KitchenAid KGCS166GWH1, KGCT055GWH0, KGCT055GBL0, KGCS166GWH0, KGCS166GSS1 Installation Guide

...Page 1

m [] []

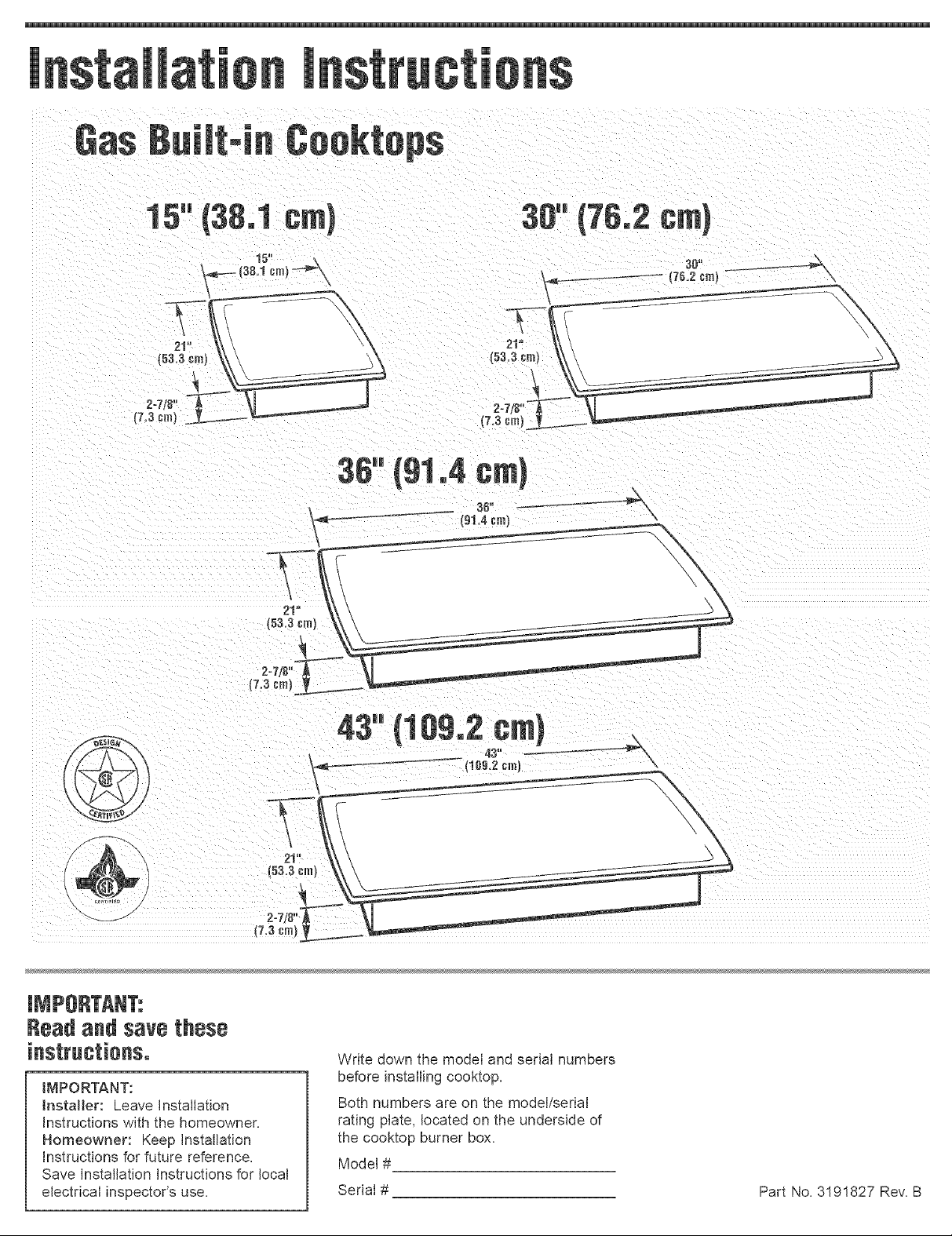

15" (38,1 cm}

278

30"(76.2cml

30" _ \

\

153,3cm)

36" (91,4 cml

36=,

- • {91,4cm_

Read and save these

IMPORTANT:

Installer: Leave Installation

Instructions with the homeowner,

Homeowner: Keep Installation

Instructions for future reference,

Save installation Instructions for local

electrical inspector's use,

43-(1o

{109,2_m_ \

Write down the model and serial numbers

before installing cooktop,

Both numbers are on the model/serial

rating plate, located on the underside of

the cooktop burner box,

Model #

Serial #

Part No, 3191827 Rev, B

Page 2

Befere youstart°°°

Your safety and the safety of

others are very important.

We have provided many important

safety messages in this manual and

on your appliance. Always read and

obey all safety messages.

This is the safety alert

symbol.

This symbol alerts you to

potential hazards that can kill or hurt

you and others.

All safety messages will follow the

safety alert symbol and either the

word "DANGER" or "WARNING".

These words mean:

You can be killed or seriously

injured if you don't immediately

follow instructions.

You can be killed or seriously

injured if you don't follow

instructions.

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

Important: Observe aH governing

codes and ordinances.

WARNING: _fthe

information in this manua_

is not followed exactly, a

fire or expRosion may result

causing property damage,

persona_ injury or death.

m Do not store or use

gasoline or other

flammable vapors and

_iquids in the vicinity of

this or any other

appliance.

WHAT TO DO _FYOU

SMELL GAS

o Do not try to _ight any

appliance.

o Do not touch any

eRectrica[ switch.

o Do not use any phone in

your building.

o _mmediatemy cam[your

gas supplier from a

neighbor's phone. Follow

the gas supp_[er's

instructions.

o _f you cannot reach your

gas supplier, call the fire

department.

_nstaHation and service

must be performed by a

quamified installer, service

agency or the gas

supplier.

Note: This cooktop is manufactured for

use with Natural gas. To convert to

LR/Propane gas, see instructions in the

Gas Conversion Kit provided in literature

package.

Proper gas suppJy connection must be

available. See "Gas supply requirements,"

Page 4.

Proper installation is your responsibility.

Have a qualified technician install this

cooktop.

Make sure you have everything

necessary for correct installation. It is the

responsibility of the installer to comply

with the installation clearances specified

on the model/serial rating plate. The

model/serial rating plate can be found on

the underside of the cooktop burner box.

Check location where cooktop will be

installed. The location should be away

from strong draft areas, such as windows,

doors and strong heating vents or fans.

Do not obstruct flow of combustion and

ventilation air.

All openings in the wall or floor where the

cooktop is to be installed must be sealed.

When installing a cooktop under existing

cabinets and the installation does not

meet the minimum cabinet clearances,

install a range hood above the cooktop to

avoid burn hazards.

Electdcat ground is required. See

"Electrical Requirements," Pages 4-5.

It is the customer's responsibility:

To contact a qualified electrical

instaJJer.

To assure that emectrical installation is

adequate and in conformance with

Nationam EJectrical Code, ANSJ/NFPA

70 -- latest edition*, or Canadian

Electrical Code, C22.1 -1982 and C22.2

No. 01982 (or Jatest edition)** and aH

local codes and ordinances.

Copies of the standards listed may be obtained

from:

*National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

** CSA Bntemational

6501 East Pmeasant Valley Rd.

C_eveJand, OH 44131-8575

neededfer

pencil

Page 3

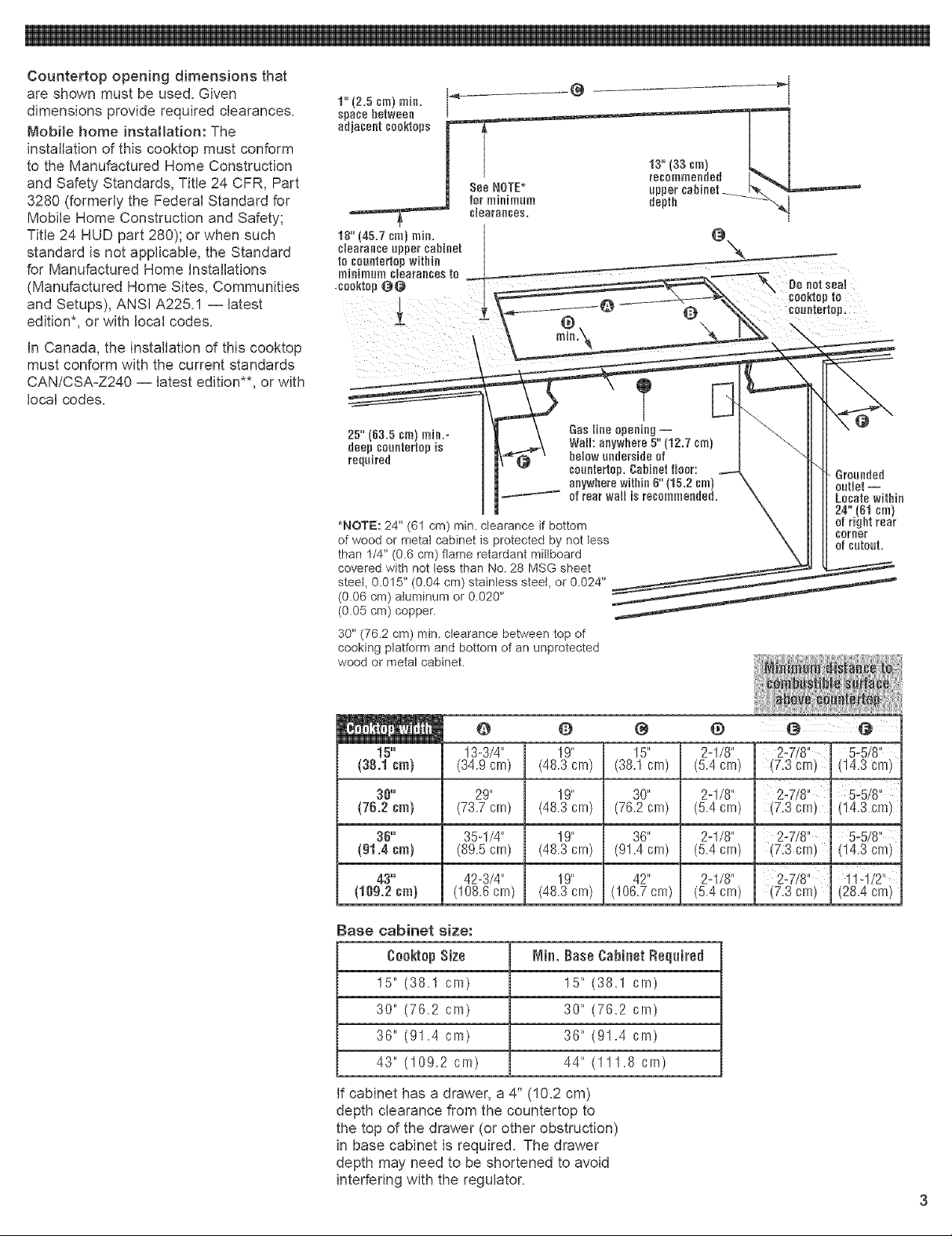

Countertop opening dimensions that

are shown must be used. Given

dimensions provide required clearances.

Mobite home installation: The

installation of this cooktop must conform

to the Manufactured Home Construction

and Safety Standards, Title 24 CFR, Part

3280 (formerly the Federal Standard for

Mobile Home Construction and Safety;

Title 24 HUD part 280); or when such

standard is not applicable, the Standard

for Manufactured Home Installations

(Manufactured Home Sites, Communities

and Setups), ANSI A225.1 -- latest

edition*, or with local codes.

in Canada, the installation of this cooktop

must conform with the current standards

CAN/CSA-Z240 -- latest edition**, or with

local codes.

1" (2.5 sin} min,

space between

adjacent cooktops

25" (63.5 crn) min,=

deep caantertop Us

required

*NOTE: 24" (61 cm) min. clearance if bottom

of wood or metal cabinet is protected by not tess

than 1/4" (0.6 cm) flame retardant mittboard

covered with not tess than No. 28 MSG sheet

steel, 0.015" (0.04 cm) stainless steel, or 0.024"

(0.06 cm) aluminum or 0.020"

(0.05 cm) copper.

30" (76.2 cm) min. clearance between top of

cooking platform and bottom of an unprotected

wood or metal cabinet.

Gas Hne apenUeg--

Walh anywhere 5""(12.7 crn)

below endersUdnof

couetertep, Cabinet floor:

anywhere within 6" (15,2 cm)

of rear wall is recommended,

,°

Do eat seal

Grounded

outlet--

Locatewithin

24"(61crn)

of right rear

career

of cutout,

e o @ @

15"

(38.1era)

38"

(76.2era)

Base cabinet size:

CooktopSize Min. BaseCabinetReqnired

15" (38.1 cm) 15" (38.1 crn)

30" (76.9 cm) 30" (78.2 crn)

36" (91.4 cm) 36" (91.4 crn)

43" (109.2 cm) 44" (111.8 crn)

If cabinet has a drawer, a 4" (10.2 cm)

depth clearance from the countertop to

the top of the drawer (or other obstruction)

in base cabinet is required. The drawer

depth may need to be shortened to avoid

interfering with the regulator.

13-3/4" 19" 15" 2-1/8"

(34.9crn) (48.3crn) (38.1crn) (5.4crn)

29"

(73.7crn}

35-1/4"

(89.5crn)

42-3/4"

(108.6crn)

19 _

(48.3cm)

19 _

(48.3crn)

19 _

(48.3cm)

30 '_

(78.2cm)

38 _

(91.4crn)

42"

(108.7cm)

2-1/8"

(5.4crn)

2-1/8"

(5.4crn)

2-1/8"

(5.4crn)

2-7/8" 5-5/8"

(7,3cm) (14,3cm)

5-5/8"

(7:3 cm) (14,3crn)

(7:3cm) (14,3cm)

1iq/2"

,7:3cm) (2&4cm)

Page 4

G8$ $U

Explosion Hazard

Use a new AGA or CSA approved

gas supply line.

Install a shut-off valve.

Securely tighten a_t gas

con nections.

If connected to LP, have a

qualified person make sure gas

pressure does not exceed 14"

water column.

Examples of a quamified person

include licensed heating

personnel, authorized gas

company personnel_ and

authorized service personnel

Failure to do so can result in

death, explosion, or fire.

Observe all governing codes and

ordinances,

Important: Cooktop must be connected

to a regulated gas supply,

A RThis installation must conform with

local codes and ordinances. In the

absence of local codes, installations must

conform with American National

Standard, National Fuel Gas Code ANSI

Z22&1 --latest edition** or CANI --

B149.1 or 2**.

BE Input ratings shown on the

model/serial rating plate are for elevations

up to 2,000 feet (610 m). For elevations

above 2,000 feet (610 m), ratings are

reduced at a rate of 4% for each 1,000

feet (305 m) above sea level.

EThe cooktop is equipped for use

with NATURAL gas. It is design-certified

by CSA International for NATURAL and

LR gases with appropriate conversion.

The model/serial rating plate, located on

the underside of the burner box, has

information on the type of gas that can be

used. Ifthis information does not agree

with the type of gas available, check with

the local gas supplier. See Page 2 for LR

gas conversion instructions.

mProvide a gas supply line of 3/4"

rigid pipe to the cooktop location. A

smaller size pipe on long runs may result

in insufficient gas supply. Pipe-joint

compounds, suitable for use with L.R gas,

must be used. With LR gas, piping or

tubing size can be 1/2" minimum. LR gas

suppliers usually determine the size and

materials used on the system.

E mIf local codes permit, a new AGA or

CSA design-certified, 4-5 foot (! .2-1.5 m)

long, 1/2" or 3/4" I.D., flexible metal

appliance connector is recommended for

connecting this cooktop to the gas supply

line. Do Not kink or damage the flexible

connector when moving the cooktop. The

pressure regulator has 3/8" female pipe

threads. You will need to determine the

fittings required, depending on the size of

your gas supply line, flexible metal

connector and shutoff valve.

shnt0ftvalve___

"open" pnniti0n _

tnc00kt0p.\__

/ _-_J gas supply

F line

EThe supply line shall be equipped

with an approved shutoff valve. This valve

should be located in the same room as

the cooktop and should be in a location

that allows ease of opening and closing.

Do Not block access to the shutoff valve.

The valve is for turning on or shutting off

gas to the appliance.

G.if rigid pipe __

is used as a gas

supply line, a combination of pipe Ill

fittings must be used to obtain an in-line

connection to the cooktop. All strains

must be removed from the supply and

fuel lines so cooktop will be level and in

line.

mThe regulator must be checked at

a minimum 1-inch (2.5 cm) water column

above the set pressure. The inlet pressure

to the regulator should be as follows for

operation and checking the regulator

setting:

NATURAL GAS:

Set pressure 4 inches (10.2 cm).

Supply pressure 7-14 inches (17.8 cm

to 35.5 cm) maximum.

L.P. GAS:

Minimum pressure 10 inches (28.4 cm).

Supply pressure 14 inches (38.8 cm).

mLine pressure testing:

Testing above 1t2 psi (3.8 kPa)

(14 inches (38.6 cm)) W.C. (gauge)

The cooktop and its individual shutoff

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures

greater than 1/2 psig (3.5kPa).

Testing below 1t2 psi (3.8 kPa)

(14 inches (38.6 cm)) WoC.(gauge) or

lower

The cooktop must be isolated from the

gas supply piping system by closing its

individual manual shutoff valve during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than 1/2 psig (3.5 kPa).

Electrical Shock Hazard

Plug into a grounded 3-prong

outlet.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these

instructions can result in death,

fire, or emectricamshock.

tf codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path is adequate.

Check with a qualified electrician if

you are not sure whether the cooktop

is properly grounded.

Do Not ground to a gas pipe.

A 120-volt, 60-Hz, AC-only, 15-ampere,

fused electrical supply is required. A

time-delay fuse or circuit breaker is

recommended. It is recommended that a

separate circuit serving only this

appliance be provided.

Page 5

Electronicignitionsystemsoperatewithin

widevoltagelimits,butpropergroundand

polarityarenecessary.Inadditionto

checkingthattheoutletprovides120=volt

Nowstart,,,

With cooktop in kitchen.

powerandiscorrectlygrounded,the

outletmustbecheckedbyaqualified

electriciantoseeifitiswired with correct

polarity. A wiring diagram is provided in

the literature package.

Important: This range is equipped with

an electronic ignition system that will not

operate if plugged into an outlet that is

not properly polarized.

This appliance, when installed, must be

electrically grounded in accordance with

local codes or, in the absence of local

codes, with the current CSA standard

C22.1. Canadian Electrical Code Part 1.

Recommended ground method

For your personal safety, this cooktop

must be grounded. This cooktop is

equipped with a 3-prong ground plug. To

minimize possible shock hazard, the cord

must be plugged into a mating 3-prong

ground-type outlet, grounded in

accordance with the National Electrical

Code ANSI/NFPA 70 latest edition* or

Canadian Electrical Code (CSA)** -- and

local codes and ordinances. If a mating

outlet is not available, it is the personal

responsibility and obligation of the _

customer to have a properly polarized _- ->-_

a qualified electrician.

Numbers

correspond to steps. 6.

E Remove foam shipping blocks and

tape from cooktop. Untape power supply

cord.

strip

4E Glass Cooktops Only:

Remove foam strip from literature

package. Apply foam strip around bottom

of cooktop flush with edge.

and grounded, 3=prong outlet installed by

gr0und=type outlet

m Remove pressure regulator,

3=pr0ng hardware package, burner grates and

groundplug caps from shipping package.

3=pr0ngpolarized __

puv_er

supply cerd

Copies of the standards listed above may be

obtained from:

*National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

** CSA International

8501 East Pmeasant Valley Rd.

C_eveJand, OH 44131-8575

Lift entire cooktop up from cutout when

repositioning cooktop in countertop

opening to prevent scratching countertop.

3E Insert cooktop into countertop

opening. Center the cooktop inthe cutout.

Check that front edge of cooktop is

parallel to front edge of countertop. Check

that all required clearances are met. Use

a pencil to outline the rear of the cooktop

on the countertop. Remove the cooktop

from the cutout and place upside down

on a protected surface.

front of ¢ooktop

5m Remove two screws from left and

right bottom edges of burner box. Place

brackets on top of burner box. Position

brackets as shown and hand=tighten one

screw into each bracket.

m Reinsert the cooktop into

countertop opening. Check that cooktop

is parallel to front edge of countertop. Lift

entire cooktop to make adjustments.

Page 6

saaktap saantertap

/

' I

clamping screw

i

burner " bracket

box

pipe-joint compound made

for use with NATURAL and L.R gas. If

flexible metal connector is used, be

certain tubing isnot kinked.

"open" pasUfl

sbntaffvaleea__jnC)_

E_ectronic _gnition System m

initial lighting

Cooktop burners use electronic igniters in

place of standing pilots. When the

cooktop control knob is pushed in and

turned to the "LITE" position, the system

creates a spark to light the burner. This

sparking continues until the control knob

is turned to the desired setting.

E SCrews

Rotate brackets away from burner

box. Install second screw into each

bracket and tighten brackets to burner

box. Insert the 2-1/2" (6.4 cm) clamping

screws intothe brackets. Use a

screwdriver to tighten clamping screws

against the underside of countertop.

Do not overtighten screws.

mInstall the pressure regulator with

the arrow on the regulator pointing up

toward unit and in a position where you

can reach the access cap.

IMPORTANT: All connections must be

wrench-tightened. Do Not make

connections to the gas regulator too tight.

Making the connection too tight may

crack the regulator and cause a gas leak.

Do Not allow the regulator to turn on the

pipe when tightening fittings.

adapter

valve sampaund regulator

All connections must be wrench=

tightened.

E Assemble flexible metal connector

from the gas supply pipe to the pressure

regulator. Youwill need to determine the

fittings required, depending on the size of

your gas supply line, flexible metal

connector and shutoff valve.

3/8"

/ _ gas supply

EOpen shutoff valve in the gas

supply line. Wait a few minutes for gas to

move through the gas line.

m Leak testing of the appliance

shall be conducted according to the

following instructions:

Use a brush and liquid detergent to test

all gas connections for leaks. Bubbles

around connections will indicate a leak. If

a leak appears, shut off gas valve

controls and adjust connections. Then

check connections again. NEVER TEST

FOR GAS LEAKS WiTH A MATCH OR

OTHER FLAME. Clean all detergent

solution from cooktop.

3m Plug power supply cord into

grounded outlet.

Put burner caps on each burner

base. Place burner grates over burner

bases and caps.

Hne

O

O0

oo

"'9_/"7tH

1 5. Check operation of the cooktop

burners. Push in and turn each control

knob to "LITE" position. The flame should

light within 4 seconds. Do Not leave the

knob in the "LITE" position after

burner Hghtso

If burners do not light properly, turn

control knob to the "OFF" position. Check

that burner cap is in the proper position.

Check that power supply cord is plugged

in and that circuit breaker or house fuse

has not blown. Check that the shutoff

valve is in the "ON" position. Check

operation again. If a burner does not light

at this point, contact your Whirlpool dealer

for assistance.

m Push in and turn each control

knob to the '%0" (or simmer) setting. The

'%0" setting of each burner has been

factory set to the lowest setting available

to provide reliable reignition of the burner.

if it does not stay lit on the '%O"setting,

check '%O"setting as follows:

a. Turn control to "LiTE" until burner

ignites.

b. Quickly turn knob down to LOWEST

POSITION.

c. If burner goes out, readjust valve as

follows:

Remove the surface burner control knob.

Insert a flat-blade screwdriver into the

hollow valve stem and engage the slotted

screw. Flame size can be increased or

decreased by turning the screw. Adjust

flame until you can quickly turn knob from

"LITE" to LOWEST POSITION without

extinguishing the flame. Flame should be

as small as possible without going out.

Page 7

If ceoktep

net operate:

ing and

maintenance

_ Check that the circuit breaker is not

tripped or the house fuse blown.

[_ Check that the power supply cord is

plugged into the outlet.

[_ Check that gas valves are turned to

the "ON" position.

[_See Use and Care Guide for

troubleshooting list.

If youneed

tf you have questions about operating,

cteaning or maintaining your cooktop:

[_ Refer to Use and Care Guide.

[_ Call the Consumer Assistance

Center. Check your Use and Care

Guide for the number to call or call

the dealer from whom you

purchased this appliance. The dealer

is listed in the Yellow Pages of your

phone directory under "Appliances --

Household -- Major -- Service and

Repair."

Maintain the quality built into your

cooktop by calling an authorized

service company.

To obtain the name and number of the

authorized service company:

[_ Contact the dealer from whom you

purchased your cooktop; or

[_] Look in the Yellow Pages of your

telephone directory under

"Appliances -- Household --

Major -- Service and Repair;" or

[_ Call the Consumer Assistance

Center. The number is listed in your

Use and Care Guide.

When you call, you will need:

[_The cooktop model number.

[_] The cooktop serial number.

Both numbers are listed on the

model/serial rating plate located on the

underside of cooktop burner box.

If removing the cooktop is necessary for

cleaning or maintenance, shut off gas

supply. Disconnect the gas and electric

supply. Remove the mounting brackets on

the right and left side of burner box. After

disconnecting the gas and electric supply,

finish removing the unit for cleaning and

servicing. Reinstall in reverse order and

check gas connection for leaks.

Page 8

ROUND BLADE

CONNECT

,250 TERMINALS

(NOT USED)

(NOT USED)

ELK _i

SWITCHES ON VALVES

ELECTRtC CIRCUtT

CLOSED WHEN KNOB IS

ROTATED 55 ° TO 95 °

COUNTER CLOCKWISE

FROM OFF

THE POWER CORD ONTNIS APPLIANCE IS EQUIPPED

WITH ATHREE PRONGED (GROUNDING) PLUG WHICH

MATES WITN STANDARD THREE PRONGED (GROUNDrNG)

WALL RECEPTACLES

VALVE

SWITCHES

PLUG

NEUTRAL 5/15

WIDE BLADE

GRN OR GRNIY ii_GROUND

120VAC 60 Hz

I PHASE

15 OR 20 AMP

WHT

I

EC3 I

L....... I

iGNITOR

ELECTRODES _ .........

[

I

I

SPARK

MODULE

YEL OR

BRN

ROUND BLADE

CONNECT

,250 TERMINALS

ELK

SWITCHES ON VALVES

ELECTRIC CIRCUIT

CLOSED WHEN KNOB IS

ROTATED 55 ° TO 95 °

COUNTER CLOCKWISE

FROM OFF

THE POWER CORD ON THIS APPLIANCE IS EQUIPPED

WITH ATNREE PRONGED (GROUNDING) PLUGWNmCN

MATES WITH STANDARD THREE PRONGED (GROUNDING)

WALL RECEPTACLES

PLUG

120VAC 60 Hz

I PHASE

15 OR 20 AMP

VALVE

SWITCHES

GRN OR GRN/Y I I GROUND

IGNITOR

WNT

I I

I I

I__ <_ YELORBRN

ELECTRODES............1............

MODULE

(41 PLACES

Caution: Label aI_ wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

GROUND

ROUND BLADE

CONNECT

.250 TERMINALS

BLK _

SWITCHES ON VALVES

ELECTRIC CIRCUIT

CLOSEDWHEN KNOB IS

ROTATED55°TO 95°

COUNTER CLOCKWISE

FROM OFF

Caution: Label aI_ wires prior to disconnection when servicing controM.

Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

THE POWER CORD ONTNIS APPLIANCE I$ EQUIPPED

WITH ATHREE PRONGED (GROUNDING) PLUG WHCN

MATES WITH STANDARD THREE PRONGED (GROUNDrNG)

WALL RECEPTACLES

VALVE

SWITCHES

PLUG

NEUTRAL5/16

WIDE BLADE

120VAC 60 Hz

I PHASE

15 OR 20 AMP

,GROUND

[

I

iGNITOR

ELECTRODES

WHT

ELK

SPARK

MODULE

: [3[]

_E_

Eli]

B,.......

BRN

YEL OR

(6) PLACES

±

Eli]

Caution: Label aII wires prior to disconnection when servicing controls.

WiNng errors can cause improper and dangerous operation.

Verify proper operation after servicing.

THE POWER CORD ON THIS APPUANCE _SEQUIPPED

W_TH A THREE PRONGED (GROUNDING) PLUG WHICH

MATES WITH STANDARD THREE PRONGED (GROUNDING)

WALL RECEPTACLES

GROUND

ROUND BLADE

FROM OFF

Caution: Label aH wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

PLUG

_ _.................NEUTRAL 5/!5

_/ WIDE BLADE

/

\.L/

BLK

GRN OR GRN]Y

GRN OR GRN/Y

ELECTRODES

120VA¢ 60 Hz

15 OR 20 AMP

I PHASE

I,GROUND

If'GROUND

SPARK

±

Part No, 3191827 Rev, B

@2000Whirlpool Corporation Benton Harbor, Michigan 49022 Printed in U,S,A,

Loading...

Loading...