Page 1

m

GAS BUILT-IN

SINGLE & DOUBLE OVENS

MODEL (single).

KGBS 146s

MODEL (double).

KGBS 246s

INSTALLATION

INSTRUCTIONS

INSTALLER: FINAL CHECK LIST

PLACEMENT OF UNIT

0 1. Properly positioned - level, aligned and square with cabinet opening.

0 2. Anchored securely to cabinet.

cl 3.0

ven must not be placed under countertop or microwave oven.

ELECTRICAL

0 1. Oven properly grounded,

0 2. Polarized three-wire 12OVAC. 15.20Ampere receptacle with 15-20ampere overcurrent

protection provided for service cord connection.

GAS SUPPLY

0 1. Supply line of 3/8” black iron pipe provided,

0 2. Manual gas shutoff valve must be installed in accessible location. Do Not install shutoff valve

behind oven.

0 3. Oven connections must be tested for gas leaks.

OPERATIONAL

[7 1. If used on LP gas, verify that pressure regulator and orifice hoods have been modified for

use with LP gas.

0 2. Oven racks installed and

0 3. Knobs secured in place and rotate freely without rubbing on edge of control panel glass

holes,

0 4. Selector switch functions in all modes.

0 5. All lights function properly.

0 6. Refer to use and care guide to set electronic clock.

0 7. Doors properly adjusted, open and close smoothly.

0 8. Unless instructed to leave for owner, remove all tags, labels and internal packing material.

slide freely in all posttions.

t

0 9. Oven has been wiped clean to remove fingerprints and other smudges.

THANK YOU INSTALLER:

1. Complete Installation Check List.

Leave all literature for customer.

2.

Notify dealer that installation is completed.

3.

FOR DETAILED INSTRUCTIONS, FOLLOW METHODS DESCRIBED IN THIS FOLDER.

Page 2

IMPORTANT: Read Before Installing to Save Time, Work,

assure proper performance, and owner’s warranty protection.

INSTALLATION INSTRUCTIONS

The oven installation must conform with local codes and ordinances and ulility regulations. In the absence of local

codes, installation must conform with American National Standard, National Fuel Gas Code ANSI Z223.1-latest

edition. It is the customer’s responsibility to contact a qualified electrical installer to assure that electrical installation

is adequate and in conformance with National Electrical Code, ANSVNFPA 70-latest edition and local codes and

ordinances.

When installed in a mobile home, the installation must conform to the Manufactured Home Construction and Safety

Standards, Title 24 CFR, Part 3280 (formerly the Federal Standard for Mobile Home Construction and Safety, Title

24, HUD, Part 280).

Fire Hazard

l

Do Not use or store gasoline, paint, thinners and other flammable materials

near oven.

l

Do Not obstruct the flow of combustion and ventilation air.

l

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

Failure to follow these instructions could result in a fire or explosion.

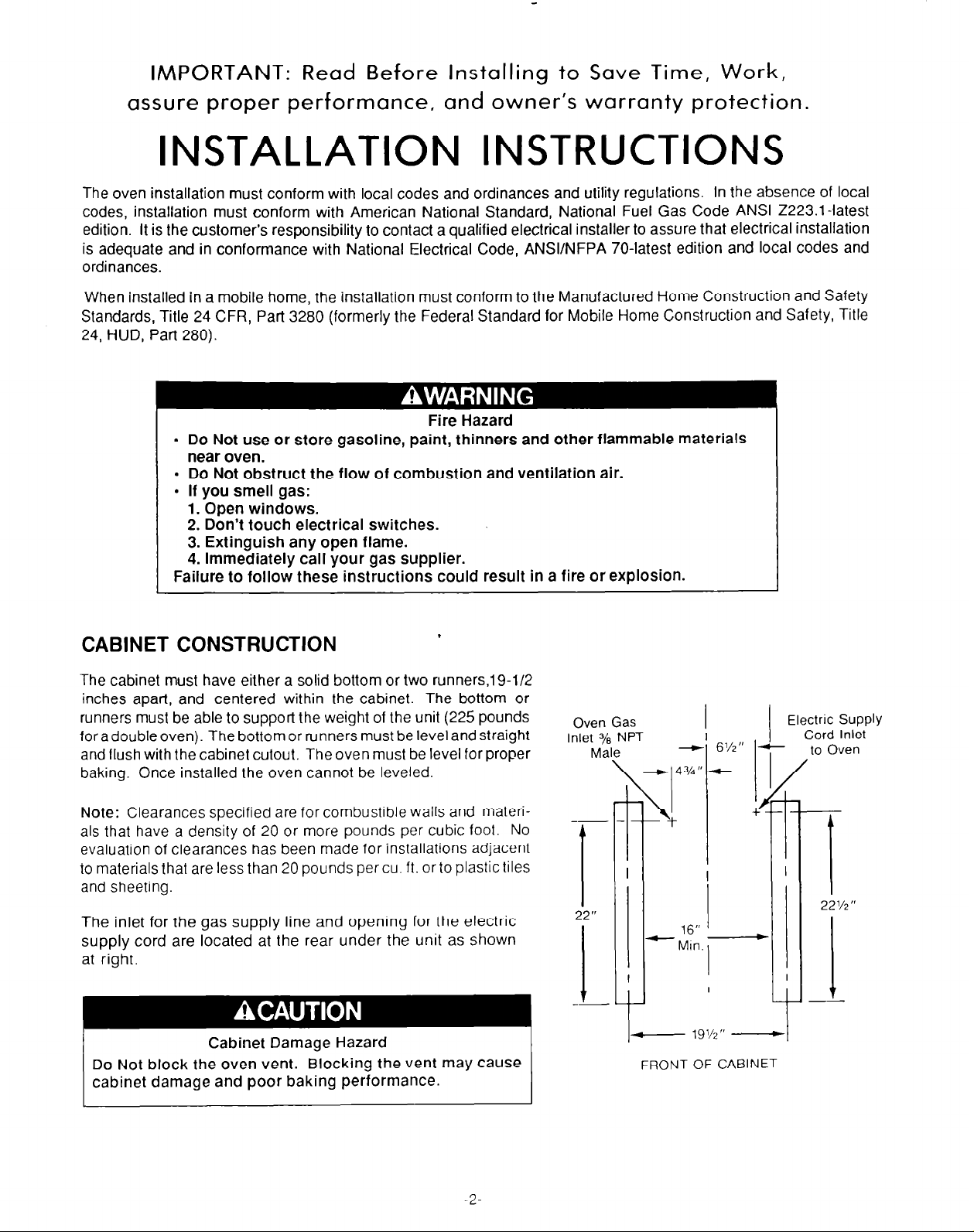

CABINET CONSTRUCTION

The cabinet must have either a solid bottom or two runners,l9-l/2

inches apart, and centered within the cabinet. The bottom or

runners must be able to support the weight of the unit (225 pounds

for a double oven). The bottom or runners must be level and straight

and flush with the cabinet cutout. The oven must be level for proper

baking. Once installed the oven cannot be leveled.

Note: Clearances specified are for combustible walls and materi-

als that have a density of 20 or more pounds per cubic foot. No

evaluation of clearances has been made for installations adjacent

to materials that are less than 20 pounds per cu. ft. or to plastictiles

and sheeting.

The inlet for the gas supply line and opening for the electric

supply cord are located at the rear under the unit as shown

at right.

Cabinet

Do

Not block

cabinet damage and poor baking performance.

the oven vent. Blocking the vent may cause

Damage Hazard

.

Oven Gas

Inlet 3/s NPT

Male

\

-

4

I

- to Oven

+

FRONT OF CABlNET

Electric Supply

Cord Inlet

2-

Page 3

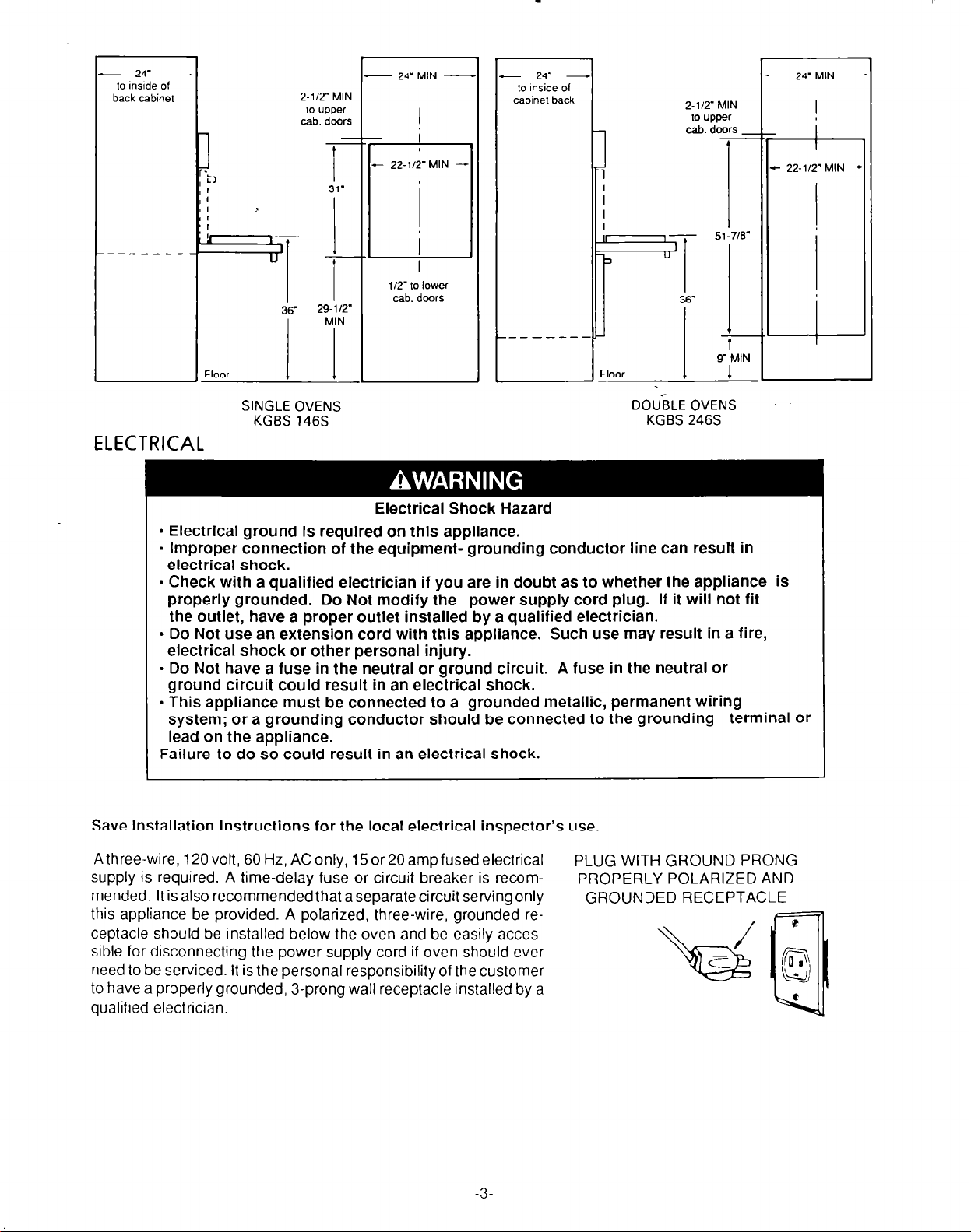

- 24‘ to inside of

back cabinet

2-l/2” MIN

to upper

cab. doors

MIN

- 24” MIN _

I

I

I

- 22-112’MIN -

i

I

l/2- to lower

cab. doors

- 24- to Inside of

cabinet back

-------

Floor

2-112” MIN

to upper

cab. doors _

,

t

9’ MIN

. 1

- 24- MIN -

- 22-112’ MIN

SINGLE OVENS

KGBS 146s

ELECTRICAL

Electrical Shock Hazard

l

Electrical ground is required on this appliance.

. Improper connection of the equipment- grounding conductor line can result in

electrical shock.

l

Check with a qualified electrician if you are in doubt as to whether the appliance is

properly grounded. Do Not modify the power supply cord plug. If it will

the outlet, have a proper outlet installed by a qualified electrician.

l

Do Not use an extension cord with this appliance. Such use may result in a fire,

electrical shock or other personal injury.

- Do Not have a fuse in the neutral or ground circuit. A fuse in the neutral or

ground circuit could result in an electrical shock.

l

This appliance must be connected to a grounded metallic, permanent wiring

system; or a grounding conductor should be connected to the grounding

lead on the appliance.

Failure to do so could result in an electrical shock.

Save Installation Instructions for the local electrical inspector’s use.

DOUiiLE OVENS

KGBS 246s

not

fit

terminal or

A three-wire, 120 volt, 60 Hz, AC only, 15 or20 amp fused electrical

supply is required. A time-delay fuse or circuit breaker is recommended. It is also recommended that a separate circuit serving only

this appliance be provided. A polarized, three-wire, grounded receptacle should be installed below the oven and be easily accessible for disconnecting the power supply cord if oven should ever

need to be serviced. It is the personal responsibility of the customer

to have a properly grounded, 3-prong wall receptacle installed by a

qualified electrician.

-3

PLUG WITH GROUND PRONG

PROPERLY POLARIZED AND

GROUNDED RECEPTACLE

Page 4

UNPACKING THE UNIT

Personal Injury

More than one person is required to lift or

move the oven because of its weight and

size. Failure to follow these instructions

may result in personal injury.

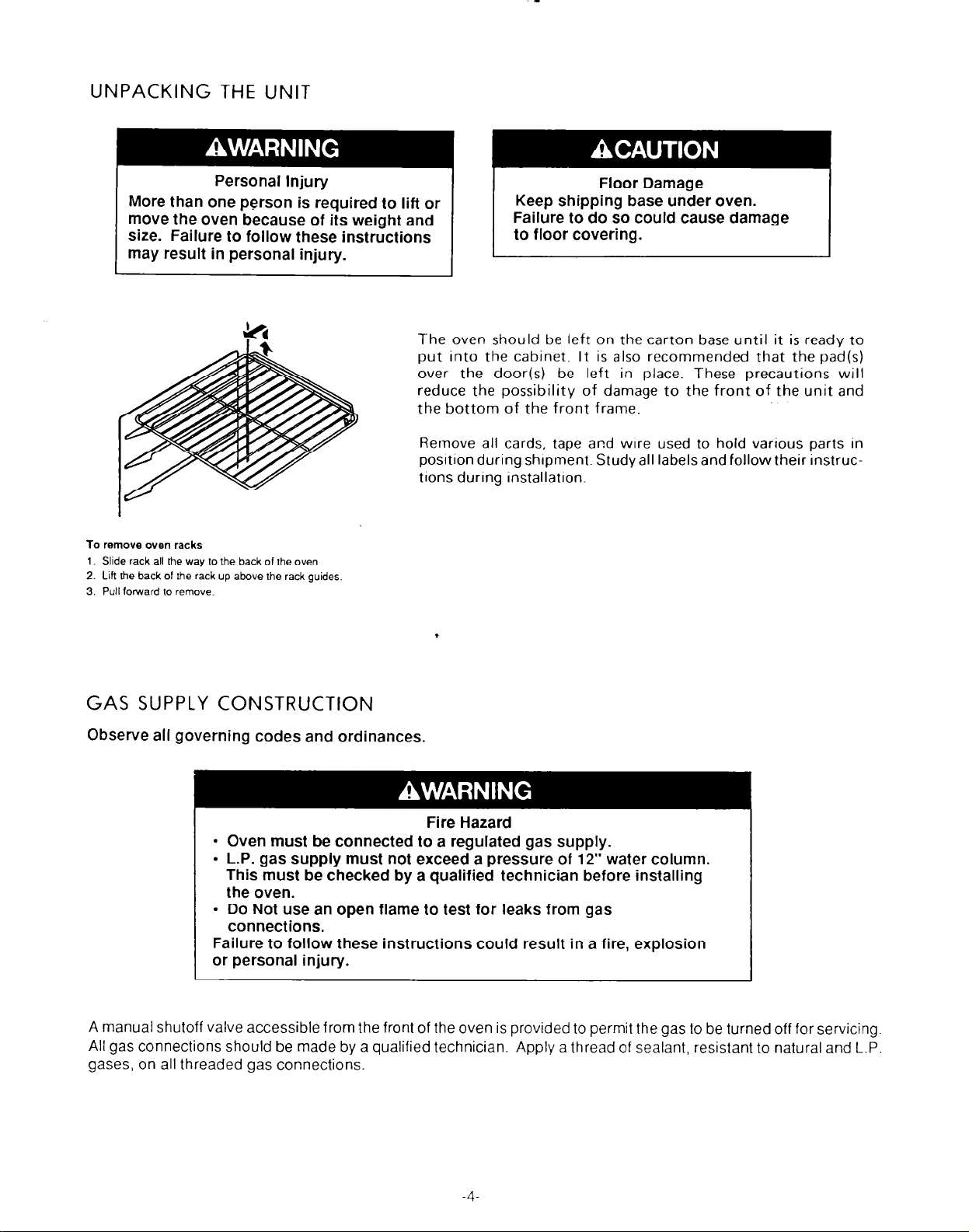

To remove oven racks

1. Slide rack all the way to the back of the oven.

2. Lift the back of the rack up above the rack guides

3. Pull forward to remove.

Floor Damage

Keep shipping base under oven.

Failure to do so could cause damage

to floor covering.

The oven should be left on the carton base until it is ready to

put into the cabinet. It is also recommended that the pad(s)

over the door(s) be left in place. These precautions will

reduce the possibilitv of damaqe to the front of the unit and

the bottom’of the frdnt frame.-

Remove all cards, tape and wire used to hold various parts in

posltion during shipment. Study all labelsand followtheir instruc-

tlons during Installation.

GAS SUPPLY CONSTRUCTION

Observe all governing codes and ordinances.

Fire Hazard

l

Oven must be connected to a regulated gas supply.

l

L-P. gas supply must not exceed a pressure of 12” water column.

This must be checked by a qualified technician before installing

the oven.

l

Do Not use an open flame to test for leaks from gas

connections.

Failure to follow these instructions could result in a fire, explosion

or personal injury.

A manual shutoff valve accessible from the front of the oven is provided to permit the gas to be turned off for servicing.

All gas connections should be made by a qualified technician. Apply a thread of sealant, resistant to natural and L.P.

gases, on all threaded gas connections.

Page 5

INSTALLING THE UNIT IN CABINET

Route electric supply cord so that it can be plugged into

receptacle after unit has been slid into place in cabinet.

Potential Personal Injury

l

Use both hands to remove oven doors.

l

Grasp only the sides of the oven door. Do Not use any

portion of the front frames or trim for lifting.

Failure to properly grasp oven door could result in

damage to product or personal injury.

The doors should be removed to decrease the weight of the

oven and provide a better hand hold on the oven while lifting

it into the cabinet.

A.

TO REMOVE

Use caution! Oven door is heavy.

1. Open door completely.

2. Depress finger tab in oven door hinge area. Push tab

toward oven. Lift tab away from door liner and slide toward

top of oven door.

3. Repeat step 2 for other side of door.

4. Close door until approximately 5 inches from fully closed

position.

5. Slide door off the hinge arm assemblies.

6. Repeat steps 1 through 5 for other door on double ovens.

DOORS (See Illus.)

DOOR REMOVE

BE SURE THAT

ARE IN PLACE TO PROVIDE PROPER AIR FLOW BETWEEN

CABINET AND OVEN.

When oven has been placed into cabinet, the bottom trim strip

is placed on the lower edge of the front frame. This is done

by loosening the three screws at the bottom of the front frame.

Place gas valve extension rod through hole in trim strip and

slide strip under screw heads until the top edge of trim meets

the lower corners of the front frame (see Illus.). Tighten screws

to hold trim to front frame. Make sure that valve is turned to

the full “on” position (pin straight and down).

MICA SPACERS AT EITHER SIDE OF OVEN

Personal Injury Hazard

Securely fasten wall oven to cabinets using the screws

provided (4 screws for a double oven or 2 screws for a

single oven). Failure

or

tip during

use and result in personal injury.

to do so could cause oven to move

Secure oven to cabinet with #8 screws provided. Do not

overtighten screws. Edge of front frame should be parallel

to cabinet. Disregard any excess screws that are left after

all screw holes in front frame have been used.

FINGER TAB

B. REPLACE OVEN RACKS IN OVEN CAVITY.

C. REINSTALL THE DOOR(S) (See Illus.)

1. Slide door hinge arms until firmly seated.

2. Lower door to full open position.

3. Push finger tabs to back. Depress the tabs and slide forward.

4. Close and reopen door slowly to make sure it has been replaced properly.

5. Repeat steps 1 through 4 for other door on double oven.

Page 6

CHECKOUT AND ADJUSTMENT

After the oven is installed and the gas connected, all gas connections MUST be tested for gas leaks. Be sure that electricity is off before turning on the gas supply. Test with pressure gauge or apply soapy solution or leak detector solution

on ALL gas connections. Repair any leaks that may appear before operating oven.

THE REGULATOR IS SET FOR USE WITH NATURAL GAS. FOR USE WITH LP GAS, THE REG-

ULATOR MUST BE CONVERTED. The gas pressure regulator is located in the compartment behind the

control frame. Removecontrol frame (see instructions below), loosen and slide the control mounting plate

out to gain access to the pressure regulator.

TO REMOVE CONTROL FRAME

t

(TYPICAL CONSOLE)

1

Remove bezel nut from oven light switch by turning

2. Remove all other knobs by pullrng straight forward,

3. Remove front 3 Phillips screws under control frame and 2 Phillips screws on top portlon of control

frame. Be sure to hold control frame in place.

4. Pull control frame forward.

counterclockwrse

v

To convert the regulator for LP gas, remove the regulator access cap (see below). Reverse cap, so that “LP” In

cap recess is showing when cap is in place. Return cap to regulator and tighten. The regulator

column (W-C.) for use with natural gas and 10” W.C. for use with LP gases. In order to check pressure

regulator, the inlet test pressure must be at least one (1”) W.C. greater (5” for natural and 1 1” for LP) than

setting. Maximum pressure to regulator must not exceed 14” W.C.

IS

set at 4” water

\

PRESSURE REGULATOR

(TYPICAL)

6-

Page 7

The appliance and Its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of % psig.

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than %

psig.

This unit may be used on natural or LP gas. A basic adjustment has been made at the factory for natural

gas.

WHEN USED WITH LP GASES: MAKE CERTAIN THAT PRESSURE REGULATOR HAS BEEN

CONVERTED FOR USE WITH LP GAS. ADJUST BURNER INPUT BY TURNING OUTER ORlFtCE

HOODS DOWN UNTIL SNUG AGAINST INNER ORIFICE NEEDLE.

Final adjustment of the air-gas mixture is made by turning the air shutter until a concise blue cone has

been obtained. If the flames lift from the burner, reduce the air opening in the shutter. If the flames are

yellow, increase the air shutter opening.

DOOR ADJUSTMENT CHECK

NEWSPAPER STRIPS

TOP OF DOOR

STRIPS

Place2’x 18”stripsofnewspaperin locarlons

indicated by illustration. Allow one end of the

paper to extend into the oven caviry. Pull

gently at each piece of paper. If door IS

properly adjusted. each piece of paper will

offer firm resistancewhen pulled. When door

I

~sourof adjustment. slide unitout farenough

IO expose hinges on each side (see preceding page). Loosen screws and move bottom

of door to a proper fit. After completing adjustment tighten all screws in hinges.

NEFI;K

SIDE OF

DOOR

NEWSPAPER STRIPS

BOTTOM OF DOOR

NEWSPAPER

SIDE OF DOOR

*

ADJUST IN

OR OUT FOR

, PROPER DOOF

SEAL-

-v

ADJUST UP OR DOWN‘V

TO ALIGN DOOR

Note: If the oven is installed on a solid bottom, the gas supply must be disconnected before the oven can be slid

forward to adjust doors.

Page 8

c”u”yu; OVEN LIGHT

>

INCI

SWITCH

- -

”

Ir-

El

= ELECTRONIC =

CLOCK

12V RELAY

ROTISSERIE

MOTOR

BAN

SCHEMATIC DIAGRAM

KGBS14BSBLO

KGBS24BSBLO

U.O.

LIGHT

L.O.

LIGHT

U.O. IND.

LIGHT

BAKE IGNITOR BAKE VALVE

BROIL IGNITOR

BROIL VALVE

I --------------------- ~~~-~~~~~~~-~~-----------------

x3--?&

0~x~x~0~x~x

CLOSED

0 = OPEN

LOWER OVEN

3 2

FAN

IND LIGHT

L 0 IND

LIGHT

BAKE IGNITOR

WARNING

DISCONNECT FROM ELECTRICAL

SUPPLY BEFORE SERVICING UNIT

BLOWER

MOTOR

BAKE VALVE

-8-

Page 9

POWER ON

IN).

WHT

OVEN IN)

LIWT

YEI

LK

1r

CAP

RED

WHT

MEAT PROBE JACK

I

S IWGL E OVEN HOOKUP

KGBSl46SBLO

YEL

SERVICE COi(3

Page 10

W”T

II ’

J GUN

1 I

POWER Oh

IN).

,BAKE VALVE

BLU

MECT PROBE JACK

‘WH T

16L

U/O BROIL ICNITOR

WHT

, CLK

u-0. IN).

LIWT

ELECTRONIC

//

\

U/G BAKE lGNlTCR

EOUB i E OVEN HOCKUF

KGbS233SBi0

-lO-

DiSCCrddECT FROM ELECTRICAL

SIJPFLY BEFORE SERVlCIr~IG UNIT

Page 11

Part No. 3177319 Rev C

(C) 1989 KitchenAid, Inc.

Prepared by KitchenAid, St. Joseph, Michigan 49085

.ll

Printed in U.S.A

Loading...

Loading...