Page 1

Installation Instructions

Undercounter Dishwasher

8574116

Instructions d'installation

Lave-vaisselle encastré

®

HOME APPLIANCES

Table of Contents.............................................................................2

Table des matières.........................................................................22

Page 2

You need to:

• Slowly open dishwasher door while someone grasps the

rear of the dishwasher. Remove shipping materials, drain

hose and lower rack. Close dishwasher door until latched.

• Observe all governing codes and ordinances.

• Install this dishwasher as specified in these instructions.

• Installation should be performed by a qualified service

technician. The dishwasher must be installed to meet all

electrical and plumbing national and local codes and

ordinances.

2

Table of Contents

Dishwasher Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tools and parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Location Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Drain Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Supply Requirements . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dishwasher Safety

Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Prepare cabinet opening

using existing utility hookups . . . . . . . . . . . . . . . . . . . . . 6

Prepare cabinet opening

where there are no existing utility hookups. . . . . . . . . . 7

Install moisture barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Prepare dishwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Make electrical connection . . . . . . . . . . . . . . . . . . . . . . 18

Connect to water supply . . . . . . . . . . . . . . . . . . . . . . . . 19

Connect to drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Secure dishwasher in cabinet opening. . . . . . . . . . . . . 20

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

WARNING

Tip Over Hazard

Do not use dishwasher until completely installed.

Do not push down on open door.

Doing so can result in serious injury or cuts.

Page 3

® Teflon is a registered trademark of E.I. Du Pont de Nemours and

Company.

® Registered trademark of TEXTRON.

Tools needed:

• electric drill with 1/2", 3/4"

and 1-1/2" hole saw bits

• small tubing cutter

• wire stripper

• 1-1/2"-2" screw-type clamp

if connecting to waste-tee

Parts needed:

• copper tubing (3/8"

recommended) or flexible

stainless steel braided fill

line

• clamp connector or

conduit connector to fit a

7/8" (2.2 cm) diameter hole

Tools needed:

• pliers

• Phillips screwdriver

• 5/16" and 1/4" nut drivers

or hex sockets

• measuring tape or ruler

• 10" adjustable wrench that

opens to 1-1/8" (2.9 cm)

• flat-blade screwdriver

• utility knife

• 2 twist-on wire connectors

which are the proper size to

connect your household

wiring to 16-gauge wiring

in dishwasher

• small level

• TORX

®

T15 screwdriver (if

installing custom front

panels)

• flashlight

• shallow pan

• 5/8" open-end wrench

• bath towel

• wood block

Parts needed:

• 90° elbow with 3/8" N.P.T.

external threads on one

end. (The other end must

fit your water supply line.)

• Teflon

®

tape or pipe joint

compound

• shims (if installed with

built-up floor)

• 4 #10 x 1/2" wood screws

(if installing custom front

panels)

Tools and Parts

Gather the required tools and parts before starting

installation.

All installations

In addition, for new installations

A

B

C

Parts supplied

A. 2 – drain hose clamps, 1 large and 1 small

B. 2 – # 10 x 1/2" Phillips-head screws

C. drain hose

Additional parts supplied with top-venting models only

D. 2 #8 x 1-3/8" TORX

®

T15 screws

E. 4 #10 x 3/8" hex-head screws

Additional part supplied with certain models

F. Bottom sound pad (located in lower rack)

G. Moisture barrier tape

Make sure all these parts are included. If not included, call

1-800-422-1230.

See separate parts list for accessories available for your

dishwasher.

Installation Requirements

3

Location Requirements

Do not run drain lines, water lines or electrical wiring where

they can interfere with or contact dishwasher motor or legs.

The location where the dishwasher will be installed must

provide clearance between motor and flooring. Motor

should not touch the floor.

Do not install dishwasher over carpeted flooring.

Protect dishwasher and water lines leading to dishwasher

against freezing. Damage from freezing is not covered by

the warranty.

A side panel kit is available from your dealer for installing

your dishwasher at the end of your cabinetry.

A moisture barrier accessory (Part No. 4396277) is available

from your dealer for installing underneath the countertop,

but is not required. This may also be obtained by calling

1-800-422-1230.

Check location where dishwasher will be installed. The

location must provide:

• easy access to water, electricity and drain.

• convenient access for loading and unloading dishes.

Corner locations require a 2" (5.1 cm) minimum clearance

between the side of the dishwasher door and the wall or

cabinet.

• square opening for proper operation and appearance.

• cabinet front perpendicular to floor.

• level floor. (If floor at front of opening is not level with

floor at rear of opening, shims may be needed to level

dishwasher.)

NOTE:To prevent shifting during dishwasher operation,

shims must be securely attached to the floor.

If dishwasher will be left unused for a period of time or in a

location where it may be subject to freezing, have it

winterized by authorized service personnel.

Make sure pipes, wires and drain hose are within the

shaded area shown in the “Cutout dimensions” section.

Helpful Tip: If the floor in the dishwasher opening is

uneven (example: tile flooring only partway into

opening) you will need to take special care in measuring

dimensions and in leveling dishwasher.

Page 4

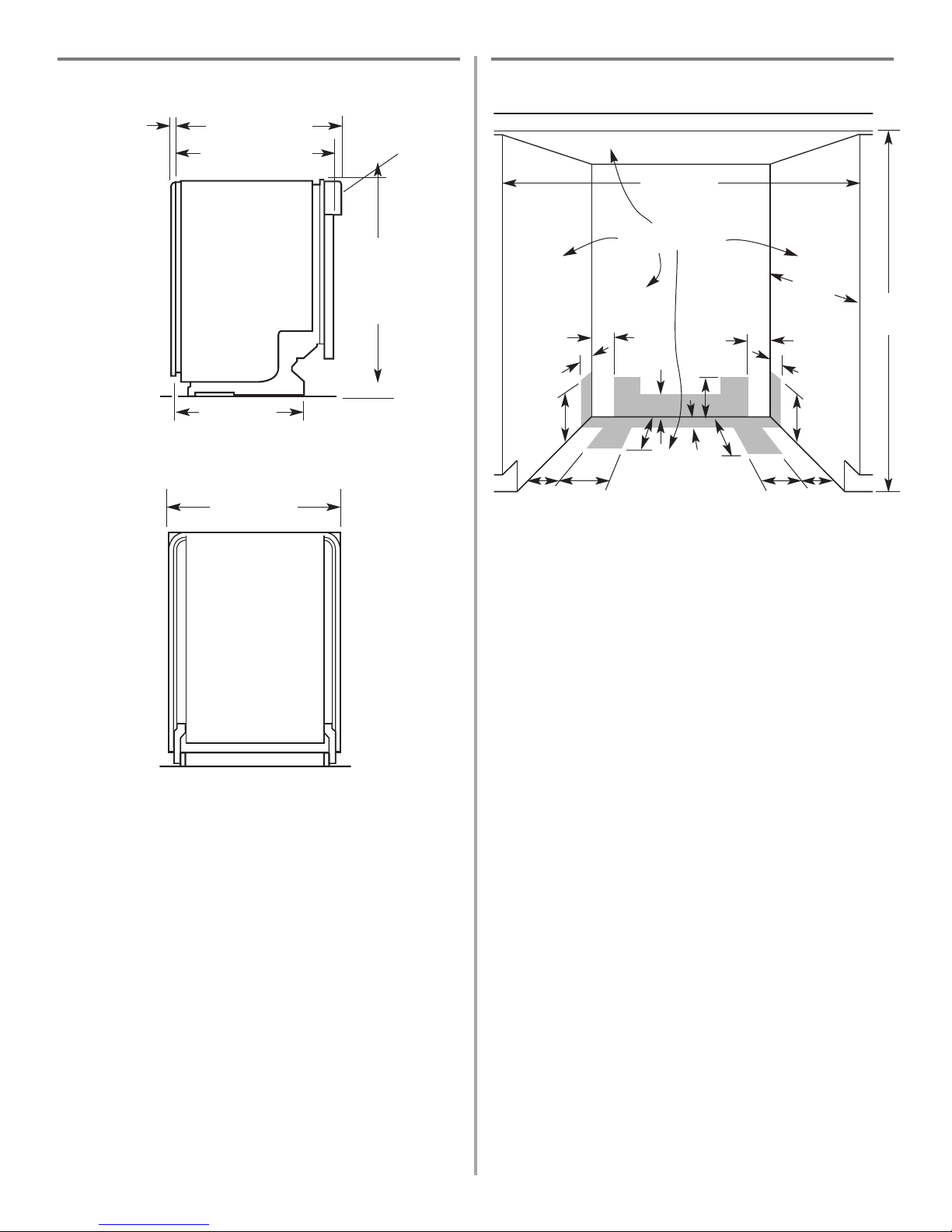

4

9"

(22.9 cm)

10"

(25.4 cm)

6" ***

(15.2 cm)

6" ***

(15.2 cm)

3-1/4"

(8.3 cm)

2-3/4"

(7 cm)

34"

(86.4 cm)

min.*

2"

(5.1 cm)

2"

(5.1 cm)

All surfaces must be free

from intrusions

2"

(5.1 cm)

3-1/4"

(8.3 cm)

3-1/4"

(8.3 cm)

2-3/4"

(7 cm)

3-1/4"

(8.3 cm)

24" (61 cm)

min.

24" (61 cm)

**

Cut holes in shaded area of cabinet walls or floor as specified below:

water line – 1/2" (1.3 cm)

drain line – 1-1/2" (3.8 cm)

direct wire – 3/4" (1.9 cm)

power supply cord – 1-1/2" (3.8 cm)

* Measured from the lowest point on the underside of countertop. May be

reduced to 33-7/8" (86 cm) by removing wheels from dishwasher.

** Minimum, measured from narrowest point of opening.

*** May be increased to 6-5/8" (16.6 cm) if height of opening is 34-1/2"

(87.6 cm) at its lowest point.

Cutout dimensions

5-1/2"

(14 cm)

3-1/2"

(8.9 cm)

Product dimensions

23-7/8" (60.6 cm)

SIDE VIEW

REAR VIEW

24-7/8" (63.2 cm)

3/4" (1.9 cm)

insulation –

may be

compressed

(not used on

all models)

24-1/2" (62.2 cm)*

front vent

21" (53.3 cm)

33-7/8"

(86 cm) min.

with wheels

removed

Page 5

5

Drain Requirements

• Use the new drain hose supplied with your dishwasher.

If this is not long enough, use a new drain hose with a

maximum length of 12 feet (3.7 m) that meets all current

AHAM/IAPMO test standards, is resistant to heat and

detergent, and fits the 1" (2.5 cm) drain connector of the

dishwasher.

• Connect drain hose to waste tee or disposer inlet above

drain trap in house plumbing and 20" (50.8 cm)

minimum above the floor. It is recommended that the

drain hose either be looped up and securely fastened to

the underside of the counter, or be connected to an air

gap.

• Use an air gap if the drain hose is connected to house

plumbing lower than 20" (50.8 cm) above subfloor or

floor.

• Use 1/2" minimum I.D. drain line fittings.

Water Supply Requirements

• A hot water line with 20-120 psi (138-862 kPa) water

pressure.

• 120°F (49°C) water at dishwasher.

• 3/8" O.D. copper tubing with compression fitting or

flexible stainless steel braided fill line (1/2" minimum

plastic tubing is not recommended).

• A 90° elbow with 3/8" N.P.T. external pipe threads on one

end.

Do not solder within 6" (15.2 cm) from water inlet valve.

Electrical Requirements

Contact a qualified electrician.

Assure that the electrical installation is adequate and in

conformance with all national and local codes and

ordinances.

You must have:

• 120-volt, 60 Hz, AC-only, 15 or 20 amp., fused electrical

supply.

• Copper wire only.

We recommend:

• A time-delay fuse or circuit breaker.

• A separate circuit.

If direct wiring dishwasher:

• Use flexible, armored or non-metallic sheathed, copper

wire with grounding wire that meets the wiring

requirements for your home and local codes and

ordinances.

• Use strain relief method provided with house wiring

junction box or install a U.L.-listed/CSA-certified clamp

connector to the house wiring junction box. If using

conduit, use a U.L.-listed/CSA-certified conduit connector.

If connecting dishwasher with a power supply cord:

• Use Power Supply Cord Kit (Part No. 4317824) marked for

use with dishwashers. Kit contents include:

– Volex, Inc., UL listed 16 gauge 3 wire power supply cord

with 3 prong grounded plug.

– Neer C-500 7/8 inch strain relief.

– 3 wire connectors.

– Part No. 302797 grommet

Follow the kit instructions for installing the power supply

cord.

• Power supply cord must plug into a mating three prong,

grounded outlet, located in the cabinet next to the

dishwasher opening. Outlet must meet all local codes and

ordinances.

air gap

Page 6

6

Installation Instructions

1. Disconnect power.

2. Turn off water supply.

Prepare cabinet opening using

existing utility hookups

• Follow the steps in this section if you are installing the

dishwasher in an existing cabinet opening with utility

hookups.

• If you are installing the dishwasher in a cabinet opening

that does not have hookups, follow the steps under

"Prepare cabinet opening where there are no existing

utility hookups" section.

1. Check that the water

line reaches to the

front left of opening

where the water

connection will be

made.

2. Check that the direct

wire reaches to the

front right of opening

where the electrical

connection will be made.

If the water line and the direct wire reach far enough into

the opening, proceed to the next section “Install the drain

hose.“ If they do not reach far enough, follow the steps

under “Prepare cabinet opening where there are no existing

utility hookups.”

6" (15.2 cm)

water

line

direct

wire

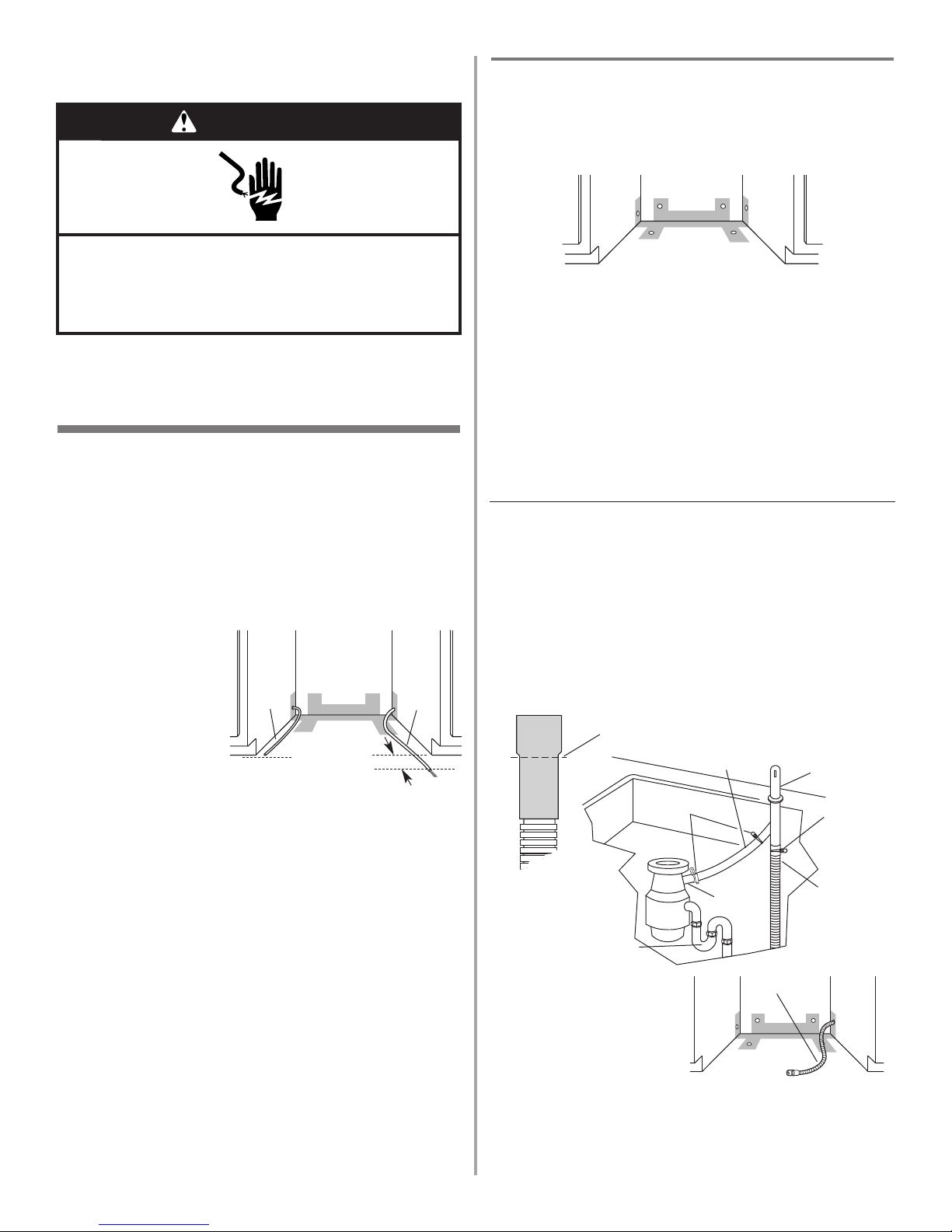

Install the drain hose

IMPORTANT: Always use a new drain hose even when

installing a new replacement dishwasher.

1. Drill a 1-1/2" (3.8 cm) diameter hole in cabinet wall or

floor on the side of the opening closest to the sink.

2. Connect drain hose to waste tee or waste disposer using

one of the following methods:

• Option 1, Waste disposer – with air gap

• Option 2, No waste disposer – with air gap

• Option 3, Waste disposer – no air gap*

• Option 4, No waste disposer – no air gap*

*an air gap is recommended

Helpful Tip: To reduce the vibration of the hose, keep the

hose away from the floor and the edge of the hole where

it passes through the cabinet.

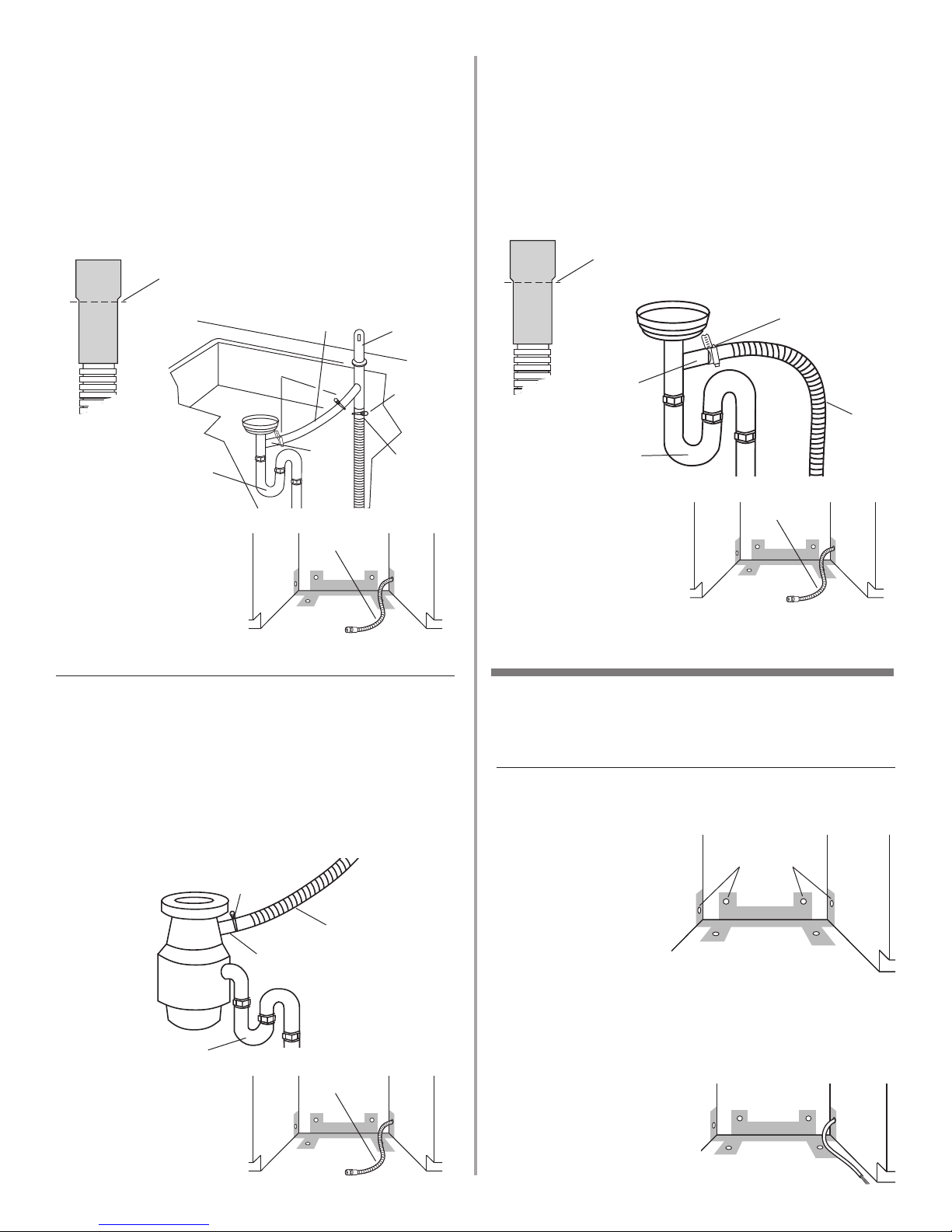

Option 1: Waste disposer – with air gap:

1. Remove the disposer knockout plug. Cut end of drain

hose if needed (do not cut ribbed section).

2. Attach drain hose to air gap with large spring-type

clamp. If the drain hose was cut, use a 1-1/2" to 2"

(3.8 to 5 cm) screw-type clamp*.

3. Use a rubber hose connector* with spring or screw-type

clamps* to connect air gap to disposer inlet.

This connection must be before the drain trap and at

least 20" (50.8 cm) above the floor where dishwasher will

be installed.

4. Insert drain hose through

hole cut in cabinet to the

front center of opening

where drain connection

will be made.

* Parts available from local plumbing supply stores

drain

hose

large

spring-type

clamp

air gap

rubber hose

connector

disposer

inlet

drain trap

drain hose –

cut here if needed

spring or

screw-type

clamps

drain hose

WARNING

Electrical Shock Hazard

Disconnect electrical power at the fuse box or circuit

breaker box before installing dishwasher.

Failure to do so can result in death or electrical shock.

Page 7

7

Prepare cabinet opening where there

are no existing utility hookups

Electrical connection

Option1: Direct wire method:

Helpful Tip: Wiring the dishwasher will be easier if you

route wire into the cabinet opening from the right side.

1. Drill a 3/4” (1.9 cm)

hole in right-hand

cabinet side, rear or

floor. Preferred and

optional locations are

shown.

2. Wood cabinet: Sand

hole until smooth.

Metal cabinet: Cover

hole with grommet, not provided.

3. Run wire into house wiring junction box.

4. Install a U.L.-listed/CSA-certified clamp connector (strain

relief) for flexible-type wire. If installing conduit, attach a

U.L.-listed/CSA-certified conduit connector to the

junction box.

5. Run other end of wire

through cabinet hole. Cable

must extend to the right

front of cabinet opening.

preferred

locations

optional

locations

Option 3: Waste disposer – no air gap:

1. Remove the disposer knockout plug. Do not cut end of

drain hose.

2. Attach drain hose to disposer inlet with large springtype clamp.

This connection must be before the drain trap and at

least 20" (50.8 cm) above the floor where dishwasher

will be installed. It is recommended that the drain hose

be looped up and securely fastened to the underside of

the counter.

3. Insert drain hose

through hole cut in

cabinet to the front

center of opening where

drain connection will be

made.

drain hose

large spring-type

clamp

disposer

inlet

drain trap

Option 4: No waste disposer – no air gap:

1. Cut end of drain hose if needed (do not cut ribbed

section).

2. Attach drain hose to waste tee with 1-1/2" to 2"

(3.8 to 5 cm) screw-type clamp*.

This connection must be before the drain trap and at

least 20" (50.8 cm) above the floor where dishwasher will

be installed. It is recommended that the drain hose be

looped up and securely fastened to the underside of the

counter.

3. Insert drain hose through

hole cut in cabinet to the

front center of opening

where drain connection

will be made.

* Parts available from local plumbing

supply stores

drain

hose

waste

tee

drain trap

screw-type clamp

drain hose –

cut here if needed

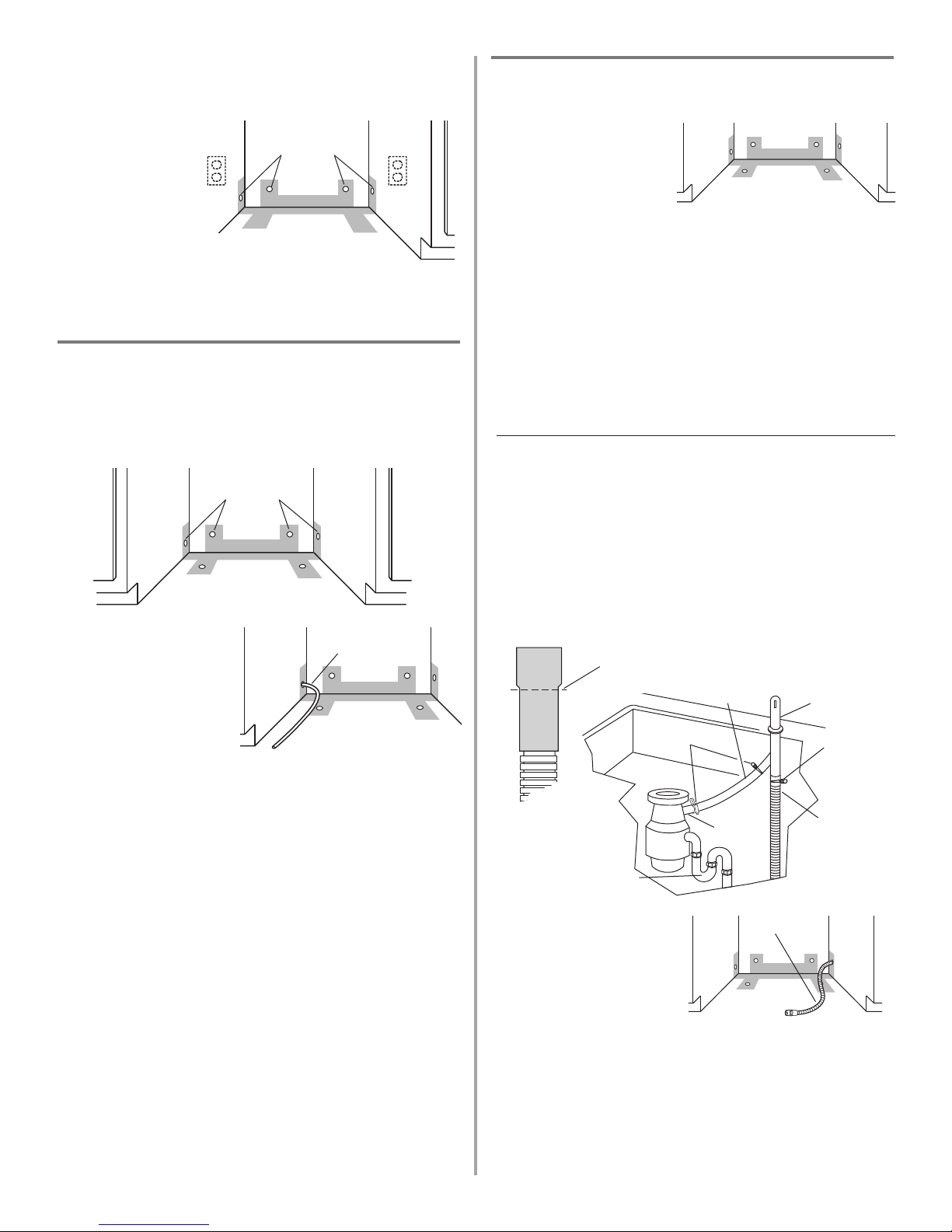

Option 2: No waste disposer – with air gap:

1. Cut end of drain hose if needed (do not cut ribbed

section).

2. Attach drain hose to air gap with large spring-type

clamp. If the drain hose was cut, use a 1-1/2" to 2"

(3.8 to 5 cm) screw-type clamp*.

3. Use a rubber hose connector* with spring or screwtype clamps* to connect air gap to waste tee.

This connection must be before the drain trap and at

least 20" (50.8 cm) above the floor where dishwasher

will be installed.

4. Insert drain hose

through hole cut in

cabinet to the front

center of opening where

drain connection will be

made.

* Parts available from local plumbing supply stores

drain hose –

cut here if needed

drain

hose

large

spring-type

clamp

air gap

rubber hose

connector

spring or

screw-type

clamps

waste

tee

drain trap

drain hose

drain hose

drain hose

Page 8

8

Option 2: Power supply cord method:

NOTE: A mating, three prong, ground-type wall receptacle is

required in a cabinet next to the dishwasher opening.

1. Drill a 1-1/2”

(3.8 cm) hole in

the cabinet rear

or side. Preferred

and optional

locations are

shown.

2. Wood cabinet:

Sand hole until

smooth.

Metal cabinet: Cover hole with grommet (Part No.

302797) included with power supply cord kit.

Install the water line

Helpful Tip: Routing the water line through the left side

of cabinet opening will make water connection easier.

1. Drill a minimum 1/2” (1.3 cm) hole in the cabinet side,

rear or floor. Preferred and optional locations are shown.

2. Measure overall length

of copper tubing

required.

3. Attach copper tubing

to the water line with a

manual shutoff valve.

4. Slowly feed copper

tubing through hole in

cabinet. Copper tubing will bend and kink easily, so be

gentle. The copper tubing should be far enough into the

cabinet opening to connect it to dishwasher inlet on the

front left of the dishwasher.

5. Turn water shutoff valve to “ON” position. Flush water

into a shallow pan to get rid of particles that may clog

the inlet valve.

6. Turn shutoff valve to “OFF” position.

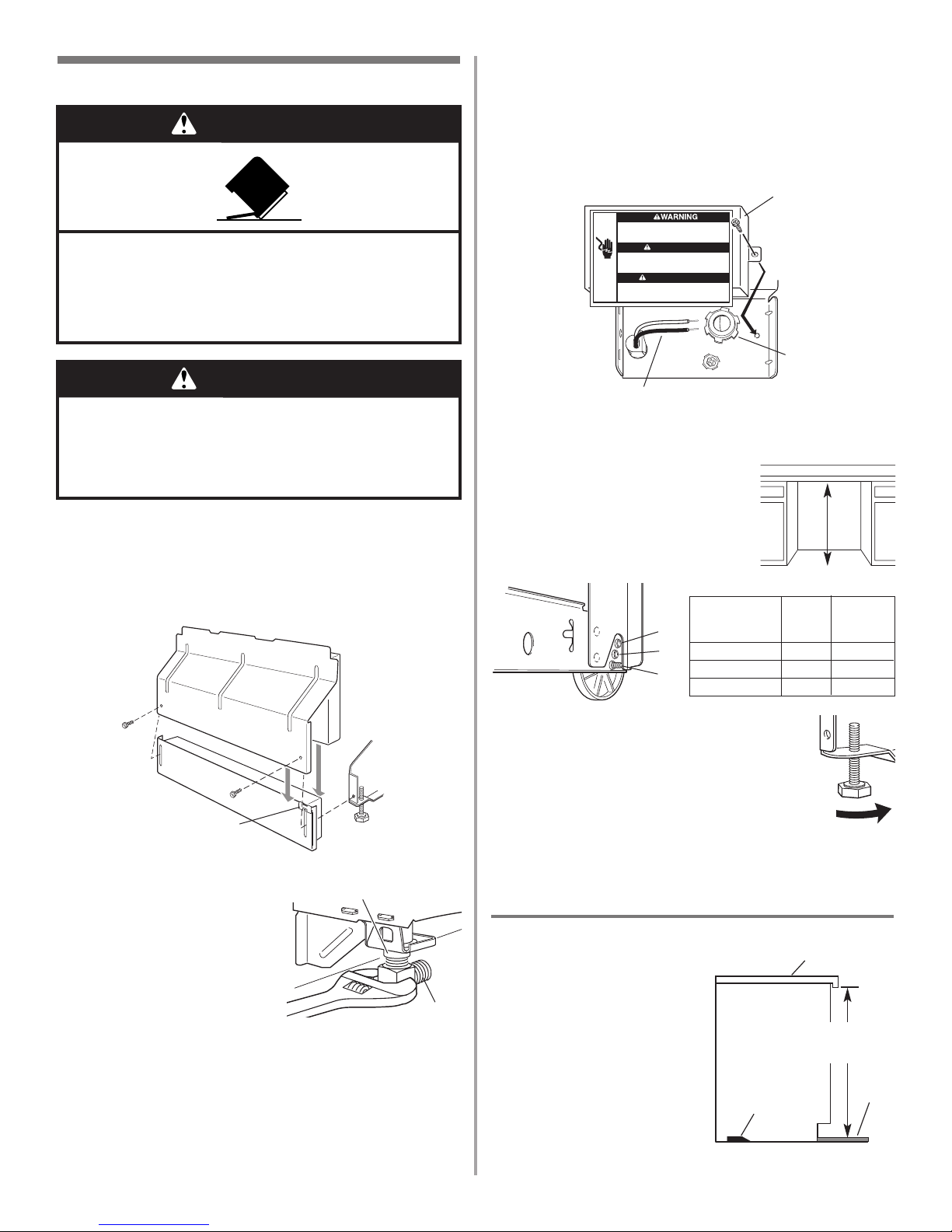

Option 1: Waste disposer – with air gap:

1. Remove the disposer knockout plug. Cut end of drain

hose if needed (do not cut ribbed section).

2. Attach drain hose to air gap with large spring-type

clamp. If the drain hose was cut, use a 1-1/2" to 2"

(3.8 to 5 cm) screw-type clamp*.

3. Use a rubber hose connector* with spring or screw-type

clamps* to connect air gap to disposer inlet.

This connection must be before the drain trap and at

least 20" (50.8 cm) above the floor where dishwasher will

be installed.

4. Insert drain hose through

hole cut in cabinet to the

front center of opening

where drain connection

will be made.

* Parts available from local plumbing

supply stores

copper

tubing

drain

hose

large

spring-type

clamp

air gap

rubber hose

connector

disposer

inlet

drain trap

drain hose –

cut here if needed

spring or

screw-type

clamps

preferred

locations

optional

locations

optional

locations

preferred

locations

Install the drain hose

IMPORTANT: Always use a new drain hose.

1. Drill a 1-1/2” (3.8 cm)

diameter hole in cabinet

wall or floor on the side

of the opening closest

to the sink.

2. Connect drain hose to

waste tee or waste disposer using one of the following

methods:

• Option 1, Waste disposer – with air gap

• Option 2, No waste disposer – with air gap

• Option 3, Waste disposer – no air gap*

• Option 4, No waste disposer – no air gap*

*an air gap is recommended

Helpful Tip: To reduce the vibration of the hose, keep the

hose away from the floor and the edge of the hole where

it passes through the cabinet.

drain hose

Page 9

9

Option 4: No waste disposer – no air gap:

1. Cut end of drain hose if needed (do not cut ribbed

section).

2. Attach drain hose to waste tee with 1-1/2" to 2"

(3.8 to 5 cm) screw-type clamp*.

This connection must be before the drain trap and at

least 20" (50.8 cm) above the floor where dishwasher will

be installed. It is recommended that the drain hose be

looped up and securely fastened to the underside of the

counter.

3. Insert drain hose through

hole cut in cabinet to the

front center of opening

where drain connection

will be made.

* Parts available from local plumbing

supply stores

Install moisture barrier (on some models)

drain

hose

waste

tee

drain trap

screw-type clamp

drain hose –

cut here if needed

Option 2: No waste disposer – with air gap:

1. Cut end of drain hose if needed (do not cut ribbed

section).

2. Attach drain hose to air gap with large spring-type

clamp. If the drain hose was cut, use a 1-1/2" to 2"

(3.8 to 5 cm) screw-type clamp*.

3. Use a rubber hose connector* with spring or screw-type

clamps* to connect air gap to waste tee.

This connection must be before the drain trap and at

least 20" (50.8 cm) above the floor where dishwasher will

be installed.

4. Insert drain hose

through hole cut in

cabinet to the front

center of opening where

drain connection will be

made.

* Parts available from local plumbing supply stores

Option 3: Waste disposer – no air gap:

1. Remove the disposer knockout plug. Do not cut end of

drain hose.

2. Attach drain hose to disposer inlet with large spring-type

clamp.

This connection must be before the drain trap and at

least 20" (50.8 cm) above the floor where dishwasher will

be installed. It is recommended that the drain hose be

looped up and securely fastened to the underside of the

counter.

3. Insert drain hose

through hole cut in

cabinet to the front

center of opening where

drain connection will be

made.

drain hose –

cut here if needed

drain

hose

large

spring-type

clamp

air gap

rubber hose

connector

spring or

screw-type

clamps

waste

tee

drain trap

drain hose

large spring-type

clamp

disposer

inlet

drain trap

drain hose

drain hose

drain hose

1. Make sure the area under the cabinet is clean and dry

for installation of the moisture barrier.

2. Remove the backing of the moisture barrier and apply to

underside of the countertop along the front edge of the

counter.

moisture

barrier

Page 10

7. Remove terminal box cover.

– If you are direct wiring: install a U.L.-listed/CSA-

certified clamp connector to the terminal box. If using

conduit, use a U.L.-listed/CSA-certified conduit

connector.

– If you are installing a power supply cord kit, do so

now, following kit instructions.

Helpful Tip: Put cardboard under dishwasher until it is

installed in cabinet opening. The cardboard will help

protect floor covering during

installation.

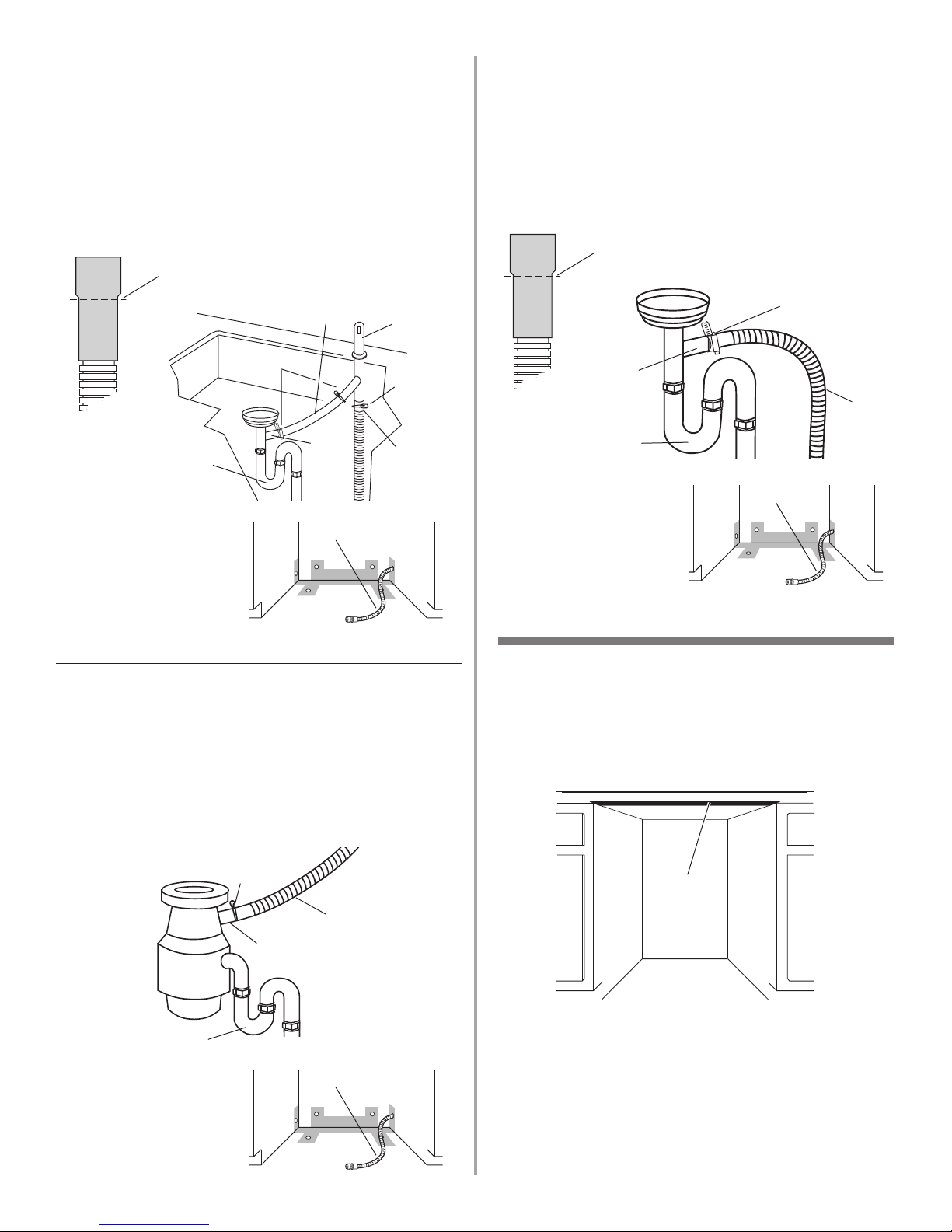

8. Measure height of cabinet opening

from underside of countertop to floor

where dishwasher will be installed

(you need the lowest point). Check

chart for that height opening. Put

wheels in the required position.

9. Turn both front leveler legs to the same

height.

If the minimum cutout height is less than

34” (86.4 cm), the rear wheels can be

removed for additional clearance. This will

allow the dishwasher to fit into a 33-7/8”

(86 cm) high cutout, but the dishwasher will

be more difficult to move into position. If

the wheels are removed, protect the floor

when moving the dishwasher.

If you have built-up floors

1. Measure height of opening

from underside of countertop

to built-up floor. If the height

is at least 33-3/4” (85.7 cm),

the dishwasher will fit into

the opening without

modification to the

countertop or flooring.

2. Put wheels in position 1 and

turn the front leveler legs up

all the way.

1

2

3

wheel

10

1

2

3

10

5

0

Number of

turns on

front leg

Wheel

position

34" (86.4 cm)

34-1/4" (87 cm)

34-1/2" (87.6 cm)

Minimum

cutout height

front leg

shim

33-3/4"

(85.7 cm)

min.

countertop

built-up

floor

1. Put corner posts from packaging behind dishwasher.

Grasp sides of dishwasher door frame and put

dishwasher on its back, resting on top of the corner posts.

2. Remove two screws attaching access panel and lower

panel to dishwasher using a 1/4” hex socket, nut driver or

Phillips screwdriver.

3. Remove panels and set panels

aside on a protective surface.

4. Check that grounding clip is

attached to the lower panel.

5. Apply Teflon® tape or pipe

joint compound to 90° elbow

fitting and connect fitting to

water inlet valve.

6. Tighten elbow until snug, and

be sure that it faces to the rear.

lower

panel

access

panel

grounding

clip

water inlet valve

elbow

dishwasher wires

cable clamp

connector

terminal

box cover

Prepare dishwasher

WARNING

Tip Over Hazard

Do not use dishwasher until completely installed.

Do not push down on open door.

Doing so can result in serious injury or cuts.

WARNING

Excessive Weight Hazard

Use two or more people to move and install

dishwasher.

Failure to do so can result in back or other injury.

ADVERTENCIA

AVERTISSEMENT

Page 11

7. Attach outer panel to full front panel panel with the four

#10-16 x 3/8" hex head screws supplied in the literature

package.

8. Attach the panel assembly to the door by reinstalling the

two uppermost side screws; do not tighten screws

completely. This will hold the panel assembly in place on

the door frame.

3. Add shims as needed in the area shown to bring

dishwasher up to proper height.

NOTE: Shims must be securely attached to floor to

prevent their movement when the dishwasher is

operated.

11

Install door panel—Pro Line®series

For top vented models with a factory-supplied stainless or

painted full front panel:

2"

(5.1 cm)

6"

(15.2 cm)

2-3/4"

(7.0 cm)

2-3/4"

(7.0 cm)

shim

shim

2 screws

factory-supplied

full front panel

top edge

4 screws

full front panel

outer panel

hex head

screw

Install the door handle (on some models)

IMPORTANT: Do not scratch the front panel during this

procedure.

1. Remove the door handle and hardware bag containing

the setscrews and Allen wrench from the cardboard box.

2. Start set screws in handle.

3. Place handle on mounting studs with the set screws

facing down.

4. Push the door handle tightly against the door. Insert the

short end of the Allen wrench into the setscrews. Tighten

the setscrews 1/4 turn past snug. Retain Allen wrench with

Installation Instructions.

Allen

wrench

setscrew

(in bottom

of handle)

handle

mounting

stud

Install the door handle—Pro Line®series

1. Remove the Pro Line®series handle and two screws from

handle package.

2. Make sure plastic

spacers are still attached

to the door.

3. Attach the handle to the

factory-supplied full

front panel as shown.

plastic spacers

1. Remove the carton containing the factory-supplied full

front panel.

2. Remove the handle package from the front of the

shipping base.

3. With a TORX

®

screwdriver, remove three screws on both

sides, as shown; hold the outer panel up while removing

the screws. Save screws for reinstallation.

4. Gently set outer panel aside.

5. Lay the factory-supplied full front panel face down on a

protective non-scratching surface.

6. Place the outer panel on the back of the full front panel;

align screw holes.

3 screws

3 screws

outer panel

Page 12

Custom door panel dimensions are:

Follow directions in Option #2 of “Install custom panel”

section.

Custom panel dimensions

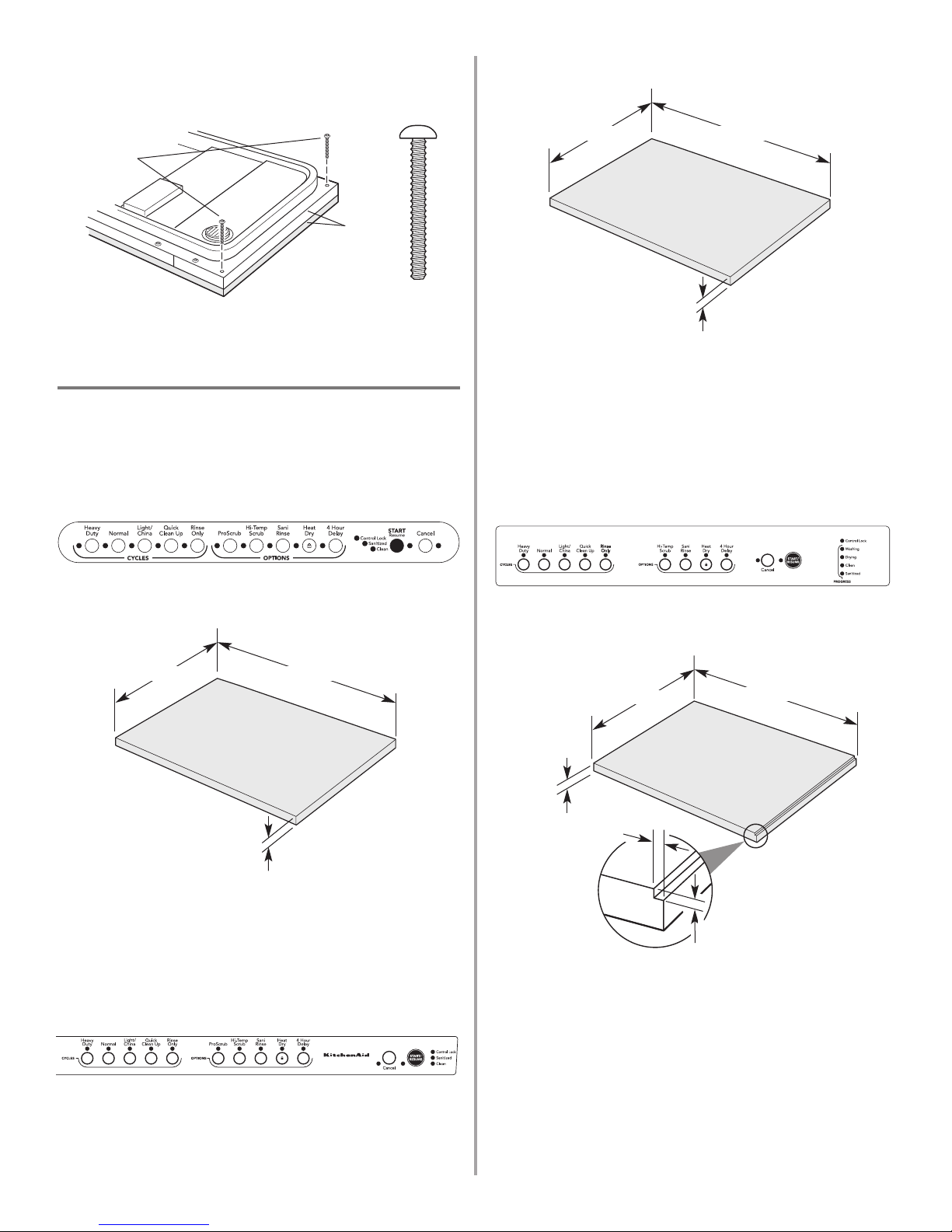

IMPORTANT: You need to know what control panel is on

your dishwasher before you order your custom door panel.

For dishwashers with the control panel shown below:

(models KUDP02FSPA, KUDS02FSPA, KUDU02FSPA)

(Your model may vary slightly from picture above.)

Custom door panel dimensions are:

Follow directions under Option #1 of “Install custom panel”

section.

For dishwashers with the control panel shown below:

(Models KUDI02FR, KUDP02FR, KUDS02FR, KUDU02FR)

(Your model may vary slightly from picture above.)

3/4" (19.1 mm)

12

*This dimension is for 4" (10.2 cm) toe kick. If the installation needs a higher toe

kick, adjust the height of the wood panel accordingly. Not recommended for

toe kicks greater than 6" (15.2 cm).

23-3/8" (59.4 cm) *30" (76.2 cm)

3/4" (19.1 mm)

*This dimension is for 4" (10.2 cm) toe kick. If the installation needs a higher toe

kick, adjust the height of the wood panel accordingly. Not recommended for

toe kicks greater than 6" (15.2 cm).

23-1/2" (59.7 cm)

*30-3/16" (76.7 cm)

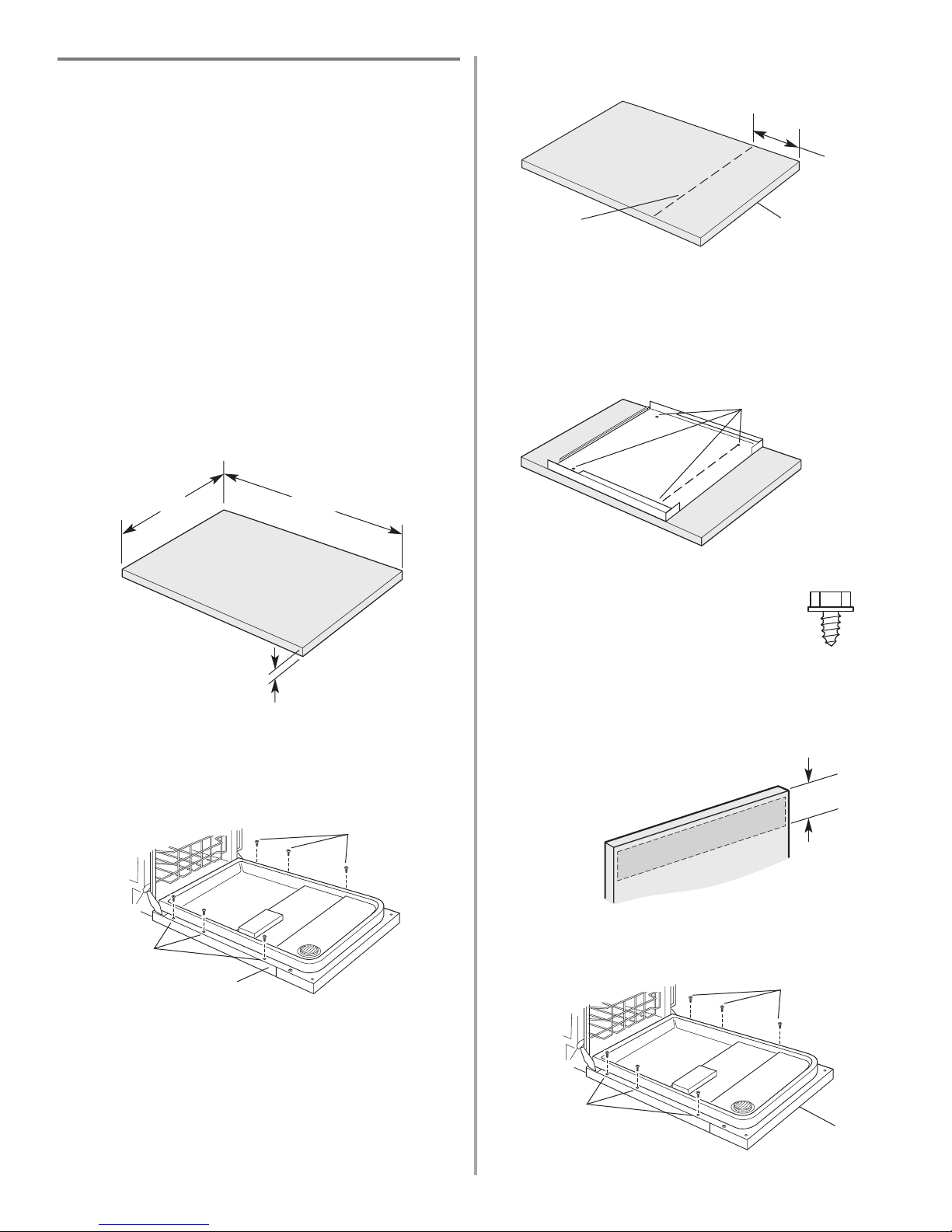

For dishwashers with the control panel shown below:

(Models KUDC02IR, KUDI02IR, KUDP02IR, KUDS02IR)

(Your model may vary slightly from picture above.)

Custom door panel dimensions are:

Follow directions in Option #3 of “Install custom panel”

section.

23-3/8" (59.4 cm)

*25-29/32" (65.8 cm)

3/4" (19.1

mm)

1/8" (3.2 mm)

1/8" (3.2 mm)

*This dimension is for 4" (10.2 cm) toe kick. If the installation needs a higher toe

kick, adjust the height of the wood panel accordingly. Not recommended for

toe kicks greater than 6" (15.2 cm).

9. Install the two #8-18 x 1-3/8" screws from the literature

package in the top corners, as shown. Align top edges of

full front panel and console; tighten corner screws.

10. Tighten the two side screws reinstalled in Step 8.

11. Reinstall and tighten the three remaining side screws.

2 screws

1-3/8"screw

align top

edges

Page 13

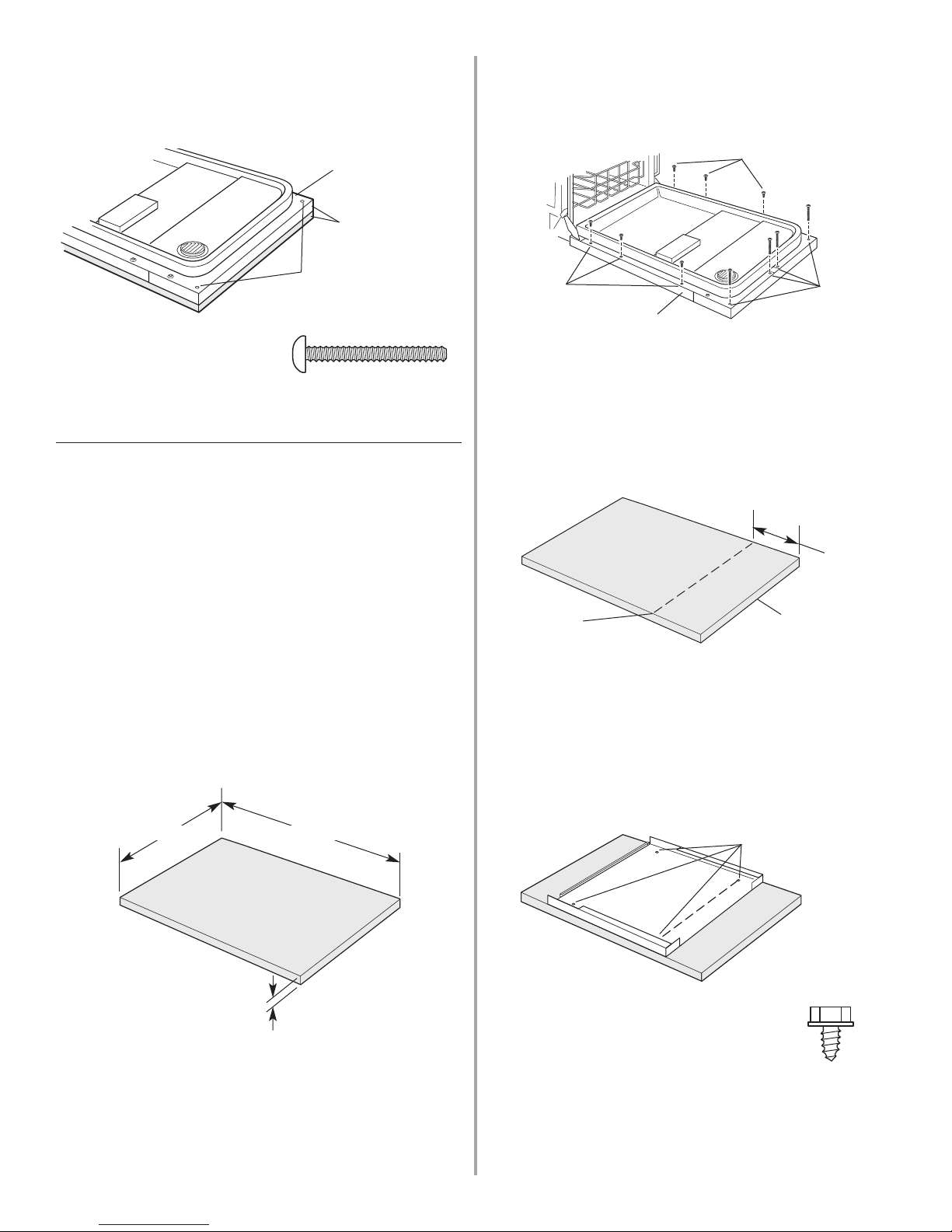

Install custom panel

Option 1: For models KUDP02FSPA, KUDS02FSPA,

KUDU02FSPA

NOTE: The handle for the custom panel is not included.

IMPORTANT: If the handle is attached from the back of the

custom panel, the screw holes should be countersunk for

the screws heads to be flush with the panel. If the handle is

attached to the front of the custom panel, the screw lengths

cannot exceed the panel thickness. For more information on

KitchenAid custom handle selection, refer to the KitchenAid

Catalog, visit www.kitchenaid.com, or call 1-800-422-1230.

NOTE: A customer-supplied full front panel must weigh no

more than 16 pounds (7.3 kg) and must be made to specific

dimensions. It is recommended that a cabinetmaker cut the

custom panel because of the precise dimensions needed.

NOTE: All mounting hardware supplied is for a 3/4"

(19.1 mm) thick wood panel. If a thinner wood panel, or

materials other than wood are used, it is the consumer’s

responsibility to obtain the proper length screws and adjust

the pilot holes accordingly.

IMPORTANT: Use a moisture resistant sealer on both sides

and all edges of the panel to protect it from humidity.

1. With a TORX

®

screwdriver, remove three screws from both

sides, as shown; hold the outer panel up while removing

the screws. Save screws for reinstallation.

2. Gently set outer panel aside.

3. Lay the cutomer-supplied custom panel face down on a

protective, non-scratching surface.

*This dimension is for 4" (10.2 cm) toe kick. If the installation needs a higher

toe kick, adjust the height of the wood panel accordingly. Not recommended

for toe kicks greater than 6" (15.2 cm).

13

23-1/2" (59.7 cm) *30-3/16" (76.7 cm)

3/4" (19.1 mm)

custom panel dimensions

4. Measure 9-29/32" (25.2 cm) from top edge and mark a line

on the back of customer-supplied custom panel.

5. Position the outer panel on the back of the customersupplied custom panel as shown, so that the top holes in

the outer panel are on the line, and both panels are

centered side to side.

6. Mark all four hole locations; remove outer panel. Drill

3/32" pilot holes 1/2" (13 mm) deep in customer-supplied

custom panel.

7. Place the outer panel on the back of the customersupplied custom panel; align holes.

8. Attach outer panel to back of customersupplied custom panel with the four

#10-16 x 3/8" hex head screws supplied in

the literature package.

9. Attach the handle. The handle should be centered on the

front of the customer-supplied custom panel in the area

shown.

IMPORTANT: Screw heads must be flush with back of

customer-supplied custom panel.

10. Attach the panel assembly to the door by reinstalling the

three screws on each side; do not tighten completely. This

will hold the panel assembly in place on the door frame.

mark pilot holes

6" (15.2 cm)

hex head

screw

3 screws

3 screws

outer panel

mark line

back

top edge

9-29/32"

(25.2 cm)

customer-supplied

custom panel

3 screws

3 screws

Page 14

1. With a T-15 TORX®screwdriver, remove three screws from

both sides of door; save screws for reinstallation. Hold the

outer panel up while removing the screws.

2. Remove four screws from the latch area and top corners

of inner panel.

3. Partially close dishwasher door; tilt outer door panel

outward to lift up and remove. Gently set outer panel

aside.

4. Lay the cutomer-supplied custom panel face down on a

protective, non-scratching surface.

5. Measure 9-29/32" (25.2 cm) from top edge of customersupplied custom panel and mark a line on the back of

panel.

6. Position the outer panel on the back of the customersupplied custom panel as shown, so that the top holes in

the outer panel are on the line, and both panels are

centered side to side.

7. Mark all four hole locations; remove outer panel and drill

3/32" pilot holes 1/2" (13 mm) deep, in customer-supplied

custom panel.

8. Place the outer panel on the back of the customersupplied custom panel; align holes.

9. Attach outer panel to back of customer-supplied custom

panel with the four #10-16 x 3/8" hex head

screws supplied in the literature package.

Option 2: For models KUDI02FR, KUDP02FR, KUDS02FR,

KUDU02FR

All models require an accessory option to attach custom

panels. Kit No. 8212489 (black) or Kit No. 8212553 (stainless

steel) are available. To order, contact customer service at

800-444-1230.

NOTE: A customer-supplied full front custom panel must

weigh no more than 16 pounds (7.3 kg) and must be made

to specific dimensions. It is recommended that a

cabinetmaker cut the custom panel because of the precise

dimensions needed.

NOTE: All mounting hardware supplied is for a 3/4"

(19.1 mm) thick wood panel. If a thinner wood panel, or

materials other than wood are used, it is the consumer’s

responsibility to obtain the proper length screws and adjust

the pilot holes accordingly.

IMPORTANT: Use a moisture resistant sealer on both sides

and all edges of the panel to protect it from humidity.

23-3/8" (59.4 cm) *30" (76.2 cm)

3/4" (19.1 mm)

11. Align the top edge of the customer-supplied custom panel

with the top of the console.

12. Drill two 3/32" pilot holes 1/2" (13 mm) deep, into the

customer-supplied custom panel, through the holes in the

top corners on the inner panel, as shown.

13. Install the two #8-18 x 1-3/8"

screws from the literature

package in the top corners

of the inner panel.

14.Tighten the six side screws reinstalled in Step 10.

14

drill through

these holes

align top edges

1-3/8"screw

4 screws

outer panel

3 screws

3 screws

*This dimension is for 4" (10.2 cm) toe kick. If the installation needs a higher toe

kick, adjust the height of the wood panel accordingly. Not recommended for

toe kicks greater than 6" (15.2 cm).

mark line

back

top edge

9-29/32"

(25.2 cm)

custom panel dimensions

mark pilot holes

hex head

screw

inner panel

Page 15

NOTE:These dimensions are for frameless custom panel

models with a 4-inch (10.2 cm) console only.

1. With a TORX

®

screwdriver, remove three screws from both

sides of door; hold the outer panel up while removing the

screws.

2. Gently set outer panel aside.

3. Lay the cutomer-supplied custom panel face down on a

protective, non-scratching surface.

4. Position the outer panel on the back of the customersupplied custom panel as shown; make sure top edge of

the outer panel is aligned with the top edge of the

customer-supplied custom panel, and both panels are

centered side to side.

5. Mark all four hole locations; remove outer panel and drill

3/32" pilot holes 1/2" (13 mm) deep, in customer-supplied

custom panel.

10. Attach the panel assembly to the door by reinstalling the

three screws on each side; do not tighten completely. This

will hold the panel assembly in place on the door frame.

11. Align the top edge of the customer-supplied custom panel

with the top of the console.

12. Drill four 1/8" pilot holes 1/2" (13 mm) deep, into the

customer-supplied custom panel, through the holes in the

top corners and latch area of the inner panel.

13. Install the four #8-18

1-3/8" screws along the top

of the inner panel.

14.Tighten the six side screws reinstalled in Step 10.

15. Before installing side trim, clean the sides of door panel.

16. Side trim pieces are held in

place with double-faced

adhesive tape. Make sure

trims are precisedly aligned;

once the trim is installed it

can not be moved.

15

customer-supplied

custom panel

double-faced

tape on inside of

trim

door panel

front

Option 3: For models KUDC02IR, KUDI02IR, KUDP02IR

KUDS02IR

All models require an accessory option to attach custom

panels. Kit No. 8171555 (black), 8171556 (white) or 8171557

(biscuit) are available. To order, call customer service at

800-444-1230.

NOTE: A custom full front panel must weigh no more

than 14 pounds (6.3 kg) and must be made to specific

dimensions. It is recommended that a cabinetmaker cut the

custom panel because of the precise dimensions needed.

IMPORTANT: Use a moisture resistant sealer on both sides

and all edges of the panel to protect it from humidity.

23-3/8" (59.3 cm)

*25-29/32" (65.8 cm)

3/4"

(19.1 mm)

1/8" (3.2 cm)

1/8" (3.2 cm)

*This dimension is for 4" (10.2 cm) toe kick. If the installation needs a higher toe

kick, adjust the height of the wood panel accordingly. Not recommended for

toe kicks greater than 6" (15.2 cm).

customer-supplied

custom panel

align top

edges

mark 4

inner holes

outer panel

3 screws

outer panel

custom panel dimensions

1-3/8"screw

3 screws

3 screws

drill through

these holes

align top edges

inner panel

Page 16

16

score line

plastic

button

bend

tabs

Choose attachment option

Using two or more people, stand the dishwasher up.

Option 1: Countertop

attachment

The dishwasher must be

secured to the cabinet. There

are two brackets on top of the

dishwasher that can be

attached to the countertop if it

is wood, laminate or other

similar surfaces. If this is not

possible, the brackets may be

moved to the sides of the

dishwasher.

NOTE: Do not attach the

dishwasher, this will be done later.

brackets

front vent

model shown

Option 2: Dishwasher side attachment

(for marble, granite or other hard surface countertop)

1. To remove the brackets from the top, flatten tab at back

of brackets with pliers, and pull the brackets out of the

slots.

tabs

2. Break off the end of the bracket along the scored line.

3. Open dishwasher door and place towel over pump

assembly and spray arm of dishwasher. This will prevent

screws from falling into pump area when securing

dishwasher to cabinet.

4. Push the plastic buttons out of the side of the tub.

NOTE: Save the buttons to cover the holes after

dishwasher is installed.

6. Place the outer panel on the back of the customersupplied custom panel and align holes.

7. Attach outer panel to back of customer-supplied custom

panel with four #10 x 1/2" wood screws (not supplied).

If the customer-supplied custom panel is less than 3/4"

(1.9 cm) thick where the screws are attached, shorter

screws maybe required.

8. Attach the panel assembly to the door by reinstalling the

three screws on each side.

3 screws

3 screws

5. Push bracket into slot on the side of dishwasher, and

bend tab in towards the side of the dishwasher so that it

keeps the bracket in place.

NOTE: Do not attach the dishwasher, this will be done

later.

WARNING

Excessive Weight Hazard

Use two or more people to move and install

dishwasher.

Failure to do so can result in back or other injury.

Page 17

4. Check that water line is on the left side of opening and

drain hose is near the center of the hole in the cabinet.

5. Slowly move dishwasher

completely into cabinet opening.

Do not kink or pinch copper

tubing, drain hose, power supply

cord or direct wire between

dishwasher and cabinet.

Helpful Tip: Once the dishwasher

is in position, you may have to

support the front of the

dishwasher by raising, lowering or shimming front feet.

6. Remove cardboard from under dishwasher.

NOTE: It is all right if dishwasher fits tightly into cabinet

opening. Do not remove insulation blanket —the blanket

reduces the sound level.

Level the dishwasher

1. Align front of dishwasher door panel with cabinet doors.

You may need to adjust alignment to be even with your

cabinets.

Helpful Tip: Prop up one side of frame to hold

dishwasher up off floor when adjusting front legs.

2. Check that leveling legs are firmly against the floor.

17

Check door spring tension

1. With another person holding the dishwasher to prevent

it from tipping, open and close the door a few times. If

the door closes or falls open under its own weight, the

door tension will need to be adjusted.

2. To adjust the door spring tension, unhook the spring

from the rear leg of dishwasher.

3. With a 5/16" nut driver or hex socket, remove the screw

from the tensioner.

4. The screw can be put into one of three holes , , in

the front leg of dishwasher. If the door closes by itself,

move the tensioner to a higher number hole and replace

screw. When door is unlatched, if it opens by itself, move

tensioner to a lower numbered hole and replace screw.

5. Re-attach door spring to rear leg. Tensioners on both

sides of dishwasher should be secured at same holes.

Move dishwasher into cabinet opening

1. Grasp the sides of the dishwasher at the edges of the

door panel.

2. Tilt dishwasher backwards on wheels and move

dishwasher close to cabinet opening. Do not push on the

front of the panel or on the console—they may dent.

3. If dishwasher has a power supply cord, insert power

supply cord into hole cut into cabinet.

If using direct wire, check that it is on the right front side

of opening.

screw

tensioner

spring

WARNING

Excessive Weight Hazard

Use two or more people to move and install

dishwasher.

Failure to do so can result in back or other injury.

Page 18

3. Connect the wires as follows using twist-on connectors

sized to connect direct wire to 16-gauge dishwasher

wire:

4. Form bare ground wire into a U-shaped hook. Wrap

ground wire hook clockwise around ground connector

and under the washer.

5. Securely tighten ground connector.

6. Tighten clamp connector or conduit connector screws.

7. Reinstall terminal box cover with wires inside terminal

box. The cover must be outside the box on the left side.

8. Make sure no wires are pinched by cover.

18

3. Close and latch the door, and place level against the

front panel. Check that dishwasher is plumb. If needed,

adjust leveling leg or add shims under rear wheel until

dishwasher is plumb.

4. Repeat for other side of dishwasher.

NOTE: Shims must be securely attached to floor to prevent

their movement when the dishwasher is operated.

5. Place level against top front

opening of tub. Check that

dishwasher is level from side to

side. If dishwasher is not level,

adjust front legs up or down

until dishwasher is level.

Make Electrical Connection

Check “Electrical requirements” section.

You need to:

• have the correct electrical supply and recommended

grounding method.

If you are:

• direct wiring, use Option 1

• using a power supply cord, use Option 2

Option 1: Direct wire method

1. Route direct wire so that it does not touch dishwasher

motor or lower part of dishwasher tub.

2. Pull direct wire through hole in terminal box.

Helpful Tip:

• Select the proper size twist-on

connectors to connect your

household wiring to 16-gauge

dishwasher wiring.

• Insert wire ends into twist-on

connector. Do not pre-twist bare wire.

• Twist connector.

• Gently tug on wires to be sure both

are secured.

ground wire

washer

ground

connector

ground wire

screws

Terminal box wire:

white

black

ground connector

Power supply wire:

white

black

ground wire

WARNING

Electrical Shock Hazard

Electrically ground dishwasher.

Connect ground wire to green ground connector in

terminal box.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

ADVERTENCIA

AVERTISSEMENT

Page 19

Connect to drain

1. To help minimize vibration, route drain hose to avoid

contact with motor, door springs, water line, cabinet,

flooring or the edge of the hole where it passes through

the cabinet.

2. Do not remove drain loop from side of dishwasher.

3. Place pan under end of drain hose. Pan will collect any

water in drain hose.

4. Place the smaller drain hose clamp onto the small end of

the drain hose.

5. Push the drain hose into the connector up to the stop on

the drain hose.

6. Use pliers to open clamp and slide clamp onto

connector between stops on connector as shown.

19

drain

loop

hose clamp

stop

connector

Option 2: Power supply cord method

1. Plug into a grounded 3 prong outlet.

2. Check that power supply cord does not touch

dishwasher motor or lower part of dishwasher tub.

Connect to water supply

Helpful Tip:

Compression fittings:

a. Slide nut onto copper tubing about 1" (2.5 cm).

b. Slide ferrule onto the tubing. Do not position ferrule

on the end of the tubing.

c. Put the tubing into the elbow as far as it will go.

d. Slide the nut and ferrule forward and start the nut

onto the elbow threads. Be gentle when handling and

positioning the copper tubing, it bends and kinks

easily.

1. To prevent vibration during operation, route the water

supply line so that it does not touch the dishwasher

base, frame or motor.

2. With copper tubing pushed into compression fitting as

far as it will go, use a wrench and tighten compression

fitting nut to elbow on water inlet valve.

3. Place paper towel under elbow. Turn on water supply

and check for leaks.

nut

ferrule

elbow

hose clamp

stops

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Page 20

20

Bottom sound pad installation (on some models)

1. Remove the bottom sound pad from inside the

dishwasher and take it out of the plastic bag.

2. Place pad on the floor in front of the dishwasher, making

sure lettering is facing up and vinyl pad faces down.

3. Fold up and hold the side panels down. Carefully slide

the pad toward the back of the dishwasher as far as it

will go, making sure not to push or pull any wires or

hoses. (Do not force.) Side panels will open to proper

position.

NOTE: If there are pipes or other obstructions coming up

through the floor, you will need to cut a slit in the pad to

fit around the obstacle.

4. Fold the front end of the pad up into position. Make sure

the vinyl pad is tucked up behind the door and the

dishwasher front legs, as shown.

Complete installation

1. Check that grounding clip is attached to the lower panel.

2. Place the lower panel behind the access panel. Some

models have insulation on the access panel which must

fall behind the insulation on the lower panel.

lower

panel

access panel

grounding

clip

Secure dishwasher in cabinet opening

1. If you have not already done so, open dishwasher door

and place towel over pump assembly and spray arm of

dishwasher. This will prevent screws from falling into

pump area when securing dishwasher to countertop.

2. Check that dishwasher is still level and centered side to

side in the opening.

3. Secure dishwasher to countertop or sides of cabinet with

two, #10 x 1/2" Phillips-head screws. The dishwasher

must be secured to keep it from tipping when door is

opened. Do not drop screws into bottom of dishwasher.

4. Open door about 3 inches (7.6 cm) and check that space

between inner door and tub is equal on both sides. If

spacing is not equal, loosen bracket screws and shift tub.

Tighten bracket screws.

5. Check that top of door does not contact screws, brackets,

or countertop. If it does, dishwasher must be lowered

and re-leveled.

6. If securing to sides of cabinet, replace the plastic buttons.

7. Remove towel from dishwasher.

8. Reinstall the lower dishrack.

plastic

button

screw to countertop

screw to

side cabinet

OR

WARNING

Tip Over Hazard

Do not use dishwasher until completely installed.

Do not push down on open door.

Doing so can result in serious injury or cuts.

Page 21

21

Check operation

1. Read the Use and Care Guide that came with your

dishwasher.

2. Check that all parts have been installed and no steps

were skipped.

3. Check that you have all the tools you used.

4. Start dishwasher and allow it to complete the shortest

wash cycle. After the first two minutes, unlatch door,

wait five seconds, then open door.

5. Check to see that there is water in the bottom of the

dishwasher tub. Check that dishwasher is working

properly. If not, see “If dishwasher does not operate”

section.

6. Disconnect power or unplug dishwasher.

If dishwasher does not operate

First try the solutions suggested here to possibly avoid the

cost of a service call.

• Has the circuit breaker tripped or the house fuse blown?

• Is the door closed tightly and latched?

• Has the cycle been set correctly to start the dishwasher?

• Is the water turned on?

If none of these work, call 1-800-422-1230.

3. Hold the two panels together and push them up against

dishwasher leg and vinyl pad.

4. Reinstall the screws through the holes in the access

panel and the slots in the lower panel. Install right side

screw first.

5. Check that the lower edge of the lower panel contacts

the floor.

6. Tighten the screws.

Direct wire method:

Power supply cord method:

7. Reconnect power or plug in dishwasher.

WARNING

Electrical Shock Hazard

Electrically ground dishwasher.

Connect ground wire to green ground connector in

terminal box.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Page 22

22

Tenir compte de ceci :

• Ouvrir lentement la porte du lave-vaisselle tandis qu’une

autre personne saisit l’arrière de l’appareil. Retirer les

matériaux d’emballage, le tuyau de décharge et le panier

inférieur. Fermer la porte du lave-vaisselle et verrouiller le

loquet.

• Respecter les dispositions de tous les codes et règlements

en vigueur.

• Installer le lave-vaisselle conformément aux prescriptions

des présentes instructions.

• L’installation devrait être exécutée par un technicien

qualifié. Veiller à respecter les dispositions de tous les

codes et règlements locaux et nationaux régissant les

installations de plomberie et d’électricité.

Table des matières

Sécurité du lave-vaisselle . . . . . . . . . . . . . . . . . . . . . . . . . .22

Exigences d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Outillage et pièces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Emplacement d’installation . . . . . . . . . . . . . . . . . . . . . . 23

Spécifications de

la canalisation d’évacuation . . . . . . . . . . . . . . . . . . . . . 24

Spécifications de

l’alimentation en eau . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Spécifications électriques . . . . . . . . . . . . . . . . . . . . . . . 24

Instructions d'installation . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Préparation des ouvertures dans les placards – utilisation

des modes de raccordement existants pour canalisations

et câblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Préparation de l’emplacement d’installation entre les

placards lorsque les canalisations et câbles n’ont pas été

installés . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installation de la barrière contre l'humidité . . . . . . . . 27

Préparation du lave-vaisselle . . . . . . . . . . . . . . . . . . . . 28

Raccordement électrique . . . . . . . . . . . . . . . . . . . . . . . . 36

Raccordement à la canalisation d’eau . . . . . . . . . . . . . 37

Raccordement à la canalisation d’évacuation . . . . . . . 37

Immobilisation du lave-vaisselle dans l’espace

d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Sécurité du lave-vaisselle

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

AVERTISSEMENT

Risque de basculement

Ne pas utiliser le lave-vaisselle jusqu’à ce qu’il soit

complètement installé.

Ne pas appuyer sur la porte ouverte.

Le non-respect de ces instructions peut causer des

blessures graves ou des coupures.

Page 23

23

®Teflon est une marque déposée de Du Pont de Nemours and Company.

®Marque déposée de TEXTRON

Outillage nécessaire :

• perceuse électrique avec

scies à trous de 1/2", 3/4" et

1 1/2"

• petit coupe-tube

• pince à dénuder

• bride de tuyau à vis de 1

1/2" – 2" pour

raccordement à la

canalisation d’égout sur un

raccord T

Pièces nécessaires :

• tube de cuivre (3/8"

recommandé) ou conduit

de raccordement flexible

avec tresse d’acier

inoxydable

• serre-câble ou connecteur

de conduit utilisable sur un

trou de diamètre

2,2 cm (7/8")

Outillage et pièces

Rassembler tous les outils et pièces nécessaires avant de

commencer l’installation.

Pour toutes les configurations d’installation

Outillage et pièces supplémentaires pour

l’installation dans un local neuf

Pièces fournies

A. 2 brides pour tuyau de décharge - 1 grosse, 1 petite

B. 2 vis Phillips n° 10 x 1/2"

C. Tuyau de décharge

Vérifier la présence de toutes ces pièces. Si l’une des pièces

mentionnées n’est pas présente, téléphoner au

1-800-422-1230.

Voir la liste séparée des pièces et accessoires disponibles

pour le lave-vaisselle.

Exigences d’installation

Emplacement d’installation

Ne pas placer canalisation d’évacuation, canalisation d’eau

ou câblage électrique à un endroit où cela susciterait

interférence ou contact avec les pieds ou le moteur du lavevaisselle.

À l’emplacement d’installation du lave-vaisselle, on doit

pouvoir établir le dégagement approprié entre le moteur et

le plancher. Le moteur ne doit pas toucher le plancher.

Ne pas installer le lave-vaisselle par-dessus un tapis.

Protéger du gel le lave-vaisselle et les canalisations d’eau

qui l’alimentent; la garantie de l’appareil ne couvre pas les

dommages imputables au gel.

Un ensemble “panneau latéral” est disponible chez les

revendeurs pour l’installation du lave-vaisselle à l’extrémité

d’une rangée de placards.

Un accessoire pare-vapeur (produit n° 4396277) est

disponible chez les revendeurs pour l’installation de

l’appareil sous le plan de travail. Cependant l’utilisation de

cet accessoire n’est pas indispensable. On peut également

commander ce produit par téléphone au 1-800-422-1230.

Inspecter l’emplacement d’installation du lave-vaisselle; il

doit comporter les caractéristiques suivantes :

• facilité d’accès aux canalisations d’eau et d’égout et à la

source d’électricité.

• accès facile pour chargement et déchargement de la

vaisselle. Dans le cas de l’installation dans un angle, on

doit pouvoir établir un dégagement de 5,1 cm (2") ou plus

entre le côté de la porte du lave-vaisselle et le mur ou le

placard.

• ouverture carrée offrant l’esthétique appropriée et

permettant un fonctionnement correct.

• façade des placards perpendiculaire au plancher.

• plancher horizontal et plat (s’il y a un écart de niveau entre

l’avant et l’arrière sur le plancher de l’emplacement

d’installation, il pourrait être nécessaire d’utiliser des cales

pour établir l’aplomb de l’appareil).

NOTE : Pour éviter tout déplacement des cales durant le

fonctionnement de l’appareil, il est nécessaire de fixer les

cales au plancher.

Si le lave-vaisselle ne doit pas être utilisé pendant une

période prolongée ou s’il est laissé à un endroit qui pourrait

être exposé au gel, veiller à faire exécuter les opérations de

pré-hivernage par un technicien compétent.

Veiller à ce que les canalisations d’eau et d’évacuation et les

câbles électriques soient dans la zone marquée en gris dans

la section “Dimensions de l’emplacement d’installation”.

Conseil utile : Si le plancher de l’espace d’installation

n’est pas parfaitement horizontal et plat (exemple :

garnissage de carrelage sur une partie seulement), on

devra accorder une attention particulière aux détails lors

du relevé des dimensions, pour pouvoir établir l’aplomb

correct du lave-vaisselle.

Outillage nécessaire :

• pince

• tournevis Phillips

• tourne-écrou ou clé à

douille – douilles

hexagonales de 5/16" ou

1/4"

• mètre-ruban ou règle

• clé à molette de 10"

(ouverture jusqu’à 2,9 cm

[1 1/8"])

• tournevis à lame plate

• couteau utilitaire

• 2 connecteurs de fils de

taille appropriée pour le

raccordement des

conducteurs de l’appareil

(calibre 16) au câblage de

la maison

• petit niveau

• tournevis TORX

®

T15

(en cas d’installation de

panneaux avant

personnalisés)

• lampe torche

• plat peu profond

• clé plate de 5/8"

• serviette de bain

• cale de bois

Pièces nécessaires :

• raccord 90° avec filetage

externe de 3/8" NPT à une

extrémité. (La configuration

de l’autre extrémité doit

être adaptée à celle de la

canalisation d’arrivée

d’eau.)

• ruban de Teflon

®

ou

composé d’étanchéité pour

tuyauteries

• cales (pour l’installation sur

un plancher à

rehaussement partiel)

• 4 vis à bois n° 10 x 1/2"

(en cas d’installation de

panneaux avant

personnalisés)

C

A

B

Pièces additionnelles fournies uniquement avec les modèles

à évacuation par le haut

D. 2 vis n° 8 x 1-3/8" TORX

®

T15

E. 4 vis à tête hexagonale n° 10 x 3/8"

Pièces supplémentaires fournies avec certains modèles

F. Coussinet du bas (situé dans le panier inférieur)

G. Barrière contre l'humidité

Page 24

24

22,9 cm

(9")

25,4 cm

(10")

15,2 cm

(6") ***

15,2 cm

(6") ***

8,3 cm

(3-1/4")

7 cm

(2-3/4")

86,4 cm

(34")

min.*

5,1 cm

(2")

5,1 cm

(2")

toutes les surfaces doivent

être exemptes de

protubérances.

5,1 cm

(2")

8,3 cm

(3-1/4")

8,3 cm

(3-1/4")

7 cm

(2-3/4")

8,3 cm

(3-1/4")

61 cm (24")

min.

61 cm (24")

**

Découper les trous dans la zone marquée en gris du plancher, du mur ou des

parois des placards, selon les spécifications ci-dessous :

Canalisation d’eau – 1,3 cm (1/2")

Canalisation d’évacuation – 3,8 cm (1-1/2")

Câble pour câblage direct – 1,9 cm (3/4")

Cordon d’alimentation – 3,8 cm (1-1/2")

* Mesure depuis le point le plus bas de la face inférieure du plan de travail.

Cette dimension peut être réduite à 86 cm (33-7/8") si on retire les roues

du lave-vaisselle.

** Dimension minimale mesurée au point le plus étroit de l’ouverture.

*** Cette dimension peut être portée à 16,6 cm (6-5/8") si la hauteur de

l’ouverture est de 87,6 cm (34-1/2") au point le plus bas.

Dimensions de l’espace d’installation

14 cm

(5-1/2")

8,9 cm

(3-1/2")

Dimensions du produit

60,6 cm (23-7/8")

1,9 cm (3/4")

le matériau

isolant (pas

utilisé sur tous

les modèles)

pourrait être

comprimé

62,2 cm (24-1/2")*

63,2 cm (24-7/8")*

évent avant

VUE LATÉRALE

VUE ARRIÈRE

53,3 cm (21")

86 cm (33-7/8")

min., avec

roues enlevées

Page 25

25

Spécifications de la canalisation

d’évacuation

• Utiliser le tuyau d’évacuation neuf fourni avec le lave-

vaisselle. Si ce tuyau n’est pas suffisamment long, utiliser

un tuyau d’évacuation neuf de longueur maximale 3,7 m

(12 pi) qui satisfait les critères de la norme AHAM/IAPMO

en vigueur, résistant à la chaleur et aux détergents, et qui

pourra être connecté sur le raccord de sortie de 2,5 cm

(1") du lave-vaisselle.

• Connecter le conduit d’évacuation à la canalisation

d’égout par l’intermédiaire d’un raccord T ou du raccord

d’un broyeur à déchets situé plus haut que le siphon du

circuit de plomberie de la maison, et à au moins 50,8 cm

(20") au-dessus du sol. On recommande de lover le tuyau

d’évacuation et de le fixer solidement sur la face

inférieure du plan de travail, ou de le raccorder à un

dispositif brise-siphon.

• Utiliser un dispositif brise-siphon si le tuyau d’évacuation

est connecté à la canalisation d’égout de la maison à

moins de 50,8 cm (20") au-dessus du sous-plancher ou du

plancher.

• Utiliser un raccord de diamètre intérieur de 1/2" ou plus.

Spécifications de l’alimentation en eau

• Canalisation d’eau chaude, sous pression de 20 à 120

lb/po

2

(138–862 kPa).

• Température de 49°C (120°F) à l’entrée du lave-vaisselle.

• Canalisation de cuivre de diamètre externe 3/8" avec

raccord à compression, ou conduit de raccordement

flexible à tresse d’acier inoxydable (l’emploi d’un tube de

plastique de 1/2" minimum est possible, mais

déconseillé).

• raccord 90° avec filetage externe de 3/8" NPT à une

extrémité.

Ne pas exécuter de raccordement par soudure à moins de

15,2 cm (6") de l’électrovanne d’admission d’eau.

Spécifications électriques

Contacter un électricien qualifié.

Vérifier que l’installation électrique est adéquate et qu’elle

satisfait les exigences de tous les codes et règlements

locaux et nationaux en vigueur.

Caractéristiques exigées :

• 120 volts CA seulement,, 60 Hz; protection par fusible

15 ou 20 A.

• conducteurs de cuivre seulement

On recommande :

• un fusible temporisé ou disjoncteur.

• une alimentation par un circuit indépendant.

Pour le raccordement direct du lave-vaisselle :

• Utiliser un câble flexible blindé ou à gaine non

métallique, des conducteurs de cuivre avec liaison à la

terre, satisfaisant les exigences des codes et règlements

locaux.

• Arrimer le câble avec le dispositif fourni sur la boîte de

connexion de la maison, ou installer un serre-câble

(homologation UL ou CSA) sur la boîte de connexion de

la maison. Dans le cas de l’emploi d’un conduit, utiliser

un connecteur de conduit (homologation UL ou CSA).

Alimentation de l’appareil par un cordon d’alimentation :

• Utiliser le cordon d’alimentation (produit n° 4317824)

identifié pour l’utilisation avec un lave-vaisselle.

L’ensemble comprend :

- cordon d’alimentation Volex Inc., avec 3 conducteurs

de calibre 16 (homologation UL) et fiche de

branchement à 3 broches pour liaison à la terre.

- serre-câble 7/8" Neer C-500

- 3 connecteurs de fils

- bague de protection n° 302797

Pour l’installation du cordon d’alimentation, procéder

conformément aux instructions fournies avec

l’ensemble.

• La fiche du cordon d’alimentation devra être branchée sur

une prise de courant à 3 alvéoles de configuration

correspondante, reliée à la terre, installée dans le placard

à côté de l’emplacement d’installation du lave-vaisselle.

La prise de courant doit satisfaire les exigences de tous

les codes et règlements locaux.

brise-siphon

Page 26

26

Instructions d’installation

1. Interrompre l’alimentation électrique.

2. Fermer l’arrivée d’eau.

Préparation des ouvertures dans les

placards – utilisation des modes de

raccordement existants pour

canalisations et câblage

• Procéder conformément aux instructions de cette section

pour l’installation de l’appareil à un emplacement déjà

doté de moyens de raccordement.

• Pour l’installation de l’appareil à un emplacement où les

canalisations et le câblage n’ont pas déjà été installés,

procéder

conformément aux

instructions

présentées à la

section “Préparation

de l’emplacement

d’installation entre

les placards lorsque

les canalisations et

câbles n’ont pas été

installés”.

1. Vérifier que la canalisation d’eau atteint le côté avant

gauche de l’espace d’installation (endroit où le

raccordement à l’appareil sera effectué).

2. Vérifier que le câble d’alimentation atteint l’angle avant

droit de l’espace d’installation (endroit où le

raccordement à l’appareil sera effectué).

Si la canalisation d’eau et le câble de raccordement

électrique sont suffisamment longs, passer à la section

suivante “Installation du tuyau d’évacuation”. Si la

canalisation d’eau et le câble électrique ne sont pas

suffisamment longs, procéder conformément aux

instructions de la section “Préparation de l’emplacement

d’installation entre les placards lorsque les canalisations et

câbles n’ont pas été installés”.

15,2 cm (6")

canalisation

d’eau

câble pour

raccordement direct

Installation du tuyau d’évacuation

IMPORTANT : On doit toujours utiliser un tuyau

d’évacuation neuf, même pour l’installation d’un lavevaisselle de remplacement.

1. Percer un trou de diamètre 3,8 cm (1 1/2") dans la paroi

du placard ou dans le plancher sur le côté de l’espace

d’installation le plus proche de l’évier.

2. Employer l’une des méthodes suivantes pour raccorder

le tuyau d’évacuation sur un raccord T ou sur un broyeur

à déchets.

• Option 1 - broyeur à déchets – avec brise-siphon

• Option 2 - pas de broyeur à déchets – avec brise-siphon

• Option 3 - broyeur à déchets – sans brise-siphon*

• Option 4 - pas de broyeur à déchets – sans brisesiphon*

* on recommande qu’un brise-siphon soit disponible

Conseil utile : Pour réduire les effets de vibration du

tuyau durant le fonctionnement, maintenir une

séparation entre le tuyau et le plancher et entre le tuyau

et la circonférence du trou de passage à travers le

placard.

Option 1 - broyeur à déchets – avec brise-siphon :

1. Ôter l’opercule arrachable sur le broyeur à déchets. Si

nécessaire, couper l’extrémité du tuyau d’évacuation (ne

pas couper dans la section ondulée).

2. Connecter le tuyau d’évacuation sur le dispositif brisesiphon avec la grosse bride à ressort. Si le tuyau

d’évacuation a été coupé, utiliser une bride à vis* de 3,8

à 5 cm (1 1/2 à 2").

3. Utiliser un raccord en caoutchouc* avec une bride à

ressort ou à vis* pour raccorder le dispositif brisesiphon à l’entrée du broyeur à déchets.

Ce raccordement doit être réalisé en amont du siphon du

circuit d’évacuation et à au moins 50,8 cm (20")

au-dessus du plancher de l’espace d’installation du

lave-vaisselle.

4. Insérer le tuyau d’évacuation à

travers le trou découpé dans le

placard et acheminer le tuyau

jusqu'à l'angle avant droit de

l'ouverture où le raccordement

du circuit d'évacuation sera

réalisé.

*Pièces disponibles dans un magasin local de fournitures de plomberie

tuyau

d’évacuation

grosse bride

à ressort

dispositif

brise-siphon

raccord en

caoutchouc

entrée du

broyeur à

déchets

siphon du circuit

d’évacuation

tuyau d’évacuation

couper ici si nécessaire

brides à

ressort

ou à vis

tuyau d’évacuation

AVERTISSEMENT

Risque de choc électrique

Interrompre l'alimentation électrique avant d'installer

le lave-vaisselle (au niveau du tableau de distribution fusible ou disjoncteur)

Le non-respect de cette instruction peut causer

un décès ou un choc électrique.

Page 27

27

Option 3 - broyeur à déchets – sans brise-siphon :

1. Ôter l’opercule arrachable du broyeur à déchets. Ne pas

couper l’extrémité du tuyau d’évacuation.

2. Connecter le tuyau d’évacuation sur le broyeur à déchets

avec la grosse bride à ressort.

Ce raccordement doit être réalisé en amont du siphon du

circuit d’évacuation et à au moins 50,8 cm (20") au-dessus

du plancher de l’espace d’installation du lave-vaisselle. On

recommande de lover le tuyau d’évacuation et de le fixer

solidement sur la face inférieure du plan de travail.

3. Insérer le tuyau d’évacuation à

travers le trou découpé dans

le placard et acheminer le

tuyau jusqu'à l'angle avant

droit de l'ouverture où le

raccordement du circuit

d'évacuation sera réalisé.

tuyau

d’évacuation

grosse bride

à ressort

entrée du

broyeur à déchets

siphon du circuit

d’évacuation

Option 4 - pas de broyeur à déchets – sans brise-siphon :

1. Si nécessaire, couper l’extrémité du tuyau d’évacuation

(ne pas couper dans la section ondulée).