the

appearance.

Latch

- For the latch to be closed.

- For the latch to have no deformation or

flaws.

- For the latch to open/close smooth-ly.

Body

End at no-load side

Hand chain

-

For the hand chain to have no deformation,

flaws, twists or kinks.

Load chain

- For the end at the no-load side to be fixed to the

body.

- To have no deformation, flaws, twists or kinks.

- To have no conspicuous rust

* Remove rust, when it is observed.

- For the load chain to be oiled.

* If it is not oiled, remove the dust and moisture on the

load chain and apply the lubricant JIS K 2246 class

1, No.1 (code: NP-9) rust preventive oil equivalent

(DAPHNE OIL COAT RL-44, IDEMITSU KOSAN

Co., LTD. recommended) Consult KITO if the usage

environment does not allow the application of

lubricating oil to the load chain.

Lifting

To carry out a lifting operation with one hand

while lightly pulling the load chain on the bottom

hook side with the other.

- To be able to hear the pawl of the brake

device sounds clicks and to move smoothly

- Bottom hook should stop when the

operation is stopped.

* If the bottom hook is entangled with the

load or hand chain, untangle the chain.

Lowering

To carry out a lowering operation with one hand

while lightly pulling the load chain on the bottom

hook side with the other.

- To make no noise during the lowering and

move smoothly.

- Bottom hook should stop when the

operation is stopped.

- If the hoist cannot be lowered, check that

bottom hook is not lowered excessively,

ant then carry out the lowering operation

by strongly pulling the hand chain for a

moment. If it is still unable to lower, consult

with the competent person, or contact

KITO.

If there are any abnormalities, consult the competent

person or contact KITO.

15

Parts List

18

32

23

31

36

35

22

27

24

23

26

28

34

25

33

29

10

2

1

12

30

11

15

14

13 21 19

17

18

9

20

16

CX005

8

7

5

6

16

Fig.

Part No. Part Name

No.

1 1001 Top hook Set 1

2 071 Hook latch Assembly 1

3 1021

4 071 Hook latch Assembly 1

3 1021 Bottom hook set 1

4 071 Hook latch Assembly 1

5 841 Load chain 1

6 041 Chain pin 1

7 042 Split pin 1

8 049 Slotted nut 1

9 5103

10 101 Frame A 1

11 102 Frame B 1

12 6104 Body assembly 1

13 106 Socket head cap screw 4

14 107 Spring lock washer 4

15 116 Load sheave 1

16 162 Chain guide 1

17 108 Socket head cap screw 4

18 109 Conical lock washer 7

Bottom hook set

with 2.5m Load chain

Gear Case Assembly (Europe)

Gear Case Assembly (Other) 1

38

37

Parts

per

Hoist

CX003 CX005

L1XA003-1001 L1XA005-1001

L1XA003-1071 L1XA005-1071

C1XA003-1011

1

L1XA003-1071

-

-

-

-

-

-

C1XG003-5103 C1XG005-5103

1

C1XD003-5103 C1XD005-5103

C1XA003-9101 C1XA005-9101

C1XA003-9102 C1XA005-9102

C1XA003-6104 C1XA005-6104

J1BE1-0502525

J1WS011-20050

C1XA003-9116 C1XA005-9116

C1XA003-9162 C1XA005-9162

J1BE2-0501515

C1XA003-9109 C1XA003-9109

4

Part code

L1XA005-1021

L1XA005-1071

KAUN043-0000

L1LA005-9041

J1PW02-016008

L1LA005-9049

J1BE1-0503522

J1WS011-20050

J1BE2-0501515

4

3

3

Fig.

Part No. Part Name

No.

19 111 Pinion 1

20 112 Gear #2 2

-

-

21 114 Load gear 1

22 5115 Hand wheel assembly 1

23 117 Snap ring 2

24 151 Friction plate 2

25 152 Ratchet disc 1

26 153 Friction disc 1

27 154 Bushing 1

28 155 Pawl 1

29 5179 Pawl spring assembly 1

30 163 Top pin 1

31 171 Wheel cover 1

32 176 Socket head cap screw 3

33 177 End pin 1

34 178 Hexagon socket set screw 1

35 203 Cam guide 1

36 842 Hand chain 1

37 933

38 045 Chain stopper link 1

Warning tag (Europe) 1

Warning tag(Other) 1

Parts

per

Hoist

C1XA003-9111 C1XA005-9111

C1XA003-9112 C1XA005-9112

C1XA003-9114 C1XA005-9114

C1XA003-5115 C1XA005-5115

J1SS000-00009 J1SS000-00009

C1XA003-9151 C1XA005-9151

C1XA003-9152 C1XA005-9152

C1XA003-9153 C1XA005-9153

C1XA003-9154 C1XA005-9154

C1XA003-9155 C1XA003-9155

C1XA003-5179 C1XA005-5179

C1XA003-9163 C1XA005-9163

C1XA003-9171 C1XA005-9171

J1BE2-0503022 J1BE2-0503522

C1XA003-9177 C1XA005-9177

J1TB011-05008 J1TB011-06008

C1XA003-9203 C1XA003-9203

K7SX025-0000 K7NZ035J0000

ER1BS9686

E7AR003S9886 E7AR003S9886

L5BA008-9045 L5BA016-9045

Part code

CX003 CX005

ER1BS9686

Table of Contents

Chapter 2

Inspection

Safety precautions .......................................................................................... 18

Recommendation for Inspection .................................................................... 20

Inspection Standard ........................................................................................ 20

Frequent Inspection .................................................................................. 21

Periodic Inspection .................................................................................... 24

Preoperational Test ................................................................................... 29

Inspection Check Sheet .................................................................................. 30

17

Safety precautions

This chapter for Chain Hoist includes important contents to prevent injury to persons performing inspection, users and

other persons and damage to property, and to disassemble/reassemble the Chain Hoist safely and correctly.

Before performing the inspection, be sure to read and follow page 5 to 16 since its contents are also important for

inspection.

Disassembly/reassembly of Chain Hoist is essential for inspection. Refer to the separate Disassembly/reassembly

Manual to perform inspection correctly.

Person to perform inspection

Inspection shall be performed only by a competent person*

* Person who is authorized by company to have expertise on the structure and device of Chain Hoist, or has

expertise and is capable of understanding page 17 to 31 and Disassembly/reassembly Manual.

When this requirement is not satisfied, consult with KITO, or request KITO for inspection.

Inspection in general

Mandatory

Prohibited

Prohibited

Prohibited

Only competent persons to perform inspection of the Chain Hoist.

Inspection performed by anyone other than a competent person may result in death or severe injury.

Do not use parts beyond their discard limit or criteria and unauthorized parts for KITO

Chain Hoist Model CX003/005.

Even though the part is an authorized part for KITO Chain Hoist, it may not be used for a different model.

Use parts correctly in accordance with the Disassembly/reassembly Manual.

Failure to do so may result in death or severe injury.

Do not perform inspection of Chain Hoist subject to a load.

When performing inspection of a Chain Hoist, place it on a floor and perform the inspection.

Performing inspection of a Chain Hoist subject to a load may result in death or severe injury.

Do not lubricate the Friction Plate.

The Friction Plate is of the dry type.

Lubricating the Friction Plate may result in death or severe injury due to insufficient braking.

18

Do not use any oil (grease, rust preventive oil, etc.) in areas near a fire or spark.

Otherwise, this may result in ignition.

Prohibited

Mandatory

Mandatory

Mandatory

Perform inspection (frequent, periodic).

Failure of inspection (frequent, periodic) causes death or severe injury.

Inspection may need to be performed earlier than inspection cycle depending on the condition of use. Inspect the hoist at

appropriate interval in consideration of the result of daily checks and operating noise.

When any defect is observed during inspection, stop using the Chain Hoist, indicate

Failure/Inspection underway and consult with the competent person, KITO or your dealer

for inspection and repair.

Use of a product with a defect may result in death or severe injury.

When annual inspection is completed, perform functional inspection (operational check)

to confirm the correct operation in accordance with the Disassembly/reassembly Manual.

Failure to do so may result in death or severe injury.

Mandatory

Mandatory

Compare the throat opening and thickness of the Top and Bottom Hooks with those when

purchased and ensure these dimensions do not exceed the criteria.

Failure to do so may result in injury or damage to property.

When any defect is observed during inspection, stop using the Chain Hoist, indicate

Failure/Inspection underway and consult with the competent person or KITO for repair.

Use of a faulty Chain Hoist may result in death or severe injury.

19

Recommendation for Inspection

Inspection is the first step to safety operation. Carry out daily inspection and

periodic inspection.

- Ensure that the operater refers to page 5 to 16 and carry out daily inspection.

- This chapter is composed of frequent and periodic inspection items (About each classification, refer to page 14).

- Inspection shall be performed by a competent person (with expertise), or consult with KITO.

- Inspection items are specified based on standard environment and conditions. Consult with KITO when using the Chain Hoist under special

environment or conditions.

- Periodic inspection needs disassembly/reassembly. Refer to the separate Disassembly/reassembly Manual for correct inspection.

Inspection Standard

Only competent persons are allowed to inspect the chain hoist.

Anyone other than a competent person inspecting may result in death or severe injury.

Mandatory

Prohibited

Prohibited

Mandatory

Mandatory

Do not use parts beyond their discard limit or criteria and unauthorized parts for the KITO

Chain Hoist Model CX003/005.

Even if the part is an authorized part for KITO Chain Hoist, it may not be used for a different model.

Use parts correctly in accordance with the Disassembly/reassembly Manual.

Failure to do so may result in death or severe injury.

Do not perform inspection of a Chain Hoist subject to a load.

Before performing inspection of a Chain Hoist, place it on a floor.

Performing inspection of a Chain Hoist subject to a load may result in death or severe injury.

Perform inspection within a specified period.

Failure of inspection (frequent, periodic) causes death or severe injury.

Inspection may need to be performed earlier than inspection cycle depending on the condition of use. Inspect the hoist at

appropriate interval in consideration of the result of daily checks and operating noise.

If a defect is found while checking the chain hoist, stop using it, place a notice indicating

"failure/inspection underway" and request a competent person or KITO to carry out repair.

Use of a product with a defect may result in death or severe injury.

20

Frequent Inspection

Check the Chain Hoist under the installation state or

on the workbench.

NOTE

Check the following items in addition to the daily inspection items.

Before a frequent inspection, perform the daily inspection.

Item Method Discard limit or criteria Action

Basic

function

Top and

Bottom

Hooks

Suspend a light load and lift/

lower it.

• Lifting operation should make regular click

sounds of the Pawl of the brake unit and

perform smoothly.

• Sounds should be at a constant level or no

irregular clicks should be heard.

• No sounds should be made when lowering.

• It should be free of any heavy pulling force.

• There should be no slip in braking.

Visual check • The hook should not be signicantly twisted

or deformed.

• Should be free of any deep notches of aws.

• Should be free of any loosened or omitted

rivets, bolts or nuts.

• Should be free of any foreign matter such as

sputter on the Hook.

Measure the dimensions of

each "a", "b" and "c" of the

Top and Bottom Hooks using

calipers.

Compare the deformation and

thickness of the Top and Bottom

Hooks with those of when

Embossed mark

purchased to check they are not

beyond the criteria.

Using Hook with dimensions beyond the criterion

a

may result in injury or damage to property.

Disassemble the Chain

Hoist to verify that

the hoist is properly

assembled and the

components are free of

defects.

Replace the Top Hook

Set or the Bottom Hook

Complete Set.

Replace the Top Hook

Set or the Bottom Hook

Complete Set.

c

b

Standard Limit

Dimension a

Dimension b 5% or more wear

Dimension c 5% or more wear

The nominal values are indicated

below for reference, however, the Hook

dimensions have tolerances to some

extent because it is forged and thermally

treated.

Rated

load (t)

0.25 39 11

0.5 45.5 12

Not to exceed the dimension when

purchased

Dimension a Dimension b Dimension c

Standard

Standard

Limit

Standard

10.5 12.5 11.9

11.4 15 14.3

Limit

(Continued on the following page)

21

Item Method Discard limit or criteria Action

Top and

Bottom

Check the deformation of the

Hook neck visually.

Hooks

Neck

Rotate Hook. • Should rotate smoothly. Replace the Top Hook

Latch Move Latch for a few times.

• The neck should not be deformed or twisted

beyond the discard limit.

Do not use Hook without Latch.

Failure to do so may result in death or severe

injury.

Replace the Top Hook

Set or the Bottom Hook

Complete Set.

Set or the Bottom Hook

Complete Set.

Replace Latch.

Load

Chain

Check abrasion visually and

using calipers.

Pitch length for 5 links

d

• Should securely close the hook throat.

• Should move smoothly.

NOTE

Carefully check the position, especially where

the Load Chain engages with the Load Sheave.

Rated

load (t)

• Check abrasion of Load Chain by measuring

the total length of 5 links of chain.

However, when the chain diameter is

excessively worn with visual check, replace

the Load Chain.

• For measuring control, measure the chain

diameter, referring to the limit value in the

above table.

Needle tip calipers are needed to measure

pitch length of 5 links and the wire diameter.

Pitch length for 5 links (mm) Chain diameter (d)mm

Standard Limit

0.25 45.5 46.8 3.2 2.9

0.5

60.5 62.3 4.3 3.9

Nominal

diameter

Limit

Replace the Bottom

Hook Complete Set.

22

Item Method Discard limit or criteria Action

Load

Chain

Visually ensure the Load

Chain is free of corrosion

(rust).

Visually check Load Chain

has no deformation or aws.

• Should be free of excessive corrosion (rust). Replace the Bottom

Hook Complete Set.

NOTE

- When abrasion of Load Chain is observed,

also check the Load Sheave for safety's

sake. (Refer to the item of Load Sheave

in the "Lifting mechanism" page of Annual

Inspection.)

- Apply lubricant JIS K 2246 class 1, No.1 (code:

NP-9) rust preventive oil equivalent (DAPHNE

OIL COAT RL-44, IDEMITSU KOSAN Co.,

LTD. recommended)

Replace the Bottom

Hook Complete Set.

Do not perform any prohibited

items in page 5 to 16. Use the

Load Chain correctly.

• Should have no deformations such as

distortion.

• Should have no deep aws.

Visually check to see if there

are any sputter on the Chain

Hoist.

• Should be free of sputter. Replace the Bottom

Hook Complete Set.

NOTE

Keep the Chain Hoist away from welding

sparks.

(Continued on the following page)

23

Worn position

Periodic Inspection

Disassemble the Chain Hoist and check each part in

detail.

When this inspection is completed, reassemble

the Chain Hoist correctly in accordance with the

Disassembly/reassembly Manual.

NOTE

Check the following items in addition to the frequent inspection items.

Perform disassembly/reassembly work correctly, referring to the

separate Disassembly/reassembly Manual.

Item Method Discard limit or criteria Action

Top Hook Measure the diameter of the

hole of the Top Yoke to insert

the Top Pin, using calipers.

When the hole is an oval

hole, measure the maximum

diameter of the oval hole.

Hole to insert Top Pin

Top Yoke

Bottom

Hook

Check the abrasion at the

worn position of the Chain of

Bottom Hook (indicated with

an arrow).

Hole diameter (d) mm

Rated load (t)

0.25 8.3 8.8

0.5

d

For Top Pin

Standard Limit

10.3 10.8

• Load Chain should be free of excessive

abrasion and deformation at the worn position

of the chain on the Bottom Yoke side.

• Perform measuring control of the chain

diameter, referring to the Frequent Inspection

(Page 21). Load Chain should not beyond the

limit of chain diameter.

• A point caliper is needed to measure the

abrasion (of chain diameter).

Replace the Top Hook

Set.

Replace the Bottom Hook

Complete Set.

24

CX003

Worn position

CX005

d

• For CX005, the diameter (d) of the chain pin

hole should not excess the limit below.

Chain pin hole diameter (mm)

Standard 10.3

Limit 10.8

Item Method Discard limit or criteria Action

Braking

mecha-

nism

Visually check the braking

surface to ensure no

abrasions or aws.

Check the crack of the

Friction Plate visually and

measure the abrasion using

calipers.

t

Two-ply

Do not lubricate the Friction

Plate.

The Friction Plate is a dry type brake.

Lubricating the Friction Plate may result in death

or severe injury due to insufficient braking.

• Should free of scars or gouged aws on the

braking surface of the Friction Disc, Friction

Plate, Ratchet Disc, and Hand Wheel

Assembly.

• The braking surface of the above mentioned

parts should not be excessively worn with

the tool marks erased and surface lustered.

• The Friction Plate should be free of chips or

cracks.

Thickness of two Friction Plates

Rated load (t)

0.25 5.0 4.5

0.5

Dimension t (mm)

Standard Limit

5.0 4.5

Replace the scarred or

worn parts.

Replace both Friction

Plates.

Measure the abrasion of

Bushing using a vernier

caliper.

A

Heat the Bushing with a

match ame to check that it is

impregnated with oil.

• Should be uniform in thickness. Replace the Bushing.

Rated load (t)

0.25 1.4 1.2

0.5

Dimension A (mm)

Standard Limit

2.0 1.8

Soak the Bushing in

turbine oil for a day and

Do not use any oil (grease, rust

wipe off excessive oil.

preventive oil, etc.) in areas near

a fire or spark.

Failure to do so may result in ignition.

• Bushing should be sufciently impregnated

with oil (such that oil oozes off the surface

when heated).

NOTE

For replacing or assembling Bushing, soak it in

turbine oil for a day, and wipe excessive oil from

its surface before reuse.

(Continued on the following page)

25

Item Method Discard limit or criteria Action

contact

contact

contact

Braking

mecha-

nism

Measure the abrasion of the

Ratchet Disc with a vernier

caliper.

D

One point

Two-point

250kg

D

Rated load (t)

0.25 33.8 32.4

0.5

Dimension D (mm)

Standard Limit

44.3 42.9

Replace the Ratchet

Disc.

Two- point

contact

Two-point

500kg

Visually check Pawl. • The Pawl should not be worn with a step on

the tip.

Abrasion

Visually check Pawl Spring

Assembly.

Visually check corrosion

(rust).

Measure the abrasion of the

Friction Disc in contact with

the Bushing (as shown in the

following gure with a dotted

• Should be free of deformations, aws,

breaks or poor spring.

• Each part should be free of excessive

corrosion (rust).

Rated load (t)

0.25 16.4 15.6

0.5

Dimension D (mm)

Standard Limit

21.9 21.1

line) with a vernier caliper.

D

Replace the Pawl.

Replace Pawl Spring

Assembly.

Replace any rusty part.

Replace Friction Disc.

26

4mm

Item Method Discard limit or criteria Action

Lifting

mecha-

nism

Visually check the abrasion

and aw of the Load Sheave.

Pocket and Tooth

Visually check the abrasion

and aw on tooth of the Load

Gear and Gear #2.

Visually check the

deformation of the Pinion.

Visually check the abrasion

and aw on the tooth of the

Pinion.

Visually check the abrasion

and aw of the Hand Wheel.

• Should be free of abrasion in the Pocket

or run-on aws on the Tooth of the Load

Sheave.

• Should be free of chips of tooth, stepped

abrasions, and aws.

• Pinion should be free of deformation, such

as bend.

• Should be free of chips of tooth, stepped

abrasions, and aws.

• Should be free of abrasion in the Pocket,

run-on aws or breaks on the Tooth of the

Hand Wheel.

Replace the Load

Sheave.

Replace the Load Gear

and the Gear #2.

Replace the Pinion.

Replace the Pinion.

Replace the Hand Wheel

Assembly.

Pocket

and Tooth

Visually check the

deformation of the Cam

Guide.

Visually check the Hand

Chain.

Body Visually check and measure

the bearing hole for Top Pin

with a vernier caliper.

a

• Cam Guide should be free of signicant

deformation.

NOTE

Deformed Cam Guide results from excessively

lowering. Instruct the operator on proper use of

the Chain Hoist.

• Should be free of deformation, such as

torsion.

• Should be free of signicant deformations or

aws.

• The dimensional difference between "a" and

"b" should be 0.5mm or less.

Replace the Cam Guide.

Replace the Hand Chain.

Replace Body Assembly.

b

(Continued on the following page)

27

Item Method Discard limit or criteria Action

A

b

b

b

Body Visually check the Pawl Shaft. • Pawl shaft should be secured to Body. Replace the Body

Assembly.

Pawl Shaft

Visually check and measure

the bearing hole of Frames

A and B for the Load Sheave

with a vernier caliper.

a

Frame A

a

Frame B

Visually check and measure

the bearing holes of Frame

B for the Gear with a vernier

caliper.

a

Visually check the

deformation and aw of the

Gear Case.

• Should be free of substantial deformations

or aws.

• The dimensional difference between "a" and

"b" should be 0.5mm or less.

• Should be free of signicant deformations or

aws.

• The dimensional difference between "a" and

"b" should be 0.5mm or less.

• Should be free of deformation of the Frame.

• Should be free of signicant deformations,

aws or cracks.

Replace the Frame A or

B.

Replace the Frame B.

Replace the Gear Case

Assembly.

28

Visually check and measure

the abrasion of holes of the

Gear Case for the Plain

Bearings with a vernier

caliper.

Plain Bearing

a

b

Visually check and measure

the deformation and abrasion

of the Top Pin with a vernier

caliper.

• Should be free of signicant deformations or

aws.

• The dimensional difference between "a" and

"b" should be 0.5mm or less.

• Signicantly deformed Top Pin has reached

the discard limit.

Rated load (t)

0.25 8 7.6

0.5

Dimension A (mm)

Standard Limit

10 9.6

Replace the Gear Case

Assembly.

Replace the Top Pin.

Item Method Discard limit or criteria Action

d

Others Visually check the

deformation of the Chain

Guide.

Chain Guide

Visually check and measure

the deformation, abrasion and

corrosion (rust) of the End

Pin with a vernier caliper.

• Should be free of crushed grooves,

deformations or cracks.

• The End Pin should be free of signicant

deformation.

• Should be free of aws or deformations.

• Should be free of signicant corrosion (rust).

(Measure dimension d.)

Rated load (t)

0.25 3.9 3.7

0.5

End Pin diameter (mm)

Standard Limit

5 4.8

Replace the Chain

Guide.

Replace the End Pin.

Preoperational Test

When the periodic inspection is

completed, perform a preoperational

test to check that the hoist operates

correctly.

Failure to do so may result in death or severe injury.

Item Method Discard limit or criteria Action

No load

test

Rated

load test

Repeat lifting and lowering a

few times.

Lift and lower the rated load

for 20 to 30cm.

Perform the items in the

"Basic function" of Frequent

Inspection.

• The Chain Hoist should be operated with a

light pulling force.

• The Chain Hoist should have regular click

sounds of Pawl when lifting.

• The Chain Hoist should have regular click

sounds of Pawl and run smoothly when

lifting.

• The sound should be at a constant level with

no irregular clicks.

• The Chain Hoist should make no sound

when lowering.

• It should be free of a heavy pulling force.

• It should be free of slip in braking.

Disassemble the Chain

Hoist to verify that the

hoist is assembled

properly and the

components are free of

defects.

29

KITO Chain Hoist Model CX

Inspection Check Sheet (for Model CX003/005)

Type Rated Load Lot No. Control No. Date of Installation Installed Place

Check mark example: ○= Good, △= To be replaced (adjusted) at next inspection, ×= Defective. To be replaced (adjusted)

Range Category Check Item

Nameplate (from daily check)

Appearance of Body and others (from daily check)

Loosened or omitted nuts (from daily check)

Lifting / lowering

Abnormal sound

Hand pulling force

Brake

Throat opening

Abrasion of Hook, Gap at Neck

Deformation, flaw

Loosened or missing bolts or nuts (from the daily check)

Rotation of Hook

Latch

Torsion (from daily check)

Oil application (from daily check)

Abrasion

Corrosion (rust)

Frequent

Inspection

Appearance

Function

Top/Bottom

Hook

Load Chain

Date of Check

30

Inspected by

Checked by

Deformation, flaw

Sputter

Inspector

Competent person

NOTE

When any defect is observed during inspection,

stop using the Chain Hoist, indicate Failure/

Mandatory

Inspection underway and consult with the

competent person or KITO for repair.

Use of a faulty Chain Hoist may result in death or severe injury.

Check mark example: ○= Good, △= To be replaced (adjusted) at next inspection, =Defective. To be replaced (adjusted)

This Check Sheet is a standard sample based on

KITO frequent and periodic inspection. Customers

should decide upon their own format of the check

sheet according to the operation environment

and conditions of the customer, and perform the

inspection. Be sure to include all check items into

the check sheet.

Range Category Check Item

Deformation of hole to combine the Top Yoke

Deformation of Bottom hook connection hole (for CX005 only)

Abrasion of the first link of Chain at the load end.

Abrasion and flaw on the braking surface

Abrasion and crack on the Friction Plate

Abrasion of Bushing

Oil impregnation of Bushing

Abrasion of Ratchet Disc

Abrasion of Pawl

Deformation and abrasion of Pawl Spring

Corrosion (rust)

Abrasion of contact surface of Bushing of Friction Disc

Abrasion and flaw of Load Sheave

Abrasion and flaw of Load Gear and Gear #2

Deformation of Pinion

Abrasion and flaw of Hand Wheel

Deformation of Cam Guide

Periodic

Inspection

Top/Bottom

Hook

Braking

mechanism

Lifting

mechanism

Date of Check

Body

Others

Test

Inspected by

Checked by

Torsion and deformation of Hand Chain

Abrasion and flaw on tooth of Pinion

Deformation of hole for Top Pin

Deformation of holes on Frames A and B for bearing

Deformation and flaw of Gear Case

Abrasion of plain bearing of Gear Case

Deformation and abrasion of Top Pin

Deformation of Chain Guide

Deformation, abrasion, and corrosion (rust) of End Pin

No load test

Rated load test

Inspector

Competent person

31

32

Chapter 3

Troubleshooting

Table of Contents

Introduction ...................................................................................................... 34

Safety Precautions .......................................................................................... 34

Troubleshooting .............................................................................................. 35

Lifting up failure ......................................................................................... 35

Lowering failure ......................................................................................... 37

33

Introduction

When a defect is observed while using the Chain Hoist or during its inspection, stop using the Chain Hoist and

repair (maintain) the hoist. This chapter describes how to troubleshoot causes of the failure and defect and to take

countermeasures for Competent person.

When a defect is found, stop using the Chain Hoist immediately and check the cause.

Most of the causes of failure or defect of the Chain Hoist come from improper usage. Carefully read Owner's

•

Manual of Chain Hoist and use the Chain Hoist correctly. Also, inform operators of the result of repair

(maintenance) and direct them to operate the Chain Hoist properly.

For repair (maintenance) of Chain Hoist, perform the repair (maintenance) correctly in accordance with

•

page 17 to 31 and separate "Disassembly/reassembly Manual".

Competent person is those authorized by the company as having expertise on the structure and device of a Chain

Hoist, or with appropriate expertise and capable of understanding page 17 to 31 and Disassembly/reassembly

Manual.

When this requirement is not satisfied, consult with KITO or your dealer.

Safety Precautions

This Troubleshooting for the Chain Hoist includes important contents to prevent injury to persons performing repair

(maintenance), users and others, and damage to property, and to perform repair (maintenance) of the Chain Hoist

safely and correctly.

Before performing repair (maintenance), be sure to read and follow page 5 to 16 since its contents are also important

for repair (maintenance).

Person to perform repair (maintenance)

Repair (maintenance) shall be performed by a competent person, or consult with KITO or your dealer.

Repair (maintenance) in general

Only competent persons are allowed to perform repair (maintenance) of the Chain Hoist.

Repair (maintenance) by anyone other than a Competent person may result in death or severe injury.

Mandatory

When replacing parts, only use parts authorized by KITO for use in the CX003/005 Chain Hoist

Models.

Mandatory

Even if the part is an authorized part for the KITO Chain Hoist, it may not be used for a different model.

Use parts correctly in accordance with the Disassembly/reassembly Manual.

After disassembling/reassembling, perform the operation check described in the Disassembly/reassembly Manual.

Failure to do so may result in death or severe injury.

34

Troubleshooting

Lifting up failure

Checking sounds from the hoist is a critical inspection point. Note the operating sound of the Chain Hoist.

For lifting, the Chain Hoist makes clicking sounds.

•

For lowering, the Chain Hoist does not make clicking sounds.

•

Symptom Cause Action

Cannot lift load.

The Pawl sounds weak

or irregularly.

• The Ratchet Disc is assembled with

its wrong side tting, as shown in the

gure.

Pawl

Rachet Disc

Reassemble the Pawl and Ratchet Disc to

ensure they engage correctly.

The Pawl makes no

sounds.

Cannot operate

manually.

• The Pawl is wrongly assembled

upside down, as shown in the gure.

Pawl

Rachet Disc

• The Pawl Shaft and Pawl clogged with

dust or rust caused by a long-term

negligent maintenance may make

poor contact for the Pawl and Ratchet

Disc.

• The positions of the "O" and "V" marks

on Gear #2 are not set correctly.

Reassemble the Pawl in the correct direction.

Perform periodic disassembly and inspection

to remove dust and rust.

Replace if found rusty signicantly.

Any irregularities such as rust may deteriorate

Pawl Spring. Replace if found rusty.

Reassemble Gears correctly.

When reassembly is completed, be sure to

perform an operational test and check that

the hoist operates smoothly.

* Assemble Gear #2 with the "O" and "V"

marks set around the Pinion as shown in

the gure.

Cannot lift the rated

load or less.

• The Load Chain is installed as twisted

or tangled, and is caught between the

Chain Guide and Load Sheave.

• Fault of Overload Limiter (OLL:

a device to prevent an excessive

overload) due to frequent lifting of an

excessive overload.

• Cam Guide contacts the inner upper

left corner of the Hand Wheel.

Pinion

Gear #2Gear #2

Reassemble the Load Chain correctly, being

careful not to assemble it twisted or tangled.

(Refer to separate Disassembly/reassembly

Manual.)

Stop using the Chain Hoist. Replace the

Hand Wheel Assembly.

Lift the rated load or less and avoid frequent

use of overload limiter.

Reassemble properly. (Refer to separate

Disassembly/reassembly Manual.)

(Continued on the following page)

35

Symptom Cause Action

Sometimes fails to lift load.

Pawl sounds weak.

Pawl sounds irregularly.

• Pawl Spring Assembly lacks spring, or

breaks.

• Pawl does not return to original

position due to accumulated rust

(corrosion).

Replace Pawl Spring Assembly.

Perform disassembly inspection regularly.

Hand Chain slips.

• Missing Pawl Spring Assembly causes

poor return.

• Poor return of Pawl due to misassembly. (Pawl Spring is caught

between the step of Pawl Shaft and

the Pawl.)

• Frequently extended use causes Pawl

or Ratchet Disc to wear with poor

engagement.

• Abrasion of sprocket of Hand Wheel.

• Elongation or abrasion of Hand Chain.

• Wrong size of Hand Chain.

Length when purchased (guideline)

a

Rated load (t) a b

0.25 14.2 2.5

0.5 20 3.5

Reassemble the hoist correctly.

When reassembly is completed, be sure to

perform an operational test, and check that

the pawl sounds click.

Replace Pawl Spring Assembly.

Perform disassembly inspection regularly.

Replace Hand Wheel Assembly.

Perform disassembly inspection regularly.

Use proper Hand Chain.

Lift a load normally but

Pawl clicking sounds

are weak (with regular

clicks).

Heavy pulling force at

no load (with occasional

squeaking sound).

Lift load only halfway

but not further.

• Weakened or broken Pawl Spring

Assembly causes insufcient force of

Pawl.

• Poor return of Pawl due to misassembly. (Pawl Spring is caught

between the step of Pawl Shaft and

the Pawl.)

• Poor gear engagement.

• Abrasion of gear tooth ank.

• Lack of lubricant caused by a longterm negligent maintenance may

result in abrasion or breakage.

• Load Chain of the Bottom Hook or

Hand Chain is entangled or twisted.

Replace the Pawl Spring Assembly.

Perform disassembly inspection regularly.

Reassemble the hoist correctly.

When reassembly is completed, be sure to

perform an operational test, and check that

the pawl sounds click.

Replace Gear.

Perform disassembly inspection regularly.

Be sure to check that the Bottom Hook is not

entangled or twisted with the Load Chain or

Hand Chain.

36

• The Overload Limiter (OLL: a device

to prevent an excessive overload) is

activated.

Reduce the load to less than the rated load.

Lowering failure

Friction Disc

Friction Disc

Lowering failure is mainly due to a deficiency of the brake.

Symptom Cause Action

Not lower load. • Leaving the Chain Hoist loaded for a

long time or subjecting to mechanical

impact during work may lock the

brake.

• Rust locks the brake. Replace the rusted part.

Hard to lower load. • Caw Guide contacts the inner upper

right corner of the Hand Wheel.

Load falls when

lowering starts.

• A foreign object between friction

surfaces.

Do not lubricate the Friction Plate.

The Friction Plate is of the dry type.

Lubricating the Friction Plate may result in death or

severe injury due to insufficient braking.

Pull the Hand Chain strongly for lowering for

a moment to release the brake.

Perform disassembly inspection regularly.

Reassemble (Refer to separate Disassembly/

reassembly Manual.)

Disassemble the Chain Hoist, remove the

object, and then reassemble.

Replace the Friction Plate if scratched.

• Brake slip caused by signicant rust. Reassemble the rusted part.

• Mis-assembly of the Friction Plate.

Friction Plates are set at only one side

as shown below, or one Friction Plate

is missing.

Rachet Disc

Friction Plates

Bushing

• Friction Plate is cracked. Replace cracked Friction Plate.

Load drifts. • Slight dust on the brake surface.

• The brake surface has oil, such as

grease, attached.

Use according to operating conditions in

page 5 to 16. After use, store the Chain Hoist

in accordance with the Maintenance and

storage in page 5 to 16.

Reassemble Friction Plates correctly as

below.

Rachet Disc

Friction Plates

Bushing

Disassemble the Chain Hoist, remove the

dust or oil, and then reassemble.

Replace the Friction Plate if scratched.

Perform disassembly inspection regularly

according to the operating environment.

• Abrasion of Friction Plate due to

frequent extended operation.

Worn Load Chain. • Lack of lubricant (frequent extended

use).

Replace worn Friction Plate.

Perform disassembly inspection regularly,

according to the frequency of operation.

Replace the abraded Load Chain.

Always apply oil to the Load Chain in

accordance with page 5 to 16. Also perform

disassembly inspection regularly.

(Continued on the following page)

37

Symptom Cause Action

Scarred or deformed

Load Chain.

• Mis-assembly causes Load Chain to

twist.

• Load Chain is entangled with Hand

Chain.

• Load Chain is in contact with an

obstacle.

• Overload elongates the Load Chain. Replace the Load Chain.

Assemble Load Chain correctly in accordance

with the Disassembly/reassembly Manual.

Before use, be sure to check that the Load

Chain is not entangled with the Hand Chain.

Prevent interference of Load Chain by other

object.

Do not wind the Load Chain around the load.

Use the hoist under the rated load.

Rust or corrosion. • Lack of oil.

• The use of a Chain Hoist exposed to

the rain

• Inuenced by seawater, chemicals,

etc

Broken Load Chain. • May result from combination with

the causes described in page 37/38,

including impact load.

• Welding heat affects strength.

• Entangled Load Chain.

Do not lift the load beyond the

rated load.

Failure to do so may result in death or severe

injury.

Thorough safety control in accordance with

the operating environment.

Remove dirt and water, and

apply oil to the neck of the Hook

and Load Chains, and then store

the Chain Hoist indoors.

Failure to do so may result in injury or damage

to property.

Cutting of Load Chain may

result in severe accidents,

including fatalities. Conduct

appropriate maintenance,

including correct handling, daily

check and inspection.

38

Symptom Cause Action

Stretched Hook. • Overload.

The Hook is to open gradually under

more than double the rated load.

• Lifting a load at the tip of the Hook. Replace the Hook.

• Improper hooking of the sling or the

use of a sling of inappropriate size

relative to the Hook.

• Slinging angle too wide.

Replace the Hook.

Hook opening indicates

overload. Do not lift the load

beyond the rated load.

Lifting a load beyond the rated load may result

in death or severe injury.

Lift a load at the center of the Hook saddle.

Replace the Hook.

Use a sling appropriate for the work.

The slinging angle should be 60 degrees or

less.

Bent hook neck. • Lifting a load at the tip of the Hook.

• Applied force from an oblique direction

to the Hook being xed.

Twisted Hook. • Winding the Load Chain around the

load.

60 degrees or less.

Replace the Hook.

Lift a load at the center of Hook

saddle.

Lifting a load at a position other than the center

of the hook saddle may cause to break the

Hook and result in death or severe injury.

Lift a load while the Top and Bottom Hooks

are aligned straight with the load direction.

Replace the Hook.

Do not wind the Load Chain around the load

as a sling.

Detached Latch. • Hook deformed by overload.

• Improper sling size to hook.

• Sling hooked on latch.

Replace the Hook.

Sling a load correctly.

39

WARRANTY

KITO Corporation (referred to after as KITO) extends the following warranty to the original purchaser (referred to after

as Purchaser) of new products manufactured by KITO (KITO’s Products)

KITO warrants that KITO’s Products, when shipped, shall be free from defects in workmanship and/or materials under

normal use and service and KITO shall, at the election of KITO, repair or replace free of charge any parts or items

which are proven to have said defects, provided that all claims for defects under this warranty shall be made in writing

immediately upon discovery and, if there is anything within one (1) year from the date of purchase of KITO’s Products

by Purchaser and provided, further, that defective parts or items shall be kept for examination by KITO or its authorized

agents or returned to KITO’s factory or authorized service center upon request by KITO.

KITO does not warrant components of products provided by other manufacturers. However to the extent possible, KITO

will assign to Purchaser applicable warranties of such other manufacturers.