KitchenAid KECD867XSS01, KECD867XSS00, KECD807XSS00, KECD807XBL00, KECD867XBL01 Installation Guide

...Page 1

30" (76.2 CM) AND 36" (91.4 CM) ELECTRIC

DOWNDRAFT COOKTOP

INSTALLATIONINSTRUCTIONS

INSTRUCTIONSD'INSTALLATIONDE LATABLEDE

CUISSON ELECTRIQUEAVEC ASPIRATION

PARLEBASDE30" (76,2 CM) ET36" (91,4 CM)

TableofContents/Tabledesmah_res

COOKTOP SAFETY ........................................................................ 2

INSTALLATION REQUIREMENTS ................................................ 3

Tools and Parts ............................................................................ 3

Location Requirements ................................................................ 3

Venting Requirements .................................................................. 5

Venting Methods .......................................................................... 6

Electrical Requirements .............................................................. 8

INSTALLATION INSTRUCTIONS .................................................. 9

Prepare Cooktop .......................................................................... 9

Install Foam Strip .......................................................................... 9

Rotate Blower - Optional .............................................................. 9

Install Cooktop ........................................................................... 11

Make Electrical Connection ....................................................... 11

Complete Installation .................................................................. 12

SleCURITle DE LA TABLE DE CUlSSON ................................. 13

EXIGENCES D'INSTALLATION ................................................ 14

Outils et pieces ........................................................................ 14

Exigences d'emplacement ...................................................... 14

Exigences concernant I'evacuation ........................................ 16

Methodes d'evacuation ........................................................... 17

Specifications electriques ....................................................... 19

INSTRUCTIONS D'INSTALLATION ......................................... 20

Preparation de la table de cuisson ......................................... 20

Installation de la bande de mousse ........................................ 20

Rotation du ventilateur- Facultative ....................................... 20

Installation de la table de cuisson ........................................... 22

Raccordement electrique ........................................................ 22

Achever I'installation ............................................................... 23

iMPORTANT:

Save for local electrical inspector's use.

iMPORTANT :

,&,conserver pour consultation par I'inspecteur local des installations 61ectriques.

W10298568A

Page 2

COOKTOP SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

2

Page 3

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Tape measure

• Flat-blade screwdriver

• Phillips head screwdriver

• Drill

• Level

• 6" socket extension

Parts supplied

• Vent grille

• Pre-filter

Parts needed

• A UL listed or CSA approved strain relief for 7/8"(2.2 cm)

knockout.

• A UL listed or CSA approved conduit connector for

1/2"(1.3 cm) trade-size metal-clad conduit

• UL listed wire connectors

Metal ducting

Wall cap

6" (15.2 cm) Round Surface Wall Cap Damper

Order Part Number A406

5" (12.7 cm) Round Surface Wall Cap Damper

Order Part Number A405

31¼"x 10" (8.3 x 25.4 cm) Surface Wall Cap Damper

Order Part Number A403

To order, see the "Assistance or Service" section of the Use

and Care Guide.

• Vent clamps

Check local codes. Check existing electrical supply. See

"Electrical Requirements" section.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

IMPORTANT: Observe all governing codes and ordinances.

When installing cooktop, use minimum dimensions given.

• To eliminate the risk of burns or fire by reaching over the

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage is to

be provided, the risk can be reduced by installing a range

hood that projects horizontally a minimum of 5" (12.7 cm)

beyond the bottom of the cabinets.

• Use the countertop opening dimensions that are given with

these Installation Instructions. Given dimensions are

minimum clearances and provide 0" (0 cm) clearance.

• Marker or pencil

• Pliers

• 1¼.drill bit

• Jigsaw

• Ratchet with 3/8"socket

• Grounded electrical supply is required. See "Electrical

Requirements" section.

• If cabinet has drawers, drawers will need to be removed and

drawer fronts installed on front of cabinet.

IMPORTANT: An under-counter built-in oven cannot be installed

under this product.

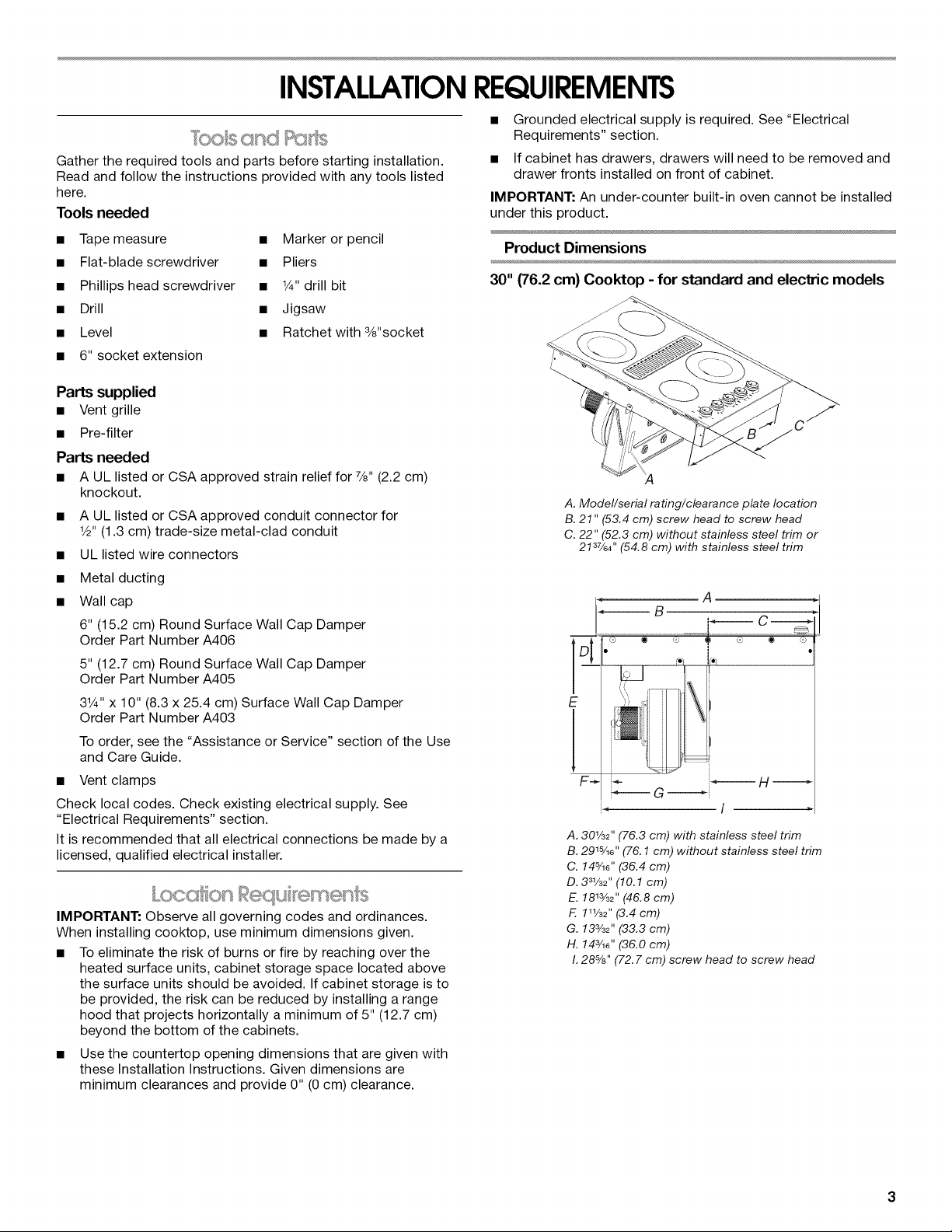

Product Dimensions

30" (76.2 cm) Cooktop - for standard and electric models

A. Model/serial rating/clearance plate location

B. 21" (53.4 cm) screw head to screw head

C. 22" (52.3 cm) without stainless steel trim or

21s7/64''(54.8 cm) with stainless steel trim

i C--------_

@ ® ©

E

J

F_ i_ i_-.------------J-H

i_--G i

A.30½_"(76.3 cm) with stainless steel trim

B.291%6'' (76.1 cm)without stainless steel trim

C. 14%d'(36.4 cm)

D. 331/32 '' (10.1 cm)

E.1813/32''(46.8 cm)

F. 1_½_'' (3.4cm)

G. 13s/3_'' (33.3 cm)

H. 14s/le''(36.0 cm)

I.28%" (72.7cm) screw head to screw head

Page 4

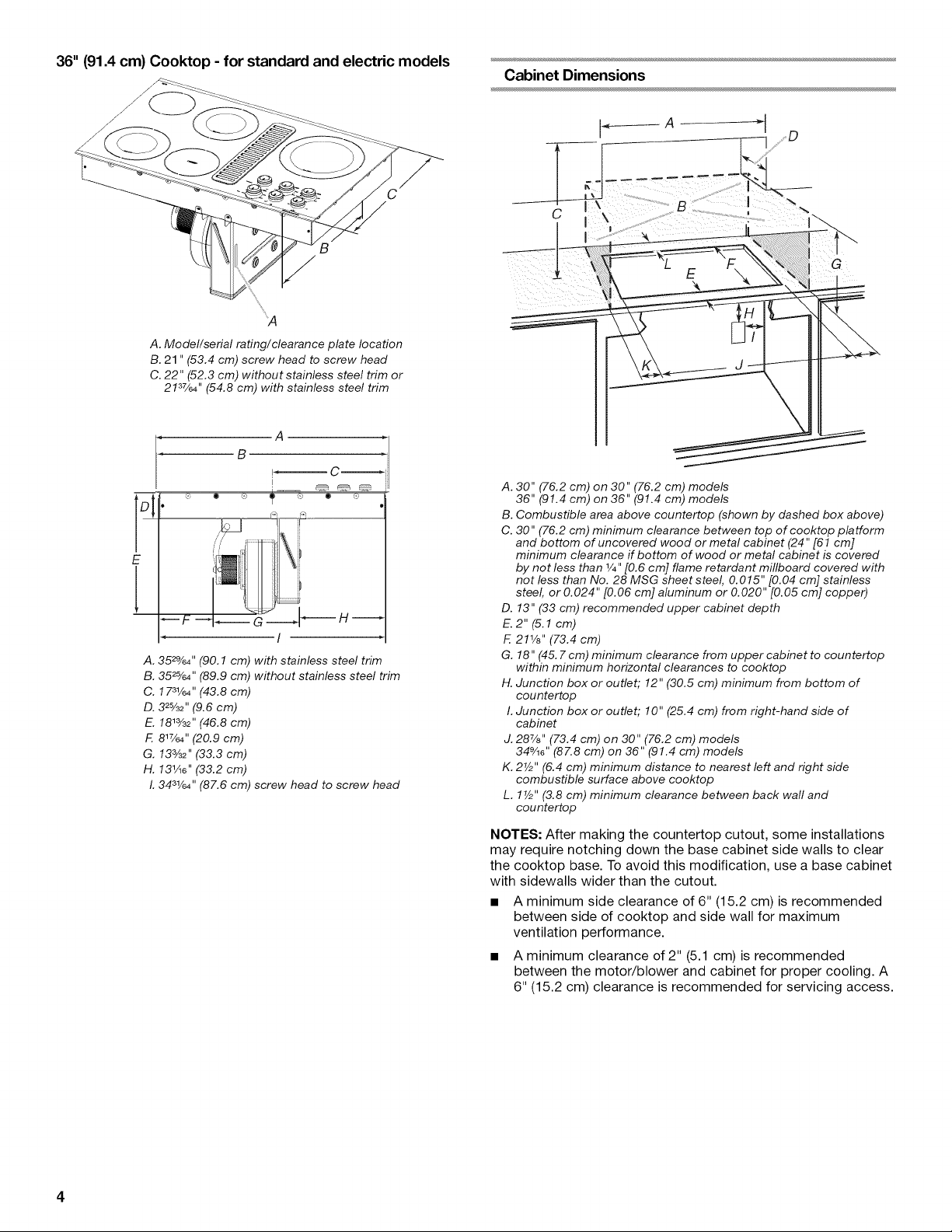

36" (91.4 cm) Cooktop -for standard and electric models

A. Model/serial rating/clearance plate location

B. 21" (53.4 cm) screw head to screw head

C. 22" (52.3 cm) without stainless steel trim or

2137/64'' (54.8 cm) with stainless steel trim

A =r

B

A. 35_%4'' (90.1 cm) with stainless steel trim

B. 35_%4" (89.9 cm) without stainless steel trim

C, 1 731/64 '' (43.8 cm)

D. 3_%_'' (9.6 cm)

E. 1813/32'' (46.8 cm)

F. 817/64 '' (20,9 cm)

G. 133/32" (33.3 cm)

H. 131/16'' (33.2 cm)

I.3431/64'' (87.6 cm) screw head to screw head

Cabinet Dimensions

C

A. 30" (76.2 cm) on 30" (76.2 cm) models

36" (91.4 cm) on 36" (91.4 cm) models

B. Combustible area above countertop (shown by dashed box above)

C. 30" (76.2 cm) minimum clearance between top of cool(top platform

and bottom of uncovered wood or metal cabinet (24" [61 cm[

minimum clearance if bottom of wood or metal cabinet is covered

by not less than 1/4"[0.6 cm] flame retardant millboard covered with

not less than No. 28 MSG sheet steel, 0.015" [0.04 cm] stainless

steel, or 0.024" [0.06 cm] aluminum or 0.020" [0.05 cm] copper)

D. 13" (33 cm) recommended upper cabinet depth

E.2"(5.1 cm)

F. 211/8'' (73.4 cm)

G. 18" (45. 7cm) minimum clearance from upper cabinet to countertop

within minimum horizontal clearances to cool(top

H. Junction box or outlet; 12" (30.5 cm) minimum from bottom of

countertop

I. Junction box or outlet; 10" (25.4 cm) from right-hand side of

cabinet

J. 287/8'' (73.4 cm) on 30" (76.2 cm) models

349/18''(87.8 cm) on 36" (91.4 cm) models

K. 2V2" (6.4 cm) minimum distance to nearest left and right side

combustible surface above coot(top

L. 1V2" (3.8 cm) minimum clearance between back wall and

countertop

NOTES: After making the countertop cutout, some installations

may require notching down the base cabinet side walls to clear

the cooktop base. To avoid this modification, use a base cabinet

with sidewalls wider than the cutout.

• A minimum side clearance of 6" (15.2 cm) is recommended

between side of cooktop and side wall for maximum

ventilation performance.

• A minimum clearance of 2" (5.1 cm) is recommended

between the motor/blower and cabinet for proper cooling. A

6" (15.2 cm) clearance is recommended for servicing access.

Page 5

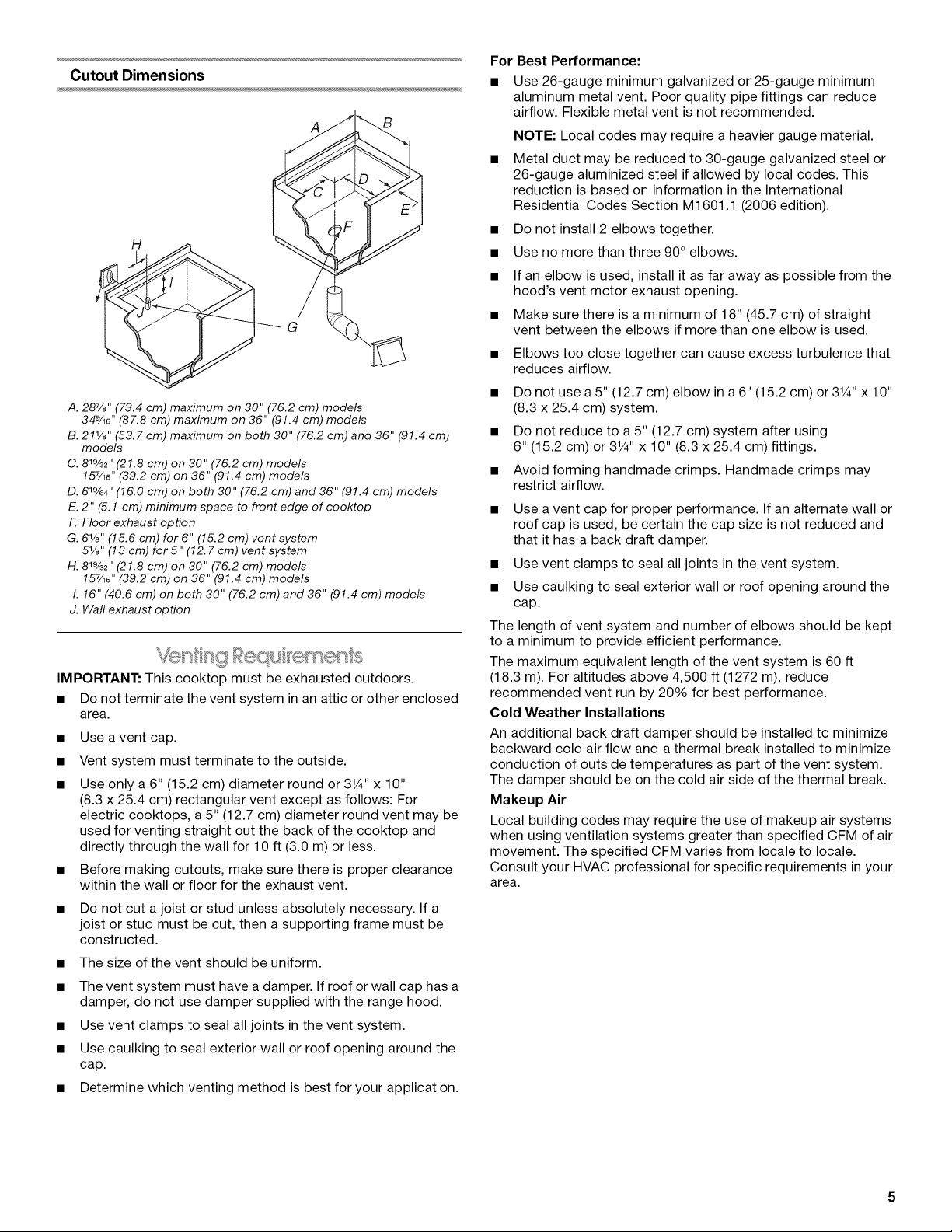

Cutout Dimensions

A B

H

A. 28%" (73.4 cm) maximum on 30" (76.2 cm) models

34%6" (87.8 cm) maximum on 36" (91.4 cm) models

B. 211/8'' (53.7 em) maximum on both 30" (76.2 em) and 36" (91.4 em)

models

C. 81%=''(21.8 em) on 30" (76.2 em) models

157/16''(39.2 em) on 36" (91.4 em) models

D. 61%4'' (16.0 em) on both 30" (76.2 em) and 36" (91.4 em) models

E. 2" (5.1 em) minimum space to front edge of eooktop

F. Floor exhaust option

G. 61/s'' (15.6 em) for 6" (15.2 em) vent system

51/8'' (13 em) for 5" (12. 7 em) vent system

H. 81%='' (21.8 em) on 30" (76.2 em) models

157/18''(39.2 em) on 36" (91.4 em) models

I. 16" (40.6 em) on both 30" (76.2 em) and 36" (91.4 em) models

J. Waft exhaust option

IMPORTANT: This cooktop must be exhausted outdoors.

• Do not terminate the vent system in an attic or other enclosed

area.

• Use avent cap.

• Vent system must terminate to the outside.

• Use only a 6" (15.2 cm) diameter round or 3W' x 10"

(8.3 x 25.4 cm) rectangular vent except as follows: For

electric cooktops, a 5" (12.7 cm) diameter round vent may be

used for venting straight out the back of the cooktop and

directly through the wall for 10 ft (3.0 m) or less.

• Before making cutouts, make sure there is proper clearance

within the wall or floor for the exhaust vent.

• Do not cut a joist or stud unless absolutely necessary. If a

joist or stud must be cut, then a supporting frame must be

constructed.

• The size of the vent should be uniform.

• The vent system must have a damper. Ifroof or wall cap has a

damper, do not use damper supplied with the range hood.

• Use vent clamps to seal all joints in the vent system.

• Use caulking to seal exterior wall or roof opening around the

cap.

• Determine which venting method is best for your application.

For Best Performance:

• Use 26-gauge minimum galvanized or 25-gauge minimum

aluminum metal vent. Poor quality pipe fittings can reduce

airflow. Flexible metal vent is not recommended.

NOTE: Local codes may require a heavier gauge material.

• Metal duct may be reduced to 30-gauge galvanized steel or

26-gauge aluminized steel if allowed by local codes. This

reduction is based on information in the International

Residential Codes Section M1601.1 (2006 edition).

• Do not install 2 elbows together.

• Use no more than three 90° elbows.

• If an elbow is used, install it as far away as possible from the

hood's vent motor exhaust opening.

• Make sure there is a minimum of 18" (45.7 cm) of straight

vent between the elbows if more than one elbow is used.

• Elbows too close together can cause excess turbulence that

reduces airflow.

• Do not use a 5" (12.7 cm) elbow in a 6" (15.2 cm) or3V4" x 10"

(8.3 x 25.4 cm) system.

• Do not reduce to a 5" (12.7 cm) system after using

6" (15.2 cm) or 3V4" x 10" (8.3 x 25.4 cm) fittings.

• Avoid forming handmade crimps. Handmade crimps may

restrict airflow.

• Use a vent cap for proper performance. If an alternate wall or

roof cap is used, be certain the cap size is not reduced and

that it has a back draft damper.

• Use vent clamps to seal all joints in the vent system.

• Use caulking to seal exterior wall or roof opening around the

cap.

The length of vent system and number of elbows should be kept

to a minimum to provide efficient performance.

The maximum equivalent length of the vent system is 60 ft

(18.3 m). For altitudes above 4,500 ft (1272 m), reduce

recommended vent run by 20% for best performance.

Cold Weather Installations

An additional back draft damper should be installed to minimize

backward cold air flow and a thermal break installed to minimize

conduction of outside temperatures as part of the vent system.

The damper should be on the cold air side of the thermal break.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements in your

area.

Page 6

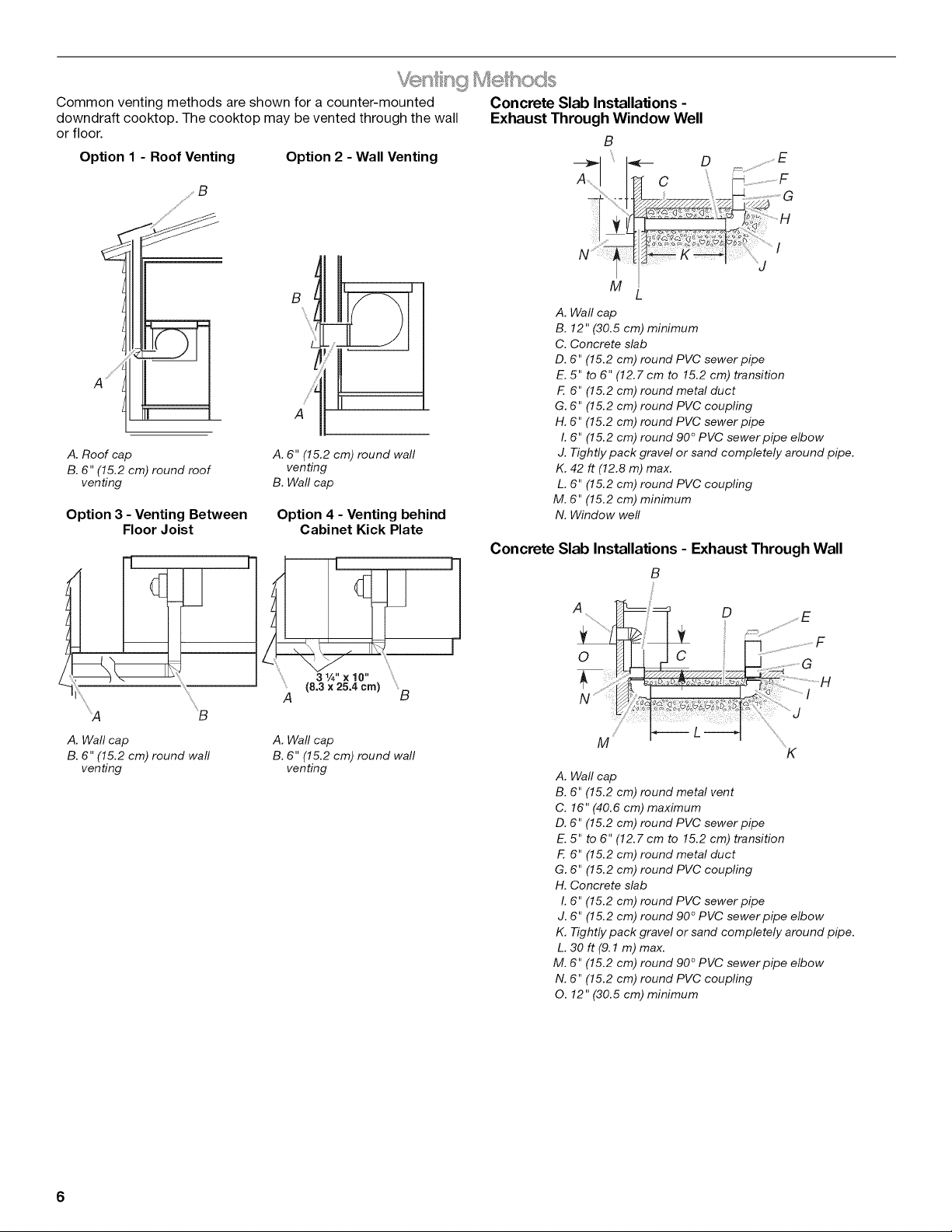

Common venting methods are shown fora counter-mounted Concrete Slab Installations -

downdraft cooktop. The cooktop may be vented through the wall Exhaust Through Window Well

or floor. B

Option 1 - Roof Venting Option 2 - Wall Venting

A. Wall cap

B. 12" (30.5 cm) minimum

C. Concrete slab

D. 6" (15.2 cm) round PVC sewer pipe

E. 5" to 6" (12.7 cm to 15.2 cm) transition

F. 6" (15.2 cm) round metal duct

G. 6" (15.2 cm) round PVC coupling

H. 6" (15.2 cm) round PVC sewer pipe

I. 6" (15.2 cm) round 90 ° PVC sewer pipe elbow

A. Roof cap

B. 6" (15.2 cm) round roof

venting

Option 3 - Venting Between

Floor Joist

A. 6" (15.2 cm) round wall

venting

B. Wall cap

Option 4 - Venting behind

Cabinet Kick Plate

Concrete

J. Tightly pack gravel or sand completely around pipe.

K. 42 ft (12.8 m) max.

L. 6" (15.2 cm) round PVC coupling

M. 6" (15.2 cm) minimum

N. Window well

Slab Installations - Exhaust Through Wall

B

L

L

L

l

L

'_A B

A. Wall cap

B. 6" (15.2 cm) round wall

venting

= " = "

A (8._'2II_m) B

A. Wall cap

B. 6" (15.2 cm) round wall

venting

A D

0

M

A. Wall cap

B. 6" (15.2 cm) round metal vent

C. 16" (40.6 cm) maximum

D. 6" (15.2 cm) round PVC sewer pipe

E. 5" to 6" (12.7 cm to 15.2 cm) transition

F. 6" (15.2 cm) round metal duct

G. 6" (15.2 cm) round PVC coupling

H. Concrete slab

I. 6" (15.2 cm) round PVC sewer pipe

J. 6" (15.2 cm) round 90 ° PVC sewer pipe elbow

K. Tightly pack gravel or sand completely around pipe.

L. 30 ft (9.1 m) max.

M. 6" (15.2 cm) round 90 ° PVC sewer pipe elbow

N. 6" (15.2 cm) round PVC coupling

O. 12" (30.5 cm) minimum

F

K

6

Page 7

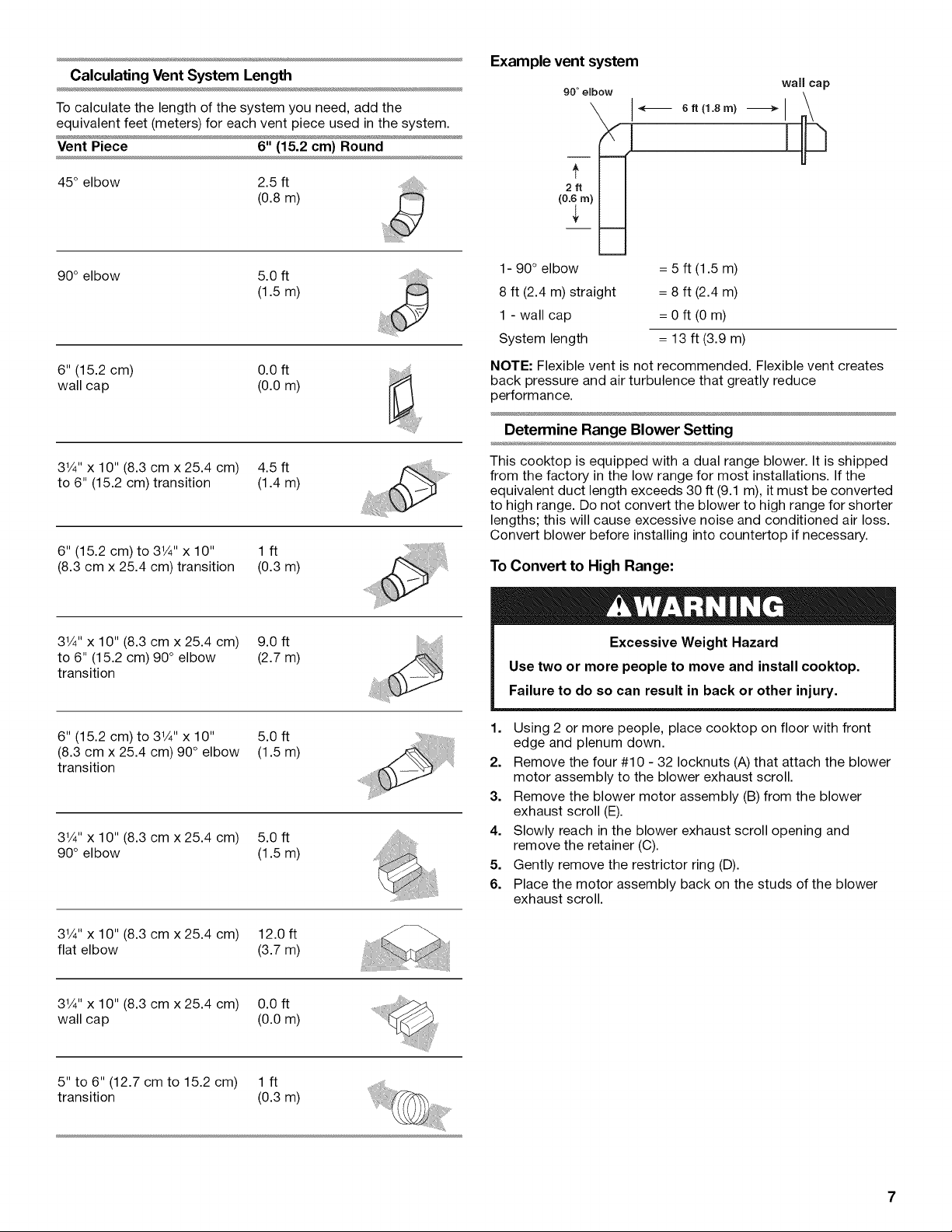

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

Vent Piece 6" (15.2 cm) Round

45° elbow 2.5 ft

(0.8m)

Example vent system

90 ° elbow

(

wall cap

I

90° elbow 5.0 ft

(1.5m)

6" (15.2 cm) 0.0 ft

wall cap (0.0 m)

31/4"x 10" (8.3 cm x 25.4 cm) 4.5 ft

to 6" (15.2 cm) transition (1.4 m)

6" (15.2 cm) to 31/4'' x 10" 1 ft

(8.3 cm x 25.4 cm) transition (0.3 m)

31/4"x 10" (8.3 cm x 25.4 cm) 9.0 ft

to 6" (15.2 cm) 90° elbow (2.7 m)

transition

1- 90 ° elbow = 5 ft (1.5 m)

8 ft (2.4 m) straight = 8 ft (2.4 m)

1 - wall cap = 0 ft (0 m)

System length = 13 ft (3.9 m)

NOTE: Flexible vent is not recommended. Flexible vent creates

back pressure and air turbulence that greatly reduce

performance.

Determine Range Blower Setting

This cooktop is equipped with a dual range blower. It is shipped

from the factory in the low range for most installations. If the

equivalent duct length exceeds 30 ft (9.1 m), it must be converted

to high range. Do not convert the blower to high range for shorter

lengths; this will cause excessive noise and conditioned air loss.

Convert blower before installing into countertop if necessary.

To Convert to High Range:

Excessive Weight Hazard

Use two or more people to move and install cooktop.

Failure to do so can result in back or other injury.

6" (15.2 cm) to 31/4'' x 10" 5.0 ft

(8.3 cm x 25.4 cm) 90 ° elbow (1.5 m)

transition

31/4"x 10" (8.3 cm x 25.4 cm) 5.0 ft

90° elbow (1.5 m)

31/4'' x 10" (8.3 cm x 25.4 cm) 12.0 ft

flat elbow (3.7 m)

31/4'' x 10" (8.3 cm x 25.4 cm) 0.0 ft

wall cap (0.0 m)

5" to 6" (12.7 cm to 15.2 cm) 1 ft

transition (0.3 m)

1. Using 2 or more people, place cooktop on floor with front

edge and plenum down.

2. Remove the four #10 - 32 Iocknuts (A)that attach the blower

motor assembly to the blower exhaust scroll.

3. Remove the blower motor assembly (B) from the blower

exhaust scroll (E).

4. Slowly reach in the blower exhaust scroll opening and

remove the retainer (C).

5. Gently remove the restrictor ring (D).

6. Place the motor assembly back on the studs of the blower

exhaust scroll.

Page 8

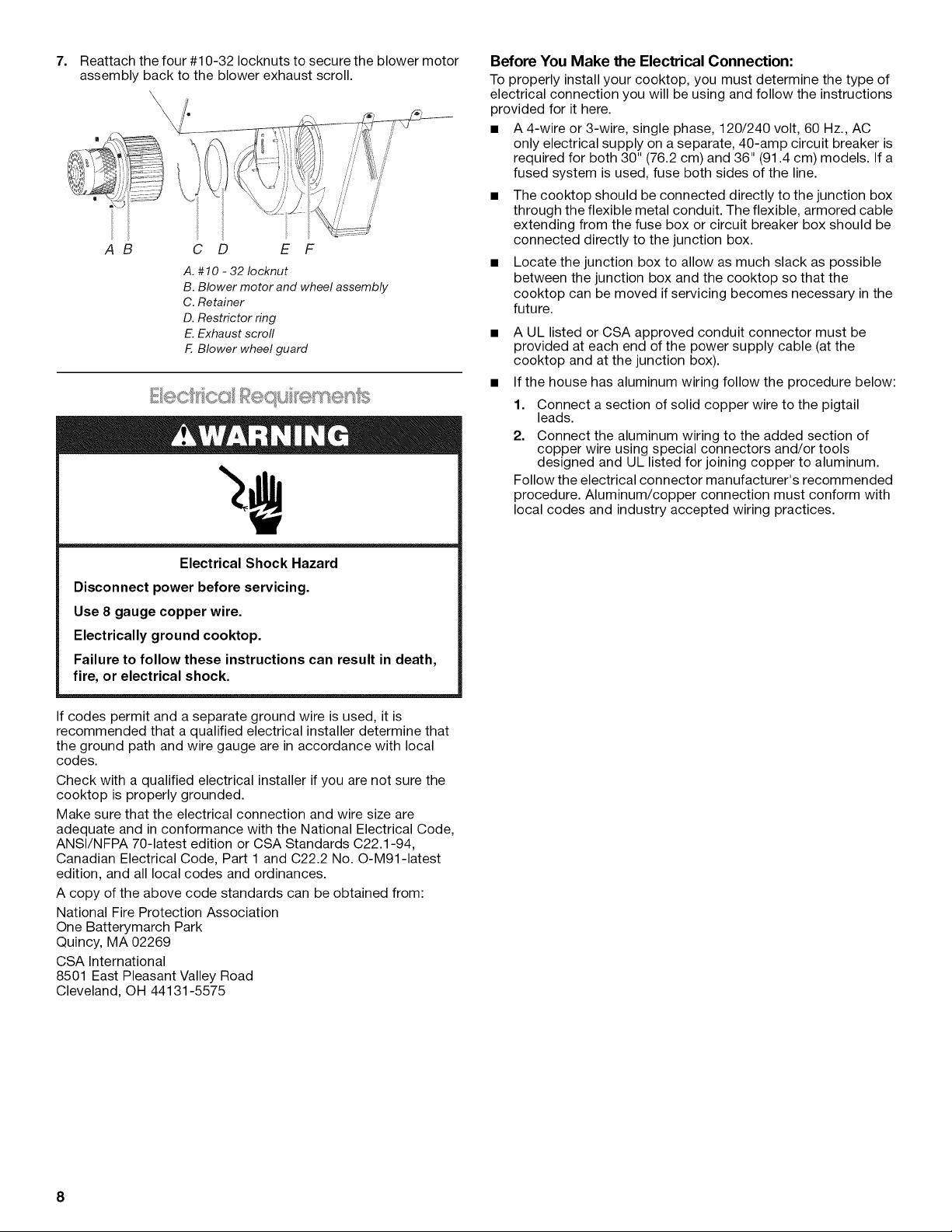

7. Reattachthefour#10-32Iocknutstosecuretheblowermotor

assemblybacktotheblowerexhaustscroll.

\

AB C D E F

A. #10 -32 Iocknut

B. Blower motor and wheel assembly

C. Retainer

D. Restrictor ring

E.Exhaust scrofl

F. Blower wheel guard

E ¸ _ _I_,_,_ I _E_I,,_ !i_£_

Before You Make the Electrical Connection:

To properly install your cooktop, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

• A 4-wire or 3-wire, single phase, 120/240 volt, 60 Hz., AC

only electrical supply on a separate, 40-amp circuit breaker is

required for both 30" (76.2 cm) and 36" (91.4 cm) models. If a

fused system is used, fuse both sides of the line.

The cooktop should be connected directly to the junction box

through the flexible metal conduit. The flexible, armored cable

extending from the fuse box or circuit breaker box should be

connected directly to the junction box.

Locate the junction box to allow as much slack as possible

between the junction box and the cooktop so that the

cooktop can be moved if servicing becomes necessary in the

future.

A UL listed or CSA approved conduit connector must be

provided at each end of the power supply cable (at the

cooktop and at the junction box).

• If the house has aluminum wiring follow the procedure below:

1. Connect a section of solid copper wire to the pigtail

leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire.

Electrically ground cooktop.

Failure to follow these instructions can result in death,

fire, or electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Check with a qualified electrical installer if you are not sure the

cooktop is properly grounded.

Make sure that the electrical connection and wire size are

adequate and in conformance with the National Electrical Code,

ANSI/NFPA 70-latest edition or CSA Standards C22.1-94,

Canadian Electrical Code, Part 1 and C22.2 No. O-M91-1atest

edition, and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

8

Page 9

INSTALLATIONINSTRUCTIONS

Decide on the final location for the cooktop.

Excessive Weight Hazard

Use two or more people to move and install cooktop.

Failure to do so can result in back or other injury.

1. Open product as instructed on product packaging.

2. Remove shipping materials and tape from cooktop.

3. Remove vent grille.

Is: mSnp

1.

Remove foam strip from the package containing literature.

2.

Remove backing from foam strip.

3.

Apply foam strip adhesive-side down around bottom of

cooktop, flush with edge.

NOTE: The foam strip keeps the underside of the cooktop

glass free from debris and helps the cooktop sit flat on

uneven counters.

A. Cooktop base

B. Foam strip

C. Glass

C

(;I

IMPORTANT: The following additional steps must be performed

if the product is being installed in peninsula or island cabinetry.

The blower exhaust scroll is shipped from the factory set to

exhaust straight out the back of the cabinet through an exterior

wall.

D

A. Vent grifle

B. Plenum

C. Removable grease filter

D. Ceramic glass top

4. Remove the removable grease filter by lifting the filter out.

5. Using 2 or more people, remove the cooktop from the carton.

6. Use foam end caps from the packaging as a work surface for

the floor or countertop.

7. Using 2 or more people, place the cooktop upside down on

the foam end caps.

8. Make sure knobs are positioned in the open areas of the end

caps.

9. Avoid placing the cooktop facedown on the control knobs.

D

/

B

F

A.Blower exhaust scroll

B.Plenum

C.Blower motor

D.Toplabel

E. 10-32 machine nuts (4)

F.Motor mounting plate

Page 10

To rotate blower:

1. Locate the four plastic plugs in the plenum bypass.

2. Use the pliers to remove the plastic plugs.

IMPORTANT: Do not throw away the plastic plugs. The

plastic plugs must be reinstalled after the blower exhaust

scroll has been rotated.

To rotate blower motor:

NOTE: The "Top" label location on the blower motor is at the

9 o'clock position.

1. Using a ratchet with a 3/8"socket and supporting the motor

with one hand, remove the four machine nuts that attach the

blower motor to the exhaust scroll.

2. Remove the blower motor and wheel assembly from the weld

studs.

D

C

A. Blower motor

B. Exhaust scroll

C. Plenum

D. Plastic plugs (4)

3. Insert the 3/8"socket and extension into the hole and use the

ratchet handle to loosen the nut half of a rotation. Repeat this

process for each of the four nuts.

4. With the nuts loosened, the blower exhaust scroll can be

easily rotated downward.

D

A

C

A. Top label

B. Blower motor

C. Motor mounting plate

D. Weld stud location

E. Blower wheel

3. When the motor mounting plate clears the threaded weld

studs, rotate the assembly clockwise 90° and reinstall the

four #10-32 machine nuts.

4. Verify the "Top" label is positioned as shown.

5. Retighten each nut with the 3/8"socket, extension and ratchet.

6. Reinstall the four plastic plugs.

10

I

A. Top label

Page 11

_,_C_Co0 i£D©

1. Using 2 or more people, place cooktop right side up into the

cutout.

NOTE: Make sure that the front edge of the cooktop is

parallel to the front edge of the countertop. If repositioning is

needed, lift entire cooktop up from the cutout to avoid

scratching the countertop.

2. For island or peninsula installations, go to "Rotate Blower -

Optional" section.

3. Connect blower exhaust scroll to ducting.

4. Use vent clamps to secure the ducting to the blower exhaust

scroll.

5. Reinstall removable grease filter.

6. Reinstall vent grille.

Mc,, <®E Connect on

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire.

Electrically ground cooktop.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Electrical Connection Options

If your home has: And you will be Go to Section:

connecting to:

4-wire A fused 4-Wire Cable from

disconnect or Power Supply

circuit breaker

box

3-wire A fused 3-Wire Cable from

disconnect or Power Supply

circuit breaker

box

4-Wire Cable from Home Power Supply to 4-Wire Cable

from Cooktop

IMPORTANT: Use the 4-wire cable from home power supply in

the U.S. where local codes do not allow grounding through

neutral, New Branch circuit installations (1996 NEC), mobile

homes and recreational vehicles, new construction, and in

Canada.

A

E

This cooktop is manufactured with the frame connected to the

bare ground wire. Connect the cooktop cable to the junction box

through the UL listed or CSA approved conduit connector.

1. Disconnect power.

2. Remove junction box cover, if present.

3. Connect the flexible cable conduit from the cooktop to the

junction box using a UL listed or CSA approved conduit

connector.

4. Tighten screws on conduit connector if present.

5. See "Electrical Connection Options Chart" to complete

installation for your type of electrical connection.

A. Cable from home power supply

B. Black wires

C. Bare ground wires

D. 4-wire cable from cooktop

E.Junction box

F. White wires

G. UL listed wire connector

H. Red wires

I. UL fisted or CSA approved

conduit connector

1. Connect the 2 black wires together using the UL listed wire

connectors.

2. Connect the 2 red wires together using the UL listed wire

connectors.

3. Connect the 2 white wires together using the UL listed wire

connectors.

4. Connect the green (or bare) ground wire from the cooktop

cable to the green (or bare) ground wire (in the junction box)

using the UL listed wire connectors.

5. Install junction box cover.

11

Page 12

3-WireCablefromHomePowerSupplyto4-WireCable

fromCooktop-U.S.only

IMPORTANT: Use the 3-wire cable from power supply where

local codes permit connecting the frame-ground conductor to

the neutral (white) junction box wire.

A

E

F

G

H

C

D

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all your tools.

3. Dispose of/recycle all packaging materials.

4. Use a mild solution of liquid household cleaner and warm

water to clean cooktop before use. Dry thoroughly with a soft

cloth. For more information, see the "Cooktop Care" section

of the Use and Care Guide.

5. Read "Cooktop Use" in the cooktop Use and Care Guide.

6. Reconnect power.

7. Use the Flow Tester Card provided with your cooktop to

check the airflow (see card for step-by-step instructions).

NOTE: If the cooktop does not work after turning on the power,

check that a circuit breaker has not tripped or a household fuse

has not blown. See "Troubleshooting" section in the Use and

Care Guide for further information.

A. Cable from home power supply

B. Red wires

C. White wire and green (or bare)

wire (from cooktop)

D. 4-wire cable from cooktop

E.Junction box

F. White wire

G. UL fisted wire connector

H. Black wires

I. UL listed or CSA approved

conduit connector

1. Connect the 2 black wires together using the UL listed wire

connectors.

2. Connect the 2 red wires together using the UL listed wire

connectors.

3. Connect the green or bare and white cooktop cable wires to

the white (neutral) wire in the junction box using the UL listed

wire connectors.

4. Install junction box cover.

If you need Assistance or Service:

Please reference the "Assistance or Service" section of the Use

and Care Guide or contact the dealer from whom you purchased

your cooktop.

12

Page 13

SECURITEDELATABLEDECUlSSON

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curit_ importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tousles messages de s_curit_ et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves & vous

et & d'autres.

Voici le symbole d'alerte de s_curit&

Tousles messages de s_curit_ suivront le symbole d'alerte de s_curit_ et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d_cbs ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s_curit_ vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

13

Page 14

EXIGENCESD'INSTALLATION

O fis ®tp

Rassembler les outils et pieces necessaires avant d'entreprendre

I'installation. Lire et suivre les instructions fournies avec chacun

des outils de la liste ci-dessous.

Outils n_cessaires

• Metre-ruban •

• Tournevis a lame plate •

• Tournevis cruciforme •

• Perceuse •

• Niveau •

• Rallonge pour cle a douille

de 6"

Pi_ces fournies

• Grille de ventilation

• Pre-filtre

Pi_ces n_cessaires

• Un collier de serrage (homologation UL ou CSA) pour alveole

defon£'able de 7/8"(2,2 cm).

• Un connecteur de conduit (homologation UL ou CSA) pour

conduit de taille commerciale (trade size) de 1/2"(1,3 cm) &

armature metallique

• Connecteurs de fils (homologation UL)

• Conduit metallique

• Bouche de decharge murale

Clapet de bouche de decharge murale & surface arrondie de

6" (15,2 cm)

Commander la piece numero A406

Clapet de bouche de decharge murale & surface arrondie de

5" (12,7 cm)

Commander la piece numero A405

Clapet de bouche de decharge murale & surface arrondie de

31¼"x 10" (8,3 x 25,4 cm)

Commander la piece numero A403

Pour commander, voir la section "Assistance ou service" du

Guide d'utilisation et d'entretien.

• Bride de conduit

Consulter les codes Iocaux. Verifier I'alimentation electrique

existante. Voir la section "Specifications electriques".

II est recommande de faire realiser tousles raccordements

electriques par un electricien qualifie agree.

IMPORTANT : Observer les dispositions de tousles codes et

reglements en vigueur. Lors de I'installation de la table de

cuisson, utiliser les dimensions minimales indiquees.

• Afin de supprimer le risque de brQlures ou d'incendie en se

penchant au-dessus des unites de surface chauffees, le

rangement en armoire au-dessus des unites de surface doit

_tre evite. Si des placards de rangement sont envisages, le

risque peut _tre reduit par I'installation d'une hotte de cuisine

depassant le bas des placards d'au moins 5" (12,7 cm)

horizontalement.

Marqueur ou crayon

Pince

Foret de 1¼,,

Scie sauteuse

Cle & cliquet avec douille de

3/8"

• Utiliser les dimensions d'ouverture du plan de travail qui sont

indiquees dans ces Instructions d'installation. Les

dimensions donnees sont les espacements minimaux et

fournissent un degagement de 0" (0 cm).

• Une source d'electricite avec liaison & la terre est necessaire.

Voir la section "Specifications electriques".

• Si le placard comporte des tiroirs, ces tiroirs doivent _tre

retires et I'avant des tiroirs installe sur I'avant du placard.

IMPORTANT • II n'est pas possible d'installer un four encastre

sous plan de travail sous ce produit.

Dimensions du produit

Table de cuisson de 30" (76,2 cm) - Pour les modules

standard et _lectriques

A

A. Emplacement/d_gagement du modele/de la plaque

signal_tique

B.21" (53,4 cm) d'une t#te de vis b I'autre

C. 22" (52,3 cm) sans garniture en acier inoxydable ou

21sz/e4"(54, 8 cm) avec garniture en acier inoxydable

B

E

1 .....................

F-*

_G_

A. 301/3_'' (76,3 cm) avec garniture en acier inoxydable

B. 29W_6" (76,1 cm) sans garniture en acier inoxydable

C. 14_/16'' (36,4 cm)

D. 3s½2" (10,1 cm)

E. 1813/32'' (46,8 cm)

F. 11½_'' (3,4 cm)

G. 13%2" (33,3 cm)

H. 14s/16'' (36,0 cm)

/. 28%" (72, 7 cm) d'une t#te de vis b I'autre

!_______C _._._._.____

6) _ @: ® @

i

I

14

Page 15

Table de cuisson de 36" (91,4 cm) - Pour les modules

standard et _lectriques

Dimensions du placard

C

A. Emplacement/d_gagement du modele/de la plaque signal_tique

B. 21" (53,4 cm) d'une t_te de vis _ I'autre

C. 22" (52,3 cm) sans garniture en acier inoxydable ou

2137/64"(54,8 cm) avec garniture en acier inoxydable

A

B

A. 35_%4" (90,1 cm) avec garniture en acier inoxydable

B.35_5/64'' (89,9 cm) sans garniture en acier inoxydable

C. 1731/64'' (43,8 cm)

D. 3_%_" (9,6 cm)

E. 1813/32''(46,8 cm)

F. 817/64 '' (20,9 cm)

G. 13s/3_'' (33,3 cm)

H. 131/16'' (33,2 cm)

I. 3431/64'' (87,6 cm) d'une t#te de vis _ I'autre

C

A. 30" (76,2 cm) sur les modeles de 30" (76,2 cm)

36" (91,4 cm) sur les modeles de 36" (91,4 cm)

B. Zone de matiere combustible au-dessus du plan de travail (espace

d_limit_ par des lignes pointill_es ci-dessus)

C. Distance minimale de s_paration de 30" (76,2 cm) entre le dessus

de la table de cuisson et le fond d'un placard m_tallique ou de bois

non couvert (distance de s_paration de 24" [61 cm] ou plus si le

fond du placard de m_tal ou de bois est recouvert d'une plaque

d'au moins 1/4"(0,6 cm) de mat_riau r_sistant aux flammes, lui-

m_me recouvert d'une feuille m_talfique d'une _paisseur

correspondant bun calibre de 28 au moins pour I'acier, 0,015"

[0,04 cm] pour I'acier inoxydable, 0,024" [0,06 cm] pour I'aluminium

ou 0,020" [0,05 cm] pour le cuivre)

D. Profondeur recommand_e pour les placards sup_rieurs : 13"

(33 cm)

E.2"(5,1 cm)

F. 211/8'' (73,4 cm)

G. Distance de s_paration minimale de 18" (45, 7 cm) entre le placard

sup_rieur et le plan de travail avec distance minimale de s_paration

horizontale pour la table de cuisson

H. Boftier de connexion ou prise _lectrique; 12" (30,5 cm) ou plus

depuis le bas du plan de travail

I. Boftier de connexion ou prise _lectrique; 10" (25,4 cm) depuis le

c6t_ droit du placard

J. 287/8" (73,4 cm) sur les modeles de 30" (76,2 cm)

349/16''(87,8 cm) sur les modeles de 36" (91,4 cm)

K. Distance de s_paration minimale de 2V2" (6,4 cm) par rapport _ la

surface de mat_riau combustible la plus proche, _ gauche ou

droite au-dessus de la table de cuisson

L. Distance de s_paration minimale de 1V2"(3,8 cm) ou plus entre la

paroi arriere et le plan de travail

REMARQUES •Apr_s le decoupage de I'ouverture dans le plan

de travail, il est possible que pour certaines configurations

d'installation, il soit necessaire d'entailler les parois laterales du

placard inferieur pour permettre le passage de la base de la table

de cuisson. Pour eviter cette modification, utiliser un placard

inferieur dont la largeur des parois laterales est superieure & celle

de I'ouverture decoupee.

• Un degagement minimum de 6" (15,2 cm) entre le c6te de la

table de cuisson et la paroi laterale est recommande pour une

performance maximale de ventilation.

• Un degagement minimum de 2" (5,1 cm) entre le moteur/

ventilateur et le placard est recommande pour que le

refroidissement puisse s'effectuer correctement. Un

degagement de 6" (15,2 cm) est recommande pour pouvoir

acceder en cas de reparation.

15

Page 16

Dimensions de I'ouverture _ d_couper

A B

H

A. 28%" (73,4 cm) maximum sur les modeles de 30" (76,2 cm)

34%6" (87,8 em) maximum sur les modeles de 36" (91,4 em)

B. 211/8'' (53, 7 em) maximum sur les modeles de 30" (76,2 em) et de

36" (91,4 cm)

C. 81%_'' (21,8 cm) sur les modeles de 30" (76,2 cm)

157/16''(39,2 cm) sur les modeles de 36" (91,4 cm)

D. 61%4'' (16,0 cm) sur les modeles de 30" (76,2 cm) et 36" (91,4 cm)

E. D_gagement minimal de 2" (5,1 cm) jusqu 'au rebord avant de la

table de cuisson

F. Option d'_vaeuation par le plancher

G. 61/6'' (15,6 cm) pour un systeme d'_vacuation de 6" (15,2 cm)

51/6'' (13 cm) pour un systeme d'_vacuation de 5" (12, 7 cm)

H. 81%_'' (21,8 em) sur les modeles de 30" (76,2 cm)

157/16''(39,2 cm) sur les modeles de 36" (91,4 cm)

I. 16" (40,6 cm) sur les modeles de 30" (76,2 cm) et de 36" (91,4 cm)

J. Option d'_vacuation par lemur

Exqj@:'_c®s co_/sc@mc_Js_ ® c_Jc_'/'o

IIIVIPORTANT : L'evacuation de cette table de cuisson doit se

faire a I'exterieur.

• Ne pas terminer le circuit d'evacuation dans un grenier ou

dans un autre espace ferme.

• Utiliser un clapet de conduit.

• Le systeme doit decharger I'air a I'exterieur.

• Utiliser uniquement du conduit metallique de 6" (15,2 cm) ou

un conduit d'evacuation rectangulaire de 31¼'' x 10" (8,3 x

25,4 cm), sauf dans les cas suivants : avec une cuisiniere

electrique, un conduit metallique rond de 5" (12,7 cm) peut

_tre utilise pour une evacuation directement depuis I'arriere

de la cuisiniere a travers lemur sur une Iongueur de 10 pi

(3,0 m) au maximum.

• Avant d'effectuer des decoupes, s'assurer qu'il y a un

degagement convenable entre lemur ou le plancher pour le

conduit d'evacuation.

• On ne doit couper un poteau de colombage ou une solive

que si c'est absolument necessaire. Dans ce cas, on devra

construire une structure de support appropriee.

• La taille du conduit doit _tre uniforme.

• Le circuit d'evacuation doit comporter un clapet. Si la bouche

de decharge murale ou par le toit comporte un clapet, ne pas

utiliser le clapet fourni avec la hotte de cuisiniere.

• Au niveau de chaque jointure du circuit d'evacuation, assurer

I'etancheite avec les brides de serrage.

• A I'aide d'un produit de calfeutrage, assurer I'etancheite

autour de la bouche de decharge a I'exterieur (&travers le

mur ou le toit).

• Determiner quelle methode d'evacuation est la plus

appropriee.

Pour obtenir la meilleure performance •

• Utiliser un conduit de ventilation en acier galvanise

d'epaisseur minimum n° 26 ou en aluminium d'epaisseur

minimum n° 25. Des raccords de mauvaise qualite peuvent

reduire le flux d'air. On deconseille I'emploi d'un conduit en

metal flexible.

REMARQUE • Les codes Iocaux pourraient exiger un

materiau plus epais.

• Le conduit metallique peut _tre reduit &une epaisseur

n° 30 pour I'acier galvanise ou n° 26 pour I'aluminium si c'est

permis par les codes Iocaux. Cette information est basee sur

I'information dans la Section des Codes Residentiels

Internationaux M1601.1 (edition 2006).

• Ne pas installer 2 coudes ensemble.

• Ne pas utiliser plus de trois coudes & 90°.

• Si I'on utilise un coude, on doit le placer le plus loin possible

de I'ouverture d'evacuation du moteur de la hotte de

ventilation.

• Veiller & incorporer une section de conduit rectiligne d'au

moins 18" (45,7 cm) entre deux raccords coudes adjacents.

• Des coudes trop rapproches peuvent occasionner une

turbulence excessive qui reduirait la circulation de I'air.

• Ne pas utiliser un coude de 5" (12,7 cm) dans un systeme de

6" (15,2 cm) ou 3V4" x 10" (8,3 x 25,4 cm).

• Ne pas reduire lesysteme &une Iongueur de 5" (12,7 cm)

apres avoir utilise des raccords de 6" (15,2 cm) ou de 3V4" x

10" (8,3 x 25,4 cm).

• €:viter le sertissage manuel. Ceux-ci peuvent restreindre le

flux d'air.

• Utiliser un clapet de conduit pour que le rendement soit

correct. Si une bouche de decharge murale ou de toit est

utilisee, s'assurer que la taille de la bouche de decharge n'est

pas reduite et qu'il a un clapet anti-reflux.

• Au niveau de chaque jointure du circuit d'evacuation, assurer

I'etancheite avec les brides de serrage.

• A I'aide d'un produit de calfeutrage, assurer I'etancheite

autour de la bouche de decharge a I'exterieur (&travers le

mur ou le toit).

La Iongueur du systeme d'evacuation et le nombre de coudes

doit _tre reduit au minimum pour une performance efficace.

La Iongueur maximale equivalente du circuit d'evacuation est de

60 pi (18,3 m). Pour les altitudes excedant 4 500 pi (1272 m),

reduire la Iongueur du systeme d'evacuation de 20 % pour une

performance optimale.

16

Page 17

Installations pour r_gions a climat froid

On devrait installer un clapet anti-reflux additionnel pour

minimiser le reflux d'air froid, et incorporer un el6ment d'isolation

thermique pour minimiser la conduction de chaleur par

I'intermediaire du conduit d'evacuation, de I'interieur de la

maison & I'exterieur. Le clapet anti-reflux doit _tre place du c6te

air froid par rapport & I'el6ment d'isolation thermique.

Air d'appoint

Le code du b&timent local peut exiger I'emploi d'un systeme de

renouvellement de Fair/introduction d'air d'appoint, Iors de

I'utilisation d'un systeme d'aspiration de debit superieur &une

valeur (pieds cubes par minute) specifi6e. Le debit specifi6 en

pieds cubes par minute varie d'une juridiction & I'autre. Consulter

un professionnel des installations de chauffage/ventilation/

climatisation au sujet des exigences specifiques applicables

clans la juridiction locale.

Les methodes d'evacuation standard illustrees correspondent &

une table de cuisson avec aspiration par le bas montee sur

comptoir. L'evacuation de la table de cuisson peut se faire par le

mur ou le plancher.

Option 1 - D_charge a Option 2 - D_charge

travers le toit travers le tour

....//g

Installationsdansdalledeb_ton - I_vacuationa & travers un

puits de fen_tre

B

A. Bouche de d_charge murale

B. 12" (30,5 cm) minimum

C. Dalle de b_ton

D. Conduit PVC pour _gout de dia. 6" (15,2 cm)

E. Raccord de transition de 5" _ 6" (12, 7cm _ 15,2 cm)

F. Conduit m_tallique de dia. 6" (15,2 cm)

G. Raccord PVC de dia. 6" (15,2 cm)

H. Conduit PVC pour _gout de dia. 6" (15,2 cm)

I. Coude _ 90 ° en PVC pour _gout de dia. 6" (15,2 cm)

J. Gravier ou sable compact_ tout autour du tuyau.

K. 42 pi (12,8 m) max.

L. Raccord PVC de dia. 6" (15,2 cm)

M. 6" (15,2 cm) minimum

N. Puits de fen_tre

A. Bouche de d_charge sur toit

B. Conduit de dia. 6" (15,2 cm)

pour sortie _ travers le toit

Option 3 - levacuation entre

les solives au plancher

x

\

B

A. Conduit de dia. 6" (15,2 cm)

pour sortie _ travers lemur

B. Bouche de d_charge murale

Option 4 - levacuation

derriere le garde-pieds de

la caisse

== ==

Installations dans dalle de b_ton - I_vacuation & travers le

mur

B

A. Bouche de d_charge murale

B. Conduit m_tallique de dia. 6" (15,2 cm)

C. 16" (40,6 cm) maximum

D. Conduit PVC pour _gout de dia. 6" (15,2 cm)

E. Raccord de transition de 5" _ 6" (12, 7cm _ 15,2 cm)

F. Conduit m_tallique de dia. 6" (15,2 cm)

G. Raccord PVC de dia. 6" (15,2 cm)

H. Dalle de b_ton

I. Conduit PVC pour _gout de dia. 6" (15,2 cm)

J. Coude _ 90 ° en PVC pour _gout de dia. 6" (15,2 cm)

K. Gravier ou sable compact_ tout autour du tuyau.

L. 30 pi (9,1 m) max.

M. Coude _ 90 ° en PVC pour _gout de dia. 6" (15,2 cm)

N. Raccord PVC de dia. 6" (15,2 cm)

O. 12" (30,5 cm) minimum

A. Bouche de d_charge murale

B. Conduit de dia. 6" (15,2 cm)

pour sortie _ travers lemur

A. Bouche de d_charge murale

B. Conduit de dia. 6" (15,2 cm)

pour sortie _ travers le mur

17

Page 18

Calcul de la Iongueur effective du circuit d'_vacuation

Pour calculer la Iongueur effective du circuit d'evacuation

necessaire, additionner les Iongueurs equivalentes (pieds/metres)

de tousles composants utilises dans le systeme.

Composant Conduit de diam_tre de 6"

(15,2 cm)

Coude a 45 ° 2,5 pi (0,8 m)

Exemple de circuit d'_vacuation

bouche de d_charge rnurale

c°udea90° _ 6pi(1,Sm) ----------__

Coude & 90 ° 5 pi (1,5 m)

Bouche de decharge murale de 0 pi (0 m)

6" (15,2 cm)

Raccord de transition de 31/4"x 4,5 pi (1,4 m)

10" (8,3 cm x 25,4 cm)

sur 6" (15,2 cm)

Raccord de transition de 6"

(15,2 cm) a 31/4'' x 10"

(8,3 cm x 25,4 cm)

Coude de transition &90° de 9 pi (2,7 m)

31/4'' x 10" (8,3 cm x 25,4 cm)

6" (15,2 cm)

Raccord coude a 90° de 6" 5 pi (1,5 m)

(15,2 cm) a 31/4'' x 10" (8,3 cm x

25,4 cm)

1 pi (0,3 m)

1 - coude a 90 °

section droite de 8 pi (2,4 m)

1 - bouche de decharge murale

Longueur totale

REMARQUE : On deconseille I'emploi d'un conduit flexible. Un

conduit flexible peut causer une retro-pression et des

turbulences de I'air, ce qui reduit considerablement la

performance.

D6terminer le r6glage du ventilateur de la cuisini_re

Cette table de cuisson est equip6e d'un ventilateur & deux debits.

Cet appareil est expedi6 & la configuration la plus basse, qui

convient & la plupart des installations. Si la Iongueur de conduit

equivalente depasse 30 pi (9,1 m), le ventilateur d'aspiration dolt

_tre converti au mode & forte aspiration. Ne pas convertir le

ventilateur d'aspiration au mode &forte aspiration pour une

courte duree ;cela entrainera un bruit excessif et une perte d'air

conditionn& Convertir le ventilateur d'aspiration avant de

I'installer sur le plan de travail, si necessaire.

= 5 pi (1,5 m)

= 8 pi (2,4 m)

= 0 pi (0,0 m)

= 13 pi (3,9 m)

Conversion au mode _ forte aspiration :

Risque du poids excessif

Utiliser deux ou plus de personnes pour d_placer et

installer la table de cuisson.

Le non=respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

Coude & 90 ° de

31/4"x 10" (8,3 cm x 25,4 cm) 5 pi (1,5 m)

Coude plat de

31/4"x 10" (8,3 cm x 25,4 cm) 12 pi (3,7 m)

Bouche de decharge murale

31/4'' x 10" (8,3 cm x 25,4 cm) 0 pi (0,0 m)

Raccord de transition de 5" & 1 pi

6" (12,7 cm & 15,2 cm) (0,3 m)

18

1. A I'aide de 2 personnes ou plus, placer la table de cuisson

sur le plancher avec le rebord avant et le plenum face vers le

bas.

2. Retirer les 4 contre-ecrous n°10-32 (A) qui fixent le moteur du

ventilateur & la spirale d'echappement du ventilateur

d'aspiration.

3. Retirer le moteur du ventilateur (B) de la spirale

d'echappement du ventilateur d'aspiration (E).

4. Atteindre lentement I'ouverture de la spirale d'echappement

du ventilateur d'aspiration et retirer le dispositif de retenue

(C).

5. Retirer doucement I'anneau d'etanch6it6 (D).

6. Reinstaller le moteur du ventilateur sur les goujons de la

spirale d'echappement du ventilateur d'aspiration.

Page 19

7. Reassembler les 4 contre-ecrous n°10-32 pour fixer le moteur

du ventilateur & la spirale d'echappement du ventilateur

d'aspiration.

AB C D E _-

A. Contre-_crous n° 10-32

B. Ensemble moteur-roue

C. Dispositif de retenue

D. Anneau d'_taneh_it_

E.Spirale d'_chappement

F. Garde-roue du ventilateur d'aspiration

Risque de choc _lectrique

D_connecter la source de courant _lectrique avant

rentretien.

Utiliser du fil en cuivre de calibre 8.

Relier la table de cuisson a la terre.

Le non-respect de ces instructions peut causer un

d_ces, un incendie ou un choc _lectrique.

Si on utilise un conducteur distinct de liaison &la terre Iorsque les

codes le permettent, il est recommande qu'un electricien qualifie

verifie que la liaison & la terre et le calibre du conducteur sont

conformes aux codes Iocaux.

Verifier avec un electricien qualifie si vous avez des doutes quant

&la qualite de la liaison &la terre de la table de cuisson.

S'assurer que la connexion electrique et le calibre des fils sont

appropries et conformes au National Electrical Code, &la norme

ANSI/NFPA 70 - derniere edition, ou & la norme CSA C22.1-94,

au Code canadien de I'electricit6, Partie 1 et C22.2 N° O-M91 -

derniere edition, et &tousles codes et r_glements Iocaux.

Pour obtenir un exemplaire des normes et codes ci-dessus,

contacter :

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

Avant d'_tablir la connexion _lectrique :

Pour installer la table de cuisson correctement, il faut etablir le

type de raccords electriques que I'on utilisera et suivre les

instructions indiqu6es ici.

• L'appareil doit _tre alimente uniquement par un circuit

monophase enCA uniquement de 120/240 Vet 60 Hz, &4 ills

ou 3 ills, sur un circuit s6pare de 40 amperes (pour les

modeles de 36" [91,4 cm] et les modeles de 30" [76,2 cm]). Si

I'on utilise un circuit proteg6 par fusible, il doit I'_tre a chaque

extremit6 du circuit.

La table de cuisson doit _tre connectee directement au

boitier de connexion par I'intermediaire du conduit metallique

flexible. Le c&ble blinde flexible sortant du boitier de

distribution (fusible ou disjoncteur) doit _tre raccorde

directement au boitier de connexion.

Placer le boitier de connexion pour laisser le plus de jeu

possible entre celui-ci et la table de cuisson pour pouvoir

deplacer la table de cuisson en cas de besoin de reparation &

I'avenir.

• Un connecteur de conduit homologue UL ou CSA doit _tre

fourni & chaque extremite du c&ble d'alimentation electrique

(& la table de cuisson et au boitier de connexion).

• Si le domicile est equipe d'un c&blage en aluminium, suivre

les instructions suivantes :

1. Raccorder une section de c&ble en cuivre massif aux

epissures flexibles.

2. Connecter le c&blage en aluminium & la section ajoutee

de c&blage en cuivre en utilisant des connecteurs et/ou

des outils specialement congus et homologu_s UL pour

fixer le cuivre &I'aluminium.

Suivre la procedure recommandee par le fabricant de

connecteurs electriques. La connexion aluminium/cuivre doit

_tre conforme aux codes Iocaux et aux pratiques de c&blage

acceptees par I'industrie.

19

Page 20

INSTRUCTIONSD'INSTALLATION

Determiner I'emplacement final de la table de cuisson.

Risque du poJds excessif

UtiJiser deux ou plus de personnes pour d_placer et

instaJJer Jatable de cuisson.

Le non=respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

1. Ouvrir la boite tel que stipule sur I'emballage du produit.

2. Enlever les materiaux d'expedition et le ruban adhesif de la

table de cuisson.

3. Retirer la grille de ventilation.

A

C

D

n de ne e mo x

1,

Enlever la bande de mousse du sachet de documentation.

2.

Retirer I'endos de la bande de mousse.

3.

Appliquer le cSte adhesif de la bande de mousse autour du

fond de latable de cuisson, en affleurement avec le rebord.

REMARQUE : La bande de mousse protege la face inferieure

du verre de la table de cuisson de tout residu et permet & la

table de cuisson de reposer a plat sur des plans de travail

irreguliers.

A. Base de la table de cuisson

B. Bande de mousse

C. Verre

ton du nt cuk2ve

IMPORTANT : Les etapes supplementaires suivantes doivent

@treexecut6es si le produit est installe dans une configuration

d'eb6nisterie en peninsule ou en ilot.

Au deballage, la spirale d'echappement du ventilateur est

orientee vers I'arriere du placard, pour une evacuation & travers

une paroi exterieure.

A. Grille de ventilation

B.Plenum

C. Filtre _ graisse amovible

D. Surface en vitroc_ramique

4. Retirer le filtre & graisse amovible en le soulevant.

5. A I'aide d'au moins 2 personnes, retirer la table de cuisson du

carton.

6. Utiliser les capuchons en mousse aux extremit6s de

I'emballage comme surface de travail pour le plancher et le

plan de travail.

7. A I'aide d'au moins deux personnes, placer la table de

cuisson & I'envers sur les capuchons en mousse des

extremit6s.

8. S'assurer que les boutons sont places dans les zones

ouvertes des capuchons des extremit6s.

9. €:viter de placer la table de cuisson avec la partie superieure

sur les boutons de commande.

o c

D

"A \ B

F

A. Volute d'_vacuation du ventilateur

B. Plenum

C. Moteur du ventilateur

D. E-tiquette indiquant le haut (Top)

E.E-crous m_caniques 10-32 (qt_ 4)

F. Platine de montage du moteur

20

Page 21

Pour tourner le ventilateur :

1. Reperer les 4 bouchons en plastique dans la derivation de la

chambre de distribution.

2. Les enlever a I'aide d'une pince.

IMPORTANT • Ne pas jeter les bouchons en plastique. Les

bouchons en plastique doivent 6tre reinstall6s une fois la

spirale d'echappement du ventilateur tournee.

C

A. Moteur du ventilateur

B. Spirale d'6chappement

C. PI6num

D. Bouchons en plastique (4)

3. Inserer la cle & douille de 3/8"et la rallonge dans le trou et

devisser recrou d'un demi-tour &raide de la poignee &

cliquet. Rep6ter cette operation pour chacun des quatre

ecrous.

4. Une fois les ecrous desserres, la spirale d'echappement du

ventilateur s'oriente sans effort vers le bas.

Pour tourner le moteur du ventilateur :

REMARQUE :L'etiquette indiquant le dessus "top" du moteur de

ventilateur se trouve a la position de 9 heures.

1. Tout en soutenant le moteur d'une main, utiliser une cle &

cliquet equip6e d'une douille de 3/8"pour retirer les quatre

ecrous &metaux fixant le moteur de ventilateur a la volute

d'evacuation.

2. Degager I'ensemble moteur-roue des goujons soudes.

D

A

C

A. Etiquette indiquant le haut (Top)

B. Moteur du ventilateur

C. Platine de montage du moteur

D. Emplacement des goujons soud6s

E. Roue du ventilateur

3. Lorsque la platine de montage du moteur est degag6e des

goujons soudes filetes, faire pivoter I'assemblage dans le

sens horaire de 90° et reinstaller les quatre boulons usines

n° 10-32.

4. Verifier que I'etiquette "Top" (dessus) est placee comme

illustre.

5. Resserrer chaque ecrou & raide de la cle & cliquet & douille

de 3/8".

6. Reinstaller les 4 bouchons d'obturation en plastique.

I

A. Etiquette indiquant le haut (Top)

21

Page 22

1= A l'aide d'au moins 2 personnes, placer la table de cuisson

dans l'ouverture en orientant la bonne surface vers le haut.

REMARQIE : S'assurer que le bord avant de la table de

cuisson est parallele au bord avant du plan de travail. S'il est

necessaire de repositionner la table de cuisson, la soulever

entierement de I'ouverture pour eviter de rayer le plan de

travail.

2. Pour des installations en lot ou en peninsule, passer a la

section "Rotation du ventilateur - Facultative".

3. Connecter la volute d'evacuation du ventilateur aux conduits.

4. Utiliser des brides de conduit pour fixer les conduits a la

volute d'evacuation du ventilateur.

5. Reinstaller le filtre a graisse amovible.

6. Reinstaller la grille de ventilation.

Risque de choc _lectrique

D_connecter la source de courant _lectrique avant

rentretien.

Utiliser du fil en cuivre de calibre 8.

Relier la table de cuisson a la terre.

Le non-respect de ces instructions peut causer un

d_cbs, un incendie ou un choc _lectrique.

Options de raccordement _lectrique

C&blage de la maison : Point de Voir la section

distribution : suivante :

4 conducteurs BoRe de C&ble &

disjoncteur ou 4 conducteurs

coupe-circuit depuis le point

avec fusible de distribution

3 conducteurs BoRe de C&ble &

disjoncteur ou 3 conducteurs

coupe-circuit depuis le point

avec fusible de distribution

C&ble & 4 conducteurs depuis le point de distribution du

domicile jusqu'au c&ble & 4 conducteurs de la table de

cuisson

IMPORTANT : Utiliser le c&ble & 4 conducteurs provenant du

point de distribution du domicile aux 12tats-Unis Iorsque les

codes ne permettent pas la mise & la terre par I'intermediaire du

conducteur neutre, en cas de nouvelle installation avec

alimentation par un circuit secondaire (1996 NEC), dans les

residences mobiles et les vehicules recr6atifs, dans les nouvelles

constructions et au Canada.

Un conducteur nu de liaison & la terre est connecte au chassis de

la table de cuisson Iors de la fabrication. Raccorder le cable de la

table de cuisson au boiler de connexion a I'aide du connecteur

de conduit homologu6 UL ou CSA.

1. Deconnecter la source de courant electrique.

2. Enlever le couvercle du boiler de connexion, le cas ech6ant.

3. Avec un connecteur de conduit (homologation UL ou CSA),

connecter le conduit de cable flexible de la table de cuisson

au boiler de connexion.

4. Serrer les vis du connecteur de conduit, le cas ech6ant.

5. Voir le "Tableau des options de raccordement electrique"

pour terminer I'installation correspondant a votre type de

raccordement electrique.

C

D

A. C#ble d'alimentation du

domicile

B. Conducteurs noirs

C. Conducteurs nus de liaison

la terre

D. C#ble _ 4 conducteurs depuis

la table de cuisson

E. Boftier de connexion

F. Conducteurs blancs

G. Connecteur de ills

(homologation UL)

H. Conducteurs rouges

I. Connecteur de conduit

(homologation UL ou CSA)

H

!

1. Connecter ensemble les 2 conducteurs noirs avec un

connecteur de fils (homologation UL).

2. Connecter ensemble les 2 conducteurs rouges avec un

connecteur de fils (homologation UL).

3. Connecter ensemble les 2 conducteurs blancs avec un

connecteur de fils (homologation UL).

4. Connecter le conducteur vert (ou nu) de liaison a la terre du

cable de la table de cuisson au conducteur vert (ou nu) de

liaison a la terre dans le boiler de connexion - utiliser un

connecteur de fils (homologation UL).

5. Reinstaller le couvercle du boiler de connexion.

22

Page 23

C&ble&3 conducteurs depuis le point de distribution du

domicile jusqu'au c&ble & 4 conducteurs de la table de

cuisson - E.-U. seulement

IMPORTANT : Utiliser le c&ble & 3 conducteurs depuis le point

de distribution Iorsque le code local en vigueur permet le

raccordement entre le conducteur de liaison & la terre du ch&ssis

et le conducteur neutre (blanc) clans le boitier de connexion.

A

C

D

A. C_ble d'alimentation

B. Conducteurs rouges

C. Conducteur blanc et nu ou vert

de liaison _ la terre (depuis la

table de cuisson)

D. C_ble _ 4 conducteurs depuis

la table de cuisson

E.BoTtler de connexion

F. Conducteur blanc

G. Connecteur de ills

(homologation UL)

H. Conducteurs noirs

I. Connecteur de conduit

(homologation UL ou CSA)

1. Connecter ensemble les 2 conducteurs noirs avec un

connecteur de fils (homologation UL).

2. Connecter ensemble les 2 conducteurs rouges avec un

connecteur de fils (homologation UL).

3. Connecter le conducteur vert ou nu et le conducteur blanc de

la table de cuisson au conducteur blanc (neutre) dans le

boitier de connexion avec un connecteur de fil

(homologation UL).

4. Reinstaller le couvercle du boitier de connexion.

E

F

G

H

Ach®v® 7 ns @on

1. Verifier que toutes les pieces sont maintenant installees. S'il

reste une piece, passer en revue les differentes etapes pour

decouvrir laquelle aurait et6 oubliee.

2. Verifier la presence de tousles outils.

3. Jeter/recycler tous les materiaux d'emballage.

4. Utiliser une solution d'eau tiede et de nettoyant menager

liquide doux pour nettoyer la table de cuisson avant

utilisation. Secher parfaitement avec un linge doux. Pour plus

de renseignements, voir la section "Entretien de la table de

cuisson" du Guide d'utilisation et d'entretien.

5. Lire "Utilisation de la table de cuisson" dans le Guide

d'utilisation et d'entretien de la table de cuisson.

6. Reconnecter la source de courant electrique.

7. Utiliser la carte de test du flux d'air fournie avec la table de

cuisson pour verifier le flux d'air (voir la carte pour des

instructions etape par etape).

REMARQUE : Si la table de cuisson ne fonctionne pas une fois

I'alimentation branchee, verifier que le disjoncteur n'est pas

declench6 ou que les fusibles ne sont pas grilles. Voir la section

"Depannage" dans le Guide d'utilisation et d'entretien pour plus

de renseignements.

Si vous avez besoin d'assistance ou de service :

Consulter la section "Assistance ou service" du Guide

d'utilisation et d'entretien ou contacter le marchand chez qui

vous avez achete votre table de cuisson.

23

Page 24

W10298568A

@2010.

All rights reserved.

Tous droits reserves.

Printed in U.S.A.

Imprime aux E.-U.

2/10

Loading...

Loading...