Page 1

Installation Instructions

Laundry

Center

Washer l Dryer

240 Volt

Page 2

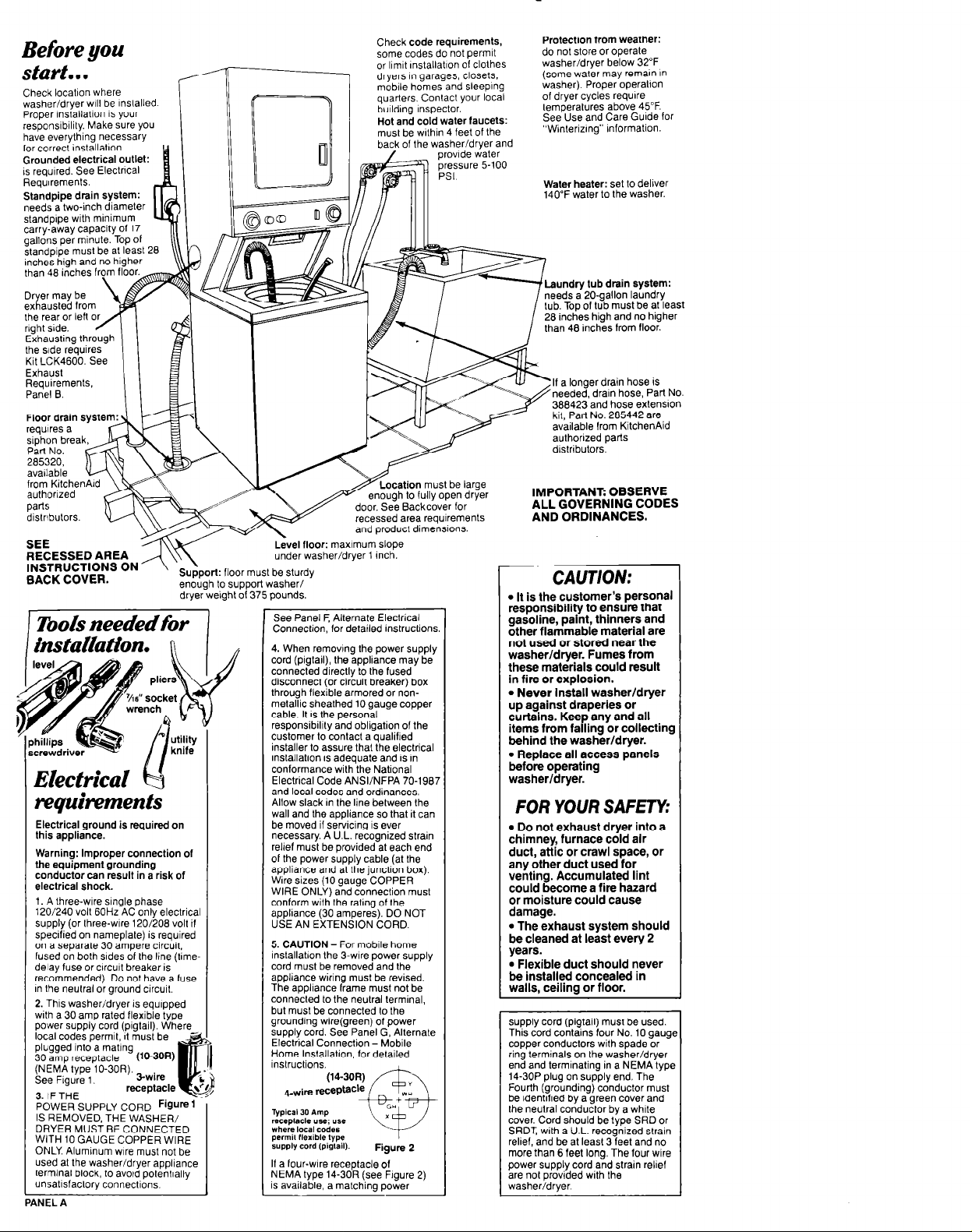

Before you

Check locatlon where

washer/dryer WIII be mstalled

Proper mstallatlon Is your

responsibility. Make sure you

have everything necessary

lor correct installallon

Grounded electrical outlet:

IS required. See Electncat

Requirements.

Standpipe drain system:

needs a two-inch diameter

standplpe with minimum

Check code requirements,

some codes do not permit

or llmlt mstallatlon of clothes

dryers ln garages, Closets.

mobile homes and sleeping

quarters. Contact your local

bulldIng Inspector.

Hot and cold water faucets:

must be wlthin 4 feet of the

back of the washer/dryer and

provide water

pressure 5-100

PSI.

Protection from weather:

do not store or operate

washer/dryer below 32°F

(some water may remam In

washer). Proper operatlon

of dryer cycles require

temoeratures above 45°F.

see’ Use and Care Guide for

“Wmterlzmg” Information.

Water heater: set to deliver

140°F water to the washer.

I”” “IWIII O,‘..mS.’

needs a 20-gallon laundry

lub. Top of lub must be at least

26 inches high and no higher

46 inches from floor.

Exhaust

Requirements,

Part No. C-ZAT\W

265320,

-.-. -- .

from KitchenAId \ m

aulhorlzed

pads

distributors

SEE

---

RECESSED AREA

INSTRUCTIONS ON

BACK COVER.

K I\\ \ I

+\

Support: floor must be sturdy

enough to support washer/

dryer-weight of 375 pounds.

7bol.s needed for I

Electrical 6

vequhments

Electrical ground is required on

this appliance.

Warning: Improper connection 01

the equipment grounding

conductor can result in a risk of

electrical shock.

1. A three-wire smgle phase

120/240 volt 60Hz AC only electrica

supply (or three-wire 120/206 volt if

specified on nameplate) is required

on a separate 30 ampere circuit,

fused on both sides of the line (time

delay fuse or clrcult breaker is

recommended). Do not have a fuse

in the neutral or ground circuit.

2. This washer/dryer IS equipped

with a 30 amp rated flexible type

power supply cord (plglail). Where

local codes permit, It must be plugged into a mating

30 amp receptacle (l&mR)

(NEMA type lo-30R). 3-wire

See Figure 1.

3. IF THE

POWER SUPPLY CORD Figure’

IS REMOVED, THE WASHER/

DRYER MUST BE CONNECTED

WITH 10 GAUGE COPPER WIRE

ONLY. Aluminum wire must not be

used at the washer/dryer appliance

terminal block, to avotd potentially

unsatisfactory connections.

4NEL A

receptacle I

&

U/

- _ _

under wasp

See Panel F. Alternate Electrical

Connection, for detailed instructions.

4. When removing Ihe power supply

cord (piglail), the appliance may be

connected directly to the fused

disconnecl (or circuit breaker) box

through flexible armored or nonmetallic sheathed 10 gauge copper

cable. It IS the personal

responsibility and obligation of the

customer to contact a qualified

installer lo assure that the electrical

installation is adequate and is in

conformance with the National

Electrical Code ANSI/NFPA 70-1967

and local codes and ordinances.

Allow slack in Ihe line between the

wall and the appliance so that it can

be moved if servicing is ever

necessary. A U.L. recognized strain

relief must be provided at each end

of the power supply cable (at the

appliance and at Ihe junction box).

Wire sizes (10 gauge COPPER

WIRE ONLY) and connection must

conform with the ratino of the

appliance (30 amperes): DO NOT

USE AN EXTENSION CORD.

5. CAUTION - For moblle home

lnstallatlon the 3-wire power supply

cord must be removed and the

appliance wiring must be revised.

The appliance frame must not be

connected to the neutral terminal,

but must be connected to Ihe

grounding wire(green) of power

supply cord. See Panel G, Alternate

Electrical Connection - Mobile

Home Installation, for detailed

instructions.

If a four-wire receptacle of

NEMA type 14.30R (see Figure 2)

IS available, a matching power

location

enough to fully open dryer

door. See Backcover for

recessed area requirements

and product dimensions.

ler/drver 1 inch

must be lame

-__- .._. -. ~~

Figure 2

\ //&ded’,,drain hose, Part No.

: If a lonoer drain hose is

366423 and hose exlenslon

kit Part No. 265442 are

available from KitchenAid

.-’ - ~~

authorized parts

dlslributors.

IMPORTANT: OBSERVE

ALL GOVERNING CODES

AND ORDINANCES.

CAUTION:

. It is the customer’s personal

responsibility to ensure that

gasoline, paint, thinners and

other flammable material are

not used or stored near the

washer/dryer. Fumes from

these materials could result

in fire or explosion.

l

Never Install washer/dryer

up against draperies or

curtains. Keep any and ail

items from falling or collecting

behind the washer/dryer.

9 Replace all access panels

before operating

washer/dryer.

FOR YOUR SAFEPY:

l

Do not exhaust dryer into a

chimney, furnace cold alr

duct, attic or crawl space, or

any other duct used for

venting. Accumulated lint

could become a fire hazard

or moisture could cause

damage.

l

The exhaust system should

be cleaned at least every 2

years.

l

Flexible duct should never

be installed concealed in

walls. ceiiina or floor.

supply cord (pigtail) must be used.

This cord contains four No. 10 gauge

copper conductors with spade or

ring terminals on the washer/dryer

end and terminating in a NEMA type

14.30P plug on supply end. The

Fourth (grounding) conductor must

be identified by a green cover and

the neutral conductor by a white

cover. Cord should be type SRD or

SRDT. with a U.L. recognized strain

relief, and be at least 3 feet and no

more than 6 feet long. The four wire

power supply cord and strain relief

are not provided with the

washer/drvec

I

Page 3

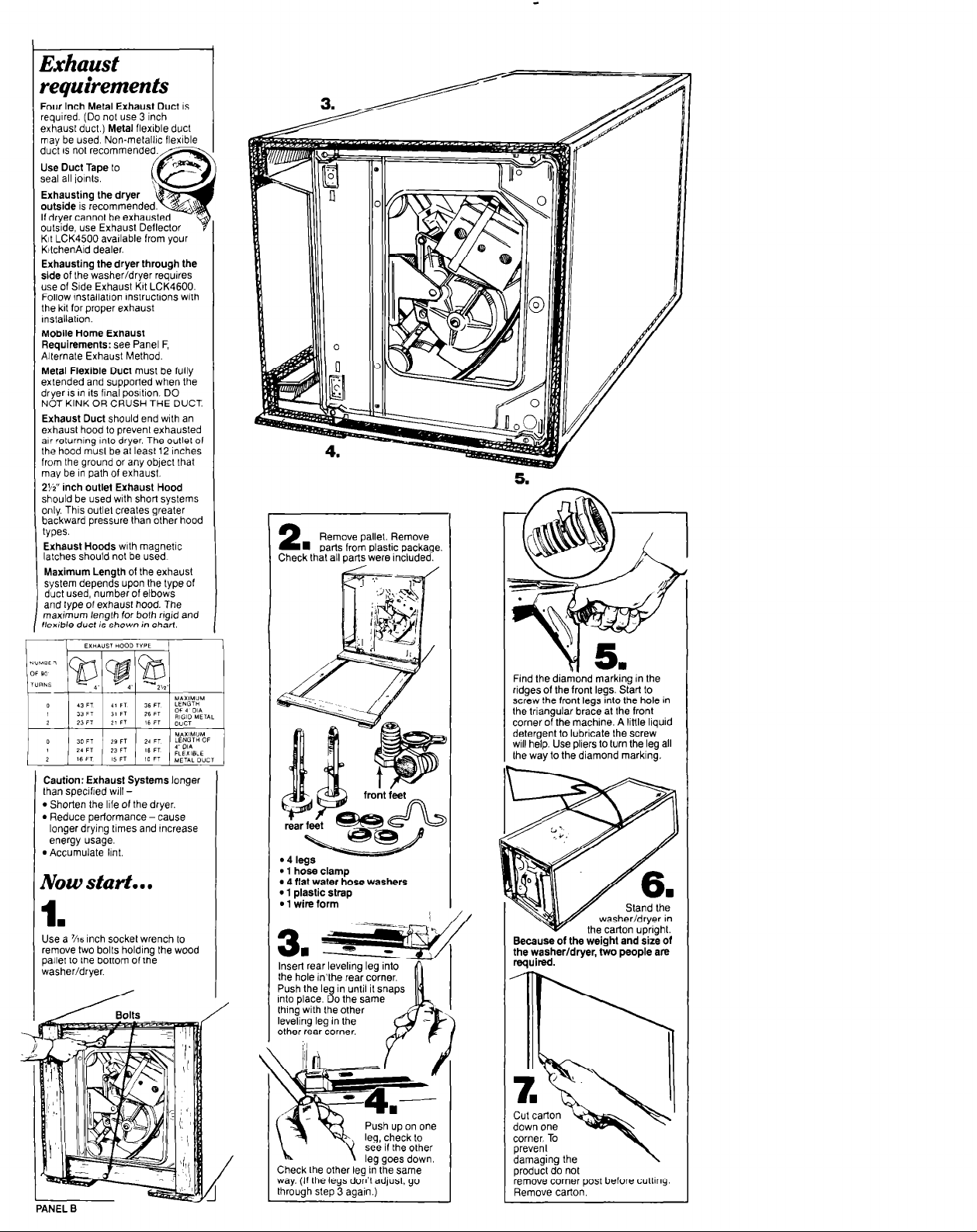

Exhaust requirements 1

Four Inch Metal Exhaust Duct IS

.equlred. (Do nol use 3

exhaust duct.) Metal

nay be used. Non-meta

duct IS not recommende

Use Duct Tape to

peal all joints.

Exhausting the dryer

outside is recommende

II dryer cannot be exhaus

sutside, use Exhaust Defl

Kit

LCK4500 available from your

KitchenAId dealer.

Exhausting the dryer through the

side of the washer/dryer requires

use of Side Exhaust Kit LCK4600.

Follow installation mstructions with

the kit for proper exhaust

mslallation.

Mobile Home Exhaust

Reouirements: see Panel F

Al&ate Exhaust Method.

Metal Flexible Duct must be fully

extended and supported when the

dryer IS III its final posItIon. DO

NOT KINK OR CRUSH THE DUCT

Exhaust Duct should end with an

exhaust hood to prevent exhausted

air returning Into dryer. The outlet 01

the hood musl be at least 12 Inches

from Ihe ground or any object lhat

may be in path of exhausl.

2%” inch outlet Exhaust Hood

should be used with short systems

only. This outlet creates greater

backward pressure than other hood

types.

Exhaust Hoods with magnetic

latches should not be used

Maximum Length of the exhaust

system depends upon the type of

duct used, number of elbows

and type of exhaust hood. The

maximum lenglh for both ngid and

flexible duct is shown in charf

in

flex~

Remove pallet. Remove

2

n

parts from plastic package.

Check thal all parts were included.

Caution: Exhaust Systems longer

than speclfled WIII -

l

Shorten the life of the dryer.

l

Reduce performance-cause

longer drying times and Increase

energy usage.

l

Accumulate Ilnt.

Now start...

1.

Use a ‘/IS Inch socket wrench to

remove two bolts holdina Ihe wood

pallet to the bottom of th>

washer/dryer.

PANEL B

l

1 h&e clamp

l 4 flat water hose washers

l

1 elastic straw

l

1 ire term ’

Insert rear levelmg leg into

the hole in’the rear corner.

Push the leg in until it snap

inlo place. Do the same

thmg with the other

leveling leg in the

other rear corner.

rw

Check Ihe other leg in the same

way. (If the legs don’t adjust, go

through step 3 again.)

Pushuponone 1

~ lea.checkto I

:ind the diamond marking in the

idges of the front legs. Start to

icrew the front legs into the hole in

he triangular brace at the front

:orner of the machine. A little liquid

detergent to lubricale the screw

VIII help. Use pliers to turn lhe leg all

he way to the diamond marking.

he washer/dryer,

~uired.

damaging the

producl do not

remove corner post before cutting.

I

Remove carton.

people are

Page 4

Remove the 2 rear corner pieces

attached to the back of washer/

dryer: Do not remove the foam

shipping pieces between the

washer and dryer until unit is in

place.

Move foam shipping pieces

outward iust enouah to clear the

washer lb. Open iasher lid. Latch

under Ihe dryer will hold lid open.

Shlpplng Strap

with key.

NOTE: Use one hand to hold

down agltator when removing

shipplng straps. After straps

ara removed release agitator, it

will move upward.

10.

Read label. Firmly jerk then pull

one of the three shipping straps up

until strap with key is.co?nplelely

removed horn washer. Repeat for

other two shipping straps.‘Put

straps in the same area as rear

corner shipping pieces.

r

11.

Remove label.

Take hoses out of basket.

1 Place hoses with other parts.

Release washer lid by pushing up

on latch. Close lid.

Pull three straps with

completely out of wa

Numbers correspond

to steps

PANEL C

: Do ns

:piea

dtyel

move foam shipping

1-n the washer and

il unit is in place.

Page 5

Use new hoses and washers

that came with your KitchenAid

washer/dryer.

coupling

m

13

Insert a flat washer Into each

end of the lnlel hoses. Check lhal

washers are firmly sealed in

couplings.

Met valves are plastic, d

strip or crossthread.

Attach hose to bottom inlet valve

opening first. Then second hose

lop inlet valve. Tighlen couplings

by hand, then use pliers to make an

addillonal Iwo-thirds turn.

washer

dlsconnecL Remove

I

IO

connector. Use pliers lo open

clamp and slide clamp over drain

hose. Check for good fll.

16

wire Iorm and

wrap around free end

of drain hose lo make

a “hook” shape.

clamp and coupling. Estimate length

of dram hose needed. Cut flexible

end of hose. (Do not cut hookshaped end of drain hose.) Push

\

I

n

and twlsl couplmg securely onto

drain hose. (You should tee1 lop Of

hose through coupling.) Slide clamp

over couplmg and hose. Remstall

drain hose. See slep 15.

Before atlachmg water Inlet hoses,

run waler through both laucets

get rid of particles in waler lines Ihat

might clog hoses.

20.

Move washer/dryer close

IO

17

lo final position. Put “hook”

a end of drain hose into

laundry tub or standpipe.

Check for proper length of

drain hose.

Atiach botiom hose (inlet marked

“H”) lo hot waler taucel. Attach top

hose (inlet marked “C”) lo cold wale1

faucet. Tighten couplings lo faucet

by hand, then use pliers to make

fmal two-thirds turn.

Numbers correspond

to steps

PANEL D

Remove and discard plug.’

Install wire form on drain

hose.

Page 6

love washerldryer to its

ermanent location.

Check levelness of

n washer/dryer by

Ilacing a carpenter’s level on top of

dasher, first side to side then front

I back. If it is not level, screw the

‘ant legs up or down to adjust. Tilt

rasher forward raising back legs 1”

IH of floor to adjust rear self:veling legs. Gently lower washer

3 floor. Make final check with level.

n

22

‘ut “hook” end of drain hose in tub

jr standpipe. Secure drain hose by

vrapping the plastic strap around

he hose as shown in Figures A-C.

f drain hose cannot be strapped in

,lace, it must be cut exactly to length

io the “hook” end is held tightly over

he edge of the tub or standpipe as

ihown m Figure D.

:HECK THAT HOSE IS NOT

MISTED OR KINKED AND IS

jECURELY IN PLACE.

24.

To exhaust the dryer straight from

lack of the washer/dryer unit,

jetermine if any additional exhaust

duct is needed (see Exhaust

qequirements. Panel 6). To exhaust

.he dryer to either side or Inside

:heck If additional exhaust duct is

Teeded and see Alternate Exhaust

Wethods. Panel F Connect exhausl

jucl to exhaust hood.

Use duct tape to seal all joints.

26.

CHECK ELECTRICAL

REQUIREMENTS. BE SURE YOU

HAVE CORRECT ELECTRICAL

SUPPLY AND RECOMMENDED

GROUNDING METHOD. Check the

installation inslructlons to see that

you have completed each step.

Complete any missed steps before

you continue.

DhilliDs screwdriver

Check that you have all of your tools

30.

Turn on waler faucets and check

for leaks. Tighten couplmgs if there

is leaking.

31.

Plug electrical cord into grounded

outlet.

32.

If access panel was removed to

install ductwork, replace access

panel. Be sure to tighten both

screws.

1

33

Take a few minules and read the

Use and Care Guide to fully

understand your new wastierldryer.

Now start the washer and allow

it to complete the regular cycle.

?xhausf ductwork can not be

:onnected from the side of the

vasher/dryer, the exhaust duct can

)e reached from the front, through

he access panel. Remove the

access panel by unscrewing 2

)hllllps heads screws located at

he top of the panel. Set panel and

icrews aside

NEL E

Check that all parts are now

installed. See parts list, Panel A.

If there is an extra part, go back

through steps to see which step

Check that you removed all the

shipping pieces including the three

shipping straps with keys.

If you do not remove the shipping

straps, your washer/dryer may

“walk” awav from its tocatlon.

Remove the tape across the dryer

lint screen. Check to be

sure lint screen is in its proper

position. Wipe out drum. Start dryer

and allow it to complete a cycle to

make sure the dryer is working

properly

35.

Finally, save all literature and keep

with the washer/dryer. Save all

shlpping materials for reshipping.

You have

successfully Installed your

KItchenAid washer/dryer.

To gel the most efliclent use from

your new washer/dryer read your

KItchenAId Use and Care Guide.

Congratulations!

Keep lnete~ation instructions nearb)

where you can refer to them.

They’ll make re-InstallIng

your KItchenAId washer/dryer

In another home es easy

es the first Instattatlon.

-

\

/

Page 7

Alternate exhaust methods

The washer/dryer mstallad in a

mobile home must be exhausted

JutsIde. When the dryer IS

exhausted through the floor, the

:xhaust system must termmate

Jutside the enclosed area under

noblIe home. Extension beyond the

enclosure will prevent lint and

noisture buildup under the mobile

Tome. See Figure 3.

Mobile home installation

To

remove the power

supply cord -

Disconnect power supply.

1, Remove the terminal block cover

from the dryer.

2. Disconnect the power supply cord

from the termmal block.

3. Use a screwdnver to slide the

strain rehe( clip away from the power

supply cord. (See Figure 5)

4. Pull downward on the power

supply cord until it IS removed from

the dryer.

7

When local codes.. .

A

n

Permit use 01 flexible type power

supply cord (pigtail) that comes

equipped with the washer/dryer but

Do Not Permit connecting the frame

grounding conductor to the neutral

wire of the power supply cord:

Alternate electrical connection

Electrical ground is required on

this appliance.

This appliance is manufactured

with the neutral terminal connected

to the frame.

To connect a separate

grounding wire -

Use grounding wire and clamp

assembly (Part No. 665463) or

No. 10 gauge minimum copper

grounding wire. Connect grounding

wire to a grounded cold water pipe’

with the clamp and then to the

external grounding connector on

washer/dryer. Do not ground to

a gas sup$y pipe. Do not connect

the Dower SUDDIV cord to electric

power supplj ;itil appliance Is

permanently grounded.

No. A

Figure 4

Grounded cold water pipe must

have metal continuity to electrical

ground and not be Interrupted by

plastic, rubber or other electrlcal

Insulating connectors such as

hoses, finings, washer or gaskets

(including water meter or pump).

Any electrical insulating connector

should be jumped as shown In

Figure 4 with a length of No. 4 wire

securely clamped to bare metal

at both ends.

4NEL F

Figure 5

Pull out power supply cord.

away trdm

power

supply cord.

To connect

Plain wire ends -

I. Strip outer covering back 3 inches

irom the end exposing the 3 wires.

2. Strip the insulation back 1 inch

from the end of each wire. Form the

Dare wire into a “U” shaped hook.

3. Loosen, do not remove, screws

from terminal block. Attach wires

according to instrucflons for type of

:onnection needed.

1. Slide the end of each wire under

the screw head with the ooen &de

si the hook on the right.. Sbueeze

the wire together to form a loop.

5. Tighten each screw firmly.

Ptaln-end field wiring

Figure 6

To use non-metallic

sheathed copper power

suppfy cabfe -

CAUTION: If non-metallic sheathed

copper power supply cable is

used, it must be used with a U.L.

recognized strain relief (U L. mark

on it or KitchenAid Part No. 667000)

to fit a one Inch hole size similar to

the one shown In Figure 7.

Figure 7

1. Remove terminal block cover.

2. Remove the grounding wire

(green) from the internal grounding

connector and fasten under center

sliver-coated terminal block screw.

See Figure 6.

3. Connect a separate copper

grounding wire (No. 10 minimum).

See “To connect a separate

grounding wire:’ Panel F for detallec

instructlone

4. Replace terminal block cover.

Page 8

When localcodes...

B.

Do Not Permit the use of Ihe flexible

power supply cord equipped with the

washer/dryer and

Permit copper power supply cable

and

Permit connecting frame grounding

conductor to Ihe neutral wire of the

power supply cable:

Figure 9

1. Remove the power cord equipped

with the washer/dryer as Instructed.

See Panel F, “To remove the power

supply cord:’

2. Install copper power supply cable

and stram relief.

3. Connect the neutral wire of the

flexible armored or non-metallic

sheathed copper power supply

cable to the center. silver-colored

terminal screw of the terminal

block. Connect the other wires to

the outer terminals. See Fiaure 9

For plain-end wires, see “TG

connect plain wire ends:’ Panel F

4. Replace the terminal block cover.

When local codes...

C

n

Do Not Permit Ihe use of the

flexible power supply cord equipped

with the washer/dryer and

Permit copper power supply cable

and

Do Not Permit connectmg frame

grounding conductor to the neutral

wire of the power supply cable:

Neutral

(whim 0, ceme,)

1. Remove the power cord equipped

with the washer/dryer as instructed.

See “To remove the power supply

cord:’ Panel E

2. Install copper power supply cable

and strain relief.

3. Remove the grounding wire

(green) from the internal grounding

connector and fasten under center,

silver-colored terminal block screw.

4. Connect the neutral wire of the

flexible armored or non-metallic

sheathed copper power supply

cable to the center, silver-colored

terminal screw oi the terminal block.

Connect the other wires to the

Outer terminals. See Figure 10. For

plain-end wires, see “To connect

plain wire ends:’ Panel F

5. Connect a separate copper

grounding wire (No. 10 minimum).

See “To connect a separate

grounding wire:’ Panel F for detailed

instructions.

6. Replace the terminal block cover.

center silvar-colorB(

terminal block screw

Figure 10

Mobile home

installation

Requires a four-wire power supply

cord or cable.

Figure 11

1. Remove the power cord equipped

with the washer/dryer as Instructed.

See Panel F, “To remove the power

supply cord:’

2. Install copper 4-wire power

supply cord and a U.L. recognized

stram relief.

3. Remove the groundmg wire

(green) from the inlernal grounding

connector and fasten under center,

silver-colored terminal block screw.

4. Connect the grounding wire

(green) of the copper 4-wire power

supply cord to the internal grounding

connector.

5. Connect the neutral wire (white) of

the power supply cord lo the center.

silver-colored terminal screw of the

terminal block. Connect the other

wires to the outer terminals. See

Figure 11.

6. Replace the termmal block cover.

PANEL G

Page 9

This appliance is

manufactured with the

neutral terminal connected

to the frame.

Replace lermitw

Mock cover.

-

PANEL G

Page 10

Recessed area

hlstructions

This washer/dryer may be installed

in a recessed area or closet.

This installation spacing is in inches

and is minimum allowable.

Additional spacing should be

considered for ease of installation

and servicing.

If closet door is installed the

minimum air openings in top and

bottom is required. Louvered doors

with equivalent air openings are

acceptable.

Other installations must use the

minimum dimensions indicated.

To prevent large amounts of lint and

moisture from accumulating and to

maintain drying efficiency, this

appliance must be exhausted

outdoors.

Recessed non-exhausted InstslWon

must use only ths msr erhsud poslUon

and Exhaust Dsfktor LCK4500

Washer

l-r-

exhausted all spsclng csn tm 0:

ie mqulred.

Front View

Duct dimensions

- 21Hr”-~

Part No. 3367262

Closet Door

Closet Door

1

46 sq. In.

f

i

14 eq. in.

f

Front View

Closet installation must be

exhaustsd.

Prepared by KitchenAid, Sl. Joseph, Michigan 49065

. I

Recess ’

Depth

2%”

Cold

Wster

Inlet

I

Recess Width

Printed in U.S.A.

Loading...

Loading...