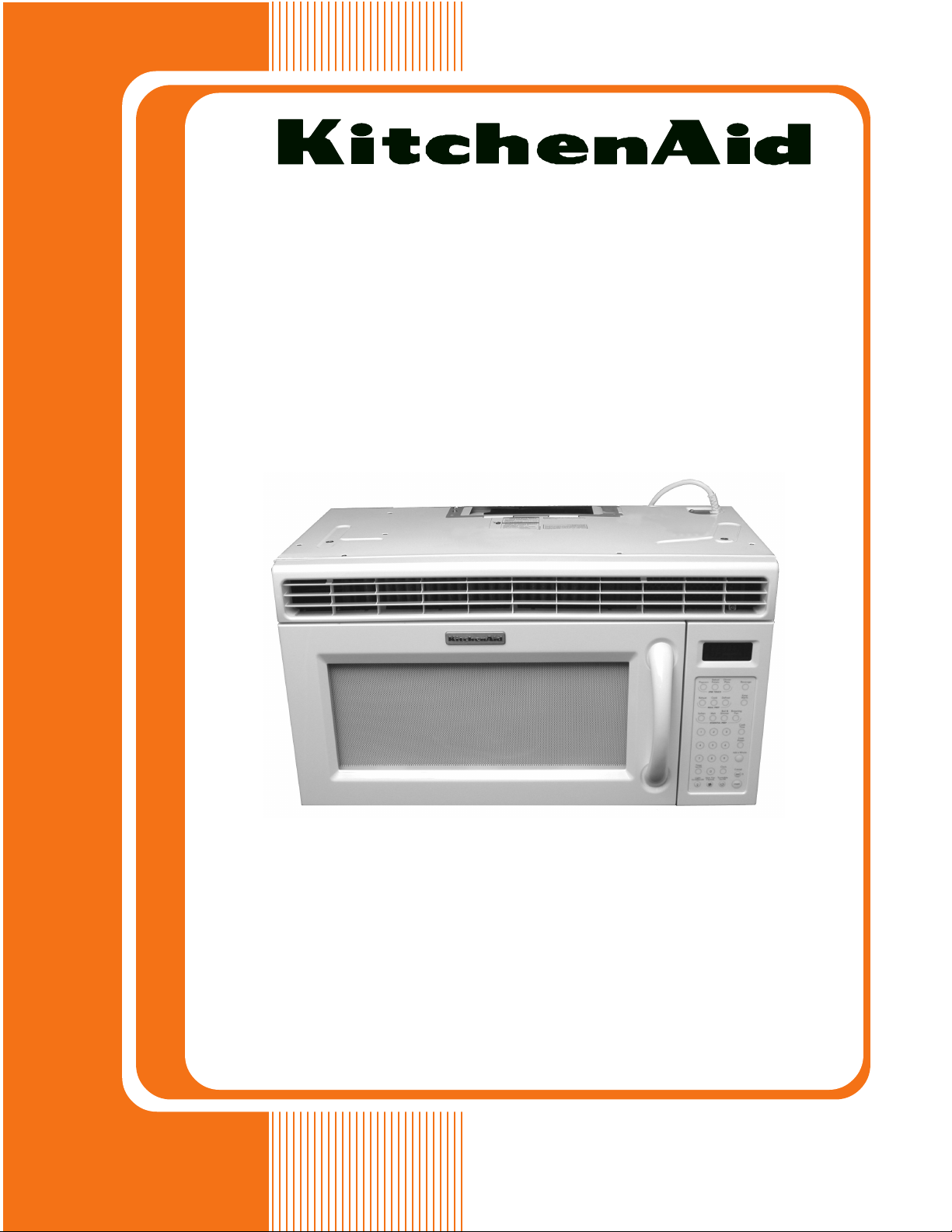

Page 1

TECHNICAL EDUCATION

Over-The-Range

Microwave Oven

KAC-39

Model: KHMS175M

JOB AID 4317357

Page 2

FORWARD

This KitchenAid Job Aid, “Over-The-Range Microwave Oven,” (Part No. 4317357), provides the

technician with information on the installation, operation, and service of the Over-The-Range

Microwave Oven. It is to be used as a training Job Aid and Service Manual.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Over-The-Range Microwave Oven.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the Microwave Oven to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2004, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Page 3

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Warning To Service Technicians ....................................................................................... 1-1

Precautions To Be Observed Before And During Servicing

To Avoid Possible Exposure To Excessive Microwave Energy ..................................... 1-2

R.F. Leakage Test ............................................................................................................. 1-3

Precautions To Be Observed When Troubleshooting ....................................................... 1-4

Model & Serial Number Designations ................................................................................ 1-5

Model & Serial Number Label And Tech Sheet Locations................................................. 1-6

Specifications..................................................................................................................... 1-7

KitchenAid Microwave Oven Warranty .............................................................................. 1-9

INSTALLATION INFORMATION ........................................................................................... 2-1

Adjusting The Exhaust Airflow ........................................................................................... 2-1

Removing & Reinstalling The Microwave Oven................................................................. 2-2

THEORY OF OPERATION ..................................................................................................... 3-1

Microwave Operation ......................................................................................................... 3-1

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Cabinet ...................................................................................................... 4-2

Removing The Bottom Cover & Hood Lamp Socket ......................................................... 4-3

Removing Cavity Thermostat 1 & The Humidity Sensor ................................................... 4-4

Removing The Stirrer Motor .............................................................................................. 4-6

Removing Cavity Thermostats 2 & 3 ................................................................................. 4-8

Removing The Hood Exhaust Fan Motor ........................................................................ 4-10

Removing The Cavity Lamp & Socket ............................................................................. 4-11

Removing The Control Panel Assembly, The Power Supply

& Display Boards, And The Keyboard .......................................................................... 4-12

Removing An Inline Fuse................................................................................................. 4-14

Removing The AC Line Filter Capacitor .......................................................................... 4-15

Removing The Cooling Fan Motor, The Exhaust Fan Thermostat,

And The Line Fuseholder ............................................................................................. 4-16

Removing The Motor Capacitor, The Magnetron

Thermostat, & The 40 W Inverter Board ...................................................................... 4-18

Removing The 1100 W Inverter Board ............................................................................ 4-20

Removing The Magnetron ............................................................................................... 4-22

Removing The Primary & Secondary Interlock Switches,

And The Monitor Switch................................................................................................ 4-24

Removing The Turntable Motor ....................................................................................... 4-26

Removing The Oven Door And The Inner Panel ............................................................. 4-27

- iii -

Page 4

COMPONENT TESTING ........................................................................................................ 5-1

Door Switches.................................................................................................................... 5-1

Touch Panel Continuity...................................................................................................... 5-2

Stirrer & Turntable Motors ................................................................................................. 5-3

AC Line Filter Capacitor..................................................................................................... 5-3

Humidity Sensor ................................................................................................................ 5-4

Cavity Thermostats 1, 2, & 3 ............................................................................................. 5-4

Line Fuse & Exhaust Fan Thermostat ............................................................................... 5-5

Motor Capacitor ................................................................................................................. 5-5

Cooling Fan Motor ............................................................................................................. 5-6

Hood Exhaust Fan Motor ................................................................................................... 5-6

Magnetron.......................................................................................................................... 5-7

Magnetron Thermostat ...................................................................................................... 5-7

Inverters ............................................................................................................................. 5-8

DIAGNOSIS & TROUBLESHOOTING ................................................................................... 6-1

Power Output Measurement .............................................................................................. 6-1

Failure Codes .................................................................................................................... 6-1

Display And Power Board Callouts .................................................................................... 6-2

Primary, Secondary, & Monitor Switch Checks ................................................................. 6-3

Touch Panel & Microcomputer Board Test ........................................................................ 6-4

WIRING DIAGRAMS & STRIP CIRCUITS ............................................................................. 7-1

Schematic Diagram ........................................................................................................... 7-1

Wiring Diagram .................................................................................................................. 7-2

Strip Circuits ...................................................................................................................... 7-3

- iv -

Page 5

GENERAL

WARNING TO SERVICE TECHNICIANS

To avoid possible exposure to microwave radiation or energy, visually check the oven for

damage to the door and door seal before

operating any oven. Use a microwave survey

meter to check the amount of leakage before

servicing. In the event the R.F. Ieakage exceeds 4 mw/cm2 at 5 cm, appropriate repair

must be made before continuing to service the

unit. Check interlock function by operating the

door latch. The oven cook cycle should cut off

before the door can be opened.

The door and latching assembly contains the

radio frequency energy within the oven. The

door is protected by three safety interlock

switches. Do not attempt to defeat them.

Under no circumstances should you try to

operate the oven with the door open.

• Proper operation of microwave ovens requires that the magnetron be properly

assembled to the waveguide and cavity.

Never operate the magnetron unless it is

properly installed.

• Be sure the “RF” seal is not damaged and

is assembled around the magnetron dome

properly when installing the magnetron.

• Routine service safety procedures should

be exercised at all times.

• Untrained personnel should not attempt

service without a thorough review of test

procedures and safety information contained in this Job Aid.

KitchenAid microwave ovens have a monitoring system designed to assure proper operation of the safety interlock systems.

The monitor switch will immediately cause the

oven fuse to blow if the door is opened and the

primary door interlock switch and/or the secondary interlock switch contacts fail in a closed

position.

CAUTION: Replace a blown fuse with a 20

ampere class H fuse only.

Test the upper and lower door interlock

switches, cook relay, and monitor switch (middle

switch) for proper operation as described in the

component test procedures, before replacing

the blown oven fuse.

Do not attempt to repair sticking contacts

of any interlock switch, safety switch, or

Cook (Latch) relay. The components must

be replaced.

Any indication of sticking contacts during component tests requires replacement of that component to assure reliability of the safety interlock system.

If the fuse is blown, the Monitor switch, and

the Primary, and Secondary interlock

switches must be replaced. Be sure they

are properly connected.

1-1

Page 6

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING

SERVICING TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

A. Do not operate or allow the oven to be

operated with the door open.

B. Make the following safety checks on all

ovens to be serviced before activating the

magnetron or other microwave source,

and make repairs as necessary:

1)Interlock Operation

2)Proper Door Closing

3)Seal and Sealing Surfaces (Arcing,

Wear, and Other Damage)

4)Damage to or Loosening of Hinges and

Latches

5) Evidence of Dropping or Abuse

C. Before turning on the microwave power

for any service test or inspection within the

microwave generating components, check

the magnetron, wave guide or transmission line, and cavity for proper alignment,

integrity, and connections.

D. Any defective or misadjusted components

in the interlock, monitor, door seal, and

microwave generation and transmission

systems shall be repaired, replaced, or

adjusted, using procedures described in

this Job Aid, before the oven is released to

the owner.

E. A microwave leakage check to verify com-

pliance with the Federal Performance Standard should be performed on each oven

prior to release to the owner.

F. Do not attempt to operate the oven if the

door glass is broken.

1-2

Page 7

R.F. LEAKAGE TEST

EQUIPMENT

• Electromagnetic energy leakage monitor

(NARDA 8100B, HOLADAY H 1501 ).

• 275 ±15 ML glass beaker.

TEST

On every service call, checks for microwave

energy emission must be made according to

the following manner.

1. Remove the cooking rack from the oven

cavity, if the microwave oven is so

equipped.

2. Place a 275 ±15 ML (9.3 oz.) glass of

water in the center of the oven bottom.

3. Select "HIGH" cook power, turn the micro-

wave oven on, and test for R.F. Ieakage at

the following locations:

a)Around the cabinet at the front.

b)Around the door.

c) Across the console panel.

d)Horizontally across the door.

e)Vertically across the door.

f) Diagonally across the door.

g)Across the air vents.

h)Across the rear air vent.

i) All lockseams.

j) Weld at bottom.

k) Bottom plate.

I) Oven feet.

4. The scan speed is one inch per second.

When checking for R.F. Ieakage, use an approved R.F. measuring device to assure less

than 4 mw/cm2 emission at 5 cm distance with

a maximum scan rate of 2.54 cm/second, in

compliance with U.S. Government Department

of Health, Education and Welfare 21CFR1030,

Performance Standard for Microwave Ovens.

NOTE: Enter leakage readings in space BEFORE and AFTER on the service document.

All microwave ovens exceeding the emission

level of 4 mw/cm2 must be reported to Dept. of

Service for Microwave Ovens immediately and

the owner should be told not to use the microwave oven until it has been repaired completely.

If a microwave oven is found to operate with the

door open, report to Dept. of Service, the

manufacturer and CDRH* immediately. Also

tell the owner not to use the oven.

The monitor switch acts as the final safety

switch protecting the customer from microwave radiation. If the monitor switch operated

to blow the fuse when the interlocks failed, you

must replace all interlock switches with new

ones, because the contacts of those interlock

switches may be melted and welded together.

If safety interlock/monitor switch replacement,

or adjustment, is required, you must reconnect

the circuit, and perform a continuity check on

the monitor circuit.

All repairs must be performed in such a manner

that microwave energy emissions are minimal.

Address for CDRH is:

Office of Compliance (HFZ-312) Center for

Devices and Radiological Health

1390 Piccard Drive

Rockville, MD 20850

* CDRH: Center for Devices and Radiological Health,

Food and Drug Administration.

A properly operating door and seal assembly

will normally register small emissions, but they

must be no greater than 4 mw/cm2 to allow for

measurement uncertainty.

1-3

Page 8

PRECAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING

The microwave oven is a high voltage, high

current appliance. It is free from danger during

ordinary use, but extreme care should be taken

during repair.

VOLTAGE CAPACITORS

WARNING

DISCHARGING HIGH

CAUTION

Service technicians should remove their

watches whenever working close to or replacing the magnetron.

DANGER

HIGH VOLTAGE AND HIGH TEMPERA-

TURE (HOT/LIVE) OF THE INVERTER

POWER SUPPLY

The high voltage inverter power supply circuit supplies very high voltage and very high

current for the magnetron tube. Though it is

free from danger in ordinary use, extreme

care should be taken during repair. The

current is extremely large, and so danger

exists because of its high current and high

voltages.

The aluminum heat sink is also energized

with high voltage (HOT), so do not touch it

when the AC input terminal is connected to

the power line. One of the IGBT switching

power devices (collector) is directly connected to the aluminum heat sink.

The aluminum heat sink may be HOT from

heat energy; therefore, extreme care should

be taken during servicing and replacing.

For about 30 seconds after the oven is

turned off, an electric charge remains in the

high voltage capacitors in the inverter power

supply circuit board.

When replacing or checking parts, remove

the power plug from the outlet. Use a screwdriver with an insulated handle, and short the

inverter output of the magnetron filament

terminals to discharge it. Be sure to touch the

chassis ground side first, and then touch the

output terminals.

WARNING

There is high voltage present, with high

current capabilities in the circuits of the primary and secondary windings, the choke

coil, and the heat sink of the inverter. It is

extremely dangerous to work on or near

these circuits with the microwave oven energized. DO NOT measure the voltage in the

high voltage circuit, including the filament

voltage of the magnetron.

WARNING

Never touch any circuit wiring with your

hand, or with an insulated tool during operation.

WARNING

INVERTER POWER

SUPPLY GROUNDING

Check the high voltage inverter power supply circuit grounding. This high voltage inverter power supply circuit board must have

a proper chassis ground by the grounding

bracket to the chassis ground; otherwise,

this H.V. inverter circuit board will expose

very high voltage, and cause extreme DANGER. Be sure to have proper grounding by

the grounding plate and screws.

WARNING

Never insert a wire, nail, or any other metal

object through the lamp holes on the cavity,

or any other holes or gaps. Doing so may act

as an antenna, and cause microwave leakage.

WARNING

Before touching any oven components or

wiring, always unplug the oven from its

power source, and discharge the capacitors in the high voltage inverter.

1-4

Page 9

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER K H M S 1 7 5 M WH 0

PRODUCT GROUP

K = KITCHENAID BRAND

PRODUCT IDENTIFICATION

CM = COUNTERTOP MICROWAVE

HM = MICROWAVE HOOD

MERCHANDISING SCHEME

S = STANDARD

C = MICRO-CONVECTION

CAPACITY / SIZE / SERIES / CONFIGURATION

08 = 0.8 CU FT

10 = 1.0 CU FT

13 = 1.3 CU FT

14 = 1.4 CU FT

17 = 1.7 CU FT

FEATURES

2 = PLUS FEATURES

5 = DELUXE FEATURES

6 = MICRO-CONVECTION

7 = MICRO-CONVECTION WITH SENSOR

YEAR OF INTRODUCTION

M = 2003

COLOR CODE

WH = WHITE, BL = BLACK, BT = BISCUIT, SS = STAINLESS STEEL

ENGINEERING CHANGE (0, 1, 2, ETC.)

SERIAL NUMBER

SERIAL NUMBER T R P 4 0 10007

MANUFACTURING SITE

TR = Oxford, MS / Shunde

YEAR OF PRODUCTION

P = 2003

WEEK OF PRODUCTION

40TH WEEK

PRODUCT SEQUENCE NUMBER

1-5

Page 10

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number label and Tech Sheet locations are shown below.

Model & Serial

Number Label Location

Tech Sheet

Location

(Behind Grille)

1-6

Page 11

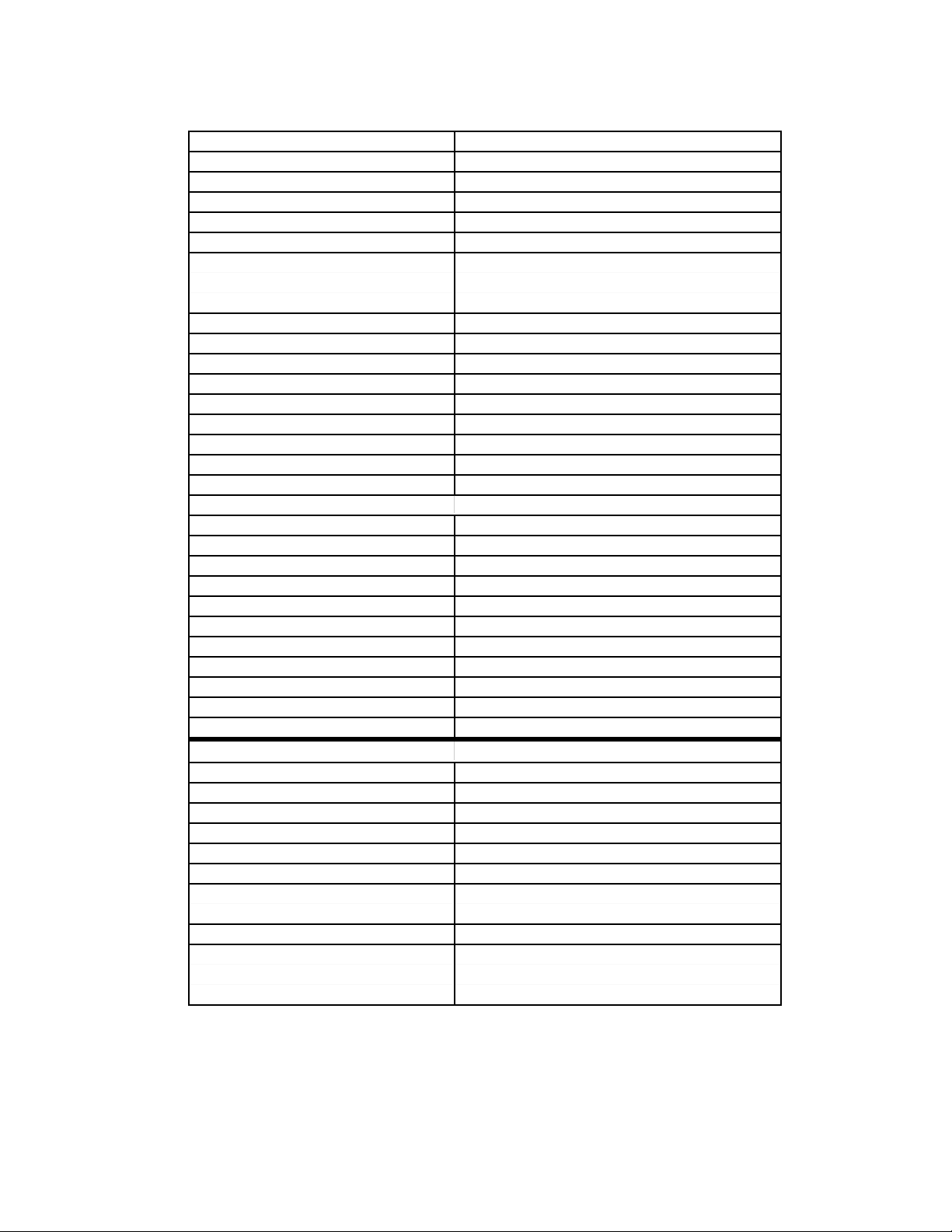

SPECIFICATIONS

MODEL KHMS175M

Colors White, Black, Biscuit , Stainless

CONTROL SYSTEM

Type Electronic

Limits 99 Min. 99 Sec.

Scale Linear (Digital)

2 Line Display with Multicolor Progress Bar

Display 5+2 Digit - Blue-Green

Fluorescent - Callouts In Display

In-Use Reprogramming Yes

More/Less Function Yes - Hidden "Cook Power" Button

Sales Demonstration Mode Yes - Hidden

Keypad Disable / Child Lockout Mode Yes - Press "Off/Cancel" Key for 5 Seconds

Cook Power Yes

Type Electronic

Range 0% - 100%

Scale Digital

Levels Ten

Exhaust Fan

Number of Speeds 5

Manual Off Yes

Auto Off No

Automatic Turn On @ 60°C, 140°F

Cooktop Light Halogen

Settings 3 levels HIGH, NIGHT & LOW

Wattage (2) 10 Watt Halogen

Light Cover Glass

Light "ON" When Cook Cycle Complete Yes

Stoppable Turntable Function / Button Yes

Technical Error Indication "F-" With Error Number

OVEN INTERIOR FEATURES

Size (inches) 22 7/8" W x 9 1/2" H x 14 1/2" D

Cooking Power 1100 Watts (IEC-705 Rating)

Turntable Yes, Sunken Flush

Glass turntable diameter 12"

Browning Pan Yes

Ventilation Axial blower

Cooling Fan Automatic - On if oven is operating,

Rack Yes

Light Automatic - Turns on when oven

door is open or oven is operating.

Sensor

Off if door open

10 Watt Halogen

1-7

Page 12

MODEL KHMS175M

DOOR FEATURES

Handle/Latch Yes/Pull to open

Seals Two Stage

(Capacitive and Reflective)

MICROWAVE SYSTEM

Distribution Top Feed with Stirrer

Magnetron Inverter Type

SAFETY FEATURES

Interlock Three Door/Latch Operated

Primary, secondary and monitor

Thermal Protectors Three - 1 Magnetron, 1 Oven Cavity, 1 Hood

VENTILATION SYSTEM

Type Convertible Recirculation or Exhaust Vertical/Horizontal

Duct Outlet Size 3 1/4"H x 10"W

Recirculation CFM Out 130

Exhaust CFM Out 175

Touch Control 5 Speed

Auto ON - High Speed YES: 60°C, 140°F

Noise Level Recirculation (Acc. to IEC 704) 67dBA

Shipped Recirculation mode

EXTERIOR FEATURES

Power Cord Length 3 Feet

OTHER SPECIFICATIONS

Electrical 120V, Single Phase, 60 Hz

1500 Watts, For Use With

15 - 20 Amp Circuit

Domestic Use Only Yes

Agency Approvals FCC, DHHS, CDRH, UL

Approx. Net Weight - Lb 63

APPROVED ACCESSORIES

Crisp Pan Yes

Exhaust Damper Assembly Yes (1 Set)

Hardware for Installation Yes (1 Set)

LITERATURE

Use & Care Guide Yes (Browning Pan instructions included)

Warranty In Use & Care Guide-1 Yr. Full, 2-5 Yr. Ltd. Mag. Tube

Tech Sheet 8185202

Job Aid 4317357

1-8

Page 13

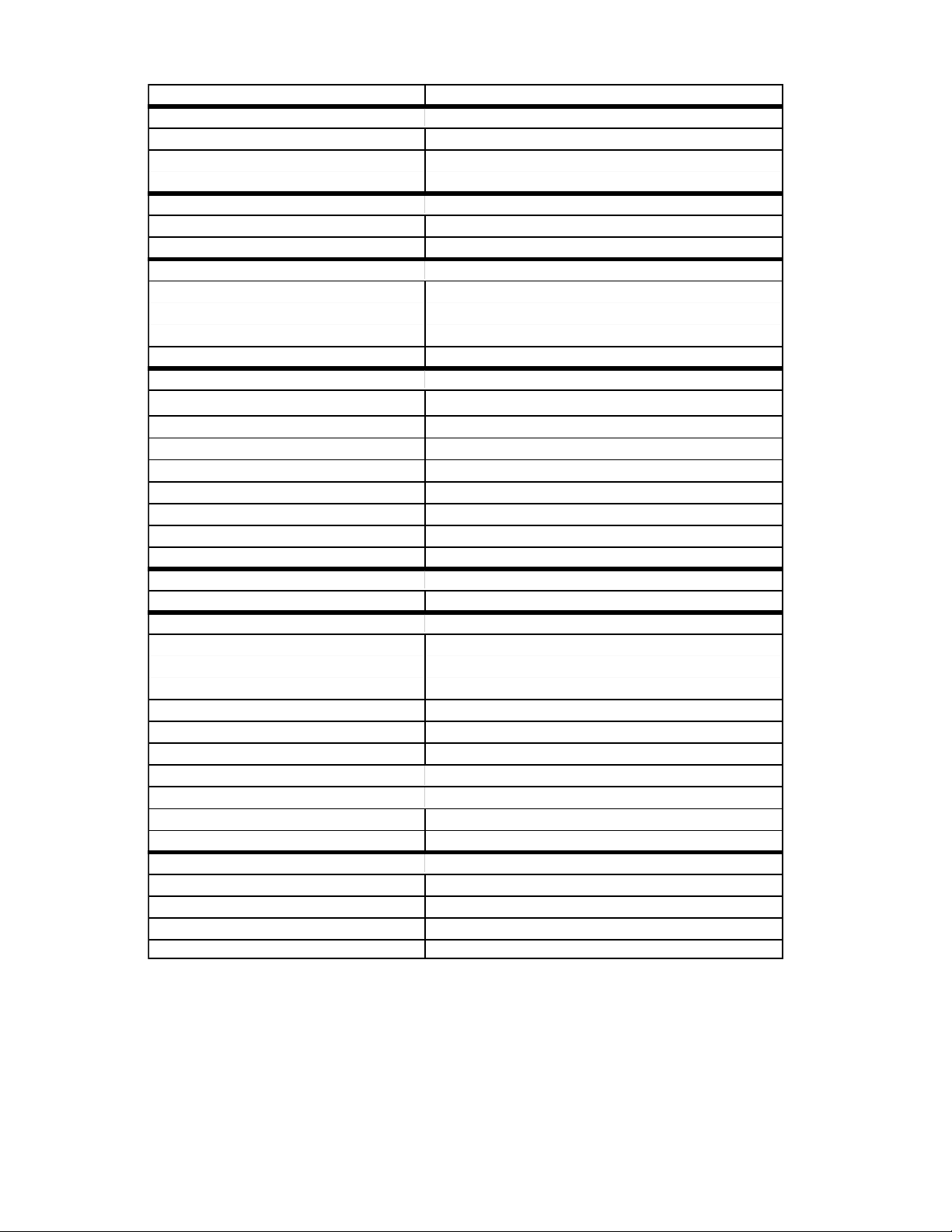

KITCHENAID MICROWAVE OVEN WARRANTY

LENGTH OF

WARRANTY:

ONE-YEAR FULL

WARRANTY

From Date of

Purchase.

LIMITED FOURYEAR WARRANTY Second

through fifth year

from Date of

Purchase.

KITCHENAID

WILL PAY FOR:

Replacement parts

and repair labor

costs to correct

defects in materials or workmanship. Service must

be provided by a

KitchenAid-designated servicing

company.

Replacement

magnetron tube on

microwave ovens if

defective in materials or workmanship.

KITCHENAID

WILL NOT PAY FOR:

A. Service calls to:

1. Correct the installation of the microwave

oven.

2. Instruct you how to use the microwave

oven.

3. Replace house fuses or correct house

wiring.

4. Replace owner-accessible light bulbs.

B. Repairs when microwave oven is used in

other than normal single-family household

use.

C. Pickup and delivery. The microwave is de-

signed to be repaired in the home.

D. Damage to the microwave oven resulting

from accident, alteration, misuse, abuse, fire,

flood, acts of God, or use of products not

approved by KitchenAid.

E. Any labor costs during the limited warranty.

F. Repairs to parts or systems resulting from

unauthorized modifications made to the

appliance.

G. Replacement parts or repair labor costs for

units operated outside the United States.

KITCHENAID OR KITCHENAID CANADA DO NOT ASSUME ANY RESPONSIBILITY FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states or provinces do not allow the

exclusion or limitation of incidental or consequential damages, so this exclusion or limitation may

not apply to you. This warranty gives you special legal rights, and you may also have other rights

which vary from state-to-state or province-to-province.

Outside the United States and Canada, a different warranty may apply. For details, please

contact your authorized KitchenAid dealer.

If you need service first see the “Troubleshooting” section of the Use and Care Guide. After

checking ”Troubleshooting,” additional help can be found by checking the “Assistance or Service” section, or by calling our Customer Interaction Center telephone numbers, listed below,

from anywhere in the U.S.A. or Canada.

KitchenAid: 1-800-422-1230

Canadian Residents call: 1-800-807-6777

1-9

Page 14

— NOTES —

1-10

Page 15

Toward Top Of Unit

Blower Air Inlet

INSTALLATION INFORMATION

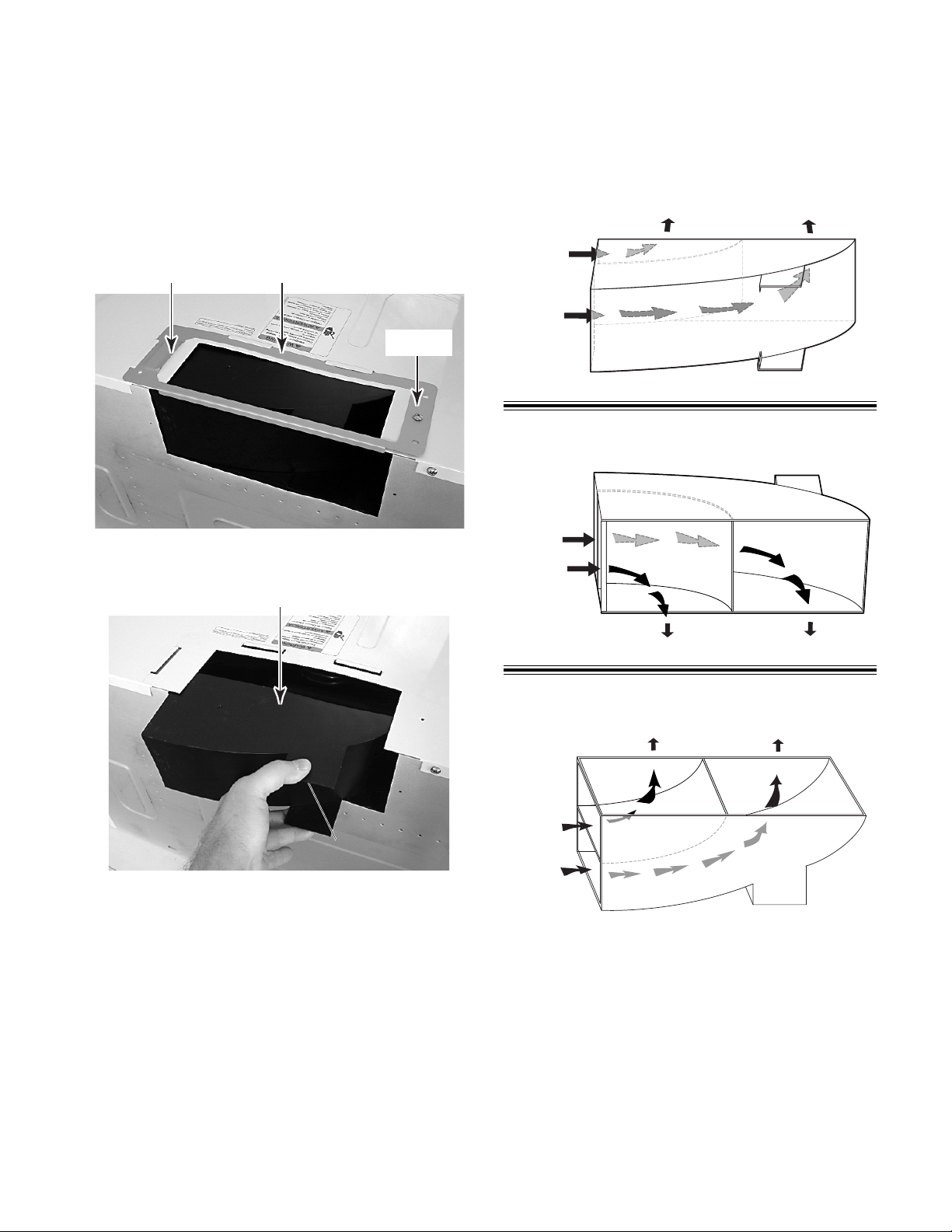

ADJUSTING THE EXHAUST AIRFLOW

1. Remove the screw from the damper plate

on top of the microwave cabinet, and

remove the plate from under the cabinet

flanges.

Flange

Damper Plate

Screw

2. Slide the air deflector out of the cabinet.

Air Deflector

Recirculating Air

Toward Front Of Unit

Blower Air Inlet

Rear Venting

Blower Air Inlet

3. Refer to the following illustrations and

determine how you would like to direct the

exhaust air out of the microwave oven.

NOTE: All microwave ovens are shipped

with the venting in the “recirculating” mode.

Toward Rear Of Unit

Top Venting

4. Rotate the air deflector so that the vanes

face in the desired direction, and slide the

air deflector back into the cabinet as far as

it will go, then reinstall the damper plate.

2-1

Page 16

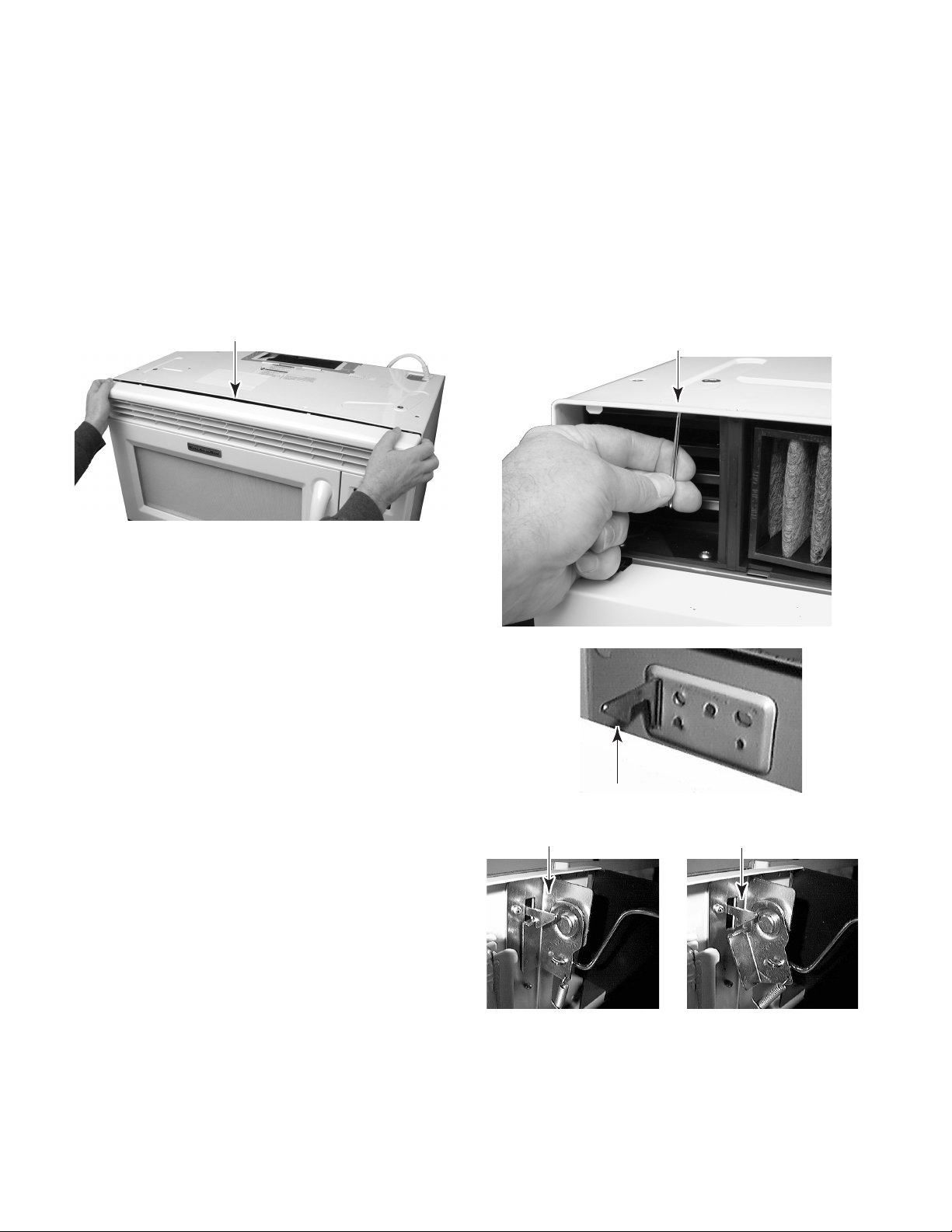

REMOVING & REINSTALLING THE MICROWAVE OVEN

To remove the microwave oven:

1. Unplug the microwave oven or disconnect

the power.

2. Open the microwave oven door.

3. Pull the top of the air grille forward to

release the clips, then lift the grille, and

remove the bottom tabs from the cabinet

slots.

Pull Top Of Air Grille Forward

4. Remove the turntable and roller assembly.

CAUTION: Use two people to support the

microwave oven when you remove it from

its mounting location.

6. Remove the two bolts that secure the

microwave oven to the upper cabinet.

7. Hold the microwave oven in place with one

hand, and pull the latching arm forward to

release the latch from the rear mounting

plate clip.

Pull Latching Arm

5. Tape the door closed.

Clip On Rear Mounting Plate

Latch Engaged

Latch Released

2-2

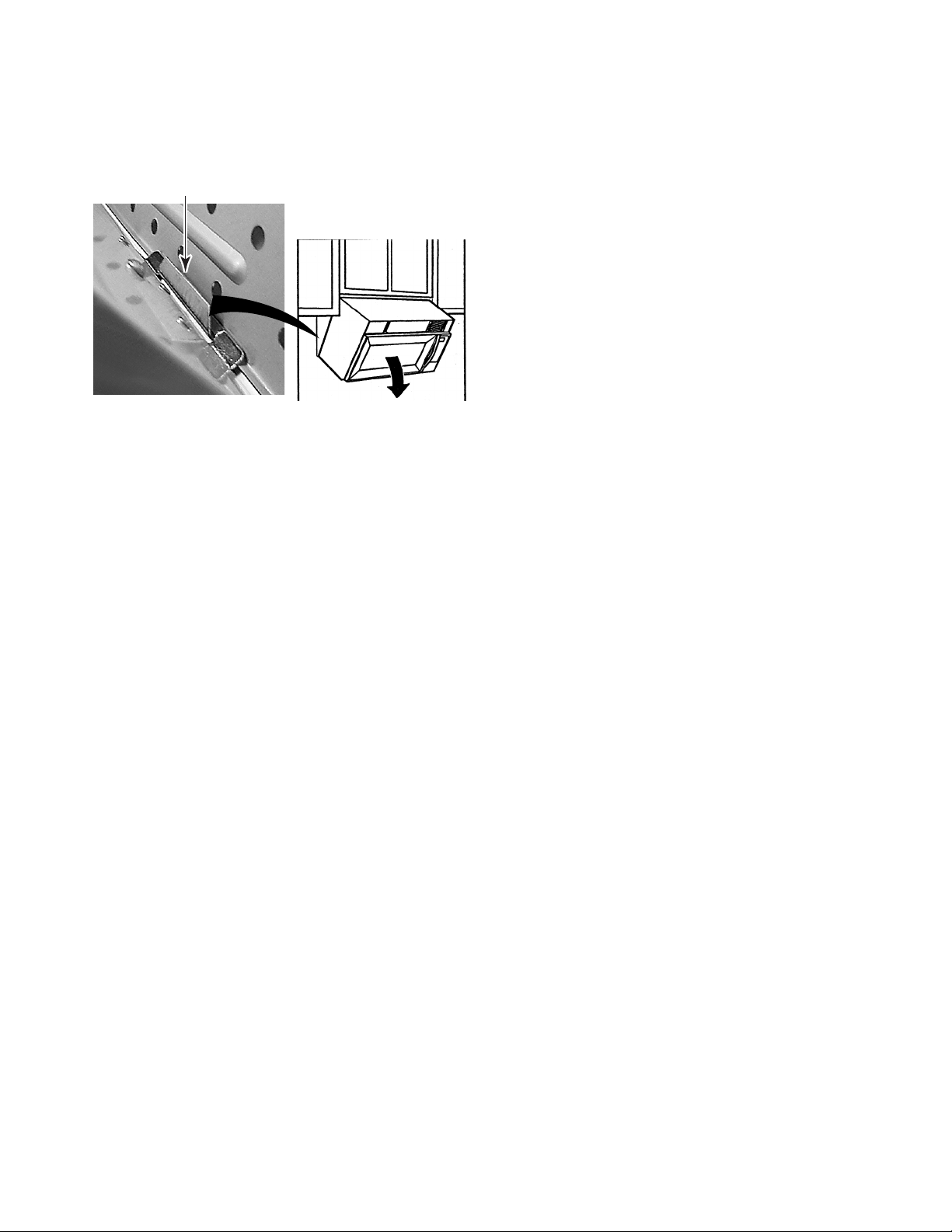

Page 17

8. Rotate the microwave oven downward,

and lift the oven to unhook it from the

bottom of the mounting plate. Set the oven

on a protected surface.

Mounting Plate Hook

To reinstall the microwave oven:

1. Carefully lift the microwave oven and hang

it on the mounting plate hooks.

2. Rotate the front of the microwave oven

cabinet downward and insert the power

supply cord through the hole in the bottom

of the cabinet.

3. Rotate the microwave oven towards the

cabinet and push the oven against the

mounting plate until the clip snaps into the

cabinet.

4. Install the two bolts that secure the microwave oven to the upper cabinet.

Rotate Down

5. Install the air grille.

6. Remove the tape from the door and replace the turntable and roller assembly.

7. Plug in the microwave oven.

2-3

Page 18

— NOTES —

2-4

Page 19

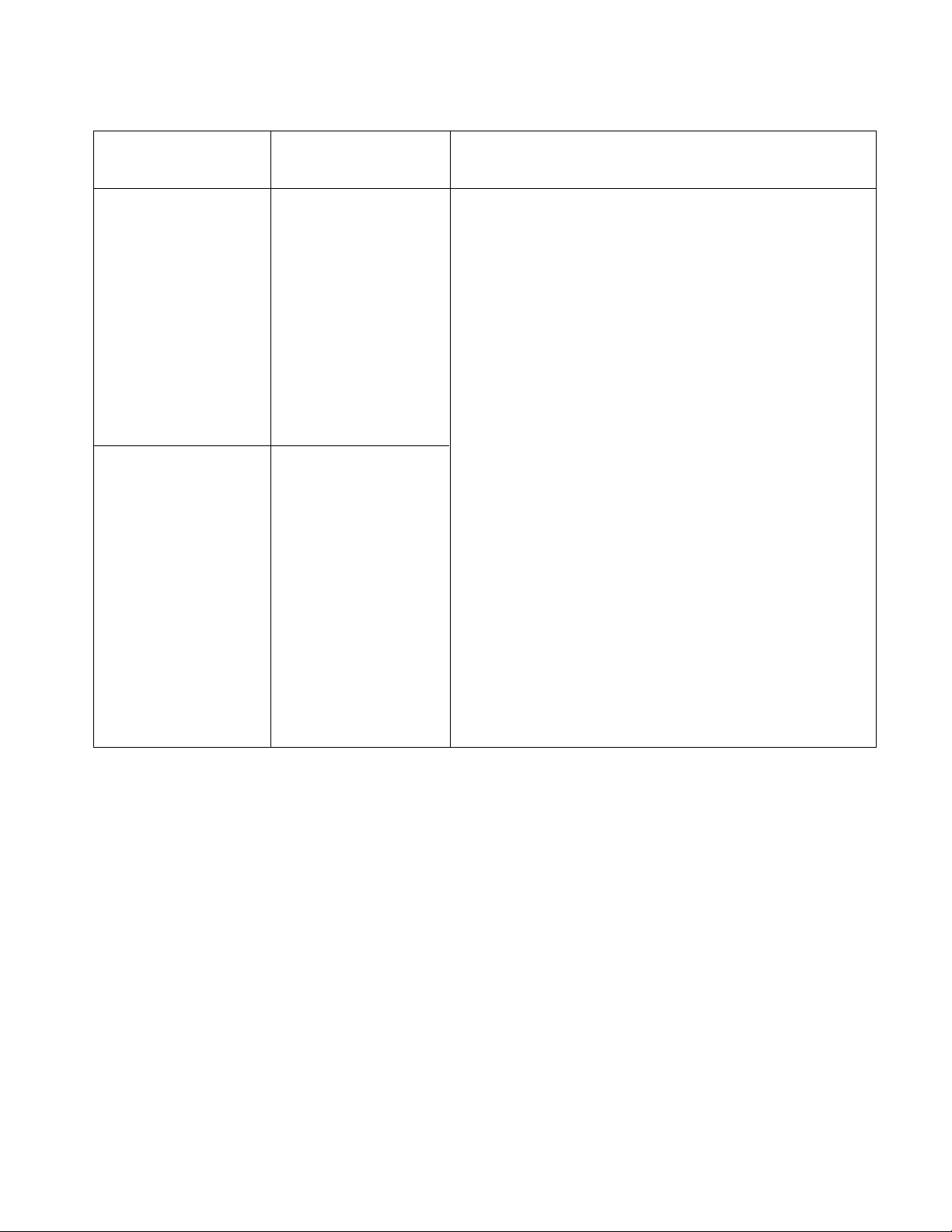

THEORY OF OPERATION

MICROWAVE OPERATION

Traditional microwave technology is only able

to generate microwave energy at full power. In

order to reduce the power when cooking, defrosting, or reheating food, the microwave cycles

on and off, intermittently heating the food at full

power, so that the food is still heated with fullpower, but for less time. This makes it difficult

to achieve slow, or simmer-type cooking.

A microwave operates at full power whenever

the magnetron is on. Reducing the power level

only reduces the time that the magnetron is on.

50% Power Cycling On & Off

(Old Technology)

Newest developed technology has the ability

to control the level of microwave energy. When

cooking, defrosting, or reheating at reduced

power levels, the food receives constant energy that is evenly dispensed, producing true

slow, or simmer-type cooking.

50% Power On Continuously

(New Technology)

Old Technology New Technology

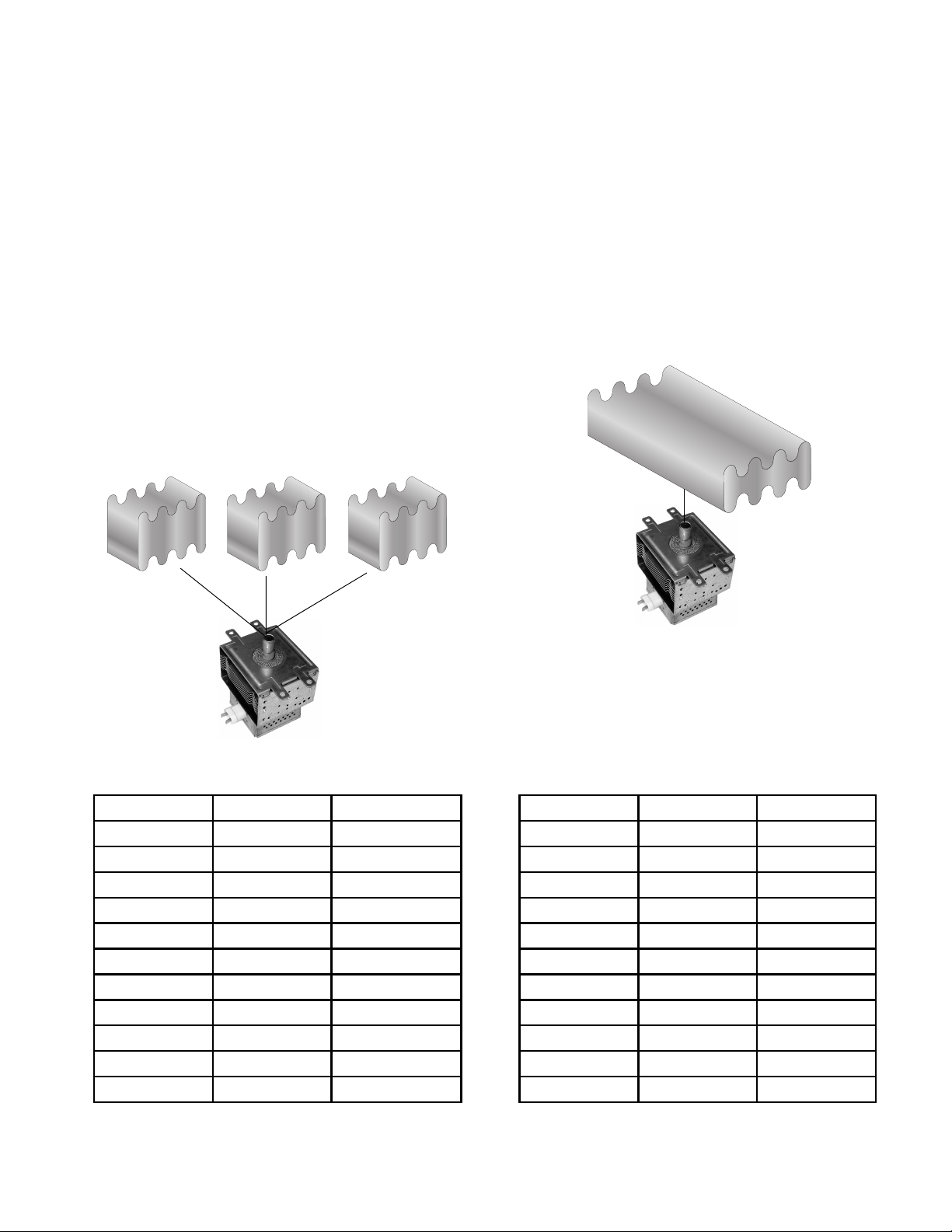

Power Level Magnetron On Magnetron Off Power Level Magnetron On Magnetron Off

0 0 Seconds 24 Seconds 0 0 Seconds 24 Seconds

1 4 Seconds 20 Seconds 1 24 Seconds 0 Seconds

2 6 Seconds 18 Seconds 2 24 Seconds 0 Seconds

3 8 Seconds 16 Seconds 3 24 Seconds 0 Seconds

4 11 Seconds 13 Seconds 4 24 Seconds 0 Seconds

5 13 Seconds 11 Seconds 5 24 Seconds 0 Seconds

6 16 Seconds 8 Seconds 6 24 Seconds 0 Seconds

7 18 Seconds 6 Seconds 7 24 Seconds 0 Seconds

8 20 Seconds 4 Seconds 8 24 Seconds 0 Seconds

9 22 Seconds 2 Seconds 9 24 Seconds 0 Seconds

10 24 Seconds 0 Seconds 10 24 Seconds 0 Seconds

3-1

Page 20

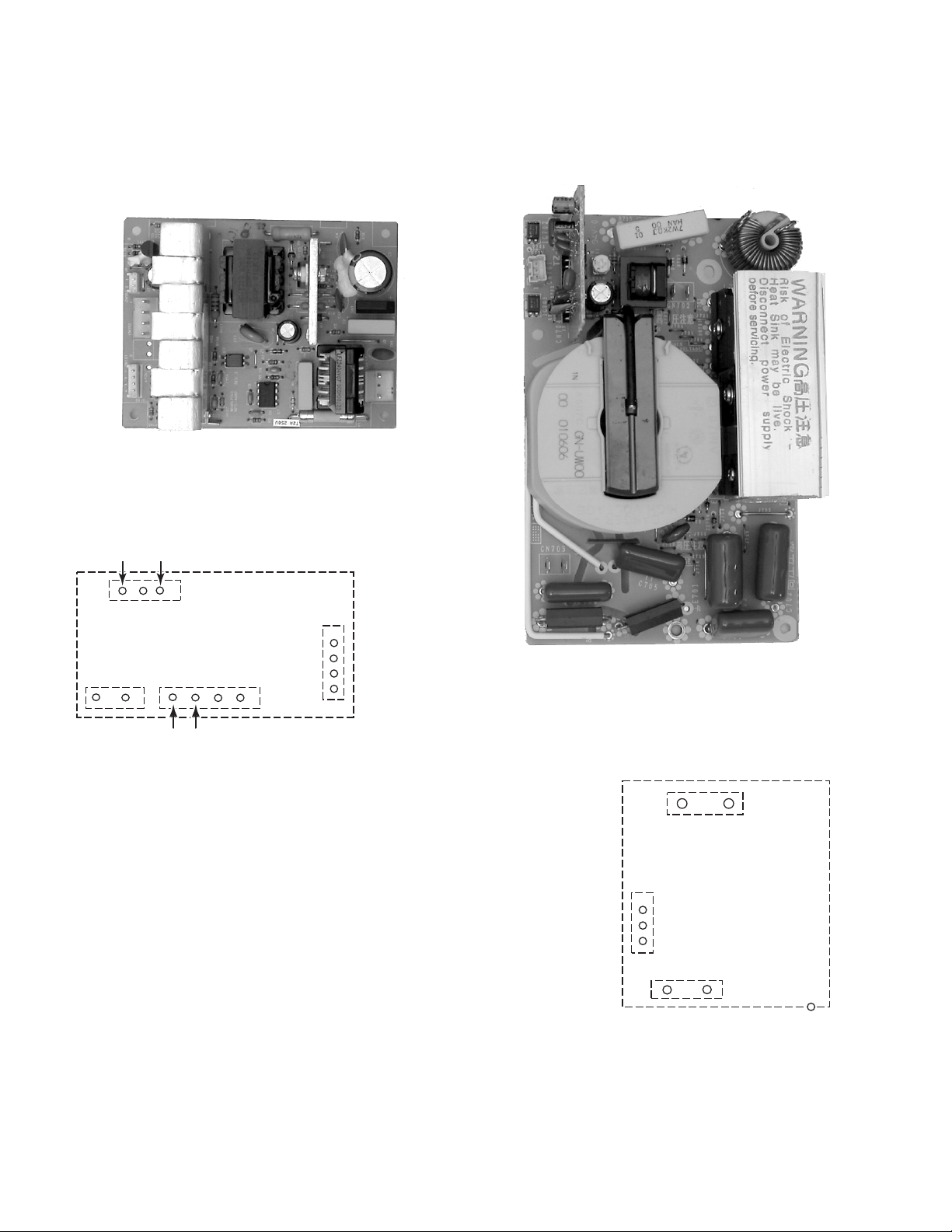

The power for the new Over-The-Range Microwave Oven is produced by 40 Watt and 1100

Watt inverters.

The 40 Watt inverter provides 12 volts DC to

operate the cooling fan and cavity lights.

40 W INVERTER

(Supplies 12 VDC To

Cooling Fan & Cavity Lights)

The 1100 Watt inverter replaces the high voltage transformer, capacitor, and diode to provide the necessary power to operate the magnetron.

120 VAC Input

1

CN1

40 W INVERTER

CN152CN153

1

To Cooling

Fan Motor

To Hood Lamp

40 W INVERTER CONNECTORS

CN151

1

1

Logic Circuit

To P3 On

Control Board

1100 W INVERTER

(Replaces The High Voltage

Transformer, Capacitor, & Diode)

120 VAC Input

CN702

1100 W INVERTER

Logic Circuit

To P2 Connector

On Control Board

1

CN701

CN703

E701

3-2

Voltage Output

To Magnetron

To Ground

1100 W INVERTER CONNECTORS

Page 21

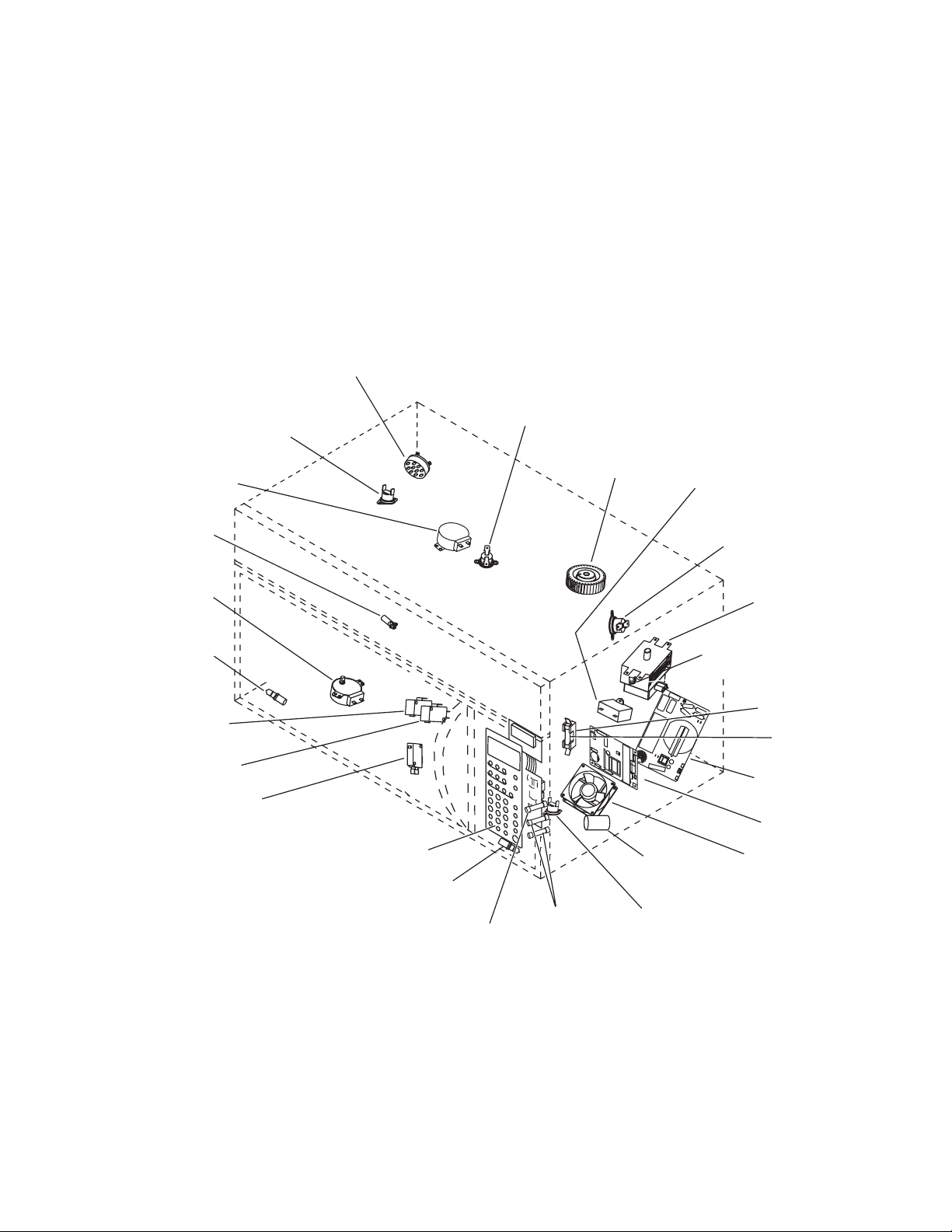

COMPONENT ACCESS

40W Inverter

Line Fuse

Cooling Fan

Motor

1100W Inverter

Magnetron

Cavity Lamp

Turntable Motor

Hood (Cooktop)

Lamp

Secondary Interlock

Switch

Primary Interlock

Switch

Hood (Cooktop) Lamp

Fuseholder

AC Line Filter

Capacitor

Control Panel Assembly

Monitor Switch

Magnetron Thermostat

Opens at 293°F (145°C)

Closes at 221°F (105°C)

Cavity

Thermostat 1

Closes at –31°F (–35°C)

Exhaust

Fan Thermostat

Opens at 104°F (40°C)

Closes at 140°F (60°C)

Stirrer Motor

Motor Capacitor

Hood Exhaust

Fan Motor

Cavity Thermostat 3

Opens at 257°F (125°C)

Closes at –31°F (–35°C)

Cavity Thermostat 2

Opens at 257°F (125°C)

Closes at –31°F (–35°C)

Fuse

(0.25 Amp.)

Fuse

(4 Amp.)

Humidity Sensor

Opens at 329°F (165°C)

This section instructs you on how to service each component inside the Over-The-Range

Microwave Oven. The components and their locations are shown below.

COMPONENT LOCATIONS

4-1

Page 22

REMOVING THE CABINET

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

4. Remove the eight screws from the back of

the unit.

Screw (1 of 8)

Back Of Unit

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the microwave oven from its

mounting location (see page 2-2 for the

procedure).

3. Tip the oven on its rear panel and remove

the two cabinet bottom screws (one on

each side) from the bottom cover, then tip

the unit to its upright position.

Bottom Cover

5. Remove the power cord cover screw and

remove the cord cover.

6. Remove the six flat-head screws from the

top of the cabinet.

7. Remove the air duct by pulling it out the

back of the unit.

8. Pull the air filter forward and remove it.

9. Pull the cabinet back so that the two slots

on each side unhook from the tabs of the

front panel, and remove the cabinet from

the oven.

Screws

Slot

Slot

4-2

Page 23

REMOVING THE BOTTOM COVER & HOOD LAMP SOCKET

2. Remove the six screws from the bottom

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

cover and lower the top edge of the cover.

Screw (1 of 6)

Bottom Cover

3. Disconnect the turntable motor connector

and the lamp connector.

4. Lift the rear edge of the bottom cover away

from the two tabs and lower the cover.

5. To remove a hood lamp socket and

lamp:

Lift The Rear Edge Of

The Bottom Cover

Away From Tabs

Lamp SocketLight Shield

a) Twist the socket and align the two tabs

with the hole slots, then pull the socket

out of the light shield hole.

b) Pull the pins of the lamp out of the

socket holes.

Turntable Motor

Connector

Lamp Connector

4-3

Hood Lamps

Page 24

REMOVING CAVITY THERMOSTAT 1

& THE HUMIDITY SENSOR

b) Press down on the locking tab in the

WARNING

holder and rotate the thermostat counterclockwise until it is free of the catches,

then lift it from the holder.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the cabinet (see page 4-2 for the

procedure).

Cavity Thermostat 1 & Humidity Sensor

Cavity Thermostat 1

4. To remove the humidity sensor:

a) Remove the top screw from the control

panel, then lift the panel, unhook the

side latching tabs, and tilt the top forward.

Press Down On

Locking Tab

Control Panel Screw

3. To remove cavity thermostat 1:

a) Disconnect the wires from the thermo-

stat terminals.

4-4

Page 25

b) Disconnect the 3-wire (red, white, &

black) sensor connector from display

board connector P5.

Humidity Sensor Connector (P5)

c) Remove the two top cover screws from

the rear panel.

Screw

e) Remove the two screws and ground

wire from the sensor and remove the

sensor from the bracket.

f) Slide the top cover to the left and un-

hook the four front locking tabs in the

cover with the slots in the chassis, (see

the lower left photo).

g) Lift the top cover and pull the sensor

cable through the access hole, and

remove the sensor.

Ground Wire Screw

Ground Wire Screw

Screw

Humidity Sensor

Rear Panel

d) Remove the three top cover screws

from the front corners.

Screws

Top Cover

Screw

Screw

Position Humidity Sensor Cable Here

Access Hole

REASSEMBLY NOTE: When you reinstall the

humidity sensor on the bracket, be sure to

position the cable facing down, as shown in the

photo.

WARNING

Electrical Shock Hazard

Connect green ground wire to ground

screw.

4 Front Top Cover Locking Tabs

Failure to do so can result in death or

electrical shock.

4-5

Page 26

REMOVING THE STIRRER MOTOR

6. Lift the left end of the top cover and prop it

WARNING

up so you can access the stirrer motor.

Stirrer Motor

Wires

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the cabinet (see page 4-2 for the

procedure).

3. Remove the three front and two rear top

cover screws (see steps 4c and 4d on

page 4-5).

4. Remove the humidity sensor ground wire

screw from the rear panel.

Ground Wire Screw

Rear Panel

Screw (1 of 2)

Raise & Prop Up

Top Cover

7. Remove the screws from the motor and

disconnect the wire connectors from the

motor terminals.

8. Open the microwave oven door.

9. Use a putty knife and pry the stirrer motor

cover with the plastic nails and bushings

off the top of the oven cavity.

Humidity Sensor

5. Slide the top cover to the left and unhook

the four front locking tabs in the cover with

the slots in the chassis, (see photo in step

4d on page 4-5 for the tab locations).

Stirrer Motor Cover

4-6

Page 27

10. Carefully pull the mica cover off the stirrer

motor opening and remove the stirrer fan.

NOTE: The cover is held in place with

Selastic adhesive.

11. Use a piece of sandpaper and clean the

adhesive and other debris from around

the stirrer motor opening.

12. Install the new stirrer motor to the unit with

the two screws you removed earlier, and

connect the wires to the terminals.

13. Appy a 1/8″ bead of Selastic around the

unpainted area of the stirrer motor opening. Make sure that the bead goes completely around the opening with no breaks,

so that a complete seal is made between

the cover and the top of the oven cavity.

14. Install the stirrer fan onto the stirrer motor

shaft as far as it will go.

15. Place the mica cover over the stirrer motor

opening and align the four holes with those

in the oven cavity. Press the cover firmly

onto the adhesive, and install the four

bushings and plastic nails in the holes.

WARNING

Stirrer Fan On Motor Shaft

Clean Around Opening

Electrical Shock Hazard

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

4-7

Page 28

REMOVING CAVITY THERMOSTATS 2 & 3

6. Lift the front of the top cover so you can

WARNING

access cavity thermostats 2 and 3, and

prop it up.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the cabinet (see page 4-2 for the

procedure).

3. Remove the three front and two rear top

cover screws (see steps 4c and 4d on

page 4-5).

4. Remove the humidity sensor ground wire

screw from the rear panel (see step 4 on

page 4-6).

Cavity Thermostat 2

7. To remove cavity thermostat 2:

a) Fold back the paper insulator.

b) Remove the wires from the terminals.

c) Remove the two mounting screws.

Top Cover

Cavity Thermostat 3

5. Slide the top cover to the left and unhook

the four front locking tabs in the cover with

the slots in the chassis, (see photo in step

4d on page 4-5 for the tab locations).

Paper Insulator

Cavity Thermostat 2

4-8

Page 29

8. To remove cavity thermostat 3:

a) Remove the wires from the terminals.

b) Remove the two mounting screws.

Cavity Thermostat 3

4-9

Page 30

REMOVING THE HOOD EXHAUST FAN MOTOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the cabinet (see page 4-2 for the

procedure).

Hood Exhaust Fan Motor

4. Remove the four hood exhaust fan motor

cover screws.

5. Remove the four hood exhaust fan motor

mounting screws and cup washers.

Hood Exhaust Fan Motor

Hood Exhaust Fan Motor

Mounting Screw (1 of 4)

Cover Screw (1 of 4)

Motor Wires

3. From the right side of the unit, disconnect

the 3-wire (red, white & black) hood exhaust fan motor connector from the main

harness connector.

Hood Exhaust Fan Motor Connector

Locking Tab (1 of 4)

Foam Tape

6. Carefully remove the tape from over the

motor wires, then press in on the four

locking tabs, and lift the cover off the hood

exhaust fan motor.

7. Remove the hood exhaust fan motor.

Hood Exhaust Fan Motor

4-10

Page 31

REMOVING THE CAVITY LAMP & SOCKET

5. Unscrew the bulb from the cavity lamp

WARNING

socket.

6. To remove the cavity lamp socket, twist

the socket to the left (counterclockwise) to

unlock it, and push it out of the mounting

hole.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Open the microwave oven door.

3. Pull the top of the air grille forward to

release the clips, then lift the grille, and

remove the bottom tabs from the cabinet

slots.

Pull Top Of Air Grille Forward

Cavity Lamp Socket

Bulb

7. Disconnect the wires from the socket terminals.

4. Lift the front of the cavity lamp cover

slightly and pull it out of the slot in the top

cover.

Cavity Lamp Cover

Socket Wires

4-11

Page 32

REMOVING THE CONTROL PANEL ASSEMBLY,

THE POWER SUPPLY & DISPLAY BOARDS,

AND THE KEYBOARD

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

b) Disconnect wire connectors P2, P3,

P5, P12, and P14 from the display and

power supply boards.

c) Disconnect the wires from the relay

terminals.

d) Remove the green ground wire from

the control panel bracket.

e) Unhook the hinge from the slot and

remove the control panel assembly from

the unit.

f) Lay the control panel assembly on a

padded surface.

Red & Org Red

P14

Relay

2. Remove the air grille from the unit (see

page 4-11 for the procedure).

3. To remove the control panel assembly:

a) Remove the top screw from the control

panel, then lift the panel, unhook the

side latching tabs, and tilt the top forward as far as the wires will allow.

Control Panel Screw

Ground

P12

P5

P3 P2

WARNING

Electrical Shock Hazard

Connect green ground wire to ground

screw.

4-12

Failure to do so can result in death or

electrical shock.

Page 33

4. To remove the power supply & display

boards:

a) Disconnect wire connector P7 from the

display board.

b) Lift the locking arm by the two end tabs

and remove the two ribbon cables from

connector P6.

c) Remove the screw from the display

board and unclip it from the locking

arms.

d) Remove the two screws from the power

supply board and unclip it from the

locking arms.

e) Remove the power supply and display

boards from the control panel.

Lift Tab

Lift Tab

5. To remove the keyboard:

a) Unclip the bracket and remove it from

the panel.

Bracket

b) Remove the two screws from the key-

board and unclip it from the panel.

c) To replace the display window on the

control panel, unclip the two tabs.

Keyboard

Display Window

Power Supply Board

P6

Screw

Screws

P7

Screw (1 of 2)

Display Board

4-13

Page 34

REMOVING AN INLINE FUSE

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

6. Unsnap the two tabs from the locking arms

on the fuseholder for the inline fuse you

are removing.

Locking Arms & Tabs

On Inline Fuseholder

2. Remove the air grille (see page 4-11 for

the procedure).

3. Open the microwave oven door.

4. Remove the control panel assembly (see

page 4-12 for the procedure).

5. Determine which of the three inline fuses

you need to remove.

3 Inline Fuses

7. Open the fuseholder, slide the ends of the

wire connectors off the ends of the fuse,

and remove the fuse.

Slide Wire Connectors

Off Ends Of Fuse

4-14

Page 35

REMOVING THE AC LINE FILTER CAPACITOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the air grille from the unit (see

page 4-11 for the procedure).

4. Discharge the 1100 W inverter (perform

steps 3 and 4 on page 4-20).

5. Remove the AC line filter capacitor from

the cooling fan motor and cut the wires

from the capacitor leads.

AC Line Filter Capacitor

3. Remove the control panel assembly (see

page 4-12 for the procedure).

Cut Both Wires

6. Splice the wires coming from the new

capacitor to the cut harness wires, and

twist a pair of wire nuts over the ends of the

cut wires.

7. Use a large bead of Selastic and adhere

the capacitor to the fan.

4-15

Page 36

REMOVING THE COOLING FAN MOTOR, THE EXHAUST

FAN THERMOSTAT, AND THE LINE FUSEHOLDER

4. To remove the cooling fan motor:

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the air grille from the unit (see

page 4-11 for the procedure).

3. Remove the control panel assembly (see

page 4-12 for the procedure).

a) Press out on the top side locking tabs,

lift the fan, and pull it forward to remove

it.

b) Disconnect the 2-wire fan motor con-

nector from connector CN153 on the

40 W inverter board.

40 W Inverter Board

Fan Motor

Connector

CN153

Locking

Tabs

Line Fuseholder

Cooling Fan Motor

Exhaust Fan

Thermostat

Located Behind Control Panel

Cooling Fan Motor

REASSEMBLY NOTE: When you reinstall the

cooling fan motor, be sure to seat the bottom

corners in the panel slots.

Bottom Corners In Slots

4-16

Page 37

5. To remove the exhaust fan thermostat:

6. To remove the line fuseholder:

a) Remove the cooling fan motor to make

accessing the thermostat easier (see

step 4 for the procedure).

b) Disconnect the wire connectors from

the thermostat terminals.

c) Press down on the locking tab with a

screwdriver blade, turn the thermostat

so the flange is over the top of the tab,

and lift the thermostat body out of the

mounting hole.

2 BrnYel & Wht

Wire Connectors

a) Disconnect the wire connectors from

the fuseholder terminals.

b) Remove the fuse from the fuseholder.

Brn

Wire

Connectors

Red & Org

Line

Fuse

Press Tab

Down

Lift

Exhaust Fan

Thermostat

c) Remove the screw from the fuseholder.

Fuseholder

Screw

Turn

4-17

Page 38

REMOVING THE MOTOR CAPACITOR, THE MAGNETRON

THERMOSTAT, & THE 40 W INVERTER BOARD

4. To remove the motor capacitor, remove

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

the phillips screw and disconnect the wire

connectors from the terminals.

Screw

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the air grille from the unit (see

page 4-11 for the procedure).

3. Remove the control panel assembly (see

page 4-12 for the procedure).

Magnetron Thermostat

Motor Capacitor

Motor Capacitor

Red - Wire Connectors - Wht

5. To remove the magnetron thermostat,

remove the two phillips screws and disconnect the wire connectors from the terminals.

Magnetron Thermostat

40 W Inverter Board

Located Behind Control Panel

4-18

Screw

2 Blu

Wire Connectors

Gry

Screw

Page 39

6. To remove the 40 W inverter board:

a)Disconnect the wire connectors from:

b) Raise the two top locking arms and

remove the inverter board.

CN1

CN151

CN152

CN153

Locking Arms

CN153

CN152

CN151

CN1

4-19

Page 40

REMOVING THE 1100 W INVERTER BOARD

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

5. Remove the 40 W Inverter Board (see

page 4-19 for the procedure).

6. Remove the exhaust fan thermostat (see

page 4-17 for the procedure).

7. Disconnect the red and white wires from

the motor capacitor, the blue and gray

wires from the magnetron thermostat, and

the brown, red, and orange wires from the

line fuseholder terminals.

8. Remove the two screws from the front

mounting panel.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the control panel assembly (see

page 4-12 for the procedure).

3. Remove the cooling fan motor (see page

4-16 for the procedure).

NOTE: Make sure to read the “Warnings” on

page 1-4 before you continue.

4. Hold a 20,000Ω (red-black-orange)

2-Watt resistor by the body with a pair of

long nosed pliers, and touch the leads to

the two discharge points on the 1100 W

inverter. Be careful not to touch the bare

resistor leads during this procedure.

Screw

Magnetron

Thermostat

(Blu & Gry)

Line

Fuseholder

(Brn, Red,

& Org)

Screw

Motor

Capacitor

(Red &

Wht)

Front

Mounting

Panel

9. Pull the front mounting panel out the front

of the unit, then remove the wires from the

side of the panel.

Front Mounting Panel

Discharge Points

Remove

Wires

4-20

Page 41

10. Disconnect the two magnetron wires from

the 1100 W inverter (CN703) and remove

them from the cover.

11. Lift the cover off the 1100 W inverter and

remove it from the unit.

Remove Magnetron Wires

Cover

13. Remove the 2 red and 2 gray wires from

the inverter terminals at CN702.

14. Release the locking arm on the 3-wire

cable at CN701 and disconnect it.

15. Remove the mounting screw from the

board and unsnap the 1100 W inverter

from the holder.

Ground Wire

2 Red & 2 Gry

(CN702)

Magnetron Wires (CN703)

12. Remove the top and bottom mounting

screws from the 1100 W inverter holder.

Slide the holder to the right so the slot is

over the tab at the bottom, and remove the

holder and inverter.

Holder Mounting Screw

Mounting Screw

3-Wire Cable CN701

16. Remove the screw and nut from the green

ground wire and remove the wire from the

1100 W inverter.

WARNING

Electrical Shock Hazard

Holder Mounting Screw

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

Slot

4-21

Page 42

REMOVING THE MAGNETRON

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the air grille from the unit (see

page 4-11 for the procedure).

5. Discharge the 1100 Watt inverter as follows. NOTE: Make sure that the screwdriver touches ground before touching the

magnetron terminals.

a) Use a plastic handle screwdriver and

touch the metal tip to the case of the

magnetron.

b) Touch the screwdriver shaft against

either of the two magnetron terminals

for approximately 5 seconds.

Touch The Screwdriver Tip

To The Magnetron Case

3. Remove the cabinet (see page 4-2 for the

procedure).

4. Remove the control panel assembly (see

page 4-12 for the procedure).

Magnetron

1100 W

Inverter Board

Touch The Screwdriver Shaft

To Either Magnetron Terminal

Front Mounting Panel Rear Mounting Panel

4-22

Page 43

6. Remove the screw from the front mounting panel.

Front Mounting Panel Screw

7. Bend the metal tab back, then slide the

two rear mounting panel tabs toward the

right side, and lower them through the

cutouts in the chassis.

8. Disconnect the two filament wires from the

magnetron terminals.

9. Remove the four mounting screws from

the magnetron. NOTE: Pull the front mount-

ing panel forward so you can access the

two front screws.

REASSEMBLY NOTE: When you reinstall the

magnetron, insert the alignment pins into their

holes at the back of the magnetron.

Magnetron

Screw (1 of 4)

Rear Mounting Panel Tabs

Lower The Rear Panel

Bend Metal Tab Back

Filament Wires

Front Panel

4-23

Page 44

REMOVING THE PRIMARY & SECONDARY INTERLOCK

SWITCHES AND THE MONITOR SWITCH

5. To remove the secondary interlock

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

switch or the monitor switch:

a) Unsnap the linking rod and remove it.

b) Carefully bend the two locking arms

back and pull the switch off the two

pins.

c) Remove the wire connectors from the

switch terminals.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Remove the air grille (see page 4-11 for

the procedure).

3. Open the microwave oven door.

4. Remove the control panel assembly (see

page 4-12 for the procedure).

Monitor

Switch

Linking Rod

Secondary

Interlock

Switch

Org-Yel

(COM.)

White (COM)

2 Blue (N.O.)

Brn-Yel (N.C.)

Red-Wht

(N.O.)

6. To remove the primary interlock switch:

a) Grip the top and bottom of the linking

rod with your fingers and carefully pull

back on the switches so that they spring

to their fully retracted position.

4-24

Pull Back

Forward

Linking

Rod

Retracted

Pull Back

Page 45

b) Use a T10 torx screwdriver and remove

the two screws from the interlock switch

assembly.

c) Pull the switch assembly away from the

front chassis and position it so that you

can access the primary interlock switch.

REASSEMBLY NOTES:

1. When reinstalling the switch assembly

after performing step 6, be sure to hook

the plastic tabs, at the top and bottom of

the switch holder, into the slotted metal

retainers in the chassis, as shown below.

Make sure that the metal retainers are not

bent up so that the tabs will not fit into

them. Otherwise, the switches may not

operate properly.

T10 Torx

Screws

Primary Interlock Switch

Locking Arm

Blu-Blk (COM)

White (N.O.)

Pin

Metal

Retainer

Slot

Switch

Holder

Tab

2. After installing the switch assembly, rotate

the linking rod and two switches to their

forward position (see the photos in step

6a). Close and open the door several

times to make sure that the switches operate normally. If not, check step 1 above for

proper installation, as well as the forward

position of the switches.

d) Carefully unhook the two locking arms

and pull the switch off the two pins.

e) Remove the wire connectors from the

switch terminals.

4-25

Page 46

REMOVING THE TURNTABLE MOTOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

2. Remove the cabinet (see page 4-2 for the

procedure).

3. Open the microwave oven door and remove the spindle from the turntable motor

shaft.

Turntable Spindle

(Inside Oven Cavity)

1. Unplug microwave oven or disconnect

power.

Turntable Motor

4. Remove the bottom cover from the microwave oven (see page 4-3 for the procedure).

5. Remove the screws from the turntable

motor and remove it.

Screws

4-26

Page 47

REMOVING THE OVEN DOOR AND THE INNER PANEL

4. Place the oven door front side down on a

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

padded surface.

5. Remove the choke screws from the door

frame.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug microwave oven or disconnect

power.

2. Open the microwave oven door.

3. Pry the choke cover away from the top

door pin, and remove the top pin from the

pivot bracket. Lift the door off the bottom

bracket, and remove it.

Top Door Pin

Pry Out Choke

Cover Here

Pivot Bracket

Choke Screws

6. Starting at the top right corner, (see the

round inset photo in the left column), pry

the choke cover out with a putty knife, and

unsnap it from the choke. Only remove the

top, bottom and right sides of the choke

cover at this time. You will remove the

handle end of the choke cover later.

Door Frame

Unsnap Choke Cover

Continued on the next page.

Choke Cover

Choke

4-27

Page 48

7. Starting at the top edge of the door near

the center and working clockwise, use a

putty knife, and pry the latching tabs of the

choke out of the door frame slots. Lift the

choke as you release the tabs so they do

not snap back into the slots. NOTE: When

you reach the handle side of door, pull

both the choke and the choke cover away

from the door frame, and then separate

the two components.

DOOR COMPONENTS

Choke Cover

Pry Out

Tab

Putty Knife

Choke With Switch Actuators

Door Frame With Outer

Glass (Plastic) & Handle

REASSEMBLY NOTE: When you reinstall the

door on the oven, insert the top pin into the

pivot bracket and press down on the pin until it

snaps into place.

8. To remove the door switch actuators from

the choke, remove the screw from each

actuator.

Choke

Screw

Door Switch Actuators

Screw

4-28

Page 49

COMPONENT TESTING

Discharge the 1100 W inverter before conducting any of the following tests (perform steps 1

through 4 on page 4-20).

All operational checks using microwave energy must be done with the microwave oven

loaded with a minimum of 275 ml (9.3 oz.) of

water in a microwave safe container.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

DOOR SWITCHES

Conduct a microwave energy test after performing any tests or repairs to the microwave.

Check that all wire leads are in the correct

position before operating the microwave oven.

Grasp wire connectors when removing the

wire leads from microwave parts.

WARNING

Refer to page 4-24 for the procedure for servicing the door switches.

1. Unplug microwave oven or disconnect

power.

2. Disconnect the wires from the switch terminals.

3. Set the ohmmeter to the R x 1 scale.

4. Touch the ohmmeter test leads to the

terminals of the primary or secondary

interlock switch (normally-open). The

meter should indicate an open circuit (infinite).

Normally-Open

Normally-Closed

5. Touch the ohmmeter test leads to the

terminals of the monitor switch (normally-

closed). The meter should indicate a closed

circuit (0 Ω).

NOTE: Pressing the actuator button should

result in opposite readings (normally-open

should read closed, and normally-closed should

read open).

5-1

Page 50

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

TOUCH PANEL CONTINUITY

To test the touch panel, perform the following

steps:

1. Unplug microwave oven or disconnect

power.

2. Disconnect the ribbon cable from the control board connector P7.

CONNECTOR (P7)

1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

RIBBON CABLE

PIN #

7

(On/Night/Off)

8

3456

Vent Fan

5 speeds

Light

Clock

3. Set the ohmmeter to the R x 1 scale.

4. Use a pair of alligator clips and clip them to

the ribbon contact numbers shown along

the top and side of the indicated keyboard

matrix, shown below.

For example:

a) Install alligator clips over contacts 5 and

17 of the ribbon cable.

b) Touch the alligator clips with the test

leads.

c) Press the BEVERAGE keypad. The

meter should indicate a resistance of

approximately 200 Ω.

Turntable

On/Off

9

Timer

Set/Off

10

11

12

13

14

15

16

17

18

1

2

7

Add a

Minute

1

Cook

Time

Reheat

Popcorn

ESD ground plane

Cook

Power

Cook

Dinner

Plate

Baked

Potato

5-2

0

5

4

9

Browning

6

23

Keep

Warm

Defrost

Beverage

START

Pan

Boil &

Simmer

Melt

Soften

Cancel

OFF

8

Page 51

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

STIRRER & TURNTABLE MOTORS

Refer to pages 4-6 and 4-26 for the procedures

for servicing the stirrer and turntable motors.

1. Unplug microwave oven or disconnect

power.

2. Disconnect the wire connectors from the

motor under test.

3. Set the ohmmeter to the R x 1K scale.

4. Touch the ohmmeter test leads to the

stirrer motor terminals . The meter should

indicate between 3300 and 4200 Ω.

5. Touch the ohmmeter test leads to the turntable motor terminals. The meter should

indicate between 2700 and 3800 Ω.

AC LINE FILTER CAPACITOR

Test Point

Test Point

Refer to page 4-15 for the procedure for servicing the AC line filter capacitor.

1. Unplug microwave oven or disconnect

power.

2. Discharge the 1100 W inverter (perform

steps 2 through 4 on page 4-20).

3. Set the ohmmeter to the R x 1000 scale.

4. Touch the ohmmeter test leads to the bare

wires near the capacitor body (you may

have to pull the insulation back slightly).

The meter should briefly indicate approximately 10K ohms, and then gradually return towards infinity.

5-3

Page 52

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

HUMIDITY SENSOR

Refer to page 4-4 for the procedure for servicing the humidity sensor.

1. Unplug microwave oven or disconnect

power.

2. Disconnect the 3-wire connector from the

control board.

3. Set the ohmmeter to the R x 1K scale.

4. Touch the ohmmeter test leads to the

indicated wire terminals of the 3-wire connector. The meter should indicate as follows:

Black to white = approximately 2800 Ω

@ 77˚F/25˚C.

White to red = approximately 2800 Ω

@ 77˚F/25˚C.

CAVITY THERMOSTATS 1, 2, & 3

Refer to pages 4-4 and 4-8 for the procedures

for servicing the cavity thermostats.

1. Unplug microwave oven or disconnect

power.

2. Disconnect the wires from the terminals.

3. Set the ohmmeter to the R x 1 scale.

4. Touch the ohmmeter test leads to the

terminals. The meter should indicate a

closed circuit (0 Ω).

NOTE: Thermostat 1 opens @ 329°F / 165°C.

Thermostats 2 and 3 open @ 257°F / 125°C . I f

the thermostat is defective, the ohmmeter will

indicate an infinite circuit.

5-4

Page 53

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

LINE FUSE & EXHAUST

FAN THERMOSTAT

Line Fuse

Refer to page 4-16 for the procedures for

servicing the line fuse and the exhaust fan

thermostat.

1. Unplug microwave oven or disconnect

power.

2. Set the ohmmeter to the R x 1 scale.

3. To test the line fuse, touch the ohmmeter

test leads to the ends of the fuse. The

meter should indicate a closed circuit

(0 Ω).

Exhaust Fan

Thermostat

MOTOR CAPACITOR

Refer to page 4-18 for the procedure for servicing the motor capacitor.

1. Unplug microwave oven or disconnect

power.

2. Discharge the 1100 W inverter (perform

steps 2 through 4 on page 4-20).

3. Disconnect the wires from the terminals.

4. Set the ohmmeter to the R x 10K scale.

5. Touch the ohmmeter test leads to the

capacitor terminals. The meter should indicate several thousand ohms and gradually return to infinity.

4. To test the exhaust fan thermostat:

a) Disconnect the wires from the termi-

nals.

b) Touch the ohmmeter test leads to the

terminals. The meter should indicate an

open circuit (infinite). NOTE: The thermostat closes @ 140˚F / 60˚C, and will

reset (open) @ 104˚F / 40˚C.

5-5

Page 54

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

COOLING FAN MOTOR (12 VDC)

Refer to page 4-16 for the procedure for servicing the cooling fan motor.

1. Unplug microwave oven or disconnect

power.

2. Disconnect the wire connectors from the

cooling fan motor terminals.

3. Set the ohmmeter to the R x 1 scale.

4. Touch the ohmmeter test leads to the

motor terminals. The meter should indicate

between 17 and 28 Ω.

5. An additional test for the cooling fan motor

is as follows (see the photo below):

a) Connect a battery connector to a fresh

9 volt battery.

b) Connect the red wire from the battery

connector to the red wire in the fan connector, and the black wire to the black

wire in the fan connector.

HOOD EXHAUST FAN MOTOR

(120 VAC)

Refer to page 4-10 for the procedure for servicing the hood exhaust fan motor.

1. Unplug microwave oven or disconnect

power.

2. Disconnect the hood exhaust fan motor

connector from the main harness connector.

3. Set the ohmmeter to the R x 1 scale.

4. Touch the ohmmeter test leads to the

motor terminals. The meter should indicate

as follows:

White to black = 30 to 60 Ω.

Red to black = 40 to 80 Ω.

Cooling Fan Motor

9 Volt Battery

5-6

Page 55

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

MAGNETRON

Filament Terminals

Refer to page 4-22 for the procedure for servicing the magnetron.

1. Unplug microwave oven or disconnect

power.

2. Discharge the 1100 W inverter (perform

step 5 on page 4-22).

3. Disconnect the wire connectors from the

filament terminals.

MAGNETRON THERMOSTAT (N.C.)

Refer to page 4-18 for the procedure for servicing the magnetron thermostat.

1. Unplug microwave oven or disconnect

power.

2. Disconnect the wires from the magnetron

thermostat terminals.

3. Set the ohmmeter to the R x 1 scale.

4. Touch the ohmmeter test leads to the

terminals. The meter will indicate a closed

circuit (0 Ω) at room temperature. NOTE:

The thermostat opens @ 293˚F / 145˚C

and resets (closes) @ 221˚F / 105˚C.

4. Set the ohmmeter to the R x 1 scale.

5. Touch the ohmmeter test leads to the

filament terminals. The meter should indicate less than 1 Ω.

6. Touch one ohmmeter test lead to the

chassis and the other to each of the filament terminals. The meter should indicate

an open circuit (infinite).

5-7

Page 56

WARNING

Electrical Shock Hazard

Power is present during the following

tests.

INVERTERS

MEASURING OVEN INPUT CURRENT

1. Remove the screw from the power cord

retaining plate and remove the plate.

2. Pull the power cord out of the cabinet and

separate the wires.

3. Connect an ammeter clamp around the

white power cord wire.

Ammeter Clamp Around

Power Cord

White Power Cord Wire

Control Power

Supply Board

Test Leads

Power Cord Retaining Plate

4. Turn the microwave oven On.

5. Check the ammeter for a 15A reading.

• If the ammeter indicates more than 0.5

amps, check the magnetron and its

wiring.

• If the ammeter indicates less than 0.5

amps, it indicates that there is no input

to the 1100 W inverter. Check for the

following:

- No AC voltage supply or control signal. Check the control power supply

board at the relay terminals for 120

VAC (see the photos at the top of the

next column).

Relay

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1100 W INVERTER

Refer to page 4-20 for the procedure for servicing the 1100 W inverter.

IMPORTANT: HIGH VOLTAGE—DO NOT

MEASURE!

5-8

Page 57

NOTE: Refer to the “Warnings” on page 1-4.

Do not attempt to repair, or make any adjustments to the inverter board.

Check Wiring

1. Unplug microwave oven or disconnect

power.

WARNING

2. Discharge the 1100 W inverter (perform

steps 2 through 4 on page 4-20).

3. Visually inspect inverter board connectors

CN701, CN702, CN703, and E701. Check

for signs of failure due to loose wiring,

unseated connectors, and discoloration

due to overheating.

CN701

(I/O Signal)

CN702

(120 VAC)

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

40 W INVERTER

Refer to page 4-18 for the procedure for servicing the 40 W inverter.

Check Wiring

1. Unplug microwave oven or disconnect

power.

2. Visually inspect inverter board connectors

CN1, CN151, CN152, and CN153. Check

for signs of failure due to loose wiring,

unseated connectors, and discoloration

due to overheating.

CN703

(High Voltage Output

To Magnetron)

E701

(Ground)

CN153 & CN152 (12 VDC)

CN151 (Signal Input)

Continued on the next page.

CN1 (120 VAC Input)

5-9

Page 58

WARNING

4. Connect power to the microwave oven.

5. Open the oven door.

6. Touch the voltmeter test probes to pins 1

and 2 of connector CN152 (refer to the

photo on the previous page). The meter

should indicate 12 volts DC.

Electrical Shock Hazard

Power is present during the following

tests.

Check DC Output Voltage

1. Unplug microwave oven or disconnect

power.

2. Tilt the control panel back so you can

access the 40 W inverter board.

3. Set the voltmeter to measure 12 volts DC.

NOTE: The 40 W inverter output voltages that

will be tested in the following steps are shown

in the chart below.

Connector Test Points

Pins 1 & 2

Output

Voltage

12 volts DCCN152

Pins 3 & 4

CN153* Pins 1 & 2 12 volts DC

* Test in “Demo Mode.”

7. Close the oven door.

8. Press the LIGHT keypad on the control

panel and set the lights to full intensity.

NOTE: Do not press the LIGHT keypad

during the measurement.

9. Touch the voltmeter test probes to pins 3

and 4 of connector CN152. The meter

should indicate 12 volts DC.

10. Press and release the CANCEL/OFF keypad.

11. Press and hold the TIMER keypad until a

small “d” appears on the display, (after

approximately 5 seconds), then release

the keypad.

12. Turn the microwave oven on.

13. Touch the voltmeter test probes to pins 1

and 2 of connector CN153. The meter

should indicate 12 volts DC.

14. Press and release the CANCEL/OFF keypad.

15. Press and hold the TIMER keypad until

the small “d” disappears from the display

and release the keypad.

5-10

Page 59

DIAGNOSIS & TROUBLESHOOTING

POWER OUTPUT MEASUREMENT

The power output of the magnetron can be

measured using the following test. Before you

perform the test:

• Make sure that the microwave oven

cavity is clean and cool.

• Check the line voltage at the microwave

oven and note the reading.

1. Fill a glass beaker with 32 oz. (1000 ml) of

tap water.

2. Stir the water with a thermometer and record

the temperature. The temperature should

be between 50° and 75°F (10° and 24°C).

FAILURE CODES

3. Place the beaker of water in the center of

the microwave oven cavity.