KitchenAid KHTU160KSS, KHTU160KBL, KHTU100KBL, KHTU100KSS, KHTU100KWH Installation Instructions

...Page 1

Installation Instructions and

Use and Care Guide

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions with

the homeowner.

Homeowner: Keep Installation Instructions for

future reference.

Save Installation Instructions for local electrical

inspector's use.

4329589/

9763392

Quick Reference

Table of Contents:

Pages

Before you start

Electrical requirements

Vent system requirements

Product dimensions

Installation steps

Wiring diagram

Use and Care Information

Warranty

Requesting Assistance

or Service

2

2

3

3

4 - 6

6

6 - 7

7

8 - 9

KHTU100 Series

KHTU160 Series

Roof-vented model shown.

30" (76.2 cm) and 36" (91.4 cm)

Traditional Series Vented and Non-Vented

Range Hoods

Page 2

2

Electrical

requirements

Before you start...

Proper installation is your

responsibility:

• Have a qualified technician install this

range hood.

• Comply with installation clearances

specified on the model/serial rating

plate.

If installation is non-vented

(recirculating), you must use Non-Vent

(recirculating) Kit Part No. 4396273,

available from your dealer. The kit fits

all models.

The model/serial rating plate is located

inside the range hood. To access,

remove the grease filters.

Range hood location should be away

from strong draft areas, such as windows,

doors and strong heating vents.

Grounded electrical connection is

required. See “Electrical requirements.”

Important:This hood must be a

minimum of 24" (61 cm) above cooking

surface.

All openings in ceiling and wall where

range hood will be installed must be

sealed.

Important: Observe all governing

codes and ordinances.

This is the safety alert symbol.

This symbol alerts you to

potential hazards that can kill

or hurt you and others.

All safety messages will follow the

safety alert symbol and either the word

“DANGER” or “WARNING”. These

words mean:

You can be killed or seriously injured

if you don’t follow instructions.

DANGER

WARNING

Your safety and the safety of

others are very important.

We have provided many important

safety messages in this manual and

on your appliance. Always read and

obey all safety messages.

All safety messages will tell you what

the potential hazard is, tell you how to

reduce the chance of injury, and tell

you what can happen if the instructions

are not followed.

You can be killed or seriously injured

if you don’t immediately

follow

instructions.

WARNING — TO REDUCE THE

RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO

PERSONS, OBSERVE THE

FOLLOWING:

Installation work and electrical

wiring must be done by qualified

person(s) in accordance with all

applicable Codes and Standards,

including fire related construction.

Sufficient air is needed for proper

combustion and exhausting of

gases through the flue (chimney)

of fuel burning equipment to

prevent back drafting. Follow the

heating equipment manufacturer’s

guideline and safety standards

such as those published by the

National Fire Protection

Association (NFPA), and the

American Society of Heating

Refrigeration and Air Conditioning

Engineers (ASHRAE), and the

local code authorities.

When cutting or drilling into wall

or ceiling, do not damage

electrical wiring and other hidden

utilities.

Ducted fans must always be

vented to the outdoors.

WARNING — To reduce the risk

of fire, use only metal ductwork.

This unit must be grounded.

Tools and materials

needed for installation:

• Phillips head

screwdriver

• drill

• 1-1/2" (4.0 cm)

drill bit

• keyhole saw

• sabre or jig saw

• metal snips

• tape (for template)

• duct tape

• pencil

• UL- or CSA-listed

1/2" (12.5 mm)

conduit connector

(for range hood)

• 1 wall or roof cap

• power supply

cable (if not

previously

installed)

• metal vent system

(if not previously

installed)

Parts supplied:

• four 2-3/4" (7 cm) screws

• four 2" (5.1 cm) screws

• hood installation template

The range hood must be connected

with copper wire only.

The range hood should be

connected directly to the fused

disconnect (or circuit breaker) box

through flexible armored or

nonmetallic sheathed copper cable.

Wire sizes (COPPER WIRE ONLY) and

connections must conform with the

rating of the appliance as specified

on the model/serial rating plate.

Wire sizes must conform to the

requirements of the National

Electrical Code ANSI/NFPA 70 —

latest edition*, or CSA Standards

C22.1-94, Canadian Electrical Code

Part 1 and C22.2 No. 0-M91 - latest

edition** and all local codes and

ordinances.

A U.L.- or CSA-listed strain relief must

be provided at each end of the power

supply cable (at the range hood and

at the junction box).

Important: Observe all governing

codes and ordinances.

It is the customer’s responsibility:

• To contact a qualified electrical

installer.

• To assure that the electrical

installation is adequate and in

conformance with National

Electrical Code, ANSI/NFPA 70

— latest edition*, or CSA

Standards C22.1-94, Canadian

Electrical Code, Part 1 and

C22.2 No.0-M91 - latest

edition** and all local codes

and ordinances.

If codes permit and a separate ground

wire is used, it is recommended that

a qualified electrician determine that

the ground path is adequate.

A 120-volt, 60-Hz, AC-only, fused

electrical system is required on a

separate 15-amp circuit, fused on

both sides of the line.

Do not ground to a gas pipe.

Check with a qualified electrician if

you are not sure range hood is

properly grounded.

Do not have a fuse in the neutral or

ground circuit.

IMPORTANT:

Save Installation Instructions for

electrical inspector’s use.

Copies of the standards listed may be

obtained from:

* National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

** CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Page 3

3

Product dimensions

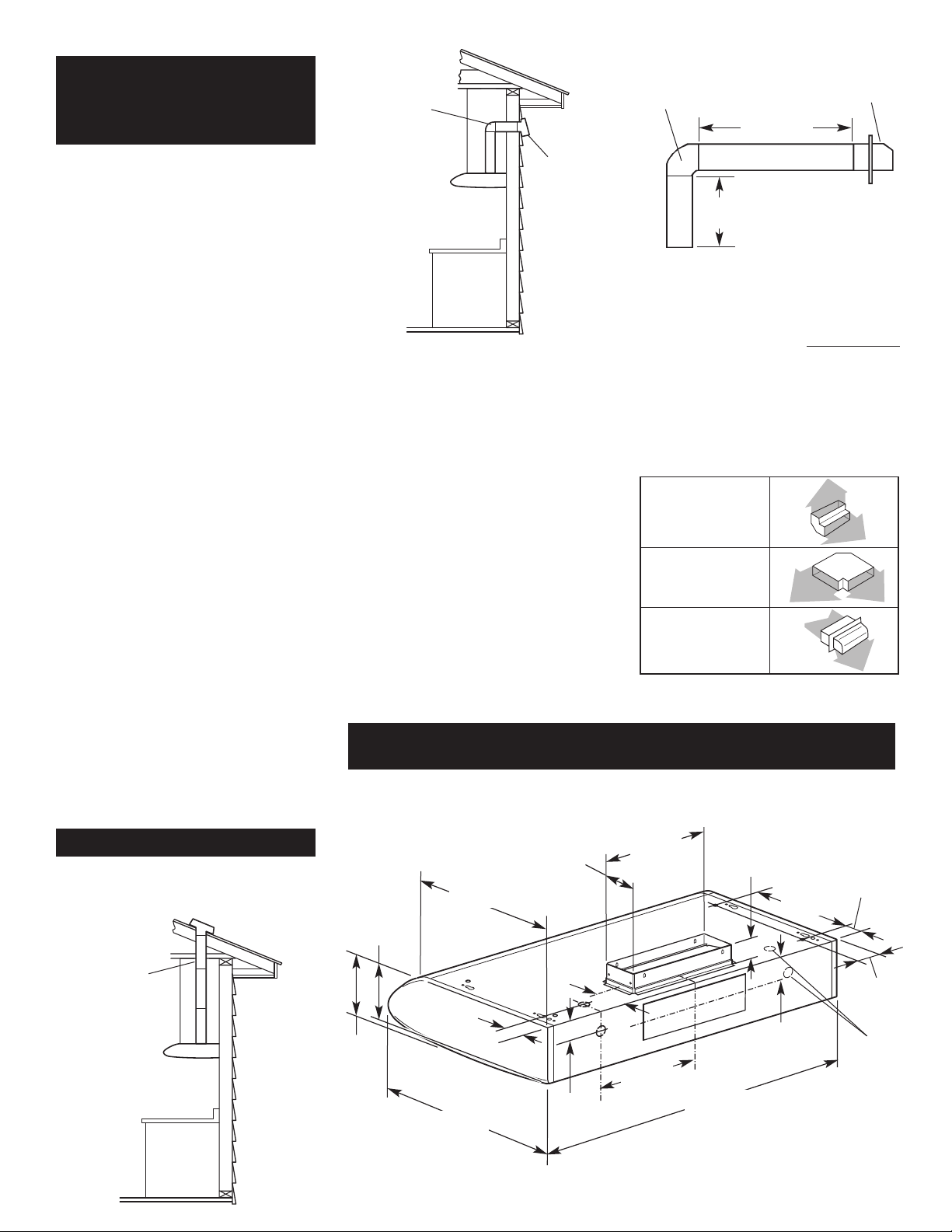

Vent system

requirements

Do not terminate the vent system

in an attic or other enclosed area.

Do not use 4"(10.2 cm) laundrytype wall caps.

Use metal vent only. Rigid metal

vent is recommended. Do not use

plastic or metal foil vent.

Flexible vent is not

recommended. Flexible vent

creates back pressure that greatly

reduces the hood's performance.

Vent system needed for

installation is not included. 3-1/4

" x

10" (8.3 cm x 25 cm) rectangular is

recommended.

Venting methods

Recommended standard

fittings

3-1/4" x 10"

(8.3 cm x 25 cm)

90° elbow

= 5 ft. (1.5 m)

3-1/4" x 10"

(8.3 cm x 25 cm)

flat elbow

= 12 ft. (3.7 m)

3-1/4" x 10"

(8.3 cm x 25 cm)

wall cap

= 0 ft. (0 m)

Roof venting

3-1/4"x 10

"

(8.3 cm x 25 cm)

vent through

the roof

Wall venting

3-1/4" x 10"

(8.3 cm x 25 cm)

vent through

the wall

wall

cap

3-1/4" x 10”

(8.3 cm x 25 cm)

90° elbow

wall

cap

Maximum length = 26 ft. (8 m)

1 — 90° elbow = 5 ft. (1.5 m)

9 ft. (2.8 m) straight = 9 ft. (2.8 m)

1 — wall cap = 0 ft. (0 m)

Length of 3-1/4" x 10"

(8.3 cm x 25 cm)

system = 14 ft. (4.3 m)

6 ft. (1.8 m)

3 ft.

(0.93 m)

3-1/4" x 10"

(8.3 cm x 25 cm)

v

ent system

Recommended vent system

length

Use 3 1/4

" x 10" (8.3 cm x 25 cm)

vent with maximum length of

26 feet (8 m) for vent system. For

best performance, use no more

than three 90° elbows. To calculate

the length of system you need,

add the equivalent feet (meters)

for each vent piece used in the

system. See the following

example.

7-3/4"

(19.6 cm)

9-15/16"

(25.2 cm)

3-3/16"

(8.1 cm)

Note: Underside of hood must be a minimum of

24" (61 cm) from cooking surface.

2-11/32"

(6.0 cm)

1-3/4"

(4.4 cm)

Do not

use these

knockouts

1-13/16"

(4.6 cm)

2-9/16"

(6.5 cm)

1-9/16"

(4.0 cm)

1-3/16"

(3.0 cm)

1-3/16"

(3.0 cm)

4-3/4"

(12.1 cm)

5-1/16"

(12.9 cm)

9-27/32"

(25.0 cm)

17-3/4"

(45.1 cm)

13-3/8"

(34.0 cm)

30" (76.2 cm)

36" (91.4 cm)

For vented models:

• The size of the vent should be

uniform.

• Use no more than three 90°

elbows.

• Make sure there is a minimum

of 24" (61 cm) of straight vent

between the elbows if more

than one elbow is used.

• Do Not install two elbows

together.

• The length of vent system and

number of elbows should be

kept to a minimum to provide

efficient performance.

• The vent system must have a

damper. If roof or wall cap has

a damper, Do Not use damper

supplied with the range hood.

• Use duct tape to seal all joints

in the vent system.

• Use caulking to seal exterior wall

or roof opening around the cap.

Note: It is recommended that the

vent system be installed before

installing the hood.

Roof-vented model shown.

Page 4

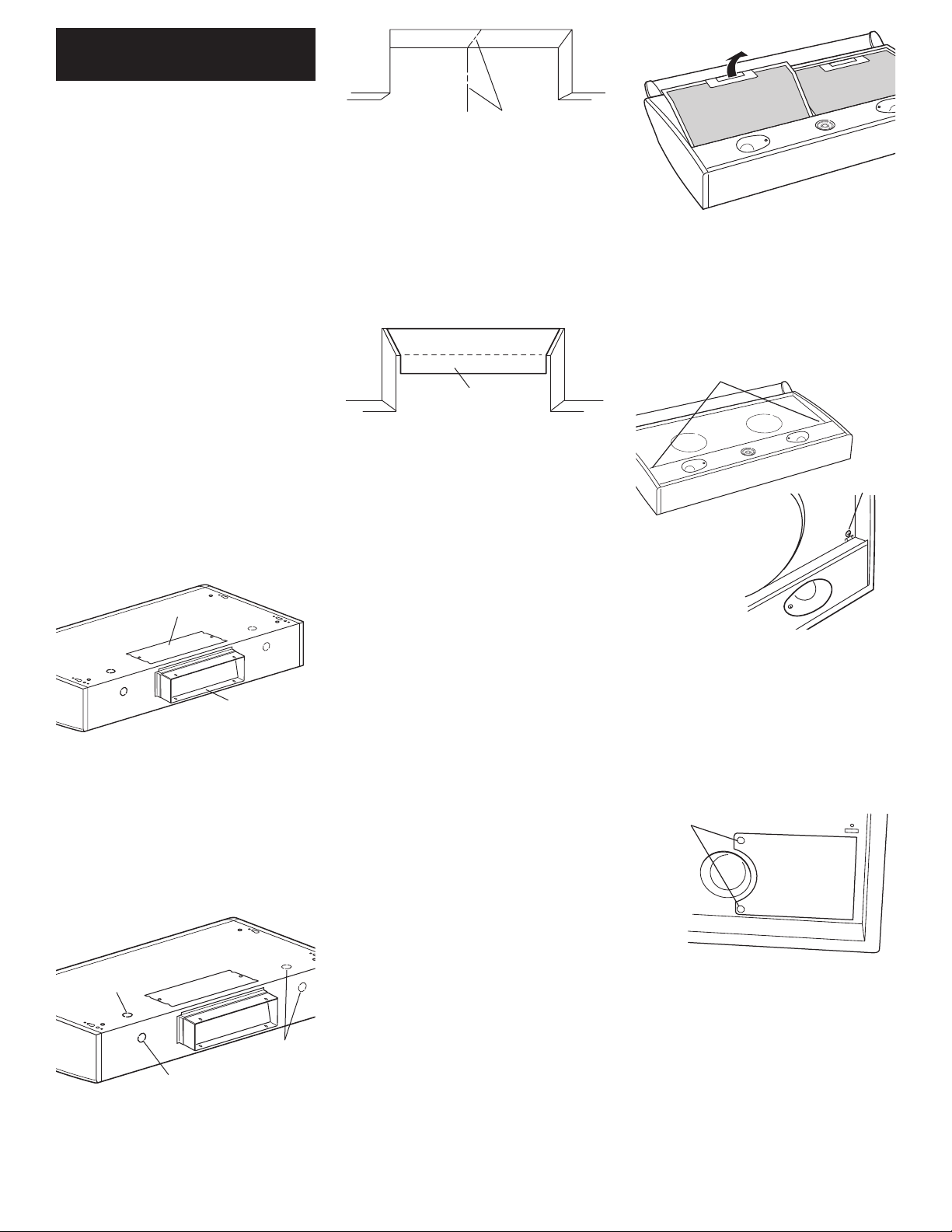

Now start...

4

1.

Put a thick protective

covering over cooktop, set-in

range or countertop to protect

from damage or dirt.

If installing over a freestanding

range, disconnect and move the

range to provide easier access to

the upper cabinet and rear wall.

Slide range onto cardboard or

hardboard before moving to

prevent damaging floor covering.

2.

Place hood on a protective

cover with filters facing down.

3.

Determine which venting

method (roof, wall or non-vented)

will be used.

• The hood is factory-set for roof

venting.

• For non-vented installations, go

to Step 4.

vent

connection

seal plate

top

knockout

If venting through the wall,

remove seal plate from back of

hood and vent connector from top

of hood. Reinstall vent connector

onback of hood and seal plate on

top of hood.

4.

Remove knockout from the

wiring opening (top or back) to be

used.

6.

Align centerlines of template

with centerlines marked on rear

wall and upper cabinet bottom.

Tape template in place. Mark

location of the four holes used to

secure hood to upper cabinet.

7.

Depending on your

installation, mark location of the

wiring hole or vent cutout in

upper cabinet or back wall needed

as shown on template.

8.

Remove template.

9.

Drill four 3/16" (5.0 mm)

diameter holes through upper

cabinet for the hood mounting

screws.

10.

Drill the 1-1/2" (4.0 cm)

wiring hole.

11.

Make the vent cutout for

3-1/4" x 10" (8.3 x 25.4 cm)

rectangular vent system. Note: It

is recommended that vent system

be installed before installing

hood.

12.

Turn the hood over so

filters face up.

template

5.

Mark centerlines on rear wall

and upper cabinet bottom.

For non-vented installations:

Extend centerline up onto soffit

above hood.

centerlines

13.

Rotate deflector away

from filters. Pull grease filter

handles toward back of hood to

release locking tabs. Lift filters up,

remove from hood and set aside.

14.

Remove 2 screws from

light panel tabs. On light panel

surface directly behind tabs, push

toward back of the hood to move

tabs out through the slots.

Remove panel and set aside with

screws.

15.

Remove 2 screws from

wiring box cover located in the

right hand rear corner and remove

cover. Attach the U.L.- or CSAlisted strain relief to the hood

wiring hole being used.

16.

Turn hood over so filters

face down.

remove

screws

wiring

box cover

back knockout

do not use

these

knockouts

screw locations

screw

Page 5

5

filter hub

22.

Reinstall light panel.

Insert light panel tabs into slots.

Push in on back of light panel and

insert the small tabs into the

locating holes in back of the

hood. Reinstall the 2 screws and

tighten securely.

20.

Connect the vent system.

Non-vented installations: Install

the grille on the soffit.

19.

Lift hood into place while

feeding wiring into wiring box.

21.

Connect the white and

black wires of power supply cable

to the white and black leads in

hood with twist-on connectors.

Connect the power supply ground

wire to the green ground screw

inside hood’s terminal box.

Replace terminal box cover.

17.

Attach hood damper into

vent connector. Make sure that

damper swings freely. If wall or

roof vent system cap has a

damper, DO NOT attach damper

that came with hood.

Non-vented (recirculating)

installations only: Assemble the

vent system you will use over the

roof vent opening but do not

attach the vent system yet.

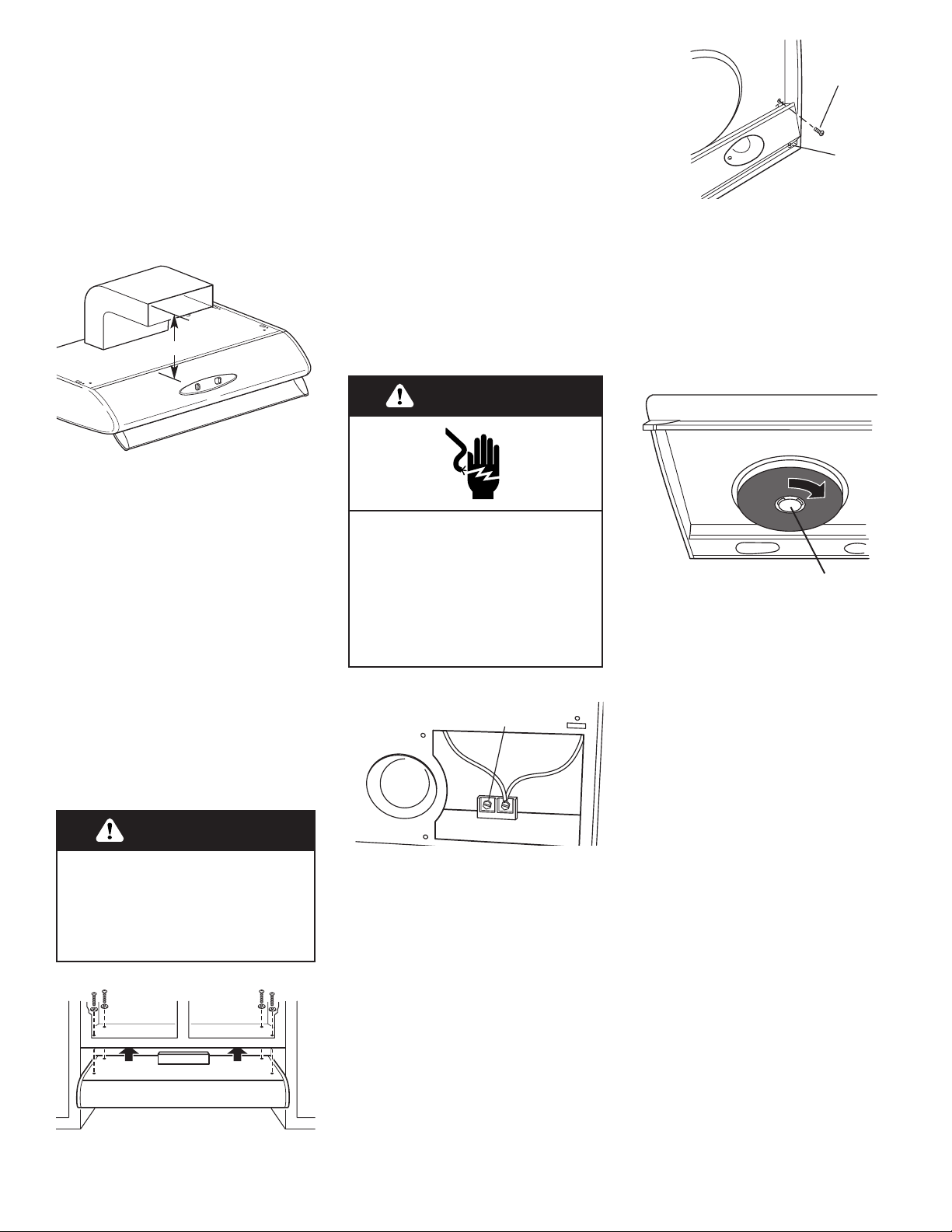

Excessive Weight Hazard

Use two or more people to move

and install range hood.

Failure to do so can result in

back or other injury.

WARNING

Electrical

connection

Electrical Shock Hazard

Disconnect power before making

electrical connections.

Connect ground wire to green

ground screw in terminal box.

Failure to do so can result in

death or electrical shock.

WARNING

23.

Non-vented (recirculating)

installations: Install the charcoal

filters. Place filter over hub in

blower openings, push up and

turn clockwise to lock filter into

place.

24.

Install the aluminum

grease filters.

install

screw

tab

green ground

screw

18.

The hood is attached to

cabinet bottom by four screws

with washers inserted through

cabinet bottom from inside of

cabinet and into hood.

• If your cabinet has a frame

around the bottom, use the

four 2-3/4" (7 cm) long screws

in parts bag.

• If your cabinet has a flush

bottom (no frame), use the four

shorter 2" (5.1 cm) long screws

in parts bag.

A

Measure distance A and transfer it

to the centerline on the soffit.

Mark and cut a 3-1/4” x 10” (8.3 cm

x 25 cm) vent opening in the soffit.

Feed enough wire into wiring box

to easily make the connections

and tighten the strain relief.

Insert the four screws through

cabinet bottom and into hood.

Start screws into hood and

tighten securely.

Page 6

6

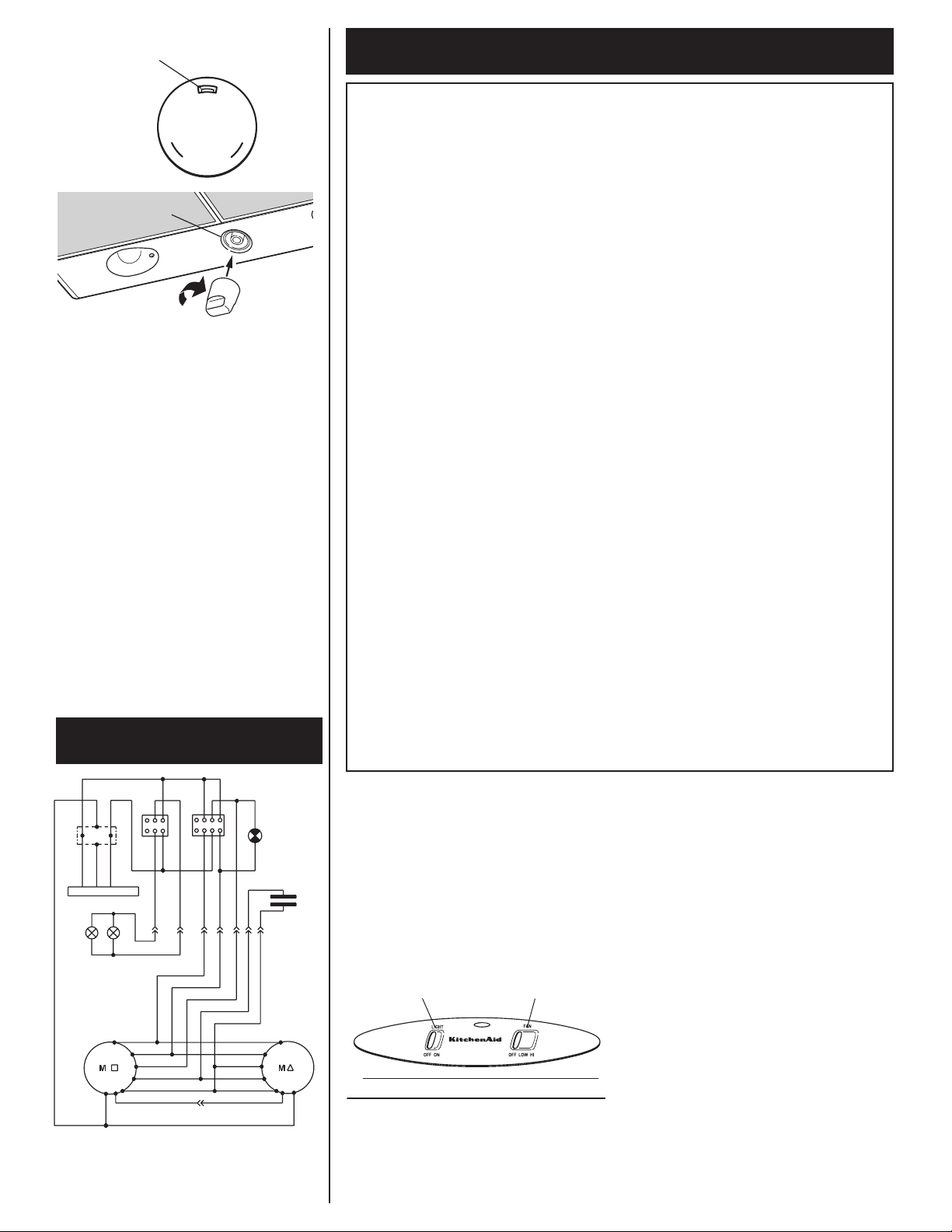

Operation of

range hood

For best results, turn range hood

fan ON at beginning of cooking

and allow it to run until all smoke

and odors are removed from the

room.

fanlight

To turn fan ON and OFF:

Slide fan control to turn fan on

and off and adjust fan speed.

Speed may be increased or

decreased anytime during range

hood operation.

To turn range hood light

ON and OFF:

Slide light control to turn on or off.

Light may be turned on or off

anytime during range hood

operation.

Deflector: When cooking will create

a lot of smoke, use the deflector.

The deflector will concentrate the

venting action of the hood.

To use deflector, grasp from inside

and pull down. Push up to return

to its original position.

Use and Care Information

WARNING — To reduce the risk of

fire or electrical shock, do not use

this fan with any solid-state speed

control device.

WARNING — TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Use this unit only in the manner

intended by the manufacturer. If

you have questions, contact the

manufacturer. Before servicing or

cleaning unit, switch power off at

service panel and lock the service

disconnecting means to prevent

power from being switched on

accidentally. When the service

disconnecting means cannot be

locked, securely fasten a

prominent warning device such as

a tag to the service panel

CAUTION: For general ventilating

use only. Do not use to exhaust

hazardous or explosive materials

and vapors.

WARNING — TO REDUCE THE

RISK OF A RANGE TOP GREASE

FIRE:

Never leave surface units

unattended at high settings.

Boilovers cause smoking and

greasy spillovers that may ignite.

Heat oils slowly on low or

medium settings.

Always turn hood ON when

cooking at high heat or when

cooking flaming foods.

Clean ventilating fans frequently.

Grease should not be allowed to

accumulate on fan or filter.

Use proper pan size. Always use

cookware appropriate for the size

of the surface element.

WARNING — TO REDUCE THE

RISK OF INJURY TO PERSONS IN

THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE

FOLLOWING:

SMOTHER FLAMES with a closefitting lid, cookie sheet, or metal

tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If

the flames do not go out

immediately, EVACUATE AND

CALL THE FIRE DEPARTMENT.

NEVER PICK UP A FLAMING PAN

— You may be burned.

DO NOT USE WATER, including

wet dishcloths or towels — a

violent steam explosion will

result. Use an extinguisher ONLY

if:

You know you have a Class ABC

extinguisher, and you already

know how to operate it.

The fire is small and contained in

the area where it is started.

The fire department is being

called.

You can fight the fire with your

back to an exit.

grease

collection

cup

grease collection

opening

26.

Turn power supply on.

Wiring diagram

25.

Remove plastic cap

located between lights. Locate

tab in cap’s large slot. Use a

small flat-bladed screwdriver and

press tab toward center of cap to

release tab. Squeeze cap to

release other 2 tabs and discard

cap.

Remove grease collection cup

from the parts bag and twist cup

clockwise into opening.

push tab

toward

center of cap

X

WIRING BO

BLK BLK

120 VAC LINE IN 60 Hz

RED

GRN

GRN

BLK

BLK

WHT

WHT

WHT

VLT

RED

RED VLT

RED

WHT

BLK

WHT

VLTVLT

WHT

BRWORG

14 Fμ

BLU

BRWORG

WHT

GRY

BLU

BRWORG

WHT

VLT

GRY

BRW

ORG

WHT

BLU

GRY

WHT

GRN

GRN

BRW

ORG

WHT

BLU

GRY

WHT

Page 7

7

Care of range hood

remove screw

Filters: For best results, remove

and clean aluminum filters often.

Filters can be cleaned in a

dishwasher or with hot sudsy

water.

Do not wash charcoal filters used

with non-vented (recirculating)

installations. Charcoal filters can

be replaced by ordering Kit Part

No. 4396273, available from your

dealer.

To remove filters: Pull the

deflector down. Push the handles

toward the back of the hood and

pull down.

Replacing lights:

Use a Phillips screwdriver to

remove screw holding the light

Cleaning grease collection cup:

Twist cup counterclockwise to

remove. Wash in hot sudsy water.

Dry, insert into opening and twist

clockwise.

Exterior surfaces: Clean with a

mild detergent and soft cloth. DO

NOT use abrasive cleaners or

steel wool.

grease

collection

cup

deflector

To reinstall filters: Insert filters

into back of hood; push up into

place while pushing back on

handles. Release handles.

KITCHENAID® VENTILATION WARRANTY

ONE YEAR LIMITED WARRANTY

For one year from the date of purchase, when this major appliance is operated and maintained according to instructions attached to or

furnished with the product, KitchenAid or KitchenAid Canada (hereafter “KitchenAid”) will pay for factory specified parts and repair

labor to correct defects in materials or workmanship. Service must be provided by a KitchenAid designated service company.

ITEMS KITCHENAID WILL NOT PAY FOR

1. Service calls to correct the installation of your major appliance, to instruct you how to use your major appliance, to replace or repair

house fuses or to correct house wiring or plumbing.

2. Service calls to repair or replace appliance light bulbs, air filters or water filters. Those consumable parts are excluded from warranty

coverage.

3. Repairs when your major appliance is used for other than normal, single-family household use.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation, installation not in

accordance with electrical or plumbing codes, or use of products not approved by KitchenAid.

5. Replacement parts or repair labor costs for units operated outside the United States or Canada.

6. Pickup and delivery. This major appliance is designed to be repaired in the home.

7. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

8. Expenses for travel and transportation for product service in remote locations.

9. The removal and reinstallation of your appliance if it is installed in an inaccessible location or is not installed in accordance with

published installation instructions.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. KITCHENAID SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

Outside the 50 United States and Canada, this warranty does not apply. Contact your authorized KitchenAid dealer to determine if

another warranty applies.

If you need service, first see the “Troubleshooting” section of the Use & Care Guide. After checking “Troubleshooting,” additional help

can be found by checking the “Assistance or Service” section or by calling KitchenAid. In the U.S.A., call 1-800-422-1230. In Canada,

call 1-800-807-6777. 10/05

lens cap. Remove the bulb and

replace with a 40W, E17 sfera,

120-volt type bulb. Reinstall light

lens.

Page 8

8

Requesting Assistance or Service

Call the KitchenAid Customer Interaction

Center toll-free at 1-800-235-0665.

Our consultants are available to assist you.

When calling: Please know the purchase date, and

the complete model and serial number

of your appliance This information will

help us better respond to your request.

Our consultants provide assistance with:

•

Features and specifications on our full line

of appliances

•

Installation information

If you need replacement parts

If you need to order replacement parts, we

recommend that you use only factory-authorized

parts. These parts will fit right and work right

because they are made to the same exacting

specifications used to build every new KitchenAid

®

appliance.

To locate factory-authorized parts in your area, call

our Customer Interaction Center telephone number,

your nearest authorized service center, or KitchenAid

Factory Service at 1-800-442-1111.

For further assistance

If you need further assistance, you can write to

KitchenAid with any questions or concerns at:

KitchenAid Brand Home Appliances

Customer Interaction Center

c/o Correspondence Dept.

2000 North M-63

Benton Harbor, MI 49022-2692

Please include a daytime phone number in your

correspondence.

•

Use and maintenance procedures

•

Accessory and repair parts sales

•

Specialized customer assistance (Spanish

speaking, hearing impaired, limited vision, etc.)

•

Referrals to local dealers, service companies, and

repair parts distributors

KitchenAid-designated service technicians are trained

to fulfill the product warranty and provide afterwarranty service anywhere in the United States.

To locate the designated KitchenAid service

company in your area, you can also look in your

telephone directory Yellow Pages.

If you need assistance or service in U.S.A.

Page 9

2. If you need service✝...

Contact your nearest KitchenAid Canada

Appliance Service branch or authorized servicing

outlet to service your appliance. (See list below.)

Make sure the service company you contact is

authorized to service your appliance during the

warranty period.

1.

Call the KitchenAid Canada

Customer Interaction Center toll-free,

8:30 a.m. – 6 p.m. (EST),

at 1-800-235-0665

...

or contact the dealer from whom you

purchased your appliance.

KitchenAid Canada Appliance Service – Consumer Services

Direct service branches:

BRITISH COLUMBIA 1-800-665-6788

ALBERTA 1-800-661-6291

ONTARIO Ottawa area 1-800-267-3456

(except 807 area code) Outside the Ottawa area 1-800-807-6777

MANITOBA, SASKATCHEWAN 1-800-665-1683

and 807 area code in ONTARIO

QUEBEC Montreal (except South Shore) 1-800-361-3032

South Shore Montreal 1-800-361-0950

Quebec City 1-800-463-1523

Sherbrooke 1-800-567-6966

ATLANTIC PROVINCES 1-800-565-1598

For further assistance

If you need further assistance, you can write to

KitchenAid Canada with any questions or concerns at:

Consumer Relations Department

KitchenAid Canada

1901 Minnesota Court

Mississauga, Ontario L5N 3A7

Please include a daytime phone number in your

correspondence.

✝

When asking for assistance or service, please

provide a detailed description of the problem,

your appliance’s complete model and serial

numbers, and the purchase date. This

information will help us respond properly to

your request.

If you need assistance or service in Canada

Requesting Assistance or Service

9

Page 10

4329589/9763392

© 2005 KitchenAid

® Registered trademark/™ trademark of KitchenAid, U.S.A., KitchenAid Canada licensee in Canada

Printed in Italy

10/20 05

Page 11

Instructions d'installation et

Guide d'utilisation et d'entretien

IMPORTANT :

Lire et conserver

ces instructions.

IMPORTANT:

Installateur :

Remettre les instructions

d’installation au propriétaire de l’appareil.

Propriétaire : Conserver les instructions

d’installation pour consultation ultérieure.

Conserver les instructions d’installation à

l’intention de l’inspecteur local des

installations électriques.

4329589/

9763392

Consultation rapide

Table des matières :

Pages

Avant de commencer...

Spécifications de

l’installation électrique

Spécifications pour modèles

avec évacuation

Dimensions du produit

Étapes de l’installation

Schéma de câblage

Utilisation et entretien

Garantie

Demande d’assistance ou de service

2

2

3

3

4 - 6

6

6 - 7

7

8 - 9

Série KHTU100

Série KHTU160

Modèle représenté pour

décharge à travers le toit.

Hottes d'aspiration pour cuisinière — série

traditionnelle avec décharge ou à recyclage

76,2 cm(30 po) et 91,4 cm (36 po)

Page 12

2

Spécifications pour

l'installation électrique

C’est à vous qu’incombe la responsabilité

de :

• Demander à un technicien qualifié

d’installer cette hotte.

• Respecter lors de l’installation les

dégagements de séparation spécifiés sur

la plaque signalétique de l’appareil.

Pour une installation avec recyclage de

l’air, on doit utiliser l’ensemble de

pièces spécial no 4396273 disponible

chez le revendeur. Cet ensemble est

utilisable avec tous les modèles.

La plaque signalétique est située à

l’intérieur de la hotte. Pour y accéder,

enlever les filtres à graisse.

La hotte d’aspiration devrait toujours

être installée loin des sources de

courants d’air comme fenêtres, portes

et bouches de chauffage.

Une prise de courant électrique reliée à

la terre est nécessaire. Voir

« Spécifications de l’installation

électrique ».

Important : Cette hotte doit être placée

à au moins 61 cm (24 po) au-dessus de

la surface d’une table de cuisson.

On doit calfeutrer toutes les ouvertures

percées dans le plafond ou le mur pour

l’installation de la hotte.

AVERTISSEMENT - POUR RÉDUIRE

LE RISQUE D’INCENDIE, CHOC

ÉLECTRIQUE OU BLESSURE,

RESPECTER LES INSTRUCTIONS

SUIVANTES :

Tout travail d’installation ou câblage

électrique doit être réalisé par une

personne qualifiée, dans le respect

des prescriptions de tous les codes

et normes applicables, y compris les

codes du bâtiment et de protection

contre les incendies. Le

fonctionnement de cet appareil peut

modifier la circulation de l’air et

affecter le fonctionnement d’un

appareil utilisant un combustible.

Respecter les directives du fabricant

de l’équipement de chauffage et les

prescriptions des normes de sécurité

- comme celles publiées par la

National Fire Protection Association

(NFPA) et l’American Society of

Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE) et les prescriptions des autorités

réglementaires locales.

Lors d’opérations de découpage et

de perçage dans un mur ou plafond,

veiller à ne pas endommager les

câblages électriques ou canalisations

qui peuvent s’y trouver.

Le conduit d’évacuation associé à un

ventilateur doit toujours décharger

l’air à l’extérieur.

AVERTISSEMENT - Pour réduire le

risque d’incendie, utiliser

uniquement des conduits

métalliques.

Cet appareil doit être relié à la terre.

Outillage et matériel

nécessaires pour

l'installation :

• tournevis Phillips

• perceuse

• foret 4 cm (1 1/2

po)

• scie à guichet

• scie sauteuse

• cisaille de

ferblantier

• ruban adhésif

(pour gabarit)

• ruban adhésif pour

conduit

• crayon

• connecteur de

conduit 12,5 mm

(1/2 po)

(homologation UL

ou CSA) (pour

hotte)

• bouche de

décharge (à travers

le mur ou toit)

• câble

d’alimentation (si

pas déjà installé)

• conduit

d’évacuation

métallique (si pas

déjà installé)

Composants fournis :

• Quatre vis de 7 cm (2-3/4 po)

• Quatre vis de 5,1 cm (2 po)

• Gabarit pour installation de la hotte

La hotte doit être raccordée

directement au coupe-circuit avec

fusible ou au disjoncteur par

l’intermédiaire de câble à conducteurs

de cuivre, à blindage métallique

flexible ou à gaine non métallique. Le

calibre des conducteurs (CUIVRE

SEULEMENT) et les connexions

doivent être compatibles avec la

demande de courant de l’appareil

spécifiée sur la plaque signalétique.

La taille des conducteurs doit satisfaire

les prescriptions du Code national des

installations électriques ANSI/NFPA 70 dernière édition*, ou des normes CSA

C22.1.94 / Code canadien des

installations électriques (partie 1) et

C22.2 N° 0-M91 - dernière édition**, et

les prescriptions de tous les codes et

règlements locaux en vigueur.

Un serre-câble (homologation UL ou

CSA) doit être installé à chaque

extrémité du câble d’alimentation (sur

la hotte et sur la boîte de connexion).

Important : Respecter les prescriptions

de tous les codes et règlements en

vigueur.

C’est au client qu’incombe la

responsabilité de :

- Contacter un électricien qualifié pour

l’installation.

- Veiller à ce que l’installation électrique

soit réalisée d’une manière adéquate et

en conformité avec les prescriptions du

Code national des installations

électriques ANSI/NFPA 70 - dernière

édition*, ou des normes CSA C22.1.94 /

Code canadien des installations

électriques (partie 1) et C22.2 N° 0-M91

- dernière édition**, et avec les

prescriptions de tous les codes et

règlements locaux en vigueur.

Si un conducteur distinct de liaison à la

terre est utilisé lorsque le code le

permet, on recommande qu’un

électricien qualifié vérifie que la liaison

à la terre est adéquate.

L’appareil doit être alimenté par un

circuit 120 volts, 60 Hz, CA seulement, 15

A, avec un fusible sur chaque

conducteur.

Ne pas utiliser une tuyauterie de gaz

pour la liaison à la terre.

En cas d’incertitude quant à la qualité de

la liaison à la terre de la hotte, consulter

un électricien qualifié.

Ne pas installer un fusible en série avec

le conducteur neutre ou le conducteur de

liaison à la terre.

IMPORTANT :

Conserver les instructions d’installation

à l’intention de l’inspecteur local des

installations électriques.

La hotte doit être raccordée au réseau

électrique uniquement avec des

conducteurs de cuivre.

On peut obtenir aux adresses suivantes

des exemplaires des normes

mentionnées :

*National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

**CSA International

8501 East Pleasant Valley Rd.

Cleveland, Ohio 44131-5575

Avant de commencer…

Votre sécurité et celle des autres est

très importante.

Nous donnons de nombreux messages

de sécurité importants dans ce manuel,

et sur votre appareil ménager. Assurezvous de toujours lire tous les messages

de sécurité et de vous y conformer.

Voici le symbole d’alerte de

sécurité.

Ce symbole d’alerte de

sécurité vous signale les dangers

potentiels de décès et de blessures

graves à vous et à d’autres.

Tous les messages de sécurité suivront

le symbole d’alerte de sécurité et le mot

«DANGER» ou «AVERTISSEMENT».

Ces mots signifient :

Risque possible de décès ou de

blessure grave si vous ne suivez pas

les instructions.

Tous les messages de sécurité vous

diront quel est le danger potentiel et

vous disent comment réduire le risque

de blessure et ce qui peut se produire

en cas de non-respect des instructions.

DANGER

Risque possible de décès ou de

blessure grave si vous ne suivez pas

immédiatement

les instructions.

AVERTISSEMENT

Important : Observer les

dispositions de tous les codes et

règlements en vigueur.

Page 13

3

Dimensions du produit

Le circuit d’évacuation d’air ne doit pas

se terminer dans un grenier ou un

autre espace fermé.

Ne pas utiliser une bouche de

décharge murale de 10,2 cm (4 po)

normalement utilisée pour un

équipement de buanderie.

Utiliser uniquement un conduit

d’évacuation métallique.

On recommande un conduit métallique

rigide. Ne pas utiliser des conduits de

plastique ou de feuille métallique.

On déconseille l’emploi d’un conduit

flexible. Un conduit flexible peut

susciter la formation d’une

rétropression, ce qui réduit

considérablement la performance de la

hotte.

• La taille du conduit d’évacuation doit

être uniforme.

• Ne pas utiliser plus de trois coudes à

90°.

• S’il y a deux raccords coudés ou plus,

veiller à ce qu’il y ait une distance

droite d’au moins 61 cm (24 po) entre

deux coudes consécutifs.

• Ne pas raccorder deux coudes

ensemble.

• Pour maximiser l’efficacité, minimiser

la longueur effective totale du circuit

d’évacuation et le nombre de coudes.

• Le circuit d’évacuation doit comporter

un clapet de réglage. Si la bouche de

décharge (sur le toit ou à travers le

mur) comporte un clapet, ne pas

utiliser le clapet fourni avec la hotte.

• Utiliser du ruban adhésif pour

conduit pour assurer l’étanchéité au

niveau de chaque jointure du circuit

d’évacuation.

• Utiliser un produit de calfeutrage

pour assurer l’étanchéité entre la

bouche de décharge et le mur ou le

toit.

Note : On recommande que le circuit

d’évacuation soit installé avant

l’installation de la hotte.

Le circuit d’évacuation nécessaire pour

l’installation du système n’est pas

inclus. On recommande l’emploi de

conduits à section rectangulaire

de 8,3 x 25 cm

(3 1/4 x 10 po).

Méthodes d'évacuation de l'air

Raccords standard

recommandés

coude à 90°

8,3 x 25 cm (3 1/4 x

10 po)

= 1,5 m (5 pi)

coude plat à 90°

8,3 x 25 cm (3 1/4 x

10 po)

= 3,7 m (12 pi)

bouche de décharge

murale 8,3 x 25 cm

(3 1/4 x 10 po)

= 0 m (0 pi)

Décharge à

travers le toit

conduit de

8,3 x 25 cm (3 1/4

x 10 po) -décharge

à travers le toit

Décharge à

travers le mur

conduit de 8,3 x

25 cm (3 1/4 x 10

po) - décharge à

travers le mur

bouche

de

décharge

murale

coude à 90°

8,3 x 25 cm (3

1/4 x 10 po)

bouche de

décharge

murale

Longueur maximale = 8 m (26 pi)

1 —

coude à 90°

= 1,5 m (5 pi)

Section droite

2,8 m (9pi) = 2,8 m (9 pi)

1 — bouche de

décharge murale = 0 m (0 pi)

Longueur effective

totale du circuit de

8,3 x 25 cm

(3 1/4 x 10 po) = 4,3 m (14 pi)

1,8 m (6 pi)

0,93 m

(3 pi)

Circuit d’évacuation en conduit de

8,3 x 25 cm (3 1/4 x 10 po)

Longueur recommandée du

circuit d’évacuation

Réaliser un circuit d’évacuation d’une

longueur effective maximale de 8 m

(26 pi), en conduits de 8,3 x 25 cm (3

1/4 x 10 po). Pour obtenir la meilleure

performance, ne pas inclure plus de

trois coudes à 90°. Pour calculer la

longueur effective du système,

déterminer la longueur équivalente en

mètres (pieds) de chaque composant

du circuit, et calculer le total. Voir

l’exemple suivant.

19,6 cm

(7 3/4 po)

25,2 cm

(9 15/16 po)

8,1 cm

(3 3/16 po)

Note : la face inférieure de la hotte doit se

trouver à au moins 61 cm (24 po) au-dessus de

la surface d’une table de cuisson.

60,0 cm

(2 11/32 po)

4,4 cm

(1 3/4 po)

Ne pas

utiliser ces

opercules

arrachables

4,6 cm

(1 13/16 po)

6,5 cm

(2 9/16 po)

4,0 cm

(1 9/16 po)

3,0 cm

(1 2/16 po)

3,0 cm

(1 3/16 po)

12,1 cm

(4 3/4 po)

12,9 cm

(5 1/16 po)

25,0 cm

(9 27/32 po)

45,1 cm

(17 3/4 po)

34,0 cm

(13 3/8 po)

76,2 cm (30 po)

91,3 cm (36 po)

Pour modèles avec évacuation :

Illustration du modèle pour

décharge par le toit

Spécifications du

circuit d'évacuation

Page 14

Commencer

maintenant

4

1.

Placer un épais matériau

protecteur sur la table de cuisson ou

la cuisinière pour la protéger contre

des dommages ou des

débris/souillures.

Dans le cas de l’installation de la hotte

au-dessus d’une cuisinière autonome,

débrancher et déplacer la cuisinière

pour obtenir un meilleur accès au

placard mural supérieur et au mur

arrière. Avant de déplacer la

cuisinière, placer celle-ci sur une

feuille de carton ou un panneau de

bois, pour ne pas endommager le

revêtement de sol.

2.

Placer la hotte sur un matériau

de protection, filtres orientés vers le

bas.

3.

Choisir la méthode de décharge

à employer (décharge par le toit, à

travers le mur, ou bien installation

avec recyclage de l’air).

• La hotte est configurée à l’usine

pour la décharge à travers le toit.

• Pour l’installation de la hotte avec

recyclage, passer à l’étape 4.

raccord de

connexion

pour décharge

plaque de fermeture

opercule

arrachable

supérieur

Pour la décharge de l’air à travers le

mur, ôter la plaque de fermeture à

l’arrière de la hotte et le connecteur

de décharge fixé au sommet de la

hotte. Réinstaller le connecteur de

décharge à l’arrière de la hotte, et

réinstaller la plaque de fermeture au

sommet de la hotte.

4.

Ôter l’opercule arrachable du

trou (au sommet ou à l’arrière) qui

doit être utilisé pour le passage du

câble.

6.

Aligner la ligne de l’axe central

du gabarit avec les lignes tracées sur

le mur arrière et sur le fond du

placard mural supérieur. Fixer le

gabarit en place avec du ruban

adhésif. Marquer la position des

quatre trous utilisés pour la fixation

de la hotte sur le placard mural

supérieur.

7.

Selon la configuration

d’installation, marquer la position du

trou de passage du câblage ou de

l’ouverture de décharge dans le

placard mural supérieur ou sur le mur

arrière, selon les indications du

gabarit.

8.

Enlever le gabarit.

9.

Percer quatre trous de 5 mm

(3/16 po) à travers le placard mural

supérieur pour les vis de montage de

la hotte.

10.

Percer le trou de 4 cm (1 1/2

po) pour le passage du câblage.

11.

Découper l’ouverture de

passage du conduit rectangulaire

d’évacuation 8,3 x 25,4 cm (3 1/4 x 10

po). Note : On recommande que le

circuit d’évacuation soit installé avant

l’installation de la hotte.

12.

Retourner la hotte pour

placer les filtres vers le haut.

gabarit

5.

Tracer les lignes correspondant

à l’axe central sur le mur arrière et sur

le fond du placard mural supérieur.

Pour une installation avec recyclage :

Prolonger l’axe central tracé jusqu’au

soffite au-dessus de la hotte.

axe central

13.

Faire pivoter le déflecteur

pour l’écarter des filtres. Tirer vers

l’arrière la zone de saisie de chaque

filtre à graisse pour libérer les onglets

de verrouillage. Soulever chaque filtre

pour l’extraire de la hotte; conserver

le filtre à part.

14.

Ôter les deux vis des onglets

du diffuseur de lumière. Sur la surface

du diffuseur de lumière, directement

derrière les onglets, pousser vers

l’arrière de la hotte pour dégager les

onglets des fentes. Enlever le

diffuseur de lumière; conserver le

diffuseur et les vis à part.

15.

Ôter les deux vis du

couvercle du boîtier de connexion

(angle arrière/à droite) et ôter le

couvercle. Installer un serre-câble

(homologation U.L. ou CSA) dans le

trou de passage de câble.

16.

Retourner la hotte pour

placer les filtres vers le bas.

Ôter les

vis

couvercle

du boîtier

de

connexion

opercule

arrachable arrière

ne pas utiliser

ces opercules

arrachables

positions des vis

vis

Page 15

5

moyeu de filtre

20.

Raccorder le conduit de

décharge.

Installation pour recyclage de l’air :

Installer la grille sur le soffite.

19.

Soulever la hotte jusqu’à sa

position d’installation, tout en

introduisant le câble d’alimentation

21.

Raccorder les conducteurs

du câble d’alimentation de la hotte

aux conducteurs de même couleur

du circuit électrique, avec des

connecteurs vissables (blanc-blanc et

noir-noir).

Ensuite connecter le conducteur de

liaison à la terre à l’intérieur de la

boîte de connexion de la hotte, avec

la vis verte.

Réinstaller le couvercle de la boîte de

connexion.

Raccordement au circuit

électrique

23.

Installations d’une hotte pour

recyclage (sans décharge) : Installer les

filtres à charbon. Placer le filtre sur

son moyeu dans chaque ouverture de

ventilateur, pousser vers le haut et

tourner dans le sens horaire pour

bloquer le filtre en place.

24.

Installer les filtres à graisse

(aluminium).

installer

la vis

onglet

vis verte pour

liaison à la terre

18.

La hotte sera fixée sur le

fond du placard mural au moyen de

quatre vis (avec rondelle) insérées à

travers le fond du placard mural

(depuis l’intérieur du placard) et dans

la hotte.

• Si le fond du placard mural

comporte un cadre formant une

cavité, utiliser les quatre vis de 7 cm

(2 3/4 po) fournies.

• Si le fond du placard ne comporte

pas de cadre ou cavité, utiliser les

quatre vis de 5,1 cm (2 po) plus

courtes, fournies.

A

Mesurer la distance A et reporter cette

dimension sur l’axe central du soffite.

Tracer/découper l’ouverture de 8,3 x

25,4 cm (3 1/4 x 10 po) dans le soffite.

dans la boîte de connexion.

Introduire une longueur suffisante

des conducteurs dans la boîte de

connexion pour pouvoir facilement

réaliser les connexions, puis serrer le

serre-câble. Insérer les quatre vis à

travers le fond du placard et dans la

hotte. Visser les vis sur la hotte et

bien serrer.

17.

Installer le clapet dans le

raccord de connexion du conduit de

décharge. Vérifier que le volet peut

pivoter librement. Si la bouche de

décharge sur le toit ou la bouche de

décharge murale comporte un clapet,

NE PAS installer le clapet fourni avec

la hotte.

Installations d’une hotte pour

recyclage (sans décharge) : Installer la

section de conduit de décharge

utilisée sur le raccord de connexion

de conduit qui serait utilisé pour la

décharge à travers le toit, mais sans la

fixer.

Risque de choc électrique

Interrompre l’alimentation

électrique avant d’effectuer des

raccordements.

Connecter le conducteur de

liaison à la terre avec la vis verte

dans la boîte de connexion.

Le non-respect de ces

instructions peut provoquer un

choc électrique ou un accident

mortel.

AVERTISSEMENT

22.

Réinstaller le diffuseur de

lumière. Insérer les onglets du

diffuseur dans leur logement.

Pousser à l’arrière du panneau

diffuseur de lumière et insérer les

petits onglets dans leur logement à

l’arrière de la hotte. Réinstaller les

deux vis et bien serrer.

Danger - poids excessif

Deux personnes ou plus doivent

intervenir pour déplacer et

installer la hotte.

Le non-respect de cette

instruction peut causer une

blessure au dos ou d’autres

blessures.

AVERTISSEMENT

Page 16

6

Utilisation de la hotte

Pour obtenir les meilleurs résultats,

mettre le ventilateur de la hotte en

marche avant le début de la cuisson,

et laisser le ventilateur fonctionner

jusqu’à ce qu’il ait évacué toutes les

fumées et odeurs de la pièce.

ventilateur

lampe

Utilisation et entretien

AVERTISSEMENT - Pour réduire le

risque d’incendie ou de choc

électrique, ne pas utiliser ce ventilateur

en conjonction avec un dispositif de

réglage de la vitesse à semiconducteurs.

AVERTISSEMENT - POUR MINIMISER

LE RISQUE D’INCENDIE, CHOC

ÉLECTRIQUE OU DOMMAGES

CORPORELS, RESPECTER LES

INSTRUCTIONS SUIVANTES :

Utiliser cet appareil uniquement de la

manière prévue par le fabricant. Pour

toute question, contacter le fabricant.

Avant d’entreprendre des opérations

de réparation ou nettoyage de

l’appareil, interrompre l’alimentation

électrique au niveau du tableau de

distribution et verrouiller le disjoncteur

pour empêcher un rétablissement

accidentel de l’alimentation. S’il n’est

pas possible de verrouiller le

disjoncteur ou autre coupe-circuit,

veiller à bien fixer sur le tableau de

distribution une étiquette proéminente

interdisant le rétablissement de

l’alimentation.

MISE EN GARDE : Cet appareil est

conçu uniquement pour la ventilation

générale. Ne pas l’utiliser pour

l’extraction de matières ou vapeurs

dangereuses ou explosives.

AVERTISSEMENT - POUR MINIMISER

LE RISQUE D’UN FEU DE GRAISSE

SUR LA TABLE DE CUISSON :

Ne jamais laisser un élément de la

table de cuisson fonctionner sans

surveillance à la puissance de

chauffage maximale; un

renversement/débordement de matière

graisseuse pourrait provoquer une

inflammation et le génération de

fumée.

Utiliser toujours une puissance de

chauffage moyenne ou basse pour le

chauffage d’huile.

Veiller à toujours faire fonctionner le

ventilateur de la hotte lors d’une

cuisson avec une puissance de

chauffage élevée ou lors de la cuisson

d’un mets à flamber.

Nettoyer fréquemment les ventilateurs

d’extraction. Veiller à ne pas laisser de

la graisse s’accumuler sur les surfaces

du ventilateur ou des filtres.

Utiliser toujours un ustensile de taille

appropriée. Utiliser toujours un

ustensile de taille adapté à la taille de

l’élément chauffant.

AVERTISSEMENT - POUR RÉDUIRE LE

RISQUE DE DOMMAGES CORPORELS

APRÈS LE DÉCLENCHEMENT D’UN

FEU DE GRAISSE SUR LA CUISINIÈRE,

APPLIQUER LES RECOMMANDATIONS

SUIVANTES :

Placer sur le récipient un couvercle

bien ajusté, une tôle à biscuits ou un

plateau métallique POUR ÉTOUFFER

LES FLAMMES, puis éteindre le

brûleur. VEILLER À ÉVITER LES

BRÛLURES. Si les flammes ne

s’éteignent pas immédiatement,

ÉVACUER LA PIÈCE ET CONTACTER

LES POMPIERS.

NE JAMAIS PRENDRE EN MAIN UN

RÉCIPIENT ENFLAMMÉ - le risque de

brûlure est élevé.

NE PAS UTILISER D’EAU ni un torchon

humide - ceci pourrait provoquer une

explosion de vapeur brûlante. Utiliser

un extincteur SEULEMENT si :

Il s’agit d’un extincteur de classe ABC,

dont on connaît le fonctionnement.

Il s’agit d’un petit feu encore limité à

l’endroit où il s’est déclaré.

Les pompiers ont été contactés.

Il est possible de garder le dos orienté

vers une sortie pendant l’opération de

lutte contre le feu.

réceptacle

du

collecteur

de graisse

ouverture pour

collecteur de

graisse

26.

Mettre l’appareil sous tension.

Schémas de câblage

25.

Enlever le cabochon de

plastique (entre les lampes). Identifier

l’onglet dans la grande fente du

cabochon. Avec un petit tournevis à

lame plate, pousser l’onglet vers le

centre du cabochon pour dégager

l’onglet. Appuyer sur le cabochon

pour dégager les deux autres onglets;

jeter le cabochon.

Trouver le réceptacle à graisse dans

le sachet de petites pièces; insérer le

réceptacle dans l’ouverture (rotation

dans le sens horaire).

pousser l'onglet

vers le centre du

cabochon

BL

BL

BL

N

N

ROUGE

ROUGE

V

V

ROUGE

BL

VIOLET

VIOLET

VIOLET

VIOLET

VIOLET

N

N

N

BL

BL

BR

BR

BR

OR

OR

OR

BL

BL

BLEU

BLEU

GR

GR

V

V

BR

OR

BL

BLEU

GR

BL

BR

OR

BL

BLEU

GR

BL

Boîte de connexion

Commande marche/arrêt du

ventilateur : Faire glisser le bouton

dans le sens approprié pour

commander la mise en marche ou

l’arrêt du ventilateur, et pour

sélectionner sa vitesse de

fonctionnement. On peut augmenter

ou réduire la vitesse du ventilateur à

tout moment durant le fonctionnement

de la hotte.

Commande marche/arrêt de la lampe :

Faire glisser le bouton dans le sens

approprié pour commander l’allumage

ou l’extinction de la lampe. On peut

allumer/éteindre la lampe à tout

moment durant le fonctionnement de

la hotte.

Déflecteur : Lorsque l’opération de

cuisson doit générer beaucoup de

fumée, utiliser le déflecteur. La

fonction du déflecteur est de

concentrer l’effet d’aspiration produit

par la hotte.

Pour déployer le déflecteur, saisir par

l’intérieur, et tirer vers le bas. Pour

rétracter le déflecteur, pousser vers le

haut.

ROUGE

Ligne 120 vca 60 Hz

GRN

X

WIRING BO

BLK BLK

GRN

120 VAC LINE IN 60 Hz

RED

VLT

BLK

WHT

WHT

RED

BRW

ORG

WHT

BLU

GRY

WHT

WHT

RED VLT

RED

WHT

GRN

VLTVLT

VLT

BLK

WHT

WHT

BRWORG

BRWORG

BRWORG

BLK

WHT

WHT

BRW

ORG

WHT

BLU

GRY

WHT

14 Fμ

BLU

GRY

BLU

GRY

GRN

Page 17

7

Entretien de la hotte

Ôter les vis

Filtres : Pour obtenir les meilleurs

résultats, enlever et nettoyer

fréquemment les filtres d’aluminium.

On peut nettoyer les filtres dans un

lave-vaisselle, ou avec de l’eau

savonneuse chaude.

Ne pas laver les filtres à charbon

utilisés dans une hotte à recyclage

(sans décharge). Pour le

remplacement des filtres à charbon,

commander les filtres neufs chez un

revendeur (ensemble no 4396273)

Dépose des filtres : Déployer le

déflecteur. Pousser sur la zone de

saisie, vers l’arrière de la hotte, et tirer

vers le bas.

Remplacement des lampes : Utiliser

un tournevis Phillips pour ôter la vis

Nettoyage du réceptacle à graisse :

Faire pivoter le réceptacle dans le sens

antihoraire pour l’enlever. Laver le

réceptacle dans de l’eau savonneuse

chaude. Faire sécher puis réinsérer le

réceptacle (rotation dans le sens

horaire).

Surfaces externes : Nettoyer avec un

détergent doux et un linge doux. NE

PAS employer un produit de nettoyage

abrasif ou de la laine d’acier.

réceptacle

à graisse

Déflecteur

Réinstallation des filtres : Insérer

chaque filtre dans l’arrière de la hotte;

pousser vers le haut pour la mise en

place tout en poussant vers l’arrière

sur la zone de saisie. Lâcher la zone

de saisie.

GARANTIE DU SYSTÈME DE VENTILATION KITCHENAID

®

GARANTIE LIMITÉE DE UN AN

Pendant un an à compter de la date d'achat, lorsque ce gros appareil ménager est utilisé et entretenu conformément aux instructions

jointes à ou fournies avec le produit, KitchenAid ou KitchenAid Canada (ci-après désignées “KitchenAid”) paiera pour les pièces

spécifiées par l'usine et la main-d'œuvre pour corriger les vices de matériaux ou de fabrication. Le service doit être fourni par une

compagnie de service désignée par KitchenAid.

KITCHENAID NE PRENDRA PAS EN CHARGE

1. Les visites de service pour rectifier l'installation du gros appareil ménager, montrer à l'utilisateur comment utiliser l'appareil,

remplacer ou réparer des fusibles ou rectifier le câblage ou la plomberie du domicile.

2. Les visites de service pour réparer ou remplacer les ampoules électriques de l'appareil, les filtres à air ou les filtres à eau. Ces

pièces consomptibles ne sont pas couvertes par la garantie.

3. Les réparations lorsque le gros appareil ménager est utilisé à des fins autres que l'usage unifamilial normal.

4. Les dommages imputables à : accident, modification, usage impropre ou abusif, incendie, inondation, actes de Dieu, installation

fautive ou installation non conforme aux codes d'électricité ou de plomberie, ou l'utilisation de produits non approuvés par

KitchenAid.

5. Le coût des pièces de rechange et de la main-d'œuvre pour les appareils utilisés hors des États-Unis ou du Canada.

6. Le ramassage et la livraison. Ce gros appareil ménager est conçu pour être réparé à domicile.

7. Les réparations aux pièces ou systèmes résultant d'une modification non autorisée faite à l'appareil.

8. Les frais de voyage ou de transport pour le service d'un produit dans les régions éloignées.

9. La dépose et la réinstallation de votre appareil si celui-ci est installé dans un endroit inaccessible ou n'est pas installé

conformément aux instructions d'installation fournies.

CLAUSE D'EXONÉRATION DE RESPONSABILITÉ AU TITRE DES GARANTIES IMPLICITES; LIMITATION DES RECOURS

LE SEUL ET EXCLUSIF RECOURS DU CLIENT DANS LE CADRE DE LA PRÉSENTE GARANTIE LIMITÉE CONSISTE EN LA

RÉPARATION PRÉVUE CI-DESSUS. LES GARANTIES IMPLICITES, Y COMPRIS LES GARANTIES APPLICABLES DE QUALITÉ

MARCHANDE ET D'APTITUDE À UN USAGE PARTICULIER, SONT LIMITÉES À UN AN OU À LA PLUS COURTE PÉRIODE AUTORISÉE

PAR LA LOI. KITCHENAID N'ASSUME AUCUNE RESPONSABILITÉ POUR LES DOMMAGES FORTUITS OU INDIRECTS. CERTAINES

JURIDICTIONS NE PERMETTENT PAS L'EXCLUSION OU LA LIMITATION DES DOMMAGES FORTUITS OU INDIRECTS, OU LES

LIMITATIONS DE LA DURÉE DES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE OU D'APTITUDE À UN USAGE PARTICULIER,

DE SORTE QUE CES EXCLUSIONS OU LIMITATIONS PEUVENT NE PAS S'APPLIQUER DANS VOTRE CAS. CETTE GARANTIE VOUS

CONFÈRE DES DROITS JURIDIQUES SPÉCIFIQUES ET VOUS POUVEZ ÉGALEMENT JOUIR D'AUTRES DROITS QUI PEUVENT

VARIER D'UNE JURIDICTION À UNE AUTRE.

À l'extérieur du Canada et des 50 États des États-Unis, cette garantie ne s'applique pas. Contacter votre marchand KitchenAid autorisé

pour déterminer si une autre garantie s'applique.

Si vous avez besoin de service, voir d'abord la section “Dépannage” du Guide d'utilisation et d'entretien. Après avoir vérifié la section

“Dépannage”, de l'aide supplémentaire peut être trouvée en vérifiant la section “Assistance ou service” ou en appelant KitchenAid. Aux

É.-U., composer le 1-800-422-1230. Au Canada, composer le 1-800-807-6777. 10/05

fixant le cabochon de la lampe.

Enlever la vieille lampe, installer une

lampe de 40 W, E17 sfera, 120 volts.

Réinstaller le cabochon.

Page 18

8

Demande d'assistance ou de service

Téléphoner au Centre d'interaction avec la

clientéle KitchenAid sans frais d'interurbain au

1-800-235-0665.

Nos consultants sont disponibles pour vous aider.

Lors de votre appel, veuillez connaître

la date d’achat et les numéros au

complet de modèle et de série de votre

appareil. Ces renseignements nous

aideront à mieux répondre à votre

demande.

Si vous avez besoin de pièces de rechange

Si vous avez besoin de commander des pièces de

rechange, nous vous recommandons d’utiliser

seulement des pièces autorisées par l’usine. Ces

pièces conviendront et fonctionneront bien parce

qu’elles sont fabriquées selon les mêmes

Pour plus d'assistance

Si vous avez besoin de plus d’assistance, vous

pouvez écrire en soumettant toute question ou

problème à :

KitchenAid Brand Home Appliances

Customer Interaction Center

C/o Correspondence Dept.

2000 North M-63

Benton Harbor, MI 49022-2692

Veuillez indiquer dans votre correspondance un

numéro de téléphone où l’on peut vous joindre dans

la journée.

Nos consultants fournissent de l’assistance pour :

- Caractéristiques et spécifications de notre gamme

complète d’appareils électroménagers

- Renseignements concernant l’installation

- Procédés d’utilisation et d’entretien

- Vente d’accessoires et de pièces de rechange

- Assistance spécialisée aux clients (langue

espagnole, malentendants, malvoyants, etc.)

- Les références aux marchands, compagnies de

service de réparation, et distributeurs de pièces de

rechange locaux.

Les techniciens de service désignés par KitchenAid

sont formés pour exécuter les travaux sous garantie

sur les produits et pour dispenser les services

nécessaires après l’expiration de la garantie, partout

aux

É.-U.

Pour localiser la compagnie de service désignée par

KitchenAid dans votre région, vous pouvez consulter

les Pages jaunes de votre annuaire de téléphone.

Si vous avez besoin d'assistance ou de service aux É.-U.

spécifications précises utilisées pour construire

chaque nouvel appareil KitchenAid®.

Pour localiser des pièces autorisées par l’usine dans

votre région, téléphonez à notre Centre

d’interaction avec la clientèle, votre Centre de

service autorisé le plus proche, ou le service de

l’usine KitchenAid en composant le

1-800-442-1111.

Page 19

2. Si vous avez besoin de service †

Communiquer avec votre succursale ou

établissement de service autorisé de

KitchenAid Canada la plus proche pour l’entretien

de votre appareil. (Voir liste ci-dessous.)

S’assurer que la compagnie de service que vous

contactez est désignée pour réparer votre

appareil durant la période de garantie.

1.

Téléphoner au Centre d’interaction avec la clientèle

KitchenAid sans frais d’interurbain entre 8 h 30 et

18 h 00 (HNE) au 1-800-235-0665...

ou communiquer avec le marchand

chez qui vous avez acheté votre appareil

électroménager.

SERVICE D’APPAREILS MÉNAGERS KITCHENAID CANADA - SERVICE AUX CONSOMMATEURS

Succursales de service direct :

COLOMBIE-BRITANNIQUE 1-800-665-6788

ALBERTA 1-800-661-6291

ONTARIO Région d'Ottawa 1-800-267-3456

(à l'exception du code régional 807) En dehors de la région d'Ottawa 1-800-807-6777

MANITOBA, SASKATCHEWAN 1-800-665-1683

et code régional 807 en ONTARIO

QUÉBEC Montréal (à l'exception de la rive sud) 1-800-361-3032

Rive Sud Montréal 1-800-361-0950

Québec 1-800-463-1523

Sherbrooke 1-800-567-6966

PROVINCES DE L'ATLANTIQUE 1-800-565-1598

Pour plus d'assistance

Si vous avez besoin de plus d’assistance, vous

pouvez écrire à KitchenAid Canada en

soumettant toute question ou préoccupation au :

Service des relations avec la clientèle

KitchenAid Canada

1901 Minnesota Court

Mississauga, Ontario L5N 3A7

✝

Lorsque vous demandez de l’assistance ou un

service, veuillez fournir une description

détaillée du problème, les numéros complets

du modèle et de série de l’appareil, et la date

d’achat. (Voir la section « Note à l’intention de

l’utilisateur. ») Ces renseignements nous

aideront à mieux répondre à votre demande.

Si vous avez besoin d'assistance au de service au Canada

Demande d'assistance ou de service

9

Veuillez indiquer dans votre correspondance un

numéro de téléphone où l’on peut vous

joindre durant la journée.

Page 20

4329589/

9763392

®

Marque de commerce ou marque de commerce déposée de KitchenAid, U.S.A., utilisation sous

licence au Canada par KitchenAid Canada

Imprimé en Italie

10/20 05

Loading...

Loading...