KitchenAid KUD01, KAD-7 User Manual

TECHNICAL EDUCATION

KAD-7

For the way it's made.™

Inc.

KUD01

STAINLESS STEEL

48

DISHWASHER

JOB AID 4317288

INTRODUCTION

This Job Aid,

mation on the operation, diagnosis and repair of the KitchenAid KUD01 series Stainless Steel Dishwasher.

KUD01 STAINLESS STEEL DISHWASHERS

tion on design, features, operation, troubleshooting, and repair procedures.

KUD01 STAINLESS STEEL DISHWASHERS

has been compiled to provide the most recent informa-

, Part No. 4317288 provides specific infor-

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the KUD01 Stainless Steel Dishwasher.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the dishwasher to proper operational status.

TO THE INSTRUCTOR/INDEPENDENT STUDENT

This Job Aid is designed to be used with the video tape,

Part No. 4317287V.

ERS,

KITCHENAID CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

KUD01 STAINLESS STEEL DISHWASH-

© 2000 KitchenAid, Inc., St. Joseph, MI 49013

II

-- NOTES --

TABLE OF CONTENTS

Section One

INSTALLATION CONSIDERATIONS .................................................. 1

GENERAL CONSIDERATION.................................................................1

Section Two

THEORY OF OPERATION ................................................................. 3

CONTROL PANELS ................................................................................3

CYCLES AND CYCLE VARIATIONS ......................................................4

AUTOMATIC PURGE FILTRATION ........................................................ 5

CANCELING A CYCLE ........................................................................... 6

CHANGING A CYCLE .............................................................................6

OPTION SELECTIONS............................................................................7

CYCLE STATUS INDICATORS............................................................... 9

FUNCTION DESCRIPTION ................................................................... 10

Section Three

COMPONENT ACCESS ...................................................................13

COMPONENT LOCATION ....................................................................13

ACCESSING COMPONENTS IN THE DOOR .......................................14

ACCESSING COMPONENTS INSIDE THE TUB ..................................17

SERVICING THE SUMP ASSEMBLY ...................................................2 0

Section Four

TROUBLESHOOTING AND DIAGNOSIS ..........................................25

TROUBLESHOOTING CHART..............................................................25

COMMON CYCLE TIME CHART...........................................................27

HOW TO USE COMMON CYCLE TIME CHART .................................. 28

COMMON CYCLE TIME CHART NOTES .............................................32

RAPID ADVANCE FEATURE & DIAGNOSTIC CYCLES .....................36

DIAGNOSTIC CYCLE TIME CHART..................................................... 37

Section Five

TECH TIPS .................................................................................... 39

WIRING DIAGRAM ................................................................................39

STRIP CIRCUITS ...................................................................................40

ELECTRONIC CONTROL CONNECTOR PINS ....................................41

MODEL/SERIAL NUMBER PLATE .......................................................42

MODEL SPECIFIC SERVICE PARTS TABLE ......................................43

KEY PAD MATRIX.................................................................................43

SPECIFICATIONS .................................................................................44

WATER USAGE.....................................................................................44

WHAT TO DO IF THE DISHWASHER DOOR DOES NOT OPEN ........45

46

III

SAFETY

! WARNING

ELECTRICAL SHOCK HAZARD

Disconnect power before servicing the dishwasher.

Replace all panels before operating the dishwasher.

Failure to do so can result in death or electrical shock.

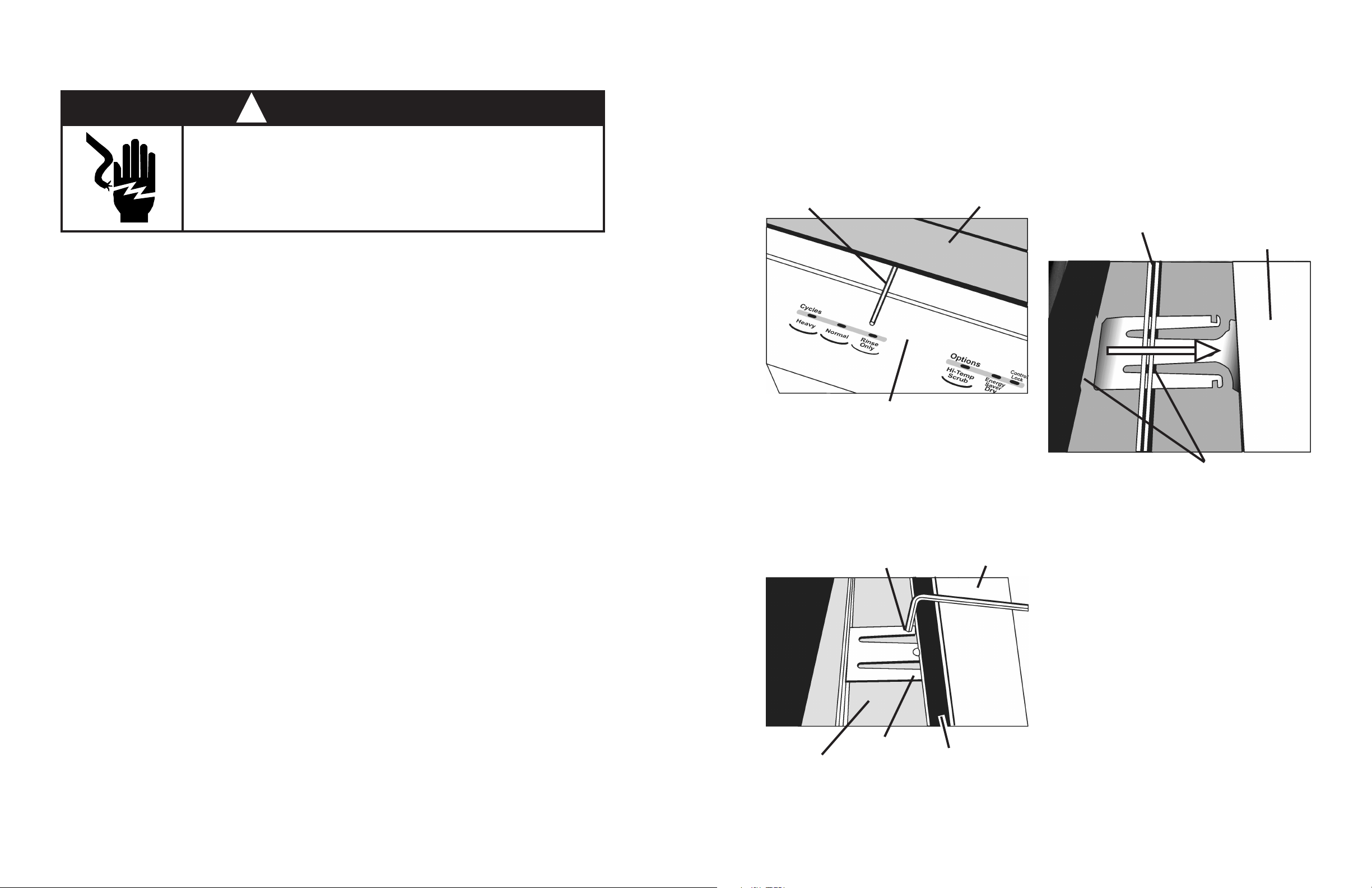

WHAT TO DO IF THE DISHWASHER DOOR DOES NOT OPEN

If the door latch assembly is damaged or malfunctions, the dishwasher door may not open. If this

occurs, the following procedure will open the dishwasher door and allow repairs to the door latch

assembly.

1. Insert an Allen wrench between the

countertop and the top of the console in

the vicinity of the door latch.

Allen Wrench

(Fig. 5-1)

Countertop

3. Open the door. The unsnapped latch

strike will remain attached to the door

catch and will be pulled out of the mount

ing slots in the support collar.

Cabinet Seal

Removed

(Fig. 5-3)

Top

of

Console

Console

Fig. 5-1

2. Turn the Allen wrench down and press

down on the latch strike retainer brackets

to release them from the support collar.

The latch strike retainer brackets are

snapped into the metal ridge on which

the cabinet seal is installed.

Press Here

(Fig. 5-2)

Top

of

Console

Mounting

Slots

Fig. 5-3

4. Remove the latch strike from the door latch

assembly.

5. Repair the door latch assembly.

6. Reinsert the latch strike into the slots in

the support collar and snap it into place.

(Fig. 3)

IV

Support

Collar

Press Here

Cabinet

Seal

Fig. 5-2

45

SECTION ONE

SPECIFICATIONS

ELECTRICAL SUPPLY: (Under Load) 60Hz, 120VAC

SUPPLY WATER FLOW RATE: (To Fill 2 Quarts (1.9 L) in 27 secs.) - 120psi Max., 20psi MIN.

SUPPLY WATER TEMPERATURE: 120° F to 160° F (49° C to 71° C)

WATER CHARGE: 1.8 Gal. (6.8 L) / First Fill

1.7 Gal. (6.5 L) / All Other Fills

LOWER SPRAY ARM ROTATION: 25 TO 40 RPM

UPPER SPRAY ARM ROTATION: 25 TO 35 RPM

APF DRAIN: .1 Gal. (.38 L) per 5 sec.

APF Pressure Switch Trip Point: 10 In. Water Column

HEATING ELEMENT HEATING RATE: 1°+ F Rise per Minute

WATER USAGE

Baked On Cookware Heavy, Normal

Soil Level

Sensed

High

Water

Usage

(gal/L)

8.8 -10.4/

33.4 -39.4

China - Light/China

Soil Level

Sensed

High

Water

Usage

(gal/L)

7.1-8.6/

26.9-32.5

INSTALLATION CONSIDERATIONS

GENERAL CONSIDERATIONS

For complete installation procedures see the “Installation Instructions” in the

literature packet provided with the dishwasher.

A video presentation,

4317280V, is available. This video covers the entire installation process.

Each location will present a different set of challenges that can be anticipated and solved before

installation begins.

• Check the planned location of the dishwasher.

• Easy access to hot water, drain line and electricity.

• Convenient access for loading. The dishwasher door should open and close freely.

• The opening under the counter should be square and the cabinet fronts should be perpendicular to the floor.

• Make sure the cabinet opening is free of intrusions such as braces or utility lines.

• Do not install the dishwasher on carpeted floors.

• An outside wall behind the dishwasher should be insulated to prevent the water line, inlet valve

and drain line from freezing and rupturing.

Key Features and Installation Considerations

, part number

Low

Quick Clean Up

First Fill

Water

Temp

Less

than

135° F

(57° C)

Greater

than

135° F

(57° C)

6.9/

26.2

Water

Usage

(gal/L)

6.9-8.4/

26.1-31.8

5.2-6.7/

19.7-25.4

Rinse Only

Low

Water

Usage

1.8-2.1/

6.9-7.9

5.5/

20.8

Additional Considerations

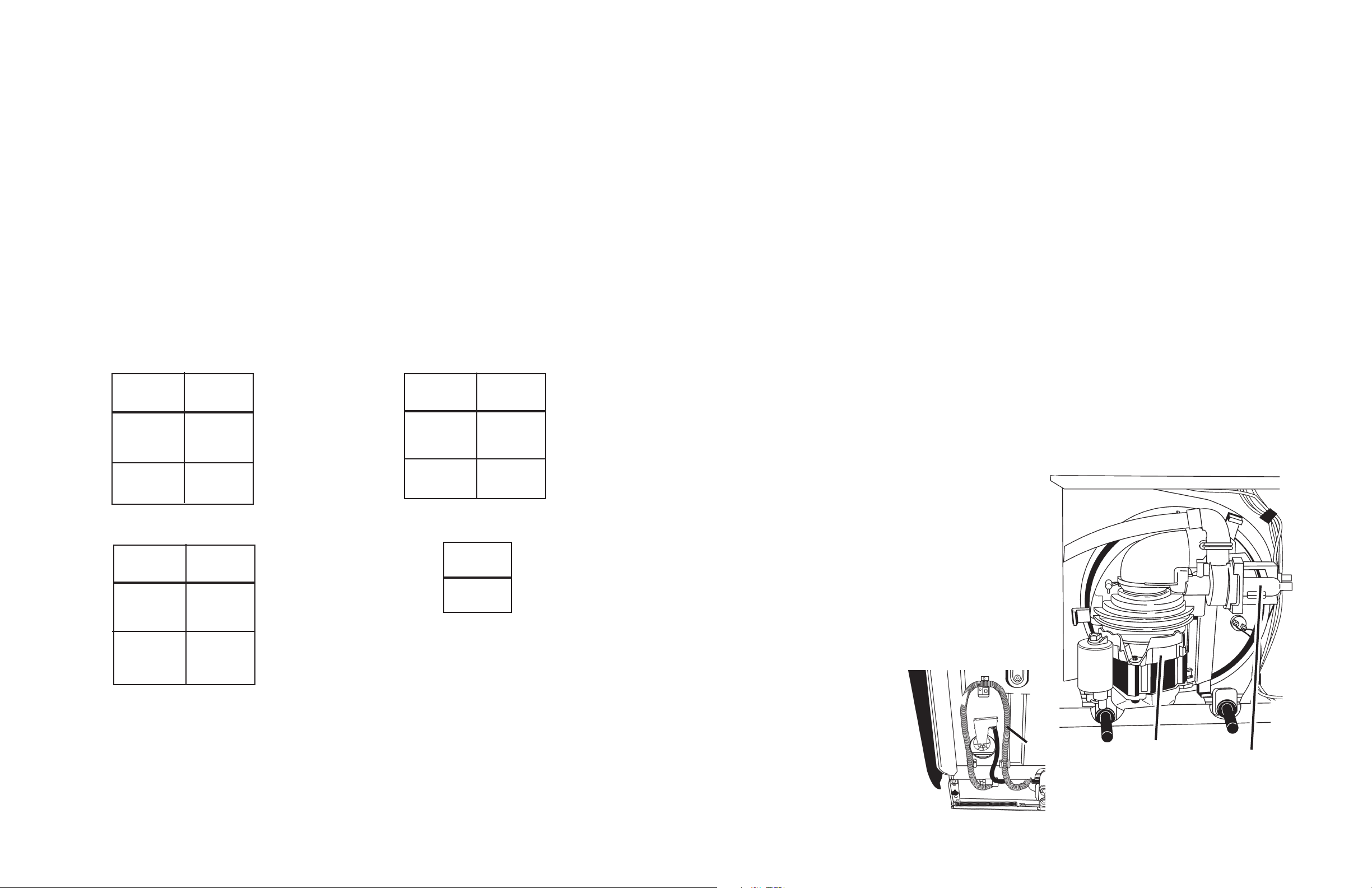

The application of a horizontal pump and filter

technology allows for the tub to be designed three

inches deeper than current models. This deeper

tub and longer door design will impact the installation process because there is less working

space available underneath the unit and correct

routing and placement of the drain hose, water

supply and electrical wiring is critical.

The tub must be level. Reduced water consumption of this dishwasher requires that it be installed

level and plumb for proper water recirculation back

into the sump area during operation.

Do not remove the drain

tube from the left side of

the tub. If the loop is

removed, the dishwasher

will not initiate Automatic

Purge Filtration. The drain

tube also contains a check

valve in the L-connector that

prevents backflow of water into

the dishwasher from the household drain system.

Drain Tube

Loop

Main Wash Motor

View of Sump Assembly from Underneath

Showing Horizontal Wash Pump Motor

and Drain Pump Motor

Drain Pump

Motor

44

1

-- NOTES --

MODEL SPECIFIC TABLES

MODEL

NO.

KUDS01DJ

KUDS01IJ

KUDR01TJ

KUDM01TJ

KUDI01TJ

MODEL

NO.

KUDS01DJ

KUDS01IJ

KUDR01TJ

KUDM01TJ

KUDI01TJ

USER

INTERFACE

8269200 (Top)

8269201 (Front)

8269199

8269198

8269197

8269196

PRESSURE

SWITCH

8268477

N/A

JUMPER

TAILS

8269202 8269207

N/A

INTERCONNECT

CARD

N/A

RINSE

DISPENSER

AID

SENSOR

8269189 8269190

8269996

N/A N/A

KEYPAD MATRIX

NUMERIC

DISPLAY

8269206

N/A

RINSE

AID

HARNESS

PUMP &

MOTOR

ASSMEBLY

8268422

WIRING

HARNESS

8269191

2

43

MODEL/SERIAL NUMBER PLATE

SECTION TWO

SERIAL NUMBER DESIGNATOR

SERIAL NUMBER

MANUFACTURING SITE

F = Findlay, OH

YEAR OF MANUFACTURE

K = 2000

WEEK OF MANUFACTURE

PRODUCT SEQUENCE NUMBER

F K 36 50001

MODEL NUMBER DESIGNATOR

MODEL NUMBER

INTERNATIONAL SALES OR

MARKETING CHANNEL

K = KITCHENAID BRAND

PRODUCT IDENTIFIER

PD = Convertable/Potable UD = Undercounter

FEATURE LEVEL: I, J, M, P, R, S

SERIES CONFIGURATION

UD JK01WHST 0

Model/Serial

Number Plate

(Left side of

frame behind

door)

THEORY OF OPERATION

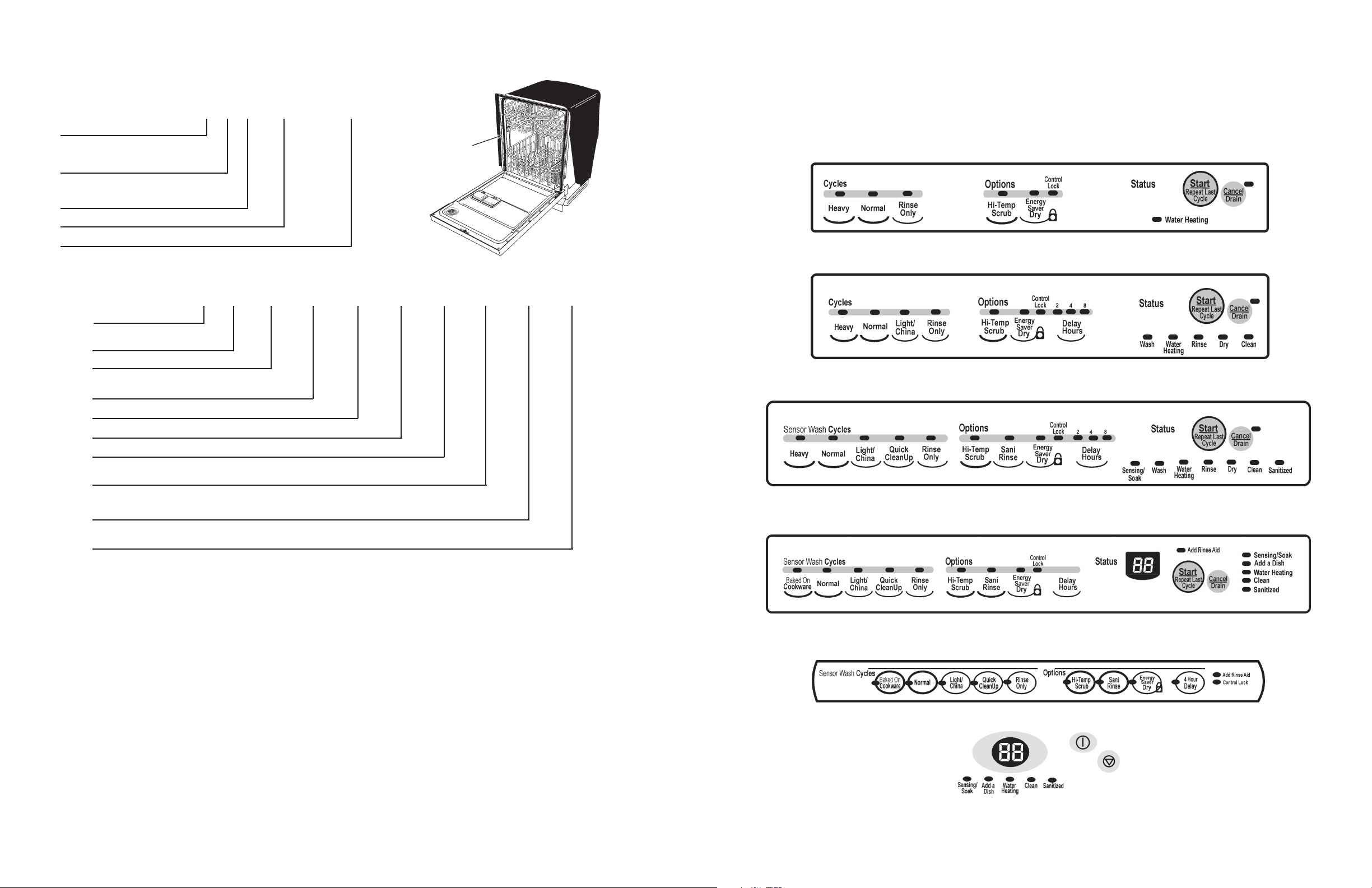

CONTROL PANELS

MODEL KUDI01TJ - 6” Console

MODEL KUDM01TJ - 6” Console

MODEL KUDR01TJ - 4” Console

FEATURES

YEAR OF INTRODUCTION

J = 2000

COLOR CODE

WH = White GR = Graphite BT = Biscuit

AL = Almond BL = Black

ENGINEERING CHANGE

0 = Basic Release; 1 = First Revision; 2 = Second Revision

MODEL KUDS01IJ - 4” Console

MODEL KUDS01DJ - 4” Split Console

TOP

42

FRONT

3

CYCLES AND CYCLE VARIATION

The KUD01 dishwasher optimizes washing performance and efficiently uses resources by varying

cycle functions and length. The selection of wash options allows the consumer to customize a cycle

for optimum washing performance. The soil sensor monitors soils in the wash water and sends input

to the electronic control. Generally, if the consumer does not choose a wash option, the electronic

control determines which cycle variation should be used.

In models without the soil sensor feature the electronic control automatically uses the Low Soil variation of the cycle unless the customer has chosen the High Temp Scrub option.

Wash Options

• The consumer’s selection of a High Temp Scrub wash option mandates a preset long version

of a wash cycle. The exception is the Normal cycle. If very little soils are present the electronic

control will use the Low Soil cycle variation with the High Temp Scrub option.

• The Sani Rinse option will mandate a higher final rinse temperature. This does not lengthen a

cycle except for the time spent in the thermal hold to raise the water temperature to the required 160° F.

• The Energy Saver Dry option merely turns off the heat during the drying function of the cycle.

Soil Sensing

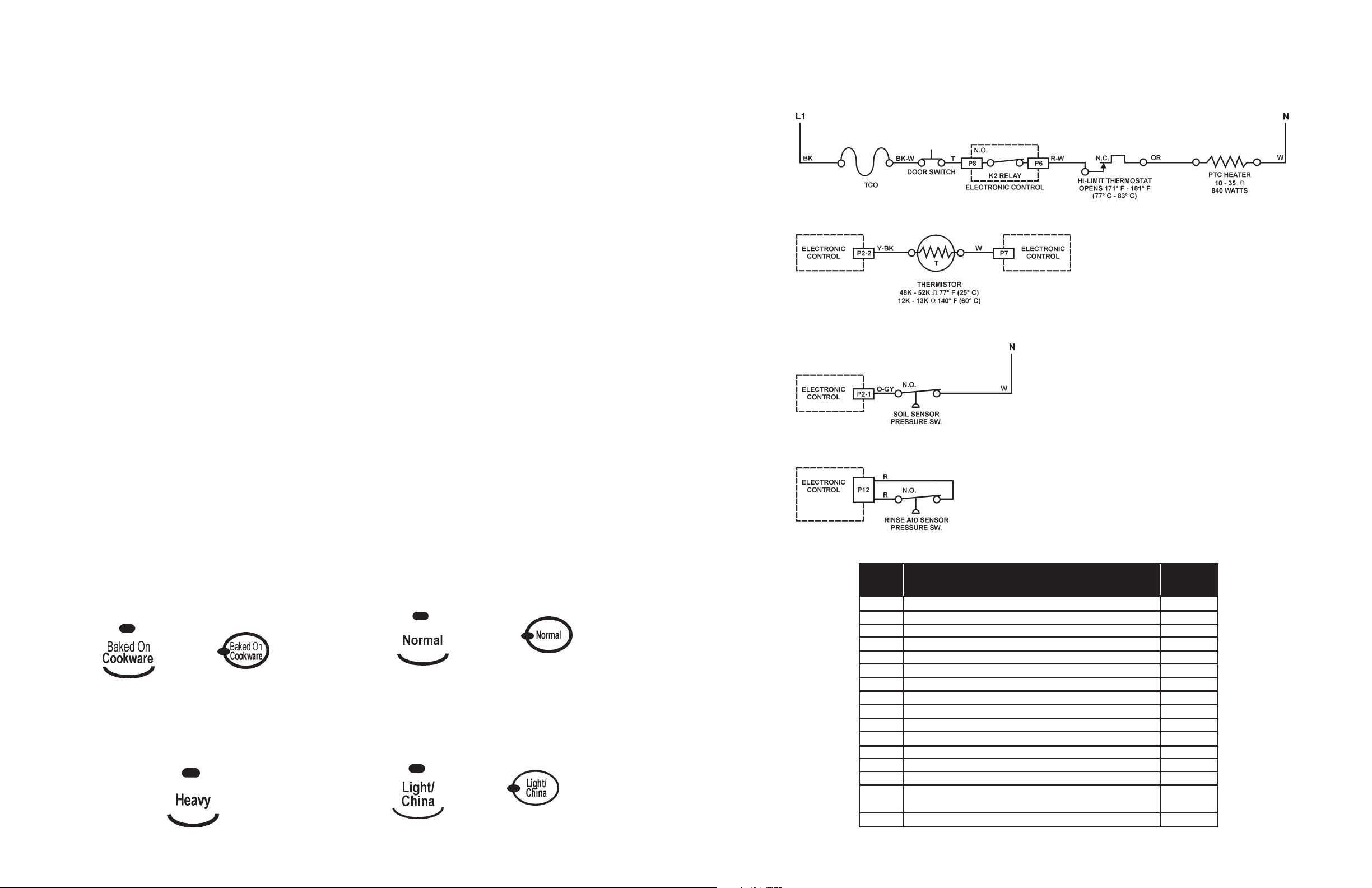

WATER HEATING

Heater Circuit

Thermistor

SOIL SENSING

* Resistance and

Wattage

Varies with Temperature

The Soil Sensor (pressure switch) monitors soil concentrations during wash functions and communicates this to the electronic control. If one or more soil sensor trips occur in the first washing interval

(interval “42”) of the Pre-Wash Period, the electronic control will use the High Soil version of the cycle.

If there are no trips and no options selected, the control uses the light soil version starting at interval

41. Soil sensor trips also invoke Automatic Purge Filtration (APF) events during the Pre-Wash and

Wash Periods. See APF description on page 5.

First Fill Water Temperature

The duration of the Quick Cleanup cycle may be modified based upon the water temperature of the

first fill. If the thermistor senses water temperature of 135°F or higher, the electronic control will eliminate the second wash function. The Quick Cleanup cycle is the only cycle in which this occurs.

Baked On Cookware

The most aggressive to virtually eliminate bacteria from the dish load. Use this cycle for hard-toclean, heavily soiled pots, pans, casseroles and

Normal

Use this cycle for loads with normal amounts of

food soil. (The energy-usage label is based on

this cycle.) Initial display time: 95 min.

regular tableware. Initial display time: 99 min.

Light/China

Heavy

Use this cycle for hard-to-clean, heavily soiled

pots, pans, casseroles and regular tableware.

Initial display time: 97 min.

Use this cycle for china and crystal. This cycle

uses a light wash and gentle dry. During heated

dry, the heating element cycles on and off. Initial

display time: 79 min.

RINSE AID SENSING

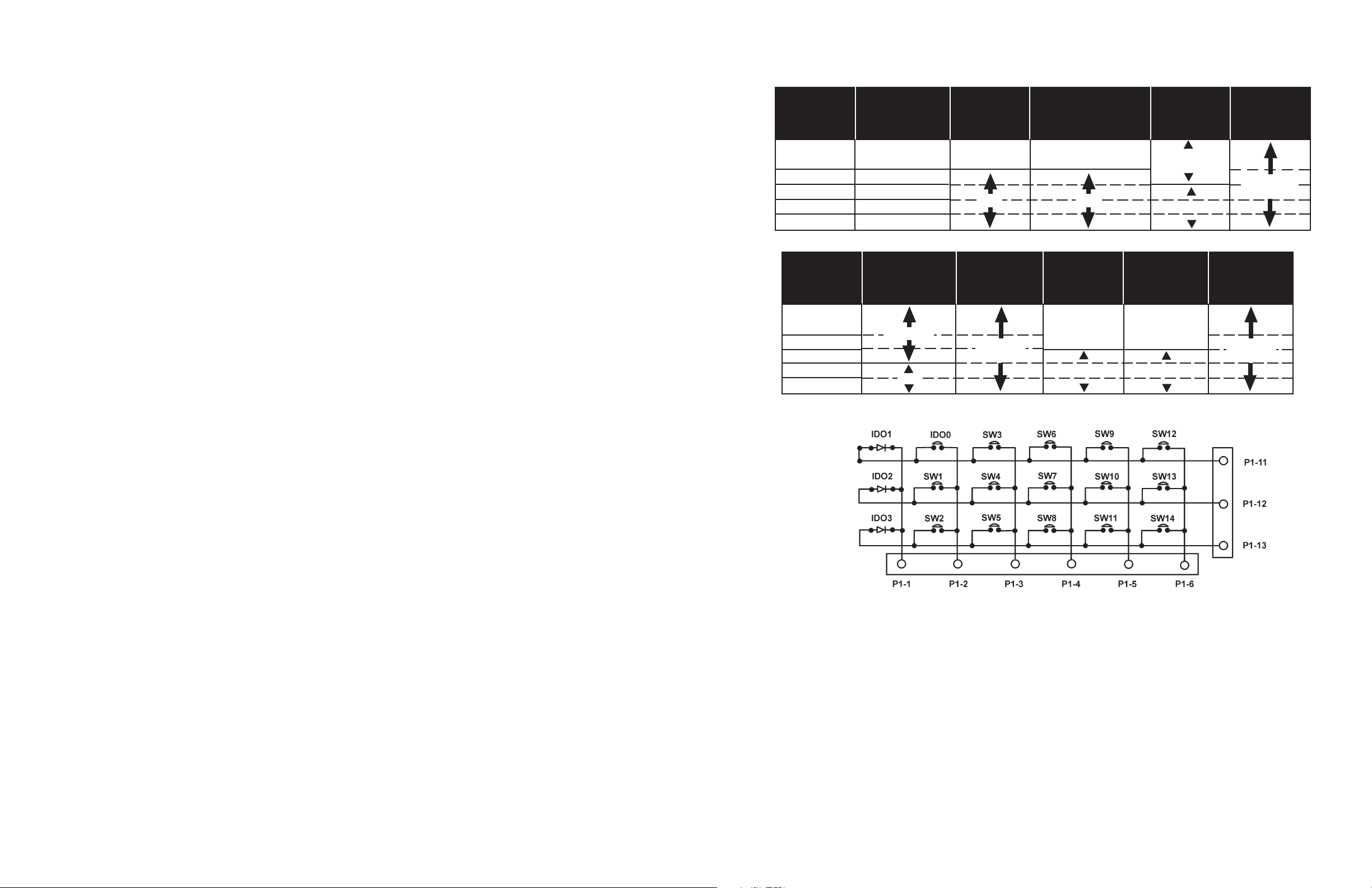

ELECTRONIC CONTROL CONNECTOR PINS

PIN

NO.

P1

P2-1

P2-2

P2-3

P2-4

P2-5

P2-6

P3

P4

P5

P6

P7

P8

P9

P10

P12

NOTE: Switch closes when significant soils accumulate in the pump.

NOTE: Switch closes when the Rinse Aid dispenser is empty.

DESCRIPTION

RIBBON CABLE TO USER INTERFACE

PRESSURE SWITCH (SOIL SENSE)

THERMISTOR

FILL VALVE

DISPENSER

OPEN

TO CONTROL POWER SUPPLY

DRAIN MOTOR

WASH MOTOR AUX WINDING

WASH MOTOR RUN WINDING

SWITCHED L1 TO HEATER

AC NEUTRAL

SWITCHED L1 FROM TCO

SWITCHED L1 TO WASH MOTOR COMMON

SWITCHED L1 TO VENT, FILL VALVE,

DISPENSER & PRESSURE SWITCH

OPTIONAL RINSE AID

WIRE

COLOR

-

O-GY

Y-BK

BR

LBU

O-BK

T

GY

Y

BU

W-R

W-V

T

R-BK

BU-BK

R

4

41

Loading...

Loading...