KitchenAid KUDE20FB*0, KUDE20IX*9, KUDE50CX*9, KUDE50FB*0, KUDE60FX*5 Technical Education

...Page 1

TECHNICAL EDUCATION

2013 Stainless Steel

Tall Tub Dishwasher

KD-15

KUDE20FB*0, KUDE20IX*9, KUDE40FX*6, KUDE48FX*5,

KUDE50CX*9, KUDE50FB*0, KUDE60FX*5, KUDE60HX*5,

*All Colors

KUDE70FX*5, KUDL15FX*6

JOB AID W10573282

Page 2

FORWARD

This KitchenAid Job Aid, "2013 Stainless Steel Tall Tub Dishwasher" (Part No. W10573282), provides the

In-Home Service Professional with informaon on the installaon, operaon, and service of the “Global

Wash System" with variable speed wash and drain motors. For specic operang informaon on the

model being serviced, refer to the “Use and Care Guide” provided with the dishwasher.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide informaon that will enable the In-Home Service Professional to

properly diagnose malfuncons and repair the "KitchenAid 2013 Stainless Steel Tall Tub Dishwasher.”

The objecves of this Job Aid are to:

• Understand and follow proper safety precauons.

• Successfully troubleshoot and diagnose malfuncons.

• Successfully perform necessary repairs.

• Successfully return the dishwasher to its proper operaonal status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on our

products by anyone other than authorized In-Home Service Professionals.

Copyright © 2013, Whirlpool Corporaon, Benton Harbor, MI 49022

ii n

KitchenAid 2013 Tall Tub Stainless Steel Dishwasher

Page 3

TABLE OF CONTENTS

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

SECTION 1 — GENERAL INFORMATION

DISHWASHER SAFETY .........................................................................................................................1-2

BEFORE USING YOUR DISHWASHER ..................................................................................................1-3

MODEL & SERIAL NUMBER LABEL .....................................................................................................1-4

TECH SHEET LOCATION .......................................................................................................................1-4

MODEL & SERIAL NUMBER NOMENCLATURE ...................................................................................1-5

PRODUCT SPECIFICATIONS ................................................................................................................1-6

PARTS & FEATURES .............................................................................................................................1-7

NOTES .................................................................................................................................................1-8

SECTION 2 — OPERATION

START-UP / QUICK REFERENCE ..........................................................................................................2-2

QUICK STEPS .......................................................................................................................................2-3

DISHWASHER USE ..............................................................................................................................2-3

CYCLE & OPTION DESCRIPTIONS ........................................................................................................2-5

DISHWASHER FEEDBACK SECTION ....................................................................................................2-8

DISHWASHER FEATURES ....................................................................................................................2-9

FILTRATION SYSTEM .........................................................................................................................2-11

DISHWASHER CARE ..........................................................................................................................2-13

CONSUMER TROUBLESHOOTING GUIDE .........................................................................................2-14

NOTES ...............................................................................................................................................2-16

SECTION 3 — INSTALLATION

DISHWASHER SAFETY .........................................................................................................................3-2

INSTALLATION REQUIREMENTS .........................................................................................................3-4

LOCATION REQUIREMENTS ................................................................................................................3-5

DRAIN REQUIREMENTS ......................................................................................................................3-7

ELECTRICAL REQUIREMENTS .............................................................................................................3-7

INSTALLATION INSTRUCTIONS ...........................................................................................................3-8

DETERMINE CABINET OPENING .......................................................................................................3-15

INSTALL DOOR HANDLE ....................................................................................................................3-16

INSTALL CUSTOM PANEL ..................................................................................................................3-16

CHOOSE ATTACHMENT OPTION .......................................................................................................3-19

PREPARE WATER SUPPLY LINE .........................................................................................................3-20

CONNECT WATER SUPPLY .................................................................................................................3-22

CONNECT TO DRAIN .........................................................................................................................3-22

MAKE DIRECT WIRE ELECTRICAL CONNECTION ..............................................................................3-23

SECURE DISHWASHER TO CABINET OPENING .................................................................................3-25

COMPLETE INSTALLATION ................................................................................................................3-26

NOTES ...............................................................................................................................................3-28

SECTION 4 — COMPONENT ACCESS

INSULATION BLANKET ........................................................................................................................4-2

DOOR LATCH STRIKE ...........................................................................................................................4-2

ADJUSTABLE DOOR SPRINGS .............................................................................................................4-3

WATER INLET & DRAIN HOSE .............................................................................................................4-3

OVERFILL ASSEMBLY ..........................................................................................................................4-4

ACCESSING DOOR COMPONENTS ......................................................................................................4-5

KitchenAid 2013 Tall Tub Stainless Steel Dishwasher

n

iii

Page 4

REMOVING USER INTERFACE .............................................................................................................4-6

REMOVING LATCH ASSEMBLY ............................................................................................................4-7

REMOVING ELECTRONIC CONTROL BOARD ......................................................................................4-8

REMOVING DISPENSER ASSEMBLY ....................................................................................................4-9

SPRAY ARMS, FEED TUBE, AND MANIFOLD .....................................................................................4-10

TUB COMPONENTS — STAINLESS STEEL TUB MODELS ...................................................................4-11

REMOVING THE UPPER RACK(S) ......................................................................................................4-12

REMOVING LOWER SPRAY ARM ......................................................................................................4-13

REMOVING FILTERS ..........................................................................................................................4-14

REMOVING PROSCRUB MANIFOLD .................................................................................................4-15

REMOVING DIVERTER DISK..............................................................................................................4-15

UNDER THE TUB COMPONENTS ......................................................................................................4-18

HEATER..............................................................................................................................................4-19

REMOVING SUMP ASSEMBLY & DRAIN PUMP ................................................................................4-20

REMOVING OPTICAL WATER INDICATOR ........................................................................................4-23

REMOVING DIVERTER MOTOR ........................................................................................................4-24

WASH MOTOR REPLACEMENT .........................................................................................................4-25

SECTION 5 — DIAGNOSTICS & TROUBLESHOOTING

SAFETY WARNINGS ............................................................................................................................5-2

WASH CYCLES .....................................................................................................................................5-3

SERVICE DIAGNOSTIC CYCLE ..............................................................................................................5-4

SERVICE DIAGNOSTIC CYCLE NOTES ..................................................................................................5-5

DIAGNOSTIC GUIDE ............................................................................................................................5-5

SERVICE DIAGNOSTICS WITH ERROR CODES .....................................................................................5-6

SERVICE ERROR CODES ......................................................................................................................5-7

TROUBLESHOOTING GUIDE .............................................................................................................5-12

SECTION 6 — TESTING

SAFETY WARNINGS ............................................................................................................................6-2

WIRING DIAGRAM ..............................................................................................................................6-3

CONTROL BOARD INFORMATION/SPECS ..........................................................................................6-4

COMPONENT TESTING .......................................................................................................................6-4

ELECTRONIC CONTROL BOARD ..........................................................................................................6-5

GENERAL THEORY OF OPERATION .....................................................................................................6-6

POWER CHECK ....................................................................................................................................6-6

DOOR SWITCH CIRCUIT ......................................................................................................................6-7

FILL CIRCUIT ........................................................................................................................................6-8

DISPENSER CIRCUIT ............................................................................................................................6-9

WATER HEATING / HEAT DRY ...........................................................................................................6-10

WATER SENSING WITH OWI SENSOR ...............................................................................................6-11

DIVERTER MOTOR ............................................................................................................................6-12

DIVERTER SENSOR / POSITION SWITCH ..........................................................................................6-13

WASH MOTOR (VARIABLE SPEED) ....................................................................................................6-14

DRAIN MOTOR (VARIABLE SPEED) ...................................................................................................6-15

VENT WAX MOTOR ...........................................................................................................................6-16

VENT FAN ..........................................................................................................................................6-17

USER INTERFACE ...............................................................................................................................6-18

PRODUCT SPECIFICATIONS & WARRANTY INFORMATION SOURCES (inside back cover)

iv n

KitchenAid 2013 Tall Tub Stainless Steel Dishwasher

Page 5

GENERAL INFORMATION

Section 1:

General Information

This secon provides general safety, parts, and informaon for

the “KitchenAid Stainless Steel Tall Tub Dishwasher.”

■ Dishwasher Safety

■ Before Using Your Dishwasher

■ Model & Serial Number Label

■ Tech Sheet Locaons

■ Model & Serial Number Nomenclature

■ Product Specicaons

■ Parts & Features

■ Notes

KitchenAid 2013 Tall Tub Stainless Steel Dishwasher

n

1-1

Page 6

GENERAL INFORMATION

Dishwasher Safety

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using the dishwasher, follow basic precauons, including the following:

■ Read all instrucons before using the dishwasher.

■ Use the dishwasher only for its intended funcon.

■ Use only detergents or rinse agents recommended for

use in a dishwasher, and keep them out of the reach of

children.

■ When loading items to be washed:

1) Locate sharp items so that they are not likely to

damage the door seal; and

2) Load sharp knives with the handles up to reduce the

risk of cut-type injuries.

■ Do not wash plasc items unless they are marked

“dishwasher safe” or the equivalent. For plasc items not

so marked, check the manufacturer’s recommendaons.

■ Do not touch the heang element during or immediately

aer use.

■ Do not operate the dishwasher unless all enclosure

panels are properly in place.

■ Do not tamper with controls.

■ Do not abuse, sit on, or stand on the door, lid, or dish

racks of the dishwasher.

■ To reduce the risk of injury, do not allow children to play

in or on the dishwasher.

■ Under certain condions, hydrogen gas may be produced

in a hot water system that has not been used for two

weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot

water system has not been used for such a period, before

using the dishwasher turn on all hot water faucets and

let the water ow from each for several minutes. This

will release any accumulated hydrogen gas. As the gas is

ammable, do not smoke or use an open ame during

this me.

■ Remove the door or lid to the washing compartment

when removing an old dishwasher from service or

discarding it.

SAVE THESE INSTRUCTIONS

State of California Proposion 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproducve harm.

1-2 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 7

Before Using Your Dishwasher

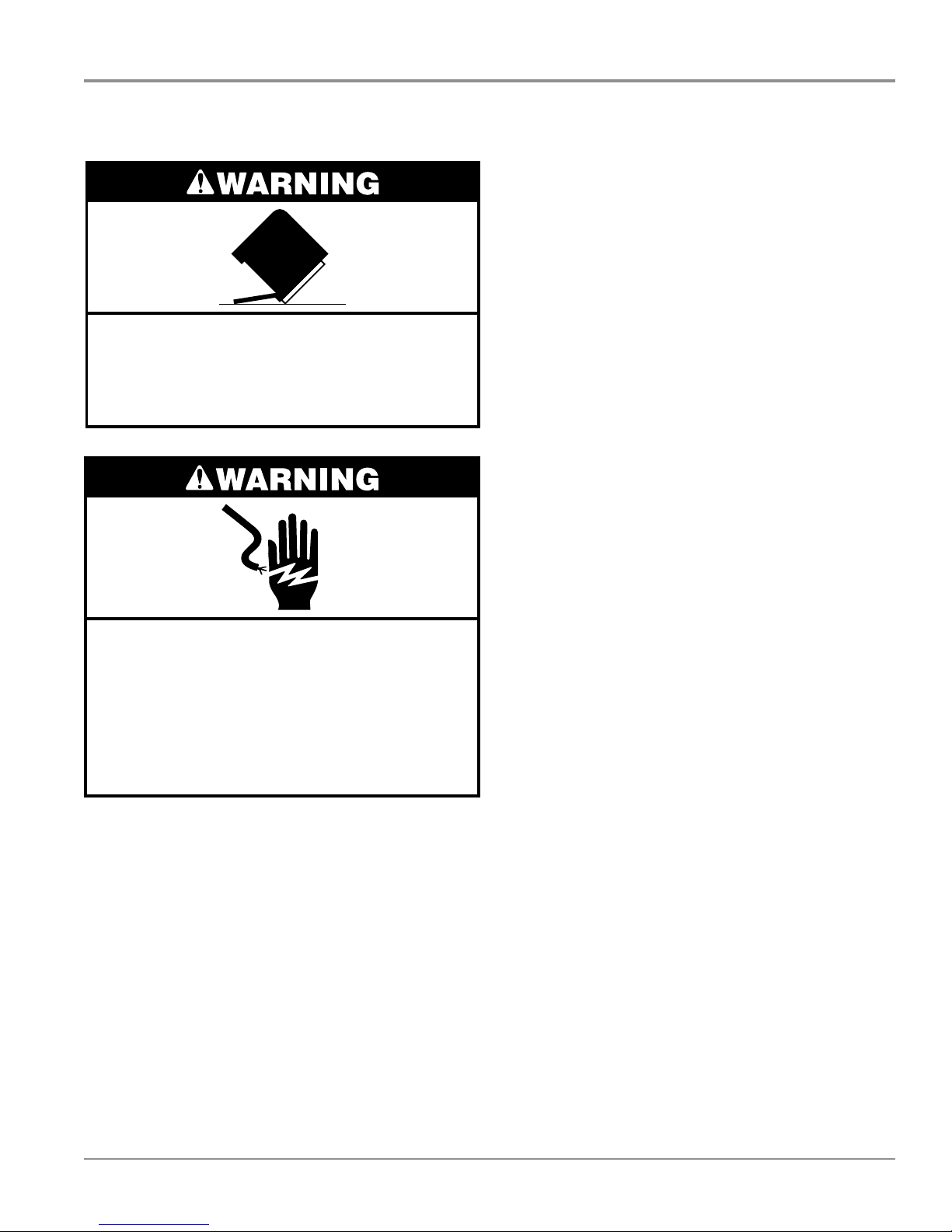

GROUNDING INSTRUCTIONS

GENERAL INFORMATION

Tip Over Hazard

Do not use dishwasher until completely installed.

Do not push down on open door.

Doing so can result in serious injury or cuts.

Electrical Shock Hazard

Electrically ground dishwasher.

Connect ground wire to green ground connector

in terminal box.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

• For a grounded, cord-connected dishwasher:

must be grounded. In the event of a malfuncon or

breakdown, grounding will reduce the risk of electric

shock by providing a path of least resistance for electric

current. The dishwasher is equipped with a cord having

an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that

is installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connecon of the equipmentgrounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representave

if you are in doubt whether the dishwasher is properly

grounded. Do not modify the plug provided with the

dishwasher; if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

• For a permanently connected dishwasher:

must be connected to a grounded metal, permanent

wiring system, or an equipment-grounding conductor must

be run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the dishwasher.

The dishwasher

The dishwasher

SAVE THESE INSTRUCTIONS

• Install where dishwasher is sheltered from the elements.

Avoid possible rupture of ll valve from freezing. Such

ruptures are not covered by the warranty. See “Storing”

secon for winter storage informaon.

• Install and level dishwasher on a oor that will hold the

weight, and in an area suitable for its size and use.

• Remove all shipping plugs from hoses and connectors

(such as the cap on the drain outlet) before installing. See

Installaon Instrucons or complete informaon.

KitchenAid 2013 Tall Tub Stainless Steel Dishwasher

n

1-3

Page 8

GENERAL INFORMATION

Model & Serial Number

Label Location

Model & Serial Number Label

Tech Sheet Location

Tech Sheet Location

(Behind Toe Kick Panel)

1-4 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 9

GENERAL INFORMATION

Model & Serial Number Nomenclature

MODEL NUMBER K UD E 60 F X BL 5

INTERNATIONAL SALES OR

MARKETING CHANNEL

K = KITCHENAID BRAND

PRODUCT IDENTIFIER

PD = Convertible/Portable UD = Undercounter

E = TRI-FILTER SYSTEM

SERIES CONFIGURATION

FEATURES

F = Fully Integrated Door C = 2.5” Console w/Display I = 2.5” Console

H = Heritage S = Water Softener

YEAR OF MODEL INTRODUCTION

X = 2010 B = CU Model

COLOR CODE

WH = White SS = Stainless Steel BL = Black

BT = Biscuit SP = Stainless Proline PA = Panel Ready

ENGINEERING CHANGE

0 = Basic Release; 1 = First Revision; 2 = Second Revision

SERIAL NUMBER F 2 25 10000

MANUFACTURING SITE

F = FINDLAY, OH

YEAR OF MANUFACTURE

2 = 2012

WEEK OF MANUFACTURE

PRODUCT SEQUENCE NUMBER

KitchenAid 2013 Tall Tub Stainless Steel Dishwasher

n

1-5

Page 10

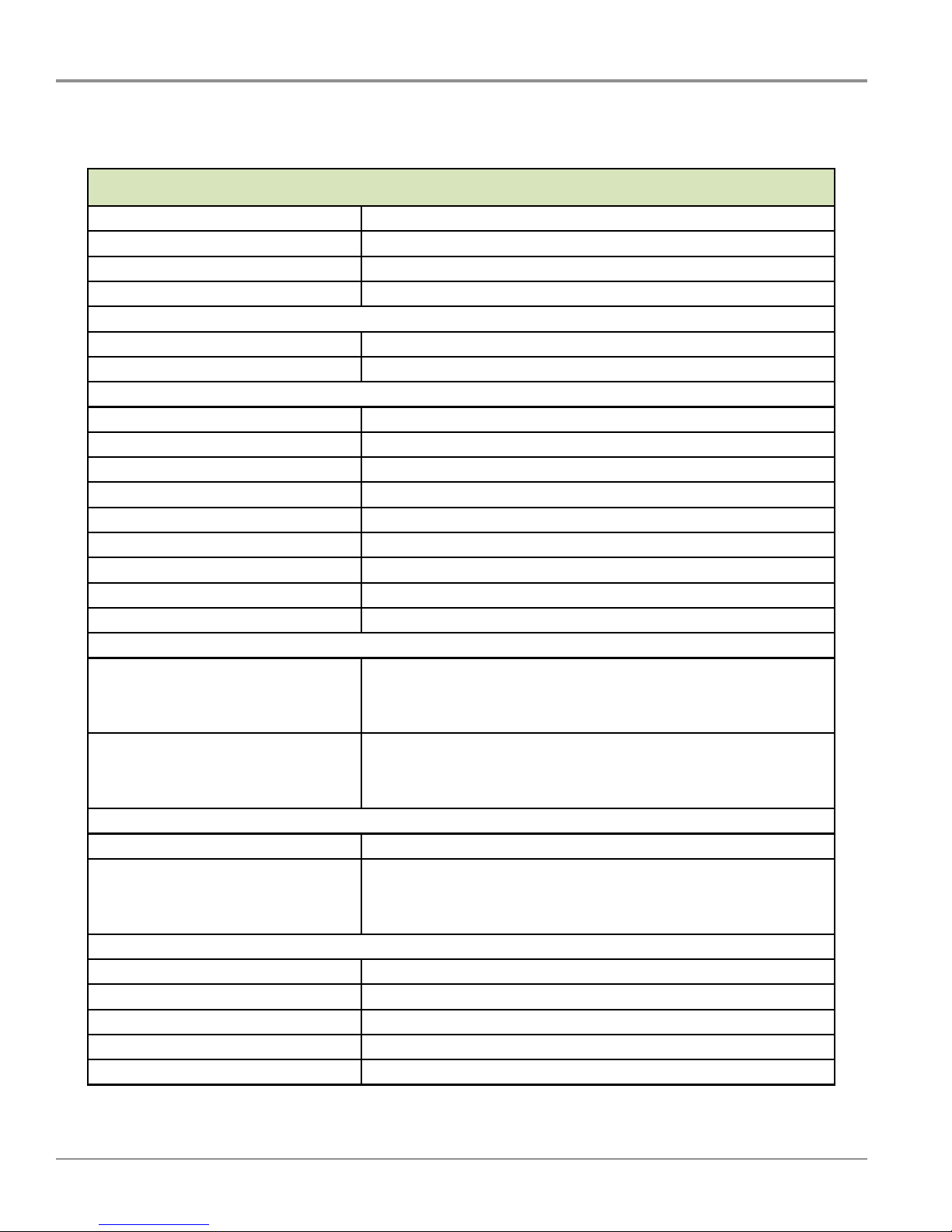

GENERAL INFORMATION

LineVoltage: 120VAC

Frequency: 60Hz

Amps: 10A

LowVoltsPowerSupply: +15V,+13V,+5V,+3.3

WaterPressure: 120psiMax,20psiMin

SupplyWaterTemperature: Minimum‐120°F(49°C)

Control: ElectronicControlw/IntegratedVSMControl

WashMotor: 3‐PhaseVariableSpeedMotor(VSM)

DrainMotor: 3‐PhaseVariableSpeedMotor(VSM)

DiverterMotor: 120VAC

FillValve: 120VAC

Heater: 120VAC

Dispenser: 120VAC

SprayArmMotor: 120VAC(somemodels)

FanMotor: +5VDC(somemodels)

Product Specifications

DISHASHERSPECIFICATIONS

Sensors: TemperatureSensor

WaterSensor(OWI)

SprayArmSensor(somemodels)

Switches: DiverterPositionSwitch(5VDC)

DoorSwitch(13VDC)

FloatSwitch(120VAC)

TCO/Bi‐Metal: IncorporatedintoControlBoard(PenninsulaSlots)

Fuses: Line(L1)Fuse

MotorControlFuse

TriacFuse

LowerWashArm: "S"Design

UpperWashArm: StraightDesign

Filtration: 3‐StageFilterSystem

ProScrub: Availableoncertainmodels

WaterSoftenerModel: KUDE60SXSS4

1-6 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 11

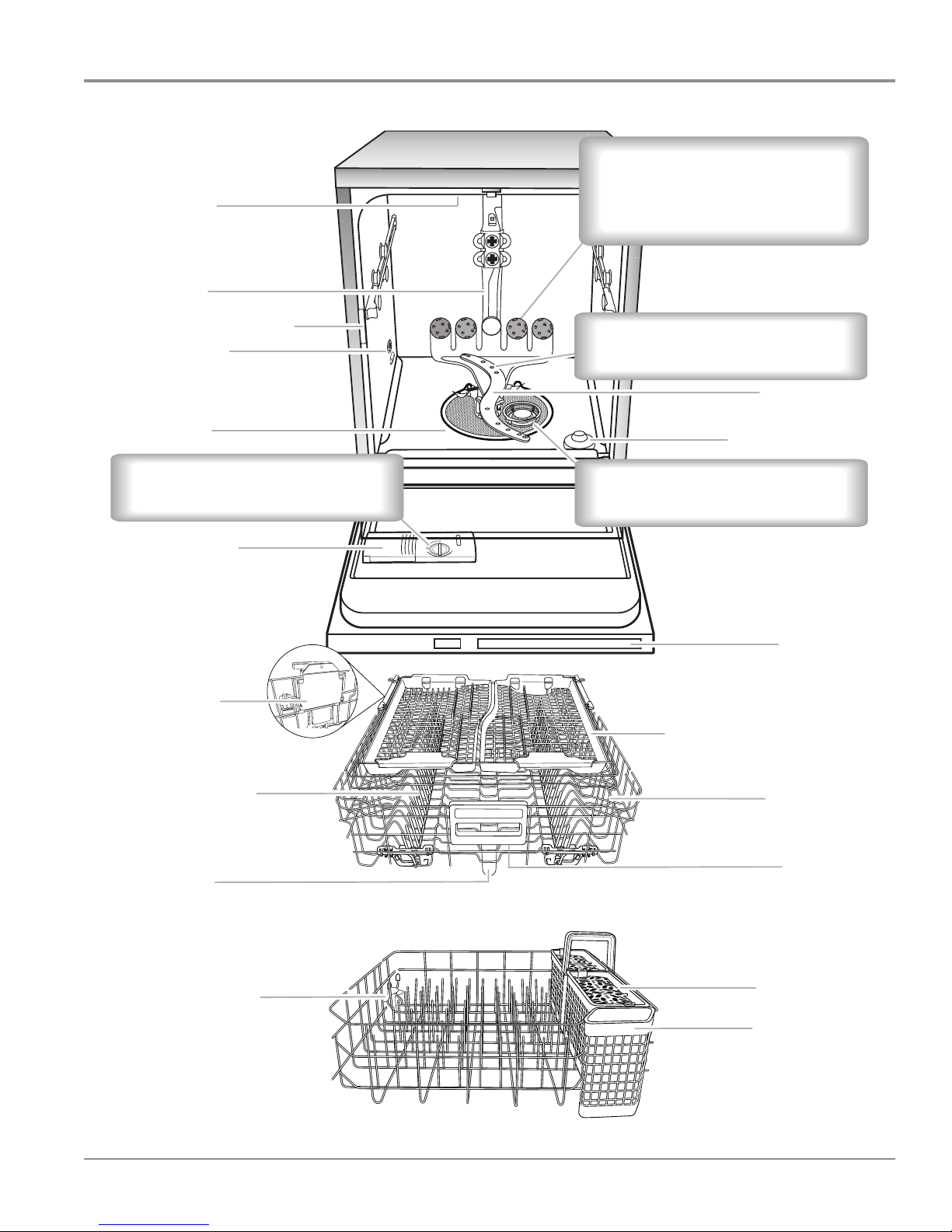

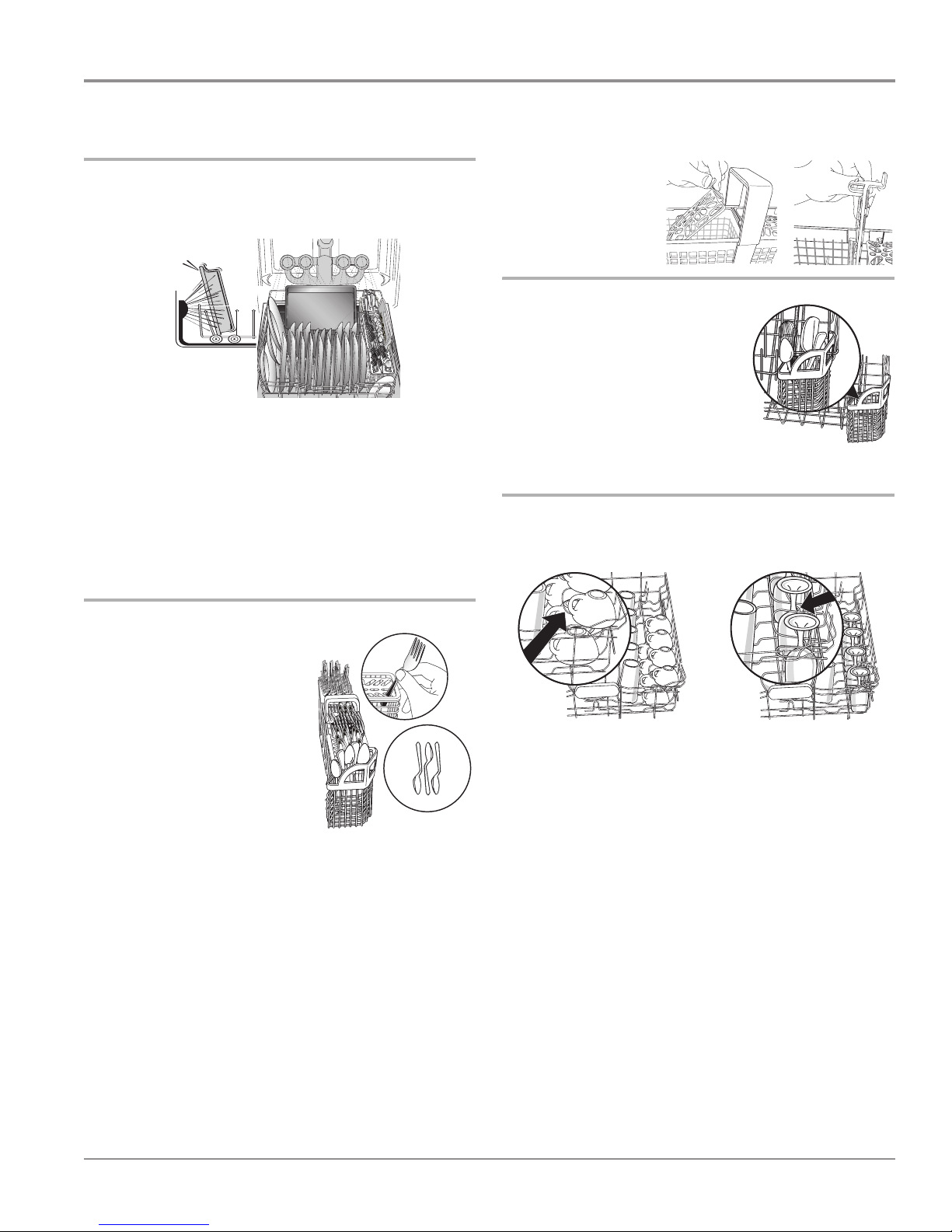

Parts and Features

Upper level wash

BOTTOM RACK

h

r

Water feed tube

Parts & Features

GENERAL INFORMATION

ProScrub® (on some models)

powerful jets target water toward pots,

pans, or casserole dishes loaded in the

back of the dishwasher to clean

stubborn messes.

Model and serial number label

Water inlet opening

Heating element

Rinse aid dispenser reduces spotting

and improves drying.

Detergent dispenser

Premium top rack

adjusters

Pressurized spray nozzles and variable

speed motor provide effective cleaning.

Lower spray arm

Overfill protection float

EQ Filtration System removes soil

from water and improves cleaning action.

Control panel

Culinary tool rack/3rd level rack

(on some models)

Flexible fold-down tines

(on some models)

Upper spray arm

Flexible fold-down tines

TOP RACK

Cup shelves wit

stemware holde

Rack handle

Silverware basket

Culinary Caddy

utensil basket

(on some models)

KitchenAid 2013 Tall Tub Stainless Steel Dishwasher

n

®

1-7

Page 12

GENERAL INFORMATION

Notes

1-8 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 13

OPERATION

Section 2:

Operation

This secon provides operaonal use and care informaon for

the “KitchenAid Stainless Steel Tall Tub Dishwasher.”

■ Start-Up / Quick Reference

■ Quick Steps

■ Dishwasher Use

■ Cycle and Opon Descripons

■ Dishwasher Feedback Secon

■ Dishwasher Features

■ Filtraon System

■ Dishwasher Care

■ Consumer Troubleshoong Guide

■ Notes

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

n

2-1

Page 14

OPERATION

Start-Up / Quick Reference (varies by model)

Start-Up / Quick Reference

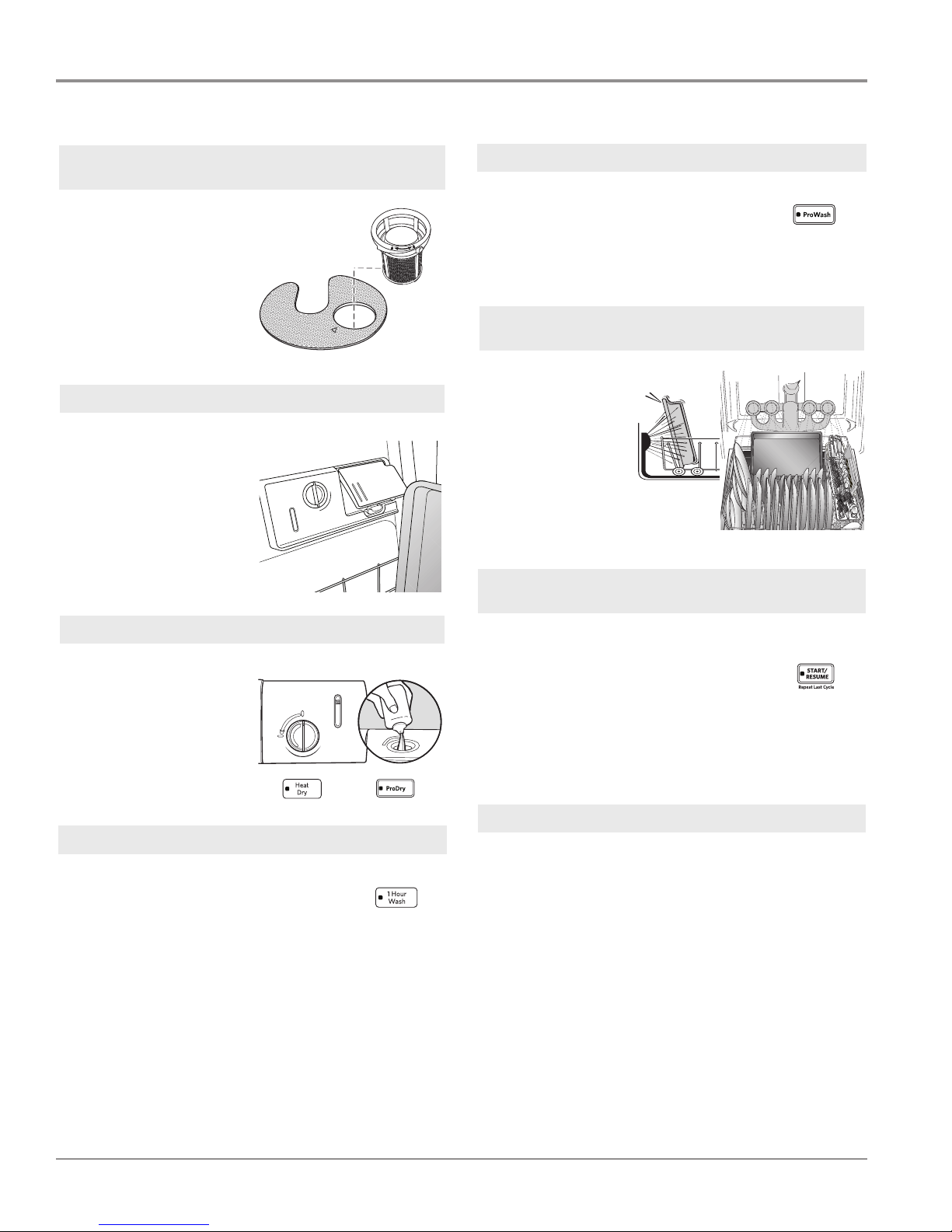

Clean EQ Wash System removable filters to maintain

peak performance.

Cleaning the filters

periodically helps keep the

dishwasher working at peak

performance. The filters can

be found at the bottom center

of your dishwasher.

See the “Filtration System”

section for information on

removing and maintaining the

filters.

W

N

O

&

D

T

H

U

S

R

U

N

P

L

O

L

N

C

U

K

IMPORTANT: Do not block detergent dispenser.

Tall items placed in the lower

rack may block the dispenser

door. Cookie sheets and

cutting boards loaded on the

left-hand side of the

dishwasher can easily block

the dispenser. If detergent is

inside of the dispenser or on

the bottom of the tub after the

cycle is complete, the

dispenser was blocked.

ProWash™ cycle for optimal cleaning

The most advanced and versatile cycle.

ProWash™ cycle senses the load size, soil

K

C

O

amount, and toughness of soil, to adjust the

cycle for optimal cleaning using only the

amount of water and energy needed. The

ProWash™ and Heavy Duty cycles are

recommended for tough soil. No need to

prerinse dishes; just scrape and load.

ProScrub® Option for loading to clean baked-on

food (some models)

When the ProScrub

option is selected, it

provides a

concentrated wash

on the back of the

lower dish rack for

hard-to-clean dishes.

Place these dishes

with the soiled

surface of the dish

toward the

ProScrub

®

spray jets

in the lower rack of

the dishwasher.

®

Press START/RESUME every time you

add a dish.

Drying - Rinse Aid is essential.

You must use a drying agent

such as a rinse aid for good

drying performance (sample

included). Rinse aid along

with the Heat Dry or ProDry™

option will provide best drying

and avoid excessive moisture

in the dishwasher interior.

USE RINSE AID FOR

BETTER DRYING

Refill

Full

Lock

Add

IMPORTANT: If anyone opens the door (such

as, for adding a dish, even during the Delay

Hours option), the Start/Resume button must

be pressed each time.

If the Start/Resume button is located on top of

door: Push door firmly closed within

3 seconds of pressing START/RESUME. If the

door is not closed within 3 seconds, the Start/

Resume button LED will flash, an audible tone

will be heard, and the cycle will not start.

or

Proper Detergent Dosing

1 Hour Wash - When you need fast results.

Efficient dishwashers run longer to save water

and energy, just as driving a car slower saves

on gas. When you need fast results, the

1 Hour Wash will clean your dishes using

slightly more water and energy. Select the

Heat Dry or ProDry™ option to speed drying

times (adds approximately 27 to 35 minutes

to the 1 Hour Wash cycle)

It is possible to use too much detergent in your dishwasher.

This can lead to etching of your dishes. See “Add Detergent” in

the “Dishwasher Use” section, to determine the amount of

detergent needed based on your water hardness.

2-2 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 15

Quick Steps

Quick Steps

Quick Steps

Dishwasher Use

1

Prepare and load

dishwasher.

3

Select a cycle and option.

2

Add detergent

for cleaning and

rinse aid for

drying.

4

Start dishwasher.

NOTE: If the Start/Resume button is located

on the top of door, push door firmly closed

within 3 seconds of pressing START/RESUME.

C

OPERATION

1

2

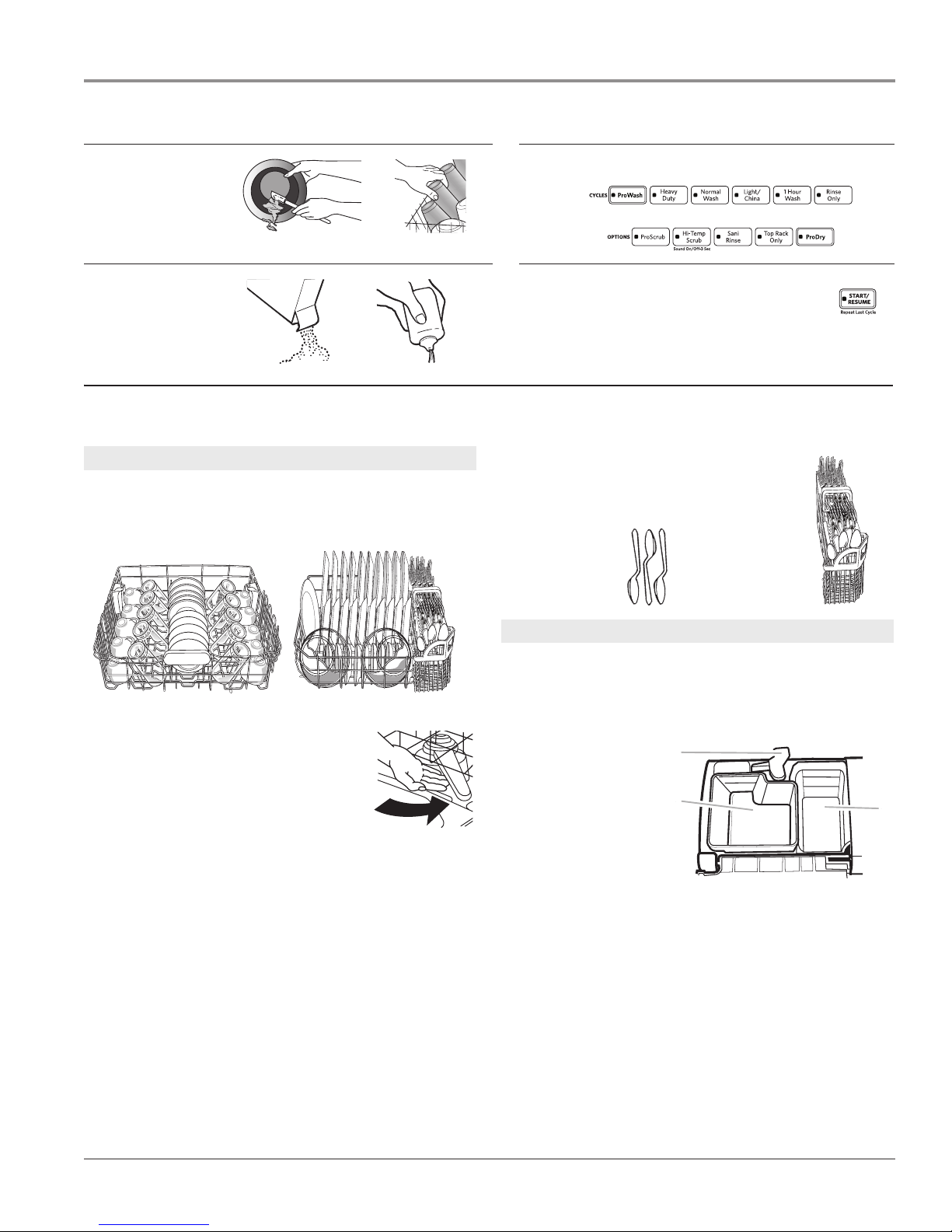

Prepare and Load the Dishwasher

IMPORTANT: Remove leftover food, bones, toothpicks and other

hard items from the dishes. Remove labels from containers before

washing.

Prepare and load

dishwasher.

Add detergent

for cleaning and

rinse aid for

drying.

STEP 1

Dishwasher Use

Select a cycle and option.

3

■ When loading silverware, always place sharp

Start dishwasher.

4

NOTE: If the Start/Resume button is located

on the top of door, push door firmly closed

within 3 seconds of pressing START/RESUME.

items pointing down. Mix items in each

section of the basket with some pointing up

and some down to avoid nesting. Spray

cannot reach nested items.

Upper rack Lower rack

Make sure nothing keeps spray arm(s) from

spinning freely. It is important for the water

spray to reach all soiled surfaces.

■ Make sure that when the dishwasher door is closed no items

are blocking the detergent dispenser.

■ Items should be loaded with soiled surfaces facing down and

inward to the spray as shown. This will improve cleaning and

drying results.

■ Avoid overlapping items like bowls or plates that may trap food.

■ Place plastics, small plates and glasses in the upper rack.

Wash only plastic items marked “dishwasher safe.”

■ To avoid thumping/clattering noises during operation, load

dishes so they do not touch one another. Make sure lightweight

load items are secured in the racks.

■ Improper loading can cause dishes to be chipped or damaged.

When loading glasses or mugs, it is best to load these items in

between rows of tines instead of loading them over tines, as

shown in the image above.

STEP 2

Add Detergent

NOTE: If you do not plan to run a wash cycle soon, run a rinse

cycle. Do not use detergent.

Use automatic dishwasher detergent only. Add powder, liquid

■

or tablet detergent just before starting a cycle.

■ Fresh automatic

dishwasher detergent

results in better

cleaning. Store tightly

closed detergent

container in a cool, dry

place.

■ The amount of detergent to use depends on:

How much soil remains on the items - Heavily soiled loads

require more detergent.

The hardness of the water - If you use too little in hard water,

dishes won't be clean. If you use too much in soft water,

glassware will etch.

Soft to Medium Water (0-6 grains per U.S. gallon)

[typical water softener water and some city water]

Medium to Hard Water (7-12 grains per U.S. gallon)

[well water and some city water]

■ Depending on your water hardness, fill the Main Wash section

of the dispenser as shown. Fill the Pre-Wash section to the

level shown, if needed.

A

Hard Water

Soft Water

B

MAIN WASH

A. Cover latch

B. Main Wash section

C. Pre-Wash section

Hard Water

Soft Water

PREWASH

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

n

2-3

Page 16

OPERATION

Dishwasher Use (continued)

NOTE: Fill amounts shown

are for standard powdered

detergent. Follow

instructions on the package

when using other dishwasher

Hard Water

Soft Water

Main Wash Pre-Wash

Hard Water

Soft Water

detergent types.

Premeasured forms are suitable for all hardness and soil levels.

Always place premeasured detergents in the main compartment

and close the lid.

Add Rinse Aid

■ Your dishwasher is designed to use rinse aid for good drying

performance. Without rinse aid your dishes and dishwasher

interior will have excessive moisture. The heat dry option will

not perform as well without rinse aid.

■ Rinse aid keeps water from forming droplets that can

dry as spots or streaks. They also improve drying by

allowing water to drain off of the dishes after the final

rinse.

■ Rinse aid helps to reduce excess moisture on the dish

racks and interior of your dishwasher.

■ Check the rinse aid indicator. Add rinse aid when indicator

drops to “Add” level.

■ To add rinse aid, turn the dispenser cap

to “Refill” and lift off. Pour rinse aid into

the opening until the indicator level is at

“Full.” Replace the dispenser cap and

turn to “Lock.” Make sure cap is fully

locked.

NOTE: For most water conditions, the

factory setting of 2 will give good

results. If you have hard water or notice

rings or spots, try a higher setting. Turn

the arrow adjuster inside the dispenser

by either using your fingers or inserting

a flat-blade screwdriver into the center

of the arrow and turning.

Refill

ILOO

PD[

¹⁄₄

turn to lock

ILOO

PD[

Lock

Full

Add

STEP 3

Select a Cycle (cycles vary by model)

See “Cycle and Option Descriptions” charts in the following

section.

Efficient dishwashers run longer to save water and energy, just as

driving a car slower saves on gas. Typical cycle time is

approximately 2¹⁄₂ hours, but can take less or more time to

complete depending on selections.

Select Options (options vary by model)

See “Cycle and Option Descriptions” charts in the following

section.

You can customize your cycles by pressing the options desired. If

you change your mind, press the option again to turn off the option.

Not all options are available for every cycle. If an invalid option is

selected for a given cycle, the lights will flash.

STEP 4

Start or Resume a Cycle

■ Run hot water at the sink nearest your dishwasher until the

water is hot. Turn off water.

Press START/RESUME once to show which

■

selections you used. Select the wash cycle and

options desired OR press START/RESUME to repeat

the same cycle and options as in the previous wash

cycle.

IMPORTANT: If anyone opens the door (such as, for adding a dish,

even during the Delay Hours option), the Start/Resume button

must be pressed each time.

■ If the Start/Resume button is located on top of door, push door

firmly closed within 3 seconds of pressing START/RESUME. If

the door is not closed within 3 seconds, the Start/Resume

button LED will flash, an audible tone will be heard, and the

cycle will not start.

2-4 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 17

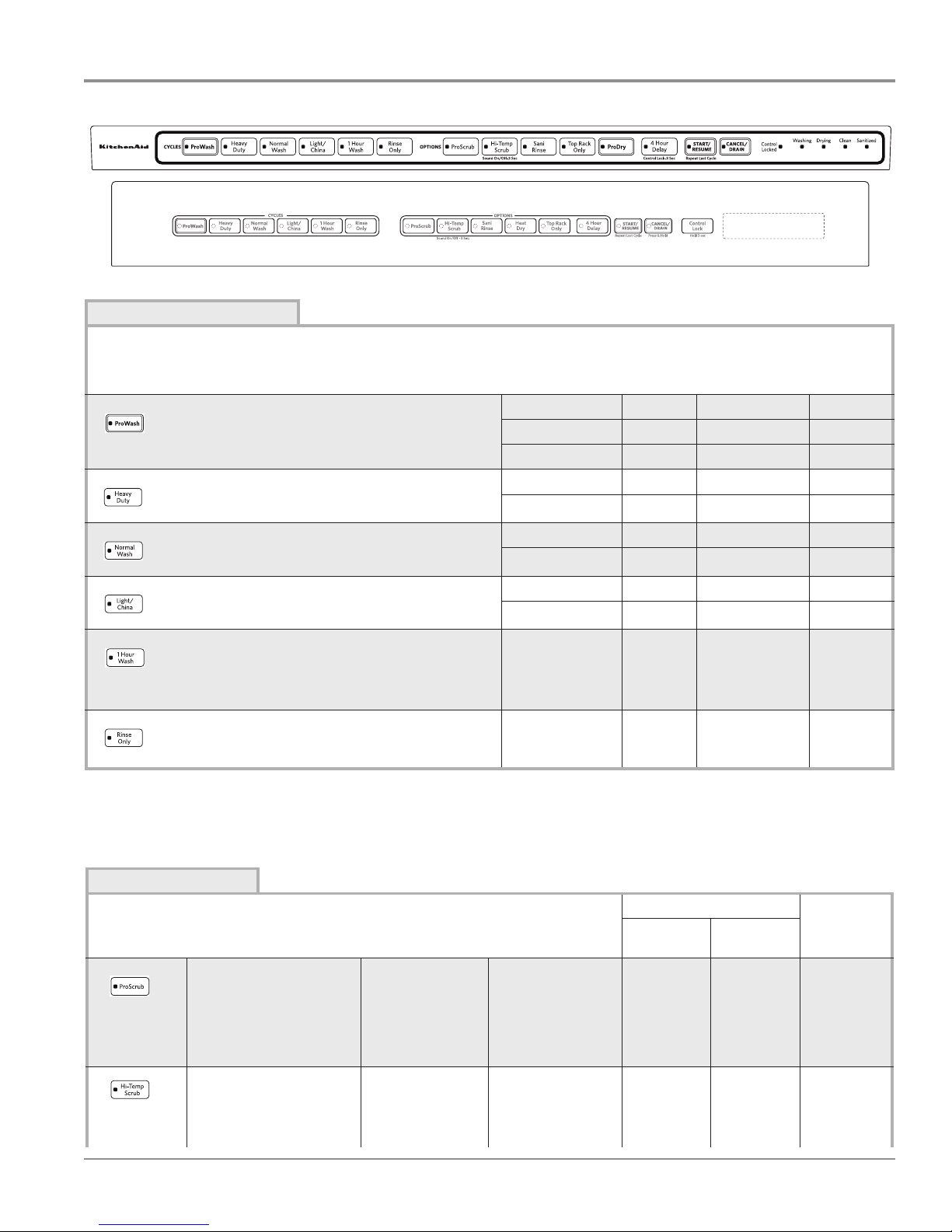

Cycle and Option Descriptions

Cycle and Option Descriptions

OPTION SELECTIONS

OPTIONS CAN BE

SELECTED WITH

WHAT IT DOES ADDED TIME TO CYCLE ADDED

WATER

GALLONS

(LITERS)

TYPICAL MAX

Cleans pans, casseroles,

etc., with tough food soil

to eliminate the need for

soaking and scrubbing of

dirty, baked-on dishes.

Heavy Duty

Normal Wash

Activates the

ProScrub

®

spray

jets to provide

intensified cleaning

power to items at

the back of the

lower rack.

53 73 0 - 3.0

(0 - 11.2)

Raises the main wash

temperature to improve

cleaning for loads

containing tough, bakedon food.

Heavy Duty

Normal Wash

Raises the main

wash temperature

from 105°F (41°C)

to 120°F (49°C).

22 40 0 - 3.0

(0 - 11.2)

This information covers several different models. Your dishwasher may not have all of the cycles and options described.

CYCLE SELECTIONS

CYCLES SOIL LEVEL WASH TIME* (MINS.)

The most advanced and versatile cycle. ProWash™

cycle senses the load size, soil amount, and toughness

of soil, to adjust the cycle for optimal cleaning using

only the amount of water and energy needed.

Use for hard-to-clean, heavily soiled pots, pans,

casseroles, and regular tableware.

Light to Medium 110 150 4.2 (16.1)

Tough/Baked-On 125 190 5.0 (19.1)

Heavy 125 190 6.8 (25.8)

Light to Medium 130 150 5.0 (19.1)

Heavy/Baked-On 140 205 6.8 (25.8)

W/O OPTIONS

Typical** Max

OPERATION

WATER

USAGE

GALLONS

(Liters)

Use for loads with normal amounts of food soil. The

energy-usage label is based on this cycle.

Use for lightly soiled items or china and crystal. Light to Medium 105 145 4.2 (15.2)

When you need fast results, the 1 Hour Wash will clean

dishes using slightly more water and energy. Select the

Heat Dry or ProDry™ option to speed drying times (add

approximately 27 to 35 minutes to the 1 Hour Wash

cycle).

Use for rinsing dishes, glasses, and silverware that will

not be washed right away.

Do not use detergent.

Wash times depend on water temperature, heavy soil condition, dish load size and options selected. Adding options will add time to the

cycle.

* Adding options will add time to the cycle. See options information section.

** This is the approximate cycle time obtained with 120°F (49°C) hot water available at the dishwasher. Increase in time results from low

temperature of the incoming water.

Light to Medium 110 150 4.0 (15.0)

Heavy 125 190 6.8 (25.8)

Heavy/Baked-On 120 185 6.8 (25.8)

All soil levels 58 62 7.9 (30.0)

All soil levels 17 20

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

n

2-5

Page 18

OPERATION

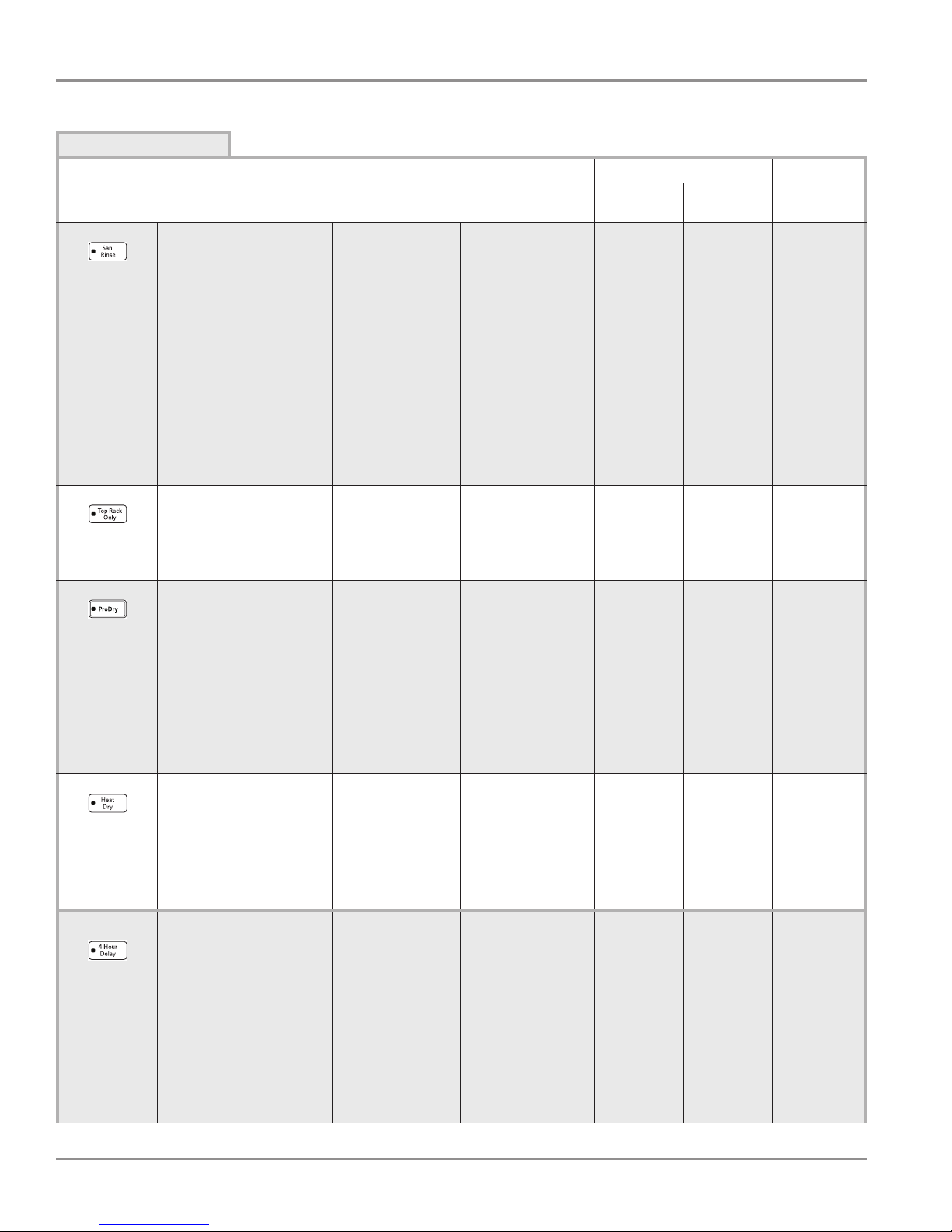

OPTION SELECTIONS

Cycle and Option Descriptions (continued)

OPTIONS CAN BE

Sanitizes dishes and

glassware in accordance

with National Sanitation

Foundation (NSF)/ANSI

Standard 184 for

Residential Dishwashers.

Certified residential

dishwashers are not

intended for licensed food

establishments. The Sani

indicator indicates at the

end of the cycle whether

the Sani Rinse option was

successfully completed. If

the indicator is not

activated, it is probably

due to the cycle being

interrupted.

For added convenience,

use for washing a small

load of dishes in the top

rack to help keep the

kitchen continuously

clean.

Dries dishes with heat and

a fan. This option with the

use of rinse aid will provide

the best drying

performance. Plastic items

are less likely to deform

when loaded in the top

rack. Turn ProDry™ option

off for an air dry.

Dries dishes with heat.

This option with the use of

rinse aid will provide the

best drying performance.

Plastic items are less likely

to deform when loaded in

the top rack. Turn Heat Dry

off for an air dry.

Runs the dishwasher at a

later time or during offpeak electrical hours.

Select a wash cycle and

options. Press 4 Hour

Delay. Press START/

RESUME. Close the door

firmly.

NOTE: Anytime the door is

opened (such as, to add a

dish), the Start/Resume

button must be pressed

again to resume the delay

countdown.

SELECTED WITH

Heavy Duty

Normal Wash

Available with any

cycle

Cannot be used

with ProScrub

Option

Available with any

cycle except Rinse

Available with any

cycle except Rinse

Available with any

cycle

Only

Only

WHAT IT DOES ADDED TIME TO CYCLE ADDED

TYPICAL MAX

Increased the main

wash temperature

from 105°F (41°C)

to 130°F (54°C) and

the final rinse from

140°F (60°C) to

155°F (68°C).

Slightly faster wash

for smaller loads

®

Uses the heating

element to heat air,

plus a system of

vents and a fan that

ventilates moist air

out of the

dishwasher to

speed drying times.

ProDry™ option

defaults to ON

when any cycle is

selected except for

1 Hour Wash.

Activates the

heating element at

the end of the wash

cycle to speed

drying times. Heat

Dry defaults to ON

when any cycle is

selected except for

1 Hour Wash.

Delays the start of a

cycle up to 4 hours

53 73 0 - 3.0

-7 -30 0

44 51 0

52 52 0

240 240 0

WATER

GALLONS

(LITERS)

(0 - 11.2)

2-6 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 19

Cycle and Option Descriptions (continued)

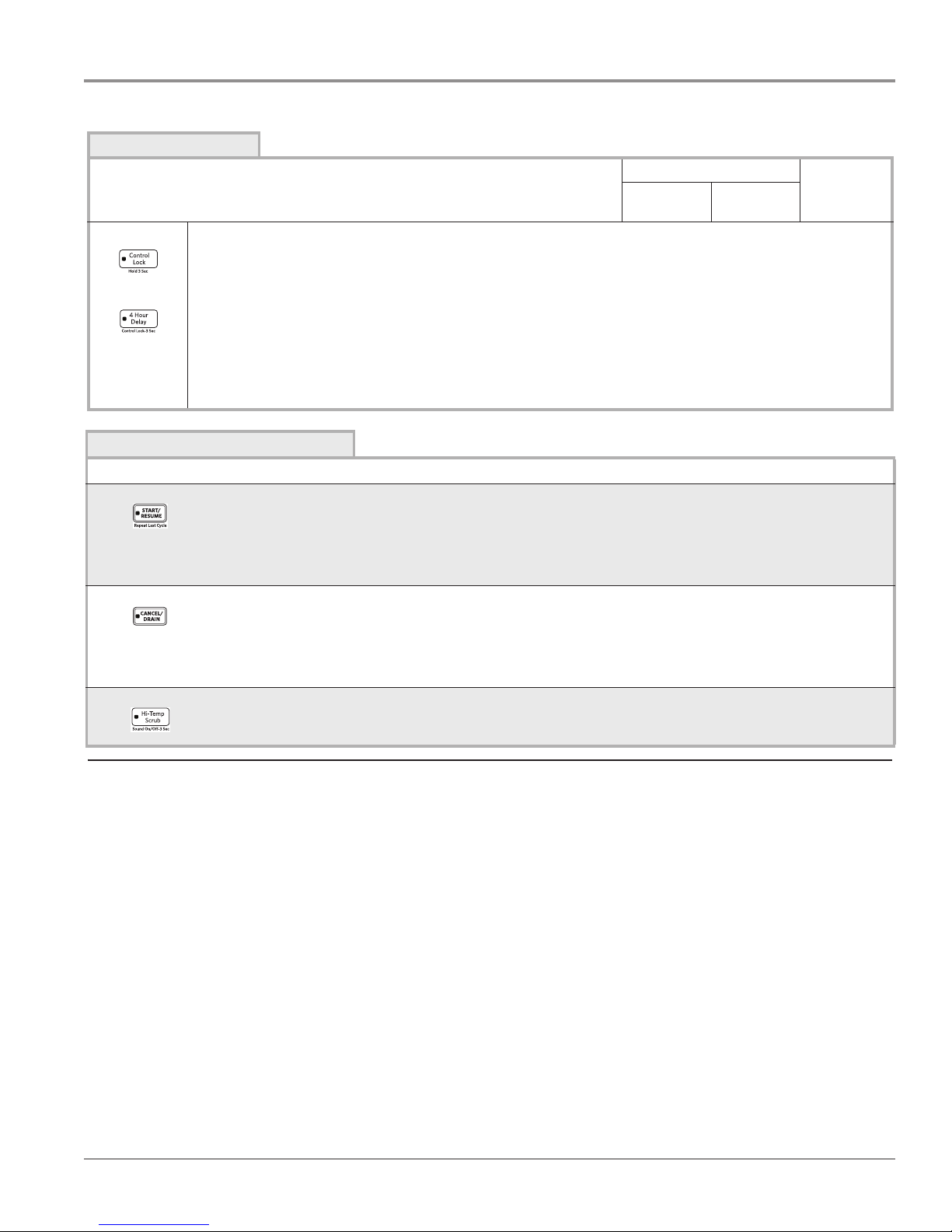

OPTION SELECTIONS

OPTIONS CAN BE

Control Lock Avoids unintended use of the dishwasher between cycles, or cycle and option changes during a cycle.

To turn on Lock, press and hold CONTROL LOCK or 4 HOUR DELAY (depending on model) for 3 seconds. The Control

Lock light will stay on for a short time, indicating that it is activated, and all buttons are disabled. If you press any button

or

CONTROLS AND CYCLE STATUS

CONTROL PURPOSE COMMENTS

while your dishwasher is locked, the light flashes 3 times. The dishwasher door can still be opened/closed while the

controls are locked.

NOTE: You may need to disable Sleep Mode by pressing either START/RESUME or CANCEL, or by opening and

closing the door before you are able to turn Control Lock off.

To turn off Control Lock, press and hold CONTROL LOCK or 4 HOUR DELAY (depending on model) for 3 seconds. The

light turns off.

NOTE: If your model requires you to press and hold 4 HOUR DELAY to lock the controls, the Control Lock LED will be

on or off to indicate if Control Lock is active or not.

To start or resume a

wash cycle

To reset any cycle or

options during

selection.

To cancel a wash

cycle after it's

started.

To turn the audible

tones on or off.

SELECTED WITH

If the door is opened during a cycle or the power is interrupted, the Start/Resume indicator

flashes. The cycle will not resume until the door is closed and START/RESUME is pressed.

NOTE: If the Start/Resume button is located on top of door, push door firmly closed within

3 seconds of pressing START/RESUME. If the door is not closed within 3 seconds, the

Start/Resume button LED will flash, an audible tone will be heard, and the cycle will not

start.

Press and hold CANCEL/DRAIN to reset any control selections made.

See “Canceling A Cycle After Dishwasher Is Started” and “Changing A Cycle After

Dishwasher Is Started” sections.

Press and hold the Hi-Temp Scrub button for 3 seconds to turn the audible tones on or off.

Only audible tones for confirming button presses can be turned on/off. Important audible

tones, such as indicating a cycle has been interrupted, cannot be deactivated.

WHAT IT DOES ADDED TIME TO CYCLE ADDED

TYPICAL MAX

OPERATION

WATER

GALLONS

(LITERS)

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

n

2-7

Page 20

OPERATION

Dishwasher Feedback Section

Control Lock Avoids unintended use of the dishwasher between cycles, or cycle and option changes during a cycle.

To turn on Lock, press and hold CONTROL LOCK or 4 HOUR DELAY (depending on model) for 3 seconds. The Control

Lock light will stay on for a short time, indicating that it is activated, and all buttons are disabled. If you press any button

while your dishwasher is locked, the light flashes 3 times. The dishwasher door can still be opened/closed while the

controls are locked.

NOTE: You may need to disable Sleep Mode by pressing either START/RESUME or CANCEL, or by opening and

closing the door before you are able to turn Control Lock off.

To turn off Control Lock, press and hold CONTROL LOCK or 4 HOUR DELAY (depending on model) for 3 seconds. The

light turns off.

NOTE: If your model requires you to press and hold 4 HOUR DELAY to lock the controls, the Control Lock LED will be

on or off to indicate if Control Lock is active or not.

CONTROLS AND CYCLE STATUS

CONTROL PURPOSE COMMENTS

To start or resume a

wash cycle

If the door is opened during a cycle or the power is interrupted, the Start/Resume indicator

flashes. The cycle will not resume until the door is closed and START/RESUME is pressed.

NOTE: If the Start/Resume button is located on top of door, push door firmly closed within

3 seconds of pressing START/RESUME. If the door is not closed within 3 seconds, the

Start/Resume button LED will flash, an audible tone will be heard, and the cycle will not

start.

To reset any cycle or

options during

selection.

To cancel a wash

cycle after it's

started.

Press and hold CANCEL/DRAIN to reset any control selections made.

See “Canceling A Cycle After Dishwasher Is Started” and “Changing A Cycle After

Dishwasher Is Started” sections.

To turn the audible

tones on or off.

Press and hold the Hi-Temp Scrub button for 3 seconds to turn the audible tones on or off.

Only audible tones for confirming button presses can be turned on/off. Important audible

tones, such as indicating a cycle has been interrupted, cannot be deactivated.

OPTION SELECTIONS

OPTIONS CAN BE

SELECTED WITH

WHAT IT DOES ADDED TIME TO CYCLE ADDED

WATER

GALLONS

(LITERS)

TYPICAL MAX

or

Canceling A Cycle

4. Press and hold CANCEL/DRAIN twice to reset the control.

5. Select new cycles and options.

Dishwasher Feedback Section

CONTROLS AND CYCLE STATUS

CONTROL PURPOSE COMMENTS

1. Open the door slightly to stop the cycle. Wait for the spraying

2. Press and hold Cancel/Drain button once. The Cancel/Drain

3. Close the door and the dishwasher starts a drain cycle (if water

Changing A Cycle After Dishwasher Is Started

1. You can interrupt a cycle and restart your dishwasher from the

2. Open the door slightly to stop the cycle. Wait for the spraying

3. Check that detergent dispenser cover is still closed. If cover is

action to stop before completely opening the door.

light will light up.

remains in bottom of dishwasher). Let the dishwasher drain

completely. The Cancel/Drain light turns off after 2 minutes.

beginning using the following procedure.

action to stop, then open the door completely.

open, you will need to refill the detergent dispenser before

restarting your new cycle.

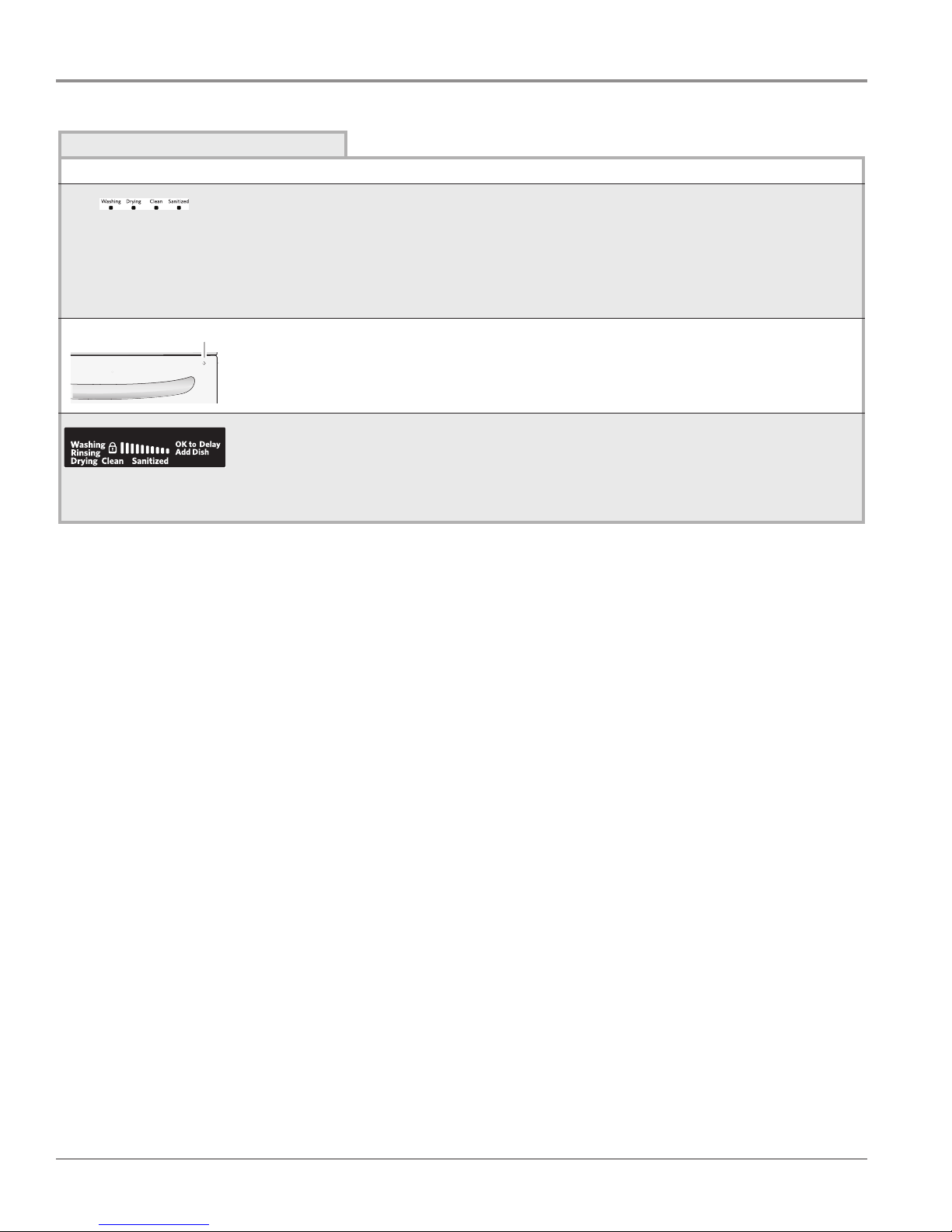

The Cycle Status Indicator

Lights are used to follow the

progress of the dishwasher

cycle. Located on the front

of the dishwasher for front

control models, and located

on the top of the door for

hidden control models.

The Front Indicator Light or

A

Single Exterior Light (A)

shows progress of your

dishwasher cycle by color

(for hidden control models

only).

The Cycle Status Display is

used to follow the progress

of the dishwasher cycle, and

to show other information.

(Available on some models

instead of Cycle Status

Indicator Lights)

Clean indicator glows when a cycle is finished.

If you select the Sani Rinse option, when the Sani Rinse cycle is finished,

the Sanitized indicator glows. If your dishwasher did not properly sanitize

your dishes, the light flashes at the end of the cycle. This can happen if the

cycle is interrupted, or the water could not be heated to the required

temperature.

The Clean and Sanitized lights go off when you open and close the door or

press and hold CANCEL.

The light will be blue if the dishwasher is washing or rinsing. The light will

be red when the dishwasher is drying. The light will be green to indicate

that the cycle is complete. If the Front Indicator Light is blinking, see

“Troubleshooting” section.

The indicators will inform you if you are able to add a dish to the cycle after

it has started. It will also inform you if the dishwasher is washing, rinsing,

drying, complete, and/or sanitized. They will show whether the control is

locked and/or the delay option is selected. A series of bars will count down

the duration of the cycle remaining from left to right. Each bar equals

approximately 24 minutes of cycle length. The bars will also count down

the delay feature from left to right, and the delay indicator will be activated.

6. Press START/RESUME.

Adding A Dish After Dishwasher Is Started

1. Check if Add a Dish indicator is lit. (Available on some models.

Otherwise, proceed to Step 2.)

2. Open the door slightly to stop the cycle. Wait for the spraying

action to stop, and then open the door completely.

3. Check whether the detergent dispenser cover is still closed. If

it is open, the wash cycle has already started and adding a

dish is not recommended.

4. If detergent has not yet been used (detergent dispenser cover

is closed), you may add a dish.

5. Press START/RESUME.

2-8 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 21

Dishwasher Features

Canceling A Cycle

1. Open the door slightly to stop the cycle. Wait for the spraying

action to stop before completely opening the door.

2. Press and hold Cancel/Drain button once. The Cancel/Drain

light will light up.

3. Close the door and the dishwasher starts a drain cycle (if water

remains in bottom of dishwasher). Let the dishwasher drain

completely. The Cancel/Drain light turns off after 2 minutes.

Changing A Cycle After Dishwasher Is Started

1. You can interrupt a cycle and restart your dishwasher from the

beginning using the following procedure.

2. Open the door slightly to stop the cycle. Wait for the spraying

action to stop, then open the door completely.

3. Check that detergent dispenser cover is still closed. If cover is

open, you will need to refill the detergent dispenser before

restarting your new cycle.

4. Press and hold CANCEL/DRAIN twice to reset the control.

5. Select new cycles and options.

6. Press START/RESUME.

Adding A Dish After Dishwasher Is Started

1. Check if Add a Dish indicator is lit. (Available on some models.

Otherwise, proceed to Step 2.)

2. Open the door slightly to stop the cycle. Wait for the spraying

action to stop, and then open the door completely.

3. Check whether the detergent dispenser cover is still closed. If

it is open, the wash cycle has already started and adding a

dish is not recommended.

4. If detergent has not yet been used (detergent dispenser cover

is closed), you may add a dish.

5. Press START/RESUME.

Dishwasher Features

Your KitchenAid dishwasher may have some or all of these features.

right-hand side of the

such

OPERATION

ProScrub® Option Wash Area

The ProScrub® option wash area is located at the back of the lower

level rack.

NOTE: You must select the ProScrub

Make sure items do not interfere with the water feed tube, spray

arms, or ProScrub

■ Keep the last tine row in the back of the lower rack in the

60° angled position when using the ProScrub

■ Load pans, casserole dishes, etc. in the back of the lower dish

rack with the soiled surfaces facing the ProScrub

and resting on the last row of tines in the angled position

■ Only one row of items may face the ProScrub

Stacking, overlapping or nesting items will keep the ProScrub

spray jets from contacting all of the surfaces.

®

spray jets.

®

option to use this feature.

®

option.

®

spray jets.

Silverware Basket

Use the slots in the covers to

keep your silverware separated

for optimum wash. There are

specially designed slots (small

round holes) for chopsticks. Mix

silverware types to keep them

separated. Load knives down,

forks up, and alternate spoons,

for best cleaning results.

NOTE: If your silverware

does not fit into the

designated slots, flip the

covers up and push them

down into the basket.

®

spray jets,

CULINARY CADDY® Utensil Basket

Use the utensil basket to hold specialty

cooking utensils (serving spoons,

spatulas, and similar items), or overflow

silverware items.

The basket hangs on the bottom rack in

the right-hand corner. Load the basket

while it is on the bottom rack or remove

the basket for loading on a counter or

table.

NOTE: Spin the spray arms. Be sure

items in the basket do not stop the

rotation of the spray arms.

SURE-HOLD® Cup and Stemware Holder

Fold down the extra shelf on the left-hand or

mid level rack to hold additional cups, stemware or long items

as utensils and spatulas.

®

NOTE: Remove the culinary tool basket(s) when washing tall

stemware or other tall items in the top rack.

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

n

2-9

Page 22

OPERATION

ess the tab on the track in and pull up the front end

move the back end of the rack, by pulling the back end out

place.

B

Dishwasher Features (continued)

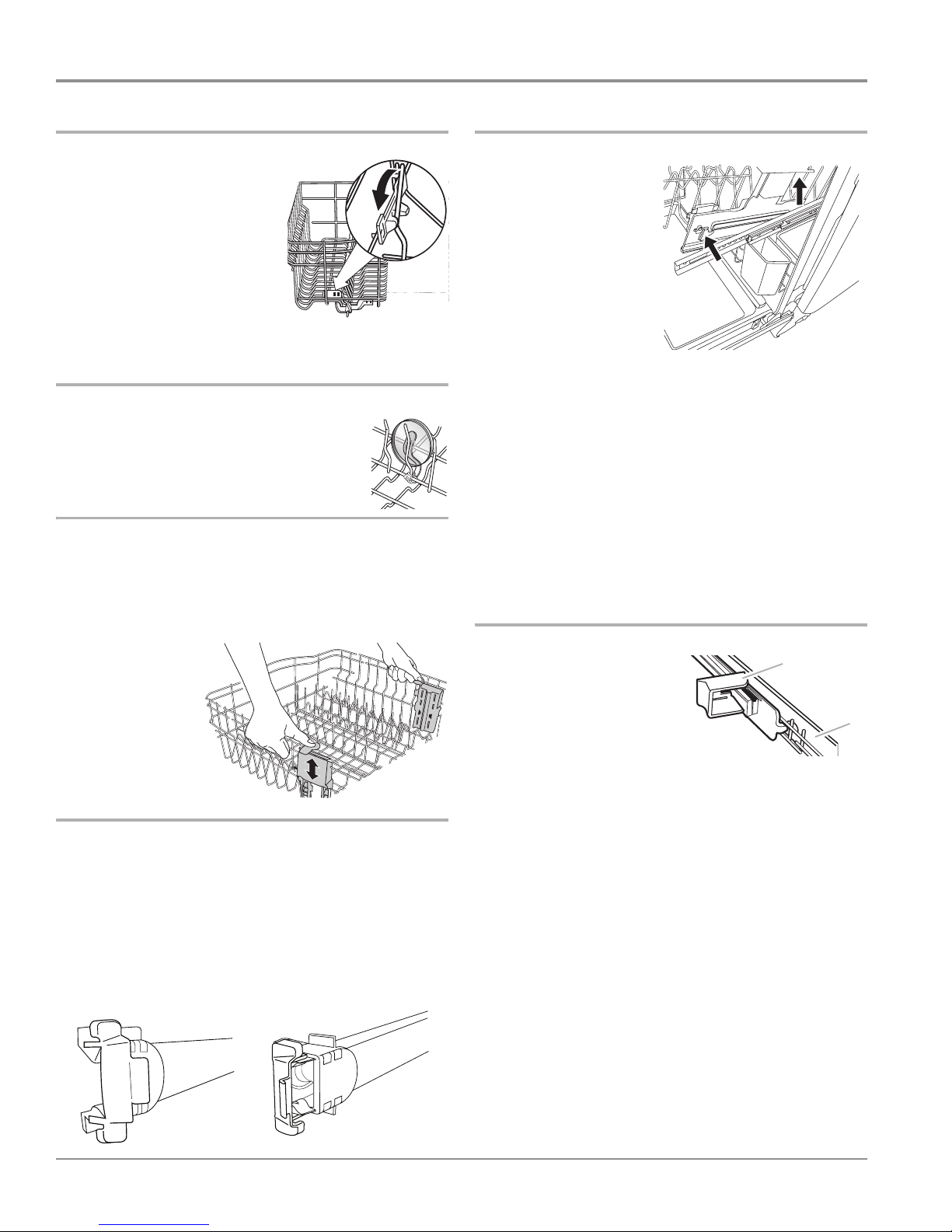

FLEXI-FOLD DOWN™ Flexible Tines

The row of tines on the left-hand and

right-hand sides of the top rack can

be adjusted to make room for a

variety of dishes.

To adjust the fold-down tines:

1. Grasp the tip of the tine that is in

the tine holder.

2. Gently push the tine out of the

holder.

3. Lay the tines down, toward the

center of the rack.

NOTE: The bottom rack may also have 1 or 2 rows of flexible tines

located in the back of the rack. Follow the same instructions to

adjust.

SURE-HOLD® Light Item Clips

The light item clips hold lightweight plastic items

such as cups, lids, or bowls in place during

washing.

To move a clip:

1. Pull the clip up and off the tine.

2. Reposition the clip on another tine.

Premium Adjustable 2-Position Top Rack

After removing the culinary tool rack, you can raise or lower the top

rack to fit tall items in either the top or bottom rack. Adjusters are

located on each side of the top rack. Each adjuster has 2 preset

positions.

To raise the rack,

is in the Up position and level.

To lower the rack,

press both rack

adjusters and slide the

rack to its Down

position and level.

press both rack adjusters and lift the rack until it

Removable Top Rack (for SatinGlide® rails)

The removable top rack allows you to wash larger items such as

pots, roasters, and cookie sheets in the bottom rack.

IMPORTANT: Remove dishes prior to removing the top rack from

dishwasher.

To remove the rack

To gain access to the track stops, pull the upper rack forward

about halfway out of the tub.

To open, flip the track stop toward the outside of the tub.

After opening both track stops, pull top rack out of the rails.

Removable Top Rack (for SatinGlide® Max rails)

The removable top rack

allows you to wash larger

items such as pots, roasters,

and cookie sheets in the

bottom rack.

IMPORTANT: Remove

dishes prior to removing the

top rack from the

dishwasher.

To remove the rack:

To gain access to the

removable tabs on the

tracks/rails, pull the upper

rack forward about halfway out of the tub.

On one side, pr

of the rack out of the track. Then repeat this step on the other side

to completely remove the front end of the rack.

Then re

with a slightly forward, and then upward motion.

To replace the rack:

Pull the tracks forward about halfway out of the tub.

Along the sides of the racks are round attachment tabs. Align the

rack's back end attachment tabs with the cutout in the track. Push

down into place.

Pull the tracks completely out, and align the rack's front end

attachment tabs with the cutout in the track. Push down into

You will hear a snap when the front end of the rack is secured into

place on each side.

Removable Culinary Tool Rack (3rd level rack)

The removable culinary tool rack

(3rd level rack) allows you to wash

larger items in the upper rack, or

remove both the culinary tool rack

and top rack to wash larger times

in the lower rack. See “Removable

Top Rack” section.

To remove the rack:

1. To access track stops, pull the

rack forward until it stops and

clicks into place.

2. To open track stops, flip the track stop to the outside of the

track.

3. After opening both track stops, slide front wheels up and out

of the slot in track. Continue to pull rack forward in track and

slide the back wheels up and out of the track.

4. Close track stops.

5. Slide rack tracks back into dishwasher.

To replace the rack:

1. Gently pull rack tracks forward in dishwasher until they stop

and click into place.

2. To open track stops, flip the track stop to the outside of the

track.

3. Place the back rack rollers on each side of the rack into the

track slot and roll the rack back into the tracks.

4. Insert front rack rollers on each side of the rack into the rack

slots.

5. Close track stops on both sides of rack and slide rack back

into dishwasher.

A

A. Track stop

B. Track

2-10 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Track stop openTrack stop closed

Page 23

Dishwasher Features (continued)

IMPORTANT: When you are using the culinary tool baskets in the

OPERATION

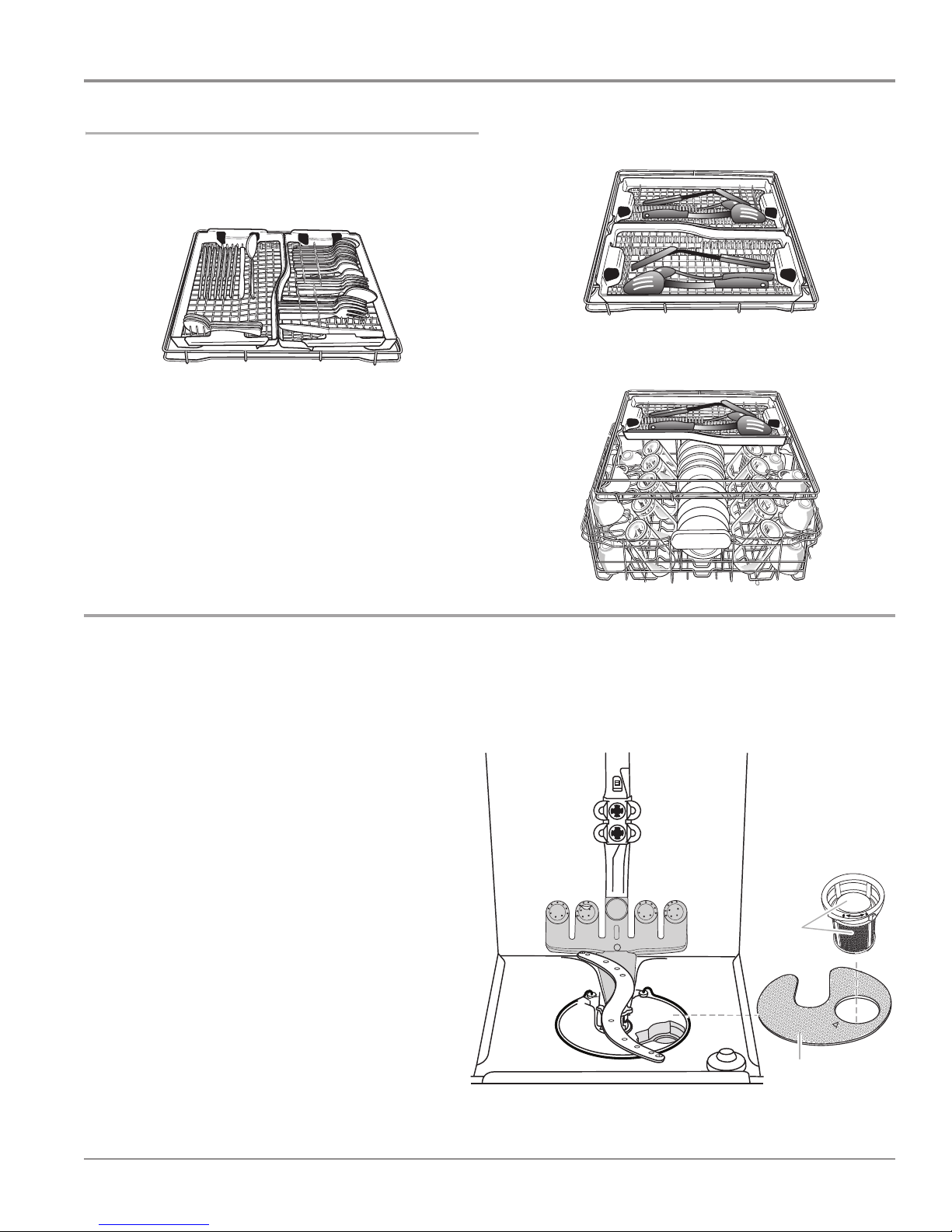

Culinary Tool Rack (3rd level rack)

The culinary tool rack is designed with 2 movable baskets to hold

extra silverware, knives and cooking utensils.

Install the baskets in this up position when you have extra

silverware and flatware to wash.

Up position

Install the baskets in this down position when you have extra

silverware, knives, or utensils requiring more room to wash.

down position, the top rack must also be in the lowest position.

Down position

Remove the front basket in the down position, when you are using

the cup shelves or other tall items in the top rack for more room.

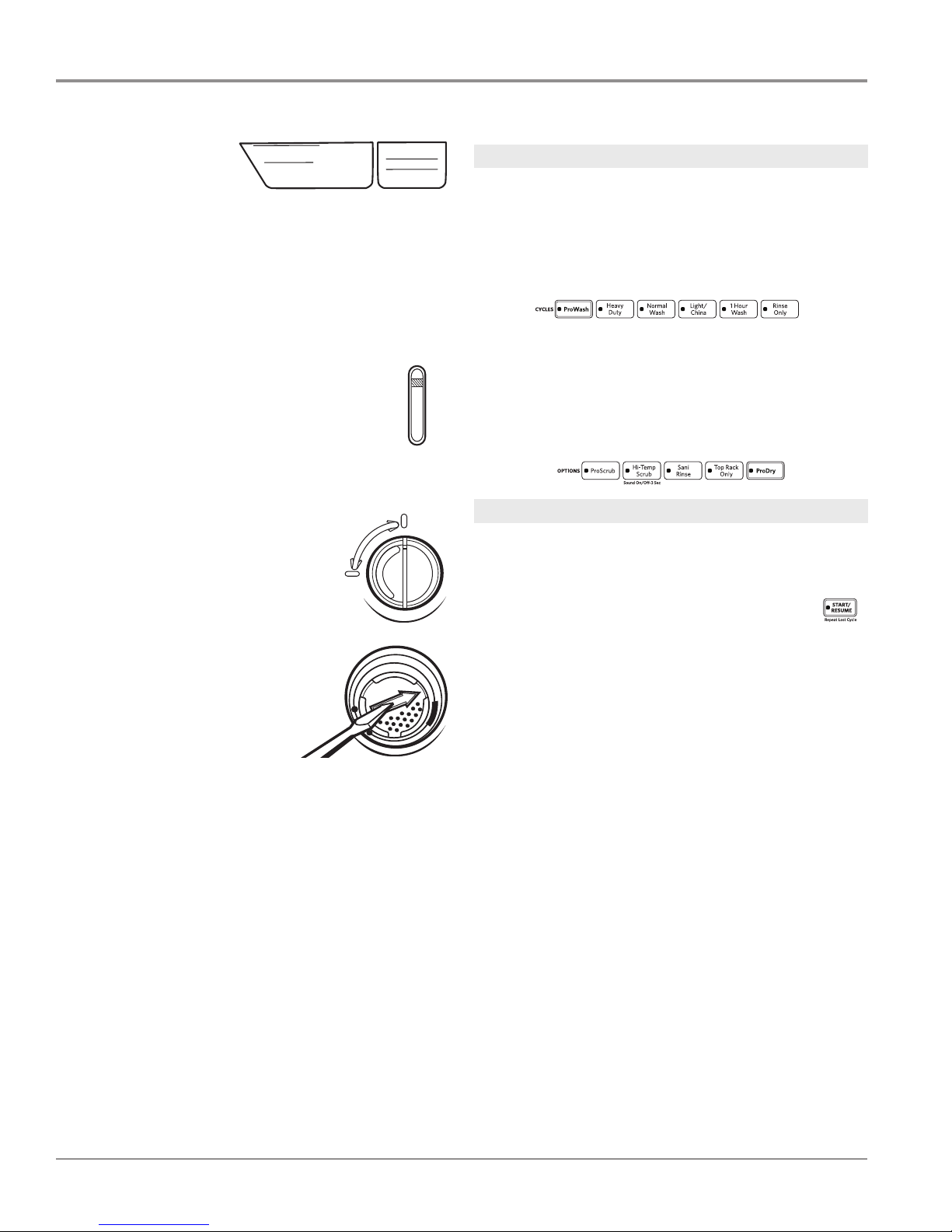

Filtration System

Filtration System

Your dishwasher has the latest technology in dishwasher filtration. This triple filtration system minimizes sound and optimizes water and

energy conservation while providing superior cleaning performance. Throughout the life of your dishwasher, the filter will require

maintenance to sustain peak cleaning performance.

The triple filter system consists of 2 parts, an upper filter

assembly and a lower filter.

■ The upper filter assembly keeps oversized items and

foreign objects, along with very fine food particles, out of

the pump.

The lower filter keeps food from being recirculated onto

■

your dishware.

The filters may need to be cleaned when:

■ Visible objects or soils are on the upper filter assembly.

■ There is degradation in cleaning performance (that is,

soils still present on dishes).

■ Dishes feel gritty to the touch.

Upper Filter

Assembly

W

N

O

&

D

T

H

U

S

R

U

N

P

L

O

C

O

L

N

U

K

It is very easy to remove and maintain the filters. The chart

below shows the recommended cleaning frequency.

Lower Filter

K

C

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

n

2-11

Page 24

OPERATION

Filtration System (continued)

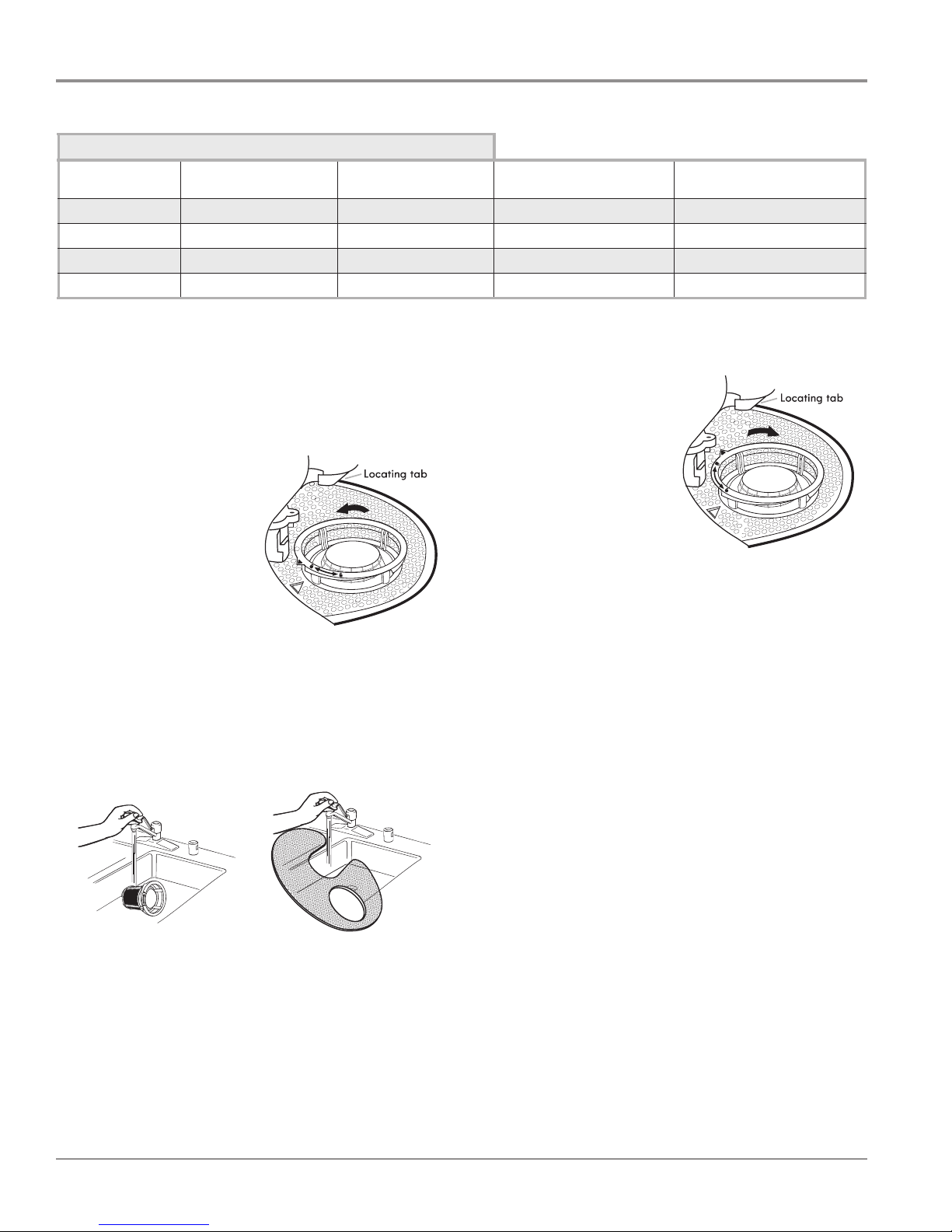

RECOMMENDED TIME INTERVAL TO CLEAN YOUR FILTER

Number of Loads

Per Week

1-3 Once per year Once per year Twice per year Every two months

4-7 Once per year Once per year Twice per year Once per month

8-12 Once per year Twice per year Every three months Every two weeks

13-14 Once per year Twice per year Every three months Once per week

*Manufacturer's recommendation: This practice will conserve the water and energy that you would have used to prepare your dishes. This

will also save you time and effort.

Very Hard Water

If you have hard water (above 15 grains), clean your filter at least

once per month. Building up of white residue on your dishwasher

indicates hard water. For tips on removing spots and stains, see

“Troubleshooting” section.

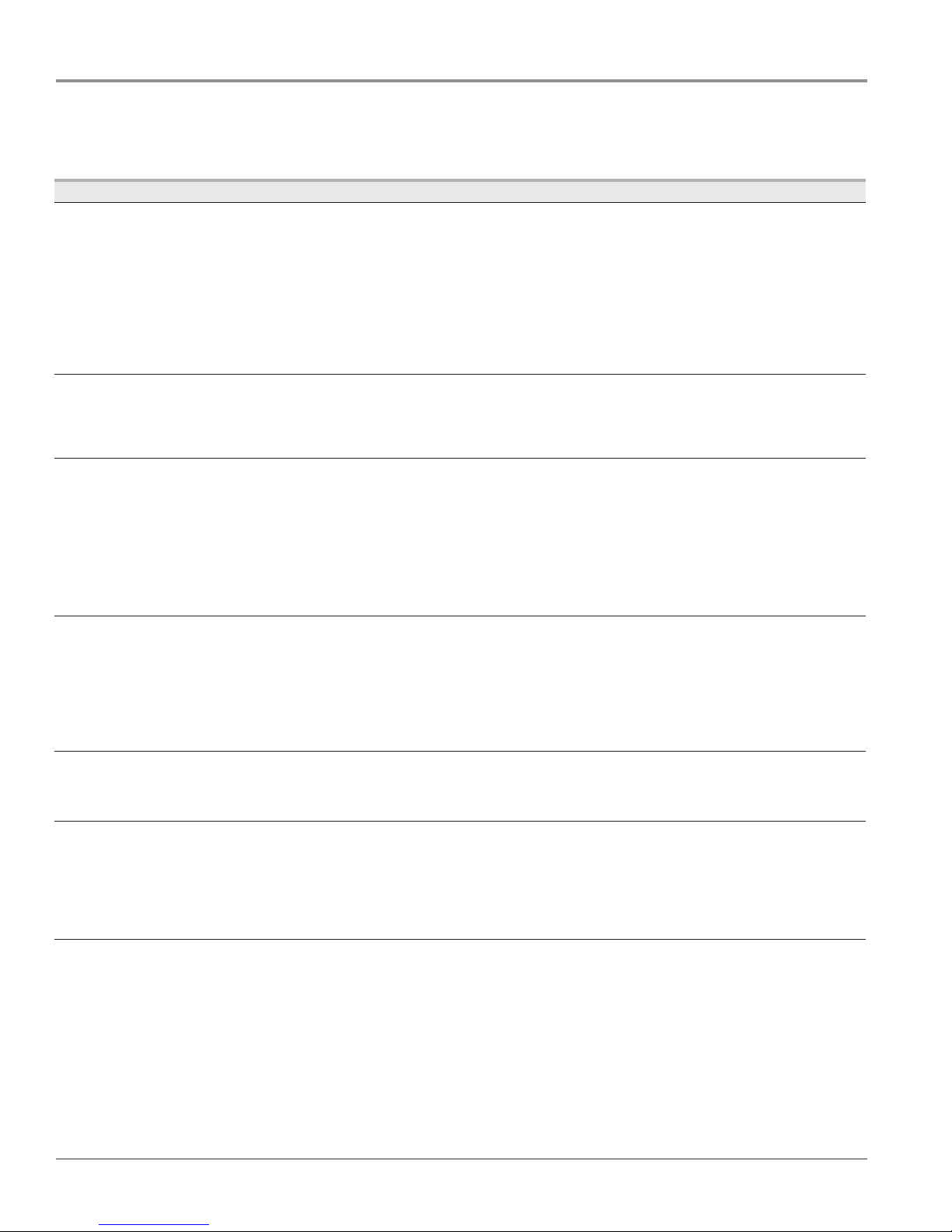

Filter Removal Instructions

1. Turn the upper filter

assembly ¹⁄₄ turn

counterclockwise and lift

out.

2. Grasp the lower filter in the

circular opening, lift

slightly, and pull forward to

remove.

3. Clean the filters as shown

below.

Cleaning Instructions

IMPORTANT: Do not use wire brush, scouring pad, etc., as they

may damage the filters.

Rinse filter under running water until most soils are removed. If you

have hard-to-remove soils or calcium deposits from hard water, a

soft brush may be required.

If you wash

before loading

To remove upper filter assembly

If you scrape and rinse

before loading

If you only scrape

before loading*

If you do not scrape or rinse

before loading

Filter Reinstallation Instructions

1. Noting the previous

illustrations, place the

lower filter under the

D

H

O

S

W

U

N

P

&

T

U

R

L

O

C

K

U

N

K

C

O

L

N

locating tabs in the bottom

of the dishwasher so the

round opening for the

upper filter assembly lines

up with the round opening

in the bottom of the tub.

O

C

K

U

N

To replace upper filter assembly

P

L

U

S

H

D

O

W

N

&

T

U

R

L

O

C

K

N

2. Insert the upper filter assembly into the circular opening in

the lower filter.

3. Slowly rotate the filter clockwise until it drops into place.

Continue to rotate until the filter is locked into place. If the

filter is not fully seated (still turns freely), continue to turn

the filter clockwise until it drops and locks into place.

NOTE: The upper filter assembly arrow does not have to

align with the arrow in the lower filter as long as the filter is

locked.

IMPORTANT: To avoid damage to dishwasher, do not operate your

dishwasher without the filters properly installed. Be sure the lower

filter is securely in place and the upper filter assembly is locked into

place. If the upper filter assembly turns freely, it is not locked into

place.

L

O

C

K

P

U

S

H

D

O

W

N

&

T

U

U

R

N

N

L

O

C

K

2-12 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 25

Dishwasher Care

Cleaning

Cleaning the exterior

OPERATION

Dishwasher Care

In most cases, regular use of a soft, damp cloth or sponge and a mild detergent is all

that is necessary to keep the outside of your dishwasher looking nice and clean. If your

dishwasher has a stainless steel exterior, a stainless steel cleaner is recommended.

Cleaning the interior

Drain Air Gap

Hard water minerals can cause a white film to build up on the inside surfaces, especially

just beneath the door area.

Do not clean the dishwasher interior until it has cooled. You may want to wear rubber

gloves. Do not use any type of cleanser other than dishwasher detergent because it may

cause foaming or sudsing.

To clean interior

Make a paste with powdered dishwasher detergent on a damp sponge and clean.

OR

Use liquid automatic dishwasher detergent and clean with a damp sponge.

OR

See the vinegar rinse procedure in “Cloudy or Spotted Dishware (and Hard Water

Solution)” in “Troubleshooting” section.

NOTE: Run a normal cycle with dishwasher detergent after cleaning the interior.

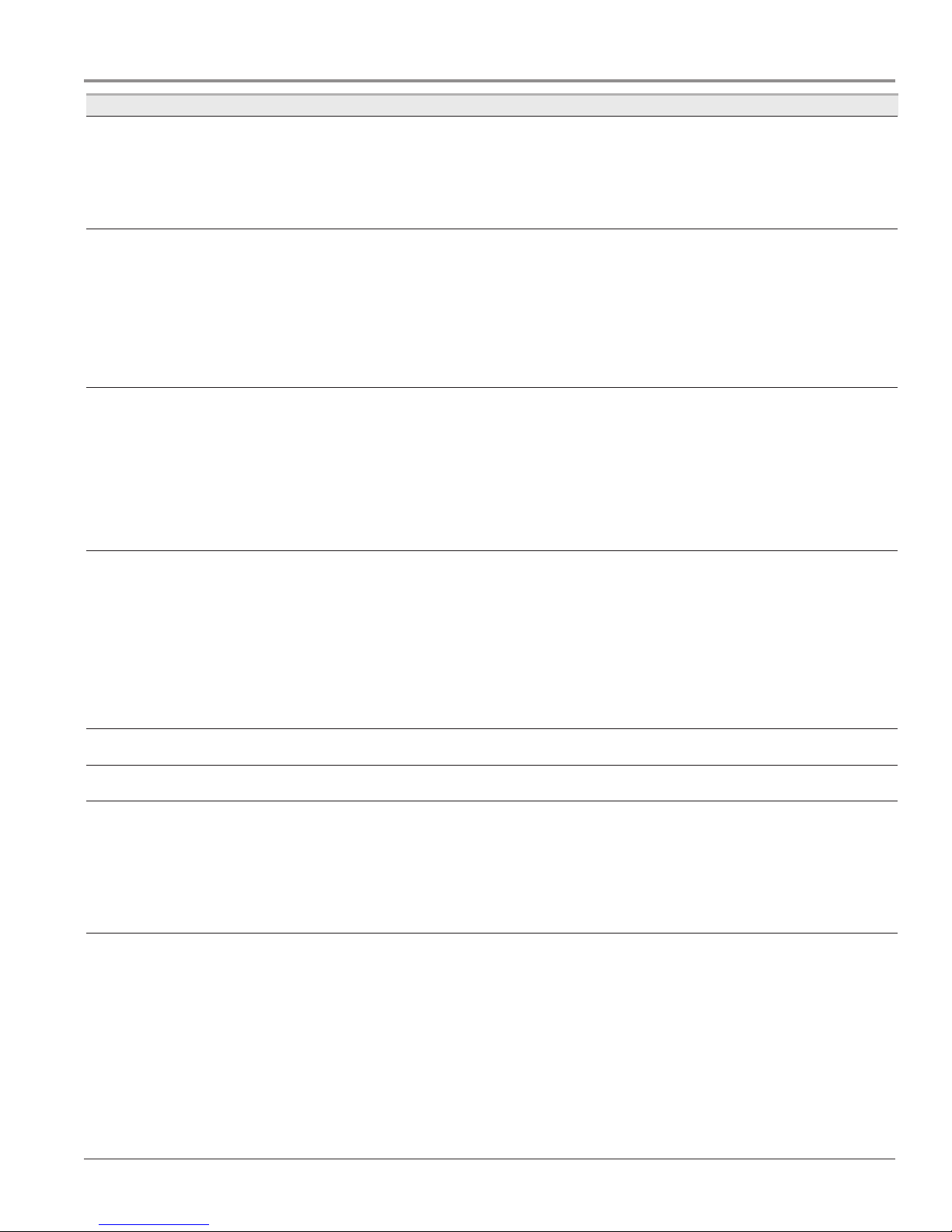

Some state or local plumbing codes require the addition of a drain air gap between a

built-in dishwasher and the home drain system. Check the drain air gap when your

dishwasher is not draining well.

The drain air gap is usually located on top of the sink or countertop near the dishwasher.

NOTE: The drain air gap is an external plumbing device that is not part of your

dishwasher. The warranty provided with your dishwasher does not cover service costs

directly associated with the cleaning or repair of the external drain air gap.

To clean the drain air gap

Storing

Storing for the summer

Storing for the winter

Clean the drain air gap periodically to ensure proper drainage of your dishwasher. With

most types, you lift off the chrome cover. Unscrew the plastic cap. Then check for any

soil buildup. Clean if necessary.

If your dishwasher is not in use during the summer months, turn off the water supply and

power supply to the dishwasher.

Avoid possible water damage to your home and dishwasher due to freezing water lines.

If your dishwasher is left in a seasonal dwelling or could be exposed to near freezing

temperatures, have your dishwasher winterized by authorized service personnel.

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

n

2-13

Page 26

OPERATION

Troubleshooting

First try the solutions suggested here or visit our website and reference FAQs (Frequently Asked Questions)

Consumer Troubleshooting Guide

In the U.S.A., www.kitchenaid.com In Canada, www.kitchenaid.ca

PROBLEM SOLUTION

DISHWASHER DOES

NOT RUN

DETERGENT REMAINS IN

THE DISPENSER OR

TABLET IS ON BOTTOM

OF TUB

CYCLE RUNS TOO LONG NOTES:

DISHWASHER NOT DRYING NOTE: Plastic and items with nonstick surfaces are difficult to dry because they have a porous

WILL NOT FILL Be sure the water is turned on to the dishwasher.

WATER REMAINS IN THE

TUB/WILL NOT DRAIN

HARD WATER

(WHITE RESIDUE ON

DISHWASHER INTERIOR OR

GLASSWARE)

NOTE: It is normal for the dishwasher to repeatedly pause several times during a cycle.

If the Start/Resume light is blinking, close the door and push START/RESUME.

Be sure the door is closed and latched.

Be sure you have disabled Sleep Mode by pressing either START/RESUME or CANCEL, or opening

and closing the door before selecting your cycle/option.

Check that there is not an interference with large casserole dishes and the wash system at the back

of the dishwasher. Adjust loading as necessary to ensure door is closed and latched.

Be sure you have selected a cycle. (See “Cycles and Options Descriptions” section.)

Be sure there is power to the dishwasher. A circuit breaker or fuse may have tripped.

If lights other than Start/Resume blink and the unit will not run, you will need to call for service.

Check for dishware such as cookie sheets, cutting boards, or large containers, etc., that may be

blocking the detergent dispenser from opening properly.

Be sure your detergent is fresh and lump free.

Be sure the cycle has completed (the Clean light is on). If it has not completed, you will need to

resume the cycle by closing the door and pressing START/RESUME.

■ To use less water and reduce energy consumption you will encounter cycles that typically run for

■ A water heater setting of 120°F (49°C) is best, the dishwasher will delay longer while heating

■ Some options will add time to the cycle. (See “Cycles and Options Descriptions” section.) The

Try the 1 Hour Wash cycle.

Run the hot water at a faucet close to the dishwasher before starting the cycle.

surface which tends to collect water droplets. Towel drying may be necessary.

Use of rinse aid along with the ProDry™ or Heat Dry option is needed for proper drying.

Proper loading of items can affect drying. (See specific loading instructions within this guide.)

Glasses and cups with concave bottoms hold water. This water may spill onto other items when

unloading.

■ Unload the bottom rack first.

■ Locate these items on the more slanted side of the rack for improved results.

Check that the float is free from obstructions. (See “Parts and Features.”)

Check for suds in the dishwasher. If foam or suds are detected, the dishwasher may not operate

properly or may not fill with water. (See “Blinking Lights” in “Troubleshooting” section.)

Be sure the cycle has completed (the Clean light is on). If it has not, you will need to resume the cycle

by closing the door and pressing START/RESUME.

If dishwasher is connected to a food waste disposer, be sure the knockout plug has been removed

from the disposer inlet.

Check for kinks in the drain hose.

Check for food obstructions in the drain or disposer.

Check your house fuse or circuit breaker.

NOTE: Extremely hard water mineral deposits can cause damage to your dishwasher and make it

difficult to achieve good cleaning. A water softener is strongly recommended if your hardness is

15 grains or more. If a water softener is not installed, the following steps may help:

Use a commercial cleaner designed for dishwashers once per month.

Clean the upper and lower filters at least once per month. (See “Cleaning Instructions” in the

“Filtration System” section.)

Always use a rinse aid.

Always use a high-quality, fresh detergent.

Use a detergent booster/water softener additive designed for dishwashers.

to possibly avoid the cost of a service call.

up to 3 hours.

cooler water.

ProDry™ or Heat Dry option adds approximately ¹⁄₂ hour.

2-14 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 27

OPERATION

PROBLEM SOLUTION

ODORS NOTE: If the dishwasher is not used daily, you can run a rinse cycle with the partial load daily until a

NOISY NOTES:

FOOD SOILS REMAIN

ON DISHES

DISHES DIRTY/SUDS IN

DISHWASHER/CYCLE NOT

COMPLETE

DID NOT SANITIZE If the sanitized light is blinking, the load is NOT sanitized. The cycle was interrupted in the final rinse,

DAMAGE TO DISHWARE Improper loading can cause dishes to become chipped or damaged. (See specific loading

BLINKING LIGHTS Blinking LED's will occur when the cycle is paused or when the cycle has been interrupted by

CLOUDY OR SPOTTED

DISHWARE (AND HARD

WATER SOLUTION)

full load is ready to run, or use the Top Rack Only option (on some models) for partial loads.

Run a vinegar rinse through the dishwasher by putting 2 cups (500 mL) of white vinegar in an upright

glass measuring cup in the lower rack. Run a normal cycle with the Heat Dry option turned off. Do

not use detergent.

The dishwasher may not be draining properly, see “Water Remains In The Tub/Will Not Drain” in the

“Troubleshooting” section.

■ Surging sounds can occur periodically throughout the cycle while the dishwasher is draining.

Normal water valve hissing may be heard periodically.

■

■ A normal snap sound may be heard when the detergent dispenser opens during the cycle and

when the door is opened at the end of the cycle.

■ Improper installation will affect noise levels.

Be sure the filters are properly installed.

A thumping sound may be heard if items extend beyond the racks and interfere with the wash arms.

Readjust the dishware and resume the cycle.

Be sure the dishwasher is loaded correctly. Improper loading can greatly decrease the washing

performance (see “Dishwasher Use” section).

Check filter to ensure it is properly installed. Clean it if needed. (See “Cleaning Instructions” in the

“Filtration System” section for details.)

Select the proper cycle and option for the type of soils. The ProWash™ or the Heavy Duty cycle with

the ProScrub

®

(on some models) option can be used for tougher loads.

Be sure the incoming water temperature is at least 120°F (49°C).

Use the proper amount of fresh detergent. More detergent is needed for heavier-soiled loads and

hard water conditions.

Scrape food from dishes prior to loading (do not prerinse).

If foam or suds are detected by the dishwasher sensing system, the dishwasher may not operate

properly or may not fill with water.

Suds can come from:

■ Using the incorrect type of detergent, such as dish detergent for hand washing dishes, laundry

detergent, or hand soap.

■ Not replacing the rinse aid dispenser cap after filling (or refilling) the rinse aid.

■ Using an excessive amount of dishwasher detergent.

Call for service.

If no water was present in the machine at any time during a heated wash cycle, the cycle will end and

the Clean LED will not come on. See “Will Not Fill” in the “Troubleshooting” section.

or the temperature for your water heater is set too low. Set your water heater to 120ºF (49°C).

instructions within this guide.)

opening the door. In this case, the Start/Resume button LED, the Cycle Status Indicator LED(s), and

the countdown bars on the Cycle Status Display all blink together to indicate that attention is

needed. See “Start or Resume a Cycle” in the “Dishwasher Use” section.

Blinking LED's can also occur when certain errors have been detected. In this case, the Clean/

Complete LED will blink 4 times in a row with a pause in between each set of blinks. When this error

occurs, the controls will lock out and not allow another cycle to be started.

Call for service.

NOTES:

■ Liquid rinse aid is necessary for drying and to reduce spotting.

■ Use the correct amount of detergent.

Confirm that the cloudiness is removable by soaking the item in white vinegar for 5 minutes. If the

cloudiness disappears, it is due to hard water. Adjust the amount of detergent and rinse aid. See

“Hard Water (White Residue On Dishwasher Interior Or Glassware)” in the “Troubleshooting” section.

If it does not come clear, it is due to etching (see below).

Be sure the incoming water temperature is set at 120°F (49°C).

Try using the High Temp and Sani Rinse options.

To remove spotting, run a vinegar rinse through the dishwasher.

■ Wash and rinse the affected dishware and load into dishwasher. Remove all silverware and metal

items. Put 2 cups (500 mL) of white vinegar in a glass measuring cup in the lower rack. Run a

normal cycle with the Heat Dry option turned off. No detergent is needed.

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

n

2-15

Page 28

OPERATION

PROBLEM SOLUTION

ETCHING (PERMANENT

CLOUDINESS)

LEAKING WATER Be sure dishwasher has been installed properly and is level.

TUB IS DISCOLORED NOTES:

This is an erosion of the surface of the glassware and can be caused by a combination of: water that

is too hot, from using too much detergent with soft water or by pre-washing. Detergent needs food

soil to act upon. If etching has occurred, the glassware is permanently damaged. To avoid further

etching, adjust the detergent amount to match the water hardness, stop pre-washing, and use water

heating options only when incoming water temperature is below 120°F (49°C).

Suds can cause the dishwasher to overflow. Measure the detergent accurately and use only

detergents designed for use in a dishwasher. Less detergent is needed in soft water. Try another

brand of detergent if sudsing continues.

To avoid rinse aid leaking from the dispenser, be sure the lid is securely attached and avoid

overfilling.

■ High iron content in the water can discolor the tub.

■ Tomato-based foods can discolor the tub or dishware.

■ A citrus-based cleaner can be used to clean.

Notes

2-16 n

KitchenAid 2013 Stainless Steel Tall Tub Dishwasher

Page 29

INSTALLATION

Section 3:

Installation

This secon provides installaon requirements and procedures

for the “KitchenAid Stainless Steel Tall Tub Dishwasher.”