KitchenAid KXW9736Y, KXW9748Y Installation Guide

36" (91.4 CM) AND 48" (121.9CM) DESIGNER

COMMERCIAL-STYLE WALL-MOUNT CANOPY

RANGE HOOD

Installation Instructions and Use & Care Guide

For questions about features, operation/performance, parts, accessories or service, call: 1-800-422-1230

In Canada, for assistance, installation and service, call: 1-800-807-6777

or visit our website at www.kitchenaid.com

or visit our website at www.kitchenaid.ca

HOTTE DE CUISINIÈRE STYLISÉE DE TYPE

COMMERCIAL, À MONTAGE MURAL -

36" (91,4 CM) ET 48" (121,9 CM)

Instructions d’installation et Guide d’utilisation et d’entretien

Au Canada, pour assistance, installation ou service composez le 1-800-807-6777

Para obtener acceso al manual de uso y cuidado en español, o para obtener información adicional acerca de su producto, visite:

Tenga listo su número de modelo completo. Puede encontrar el número de modelo y de serie dentro de la cavidad superior de la puerta.

ou visitez notre site web à www.kitchenaid.ca

www.kitchenaid.com.

Table of Contents/Table des matières.............................................................................2

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS.

FOR RESIDENTIAL USE ONLY.

IMPORTANT : LIRE ET CONSERVER CES INSTRUCTIONS.

POUR UTILISATION RÉSIDENTIELLE UNIQUEMENT.

LI3ZBB/W11374535A

TABLE OF CONTENTS

TABLE DES MATIÈRES

RANGE HOOD SAFETY .................................................................2

INSTALLATION REQUIREMENTS................................................4

Tools and Parts............................................................................4

Location Requirements................................................................4

Venting Requirements..................................................................5

Electrical Requirements ...............................................................6

INSTALLATION INSTRUCTIONS..................................................7

Prepare Location..........................................................................7

Install Range Hood.......................................................................8

Install Range Hood Internal Blower Motor...................................8

Install Range Hood In-Line (External Type) Blower Motor ........10

Make Electrical Connections for In-Line Blower

Motor System..................................................................

Make Electrical Power Supply Connection to Range Hood .....13

Install Chimney Covers ..............................................................14

Complete Installation and Check Operation..............................14

RANGE HOOD USE......................................................................15

Range Hood Controls ................................................................15

RANGE HOOD CARE ...................................................................16

Cleaning......................................................................................16

WIRING DIAGRAM .......................................................................17

ASSISTANCE OR SERVICE.........................................................18

In the U.S.A. ...............................................................................18

In Canada ...................................................................................18

Accessories ................................................................................18

...........12

SÉCURITÉ DE LA HOTTE DE CUISINIÈRE ...............................21

EXIGENCES D'INSTALLATION ...................................................23

Outils et pièces...........................................................................23

Exigences d'emplacement.........................................................23

Exigences concernant l'évacuation ...........................................24

Spécifications électriques..........................................................26

INSTRUCTIONS D'INSTALLATION.............................................26

Préparation de l'emplacement...................................................26

Installation de la hotte................................................................27

Installation du moteur du ventilateur interne de la hotte...........28

Installation du moteur du ventilateur en ligne (externe) de

la hotte................

Réalisation des connexions électriques du système du

moteur du ventilateur en ligne....................................................32

Réalisations des connexions de l’alimentation

électrique à la hotte....................................................................33

Installation du cache-cheminée .................................................34

Achever l'installation et vérifier le fonctionnement ....................34

UTILISATION DE LA HOTTE .......................................................35

Commandes de la hotte de cuisinière .......................................35

ENTRETIEN DE LA HOTTE..........................................................36

Nettoyage ...................................................................................36

SCHÉMA DE CÂBLAGE...........................................

ASSISTANCE OU SERVICE.........................................................38

Au Canada..................................................................................38

Accessoires ................................................................................38

........................................................................30

....................37

RANGE HOOD SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

■ Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

■ Before servicing or cleaning the unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag,

to the service panel.

■ Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

■ Do not operate any fan with a damaged cord or plug.

Discard fan or return to an authorized service facility for

examination and/or repair.

■ Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), the American Society for

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

■ When cutting or drilling into wall or ceiling; do not damage

electrical wiring and other utilities.

■ Ducted fans must always be vented outdoors.

CAUTION: For general ventilating use only. Do not use

to exhaust hazardous or explosive materials and vapors.

CAUTION: To reduce risk of fire and to properly exhaust

air, be sure to duct air outside - do not vent exhaust air into

spaces within walls or ceilings, attics or into crawl spaces,

or garages.

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY

METAL DUCTWORK.

WARNING: TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

■ Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

■ Always turn hood ON when cooking at high heat or when

flambeing food (i.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambé).

■ Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

■ Use proper pan size. Always use cookware appropriate for

the size of the surface element.

WARNING: TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING:

■ SMOTHER FLAMES with a close fitting lid, cookie sheet, or

metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out

immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

■ NEVER PICK UP A FLAMING PAN - you may be burned.

■ DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

■ Use an extinguisher ONLY if:

– You know you have a class ABC extinguisher, and you

already know how to operate it.

– The fire is small and contained in the area where it

started.

– The fire department is being called.

– You can fight the fire with your back to an exit.

a

Based on "Kitchen Fire Safety Tips" published by NFPA.

■ WARNING: To reduce the risk of fire or electrical shock,

do not use this fan with any solid-state speed control

device.

a

READ AND SAVE THESE INSTRUCTIONS

3

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Too ls n ee ded

■ Level

■ Drill

■ Drill 1¼" (3 cm) drill bit

■ ³⁄₃₂" (2.4 mm) drill bit if installing into wood

■ Pencil

■ Wire stripper or utility knife

■ Tape measure or ruler

■ Pliers

■ Caulking gun and weatherproof caulking compound

■ Vent clamps

■ Jigsaw or keyhole saw

■ Flat-blade screwdriver

■ Metal snips

■ Phillips screwdriver

■ Scissors

Parts needed

■ Home power supply cable

■ 1 - ½" (12.7 mm) UL listed or CSA approved strain relief

■ 3 UL listed wire connectors

■ 1 wall or roof cap

■ Metal vent system

■ 2 - 175-watt max heat lamp bulbs

■ Blower motor system - internal or external (see “Blower

Motor System” in the “Accessories” section.)

Parts supplied

Remove parts from packages. Check that all parts are included.

■ 2 metal grease filters for 36" (91.4 cm) models

3 metal grease filters for 48" (121.9 cm) models

■ Damper

■ 2 - Vent cover support brackets

■ 2 - 10 x 50 mm mounting screws

■ 2 - 8 x 40 mm mounting screws

■ 2 - D5.3 x 20 mm washers

■ 4 - 5 x 45 mm screws

■ 6 - 4.2 x 8 mm screws

■ T-20 TORX

®†

adapter

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

Have a qualified technician install the range hood. It is the

installer's responsibility to comply with installation clearances

specified on the model/serial rating plate. The model/serial rating

plate is located inside the range hood on the rear wall of the

range hood.

Canopy range hood location should be away from strong draft

areas, such as windows, doors and strong heating vents.

Cabinet opening dimensions that are shown must be used. Given

dimensions provide minimum clearance.

The canopy range hood is factory set for venting through the roof

or through the wall.

All openings in ceiling and wall where canopy range hood will be

installed must be sealed.

For Mobile Home Installations

The installation of this range hood must conform to the

Manufactured Home Construction Safety Standards, Title 24

CFR, Part 328 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD, Part 280) or when such

standard is not applicable, the standard for Manufactured Home

Installation 1982 (Manufactured Home Sites, Communities and

Setups) ANSI A225.1/NFPA 501A, or latest edition, or with local

codes.

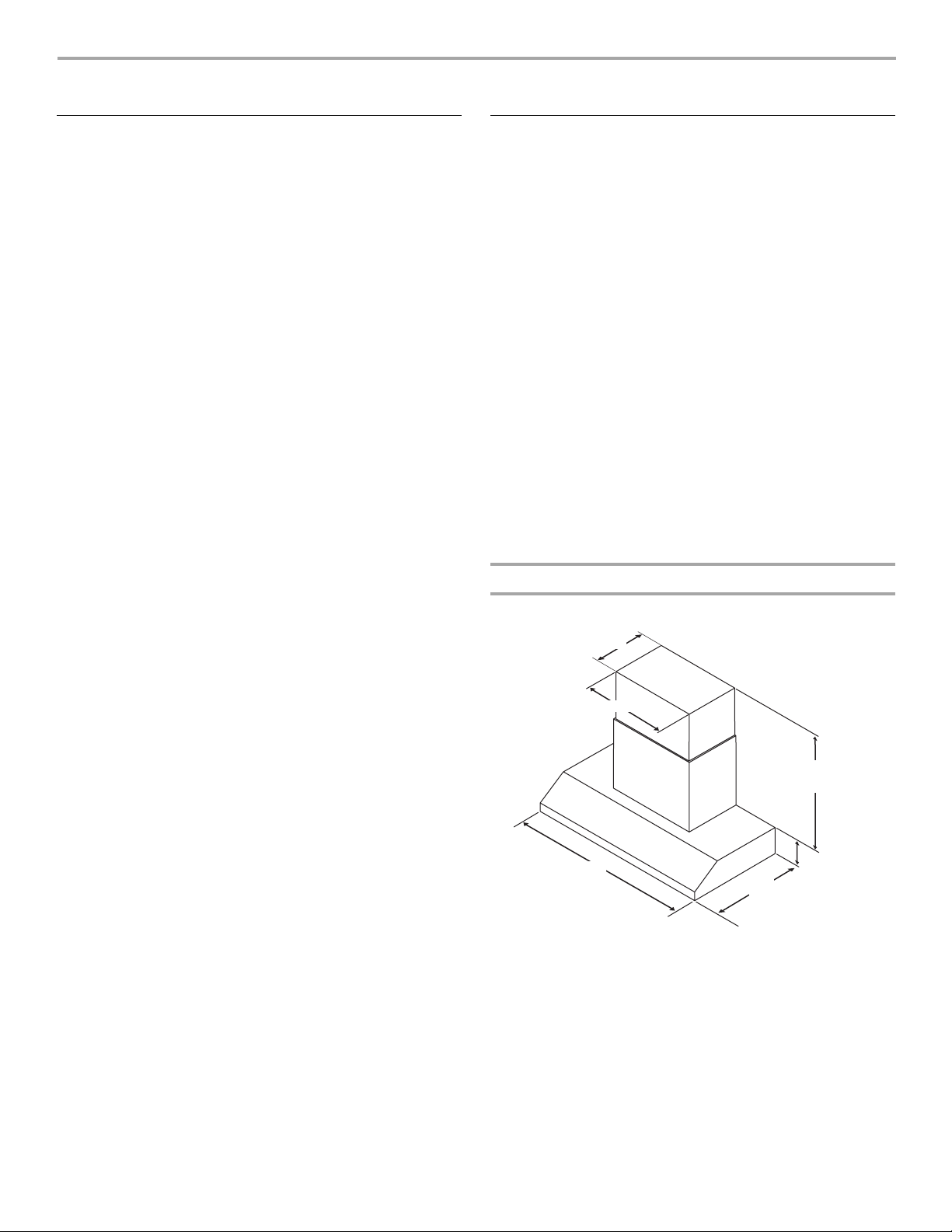

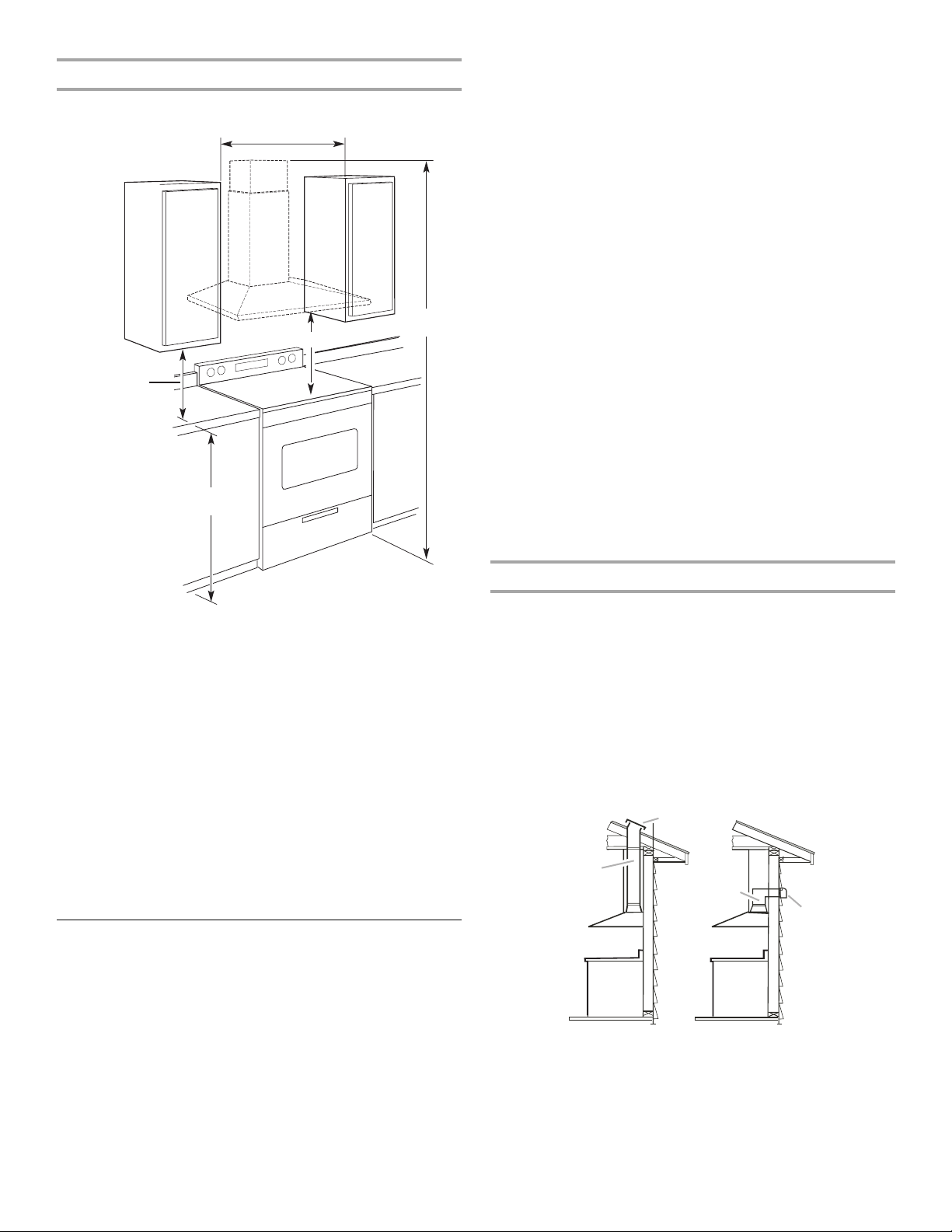

Product Dimensions

Vented Installations

11⁵⁄₁₆" (28.7 cm)

22³⁄₄" (57.8 cm)

24½" (62.3 cm) min.

32⁷⁄₁₆" (82.4 cm) max.

36" (91.4 cm)

or 48" (121.9 cm)

25" (63.5 cm)

7⁷⁄₈" (20.0 cm)

†®TORX is a registered trademark of Saturn Fasteners, Inc.

4

Installation Dimensions

36" (91.4 cm) or 48" (121.9 cm)

or cabinet opening width

(if installed between cabinets)

For the most efficient and quiet operation:

■ Use no more than three 90° elbows.

■ Make sure there is a minimum of 24" (61.0 cm) of straight

vent between the elbows if more than 1 elbow is used.

■ Do not install 2 elbows together.

■ Use clamps to seal all joints in the vent system.

■ The vent system must have a damper. If the roof or wall cap

has a damper, do not use the damper supplied with the range

hood.

■ Use caulking to seal exterior wall or roof opening around the

cap.

■ The size of the vent should be uniform.

See Note*

X*

18" (45.7 cm) min.

clearance upper

cabinet to countertop

36" (91.4 cm)

countertop height

*NOTE: The range hood chimneys are adjustable and designed

to meet varying ceiling or soffit heights depending on the

distance “X” between the bottom of the range hood and the

cooking surface. For higher ceilings, an Extension Kit Part

Number W10352733 is available from your dealer or an

authorized parts distributor. The chimney extension replaces the

upper chimney shipped with the range hood.

IMPORTANT:

Minimum distance “X”: 24" (61 cm) from electric cooking

surfaces

Minimum distance “X”: 30" (76.2 cm) from gas cooking

surfaces

The chimneys can be adjusted for ceilings between 8' 2³⁄₈" (2.5 m)

and 8' 10⁵⁄₁₆" (2.7 m) when mounted at 30" (76.2 cm) height over

a gas cooking surface.

The chimneys can be adjusted for ceilings between 7' 8³⁄₈" (2.4 m)

and 8' 4⁵⁄₁₆" (2.55 m) when mounted at 24" (61 cm) height over

electric cooking surface.

Cold weather installations

An additional back draft damper should be installed to minimize

backward cold air flow and a thermal break should be installed to

minimize conduction of outside temperatures as part of the vent

system. The damper should be on the cold air side of the thermal

break.

The break should be as close as possible to where the vent

system enters the heated portion of the house.

Makeup air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

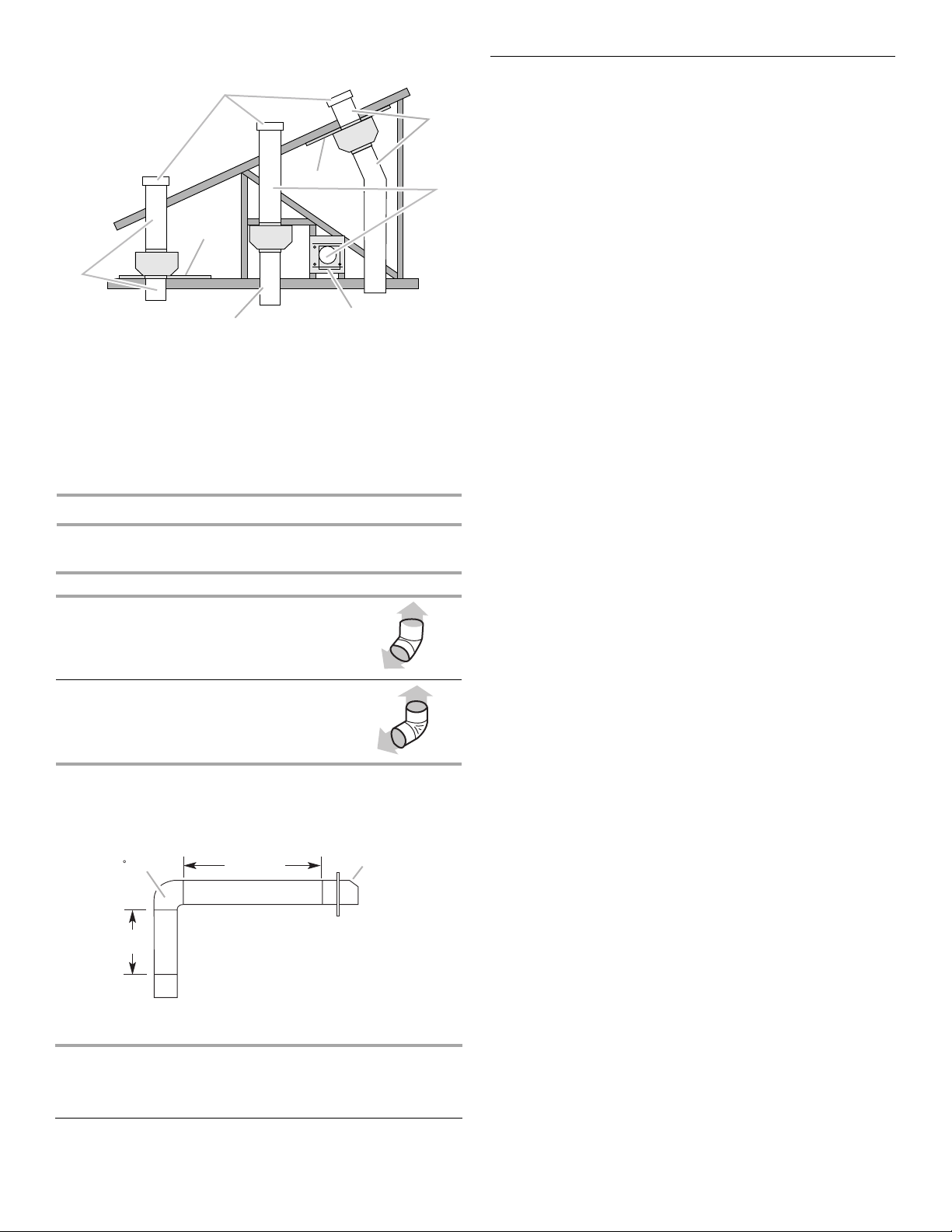

Venting Methods

Typical Internal Blower Motor System Venting Installations

A 10" (25.4 cm) round vent system is needed for installation (not

included). The range hood exhaust opening is 10" (25.4 cm)

round.

NOTE: Flexible vent is not recommended. Flexible vent creates

back pressure and air turbulence that greatly reduce

performance.

Vent system can terminate either through the roof or wall. To vent

through the wall, a 90º elbow is needed.

Roof Venting Wall Venting

A

B

B

A

Venting Requirements

■ Vent system must terminate to the outdoors.

■ Do not terminate the vent system in an attic or other enclosed

area.

■ Do not use 4" (10.2 cm) laundry-type wall caps.

■ Use metal vent only. Rigid metal vent is recommended.

Plastic or metal foil vent is not recommended.

■ The length of vent system and number of elbows should be

kept to a minimum to provide efficient performance.

A. Roof cap

B. 10" (25.4 cm)

round vent

A. Wall cap

B. 10" (25.4 cm)

round vent

5

Typical In-line Blower Motor System Venting Installations

A

C

A

E

D

D

A

B

A. 10" (25.4 cm) round vent

B. Mount on top of ceiling joists.

C. Roof caps

D. Plywood (optional on some installations)

E. Mount on underside of roof rafters.

F. Mount from cross-members tied to trusses.

G. Duct horizontal; mount to cross-members

tied to trusses.

H. Wall cap

F

A

G

H

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

Vent Piece Equivalent Length

45° elbow 2.5 ft

90° elbow 5.0 ft

(0.8 m)

(1.5 m)

Electrical Requirements

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70 (latest

edition), or CSA Standards C22.1-94, Canadian Electrical Code,

Part 1 and C22.2 No. 0-M91 (latest edition) and all local codes

and ordinances.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ A 120 volt, 60 Hz., AC only, 15-amp, fused electrical circuit is

required.

■ If the house has aluminum wiring, follow the procedure

below:

1. Connect a section of solid copper wire to the pigtail

leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

■ Wire sizes and connections must conform with the rating of

the appliance as specified on the model/serial rating plate.

The model/serial plate is located behind the filter on the rear

wall of the range hood.

■ Wire sizes must conform to the requirements of the National

Electrical Code, ANSI/NFPA 70 (latest edition), or CSA

Standards C22. 1-94, Canadian Electrical Code, Part 1 and

C22.2 No. 0-M91 (latest edition) and all local codes and

ordinances.

The maximum equivalent vent lengths are:

10" (25.4 cm) round vent - 60 ft (18.3 m)

Example vent system

90 elbow

2 ft

(0.6 m)

6 ft (1.8 m)

The following example falls within the maximum recommended

vent length.

1 - 90° elbow = 5.0 ft (1.5 m)

1 - wall cap = 0.0 ft (0.0 m)

8 ft (2.4 m) straight = 8.0 ft (2.4 m)

Length of system = 13.0 ft (3.9 m)

Wall cap

6

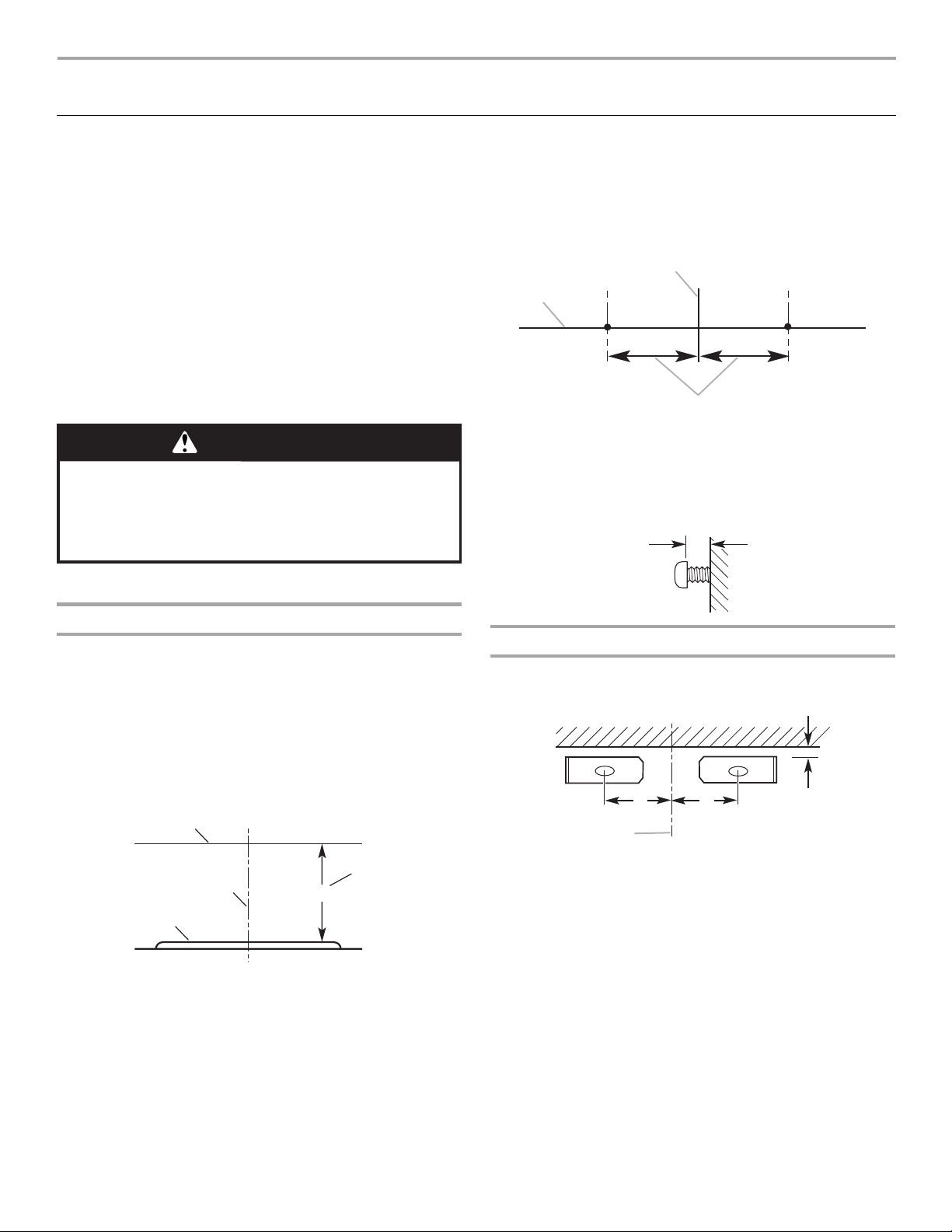

INSTALLATION INSTRUCTIONS

Prepare Location

■ It is recommended that the vent system be installed before

range hood is installed.

■ Before making cutouts, make sure there is proper clearance

within the ceiling or wall for exhaust vent.

■ Range hood is to be installed 24" (61.0 cm) min. for electric

cooking surfaces, 30" (76.2 cm) min. for gas cooking

surfaces, to a suggested maximum of 36" (91.4 cm) above

the cooking surface.

■ Check your ceiling height and the range hood height

maximum before you select your range hood.

1. Disconnect power.

2. Determine which venting method to use: roof or wall.

3. Select a flat surface for assembling the range hood. Place

covering over that surface.

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

4. Drill ³⁄₃₂" (2.4 mm) pilot holes for installation into wood. The

screws provided for mounting this range hood must be

fastened into solid wood. Do not fasten only into sheet rock.

IMPORTANT: All screws must be installed into wood. If there

is no wood to screw into, additional wall framing supports

may be required.

B

A

C

A. Horizontal line

B. Vertical centerline of range hood

C. 5¹¹⁄₁₆" (14.4 cm)

5. Install the 4.2 x 9.5 cm mounting screws. Leave a

¹⁄₄" (6.4 mm) gap between the wall and the back of the screw

head to slide range hood into place.

¹⁄₄"

(6.4 mm)

4. Using 2 or more people, lift range hood onto covered surface.

Range Hood Mounting Screws Installation

1. Determine and mark the centerline on the wall where the

range hood will be installed.

2. Based on the ceiling or soffit height, determine the distance

“X” (24" [61.0 cm] min. from electric cooking surface or

30" [76.2 cm] min. to gas cooking surface, suggested

36" [91.4 cm] max.) needed between the cooking surface and

the bottom of the range hood. To this distance, add

17¹⁄₈" (43.5 cm) and draw a horizontal line (A) about

24" (61.0 cm) long centered on the vertical centerline (B) at

this distance.

A

D

B

C

A. Horizontal line

B. Vertical centerline

C. Cooking surface

D. Distance “X” (24" [61.0 cm] min. from

electric cooking surface, 30" [76.2 cm] min.

from gas cooking surface, suggested 36"

[91.4 cm] max.) +17

X + 17¹⁄₈" (43.5 cm)

¹⁄₈

" (43.5 cm)

Chimney Support Bracket Installation

1. Place two of the chimney brackets against the wall so that

their top edges are ¹⁄₁₆" (2.0 mm) from the ceiling or soffit and

level. Mark holes.

C

C

A

A. Vertical centerline

B.

¹⁄₁₆

" (1.6 mm)

⁹⁄₁₆

" (26.9 cm)

C. 10

2. Drill pilot holes.

■ If installing into wood, drill 4 - ³⁄₃₂" (2.4 mm) pilot holes.

3. Attach each bracket to the wall with a 4.2 x 9.5 cm mounting

screw. Tighten screws securely.

B

3. Following the illustrations in Step 4, mark points on each side

of the horizontal line as measured from the vertical centerline.

7

Complete Preparation

1. Determine and make all necessary cuts in the wall for the vent

system. Install the vent system before installing the range

hood. See the “Venting Requirements” section.

2. Determine the location where the power supply cable will be

run through the wall. Be sure that the location will be covered

by the chimney of the range hood.

3. Drill a 1¹⁄₄" (3.2 cm) hole at this location.

4. Pull enough power supply cable through the wall to allow for

easy connection to the terminal box.

NOTE: Your range hood requires you to purchase either an

internal type or an in-line (external type) blower motor system.

For internal blower systems, there are blower motor mounting

parts in the blower motor installation packet that must be added

to the range hood prior to mounting the range hood to the wall.

See the “Install Range Hood Internal Blower Motor” section and

the instructions supplied with the blower motor.

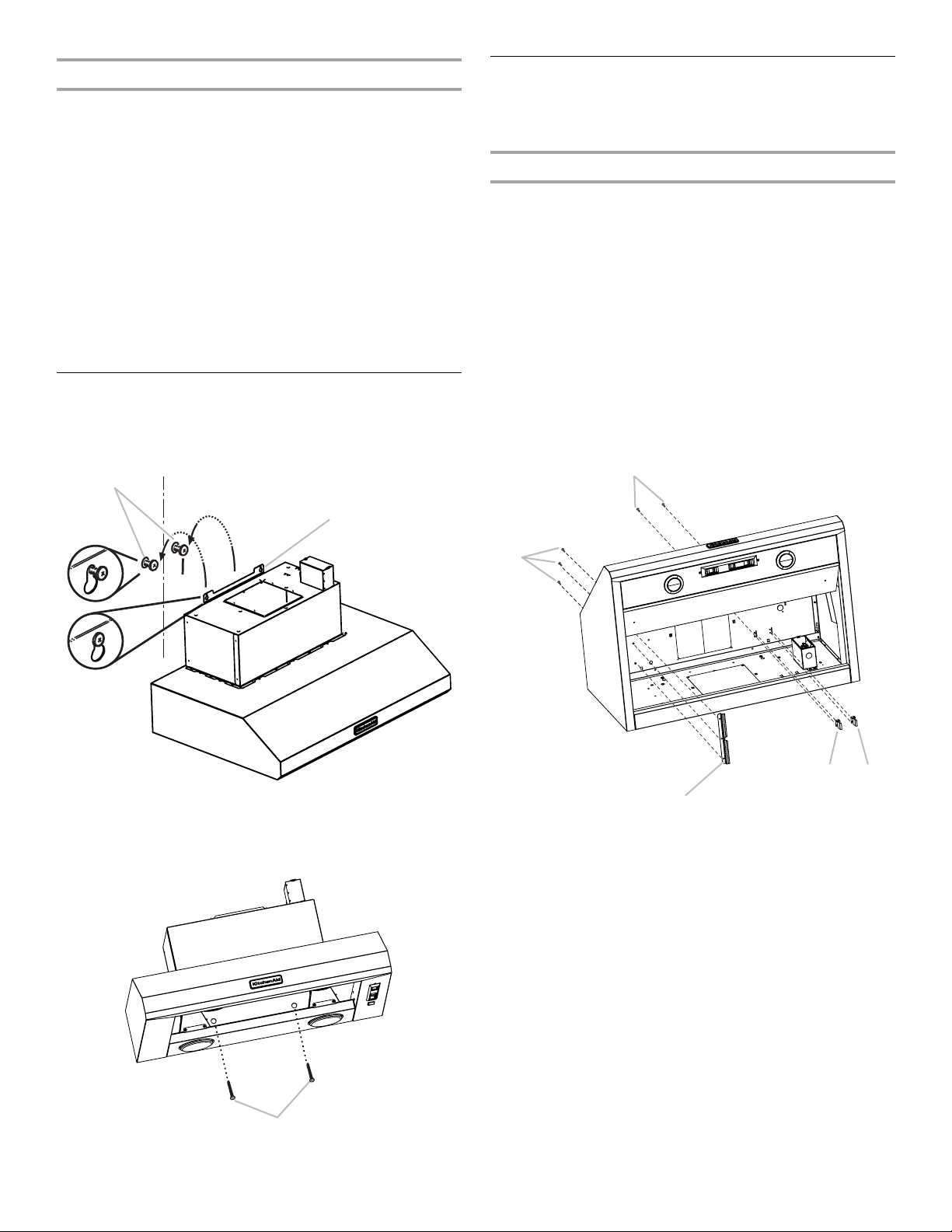

Install Range Hood

1. Remove the grease filter. See “Range Hood Care” section.

2. Using 2 or more people, hang range hood on 2 mounting

screws through the mounting slots on back of range hood.

A

B

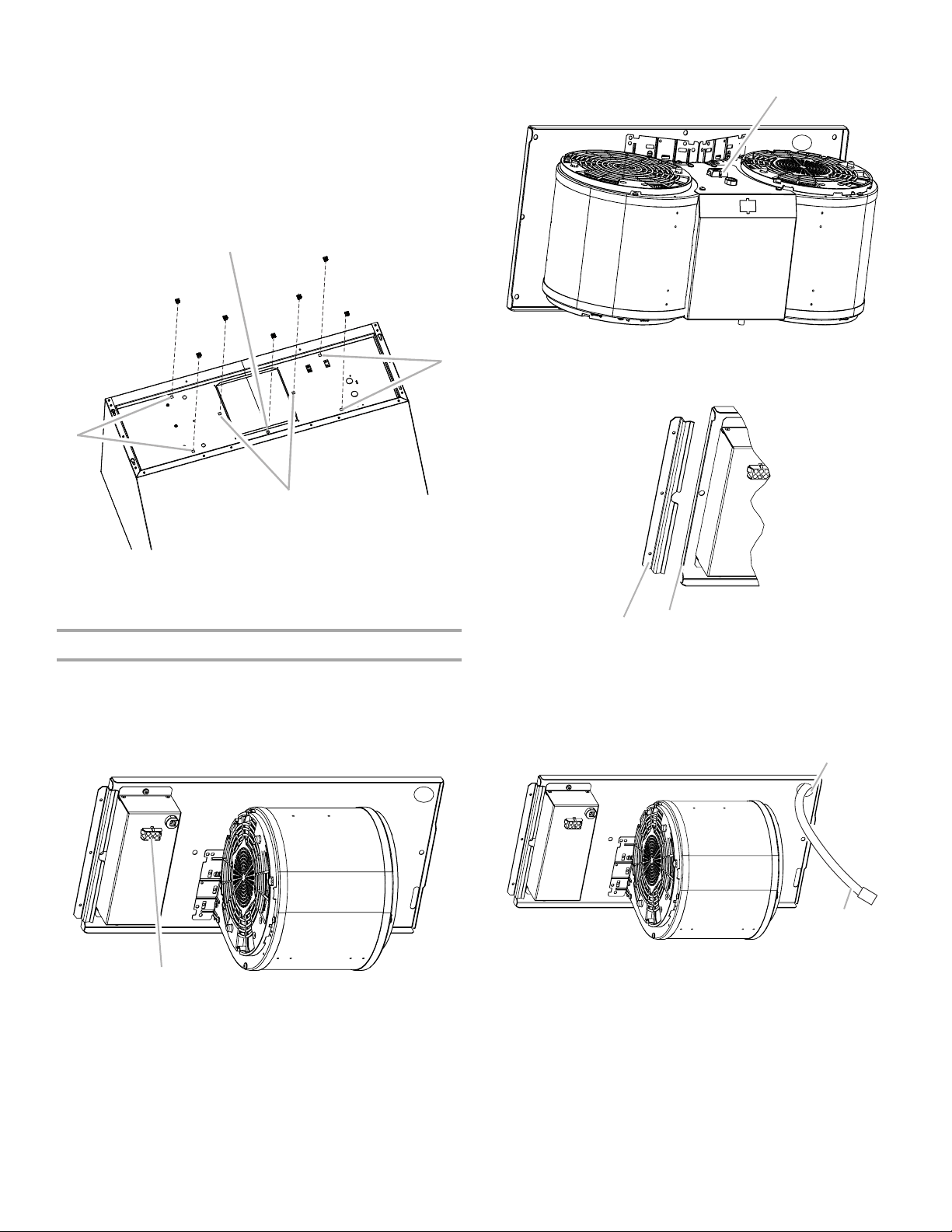

Install Range Hood Internal Blower Motor

NOTE: Your range hood requires you to purchase either an

internal type or an in-line (external type) blower motor system.

See “Blower Motor System” in the “Accessories” section.

Prepare the Internal Blower System

IMPORTANT: Perform steps 1-4 before mounting the range

hood.

1. Remove grease filters from range hood. See the “Range

Hood Care” section in the Use and Care Guide.

2. Install the motor support bracket using three 4.2 x 8 mm

screws. Screw bracket to the inside top or back (alternate

location on some models), toward the left side of the range

hood.

3. Install motor spring clip using two 4.2 x 8 mm screws. Screw

spring clip to the inside top or back (alternate location on

some models) of the range hood at the proper location for the

selected motor system. Slide the mounting tab of the spring

clip through the slot in the panel and secure with the screws.

Use the inside set of mounting holes for the single motor

system. Use the outside set of mounting holes for the dual

motor system.

B

A. Mounting screws

B. Mounting slots

3. Level the range hood and tighten upper mounting screws.

4. Install 2 - 5 x 45 mm lower mounting screws and tighten.

A

E

D

C

A. 4.2 x 8 mm screws (3) for motor support bracket

B. 4.2 x 8 mm screws (2) for motor spring clip

C. Motor support bracket

D. Motor spring clip (single motor assembly location)

E. Motor spring clip (dual motor assembly location)

A

A. Lower mounting screws

8

4. Install the 6 mm nuts to the outside top or outside back

A

(alternate location on some models) of the range hood at the

proper location for the selected motor system.

■ Two 6 mm nuts are required for the single motor system.

Clip nuts into the small square notches located at the left

and right end of the square vent opening.

■ Five 6 mm nuts are required for the dual motor system.

Clip nuts into the small square notches, one located in the

front of the square vent opening and the other four

located at the left and right ends of the square vent

opening.

A

A

B

Dual Blower Motor Assembly

A

A. Wiring connection

2. Slide the left mounting plate flange under the motor mounting

bracket.

A. Clip nut locations for dual motor assembly (5)

B. Clip nut locations for single motor assembly (2)

5. Mount range hood. See the “Install Range Hood” section.

Install Range Hood Internal Blower Motor

1. Install the range hood blower motor assembly inside the

range hood canopy with the wiring connection to the left for

the single motor system and to the front or top for the dual

motor system.

Single Blower Motor Assembly

A

A. Wiring connection

B

A

A. Motor mounting bracket

B. Mounting plate left flange

3. Run the power supply wires and connector from the range

hood through the hole in the right end of the motor mounting

plate.

A

B

A. Motor mounting plate hole

B. Power supply wires and connector

9

4. Push the right end of the motor mounting plate up and snap it

A

B

into the spring tab.

NOTE: The spring tab should be outside the slot in the

mounting plate.

A. Motor mounting plate

B. Spring clip

5. Align mounting holes and install 6 x 16 mm screws and

6.4 mm lock washers.

A

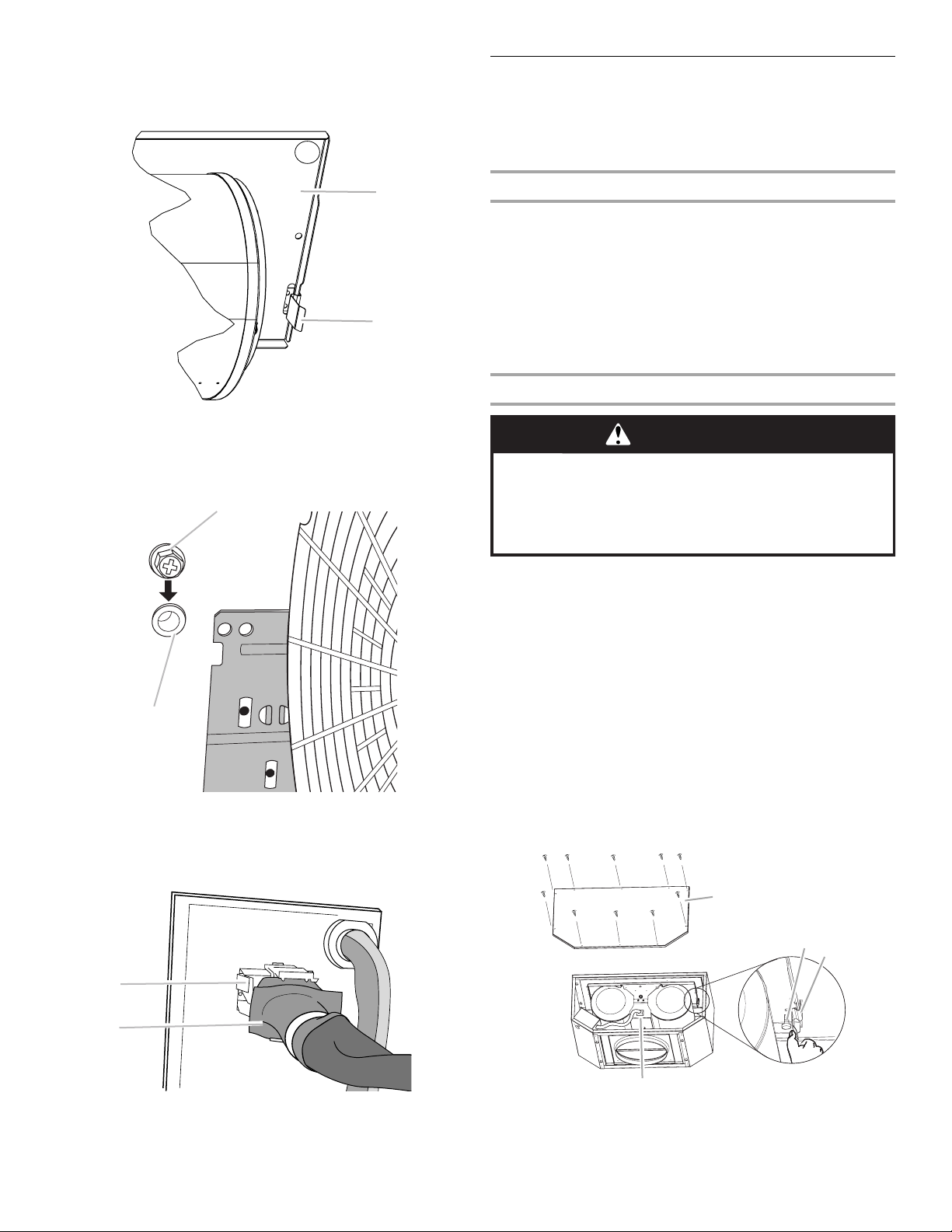

Install Range Hood In-Line (External Type)

Blower Motor

NOTE: Your range hood requires you to purchase either an

internal type or an in-line (external type) blower motor system.

See “Blower Motor System” in the “Accessories” section.

Prepare for Mounting the In-Line Blower System

The in-line blower system must be fastened to a secure structure

of the roof, ceiling, wall, floor, or new or existing frame

construction. The 4 holes on either the inlet (bottom) side or the

outlet (top) side of the blower must be used to mount the in-line

blower system to the structure.

NOTE: The mounting hole locations must span the studs.

Additional stud framing may be required. Plywood may be used

to span open areas between ceiling joists or roof rafters to aid

installation. This structure must be strong enough to support the

weight of the in-line blower system (50 lb [22.6 kg] min).

Prepare the In-line Blower System

WARNING

Excessive Weight Hazard

Use two or more people to move and install in-line

blower motor system.

Failure to do so can result in back or other injury.

B

A. Screw with lock washer

B. Mounting hole

6. Attach power supply connector from the range hood to the

connector on the blower motor assembly wiring box.

A

B

1. Using 2 or more people, move the in-line blower motor

system to the mounting location.

2. Remove the 10 screws from the front cover of the in-line

blower motor housing and set them aside.

3. Remove the front cover of the in-line blower motor housing

and set it aside.

NOTE: To make the blower motor housing easier to mount,

the blower motor assembly can be removed. If you do not

want to remove the blower motor assembly, proceed to

“Install In-line Blower System” in this section.

4. Disconnect the motor electrical plug from the blower motor

assembly.

5. Remove the screws that secure the blower motor assembly

to the in-line blower housing and set them aside.

6. Pull the spring clip to release the blower motor assembly.

Remove the blower motor assembly from the housing and

place it on a covered surface.

A

B

C

A. Wiring box connector

B. Power supply connector from range hood

7. Go to the “Make Electric Power Supply Connection to Range

Hood” section.

10

D

A. Front cover

B. Blower mounting screws

C. Spring clip

D. Motor electrical plug

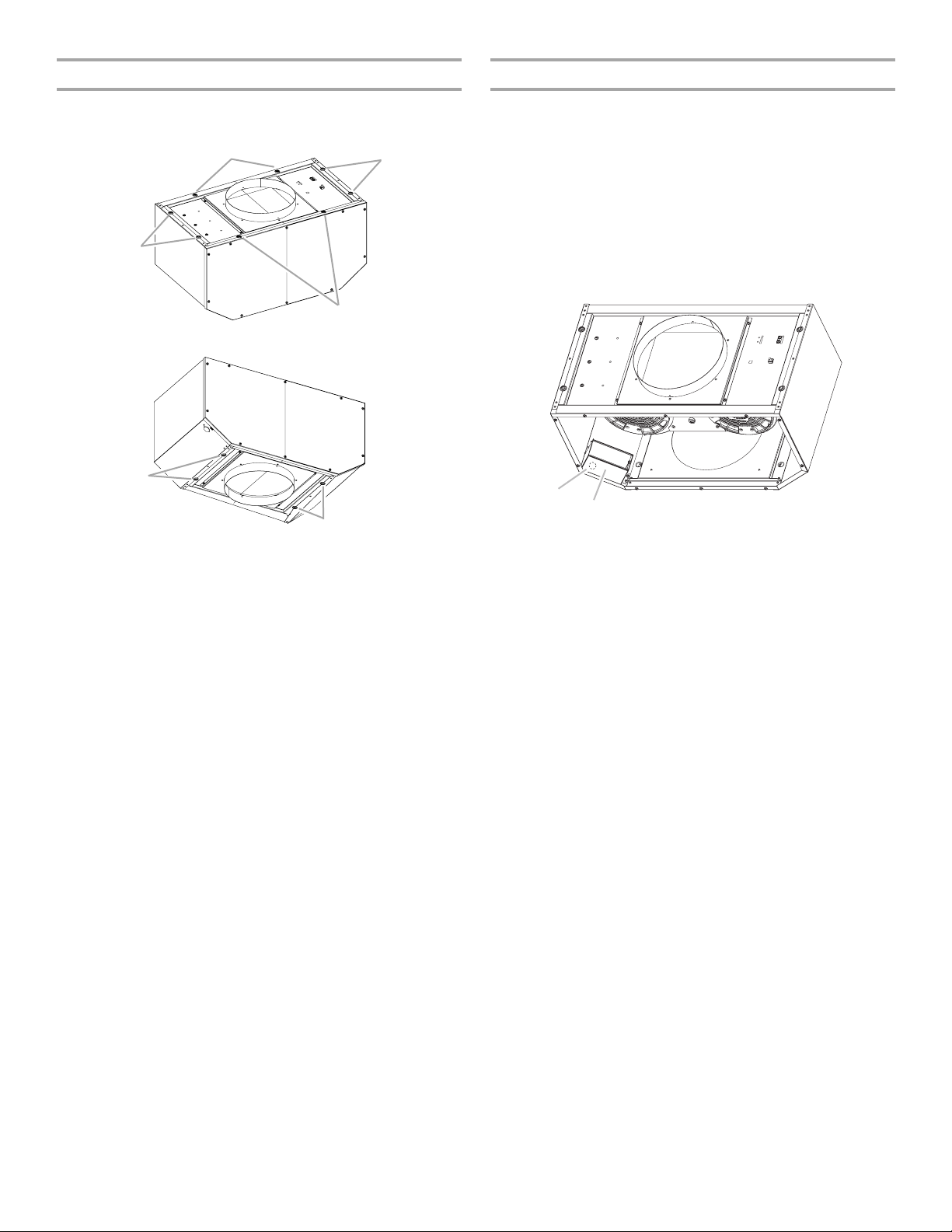

Install In-line Blower System

A

Complete Preparation

NOTE: The blower motor housing can be mounted using 4 holes

from either the inlet side or the outlet side of the blower.

A

A

A

A

A

A. Mounting holes

1. Determine and make all necessary cuts for the vent system.

IMPORTANT: When cutting or drilling into the ceiling or wall,

do not damage electrical wiring or other hidden utilities.

2. Determine the location where the ¹⁄₂" (1.3 cm) wiring conduit

will be routed through the ceiling or wall between the in-line

blower and the range hood.

3. Drill a 1¹⁄₄" (3.2 cm) hole at this location.

4. Locate the electrical terminal boxes in the in-line blower

housing and range hood (see “Complete Preparation” in the

“Prepare Location” section). Remove the terminal box covers

and set the covers and screws aside.

B

A

A. Electrical terminal box

B. Electrical knockout

1. Position the in-line blower motor housing in its mounting

location and mark the 4 mounting hole locations.

2. Drill 4 mounting pilot holes using a ³⁄₁₆" (0.48 cm) drill bit.

3. Attach the in-line blower motor housing to the mounting

location with four 6 x 80 mm mounting screws and washers.

4. If it is removed, reinstall the blower motor assembly and

secure it with the screws previously removed.

5. If it is removed, reattach the motor electrical plug to the

connector on the blower motor assembly.

5. Remove the electrical knockout from the in-line blower

housing and range hood (see “Complete Preparation” in the

“Prepare Location” section) to prepare for the installation of

the UL listed or CSA approved ¹⁄₂" (1.3 cm) wiring conduit and

conduit connector.

6. With the range hood mounted (see the “Install Range Hood”

section), run the ¹⁄₂" (1.3 cm) wiring conduit between the inline blower motor housing and the range hood. Pull enough

¹⁄₂" (1.3 cm) wiring conduit to allow for easy connection to the

terminal boxes in the in-line blower housing and range hood.

7. Run the six 18 AWG wires through the ¹⁄₂" (1.3 cm) wiring

conduit and conduit connectors and into the terminal boxes

on the in-line blower housing and range hood. Leave enough

wire length in each terminal box to make the wiring

connections.

8. Install the conduit connectors and conduit to the in-line

blower housing and range hood electrical terminal boxes.

9. Connect the vent system to the range hood and in-line blower

system and seal all joints with clamps.

11

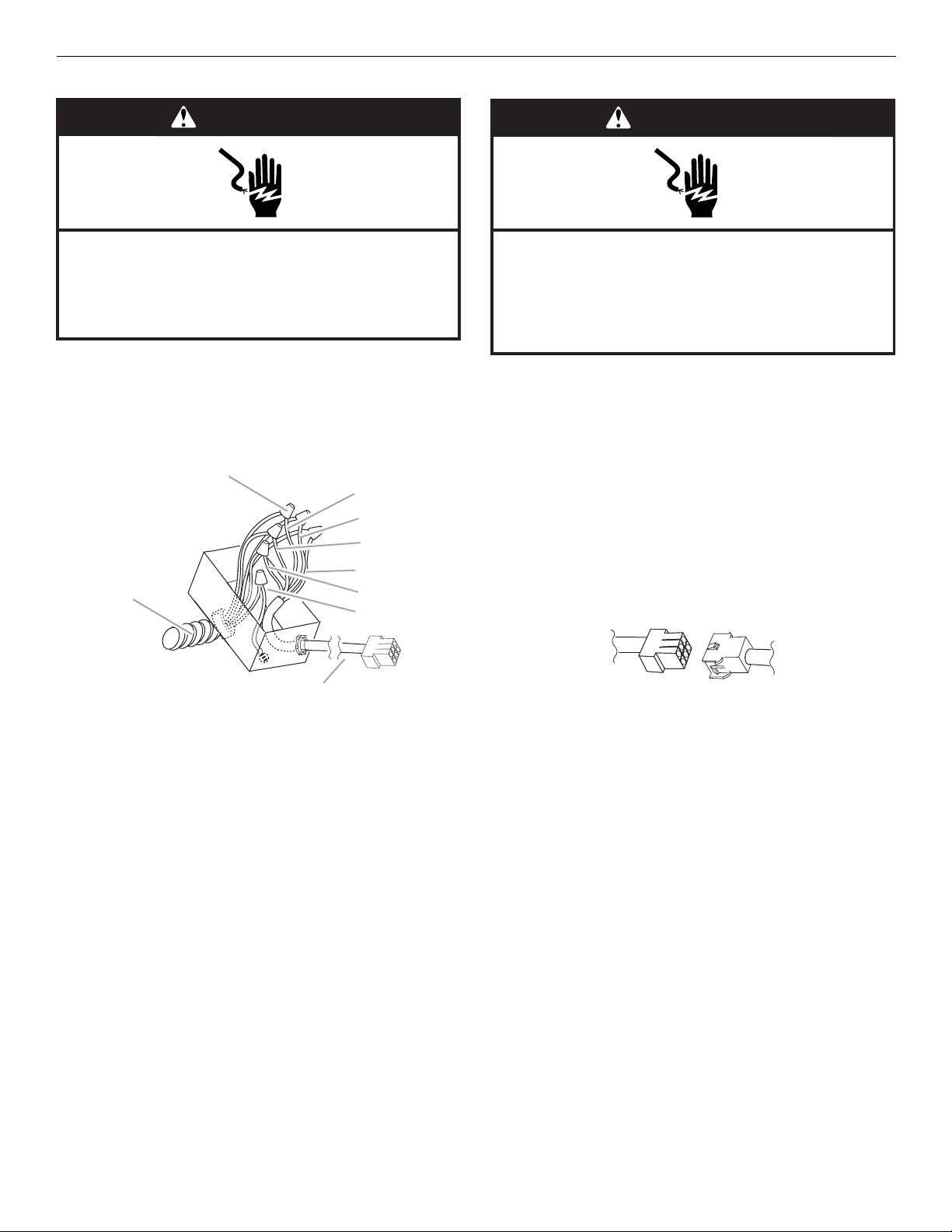

Make Electrical Connections for In-Line Blower Motor System

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

Electrical Connection Inside In-line Blower System

1. Disconnect power.

2. Connect the wires from the wiring conduit to the wires from

the motor electrical plug cable inside the in-line blower

housing terminal box.

B

C

D

E

F

A

G

H

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

8. Connect the green (or yellow/green) ground wire to the

green/yellow ground wire (H) in the terminal box using UL

listed wire connectors.

9. Reinstall the in-line blower terminal box cover and screw.

10. Reinstall the front cover of the in-line blower housing and

secure it with 10 mounting screws.

Electrical Connection Inside Range Hood Between In-line

Blower System and Range Hood

1. With the range hood mounted (see the “Install Range Hood”

section), locate the wiring cable connector inside the range

hood.

2. Connect the 6-wire connector assembly supplied with the

in-line blower motor system to the mating cable connector

from the range hood.

I

A. UL listed or CSA approved

¹⁄₂

" (1.3 cm) wiring conduit

B. UL listed wire connectors

C. Black wires

D. White wires

E. Red wires

3. Use UL listed wire connectors and connect the black wires

(C) together.

4. Use UL listed wire connectors and connect the white wires

(D) together.

5. Use UL listed wire connectors and connect the red wires (E)

together.

6. Use UL listed wire connectors and connect the blue wires (F)

together.

7. Use UL listed wire connectors and connect the gray wires (G)

together.

F. B lu e w ire s

G. Gray wires

H. Green (or yellow/green)

and green/yellow wires

I. Motor electrical plug cable

3. Locate the terminal box inside the range hood and install a

¹⁄₂" (1.3 cm) UL listed or CSA approved strain relief (see

“Complete Preparation” in the “Prepare Location” section).

4. Run the wire ends from the 6-wire connector assembly

through the ¹⁄₂" (1.3 cm) strain relief, leaving enough wire

length to make the wiring connections. Tighten the strain

relief screws.

5. Connect the wires from the 6-wire connector assembly to the

wires from the wiring conduit inside the range hood terminal

box.

6. Connect the same color wires to each other (black to black,

white to white, etc.) using UL listed wire connectors.

NOTE: Connect the green (or green/yellow) ground wire from

the wiring conduit to the green (or bare) ground wire from the

home power supply using UL listed wire connectors (see the

“Make Electrical Power Supply Connection to Range Hood”

section).

12

Loading...

Loading...