Page 1

KAR-14

TECHNICAL EDUCATION

15″ & 18″ AUTOMATIC

ICE MAKERS

KUIS155H,

KUIA15NRH, KUIA15NLH,

KUIA15RRL, KUIA15PLL,

KUIS15NRH, KUIS15PRH

KUIS185J,

KUIA18NNJ, KUIA18PNL,

KUIS18NNJ, KUIS18PNJ,

KUIV18NNM

JOB AID 4317339

Page 2

FORWARD

This KitchenAid Job Aid “15″ & 18″ Automatic Ice Makers” (Part No. 4317339), provides the

technician with information on the installation, operation, and service of the 15″ & 18″ Automatic

Ice Makers. It is to be used as a training Job Aid and Service Manual. For specific information on

the model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the ice

maker.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the KitchenAid 15″ & 18″ Automatic Ice Makers.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the ice maker to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2003, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Page 3

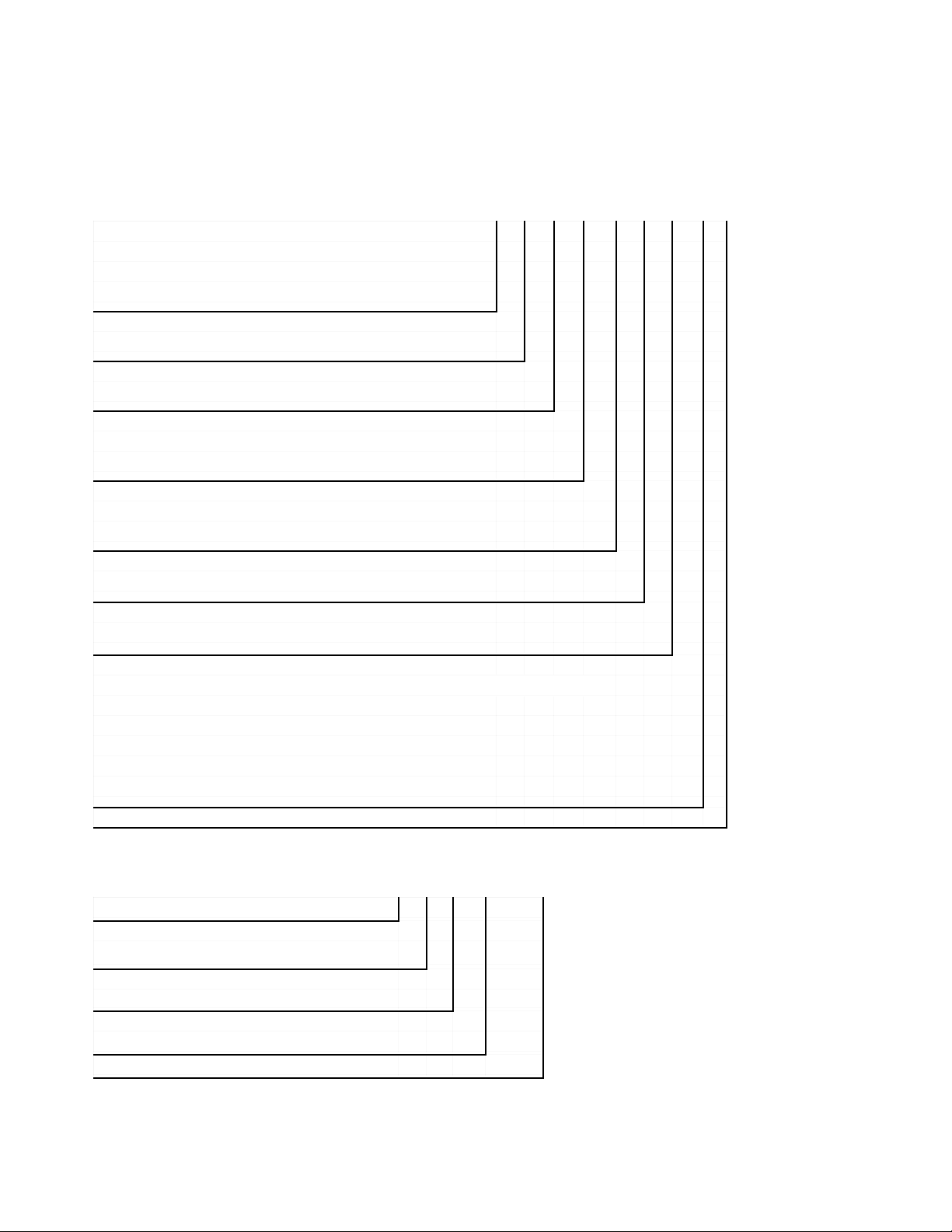

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

KitchenAid Model & Serial Number Designations—Models Prior To 2003........................ 1-3

KitchenAid Model & Serial Number Designations—Models Starting With 2003 ................ 1-4

Model & Serial Number Label Location ............................................................................. 1-5

Specifications..................................................................................................................... 1-6

KitchenAid Ice Maker Warranty ......................................................................................... 1-7

INSTALLATION INFORMATION ........................................................................................... 2-1

Electrical Supply Requirements ......................................................................................... 2-1

Water Supply And Drain Connections ............................................................................... 2-2

THEORY OF OPERATION ..................................................................................................... 3-1

Operating Systems ............................................................................................................ 3-1

Operational Cycles ............................................................................................................ 3-4

New Ice Maker Control Board (#6100499) ........................................................................ 3-6

Models With Internal Drain Pumps .................................................................................... 3-7

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Bin Thermistor, Cutter Grid, Evaporator Thermistor,

& Water Distributor ........................................................................................................ 4-2

Removing The Electronic Control Housing Components .................................................. 4-5

Removing The Water Recirculation Pump......................................................................... 4-7

Removing The Condenser Fan Motor ............................................................................... 4-8

Removing The Evaporator ............................................................................................... 4-11

Removing The Water Inlet Valve ..................................................................................... 4-15

Removing The Hot Gas Valve & Solenoid ....................................................................... 4-16

Removing The Condenser ............................................................................................... 4-17

Removing The Compressor ............................................................................................. 4-18

Removing The Internal Drain Pump ................................................................................ 4-20

Removing The Ice Maker Door & Gasket (15″ Models)................................................... 4-21

Removing The Ice Maker Door & Gasket (18″ Models)................................................... 4-22

COMPONENT TESTING ........................................................................................................ 5-1

Bin Thermistor ................................................................................................................... 5-1

Evaporator Thermistor ....................................................................................................... 5-1

Cutter Grid ......................................................................................................................... 5-2

Cutter Grid Transformer..................................................................................................... 5-2

Water Recirculation Pump ................................................................................................. 5-3

Condenser Fan Motor ........................................................................................................ 5-3

Water Inlet Valve Solenoid ................................................................................................ 5-4

Hot Gas Valve Solenoid..................................................................................................... 5-4

Compressor, Overload Protector, & Relay ........................................................................ 5-5

Pushbutton Switch Assembly ............................................................................................ 5-7

- iii -

Page 4

Page

DIAGNOSIS & TROUBLESHOOTING ................................................................................... 6-1

Water And Its Effect On Making Ice................................................................................... 6-1

Troubleshooting Chart ....................................................................................................... 6-2

Diagnostic Flow Chart For Ice Maker Control Board #6100499 ........................................ 6-5

WIRING DIAGRAM & STRIP CIRCUITS ............................................................................... 7-1

Wiring Diagram .................................................................................................................. 7-1

Strip Circuits ...................................................................................................................... 7-2

TECH TIPS ............................................................................................................................. 8-1

Cleaning The Ice Maker..................................................................................................... 8-1

Cleaning The Evaporator Plate ...................................................................................... 8-1

Adjusting The Ice Thickness .............................................................................................. 8-3

- iv -

Page 5

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

ELECTRICAL POWER SUPPLY &

GROUNDING REQUIREMENTS

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

WARNING

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

1-1

Page 6

WARNING

Electrical Shock Hazard

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere.

ESD may damage or weaken the electronic control assembly. The new control

assembly may appear to work well after

repair is finished, but failure may occur at

a later date due to ESD stress.

• Use an antistatic wrist strap. Connect the

wrist strap to the green ground connection point, or to an unpainted metal surface in the appliance.

- OR -

• Touch your finger repeatedly to a green

ground connection point, or to an unpainted metal surface in the appliance.

• Before removing the part from its package, touch the antistatic bag to a green

ground connection point, or to an unpainted metal surface in the appliance.

• Avoid touching electronic parts, or terminal contacts. Handle the electronic control assembly by the edges only.

• When repackaging the failed electronic

control assembly in an antistatic bag,

observe the previous instructions.

1-2

Page 7

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODELS PRIOR TO 2003

MODEL NUMBER

MODEL NUMBER K UI S 15 5 H LS 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

K = KITCHENAID

PRODUCT IDENTIFICATION

UI = UNDERCOUNTER ICE MAKER

MERCHANDISING SCHEME

A = ARCHITECT

S = STANDARD

CAPACITY / SIZE / SERIES / CONFIGURATION

15 = 15" WIDE

18 = 18" WIDE

FEATURES

5 = 50 POUNDS

YEAR OF INTRODUCTION

H = 1999

COLOR CODE

BL = BLACK; BT = BISCUIT; BS = BLACK & STAINLESS STEEL

LS = LEFT SWING STAINLESS ARCHITECT

RS = RIGHT SWING STAINLESS ARCHITECT

PB = BLACK W/PUMP

PW = WHITE W/PUMP

WH = WHITE

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

SERIAL NUMBER E M 0 4 54321

DIVISION RESPONSIBILITY

E = EVANSVILLE, IN

YEAR OF PRODUCTION

M = 2002, P = 2003

WEEK OF PRODUCTION

04 = 4th WEEK

PRODUCT SEQUENCE NUMBER

1-3

Page 8

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODELS STARTING WITH 2003

MODEL NUMBER

MODEL NUMBER K UI S 15 NR H S 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

K = KITCHENAID

PRODUCT IDENTIFICATION

UI = UNDERCOUNTER ICE MAKER

MERCHANDISING SCHEME

A = ARCHITECT

S = STANDARD

V = SIGNATURE SERIES

CAPACITY / SIZE / SERIES / CONFIGURATION

15 = 15" WIDE

18 = 18" WIDE

FEATURES

PR = PUMP, RIGHT HAND DOOR SWING

PL = PUMP, LEFT HAND DOOR SWING

PN = PUMP, NON-REVERSIBLE DOOR SWING

NR = NON-PUMP, RIGHT HAND DOOR SWING

NL = NON-PUMP, LEFT HAND DOOR SWING

NN = NON-PUMP, NON-REVERSIBLE DOOR SWING

YEAR OF INTRODUCTION

H = 1999, J = 2000, K = 2001, L = 2002, M = 2003

COLOR CODE

B = BLACK, W = WHITE, S = STAINLESS

T = BISCUIT, M = METEORITE

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

SERIAL NUMBER E P 04 54321

DIVISION RESPONSIBILITY

E = EVANSVILLE, IN

YEAR OF PRODUCTION

P = 2003, R = 2004

WEEK OF PRODUCTION

04 = 4th WEEK

PRODUCT SEQUENCE NUMBER

1-4

Page 9

MODEL & SERIAL NUMBER LABEL LOCATION

The Model/Serial Number label location is shown below.

Model & Serial

Number Location

1-5

Page 10

SPECIFICATIONS

AC Power Supply ...........................................................97 to 127 VAC (rated 115VAC), 60 Hz

Amperage .......................................................................................................... 3.6 Amps (max)

Minimum Circuit Capacity ............................................................................................ 15 Amps

Ice Production per 24 hours (Approximate) ................................................................................

Ambient Temperature

70°F (21°C) 46 lbs (21 kg)

80°F (27°C) 47 lbs (21 kg)

90°F (32°C) 40 lbs (18 kg)

100°F (38°C) 40 lbs (18 kg)

110°F (43°C) 38 lbs (17 kg)

Ice Shape ...................................................................................................... 3/4″ x 3/4″ Square

Ice Thickness @ Normal Setting (Approximate) .................................................0.32″ (8.1 mm)

Ice Thickness @ Thin Setting (Approximate) ...................................................... 0.28″ (7.0 mm)

Ice Thickness @ Thick Setting (Approximate) ................................................... 0.39″ (9.9 mm)

Storage Capacity (Approximate) ....................................................................... 24 lbs. (10.9 kg)

Exterior Dimensions (W x D x H) .....15″ or 18″ x 24″ x 34″ (381 or 457.2 x 609.6 x 863.6 mm)

Exterior Finish .......................................................................... Stainless Steel or Painted Steel

Net Weight ................................................... 15″ = 94 lbs. (42.6 kg) 18″ = 123 lbs. (55.8 kg)

Cube Thickness Control ......................... Thermistor under Evaporator & Control Board Setting

Harvest Control ...................................... Thermistor under Evaporator & Control Board Setting

Bin Ice Level Control ...........................................................................Thermistor on side of Bin

Refrigerant ....................................................................................................................... R134a

Ambient Temperature .............................................................................................. 55 to 100°F

Water Pressure .................................................................................................... 20 to 120 psig

Water Consumption (Dependent On Water Pressure)..................... 6 to 10 gallons per 4 hours

Water Temperature

60°F (15°C)

1-6

Page 11

KITCHENAID ICE MAKER WARRANTY

1-7

Page 12

— NOTES —

1-8

Page 13

INSTALLATION INFORMATION

ELECTRICAL SUPPLY REQUIREMENTS

WARNING

Electrical Shock Hazard

• A 115 Volt, 60 Hz, AC only 15 ampere electrical

supply, properly grounded in accordance

with the National Electrical Code and local

codes and ordinances, is required.

• It is recommended that a separate circuit,

serving only the ice maker, be provided. Use

a receptacle which cannot be turned off by a

switch or pull chain.

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

Before you move the ice maker into its final

location, it is important to make sure you have

the proper electrical connection:

Recommended Grounding Method

For personal safety, this appliance must be

grounded. This appliance is equipped with a

power supply cord having a 3-prong grounding

plug. To minimize possible shock hazard, the

cord must be plugged into a mating, 3- prong,

grounding-type wall receptacle, grounded in

accordance with the National Electrical Code

and local codes and ordinances. If a mating

wall receptacle is not available, it is the personal responsibility of the customer to have a

properly grounded, 3-prong wall receptacle

installed by a qualified electrician.

2-1

Page 14

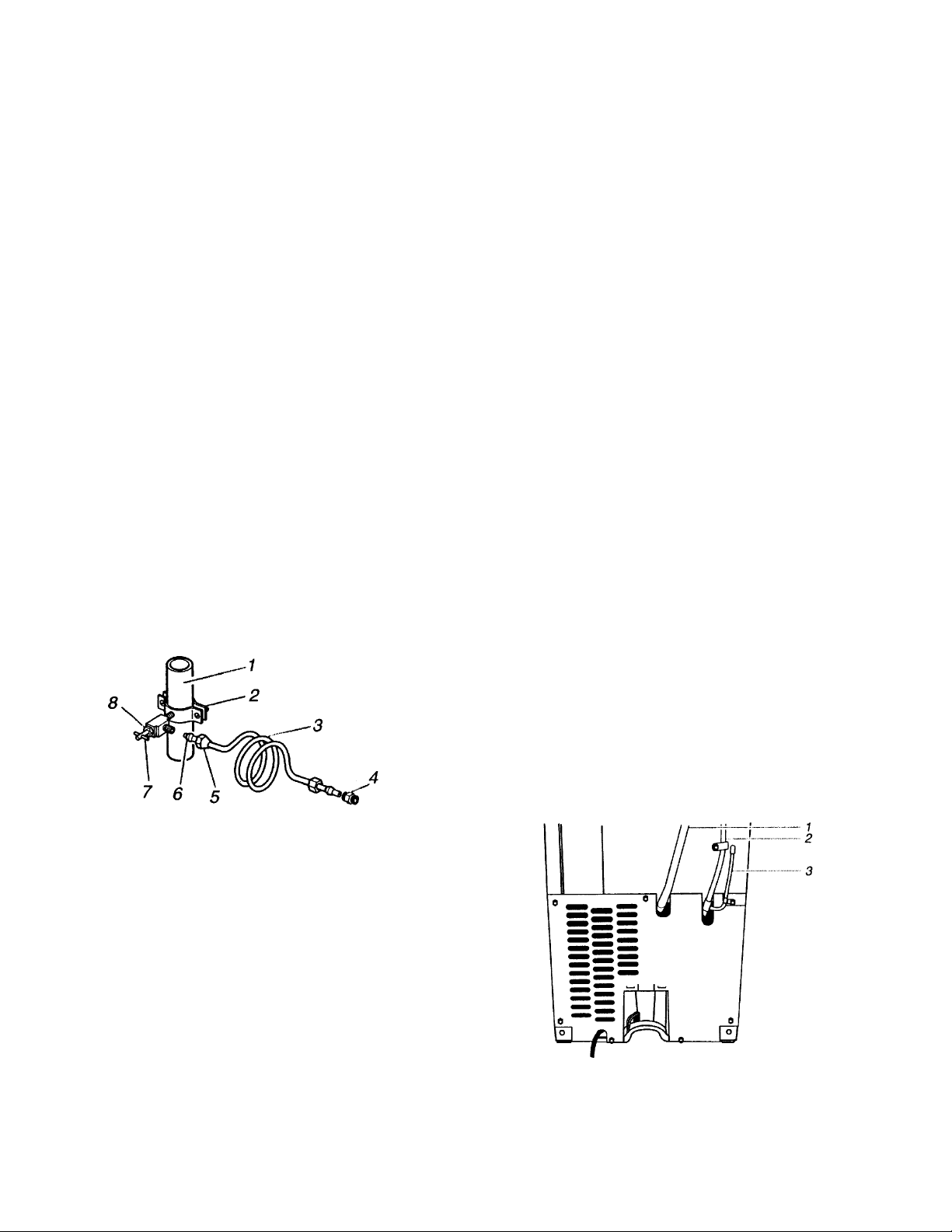

WATER SUPPLY AND DRAIN CONNECTIONS

CONNECTING THE WATER LINE

1. Turn off the main water supply.

2. Turn on the nearest faucet and allow it to

run long enough to clear line of water.

3. Find a 1/2″ (12.70 mm) to 1-1/4″ (3.18 cm)

vertical cold water pipe near the ice maker.

NOTE: A horizontal pipe will work, but drill on

the top side of the pipe, not the bottom. This will

keep water away from the drill motor, and also

keeps normal sediment from collecting in the

valve.

4. Using a grounded drill, drill a 1/4″ (6.35 mm)

hole in the cold water pipe you have selected.

5. Fasten a shutoff valve to the cold water

pipe with a pipe clamp. Make sure that the

outlet end is firmly in the 1/4″ (6.35 mm)

drilled hole, and that the washer is under

the pipe clamp.

IMPORTANT: Do not use a piercing-type, or a

3/16″ (4.76 mm) saddle-type valve. These can

reduce water flow and easily become clogged.

8. Use 1/4″ (6.35 mm) O.D. copper tubing for

the cold water supply and:

a)Measure from the connection at the

back of the ice maker to the cold water

pipe.

b)Add an extra 36″ (91.4 cm) to ensure

that you have the proper length. Make

sure both ends of the copper tubing are

cut square.

c) Slip a compression sleeve and com-

pression nut over the ends of the copper tubing.

d)Insert the end of tubing into the water

shutoff outlet as far as it will go, and

screw the compression nut onto the

outlet. Tighten the compression nut with

an adjustable wrench, but do not overtighten it.

9. Place the free end of the copper tubing

into a container or sink, and turn on the

main water supply. Flush the tubing until

water is clear, and then turn off the shutoff

valve on the water pipe. NOTE: Always

drain the water line before making the final

connection to the inlet of the water valve to

prevent a possible water valve malfunction.

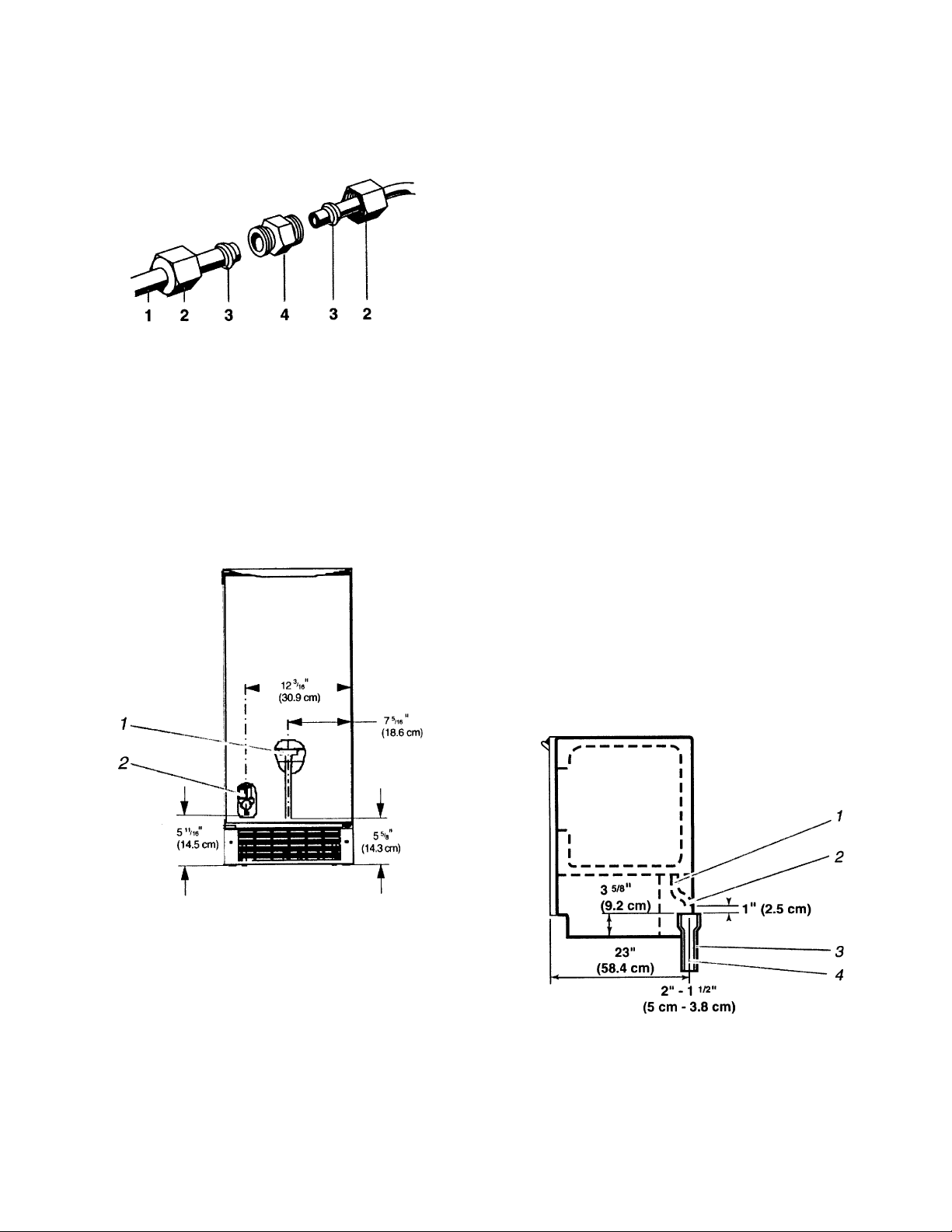

1. Cold Water Pipe 5. Compression Nut

2. Pipe Clamp 6. Compression Sleeve

3. Copper Tubing 7. Shutoff Valve

4. Coupling (purchased) 8. Packing Nut

6. Tighten the packing nut.

7. Tighten the pipe clamp screws carefully

and evenly so that the washer makes a

watertight seal. Do not overtighten the

pipe clamp. If the water line is soft copper

tubing, you could crush it.

10. Bend the copper tubing to meet the water

line inlet, located on the back of the ice

maker cabinet, as shown below.

1. Drain Hose (Drain Pump models only)

2. Vent Hose (Drain Pump models only)

3. Water Supply Line

2-2

Page 15

11. Thread the nut onto the coupling at the

end of the copper tubing. Tighten the nut

by hand. Then tighten it with a wrench two

more turns. Do not overtighten.

CONNECTING THE DRAIN

Gravity Drain System

Connect the ice maker drain so that it is in

accordance with all state and local codes and

ordinances. If the ice maker is provided with a

gravity drain system, use the following guidelines when installing the drain lines. This will

prevent water from flowing back into the ice

maker storage bin and onto the floor, causing

water damage.

1. Line to ice maker 3. Ferrule (purchased)

2. Nut (purchased) 4. Coupling (purchased)

12. Remove the four screws from the lower

access panel and remove the panel from

the front of the ice maker.

NOTE: To prevent rattling, keep the copper

tubing from touching the cabinet side wall, or

any other parts inside the cabinet.

FRONT VIEW

• Drain lines must have a minimum of 5/8″

(15.88 mm) inside diameter.

• Drain lines must have a 1″ drop per 48″ (2.54 cm

drop per 122 cm) of run, or 1/4″ drop per 12″

(6.35 mm per 30.48 cm) and not have any

low points where water can settle.

• The floor drains must be large enough to

accommodate drainage from all drains.

• The ideal installation has a standpipe with a

1-1/2″ (3.81 cm) to 2″ (5.08 cm) PVC drain

reducer installed directly below the outlet of

the drain tube, as shown. You must maintain

a 1″ (2.54 cm) air gap between the drain

hose and the standpipe.

• It may be desirable to insulate the drain line

up to the drain inlet.

SIDE VIEW

1. Water Pan Drain

2. Water Valve

13. Turn the shutoff valve ON.

14. Check the water connections for leaks,

and carefully tighten any that are leaking.

15. Reinstall the lower access panel with its

four screws.

1. Drain Hose

2. 1″ (2.54 cm) Air Gap

3. PVC Drain Reducer

4. Center of drain should be 23″ (58.4 cm) from

front of door, with or without the 3/4″ (1.91 cm)

panel on the door.

2-3

Page 16

After ensuring that the drain system is adequate, use the following steps to properly

place the ice maker:

1. Plug in the ice maker or reconnect power.

Drain Pump System (On Some Models)

Connect the drain pump hose (provided with

the product) to the drain in accordance with all

state and local codes and ordinances.

2. Recheck the ice maker and make sure

that it is level.

3. Push the ice maker into position so that

the drain tube is positioned over the PVC

drain reducer.

4. If it is required by the local sanitation code,

seal the cabinet to the floor with an approved caulking compound after all water

and electrical connections have been

made.

NOTE: If the drain hose becomes twisted and

water cannot drain, the ice maker will not operate.

2-4

Page 17

THEORY OF OPERATION

OPERATING SYSTEMS

There are three operating systems in the ice

maker:

• Refrigeration System

• Water System

• Electrical System

REFRIGERATION SYSTEM

The refrigeration system in the ice maker is

very similar to the system used in other refrigeration appliances. The refrigerant used in this

unit is R134a.

There are two very important additions to the

refrigeration system in the ice maker: the Hot

Gas Valve, and the Condenser Accumulator

Tube. The components operate as follows:

• Hot Gas Valve - Allows high pressure

refrigerant gas to bypass the condenser

and flow through the condenser accumulator tube.

• Condenser Accumulator Tube - Hot gas

pushes liquid refrigerant through the accumulator tube into the evaporator,

helping to evenly heat the evaporator

plate so that the ice slab releases

quickly and evenly.

3-1

Page 18

WATER SYSTEM

The water system provides:

• Fresh water for ice production

• Water recirculation as ice is produced

The water system also flushes away minerals

and contaminates, circulates cleaning solution

during the clean cycle, and provides drainage.

The hardness of the water supplied to the ice

maker will affect the quality of the ice that is

produced. It may also affect the operation of

the water system.

Water Distributor

Evaporator

A water softener, or polyphosphate feeder, will

not cure all of the problems associated with

hard water, but they can be used to reduce

scale buildup in the ice maker. NOTE: Some

polyphosphate feeders will cause a slime

buildup in the water system when the water

supply has a low mineral content.

The ice maker’s water system is shown below.

Reservoir Pan

Water

Inlet Tube

Water

Inlet Valve

Cutter Grid

Water Pump

Outlet Tube

Bin Water Inlet Tube

Water Pump

Reservoir Drain

Standpipe

To Bin Drain

From Water Supply

3-2

Page 19

ELECTRICAL SYSTEM

The ice maker’s electrical system provides

power for the refrigeration and water systems,

and controls the operational cycling.

3-3

Page 20

OPERATIONAL CYCLES

There are three main operational cycles for the

ice maker (more detailed operation is found in

the flow chart on page 6-5):

• Ice Making

• Harvest

• Diagnostics/Clean

ICE MAKING CYCLE

In addition, there are two possible “Off” cycles

for the ice maker. They occur when:

1. The bin is full of ice and the service

control switch is turned “ON” (Idle

mode).

2. The service control switch is turned

“OFF” while power is still supplied to

the unit.

Electrical System

Power is supplied through the service control

switches to the primary side of the voltage

step-down transformer, (120 VAC reduced to

8.7 VAC for the cutter grid and the bin light),

and the electronic control board. The electronic control board in turn supplies 120 VAC to

the water recirculating pump, water inlet valve,

hot gas solenoid, condenser fan motor, and

compressor. An evaporator thermistor supplies temperature information to the electronic

control.

Refrigeration System

The hot gas refrigerant, under high pressure, is

forced through the condenser, where it changes

into a liquid, and flows through the drier and

capillary tube into the evaporator. Under low

pressure in the evaporator, the liquid refrigerant absorbs heat from the water flowing over

the evaporator. The refrigerant evaporates into

a gas, and passes into the accumulator. As a

low pressure gas, the refrigerant flows back

through the suction line of the heat exchanger,

to the compressor.

During the Ice Making cycle, some of the hot

gas that is in the condenser accumulating tube,

condenses to a liquid, and remains in the

accumulating tube.

During the later stages of the Ice Making cycle,

as the ice slab forms on the evaporator freezing plate, some of the refrigerant passing

through the evaporator will not evaporate into

a gas, but will remain a liquid. This liquid

refrigerant will settle in the accumulator, while

the refrigerant vapor is sucked off through the

suction tube at the top of the accumulator. This

accumulated liquid refrigerant will eventually

be evaporated by the warmed refrigerant gas

passing through the accumulator during the

Harvest cycle, and during the beginning of the

next Ice Making cycle.

NOTE: It is very important that the accumulator

is not tilted out of a horizontal position. If

moved, it could cause compressor failure.

Water System

The water recirculating pump moves the water

from the reservoir pan up to the distributor,

where it flows out over the evaporator freezing

plate.

Water that does not freeze on the evaporator

plate runs off the front edge, and falls back into

the reservoir, where it is recirculated back to

the water distributor.

As the ice slab forms, the minerals in the water

are on the surface of the ice. The water flowing

over the top of the ice slab washes these minerals back into the water reservoir pan. The water

continues to recirculate until the ice slab reaches

the set thickness. Thickness is determined by

the placement of the P4 jumper, located on the

control board.

Control board #6100499 with Code Date MGR/

0245 (45th week, 2002), or higher, will allow ice

thickness adjustments (see “Adjusting The Ice

Thickness” on page 8-3).

3-4

Page 21

HARVEST CYCLE

Electrical System

When the set temperature of the evaporator

thermistor is reached, it signals the electronic

control to terminate power to the condenser

fan, and the water recirculating pump. Power is

then supplied to the hot gas valve and water fill

valve solenoids.

If the evaporator thermistor is unplugged, the

control defaults to the maximum freeze and

harvest times.

Refrigeration System

The hot gas valve opens, allowing high pressure refrigerant gas to bypass the condenser,

and flow through the condenser accumulating

tube. The hot gas pushes the liquid refrigerant

that has accumulated in the accumulator tube

up into the evaporator. The hot liquid refrigerant evenly heats the evaporator plate so that

the ice slab releases quickly and evenly.

The ice slab, when released, slides off of the

evaporator plate onto the cutter grid.

Water System

The water valve opens, allowing water to flow

into the water reservoir pan. As the reservoir

fills, the mineral-laden water from the previous

Ice Making cycle, is flushed out the overflow

tube.

As a result of the hot gas flow and the ice sliding

off the evaporator plate, the evaporator temperature begins to rise. When the evaporator

thermistor reaches the set temperature (6.5°F),

the unit switches to the Ice Making cycle. This

cycling between Ice Making and Harvest, continues until the ice bin is full.

The electronic control board controls the various components and systems in the ice maker

for each of the Ice Making and Harvest cycles.

When the ice maker’s service control switch is

in the “On” position, and the bin is not full of ice,

the evaporator thermistor determines whether

the unit will be in the Ice Making, or the Harvest

cycle.

If the thermistor is unplugged from the control

board, the unit will cycle using maximum freeze

and harvest times.

DIAGNOSTICS / CLEAN CYCLE

Electrical System

Power is supplied to the electrical components

through the service control switch.

The electronic control board controls the various components and systems during the Diagnostics/Clean cycle. During the first 25 seconds of the cycle, each component will operate

for 5 seconds.

For the order of the components cycled, see

the flow chart on page 6-5.

Water System

When the service control switch is in the ‘’Clean”

position, the water recirculating pump circulates the cleaning solution that has been added

to the reservoir, up to the water distributor,

across the evaporator, and back into the reservoir, where it is recirculated.

3-5

Page 22

NEW ICE MAKER CONTROL BOARD (#6100499)

NOTE: Due to a quality improvement, the new

control board will replace the older design

(#2185947).

If you are replacing control board #2185947,

please read the improvements listed below. If

you are replacing control board #6100499, you

may disregard the following information.

There are no differences in mounting or wiring

the new control board. Improvements were

made to support low voltage applications.

Additional improvements include the following:

• A 15-minute minimum, and 25-minute

maximum, ice making cycle time limit.

This eliminates the production of ice slabs

that are too thin or too thick. Control

boards with Code Date MGR/0245, (45th

week, 2002), or higher, will allow ice

thickness adjustments by moving the

jumper at P4 (see “Adjusting The Ice

Thickness” on page 8-3).

• During a harvest, the water valve “on

time” is now limited to 1 minute to reduce

water usage. This also eliminates the

condition of the water valve being energized for an unlimited amount of time if

the evaporator thermistor is not located

correctly, or if the reversing valve has

failed or is unplugged. If the evaporator

thermistor is unplugged, a 25-minute default freeze, and 4-minute harvest interval will occur.

If the unit stays in harvest mode for more

than 16 minutes, the unit will go into a

failure mode, shutting the unit down, and

flashing the LED light. To get out of failure

mode, shut the unit off, and then back on

again. This will reset the control board. If

the failure was not corrected, the unit will

return to failure mode when the unit

reaches it’s 16-minute cycle again. If this

occurs, find the cause of the failure, and

repair it, then unplug the unit to reset the

board.

• The diagnostic mode sequence was

changed, moving the bin and evaporator

thermistor checks to the beginning of the

sequence. The old boards had these

checks at the end of the sequence.

• Whenever the unit has reached a failure

mode, the LED will flash, and the unit will

shut down. If the failure was caused during a harvest cycle which lasted more

than 16 minutes, the LED will remain

flashing on & off in half-second increments. If the failure is caused by a faulty

bin thermistor, (not detected), the LED

will remain flashing on & off in 1-second

increments. These are the only two failures that cause the unit to reach a shutdown failure mode.

• During the Clean cycle, the control board

performs the diagnostics first. If the bin

thermistor is not detected, the LED will

flash two times. This is followed by a

3-second delay. If the evaporator thermistor is not detected, the LED will flash

on five times. This will be followed by a

3-second delay. The LED will then come

back on, and remain on for the remainder

of the Clean cycle, and until the unit is

turned back on.

The following check can be done on the

board & thermistors:

- Unplug either thermistor electrical

connection.

- Press the Clean switch. The LED

should flash as described above, depending upon which thermistor is unplugged, or if both are unplugged.

For step-by-step operation, see the flow chart

on page 6-5.

3-6

Page 23

MODELS WITH INTERNAL DRAIN PUMPS

The power cord on the internal drain pump is

connected to a 120 VAC wall outlet. The ice

maker is then connected to the 120 VAC outlet

on the drain pump. If the drain pump fails, or if

the drain becomes blocked, power is shut off to

the 120 VAC outlet on the drain pump.

When the unit is first plugged in, the drain pump

will run for 20 seconds. The power can be

disconnected and reconnected to verify that

the pump is operating properly.

Water from the ice maker reservoir, or melting

ice from the bin, drains down the bin drain tube

Pump Inlet

Overfill Contact

Full Contacts

Vent Outlet

into the pump inlet, and then into the drain

pump chamber. As the water level rises, it

bridges the “full” contacts, and the pump starts

to run. The pump discharges the water through

the outlet and the check valve. When the “full”

connection is removed, the pump runs for an

additional 12 seconds to empty the tank.

If the water level in the drain pump continues to

rise, due to a slow or blocked drain, or a

blocked vent hose, and touches the “overfill”

contact, power will be turned off to the drain

pump’s 120 VAC outlet, causing the ice maker

to turn off.

White

Black

Green

Pump Outlet &

Check Valve

Contacts Sense Continuity

Through The Water

Screen

Washer

Connector Hose

(Contains Screen Washer)

3-7

Page 24

— NOTES —

3-8

Page 25

COMPONENT ACCESS

This section instructs you on how to service each component inside the KitchenAid Automatic Ice

Maker. The components and their locations are shown below.

COMPONENT LOCATIONS

Cutter Grid Transformer

Evaporator

NOTE: The Evaporator

Thermistor Is Located On

Tubing Below The Evaporator

Cutter Grid

Water Recirculation Pump

Compressor

Condenser Fan Motor

Light Switch

Electronic Control Board

Pushbutton Switch

Assembly

Bin Thermistor

Hot Gas Valve & Solenoid

(Behind Condenser)

Water Inlet Valve

Condenser

Condenser Accumulator Tube

4-1

Page 26

REMOVING THE BIN THERMISTOR, CUTTER GRID,

EVAPORATOR THERMISTOR, & WATER DISTRIBUTOR

6. To remove the bin thermistor:

WARNING

a) Disconnect the bin thermistor connec-

tor from the bottom of the control housing.

b) Pull the bin thermistor out of the retain-

ing clamp and remove it.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Cover or remove the ice from the storage

bin.

4. Place a cloth in the drain hole to prevent

hardware from falling inside.

5. Remove the two hex-head screws from

the cutter grid cover and remove the cover.

Cutter Grid Cover

Control Housing

Connector

Bin Thermistor

Retaining Clamp

7. To remove the cutter grid:

a) Disconnect the cutter grid and bin ther-

mistor connectors from the bottom of

the control housing.

b) Remove the two hex-head screws from

both sides of the cutter grid.

Cutter Grid Cover Screws

Cutter Grid Cover

Spacer Bracket (Left Side)

18″ Models

Bin Thermistor Connector

Cutter Grid Connector

Cutter Grid Screws

4-2

Page 27

c) Slide the cutter grid forward and out of

the unit and place it on a work surface.

Be careful not to scratch the ice maker

liner.

d) Remove the spacer from the right cut-

ter grid bracket tab.

8. To remove the evaporator thermistor:

a) Remove the cutter grid from the unit

(see step 7 on page 4-2 for the procedure).

b) Disconnect the evaporator thermistor

connector from the bottom of the control housing.

c) Remove the two hex-head mounting

screws from the water trough and pull

the trough from the unit.

SpacerSlide Out Cutter Grid

e) Lift the two ice guides from the cutter

grid tabs. Note the orientation of the

guides with the straight side facing in.

There should be a slight outward tilt

after the guides are installed. Bend the

metal tabs outward, if necessary.

Cutter Grid

Ice Guides

Control Housing

Water Trough Screws

Evap Thermistor Connector

Water Trough

d) Reach behind the accumulator, and

unclip the evaporator thermistor from

the evaporator tubing and remove it.

Evaporator Thermistor

Position Ice Guide

With Straight Side

As Shown

Accumulator

Bottom Of The Evaporator

Continued on the next page.

4-3

Page 28

9. To remove the water distributor:

a) Remove the cutter grid from the unit

(see step 7 on page 4-2 for the procedure).

b) Pull out on the left and right water dis-

tributor retainers, and remove the tabs

from the slots in the evaporator. Pull the

distributor forward and remove the water

hose.

Water Distributor

Water Hose

Tab

Retainer

Water Distributor

4-4

Page 29

REMOVING THE ELECTRONIC CONTROL

HOUSING COMPONENTS

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

NOTE: The control housing components consist of:

• (1) Electronic control board

• (2) Cutter grid transformer

• (3) Light switch

• (4) Pushbutton switch assembly

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Cover or remove the ice from the storage

bin.

4. Remove the cutter grid cover and the

cutter grid (see page 4-2 for the procedures).

5. Disconnect the remaining two connectors

(bin and evaporator thermistors) from the

bottom of the control housing.

6. Remove the four hex-head screws from

the control housing and lower the housing

so that you can access the components.

Control Panel

2

4

3

7. To remove the electronic control board:

a) Disconnect the three harness connec-

tors from the board terminals.

b) Remove the two mounting screws.

Three (3) Harness Connectors

Screw

1

4 Control Housing Screws

4-5

Electronic Control Board

Continued on the next page.

Screw

Page 30

8. To remove the cutter grid transformer:

a) Disconnect the white & yellow wires

from the primary terminals, and the

black/white wires from the secondary

terminals.

b) Remove the two mounting screws from

the transformer bracket.

c) Disconnect the green ground wire from

its terminal.

Cutter Grid Transformer

Green Ground Wire

NOTE: If the pushbutton switch assembly or

light switch is replaced, the replacement part

and decorative overlay must be ordered using

the model number of the ice maker. The service replacement switch is not supplied with a

decorative overlay.

9. To remove the light switch or push-

button switch assembly:

a) Peel off the decorative overlay from the

front of the control housing.

Decorative Overlay

b) Disconnect the wires from the switch

terminals.

c) Press the locking arms and push the

switch assembly out of the housing.

Primary Wires

Secondary Wires

Screw (1 of 2)

WARNING

Electrical Shock Hazard

Connect green ground wire to ground

terminal.

Locking Arm

Light Switch

Locking

Arms

Four (4) Wires

Pushbutton Switch Assembly

Failure to do so can result in death or

electrical shock.

4-6

Page 31

REMOVING THE WATER RECIRCULATION PUMP

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

7. Remove the hex-head screw from the

water recirculation pump shield and remove the shield (see the lower left photo).

8. Pull the water fill tube out of the slot in the

water recirculation pump bracket.

9. Remove the three hex-head screws from

the water recirculation pump bracket.

10. Disconnect the water recirculation pump

3-wire connector from the harness and

remove the pump.

11. Disconnect the water tube from the pump.

Water Fill Tube

3. Remove the ice from the storage bin.

4. Unscrew the drain cap from the reservoir,

drain the water, and replace the cap tightly.

5. Place a cloth in the drain hole to prevent

hardware from falling inside.

6. Remove the two thumbscrews from the

reservoir and remove the reservoir from

the unit.

Spacer Bracket (Left Side) 18″ Models

Screw

Water Recirculation

Pump Shield

3-Wire Connector

3 Bracket Screws

Water Tube

Thumbscrew

Water Reservoir

Thumbscrew

Drain Cap

4-7

Page 32

REMOVING THE CONDENSER FAN MOTOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Remove the ice from the storage bin.

4. Disconnect the water and drain lines from

the ice maker and remove the unit from its

installation.

6. Remove the two 5/16″ screws from the

front of the cabinet.

7. Disconnect the water outlet tubing from

the water valve.

8. Disconnect the electrical connectors from

the water inlet valve and hot gas valve

terminals.

Electrical Connectors

Water Inlet Valve Hot Gas Valve

5. Remove the four hex-head screws from

the front panel and remove the panel.

Front Panel Screws

Screw

NOTE: If the unit you are servicing is equipped

with an internal drain pump, perform steps 9

and 10. If the unit does not have an internal

pump, skip those steps, and proceed to step 11

on the next page.

9. From the back of the unit, remove the four

screws from the unit compartment cover

and remove the cover.

Water Outlet Tubing

Screw

Unit Compartment Cover

4-8

4 Screws

Page 33

10. Disconnect the inlet tube and the vent tube

from the internal drain pump.

Disconnect Tubing

Internal Drain Pump

11. Tilt the front of the cabinet up until you can

access the two side screws on the condenser fan motor shroud, and secure the

cabinet so that it cannot tip forward or

backward.

12. Disconnect the wire connector from the

condenser fan motor.

13. Remove the four screws (two bottom and

two side) from the condenser fan motor

shroud. Slide the shroud assembly back

towards the compressor, and then lift and

remove the assembly from the unit.

Motor Connector

Tilt Cabinet Back

Condenser Fan Motor Bottom Shroud Screws

Condenser Fan Motor Left Side Shroud Screw

Prop Up Securely

4-9

Continued on the next page.

Page 34

14. Remove the nut from the condenser fan

motor blade and remove the blade. NOTE:

Make sure to reinstall the fan with the

“NUT SIDE” marking facing the nut.

Nut

Marking On Fan

15. Remove the three hex-head screws from

the condenser fan motor and remove it

from the shroud.

Condenser Fan Motor Screw (1 of 3)

4-10

Page 35

REMOVING THE EVAPORATOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Remove the ice from the storage bin.

4. Remove the cutter grid and the evaporator

thermistor from the unit (see pages 4-2

and 4-3 for the procedures).

5. Disconnect the bin thermistor connector

from the bottom of the control housing

(see page 4-2).

7. Remove the two 5/16″ hex-head screws

from the top hinge and remove the hinge.

Hinge Screws

8. Remove the two front and two rear screws

from the cabinet top.

2 Hex-Head Screws

6. Remove the top door screw from the ice

maker door, and pull the door off the

bottom hinge.

Top Door Screw

Screw Screw

9. Lift the cabinet top and position it forward

on top of the unit.

Continued on the next page.

4-11

Page 36

10. 18″ Models Only: Remove the six screws

from the counterbalance plate and remove the plate from the rear of the unit.

11. From the rear of the unit, remove the six

hex-head screws from the channel cover

and remove the cover.

12. Remove the four screws from the unit compartment cover and remove the cover.

13. Cut the tie wrap from around the tubing

and wire harness inside the channel.

Screw (1 of 6)

Channel Cover

(6 Screws)

Counterbalance Plate

18″ Models

Tie Wrap

14. Remove the two screws from the reservoir

water trough and remove the trough.

Screw

Water Trough

Screw

Unit Compartment Cover

(4 Screws)

4-12

Page 37

15. Remove the hex-head screw from the

water recirculation pump shield and remove the shield.

16. Remove the water fill tube from the notch

in the water recirculation pump bracket,

and pull the free end of the water line up,

out of the unit.

Water Recirculation Pump Shield

Screw

Retainer

Tab

Water Distributor

Hose

Evaporator

Water Fill Tube

Refer to the photos at the top of the next

column.

17. Pull out on the left and right water distributor retainers and remove the tabs from the

slots in the evaporator, disconnect it from

the hose, and remove it.

18. Remove the four screws from the evaporator, then carefully lift the evaporator just

high enough to remove the two right spacers.

2 Screws

2 Screws & Spacers

19. Remove the Permagum from the liner

channel.

Remove Permagum

Continued on the next page.

4-13

Page 38

20. Lift the cabinet top off the unit and stand it

on the floor near the rear of the unit.

21. Lift the evaporator and its connecting tubing high enough from the unit to access

the tubing underneath.

22. Access the sealed system and discharge

the refrigerant into an approved recovery

system.

REASSEMBLY NOTES:

• When installing the new evaporator, use a

generous amount of thermal heat trap paste

between the hot gas valve, and the evaporator tubing joint to protect the hot gas valve

when brazing.

• Be sure to reinstall the Permagum in the

liner channel of the cabinet around the wire

sheath and tubing, so that there are no air

leaks after the cabinet top is installed (see

the photo in step 19 on page 4-13).

Suction Line

23. Unbraze (and cut) the evaporator from the

tubing at the following locations:

• Suction line at the compressor.

• Hot gas line at the hot gas valve.

• Cut capillary tube at the filter/drier.

Hot Gas

Valve Joint

Filter/Drier Capillary Tube

4-14

Page 39

REMOVING THE WATER INLET VALVE

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Disconnect the water and drain lines from

the ice maker and remove the unit from its

installation.

4. Remove the four hex-head screws from

the front panel and remove the panel.

Water Inlet Valve

5. Disconnect the water inlet and outlet tubing from the water inlet valve.

6. Remove the two hex-head screws from

the water inlet valve bracket.

Water Inlet Valve

Inlet Tubing

Front Panel Screws

Bracket

Screws

Outlet Tubing

7. Disconnect the 2-wire connector from the

water inlet valve terminals.

2-Wire Connector

4-15

Page 40

REMOVING THE HOT GAS VALVE & SOLENOID

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

2-Wire Connector 7mm Nut

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Tip the front of the cabinet back and prop

it up (see steps 2 through 11 on pages 4-8

and 4-9 for the procedure).

Hot Gas Valve & Solenoid

Hot Gas Valve Solenoid

4. To remove the hot gas valve:

a) Remove the solenoid from the hot gas

valve (see step 3 for the procedure).

b) Access the sealed system and dis-

charge the refrigerant into an approved

recovery system.

c) Unbraze the hot gas valve from the

tubing.

Hot Gas Valve

3. To remove the hot gas valve solenoid

(see the photo at the top of the next

column):

a) Disconnect the 2-wire connector from

the solenoid terminals.

b) Remove the 7mm hex-head screw from

the solenoid and lift the solenoid off the

hot gas valve.

Valve Tubing Joints

REASSEMBLY NOTE: When installing the new

hot gas valve, use a generous amount of

thermal heat trap paste between the valve and

tubing joints to protect the valve when brazing.

4-16

Page 41

REMOVING THE CONDENSER

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Tip the front of the cabinet back and prop

it up (see steps 2 through 11 on pages 4-8

and 4-9 for the procedure).

3. Remove the four condenser fan motor

screws from the fan motor shroud and pull

the motor assembly back away from the

evaporator as far as possible, but do not

remove it (see step 13 on page 4-9 for the

procedure).

4. Remove the two mounting screws from

the condenser bracket flanges.

5. Access the sealed system and discharge

the refrigerant into an approved recovery

system.

6. Unbraze the two condenser joints from the

tubing.

Condenser

Condenser

Tubing Joints

2 Condenser Bracket Screws

4-17

Page 42

REMOVING THE COMPRESSOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

6. Remove the terminal cover using a standard screwdriver. Insert the screwdriver

into the cover slot, and press down to

unsnap and remove it.

Compressor

1. Unplug ice maker or disconnect power.

2. Open the ice maker door.

3. Remove the ice from the storage bin.

4. Disconnect the water and drain lines from

the ice maker and remove the unit from its

installation.

5. At the rear of the unit, remove the four

screws from the unit compartment cover

and remove the cover.

Unit Compartment Cover

4 Screws

Terminal Cover

Press Down

With Screwdriver

7. Remove the wires from the ground terminal, the overload protector terminal, and

the relay terminal.

8. Pull the overload protector and relay from

the compressor pins.

Ground Wire

4-18

Overload

Protector

Relay

Page 43

9. Pull the two clips off the rear studs of the

compressor.

Clip On Stud

10. Tip the front of the cabinet back and prop

it up (see steps 5 through 11 on pages 4-8

and 4-9 for the procedure).

15. Pull the two clips off the front compressor

mounting studs.

16. Lift the compressor off the four mounting

studs and remove it from the unit. Remove

the four metal spacers and rubber isolators from the compressor stud locations.

Suction Line

Compressor

Filter/Drier

11. Access the sealed system and discharge

the refrigerant into an approved recovery

system.

Discharge Line

2 Clips, Metal Spacers, & Rubber Isolators

WARNING

Electrical Shock Hazard

Connect green ground wire to ground

terminal.

Failure to do so can result in death or

electrical shock.

12. Cut the suction and discharge lines from

the compressor.

13. Cut the filter/drier from the system (do not

use a torch to remove the filter/drier).

14. Unbraze the compressor suction and discharge joints from the tubing.

Perform the following steps after installing the

new compressor.

1. Install the overload protector and relay on

the compressor pins.

2. Connect the wires to the ground terminal,

the overload protector terminal, and the

relay terminal.

4-19

Page 44

REMOVING THE INTERNAL DRAIN PUMP

(ONLY ON SOME MODELS)

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

5. Loosen the clamps and pull the ends of the

three water lines from the internal drain

pump.

6. Disconnect the power cord plug from the

internal drain pump.

7. Remove the two mounting screws from

the internal drain pump.

Remove Ends Of 3 Water Lines

2. Remove the ice from the storage bin.

3. Disconnect the water and drain lines from

the ice maker and remove the unit from its

installation.

4. At the rear of the unit, remove the four

screws from the unit compartment cover

and remove the cover.

Unit Compartment Cover

4 Screws

Internal Drain Pump

Disconnect Power Cord Plug

Remove Screws

8. Remove the internal drain pump from the

unit.

4-20

Page 45

REMOVING THE ICE MAKER DOOR & GASKET

(15″ MODELS)

1. To remove the door, remove the top door

screw from the ice maker door, and pull

the door off the bottom hinge.

Top Door Screw

2. To remove the door gasket:

a) Open the ice maker door.

b) Pull the gasket out of the door track.

NOTE: Be sure to check the new gasket for a proper seal after you install it.

Door Track

Door Gasket

4-21

Page 46

REMOVING THE ICE MAKER DOOR & GASKET

(18″ MODELS)

The 18˝ Ice Maker has a spring-loaded, dropdown door. Since the door design is somewhat

unique, accessing procedures are included

below.

1. Remove the two top and two bottom screws

from the grille and remove it from the front

of the ice maker.

Top Grille

Screws (1 of 2)

2. Remove the end of the spring from the

door bracket and the screw from the bottom of the door hinge.

Bracket

Hinge Bottom Hinge

Spring Screw

Bottom Grille

Screws (1 of 2)

3. Open the ice maker door and remove the

four front hinge screws (2 per hinge) and

remove the door. NOTE: Support the door

while you remove the screws to prevent it

from falling off the unit.

Hinge Screws

(2 each side)

4-22

Page 47

4. Remove the two screws from the bottom

door cap.

Bottom Door Cap Screws

5. Remove the three screws from the door

handle and the top door cap and remove

the handle and cap from the door.

Handle & Cap Screw (1 of 3)

7. Remove the six screws from the inner

door panel and remove the panel.

Inner Door Panel

Screw (1 of 6)

8. Slide the door insulation out of the top of

the outer door panel.

Slide Cap Off Door

6. Peel the gasket from the grooves in the

door and remove the gasket.

Gasket

Slide Out Here

Door Insulation

Outer Door Panel

Continued on the next page.

Door Channel

4-23

Page 48

9. Slide the bottom door cap and channel

supports out of the outer door panel.

Outer

Door

Panel

10. Slide the bottom door cap off the channel

supports.

Channel Supports

Slide Bottom Door Cap

Off Channel Supports

Door

Hinge

Slide Bottom Door Cap & Channel

Supports Out Of Outer Door Panel

Hinge Pin

Channel Support

11. To remove the door hinge, pull the hinge

pin out of the channel support and remove

the hinge.

Door Hinge

Hinge Pin

Channel Support

4-24

Page 49

REASSEMBLY NOTES:

1. To reassemble the unit, reverse the disassembly procedure.

2. Slide the edge of the outer door panel

between the tabs and the inside edge of

the top door cap.

3. When you reinstall the inner door panel,

slide the edge under the door handle, as

shown below.

Door Handle

Tab

Inside Edge Of

Inner Door Panel

Top Door Cap

Outer Door Panel

Top Door Cap

4. Before you reinstall the grille, position the

insulation pads and the air block as shown

below.

Air Block

4-25

Insulation Pads

Page 50

— NOTES —

4-26

Page 51

COMPONENT TESTING

(

)

(

)

(0)

(10)

(21)

(32)

(

)

(

)

(0)

(10)

(21)

(32)

Before testing any of the components, perform

the following checks:

• Control failure can be the result of corrosion

on connectors. Therefore, disconnecting and

reconnecting wires will be necessary throughout test procedures.

• All tests/checks should be made with a VOM

or DVM having a sensitivity of 20,000 ohmsper-volt DC, or greater.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

BIN THERMISTOR

• Check all connections before replacing components, looking for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

• Resistance checks must be made with power

cord unplugged from outlet, and with wiring

harness or connectors disconnected.

WARNING

EVAPORATOR THERMISTOR

Refer to page 4-2 for the procedure for servicing the bin thermistor.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the appropriate scale.

3. For the most accurate measurement, immerse the thermistor in ice water for 5

minutes, then use the 32°F/0°C reading in

the chart.

4. Touch the ohmmeter test leads to the two

bin thermistor connectors. The meter

should indicate as shown in the following

chart.

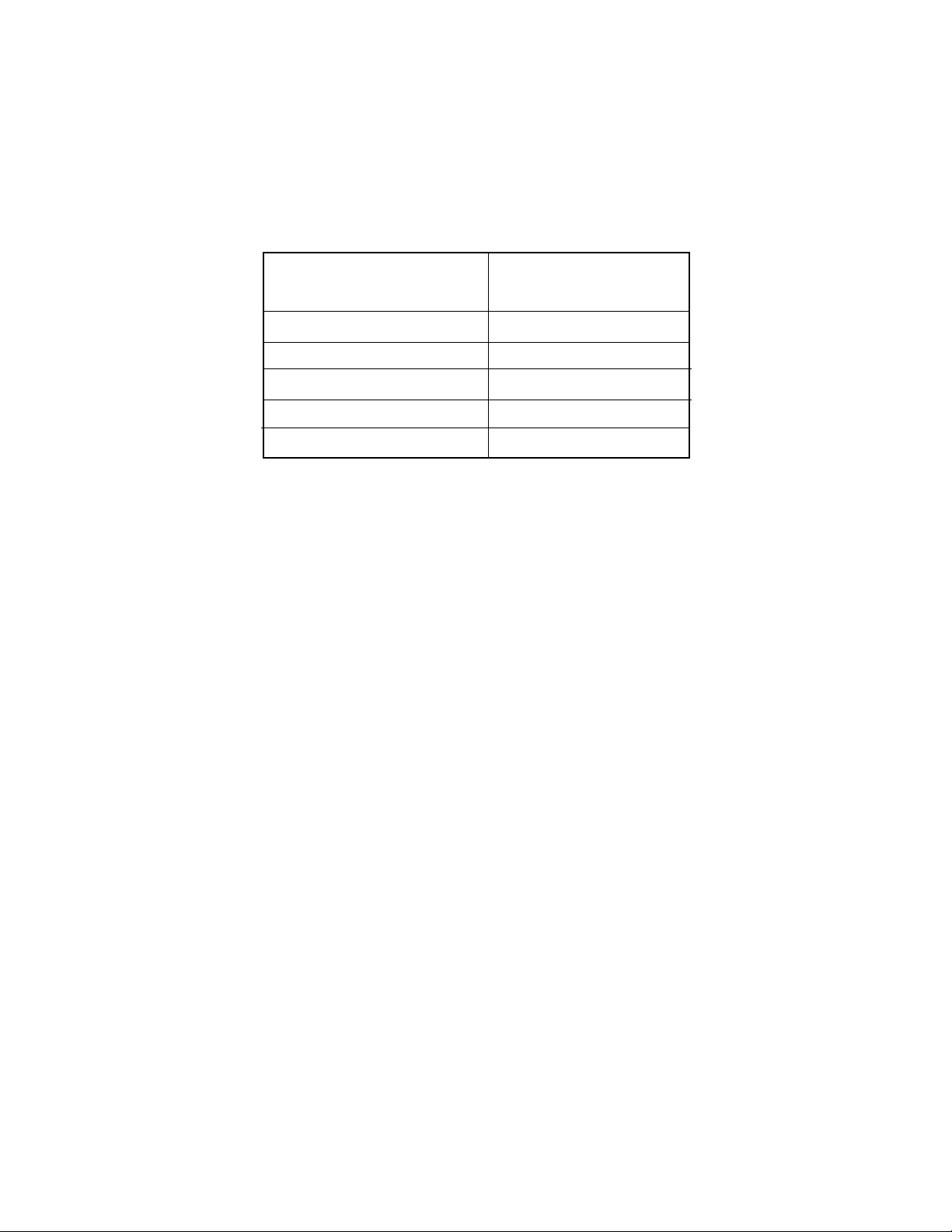

Sensor Temperature

°F (°C)

0

–18

–12

10

32

50

70

90

Resistance Ω

81,715 - 99,874

59,422 - 72,627

30,266 - 36,992

18,219 - 22,267

10,280 - 12,564

6,387 - 7,807

Refer to page 4-2 for the procedure for servicing the evaporator thermistor.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the appropriate scale.

3. For the most accurate measurement, immerse the thermistor in ice water for 5

minutes, then use the 32°F/0°C reading in

the chart.

4. Touch the ohmmeter test leads to the two

evaporator thermistor connectors. The

meter should indicate as shown in the

following chart.

Sensor Temperature

°F (°C)

0

–18

–12

10

32

50

70

90

Resistance Ω

81,715 - 99,874

59,422 - 72,627

30,266 - 36,992

18,219 - 22,267

10,280 - 12,564

6,387 - 7,807

5-1

Page 52

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

CUTTER GRID

Refer to page 4-2 for the procedure for servicing the cutter grid.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Touch the ohmmeter test leads to the pins

of the cutter grid 2-wire connector. The

meter should indicate 4 to 5 Ω.

CUTTER GRID TRANSFORMER

Primary

Refer to page 4-5 for the procedure for servicing the cutter grid transformer.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Touch the ohmmeter test leads to the

primary terminals of the cutter grid transformer. The meter should indicate between 12 and 18 Ω.

Secondary

4. Touch the ohmmeter test leads to the

secondary terminals of the cutter grid transformer. The meter should indicate less

than 1 Ω.

5-2

Page 53

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WATER RECIRCULATION PUMP

Refer to page 4-7 for the procedure for servicing the water recirculation pump.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 100 scale.

3. Touch the ohmmeter test leads to the

outside water recirculation pump wire connector pins. The meter should indicate

between 17 and 23 Ω.

CONDENSER FAN MOTOR

Refer to page 4-8 for the procedure for servicing the condenser fan motor.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Touch the ohmmeter test leads to the

outside pins of the condenser fan motor

connector. The meter should indicate between 265 and 285 Ω.

5-3

Page 54

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WATER INLET VALVE SOLENOID

Refer to page 4-15 for the procedure for servicing the water inlet valve.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 100 scale.

3. Touch the ohmmeter test leads to the

water inlet valve solenoid terminals. The

meter should indicate between 2650 and

2750 Ω.

HOT GAS VALVE SOLENOID

Refer to page 4-16 for the procedure for servicing the hot gas valve solenoid.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Touch the ohmmeter test leads to the pins

of the hot gas valve solenoid 2-wire connector. The meter should indicate between

365 and 390 Ω.

5-4

Page 55

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

COMPRESSOR, OVERLOAD

PROTECTOR, & RELAY

Overload

Common (C)

Start (S)

Relay

Refer to page 4-18 for the procedure for servicing the compressor.

1. Unplug ice maker or disconnect power.

Run (M)

3. To test the compressor windings:

a) Touch one of the ohmmeter test leads

to the Common (C) pin, and the other

lead to the Start (S) pin. The meter

should indicate between 8 and 11 Ω.

b) Touch one of the ohmmeter test leads

to the Common (C) pin, and the other

lead to the Run (M) pin. The meter

should indicate between 2 and 3 Ω.

Run (M)Start (S)

2. Set the ohmmeter to the R x 1 scale.

Common (C)

Continued on the next page.

5-5

Page 56

4. To test the relay:

a) Position the relay with the coil facing

down, as shown below.

b) Insert the tip on one of the ohmmeter

test leads into the Run (M) pin socket,

and touch the other ohmmeter lead to

the spade terminal. The meter should

indicate a closed clrcuit (0 Ω).

d) Turn the relay over so that the coil faces

up, as shown below.

e) With the tip of the ohmmeter test leads

at the Start (S) and Run (M) pin sockets, the meter should indicate a closed

circuit (0 Ω).

c) Move the tip of the ohmmeter test lead

from the spade terminal into the Start

(S) pin socket. Leave the other ohmmeter lead at the Run (M) location. The

meter should indicate an open circuit

(infinite).

Spade Terminal Run (M) Start (S)

Relay Coil

Relay Coil

Run (M) Start (S) Spade Terminal

5-6

Page 57

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

PUSHBUTTON SWITCH ASSEMBLY

Refer to page 4-5 for the procedure for servicing the pushbutton switch assembly.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

Yellow (Y) White/Black (W/BK)

POWER

OFF ON

Black (BK)

1/4"

CLEAN

Black (BK)

1/8"

3. Disconnect the four wire connectors from

the pushbutton switch assembly.

4. Touch the ohmmeter test leads to the test

points shown in the chart below. The meter

reading should indicate as shown.

Switch Position Test Point Reading

OFF

ON

CLEAN

Y - BK (1/4″) Open (infinite)

W/BK - BK (1/8″) Open (infinite)

Y - BK (1/4″) Closed (0 Ω)

W/BK - BK (1/8″) Open (infinite)

Y - BK (1/4″) Closed (0 Ω)

W/BK - BK (1/8″) Closed (0 Ω)

5-7

Page 58

— NOTES —

5-8

Page 59

DIAGNOSIS & TROUBLESHOOTING

INGREDIENT

EFFECT CORRECTION

Algae

Minerals:

Sodium

Potassium

Magnesium

Calcium

Objectionable Taste and Odor

Cloudy Ice

Slow Cutting

Refreezing

Carbon Filter

1. Check for water flow

restriction.

2. Polyphosphate feeder or

water softener

3. Change water source

INGREDIENT

EFFECT CORRECTION

Iron

Chlorine

Manganese

Permanent Hardness

Calcium or Magnesium

Sulfates

Chlorides

Nitrates

Temporary Hardness

Calcium or Magnesium

Carbonates

Staining (Aesthetics only)

Scale

Scale

1. Use only Ice Machine

Cleaner P/N 8171307

Use only Ice Machine

Cleaner P/N 8171307

2. Water softener and iron

filter

1. Abrasive cleaning

2. Polyphosphate feeder or

water softener reduces

or eliminates need for

abrasive cleaning

1.

2. Polyphosphate feeder or

water softener reduces

frequency of cleaning by

50%

RECOMMENDATIONS:

Water softeners or polyphosphate feeders are not cure-alls, but do reduce and, in some cases,

prevent scale buildup. Use only Ice Maker Cleaner (P/N 8171307) if there is scale buildup on

evaporator plate or in water hoses.

CAUTION: Some polyphosphate feeders cause slime buildup. Their use in low mineral content

water should be carefully considered.

NOTE: Reverse Osmosis filters are NOT RECOMMENDED with this unit. These filters can

limit the water flow to the unit and limit its capacity to produce sufficient ice.

Water Hardness Test Kit:

A Water Hardness Test Kit (P/N 4171690) is available from FSP

Parts Distribution.

WATER AND ITS EFFECT ON MAKING ICE

Quality ice is defined as solid, clear, and free of

taste or odor. All ice makers can provide this

type of ice only if the water used to produce the

EFFECT ON ICE QUALITY

EFFECT ON ICE MAKER

ice is pure, and free of mineral contamination.

The following charts show some of the problems that can affect ice production.

6-1

Page 60

TROUBLESHOOTING CHART

Problem Probable Cause Test Procedure-Action

No power at wall outlet Check circuit breaker/fuses

Will not run

No power at drain pump

power outlet

Open selector switch

Loose connections

at selector switch

or control board

No power through

power cord

Room temperature below

55°F (13°C)

Ice touching bin thermistor Normal operation

Water supply turned off Turn on water supply

Loose or missing

reservoir cap

Water slide return tube

out of reservoir

Check for kinked drain hose,

blocked screen or blocked vent

outlet or hose.

Check for continuity from

terminals 1 - 2 on selector switch

Repair connections

Check continuity of power

cord and replace if open

Bin thermistor has unit shut off

Customer Instruction

Tighten or replace

Reposition tube

Will not make ice

Water reservoir is empty

Evaporator is cold with

thin or no ice slab

Inlet tube out of position

and missing reservoir

Water inlet tube frozen

near evaporator

Defective inlet water valve Test and repair or replace

An ice slab only partially

released from evaporator

and water was bridged

down into the bin

evaporator plate (see procedure

Reposition tube

Thaw and reposition tube

Look for interference with

cutter grid and clean the

on page 8-1)

6-2

Page 61

Problem Probable Cause Test Procedure-Action

Will not make ice

Water reservoir is empty.

Evaporator is cold with

3/4" thick or larger ice slab

Will not make ice

Water reservoir is full

Evaporator is cold with

thin/partial/irregular

or no ice slab

Slab will not release during

harvest due to scale build up

Defective or disconnected hot

gas solenoid

Defective hot gas valve Test and repair or replace

Room temperature over

100°F (38°C)

Seeping water valve

Condenser is hot

Partial refrigerant leak or

restriction (U shaped slab)

Blocked condenser or stalled

fan motor

Tube not attached to outlet

of recirculation pump

Clean the evaporator plate

(see procedure on page 8-1)

Test and repair or replace

Customer instruction

Replace water valve

Check for leak/restriction and

repair or replace defective

component

Clean condenser, repair

or replace motor

Reattach tube

Will not make ice

Water reservoir is full

Evaporator is warm

Poor ice production

Defective recirculating pump

Partially blocked water

distributor

Compressor is not running

Blocked condenser or stalled

fan motor

Unit is in the startup mode Wait 5 minutes and recheck

Room temperature below

55°F (13°C)

Seeping water valve

Condenser is hot

Slow or defective drain or

drain pump causing water to

back up into the bin

Repair or replace the pump motor

assembly

Clean distributor and evaporator

Test compressor, relay and

overload

Clean condenser, repair or

replace motor

Bin thermistor has unit shut off

Customer Instruction

Replace water valve

Repair or replace drain

or drain pump

6-3

Page 62

Problem Probable Cause Test Procedure-Action

Too much ice in bin Defective bin thermistor Replace

The slab dropping off the plate

and ice dropping from the

cutter grid into an empty

bin are normal sounds

The reservoir is empty. Look for

a partially released slab,

interference with cutter grid etc

and clean the evaporator plate,

(see procedure on page 8-1)

Noisy

Banging sound

Grinding, cavitating sound

Ice freezing together

in the bin

Cloudy, soft, thin,

or poor tasting ice

Clean light is flashing

(see Failure Mode

on page 6-10)

Grinding, cavitating sound

from recirculation pump

Noisy drain pump Repair or replace

Normal

Poor water quality See chart on page 6-1

Open or disconnected bin

thermistor or thermistor

wiring

Defective, loose or

mispositioned evaporator

thermistor

If the reservoir is full

replace the pump

This is normal with

low customer useage

Test thermistor & wiring

harness or reconnect

Test thermistor & wiring

harness or reconnect

6-4

Page 63

DIAGNOSTIC FLOW CHART FOR

ICE MAKER CONTROL BOARD #6100499