Kitchenaid KXU8036YSS Owners Manual

30" (76.2 CM) AND 36" (91.4 CM)

COMMERCIAL STYLE

WALL-MOUNT CANOPY RANGE HOOD

Installation Instructions and Use and Care Guide

For questions about features, operation/performance, parts, accessories,

In Canada, for assistance, installation, and service, call: 1-800-807-6777 or visit our website at www.kitchenaid.ca.

or service, call: 1-800-422-1230

or visit our website at www.kitchenaid.com.

HOTTE D’EXTRACTION À MONTAGE

MURALDE STYLE COMMERCIAL DE

30" (76,2 CM) ET 36" (91,4 CM)

Instructions d’installation et Guide d’utilisation et d’entretien

Au Canada, pour assistance, installation ou service composez le 1-800-807-6777

ou visitez notre site web à www.kitchenaid.ca.

CAMPANA DE COCINA CON ESCUDETE

DEMONTAJE EN LA PARED, COMERCIAL

30”(76,2 CM) Y 36” (91,4 CM)

Instrucciones de instalación y Manual de uso y cuidado

Si tiene preguntas respecto a características, funcionamiento, rendimiento, piezas, accesorios o servicio técnico, llame al: 1-800-422-1230

En Canadá, para obtener asistencia, instalación y servicio, llame al: 1-800-807-6777 o visite nuestro sitio web en www.kitchenaid.ca.

Table of Contents/Table des matières/Índice ����������������������������������������������������������������������������������������2

o visite nuestro sitio web en www.kitchenaid.com.

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS. FOR RESIDENTIAL USE ONLY.

IMPORTANT : LIRE ET CONSERVER CES INSTRUCTIONS. POUR UTILISATION RÉSIDENTIELLE UNIQUEMENT.

IMPORTANTE: LEA Y GUARDE ESTAS INSTRUCCIONES. SÓLO PARA USO RESIDENCIAL.

LI3Y4C/W11165203A

TABLE OF CONTENTS

RANGE HOOD SAFETY .................................................................3

INSTALLATION REQUIREMENTS .................................................5

Tools and Parts �����������������������������������������������������������������������������5

Location Requirements ����������������������������������������������������������������5

Venting Requirements ������������������������������������������������������������������6

Electrical Requirements ���������������������������������������������������������������7

INSTALLATION INSTRUCTIONS ...................................................8

Prepare Location ��������������������������������������������������������������������������8

Install Range Hood ���������������������������������������������������������������������10

Make Electrical Connection �������������������������������������������������������10

Install Vent Covers (Optional) �����������������������������������������������������11

Complete Installation �����������������������������������������������������������������11

TABLE DES MATIERES

SÉCURITÉ DE LA HOTTE DE CUISINIÈRE ...............................16

EXIGENCES D’INSTALLATION ...................................................18

Outils et pièces ���������������������������������������������������������������������������18

Exigences d’emplacement ���������������������������������������������������������18

Exigences concernant l’évacuation �������������������������������������������19

Spécications électriques ����������������������������������������������������������20

INSTRUCTIONS D’INSTALLATION .............................................21

Préparation de l’emplacement ���������������������������������������������������21

Installation de la hotte ����������������������������������������������������������������23

Raccordement électrique �����������������������������������������������������������24

Installation des cache-conduits (facultatif) ��������������������������������24

Achever l’installation ������������������������������������������������������������������24

RANGE HOOD USE ......................................................................11

Range Hood Controls ����������������������������������������������������������������11

RANGE HOOD CARE ...................................................................12

Cleaning �������������������������������������������������������������������������������������12

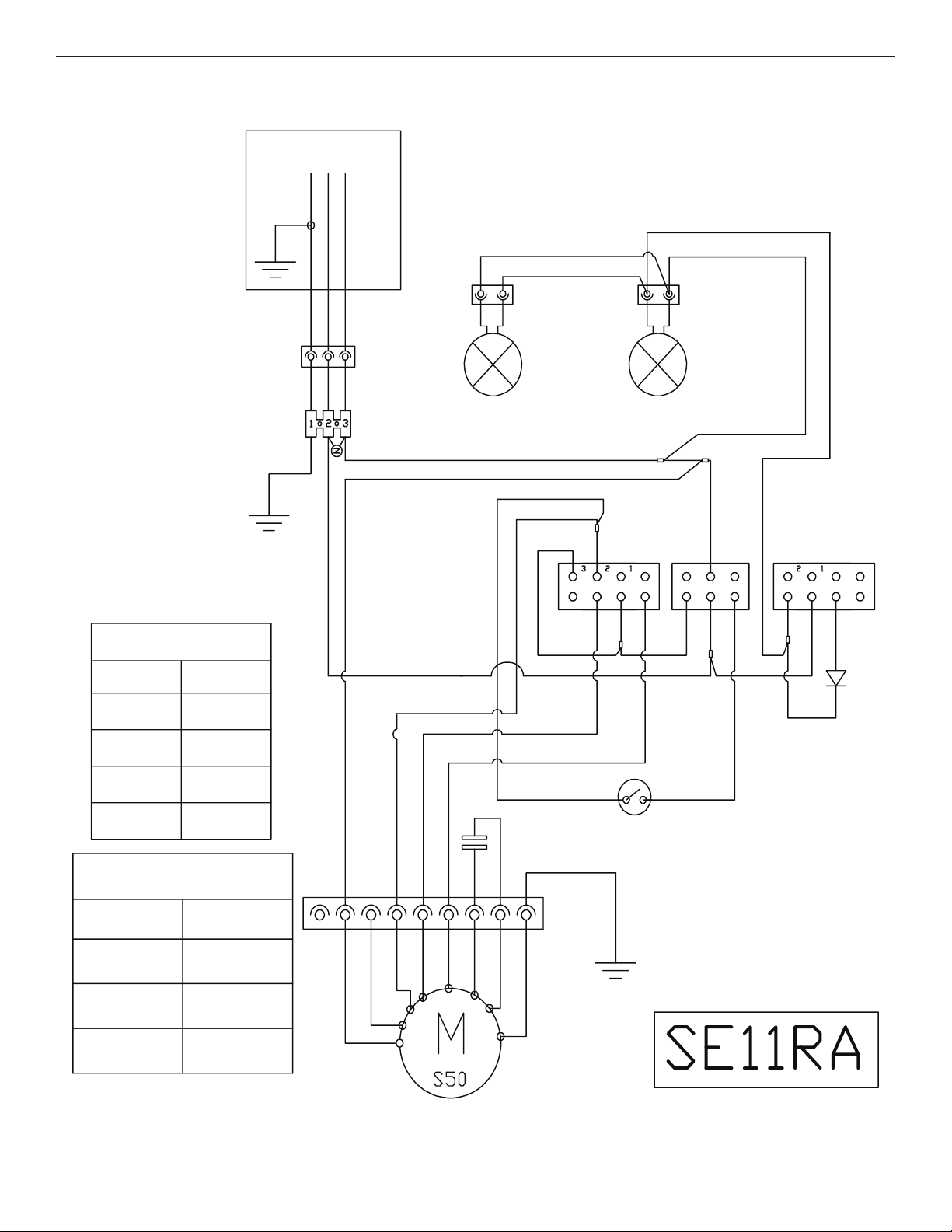

WIRING DIAGRAM .......................................................................13

WHIRLPOOL SERVICE ................................................................14

WARRANTY ..................................................................................15

UTILISATION DE LA HOTTE .......................................................25

Commandes de la hotte de cuisinière ���������������������������������������25

ENTRETIEN DE LA HOTTE .........................................................26

Nettoyage �����������������������������������������������������������������������������������26

SCHÉMA DE CÂBLAGE ...............................................................27

SERVICE WHIRLPOOL ................................................................28

GARANTIE .....................................................................................29

ÍNDICE

SEGURIDAD DE LA CAMPANA DE COCINA ............................30

REQUISITOS DE INSTALACIÓN .................................................32

Herramientas y piezas ����������������������������������������������������������������32

Requisitos de ubicación �������������������������������������������������������������32

Requisitos de ventilación �����������������������������������������������������������33

Requisitos eléctricos ������������������������������������������������������������������34

INSTRUCCIONES DE INSTALACIÓN .........................................35

Preparación de la ubicación ������������������������������������������������������35

Instalación de la campana para cocina �������������������������������������37

Conexión del suministro eléctrico ����������������������������������������������37

Instalación de las cubiertas de la ventilación (opcional) �����������38

Completar la instalación ������������������������������������������������������������38

USO DE LA CAMPANA PARA COCINA ......................................38

Controles de la campana de cocina ������������������������������������������38

CUIDADO DE LA CAMPANA PARA COCINA ............................39

Limpieza �������������������������������������������������������������������������������������39

DIAGRAMA DE CABLEADO ........................................................40

WHIRLPOOL SERVICE ................................................................41

GARANTÍA.....................................................................................42

2

RANGE HOOD SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

3

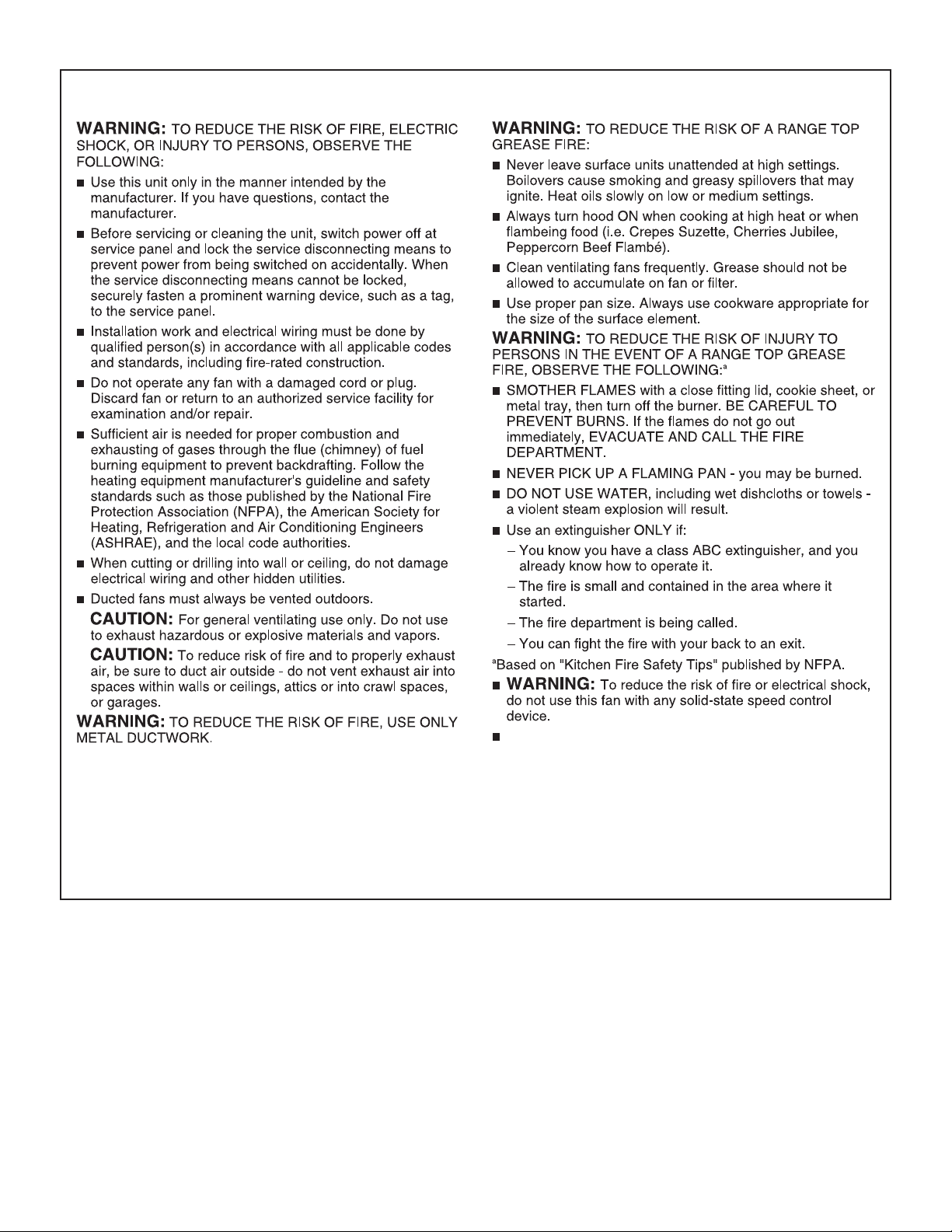

IMPORTANT SAFETY INSTRUCTIONS

This appliance is not intended for use by people

(including children) whose physical, sensory or mental

capacities are different or impaired or who lack the

necessary experience or knowledge/expertise to do so,

unless such persons are supervised or are trained to

operate the appliance by a person who accepts

responsibility for their safety.

READ AND SAVE THESE INSTRUCTIONS

4

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation�

Read and follow the instructions provided with any tools listed

here�

Tools needed

■ Level

■ Drill with 1

5/16" (7�9 mm) drill bits

■ Pencil

■ Wire stripper or utility knife

■ Tape measure or ruler

■ Pliers

■ Caulking gun and weatherproof caulking compound

■ Jigsaw or keyhole saw

■ Flat-blade screwdriver

■ Metal snips

■ Phillips screwdriver

■ Metric hex key set

Parts needed

■ Home power supply cable

■ 1/2" (12�7 mm) UL Listed or CSA approved strain relief

■ 3 UL Listed wire connectors

■ 1 wall or roof cap

■ Metal vent system

■ Vent clamps/duct tape as required

Parts supplied

Remove parts from packages� Check that all parts are included�

■ Hood canopy assembly with ventilator and light bulbs

installed

1

■ 3

/4" x 10" (8�3 cm x 25�4 cm) rectangular vent connector

■ 2 metal grease lters for 30" (76�2 cm) model

■ 3 metal grease lters for 36" (91�4 cm) model

■ T20

■ 4 - 5 x 45 mm mounting screws

■ 6 - 4�5 x 13 mm screws

■ 3 - 4 x 8 mm screws

■ 4 - 10 x 50 wall anchors

1

/4" (3�0 cm), 3/16" (4�8 mm), 1/8" (3�0 mm), and

®

Torx®† adapter

Location Requirements

IMPORTANT: Observe all governing codes and ordinances�

Have a qualied technician install the range hood� It is the

installer’s responsibility to comply with installation clearances

specied on the model/serial rating plate� The model/serial

rating plate is located behind the left lter on the rear wall of the

venthood�

Canopy hood location should be away from strong draft areas,

such as windows, doors, and strong heating vents�

Cabinet opening dimensions that are shown must be used�

Given dimensions provide minimum clearance�

Grounded electrical outlet is required� See the “Electrical

Requirements” section�

The canopy hood is factory set for venting through the roof

orwall�

All openings in ceiling and wall where canopy hood will be

installed must be sealed�

For Mobile Home Installations

The installation of this range hood must conform to the

Manufactured Home Construction Safety Standards, Title 24

CFR, Part 328 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD, Part 280) or when such

standard is not applicable, the standard for Manufactured Home

Installation 1982 (Manufactured Home Sites, Communities and

Setups) ANSI A225�1/NFPA 501A, or latest edition, or with local

codes�

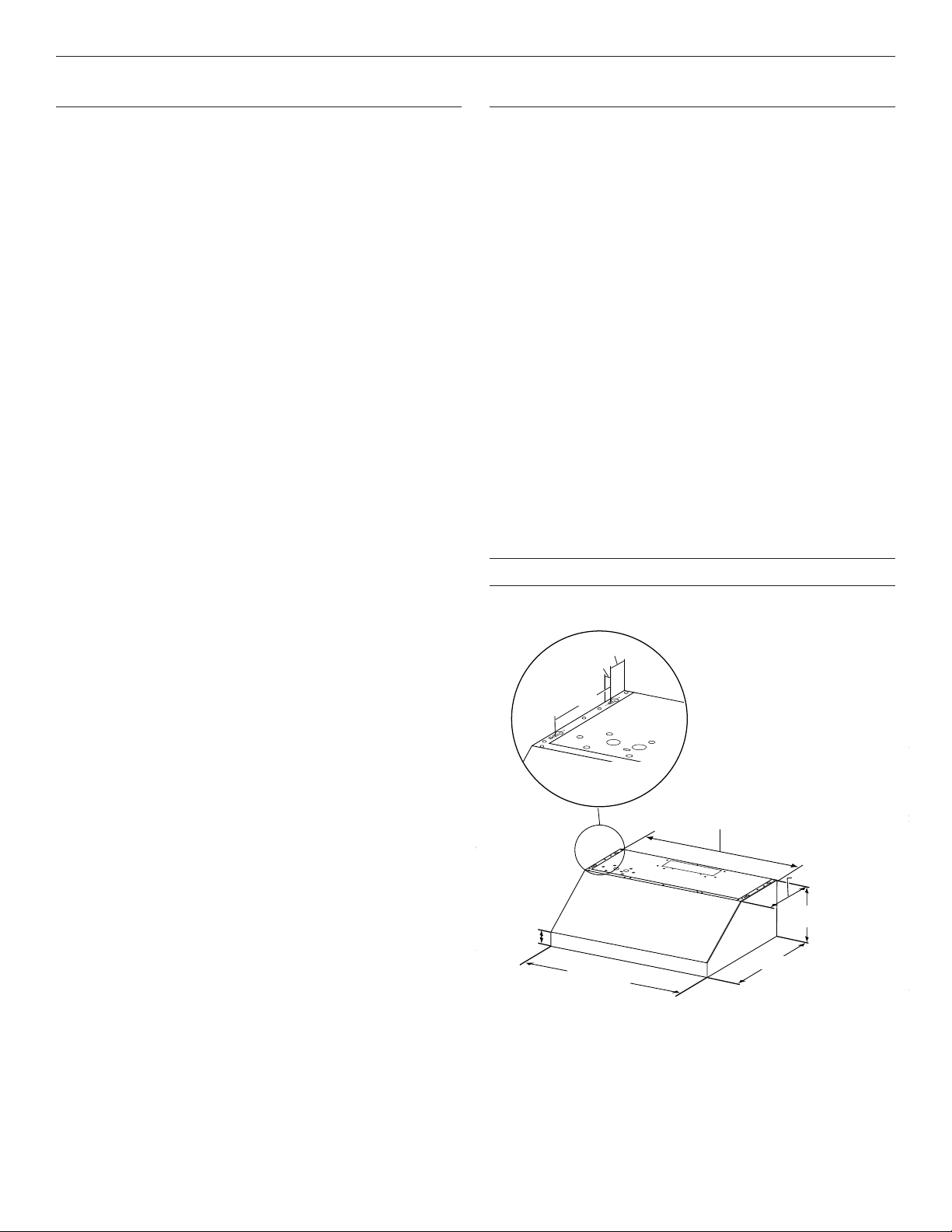

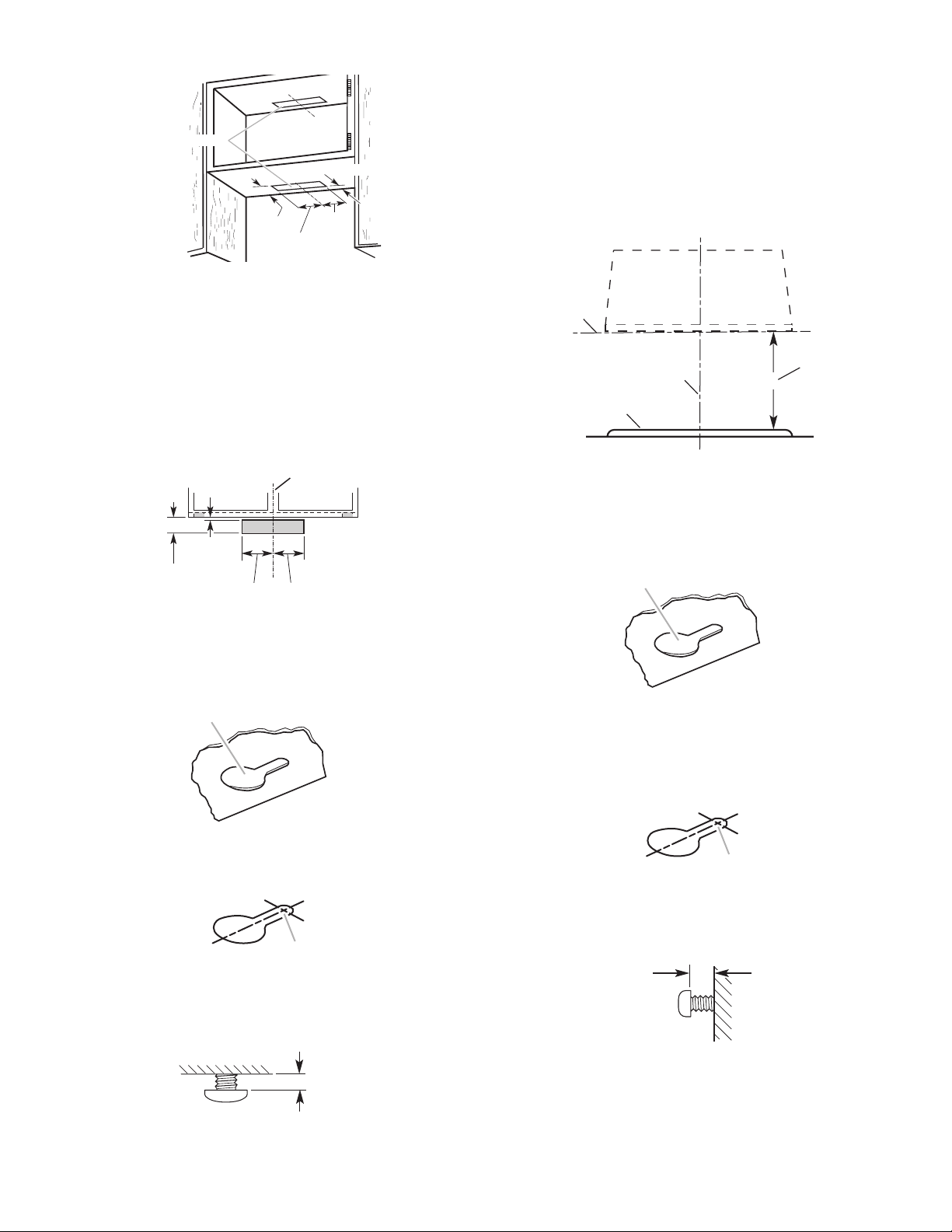

Product Dimensions

Front View

2⁹⁄₁₆"

(6.5 cm)

³⁄₈"

(1.0 cm)

7½"

(19.0 cm)

29¹⁄₈" (74.0 cm): 30" (76.2 cm) models

35¹⁄₈" (89.2 cm): 36" (91.4 cm) models

12"

(30.5 cm)

10"

3¹⁄₈"

(7.9 cm)

30" (76.2 cm)

36" (91.4 cm)

(25.4 cm)

23" (58.4 cm)

†®TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC�

5

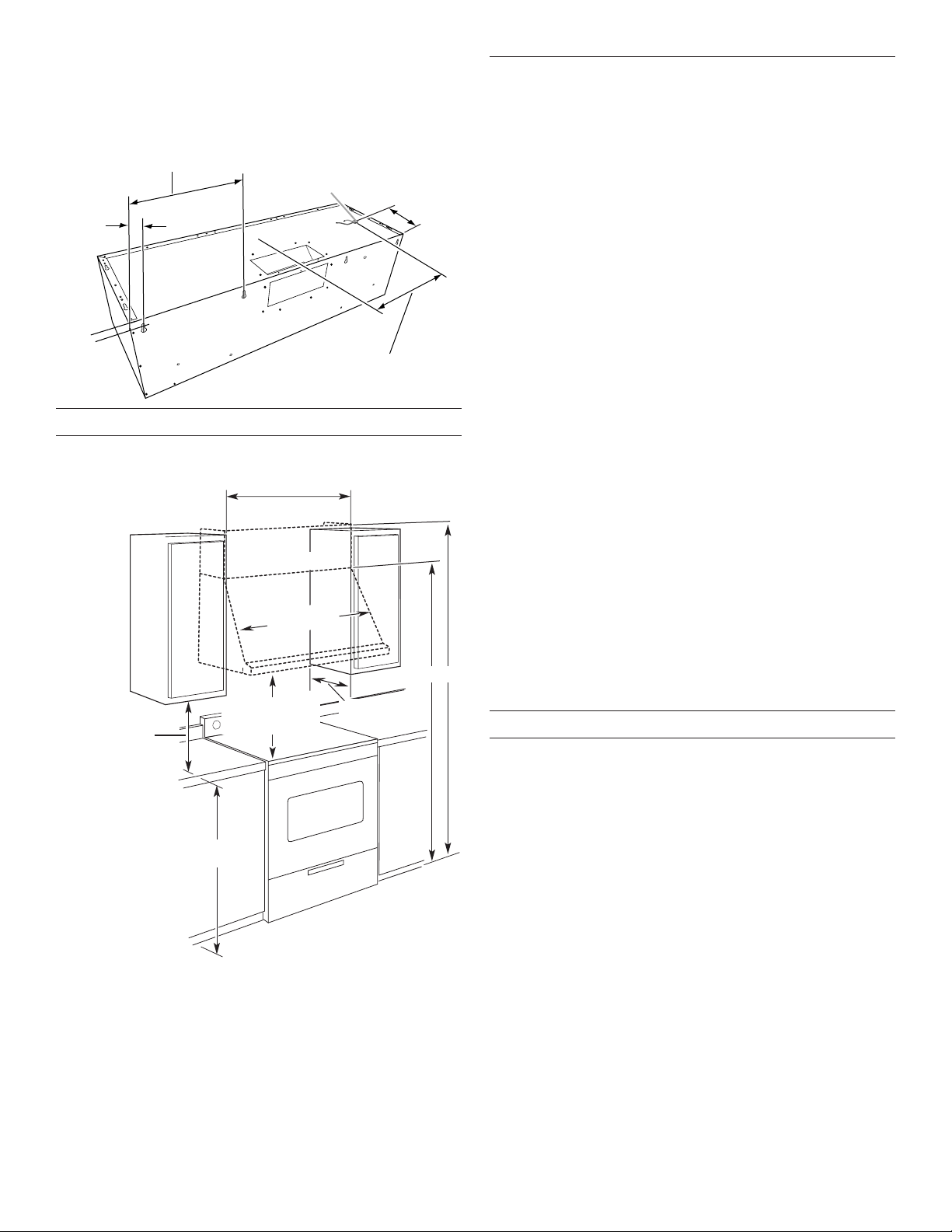

Back View

(20.0 cm)

30" (76.2 cm) models: 12¼" (31.1 cm)

(1.6 cm)

18"

cabinet

30" (76.2 cm) or 36" (91.4 cm)

7" (17.8 cm): 30" (76.2 cm) models

9⁷⁄₈" (25.0 cm): 36" (91.4 cm) models

1¹⁄₈"

(2.9 cm)

⁵⁄₈"

Cabinet Dimensions

36" (91.4 cm) models: 15" (38.1 cm)

Wiring knockout

7⁷⁄₈"

12³⁄₁₆" (31.0 cm)

Venting Requirements

■ Vent system must terminate to the outdoors�

■ Do not terminate the vent system in an attic or other

enclosed area�

■ Do not use a 4" (10�2 cm) laundry-type wall cap�

■ Use metal vent only� Rigid metal vent is recommended�

■ The length of vent system and number of elbows should be

kept to a minimum to provide efcient performance�

For the most efficient and quiet operation:

■ Use no more than three 90° elbows�

■ Make sure there is a minimum of 24" (61�0 cm) of straight

vent between the elbows if more than one elbow is used�

■ Do not install two elbows together�

■ Use clamps or duct tape to seal all joints in the vent system�

■ The vent system must have a damper� If roof or wall cap has

a damper, do not use damper supplied with the range hood�

■ Use caulking to seal exterior wall or roof opening around

thecap�

■ The size of the vent should be uniform�

(45.7 cm) min.

clearance upper

to countertop

cabinet opening width

(If installed between cabinets)

Duct cover (if used)

Min. cabinet

opening width

Canopy

X

countertop height

Bottom of canopy

to cooking surface

36" (91.4 cm)

13" (33.0 cm)

Cold Weather Installations

An additional back draft damper should be installed to minimize

backward cold air ow and a thermal break should be installed

to minimize conduction of outside temperatures as part of the

vent system� The damper should be on the cold air side of the

thermal break�

The break should be as close as possible to where the vent

system enters the heated portion of the house�

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specied CFM of air

movement� The specied CFM varies from locale to locale�

A

B

Consult your HVAC professional for specic requirements in

yourarea�

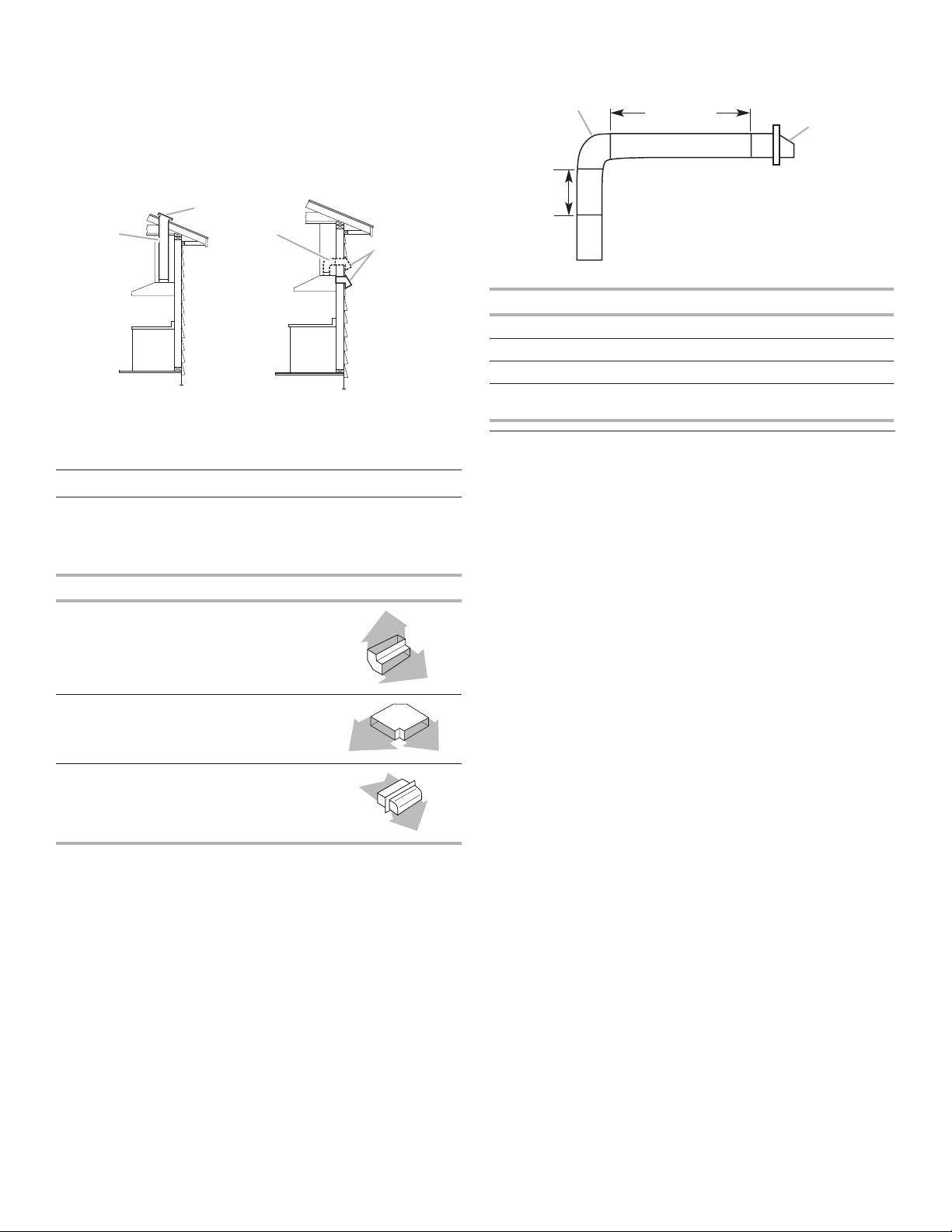

Venting Methods

This canopy hood is factory set for venting through the roof

orwall�

A 31/4" x 10" (8�3 x 25�4 cm) rectangular vent system is needed

for installation (not included)� The hood exhaust opening is

31/4"x 10" (8�3 x 25�4 cm)� Vent system can terminate either

through the roof or wall� To vent out of the top of the range hood

and through a wall, a 90° elbow is needed� See “Install Range

Hood” section for details for installing the damper�

NOTE: Flexible vent is not recommended� Flexible vent

creates back pressure and air turbulence that gently reduce

performance�

A. For installations with canopy

only. 70" (177.8 cm) minimum

above electric cooking surface.

76" (193.0 cm) minimum above

gas cooking surface.

B. For installations with optional

duct cover. 82" (208.3 cm)

minimum above electric

cooking surface. 88”

(223.5 cm) minimum above

gas cooking surface.

IMPORTANT: Minimum distance “X” : 24" (61�0 cm) to electric

cooking surface and 30" (76�2 cm) to gas cooking surface�

Suggested maximum distance “X” : 36" (91�4 cm)�

6

B

A

B

3¹⁄₄" x 10"

(0.6 m)

Rear discharge

This range hood can be vented directly out the back using the

31/4" x 10" (8�3 cm x 25�4 cm) rectangular damper (supplied)

along with a 31/4" x 10" (8�3 cm x 25�4 cm) rectangular vent

system (not supplied)� See the “Install Range Hood” section for

details for installing the damper�

Roof Venting

Wall Venting

(top or rear discharge)

A. Roof cap

B. 31/4" x 10" (8.3 x 25.4cm)

rectangular metal vent

A. Wall cap

B. 31/4" x 10" (8.3 x 25.4cm)

rectangular metal vent

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system�

31/4" x 10" (8.3 x 25.4 cm) Vent System

Vent Piece

31/4" x 10" (8�3 cm x 25�4 cm)

90° elbow

31/4" x 10" (8�3 x 25�4 cm)

at elbow

31/4" x 10" (8�3 x 25�4 cm)

wall cap

5�0 ft

(1�5 m)

12�0 ft

(3�7 m)

0�0 ft

(0�0 m)

Example vent system

elbow

6 ft (1.8 m)

Wall cap

(8.3 x 25.4 cm)

2 ft

A

Maximum Recommended Length = 35 ft (10.7 m)

1 - 90° elbow = 5�0 ft (1�5 m)

8 ft (2�4 m) straight = 8�0 ft (2�4 m)

1 - wall cap = 0�0 ft (0�0 m)

Length of 31/4" x 10" (8�3 cm x 25�4 cm)

= 13�0 ft (3�9 m)

system

Electrical Requirements

Observe all governing codes and ordinances�

Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70

(latest edition), or CSA Standards C22�1-94, Canadian Electrical

Code, Part 1 and C22�2 No� 0-M91 (latest edition) and all local

codes and ordinances�

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that the

ground path is adequate�

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ A 120 volt, 60 Hz�, AC only, 15-amp, fused electrical circuit is

required�

■ If the house has aluminum wiring, follow the procedure

below:

Connect the aluminum wiring using special connectors

and/or tools designed and UL listed for joining copper to

aluminum�

Follow the electrical connector manufacturer’s recommended

procedure� Aluminum/copper connection must conform with

local codes and industry accepted wiring practices�

■ Wire sizes and connections must conform with the rating of

the appliance as specied on the model/serial rating plate�

The model/serial plate is located behind the lter on the rea

wall of the range hood�

■ Wire sizes must conform to the requirements of the National

Electrical Code, ANSI/NFPA 70 (latest edition), or CSA

Standards C22� 1-94, Canadian Electrical Code, Part 1 and

C22�2 No� 0-M91 (latest edition) and all local codes and

ordinances�

7

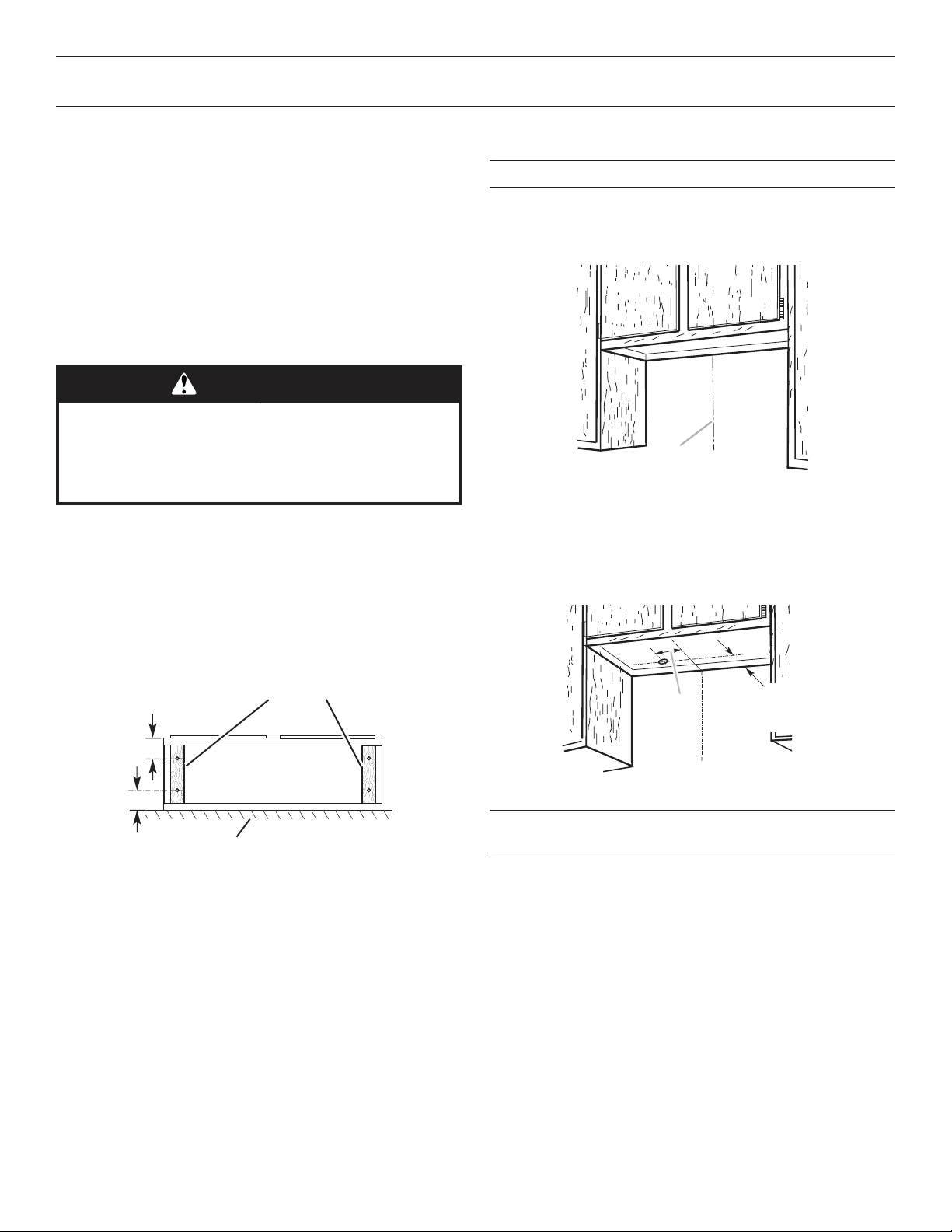

INSTALLATION INSTRUCTIONS

Wall

Wood filler strips

3" (7.6 cm)

" (20.0 cm)

Prepare Location

■ It is recommended that the vent system be installed before

hood is installed�

■ If you are installing a full width duct cover, follow the

instructions included with that product�

■ Before making cutouts, make sure there is proper clearance

within the ceiling or wall for exhaust vent�

■ Check your ceiling height and the hood height maximum

before you select your hood�

1. Disconnect power�

2. Determine which venting method to use: roof or wall�

3. Select a at surface for assembling the range hood� Place

covering over that surface�

WARNING

Excessive Weight Hazard

Use two or more people to move and install

range hood.

Failure to do so can result in back or other injury.

Determine Wiring Hole Location

Cut only one 11/4" (3�2 cm) diameter wiring access hole� See

Step 2 for wiring hole location instructions�

1. Determine and clearly mark a vertical centerline on the wall

and cabinet in the area the vent opening will be made�

A

A. Centerline

4. Using two or more people, lift range hood onto covered

surface�

NOTE: This range hood can be mounted to the cabinets or

to the wall�

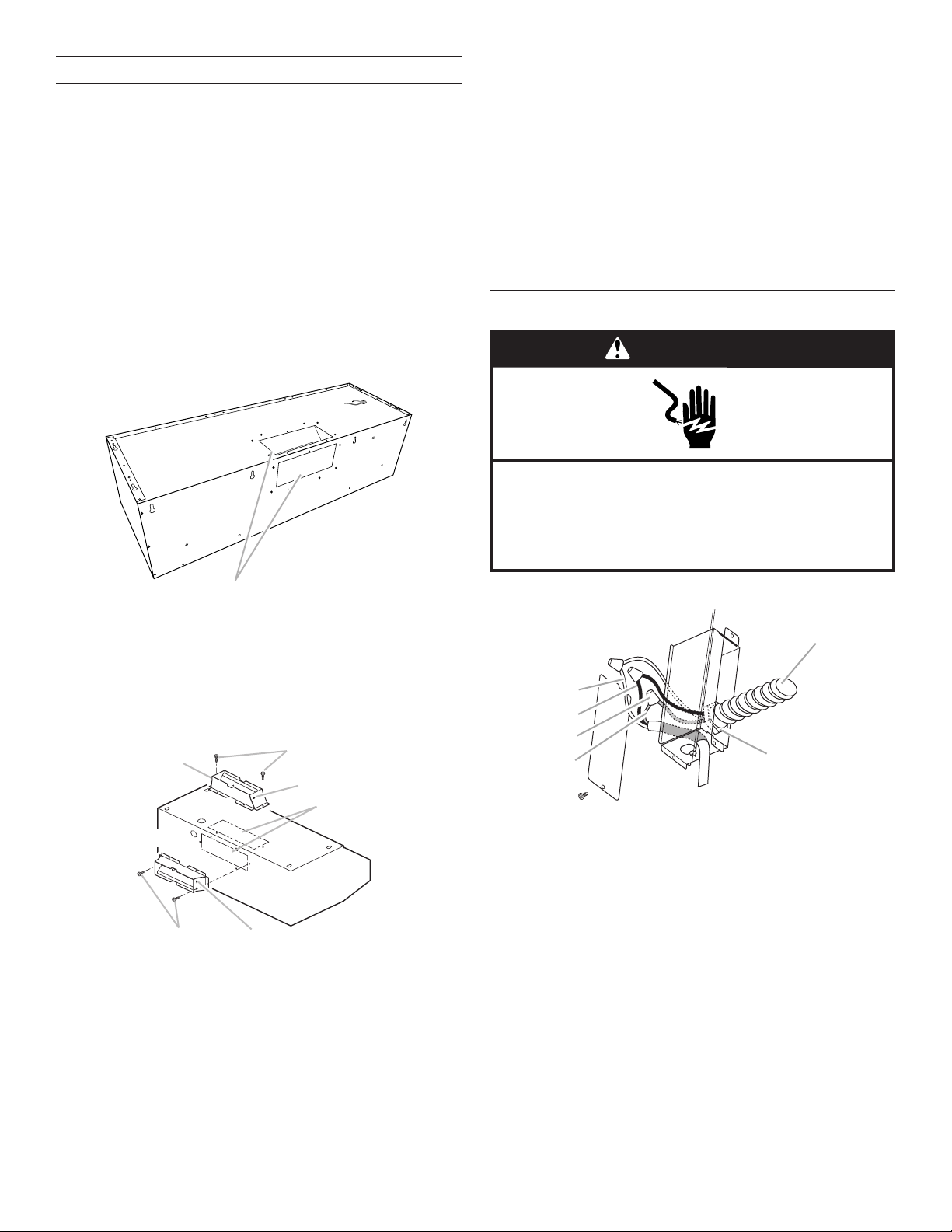

For Cabinet Installations

1. If cabinet has recessed bottom, add wood ller strips on

each side� Install screws to attach ller strips in locations

shown�

(recessed cabinet

3" (7.6 cm)

bottoms only)

Cabinet

bottom

2. To wire through top:

Mark a line distance “A” from the left of the centerline on the

underside of the cabinet� Mark the point on this line that is

77/8" (20�0 cm) from back wall� Drill a 11/4" (3�2 cm) diameter

hole through the cabinet at this point�

7⁷⁄₈

A

Centerline

A. 123/16" (31.0 cm)

from wall,

not cabinet

frame

Cut Openings for 31/4" x 10" (8.3 cm x 25.4 cm)

Rectangular Vent System

Roof Venting

To make a 4" x 101/2" (10.2 cm x 26.7 cm) rectangular cutout

on the underside of cabinet top and bottom:

1. Mark lines 1/2" (1�3 cm) and 41/2" (11�4 cm) from the back

wall on the centerline of the underside of cabinet�

2. Mark lines 51/4" (13�3 cm) to the right and left of the

centerline on the underside of cabinet�

3. Use saber or keyhole saw to cut a rectangular opening for

vent�

8

4. Repeat steps 1-3 for the underside of the top of the cabinet�

Cabinet cutouts

³⁄₈"

3 ⁷⁄₈"

Cabinet

front

(0.9 cm)

(9.8 cm)

5

¹⁄₄

"

(13.3 cm)

Centerline

5

¹⁄₄

"

(13.3 cm)

A

A

(6.4 mm)

A

A

A

*¹⁄₂" (1.3 cm)

*4¹⁄₂"

(11.4 cm)

*From wall, not cabinet frame

5¹/₄"

(13.3 cm)

5¹/₄"

(13.3 cm)

Wall Venting Under Cabinet

To make a 31/2" x 101/2" (8.9 cm x 26.7 cm) rectangle in

thewall:

1. Make two lines by measuring 3/8" (9�5 mm) and 37/8"

(9�8cm) down from underside of cabinet and mark on the

centerline on the back wall�

2. Mark lines 51/4" (13�3 cm) to the right and left of the

centerline on the wall�

Use saber or keyhole saw to cut a rectangular opening in the

wall for the vent�

For Wall Installations:

1. Determine and mark the centerline on the wall where the

canopy hood will be installed�

2. Select a mounting height between a minimum of 24"

(61�0cm) for electric cooking surfaces and 30" (76�2 cm) for

gas cooking surfaces� The suggested maximum height is 36"

(91�4 cm) above the range to the bottom of the hood� Mark a

horizontal reference line on the wall�

3. Using two or more people, center the hood on the vertical

centerline, then align the bottom of the hood with the

horizontal reference line marked on the wall�

B

D

A. Horizontal reference line

B. Vertical centerline

C. Mounting height

D. Cooking surface

C

X

3. Lift the range hood up under cabinet and determine nal

location by centering beneath cabinet� Mark on the

underside of cabinet the location of the four keyhole

mounting slots on the range hood� Set range hood aside on

a covered surface�

A. Keyhole slot

4. Use 1/8" (3�0 mm) drill bit and drill four pilot holes as

shown�

A. Drill pilot hole.

5. Install the 4 - 4�5 x 13 mm mounting screws in pilot

holes� Leave about 1/4" (6�4 cm) space between screw

heads and cabinet to slide range hood into place�

4. Mark centers of the fastener locations to the wall� Set range

hood aside on a covered surface�

A. Keyhole slot

IMPORTANT: All screws must be installed into wood� If there

is no wood to screw into, additional wall framing supports

may be required�

5. Drill 3/16" (4�8 mm) pilot holes at all locations where screws

are being installed into wood�

A. Drill pilot hole.

6. Install the 4 - 5 x 45 mm mounting screws� Leave a 1/4"

(6�4mm) gap between the wall and the back of the screw

head to slide range hood into place�

¹⁄₄"

(6.4 mm)

7. Determine and make all necessary cuts in the wall or ceiling

for the vent system� Install the vent system before installing

the hood� See the “Venting Requirements” section�

¹⁄₄"

9

Complete Preparation

A

B

B

D

E

1. Determine the required height for the home power supply

cable and drill a 11/4" (3�2 cm) hole at this location�

2. Run the home power supply cable according to the National

Electrical Code or CSA Standards and local codes and

ordinances� There must be enough 1/2" (12�7 mm) conduit

and wires from the fused disconnect (or circuit breaker) box

to make the connection in the hood’s electrical terminal box�

NOTE: Do not reconnect power until installation is complete�

3. Remove the grease lters� See the “Range Hood

Care”section�

4. Remove terminal box cover and set aside�

5. Remove knockout from the top of the vent hood and install a

UL Listed or CSA approved 1/2" (12�7 mm) strain relief�

Install Range Hood

1. Depending on your installation, remove either top or rear

rectangular vent knockout�

4. Using two or more people, lift the hood into nal position�

Feed enough electrical wire through the 1/2" (12�7 mm)

ULListed or CSA approved strain relief to make connections

in the terminal box� Tighten the strain relief screws�

5. Position the range hood so that the large end of the keyhole

slots are over the mounting screws� Then push the hood

toward the wall (for cabinet mounting) or allow the range

hood to slide down to the marked mounting height (for wall

mounting) so that the screws are in the neck of the slots�

Tighten the mounting screws, making sure the screws are

in the narrow neck of slots� (For wall mount, check that the

hood is level)�

6. Connect ventwork to hood� Seal joints with clamps to make

secure and airtight�

7. Check that back draft dampers work properly�

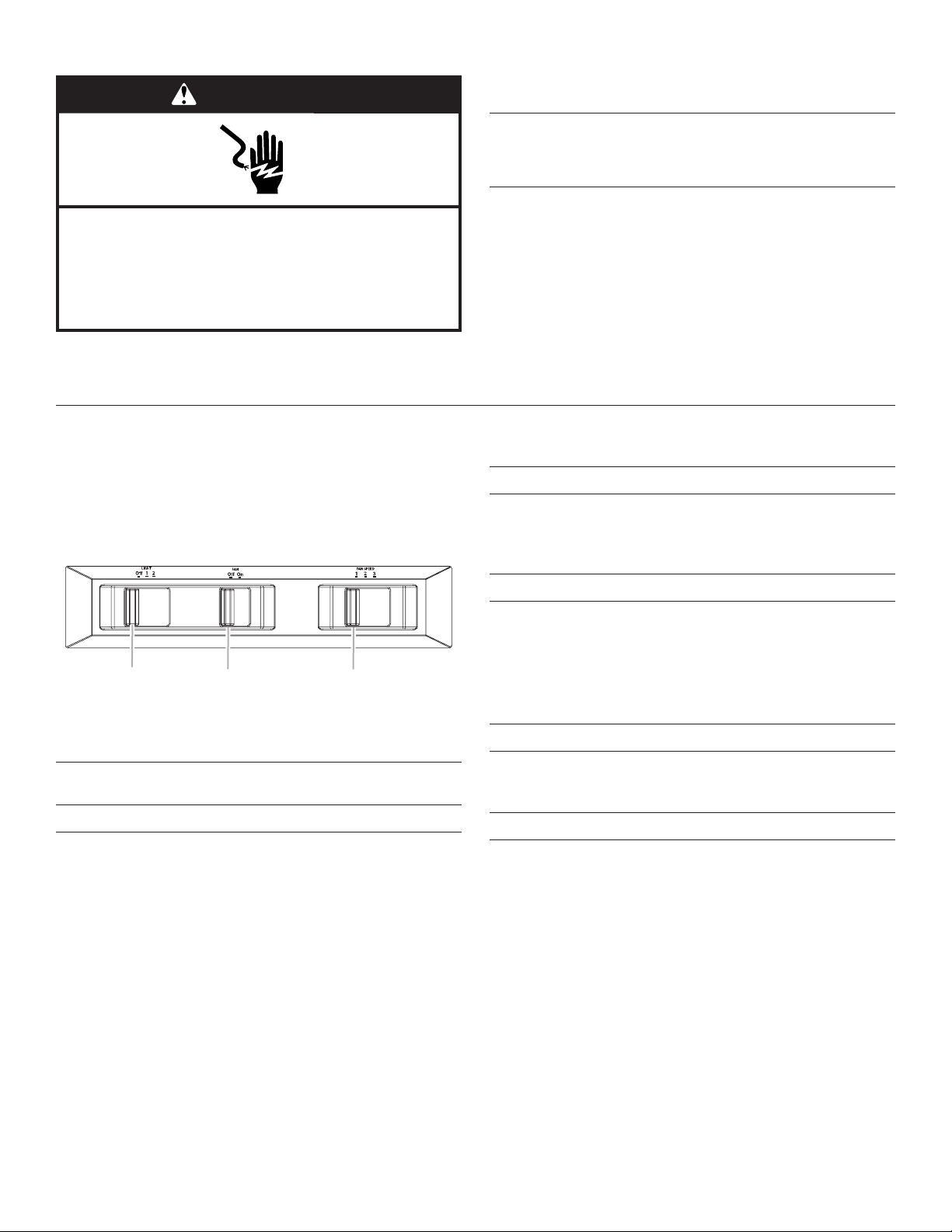

Make Electrical Connection

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

A. Vent knockouts

2. Remove tape from damper ap�

NOTE: The 31/4" x 10" (8�3 x 25�4 cm) rectangular damper

can be installed up to 1" (2�5 cm) on either side of the hood

center to accommodate off center duct work

3. Attach the 31/4” x 10" (8�3 x 25�4 cm) rectangular vent

connector to the range hood using sheet metal screws�

A

C

D

E

C

A. Top venting

B. Sheet metal screws

C. Hinge pin

D. Vent knockouts

E. Rear venting

NOTE: If the wall cap is directly behind the 31/4" x 10" (8�3 x

25�4 cm) rectangular vent connector, check that the damper

and the wall cap do not interfere with each other� Remove

the damper from the 31/4" x 10" (8�3 x 25�4 cm) rectangular

vent connector if they interfere�

1. Disconnect power�

A

B

C

F

A. White wires

B. Black wires

C. UL Listed wire connector

D. Green (or bare) and yellow-green ground wire

E. Home power supply cable

F. UL Listed or CSA approved 1/2" (12.7 mm) strain relief

2. Use UL Listed wire connectors and connect white wires (A)

together�

3. Use UL Listed wire connectors and connect black wires (B)

together�

10

WARNING

B

C

5. Install terminal box cover�

6. Check that all light bulbs are secure in their sockets�

7. Reconnect power�

Install Vent Covers (Optional)

If you are installing an optional full width duct cover, follow the

instructions included with that product�

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire

in terminal box.

Failure to do so can result in death or electrical shock.

4. Connect green (or bare) ground wire from home power

supply to yellow-green ground wire (C) in terminal box using

UL Listed wire connectors�

RANGE HOOD USE

The range hood is designed to remove smoke, cooking vapors,

and odors from the cooktop area� For best results, start the hood

before cooking and allow it to operate several minutes after

the cooking is complete to clear all smoke and odors from the

kitchen�

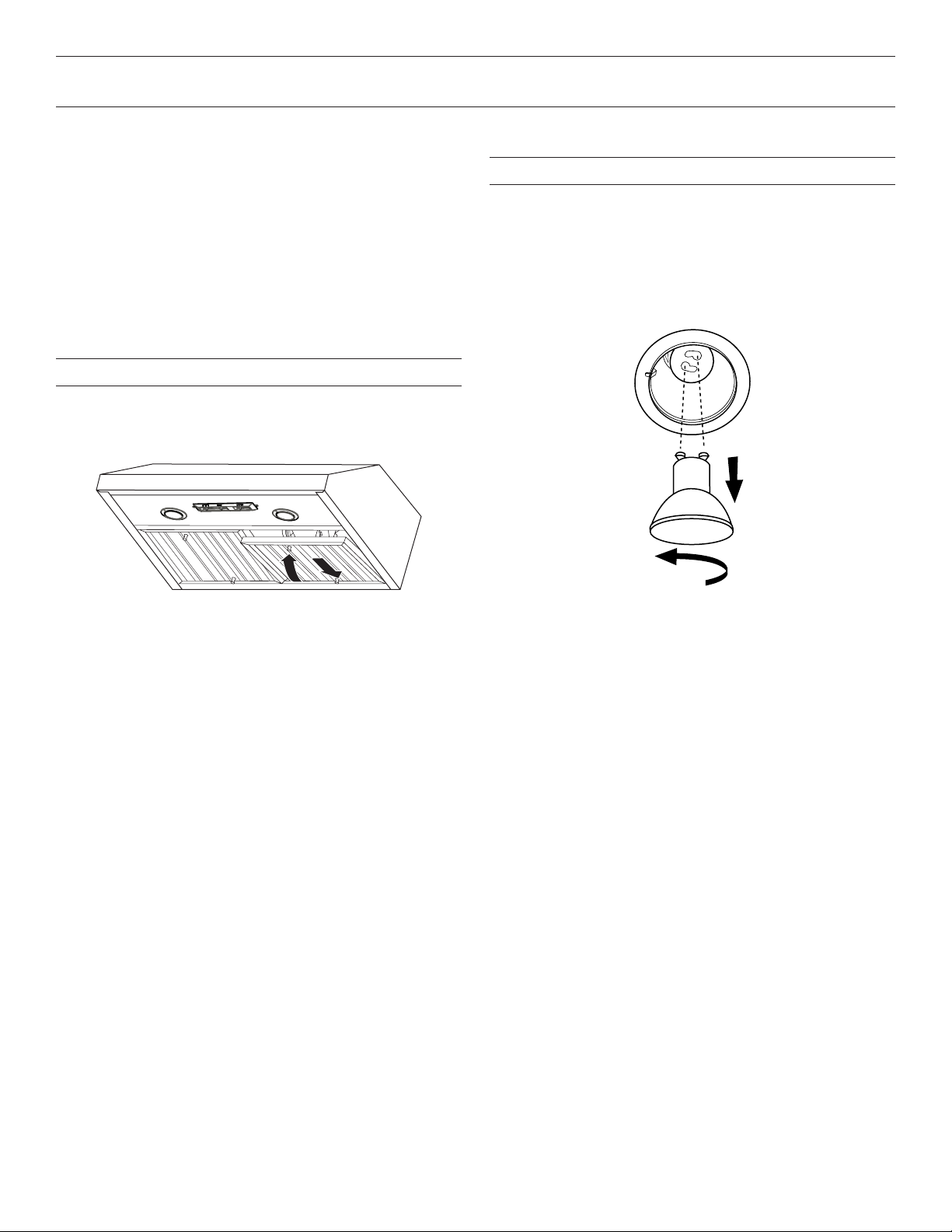

The hood controls are located on the underside of the

rangehood�

A

A. Light control

B. Blower control

C. Fan speed control

Complete Installation

1. Install metal grease lters� See the “Range Hood

Care”section�

2. Check the operation of the range hood blower and light� See

the “Range Hood Use” section�

NOTE: To get the most efcient use from your new range

hood, read the “Range Hood Use” section�

Operating the fan

1. Move the fan switch to the on position to turn the fan on� The

fan will begin operating at the speed set on the fan speed

switch�

2. Move the fan switch to the Off position to turn the fan off�

Auto on fan

The range hood is equipped with a sensor to automatically turn

on the fan when excessive heat is detected in the control area�

When the fan switch is in the off position, this sensor will turn the

fan to high speed when necessary� When the heat decreases,

the fan will turn off�

When the fan switch is in the on position, the heat sensor is not

active, and the range hood functions normally�

Adjusting the fan

Range Hood Controls

Operating the light

1. Move the light switch to the “1” position to turn range hood

light to night light setting�

2. Move the light switch to the “2” position to turn range hood

light to full light setting�

3. Move the light switch to the “Off” position to turn range hood

light off�

The fan has three speed controls� Move the fan speed switch to

“1” position for low speed, “2” position for medium speed, or “3”

position for high speed�

Thermal protector

The range hood is equipped with a thermal protector to avoid

overheating conditions� If the range hood shuts off while in use,

move fan slider switch to off to turn off the range hood� Wait

approximately 60 minutes, then move slider to on to restart the

range hood�

11

RANGE HOOD CARE

Cleaning

IMPORTANT: Clean the hood and grease lters frequently

according to the following instructions� Replace grease lters

before operating hood�

Exterior Surfaces:

To avoid damage to the exterior surface, do not use steel wool

or soap-lled scouring pads�

Always wipe dry to avoid water marks�

Cleaning Method:

■ Liquid detergent soap and water, or all-purpose cleanser�

■ Wipe with damp soft cloth or nonabrasive sponge, then rinse

with clean water and wipe dry�

Metal Grease Filter

To Remove Metal Grease Filters:

1. Use two hands to remove the metal grease lters� Grasp

lter handles, push toward the rear of the range hood, and

pull down on the front handle to remove�

Replacing a Halogen Lamp

Turn off the range hood and allow the halogen lamp to cool� To

avoid damage or decreasing the life of the new lamp, do not

touch lamp with bare ngers� Replace lamp, using tissue or

wearing cotton gloves to handle lamp�

If new lamps do not operate, make sure the lamps are inserted

correctly before calling service�

1. Disconnect power�

2. Push up on the lens and turn it counterclockwise�

2. Repeat for each grease lter�

3. Wash metal grease lters as needed in a dishwasher or hand

wash in a hot detergent solution to clean�

To Reinstall Metal Grease Filters:

1. Grasp lter handles and place rear of lter into rear track�

2. Push down on the rear handle and set the front of the grease

lter into the front track to secure�

3. Repeat for each lter�

3. Remove the lamp and replace it with a 120-volt, 50-watt

maximum halogen lamp with a GU10 base� Turn it clockwise

to lock it into place�

4. Repeat steps 2-3 for the other lamp if needed�

5. Reconnect power�

12

WIRING DIAGRAM

Junction Box

N

L

GND

W

BK

Y/G

Y

W

Y

W

W

Motor Resistance

(Ohms)

Blue - Red

Blue - Gray

Blue - Black

Blue - White

Room Temp.

Motor

Characteristics

Power Supply

18

14.3

9.8 (max)

21.6 (min)

41˚F (23˚C)

120 VAC

BU

BK

BU

BK

GY

Speed 3

Speed 2

Speed 1

W

Y

25uF

BR

BR

BK

BR

Fan Speed

GY

R R

BR

Temperature

Y/G

R

Sensor

W

Off

On

Fan

W

BK

BR

BR

Y

Off

Light

Y

BK

Y

Frequency

Power Absorption

Current

60 HZ

420 W

3.7A

BU

GY

BK

R

Y

W

BR

Y/G

13

ASSISTANCE OR SERVICE

When calling for assistance or service, please know the

purchase date and the complete model and serial number of

your appliance� This information will help us to better respond to

your request�

If you need replacement parts

If you need to order replacement parts, we recommend that

you use only factory specied parts� Factory specied parts will

t right and work right because they are made with the same

precision used to build every new appliance� To locate factory

specied replacement parts in your area, call us or your nearest

designated service center�

In the U.S.A.

Ifyou have any problems or questions, call KitchenAid at

1-800-422-1230�

Our consultants provide assistance with:

■ Scheduling of service� KitchenAid appliances designated

service technicians are trained to fulll the product warranty

and provide after-warranty service anywhere in the United

States�

■ Features and specications on our full line of appliances�

■ Referrals to local KitchenAid appliance dealers�

■ Installation information�

■ Use and maintenance procedures�

■ Accessory and repair parts sales�

■ Specialized customer assistance (Spanish speaking, hearing

impaired, limited vision, etc�)�

Accessories

Full Width Chimney Cover

Order Part Number W10272079 for 30” (76�2 cm) model

Order Part Number W10272080 for 36” (91�4 cm) model

In Canada

Ifyou have any problems or questions, call KitchenAid at

1-800-807-6777�

Our consultants provide assistance with:

■ Scheduling of service� KitchenAid appliances designated

service technicians are trained to fulll the product warranty

and provide after-warranty service anywhere in Canada�

■ Features and specications on our full line of appliances�

■ Referrals to local KitchenAid appliance dealers�

■ Use and maintenance procedures�

■ Accessory and repair parts sales�

For further assistance:

If you need further assistance, you can write to KitchenAid with

any questions or concerns at:

KitchenAid Brand Home Appliances

Customer eXperience Centre

200 - 6750 Century Ave�

Mississauga, Ontario L5N 0B7

Please include a daytime phone number in your correspondence�

For further assistance:

If you need further assistance, you can write to KitchenAid with

any questions or concerns at:

KitchenAid Brand Home Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

Please include a daytime phone number in your correspondence�

14

Loading...

Loading...